Page 1

(1*,1((5,1*,1&

DAQ-12

Data Acquisition Adapter

For 16 bit ISA compatible machines

Users Manual

INTERFACE CARDS FOR PERSONAL COMPUTERS

OMEGA ENGINEERING, INC. TEL: (203) 359-1660

One Omega Drive FAX: (203) 359-7700

P.O. Box 4047 Toll free: 1-800-826-6342

Stamford, CT 06907-4047 E-mail: das@omega.com

http://www.dasieee.com

Page 2

WARRANTY/DISCLAIMER

DAQ-12 Users Manual 2

OMEGA ENGINEERING, INC., warrants this unit to be free of defects in materials and workmanship fo r a period of 13

months from the date of purchase. OMEGA warranty adds an additional one (1) month grace period to the normal one (1)

year product warranty

coverage on each product. If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number im mediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge. OMEGA’s

warranty does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation o utside design limits, impr oper repair or unauthorized modif ication. This WARRANTY is

VOID if the unit shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Com ponents which wear are not warranted, including but not limited to contact

points, fuses and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products

in accordance with information provided from OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND

ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PU RPOSE ARE HEREBY D ISCLAIMED . LIMITA TION O F LIABILITY: The remedi es of purc haser set

forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.

to cover shipping and handling time. This ensures that OMEGA’s customers receive maximum

CONDITION S: Equipment so ld by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Comp onent”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity, medical application or used on humans.

Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans or

misused in any way, OMEGA assum es no respo nsibility as set forth in o ur basic WA RRAN TY/DISCLAI MER language, and

additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). THE ASSIGNED

NUMBER SHOULD THEN BE MARKED ON THE OUTSIDE OF THE RETURN PACKAGE AND ON ANY

CORRESPONDEN CE. THE PURCHASER IS RESPONSIBLE FOR SHIPPING C HARGES, FREIGHT, IN SURANCE AND

PROPER PACKAGING TO PREVENT BREAKAGE IN TRANSIT.

FOR WARRANTY

(1) P.O. Number under which the product was purchased,

(2) Model and serial number of the product under warranty, and

(3) Repair instructions and/or specific problems relative to the product.

FOR NON-WARRANTY

BEFORE contacting OMEGA:

(1) P.O. Number to cover the cost of the repair,

(2) Model and serial number of the product, and

(3) Repair instructions relative to the product.

RETURNS, please have the following information available BEFORE contacting OMEGA:

REPAIRS, consult OMEGA fo r current repair charges. Have the fo llowing information available

OMEGA’s policy is to make running changes, not model changes, whenever an improvem ent is possible. This af fords our

customers the latest in technology and engineering. OM EGA is a registered trademark of OMEGA EN GI N EERIN G, I N C. ©

Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated or reduced to any electronic medium or machine readable form , in whole or in part, without prior

written consent of OMEGA ENGINEERING, INC.

Page 3

Declaration of Conformity

DAQ-12 Users Manual 3

Manufacturer's Name: Omega Engineering, Inc.

Manufacturer’s Address: One Omega Drive

Stamford, CT 06907-0047

Application of Council Directive: 89/336/EEC

Standards to which

Conformity is Declared: * EN50081-2

(EN55022, EN60555-2, EN60555-3)

* EN50082-1

(IEC 801-2, IEC 801-3, & IEC 801-4)

Type of Equipment: Information Technology Equipment

Equipment Class: Light Industrial Equipment

Product Name: ISA Data Acquisition Card

Model Number : DAQ-12

Page 4

OMEGAnet On-line Service: Internet e-mail:

DAQ-12 Users Manual 4

http://www.omega.com

Servicing North America

: One Omega Drive, Box 4047 E-mail: info@omega.com

USA

ISO 9001 Certified

Canada

: 976 Bergar E-mail: info@omega.com

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

info@omega.com

:

For immediate technical or application assistance

USA and Canada

Mexico and Latin America

: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378/ 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

: Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espanol: (001) 203-359-7803 E-mail: espanol@omega.com

SM

:

SM

SM

Benelux

Czech Republic

France:

Germany/Austria

: Postbus 8034, 1180 LA Amstelveen, The Netherlands

: ul.Rude armady 1868, 733 01 Karvina-Hraniee

Servicing Europe

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

E-mail: nl@omega.com

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

Toll Free: 0800-1-66342 E-mail: czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

E-mail: france@omega.com

: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

E-mail: germany@omega.com

:

Page 5

United Kingdom: One Omega Drive, River Bend Technology Drive

DAQ-12 Users Manual 5

ISO 9002 Certified

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that app ly.

OMEGA is constantly pursuing certification of it’s products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc.

accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, p atient

connected applications.

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

E-mail: info@omega.co.uk

Page 6

Table of Contents

4.2 Programming the 8254 Counter/Timer

28

4.1.9 8254 Control Word/Status Register

28

4.1.8 Multi-Function Timer Register

28

4.1.7 Clock Rate Register (high word)

28

4.1.6 Clock Rate Register (low word)

28

4.1.5 D/A Converter 1 Register

28

4.1.4 D/A Converter 0 Register

27

4.1.3 A/D Converter Data Register

27

4.1.2 Start of Conversion Register

25

4.1.1 Control Word Register

4.1 Register Description

4. Register Description and Programming

3. External Connections

22

2.8.1 External Interrupt

2.8 Interrupts

2.7 Direct Memory Access

2.6 Trigger Selection

19

2.5.2 External Clock

18

2.5.1 Internal Clock

2.5 Clock Selection

2.4 Base Address

2.3 Digital Input/Output

2.2 Digital to Analog Converters

2.1 Analog to Digital Converter

2. Circuit Board Description and Configuration

1.2 DAQ-12 Specifications

1.1 Installation

1. Introduction

DAQ-12 Users Manual 6

.........................................................

........................................................

.............................................

..............

......................................

.....................................

.............................................

.....................................................

...................................................

.....................................................

....................................................

.................................................

...........................................

........................................................

.................................................

.............................................

8

8

9

10

10

14

16

16

17

20

21

22

23

.....................

..............................................

.............................................

.........................................

.......................................

...........................................

...........................................

......................................

.....................................

.......................................

...................................

............................

25

25

29

Page 7

List of Figures and Tables

25

Table 4-1. DAQ-12 Address Map

15

Table 2-3. D/A Converter Mode Selection Options

14

Table 2-2. A/D Conversion Format Examples

12

Table 2-1. Recommended Input Ranges and Gain Settings

23

Figure 3-1. 62 Pin Connector Diagram

22

Figure 2-11. Jumpers J10 and J11 Configuration

21

Figure 2-10. Jumpers J8 and J9 Configuration

20

Figure 2-9. Jumper J2 Configuration

20

Figure 2-8. Pre-Divider External Clock Pulses

19

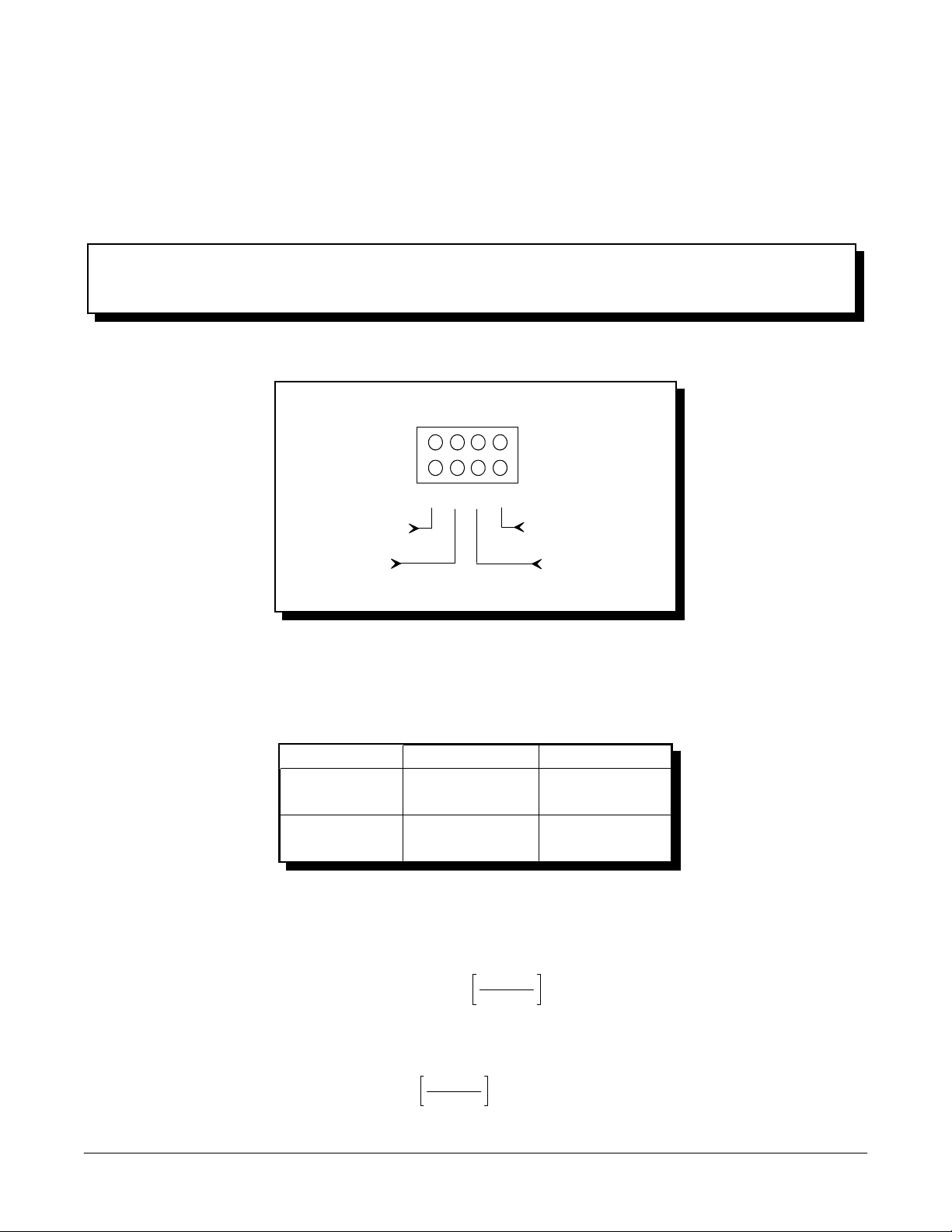

Figure 2-7. Sampling Rate External Clock Pulses

17

Figure 2-6. Jumper J3 Configuration

16

Figure 2-5. I/O Base Address Selection

14

Figure 2-4. Jumper J4 Configuration

13

Figure 2-3. Jumper J6 Configuration

11

Figure 2-2. Jumper J7 Configuration

10

Figure 2-1. Jumper J1 Configuration

.............................................

DAQ-12 Users Manual 7

.............................................

.............................................

.............................................

..........................................

.............................................

..................................

.....................................

.............................................

......................................

....................................

...........................................

....................................

................................

...............................................

.........................

Page 8

1. Introduction

The DAQ-12 is a high speed data acquisition adapter for IBM AT and compatible machines

DAQ-12 Users Manual 8

offering eight differential analog input channels with 16-bit resolution, two analog output

channels with 12-bit resolution and four digital input/output lines. Other features of the

DAQ-12 include:

Analog to Digital Converter

200 KHz maximum sampling rate

Bipolar input ranges from ±10mV to ±10 volts

Unipolar input ranges from 20mV to 10 volts

Programmable gain selection

Two DMA channels for continuous acquisition

Internal or external clock and trigger

Digital to Analog Converters

Two independent analog output channels

Output ranges of 0 to ±5 volts

Internal or external voltage reference

Two DMA channels for continuous output

Other Features

Interrupt on one of four sources including an external interrupt input

High density D-62 connector for reduced noise

1.1 Installation

1. Configure the DAQ-12 utilizing the instructions in Chapter 2: Circuit Board

Description and Configuration.

2. Ensure that power is not applied to the computer system.

3. Remove the cover according to the instructions provided by the system

manufacturer.

4. Insert the DAC-16 into any vacant ISA expansion slot. The board is secured to the

slot by installing the Option Retaining Bracket (ORB) screw.

5. Replace the system cover per manufacturer instructions.

Page 9

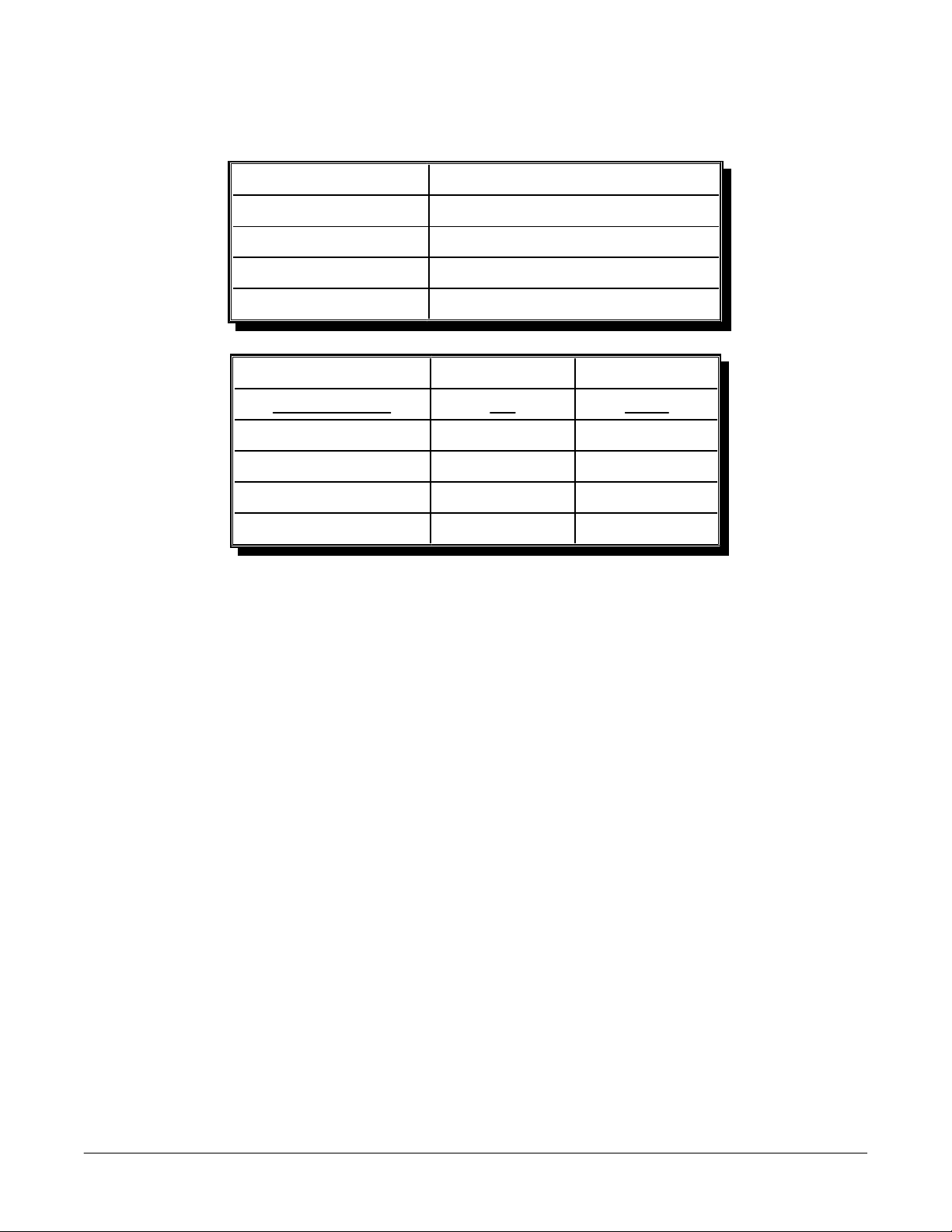

1.2 DAQ-12 Specifications

DACK 5, 6, 7

DRQ 5, 6, 7

DMA Levels:

IRQ 2, 3, 4. 5, 6, 7, 10, 11, 12, 14, 15

Interrupt Levels:

0000H - FFFFH

I/O Address Range:

ISA 16-bit

Bus Interface:

491.4mA

374.9 mA

+12 volts

---

---

-12 volts

1204.9mA

1069.0 mA

+5 volts

---

---

-5 volts

I(ms)

I(t)

Power Supply

Power Requirements:

DAQ-12 Users Manual 9

I(t) = Typical Current / I(ms) = Maximum Statisical Current

Page 10

2. Circuit Board Description and Configuration

The base address of the DAQ-12 is selected using switches SW1 and SW2. The operating

DAQ-12 Users Manual 10

mode of the DAQ-12 is controlled by jumpers J1 through J7, while DMA and interrupt

selections are set with jumpers J8 through J11. Connections to external equipment are made

through the high density 62-pin connector CN1.

2.1 Analog to Digital Converter

The analog to digital (A/D) section of the DAQ-12 accepts up to 8 differential or 16 single

ended inputs fr om the D- 62 connector. T hese inputs pa ss thr ough a multi plex er circui t whi ch

selects the channel to be converted. The selected input is then amplified and presented to the

A/D converter to b e d i g itized. T he d igital output of the A /D i s latched into a b uffer to be r ea d

by the computer. The multi plexer ci rcuit (MUX) sele cts one of the analog input channel s to be

input to the A/D converter. The typical characteristics of the multiplexer circuit are:

switching time: 0.5 us

settling time: 3.0 us

Before opera ting the DAQ-12, the multiplexer ci rcuit must be configured to accept either

differential or single-ended analog inputs. Single-ended mode measures the voltage

difference between the input signal and the analog ground reference of the DAQ-12 (e.g.

CH0+ and ground) while differential mode measures the voltage difference between two

input signals (e.g. CH0+ and CH0-).

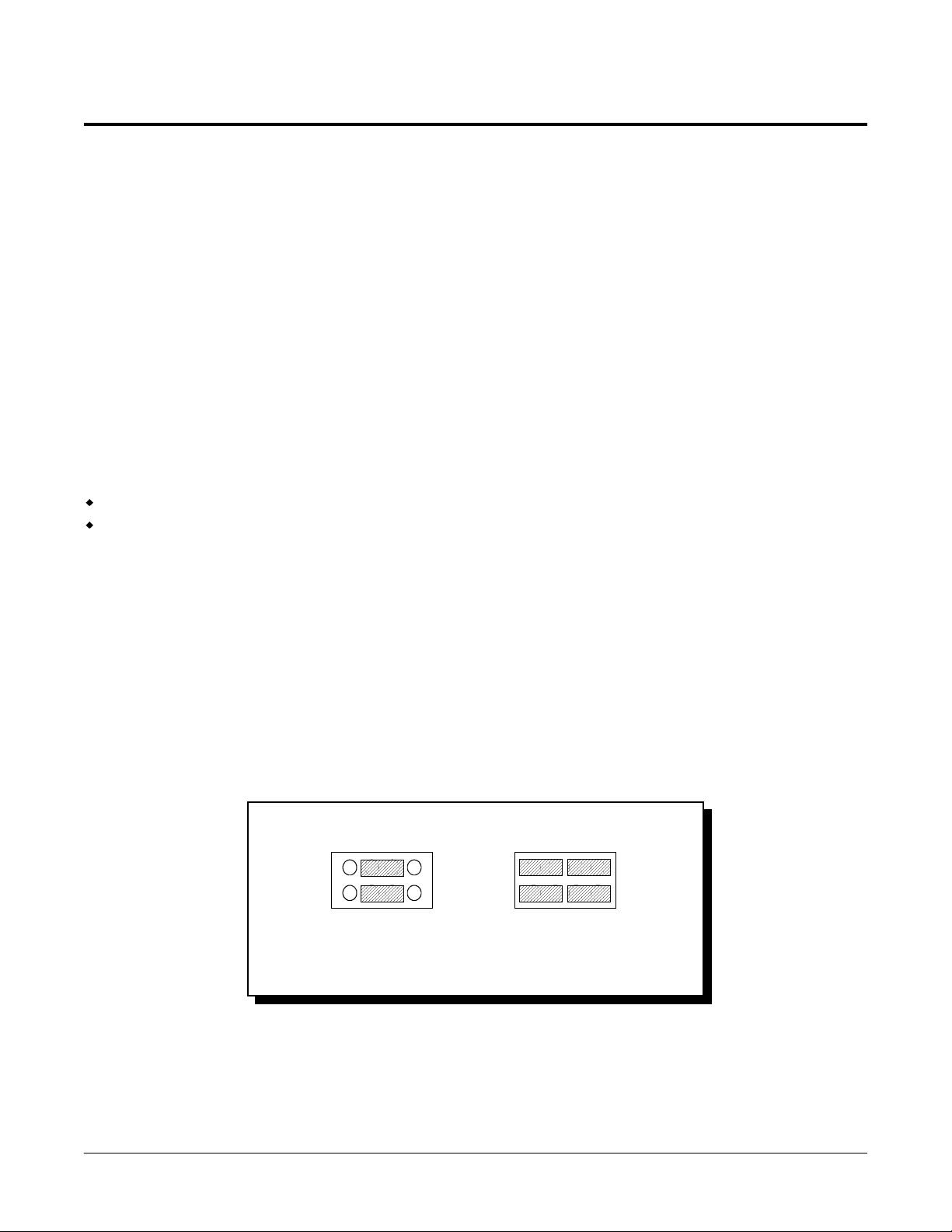

Jumper J1 is used to configure the DAQ-12 for either single ended or differential inputs a

shown in Figure 2-1. Once configured, the input channel is software selectable through the

control word register.

5 6 7 8

1 2 3 4

8 Differential Channels

Figure 2-1. Jumper J1 Configuration

J1

5 6 7 8

1 2 3 4

16 Single Ended Channels

Page 11

The amplifier stage of the A/D converter circuit performs two functions: (1) amplifies low

level input signals and (2) converts this input signal into a voltage range acceptable to the

DAQ-12 Users Manual 11

A/D converter. Seven gain levels are software selectable for the amplifier stage of the A/D

circuit. To support high level input signals, the DAQ-12 provides input gain selections of

1, 2, 4 and 8. For signals requiring greater ampl ification, the DAQ-12 provides input gains

of 1, 10, 100 and 500. The gain setting is determi ned by the value written to the gain control

register.

In order to provide a full +10 volt input range and for greater overall versatility, the

DAQ-12 is equipped with a 'divide by 2' pre-scaling circuit. With the pre-scaler enabled, the

resultant high level input gain selections become ½, 1, 2 and 4 and the low level input gain

selections become ½, 5, 50 and 250. Figure 2-2 illustrates jumper J7 (Pre-scaler) configuration

options.

NOTE: The unipolar / bipolar input selection is controlled by the A/D converter and is

selected independent of the single-ended or differential input mode configuration of the

multiplexer and amplifier circuits.

J7

Disable Pre-Scaler

(factory default)

Enable Pre-Scaler

Figure 2-2. Jumper J7 Configuration

Page 12

Table 2-1 details the available gain settings and resulting input ranges for the various

83

2-34+2.5/ ±1.25

82

2-32+5/ ±2.5

81

2-31+10/ ±5

80

2-3½N/A*/ ±10

03

2-3

250

+0.04/±0.02

02

2-350+0.2/±0.1

01

2-3

5

+2/±1

00

2-3½N/A*/±10

83

1-28+1.25/±0.625

82

1-24+2.5/±1.25

81

1-22+5/±2.5

80

1-21+10/±5

03

1-2

500

+0.02/±0.01

02

1-2

100

+0.1/±0.05

01

1-210+1/±0.5

00

1-21+10/±5

---

---

Gain

Unipolar / Bipolar

Gain Byte (HEX)

Amplifier

Maximum Input Voltage

DAQ-12 Users Manual 12

input configur ations. Note that the 'gain b yte' f iel d i n Tabl e 2-1 is the val ue wri tten to the

DAQ-12's gain control register. (* indicates unipolar mode not available with gain of

J7

½ ).

Table 2-1. Recommended Input Ranges and Gain Settings

Page 13

The final stage of the A/D converter circuit is the A/D converter IC. The converter must be

DAQ-12 Users Manual 13

configured for unipolar or bipolar input voltages as shown in Figure 2-3. When configured

for unipolar oper ation, the anal og input multi pli ed b y the gai n setting must b e in the ra nge of

0 volts (analog ground) to +10 volts. When configured for bipolar operation, the analog

input multiplied by the gain setting must be in the range of -5 volts to +5 volts.

J6

4 5 6

1 2 3

Bipolar

Figure 2-3. Jumper J6 Configuration

WARNING: The user must ensure that the maximum input voltage multiplied by the

amplifi er gain does not exce ed the range of 0 to +10 vol ts for unipolar oper ation or -5 to

+5 volts for bipolar operation.

Although the A/D converter prod uces 12-bi t digi tal 'codes' to repr esent the input vol tage, the

DAQ-12 converts these 'codes' into standard 16-bit signed integer values before returning

them to the PC. When the A/D converter is configur ed for unipolar oper ation, the DAQ-12

returns values in the range of 0 to 4095. When conf ig ured for b ipol ar operation, values in the

range of -2048 to +2047 are returned.

J6

4 5 6

1 2 3

Unipolar

In order to calcula te the actual input vol tage f rom the value pr ovide d by the D AQ-12, the user

must know the configuration (unipolar / bipolar) and the gain setting used to acquire the

data. Given this information, the input voltage can be calculated using the following

equations:

Unipolar mode: input = *

Bipolar mode: input = *

CODE

4096

CODE

2048

10V

GAIN

5V

GAIN

Page 14

n/a

0000 1111 1111 1111

10

0000 0111 1111 1111

0000 1000 0000 0000

5

0000 0100 0000 0000

0000 0100 0000 0000

2.5

0000 0000 0000 0000

0000 0000 0000 0000

0

1111 1100 0000 0000

n/a

-2.5

1111 1000 0000 0000

n/a

-5

BipolarUnipolarVoltage

DAQ-12 Users Manual 14

CodeCode

Table 2-2. A/D Conversion Format Examples

NOTE: The 'voltage' column is the voltage applied to the A/D converter. This voltage is

equivalent to the input voltage multiplied by the amplifier gain.

2.2 Digital to Analog Converters

The digital to analog (D/A) section of the DAQ-12 consists of two independent 12-bit

multiplyi ng D/A converter s, and two i ndepende nt two-stage output ampli fiers. Digi tal data,

(output to the D/A converter by the CPU), is converted to an analog voltage by the D/A

converter, ampl ified b y the output amplifie rs and becomes output to the 62 pin connector at

CN1. T he D /A converter s use d on the DA Q-12 a re 12- bi t resol ution converte rs. Of the 16 bi ts

written to the D /A, only the 12 least sig nificant bits ( D0 - D11) are used f or the conversion.

The 4 most significant bits (D12 - D15) are ignored.

The DAQ-12 implements multiplying D/A converters which makes the analog output

proportional to a reference voltage applied to the D/A. Under normal circumstances, the

reference voltage should be applied from the internal +5V reference source. An external

reference vol tag e may also be suppl i e d to the D/A. This input fr om the D - 6 2 connector should

not exceed 5 volts and has a typical input impedance of 7.5Kohms. The D/A reference voltage

source is selected using jumper J4 as illustrated in Figure 2-4.

D/A channel 0 reference

External SourceInternal Source

4 5 6

J4

1 2 3

External SourceInternal Source

D/A channel 1 reference

Figure 2-4. Jumper J4 Configuration

Page 15

The D/A conve rter channels may also b e operate d in unipol ar mod e: 0 to +5 volts, or bipolar

connect 4-8

connect 2-6

connect 3-7

connect 1-5

DAQ-12 Users Manual 15

mode: -5 to +5 volts. The output mode is selected using jumper J5 as shown in Figure 2-5. In

addition, a gain selection jumper is provided to select an output gain of 1 or 2. When using

an external voltage reference, this gain can be used to amplify the D/A output for small

reference voltages.

WARNING: When the internal voltage reference is used,the D/A gain MUST be set to the

gain = 1 position.

5 6 7 8

J5

1 2 3 4

Channel 0 select

Channel 0 gain

Channel 1 gain

Channel 1 select

Figure 2-5. Jumper J5 Configuration

Table 2-3 lists configuration options for jumper J5.

Channel 1Channel 0

Bipolar

Unipolar

open 1-5

open 3-7

Gain = 1

Gain = 2

open 2-6

open 4-8

Table 2-3. D/A Converter Mode Selection Options

When configured for unipolar operation, the output voltage can be calculated from the

equation:

A = V * * gain

out ref

CODE

4096

For bipolar operation, the equation becomes:

CODE

2048

ref

A = - 1 * V * gain

out

Page 16

2.3 Digital Input/Output

The DAQ-12 offers four bits of digital output and four bits of digital input for

DAQ-12 Users Manual 16

control/monitoring of external digital devices. The four digital output lines are LS TTL

compatible and will initialize low (0 volts) on power-up. The four digital inputs are also LS

TTL compatible. There is no termination provided on the digital input lines and a read of an

unused digital input will result in an indeterminate value.

2.4 Base Address

The DAQ-12 uses 16 consecutive I/O address locations in the range 0 to 0FFFFH. Two

six-position switches (SW1 and SW2) are used to select the base address. SW1 controls

address lines A15 - A10, and SW2 controls A9 - A4. Address lines A3 - A0 are used

internally b y the DAQ-12 to sel ect which r egister to access. When selecti ng a base add ress for

the DAQ-12, an address selection switch in the "OFF" position corresponds to an address

bit of "1" while a switch in the "ON" position corresponds to an address bit of "0". The base

address of the DAQ-12 must be set on a 16 byte boundary, meaning A3 - A0 are "0". The

address of the DAQ-12 as shipped from the factory is 0300H. This setting and other examples

are shown in the Figure 2-5.

xxxxx

x

123456

O

N

A A A A A A A A A A AA

15 14 13 12 11 10 9 8 7 6 5 4

SW1

xxxxxx

123456

O

N

SW2

03 00

0

00000 11 0000

A

123456

O

N

D

123456

O

N

123456

O

N

Example1: Base I/O Address = 0300H

6

0

11010 10 1110

123456

O

N

Example 2: Base I/O Address = 6AD0H

0000

Bit=0 Bit=1

0

xxxx Hex

0000 : 0

0001 : 1

0010 : 2

0011 : 3

0100 : 4

0101 : 5

0110 : 6

0111 : 7

1000 : 8

1001 : 9

1010 : A

1011 : B

1100 : C

1101 : D

1110 : E

1111 : F

Figure 2-5. I/O Base Address Selection

Page 17

2.5 Clock Selection

The DAQ-12 i s equipped with a prog rammable clock circuit to produce data sampling r ates

DAQ-12 Users Manual 17

independent from the clock rate of the host computer. An onboard 8254 programmable

interval timer, with a 10 MHz clock input and either two or three cascaded 16-bit timers,

provides the sampl ing rate. T his enabl es the sampling rate to be adjusted f rom 5 us between

samples to almost a year between samples, in as small as 100ns increments.

The DAQ-12's sampling rate can al so b e generated from an external clock input. This external

clock can be connected directly to the A/D converter or through a 16-bit pre-divider, the

multi-function timer. Samples are taken on the low to high transition of the clock.

WARNING: For the DAQ-12, the maximum data sampling rate is 5us. This restricts

clock frequency to a maximum of 200 KHz. Sampling rates in excess of 200 KHz may

result in erratic operation and unpredictable results.

The clock source, internal or external clock, is software selectable through the DAQ-12's

control word register. The configuration of the clock source itself is controlled by jumper block

J3 as shown in Figure 2-6, (* indicates factory default).

J3

5 6 7 8

1 2 3 4

Figure 2-6. Jumper J3 Configuration

Internal Timer: 2 timers cascaded

connect 1-2, 4-8, 6-7*

3 timers cascaded

connect 1-5, 2-6, 7-8

External Timer: w/o pre-divider

connect 1-2, 3-7, 4-8

with pre-divider

connect 1-5, 2-3, 7-8

Page 18

2.5.1 Internal Clock

Sampling rates for the internal clock can be calculated using the following equation:

DAQ-12 Users Manual 18

t = 100ns * [N1*N2] or

f = 10MHz / [N1*N2]

where N1 is the low 16-bits of the clock divider and N2 is the high 16-bits of the clock

divider. The following criteria must be met when selecting values for N1 and N2:

2 < N1 < 65,535

2 < N2 < 65,535

N1 * N2 > 50

Using the equations above, the minimum and maximum data sampli ng rates for the internal

clock can be calculated.

Maximum sampling rate: Minimum Sampling Rate:

N1 = 2, N2 = 25 N1 = 65535, N2 = 65535

t = 100 x 10 * [(2)*(25)] t = 100 x 10 * [(65535)*(65535)]

t = 100 x 10 * 50 t = 100 x 10 * [4.295 x 10 ]

−9 −9

−9 −99

t = 5 us t = 429.5 sec

f = 10 x 10 / [(2)*(25)] f = 10 x 10 / [(65535)*(65535)]

f = 10 x 10 / 50 f = 10 x 10 / [4.295 x 10 ]

66

669

f = 200 Khz f = 2.328 mHz

If extremely slow data sampling rates are needed, the third 8254 timer, the multi-function

timer, can be cascaded with the other two to produce a 48-bit clock divider. The sampling

rates are then calculated as follows:

t = 100ns * [N1*N2*N3] or

f = 10MHz / [N1*N2*N3]

where N1 is the low 16-bits of the clock divider, N2 is the intermediate 16-bits of the clock

divider, and N3 is the high 16-bits of the divider. The following criteria must be met when

selecting values for N1, N2, and N3:

2 < N1 < 65,535

2 < N2 < 65,535

2 < N3 < 65,535

N1 * N2 * N3 > 50

Page 19

When configured for a 48-bit divider, the first sampling period will be slightly longer than

the others because the first clock period is required to load the initial value of the

DAQ-12 Users Manual 19

multi-function timer. The following equation calculates the additional time of the first period:

t = 100ns * [N1 * N2]

add

To minimize the amount of additional time required for the first sample, select clock dividers

such that N1 and N2 are as small as possible and N3 is as large as possible. Using the

equations above, the minimum and maximum data sampling rates and the amount of

additional time required for the first sample can be calculated.

Maximum sampling rate: Minimum sampling rate:

N1 = 2, N2 = 5, N3 = 5 N1 = 65535, N2 = 65535, N3 = 65535

t = 100 x 10 * [(2)*(5)*(5)] t = 100 x 10 * [(65535)*(65535)*(65535)]

t = 100 x 10 * 50 t = 100 x 10 * [2.815 x 10 ]

t = 5 us t = 28.146 x 10 sec

−9 −9

−9 −914

6

t = 325 days, 18 hours, 23 minutes, 29 sec

f = 10 x 10 / [(2)*(5)*(5)]

f = 10 x 10 / 50 f = 10 x 10 / [(65535)*(65535)*(65535 )]

f = 200 Khz f = 10 x 10 / [2.815 x 10 ]

6

66

614

f = 35.529 nHz

t = 100 x 10 * [2 * 5] t = 100 x 10 * [65535 * 65535]

add

t = 100 x 10 * 10 t = 100 x 10 * [4.295 x 10 ]

t = 1 us t = 429.5 sec

add

add add

−9

−9

add

add

−9

−99

2.5.2 External Clock

The external cl ock input to the DAQ-12 is a TTL level (0 - 5 volt) signal. This input may be

used to control the sampling rate directly, or it may be fed through a pre-divider (the

multi-function timer) with the timer output controlling the A/D sampling rate. When used to

control the sampling rate directly, the frequency of the external clock input may be varied

from DC to 100 KHz as long as the width of the low and high portions of the clock are a

minimum of 1 us each. The A/D conversion cycle will begin on each rising edge of the

external clock input. (See Figure 2-7).

1 usec min 1 usec min

5 usec

min

Figure 2-7. Sampling Rate External Clock Pulses

Page 20

When the multi-function timer is used as a pre-divider, the frequency of the external clock

input may b e varied from DC to 10 MHz as long as the high portion of the cl ock is at least

DAQ-12 Users Manual 20

30ns and the low portion i s at least 50ns. Except for the fi rst period, the sampli ng rate of the

DAQ-12 will be the external clock frequency divided by the count value written to the

multi-functi on timer. Si nce one clock pul se is requi red to load the initi al count val ue into the

timer, the first sampling interval will be one clock cycle longer than the rest. The valid range

of count values for the multi- function timer is 2 < count < 65,535 but the resulting sampling

rate must be less than 200KHz to assure proper operation of the A/D converter circuitry.

(See Figure 2-8).

30 nsec min 50 nsec min

100 nsec

min

Figure 2-8. Pre-Divider External Clock Pulses

2.6 Trigger Selection

The DAQ-12 is capable of accepting an internal software trigger or an external hardware

trigger. The trigger selection and trigger level bits in the DAQ-12 control word register select

the trigger source and level. Upon reset, the trigger selection and trigger level bits default to

the internal software trigger. When the internal trigger is used, an output to the

start-of-conversion register will trigger the DAQ-12 to begin sampling the input. For

triggering off an external event, the DAQ-12 accepts a level sensitive, TTL compatible trigger

input from the D-62 connector. The trigger level bit in the DAQ-12 control word register

determines which TTL level is used to trigger the A/D converter to begin sampling.

When an internal clock source is used, a delay of not more than 225ns will occur between the

trigger and the first data sample. When an external clock is used, the delay will be dependent

on the freque ncy and d uty cycl e of the clock i nput. I f these de lays ar e unacceptabl e, the cl ock

and trigger circuitry can be bypassed and a start of conversion pulse can b e input directly

into the A/D circuitry with a maximum delay of 25ns. If the user controls the start of

conversion pulse directly, the sample will be taken on the low to high transition of the pulse,

the pulse must have a dur ation of at least 5 us, and the d uty cycl e must be b etween 5 and 80

percent. Jumper J2, shown in Figure 2-9, configures start of conversion control.

J2

Start of Conversion:

(* indicates factory default)

DAQ-12 controlled: connect 1-2*

1 2 3

Figure 2-9. Jumper J2 Configuration

User controlled: connect 2-3

Page 21

2.7 Direct Memory Access

Direct Memory Access (DMA) transfers provide a way of transferring data from the

DAQ-12 Users Manual 21

DAQ-12's A/D converter into the personal computer's memory without using the Central

Processing Unit (CPU). DMA capability enables other system software to be executed while

data is being input from the DAQ-12.

The DAQ-12 actually implements two DMA channels. The advantage of having two DMA

channels is that one channel can be transferring data while the second channel is being

programmed. When the first channel is finished, the second channel will automatically take

over and continue the data transfer. The fi rst channel can then be re-prog rammed while the

second channel is transferring data. In this way, the DAQ-12 can acquire data continuously

until terminated by the user.

The DAQ-12 supports 16-bit DMA transfers on channels 5, 6, and 7. The DMA channel(s)

are selected by jumpers J8 and J9 as shown in Figure 2-10.

DMA Cha nnel 1 DMA Cha nnel 2

J8

DRQ7

DACK7

DRQ6

DACK6

DRQ5

DACK5

J9

DRQ7

DACK7

DRQ6

DACK6

DRQ5

DACK5

Figure 2-10. Jumpers J8 and J9 Configuration

WARNING: To properly implement the DMA capability, the DRQ and DACK of each

DMA channel must be jumpered to the same number, i.e. DRQ 5/DACK 5. If both DMA

channels are to be used, each channel must be jumpered to a different number, i.e.

channel 1 is jumpered to DRQ 5 /DACK 5 and channel 2 is jumpered to DRQ

7/DACK 7.

Page 22

2.8 Interrupts

DAQ-12 Users Manual 22

The DAQ-12 is capable of generating an interrupt from one of four sources:

1. End of conversion signal

2. DMA terminal count

3. Multi-function timer output

4. External interrupt input

The interrupt source is software selected through the DAQ-12 control word register. The

interrupt level is selected using the jumpers J10 and J11 as shown in Figure 2-11.

J10

IRQ 14

IRQ 15

IRQ 12

IRQ 11

IRQ 10

IRQ 3

IRQ 2

IRQ 4

IRQ 5

IRQ 6

J11

IRQ 7

Factory default = IRQ 5

Figure 2-11. Jumpers J10 and J11 Configuration

2.8.1 External Interrupt

The external interrupt is a TTL compatible input from the D-62 connector. An interrupt

request is generated on a high to low transition of this input.

Page 23

3. External Connections

The DAQ-12 is equipped with a high density 62-pin connector as shown in Figure 3-1.

DAQ-12 Users Manual 23

2 - CH1+

4 - CH2- (CH10+)

6 - CH4+

8 - CH5- (CH13+)

10 - CH7+

12 - AOUT0

14 - DOUT0

6 - DOUT3

18 - EXT TRIG

20 - DIN1

22 - CH0+

24 - CH1- (CH9+)

26 - CH3+

28 - CH4- (CH12+)

30 - CH6+

32 - CH7- (CH15+)

34 - AOUT1

36 - DOUT1

38 - EXT INT

40 - DIN3

42 - DIN0

43 - CH0- (CH8+)

45 - CH2+

47 - CH3- (CH11+)

49 - CH5+

51 - CH6- (CH14+)

53 - VREF0

55 - VREF1

57 - DOUT2

59 - EXT CLK

61 - DIN2

1

2

4

10

11

12

13

14

15

16

17

18

19

20

21

22

43

23

44

24

26

27

28

30

31

32

33

34

36

37

40

25

29

35

38

39

41

42

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

3

5

6

7

8

9

Figure 3-1. 62 Pin Connector Diagram

Analog Ground - 1, 3, 5, 7, 9, 11, 13, 44, 46, 48, 50, 52, 54

Digital Ground - 15, 17, 19, 21, 37, 39, 41, 56, 58, 60, 62

Page 24

CHx-, CHx+ : Analog inputs to the analog to digital converter. When using differential input

DAQ-12 Users Manual 24

mode, eight input channels are available (CH0+ to CH7+). When using single-ended

inputs, 16 channels are available (CH0+ to CH15+). The first eight channels are input

through the connections marked CH0+ to CH7+ and the second ei ght channels through CH 0to CH7-.

AOUT0, AOUT1: Analog outputs from the digital to analog converters. Polarity and

maximum amplitude depend on the jumper settings and voltage references. Output

resistance of the analog outputs is typically 70 ohms.

VREF0, VREF1: External voltage references for the digital to analog converters. Input range is

0 to 5.0 volts with a no-load input resistance of 7.5 Kohms typical.

EXT CLK, EXT TRG, EXT INT: External clock, trigger, and interrupt inputs respectively.

Inputs are TTL compatible.

DOUT0, DOUT1, DOUT2, DOUT3: TTL compatible digital output lines.

DIN0, DIN1, DIN2, DIN3: TTL compatible input lines.

Page 25

4. Register Description and Programming

The DAQ-12 uses 16 consecutive I/O address locations in the range 0 to FFFFH. The card

Read/Write 8-bit 8254 Control Word/Status Register

Base F *

Read/Write 8-bit Multi-function Timer Register

Base E *

Read/Write 8-bit Clock Rate Register (high)

Base + D *

Read/Write 8-bit Clock Rate Register (low)

Base + C *

Reserved

Base A, B

Read/Write 8-bit Gain Control Register

Base 9

Read/Write 8-bit Digital Input/Output Register

Base + 8

Write only 16-bit D/A Channel 1 Register

Base + 6, 7

Write only 16-bit D/A Channel 0 Register

Base + 4, 5

Write only 16-bit Start Conversion Register

Base + 2, 3

Read/Write 16-bit Control Word Register

Base + 0, 1

DAQ-12 Users Manual 25

utilizes these addresses for the registers listed in Table 4-1. (* indicates registers located in

8254 counter).

Read only 16-bit A/D Data Register

Table 4-1. DAQ-12 Address Map

4.1 Register Description

4.1.1 Control Word Register

The control word register defines and controls many of the DAQ-12'S data conversion

functions. This register is 16-bit read/write.

Write Read Write Read

D15 INT2 INT2 D7 RUN RUN

D14 INT1 INT1 D6 0 EOC

D13 INT0 INT0 D5 0 VALID

D12 DMAEN DMAEN D4 DMASL DMASL

D11 DMACT DMACH D3 CHSL3 CHSL3

D10 LEVEL LEVEL D2 CHSL2 CHSL2

D9 TRIG TRIG D1 CHSL1 CHSL1

D8 CLK CLK D0 CHSL0 CHSL0

Page 26

INT2, INT1 and INT0 control the DAQ-12 interrupt source.

DAQ-12 Users Manual 26

DMAEN - enables / disables DMA. When set, logic 1, DMA transfers are enabled.

DMACT - enables the multi-channel DMA capability of the DAQ-12. When set, logic 1, a

terminal count on the active D MA channel causes DMA transfers to begi n on the "stand-by"

channel. When cleared, logic 0, DMA transfers halt when the terminal count is reached on

the active channel.

DMACH - indicates which of the DAQ-12'S DMA channels is currently active to transfer

data. Logic 0 indicates DMA channel 0, logic 1 indicates DMA channel 1.

DMASL - When using differential input mode, eight input channels are available (CH0+

through CH7+). When using single-ended i nputs, 16 channels are avai l abl e ( CH0+ through

CH15+). Th e first eight channels are i nput through the connections marked CH0+ throug h

CH7+ and the second eight channels through CH0- through CH7-.

INT2 INT1 INT0 DESCRIPTION

0 0 0 Interrupt disabled

1 0 0 Interrupt timer 2

1 0 1 Interrupt on terminal count

1 1 0 External interrupt

1 1 1 Interrupt on end of conversion

LEVEL - selects the edge of the external trigger input. When set, logic 1, A/D conversions

will begin on the falling edge of the external trigger input. When cleared, logic 0,

conversions will begin on the rising edge of the external trigger. IMPORTANT: LEVEL

must be logic 0 when internal triggering is used.

TRIG - selects betwee n internal a nd e x ter n al trigger s. When set, log ic 1, the e xte r na l tr igger

is selected.

CLK - sel ects between internal and external clock sources. When set, logic 1, the external

clock source is selected.

RUN - when set, logic 1, the A/D converter is placed in the 'run' mode and will begin

converting data when a trigger is received. RUN may be cleared at any time by writing a

"0" to it. When using DMA transfers, RUN is automatically cleared when a terminal count is

received with DMACT set to "0".

EOC - when set, indicates an end of conversion has taken place and the data is available in

the A/D converter data register.

Page 27

VALID - when set, logic 1, indicates at least one data sample was lost because it was read by

DAQ-12 Users Manual 27

the personal computer before the next sample was converted. Data was lost because the

sampling ra te was too fast for the computer to acquire the data. VA LID is reset b y writi ng to

the start conversion register.

CHSL2, CHSL1, CHSL0 - select the multiplexer channel for the analog input signal. (*

denotes only available in single ended input mode).

CHSL3 CHSL2 CHSL1 CHSL0 MUX channel

0000channel 0

0001channel 1

0010channel 2

0011channel 3

0100channel 4

0 1 0 1 channel 5

0110channel 6

0111channel 7

1000channel 8*

1001channel 9*

1010channel 10*

1011channel 11*

1100channel 12*

1101channel 13*

1110channel 14*

1111channel 15*

4.1.2 Start of Conversion Register

The start of conversion register is 16-bit write only and performs two functions:

1. When configured for internal triggering, writing a "0" to this register generates the

software trigger, starting the data conversion process.

2. Writing a "0" to this register at any time resets the VALID bit in the control word

register. This allow s the VALID b it to be reset at any ti me duri ng the conversion

process or before the event of an external trigger.

4.1.3 A/D Converter Data Register

An input to this register return s the last digital value converted by the A/D converter. T his

register is 16-bit read only.

Page 28

4.1.4 D/A Converter 0 Register

An output to this register causes the lower twelve bits of data to be converted to an analog

DAQ-12 Users Manual 28

output on D/A converter channel 0. The four most significant bi ts of data are i gnored. This

register is 16-bit write only.

4.1.5 D/A Converter 1 Register

An output to this register causes the lower twelve bits of data to be converted to an analog

output on D/A converter channel 1. The f our most signif icant bits of d ata are ig nored. Thi s

register is 16-bit write only.

The remaining four registers are contained in an 8254 counter/timer.

4.1.6 Clock Rate Register (low word)

The low word of the clock divider is contained in counter 0 of an 8254 counter/timer. The

output of this counter i s cascaded i nto the input of counter 1 to pr oduce a 32- bit time r. Mode

2 must be selected for counter 0 with a minimum count of 2. This register is 8-bit read/write.

4.1.7 Clock Rate Register (high word)

The high word of the clock divi der is contained in counter 1 of the 8254 counter/timer. Mode

2 must be selected for counter 1 with a minimum count of 2. This register is 8-bit read/write.

4.1.8 Multi-Function Timer Register

The multi-function timer is i mplemented using counter 2 of the 8254 counter/timer. Mode

2 must be selected for this timer with a minimum count of 2. This register is 8-bit

read/write.

4.1.9 8254 Control Word/Status Register

This register is used to program the mode and report the status of the 8254 counter/timer.

This register is 8-bit read/write.

Page 29

4.2 Programming the 8254 Counter/Timer

This section provides programming information for the 8254 counter/timer as implemented

DAQ-12 Users Manual 29

on the DAQ-12. For more details on the 8254, consult the Intel Micro-processor and Peripheral

Handbook.

To program any of the counters contained in the 8254 counter/timer, three steps are required:

1. Write the configuration by te to the 8254 mode select/status register. This byte sets

the operating mode of the selected counter.

2. Write the least significant byte of the count value to the selected counter register.

3. Write the most significant byte of the count value to the selected counter register.

The following examples illustrate the programming sequence for each of the counters in the

8254. The variable 'base_address' is the base add ress of the DAQ-12 as defined by the address

selection switches.

Counter 0 - Clock rate register (low word)

operating mode: 2

minimum count value: 2

configuration byte: 0 / 0 / 1 / 1 / 0 / 1 / 0 / 0 = 34H

Example: Program the value 2675H into the low word of the clock rate register.

output 34H to base_address + 0FH

output 75H to base_address + 0CH

output 26H to base_address + 0CH

Example: Program the value 0008H into the low word of the clock rate register.

output 34H to base_address + 0FH

output 08H to base_address + 0CH

output 00H to base_address + 0CH

Page 30

Counter 1 - Clock rate register (high word)

operating mode: 2

DAQ-12 Users Manual 30

minimum count value: 2

configuration byte: 0 / 1 / 1 / 1 / 0 / 1 / 0 / 0 = 74H

Example: Program the value 13A4H into the high word of the clock rate register.

output 74H to base_address + 0FH

output A4H to base_address + 0DH

output 13H to base_address + 0DH

Example: Program the value FFFFH into the high word of the clock rate register.

output 74H to base_address + 0FH

output FFH to base_address + 0DH

output FFH to base_address + 0DH

Counter 2 - Multi-function timer register

operating mode: 2

minimum count value: 2

configuration byte: 1 / 0 / 1 / 1 / 0 / 1 / 0 / 0 = B4H

Example: Program the value 000AH into the multi-function timer register.

output B4H to base_address + 0FH

output 0AH to base_address + 0EH

output 00H to base_address + 0EH

Example: Program the value 0100H into the multi-function timer register.

output B4H to base_address + 0FH

output 00H to base_address + 0EH

output 01H to base_address + 0EH

Page 31

DAQ-12 Users Manual

Version 2.20

January 28, 1999

Part No. 940-0030-220

Loading...

Loading...