Omega Lift 13200, 13120 User Manual

Operating Instructions

& Parts Manual

Hydraulic Toe Jacks

Model Number

13120

13200

Capacity

6 Ton

10 Ton

Shinn Fu Co. of America, Inc. ©2002

10939 N. Pomona Avenue

Kansas City , MO 64153

OIPM # 13120-TJ2

Printed in T aiwan

Save these instructions. For your safety , read, understand, and follow the information provided with and on this

jack. The owner and operator of this equipment shall have an understanding of this jack and safe operating

procedures before attempting to use. The owner and operator shall be aware that use and repair of this product

may require special skills and knowledge. Instructions and safety information shall be conveyed in the operator's

native language before use of this jack is authorized. If any doubt exists as to the safe and proper use of this jack,

remove from service immediately . Inspect before each use. Do not use if broken, bent, cracked or damaged parts

are noted. Any jack that appears damaged in any way , or operates abnormally shall be removed from service

immediately . If the jack has been or suspected to have been subjected to a shock load (a load dropped suddenly ,

unexpectedly upon it), immediately discontinue use until jack has been checked by an Omega authorized service

center. It is recommended that an annual inspection be done by qualified personnel. Labels and Operator’s

Manuals are available from manufacturer (see Replacement Parts, page 6).

PRODUCT DESCRIPTION

Omega Hydraulic T oe Jacks are designed for lifting, but not sustaining, loads ranging from 6 tons thru 10 tons

depending on the rated capacity of the jack. They are designed to be used vertically . After lifting, loads must be

immediately supported by appropriate means. Each model is suitable for use in an appropriately rated and

designed vertical or bench press structure. These jacks are not recommended for use in lifting or positioning

construction trailers, houses and/or other building structures.

SPECIFICATIONS

Base Size (L x W)Model Capacity Lifting Range - Toe Lifting Range - Head

6 Ton 7 1/2" X 4 5/8" 10 1/2" ~ 15 5/8"13120 7/8" ~ 6"

10 Ton 7 1/2" X 5 3/8" 1 1" ~ 16 1/8"13200 1 1/8" ~ 6 1/4"

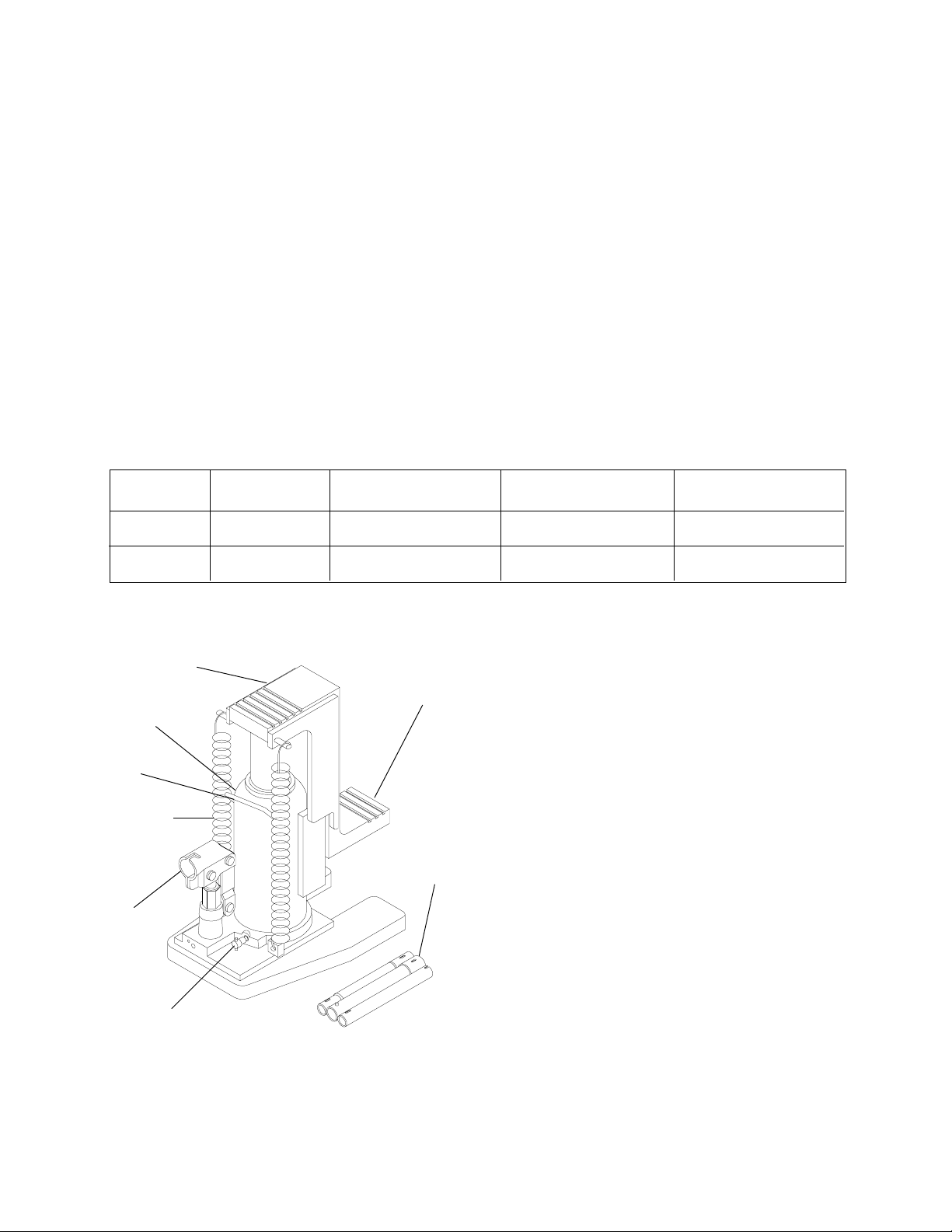

head saddle

oil filler plug / screw*

(not shown)

carry handle

return spring

handle sleeve

release valve

* oil filler screw for 13200

Figure 1 - Model 13120 & 13200 Nomenclature

OIPM#13120-TJ2

toe saddle

handle

BEFORE USE

1. Verify that the product and the application are

compatible, if in doubt call Omega T echnical

Service (888)332-6419.

2. Before using this product, read the operator's

manual completely and familiarize yourself

thoroughly with the product and the hazards

associated with its improper use.

3. Assemble handle sections by lining up spring clip of

smaller diameter handle section with slot of larger

handle section. Press down the spring clip and slide

smaller diameter section until clip is secure in slot.

4. With the notched end of the provided handle,

engage and open the release valve

(counterclockwise no more than 1/2 full turn).

5. With ram fully retracted, locate and remove the oil

filler plug/screw. Insert the handle into the handle

sleeve, then pump 6 to 8 strokes. This will help

release any pressurized air which may be trapped

within the reservoir. Ensure the oil level is just below

the oil filler plug/screw hole. Reinstall the oil filler

plug/screw.

6. Check to ensure that the pump operates smoothly

before putting into service. Replace worn or

damaged parts and assemblies with Omega

Authorized Replacement Parts only .

7. Inspect before each use. Do not use if bent, broken

or cracked components are noted.

2

!

WARNING

Study , understand, and follow all instructions before

operating this device. Do not exceed rated capacity .

Use only on hard, level surfaces. Lifting device only .

Immediately after lifting, support the vehicle with

appropriate means. Failure to heed these markings

may result in personal injury and/or property

damage.

OPERATION

Lifting

1. Assemble 3 pc. handle, ensure that spring clips

align with slots.

2. Secure the load to prevent inadvertent shifting and

movement.

3. Position the jack near desired lift point.

4. Close the release valve by turning it clockwise until

it is firmly closed.

WARNING

!

T o avoid crushing and related injuries:

NEVER work on, under or around a load supported

only by a jack. AL WAYS use adequately rated jack

stands.

Note: Use the handle provided with this product or an

authorized replacement handle to ensure proper

release valve operation. When using to lift vehicle, lift

only on the manufacturer’s recommended lift points

and in accordance with the published guidelines in

your vehicle owners manual. Always use jack stands

to support the load immediately after lifting.

5. Insert and secure handle into handle sleeve. Pump

handle until saddle contacts load.

6. Raise load to desired height, then immediately

transfer the load to appropriately rated support

devices such as jack stands.

OPERA TION (continued)

Lowering

1. Raise load enough to carefully remove jack stands.

2. Insert handle onto release valve and slowly turn

handle counterclockwise, but no more than 1/2

turn.

3. If load fails to lower:

a. Carefully transfer the load to another lifting

device and jack stands.

b. Carefully remove affected jack, and then the

jack stands. Lower the load, again by slowly

turning the release valve no more than 1/2 turn.

! SAFETY MESSAGE !

Be sure all tools and personnel are clear before

lowering load. No alterations shall be made to this

device. Only attachments and/or adapters supplied

by the manufacturer shall be used.

4. After removing jack from under the load, push ram

and handle sleeve down to reduce exposure to rust

and contamination.

3

OIPM#13120-TJ2

Loading...

Loading...