Page 1

FPR130 Series

Visual Flow Indicator with Pulse Output

M-1982/1112

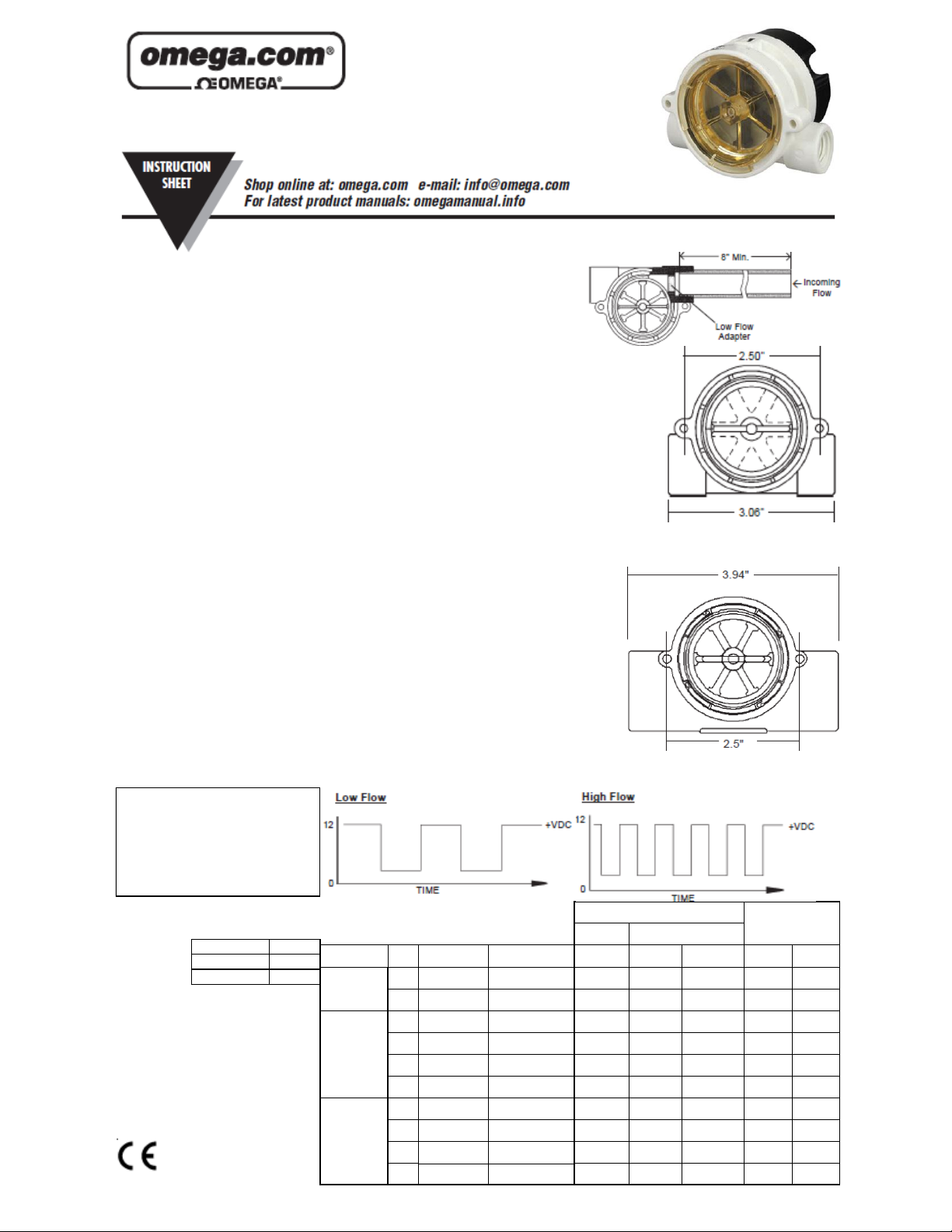

Description: FP R1 3 0 units m oni t o r d ynam i c flui d f low. T h e ro t o r re a c t s to

turbulenc e , p u l s a t i on, e n t r a i n e d a i r , a n d o t her f l o w a b n o rm a l i t i e s i n duced i n

the fl o w st r eam by ot he r pr o c es s ha r d w are. Fo r op tim u m pe r f orm a n c e , in s t a l l

units w h e r e n om i n a l f l o w co n d i t i o n s exi s t , w i t h port s l o c a t e d a t t h e top. I n c o m -

ing f low m ay b e p l a c ed to eithe r po r t . A mi n i m u m o f 8” of st r a i g h t pi p e on th e

inlet s i d e i s r e q u i red.

Installation: FP R1 3 0 serie s sensors co nn e c t t o pi pi n g vi a NPT mati n g

thread fo rm s . T h e fol l o w i n g gui d e l i n e s a r e p r o v i d e d t o a s s i s t wi t h inst a l l a t i o n f o r a leak free se a l , wi t h o u t dam a g e to t h e unit: 1. Ap p l y pi pe th r e ad se a l ant to mal e pi pe th r e a d s .

2.Th r e a d un i t onto ma l e pi pe th r e a d u n t i l ha n d -t i g h t . 3. Ti g h t e n pipe 1 to 1 - 1 / 2 ad dit i o n a l

turns. 4 . If im p r o p e r se a l resul t s , co n t i n u e tu r n i n g pi p e into u n i t i n 1/ 4 tu r n inc r e m e n t s . Do

not e xce e d o n e a d diti o n a l t u r n . R ecom m e n d e d P i p e S eal a n t : P F A T h r e a d T a p e .

Panel Mountin g: Any FP R 1 3 0 se r i e s se n s o r m ay b e pa n e l mo u n t e d u s i ng h o l e s in t e -

grated in to th e bo d i es . Two (2 ) mounting ears ar e p r o v i ded at t h e b o d y c e n t e r l i n e t o r e ceive #8 se l f - t a p p i n g s cre w s . NO T E : A NS I T Typ e 23 se l f -t a p p i n g sc r e w s a r e re c o m m e n d ed. T h e y m a y be replac e d w i th s t a n d a rd m a c hine s c re ws i f reins t a l l a t i o n sh oul d b e r e quired.

Filtration and C l e a n i n g: 15 0 micron fi ltrati o n is r e c o m me n d e d . Howev e r , sh ou l d

foreign pa r t i c l e s en t e r th e FP R 1 3 0 s e n s or, acc u m u l a t i o n is ea s i ly cl eare d by rem o v i n g th e

lens fr om the bod y. T h e lens i s rem o v e d b y tur n i n g i t s ce n t e r r i b 4 5 ° c o u n t e r -c loc k w i s e

and t h e n pull i n g i t o ut . T o r ei n s t a l l the l e n s , si m p l y r e v e r s e t h e pr o c e s s . P r essu r e m u s t b e

reliev e d f r o m t h e s ystem p r i o r t o s e n s or cl e a n -o u t .

NOTE S : Pr oduct must be m a i n t a i n e d and in stall e d in s t r i c t a c c o r d a n c e wi t h t h e Nati o n a l

Elec t r i c a l C o d e a nd O m e g a p r oduct c a t a l o g a n d i ns t r u c t i o n b ul l e t i n . F a i l u r e t o o b serve t h i s w a r n i ng c ould r e s ult i n s e r i o u s in j u ries o r da m a g e s . A n a p p r o priate explo sion- p r o o f e n c l o s ur e o r i n t r i nsic a l l y s a f e in t e r f a c e d evi c e m u s t be u s e d f o r ha z a r d o u s

area ap plic a t i o n s in v o l v i n g s u c h thi n g s as (b u t n o t l i m i t e d t o ) ignit a b l e mi xtures ,

com b u s t i b l e dust a n d f l a m m a b le m ateri a l s . P res s u r e an d t em p e r a t u r e lim i t a t i o n s

sho wn o n in d i v i d u a l c a t alog p a g es a n d dr a w i n g s fo r th e speci f i e d fl o w swi t c h e s mu s t

not b e e xce e d e d . Th e s e p r e s s ur e s a n d te m p e r a t u r e s t a k e i n t o cons i d e r a t i o n po s s i b l e

s ys tem s u r ge p r e s s u r e s / t em p e r a t u r e s a nd t h e i r fr e q u e n c i e s . Selec t i o n o f ma t e r i als

for c o m p a t i b i l i t y with t h e m e d ia i s c r i t i cal t o t h e l i f e and o p e r a t i o n o f O m e g a f l ow

swi tc h e s . Ta k e ca r e in the pr o p e r selecti o n of material s of co ns t r u c t i o n ; pa rti c u l a r l y

we tt e d m a t e r i a l s. L i f e e xpect a n c y o f s wit c h c o n t a c t s v a r i e s with a p p l i c a t i o n s. C o n t a c t

Ome g a i f l ife c y c l e tes t i n g i s r e q u i r e d . A m b i e n t tem p e r a t u r e ch a n g e s do a f f e c t sw i t c h

set p oint s , si nc e th e specif i c gravit y of a liqui d ca n v ar y wi th te m p erat u r e . Fl ow

swi tc h e s have be e n de s i g ned to re s i s t s h o c k a n d vibrat i o n ; how e v e r , shock an d vi bration s h o u l d b e m in i m i z e d . L i q u i d m e d i a c o n t a i n i ng p a r t i c u l a t e a n d /or d e b r i s s h o u l d

be fi lt e r e d to ens u r e p r o p e r o p e r a t i o n o f O m e g a p r o d u c ts. E l e c t r i c a l e n t r i e s a n d

moun t i n g p o i n t s m a y re qui r e l i q u i d / v a p o r s eali n g i f l o c a t e d i n a n e n c l osed t a n k . F l o w

swi tc h e s m u s t n o t be fi e l d r e p a i red. P h y s i c a l d a m ag e d s u s t a i n e d b y t h e p r o d u c t m ay r e n d e r i t u n servi c e a b l e .

Signal Output: Output signal is an on/off

pulse of the DC voltage supplied to the

unit. It is compatible with all digital logic

families. Input voltage range is 4.5

to 24 VDC. Frequency of the output pulse

is proportional to the flow rate and ranges

from approximately 15 Hz at low flow to

225 Hz at high flow.

.25”, .50” Plastic and Brass Bodies*

*BSPP plastic units are 4.95”

.75” Brass Bodies

Elec t r i c a l Da t a : In pu t Pow e r an d

output a r e c o n n e c ted v i a a mu l t i c o nd uc t or , PV C - ja ck e t ed 2 4”

cable.

+VDC Red

Ground Black

Signal Output White

This product is suitable for Class I and Class II

applications only, per the requirements of

standard EN60730 and any additional specific

requirements for a particular application or

medium being sensed. Class I compliance of

metal bodied units requires a ground connection between the metal body and the earthing

system of the installation. Class I compliance of

plastic bodied units in contact with a conductive

medium requires that the medium be effectively

earthed so as to provide an earthed barrier

between the unit and accessible areas. For

Class III compliance, a supply at safety extra-

low voltage (SELV) must be provided. Please consult the Factory for

compliance information on specific

part numbers.

Port

Body Material

Polypropylene

Brass

Stainless Steel

Part Number

Size

NPT Threads

.25” FPR131 FPR131-BSP 0.5 - 5.0 0.1 - 1.0 152147 2196 10,900

.50” FPR132 FPR132-BSP 4.0 - 20.0 1.5 - 12.0 151832 611 959

.25” FPR133 FPR133-BSP 0.5 - 5.0 0.1 - 1.0 152147 2196 10900

.50” FPR134 FPR134-BSP 4.0 - 20.0 1.5 - 12.0 133743 611 959

.75” FPR135 FPR135-BSP 5.0 - 30.0 N/A N/A 385 N/A

1.00” FPR136 FPR131-BSP 8.0 - 60.0 N/A N/A 180 N/A

.25” FPR133-SS FPR133-BSP-SS 0.5 - 5.0 0.1 - 1.0 152147 2196 10900

.50” FPR134-SS FPR134-BSP-SS 4.0 - 20.0 1.5 - 12.0 133743 611 959

.75” FPR135-SS FPR135-BSP-SS 5.0 - 30.0 N/A N/A 385 N/A

1.00” FPR136-SS FPR131-BSP-SS 8.0 - 60.0 N/A N/A 180 N/A

Part Number

BSPP Threads

Flow Range—GPM

Standard Low Flow

Range Range

Adapter Part

Number

K-Factor

(Pulses/Gal)

Standard Low Flow

Page 2

159192 rev C

Loading...

Loading...