Page 1

www.omega.com

e-mail: info@omega.com

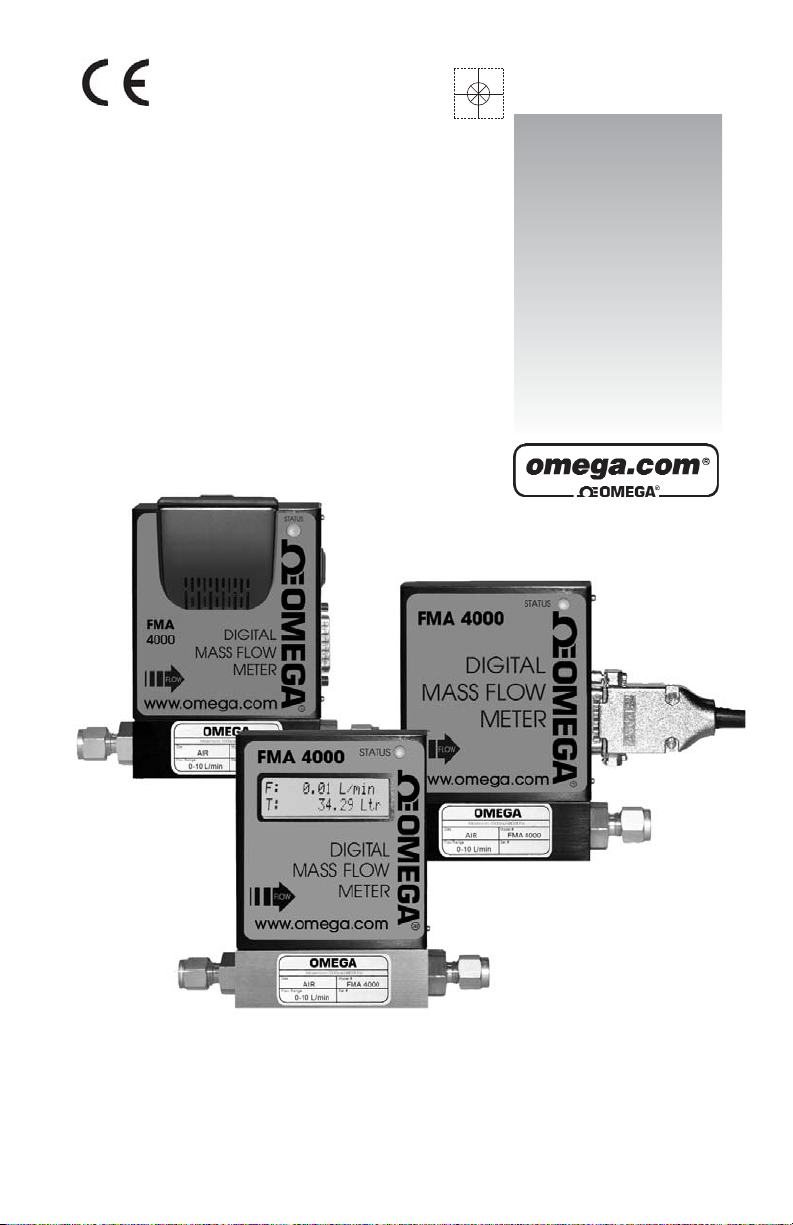

User’s Guide

FMA 4000

Digital Mass Flow Meters

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@ omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@ omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@ omega.com

FAX: (001) 203-359-7807 info@ omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@ omegaeng.nl

Czech Republic: Rude´ arm-dy 1868, 733 01 Karvin- 8

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@ omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@ omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@ omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611

Toll Free in United Kingdom: 0800-488-48 FAX: +44 (0)161 777 6622

e-mail: sales@ omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@ omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

TABLE OF CONTENTS

1. UNPACKING THE FMA 4000 MASS FLOW METER...................................

1.1 Inspect Package for External Damage.................................................

1.2 Unpack the Mass Flow Meter...............................................................

1.3 Returning Merchandise for Repair.......................................................

2. INSTALLATION........................................................................................

2.1 Primary Gas Connections.................................................................

2.2 Electrical Connections......................................................................

2.2.1 Power Supply Connections..............................................................

2.2.2 Output Signals Connections..............................................................

2.2.3 Communication Parameters and Connections...................................

3. PRINCIPLE OF OPERATION...................................................................

4. SPECIFICATIONS...................................................................................

5. OPERATING INSTRUCTIONS..................................................................

5.1 Preparation and Warm Up..................................................................

5.2 Swamping Condition.......................................................................

5.3 FMA 4000 Parameters Settings...........................................................

5.3.1 Engineering Units Settings...............................................................

5.3.2 Gas Table Settings..............................................................................

5.3.3 Totalizer Settings.............................................................................

5.3.4 Flow Alarm Settings........................................................................

5.3.5 Relay Assignment Settings..............................................................

5.3.6 K Factors Settings...........................................................................

5.3.7 Zero Calibration...............................................................................

5.3.8 Self Diagnostic Alarm.......................................................................

5.4 Analog output Signals configuration...................................................

6. MAINTENANCE.........................................................................................

6.1 Introduction......................................................................................

6.2 Flow Path Cleaning...........................................................................

6.2.1 Restrictor Flow Element (RFE)........................................................

6.2.2 FMA 4000 model.............................................................................

1

1

1

1

1

1

3

3

3

4

6

7

9

9

10

11

11

12

12

13

14

14

15

17

17

18

18

19

19

19

Page 4

7. CALIBRATION PROCEDURES.................................................................

7.1 Flow Calibration...............................................................................

7.2 Gas Calibration of FMA 4000 Mass Flow Meter................................

7.2.1 Connections and Initial Warm Up.....................................................

7.2.2 ZERO Check/Adjustment Adjustment.................................................

7.2.3 Gas Linearization Table Adjustment.................................................

7.3 Analog output Calibration of FMA 4000 Mass Flow Meter..............

7.3.1 Initial Setup.......................................................................................

7.3.2 Gas flow 0-5 Vdc analog output calibration....................................

7.3.3 Gas flow 4-20 mA analog output calibration...................................

8. RS485 / RS232 SOFTWARE INTERFACE COMMANDS.........................

8.1 General............................................................................................

8.2 Commands Structure.........................................................................

8.3 ASCII Commands Set.........................................................................

9. TROUBLESHOOTING................................................................................

9.1 Common Conditions........................................................................

9.2 Troubleshooting Guide.....................................................................

9.3 Technical Assistance.......................................................................

10. CALIBRATION CONVERSIONS FROM REFERENCE GASES...................

APPENDIX I OMEGA FMA 4000 EEPROM Variables..............................

APPENDIX II INTERNAL USER SELECTABLE GAS FACTOR TABLE

(INTERNAL “K” FACTORS)........................................................

APPENDIX III GAS FACTOR TABLE (“K” FACTORS)....................................

APPENDIX IV COMPONENT DIAGRAM......................................................

APPENDIX V DIMENSIONAL DRAWINGS.................................................

APPENDIX VI WARRANTY...........................................................................

20

20

21

21

21

21

23

24

25

25

26

26

26

28

34

34

35

37

37

38

41

42

46

48

50

TRADEMARKS

Buna-N®-is a registered trademark of DuPont Dow Elastomers.

Kalrez®-is a registered trademark of DuPont Dow Elastomers.

Neoprene

®

-is a registered trademark of DuPont.

Omega

®

-is a registered trademark of Omega Engineering Inc.

Page 5

1

1. UNPACKING THE FMA 4000 MASS FLOW METER

1.1 Inspect Package for External Damage

Your FMA 4000 Mass Flow Meter was carefully packed in a sturdy cardboard carton, with anti-static cushioning materials to withstand shipping shock. Upon

receipt, inspect the package for possible external damage. In case of external

damage to the package contact the shipping company immediately.

1.2 Unpack the Mass Flow Meter

Open the carton carefully from the top and inspect for any sign of concealed shipping damage. In addition to contacting the shipping carrier please forward a copy

of any damage report to Omega7 directly.

When unpacking the instrument please make sure that you have all the items

indicated on the Packing List. Please report any shortages promptly.

1.3 Returning Merchandise for Repair

Please contact an OMEGA7 customer service representative and request a

Return Authorization Number (AR).

It is mandatory that any equipment returned for servicing be purged and neutralized of any dangerous contents including but not limited to toxic, bacterially infectious, corrosive or radioactive substances. No work shall be performed on a

returned product unless the customer submits a fully executed, signed SAFETY

CERTIFICATE. Please request form from the Service Manager.

2. INSTALLATION

2.1 Primary Gas Connections

Please note that the FMA 4000 Mass Flow Meter will not operate with liquids. Only

clean gases are allowed to be introduced into the instrument. If gases are contaminated they must be filtered to prevent the introduction of impediments into the

sensor.

Page 6

2

CAUTION: FMA 4000 TRANSDUCERS SHOULD NOT BE USED FOR

MONITORING OXYGEN GAS UNLESS SPECIFICALLY CLEANED AND

PREPARED FOR SUCH APPLICATION.

For more information, contact Omega7.

Attitude limit of the Mass Flow Meter is ±15Ffrom calibration position (standard

calibration is in horizontal position). This means that the gas flow path of the Flow

Meter must be within this limit in order to maintain the original calibration accuracy. Should there be need for a different orientation of the meter, re-calibration may

be necessary. It is also preferable to install the FMA 4000 transducer in a stable

environment, free of frequent and sudden temperature changes, high moisture,

and drafts.

Prior to connecting gas lines inspect all parts of the piping system including ferrules and fittings for dust or other contaminant’s.

When connecting the gas system to be monitored, be sure to observe the direction of gas flow as indicated by the arrow on the front of the meter.

Insert tubing into the compression fittings until the ends of the properly sized tubing home flush against the shoulders of the fittings. Compression fittings are to be

tightened to one and one quarter turns according to the manufacturer's instructions. Avoid over tightening which will seriously damage the Restrictor Flow

Elements (RFE's)!

CAUTION: For FMA 4000 model, the maximum pressure in the

gas line should not exceed 500 PSIA (34.47 bars). Applying pressure above

500 PSIA (34.47 bars) will seriously damage the flow sensor.

FMA 4000 transducers are supplied with either standard 1/4 inch, or optional 1/8

inch inlet and outlet compression fittings which should NOT be removed unless

the meter is being cleaned or calibrated for a new flow range.

Using a Helium Leak Detector or other equivalent method, perform a thorough

leak test of the entire system. (All FMA 4000's are checked prior to shipment for

leakage within stated limits. See specifications in this manual.)

Page 7

3

2.2 Electrical Connections

FMA 4000 is supplied with a 15 pin “D” connector. Pin diagram is presented in

Figure b-1.

2.2.1 Power Supply Connections

The power supply requirements for FMA 4000 transducers are: 11 to 26 Vdc,

(unipolar power supply)

DC Power (+) --------------- pin 7 of the 15 pin “D” connector

DC Power (-) --------------- pin 5 of the 15 pin “D” connector

CAUTION: Do not apply power voltage above 26Vdc.

Doing so will cause FMA 4000 damage or faulty operation.

2.2.2 Output Signals Connections

CAUTION: When connecting the load to the output terminals, do not exceed

the rated values shown in the specifications. Failure to do so might cause

damage to this device. Be sure to check if the wiring and the polarity of the

power supply is correct before turning the power ON. Wiring error may cause

damage or faulty operation.

FMA 4000 Mass Flow Meters are equipped with either calibrated 0-5 or calibrated 4-20 mA output signals (jumper selectable). This linear output signal represents 0-100% of the flow meter’s full scale range.

WARNING: The 4-20 mA current loop output is self-powered (non-isolated).

Do NOT connect an external voltage source to the output signals.

Flow 0-5 VDC or 4-20 mA output signal connection:

Plus (+) -------------------------- pin 2 of the 15 pin “D” connector

Minus (-) -------------------------- pin 1 of the 15 pin “D” connector

To eliminate the possibility of noise interference, use a separate cable entry for

the DC power and signal lines.

Page 8

2.2.3 Communication Parameters and Connections

The digital interface operates via RS485 (optional RS232) and provides access to

applicable internal data including: flow, CPU temperature reading, auto zero, totalizer and alarm settings, gas table, conversion factors and engineering units selection, dynamic response compensation and linearization table adjustment.

Communication Settings for RS485 / RS232 communication interface:

Baud rate: ...................... 9600 baud

Stop bit: ...................... 1

Data bits: ...................... 8

Parity: ...................... None

Flow Control: ...................... None

RS485 communication interface connection:

The RS485 converter/adapter must be configured for: multidrop, 2 wire, half

duplex mode. The transmitter circuit must be enabled by TD or RTS (depending

on which is available on the converter/adapter). Settings for the receiver circuit

should follow the selection made for the transmitter circuit in order to eliminate

echo.

RS485 T(-) or R(-) ...................... pin 8 of the 15 pin “D” connector (TX-)

RS485 T(+) or R(+) ...................... pin 15 of the 15 pin “D” connector (RX+)

RS485 GND (if available) ...................... pin 9 of the 15 pin “D” connector (GND)

RS232 communication interface connection:

Crossover connection has to be established:

RS232 RX (pin 2 on the DB9 connector) ..... pin 8 of the 15 pin “D” connector (TX)

RS232 TX (pin 3 on the DB9 connector) ..... pin 15 of the 15 pin “D” connector (RX)

RS232 GND (pin 5 on the DB9 connector) ..... pin 9 of the 15 pin “D” connector (GND)

4

Page 9

5

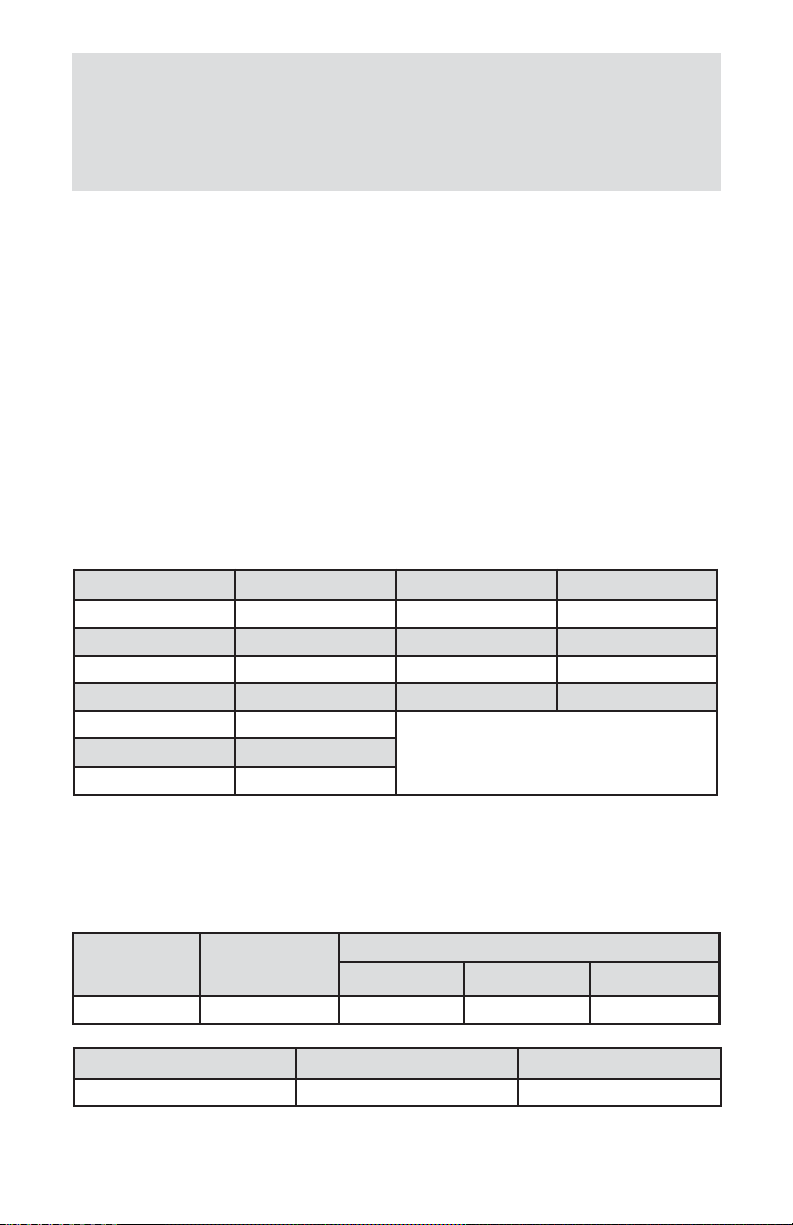

PIN FMA 4000 FUNCTION

1 Common, Signal Ground For Pin 2

(4-20 mA return).

2 0-5 Vdc or 4-20mA Flow Signal Output.

3 Relay No. 2 - Normally Open Contact.

4 Relay No. 2 - Common Contact.

5 Common, Power Supply

(- DC power for 11 to 26 Vdc).

6 Relay No. 1 - Common Contact.

7 Plus Power Supply

(+ DC power for 11 to 26 Vdc).

8 RS485 (-) (Optional RS232 TX).

9 RS232 Signal GND (RS485 GND Optional).

10 Do not connect (Test/Maintenance terminal).

11 Relay No. 2 - Normally Closed Contact.

12 Relay No. 1 - Normally Open Contact.

13 Relay No. 1 - Normally Closed Contact.

14 Do not connect (Test/Maintenance terminal).

15 RS485 (+) (Optional RS232 RX).

Shield Chassis Ground.

Figure b.1 - FMA 4000 15 PIN “D” CONNECTOR CONFIGURATION

IMPORTANT NOTES:

Generally, “D” Connector numbering patterns are standardized. There are, however, some connectors with nonconforming patterns and the numbering

sequence on your mating connector may or may not coincide with the numbering

sequence shown in our pin configuration table above. It is imperative that you

match the appropriate wires in accordance with the correct sequence regardless

of the particular numbers displayed on the mating connector.

Make sure power is OFF when connecting or disconnecting any cables in

the system.

The (+) and (-) power inputs are each protected by a 300mA M (medium time-lag)

resettable fuse. If a shorting condition or polarity reversal occurs, the fuse will cut

power to the flow transducer circuit. Disconnect the power to the unit, remove the

faulty condition, and reconnect the power. The fuse will reset once the faulty condition has been removed. DC Power cable length may not exceed 9.5 feet (3

meters). Use of the FMA 4000 flow transducer in a manner other than that specified in this manual or in writing from Omega, may impair the protection provided

by the equipment.

Page 10

3. PRINCIPLE OF OPERATION

The stream of gas entering the Mass Flow transducer is split by shunting a small

portion of the flow through a capillary stainless steel sensor tube. The remainder of

the gas flows through the primary flow conduit. The geometry of the primary conduit and the sensor tube are designed to ensure laminar flow in each branch.

According to principles of fluid dynamics the flow rates of a gas in the two laminar

flow conduits are proportional to one another. Therefore, the flow rates measured

in the sensor tube are directly proportional to the total flow through the transducer.

In order to sense the flow in the sensor tube, heat flux is introduced at two sections of the sensor tube by means of precision wound heater-sensor coils. Heat is

transferred through the thin wall of the sensor tube to the gas flowing inside. As

gas flow takes place heat is carried by the gas stream from the upstream coil to

the downstream coil windings. The resultant temperature dependent resistance

differential is detected by the electronic control circuit. The measured temperature

gradient at the sensor windings is linearly proportional to the instantaneous rate

of flow taking place.

An output signal is generated that is a function of the amount of heat carried by

the gases to indicate mass-molecular based flow rates.

Additionally, the FMA 4000 Mass Flow Meter incorporates a Precision Analog

Microcontroller (ARM7TDMI7 MCU) and non-volatile memory that stores all hard-

ware specific variables and up to 10 different calibration tables. The flow rate can

be displayed in 23 different volumetric or mass flow engineering units. Flow meter

parameters and functions can be programmed remotely via the RS485/RS232

(optional) interface. FMA 4000 flow meters support various functions including:

programmable flow totalizer, low, high or range flow alarm, automatic zero adjustment (activated via local button or communication interface), 2 programmable

SPDT relays output, 0-5 Vdc / 4-20 mA analog outputs (jumper selectable), self

diagnostic alarm, 36 internal and user defined K-factor. Optional local 2x16 LCD

readout with adjustable back light provides flow rate and total volume reading in

currently selected engineering units and diagnostic events indication.

6

Page 11

7

4. SPECIFICATIONS

FLOW MEDIUM: Please note that FMA 4000 Mass Flow Meters are designed to work only

with clean gases. Never try to measure flow rates of liquids with any FMA 4000.

CALIBRATIONS: Performed at standard conditions [14.7 psia (101.4 kPa) and 70

F

F

(21.1

F

C)] unless otherwise requested or stated.

ENVIRONMENTAL (PER IEC 664): Installation Level II; Pollution Degree II.

FLOW ACCURACY (INCLUDING LINEARITY): ±1% of FS at calibration temperature and

pressure.

REPEATABILITY: ±0.15% of full scale.

FLOW TEMPERATURE COEFFICIENT: 0.15% of full scale/

F

C or better.

FLOW PRESSURE COEFFICIENT: 0.01% of full scale/psi (6.895 kPa) or better.

FLOW RESPONSE TIME: 1000ms time constant; approximately 2 seconds to within ±2%

of set flow rate for 25% to 100% of full scale flow.

MAXIMUM GAS PRESSURE: 500 psig (3447 kPa gauge).

MAXIMUM PRESSURE DROP: 0.18 PSID (at 10 L/min flow). See Table IV for

pressure drops associated with various models and flow rates.

GAS AND AMBIENT TEMPERATURE: 41

F

F to 122 FF (5 FC to 50 FC).

RELATIVE GAS HUMIDITY: Up to 70%.

LEAK INTEGRITY: 1 x 10-9sccs He maximum to the outside environment.

ATTITUDE SENSITIVITY: Incremental deviation of up to 1% from stated accuracy, after re-

zeroing.

OUTPUT SIGNALS: Linear 0-5 Vdc (3000 ohms min load impedance);

Linear 4-20 mA (500 ohms maximum loop resistance).

Maximum noise 20mV peak to peak (for 0-5 Vdc output).

TRANSDUCER INPUT POWER: 11 to 26 Vdc, 100 mV maximum peak to peak output

noise.

Power consumption: +12Vdc (200 mA maximum);

+24Vdc (100 mA maximum);

Circuit board have built-in polarity reversal protection, 300mA resettable fuse provide

power input protection.

WETTED MATERIALS: Anodized aluminum, brass, 316 stainless steel, 416 stainless steel,

FKM, O-rings; BUNA-N7, NEOPRENE7 or KALREZ7 O-rings are optional.

Page 12

CAUTION: Omega makes no expressed or implied guarantees of corrosion

resistance of mass flow meters as pertains to different flow media reacting with

components of meters. It is the customers' sole responsibility to select the

model suitable for a particular gas based on the fluid contacting (wetted)

materials offered in the different models.

INLET AND OUTLET CONNECTIONS: Model FMA 4000 standard 1/4" compression fittings.

Optional 1/8" or 3/8" compression fittings and 1/4" VCR fittings are available.

DISPLAY: Optional local 2x16 characters LCD with adjustable backlight (2 lines of text).

CALIBRATION OPTIONS: Standard is one 10 points NIST calibration.

Optional, up to 9 additional calibrations may be ordered at additional charge.

CE COMPLIANCE: EMC Compliance with 89/336/EEC as amended.

Emission Standard: EN 55011:1991, Group 1, Class A.

Immunity Standard: EN 55082-1:1992.

8

*Flow rates are stated for Nitrogen at STP conditions [i.e. 70 FF (21.1 FC) at 1 atm].

For other gases use the K factor as a multiplier from APPENDIX III.

TABLE IV PRESSURE DROPS

MODEL

FLOW RATE

[std liters/min]

MAXIMUM PRESSURE DROP

[mm H2O] [psid] [kPa]

FMA 4000 up to 10 130 0.18 1.275

CODE

scc/min [N2]

CODE

std liters/min [N2]

00 0 to 5 07 0 to 1

01 0 to 10 08 0 to 2

02 0 to 20 09 0 to 5

03 0 to 50 10 0 to 10

04 0 to 100

05 0 to 200

06 0 to 500

TABLE I FMA 4000 LOW FLOW MASS FLOW METER*

FLOW RANGES

MODEL

WEIGHT

SHIPPING WEIGHT

FMA 4000 transmitter 2.20 lbs. (1.00 kg) 3.70 lbs. (1.68 kg)

Page 13

9

5. OPERATING INSTRUCTIONS

5.1 Preparation and Warm Up

It is assumed that the Mass Flow Meter has been correctly installed and thoroughly leak tested as described in section 2. Make sure the flow source is OFF.

When applying power to a flow meter within the first two seconds, you will see on

the LCD display: the product name, the software version, and revision of the EEPROM table (applicable for LCD option only).

Figure b-2: FMA 4000 first Banner Screen

Within the next two seconds, the RS485 network address, the analog output settings, and currently selected gas calibration table will be displayed (applicable for

LCD option only).

Figure b-3: FMA 4000 second Banner Screen

Note: Actual content of the LCD screen may vary depending on the

model and device configuration.

After two seconds, the LSD display switches to the main screen with the

following information:

- Mass Flow reading in current engineering units (upper line).

- Totalizer Volume reading in current volume or mass based

engineering units (lower line).

Figure b-4: FMA 4000 Main Screen

OMEGA FMA 4000 485

S: Ver1.4 Rev.A0

Ad: 11 Out: 0-5Vdc

Gas# 1 AIR

F: 50.0 L/min

T: 75660.5 Ltr

Page 14

10

During initial powering of the FMA 4000 transducer, the flow output signal will be

indicating a higher than usual output. This is an indication that the FMA 4000

transducer has not yet attained its minimum operating temperature. This condition

will automatically cancel within a few minutes and the transducer should eventually indicate zero.

For the FMA 4000 transducer with LCD option: If the LCD diagnostic is activated,

the second line of the LCD will display the time remaining until the end of the

warm up period (Minutes:Seconds format) and will alternatively switch to Totalizer

reading indication every 2 seconds.

Figure b-5: FMA 4000 Main Screen during Sensor Warm up period.

5.2 Swamping Condition

If a flow of more than 10% above the maximum flow rate of the Mass Flow Meter

is taking place, a condition known as “swamping” may occur. Readings of a

“swamped” meter cannot be assumed to be either accurate or linear. Flow must

be restored to below 110% of maximum meter range. Once flow rates are lowered

to within calibrated range, the swamping condition will end. Operation of the meter

above 110% of maximum calibrated flow may increase recovery time.

Note: Allow the Digital Mass Flow Meter to warm-up for a MINIMUM

of 6 minutes.

Note: During the first 6 minutes of the initial powering of the FMA 4000

transducer, the status LED will emit CONSTANT UMBER light.

Note: After 6 minutes of the initial powering of the FMA 4000 the

transducer, status LED will emit a constant GREEN light (normal

operation, ready to measure). For FMA 4000 with LCD option, the

screen will reflect flow and totalizer reading. (see Figure b-4).

F: 50.0 L/min

** WarmUp 2:39 **

Page 15

11

5.3 FMA 4000 Parameters Settings

5.3.1 Engineering Units Settings

The FMA 4000 Mass Flow Meter is capable of displaying flow rate with 23 different

Engineering Units. Digital interface commands (see paragraph 8.3 ASCII Command

Set “FMA 4000 SOFTWARE INTERFACE COMMANDS”) are provided to:

- get currently active Engineering Units

- set desired Engineering Units.

The following Engineering Units are available:

TABLE VI UNITS OF MEASUREMENT

NUMBER INDEX

FLOW RATE

ENGINEERING

UNITS

TOTALIZER

ENGINEERING

UNITS

DESCRIPTION

1 0 % %s Percent of full scale

2 1 mL/sec mL Milliliter per second

3 2 mL/min mL Milliliter per minute

4 3 mL/hr mL Milliliter per hour

5 4 L/sec Ltr Liter per second

6 5 L/ min Ltr Liter per minute

7 6 L/hr Ltr Liter per hour

87

m

3

/sec m

3

Cubic meter per second

98

m

3

/ min m

3

Cubic meter per minute

10 9

m

3

/hr m

3

Cubic meter per hour

11 10

f

3

/sec f

3

Cubic feet per second

12 11

f

3

/min f

3

Cubic feet per minute

13 12

f

3

/hr f

3

Cubic feet per hour

14 13 g/sec g Grams per second

15 14 g/min g Grams per minute

16 15 g/hr g Grams per hour

17 16 kg/sec kg Kilograms per second

18 17 kg/min kg Kilograms per minute

19 18 kg/hr kg Kilograms per hour

20 19 Lb/sec Lb Pounds per second

21 20 Lb/min Lb Pounds per minute

22 21 Lb/hr Lb Pounds per hour

23 22 User UD User defined

Page 16

5.3.2 Gas Table Settings

The FMA 4000 Mass Flow Meter is capable of storing calibration data for up to 10

different gases. Digital interface commands are provided to:

- get currently active Gas Table number and Gas name

- set desired Gas Table.

5.3.3 Totalizer Settings

The total volume of the gas is calculated by integrating the actual gas flow rate

with respect to the time. Digital interface commands are provided to:

- reset the totalizer to ZERO

- start the totalizer at a preset flow

- assign action at a preset total volume

- start/stop (enable/disable) totalizing the flow

- read totalizer via digital interface

The Totalizer has several attributes which may be configured by the user.

These attributes control the conditions which cause the Totalizer to start integrating the gas flow and also to specify actions to be taken when the Total Volume is

outside the specified limit.

Totalizer action conditions become true when the totalizer reading and preset

“Stop at Total” volumes are equal.

12

Note: Once Flow Unit of Measure is changed, the Totalizer’s

Volume/Mass based Unit of Measure will be changed automatically.

Note: By default the FMA 4000 is shipped with at least one valid

calibration table (unless optional additional calibrations were ordered).

If instead of the valid Gas name (for example NITROGEN), the LCD

screen or digital interface displays Gas designator as “Uncalibrated”,

then the user has chosen the Gas Table which was not calibrated.

Using an “Uncalibrated” Gas Table will result in erroneous reading.

Note: Before enabling the Totalizer, ensure that all totalizer settings

are configured properly. Totalizer Start values have to be entered in

%F.S. engineering unit. The Totalizer will not totalize until the flow rate

becomes equal to or more than the Totalizer Start value. Totalizer Stop

values must be entered in currently active volume / mass based

engineering units. If the Totalizer Stop at preset total volume feature is

not required, then set Totalizer Stop value to zero.

Page 17

Mode Enable

/Disable - Allows the user to Enable/Disable Flow Alarm.

Low Alarm - The value of the monitored Flow in % F.S. below

which is considered an alarm condition.

Note: The value of the Low alarm must be less than the

value of the High Alarm.

High Alarm- The value of the monitored Flow in % F.S. above

which is considered an alarm condition.

Note: The value of the High alarm must be more than the

value of the Low Alarm.

Action Delay- Th e ti me i n se conds that the Flow rate value must remain

above the high limit or below the low limit before an alarm

condition is indicated. Valid settings are in the range of 0

to 3600 seconds.

13

Local maintenance push button is available for manual Totalizer reset on the field.

The maintenance push button is located on the right side of the flow meter inside

the maintenance window above the 15 pin D-connector (see Figure c-1 “FMA

4000 configuration jumpers”).

5.3.4 Flow Alarm Settings

FMA 4000 provides the user with a flexible alarm/warning system that monitors

the Gas Flow for conditions that fall outside configurable limits as well as visual

feedback for the user via the status LED and LCD (only for devices with LCD

option) or via a Relay contact closure.

The flow alarm has several attributes which may be configured by the user via a

digital interface. These attributes control the conditions which cause the alarm to

occur and to specify actions to be taken when the flow rate is outside the specified conditions.

Note: In order to locally Reset Totalizer, the reset push button must be

pressed during power up sequence. The following sequence is

recommended:

1. Disconnect FMA 4000 from the power.

2. Press maintenance push button (do not release).

3. Apply power to the FMA 4000 while holding down the maintenance

push button.

4. Release maintenance push button after 6 seconds. For FMA 4000

with optional LCD, when FMA 4000 Main Screen appears

(see Figure b-4).

Page 18

The current Flow Alarm settings and status are available via digital interface (see

paragraph 8.3 ASCII Command Set “FMA 4000 SOFTWARE INTERFACE COMMANDS”).

5.3.5 Relay Assignment Settings

Two sets of dry contact relay outputs are provided to actuate user supplied equipment. These are programmable via digital interface such that the relays can be

made to switch when a specified event occurs (e.g. when a low or high flow alarm

limit is exceeded or when the totalizer reaches a specified value).

The user can configure each Relay action from 6 different options:

No Action : (N) No assignment (relay is not assigned to any events and not energized).

Totalizer > Limit : (T) Totalizer reached preset limit volume.

High Flow Alarm : (H) High Flow Alarm condition.

Low Flow Alarm : (L) Low Flow Alarm condition.

Range between H&L : (R) Range between High and Low Flow Alarm condition.

Manual Enabled : (M) Activated regardless of the Alarm and Totalizer conditions.

5.3.6 K Factors Settings

Conversion factors relative to Nitrogen for up to 36 gases are stored in the FMA

4000 (see APPENDIX II). In addition, provision is made for a user-defined conversion factor. Conversion factors may be applied to any of the ten gas calibrations via digital interface commands.

14

Latch Mode- Controls Latch feature when Relays are assigned to

Alarm event. Following settings are available:

0 - Latch feature is disabled for both relays

1 - Latch feature is enabled for Relay#1 and disabled for Relay#2

2 - Latch feature is enabled for Relay#2 and disabled for Relay#1

3 - Latch feature is enabled for both relays.

Note: If the alarm condition is detected, and the Relay is assigned to

Alarm event, the corresponding Relay will be energized.

Note: By default, flow alarm is non-latching. That means the alarm is

indicated only while the monitored value exceeds the specified

conditions. If Relay is assigned to the Alarm event, in some cases, the

Alarm Latch feature may be desirable.

Page 19

15

The available K Factor settings are:

• Disabled (K = 1).

• Internal Index The index [0-35] from internal K factor table

(see APPENDIX II).

• User Defined User defined conversion factor.

5.3.7 Zero Calibration

The FMA 4000 includes an auto zero function that, when activated, automatically adjusts the mass flow sensor to read zero. The initial zero adjustment for your

FMA 4000 was performed at the factory. It is not required to perform zero calibration unless the device has zero reading offset with no flow conditions.

Shut off the flow of gas into the Digital Mass Flow Meter. To ensure that no seepage or leak occurs into the meter, it is good practice to temporarily disconnect the

gas source. The Auto Zero may be initiated via digital communication interface or

locally by pressing the maintenance push button, which is located on the right side

of the flow meter inside the maintenance window above the 15 pin D-connector

(see Figure c-1 “FMA 4000 configuration jumpers”).

To start Auto Zero locally, press the maintenance push button. The status LED will

flash not periodically with the RED light. On the FMA 4000 with optional LCD, the

following screen will appear:

Note: The conversion factors will not be applied for % F.S.

engineering unit.

Note: Before performing Zero Calibration, make sure the device is

powered up for at least 15 minutes and absolutely no flow condition is

established.

Note: The same maintenance push button is used for Auto Zero

initiation and Totalizer reset. The internal diagnostic algorithm will

prevent initiating Auto Zero function via the maintenance push button

before the 6 minutes sensor warm up period has elapsed.

Page 20

16

Figure b-6: FMA 4000 Screen in the beginning of Auto Zero procedure.

The Auto Zero procedure normally takes 1 - 2 minutes during which time the DP

Zero counts and the Sensor reading changes approximately every 3 to 6 seconds.

Figure b-7: FMA 4000 during the Auto Zero procedure.

The nominal value for a fully balanced sensor is 120 Counts. If the FMA 4000’s

digital signal processor was able to adjust the Sensor reading within 120 ± 10

counts, then Auto Zero is considered successful. The status LED will return to a

constant GREEN light and the screen below will appear:

Figure b-7: FMA 4000 during the Auto Zero procedure.

If the device was unable to adjust the Sensor reading to within 120 ± 10 counts,

then Auto Zero is considered as unsuccessful. The constant RED light will appear

on the status LED. The user will be prompted with the “AutoZero ERROR!” screen.

AUTOZERO IS ON!

AUTOZERO IS ON!

S: 405 DP: 512

AutoZero is Done

S: 122 DP: 544

Note: The actual value of the Sensor and DP counts will vary for each

FMA 4000.

Note: For FMA 4000 with RS232 option all Auto Zero status info

available via digital communication interface.

Page 21

17

5.3.8 Self Diagnostic Alarm

FMA 4000 series Mass Flow Meters are equipped with a self-diagnostic alarm

which is available via multicolor LED, digital interface and on screen indication (for

devices with optional LCD). The following diagnostic events are supported:

5.4 Analog Output Signals configuration

FMA 4000 series Mass Flow Meters are equipped with calibrated 0-5 Vdc and 420 mA output signals. The set of the jumpers (J7A, J7B, J7C) located on the right

side of the flow meter, inside of the maintenance window above the 15 pin D-connector (see Figure c-1 “FMA 4000 configuration jumpers”) are used to switch

between 0-5 Vdc or 4-20 mA output signals (see Table VI).

NUMBER

DIAGNOSTIC

ALARM DESCRIPTION

LED COLOR

AND PATTERN

PRIORITY

LEVEL

1

Auto Zero procedure is running

Not periodically

flashing RED

0

2

FATAL ERROR (reset or

maintenance service is required for

return in to the normal operation)

Constant RED 1

3

CPU Temperature too high

(Electronics Overheating)

Flashing RED/UMBER 2

4

Sensor in the warm up stage

(first 6 minutes after power up

sequence, normal operation, no

critical diagnostic events present)

Constant UMBER 3

5

Flow Sensor Temperature too low Flashing UMBER/OFF 4

6

Flow Sensor Temperature too high Flashing RED/OFF 5

7

Totalizer Reading hit preset limit Flashing GREEN/UMBER 6

8

Low flow Alarm conditions Flashing GREEN/OFF 7

9

High flow Alarm conditions Flashing GREEN/RED 8

10

Normal operation, no diagnostic

events

Constant GREEN 9

Note: [0] - Priority Level is highest (most important). When two or more

diagnostic events are present at the same time, the event with the

highest priority level will be indicated on the status LED and displayed

on the LCD (if equipped). All diagnostic events may be accessed

simultaneously via digital communication interface (see paragraph 8.3

“ASCII Command Set”).

Page 22

18

Analog output signals of 0-5 Vdc and 4-20 mA are attained at the appropriate pins of

the 15-pin “D” connector (see Figure b-1) on the side of the FMA 4000 transducer.

Tabl e V I Analog Output Jumper Configuration

See APPENDIX IV for actual jumpers layout on the PCB.

6. MAINTENANCE

6.1 Introduction

It is important that the Mass Flow Meter is only used with clean, filtered gases.

Liquids may not be metered. Since the RTD sensor consists, in part, of a small

capillary stainless steel tube, it is prone to occlusion due to impediments or gas

crystallization. Other flow passages are also easily obstructed.

Therefore, great care must be exercised to avoid the introduction of any potential

flow impediment. To protect the instrument, a 50 micron (FMA 4000) filter is built

into the inlet of the flow transducer. The filter screen and the flow paths may require

occasional cleaning as described below. There is no other recommended maintenance required. It is good practice, however, to keep the meter away from vibration, hot or corrosive environments and excessive RF or magnetic interference.

If periodic calibrations are required, they should be performed by qualified personnel and calibrating instruments, as described in section 7. It is recommended

that units are returned to Omega

®

for repair service and calibration.

ANALOG SIGNAL

OUTPUT

0-5 Vdc 4-20 mA

Flow Rate Output

Jumper Header J7

J7.A

J7.B

J7.C

5-9

6-10

7-11

J7.A

J7.B

J7.C

1-5

2-6

3-7

Note: Digital output (communication) is simultaneously available with

analog output.

CAUTION: TO PROTECT SERVICING PERSONNEL IT IS

MANDATORY THAT ANY INSTRUMENT BEING SERVICED IS

COMPLETELY PURGED AND NEUTRALIZED OF TOXIC,

BACTERIOLOGICALLY INFECTED, CORROSIVE OR RADIOACTIVE

CONTENTS.

Page 23

19

6.2 Flow Path Cleaning

Before attempting any disassembly of the unit for cleaning, try inspecting the flow

paths by looking into the inlet and outlet ends of the meter for any debris that may

be clogging the flow through the meter. Remove debris as necessary. If the flow

path is clogged, proceed with steps below.

Do not attempt to disassemble the sensor. If blockage of the sensor tube is not alleviated by flushing through with cleaning fluids, please return meter for servicing.

6.2.1 Restrictor Flow Element (RFE)

The Restrictor Flow Element (RFE) is a precision flow divider inside the transducer which splits the inlet gas flow by a preset amount to the sensor and main

flow paths. The particular RFE used in a given Mass Flow Meter depends on the

gas and flow range of the instrument.

6.2.2 FMA 4000 Model

Unscrew the inlet compression fitting of meter. Note that the Restrictor Flow

Element (RFE) is connected to the inlet fitting. Carefully disassemble the RFE

from the inlet connection. The 50 micron filter screen will now become visible.

Push the screen out through the inlet fitting. Clean or replace each of the removed

parts as necessary. If alcohol is used for cleaning, allow time for drying.

Inspect the flow path inside the transducer for any visible signs of contaminant. If

necessary, flush the flow path through with alcohol. Thoroughly dry the flow paths

by flowing clean dry gas through.

Carefully re-install the RFE and inlet fitting avoiding any twisting and deforming to

the RFE. Be sure that no dust has collected on the O-ring seal.

CAUTION: DISASSEMBLY MAY COMPROMISE CURRENT CALIBRATION.

NOTE: OVER TIGHTENING WILL DEFORM AND RENDER THE RFE

DEFECTIVE. IT IS ADVISABLE THAT AT LEAST ONE CALIBRATION

POINT BE CHECKED AFTER RE-INSTALLING THE INLET FITTING.

SEE SECTION (7.2.3).

Page 24

20

7. CALIBRATION PROCEDURES

7.1 Flow Calibration

Omega

®

Engineerings' Flow Calibration Laboratory offers professional calibration

support for Mass Flow Meters using precision calibrators under strictly controlled

conditions. NIST traceable calibrations are available. Calibrations can also be performed at customers' site using available standards.

Factory calibrations are performed using NIST traceable precision volumetric calibrators incorporating liquid sealed frictionless actuators.

Generally, calibrations are performed using dry nitrogen gas. The calibration can

then be corrected to the appropriate gas desired based on relative correction [K]

factors shown in the gas factor table (see APPENDIX III). A reference gas, other

than nitrogen, may be used to better approximate the flow characteristics of certain gases. This practice is recommended when a reference gas is found with thermodynamic properties similar to the actual gas under consideration. The appropriate relative correction factor should be recalculated (see section 9).

It is standard practice to calibrate Mass Flow Meters with dry nitrogen gas at

70.0

F

F (21.1 FC), 20 psia (137.9 kPa absolute) inlet pressure and 0 psig outlet

pressure. It is best to calibrate FMA 4000 transducers to actual operating conditions. Specific gas calibrations of non-toxic and non-corrosive gases are available

for specific conditions. Please contact your Omega

®

for a price quotation.

It is recommended that a flow calibrator be used which has at least four times better collective accuracy than that of the Mass Flow Meter to be calibrated.

Equipment required for calibration includes: a flow calibration standard, PC with

available RS485 / RS232 communication interface, a certified high sensitivity

multi meter (for analog output calibration only), an insulated (plastic) screwdriver,

a flow regulator (for example - metering needle valve) installed upstream from the

Mass Flow Meter, and a pressure regulated source of dry filtered nitrogen gas (or

other suitable reference gas). Using Omega

®

supplied calibration and mainte-

nance software to simplify the calibration process is recommended.

Gas and ambient temperature, as well as inlet and outlet pressure conditions,

should be set up in accordance with actual operating conditions.

NOTE: REMOVAL OF THE FACTORY INSTALLED CALIBRATION

SEALS AND/OR ANY ADJUSTMENTS MADE TO THE METER, AS

DESCRIBED IN THIS SECTION, WILL VOID ANY CALIBRATION

WARRANTY APPLICABLE.

Page 25

21

7.2 Gas Flow Calibration of FMA 4000 Mass Flow Meter

FMA 4000 Mass Flow Meters may be field recalibrated/checked for the same

range they were originally factory calibrated for. When linearity adjustment is

needed or flow range changes are being made, proceed to step 7.2.3. Flow range

changes may require a different Restrictor Flow Element (RFE). Consult Omega

®

for more information.

7.2.1 Connections and Initial Warm Up

Power up the Mass Flow Meter for at least 15 minutes prior to commencing the

calibration procedure. Establish digital RS485 / RS232 communication between

PC (communication terminal) and the FMA 4000. Start Omega

®

supplied calibra-

tion and maintenance software on the PC.

7.2.2 ZERO Check/Adjustment

Using Omega

®

supplied calibration and maintenance software open Back Door

access:

Query/BackDoor/Open

When software prompts with Warning, click the [YES] button. This will open the

access to the rest of the Query menu.

Start Sensor Compensated Average reading:

Query/Read/ SensorCompAverage

This will display Device Sensor Average ADC counts.

With no flow conditions, the sensor Average reading must be in the range 120±

10 counts. If it is not, perform Auto Zero procedure (see section 5.3.10 “Zero

Calibration”).

7.2.3 Gas Linearization Table Adjustment

All adjustments in this section are made from the outside of the meter

via digital communication interface between a PC (terminal) and FMA

4000. There is no need to disassemble any part of the instrument or

perform internal PCB component (potentiometers) adjustment.

Note: Your FMA 4000 Digital Mass Flow Meter was calibrated at the

factory for the specified gas and full scale flow range (see device’s

front label). There is no need to adjust the gas linearization table

unless linearity adjustment is needed, flow range has to be changed,

or new additional calibration is required. Any alteration of the gas

linearization table will VOID calibration warranty supplied with instrument.

Page 26

22

Gas flow calibration parameters are separately stored in the Gas Dependent portion of the EEPROM memory for each of 10 calibration tables. See APPENDIX I

for complete list of gas dependent variables.

The FMA 4000 gas flow calibration involves building a table of the actual flow values (indexes 114, 116, 118, 120, 122, 124, 126, 128, 130, 132, 134) and corresponding sensor readings (indexes 113, 115, 117, 118, 119, 121, 123, 125, 127,

129, 131, 133).

Actual flow values are entered in normalized fraction format: 100.000 % F.S. corresponds to 1.000000 flow value and 0.000 % F.S. corresponds to 0.000000 flow

value. The valid range for flow values is from 0.000000 to 1.000000 (note: FMA

4000 will accept up to 6 digits after decimal point).

Sensor readings are entered in counts of 12 bits ADC output and should always

be in the range of 0 to 4095. There are 11 elements in the table so the data should

be obtained at an increment of 10.0 % of full scale (0.0, 10.0, 20.0, 30.0, 40.0,

50.0, 60.0, 70.0, 80.0, 90.0 and 100.0 % F.S.).

If a new gas table is going to be created, it is recommended to start calibration

from 100% full scale. If only linearity adjustment is required, calibration can be

started in any intermediate portion of the gas table.

Using the flow regulator, adjust the flow rate to 100% of full scale flow. Check the

flow rate indicated against the flow calibrator. Observe the flow reading on the

FMA 4000. If the difference between calibrator and FMA 4000 flow reading is

more than 0.5% F.S., make a correction in the sensor reading in the corresponding position of the linearization table (see Index 133).

If the FMA 4000 flow reading is more than the calibrator reading, the number of

counts in the index 133 must be decreased. If the FMA 4000 flow reading is less

than the calibrator reading, the number of counts in the index 133 must be

increased. Once Index 133 is adjusted with a new value, check the FMA 4000 flow

rate against the calibrator and, if required, perform additional adjustments for

Index 133.

Note: Make sure the correct gas number and name selected are

current. All adjustments made to the gas linearization table will be

applied to the currently selected gas. Use Gas Select command via

digital communication interface (see paragraph 8.3 ASCII Command

Set “FMA 4000 SOFTWARE INTERFACE COMMANDS”) or Omega

®

supplied calibration and maintenance software to verify current gas

table or select a new gas table.

Note: Do not alter memory index 113 (must be 120 counts) and 114

(must be 0.0). These numbers represent zero flow calibration points

and should not be changed.

Page 27

If a simple communication terminal is used for communication with the FMA 4000,

then “MW” (Memory Write) command from the software interface commands set

may be used to adjust sensor value in the linearization table (see section 8.3 for

complete software interface commands list).

Memory Read “MR” command can be used to read the current value of the index.

Assuming the FMA 4000 is configured with RS485 interface and has address

“11”, the following example will first read the existing value of Index 133 and then

write a new adjusted value:

!11,MR,133[CR] - reads EEPROM address 133

!11,MW,133,3450[CR] - writes new sensor value (3450 counts) in to the index 133

Once 100% F.S. calibration is completed, the user can proceed with calibration for

another 9 points of the linearization table by using the same approach.

7.3 Analog output Calibration of FMA 4000

Mass Flow Meter

FMA 4000 series Mass Flow Meters are equipped with

calibrated 0-5 Vdc and 4-20 mA output signals. The set

of the jumpers (J7A, J7B, J7C) on the printed circuit

board is used to switch between 0-5 Vdc and 4-20 mA

output signals (Figure c-1 “FMA 4000 configuration

jumpers”).

Figure c-1 FMA 4000 Analog Output Configuration Jumpers

23

Note: It is recommended to use Omega®supplied calibration and

maintenance software for gas table calibration. This software includes

an automated calibration procedure which may radically simplify

reading and writing for the EEPROM linearization table.

FUNCTION J7A

J7B J7C

JCD

ANALOG 0-5 VDC 5-9 6-10 7-11

OUTPUT 4-20 mA 1-5 2-6 3-7

RS485

TERMINAL

RESISTOR

OFF

8-12

ON 4-8

J7 Jumpers

9

10

11

12

5

6

7

8

1

2

3

4

A

B

CD

AutoZero/Reset

push button.

Page 28

24

The FMA 4000 analog output calibration involves calculation and storing of the

offset and span variables in the EEPROM for each available output. The 0-5 Vdc

output has only scale variable and 20 mA output has offset and scale variables.

The following is a list of the Gas independent variables used for analog output

computation:

Index Name Description

25 AoutScaleV - DAC 0-5 Vdc Analog Output Scale

27 AoutScale_mA - DAC 4-20mA Analog Output Scale

28 AoutOffset_mA - DAC 4-20mA Analog Output Offset

7.3.1 Initial Setup

Power up the Mass Flow Meter for at least 15 minutes prior to commencing the

calibration procedure. Make sure absolutely no flow takes place through the

meter. Establish digital RS485 / RS232 communication between PC (communication terminal) and FMA 4000. The commands provided below assume that calibration will be performed manually (w/o Omega

®

supplied calibration and main-

tenance software) and the device has RS485 address 11. If Omega

®

supplied calibration and maintenance software is used, skip the next section and follow the

software prompts.

Note: The analog output available on the FMA 4000 Digital Mass Flow

Meter was calibrated at the factory for the specified gas and full scale

flow range (see the device’s front label). There is no need to perform

analog output calibration unless the EEPROM IC was replaced or

offset/span adjustment is needed. Any alteration of the analog output

scaling variables in the Gas independent table will VOID calibration

warranty supplied with instrument.

Note: It is recommended to use the Omega®supplied calibration and

maintenance software for analog output calibration. This software

includes an automated calibration procedure which may radically

simplify calculation of the offsets and spans variables and, the reading

and writing for the EEPROM table.

Page 29

25

Enter Backdoor mode by typing: !11,MW,1000,1[CR]

Unit will respond with: !11,BackDoorEnabled: Y

Disable DAC update by typing: !11,WRITE,4,D[CR]

Unit will respond with: !11,DisableUpdate: D

7.3.2 Gas flow 0-5 Vdc analog output calibration

1. Install jumpers J7A, J7B and J7C on the PC board for 0-5 Vdc output (see Table VI).

2. Connect a certified high sensitivity multi meter set for the voltage measurement to the

pins 2 (+) and 1 (-) of the 15 pins D connector.

3. Write 4000 counts to the DAC channel 1: !11,WRITE,1,4000[CR]

4. Read voltage with the meter and calculate:

5. Save FlowOutScaleV in to the EEPROM: !11,MW,25,X[CR]

Where: X – the calculated AoutScaleV value.

7.3.3 Gas flow 4-20 mA analog output calibration

1. Install jumpers J7A, J7B and J7C on the PC board for 4-20 mA output (see Table VI).

2. Connect a certified high sensitivity multi meter set for the current measurement to

pins 2 (+) and 1 (-) of the 15 pins D connector.

3. Write 4000 counts to the DAC channel 1: !11,WRITE,1,4000[CR]

4. Read current with the meter and calculate:

5. Write zero counts to the DAC channel 1: !11,WRITE,1,0CR]

6. Read offset current with the meter and calculate:

7. Save AoutScale_mA in to the EEPROM: !11,MW,27,Y[CR]

Save AoutOffset_mA in to the EEPROM: !11,MW,28,Z[CR]

Where: Y – the calculated AoutScale_mA value.

Z – the calculated AoutOffset_mA value.

Note: When done with the analog output calibration make sure the

DAC update is enabled and the BackDoor is closed

(see command below).

Page 30

26

Enable DAC update by typing: !11,WRITE,4,N[CR]

Unit will respond with: !11,DisableUpdate: N

Close BackDoor access by typing: !11,MW,1000,0[CR]

Unit will respond with: !11,BackDoorEnabled: N

8. RS485 / RS232 SOFTWARE INTERFACE COMMANDS

8.1 General

The standard FMA 4000 comes with an RS485 interface. For the optional RS232

interface, the start character (!) and two hexadecimal characters for the address

must be omitted. The protocol described below allows for communications with

the unit using either a custom software program or a “dumb terminal.” All values

are sent as printable ASCII characters. For RS485 interface, the start character is

always (!). The command string is terminated with a carriage return (line feeds are

automatically stripped out by the FMA 4000). See section 2.2.3 for information

regarding communication parameters and cable connections.

8.2 Commands Structure

The structure of the command string:

!<Addr>,<Cmd>,Arg1,Arg2,Arg3,Arg4<CR>

Where:

! Start character **

Addr RS485 device address in the ASCII representation of hexadecimal

(00 through FF are valid).**

Cmd The one or two character command from the table below.

Arg1 to Arg4 The command arguments from the table below.

Multiple arguments are comma delimited.

CR Carriage Return character.

Several examples of commands follow. All assume that the FMA 4000 has been

configured for address 18 (12 hex) on the RS485 bus:

1. To get current calibration tables: !12,G<CR>

The FMA 4000 will reply: !12,G 0 AIR<CR>

(Assuming Current Gas table is #0, calibrated for AIR )

2. To get current Alarm status: !12,A,R<CR>

The FMA 4000 will reply: !12,N<CR> (Assuming no alarm conditions)

3. To get a flow reading: !12,F<CR>The FMA 4000 will reply:

!12,50.0<CR> (Assuming the flow is at 50% FS)

4. Set the high alarm limit to 85% of full scale flow rate:

!12,A,H,85.0<CR>

The FMA 4000 will reply: !12,AH85.0<CR>

Note: ** Default address for all units is 11. Do not submit start

character and two character hexadecimal device address for

RS232 option.

Page 31

27

The global address can be used to change RS485 address for a particular device with

unknown address:

1. Make sure only one device (which address must be changed) is connected to the

RS485 network.

2. Type the memory write command with global address: !00,MW,7,XX[CR] where

XX, the new hexadecimal address, can be [01 – FF].

After assigning the new address, a device will accept commands with the new address.

Note: Address 00 is reserved for global addressing. Do not assign, the

global address for any device. When command with global address is

sent, all devices on the RS485 bus execute the command but do not

reply with an acknowledge message.

Note: Do not assign the same RS485 address for two or more

devices on the same RS485 bus. If two or more devices with the same

address are connected to the one RS485 network, a communication

collision will take place on the bus and communication errors will occur.

Page 32

28

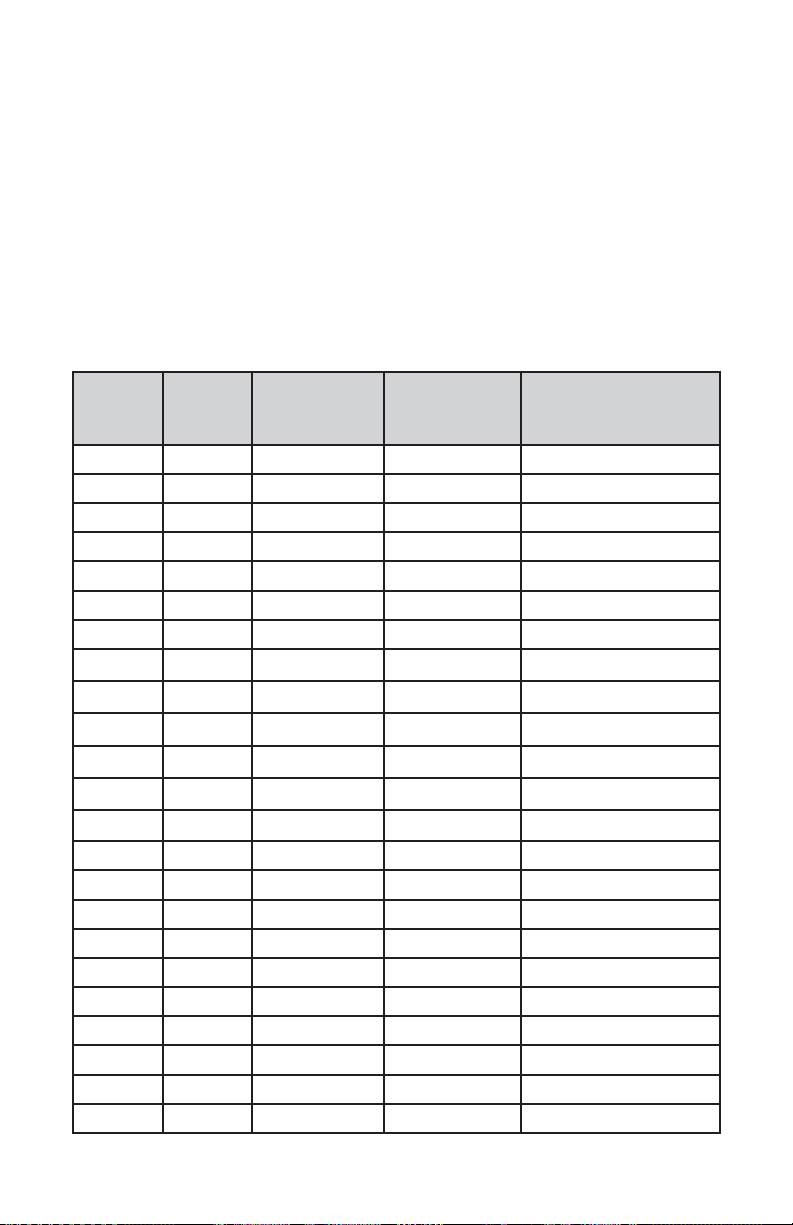

8.3 ASCII Commands Set

OMEGA FMA 4000 SOFTWARE INTERFACE COMMANDS

COMMAND

NAME

DESCRIPTION

No.

COMMAND SYNTAX

Command Argument 1

Argument 2 Argument 3

Argument 4 Response

Flow Requests the current flow

sensor reading in current EU

1

F <Value> (Actual flow in

current engineering units)

Diagnostic Enable / Disable LCD

Diagnostic messages (only

for LCD option).

Request current status of

the Diagnostic events, LED

status and LCD diagnostic

mode (enabled/disabled).

2

D

E (enable LCD

** Diagnostic Messages)

D:E

D (disable LCD

** Diagnostic Messages)

D:D

NO ARGUMENT

(read current status of

the diagnostic word)

D:0x0,L:9,E

0x0 – diagnostic word

9 - current LED status

E - LCD mode (enabled)

Roll back to

N

2

feature.

Enable / Disable Roll back

to N

2

feature.

3 N E

(enable Roll back to N

2

)

N:E

D

(enable Roll back to N

2

)*

N:D

NO ARGUMENT

(read current mode of

the N2 Roll back )

N:DOrN:E

Gas Select

Selects one of the ten

primary gas calibration

tables to use. Tables are

entered via the MEM

commands at time of

calibration.

4 G

0 (gas 0)*to9 (gas 9)

G0 through G9,

<Gas Name>

NO ARGUMENT

(read status)

G0 through G9,

<Gas Name>

Note: An “*” indicates power up default settings. An “**” indicates optional feature not available on all models.

Page 33

29

COMMAND

NAME

DESCRIPTION

No.

COMMAND SYNTAX

Command

Argument 1

Argument 2

Argument 3

Argument 4 Response

Auto

Zero

Starts /reads the status of

the auto zero feature (Note:

The Z,N command can be

used only when absolutely

no flow thru the meter and

no earlier then 6 minutes after

power up. It can take several

minutes to complete. Unit will

not respond to other commands

when this is in progress.)

5 Z

N (do it now) ZN

W (Write Zero to

EEPROM)

ZW (when done)

S (status while auto

zero in progress)

ZNI,<value> while Z,N

is in progress.

V (Display zero value)

ZV,<zero value>

Flow

Alarms

Sets / reads the status of

the gas flow alarms.

Note: High and Low limits

have to be entered in the

%F.S. High alarm value

has to be more than Low

alarm value.

Alarm conditions:

Flow > High Limit = H

Flow < Low Limit = L

Low < Flow < High = N

6 A H (high flow limit) <Value> (0-100%FS) AH<Value>

L (low flow limit) <Value> (0-100%FS)

AL<Value>

A (action delay in seconds)

<Value> (0-3600 sec.)

AA:<Value>

E (enable alarm) AE

D (disable alarm)* AD

R (read current status)

N (no alarm)

H (high alarm)

L (low alarm)

S (Read current settings)

AS:M,L,H,D,B where:

M – mode (E/D)

L – Low settings (%FS)

H – High settings (%FS)

D – Action Delay (sec)

B – Latch mode (0-3)

B Block (Latch) mode

<Value> (0-disabled*)

(1-enabl’d L)

(2-enabl’d H)

(3 –both L,H)

AB:<Value> where:

Value = 0 - 3

Page 34

30

COMMAND

NAME

DESCRIPTION

No.

COMMAND SYNTAX

Command

Argument 1

Argument 2 Argument 3 Argument 4 Response

Relay

Action

Assigns action of the two SPDT

relays. The coil is energized

when the condition specified by

an Argument 2 becomes true.

Argument 2:

N - no action, relay disabled*

T - totalizer reading > limit

H - high flow alarm

L - low flow alarm

R - Range between High &

Low alarms

M - Manual Relay overdrive

S - Read current status

7

R 1 (relay 1)

2 (relay 2)

N* R1N or R2N

T R1T or R2T

H R1H or R2H

L R1L or R2L

R

R1R or R2R

M

R1M or R2M

S

RxN, RxT, RxH,

RxL, RxR , RxM

Totalizer

Sets and controls action of the

flow totalizer.

NOTE: If Warm Up Delay option

is set to E (enabled) the Totalizer

will not totalize the flow during

first 6 minutes after power up.

8 T

Z (Reset to zero)

TZ

F (start totalizer at flow F.S.)

L (Limit gas volume in current E.U.)

<value>

(flow %FS)

TF<value>

<value>

(gas volume)

TL<value>

D (disable totalizer)

TD

E (enable totalizer)

TE

R (read current totalizer volume) <value> (in current EU)

W (Warm Up Delay)

E – enable

D – disable*

TW:E or TW:D

S (setting status)

TS: Mode, Start,

Limit, Warm Up

Page 35

31

COMMAND

NAME

DESCRIPTION

No.

COMMAND SYNTAX

Command Argument 1

Argument 2 Argument 3

Argument 4 Response

K Factors

Applies a gas correction

factor to the currently

selected primary gas

calibration table.

(NOTE: does not work with

% F.S. engineering unit.)

See list of the internal

K-factors in the operating

manual.

9 K

D*(disable, sets K=1) KD

I (Internal K-factor) No argument

(enable previously set

internal K-factor)

KI,<value>,<Gas>

Gas Index (0 -35) KI,<Index>,<Gas>

U (user specified factor) No argument

(enable previously set

user K-factor)

KU,<value>

<value>

(decimal correction

factor) (0-1000)

KU,<value>

S (status) SK, <Mode>, <Index>,

<Value> where:

Mode: D, I, U

Index: 0-35

Value: K-Factor value

Page 36

32

COMMAND

NAME

DESCRIPTION

No.

COMMAND SYNTAX

Command Argument 1 Argument 2 Argument 3 Argument 4 Response

Units

Set the units of

measure for gas

flow and totalizer

reading.

Note: The units

of the totalizer

output are not

per unit time.

10

U

% (% full scale)* U:%

mL/sec

U:mL/sec

mL/min

U:mL/min

mL/hr U:mL/hr

L/sec U:L/sec

L/min

U:L/min

L/hr U:L/hr

m3/sec

U:m3/sec

m3/min

U:m3/min

m3/hr U:m3/hr

f3/sec U:f3/sec

f3/min U:f3/min

f3/hr U:f3/hr

g/sec

U:g/sec

g/min

U:g/min

g/hr U:g/hr

kg/sec U:kg/sec

kg/min

U:kg/min

kg/hr U:kg/hr

Lb/sec U:Lb/sec

Lb/min

U:Lb/min

Lb/hr

U:Lb/hr

USER (user defined)

<value> (conversion

factor from L/min)

S - seconds

M – minutes

H – hours (Time base)

Y - use density

N – do not use

density

U:USER,<Factor>,

<Time base>,

<Density mode>

No Argument

<status>Returns current EU.

U,<EU name>

Page 37

33

UART Error Codes:

1 - Not Supported Command or Back Door is not enabled.

2 - Wrong # of Arguments.

3 - Address is Out of Range (MR or MW commands).

4 - Wrong # of the characters in the Argument.

5 - Attempt to Alter Write Protected Area in the EEPROM.

6 - Proper Command or Argument is not found.

7 - Wrong value of the Argument.

8 - Reserved.

9 - Manufacture specific info EE KEY (wrong key or key is disabled).

COMMAND

NAME

DESCRIPTION

No.

COMMAND SYNTAX

Command Argument 1 Argument 2 Argument 3

Argument 4

Response

Maintenance

Timer

Hours since last time unit

was calibrated.

11

C

R (read timer) <Value> (in Hours)

C(set timer to zero) CC

Full Scale

Returns the full scale rated flow in

L/min. (Note: This term is not

multiplied by the current K factor)

12

E

<Value>

(in L/min)

LCD Back

Light

LCD Back Light control

(0-100.0%)

0 - off

100 - Maximum Intensity

13 B 0 to 100% B:<Counts>

where:

Counts (0 – 4095)

B:<Value>

where:

Value (0 – 100.0)

No Argument

<Current settings>

Read

EEPROM

Memory

Reads the value in the

specified memory location.

14 MR 0000 to999

(Table Index)

<value>

Write

EEPROM

Memory

Writes the specified value to the

specified memory location. Use

Carefully, can cause unit to

malfunction. (Note: Some addresses

are write protected!)

15

MW 0000 to 999

(Table Index)

Value

MW,XXX,<Value>

where:

XXX=Table Index

Page 38

34

9. TROUBLESHOOTING

9.1 Common Conditions

Your FMA 4000 Digital Mass Flow Meter was thoroughly checked at numerous

quality control points during and after manufacturing and assembly operations. It

was calibrated according to your desired flow and pressure conditions for a given

gas or a mixture of gases.

It was carefully packed to prevent damage during shipment. Should you feel that

the instrument is not functioning properly, please check for the following common

conditions first:

Are all cables connected correctly? Are there any leaks in the installation? Is the

power supply correctly selected according to requirements? When several meters

are used a power supply with appropriate current rating should be selected.

Were the connector pinouts matched properly? When interchanging with other

manufacturers' equipment, cables and connectors must be carefully wired for correct pin configurations. Is the pressure differential across the instrument sufficient?

Page 39

9.2 Troubleshooting Guide

35

NO. INDICATION LIKELY REASON SOLUTION

1 No zero reading after

15 min. warm up time

and no flow condition.

Embedded temperature

has been changed.

Perform Auto Zero Procedure (see section

5.3.6 “Zero Calibration”).

2 Status LED indicator

and LCD Display

remains blank when

unit is powered up. No

response when flow is

introduced from analog

outputs 0-5 Vdc or

4-20 mA.

Power supply is bad or

polarity is reversed.

Measure voltage on pins 7 and 5 of the 15

pin D-connector. If voltage is out of

specified range, then replace power supply

with a new one. If polarity is reversed

(reading is negative) make correct

connection.

PC board is defective. Return FMA 4000 to factory for repair.

3 LCD Display reading or

/ and analog output

0-5 Vdc signal fluctuate

in wide range during

flow measurement.

Output 0-5 Vdc signal

(pins 2–1 of the

D-connector) is shorted

on the GND or

overloaded.

Check external connections to pin 2 – 1, of

the D-connector. Make sure the load

resistance is more than 1000 Ohm.

4 LCD Display reading

does correspond to the

correct flow range, but

0-5 Vdc output signal

does not change

(always the same read

ing or around zero).

Output 0-5 Vdc

schematic is burned

out or damaged.

Return FMA 4000 to factory for repair.

Analog flow output

scale and offset

variable are corrupted.

Restore original EEPROM scale and offset

variable or perform analog output

recalibration (see section 7.3).

5 LCD Display reading

and 0-5 Vdc output

voltage do correspond

to the correct flow

range, but 4-20 mA

output signal does not

change (always the

same or reading

around 4.0 mA).

External loop is open or

load resistance more

than 500 Ohm.

Check external connections to pins 2 and

15 of the D-connector. Make sure the loop

resistance is less than 500 Ohm.

Output 4-20 mA

schematic is burned

out or damaged.

Return FMA 4000 to factory for repair.

6 Calibration is off (more

than ±1.0 % F.S.).

FMA 4000 has initial

zero shift.

Shut off the flow of gas into the FMA 4000

(ensure gas source is disconnected and no

seepage or leak occurs into the meter).

Wait for 15 min. with no flow condition and

perform Auto Zero calibration Procedure

(see section 5.3.7 “Zero Calibration”).

7 LCD Display reading is

above maximum flow

range and output volt

age 0-5 Vdc signal is

more than 5.0 Vdc

when gas flows

through the FMA 4000.

Sensor under

swamping conditions

(flow is more than 10%

above maximum flow

rate for particular

FMA 4000).

Lower the flow through FMA 4000 within

calibrated range or shut down the flow

completely. The swamping condition will

end automatically.

PC board is defective. Return FMA 4000 to factory for repair.

Page 40

36

NO. INDICATION LIKELY REASON SOLUTION

8 Gas flows through the

FMA 4000, but LCD

Display reading and the

output voltage 0-5 Vdc

signal do not respond

to flow.

The gas flow is too low

for particular model of

FMA 4000.

Check maximum flow range on transducer’s

front panel and make required flow

adjustment.

FMA 4000 models:

RFE is not connected

properly to the inlet

fitting.

Unscrew the inlet compression fitting of the

meter and reinstall RFE (see section 6.2.2).

NOTE: Calibration accuracy can be affected.

Sensor or PC board is

defective.

Return FMA 4000 to factory for repair.

9 Gas does not flow

through the FMA 4000

with inlet pressure

applied to the inlet

fitting. LCD Display

reading and output

voltage 0-5 Vdc signal

show zero flow.

Filter screen obstructed

at inlet.

Flush clean or disassemble to remove

impediments or replace the filter screen

(see section 6.2).

NOTE: Calibration accuracy can be affected.

10 Gas flows through the

FMA 4000, output

voltage 0-5 Vdc signal

does not respond to

flow (reading near

1mV).

Direction of the gas

flow is reversed.

Check the direction of gas flow as indicated

by the arrow on the front of the meter and

make required reconnection in the

installation.

FMA 4000 is connected

in the installation with

back pressure

conditions and gas leak

exist in the system.

Locate and correct gas leak in the system.

If FMA 4000 has internal leak return it to

factory for repair.

11 The Status LED

indicator is rapidly

flashing with UMBER

color on /off.

Sensor temperature is

too low.

Make sure the ambient and gas

temperatures are within specified range

(above 5

F

C)

12 The Status LED

indicator is rapidly

flashing with RED color

on /off.

Sensor temperature is

too high.

Make sure the ambient and gas

temperatures are within specified range

(below 50

F

C).

13 The Status LED

indicator is rapidly

flashing with RED and

UMBER colors.

MCU temperature is too

high (overload).

Disconnect power from the FMA 4000.

Make sure the ambient temperature is with

in specified range (below 50

F

C). Let the

device cool down for at least 15 minutes.

Apply power to the FMA 4000 and check

status LED indication. If overload condition

will be indicated again the unit has to be

returned to the factory for repair.

14 The Status LED

indicator is constantly

on with the RED light.

Fatal Error (EEPROM

or Auto Zero error).

Cycle the power on the FMA 4000. If Status

LED still constantly on with RED light, wait

6 minutes and start Auto Zero function (see

5.3.7 Zero Calibration). If after Zero

Calibration the Fatal Error condition will be

indicated again the unit has to be returned

to the factory for repair.

Page 41

9.3 Technical Assistance

OMEGA7 Engineering will provide technical assistance over the phone to qualified repair personnel. Please call our Flow Department at 800-872-9436 Ext.

2298. Please have your Serial Number and Model Number ready when you call.

37

Q

O2

= Q

a

= Q

r

X K = 1000 X 0.9926 = 992.6 sccm