Page 1

LV-1201, LV-1202, LV-1203

Non-Magnetic, Side

Liquid

Level Switches

Operator’s Manual:

GENERAL DESCRIPTION

The OMEGA@ LV-1200 Series Level Switches feature a non-magnetic design

suitable for application where magnetic particles

Series features a plastic and 316

more corrosive applications.

The LV-1200 Series can be used in highly particle contaminated liquids such as

sewage, machine cutting oils and medium slurries under conditions of crystalliza-

tion below liquid surface, drying-caking

With the LV-1200 Series, particle contamination resistance is provided by a flexible

filter boot which prevents crystallization, caking, heavy dirt concentration, slurries,

scum, etc. from affecting the operation of the unit.

FEATURES

??

Rugged Industrial Design

??

Non-Magnetic Design Suitable for Rusty Environments

?

15A SPDT Switch Directly Controls Pump

Motint

M0776/0499

SS construction, or a

lie:

rust) are present. The LV-1200

Hastelloy C construction for

ar

liquid-air interface, and scum formations.

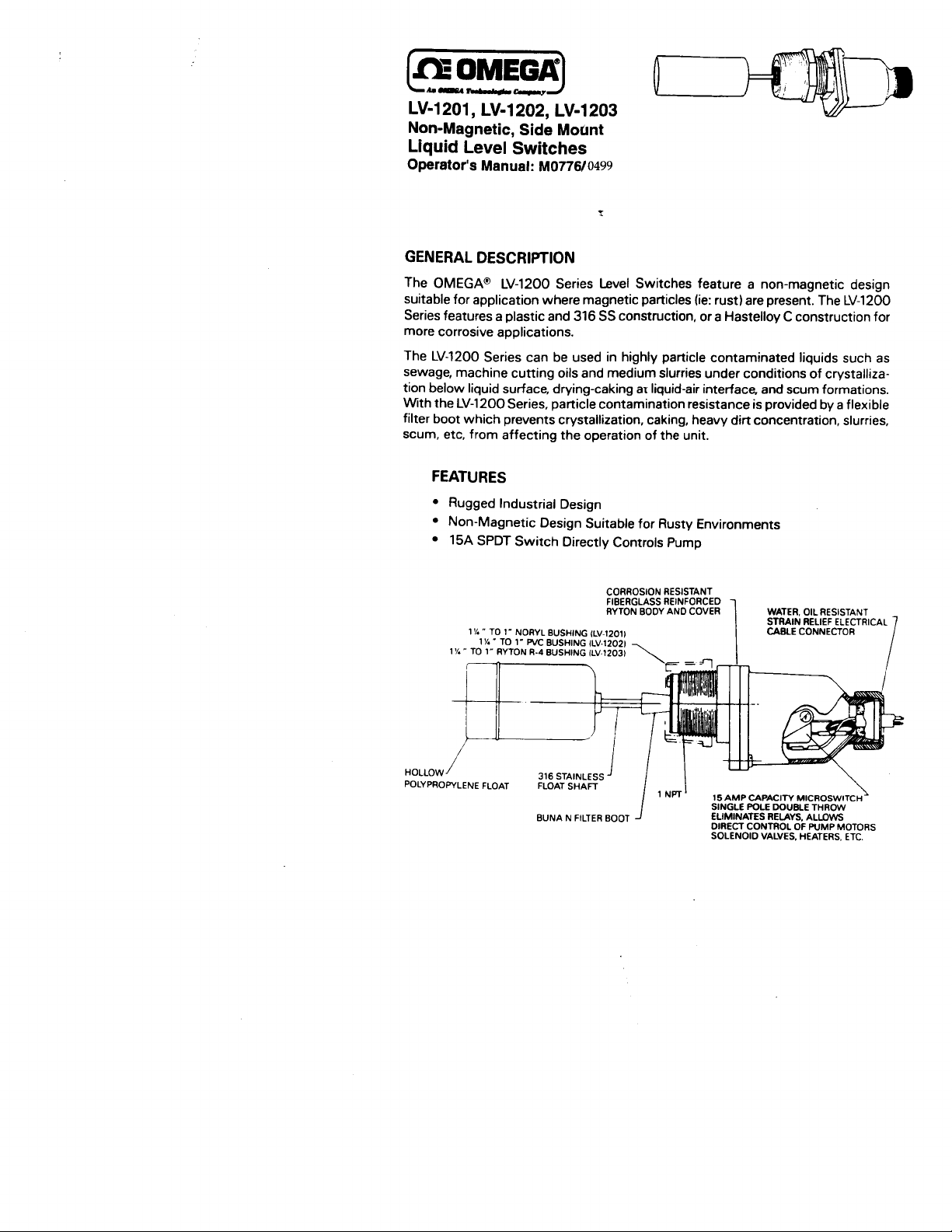

HOLLOW

POLYP

1%” TO 1” NORYL BUSHING

”

TO 1” RYTON R-4 BUSHING X

1

ROPYLENE FLOAT

1%

l-

PVC BUSHING - TO

FLOAT SHAFT

BUNA

CORROSION RESISTANT

FIBERGLASS REINFORCED

RYTON BODY AND COVER

(LV-1201)

(LV.1202)

ILV1203l

BOOT

N FILTER

WATER, OIL RESISTANT

STRAIN RELIEF ELECTRICAL

CABLE CONNECTOR

\

1

_

15 AMP CAPACITY MICROSWIT

SINGLE POLE DOUBLE THROW

ELIMINATES RELAYS, ALLOWS

DIRECT CONTROL OF PUMP MOTORS

SOLENOID VALVES, HEATERS, ETC.

7

Page 2

SPECIFICATIONS

RELAY SWITCH:

MAX.

TEMPERATURE/

PRESSURE:

LIQUID LEVEL CHANGE

TO ACTIVATE SWITCH:

MIN. SPECIFIC GRAVITY:

SPDT

medium

Model LV-1201: 75

Models LV-1202

@

%

Model

75OF;

”

@

15A

LV-liO1:

125

or

250

PSIG

&

LV-1203: 50

0.6; Models

Vat;

lO,OOO,OOO operations

75 ”F,

@

LV-1202

PSIG

200

PSIG

200°F,

81

Model LV-1203: 0.7

50°F;

@

PSIG

100 @

WETTED PARTS:

WATER RESISTANT

STRAIN RELIEF FITTING: For cable diameters 0.250”

WEIGHT:

LV-1201:

Noryl (a phenylene oxide based resin), 316

Buna

N;

LV-1202: Ryton, 316 SS,

LV-1203: Ryton R-4, Hastelloy C, Viton

‘/4

lb.

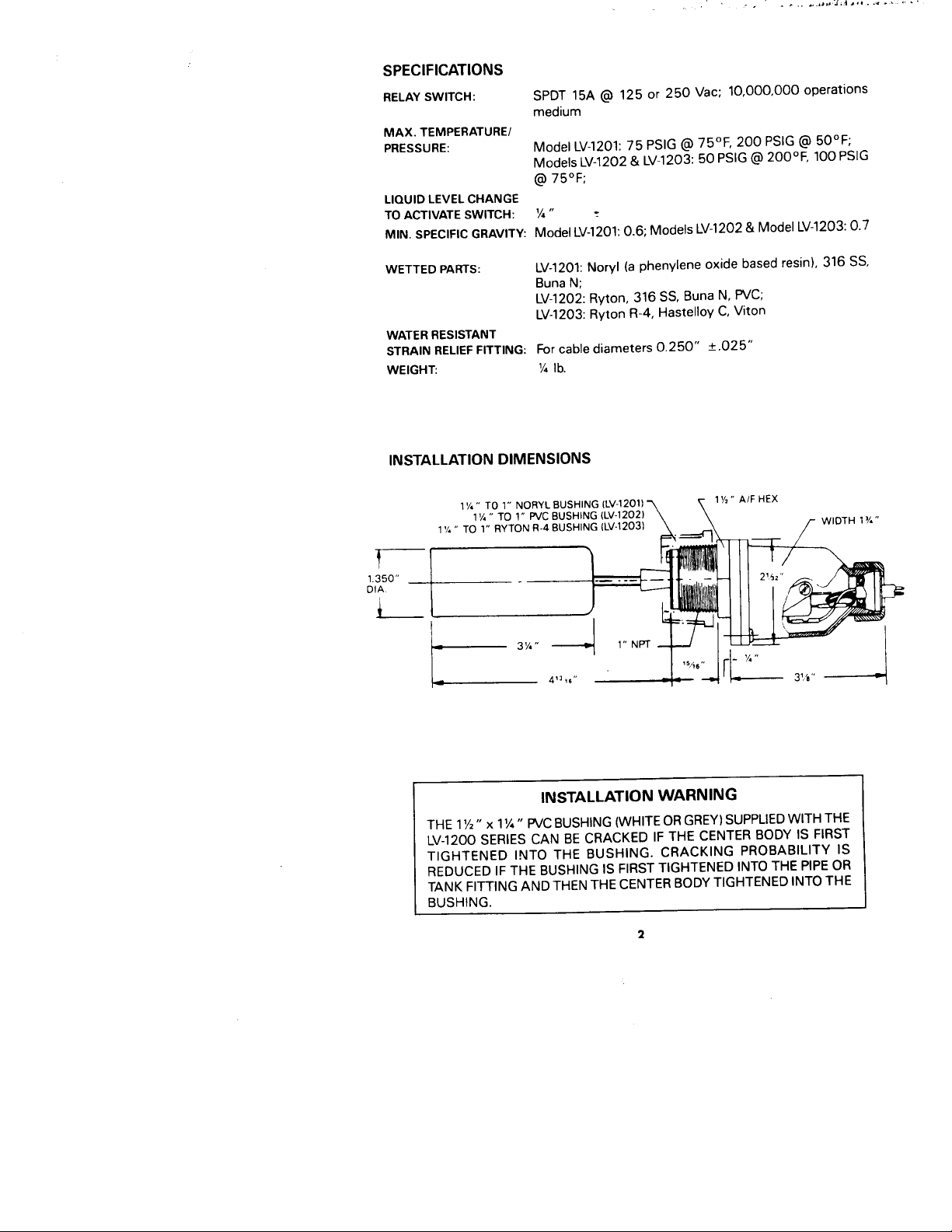

INSTALLATION DIMENSIONS

”

TO 1” NORYL

1%

1% ” TO

”

1%

TO 1” RYTON R-4

1.

DI

BUSHING

I”

WC BUSHING

BUSHING ILV-1203)

ILV-1201)

,,l 202,\

Buna

SS.

N, WC;

+.025”

INSTALLATION WARNING

GREY)

”

PVC BUSHING (WHITE OR

”

THE 1%

LV-1200 SERIES CAN BE CRACKED IF THE CENTER BODY IS FIRST

TIGHTENED INTO THE BUSHING. CRACKING PROBABILITY IS

REDUCED IF THE BUSHING IS FIRST TIGHTENED INTO THE PIPE OR

TANK FITTING AND THEN THE CENTER BODY TIGHTENED INTO THE

BUSHING.

x 1%

2

SUPPLIED WITH THE

Page 3

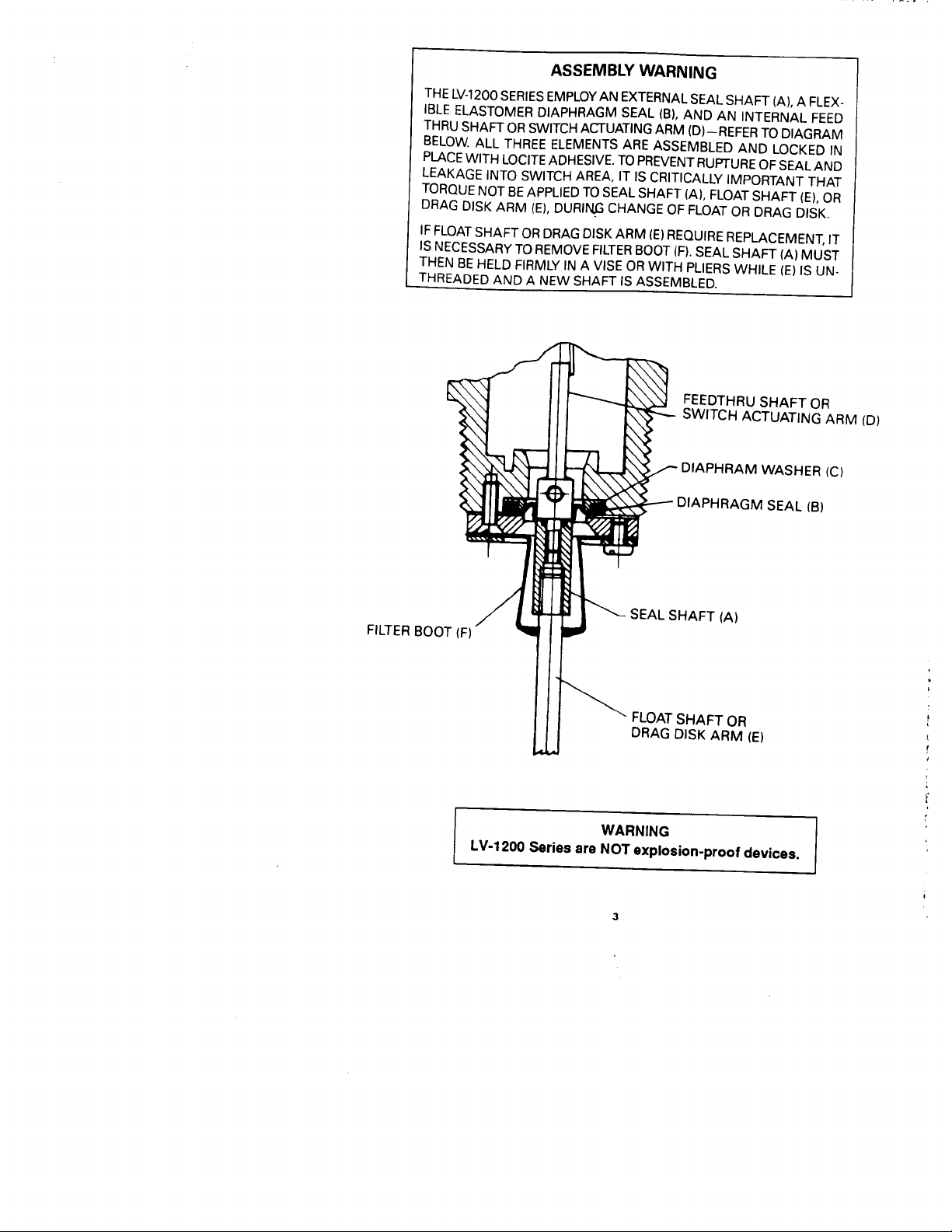

ASSEMBLY WARNING

LV-1200 SERIES EMPLOY AN EXTERNAL SEAL SHAFT (A), A FLEX-

THE

IBLE ELASTOMER DIAPHRAGM

THRU SHAFT OR SWITCH ACTUATING ARM (D)-REFER TO DIAGRAM

BELOW. ALL THREE ELEMENTS ARE ASSEMBLED AND LOCKED IN

PLACE WITH

LEAKAGE INTO SWITCH AREA, IT

TORQUE NOT BE APPLIED TO SEAL SHAFT (A), FLOAT SHAFT

DRAG

IF FLOAT SHAFT OR DRAG DISK ARM (E) REQUIRE REPLACEMENT, IT

IS NECESSARY TO REMOVE FILTER BOOT (F). SEAL SHAFT (A) MUST

THEN BE HELD FIRMLY IN A VISE OR WITH PLIERS WHILE

THREADED AND A NEW

LOCITE ADHESIVE. TO PREVENT RUPTURE OF SEAL AND

DISK ARM (E), DURING CHANGE OF FLOAT OR DRAG DISK.

SHAFT

SEAL

(B), AND AN INTERNAL FEED

IS

CRITICALLY IMPORTANT THAT

IS

ASSEMBLED.

FEEDTHRU SHAFT OR

SWITCH ACTUATING ARM

(El

(El,

IS

OR

UN-

(D)

FILTER BOOT (F)

DIAPHRAM

DIAPHRAGM SEAL (B)

.‘-SEALSHAFT

1 &i

I

r--

1

LV-1200 Series are NOT explosion-proof devices.

FLOAT SHAFT OR

DRAG DISK ARM (E)

WARNING

3

WASHER

(C)

Page 4

INSTALLATION AND OPERATION

The LV-1200

supplied

LV-1202, and Ryton R-4 for Model LV-1203)

Series Liquid Level

with a 1

1”

Switch is for side-mounting

(No@,

bushing l/4” x

Model LV-1201; PVC, Model

threaded in place

ONLY. It is

to

with 2

3

wraps of Teflon tape, which must be intact or renewed if the bushing and

switch are separated before assembly in tank. Care must be exercised

when threading the bushing into plastic or metal fittings.

APPLY

a

minimum of 2 to a maximum of 3 wraps of Teflon tape to the threads of

the bushing. This is especially important if the unit is to be used

fittings where coarse metal threads could gall plastic if not lubricated. The

plastic bushing

CAN BE CRACKED if the main body of the level switch is

in metal

tightened into it FIRST. Cracking will not occur if the bushing is FIRST

tightened into the pipe or tank fitting and THEN the LV-1200 body is

tightened into the bushing.

Therefore:

1.

Teflon tape thread and tighten plastic bushing into pipe or tank fitting.

5teP

3teP

2. Teflon tape thread and tighten the LV-1200 Switch into plastic bushing by

applying

body points UPWARD and the threads are leak

wrench to hexagon section. Repeat Steps 1 and 2 until the arrow on the

tight.

NOTE

Plumber ’s tools such as pipe wrenches are not recommended. If possible,

use a ‘Rigid ’ type wrench where the smooth jaws closely fit the hexagon

section.

ELECTRICAL WIRING

Remove the gland nut, grommet and switch cover.

Strip the outer jacket of the electrical cord back approximately

insulation from the individual conductors back approximately

Slip on terminals are supplied with each switch. Remove them from the switch

terminals and crimp on or solder to the electrical leads.

Feed the electrical cable through the gland nut, grommet and switch cover as

shown below.

1%

%

“.

I’.

Strip the

n

Apply slip on terminals to appropriate contacts of the microswitch.

Slide the cover down the cable and fasten it to the body of the switch with the

4 screws provided.

Slide the grommet down the cable until the outer jacket is level with the small

end of the grommet and then push the grommet into the tapered end of the cover.

Hold the cable jacket to prevent rotation and thread the gland nut firmly onto the

cover.

5

Page 5

Figure 1: Wiring Schematic for power applied to the load when the liquid

the set point (power to the load is interrupted when the level increases to above

than

the set point).

level is less

DECREASING

BELOW SET POINT MOVES

1

ACTUATOR IN DIRECTION SHOWN

A

I

I

?

MICROSWITCH

Figure 2: Wiring Schematic for power applied to the load when the liquid level is

greater than the set point (power to the load is interrupted when the level decreases

to below the set point).

INCREASING

ABOVE SET POINT MOVES

ACTUATOR IN DIRECTION SHOWN

r

-NC

4.

CO M

LIQUID LEVEL

LOAD

-

(HOT)

LINE

LIQUID LEVEL

LOAD

(HOT)

MICROSWITCH

Microswitch actuation point may be monitored by an audible click or with an OHM

meter before connecting the line power to the terminal strip or by monitoring the

voltage supplied to the load through the microswitch.

5

LINE

Page 6

10399 6. GROMMET

5.

STRAIN RELIEF

10399

10399-Z. COVER

-3. 4 RETAINING SCREWS

SHOWN1INOT

NUT

10399-19. MICROSWITCH BRACKET

10399 20. 2 SCREWS

21. 2 SPLIT LOCKWASHERS .

10399 26

10399-13. FILTER BOOT CLAMP RING

10399 12. FILTER BOOT

IF FLOAT IS TO BE REMOVED

FROM ASSEMBLY, THE FLOAT

SHAFT

PLIERS OR IN A VICE TO

PREVENT UNTHREADING FROM

THE SEAL SHAFT

”

BUSHING

x

1

I’.

1”

BUSHING

x ” 1’.

29

14. 3 RETAINING SCREWS

-178.

FLOAT

MUST BE GRIPPED BY

il

IRYTONI 10399.17A. FLOAT

INORYLI

IAI

ILV-12011

iLV

12021

N

::

2

.‘,

/

+ % -

10399 22. MICROSWITCH COMPLETE

WITH 2 SLIP ON TERMINALS

,/-10399.23.

BODY COMPLETE WITH

Al SEAL SHAFT

81

DIAPHRAGM

Cl DIAPHRAGM WASHER

FEEDTHRU SHAFT

DI

El PIVOT PIN

FI CAP

\

2 SCREWS

-24. 2 NUTS

25. 2 SPLIT LOCKWASHERS

26, 1 PLAIN WASHER

10399 4 0 RING

fSONlCALLY WELDED1

10399~16.

FLOAT SHAFT

I

‘F’COVER

SUPPLIED FITTING FOR

FLEXIBLE CONDUIT

LV-1201 AND LV-1202 PARTS LIST DIAGRAM

6

TO SUIT CUSTOMER

>,,”

Page 7

10403-6.

GROMMET

10403.5. STRAIN RELIEF NUT

10403-2.

/

COVER

3. 4 RETAINING SCREWS

INOT

SHOWNI

MICROSWITCH B

2

10403-19,

10403 13. FILTER BOOT CLAMP RING

SCREWS

IT, r01 1 ,n

.14.

3 RETAINING SCREWS

10403-12. FILTER BOOT

_^.,....^.

’

RA

-/

10403-21. MICROSWITCH

3 SLIP ON TERMINALS

Al SEAL SHAFT

Bl

Ci

m

B

El PIVOT

r,^.^.^^_

WITH

10403.22. 2

-

DIAPHRAGM

DIAPHRAGM WAS

.z.zcn-TuDI

LLYl I “I

SCREWS

-23.2 NUTS

SPLIT LOCKWASHERS

-24. 2

-25, 1

PLAIN WASHER

10403-4.

rll” I

J”Nr

nnu

PIN

.-...

FLOATSHAFT

CKET1o403-16.

.---

510403-l. BODY COMPLETE WITH

-E

ii ‘i

~10403-15,

O-RING

HER

r_

I

-3

nrn,

COMPLETE

10403.16, FLOAT

FROM

MUST BE GRIPPED BY PLIERS

OR

IN A VICE TO PREVENT

.^_^__

A=+LI.IDLI,

.^...^

tA”lNCI

UNTHRr

k”“M

-_..-.._-

IFFLoA_

__^..

~1v-1

StAL

an-r

--_..

(Al

SHAFT

I

1

L

I I

1

I

J

LV-1203 PARTS LIST DIAGRAM

‘F’

COVER TO SUIT CUSTOMER

;;;PXq;;;J~;lN~FOR

1

%”

Page 8

elqepaa~-eu!qmu

‘LUJO,

u!

s!

/I!edal

e1qel!efts

uo!lelq!lec?/~!edeJ

ulnlel

Gu!sy

~no

,o

ql!~

3SOdYnd

8sny.u

e

alO*

eql,!

‘uoyxuqlelu

s!ql

quou

1011

umwe~o~du!

‘elq!ssod

eql,o

uo!leu~~o,u!

01

‘A1y38

emaplocm

medda

‘UW,OP

‘SSSlS,,WA.N

:uopeylddes!u

he ilnsal

s!

,!

‘v~)3wO

l!un s!

‘Bug1

(L)

aas16

‘perdo

e6evmd

-0tld

a32luotilnv

‘iueuuedea

leseqmd

eql

vg3wO

3W

DNIQlll3NI

‘33A30SlWHM

~933JO

Aq

JO

,o

aql

~.nw

mnsue

e+ues

10

cy~ds

ISa3

,o elf1

t13aHo

NlVlEO

lewolsn~

JO

!jsnuew

aNIX

,o

qyq~

I!

eA!B

us

sumlqold

,o

WnpoJd pus

Bu!Mo~~o,

WlVd3kl-

ep!slno

AWU

,ou seumsss

ANV

WJ,

pus

e)e pe6eump

uo!leu!uexe

hq

luecuvadea

II!M

pez!~oqlnv us

h~ol~e,syas

mqwnu

eqlm~o3

luem3

slmpmd

leql

‘saanpord

s!qx

~!un

pus 01

AEU

eq

aloAk+

NV

~emoslleym

S3IlNWYIIVM

pe6awep

~Nvu!jvm

ems!

‘~NI),~=JNIDN~

‘3~1

yomefe

umpeu

mmueqm

xmpold

eql

ti3wuvd3a

lsnw

3Nlu33NlgN3

ec+Jeg

s!ql

suopm~lsu! lo/pue

01

6u!laeluoo :VE)~WO

JO

,

uo

‘PaAJesal

uO!lslus~~n~P

‘3NI

v3u!~eau!Bue

S&!le,e~

01 aql

pue lapas

‘uopeJq!(e3

lequm”

SrreH

oql

vg3wO

331hu3s

NI)

U3SVH3Und

S3lWlDNI

Alyqsg

JO

Aue

eql u!

10

‘smyl

mem JO

emep!Ae

Bu!eq

xmpold

uo!IsIIelsu!

s”o!ssyo

su

slueuodwo3

.eBJeqD

?senbeJ

JeAo3

AlueueM

melmu

sloue

,o s!ql

‘Jerremoq

Cl3lldHlll-W

SNOUWlN3S3Yd3U

JO

p.!#mds

qD!qm

,o

‘JeAeMoH

eql plnoqs

ue

sppe leuo!l!ppe euo

d!qsuewyom

v’E)=~yyo

slq6!J

‘DNlki33NION3

pus

@edeM’s

1epow.t

‘ a’,,‘,

3t10338

m6mql

l~nsuo~

&iOj

t10 -

u3wom3

‘VD3WO

eqlol

vg3wO

SIS3llO3Y

/

WOJ,

Aua

e6eurap

u!

pesn eq

JO

ql!m

em

eql

,o

u! eql

uo!lsJadeJd

CINV

3l.U

CINW

II!M

.q

0811

‘syod

‘10~1~03

JO

ou

le

uodn

uo

qx8

,I

01 Buflpueq Bu!dd!qs pus

v~)3wO

s(e!mew

pus

A.lNWWWJl

Uell!JM

lUeSUO3

‘DNllj33NIDN3

‘3NI

V33WO

lmpold

SBM

SAsq

eql

sm3wa

tsumaoud

01

‘pelelstml

10

lmpold

3~0336

40

10818~

Buyum

cy,!aeds

--Id

&t

01

Jo

pempe,

hue

IIV

lo”

lepow ‘se6ueqa

~epun

NWlUY

‘Jeuuew

Aq 8!

s,vg3wO

vg3wO

llnsel

leql ~101,

MlllUV1NVH3U3HI

SSlNlM YOj \I UWlll3lUVd

JO

p.malm#numlu

.I@

,O II s”O~J.lr

~XWJO~

‘sesn, pus

S.vg3wO

10

!uo!lelq!A JedoJdw! :uo!lay,!3edo

peledurel

‘essqlmd

u!

SUO~%SO66nS

UO

epnf~!

peJ!edeJ

10

peaeidel

Jewolsn3 fm!r\,eg

umu!xaru

,o

,o

ql!M smoqs

elep

eel, ,o

sloe,ep

WuaP@Jl

eql

u! A6o~ouq3el

Eup3sluo3

‘smrruatl

mqu~nu plnoqr ueql pezjlaw eq

wotlj

qms

sse(wmq

*!ql

helntma

U3HlO

mmd

? ??

eseql

‘umunl

Bu!Aeq

eq

Alele!peuu!

enyam

e6eleho3

JWA

uoy

Jo!Jd

eleur

‘se6ueq3

,o

ANV

pj”oqs

luetudfnbe

se6erusp

Wmpord A)USuBM

‘pempo~de~

VD3wO

smuolsn3

lo/pus

surelqold

eql

.ecumpuodssmo3

u!

e

JO,,0

IJ!M

helm,

SUO

PsJels!6SJ

s!

01

‘lmpold

suo!lm~ls8u!

lspu”

uo!leuo,u!

lEIlwgavlA

‘(SAw3a

eyl

peu6!sse

t138wnN

E)NINklt-l13tj

luewdgbe

vg3wO

:NOlllaNO3

u!

eql yenueru

umlnaoeld

J O

, ueeq seq uezfel

JO

ON S3IlNVWVM 30

rmqa

qa

~016

JO

‘leeq amls!ou~

emep!r\e

,o

ueeq

leqwnu

uodn euoqd UW!JM Jo

eql IO, ‘uopenlsrre

[euou

(L)

sluem~

sgl

ly eq 01

mo

‘Q3SVH3Wld

leqtu””

q3!qM eql

ttlvi

pus ploq

‘gN,u33N,DN3‘3NI

leqlfeu seumsse Ql!q!suodseJ 10, he

ld33X3 lVH1

Btqleledo suo!l!puo~ ep!slno

01

40 pi

sqwotu

JO u!

‘ued lnOql!M

el0qt.t

‘perdoaozoqd

lqB!JAdoD

sp~o,,s

01 eql

pus la!ms mqrunu

hue

eql

&uepu!

JO, Aue

alSS3YdX3‘03lldWlLIO

W

peumlel

eqa

po!led e

VD3wO

s!

s

s,v~3wOAyod

et.!le\el

J!sdey’c

‘Alueuempue

~epomy

.__

:vc)3wo

Bu!Mo~~o,

elqel!SAe

gNISS33

Nm3tl

3klO338

lDeJ!a

11s

AWJJSM +edeJ pus sep!nbuys$senbel

,o

as” eql

Tvl33dS

uopetmo,u!peugluoa

Al!yqa!l

W93WOS3XVW

vg3~0S!

esns!u

em 10” ‘pelueuann

e,yssezme:uo!souof~

umleu(uv)

va3wa

s!ql

‘O’d’L

tloj

pusuo

h&t3

ANVMNWYLIWM

QuoS~UILI.M

mqlo

l!unsmoqs

puno,01 en!me,ep eq l!

eq

lsqls,v~)3wO

s~etuolsrm

poped01

9661

,l!rn

JO,

Q

Loading...

Loading...