Page 1

185-210 DUS

JD 4045

OMEGA TOOL

OPERATORS, MAINTENANCE,

AND PARTS MANUAL

SERIAL NUMBER_________________________________________

MODEL NUMBER_________________________________________

P/N: 307271

06/17/2008 MCM

Page 2

Page 3

TABLE OF CONTENTS

INTRODUCTION .............................................................................................................................. 6

SECTION 1 SAFETY......................................................................................................................... 9

1.1 PARKING .......................................................................................................................................9

1.2 BEFORE STARTING THE COMPRESSOR ................................................................................ 9

1.3 COMPRESSOR USE AND COMPRESSED AIR ........................................................................ 9

1.4 SERVICING ..................................................................................................................................10

1.5 LIFTING .......................................................................................................................................10

SECTION 2 DESCRIPTION...........................................................................................................11

2.1 INTRODUCTION......................................................................................................................... 11

2.2 ROTARY COMPRESSOR COMPONENTS ..............................................................................11

2.3 ENGINE COMPONENTS ...........................................................................................................12

2.4 CHASSIS ......................................................................................................................................13

2.5 ENCLOSURE ...............................................................................................................................13

2.6 INSTRUMENT PANEL DOOR ................................................................................................... 1 3

SECTION 3 OPERA TION.............................................................................................................. 14

3.1 START UP PREPARATION ........................................................................................................14

3.2 STARTING PROCEDURE .......................................................................................................... 14

3.3 EMERGENCY SHUTDOWN PROCEDURE ............................................................................1 4

3.4 ROUTINE SHUTDOWN PROCEDURE ....................................................................................14

SECTION 4 MAINTENANCE ....................................................................................................... 15

4.1 ENGINE FUEL SPECIFICATIONS.............................................................................................15

4.2 ENGINE OIL AND FILTER.........................................................................................................16

4.3 ENGINE COOLING SPECIFICATIONS.....................................................................................1 6

4.4 FAN ...............................................................................................................................................17

4.5 RADIATOR PRESSURE CAP ....................................................................................................1 7

4.6 RADIATOR...................................................................................................................................17

4.7 COMPRESSOR OIL ....................................................................................................................17

4.8 COMPRESSOR & ENGINE AIR FILTER MAINTENANCE ................................................... 2 0

4.9 COMPRESSOR OIL THERMOSTATIC VALVE .......................................................................21

4.10 COMPRESSOR AIR/OIL SEPARATOR................................................................................... 21

4.11 BELTS & BELT ADJUSTMENT ..............................................................................................21

4.12 CONTROLS-OPERATION AND ADJUSTMENTS.................................................................22

4.13 INSTRUMENTS ........................................................................................................................23

4.14 BATTERY ...................................................................................................................................23

4.15 MAINTENANCE SCHEDULE ................................................................................................. 2 4

4.16 DAILY OPERATION .................................................................................................................24

4.17 MAINTENANCE SCHEDULE CHART...................................................................................25

4.18 RECOMMENDED SPARE PARTS LIST .................................................................................26

4.19 PROCEDURE FOR ORDERING PARTS.................................................................................2 6

SECTION 5 TROUBLESHOOTING ............................................................................................ 27

5.1 TROUBLESHOOTING................................................................................................................27

5.2 TROUBLESHOOTING CHART ................................................................................................. 2 8

WARRANTY ..................................................................................................................................... 31

SECTION 6 ASSEMBLY_DRAWINGS......................................................................................... 37

P/N: 307271

4

Page 4

Page 5

INTRODUCTION

OWNER’S RESPONSIBILITY

Your new Boss air compressor was engineered, built and tested to ensure the user both dependable and

economical service. This compressor has also been certified as conforming to the applicable Noise Emission

standards of the Environmental Protection Agency .

Continuation of this unit’s performance depends upon the care it receives during use. Therefore, operation

and maintenance procedures described in this manual should be followed carefully. The operator and

service personnel responsible for the care of this unit should be thoroughly familiar with this information.

It is the owner’s and/or operator’s responsibility to perform all safety checks and to ensure that all lubrication,

maintenance instruction and recommended practices are followed for safe operation. If disassembly or

replacement is required, particularly of internal parts, we recommend the owner see his dealer and not

attempt the repair himself.

It is owner’s responsibility to ensure that the preventive maintenance program is followed at the recommended

intervals. Proper care and service will assure long service life with a minimum of problems and operating

expenses.

W e recommend that the owner and operator be thoroughly familiar with the contents of the manual.

If you encounter difficulties which you cannot diagnose our service personnel are prepared to help you.

Our toll free number is 1-800-635-6587. Outside the continental United States and Canada our number is

219-324-7776.

The model and serial number information is requested on all correspondence. This information can be

found on the Model Number Identification Plate. The information contained on the identification plate

should be transferred to the cover page of the manual for future reference.

6

P/N: 307271

Page 6

WARNING

ALL UNITS ARE SHIPPED WITH A DET AILED OPERA TORS AND P ARTS MANUAL.

THIS MANUAL CONTAINS VITAL INFORMATION FOR THE SAFE USE AND

EFFICIENT OPERATION OF THIS UNIT. CAREFULLY READ THE OPERATORS

MANUAL BEFORE STARTING THE UNIT. FAILURE TO ADHERE TO THE

INSTRUCTIONS COULD RESULT IN SERIOUS BODILY INJURY OR PROPERTY

DAMAGE.

AIR COMPRESSOR SAFETY PRECAUTIONS

Safety is basically common sense. There are standard safety rules but each situation has its own peculiarities,

which cannot always be covered by rules. Therefore with your experience and common sense, you are in

a position to do something about safety. Lack of attention to safety can result in: accidents, personal

injury, reduction of efficiency and worst of all - Loss of Life. Watch for safety hazards. Correct them

promptly . Use the following safety precautions as a general guide to safe operation:

Do not attempt to remove any compressor parts without first relieving the entire system of pressure.

Do not attempt to service any part while machine is operating.

DANGER

CHECK THE COMPRESSOR SUMP OIL LEVEL ONL Y WHEN THE COMPRESSOR

IS NOT OPERATING AND SYSTEM IS COMPLETELY RELIEVED OF PRESSURE.

OPEN SERVICE VALVE TO ENSURE RELIEF OF SYSTEM AIR PRESSURE WHEN

PERFORMING MAINTENANCE ON COMPRESSOR AIR/OIL SYSTEM. FAILURE

TO COMPLY WITH THIS WARNING MAY CAUSE DAMAGE TO PROPERTY AND

SERIOUS BODILY HARM.

Do not operate the compressor at pressures or speeds in excess of its rating.

Periodically check all safety devices for proper operation.

Do not play with compressed air . Pressurized air can cause serious injury to personnel.

Exercise cleanliness during maintenance and when making repairs by covering parts and exposed openings.

P/N: 307271

7

Page 7

USER MODIFICATION

This Boss compressor incorporates numerous features to minimize noise emissions from the unit during

operation. This configuration has been tested for noise emissions at conditions specified by the U.S.

Environmental Protection Agency . Conformance to regulations requires the incorporation of the following

notification and definition in the OPERA TION AND MAINTENANCE MANUAL.

T AMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law prohibits the following act:

1. The removal, rendering inoperative, other than for purposes of maintenance, repair or replacement

of any device or element of design incorporated into any new compressor for the purpose for noise

control prior to its sale or delivery to the ultimate purchaser .

2. The use of the compressor after such device or element of design has been removed or rendered

inoperative by any person.

Among the acts included in the prohibition against tampering are those listed:

1. Removal or rendering inoperative any of the following:

a. The engine exhaust system including the manifold, muffler or tailpipe.

b. Any of the enclosure components and associated sound barrier materials.

c. The sound baffles in the intake, exhaust and cooling system gas paths.

d. The air intake system including the air cleaner, the intake ducting, valve cover and gaskets.

2. Removal of any of the following:

a. Engine mounts or other sound isolating barriers in the system.

b. Fan shrouding and sound hood.

3. Operation of the compressor with any of the enclosure doors open.

8

P/N: 307271

Page 8

SECTION 1 SAFETY

1.1 PARKING

CHOOSING A P ARKING SITE

1. Park the compressor on a level firm area. Never park on a grade of more than 15 degrees (27%).

If you must park on any grade, park across the grade so that the compressor does not tend to roll.

2. Park so that the wind carries exhaust fumes and radiator heat away from the compressor inlet.

3. Park away from work site dust.

4. Stay clear of electrical power lines. Keep the towing vehicle or equipment carrier , compressor,

hoses, tools and all personnel at least 10 feet from power lines and buried cables.

1.2 BEFORE STARTING THE COMPRESSOR

1. Check fluids levels and for possible leaks.

2. Use adequate hose and couplings with safety locks or pins.

3. Remove all tools and/or loose items from engine compartment.

4. Relieve any pressure in receiver tank.

5. Use proper eye and ear protection.

1.3 COMPRESSOR USE AND COMPRESSED AIR

1. Air from this machine is not fit for human breathing or food processing.

2. Never operate in an enclosed area.

3. Never use compressed air to clean your clothes and never direct it at another person, it can kill.

4. Always wear eye protection.

5. Install velocity fuse (“OSHA”) upstream of hose to prevent hose whip in case of a rupture.

6. Keep doors or hoods closed on machines in operation.

7. Do not touch hot surfaces or moving parts, such as exhaust or fans.

8. Do not adjust or restrict relief valves.

9. Do not refuel while machine is running; shut down and allow to cool before refueling.

10. Do not jump-start with cable connections directly on battery .

12. Do not use air at pressure higher than 30 PSIG (207 KP A) for cleaning purposes. Use of higher air

pressure can cause injury to the operator .

13. Keep compressor panels closed except when making repairs, adjustments, or servicing the

compressor .

14. Make sure all personnel are out of and clear of the compressor before starting or operating it.

15. Do not use either cylinder or air line antifreeze compound in confined area.

P/N: 307271

9

Page 9

1.4 SERVICING

1. Before servicing compressor, relieve receiver pressure and allow to cool.

2. Be sure all access panels are opened and/or removed.

3. Wipe up all spills resulting from servicing.

4. Disconnect the grounded (negative) battery connection before making repairs or cleaning inside

the enclosure.

5. Do not use flammable solvents for cleaning the compressor .

6. Radiator coolant is under pressure. Do not remove radiator cap quickly, it may cause spray of

scalding coolant and severe burns to operator.

7. Make repairs only in clean, dry and well-lighted and well-ventilated areas.

8. Keep all parts of the body and any hand held tools or other metal objects away from exposed live

parts of the electrical system.

9. Replace damaged fuel tanks or lines immediately . DO NOT WELD on or near fuel tanks or lines.

10. Make sure all personnel are out of the compressor before closing and/or replacing panels.

1.5 LIFTING

1. If the compressor is provided with a lifting bail, then lift by the bail. If no bail is provided, then lift

by sling.

2. When lifting by helicopter , use a sling. Do not lift by unit lifting bail.

3. Inspect the entire lifting, rigging and supporting structure to ensure it is in good condition and has

a rated capacity of at least the gross weight of the compressor plus 50%.

10

P/N: 307271

Page 10

SECTION 2 DESCRIPTION

2.1 INTRODUCTION

Your Boss compressor is a gas/diesel driven Rotary Screw Compressor unit that provides superior

performance and reliability along with a minimal amount of required maintenance.

2.2 ROTARY COMPRESSOR COMPONENTS

COMPRESSOR DESCRIPTION

The compressor assembly is a positive displacement, oil flood lubricated, screw type unit employing one

stage of compression to achieve the desired pressure. Components include a housing (stator), two screws

(rotors), gears, bearings and bearing supports.

In operation, two helical grooved rotors mesh to compress air. Inlet air entering the casing is compressed

as the male lobes roll down the female grooves, pushing trapped atmospheric air along and compressing it

in one stage of compression. This process delivers smooth-flowing air at full pressure to the receiver .

T o illustrate the compression sequence, consider the action of the male lobe as similar to a ball. As a helix

rotates, the ball (male lobe) meshes with the groove to start a compression cycle with trapped atmospheric

air. As the ball moves down the groove, air is compressed. Atmospheric air fills in behind the ball preparing

the groove for another compression cycle as rotation continues and the male lobe again meshes with the

groove.

During the compression cycle, oil is injected into the compressor for the purpose of lubrication, cooling

and sealing. Compressed air laden with oil leaves the compressor unit through a discharge port, which is

designed to give optimum performance within the desired discharge pressure range.

AIR FIL TER

The Rotary Screw Compressor unit and engine are protected by a high efficiency , two-stage air filtering

system. This is a dry filter that requires maintenance when the air filter restriction gauge says it is time.

OIL COOLING

The compressor is an “oil flooded” compressor . The oil lubricates, seals and cools the internals of the

compressors as it is injected into the compressor. The oil goes through the compressor with the air where

it picks up the heat generated by the compression process then seals the spaces between moving parts and

lubricates bearings. The hot oil must be cooled. It is separated from the air, passed through the oil cooler

(mounted next to the engine radiator), through a thermostatic valve (that helps to rapidly warm cold oil at

start-up), then through a full flow oil filter and then back into the compressor. See instructions 4.10 and

4.13 for oil filter element and air/oil separating element servicing.

11

P/N: 307271

Page 11

AIR/OIL SEP ARATOR

At the compressor discharge the compressed air and the hot oil flow into a steel ASME coded pressure

vessel (rated at 175 psig-250psig) that acts as a reservoir for the air and separates out the oil. From the

bottom of this oil sump the oil leaves the vessel on its way to the oil cooler . The air and the slight oil mist

still entrained in the air flow through the separator element, which removes the last of the oil from the air.

The air passes on out to its final use and the separated oil goes through the scavenge line to the compressor

to re-enter the system.

As the compressor air leaves the receiver it goes through a minimum pressure valve that is set to maintain

at least 80 psig (55kpa) in the receiver when the compressor is running. The purpose of this pressure is to

ensure that there is pressure to force the oil out of the bottom of the receiver, through the oil cooling system,

so that sufficient oil is injected into the compressor .

CONTROL SYSTEM

The Boss compressor system is simple to operate. Starting procedure is explained in section 3 and on the

instrument panel door of the compressor. Each machine has an On/Of f switch and a safety bypass switch

that bypasses the safety shutdowns. Once the machine is “on line” and in the run position, control is

automatic. The control system senses the need for air and adjusts the speed of the engine and compressor

as well as the opening of the compressor inlet valve to supply the amount of air needed. If the air demand

is zero, the engine and compressor “idle” and the inlet valve is shut to control the air entering the compressor.

If the demand is maximum, the opposite happens, full speed and wide-open inlet valve. Intermediate air

demands give intermediate speeds and valve openings for maximum operating efficiency . Service and

adjustments are in section 4.14.

2.3 ENGINE COMPONENTS

ENGINE DESCRIPTION

The engine in each Boss compressor system is selected to have reserve horsepower and speed necessary to

drive the compressor and all accessories when operating up to a discharge pressure 100 psig (686kpa) to

220 psig (1509kpa).

RADIATOR

The radiator is selected to handle the heat load of the engine. Mounted next to the compressor oil cooler.

Cooling air is moved through these two coolers with a specially selected engine fan. The system is designed

to handle extreme heat conditions.

FUEL SYSTEM

All units are supplied with fuel tank capacity adequate for a day’ s normal operation, fuel filtering system

and optional low fuel shutdown. See section 4.3 for fuel servicing.

MUFFLER

Engine noise is reduced by a durable, low restriction engine muffler .

12

P/N: 307271

Page 12

2.4 CHASSIS

FRAME

The entire compressor frame and body is “utilized” and constructed of 3/16" or 10 gauge steel plate,

resulting in light weight while providing a much stronger body than conventional designs of light sheet

metal over structural members.

2.5 ENCLOSURE

Enclosure is 14 gauge metal with powder coat finish. Each access panel has lockable handles with mechanical

props.

2.6 INSTRUMENT PANEL DOOR

Lockable instrument panel doors provide access to all controls and gauges.

13

P/N: 307271

Page 13

SECTION 3 OPERA TION

3.1 START UP PREPARATION

1. Check engine and compressor oil levels. Do not overfill.

2. Check coolant level in radiator (Fill at coolant recovery bottle).

3. Check for fuel, oil and coolant leaks.

4. Check air cleaner, clamps and hoses.

5. Check battery connections.

6. Check and adjust tension of fan belts.

NOTE: This unit has minimum air pressure valve to assure compressor oil flow . There will be no airflow

from the compressor if receiver pressure is less that 80 PSIG.

3.2 STARTING PROCEDURE

1. Close service valves and move unloader valve to “ST AR T” position

2. Press and hold bypass button and turn starter switch to “ST AR T” position. If engine fails to start.

DO NOT attempt to restart until cranking motor stops rotating. Before restarting, starter switch

must be returned to “OFF” position

3. When engine starts, release starter switch and hold bypass button down until oil pressure reaches

15PSI then release. Maintain unloader valve at “START” position until engine is warm and

operating smoothly , then move unloader valve to “RUN” position.

3.3 EMERGENCY SHUTDOWN PROCEDURE

Turn start stop switch to “OFF” position

3.4 ROUTINE SHUTDOWN PROCEDURE

1. Move unloader to start position

2. Allow compressor to run 2 to 3 minutes to cool.

3. Move on/off switch to “OFF” position

14

P/N: 307271

Page 14

SECTION 4 MAINTENANCE

4.1 ENGINE FUEL SPECIFICATIONS

WARNING

DO NOT MIX GASOLINE OR ALCOHOL WITH DIESEL FUEL. THIS MIXTURE

CAN CAUSE AN EXPLOSION.

CAUTION

DUE TO THE PRECISE TOLERANCES OF DIESEL INJECTION SYSTEMS, IT IS

EXTREMEL Y IMPROTANT THA T THE FUEL BE KEPT CLEAN AND FREE OF DIRT

OR WA TER. DIRT OR W ATER IN THE SYSTEM CAN CAUSE SEVERE DAMAGE T O

BOTH THE INJECTION PUMP AND THE INJECTION NOZZLE.

USE ASTM NO.2D FUEL WITH A MINIMUM CET ANE NUMBER OF 40. NO.2 DIESEL.

FUEL GIVES THE BEST ECONOMY AND PERFORMANCE UNDER MOST

OPERATING CONDITIONS. SEE ENGINE MANUFACTURES OPERATORS/

INSTRUCTION MANUAL FOR THE PROPER ENGINE FUEL FOR THE BRAND

ENGINE IN YOUR BOSS COMPRESSOR.

HIGH AL TITIDE AND LOW TEMPERATURE FUELS

Fuels with cetane numbers higher than 40 may be needed in high altitudes or extremely low ambient

temperatures to prevent misfires and excessive smoke.

COLD WEA THER FUEL

At opening temperatures below 0 degrees C (32 degrees F) use a blend of No.1D and No.2D fuels, also

know as “winterized” No.2D. NOTE: No.1D fuel can be used; however, fuel economy will suffer .

Use low sulfur content fuel having a cloud point that is at least 10 degrees below the lower expected fuel

temperature. Cloud point is the temperature at which wax crystals begin to form in diesel fuel.

The viscosity of the fuel must be kept above 1.3 centistokes to provide adequate fuel system lubrication.

ENGINE FUEL FIL TER

See engine manufactures operator/instruction manual for the proper fuel filter replacement changing intervals

for the brand engine in your Boss compressor.

WARNING

KEEP HANDS AND FINGERS CLEAR OF FUEL FITTINGS. HIGH PRESSURE OF

THE FUEL CAN CAUSE PENETRA TION OF THE SKIN. SEEK IMMDIA TE MEDICAL

A TTENTION IF SKIN IS BROKEN BY THE FUEL SPRA Y.

15

P/N: 307271

Page 15

4.2 ENGINE OIL AND FILTER

See engine manufactures operator/instruction manual for the proper engine oil and filter changing intervals

for the brand engine in your Boss compressor.

OIL FIL TER REPLACEMENT

1. Clean the area around the lubricating filter head.

2. Remove the filter.

3. Clean the o-ring surface of the filter head.

NOTE: The o-ring can stick on the filter head. Make sure it is removed.

4. Apply a light film of lubricating oil to the o-ring-sealing surface before installing.

5. Install the filter as specified by the filter manufacturer.

CAUTION

MECHANICAL OVER-TIGHTENING MAY DIST ORT THE THREADS OR DAMAGE

THE FIL TER ELEMENT SEAL.

4.3 ENGINE COOLING SPECIFICATIONS

Diesel engines require a balanced coolant mixture of water and ethylene glycol base antifreeze. This

protects the engine cooling system from corrosions as well as freezing damage. The Boss compressor is

shipped from the factory with a 50/50 mixture of water and ethylene glycol. In tropical climates where

freeze protection is not required, glycol engine coolant should still be used. It will help prevent corrosion

and pitting of cylinder liners. See engine manufactures operator/instruction manual for the proper engine

coolant for the brand engine in your Boss compressor.

MIXTURES:

Antifreeze concentration level should not exceed recommended levels. Doing so can cause cooling system

failure.

· Use a high quality , low silicate antifreeze

· A mixture of 50% antifreeze and 50% water is required for temperatures above –37 º C (-34 ºF).

· A mixture of 60% antifreeze and 40% water us required for environments below –37 ºC (-34 ºF). This

provides protection to –54 ºC (-65 ºF).

· Never exceed a 60% antifreeze and 40% water mix.

ENGINE COOLING SYSTEM

All engines have a pressurized cooling system that contains a 50/50 mixture of water and ethylene glycol.

Daily maintenance of the system includes a check of the coolant level, proper belt adjustment of fan and

water pump drives, soundness of fan and cleanliness of the radiator and oil cooler to permit airflow . Further

cooling system maintenance is defined in the engine maintenance manual.

16

P/N: 307271

Page 16

COOLANT LEVEL

Before each start-up, when radiator is cold, the coolant should be checked. When needed, refill with a 50/

50 solution of water and ethylene glycol, DO NOT use 100% antifreeze for “topping off”.

WARNING

CHECK THE COOLANT LEVEL ONL Y WHEN THE ENGINE IS STOPPED AND THE

TEMPERATURE IS BELOW 160ºF (70ºC) FAILURE TO DO SO CAN CAUSE

PERSONAL INJURY FROM HEA TED COOLANT SPRAY .

4.4 FAN

Check the fan for cracks, loose rivets, and bent or loose blades. Make sure it is securely mounted. Tighten

the cap screws if loose. Replace damaged fans.

WARNING

NEVER USE THE FAN TO ROTATE THE ENGINE. THE BLADE(S) CAN BE

DAMAGED CAUSING A F AN FAILURE, WHICH CAN RESUL T IN PERSONAL INJUR Y

OR PROPERTY DAMAGE.

4.5 RADIATOR PRESSURE CAP

If coolant continually spills from radiator through the overflow then the radiator cap should be tested and/

or replaced with a cap of the same pressure rating, generally 13 PSI. Be sure cap is turned to the proper

secure position.

4.6 RADIATOR

Any sign of leakage from the radiator may justify a pressure test to assure its soundness. Radiator leaks

should only be repaired by qualified service people. Dirt that clogs the cooling fins of the radiator should

be removed. The use of an air stream of high-pressure steam cleaner should be done with caution so as to

not damage the delicate fins. Bent cooling fins will reduce the cooling capability of the radiator .

4.7 COMPRESSOR OIL

The life and proper operation of the compressor is dependent on adequate and clean compressor oil.

DEXRON® - III Automatic Transmission Fluid is supplied with the new machine and should be used for

proper level maintenance and for oil changes. We recommend that you use DEXRON® - III Automatic

Transmission Fluid.

WARNING

DO NOT REMOVE CAPS OR OTHER COMPONENTS WHEN COMPRESSOR IS

RUNNING OR PRESSURIZED. BEFORE DOING SO, STOP COMPRESSOR AND

RELIEVE ALL INTERNAL PRESSURE.

17

P/N: 307271

Page 17

COMPRESSOR OIL SPECIFICA TIONS

It is permissible to use oils other than the A TF shown above; such as Hydraulic oil. If they are used then

they must have at least the following minimum properties:

• ISO grade 32

• CPS No. 255675

• API Gravity -

• Viscosity , Kinematic

cst at 40 degrees C 33.6

cst at 100 degrees C 5.5

• Viscosity saybolt

SUS at 100 degrees F 173

SUS at 210 degrees F 45

• Viscosity index 98

• Pour point deg. C(deg F) -33(-27)

• Flash point deg.C(deg.F) 204(399)

• Oxidation stability

• Hours to 2.0 mg KOH/g

acid no., ASTM D 943 >600

The advantage in using DEXRON® - III in the compressor is that it is good lubricant suitable to its application

and it is readily available. There are other oils that may be used that have longer life. They are better able

to stand the extreme operating conditions. Whether or not to use these oils is a decision that depends upon

the operating conditions. V ery frequent oil changes are necessary in extremely hot, dirty operating conditions

and if the compressor is operating in a remote, difficult-to-reach service location then perhaps it would be

better to use the DEXRON® - III because of availability and cost. If, however service is convenient and

attentive so that the oil can be used for as long as it will provide good protection; then higher quality oils

may be used that will extend the life of the compressor .

WARNING

BOSS DOES NOT RECOMMEND MIXING DIFFERENT TYPES OF OILS. WHEN

CHANGING TO A DIFFERENT TYPE OIL, CLEAN COOLER, AIR/OIL RECEIVER

AND LINES THOROUGHLY .

ADDING COMPRESSOR OIL

1. Level the compressor to assure oil level indicator will be accurate.

2. Remove any dirt around fill cap, which is located on or near the air/oil receiver and then remove

the fill cap itself.

3. Inspect the fill cap for damage and cleanliness. Replace if necessary .

4. Proper oil can then be added until the oil level reaches halfway in the sight-level tube or the

“bullseye”.

5. Replace full cap securely-never put cap on without tightening immediately .

6. Do not over fill the sump tank. This will cause oil to spray out of the blowdown valve and/or

service valve.

18

P/N: 307271

Page 18

CAUTION

DO NOT REPLACE FILL CAP WITH A PIPE CAP; SERIOUS INJURY OR DAMAGE

COULD RESULT . THE THREADS ARE DIFFERENT . AL W AYS ENSURE A STRAIGHT

THREAD FILL CAP IS USED.

CHANGING COMPRESSOR OIL

1. Oil and air filter will help prolong oil life. If the oil appears dirty or it has a foul smell it should be

replaced.

2. Change compressor oil and filter every 500 hours.

3. Remove fill cap and drain oil from the bottom of the air/oil receiver . Oil will drain more quickly

and completely if it is warm from operation.

4. Close all drains and replace oil with fresh oil to proper level. Replace fill cap and run the unit

briefly to see if more oil needs to be added and to ensure there or no leaks.

COMPRESSOR OIL FILTER

The oil filter in the compressor lubrication system is of the full flow spin-on canister type. Initially the

filter should be replaced after the first 50 hours, then every 500 hours or sooner if indicated. A dirty filter

can restrict oil flow , causing high oil temperature condition, which will result in a unit shutdown.

CAUTION

SUBSTITUTE FIL TERS MA Y HAVE INADEQUA TE WORKING PRESSURE LIMITS,

RESULTING IN ELEMENT LEAKAGE OR RUPTURE. REPLACEMENT FILTERS

MUST BE THE SAME QUALITY AND TYPES AS THE ORIGINAL BOSS AIR

COMPRESSORS FIL TER.

COMPRESSOR OIL FIL TER REPLACEMENT

1. Using a strap wrench, remove the old element and o-ring.

2. Clean o-ring seating surface.

3. Apply a light film of oil to the new o-ring.

4. Hand tighten new element until new o-ring is seated in the o-ring groove.

5. Continue tightening element by hand an additional ½ to ¾ turn.

6. Restart machine and check for leaks.

CAUTION

MECHANICAL OVER-TIGHTENING MAY DIST ORT THE THREADS OR DAMAGE

THE FIL TER ELELMENT SEAL.

19

P/N: 307271

Page 19

4.8 COMPRESSOR & ENGINE AIR FILTER MAINTENANCE

ELEMENT REPLACEMENT

1. Loosen the clamps that secure the dust cup to the body and remove the cover .

2. Empty the dirt from the dust cup.

3. Remove the element.

4. Clean the canister and dust cap with a damp cloth inside and out. DO NOT blow dirt out with

compressor air.

5. At this time clean or replace the element.

6. Replace the element.

7. Reposition the cover and tighten the clamp, INST ALL WITH “TOP” UP.

8. Reset the air filter restriction indicator (if supplied) and the machine will be ready for operation.

CAUTION

WHEN CLEANING AN ELEMENT, THE ELEMENT WILL BE DAMAGED IF YOU

EXCEED THE RECOMMENDED MAXIMUM PRESSURE FOR COMPRESSED A I R

(30 PSI/200 KP A).

CAUTION

DO NOT STRIKE THE ELEMENT AGAINST AN Y HARD SURF ACES AND POSSIBL Y

RUPTURE THE ELEMENT . NEVER BLOW DIR T OUT OF THE INTERIOR OF THE

FIL TER HOUSING. THIS MA Y INTRODUCE DUST DOWNSTREAM OF THE FIL TER.

INSTEAD, USE A CLEAN DAMP CLOTH. DO NOT OIL ELEMENT .

AIR FIL TER ELEMENT CLEANING

The air filter element is cleaned by using compressed air. The maximum amount of times that an element

should be cleaned is (2) times; however the element should be used no longer than a period of one(1) year

without changing.

Prior to cleaning an element, check the element for damage. Damaged elements must be replaced.

When cleaning the element with compressed air, never let the air pressure exceed 30 PSIG (200 kpa).

Reverse flush the element by , directing the compressed air up and down the pleats in the filter media from

the “clean side” of the element. Continue reverse flushing until all dust is removed. Should any oil or

greasy dirt remain on the filter surface, the element should then be replaced.

ELEMENT INSPECTION:

1. Place a bright light inside the element to inspect for damaged or leak.

2. Inspect all gaskets and gasket contact surfaces of the housing. Should faulty gaskets be evident,

correct the condition immediately . If the clean element is to be stored for later use, it must be stored

in a clean container .

3. After the element has been installed, inspect and tighten all air inlet connections prior to resuming

operation.

20

P/N: 307271

Page 20

4.9 COMPRESSOR OIL THERMOSTATIC VALVE

The oil thermostatic valve acts as a thermostatically controlled by-pass valve and allows varying amounts

of oil, depending upon the temperature, to by-pass cooler during the warm up period. When circulated oil

reaches a temperature of 140 º F , the valve closes the by-pass completely and all the oil is circulated though

the cooler . The oil cooler by-pass is restricted enough to cause some warm oil to flow through the cooler

during the warm-up period, maintaining a higher average compressor oil temperature. This reduces

condensation in the oil system and also reduces the possibility of a slug of cold oil from the cooler, causing

a momentary high restriction and a temporary reduction in the oil pressure, hence oil flow .

CLEANING OIL THERMOST A T

1. If it becomes necessary to take the thermostat apart and clean it, disassemble at the bolted flange

and remove the element.

2. If coated or dirty , clean as necessary . The element and rubber seal ring should be cleaned only with

hot water.

3. Inspect the element for bent or dented parts.

4. Replace any damage part during cleaning and assembling the pipe openings should be closed with

tape or plugs until pipe connections made.

4.10 COMPRESSOR AIR/OIL SEPARATOR

WARNING

DO NOT REMOVE CAPS, PLUGS OR OTHER COMPONENTS WHEN COMPRESSOR

IS RUNNING OR PRESSURIZED. PERSONAL INJURY WILL RESULT. BEFORE

DOING SO, ST OP COMPRESSOR AND RELIEVE ALL INTERNAL PRESSURE.

The separator element is located in the top of the air-oil receiver/separator tank. Here the oil mist contained

in the air is removed prior to the final discharge of air . Air should be taken only from the outlet service

valves on the center of the top end of the separator-never directly from the receiver/separator fittings on the

side of the tank. When the oil vapor in the discharge air becomes excessive, the separator element may

need replacing. This should not be necessary more than once a year under normal operating conditions.

SEP ARA TOR ELEMENT REPLACEMENT

1. The element may be replaced by removing the head from the top of separator and pulling the

element out. Only a factory element should be used as a replacement.

2. The separator element flange must have a gasket on each side to seal the head on one side and the

vessel on the other . The staple in each gasket must be left in the gasket, it acts as a static ground.

3. Re-torque the head bolts uniformly to a specification of 220ft-1b.(dry) or 170ft-lb. (wet) when

replacing the separator head.

4.11 BELTS & BELT ADJUSTMENT

V isually inspect the belts. Replace belts if cracked or frayed. Check engine manual for proper belt tension.

21

P/N: 307271

Page 21

4.12 CONTROLS-OPERATION AND ADJUSTMENTS

The compressor system is designed to match air supply and engine performance with the demand. The

components of the control system are, the blowdown valve, start-run solenoid, compressor inlet valve,

pressure regulator and an engine air cylinder .

The start-run valve that is open in the start run position. This allows air to by-pass the pressure regulator

and go directly to the compressor inlet valve, closing it and to the engine air cylinder, holding the throttle

at idle. When switched to the run position, shutting off the by-pass air . Control air now has to go through

the pressure regulator.

The pressure regulator is referred to as a positive type and its operation is proportional to system pressure.

As pressure increases it opens, allowing air to pressurize the inlet valve and air cylinder. When there is an

air demand, the pressure decreases and the regulator starts to close, relieving the pressure in the inlet valve

and air cylinder. An orifice in the regulator bleeds the air out of control line between regulator , engine air

cylinder and inlet valve supplies a signal proportional to the system pressure the inlet valve will modulate.

With no air demand the pressure rises, the signal air from the regulator closes the inlet valve. When an air

demand is present or the pressure falls, the air signal is removed allowing the inlet valve to open to match

air demand.

The blowdown valve has two functions in the system. First it prevents excessive pressure in the start and

unload modes by bleeding off the small amount of air being drawn in during idle. Secondly it relieves or

blows down the system on shutdown. This valve is not adjustable.

ADJUSTMENT

When performing control adjustments care must be taken in regard to safety as the compressor must be

running. Be aware of moving parts, as well as, hot items, such as fans, belts and exhaust components.

IDLE OR UNLOAD SPEED ADJUSTMENT (For 100 PSI System)

With the compressor warmed up and all service valves closed, move start-run switch to run position. Air

pressure will build to 120 psig. If air pressure is less than 120 psig, adjust regulator up by turning the

adjusting screw clockwise. If air pressure is greater than 120 psig, adjust regulator down by turning the

adjusting screw counter-clockwise. Check engine speed with a photo tachometer .

If idle speed is not as listed in specifications, adjustment will be required.

Note: If your unit is rated at a higher pressure add 20psi to the working pressure for unload pressure; ex:

150 PSI working = 170 unload.

IDLE SPEED ADJUSTMENT PROCEDURES

On the injection pump throttle arm, there are two adjusting screws. The air cylinder connected to the

throttle arm, this air cylinder moves throttle to increase and decrease engine speed with air demand. When

adjusting idle speed, the air cylinder should be fully extended moving throttle arm towards front of engine.

T o adjust idle speed, loosen locknut on adjusting screw towards rear of engine. Turning adjustment screw

clockwise will increase speed. If proper speed cannot be obtained with the adjustment screws, it may

require loosing the locknut on air cylinder shaft and adjusting clevis. By turning clevis onto shaft speed

will increase, by turning clevis out, speed will decrease. After proper speed is set, tighten all locknuts.

22

P/N: 307271

Page 22

PRESSURE REGULA TOR ADJUSTMENT

After setting idle speed and compressor is in run position, the pressure regulator adjustment can be checked

and adjusted if required.

The air cylinder receives an air signal from the pressure regulator. This air cylinder controls engine speed

with air demand. T o adjust pressure regulator , with compressor in the run position, open service valve

slightly to allow air to bleed out. By watching air pressure gauge note when air cylinder starts to retract,

this should be approximately 105 psig. If cylinder does not start to retract until at a lower pressure, the

regulator is set to low . The regulator has a locknut and adjustment screw. Loosen the locknut and turn

adjustment screw clockwise to increase the pressure. Turning screw counter clockwise decreases pressure.

After adjustment is complete, tighten locknut.

Note: If you unit is rated a higher pressure add 5 PSI to the working pressure; ex: 150 PSI working = 155

retract pressure.

RA TED SPEED ADJUSTMENT

With the compressor in a run position open service valve slowly until pressure gauge is reading 100 PSI

(working pressure). Check that air cylinder is fully retracted, moving throttle arm to full speed and check

the engine speed. Adjust the speed to within the specifications in the front of this manual. T o adjust there

are two adjusting screws on throttle arm, the adjusting screw towards rear of engine is the high-speed

adjustment. Loosen locknut on adjustment screw by turning screw counter clockwise, speed increases,

after setting speed to specifications, tighten locknut, close service valve and allow compressor to unload

and return to idle.

4.13 INSTRUMENTS

The standard control panel has gauges for air pressure, oil pressure, coolant temperature, ammeter and

hourmeter . Also included is an ignition switch, start/run valve and safety bypass switch. The safety bypass

switch cuts out the low oil pressure switch to permit starting. The low oil pressure switch is normally opens

and closes upon activation. Safety shutdowns are also provided for high compressor oil temperature and

high engine coolant temperature. These switches are normally closed and upon activation. If the compressor

will not start or shuts down while in operation without an obvious malfunction, each switch can be checked

individually by connecting a jumper wire across the terminal posts one switch at a time. The defective

switch must be replaced.

NOTE: the existing wiring harness must be connected to the safety switches while making the above

check.

4.14 BATTERY

Batteries supplied with Boss compressors are selected to have ample cold cranking amperes for quick

starts in inclement weather. Keep them fully char ged and if replacement is necessary the replacement must

be of equal capacity .

WARNING

BA TTER Y GAS CAN EXPLODE CAUSING ACID BURN TO SKIN AND BLINDNESS.

DO NOT OVERCHARGE OR JUMP THE BATTERY INCORRECTLY .

23

P/N: 307271

Page 23

4.15 MAINTENANCE SCHEDULE

A good maintenance program is the key to long machine life. Follow a regular schedule of inspection and

servicing, based on operating hours. Keep an accurate logbook for maintenance, servicing and operating

hours. Use the factory recommended Periodic Maintenance schedule (based on favorable operating

conditions) to serve as a guide to get long and efficient machine life. Regular service periods are

recommended for normal service and operating conditions. For engine maintenance, refer to the engine

manual where a detailed description of service instructions is given. For continuous duty, extreme

temperature, etc., service more frequently. Neglecting routine maintenance can result in machine failure

or permanent damage.

WARNING

DO NOT REMOVE CAPS, PLUGS OR OTHER COMPONENTS WHEN COMPRESSOR

IS RUNNING OR PRESSURIZED. SEVERE PERSONAL INJURY MA Y RESUL T . STOP

COMPRESSOR AND RELIEVE ALL INTERNAL PRESSURE BEFORE DOING SO.

4.16 DAILY OPERATION

Prior to starting the machine, it is necessary to check the oil level in the sump. Should the level be low , add

the necessary amount. If the addition of oil become too frequent, a simple problem may have developed

which is causing this excessive loss. See the troubleshooting section under Excessive Oil Consumption for

a probable cause and remedy . Also check the linkage prior to starting.

NOTE: the radiator and engine cooling system should be drained and flushed every two years. Replace the

coolant with a mixture of 50% ethylene glycol and 50% water. Do not use a leak sealing type of antifreeze.

Should a 100% water solution be used, a rust inhibitor must be added.

After a routine start has been made, observe the instrument panel gauges. After the machine has warmed

up, it its recommended that general check on the overall machine and instrument panel be made to assure

the compressor is running properly . Also check the air filter maintenance indicator (if supplied). Should

the indicators show red, clean or replace the elements immediately. (See engine manual.)

24

P/N: 307271

Page 24

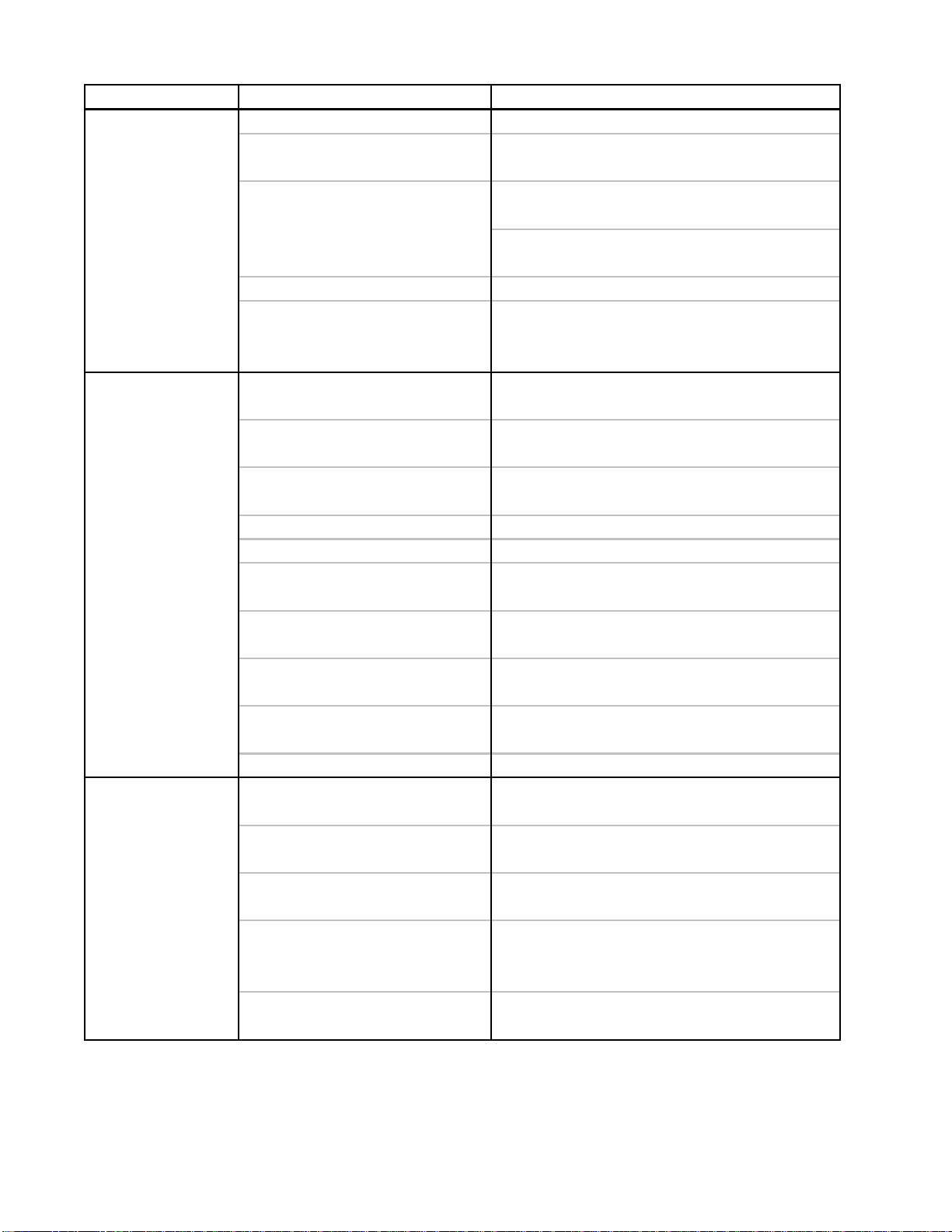

4.17 MAINTENANCE SCHEDULE CHART

I NT ERVA L REQUI RED M AINTENANCE REFERENCE

1. Chec k compressor system fluid level.

2. Check radiat or coolant level in coolant recovery tank.

EVERY 10

HOURS OR

DAILY

EVERY 50

HOURS OR

WEEKLY

EVER 500

HOURS

EV E RY 1000

HOURS

3. Chec k fuel s upply after running.

4. Chec k ai r filt er maint enance indic at or (if equppied).

5. Chec k for fuel, oil , ai r, and water leak s .

6. Chec k bat t ery m ount ing for security .

7. Drain water and sediment from fuel tank. Drain at bottom of tank.

1. Clean return line orific e after i nit i al s t art only.

2. Drain water from com pressor oil reservoir. More frequent

draining may be required under high humidi t y c onditions .

3. Ins pecting l ifting frame (and before each l ift ).

1. Change air end fluid and flui d filt er elem ent s .

2. Clean battery terminals, check battery hold-downs and

cabl es for wear.

3. Chec k ai r filt er piping, fit t i ngs , and c lam ps .

4. Chec k radi ator hos es and clamps .

5. Chec k engi ne and air end mounts .

6. Chec k fan belt t ens i on.

1. Inst al l new air filter el ement s (s hort er int erval s may be

necessary under dusty conditions).

2. Chec k al l door gask et s , hinges, and lat ches to m ai ntai n

acoustics s eal.

3. Drain engine radiat or cool ant . Clean and flush c ool ing

system. Refill with coolant.

4. Chec k engi ne and com pres s or s hut down switches .

5. Check res ervior pres s ure relief valve.

6. Ins tall new fuel filter and water separator element s

Drain at bottom of reservoi r.

NOTICE: Check engine operator’s manual for requir ed service and service intervals.

P/N: 307271

25

Page 25

4.18 RECOMMENDED SPARE PARTS LIST

ENIGNE5404DJ

TNEMELERETLIFRIAENIGNE410203

TNEMELERETLIFLIOROSSERPMOC39082-421

TNEMELELIO/RIAROTARAPES00752-4

21

TNEMELERETLIFRIAROSSERPMOC410203

COMPLETE KITS ARE ALSO A V AILABLE THA T INCLUDE ALL THE ABOVE P ARTS.

KIT FOR JOHN DEERE 4045 WITH 10G COMPRESSOR...............................................................801 14

4.19 PROCEDURE FOR ORDERING PARTS

Parts can be ordered directly from the factory . When ordering parts always indicate the serial number of

the unit. For parts call 1-800-635-6587.

26

P/N: 307271

Page 26

SECTION 5 TROUBLESHOOTING

5.1 TROUBLESHOOTING

If the unit will not crank when a “ST AR T” is attempted, DO NOT jump-start without first considering the

following:

• If there is obvious battery damage such as a cracked or broken case, replace battery

• Check for loose battery cables. T ighten if necessary

• Check terminals for corrosion, clean if necessary

1. Connect the first jumper cable from positive “+” (red) terminal of the discharged battery to the

positive “+” (red) terminal on the booster battery . NEVER connect “+” (red) to “-” (black). DO

NOT PERMIT vehicles to touch each other as this could establish a ground connection and

counteract the benefits of this procedure.

2. Connect one end of second jumper cable to the ground negative “-” (black) terminal of the booster

battery. Connect the other end of this jumper cable to a solid, stationary metallic point on the

compressor with the discharged battery but at a point A W AY from the battery (at least 18 inches or

more) if possible. DO NOT connect directly to the negative post of the discharged battery .

3. Disconnect positive battery terminal whenever using a high rate charge. Start the compressor in

accordance with normal procedure. When the engine is operating smoothly disconnect the jumper

cable end at the engine block before disconnecting the jumper cables from the other position.

Y our Boss compressor has safety switches that protect the engine and compressor from permanent damage.

The safety switches are as follows:

1. Engine Oil Pressure: This is a normally open switch that closes with 15 PSI of engine oil pressure.

2. Engine Coolant T emperature: This is a normally closed that opens a 220° F .

3. Compressor Oil T emperature: This is a normally closed switch that opens at 245°F.

All above switches are in series with the power feed to the engine fuel solenoid. If any of the switches open,

power to the solenoid is lost and the engine shuts down.

WARNING

OPERA TING WITHOUT SAFETY SWITCHES COULD CAUSE SEVERE PERSONAL

INJURY OR DEATH AND CAUSE SIGNIFICANT PROPERTY DAMAGE. IT WILL

VOID EXISTING WARRANTIES. ALWAYS ENSURE THAT ALL SAFETY SYSTEMS

ARE FUNCTIONAL.

27

P/N: 307271

Page 27

5.2 TROUBLESHOOTING CHART

The information contained in the troubleshooting chart has been compiled from field report data and factory

experience. It contains symptoms and usual causes for the report data and factory experience. It contains

symptoms and usual causes for the described problems; however, do not assume that these are the only

problems that may occur . All available data concerning the trouble should be systematically analyzed.

Before undertaking any repairs or component replacement procedures, a detailed visual inspection is worth

performing for almost all problems and may avoid unnecessary additional damage to the machine.

• Check for loose wiring.

• Check for damaged piping.

• Check for parts damaged by hear or an electrical short circuit, usually apparent by discoloration or

a burnt odor .

Should your problem persist after making the recommended checks, consult your nearest Boss Air

Compressor distributor or the Boss Air Compressor factory by calling 1-800-635-6587 or (219) 324-

7776.

SYMPTOM CAUSE REMEDY

Chec k the battery t erm i nal s for ti ghtness

and c orrosion.

a. Check voltage and charge or repl ac e

the battery.

b. Unit may be jum p-st art ed.

Clean and tighten conne cti ons.

Repair or repl ace t he fault y c om pone nts.

a. Check fuel level and add if nec ess ary.

b. If the uni t h as ran out of fuel it may be

nec ess ary to pri m e the fuel s ystem.

a. Check fuel line c onn ec tions and

tighten or repa i r.

b. P ri m e t h e fuel sy stem .

Replace the swit ch.

a. Wit h i g ni t i on a nd s afet y by pass o n,

c heck for voltage at t he solenoi d.

b. Check safety swit ches .

Machine will not

crank.

Mac hine cranks ,

but will not s t art.

Faulty battery c onnect ions.

Low battery voltage.

Faulty i gni t i on switch. Replace the swit ch.

Starter soleno id connec tions

are loose or c orroded.

Faulty st art er solenoi d or

starter.

No fuel.

Air in the fuel system

Defective safety bypass

switch.

Fuel solenoid inoperat i ve.

28

P/N: 307271

Page 28

SYMPTOM CAUSE REMEDY

Out of fuel Chec k fuel l evel and add fuel if nec ess ary.

Fuel filter restric t ed. Change fuel filter.

a. E n gine c ol l ant level low; add coolan t.

b. Com p ress or o i l and r adiator fl ow

res t ri c t ed; clean coolers.

c. Fan belts s l i pp i ng or broken; re pair or

Machine shuts

down with air

deman d pre sent .

Machine will not

buil d up p ress ure

With no demand

the compressor

buil ds exc es sive

pressure.

Insufficent air

delivery

Safety shut d own switc hes

activated.

Defective safety shutdown

switch.

Thermost atic valve

malfunctioning.

Defective gau ge . Replace t h e ga uge.

Ai r d em a nd too great.

Bl owd own valve open.

Faul ty coupl ing. Replace t h e coupl i ng.

Defective gau ge . Replace t h e ga uge.

Ai r cy l i n de r not full y

extending.

Press u re reg ul a tor not

properl y adju sted or faul ty .

Compress or undersi z ed for

the ai r r equ irement .

Engine s pe ed low. Chec k s pe ed a nd a dj ust as nec e ss ary.

Ai r i n tak e rest ri ct ed

Faul ty d ri ve coupl ing. Replace t h e coupl i ng.

replace.

d. Com p ress or o i l l ow; add oi l .

e. E n gine oil l evel low; add oi l .

f. Com p ress or o i l fil ter res trict e d; change

the filter.

g. E n gine oil fil ter restri ct ed; c han ge the

filter.

Chec k t he shut d own swit ches.

Clean o r rep l ace t he thermo stati c

element.

Chec k s ervic e l ines for l eaks or op en

valves.

a. Check to s ee fit th e b l owdown valve is

get ting a p i l ot s i gna l .

b. Repa i r or service val ve.

a. Check for rest ri ctions i n the c on t rol

lines.

b. Repa i r or replace cont rol air cylinder.

c. Check that the inlet valve is closing.

a. Adjust the regulator

b. Repa i r or replace the regul ator.

Rec heck max i m um air requ i re m ent.

a. Check air filter for dirt and ma ke s ure

the indicator is working.

b. Loo k for obs truc tions in the fil t er a nd

inlet piping.

c. Check that the inlet valve is opening

fully.

29

P/N: 307271

Page 29

SYMPTOM CAUSE REMEDY

A

Oil reserve over fil l ed. Drain to t he p roper l evel.

Excessive

compressor oil

consumption.

Leak i n the c om p ress or oi l

system.

Oil sc avenge line n ot removing

the oil from the separator.

Sepa rator element d am a ged. Repla ce th e el ement .

Compress or un dersized for

the ai r re qui re m ent.

Unit b ei n g operating i n an

area with li m ited fresh air.

Fan bel ts are l oose or broken. Tight en o r replace .

Chec k all pi pi ng lines and c o nnect i on s;

repai r as nec e ssa ry.

a. Check sc avenge line a nd its ch eck

valve for restrictions; clea r as n eces sary.

b. Make sure that the scavenge line

reac h es th e bo t tom of t h e separator.

Operating at low pre ssur es increas es t he

oil c arry over; rechec k t he load

requirements.

Reposit i on the unit or open up the

confinement.

Compressor

ov erheating

High fuel

consumption

Dirt bu i l d up o n t he coolers.

Compress or l e vel l o w. Check and fill to proper l evel.

Compress or oil fil ter dirty . Repla ce th e filter.

Thermost atic valve

malfunctioning.

Res t riction i n the c om p ress or

oil l i n es.

Restrict i on i n side the oil

cooler.

Operat ing th e compre sso r

wit h the panels removed.

Coolant level low. Ad d coola nt to the proper level .

Leaks in the fuel system.

Engine not at c orrect

operat i n g speed.

Press ure to regulator set too

high.

Engine air i n take i s res tric ted.

Incorrect injection timing.

Clean the c ool e r t ho roug hl y. B e c are ful

not to dam age t he fi ns.

Clean or rep l ace t he el ement .

Clean or rep l ace t he l i ne s.

Clean i nternal tubes of the cooler.

Reins t all panels.

Chec k all the fuel l ine s and c o nne cti on s;

repai r or re pl ace as neces sary.

Ad j ust the engi ne t o i ts p rope r speed.

djust regulator to correct pressure for the

unit.

Insp ect the ai r i ntak e sy ste m chec king for

any re stri ct i on ; cl e an re pai r or rep l ace as

necessary.

Ad j ust to sp ecificat i ons in the engi ne

manual.

30

P/N: 307271

Page 30

WARRANTY

Boss Industries, Inc. (BOSS) warrants that this Rotary Screw Compressor unit conforms to applicable

drawings and specifications approved in writing by BOSS. The unit assembly will be free from defects

in material and workmanship for a period of three (3) years from the date of initial operation or fortytwo (42) months from the date of shipment, whichever period first expires. All other components and

parts of BOSS manufacture will be free from defects in material and workmanship for a period of one

(1) year from the date of initial operation or eighteen (18) months from the date of shipment, whichever

period first expires. If within such period BOSS receives from the Buyer written notice of and alleged

defect in or nonconformance of the unit, all other components and parts of BOSS manufacture and if in

the judgment of BOSS these items do not conform or are found to be defective in material of

workmanship, BOSS will at its option either, (a) furnish a Service Representative to correct defective

workmanship, or (b) upon return of the item F.O.B. BOSS original shipping point, repair or replace the

item or issue credit for the replacement item ordered by Buyer, (Defective material must be returned

within thirty (30) days of return shipping instructions from BOSS. Failure to do so within specified

time will result in forfeiture of claim), or (c) refund the full purchase price for the item without interest.

Factory installed units will also include warranty on installation for a period of one (1) year. This

warranty does not cover damaged caused by accident, misuse or negligence. If the compressor unit is

disassembled the warranty is void. BOSS’ s sole responsibility and Buyer’s exclusive remedy hereunder

is limited to such repair, replacement, or repayment of the purchase price. Parts not of BOSS manufacture

are warranted only to the extent that they are warranted by the original manufacture. BOSS shall have

no responsibility for any cost or expense incurred by Buyer from inability of BOSS to repair under said

warranty when such inability is beyond the control of BOSS or caused solely by Buyer.

There are no other warranties, express, statutory or implied, including those of merchantability and

of fitness of purpose; nor any affirmation of fact or representation that extends beyond the description

of the face hereof.

This warranty shall be void and BOSS shall have no responsibility to repair, replace, or repay the

purchase price of defective or damaged parts or components resulting directly or indirectly from the

use of repair or replacement parts not of BOSS manufacture or approved by BOSS or from Buyer’s

failure to store, install, maintain, and operate the compressor according to the recommendations contained

in the Operating and Parts Manual and good engineering practice. The total responsibility of BOSS

for claims, losses, liabilities or damages, whether in contract or tort, arising out of or related to its

products shall not exceed the purchase price. In no event shall BOSS be liable for any special, indirect,

incidental or consequential damages of any character, including, but not limited to, loss of use of

productive facilities or equipment, loss of profits, property damage, expenses incurred in reliance on

the performance of BOSS, or lost production, whether suffered by Buyer or any third party.

BOSS INDUSTRIES, INC.

1761 GENESIS DRIVE

LAPORTE, IN 46350

(219) 324-7776 Phone

(219) 324-7470 Fax

31

P/N: 307271

Page 31

SUMMARY OF MAIN WARRANTY PROVISIONS

As claims, policies and procedures are governed by the terms of the BOSS Industries, Inc. (BOSS) warranty ,

it is necessary to outline some of the more important provisions.

The BOSS warranty applies only to new and unused products, which, after shipment from the factory , have

not been altered, changed, repaired or mistreated in any manner whatsoever . Normal maintenance items

such as lubricants and filters are not warrantable items.

Parts not of BOSS manufacture are warranted only to the extent they are warranted by the original

manufacturer.

Damage resulting from abuse, neglect, misapplication or overloading of a machine, accessory or part is not

covered under warranty.

Deterioration or wear occasioned by chemical and/or abrasive action or excessive heat shall not constitute

defects.

Parts replacement and/or correction of defective workmanship will normally be handled by BOSS Industries,

Inc. or their authorized distributor.

Failure to file a detailed warranty claim/service report for each occurrence of material defect of defective

workmanship will cause warranty claim to be rejected.

Defective material must be returned within 30 days of receipt of shipping instructions. Failure to do so

within specified time will result in forfeiture of claim.

The distributor is responsible for the initial investigation and write up of the warranty claim.

Distributor shall be allowed

report.

W arranty for failure of BOSS replacement parts covers the net cost of the part only , not labor and mileage.

The BOSS warranty does not cover diagnostic calls and travel. That is time spent traveling to the machine

to analyze the problem and returning with the proper tools and parts to correct the problem.

Boss will deduct from allowable credits for excess freight caused by sender failing to follow return shipping

instructions.

Distributors or end-user automatically deducting the value of a warranty claim from outstanding balances

due and payable to BOSS prior to receiving written notification of BOSS approval of the warranty claim

may be subject to forfeiture of the entire claim.

no more than 30 days from date of repair to file a warranty claim/service

32

P/N: 307271

Page 32

WARRANTY/RETURN GOODS INSTRUCTIONS

The warranty/return procedure outlined below is provided to give the claimant the information necessary

to file a warranty/return claim, and enable BOSS INDUSTRIES the ability to best serve its’ customers.

Please see the following instructions to initiate a return:

Contact BOSS INDUSTRIES Returns Department by telephone at 219.324.7776 or via email at

service@bossair .com. Y ou may also send a fax at 219.324.7470.

WARRANTY CLAIMS – PREPARATION OF PART RETURN

Parts returned to the factory must be properly packaged to prevent damage during shipment. Damage to a

part as a result of improper handling or packing could be cause for denial. When addressing the package

for shipment, the following information must be on the outside of, or tagged clearly , to the package.

1. Return Goods Authorization #.

2. Distributor or end-users return address.

3. Correct factory address.

4. Number of packages pertaining to each claim.

NOTE: Our warranty requires that all defective parts be returned to BOSS INDUSTRIES freight prepaid.

Items sent without RGA number will not be accepted. Unauthorized Returns Will Immediately Be Refused

At Dock.

RETURN OR WARRANTY CLAIMS – FILING PROCEDURES

1. Initiate through a purchase order for warranty part or request for credit.

2. RGA will accompany replacement part.

3. BOSS INDUSTRIES will confirm disposition of failed part within 30 days of receipt and or request

additional information.

4. Claim denial will result in issuance of a letter of denial.

5. BOSS INDUSTRIES will consider each claim on its’ own merit and reserves the right to accept or

reject claim request. In case of air-ends, these will be returned to the manufacturer for their analysis/

input.

6. Send W arranty Claim to:

BOSS INDUSTRIES, INC.

1761 Genesis Drive

LaPorte, IN 46350

Attn: Returns Dept.

33

P/N: 307271

Page 33

GENERAL

An approved claim depends on the following provision:

1. An RGA # must be issued by BOSS INDUSTRIES. (See filing procedures.)

2. Failed part must be returned within 30 days of original invoice date, freight prepaid, with RGA #.

3. Part is determined to be defective.

4. W orkmanship is determined to be defective.

5. Machine is within warranty period.

6. Machine has been operated within design conditions.

Claims made through distributors must be verified by distributor prior to contacting BOSS INDUSTRIES.

DAMAGE IN TRANSIT

Do not return damaged merchandise to BOSS INDUSTRIES, please follow claim procedure.

1. Loss in transit:

The merchandise in our kit or provided in our factory installations has been thoroughly inspected

or carefully installed and tested before leaving our plant. However, regardless of the care taken at

the factory, there is a possibility that damage may occur in shipment. For this reason, it is

recommended that the unit be carefully inspected for evidence of possible damage or malfunction

during the first few hours of operation. Responsibility for the safe delivery of the kit or factory

installed unit was assumed by the carrier at the time of shipment. Therefore, claims for loss or

damage to the contents of the kit or factory installed unit should be made upon the carrier.

2. Concealed loss or damage:

Concealed loss or damage means loss or damage, which does not become apparent until the kit is

unpacked or the factory-installed unit is run by the end-user. The contents of the kit or factory

installed unit may be damaged due to rough handling while in route to its destination, even thought

the kit or factory installed unit shows no external damage. When the damage is discovered upon

unpacking, make a written request for inspection by the carrier agent within fifteen days of delivery

date. Then file a claim with the carrier since such damage is the carrier’s responsibility .

By following these instructions carefully, we guarantee our full support of your claims, to protect you

against loss from concealed damage.

3. Visible Loss or Damage

Any external evidence of loss or damage must be noted on the Freight Bill or Express Receipt, and

signed by the carrier’s agent. Failure to adequately describe such external evidence of loss, or

damage may result in the carrier refusing to honor a damage claim. The carrier will supply the

form required to file such a claim.

34

P/N: 307271

Page 34

SCREW COMPRESSOR AIR-END EXCHANGE PROGRAM

Replacement air-ends are available from the factory . For current prices and availability, contact BOSS

INDUSTRIES, Inc. or an authorized BOSS INDUSTRIES distributor. Prices are F .O.B. shipping point.

Prices do not include labor for removal or installation.

35

P/N: 307271

Page 35

NOTES

36

P/N: 307271

Page 36

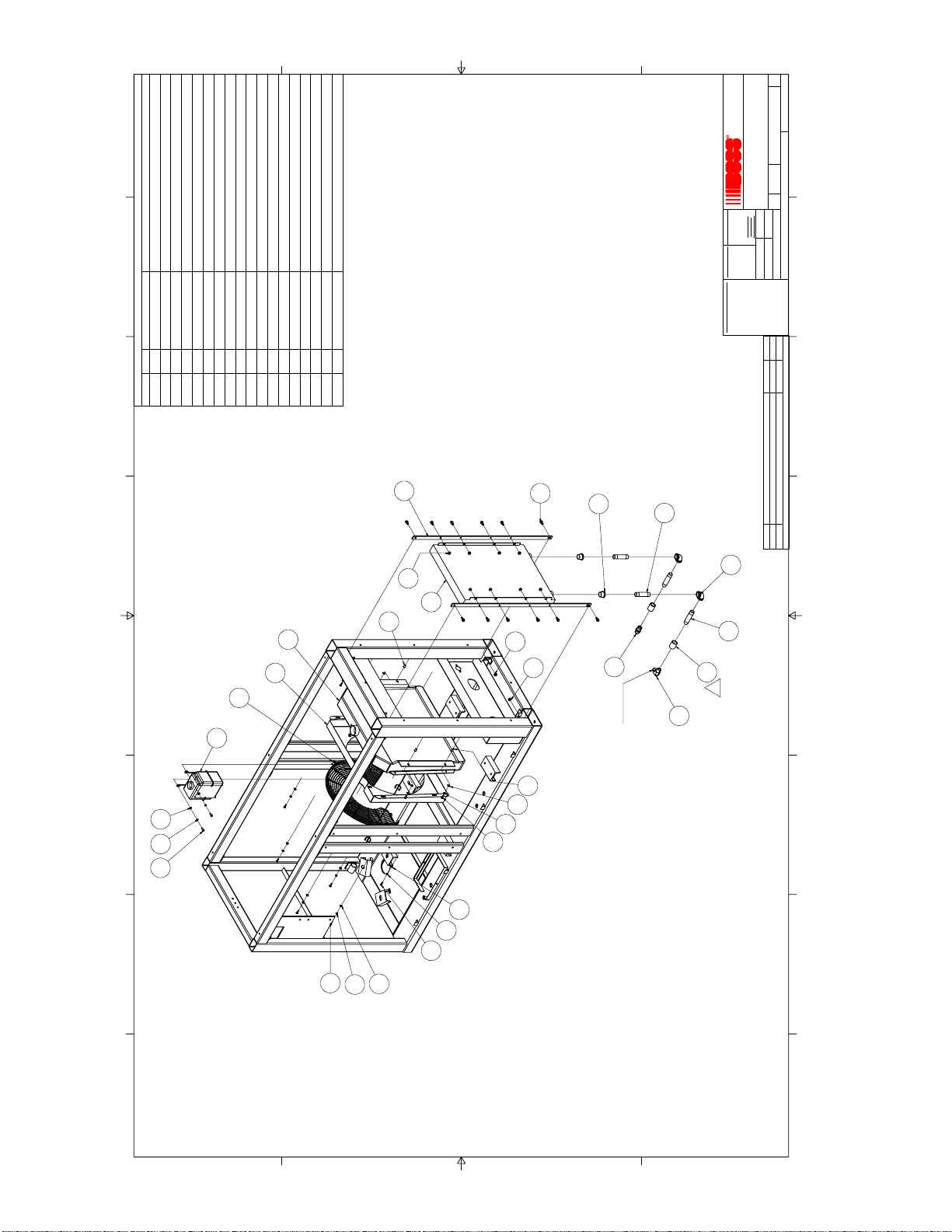

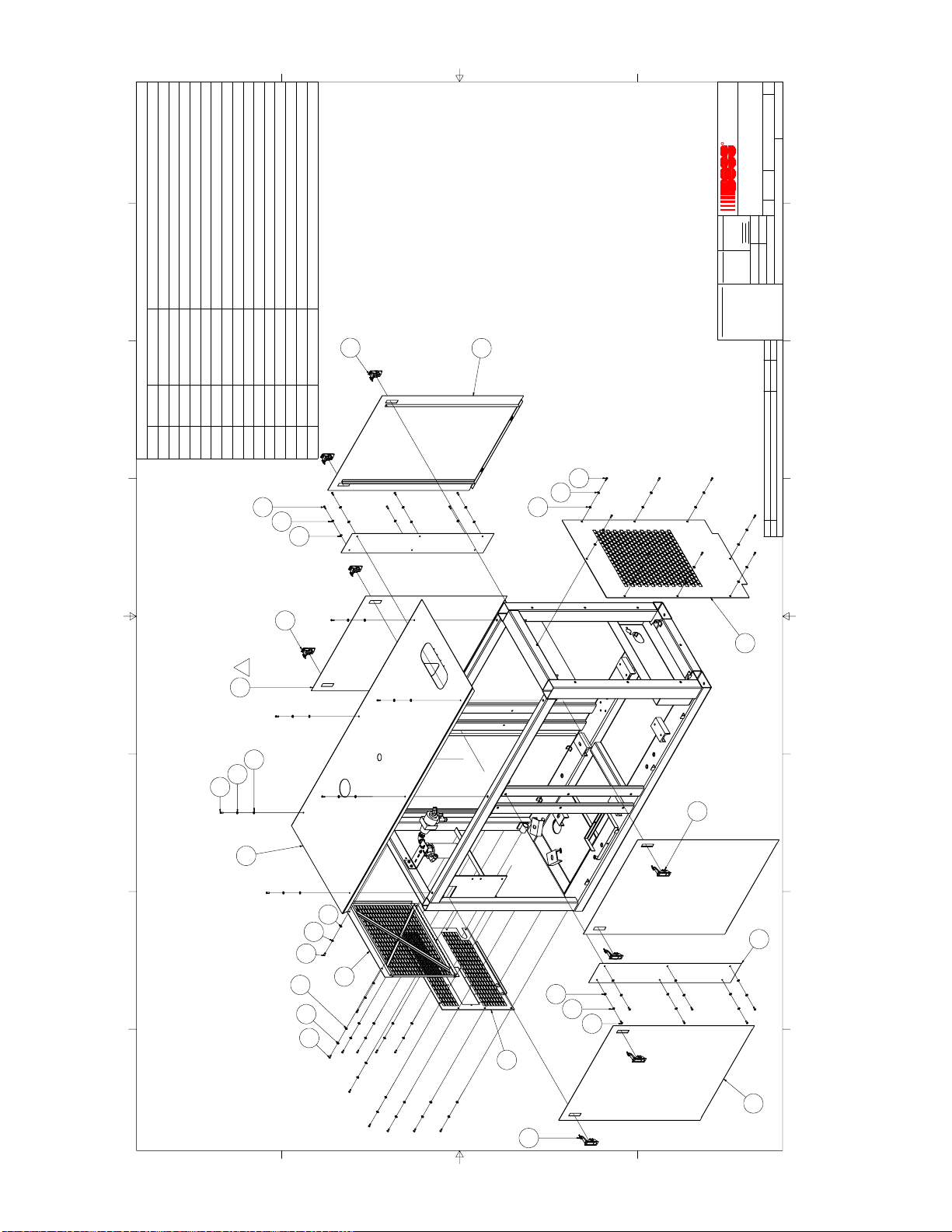

SECTION 6

ASSEMBLY_DRAWINGS

37

P/N: 307271

Page 37

3

REV

1 1

OF

BOSS INDUST RIES

1761 GENESIS DR.

1

DESCRIPTIONPART NUMBERQTYITEM

55 in

[1398.2 mm]

Parts List

2

FRAME & PARTS, OMEGA 185-210 DUS10063311

ENGINE & PARTS, OMEGA 185-210 DUS10063412

COMPRESSOR & PARTS, OMEGA 185-21 0 DUS10063513

COOLERS & PARTS, OMEGA 185-210 DU S10063614

SUMP TANK & PARTS, OMEGA 185-210 D US

INSTR PANEL & PARTS, OMEGA 185-210 DUS10063816

HOSE SYSTEM & PARTS, OMEGA 185-2 10 DUS

CANOPY & PARTS, OMEGA 185-210 DUS10064018

OPT, OIL/FLUID DRAINS INST-PANEL EN D604171NS

MANUAL, OMEGA 185-210 DUS

10063715

10063917

3072711

3

LA PORTE, IN 46350

R

DESCRIPTION

1/16

1°

.03

`

`

`

ANGULAR

DECIMAL

DO NOT SCALE

FRACTIONAL

UNMACHINED SURFACES

.020

.010

.015

`

`

`

NOMINAL DIM.

5.001 TO 10.000

0.000 TO 1.000

1.001 TO 5.000

MACHINED SURFACES

PROPRIETARY INFORMATION

THIS DRAWING AND ALL ITS

CONTENTS ARE P ROPERTY

OF BOSS INDUSTRIES, INC.

AND MUST NOT BE COPIED

OR MADE PUBLIC. IT IS

1

SHEET

10095-001

DWG NO

SCALE

1=8

185-210 DUS JD4045AUX 10G OMEGA WHITE

D

SIZE

TOLERANCES

2/26/2008

UNLESS NOTED

.025

`

2

10.001 & OVER

N/A

BSM

CHECKED

DRAWN

PATH

MATERIAL

G:\Inventor Files\10k\10095-001.dwg

LOANED AND IS SU BJECT TO

RETURN UPON DEMAND. THE

INFORMATION CONTAINED IN

THIS DRAWING IS

CONFIDENTIAL A ND MUST

NOT BE USED, DIRECTLY OR

INDIRECTLY, IN ANY WAY

DETRIMENTAL TO THE

INTEREST OF BOSS

INDUSTRIES, INC.

6/13/2008 MCM

3

NS

REVISION HISTORY

UPDATED SUB BILLS 100633 TO REV 1 AND

100636 TO REV 2

3

2 UPDATED SUB BILL 100640 TO REV 1 6/5/2008 MCM

1 UPDATED SUB BILL 100636 TO REV 1 4/18/2008 MCM

4

5/8 in THRU

4 - PLACES

n

REV DESCRIPTION DATE ENG

4

31 in

[787.4 mm]

1 in THRU

8 - PLACES

n

24 in

[609.6 mm]

5

4 1/4 in

[108.0 mm]

85 in

6

[2160.4 mm]

31 5/8 in

15 7/8 in

[803.1 mm]

[403.2 mm]

7

3 in

75 in

[1905.0 mm]

[76.2 mm]

79 in

[2006.6 mm]

5

6

7

2 in

[50.8 mm]

24 1/8 in

[612.8 mm]

2 7/8 in

[73.0 mm]

8

8

38

P/N: 307271

D D

C C

B B

A A

Page 38

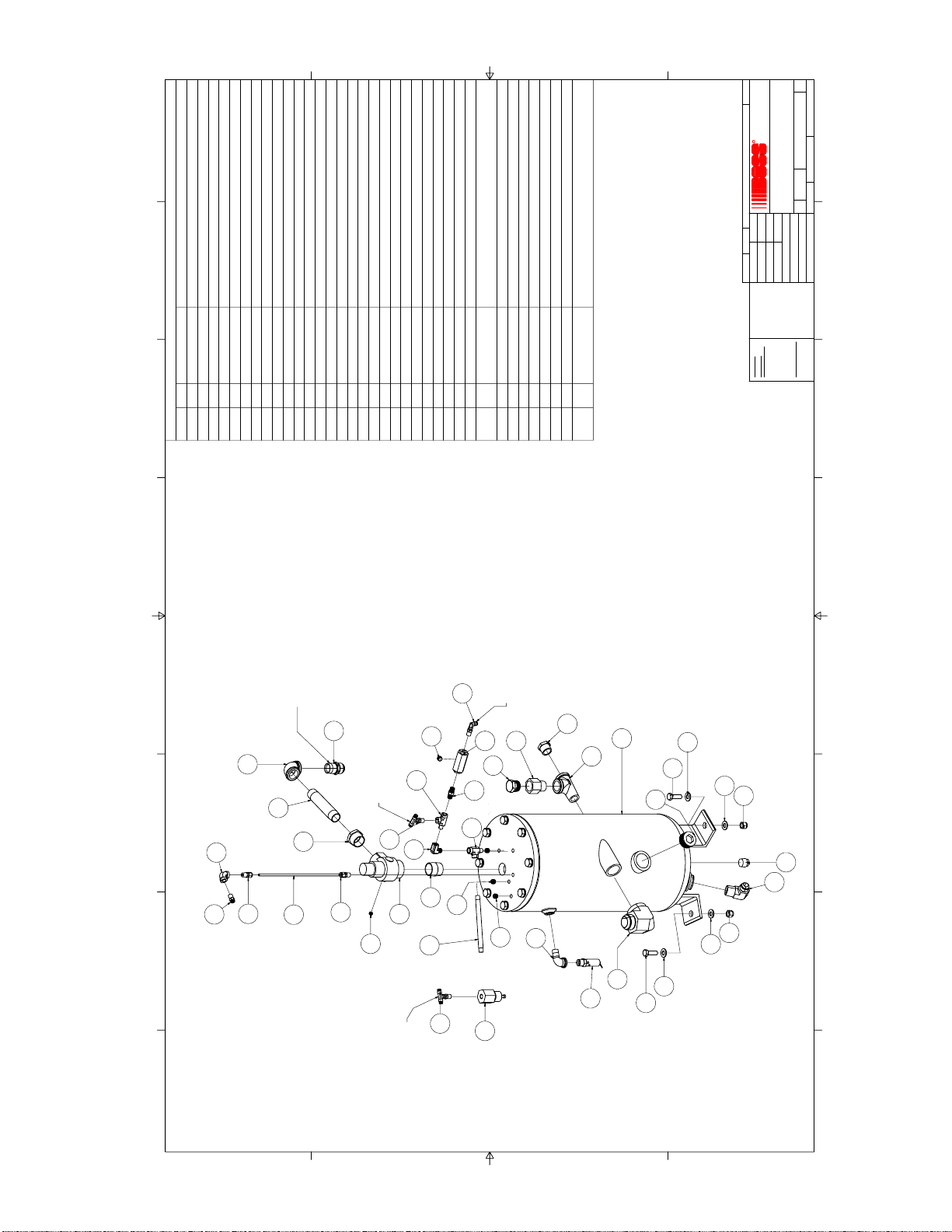

AA

BB

CC

DD

D

C

B

A

1

REV

1

OF

1

BOSS INDUSTRI ES

1761 GENESIS DR.

LA PORTE, IN 46 350

1

11

1

DESCRIPTIONPART NUMBERQTYITEM

Parts List

R

DESCRIPTION

1/16

1°

.03

`

`

`

TOLERANCES

ANGULAR

DECIMAL

DO NOT SCALE

UNLESS NOTED

FRACTIONAL

UNMACHINED SURFACES

.020

.025

.010

.015

`

`

`

`

NOMINAL DIM.

10.001 & OVER

5.001 TO 10.000

0.000 TO 1.000

1.001 TO 5.000

MACHINED SURFACES

FRAME & PART, OMEGA 185-210 DUS

2/8/2008

MCM

DRAWN CHECKED

SHEET

1

11

1

100633

DWG NO

SCALE

1=8

C

SIZE

N/A

PATH

MATERIAL

G:\Inventor Files\ 100k\100633.dwg

FRAME, OMEGA 185-210 DUS30725211

INSERT, 1/4-20UNC AKS4-420-165120-36992402

HEAD, OIL FILTER 3/4 FNPT 15-PSI BY PASS30059913

FILTER, COMPR OIL 185/210 PORT

ELBOW, HYD 3/4 MJIC X 3/4 MNPT960212-07515BRACKET, COALESCER/OIL FILTER30604216

WASHER, FLAT GR5 1/4938604-07167WASHER, LOC GR5 1/4938004-06248

BOLT, HEX GR5 1/4-20 X 1929104-100

NIPPLE, PIPE 3/4 X 2 GAL SCH40922112-020110

ELBOW, PIPE 3/4 GAL 150PSI

NIPPLE, HYD HEX 3/4

THERMOSTAT, BYPASS VALVE 170F 3/4"FNPT303971113

ELBOW, HYD 45° 3/4 MJIC X 3/4 MNPT960012-075114

TEE, MR 3/4 NPT X 3/4 JIC976512-1212115

2

22

2

124-2809314

901515-030111

960412-075112

4

9

14

15

1

1

2

2

22

PROPRIETARY INFORMATION

THIS DRAWING AND A LL ITS

CONTENTS ARE PRO PERTY

OF BOSS INDUSTRIES, INC.

AND MUST NOT BE CO PIED

OR MADE PUBLIC. IT IS

LOANED AND IS SUBJ ECT TO

RETURN UPON DEMAND. THE

INFORMATION CONTAIN ED IN

2

THIS DRAWING IS

CONFIDENTIAL AND MUST

NOT BE USED, DIRECTLY OR

INDIRECTLY, IN ANY WAY

DETRIMENTAL T O THE

INTEREST OF BOSS

INDUSTRIES, INC.

6/16/2008 MCM

REVISION HISTORY

13

3

33

3

12

11

3

33

3

UPDATED 307252 TO REV 1. ADDED (2)

938604-071.

1

REV DESCRIPTION DATE ENG

9

10

8

7

6

2

1

4

44

4

7

3

5

4

D

DD

D D

C

CC

C C

B

BB

B B

A

AA

A A

4

44

4

39

P/N: 307271

Page 39

8

ITEM

1 1 307207

2 1 150-90729 MOUNT, ENGINE FR RH (O) (REV E)

3 1 150-90665 MOUNT, ENGINE FR LH (O) (REV D)

4 2 150-90673 MOUNT,ENGINE REAR (O)

5

6 1 154-90975 COUPLING, FLEX. 185-250

7 2 980100-250

8 1 302423-100 CAP, RAIN 2 1/2

D D

9 1 158-65476 TUBE, INTAKE 90DG 2 1/2 185DRG

10 1 150-90666

11 1 302015 BAND, AIR FILTER MTG 7.18

12 1 158-65921 EXHAUST ELBOW ASSY

13 1 158-65875

14 1 120-34188 CLAMP, MUFFLER MOUNTING 6 1/2

15 1 303150 SWITCH, TEMP 220 F NC GOLD CONTACTS

16 1 123-33230 SENDER, COOLANT TEMPERATURE 3/8

17 1 123-19735 SENDER, OIL PRESSURE

18 1 907602-015 BUSHING, RED 1/2 X 3/8 GAL

19 1 922102-015

20 1 901115-005 ELBOW, PIPE STREET 1/8 GAL

21 1 902415-005 TEE, PIPE 1/8 GAL 150PSI

22 2 929808-125

23 1 924404-145 NUT, NYLOC GR5 1/4-28

24 2 305891 SPACER, ENGINE FRONT OMEGA TOOL

25 2 120-16832 WASHER, SNUBBING .531 ID (B)

26 2 929808-300 BOLT, HEX GR8 1/2-13 X 3

27 2 925508-262 NUT, NYLOC GR8 1/2-13

28 4 938208-112 WASHER, FLAT GR8 1/2

29 1 120-36345 CYLINDER, AIR ENGINE SPEED

30 1 120-19071

31 1 158-36347 BRACKET,PIVOT AIR CYLINDER

32 1 307055 BRACKET, AIR CYLINDER

33 4 929216-350

C C

34 8 929212-300 BOLT, HEX 12MM X 30MM GR 10.9

35 8 938812-250 WASHER, LOC 12MM

36 5 938808-200 WASHER, LOC 8MM

37 4 929208-120 BOLT, HEX 8MM X 120MM GR 10.9

PART NUMBER

QTY

2 302764 ISOLATOR, VIBRATION 1000 LB 185-210

7

Parts List

ENGINE, JD4045 W SAE-A AUX DRIVE

CLAMP, EXHAUST 2 1/2

BRACKET,ASSY ENG. AIR CLEANER

BRACKET MUFFLER (REV C)

NIPPLE, PIPE 1/8 X 1 1/2 GAL SCH40

BOLT, HEX GR8 1/2-13 X 1 1/4

JD4045 (REV 1)

BALL JOINT, 1/4-28 THRD

BOLT, HEX GR10.9 16MM X 35MM

6

DESCRIPTION

5

4

ITEM

38 1 156-35136

39 1 304934 SPACER, FAN JD 3 3/4" LG.

40

41 1 980704-012M ELBOW, HYD 1/8 MNPT X 1/4 TUBE SWVL