Page 1

OAL-100 INSTALATION INSTRUCTIONS

WARNING! AVOID ELECTRICAL SHOCK

DISCONNECT POWER DURING INSTALLATION

PLEASE READ ALL INSTRUCTIONS BEFORE INSTALLATION

POWER SUPPLY REQUIRED 115+/- 5VAC-60 HZ 0.4AMPS

CONTROL BOARD POWER SUPPLY 16VDC

CONTROL BOARD TO BE GROUNDED

KEEP FINGERS & CLOTHING CLEAR OF ALL MOVING PARTS

ADJUSTMENTS TO BE PERFORMED BY APPROVED TECHNICIAN ONLY

ALTERATION TO ANY COMPONENTS IS PROHIBITED

REMOVE ANY MECHANICAL DEVICES OR LOCKS THAT INTERFERE WITH

THE OPERATION OF THE DOOR, (OTHER THAN PARTS INTEGRATED WITH

THE OPERATOR SYSTEM).

OPERATOR TO BE INSTALLED 8 FEET MINIMUM ABOVE GROUND IF THERE

ARE ANY EXPOSED MOVING PARTS

O M E G A A U T O M A T I C S 2 0 1 8

V 2 . 0

Page 2

Mounting the Operator:

Fasteners

120 VAC

Notes:

-Ensure that door swings and latches easily before attempting to add operator

-Remove cover from operator

-Operator to wall mounting must be very strong!

-All loads from high winds & other overloads will be transferred thru the fasteners to the wall

-Use appropriate fasteners and anchors for the type of wall being mounted to

-Mounting to drywall construction requires plwood backer inside the wall to attach operator

-If the door framing is proud of the wall, place a filler allowing the operator to sit flat & plumb

-Attach to vertical jamb tubes when mounting to curtain wall

filler

drill & fasten

thru

slots

plywood

back

er

board

operator

back

plate

drywall mounting curtain wall mounting

fasten to jamb tubes

fasten along header

O M E G A A U T O M A T I C S 2 0 1 8

V 2 . 0

Page 3

Push Arm:

- Requires cutting of the round bar

- Mount block 14 1/2" from hinge

- Install arm onto spindle as per diagram

- Close door and place round shaft beside tube

- Cut the round rod 2" past last grub screw

- Rod can be slid in out for final adjustment

- Slide rod into position and tighten grub screws

- Remove complete arm from the shaft

- Use jumper wire to "hold open" the motor

- Position the door in full open position

- Typically 90 to 105 degrees

- Reinstall arm onto shaft and tighten screw

(3/16")

- Install safety washer & screw

- Remove jumper wire & adjust magnets

- See "setting the magnets"

shaft

screw

high mount

safety washer

screw

14 1/2"

low mount

1 1/2"

4 1/8"

2 1/2"

tube

rod

O M E G A A U T O M A T I C S 2 0 1 8

block

V 2 . 0

Page 4

Pull Arm:

-Install roller onto arm (5/32" allen)

-Install jumper wire to "hold open" motor

-Slide arm onto shaft, typically 90 to 105

degrees & tighten pinch screw

-Remove jumper wire so roller contacts door

-Roller needs to be vertically centered in track

-Fasten track to door (see diagram)

-Place end caps on the track

-Install safety washer & screw

-Adjust magnets; see "setting the magnets"

1 3/4"

shaft

center wheel

screw

safety washer

1 1/2" minimum

arm

roller

track

fasten pull track to door

fasten pull track

to

door

O M E G A A U T O M A T I C S 2 0 1 8

V 2 . 0

Page 5

Wiring:

control board

to motor

to magnet

switches

120 VAC

to be connected by

Notes:

- Run 120 VAC power lines as per building code

- Run low voltage wires to/from any input/outputs such as buttons or strikes

- Power is to be connected by authorized electrician to local codes

- Once power is hooked up the unit can be test cycled by pressing "ACT"

- Ensure that operator is working properly before adding inputs/outputs

- Magnets must be properly positioned in order for operator to function (see setting the magnets)

- Full open position is limited by an internal stop not the magnets

- The magnets

- Magnets can be adjusted to change the point where the door slows for back check and latch

- Use a jumper wire to hold operator in full open position to attach arm.

- Have certified Electrician to do installation ONLY!

- Have certified Electrician to hook the wire into the power side properly.

- Add the L1, N, and G labels on the wires before installing the system.

confirm the door position to the control board

authorized electrician

on/off

switch

Test & Hold Open:

O M E G A A U T O M A T I C S 2 0 1 8

use jumper wire

from COM

to ACT 1

to hold open

press ACT to test

V 2 . 0

Page 6

Setting the Magnets

Left Push Back Check Right Push Back Check

Left Push Latch Right Push Latch

Left Pull Back Check

Right Pull Back Check

Left Pull Latch

O M E G A A U T O M A T I C S 2 0 1 8

Right Pull Latch

V 2 . 0

Page 7

Inputs/Outputs:

Push Buttons

Notes:

- Connecting terminals COM to ACT1 will activate the operator to open

- Push buttons, card readers etc will all wire the same

- Multiple inputs can be wired together

- Use 20 gauge wire

Strike

Notes:

- use terminals LOCK & +24 to signal

strike

- use 20 gauge wire

Programming Functions Range Units Default

1. overload 50-99 % 50

2. activation delay 0-99 0.1seconds 0

3. back check 0-99 % 20

4. holding time 0-99 1.0 seconds 15

5. opening speed 10-70 % 50

6. closing speed 0-99 % 20

7. latching speed 0-99 % 5

8. hold open 0-1 on/off 0

9. power assist 0-1 on/off 0

10. reactivation 0-1 on/off 0

O M E G A A U T O M A T I C S 2 0 1

8

V 2 . 0

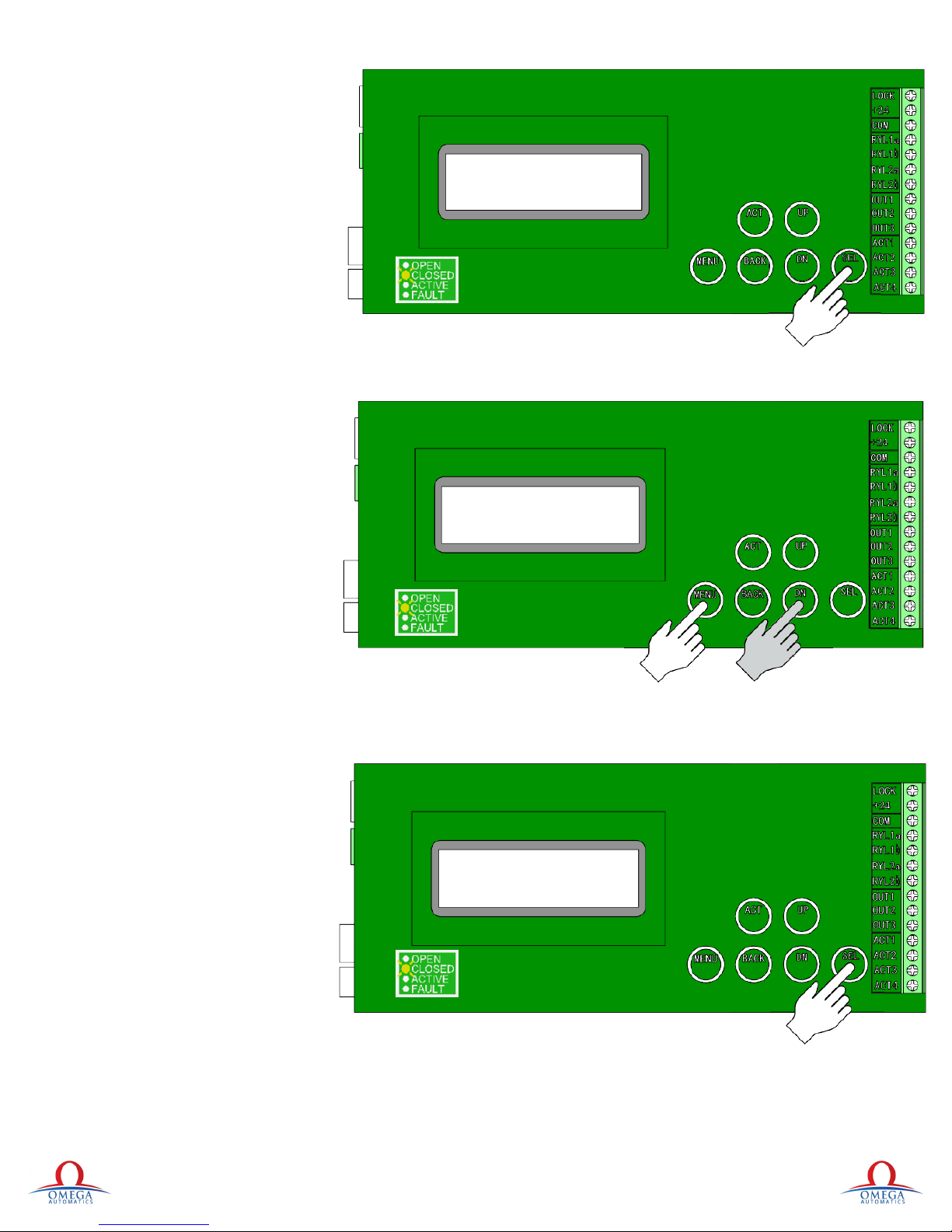

Page 8

Programming:

Step 1:

- door must

- screen will say "DOOR CLOSED"

- closed light will be illuminated

Step 2:

- Press MENU button to enter

programming

be in closed position

DOOR CLOSED

DOOR CLOSED

Step 2b:

- Press SEL (select)

O M E G A A U T O M A T I C S 2 0 1 8

MAIN MENU

(Settings)

V 2 . 0

Page 9

Programming:

Step 3:

- Press UP & DN buttons to scroll

Step 4:

- Press SEL to enter parameter

SETTINGS (01)

Overload 50

Step 4b:

- Press UP & DN to change value

SETTINGS 01

Overload (50)

SETTINGS 01

Overload (50)

O M E G A A U T O M A T I C S 2 0 1 8

V 2 . 0

Page 10

Programming:

Step 5:

- Press SEL to exit parameter

Forced Relearn

Step 1:

- From "DOOR CLOSED" screen

- Press MENU

- Press DN twice

SETTINGS (01)

Overload 50

DOOR CLOSED

Step 1b:

- Screen reads "MAIN MENU"

(Calibrate)

- Press SEL twice for next screen

X-2

MAIN MENU

(Calibrate)

X-2

O M E G A A U T O M A T I C S 2 0 1 8

V 2 . 0

Page 11

Programming:

Step 3:

- Press MENU then ACT

- Screen reads "CALIBRATE"

Step 3b:

- Screen reads "RELEASE STRIKE"

(Learning)

- Once one cycle is complete board

has relearned itself

CALIBRATE

Relearn Next ACT

RELEASE STRIKE

(Learning)

O M E G A A U T O M A T I C S 2 0 1 8

V 2 . 0

Page 12

Cover:

- Snap cover onto backer plate

- Attach cover fasteners

Stickers:

- Apply warning stickers to door

- Refer to local codes for proper heights

Cover

Cover Fastener

AAADM

Sticker

O M E G A A U T O M A T I C S 2 0 1 8

58" ±5

42"

V 2 . 0

Loading...

Loading...