Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User ’s Guide

M-4292/1006

PCL340 Series

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karvina´, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0) 5 9 6 3 1111 4

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Contacting OMEGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Standard Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. Calibrator Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Calibrator Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Using the Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.3 Using the Zero Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.4 Other Menu Controlled Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3. Measuring Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.1 Media Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.2 Measuring Pressure with External Modules . . . . . . . . . . . . . . . . . . . . .12

4. Measuring Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5. Measuring Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6. Performing a Pressure Switch Test . . . . . . . . . . . . . . . . . . . . . . . . .15

7. Calibrating Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.1 Using the mA Input Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.2 Calibrating a Pressure-to-Current Transmitter . . . . . . . . . . . . . . . . . . . .18

7.3 Percent Error Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

8. Factory Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

9. Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

9.1 Remote Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

9.2 Setting up the RS-232 Port for Remote Control . . . . . . . . . . . . . . . . . .23

9.3 Changing Between Remote and Local Operation . . . . . . . . . . . . . . . .24

9.4 Using Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

9.5 Remote Commands and Error Codes . . . . . . . . . . . . . . . . . . . . . . . . .27

9.6 Entering Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

10. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

11. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

11.1 Replacing Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

11.2 Cleaning the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

11.3 Service Center Calibration or Repair . . . . . . . . . . . . . . . . . . . . . . . . .36

Page 4

Page 5

1. Introduction

The OMEGA PCL340 Series is designed to be a simple to use yet

very versatile pressure calibrator. Its internal pressure sensor

combined with inputs for mA, voltage and switch contacts allow the

PCL340 Series to calibrate a variety of pressure devices. An external

pressure module option allows an even wider range of pressure

calibration options including absolute and differential.

1.1 Customer Service

Omega Engineering

One Omega Drive

Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

Fax: (203) 359-7900

www.omega.com

email: info@omega.com

1.2 Standard Equipment

Check to see if your calibrator is complete. It should include: PCL340

Series Calibrator, instruction manual, test leads, carrying case,

calibration certificate with data.

1.3 Safety information

Symbols Used

The following table lists the International Electrical Symbols. Some or

all of these symbols may be used on the instrument or in this

manual.

Symbol Description

AC (Alternating Current)

AC-DC

Battery

CE Complies with European Union Directives

DC

1

Page 6

Symbol Description

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Read the User’s Manual (Important Information)

Off

On

The following definitions apply to the terms “Warning” and “Caution”.

• “Warning” identifies conditions and actions that may pose hazards

to the user.

• “Caution” identifies conditions and actions that may damage the

instrument being used.

Use the calibrator only as specified in this manual, otherwise injury

and damage to the calibrator may occur.

Warning

To avoid possible electric shock or personal injury:

• Do not apply more than the rated voltage. See specifications for

supported ranges.

• Follow all equipment safety procedures.

• Never touch the probe to a voltage source when the test leads are

plugged into the current terminals.

• Do not use the calibrator if it is damaged. Before you use the

calibrator, inspect the case. Look for cracks or missing plastic. Pay

particular attention to the insulation surrounding the connectors.

2

Page 7

3

• Select the proper function and range for your measurement.

• Make sure the battery cover is closed and latched before you

operate the calibrator.

• Remove test leads from the calibrator before you open the battery

door.

• Inspect the test leads for damaged insulation or exposed metal.

Check test leads continuity. Replace damaged test leads before

you use the calibrator.

• When using the probes, keep your fingers away from the probe

contacts. Keep your fingers behind the finger guards on the

probes.

• Connect the common test lead before you connect the live test

lead. When you disconnect test leads, disconnect the live test lead

first.

• Do not use the calibrator if it operates abnormally. Protection may

be impaired. When in doubt, have the calibrator serviced.

• Do not operate the calibrator around explosive gas, vapor, or dust.

• When measuring pressure, make sure the process pressure line is

shut off and depressurized before you connect it or disconnect it

from the pressure module.

• Disconnect test leads before changing to another measure or

source function.

• When servicing the calibrator, use only specified replacement

parts.

• To avoid false readings, which could lead to possible electric shock

or personal injury, replace the battery as soon as the battery

indicator appears.

Caution

To avoid possible damage to calibrator or to equipment under test:

• Use the proper jacks, function, and range for your measurement or

sourcing application.

Page 8

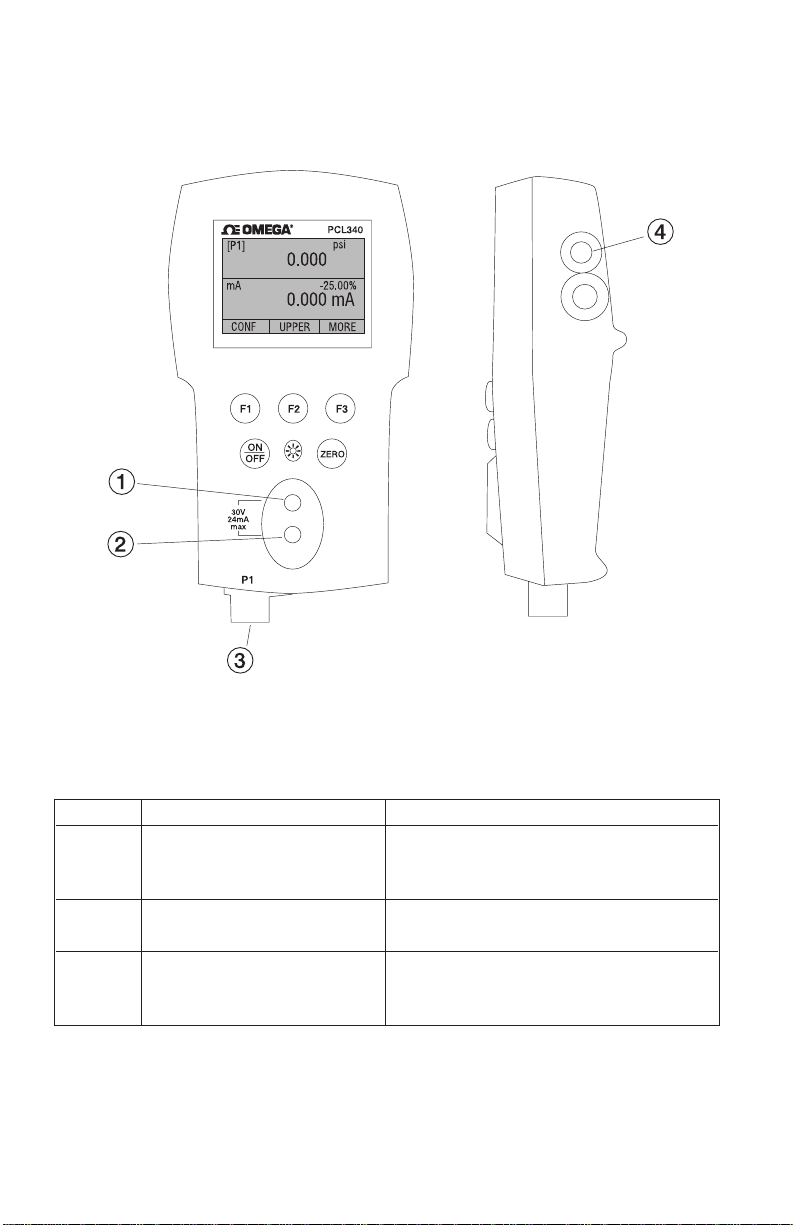

2. Calibrator Interface

Figure 1 shows the location of the process measurement inputs,

while table 1 describes their use.

Figure 1

Process Measurement Inputs

Table 1 Process Measurement Inputs

No. Name Description

1, 2 Input Terminals These terminals are used to

measure current, voltage and a

contact closure for switch test.

3 P1 Pressure Port This is the connection for the

internal sensor P1

4 Serial Interface This is used to interface to optional

external modules or optional serial

control.

Figure 2 shows the location of the keys. Table 2 describes the

function of each key.

4

Side View

Page 9

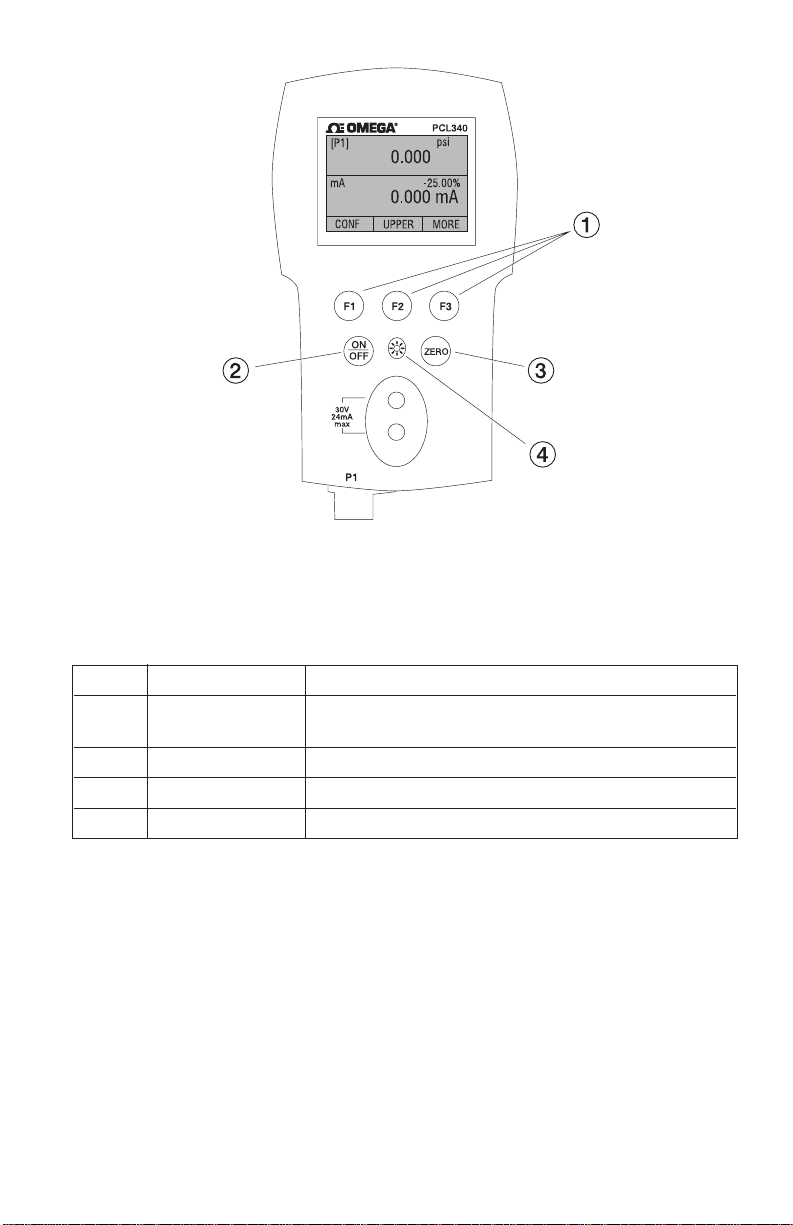

Figure 2

Keypad

Table 2 Key Functions

No. Name Description

1 Function Keys These keys are used in various ways, primarily to

configure the calibrator

2 ON/OFF Key This key is used to turn the calibrator on and off

3 ZERO Key This key is used to zero pressure measurements

4 Backlight Key This key is used to turn the backlight on and off

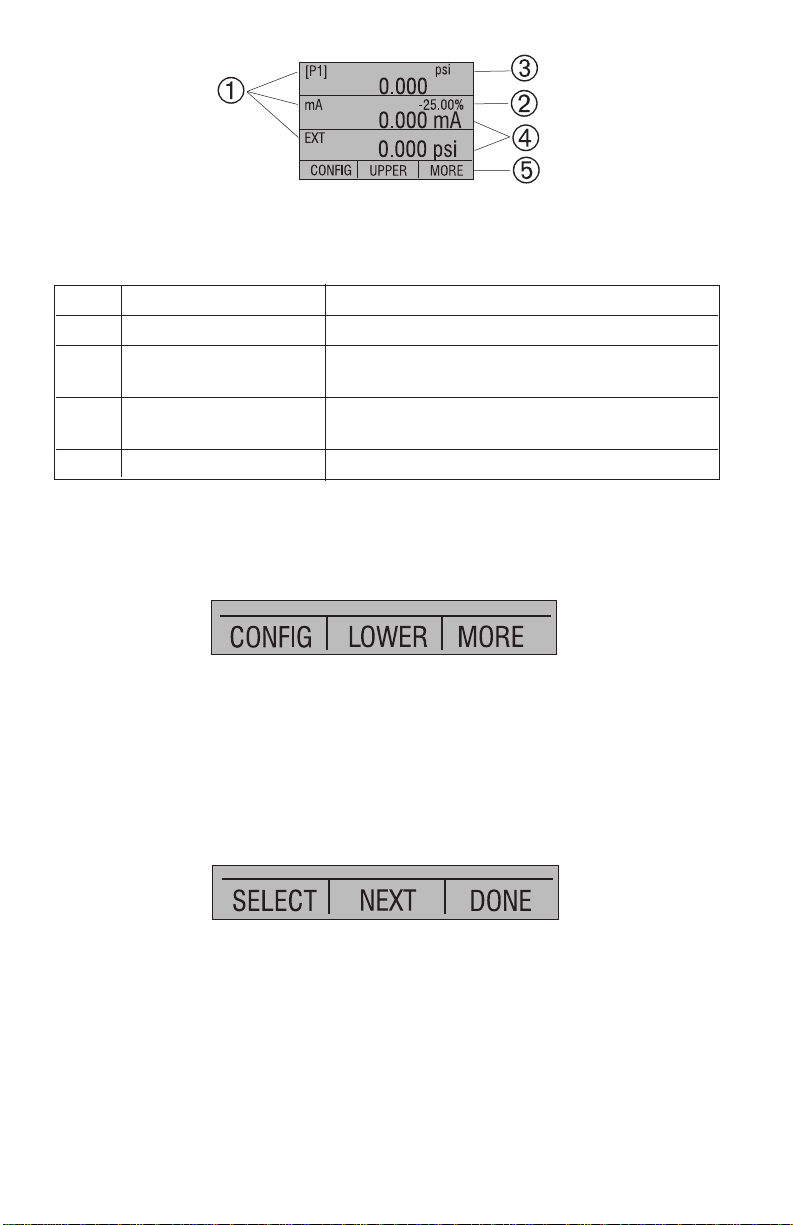

2.1 Calibrator Display

The Calibrator Display consists of two regions: The menu bar

(located along the bottom of the screen) is used to access a menu

system. The main display (the rest) consists of up to three process

measurement sub-regions. These sub-regions will henceforth be

referred to as the UPPER, MIDDLE and LOWER displays. Figure 3

shows the location of the different display fields while table 3

describes them.

5

Page 10

6

Figure 3

Display

Table 3 Display Functions

No. Name Description

1 Primary Parameters Indicates what is being measured.

2 Span Indicator Indicates the percent of the 4 to 20 mA span.

(For mA and mA Loop functions only)

3 Pressure Units Indicates one of 17 pressure units available

for display.

4 Units Indicates the unit of measure for the display.

2.1.1 Main Menu Functionality

There are three options on the Main Menu, CONFIG, {current

display} and MORE. The Main Menu is home for the menu display.

2.1.1.1 Setting the Current Display

The current display is indicated by the center option on the Main

Menu, pressing the F2 key will toggle the current display.

2.1.1.2 Setting Current Display Parameters

To set the parameters of the current display use the CONFIG option

to get to the Display Configuration Menu.

Here the SELECT option will toggle through the choices for each

parameter. The first parameter is MODE . Since voltage, current and

switch test modes all use the same jacks, two of these functions

cannot be used concurrently. The ability to select certain functions is

limited based on what is already selected in another active display.

The NEXT option is used to change to the second parameter. Only

Pressure modes have a second parameter. Pressures can be read in

13 engineering units.

Page 11

7

OTHER DISPLAYS

With a single display the following modes are available:

P[1] = Pressure on left side sensor.

[EXT] = Pressure with external pressure module.

P[1] ST = Switch Test with left side sensor.

[EXT] ST = Switch Test with external pressure module.

mA = Milliamps measure without loop power.

mA LOOP = Milliamps measure with loop power.

VOLTS = Voltage Measure.

The following table shows which functions are available concurrently.

An X in a column indicates that the mode in the current display will

not be available for selection if the mode in that row is in use in any

other active display.

Table 4 Mode Concurrency

CURRENT DISPLAY

P[1] [EXT] P[1] [EXT] mA mA Volts

ST ST Loop

P[1]

[EXT]

P[1]ST X X X X X

[EXT]ST X X X X X

mA X X X X

mA Loop X X X X

Volts X X X X

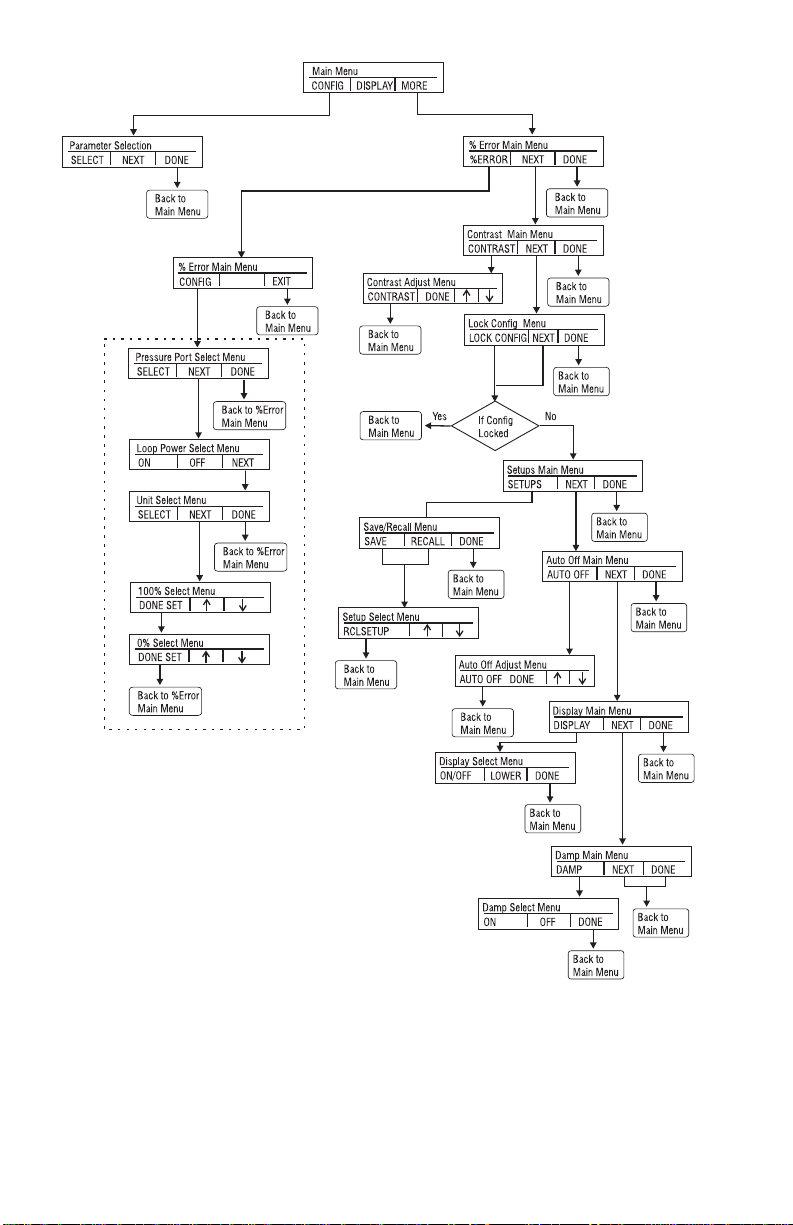

2.1.1.3 Accessing Other Menus

Use the MORE option on the Main Menu to access the other menu

functions.

Page 12

8

Figure 4

Menu Map

Page 13

9

2.2 Using the Backlight

The backlight is controlled by the dedicated backlight key. It toggles

on and off when the key is pressed; this is one of the few functions

that cannot be controlled by the serial interface.

2.3 Using the Zero Function

When the ZERO_KEY is pressed, the calibrator will zero the current

display if a pressure mode is selected, and the pressure is within the

zero limit.

2.3.1 Internal Sensor and Pressure Module (non-absolute)

When a sensor or module is selected on the current display and the

ZERO_KEY is pressed the calibrator subtracts the current reading

from the output.

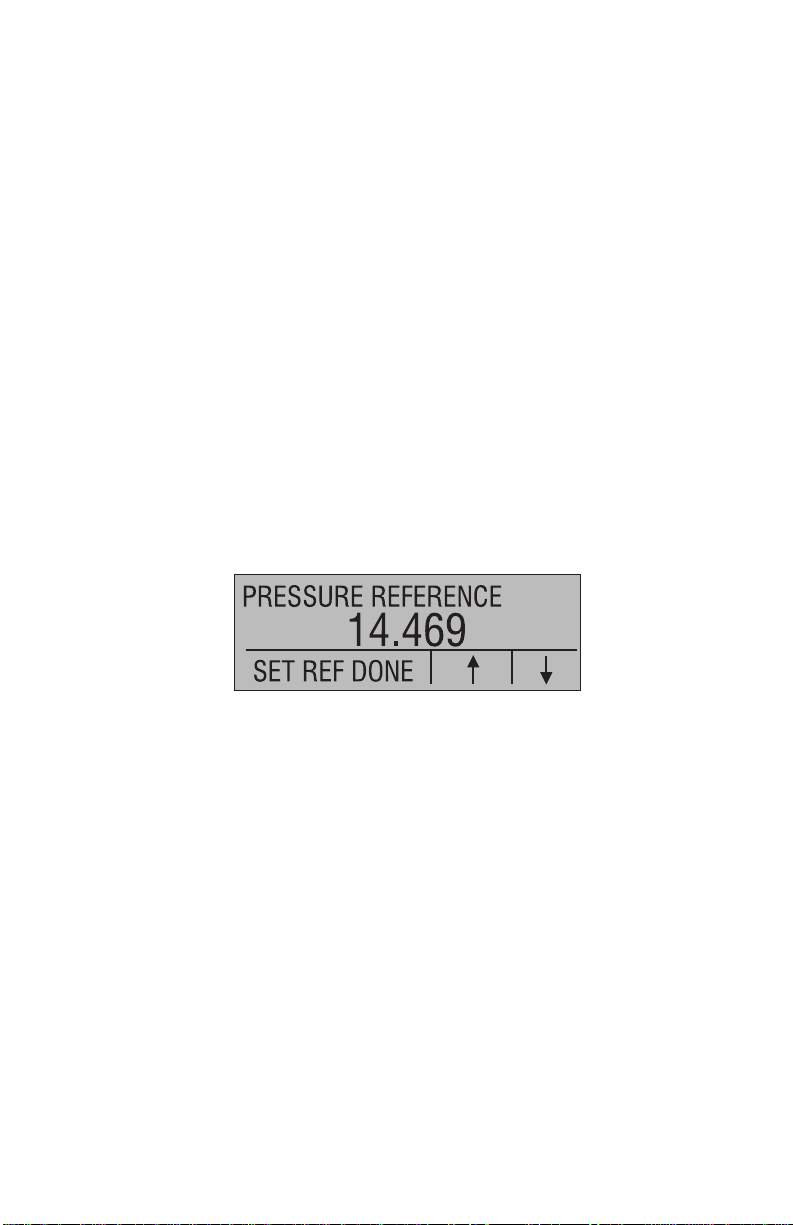

2.3.2 Absolute Pressure Module

When an absolute pressure module is selected on the current

display and the ZERO_KEY is pressed the calibrator prompts the

user to enter the barometric reference pressure. This is done using

the arrow keys (F2 and F3 Keys).

2.4 Other Menu Controlled Functions

There are eight ‘sub-main’ menus that can be accessed through the

MORE option of the Main Menu. A ‘sub-main’ menu contains three

options. The first option is unique to the function. The second and

third options of a ‘sub-main’ menu are always the same. The NEXT

option leads to the next ‘sub-main’ menu and the DONE option

returns home . For the last ‘sub-main’ menu the NEXT option wraps

around to home. See Figure 4 for a detailed mapping of the menu

structure.

A note on naming convention:

If a ‘sub-main’ menu has subordinate menus, it will henceforth be

referred to as {function} Main Menu. E.g. the display contrast submain menu will be called the Contrast Main Menu. If not it will be

called the {function} menu.

Page 14

10

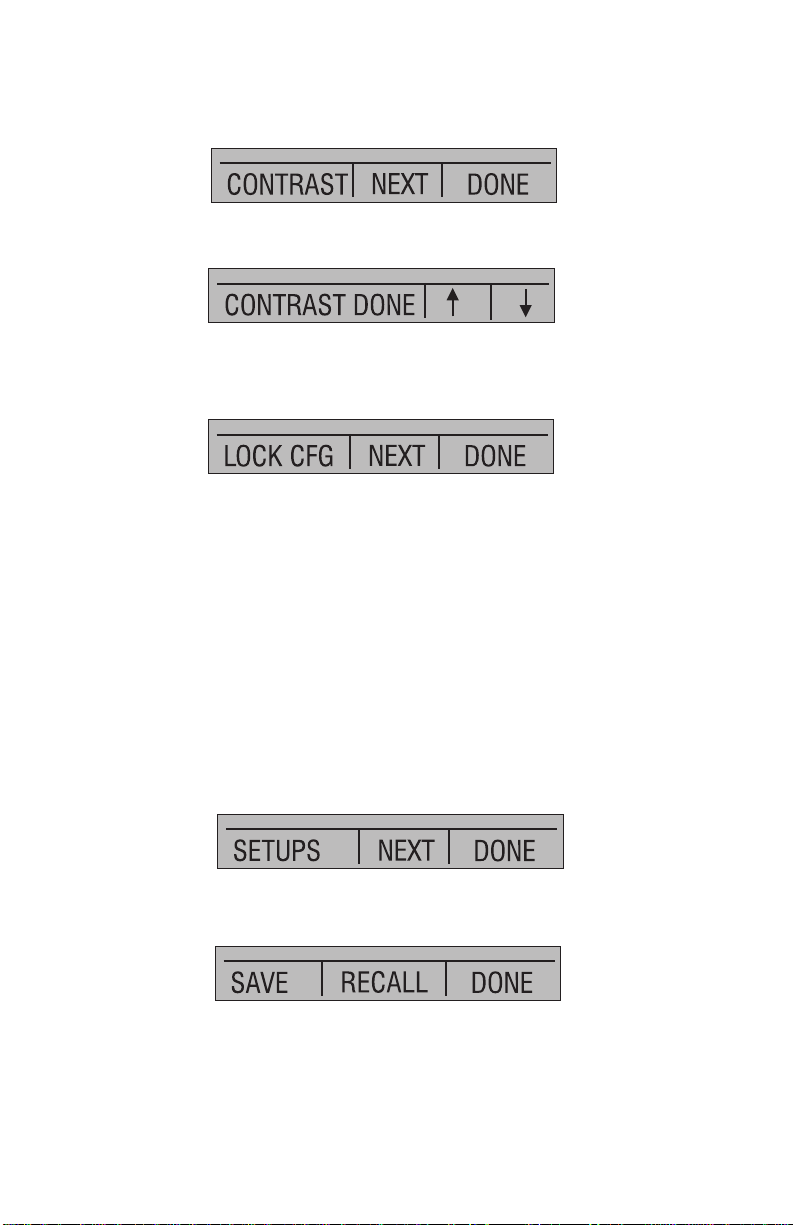

2.4.1 Setting the Contrast

From the Contrast Main Menu choose the CONTRAST option to

access the Contrast Adjustment Menu.

Use the arrow keys to adjust the display contrast to the desired level

and then use the CONTRAST DONE option to return home.

2.4.2 Locking and Unlocking Configurations

Use the LOCK CFG or UNLOCK CFG option of the Configuration

Lock Menu to lock or unlock the display configuration.

When the LOCK CFG option is chosen the menu display returns

home and the CONFIG option on the Main Menu indicates that it is

locked. Also all menus are locked out with the exception of the

Contrast Adjustment menus and the Configuration Lock Menu.

When the UNLOCK CFG option is chosen the configuration is

unlocked and the menu display continues to the next sub-main

menu.

2.4.3 Saving and Recalling Setups

The calibrator will automatically save the current set-up for recall at

power-up. Additionally 5 set-ups can be accessed through the

SETUPS menu. Select the SETUPS option from the Setups Main

Menu.

Choose SAVE to save a set-up , RECALL to recall the set-up, or

DONE to do nothing and return home.

If SAVE or RECALL is selected use the arrow keys to select the setup location. Then use the save option to store the current set-up into

the selected location or the recall option to recall the set-up stored in

the selected location. The display menu will automatically go home.

Page 15

11

2.4.4 Setting AutoShut-off Parameters

The calibrator can be set to automatically shut-off after a selected

number of minutes; this function can also be disabled. To set the

auto shut off parameters select the AUTO OFF option on the Auto

Shut Off Main Menu.

Use the arrow keys to select the number of minutes before the

calibrator turns off or disable auto shut-off by scrolling all the way

down.

Use the AUTO OFF DONE option to set the parameters and return

home. The auto shut off time is reset whenever a key is pressed.

2.4.5 Activating and Deactivating a Display

Use the DISPLAY option on the Display Selection Main Menu to

access the Display Activation Menu.

The {function} option can be used to select which display to act

upon. The ON/OFF option turns the selected display on or off. The

selected display and current on/off state are displayed in the lower

display.

Use the DONE option to save the changes and return home. When

a display is deactivated its configuration is retained. When the

display is activated its configuration is checked against the

Page 16

12

configurations of the other currently active displays, if the

configurations are in conflict the recalled display’s configuration is

modified to avoid the conflict. If all three displays are deactivated the

LOWER display will come on automatically

3. Measuring Pressure

To measure pressure, connect the calibrator using an appropriate

fitting. Choose a pressure setting for the display being used. The

calibrator is equipped with one internal sensor and many optional

external Pressure Modules are available. Be sure to choose the

sensor based on working pressures and accuracy.

Figure 5

Use the (ZERO) key to zero the pressure sensor when vented to

atmospheric pressure.

Important NOTE: To ensure accuracy of the calibrator it is critical

to zero the calibrator before a device is calibrated.

3.1 Media Compatibility

The calibrator utilizes a media isolated sensor to prevent sensor

contamination. Whenever possible clean, dry air is the media of

choice. If that is not always possible, make sure that the media is

compatible with Nickel Plated Brass, Silicon, RTV, glass, and ceramic

materials.

3.2 Measuring Pressure with External Modules

The calibrator provides a digital interface to External Pressure

Modules. These modules are available in various ranges and types

Page 17

13

including gauge, vacuum, differential and absolute. The modules

work seamlessly with the calibrator. Simply plug them into the

interface and select [EXT] (external sensor). Since the interface

between the calibrator and the module is digital all the accuracy and

display resolution is derived from the module.

Figure 6

4. Measuring Current

To measure current use the input terminals in the front of the

calibrator. Select the mA function on one of the displays. Current is

measured in mA and percentage of range. The range on the

calibrator is set to 0% at 4 mA and 100% at 20 mA.

For example:

If the current measured is displayed as 75% then the mA value is 16

mA.

Page 18

Figure 7

5. Measuring Voltage

To measure voltage use the input terminals in the front of the

calibrator. Select the Volts function on one of the displays. The

calibrator can measure up to 30V.

Figure 8

14

Page 19

6. Performing a Pressure Switch Test

Figure 10

To perform a switch test, follow these steps:

1. Change the setup to Setup 4 (default switch test).

Setup 4: The upper display is set to [P1] ST, all other displays

are off.

Important NOTE: The pressure Switch Test can be performed

with the following functions[P1] ST, or EXT ST.

2. Connect the calibrator to the switch using the pressure switch

terminals. The polarity of the terminals does not matter. Then

connect the pump to the calibrator and the pressure switch.

3. Make sure the vent on the pump is open. Zero the calibrator if

necessary. Close the vent after zeroing the calibrator.

4. The top of the display will read “CLOSE”.

15

Pressure switch

under test

Page 20

5. Apply pressure with the pump slowly until the switch opens.

Important NOTE: In the switch test mode the display update rate is

increased to help capture changing pressure inputs. Even with this

enhanced sample rate pressurizing the device under test should be

done slowly to ensure accurate readings.

6. Once the switch is open, “OPEN” will be displayed, bleed the

pump slowly until the pressure switch closes.

7. At the top of the display it will now read, “SW OPENED AT” and

give you the pressure that the switch opened at.

8. Press the “NEXT” option to view when the switch closed, and the

dead band.

16

Page 21

17

9. Press the “NEW TEST” option to clear the data and perform

another test.

10. Press the “DONE” option to end the test and return to the

standard pressure setting.

Example:

[P1] ST will return to [P1].

Important NOTE: The previous example uses a normally closed

switch. The basic procedure is still the same for a normally open

switch, the display will just read “OPEN” instead of “CLOSE”.

7. Calibrating Transmitters

7.1 Using the mA Input Function

The mA input function allows the user to read back the 4-20 mA

output from the device being calibrated. This can be done in one

of two ways.

1) Passively - Where the device under test directly generates 4-20

mA and can be read by the calibrator.

2) Actively – Where the calibrator supplies 24 VDC loop power to the

device under test to power the device while reading the resulting

4-20 mA signal.

Page 22

18

7.2 Calibrating a Pressure-to-Current Transmitter

To calibrate a pressure-to-current transmitter (P/I), perform the

following steps:

1. Connect the calibrator and the pump to the transmitter.

2. Apply pressure with the pump.

3. Measure the current output of the transmitter.

4. Ensure the reading is correct. If not, adjust the transmitter as

necessary.

Figure 11.

7.3 Percent Error Function

The calibrator features a unique function which can calculate

pressure vs. milliamp error as a percentage of the 4 to 20 mA loop

span. The percent error mode uses all 3 screens and has a unique

menu structure. It simultaneously displays pressure, mA and

percent error.

Page 23

19

Figure 12.

Example:

Suppose a pressure transmitter under test is 30 psi (2 Bar) Full Scale

and outputs a corresponding 4 to 20 mA signal. The user can

program in a 0 to 30 psi pressure span into the calibrator and the

calibrator will calculate and display the deviation or % Error from the

expected 4 to 20 mA output. This eliminates the need for manual

calculations and also helps if it becomes difficult to set an exact

pressure with an external pump.

To use the %ERROR function proceed as follows:

1. With the calibrator turned on and operating press the F3 key to

activate the MORE menu option. Now press the F1 key to activate

the %ERROR option.

2. Press the F1 key to select the CONFIG option.

3. The first option is setting the Port, use the select option to scroll

through the port choices, when finished select the NEXT option.

Page 24

20

4. LOOP POWER can be toggled on/off, select NEXT when done.

5. Use SELECT to toggle through the UNIT options, and select NEXT

to move on.

6. Use the ↑ and ↓ arrows to set the 100% point of the desired

pressure range, select DONE SET when finished.

7. Again, use the arrows to set 0% point and select DONE SET when

finished and the %ERROR mode will be ready to use.

Page 25

21

Note: The 0% and 100% point will be saved in non-volatile memory

until they are changed again by the user for the internal sensors, and

external pressure modules. When using an external module the 0%

and 100% are set to low and full scale of the module until the user

changes it, or if it was previously saved.

8. Factory Setups

The Calibrator is loaded with five factory setups. These setups are

shown below.

Setup 1: The upper display is set to [P1] mode and the middle is set

to mA, lower is off.

Setup 2: The upper display is set to [EXT] mode and the middle is

set to mA, lower is off.

Page 26

22

Setup 3: The upper display is set to [P1] mode and the middle is set

to [VOLTS] mode, lower is off.

Setup 4: The upper display is set to [P1], the lower display is set to

[EXT].

Setup 5: The upper display is set to [P1], and the lower display is set

to mA Loop.

Page 27

23

9. Remote Operation

9.1 Remote Interface

The calibrator can be remotely controlled using a PC terminal, or by

a computer program running the calibrator in an automated system.

It uses an RS-232 serial port connection for remote operation.

NOTE: To use the remote control option a custom RS-232

cable must be purchased from OMEGA (LEM232). To contact

OMEGA refer to Section 1.1 of this manual. W ith this connection

the user can write programs on a PC, with Windows languages like

Visual Basic to operate the calibrator, or use a W indows terminal,

such as Hyper Terminal, to enter single commands. Typical RS-232

remote configurations are shown in Figure 13.

Figure 13. Calibrator-to-Computer Connection

9.2 Setting up the RS-232 Port for Remote Control

Note: The RS-232 connection cable should not exceed 15m unless

the load capacitance measured at connection points is less than

2500pF.

Serial parameter values:

9600 baud

8 data bits

1 stop bit

no parity

Xon/Xoff

EOL (End of Line) character or CR (Carriage Return) or both

Page 28

24

To set up remote operation of the calibrator on the Windows Hyper

Terminal, connected to a COM port on the PC as in Figure 23, use

the following procedure:

1. Start Hyper Terminal (located in Accessories/Communications of

the Windows Start menu)

2. Select New Connection.

3. For Name enter PCL340. Select the serial port that the calibrator

is connected to.

4. Enter the above information for port settings.

5. Select ASCII setup from File/Properties/Settings and mark these

choices:

Echo typed characters locally

Wrap lines that exceed terminal width

6. Select Ok

7. To see if the port works enter *IDN?. This command will return

information on the calibrator.

9.3 Changing Between Remote and Local Operation

There are three modes of operation of the calibrator, Local, Remote,

and Remote with Lockout. Local mode is the default mode.

Commands may be entered using the keypad on the calibrator or

using a computer. In Remote mode the keypad is disabled, and

commands may only be entered using a computer, but choosing

[GO TO LOCAL] from the menu on the calibrator display will restore

keypad operation. In Remote with Lockout, the keypad can not be

used at all. To switch modes proceed as follows:

1. To enable Remote mode, type in the serial command REMOTE

at the computer terminal.

2. To enable Remote with Lockout, type in “REMOTE LOCKOUT” in

either order.

3. To switch back to local operation enter LOCAL at the terminal.

This command also turns off LOCKOUT if it was on. For more

information on commands refer to the Remote Commands

section.

9.4 Using Commands

9.4.1 Command types

Refer to the Section 10.5 on Remote Commands for all available

commands.

Page 29

25

The calibrator may be controlled using commands and queries. All

commands may be entered using upper or lower case. The

commands are divided into the following categories:

Calibrator Commands

Only the calibrator uses these commands. For example

VAL?

asks for the values displayed on the calibrator display.

Common Commands

Standard commands used by most devices. These commands

always begin with an “*”. For example

*IDN?

tells the calibrator to return its identification.

Query Commands

Commands that ask for information, they always end with a “?”. For

example:

FUNC?

Returns the current modes of the calibrator displays.

Compound Commands

Commands that contain more than one command on one line. For

example;

PRES_UNIT LOWER, PSI, PRES_UNIT?

Sets the pressure units to PSI and queries it to verify. It will return:

PSI, PSI, PSI

9.4.2 Character Processing

The data entered into the calibrator is processed as follows:

• ASCII characters are discarded if their decimal equivalent is less

than 32 (space), except 10 (LF) and 13 (CR):

• Data is taken as 7-bit ASCII

• The most significant data bit is ignored.

• Upper or lower case is acceptable.

9.4.3 Response Data Types

The data returned by the calibrator can be divided into four types:

Page 30

Integer

For most computers and controllers they are decimal numbers

ranging from -32768 to 32768. For example:

FAULT? could return 110

Refer to the Error Codes table (Table 8) for more information on error

codes.

Floating

Floating numbers have up to 15 significant figures and exponents.

For example:

ZERO_MEAS returns 1.210000E-2, PSI

Character Response Data (CRD)

Data returned as keywords. For example:

PRES_UNIT? returns PSI, NONE, NONE

Indefinite ASCII (IAD)

Any ASCII characters followed by a terminator. For example:

*IDN? returns BETA, 301, 250, 1.00

9.4.4 Calibrator Status

Error Queue

If an error occurs due to invalid input or buffer overflow, its error code

is sent to the error queue. The error code can be read from the

queue with the command FAULT?. The error queue holds 15 error

codes. When it is empty, FAULT? returns 0. The error queue is

cleared when power is reset or when the clear command *CLS is

entered.

Input Buffer

Calibrator stores all received data in the input buffer. The buffer holds

250 characters. The characters are processed on a first in, first out

basis.

26

Page 31

9.5 Remote Commands and Error Codes

The following tables list all commands, and their descriptions, that

are accepted by the calibrator.

Table 5: Common Commands

Command Description

*CLS (Clear status.) Clears the error queue.

*IDN? Identification query. Returns the manufacturer, model

number, and firmware revision level of the Calibrator.

*RST Resets the calibrator to the power up state.

Table 6: Calibrator Commands

Command Description

DAMP Turns Damp on or off.

DAMP? Returns if DAMP is on/off

DISPLAY Turns on/off the displays specified in the command

DISPLAY? Returns which displays are on/off

FAULT? Returns the most recent error code

ERROR_LOOP Turns loop power on or off in percent error mode

ERROR_LOOP? Returns the current state of loop power in error mode

ERROR_MODE Turns percent error mode on or off

ERROR_MODE? Returns whether percent error mode is on or off

ERROR_PORT Set the pressure port for percent error mode

ERROR_PORT? Returns the pressure port for percent error mode

FUNC Sets the display mode as specified in the command

FUNC? Returns the current mode of the upper, middle, and

lower display

HI_ERR Sets the 100% of span limit for percent error mode

HI_ERR? Returns the 100% of span limit for percent error mode

LOCAL Returns user to manual operation of the calibrator

LOCKOUT Locks out the keypad of the calibrator in remote opera-

tion

LO_ERR Sets the 0% of span limit for percent error mode

LO_ERR Returns the 0% of span limit for percent error mode

PRES_UNIT Set the pressure unit for the indicated display

PRES_UNIT? Returns the pressure from the indicated display

REMOTE Puts the calibrator in remote mode

27

Page 32

28

ST_START Starts a switch test

ST_OPEN? Returns pressure value at which the switch opened

ST_CLOSE? Returns pressure value at which the switch closed

ST_DEAD? Returns pressure value of the deadband of the switch

VAL? Returns the measured values

ZERO_MEAS Zeros the pressure module

ZERO_MEAS? Returns the zero offset of the pressure module

Table 7: Parameter units

Units Meaning

MA milliamps of current

V Voltage in volts

PSI Pressure in pounds per square-inch

INH2O4C Pressure in inches of water at 4°C

INH2O20C Pressure in inches of water at 20°C

CMH2O4C Pressure in centimeters of water at 4°C

CMH2O20C Pressure in centimeters of water at 20°C

BAR Pressure in bars

MBAR Pressure in millibars

KPAL Pressure in kiloPascals

INHG Pressure in inches of mercury at 0°C

MMHG Pressure in millimeters of mercury at 0°C

KG/CM2 Pressure in kilograms per square-centimeter

ON Turn something on

OFF Turn something off

UPPER Upper Display

MIDDLE Middle Display

LOWER Lower Display

DCI Current measure function

DCI_LOOP Current measure function with loop power

DCV Voltage measure function

P1 Port P1 pressure measure function

P1_ST Switch Test with port P1 pressure measure function

Page 33

29

Table 8: Error Codes

Error Number Error Description

100 A non-numeric entry was received where it should be a

numeric entry

101 Too many digits entered

102 Invalid units or parameter value received

103 Entry is above the upper limit of the allowable range

104 Entry is below the lower limit of the allowable range

105 A required command parameter was missing

106 An invalid command parameter was received

107 Pressure not selected

108 Invalid sensor type

109 Pressure module not connected

110 An unknown command was received

111 Bad Parameter received

112 The serial input buffer overflowed

113 Too many entries in the command line

114 The serial output buffer overflowed

9.6 Entering Commands

Commands for the calibrator may be entered in upper or lower case.

There is at least one space required between the command and

parameter, all other spaces are optional. Almost all commands for

the calibrator are sequential; any overlapped commands will be

indicated as such. This section will briefly explain each of the

commands and describe their general use, which will include any

parameters that may be entered with the command as well as what

the output of the command is.

9.6.1 Common Commands

*CLS

Clears the error queue. Also terminates all pending operations. When

writing programs, use before each procedure to avoid buffer

overflow.

*IDN?

Returns the manufacturer, model number, and firmware revision of

the Calibrator. For example:

*IDN? will return BETA, 301, 0, 1.00

Page 34

30

9.6.2 Calibrator Commands

DAMP

Turns the dampening function on or off.

For example:

If you send DAMP ON this will turn the dampening function

on.

DAMP?

Returns the current state of the dampening function.

For example:

If you send DAMP? It will return ON if the dampening

function is on.

DISPLAY

Turns the indicated display on or off.

For example:

If you send DISPLAY LOWER, ON this will turn the lower

display on.

DISPLAY?

Returns the current state of the each of the displays.

For example:

If you send DISPLAY? It will return ON, ON, ON if the all

the displays are on.

FAULT?

Returns the error code number of an error that has occurred.

The command may be entered when the previous command did

not do what it was meant to do.

For example, if a value for current output is entered that is bigger

than the supported range (0-24mA) FAULT? Would return:

103 which is the code number for an entry over range.

Refer to the Error Codes table for more information on error code

numbers.

Page 35

31

ERROR _LOOP

Turns loop power on or off in percent error mode.

For example:

To set loop power on send ERROR_LOOP ON.

ERROR _LOOP?

Returns the current state of loop power in percent error mode.

For example:

If you send ERROR_LOOP? It will return ON if loop power

is on in error mode.

ERROR_ MODE

Turns percent error mode on and off.

For example:

To turn on percent error mode send ERROR_MODE ON.

ERROR _ MODE?

Returns the current state of percent error mode.

For example:

If you send ERROR_MODE? It will return ON if the

calibrator is in percent error mode.

ERROR_ PORT

Sets the pressure port for percent error.

For example:

To set the pressure port for percent error to [P1] send

ERROR_ PORT P1.

ERROR _ PORT?

Returns the current pressure port for percent error mode.

For example:

If you send ERROR _PORT?, it will return P1 if the

pressure port in percent error is [P1].

Page 36

FUNC

Sets the display indicated in argument one to the function

indicated in argument 2.

For example:

To set the lower display to P1 Pressure mode send FUNC

LOWER,P1.

FUNC?

Returns the current mode of all displays. For example if the

calibrator is set to [P1] ST on the upper display, [P1] on the

middle, and the lower display is off, FUNC? Would return:

ST_P1,P1,NONE

HI_ERR

Sets the 100% point for the percent error mode calculation in the

current engineering units.

For example:

To set the 100% point to 100 psi send HI_ERR 100.

HI_ERR?

Returns the 100% point for the percent error mode calculation.

For example:

If the 100% point is set to 100 psi, HI_ERR? would return

1.000000E+02, PSI .

LOCAL

Restores the calibrator to local operation if it was in remote

mode. Also clears LOCKOUT if the calibrator was in lockout

mode.

LOCKOUT

Sending this command sets the lockout state, when the unit is in

REMOTE or goes to remote it prohibits use of the keypad

completely. The lockout state can only be cleared by sending

the LOCAL command.

32

Page 37

LO_ERR

Sets the 0% point for the percent error mode calculation in the

current engineering units.

For example:

To set the 0% point to 20 psi send LO_ERR 20.

LO_ERR?

Returns the 0% point for the percent error mode calculation.

For example:

If the 0% point is set to 20 psi, LO_ERR? would return

2.000000E+01, PSI .

PRES_UNIT

Used to set the pressure unit for the indicated display

For example:

To set the pressure unit to psi on the lower display send

PRES_UNIT LOWER, PSI.

33

Page 38

PRES_UNIT?

Returns the pressure unit used when measuring pressure for

each of the 3 displays.

REMOTE

Puts the calibrator in remote mode. From the remote mode the

user can still use the keypad to get back to local unless the

command LOCKOUT was entered before REMOTE. Than the

keypad is totally locked out, and the user has to send the LOCAL

command to get back to local operation.

ST_START

Starts a switch test.

ST_CLOSE?

Returns the pressure that the switch closed at in the current

pressure units.

ST_OPEN?

Returns the pressure that the switch opened at in the current

pressure units.

ST_DEAD?

Returns deadband of the switch in the current pressure units.

VAL?

Returns the value of any measurement taking place on the upper

and lower display. For example, if the upper display is measuring

5mA, and the lower display is measuring 10V, then VAL? will

return:

5.000000E-03, A, 1.000000E+01, V

ZERO_MEAS

Zeroes the attached pressure module. Enter the zeroing value in

PSI after the command when zeroing an absolute pressure

module.

ZERO_MEAS?

Returns the zero offset or the reference value for absolute

pressure modules.

34

Page 39

10. Specifications (18 °C to 28 °C unless otherwise noted.)

General

Instrument Setup Recall 5; last used on power-up

Environmental

Operating Temperature -10 °C to +50 °C

Storage Temperature -20 °C to +60 °C

Power Requirements 6.0 VDC

Battery Four (4) standard AA cells

Battery Life > 25 hours, typical usage

Physical

Dimensions 8.3” H x 3.9” W x 1.8” D (21.082 x 9.906 x 4.572 cm)

Weight 1 lb. 4 oz. (0.567 kg)

Connectors/Ports Pressure - one, 1/8” NPT (2 ports on differential models)

BetaPort-P pressure module

Included Accessories Soft case, batteries, manual, NIST-traceable certificate,

and test leads

Ranges

Available Pressure

1 psi, 5 psi, 30, psi, 100 psi, 300 psi

mA 0 to 24.000 mA

Volts 0 to 30.000 VDC

Engineering Units psi, bar, mbar, kPa, kgcm2, cmH2O@4°C,

cmH2O@20°C, mH2O@4°C, mH2O@20°C, inH2O@4°C,

inH2O@20°C, inH2O@60°F, mmHg@0°C, inHg@0°C,

ftH2O@4°C, ftH2O@20°C, ftH2O@60°F

Accuracy

Pressure

5, 30, 100, 300 psi ±0.05% F.S.

1 psi ±0.075% F.S.

mA ±0.015% of rdg±0.002mA

Volts ±0.015% of reading ±0.002V

Temperature Effect

No effect on accuracy on all functions from 18°C to 28°C

Add ±0.005% F.S./°C for temps outside of 18°C to 28°C

35

Page 40

11. Maintenance

11.1 Replacing Batteries

Replace batteries as soon as the battery indicator turns on to avoid

false measurements. If the batteries discharge too deeply the

PCL340 will automatically shut down to avoid battery leakage.

Note: Use only AA size alkaline batteries or optional rechargeable

battery pack.

11.2 Cleaning the Unit

Warning

To avoid personal injury or damage to the calibrator, use only the

specified replacement parts and do not allow water into the case.

Caution

To avoid damaging the plastic lens and case, do not use solvents or

abrasive cleansers.

Clean the calibrator with a soft cloth dampened with water or water

and mild soap.

11.3 Service Center Calibration or Repair

Only qualified service personnel should perform calibration, repairs,

or servicing not covered in this manual. If the calibrator fails, check

the batteries first, and replace them if needed.

Verify that the calibrator is being operated as explained in this

manual. If the calibrator is faulty, call Omega's customer service

department for an AR number to return the unit. Be sure to pack the

calibrator securely, using the original shipping container if it is

available.

36

Page 41

Page 42

Page 43

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and

workmanship for a period of 13 months from date of purchase. OMEGA’s Wa rranty adds an

additional one (1) month grace period to the normal one (1) year product warranty to cover

handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage

on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized R eturn (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired

or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any

action of the purchaser, including but not limited to mishandling, improper interfacing, operation

outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence

of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration;

improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s

control. Components which wear are not warranted, including but not limited to

contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for

any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENT ATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED,

EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not ex ceed the purchase price of the component upon which liability is based. In no event shall OMEGA be

liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as

a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity;

or (2) in medical applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language,

and, additionally, purchaser will indemnify OMEGA and hold OM EGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked

on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR W

ARRANTY RETURNS, please have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without

the prior written consent of OMEGA ENGINEERING, INC.

Page 44

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gages

MU

Load Cells & Pressure Gages

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

MU

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Datalogging Systems

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

MU

pH, Conductivity & Dissolved Oxygen Instruments

M4292/1006

Loading...

Loading...