Page 1

PSW20 Series

Pressure, vacuum or differential pressure switches

INSTRUCTION

SHEET

Shop online at: omega.com e-mail: info@omega.com

For latest product manuals: omegamanual.info

M4067-0504

Installation Instructions for OMEGA PSW20 Series: Pressure, Vacuum and Differential

Pressure Switches.

General

The PSW20 series is single pole switch that can be used as a pressure or vacuum switch (from 0.40 in W. C. to

20 inches W. C.) or as a pressure differential switch. The switch can respond to rapid pulsing and the gold

plated silver contacts will handle low level switching currents.

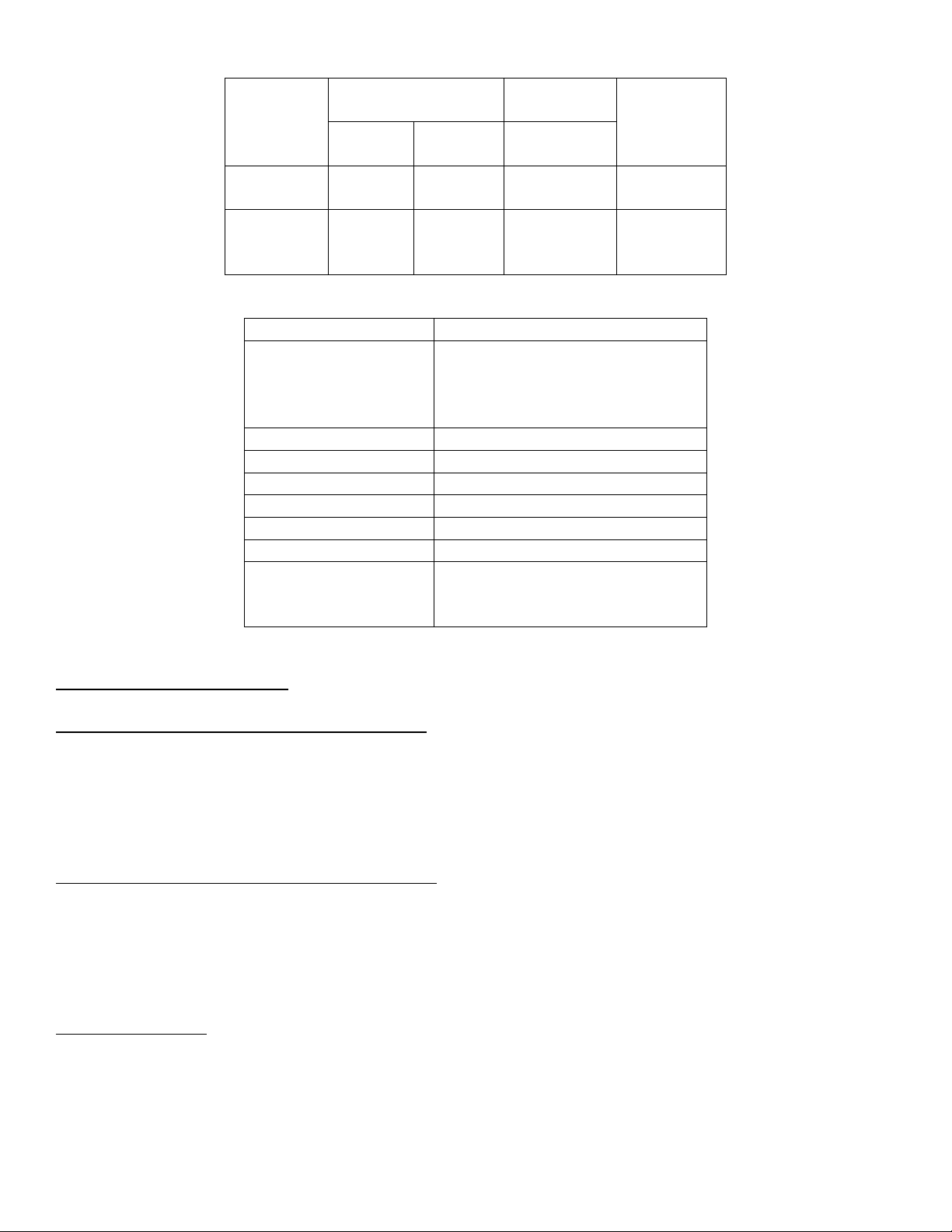

Mounting Instructions

Switch may be mounted in horizontal or vertical position, through 0.12" (3mm) holes on 1.34" (34mm)

centerline, with suitable clearances to accommodate 0.15" I.D tubing and electrical connectors – see diagram

for dimensions.

Electrical, Pneumatic and Material/Mechanical Specification

Part

Number

Pressure range

(inches water, gauge)

Pressure Vacuum Differential

PSW20A 0.4-15 0.4-15 .04-15

PSW20B 1-20 1-20 1-20

Page 2

Standard

Electrical rating

Number

PSW20A 750ma

PSW20B 1 amp

Body Acetal

Diaphragm EPDM is standard; Nitrile

Contacts Gold plated silver

Springs Plated phosphor bronze

Terminals Plated copper or brass

Adjusting screw Stainless steel or zinc plated SS

Weight 9 grams (0.3oz)

Operating temperature -30 C to +65 C (-23F to 149F)

Listings UL recognized for 100,000

Max.

Resistive

250VAC

250

VAC

Min

Resistive

5 ma

3 VDC

5 ma

3 VDC

available. NOTE: EPDM should

not be used in petroleum

applications

operations

CSA certified

Repeat

AccuracyPart

Constant

Temperature

+/- 4% 0.04

+/- 3% 0.02

Contact

Resistance

(ohms)

Connections and Adjustment

Pressure Switching – Normally Open Contacts

Connect the pressure source to inlet port B (see diagram) and set the adjusting screw to the desired pressure.

Turning the screw clockwise narrows the gap between contacts and decreases the pressure set point. Turning the

pressure adjusting screw counterclockwise increases the set point. Note: the media entering the

diaphragm through Port B is separated from the electrical contacts by the diaphragm.

Pressure Switching – Normally Closed Contacts

Connect the pressure source to Port A and monitor continuity across the terminals. Slowly turn the adjusting

screw clockwise, narrowing the gap between contacts until the contacts are closed. Apply the set point pressure

which will open the contacts. Continue to turn the adjusting screw clockwise until the contacts

make and break at the desired point.

Vacuum Switching

Repeat the above procedure using Port A for Normally Open Contacts and Port B for Normally Closed

Contacts.

Page 3

Media in Contact with Electrical Contacts

Note that the pressure media entering through Port A is in direct contact with the electrical contacts in the

switch, whereas the pressure media entering through Port B is separated from the electrical contacts by the

diaphragm.

Note: The EPDM diaphragm should not be used with petroleum products. Specify Nitrile for these applications.

Page 4

Servicing Europe:

OMEGAnet®Online Service Internet e-mail

Benelux:

www.omega.com info@omega.com

USA:

ISO 9001 Certified

Canada:

Servicing North America:

One Omega Drive, Box 4047

Stamford CT 06907-0047

Te l: (203) 359-1660 FA X: (203) 359-7700

e-mail: info@omega.com

976 Bergar

Laval (Quebec) H7L 5A1, Canada

Te l: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

Czech Republic:

France:

Germany/Austria:

For immediate technical or application assistance:

USA and Canada:

Mexico:

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the

European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, human applications.

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

En Espan˜ol: (001) 203-359-7803 e-mail:espanol@omega.com

FA X: (001) 203-359-7807 info@omega.com.mx

®

®

United Kingdom:

®

ISO 9002 Certified

Postbus 8034, 1180 LAAmstelveen, The Netherlands

Te l: +31 (0)20 3472121 FAX: +31 (0)20 6434643

To ll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Frystatska 184, 733 01 Karviná, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

To ll Free: 0800-1-66342 e-mail: info@omegashop.cz

11, rue Jacques Cartier, 78280 Guyancourt, France

Te l: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

To ll Free in France: 0800 466 342

e-mail: sales@omega.fr

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Te l: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

To ll Free in Germany: 0800 639 7678

e-mail: info@omega.de

One Omega Drive, River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

To ll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase.

OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and

shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR)

number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced

at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows

evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are not

warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any

omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not

exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or

special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in

or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic

WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO

OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER

TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

PATENT NOTICE: U. S. Pat. No. 6,074,089; 5,465,838 / Canada 2,228,333; 2,116,055 / UK GB 2,321,712 / Holland 1008153 / Israel 123052 / France

2 762 908 / EPO 0614194. Other patents pending.

FOR W

ARRANTY RETURNS, please have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and

engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

Have the following information available BEFORE contacting OMEGA:

consult OMEGA for current repair charges.

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to the product.

M4067/0504

RETURN REQUESTS / INQUIRIES

Loading...

Loading...