Page 1

1

Page 2

2

Page 3

Introduction / Table of Contents Step One

An ultrasonic sound wave is pulsed from the base of the transducer. The sound wave reflects against the

process medium below it. The sound wave energy is returned to the transducer. The microprocessor based

electronics measures the time of flight between the sound pulse generation and its receipt. This translates into

the distance or range between the transducer and process media below.

NEW FEATURES

Reflective Ultrasonic Technology

Simple configuration with LVCN414-SW software configuration

Increased temperature range

Increased output filtering

TABLE OF CONTENTS

Introduction: .......................................................................................................................................................... 3

Specifications: ........................................................................................................................................... 5

Dimensions: .............................................................................................................................................. 6

About this manual: .................................................................................................................................... 7

Getting Started: ..................................................................................................................................................... 8

Setup Overview: ........................................................................................................................................ 8

Reflective Technology: .............................................................................................................................. 8

Components: ............................................................................................................................................. 9

Basic Configuration: ................................................................................................................................ 10

Basic Relay Settings: .............................................................................................................................. 10

Understanding Sensor Height: ................................................................................................................ 11

Understanding Fill-Height: ................................................................................................................. 12-13

Sensor Output to Local Display: ............................................................................................................. 14

Configuration: .................................................................................................................................................... 15

Configuring LVU500 Series with LVCN414-SW Software: ..................................................................... 15

Step 1 – Install LVCN414-SW Software: ................................................................................................ 16

Software System Requirements: ................................................................................................. 16

USB

Step 2 – Measure the Tank: .................................................................................................................... 17

Step 3 – Sensor Configuration: ............................................................................................................... 18

Step 4 – Dimensional Entry: ................................................................................................................... 19

Step 5 – Tank Level Confirmation: .......................................................................................................... 20

Step 6 – Write to Unit: ............................................................................................................................. 20

Installation: .......................................................................................................................................................... 21

Mounting Guide: ...................................................................................................................................... 21

Fitting Selection: ................................................................................................................................ 22-24

®

Fob (LVU500-USB) Interface: ........................................................................................... 16

3

Page 4

Introduction / Table of Contents Step One

Wiring: ................................................................................................................................................................. 25

Wiring Diagram – Sample: ...................................................................................................................... 25

Wiring LVU500 series: ............................................................................................................................ 25

Wire Connections: ................................................................................................................................... 26

General Notes for Electrical Connections, Usage and Safety: ............................................................... 26

Common Wiring to Displays, Controllers & PLCs: .................................................................................. 27

Switching Inductive Loads: ..................................................................................................................... 28

Voltage Output: ....................................................................................................................................... 28

LVCN414-SW Software Appendix: ..................................................................................................................... 29

Sensor Configuration: ........................................................................................................................ 29-35

Number of Pumps: ...................................................................................................................... 29

Pump/Valve Action: ..................................................................................................................... 30

Pump/Valve Mode: ...................................................................................................................... 31

Relay Fail-Safe: ........................................................................................................................... 32

Switch/Alarm Configuration: ........................................................................................................ 33

Switch Hysteresis/Dead Band: .................................................................................................... 34

Loop Fail-Safe: ............................................................................................................................ 35

Output at Empty: ......................................................................................................................... 35

Volumetric Configuration: ................................................................................................................... 36-38

Tank Level Confirmation: ........................................................................................................................ 39

Write to Unit” ........................................................................................................................................... 40

Appendix: ............................................................................................................................................................ 41

Factory Settings: ..................................................................................................................................... 41

User Settings: ......................................................................................................................................... 41

Troubleshooting: ................................................................................................................................ 41-42

Warranty: ............................................................................................................................................................ 43

4

Page 5

Introduction (continued) Step One

SPECIFICATIONS

Electrical:

Supply Voltage: 14-28 Vdc

Signal output: 4 to 20 mA current loop; 22 mA

max.

Signal invert: 4-20mA or 20-4mA

Signal fail-safe: 4mA, 20mA, 21mA, 22mA or

hold last value

Loop resistance: 500 Ohms @ 24 VDC

Contact type: (4) SPST relays, 1A

Contact fail-safe: Power loss: Hold last

Power on: Open, close or hold

last

Hysteresis: Selectable

Mechanical:

Enclosure: Polypropylene (PP-FR GF30)

Transducer: Polyvinylidene Fluoride (PVDF)

Cable jacket mat’l: Polyurethane

Cable type: 9-conductor

Cable length: 4’ (121.9 cm)

Process Mount: 2" NPT or 2” G

Gasket: FKM (G thread only)

Classification: General purpose

Compliance: CE, RoHS

Environmental:

Process temperature: F: -40° to 176°

C: -40° to 80°

Temp. compensation: Automatic

Ambient temp.: F: -31° to 140°

C: -35° to 60°

Pressure: 30 psi, derated @ 1.667 psi per

degree C above 25 °C

Enclosure: IP68, NEMA 6P

Functional:

Range: LVU501: 1.5m (4.92 feet)

LVU503: 3.0m (9.84 feet)

Dead band: LVU501: 3.8cm (1.5

LVU503: 10cm (4 inches)

Accuracy: LVU501: 0.125” (3mm)

LVU503: 0.2% of Range in

Resolution: 0.125" (3mm)

Beam width: 2” (5cm)

Configuration: LVCN414-SW configuration

Memory: Non-volatile

inches)

air at 20 °C

software

5

Page 6

Introduction (continued) Step One

DIMENSIONS

Dimensions for LVU501 & LVU503 Series

Cable Dimensions for LVU501 & LVU503 Series

6

Page 7

Introduction (continued) Step One

About this Manual: PLEASE READ THE ENTIRE MANUAL PRIOR TO INSTALLING OR USING THIS

PRODUCT. This manual includes information on the LVU500 series Ultrasonic Level Transmitter from

OMEGA ENGINEERING. Please refer to the part number located on the sensor label to verify the exact model

configuration, which you have purchased.

User’s Responsibility for Safety: OMEGA ENGINEERING manufactures a broad range of level sensing

technologies. While each of these sensors is designed to operate in a wide variety of applications, it is the

user’s responsibility to select a sensor model that is appropriate for the application, install it properly, perform

tests of the installed system, and maintain all components. The failure to do so could result in property

damage or serious injury.

Proper Installation and Handling: Only professional staff should install and/or repair this product. Never

over tighten the sensor within the fitting. Always check for leaks prior to system start-up.

Wiring and Electrical: A supply voltage of 14 to 28 VDC is used to power the LVU500 series. Electrical

wiring of the transmitter should be performed in accordance with all applicable national, state, and local codes.

Material Compatibility: The enclosure is made of Polypropylene (PP-FR GF30). The transducer is made

of Polyvinylidene Fluoride (PVDF). Make sure that the model, which you have selected, is chemically

compatible with the application media.

Enclosure: While the sensor housing is liquid-resistant the LVU500 series is not designed to be

operational when immersed. It should be mounted in such a way that the enclosure and transducer do not

come into contact with the application media under normal operational conditions.

Handling Static-Sensitive Circuits/Devices: When handling the transmitter, the technician should follow

these guidelines to reduce any possible electrostatic charge build-up on the technician’s body and the

electronic part.

1. Always touch a known good ground source before handling the part. This should be repeated while

handling the part and more frequently after sitting down from a standing position, sliding across the seat

or walking a distance.

2. Avoid touching electrical terminals of the part unless making connections.

Make a Fail-Safe System: Design a fail-safe system that accommodates the possibility of switch and/or

power failure. OMEGA ENGINEERING recommends the use of redundant backup systems and alarms in

addition to the primary system.

Flammable, Explosive or Hazardous Applications:

The LVU500 series should not be used within classified hazardous environments.

Warning: Always use the FKM gasket when installing the “G” threaded version of LVU500 series.

Warning: Make sure that all electrical wiring of the switch is in accordance with applicable NEC codes.

7

Page 8

Getting Started Section Two

SETUP OVERVIEW

Below highlights the initial steps in setting up your sensor for operation.

1. Check Part Number (Section Two)

a. Confirm that the sensor’s part number matches the ordered part number and all components

are provided with the model delivered.

2. Measurements, Installation & Software (Section Two)

a. Understand the location placement of the sensor relative to Measurement Range including

Sensor Height and Fill-Height settings.

b. Download the LVCN414-SW software from omega.com/ftp.

3. Configure Sensor with LVCN414-SW (Section Three)

a. Section 3 contains information on using the LVCN414-SW configuration software.

4. Install the sensor (Section Four)

a. Section 4 contains information about the sensor location placement and its mechanical

installation.

5. Wire the sensor (Section Five)

a. Section 5 contains information about the sensor’s electrical wiring and power requirements.

REFLECTIVE TECHNOLOGY

Condensation is the most common variable in liquid level applications. Condensation attenuates the acoustic

signal of ultrasonic sensors with horizontal transducers, weakening their signal strength and signal to noise

ratio by up to 50%, and substantially reducing their measurement reliability. At the core of Reflective

Technology is a simple fact. Unlike flat horizontal surfaces, significant water droplets cannot adhere to smooth

vertical surfaces. By orienting the transducer vertically, condensation runs off the transducer and does not

affect sensor performance. The unimpeded transmit and receive signals are redirected to and from the liquid

off a 45º reflector, delivering reliable level measurement.

FLAT TRANSDUCER REFLECTIVE TRANSDUCER

Signal Attenuation Reliable Measurement

8

Page 9

Getting Started (continued) Section Two

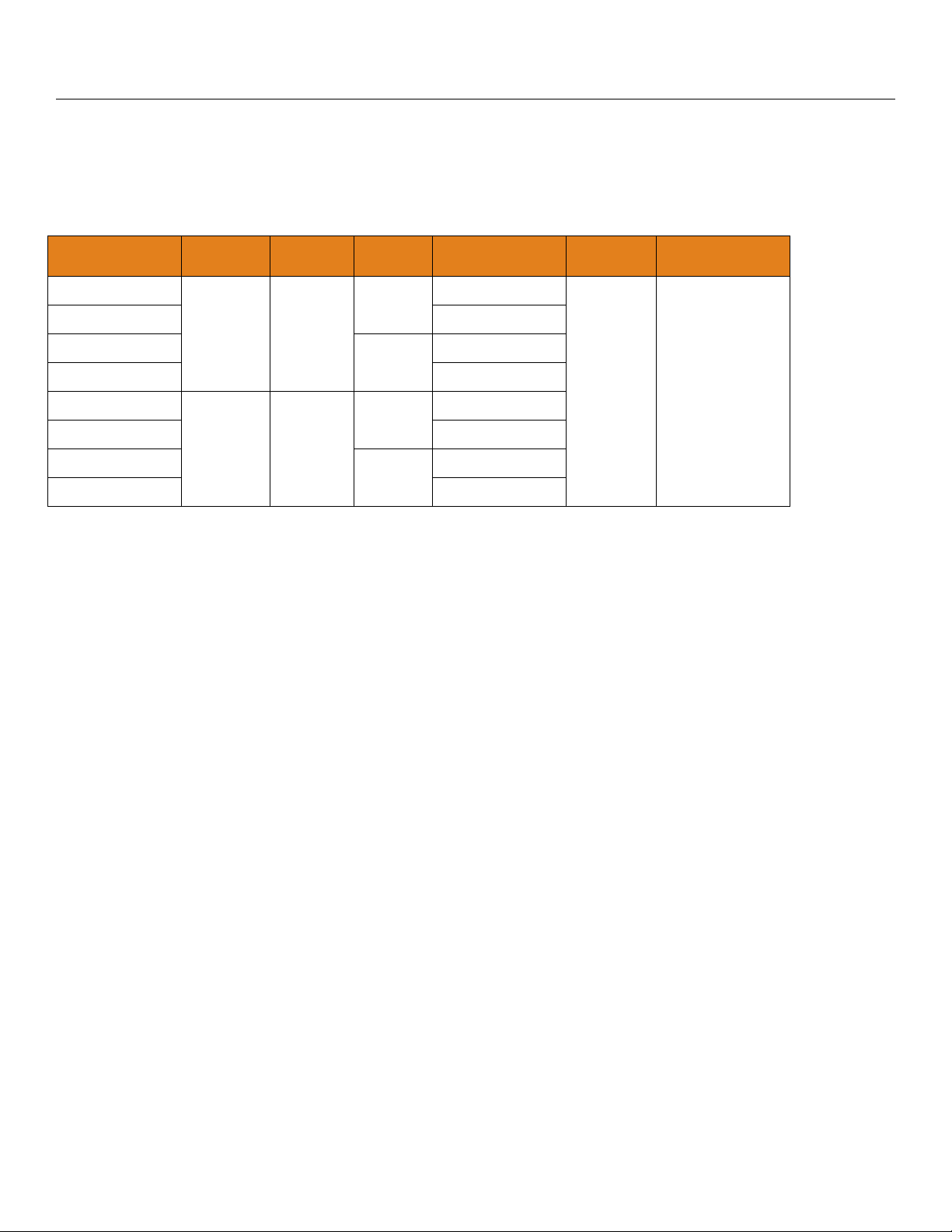

COMPONENTS

The LVU500 series is offered in two different models with 4-20 mA output and relay control. Depending on the

model purchased, you may or may not have been shipped all the components shown below. All G threaded

process mounts require a FKM gasket for installation and operation of LVU500 series.

P/N

LVU503-B

LVU503 Included

LVU503-G-B

LVU503-G Included

LVU501-B

LVU501 Included

LVU501-G-B

LVU501-G Included

FKM Gasket (G threaded version only)

o Part #210138

Fob (LVU501, LVU501-G, LVU503 & LVU503-G version only)

o Part #LVU500-USB

Quick Start Guide

Max.

Range

9.8’

(3m)

4.9’

(1.5m)

Dead

Band

4”

(10cm)

1.5”

(3.81cm)

Thread Fob Output Configuration

2” NPT

2” G

2” NPT

2” G

Not Included

Not Included

Not Included

Not Included

4-20mA

&

4 SPST

Relays

LVCN414-SW

only

9

Page 10

Getting Started (continued) Step Two

BASIC CONFIGURATION

The LVU500 series can be configured using the Omega Engineering on-line free LVCN414-SW software

download coupled to a USB

The LVU500 series can be configured before installation or after installation. The transmitter features nonvolatile memory, so any settings configured before installation will not be lost when the sensor is powered

down To start, the following information is required:

Basic Tank Information

o HEIGHT (Sensor Height) – Distance from

the bottom of the tank to the bottom of the

sensor.

o FILL-H (Fill-Height) – Maximum fill height

of the liquid from the bottom of the tank.

Power:

o Provide input power to the LVU500

series.

®

port with a USB® Fob.

Note: The HEIGHT and Fill-Height (FILL-H) settings also determine the 4 to 20 mA current span. The

HEIGHT setting determines the 4mA position and the FILL-H setting determines the 20 mA position.

BASIC RELAY SETTINGS

High Alarms (Hi) – Used to energize a relay

(ON) when the level reaches the Hi setting.

Relay will de-energize (OFF) when level falls

below the original setting.

Tank Fill (ON & OFF) – Used to automatically

fill a tank using only one relay. Relay

energize at ON level and remains energized

until it reaches the OFF level where it deenergizes. Relay remains de-energized until

the level falls below ON level.

Tank Empty (not shown) – is the exact

opposite of Tank Fill. One relay is used to

empty the tank with ON set to a high point in

the tank and OFF set to a low point.

Lo Alarms (Lo) – Used to energize a relay (ON) when the level falls below the Lo setting. Relay will

de-energize (OFF) when level rises above the original setting.

Note: All relay settings are referenced from the Empty or 4mA setting of the tank.

10

Page 11

Getting Started (continued) Step Two

UNDERSTANDING SENSOR HEIGHT

This is a critical setting for LVU500 series. Sensor Height (SH) defines the location of the sensor from the

bottom of the tank. The value must take into account the shape of the tank and any risers, fittings, structures

or extensions associated with the tank or the installation (see examples below). The reference point for

definition of the Sensor Height is always the bottom of the mounting nut.

Sensor Off-center

Simple Vertical Tank Dome Top Raises HEIGHT

Changes HEIGHT

Simple Open Top Tank Sensor Extends into Sump

Simple Horizontal Tank Riser Elevates HEIGHT

Cone Bottom

Elevates HEIGHT

Mounting Fixture

Elevates HEIGHT

11

Page 12

Getting Started (continued) Step Two

UNDERSTANDING FILL-HEIGHT

This is another critical setting for the LVU500 series. Fill-Height defines the location of the highest point in the tank

where the sensor will read level changes. When the level rises above Fill-Height, the sensor will read full (as long

as the level does not enter the dead band). The reference point for definition of Fill-Height is always from the

bottom location of the Sensor Height. The value must take into account the sensors dead band, any risers, fittings,

structures or extensions associated with the tank or the installation as well as the tanks geometry.

Example #1 – Flat Top Tanks

Tank A is a vertical tank with a flat top. The

highest value for Fill-Height can be calculated by

subtracting the Dead Band from the Sensor Height.

Fill-Height = Sensor Height – Dead Band

Tank B is another vertical tank with a riser that

matches the dead band of the sensor. In this case,

the Fill-Height will be set to the top of the tank.

Note: The ratio of height to diameter of the riser

must be no greater than 2:1. Any higher and the

sensor will target the inside wall of the riser.

Example #2 – Dome Top Tanks

Tank C has a tall enough dome whereas the Dead

Band is above the straight side of the tank. The

Fill-Height can be set to the top of the straight side

(this is advantageous because the top of the

straight side is typically a known volume of liquid).

The sensor is moved to a flat part of Tank D. As a

result, the Dead Band is now below the straight

side of the tank. Fill-Height cannot be set to match

the straight side of the tank. Calculate Fill-Height

as follows:

Fill-Height = Sensor Height – Dead Band

Example #3 – Horizontal Tanks

Tank E is a horizontal tank with a rounded top.

The highest value for Fill-Height can be calculated

by subtracting the Dead Band from the Sensor

Height.

Fill-Height = Sensor Height – Dead Band

Tank F is another horizontal tank with a riser that

matches the dead band of the sensor. In this case,

the Fill-Height will be set to the top of the tank.

Note: The ratio of height to diameter of the riser

must be no greater than 2:1. Any higher and the

sensor will target the inside wall of the riser.

12

Page 13

Getting Started (continued) Step Two

Example #4 – Cone Bottom Tank

Tank G and Tank H are both vertical tanks that are

being supported above ground level with tank

stands. The location of the Sensor Height (Tank G

- bottom of tank or Tank H – ground level) will

influence the Fill-Height setting.

Note: Fill-Height must always be referenced to the

lowest location of the Sensor Height.

Since Tank G is off of the ground, the lowest

location may be difficult to identify/measure. This

location is required if the Volumetric Mode in

LVCN414-SW software is used.

Tank H uses ground level as the main reference

location. This method is easiest to use and ideal

for using the Distance Mode of LVCN414-SW

software.

Cone and Rounded Bottom Tanks

The location of an LVU500 series

on the installation of the sensor. Be sure to understand the geometry directly underneath the sensor. Cone or

rounded bottom tanks will provide off angled surfaces that can reflect the ultrasonic sound energy away from

the sensor as the liquid level is lowered.

#1 Center of Cone #2 Above an Angled Tank

Does not impede sensor’s

Tank

Geometry

Distance

Reading

performance. Sensor is able

to track the entire range of

the tank.

Sensor Height is typically

set to the bottom of the tank.

Sensor will track the full

range of the tank.

installed along the top of a cone or rounded bottom tank may have an effect

#3 Above an Angled Tank

Bottom (straight side only)

Does not impede sensor’s

performance as long as the

level remains within the

straight side of the tank wall.

Sensor Height is typically

set to the bottom of the

straight side. Sensor will

only tack the straight side of

the tank.

Bottom (full range)

Does impede sensor’s

performance. The angled

bottom will reflect ultrasonic

energy away from the

sensor.

Sensor Height is set to the

bottom of the tank; the

sensor will function as long

as the level is within the

straight side of the tank.

13

Page 14

Getting Started (continued) Step Two

SENSOR OUTPUT TO LOCAL DISPLAY/CONTROLLER

LVU500 series outputs a 4-20 mA signal to a local display/controller or to remote devices such as PLCs,

SCADA, DCS or other displays/controllers. The 4-20 mA signal is set relative to the Sensor Height and FillHeight settings. These settings create an operational range that can be translated into a level reading in

defined units (i.e. inches, feet, gallons, meters, liters, etc.).

Tank A

In the Tank A example, the Sensor Height sets the 4mA to the bottom of the tank. Fill-Height sets the 20mA to

the top of the straight side of the tank.

In the Tank B example, the 4-20mA sensor range is correlated to actual units of level measurement. The

operational range now will have engineering values of 0 to 10 feet or 0 to 1000 gallons or 0 to 120 inches.

In the Tank C example, the 20mA setting was lowered by 1 foot, so the engineering values for the new shorter

operational ranges are either 0 to 9 feet, 0 to 900 gallons or 0 to 108 inches.

Tank B

Tank C

14

Page 15

Configuration Step Three

LVU500 series

can be configured before installation. The transmitter features non-volatile memory, so any

setting configured before installation will not be lost when the switch is powered down. To configure, follow the

steps below:

1. Install LVCN414-SW software

a. Go to omega.com/ftp and select the installer program.

b. Review how USB

®

Fob interfaces with LVU500 series and your computer.

2. Measure the Tank

a. Begin by measuring the key tank and fitting dimensions.

b. Include all settings for each relay.

c. Correct tank dimensions will result in accurate sensor measurement.

3. Sensor Configuration

a. Configures Number of Pumps, Pump/Valve Action, Pump/Valve Mode, Relay Fail-Safe,

Switch/Alarm Configuration, Switch Hysteresis/Dead Band, Loop Fail-Safe & Output at Empty for

the sensor.

4. Dimensional Entry

a. Distance Mode (default)

i. Basic information for operation (Sensor Height & Fill-Height).

ii. Relay activation settings.

5. Tank Level Confirmation

a. Confirm the values are accurate for the application.

6. Write to Unit

a. Uploads configuration into the sensor.

b. Access to a customer wiring diagram specific to the relay configuration.

15

Page 16

®

Configuration (continued) Step Three

STEP 1 – INSTALL LVCN414-SW SOFTWARE

LVU500 series is configured through LVCN414-SW, a PC software program. LVCN414-SW is a free download

from Omega Engineering’s website. You must download and install LVCN414-SW prior to plugging in the

®

Fob (LVU500-USB).

USB

Please go to http://www.omega.com/ftp

.

Click on Flow, Level, pH, Environmental, and Pressure Section and press on Products

Select the LVCN414 folder

Select the installer - LVCN414InstallerverXpXX.zip, This will download the installer onto your computer.

Once completed, run the installer.

LVCN414-SW SOFTWARE SYSTEM REQUIREMENTS

Windows® 2000, XP, Vista, 7, 8, 10

32 or 64-bit system

1 USB

®

2.0 port

10 mB hard drive space

256 mB RAM

Internet connection

USB® FOB INTERFACE

LVU500 series communicates with LVCN414-SW through a USB

Before plugging your Fob into your computer’s USB

®

port, be sure that you have installed LVCN414-SW (see

®

interface called a Fob (LVU500-USB).

omega.com/ftp) on your computer.

Connect the red, green, white and black wires from LVU500 series into the correct terminals on the Fob.

Tighten the screws on the terminals. Plug your Fob into the USB

®

port of your computer.

Wiring to Fob (LVU500-USB)

LVU500-USB USB

Fob

Wiring is identical for all LVU500 series – Use only the Red, Black, Green and White wires.

The maximum cable distance between the computer and LVU500 series is 15’. This only applies for

configuring the LVU500 series.

Once LVU500 series is configured and prior to installation, isolate the white and green wires from active

power to prevent a short from the configuration circuit.

The LVU500-USB is backward compatible with previous sensors that used the LVCN414-USB.

Note: When using the Fob, do not add VDC or VAC power. The Fob, when connected to the computer, will

provide the required power to the LVU500 series.

16

Page 17

Configuration (continued) Step Three

STEP 2 - MEASURE THE TANK

Measuring the tank is one of the most important aspects in

configuring the sensor. When measuring the tank, take

into account the location of the sensor with respect to

fittings, risers, dome tops and bottoms, and identify where

the measurements are taken from the sensor. The Sensor

Height is influenced by the installation location. Sensors

mounted along the sloped portion of the tank will result in a

lower (HEIGHT) value. On the other hand, sensors

installed in risers/nozzles will result in a higher (HEIGHT)

value.

The basic measurements (Height and Fill-H) for configuration are described below:

1. HEIGHT (Sensor Height) - Distance from the Bottom of

Sensor (sensor’s measurement location) to the bottom of

the tank.

a. The Sensor Height is typically set to the bottom of

the tank.

b. This setting determines the 4mA location.

2. FILL-H (Fill-Height) - Distance from the bottom of the

tank to the level of liquid where the tank is full is FILL-H.

a. The FILL-H is typically set to the liquid full level.

b. This setting determines the 20 mA location.

c. 20mA cannot be set within the sensor’s dead

band [8” (20cm) from bottom of sensor]. Largest

FILL-H value will be as follows:

Largest FILL-H = HEIGHT – 8” (20cm)

3. Relay Set Points – Distance from the bottom of the tank

to the level of liquid where each relay activates.

a. Pumps/Valves have two set points, one for ON

and the other for OFF.

b. Alarms have one set point which can be used as

a high alarm (energized with level above set

point) or a low alarm (energized with level below

set point).

c. Independent Relays each have two set points,

one for ON and the other for OFF.

17

Page 18

Configuration (continued) Step Three

With the LVU500 series connected to your computer, open the LVCN414-SW software by clicking on the

LVCN414-SW icon. Follow steps 1-4 to configure the transmitter. Click “Help” in the lower right hand corner

and open the help menu of LVCN414-SW for instructions on LVCN414-SW. If you need additional assistance

using LVCN414-SW, please contact a Omega Engineering sales applications engineer at (833) 484-6072.

Note: For complete information on the LVCN414-SW software, please refer to the LVCN414-SW manual

located at omega.com/ftp.

STEP 3 – SENSOR CONFIGURATION:

Configures the relays in terms of pump/valve operations and level alarms as well as the setting fail-safe for

relays and signal output. Refer to SENSOR CONFIGURATION on page 29 for detailed information on the

different settings.

18

Page 19

Configuration (continued) Step Three

STEP 4 – DIMENSIONAL ENTRY:

Distance Mode (default): Output of sensor is based on the distance (height of liquid) in the tank. Any

change in liquid level will reflect linearly to the current output. Note: Most applications will fall into this

category. For Volumetric outputs, refer to VOLUMETRIC CONFIGURATION on page 36. The two

values (Sensor Height and Fill-Height) below set the 4-20 mA current span for the sensor. Both values

will be set in the units shown under Height Units.

Height Units: Confirm units for use in Sensor Height and Fill-Height settings.

Sensor Height: Sets the location for 4mA. It is based on the distance from the Empty level

position to the Measurement location for the sensor (see below).

Fill-Height: Sets the location for 20mA. It is based on the distance from the Empty level

position to the Full level position (see below).

Relay Units: Confirm units for use in setting the relays.

Relay Settings: Sets the location for each relay activation point. All values are based upon the

distance or volume from Empty level position. Each setting will have a descriptor for its

function. I.E. Hi-1 for high level alarm #1 or Lo-2 for low level alarm #2. Note: Units for the

relays are independent of the units used for Sensor Height and Fill-Height.

19

Page 20

Configuration (continued) Step Three

STEP 5 – TANK LEVEL CONFIRMATION:

Verify the Height Units, Sensor Height, Fill-Height, Relay Units & Relay Settings. All values were calculated

and set in the previous Dimensional Entry window. Make any adjustments if required.

STEP 6 – WRITE TO UNIT:

This LVCN414-SW operation uploads configuration into the sensor. Other features in the section include

providing a custom wiring diagram specific to the signal output and saving the configuration file to your hard

drive.

20

Page 21

Installation Step Four

LVU500 series should always be mounted perpendicular to the liquid surface (use the provided FKM mounting

gasket for G threaded versions only). Make sure that the fitting and transmitter threads are not damaged or

worn. Always hand-tighten the transmitter within the fitting. Perform an installed leak test under normal

process conditions prior to system start up.

MOUNTING GUIDE

1. Do not mount at an angle

2. Liquid should never enter the dead band

3. Side Wall:

a. Mount at least 3” from the side wall

4. Do not mount where obstacles will intrude on sensor’s

beam width

5. Do not mount in a vacuum

6. Avoid mounting in the center of a dome top tank.

7. In cone bottom tank, position the sensor over the

deepest part of the tank.

Do not install at an

angle relative to the

liquid.

Do not install within

3” of tank sidewall.

Installation in existing fittings: If the existing fitting is

larger than the threads of the LVU500 series, select a

reducer bushing such as the LVU800-3N40 (3” thread x 2”

thread) or LVU800-4N80 (4” thread x 2” thread).

LVU800-3N40

Do not install with

objects in the

Do not install in

applications with

vacuum.

beam.

21

Page 22

Installation (continued) Step Four

FITTING SELECTION

Check the part number to determine the required fitting mount size and thread type. The LVU500 series is

commonly installed in tank adapters, flanges, brackets or standpipes. Note: Only use the gasket when

installing an LVU500 series with a G thread (straight thread).

1. Tank Adapter: Select a tank adapter fitting, such as the LVU800-2B tank adapter.

a. For best results, select a 3” tank adapter (LVU800-3B) and add a reducer bushing such as the

LVU800-3N40, thread x thread, reducer bushing.

b. Avoid tank adapter (thread x thread) styles and/or pipe stops forward of the installed transducer.

c. Always mount the tank adapter so the majority of fitting is outside the tank.

i. Note: Never mount the tank adapter upside down or where the bulk of the material is

inside the tank.

2” Tank Adapter

Socket x Thread

(LVU800-2B shown)

2. Riser: Installations with tall, narrow risers can impede the acoustic signal.

a. Core Out Concrete: Applications where a tank with a concrete ceiling that has been cored out

can also be considered as a riser type application. In these applications follow a 2:1 ratio (Core

Height to Inner Diameter) for the diameter of the core.

a. 2” (5 cm) diameter risers should be no taller than 4” (10 cm). Larger diameter risers should be

no taller than 12” (30.5 cm).

Riser Specifications

Inner

Diameter

2” (5cm)

4” (10cm)

6” (15cm)

Note: Do not exceed the dimensions listed above.

Tank Adapter (LVU800-3B)

w/ 3”x 2” Reducer Bushing

(LVU800-3N40)

Maximum

Height

4” (10cm)

8” (20cm)

12” (30cm)

Do not use thread x thread

Tank Adapter

Thread x Thread

Note: If attempting to raise the

sensor above the top of the tank

to allow for a higher fill capacity,

avoid the use of tall and narrow

risers. The example to the left

exceeds the dimensions listed in

the Riser Specifications chart.

Use a larger tank adapter which

takes into account the Riser

Specifications.

22

Page 23

Installation (continued) Step Four

3. Flange: If installing on a flange, select a flange with a minimum thread of 2” thread that is above

the plane of the flange, such as the LVU800-2F.

a. Use a flange with a 3” thread and add a 3” to 2” reducer bushing to complete the installation.

2” Flange w/

thread out of plane

(LVU800-2F)

3” Flange (LVU800-3F)

w/ Reducer Bushing

(LVU800-3N80)

4. Side Mount Bracket: For installations in open tanks and sumps, use the LVM-30 series side

mount bracket.

LVM-30 Shown

Note: The Side Mount Bracket (LVM-30 series) is not designed for use with stand pipes or as a

method to secure stand pipes. There are too few threads to properly hold the sensor and the

stand pipe.

23

Page 24

Installation (continued) Step Four

5. Stand Pipe: A standpipe maybe used to dampen turbulence or when foam is present in the

application.

a) Pipe can be constructed from any material.

b) Select a minimum 2” ID pipe or greater for the stand pipe.

i) 3” ID pipe is ideal due to larger inside surface area.

c) Use a coupling and reducer bushing to attach the LVU500

series to the pipe.

i) Use a reducer bushing such as LVU800-3N80 (3”

Thread x 2” Thread) fitting or the LVU800-3S80 (3” Slip

x 2” Thread) fitting.

d) The pipe length should run the measurement span. The

bottom of the pipe should remain submerged at all times to

prevent foam from entering the pipe.

e) Cut a 45°notch at the bottom of the pipe. Drill a

1/4”pressure equalization hole in the dead band.

f) The pumps should not drive liquid past the open end of the

stand pipe which causes the liquid in the pipe to oscillate.

Note: Never allow the bottom of the stand pipe to become

exposed to air. This will break the liquid seal which will

prevent echoes from returning back to the sensor.

LVU500

series

3” x 2”

Reducer Bushing

(TxT)

Vent Hole (1/4”)

3” Coupling

(S x T)

3” PVC Pipe

LVU500 series attached to a

LVU800-3S40 (3” x 2” reducer

bushing) to a Slip x Thread 3”

Coupling.

24

Avoid the use of a tee within the

stand pipe. A tee can create false

signals impeding the sensor’s

performance.

Page 25

Wiring Step Five

WIRING DIAGRAM - SAMPLE

SampleWiringDiagram

Diagram will change based upon

the sensor’s configuration, use

LVCN414‐SW to view appropriate

wiringdiagram.

WIRING LVU500 SERIES

Once LVU500 series has been configured; follow the Wiring Diagram provided by the LVCN414-SW software.

A typical wiring diagram is shown above. Omega Engineering recommends using a qualified licensed

electrician to wire the LVU500 series with your application’s components.

Configure your LVU500 series with LVCN414-SW and use the wiring diagram button to view the

appropriate diagram. Each configuration will have its own unique diagram. The diagram shown above is

only a sample and should not be used as a wiring diagram.

LVU500 series is a loop powered 4-20mA device. The power loop and current output loop are shared

by the Red and Black wires.

Relays are all dry contacts so polarity can be revered from the example shown in the wiring diagram.

Always use stepper relays between the sensor and external loads. For DC circuits, always use a catch

diode such as 1N4148, shown on the Wiring diagram above supplied by LVCN414-SW.

Once LVU500 series is configured, isolate the white and green wires from active power to

prevent a short of the configuration circuit.

25

Page 26

Wiring (continued) Step Five

WIRE CONNECTIONS

Red (+) & Black (-): Red [(+) Power] and Black [(-) Return] leads are for

connection to a 24 VDC power supply or to a 4-20 mA loop power

source. The red and black wires can be extended up to 1,000 feet using

a 22-gauge or larger wire.

White & Green: White [(W) TX] and Green [(G) RX] leads are reserved

for use with LVCN414-SW. These wires should only be connected to

LVU501 and LVU503 Series

Blue, Orange, Yellow, Purple & Brown: Blue (RLY1), Orange (RLY2), Yellow (RLY3) & Purple (RLY4) wires are

the relay contacts (normally open) from each of the relays respectively. The Brown wire (RLY Common) is the

common for all the relays. Relay selection is determined by the configuration in LVCN414-SW. Relays are all dry

contacts so polarity can be revered from the example shown in the wiring diagram.

one device at a time (i.e. only to LVCN414-SW). In addition, these

wires should not be connected to LVCN414-SW while power is supplied

from any source other than the LVU500-USB series Fob. The maximum

cable distance between the computer and LVU500 series is 15’. Note:

Never allow the white or green wires to touch any power supply.

LVU500 series uses latching relays. When power is r emoved t o the se nsor, the r elays will rem ain in t heir last state.

Ex: If the relay is energized, when po wer is rem oved, the r elay will rem ain in an energi zed state.

GENERAL NOTES FOR ELECTRICAL CONNECTIONS, USAGE AND SAFETY

Where personal safety or significant property damage can occur due to a spill, the installation

must have a redundant backup safety system.

Wiring should always be completed by a licensed electrician.

Supply voltage should never exceed 28 VDC.

Do not exceed 28 VDC power on the relays within LVU500 series.

Always use stepper relays between the sensor and external loads. For DC circuits use a catch diode

such as 1N4148, shown on the previous page.

Protect the sensor from excessive electrical spikes by isolating the power, whenever possible.

The sensor materials must be chemically compatible with the liquids to be measured.

Design a fail-safe system for possible sensor and/or power failure.

o During power failure, relays will remain in their current state and will not change until power is

restored and the signal is reacquired.

Never use the sensor in environments classified as hazardous.

26

Page 27

Wiring (continued) Step Five

COMMON LOOP POWERED 4-20MA WIRING TO DISPLAY, CONTROLLERS & PLC’S (CONTINUED)

LVCN-51 Series

Level Controller

*JWA mode (Factory Setting)

LVCN-51 Series

Level Controller

*JWB mode

Generic Loop

Powered Display

* Refer to the LVCN-51 Series, Level Controller manual for information on JWA mode and JWB mode settings

in the controller.

Generic PLC

27

Page 28

Wiring (continued) Step Five

SWITCHING INDUCTIVE LOADS

The use of suppressors (snubbers) is always recommended when switching inductive loads to prevent

disrupting the microprocessor’s operation. The suppressors also prolong the life of the relay contacts.

Suppression can be obtained with a catch diode for DC circuits and a resistor-capacitor (RC) for AC circuits.

Catch Diode

Always use stepper relays between the sensor and external loads.

For DC circuits always use a catch diode such as 1N4148, shown

on left.

Refer to the following circuits for RC network assembly and installation:

Choose R and C as follows:

R: 0.5 to 1 Ohms for each volt across the contacts

C: 0.5 to 1 μF for each amp through closed contacts

Notes:

1. Use capacitors rated for 250 VAC.

2. RC networks may affect load release time of solenoid loads. Check

to confirm proper operation.

3. Install the RC network at the meters relay screw terminals. An RC

VOLTAGE OUTPUT

network may also be installed across the load. Experiment for best

results.

LVU500 series can be configured as a 0 to 5 VDC output. A resistor will need to be added to the circuit to

enable a voltage output (refer to the wiring diagram below).

0-5 VDC output

o Add a 250 Ohm resistor

o Actual output will be 0.8 to 5 VDC

28

Page 29

LVCN414-SW Appendix Section Six

This section of LVCN414-SW is where you select the sensor configuration settings. Start from the top and

work to the bottom, choosing the selections that are applicable to your configuration. “Not Applicable” will

automatically show when a selection doesn’t apply to your configuration settings, and you may move on. All

configuration settings must be selected or have “Not Applicable” before you can continue to the next step.

SENSOR CONFIGURATION

NUMBER OF PUMPS

This feature allows you to select the number of pumps or valves used

with the LVU500 series. This setting activates the control capabilities of

one or two relays. Control relays are often referred to as latching

relays.

o Switch/Alarms Only – The relays will be standard single point

non-latching relays. Use this setting for high and/or low alarms.

o 1-Pump/Valve – One relay will be configured as a control or

latching relay (relay will have a start level and a separate stop

level). Use this setting to control one pump or valve for

automatic filling or emptying of a tank.

Note: Right click on any

item to open the help menu.

Note: To reset the

configuration table, press

the Clear Screen button.

o 2-Pumps/Valves – Two relays are configured as control or

latching relays. Each relay will have a unique start level and a

common stop level. Use this setting to control two pumps or

valves for automatic filling or emptying of a tank.

o 4-20mA Transmitter Only – This setting will disengage all of

the relays. Use this function if you are not using any relays and

using only the 4-20 mA current output.

o Independent Relays – This setting will override the

Switch/Alarm Configuration and allow all 4 relays to be set

independent of the other relays. Each relay will have its own

unique ON and OFF setting (see below).

29

Page 30

LVCN414-SW Appendix (continued) Section Six

PUMP/VALVE ACTION

This feature allows you to select whether the pumps or valves will be

used to automatically fill or empty the tank. For 2-Pump/Valve mode,

both devices must be used in the same (automatic fill or empty) way.

You cannot set one relay for fill and the other for empty.

o Empties Tank – Sets the relay(s) to automatically empty a tank.

The start level will be above the Stop level for each relay.

o Fills Tank – Sets the relay(s) to automatically fill a tank. The

start level will be below the Stop level for each relay.

o Not Applicable – Appears when this function is not available

based on previous selections.

Empties Tank Fills Tank

(Auto Empty) (Auto Fill)

Note: Right click on any item to open the help menu.

Note: To reset the configuration table, press the Clear Screen button.

30

Page 31

LVCN414-SW Appendix (continued) Section Six

PUMP/VALVE MODE

This feature allows you to select the control mode for a latching relay.

Pump/Valve mode is not active for Switch/Alarms Only or 4-20 mA

Transmitter Only.

o Simplex – Allows the relay to be used for automatic fill or

empty. This is the default and only mode when 1-Pump/Valve

is selected.

o Simplex used to Empty Tank

o Lead/Lag – Allows two relays to have unique start levels and a

common stop level. The first relay will be identified as the lead

relay and the second relay as the lag. Each time the lead level

is reached, the first relay will always start. The lag relay will

only start when the lag level is reached. All relays will stop at

the common off level.

o Lead/Lag used to Empty Tank

o Duplex – Allows two relays to have two different start levels, a

common stop level and will alternate the relays when the first

start level is reached. The two relays will alternate each time the

lead level is reached and the remaining relay will start when the

lag level is reached. All relays will stop at the common off level.

o Duplex used to Empty Tank

o Not Applicable – Appears when this function is not available

based on previous selections.

Note: Right click on any item to open the help menu.

Note: To reset the configuration table, press the Clear Screen button.

31

Page 32

LVCN414-SW Appendix (continued) Section Six

RELAY FAIL-SAFE

This feature allows you to select the fail-safe mode for the relays in the

event that the sensor looses echo confidence. When the sensor

regains echo confidence, the output current will revert back to the

current level condition.

o Relays Off – The relays will revert to the OFF state. This

appears when Switch/Alarms Only is selected.

o Relays On – The relays will revert to the ON state. This

appears when Switch/Alarms Only is selected.

o Hold State – The relay(s) will remain in the same state as the

last confident echo detected. When the sensor regains echo

confidence, the relays will revert to the current level.

o Pump/Valves Off – The relays will revert to the OFF state. This

appears when 1-Pump/Valve or 2-Pumps/Valves are selected.

o Pump/Valves On – The relays will revert to the ON state. This

appears when 1-Pump/Valve or 2-Pumps/Valves are selected.

o Not Applicable – Appears when this function is not available

based on previous selections.

Note: Right click on any item to open the help menu.

Note: To reset the configuration table, press the Clear Screen button.

32

Page 33

LVCN414-SW Appendix (continued) Section Six

SWITCH/ALARM CONFIGURATION

This feature allows you to select the relay operation for the switch /

alarm (used as a high or low alarm). The number of available relays is

based upon the previous settings.

o No Alarm – Turns OFF all remaining relays.

o High Alarms – Sets 1 to 4 High Alarms (1-High, 2-High, 3-

High, 4-High).

o Low Alarms – Set 1 to 4 Low Alarms (1-Low, 2-Low, 3-Low or

4-Low).

o Combination Alarms – Sets a combination of High and Low

Alarms (1-Low 1-High, 1-Low 2-High, 2-Low 1-High, 2-Low 2-

High, 1-Low 3-High, 3-Low 1-High).

o Not Applicable – Appears when this function is not available

based on previous selections.

High Alarm Low Alarms Combination Alarms

(4 High) (4 Low) (2 High and 2 Low)

Note: Right click on any item to open the help menu.

Note: To reset the configuration table, press the Clear Screen button.

33

Page 34

LVCN414-SW Appendix (continued) Section Six

SWITCH HYSTERESIS/DEAD BAND

This feature allows you to select a hysteresis or dead band for the

remaining high and/or low alarms.

o Options for Hysteresis/Dead band – No Hysteresis, ¼”, ½”,

1”, 2”, ½ cm, 1cm, 2 cm, 5 cm or Not Applicable.

o High Alarms – Relay activates above the set point. Relay will

deactivate when the level goes below the set point plus the

value of the hysteresis.

o Low Alarms – Relay activates below the set point. Relay will

deactivate when the level goes above the set point plus the

value of the hysteresis.

High Alarm w/ Hysteresis Low Alarm w/ Hysteresis

Note: Right click on any item to open the help menu.

Note: To reset the configuration table, press the Clear Screen button

34

Page 35

LVCN414-SW Appendix (continued) Section Six

LOOP FAIL-SAFE

This feature allows you to select the fail-safe current output if the sensor

looses echo confidence. When the sensor regains echo confidence, the

output current will revert back to the current level condition.

o Hold Last Value – The output will remain in the same state as

the last validated echo detected. Example: If the output was 6.7

mA just prior to the lost signal, the sensor will continue to output

6.7 mA until echo confidence is regained.

o Empty - The output will revert to the current value for an empty

condition. When 4 mA at Bottom is selected, the sensor will

output 4 mA during a fail-safe condition. If 20 mA at Bottom is

selected, the sensor will output 20 mA during a fail-safe

condition.

o Full – The output will revert to the current value for a full

condition. When 4 mA at Bottom is selected, the sensor will

output 20 mA during a fail-safe condition. If 20 mA at Bottom

is selected, the sensor will output 4 mA during a fail-safe

condition.

o Overfill (21mA) – The sensor will output 21mA during a fail-

safe condition.

o Overfill (22mA) – The sensor will output 22mA during a fail-

safe condition.

OUTPUT AT EMPTY

This feature allows you to select the orientation of the 4 to 20mA output

(4 to 20 mA or 20 to 4 mA). Choose which output setting best fits the

application. Factory default is 4mA at bottom and 20mA at top, as this

configuration scenario is an industry standard. When connecting your

sensor to a display, you must account for your output orientation setting.

o 4mA at Bottom – The output current will be 4mA when the

sensor measures an empty tank and 20mA when the sensor

measures a full tank.

o 20mA at Bottom – The output current will be 20mA when the

sensor measures an empty tank and 4mA when the sensor

measures a full tank.

Note: Right click on any item to open the help menu.

Note: To reset the configuration table, press the Clear Screen button

35

Page 36

LVCN414-SW Appendix (continued) Section Six

VOLUMETRIC CONFIGURATION

The sensor may be configured in volumetric units

(Gallons or Liters) or Distance (Height of Liquid)

units (inches, cm, feet or meters). LVCN414-SW

will default to Distance (Height of Liquid) with units

of Inches. To change units or change from

Distance to Volume, press the Volumetric Mode

button as located near the center of the window.

Distance (Height of Liquid): When this is selected,

the sensor will always output a linear output

proportional to the height of liquid (regardless of the

tank shape). In the two drawings below, the Sensor

High is set to 64” and Fill-Height is set to 60”. If the

tank is empty, the sensor will output 4mA. If the level

is at 30”, then the sensor will output 12mA. Either

tank can be configured with a display from 0” to 60”

and the sensor will always output the height of liquid.

Volume: When volume is selected, the 4-20 mA output from the sensor will be proportional to the volume of

the tank, not the height of the tank. This means that the current output will track the volume of the tank (in

gallons or liters). Depending on the shape of the tank, the values may be a linear or non-linear scale. In the

same examples below, the sensors are also configured with SH = 64” and FH = 60”. The current output in a

linear tank will act as expected with volume increase matching equal changes to level. However, the current

output in the Non-Linear tank will reflect the actual changes in volume. So even though the liquid height

changes incrementally the same amount, the volume change will adjust throughout the entire span of the tank.

The advantage of this is that sensor does all the math so you can read tank volume using a simple two-point

display/controller such as the DataLoop

Linear Tank Example

™

LI25 series or DataView™ LI55 series.

Non-Linear Tank Example

Note: In the above illustration, 10” of liquid will always

be equal to 100 gallons of liquid (1” = 10 gallons).

Note: In the above illustration, 1” of liquid does not equal 10

gallons. The 10” at the bottom represents a rise of 62.8

gallons. As a change between 10” and 20” represents an

increase of 109.6 gallons (i.e. 172.4 gallons – 62.8 gallons).

36

Page 37

LVCN414-SW Appendix (continued) Section Six

Shape Selection Window: This window will shows the different tank shape options available in LVCN414-

SW.

Vertical Cylinder

Vertical Cylinder with Cone Bottom

Horizontal Cylinder with End caps

Horizontal Cylinder with Spherical Ends

Spherical

Rectangular

Strapping Table – Use this feature for manual entry

of measured tank distances and volumes.

Select any of the above tank shapes and press OK to

confirm.

A. Dimensional Entry – Vertical Cylinder Example: Choose the Sensor Output Units as Distance or

Volume. After choosing the Sensor Output Units, select the units of measurement in the pull down to

the left.

Units of Measurement

Distance Volume

Inches

Cm

Feet

Gallons

Liters

Meters

Distance – Sensor Output Units (Vertical Cylinder Example):

Enter the dimensions of the tank. You must

enter data in all fields shown.

Sensor Height: Distance from the bottom

of the tank to the top of the threads.

Fill Height: Distance from the bottom of

the tank to the operational full level of liquid

(20mA). This setting defines the location of

full current output and is the top of the

sensor’s measurement range.

Riser Height: Distance the sensor is

above the top of the tank (including all

fittings). Measured from the bottom of the

sensor.

37

Page 38

LVCN414-SW Appendix (continued) Section Six

Volume – Sensor Output Units (Vertical Cylinder Example):

Enter the dimensions of the tank. You must

enter data in all fields shown.

Sensor Height: Distance from the bottom of

the tank to the top of the threads.

Fill Height: Distance from the bottom of the

tank to the operational full level of liquid

(20mA). This setting defines the location of

full current output and is the top of the

sensor’s measurement range.

Riser Height: Distance the sensor is above

the top of the tank (including all fittings).

Measured from the bottom of the sensor.

Height: Distance from the bottom of the tank to the top of the straight side wall.

Diameter: Distance of the inside tank diameter.

Volume – Tank Capacity (Vertical Cylinder Example): After entering the dimensions, press the Capacity

button to show the Calculated Capacity of the tank. If the Calculated Capacity is slightly different than the

expected capacity, click on the Adjust Capacity box and enter the expected capacity of the tank. If the

Adjusted Capacity is more than 10% of the Calculated Capacity, recheck the dimensions information entered

above.

When all dimensions are entered, press the Apply button to return to the previous Configuration window.

Apply – Transfers the dimensions to the original Configuration window.

Tanks – Returns to the previous Shape Selection window.

Cancel – Returns to the Configuration window without saving any information.

Help – Jumps to the Help menu.

38

Page 39

LVCN414-SW Appendix (continued) Section Six

TANK LEVEL CONFIRMATION

This section of LVCN414-SW is where you confirm the values set in the previous step. The values were

entered under the Dimensional entry window. To edit these settings, you must go back to the Dimensional

entry window via the Volumetric Mode button.

Height Units: Units selected for configuration. When used as a device to measure the distance (height

of liquid), the options are inches, cm, feet or m. When used as a device to measure the volume of

liquid, the options are gallons or liters.

Sensor Height: Distance from the bottom of the tank to the bottom of the top of the threads.

Fill-Height: Distance from the bottom of the tank to the operational full level of liquid (20mA). This

setting defines the location of full current output and is the top of the sensor’s measurement range.

Capacity: The total volume of the tank. Only shown when gallons or liters are selected.

Note: By extending the empty (4mA) to the bottom of the tank, the 4-20 mA output will track the volume of the tank.

This allows any local display to read the actual volume of liquid without the need for any unique configuration. This

feature is very useful with any non-linear tanks such as horizontal, spherical or tanks with cone bottoms.

HeightUnits

SensorHeight

Fill‐Height

*RelaySettings

Capacity

Volumetric Sensor Output: The

volumetric mode button will be

highlighted in Blue when a

volume output is selected.

* Relay settings are based upon the configurations selected under the Config pull-down menus.

39

Page 40

LVCN414-SW Appendix (continued) Section Six

WRITE TO UNIT

After you have entered configurations, selected and configured the Tank

Shape and entered the Tank Values, click “Write to Unit” and load the

configuration into the memory of the sensor. When completed, this

configuration will remain inside the sensor memory and will not change

unless the sensor is connected to the software and a new configuration

is written to the sensor. Loss of power will not change or lose the

configuration within sensor memory.

Next, use the file management features to save your configuration by

clicking “Save Config File” and print your wiring diagram by clicking

“Wiring Diagram.”

Write to Unit

Wiring diagram

Save Config File

“Save Config File” will save this configuration as a text file which can be loaded back into LVCN414-SW by

pressing the “Open Config File” button. It is good practice to save the configuration file for each different

configuration with a unique name for easy identification. If using multiple sensors in identical applications, then

use of a single configuration file is recommended.

“Wiring Diagram” will display a PDF file showing the unique wiring for the specific configuration created in

LVCN414-SW. The PDF can be printed or emailed. It is good practice to save the wiring diagram as a

backup

.

“Advanced” is a feature setting designed to help solve performance or operational issues for specific

applications. Changing these setting will alter the factory default performance or operation, of your sensor.

Increase Output Filtering: Placing a check mark in the box will increase the filtering (averaging) of the

analog output. Use this filter if the 4 to 20 mA output requires

a smoother output for the application such as open channel

flow measurement.

Decrease Output Filtering: Placing a check mark in the box

will eliminate all filtering (averaging) of the analog output which

enables a pulse by pulse level reading. Use this filter to see

changes in level after every echo pulse.

Note: Never check increase output filtering and decrease output

filtering at the same time.

Stabilize Output in Dead Band: Placing a check mark in the

box will activate a filter to hold the output at Full if the level

enters the dead band of the LVU500 series. This filter requires the level to leave the dead band at a

smooth and steady rate.

Reduce Fast Level Jump Response Time: Changes the sensor’s response time from 60 seconds to

10 seconds. This filter prevents the sensor from making a quick jump in level if a false signal suddenly

appears. Change the response time if application involves expected quick level changes.

Increase LOST Response Time: Changes the sensor’s response time from 60 seconds to 180

seconds. This filter sets the time the sensor waits before entering a LOST state. Change the response

time if you want to delay the sensor from stating LOST.

40

Page 41

Appendix Section Seven

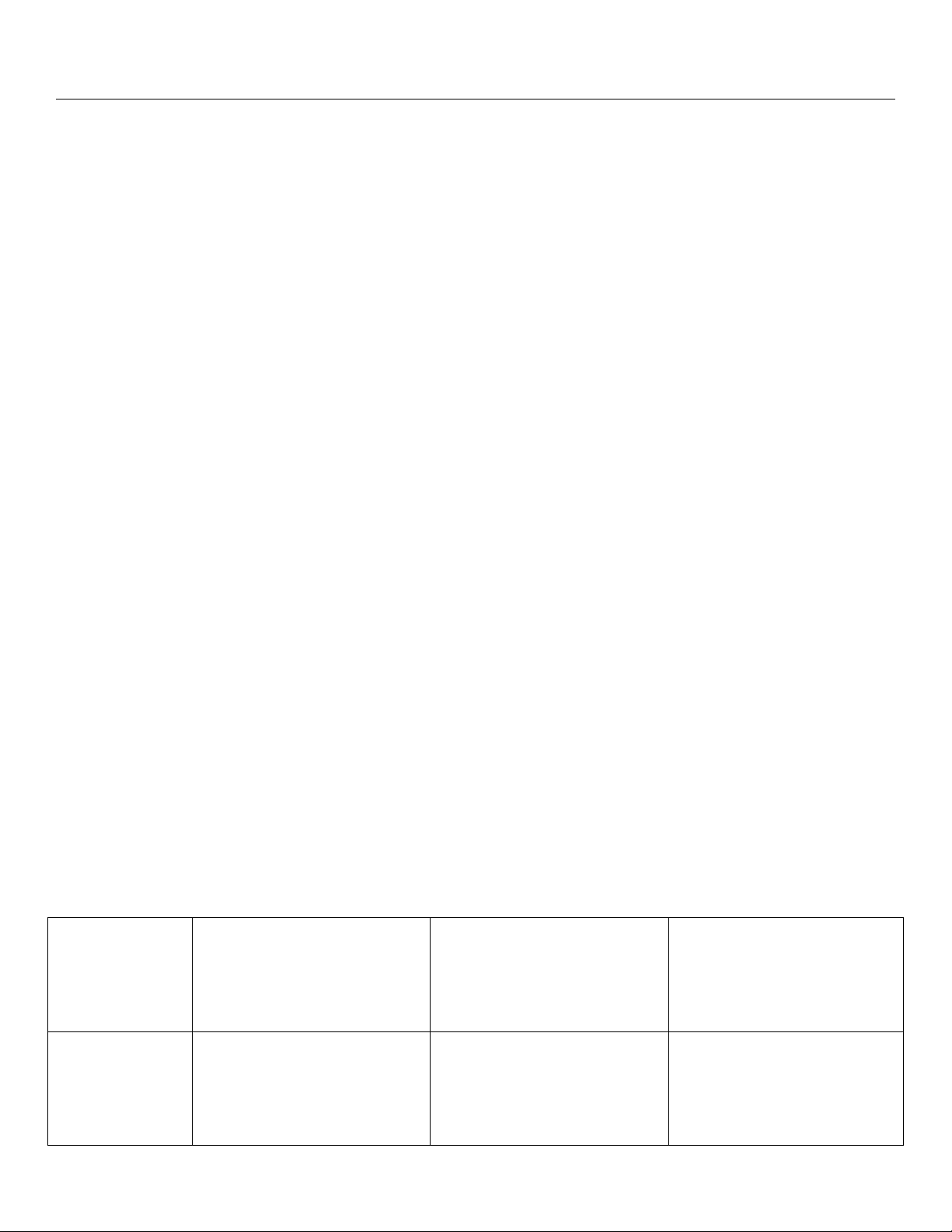

FACTORY SETTINGS

LVU500 series Sensor Height Fill-Height

LVU503 Series 118.1” (300 cm) 114.1” (290 cm)

LVU501 Series 59.1” (150 cm) 57.6” (146.2 cm)

USER SETTINGS

Fill out the chart below and keep as a record of your configuration.

Tank

Height = Fill-H =

Units

Inches Feet cm Meter

Display

Air Liquid

Safe

22mA 21 mA 20mA Hold Last 4mA

Rev mA

4mA @ Bottom 4mA at Top

Start-up

4mA 12mA 20mA 22mA

Relay(s)

Relay 1 (Blue) Relay 2 (Orange) Relay 3 (Yellow) Relay 4 (Purple)

ON

OFF

TROUBLESHOOTING

PROBLEM SOLUTION

Transmitter indicates a

current of 0 mA:

Transmitter jumps to a

current reading between

19 and 20 mA:

Transmitter indicates a

current over 23 mA:

Check the wiring for an open circuit. An open circuit is the most common issue

with a 0 mA signal.

Check the installation of the transmitter. Bad installation fittings will cause

false signals near the top of the tank, which typically translates to a signal

between 19 and 20 mA. Also look for interference just below the transmitter. If

the transmitter is installed in a metal fitting, switch to a plastic fitting.

Immediately check the wiring for a short circuit. The LVU500 series is current

limited to 22 mA. Anything above 23 mA indicates a short circuit.

41

Page 42

Appendix (Continued) Section Seven

TROUBLESHOOTING (CONTINUED)

PROBLEM SOLUTION

Transmitter always jumps

to the LOST condition.

Transmitter output is opposite of the level of liquid.

No Unit Detected in

LVCN414-SW.

Internet error. The server

name or address could not

be resolved.

Cannot access some of

the configuration features

in LVCN414-SW.

Relay closes, but does not

open again.

Relay chatters on and off

repeatedly.

No unit detected error 1 Both errors can occur when the Display is still plugged in when connecting to

Data page read error 2

Data page read error X

(X is any number greater

than 2)

-1 No device is attached to

the USB Fob, or it is

attached incorrectly.

Please correct and try

again.

-2 Program to loader error

open wires

Check the dimensional configuration (Sensor Height and Fill Height) of

LVU500 series. Make sure that the Fill-H setting corresponds to the full level of

liquid (measured from the bottom up) and not the distance from the transmitter

to the liquid (top down).

Check the Output at Empty Setting in LVCN414-SW.

If LVCN414-SW cannot detect LVU500 series when connected to the

computer:

®

Check that the LVU500-USB Fob is connected to the USB

port.

Check that all four wires (Red, Black, White and Green) are securely

attached to the Fob.

Check Device Manager and confirm that both drivers (LVCN414-SW

Configuration & EchoFob) are present.

If the above do not work, reinstall the LVCN414-SW software while the

computer is in Safe Mode.

This is a warning indicating that the computer configuring LVU500 series is not

connected to the Internet. Click OK to continue. Omega Engineering recommends

being connecting to the Internet during configuration. But, not being connected to

the Internet will not prevent LVU500 series from being configured.

As choices are made in Configuration, LVCN414-SW will begin to eliminate

functions that are not applicable to a configuration. To reset Configuration or

get access to all the features, click on the Clear Screen button.

An inductive kick may be holding the relay closed. If switching 24 VDC, make

sure a diode has been installed to act as a snubber (see Step Nine). Note:

LVU500 series uses latching relays. When power is removed to the sensor, the

relays will remain in their last state. Ex: If the relay is energized, when power is

removed, the relay will remain in an energized state.

Most likely the turbulence in the tank is causing the chatter. Increase the

Hysteresis setting in LVCN414-SW to eliminate the chatter.

LVCN414-SW. Remove the display from its plug and try again.

Make sure display is removed. If issue persists, contact a Omega Engineering

representative.

1. Check the wires connected to the USB Fob as well as to the LVU500 series

terminals.

2. Make sure the cable length between the sensor and the computer is less

than 15’ of total cable.

3. Make sure the display was removed from its plug.

4. If this persists, reboot computer in SAFE mode and re-install the LVCN414SW installer program.

Check the wires connected to the USB Fob as well as to the LVU500 series

terminals.

42

Page 43

43

Page 44

44

Loading...

Loading...