Page 1

User’s Guide

USA

MADE IN

www.omega.com

e-mail: info@omega.com

iSeries info:

www.omega.com/specs/iseries

Temperature & Process Controller Manual

CNi8, CNi8C, CNi8DH, CNi8DV,

CNi16, CNi16D, CNi32

Shop on line at

Page 2

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark

to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

!

This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or

commissioning this device as the guide contains important information relating to safety and EMC.

®

®

OMEGAnet® On-Line Service

www.omega.com

Internet e-mail

info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada:; 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

Mexico and TEL: (001)800-TC-OMEGA® FAX: (001) 203-359-7807

Latin American: En Espa

e-mail: espanol@omega.com

ñol: (001) 203-359-7803

®

®

®

Servicing Europe:

Czech Republic: Frystatska 184, 733 01 Karviná

TEL: +420 59 6311899 FAX: +420 59 6311114

e-mail: info@omegashop.cz

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 7056 9398-0 FAX: +49 7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive

ISO 9002 Certified River Bend Technology Centre

Northbank, Irlam Manchester M44 5BD United Kingdom

TEL: +44 161 777 6611 FAX: +44 161 777 6622

Toll Free in England: 0800 488 488

e-mail: sales@omega.co.uk

Page 3

TABLE OF CONTENTS

Part 1: Introduction............................................................................................2

1.1 Description .................................................................................2

1.2 Safety Considerations ...............................................................3

1.3 Before You Begin .......................................................................4

Part 2: Setup.......................................................................................................5

2.1 Front Panel .................................................................................6

2.2 Rear Panel Connections............................................................7

2.3 Electrical Installation .................................................................7

2.3.1 Power Connections........................................................7

2.3.2 Thermocouple - Input Connection................................8

2.3.3 Two / Three / Four Wire RTD-Hookups.........................9

2.3.4 Process Current - Wiring Hookup...............................10

2.3.5 Process Voltage - Wiring Hookup...............................10

2.3.6 Wiring Outputs - Wiring Hookup.................................11

2.3.7 Dual Display Color Setup ............................................13

Part 3: Operation: Configuration Mode .........................................................14

3.1 Introduction ..............................................................................14

Turning your Instrument On for the First Time

Buttons Functions in Configuration Mode

3.2 Menu Configuration ................................................................15

3.2.1 ID Number .....................................................................16

3.2.2 Setpoints.......................................................................17

3.2.3 Configuration Menu ....................................................18

3.2.4 Input Type Menu ...........................................................18

Input Type (Thermocouple) ........................................19

Input Type (RTD)...........................................................20

Input Type (Process) ...................................................21

3.2.5 Reading Configuration Menu .....................................21

3.2.6 Alarm 1 Menu ...............................................................25

3.2.7 Analog Output (Retransmission) Menu......................29

3.2.8 Alarm 2 Menu................................................................32

3.2.9 Loop Break Time Menu/Field Calibration...................33

3.2.10 Output 1 Menu ..............................................................35

3.2.11 Output 2 Menu ..............................................................42

3.2.12 Ramp and Soak Menu ..................................................45

3.2.13 ID Code Menu ...............................................................47

3.2.14 Communication (Options) Menu.................................49

3.2.15 Display Color Selection Menu.....................................55

Part 4: Specifications ......................................................................................58

Part 5: Factory Preset Values.........................................................................62

Part 6: CE APPROVAL INFORMATION...........................................................64

i

Page 4

LIST OF FIGURES:

Figure 2.1 Front Panel Display..............................................................................5

Figure 2.2 Rear Panel Power and Output Connector Labels..............................6

Figure 2.3 Rear Panel Input Connector Labels....................................................6

Figure 2.4 Main Power Connections.....................................................................7

Figure 2.5 Thermocouple Wiring Hookup ............................................................8

Figure 2.6 Two/Three/Four-wire RTD

a) RTD-1000 ohm and 500 ohm Wiring Hookup ..............................9

b) RTD-100 ohm Wiring Hookup .......................................................9

Figure 2.7 Process Current Wiring Hookup

(Internal and External Excitation) .....................................................10

Figure 2.8 Process Voltage Wiring Hookup

a) Without Sensor Excitation ..........................................................10

b) With Sensor Excitation................................................................10

Figure 2.9 Output Connections:

a) Mechanical Relay and SSR Outputs – Wiring Hook up ............11

b) Pulse and Analog Outputs – Wiring Hook up............................11

Figure 2.10 Typical Application .............................................................................11

Figure 2.11 Communication Output:

a) RS-232 Output – Wiring Hook up ...............................................12

b) RS-485 Output – Wiring Hook up ...............................................12

Figure 2.12 Excitation Output................................................................................12

Figure 2.13 Snubber Circuits Wiring Hookup ......................................................12

Figure 2.14 i/8DH and i/8DV Locations of S1 and Jumper Positions ................13

Figure 2.15 i/16D Location of S1 and Jumper Positions ....................................13

Figure 3.1 Flow Chart for ID and Setpoints........................................................15

Figure 3.2 Flow Chart for Configuration Menu ..................................................18

Figure 3.3 Flow Chart for Input Type Menu ........................................................18

Figure 3.4 Flow Chart for Reading Configuration .............................................21

Figure 3.5 Flow Chart for Alarm 1.......................................................................25

Figure 3.6 Flow Chart for Analog Output (Retransmission).............................29

Figure 3.7 Flow Chart for Alarm 2.......................................................................32

Figure 3.8 Flow Chart for Loop Break Time/Field Calibration..........................33

Figure 3.9 Flow Chart for Output 1 .....................................................................35

Figure 3.10 Flow Chart for Output 2 .....................................................................42

Figure 3.11 Flow Chart for Ramp and Soak .........................................................45

Figure 3.12 Flow Chart for ID Code.......................................................................47

Figure 3.13 Flow Chart for Communication Option ............................................49

Figure 3.14 Flow Chart for Display Color Selection............................................55

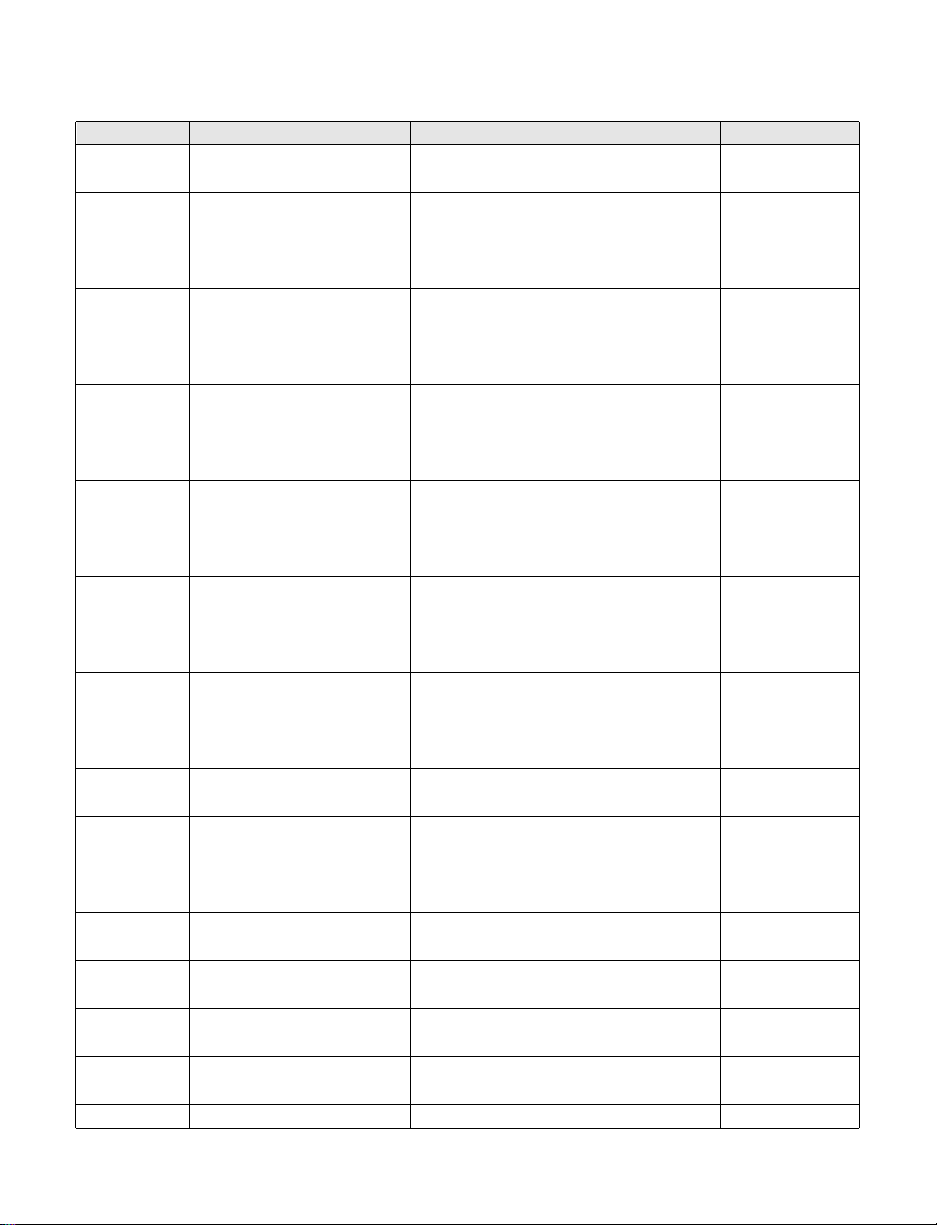

LIST OF TABLES:

Table 2.1 Front Panel Annunciators....................................................................5

Table 2.2 Rear Panel Connector..........................................................................6

Table 2.3 Fuse Requirement ................................................................................7

Table 2.4 TC Wire Color Chart .............................................................................8

Table 3.1 Button Function in Configuration Mode...........................................14

Table 3.2 Conversion Table................................................................................24

Table 4.1 Input Properties..................................................................................61

Table 5.1 Factory Preset Values........................................................................62

ii

Page 5

NOTES, WARNINGS and CAUTIONS

Information that is especially important to note is identified by following labels:

• NOTE

• WARNING or CAUTION

• IMPORTANT

• TIP

NOTE: Provides you with information that is important to successfully

setup and use the Programmable Digital Meter.

CAUTION or WARNING: Tells you about the risk of electrical shock.

CAUTION, WARNING or IMPORTANT: Tells you of circumstances or

practices that can effect the instrument’s functionality and must refer

to accompanying documents.

TIP: Provides you helpful hints.

1

Page 6

PART 1

INTRODUCTION

1.1 Description

This device can be purchased as monitor (read process value only) or as

a controller.

• The iSeries controller offers unparalleled flexibility in process measurement.

Each unit allows the user to select the input type, from 10 thermocouple

types (J, K, T, E, R, S, B, C, N and J DIN), Pt RTDs (100, 500 or 1000 Ω,

with either 385 or 392 curve), DC voltage, or DC current. The voltage/current

inputs are fully scalable to virtually all engineering units, with selectable

decimal point, perfect for use with pressure, flow or other process input.

• The temperature control can be achieved by using on/off or PID heat/cool

control strategy. Control can be optimized with an auto tune feature. The

instrument offers a ramp to setpoint with timed soak period before switching

off the output.

• The iSeries device features a large, three color programmable display with

capability to change a color every time the Alarm is triggered. The standard

features include dual outputs with relay, SSR, dc pulse, analog voltage or

current. Options include programmable RS-232 or RS-485 serial

communication and excitation. Analog Output is fully scalable and may be

configured as a proportional controller or retransmission to follow your

display. Universal power supply accepts 90 to 240 Vac. Low voltage power

option accepts 24 Vac or 12 to 36 Vdc.

2

Page 7

1.2 Safety Considerations

This device is marked with the international caution symbol. It is important

to read this manual before installing or commissioning this device as it

contains important information relating to Safety and EMC

(Electromagnetic Compatibility).

This instrument is a panel mount device protected in accordance with

EN 61010-1:2001, electrical safety requirements for electrical equipment

for measurement, control and laboratory. Installation of this instrument

should be done by qualified personnel. In order to ensure safe operation,

the following instructions should be followed.

This instrument has no power-on switch. An external switch or circuitbreaker shall be included in the building installation as a disconnecting

device. It shall be marked to indicate this function, and it shall be in close

proximity to the equipment within easy reach of the operator. The switch or

circuit-breaker shall meet the relevant requirements of IEC 947–1 and

IEC 947-3 (International Electrotechnical Commission). The switch shall

not be incorporated in the main supply cord.

Furthermore, to provide protection against excessive energy being drawn

from the main supply in case of a fault in the equipment, an overcurrent

protection device shall be installed.

• Do not exceed voltage rating on the label located on the top of the

instrument housing.

• Always disconnect power before changing signal and power

connections.

• Do not use this instrument on a work bench without its case for safety

reasons.

• Do not operate this instrument in flammable or explosive atmospheres.

• Do not expose this instrument to rain or moisture.

• Unit mounting should allow for adequate ventilation to ensure

instrument does not exceed operating temperature rating.

• Use electrical wires with adequate size to handle mechanical strain

and power requirements. Install without exposing bare wire outside the

connector to minimize electrical shock hazards.

EMC Considerations

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wires close to the instrument if EMC

problems persist.

Failure to follow all instructions and warnings may result in injury!

3

Page 8

1.3 Before You Begin

Inspecting Your Shipment:

Remove the packing slip and verify that you have received everything

listed. Inspect the container and equipment for signs of damage as soon

as you receive the shipment. Note any evidence of rough handling in

transit. Immediately report any damage to the shipping agent. The carrier

will not honor damage claims unless all shipping material is saved for

inspection. After examining and removing the contents, save the packing

material and carton in the event reshipment is necessary.

Customer Service:

If you need assistance, please call the nearest Customer Service

Department, listed in this manual.

Manuals, Software:

The latest Operation and Communication Manual as well as free

configuration software and ActiveX controls are available from

the

website listed in this manual or on the CD-ROM enclosed with your

shipment

.

For first-time users: Refer to the QuickStart Manual for basic operation

and set-up instructions.

If you have the Serial Communications/Ethernet Option you can easily

configure the controller on your computer or on-line.

To Disable Outputs:

To ensure that menu changes are properly stored, Standby Mode should

be used during setup of the instrument. During Standby Mode, the

instrument remains in a ready condition, but all outputs are disabled.

Standby Mode is useful when maintenence of the system is necessary.

When the instrument is in "RUN" Mode, push d twice to disable all

outputs and alarms. It is now in "STANDBY" Mode. Push d once more

to resume "RUN" Mode.

PUSH d TWICE to disable the system during an EMERGENCY.

To Reset the Meter:

When the controller is in the "MENU" Mode, push c once to direct

controller one step backward of the top menu item.

Push c twice to reset controller, prior to resuming "Run" Mode except

after "Alarms", that will go to the "Run" Mode without resetting the

controller.

4

Page 9

PART 2

SETUP

2.1 Front Panel

Figure 2.1 Front Panel Display

Table 2.1 Front Panel Annunciators

1 Output 1/Setpoint 1/ Alarm 1 indicator

2 Output 2/Setpoint 2/ Alarm 2 indicator

°C °C unit indicator

°F °F unit indicator

PV Upper Display shows the Process Value

SV Lower Display shows the Setpoint 1 Value

a

Changes display to Configuration Mode

and advances through menu items*

b

Used in Program Mode and Peak Recall*

c

Used in Program Mode and Valley Recall*

d

Accesses submenus in Configuration Mode

and stores selected values*

* See Part 3 Operation: Configuration Mode

The Dual Display model allows the user to observe the Process Value

(upper display) and Setpoint 1 Value (lower display) at the same time.

5

Refer to the Quick Start

Guide for assembly and

disassembly instructions.

Page 10

2.2 Rear Panel Connections

The rear panel connections are shown in Figures 2.2 and 2.3.

Figure 2.2 Rear Panel Power and Output Connections

Figure 2.3 Rear Panel Input Connections

Table 2.2 Rear Panel Connector

POWER AC/DC Power Connector: All models

INPUT

Input Connector:

All models TC, PR (Process), RTD

OUTPUT 1 Based on one of the following models:

Relay SPDT

Solid State Relay

Pulse

Analog Output (Voltage and Current)

OUTPUT 2 Based on one of the following models:

Relay SPDT

Solid State Relay

Pulse

OPTION

Based on one of the following models:

RS-232C or RS-485 programmable

Excitation

6

6 5 4 6 5 4 6 5 4 3 2 1 3 2 1

8 7 6 5 4 3 2 1

Page 11

2.3 Electrical Installation

2.3.1 Power Connections

Caution: Do not connect power to your device until you have completed all

input and output connections. Failure to do so may result in injury!

Connect the main power connections as shown in Figure 2.4.

Figure 2.4 Main Power Connections

Table 2.3 Fuse Requirement (see specifications)

FUSE Connector Output Type For 115Vac For 230Vac DC

FUSE 1 Power N/A 100 mA(T) 100 mA(T) 100 mA(T)

FUSE 2 Power N/A N/A N/A 400 mA(T)

For the low voltage power option, in order to maintain the same degree of

protection as the standard high voltage input power units (90 - 240 Vac),

always use a Safety Agency Approved DC or AC source with the same

Overvoltage Category and pollution degree as the standard AC unit (90 240 Vac).

The Safety European Standard EN61010-1 for measurement, control,

and laboratory equipment requires that fuses must be specified based on

IEC127. This standard specifies for a Time-lag fuse, the letter code “T”.

The above recommended fuses are of the type IEC127-2-sheet III. Be

aware that there are significant differences between the requirements

listed in the UL 248-14/CSA 248.14 and the IEC 127 fuse standards. As a

result, no single fuse can carry all approval listings. A 1.0 Amp IEC fuse

is approximately equivalent to a 1.4 Amp UL/CSA fuse. It is advised to

consult the manufacturer’s data sheets for a cross-reference.

7

Use copper conductors

only for power connections

Page 12

2.3.2 Thermocouple

The figure below shows the wiring hookup for any thermocouple type. For

example, for Type K hookup, connect the yellow wire to the "2" terminal and the

red wire to the "1(-)" terminal.

When configuring your controller, select Thermocouple and Thermocouple

Type in the Input Type menu (see Part 3).

Figure 2.5 Thermocouple Wiring Hookup

8

TYPE Input Connector Jacket (external insulation)

Terminal 1 (-) Terminal 2 (+) Extension Grade

J Red White dark-Brown Black

K Red Yellow dark-Brown Yellow

T Red Blue dark-Brown Blue

E Red Purple dark-Brown Purple

N Red Orange dark-Brown Brown

R Red Black - Green

S Red Black - Green

B Red Gray - Black

Table 2.4 TC Wire Color Chart

Page 13

9

2.3.3 Two/Three/Four-Wire RTD

The figures below show the input connections and input connector jumpers

(shown in bold lines) required to hookup a 2-, 3- or 4-wire RTD.

Figure 2.6 a) RTD-1000 ohm and b) RTD-100 ohm Wiring Hookup

500 ohm Wiring Hookup

The two-wire connection is simplest method, but does not compensate for

lead-wire temperature change and often requires calibration to cancel lead-wire

resistance offset.

The three-wire connection works best with RTD leads closely equal in

resistance. The device measures the RTD, plus upper and lower lead drop

voltage and the subtracts twice the measured drop in the lower supply current

lead producing excellent lead-resistance cancellation for balanced

measurements.

The four-wire RTD hookup is applicable to unbalanced lead resistance and

enables the device to measure and subtract the lead voltage, which produces

the best lead-resistance cancellation.

When configuring your controller, select RTD type and RTD value in the

Input Type menu (see Part 3).

If the input wires of the meter get disconnected or broken, it will display

+OPN “Input (+) Open” message except in case of 500/1000 Ω 2-wire

RTD. In this case the display shows -OPN “Input (-) Open” message. For

safety purpose you may want to set up your alarm to be triggered when

input is open. See Alarm 1 & 2 chapters for details.

RTD (1000/500Ω) 4-Wire

RTD (1000/500Ω) 3-Wire

RTD (1000/500Ω) 2-Wire

RTD (100Ω) 4-Wire

RTD (100Ω) 3-Wire

RTD (100Ω) 2-Wire

Page 14

10

2.3.4 Process Current

The figure below shows the wiring hookup for Process Current 0 – 20 mA.

Figure 2.7 Process Current Wiring Hookup

(Internal and External Excitation)

When configuring your instrument, select Process Type in the Input Type Menu

(see Part 3).

2.3.5 Process Voltage

The figure below shows the wiring hookup for Process Voltage 0 – 100 mV,

0 – 1 V, 0 – 10 V.

Figure 2.8

a) Process Voltage Wiring Hookup b) Process Voltage Wiring Hookup

with Sensor Excitation without Sensor Excitation

RL - Voltage limited resistor, which allows to convert 24 Vdc internal excitation

voltage to the appropriate process input value. For instance: if the potentiometer

value is equal to 10 kΩ, the minimum RL is 14 kΩ for 10 V process input.

When configuring your instrument, select Process Type in the Input Type Menu

(see Part 3).

Page 15

11

2.3.6 Wiring Outputs

This meter has two factory installed outputs. The SPDT Mechanical Relay, SPST

Solid State Relay, Pulse and Analog Output Connection are shown below.

Figure 2.9

a) Mechanical Relay and SSR b) Pulse and Analog

Outputs Wiring Hookup Outputs Wiring Hookup

Use copper conductors

only for power connections

TEMPERATURE

CONTROLLER

CONTROL

SIDE

dc INPUT

SSR

ac INPUT

SSR

ac INPUT

SSR

LOAD

SIDE

HEATER

Vac

Vac

dc CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH dc VOLTAGE SSR DRIVER OUTPUT

FAST BLOW

FUSE

0 or 5 Vdc,

TYPICALLY

431

2

TEMPERATURE

CONTROLLER

CONTROL

SIDE

LOAD

SIDE

HEATER

Vac

Vac

ac CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH MECHANICAL RELAY OUTPUT

FAST BLOW

FUSE

Vac

DRIVING

SSR

431

2

TEMPERATURE

CONTROLLER

CONTROL SIDE

LOAD

RESISTOR

LOAD

SIDE

HEATER

Vac

Vac

ac CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH TRIAC OUTPUT

FAST BLOW

FUSE

Vac

DRIVING

SSR

431

2

Figure 2.10 Typical Applications

Page 16

This device may have a programmable communication output. The

RS-232 and RS-485 Output Connection are shown below.

External RS-232 connections are not available with -EI or C4EI options.

Figure 2.11

a) RS-232 Output Wiring Hookup b) RS-485 Output Wiring Hookup

This device may also have an

excitation output.

If the Dual Display model has a Low

Voltage power supply option, then

excitation is not available.

Excitation is not available if

communication option is installed.

Figure 2.12 Excitation Output

This device has snubber circuits

designed to protect the contacts of the

mechanical relays when it switches to

inductive loads (i.e. solenoids, relays).

These snubbers are internally

connected between the Common (C)

and Normally Open (NO) relay contacts

of Output 1 and Output 2.

If you have an inductive load

connected between Common (C) and

Normally Closed (NC) contacts of the

mechanical relays and you want to

protect them from the rush current

during the switching period, you have

to connect an external snubber circuit

between Common (C) and Normally

Closed (NC) contacts as indicated in

Figure 2.13.

12

Figure 2.13

Snubber Circuits Wiring

Hookup

Page 17

2.3.7 Dual Display Color Setup

The dual display option allows the user to change the color of the upper and

lower displays.

To change the color of the upper display, see Section 3.2.15

(Display Color section).

To change the color of the lower display follow the instructions below:

The unit should be removed from the panel and opened.

Refer to the Quick Start Guide for assembly and disassembly instructions.

The S1 jumper is located on the back side of the display board.

The location of S1 and pin selection jumpers are shown below.

Use a jumper for GREEN or RED, never leave S1 open.

Figure 2.14 i/8D Location of S1 and Selectable Jumper Positions

Figure 2.15 i/16D Location of S1 and Selectable Jumper Positions

13

i/8DH

Dual

Horizontal

i/8DV

Dual

Vertical

Page 18

14

PART 3

OPERATION: Configuration Mode

3.1 Introduction

The instrument has two different modes of operation. The first, Run Mode, is

used to display values for the Process Variable, and to display or clear Peak

and Valley values. The other mode, Menu Configuration Mode, is used to

navigate through the menu options and configure the controller. Part 3 of this

manual will explain the Menu Configuration Mode. For your instrument to

operate properly, the user must first "program" or configure the menu options.

Turning your Controller On for the First Time

The device becomes active as soon as it is connected to a power source. It

has no On or Off switch. The device at first momentarily shows the software

version number, followed by reset

RST

, and then proceeds to the Run Mode.

For first-time users: Refer to the QuickStart Manual for basic operation

and set-up instructions.

If you have the Serial Communications/Ethernet Option you can easily

configure the controller on your computer or on-line.

Table 3.1 Button Function in Configuration Mode

• To enter the Menu, the user must first press

a

button.

• Use this button to advance/navigate to the next menu item. The user can navigate

through all the top level menus by pressing a.

• While a parameter is being modified, press ato escape without saving the parameter.

• Press the up bbutton to scroll through “flashing” selections. When a numerical value is

displayed press this key to increase value of a parameter that is currently being modified.

• Holding the bbutton down for approximately 3 seconds will speed up the rate at which

the set point value increments.

• In the Run Mode press bcauses the display to flash the PEAK value – press again to

return to the Run Mode.

• Press the down cbutton to go back to a previous Top Level Menu item.

• Press this button twice to reset the controller to the Run Mode.

• When a numerical value is flashing (except set point value) press cto scroll digits from

left to right allowing the user to select the desired digit to modify.

• When a setpoint value is displayed press cto decrease value of a setpoint that is

currently being modified. Holding the cbutton down for approximately 3 seconds will

speed up the rate at which the setpoint value is decremented.

• In the Run Mode press c causes the display to flash the VALLEY value – press again to

return to the Run Mode.

• Press the enter d button to access the submenus from a Top Level Menu item.

• Press d to store a submenu selection or after entering a value — the display will flash a

STRD

message to confirm your selection.

• To reset flashing Peak or Valley press d.

• In the Run Mode, press d twice to enable Standby Mode with flashing

STBY

.

Reset: Except for Alarms, modifying any settings of the menu configuration

will reset the instrument prior to resuming Run Mode.

a

MENU

b

(UP)

c

(DOWN)

d

ENTER

Page 19

15

3.2 Menu Configuration

It is required that you put the controller in the Standby Mode for any

configuration change other than Setpoints & Alarms.

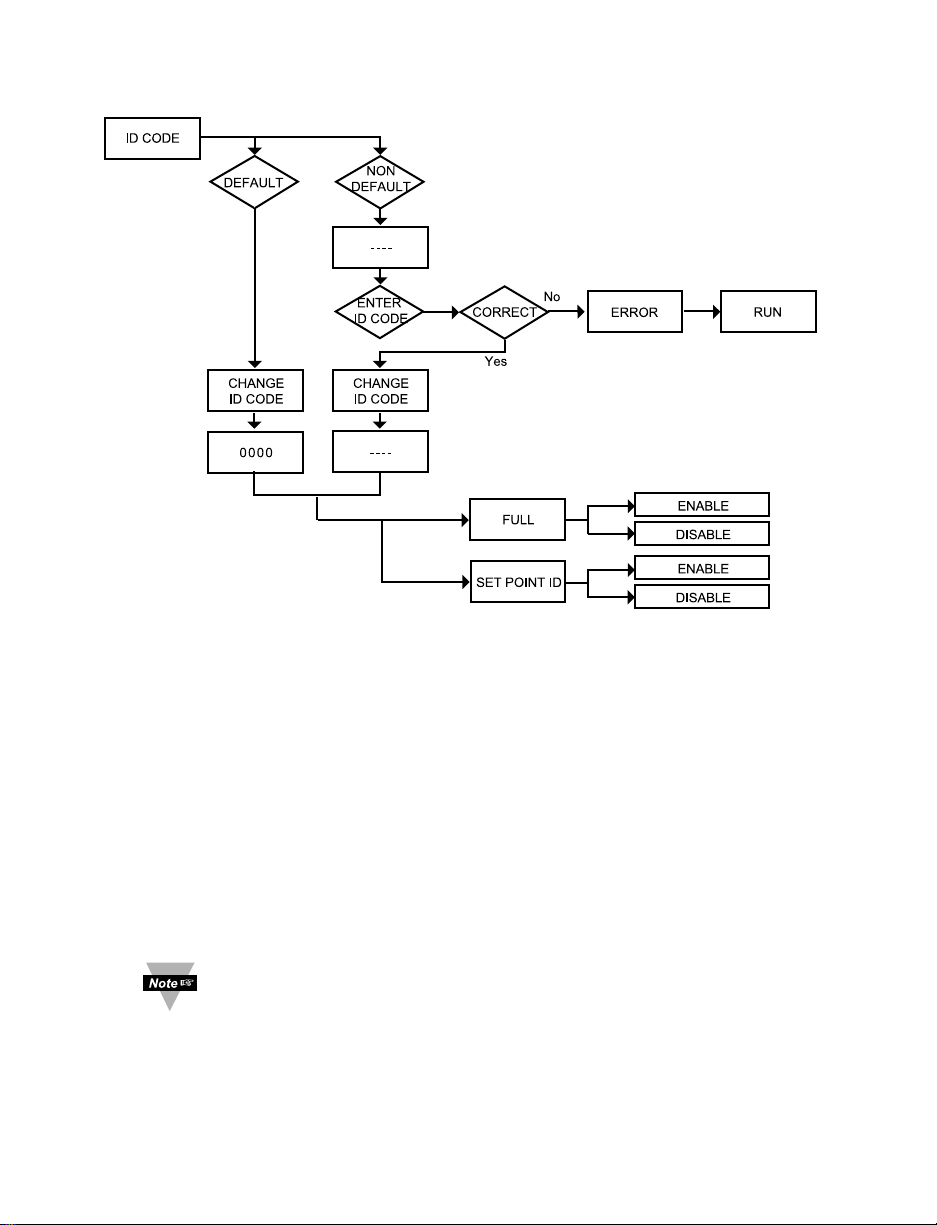

Figure 3.1 Flow Chart for ID and Setpoints

Page 20

16

3.2.1 ID Number

SEE ID MENU SELECTION IN CONFIGURATION SECTION FOR

ENABLE/DISABLE OR CHANGE ID CODE.

If ID Code is Disabled or set as Default (0000) the menu will skip ID step

to Setpoint Menu.

If ID Code is set to Full Security Level and user attempts to enter the

Main Menu, they will be prompted for an ID Code.

If ID Code is set to Setpoint/ID Security Level and user attempts to enter

the Configuration Menu, they will be prompted for an ID Code.

ENTERING YOUR NON-DEFAULT FULL SECURITY ID NUMBER.

Press a 1) Display shows ID.

Press d 2) Display advances to

____

.

Press b & c 3) Press bto increase digit 0-9. Press cto activate next digit

(flashing). Continue to use band c to enter your 4-digit ID

code.

Press d 4) If the correct ID code is entered, the menu will advance to the

Setpoint 1 Menu, otherwise an error message

ERRo

will be

displayed and the instrument will return to the Run Mode.

To change ID Code, see ID Menu in the Configuration section.

ENTERING YOUR NON-DEFAULT SETPOINT/ID SECURITY ID NUMBER.

Press a 5) Display shows

SP1

Setpoint 1 Menu.

Press a 6) Display shows

SP2

Setpoint 2 Menu.

Press a 7) Display shows IDID Code Menu.

Press d 8) Display advances to

____

.

Press b & c 9) Use b and c to change your ID Code.

Press d 10) If correct ID Code is entered, the display will advance to the

INPT

Input Menu, otherwise the error message

ERRo

will be

displayed and the controller will return to the Run Mode.

To prevent unauthorized tampering with the setup parameters, the

instrument provides protection by requiring the user to enter the ID Code

before allowing access to subsequent menus. If the ID Code entered

does not match the ID Code stored, the controller responds with an error

message and access to subsequent menus will be denied.

Use numbers that are easy for you to remember. If the ID Code is

forgotten or lost, call customer service with your serial number to access

and reset the default to

0000

.

Page 21

17

3.2.2 Set Points

SETPOINT 1:

Press a 1) Press a, if necessary until

SP1

prompt appears.

Press d 2) Display shows previous value of “Setpoint 1”.

Press b & c 3) Press b and c to increase or decrease Setpoint 1

respectively.

Holding b & c buttons down for approximately 3 seconds will speed up the

rate at which the Setpoint value increments or decrements.

Press b & c 4) Continue to use b and c to enter your 4-digit Setpoint 1 value.

Press d 5) Display shows

STRD

stored message momentarily and then

advances to

SP2

only, if a change was made, otherwise press

a to advance to

SP2

Setpoint 2 Menu.

SETPOINT 2:

Press d 6) Display shows previous value of “Setpoint 2”.

Press b & c 7) Press b and c to increase or decrease Setpoint 2

respectively.

Holding b & c buttons down for approximately 3 seconds will speed up

the rate at which the setpoint value increments or decrements.

Press d 8) Display shows

STRD

stored message momentarily and then

advances to

CNFG

only, if a change was made, otherwise press

a to advance to

CNFG

Configuration Menu.

Page 22

18

3.2.3 Configuration Menu

Figure 3.2 Flow Chart for Configuration Menu

Enter Configuration Menu:

Press a 1) Press a, if necessary, until

CNFG

prompt appear.

Press d 2) Display advances to

INPT

Input Menu.

Press a 3) Pressing and releasing a to scroll through all available

menus of Configuration section.

3.2.4 Input Type Menu

Figure 3.3 Flow Chart for Input Type Menu

Page 23

19

Input Type (Thermocouple)

ENTER INPUT TYPE MENU:

Press a 1) Press a, if necessary, until

CNFG

prompt appears.

Press d 2) Display advances to

INPT

Input Menu.

Press d 3) Display flashes

T.ç, RTD

or

PROC

(Thermocouple, RTD or

Process). If the displayed input type is

T.ç

, press a to skip to

step 6 (

T.ç

stops flashing).

THERMOCOUPLE SUBMENU:

Press b 4) Scroll through the available selection to

T.ç

(flashing).

Press d 5) Display shows

STRD

stored message momentarily and then

T.ç

(not flashing).

Press d 6) Display flashes previous thermocouple type selection. i.e.

J

(see below for types).

Press b 7) Scroll through the available thermocouple types to the

selection of your choice.

Press d 8) Display shows

STRD

stored message momentarily and then

advances to the

RDG

Reading Configuration Menu.

Use the Input Type (Thermocouple) (RTD) or (Process) and verify your

Electrical Installation (see section 2.3).

Thermocouple Types: J, K, T, E, N, DIN J, R, S, B, C

Display:

JKTEN DNJ RSBC

Page 24

20

Input Type (RTD)

ENTER INPUT TYPE MENU:

Press a 1) Press a, if necessary, until

CNFG

prompt appears.

Press d 2) Display advances to

INPT

Input Menu.

Press d 3) Display flashes

T.ç

,

RTD

or

PROC

(Thermocouple, RTD or

Process). If the displayed input type is

RTD

, press a to skip to

step 6 (

RTD

stops flashing).

RTD SUBMENU:

Press b 4) Scroll through the available selection to

RTD

(flashing).

Press d 5) Display shows

STRD

stored message momentarily and then

RTD

(not flashing).

Press d 6) Display flashes previous RTD type selection i.e.

392.2

(see below for RTD types selection).

Press b 7) Scroll through the available RTD types to the selection of

your choice.

Press d 8) Display shows

STRD

stored message momentarily and then

advances to

RTD

RTD value.

RTD Types: 392 385 Two, Three or Four-wire

Display:

392.2,392.3,392.4,385.2,385.3,385.4

Last digit indicates: 2-, 3- or 4-wire input.

RTD VALUE SUBMENU:

Press d 9) Display flashes previous RTD value selection i.e.

100_

(see below for RTD value selection).

Press b 10) Scroll through the available RTD values to the selection of

your choice.

Press d 11) Display shows

STRD

stored message momentarily and then

advances to

RDG

Reading Configuration Menu.

RTD Values: 100 ohm 500 ohm 1000 ohm

Display:

100_ 500_ 1000

Page 25

21

Input Type (Process)

ENTER INPUT TYPE MENU:

Press a 1) Press a, if necessary, until

CNFG

prompt appears.

Press d 2) Display advances to

INPT

Input Menu.

Press d 3) Display flashes

T.ç, RTD

or

PROC

(Thermocouple, RTD or

Process). If the displayed input type is

PROC

, press a to skip to

step 6 (

PROC

stops flashing).

PROCESS SUBMENU:

Press b 4) Scroll through the available selection to

PROC

(flashing).

Press d 5) Display shows

STRD

stored message momentarily and then

PROC

(not flashing).

Press d 6) Display flashes previous Process type selection. i.e.

0-10

(see below for Process types selection).

Press b 7) Scroll through the available Process types to the selection of

your choice.

Press d 8) Display shows

STRD

stored message and then advances to

RDG

Reading Configuration Menu.

Process Types: 100 mV 1 V 10 V 0 – 20 mA

Display:

0-0.1 0-1.0 0-10 0-20

For 4-20 mA Input select 0-20 mA then adjust the Input/Reading accordingly.

To adjust 4-20 mA input, see example under INPUT/READING submenu. The

factory preset value is 4-20 mA.

3.2.5 Reading Configuration

Figure 3.4 Flow Chart for Reading Configuration Menu

It is required that you put the controller in the Standby Mode for any

configuration change other than Set Points & Alarms.

Page 26

22

ENTER READING CONFIGURATION MENU:

Press

a

1) Press a, if necessary, until

CNFG

prompt appears.

Press

d

2) Display advances to

INPT

Input Menu.

Press

a

3) Display advances to

RDG

Reading Configuration Menu.

Press

d

4) Display advances to

DEC

Decimal Point.

DECIMAL POINT SUBMENU:

Press

d

5) Display flashes previous selection for Decimal location.

Press

b

6) Scroll though the available selections and choose Decimal

location:

FFFF

or

FFF.F

(also

FF.FF

and

F.FFF

— if

PROC

Process type was selected in the Input Type Menu).

Press

d

7) Display shows

STRD

stored message momentarily and then

advances to

TEMP

Temperature Unit.

Decimal Point for Process Input Type is passive.

TEMPERATURE UNIT SUBMENU:

Press

d

8) Display flashes previous Temperature Unit selection.

Press

b

9) Scroll though the available selections to the Temperature Unit

of your choice: °For °C.

Press

d

10) Display shows

STRD

stored message momentarily and then

advances to

FLTR

Filter Constant.

FILTER CONSTANT SUBMENU:

Press

d

11) Display flashes previous selection for Filter Constant.

Press

b

12) Scroll though the available selections:

0001,0002,0004,0008,0016,0032,0064,0128

Press

d

13) Display shows

STRD

stored message momentarily only, if

change was made, otherwise press ato advance to the next

menu.

If Process was selected in the Input Type Menu the display will

advance to

IN.RD

Input/Reading Submenu, otherwise the

display advances to the

ALR1

Alarm 1 Menu.

The Filter Constant Submenu allows the user to specify the

number of readings stored in the Digital Averaging Filter.

For PID control select filter value 0001-0004. A filter value of 2 is

approximately equal to 1 second RC low pass time constant.

Page 27

23

Reading Configuration (If Process was selected)

INPUT/READING (SCALE AND OFFSET) SUBMENU:

Input Voltage or Current can be converted or scaled into values appropriate for

the process or signal being measured. So, a reading may be displayed, for

example, in units of weight or velocity instead of in amperes or volts.

The instrument determines Scale and Offset values based on two user-provided

input values entered with the corresponding readings. Note that “In1” Input 1 and

“In2” Input 2 are represented and entered as a product of the input

voltage/current and the conversion number from the Table 3.1.

The following instructions include details for a specific scenario in which a

4-20 mA input (in the 20 mA Process Mode) is to be represented as a

measurement of 0-100 percent.

Press

d

14) Press dat the

IN.RD

prompt. Display shows

IN1

Input 1

submenu.

Press

d

15) Display shows Input 1 value with 1stdigit flashing.

Press b& c16) Use band cbuttons to enter

IN1

value.

The

IN1

value = min. input value * conversion number.

Disregard the position of the decimal point (2000 counts may

actually appear as “200.0”, “20.00”, or “2.000”).

Example: 4 mA as 4(mA) x 500 = 2000.

Press

d

17) Display advances to

RD1

Reading 1 Submenu.

Press b& c18) Use band cbuttons to enter

RD1

value.

This value represents

IN1

in terms of some meaningful

engineering units. To show the 4 mA as zero percent enter

RD1

value = 0000.

Example:

RD1

value = 0000.

Press

d

19) Display IN!2 Input 2 Submenu.

Press

d

20) Display shows Input 2 value with 1stdigit flashing.

The IN!2 value = max. input value * conversion number.

Example: 20(mA) x 500 = 10000 (9999).

Press b& c21) Use band c buttons to enter IN!2 value.

Press

d

22) Display advances to RD!2 Reading 2 Submenu.

Press b& c23) Use b and c buttons to enter RD!2 value.

Example: RD!2 value = 0100.

Press

d

24) Display flashes

STRD

stored message momentarily and

then advances to

ALR1

only, if change was made, otherwise

press dto advance to

ALR1

Alarm 1 Menu.

Page 28

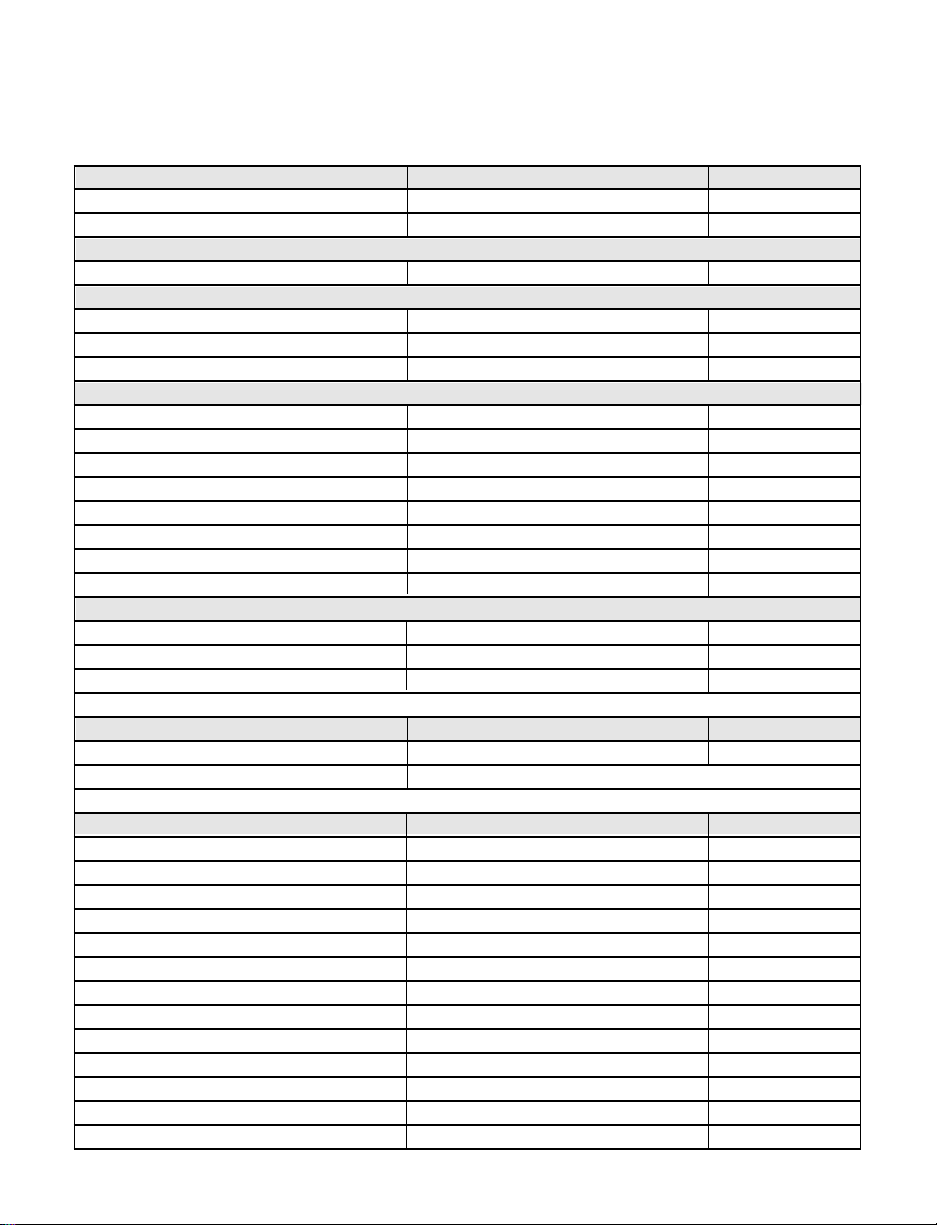

24

Conversion number is a coefficient of conversion between input values

and real full display range (10000 counts shown as 9999). See Table 3.2

below for proper conversion number.

Table 3.2 Conversion Table

RANGE CONVERSION NUMBER

100 mV 10000 / (100 x 1) = 100

1 V 10000 / (1000 x 1) = 10

10 V 10000 / (1000 x 10) = 1

0 -20 mA 10000 / (20 x 1) = 500

Example =

0 - 1 V = 0 - 100.0

In 1 = 0

Rd 1 = 0

Inp 2 = 9999

Rd 2 = 100.0

Page 29

25

3.2.6 Alarm 1

This unit is equipped with two physical outputs that can only be configured as

follows: Alarm 1 & Alarm 2, Alarm 1 & Output 2, Output 1 & Alarm 2, Output 1

& Output 2, Analog Out 1 & Alarm 2, Analog Out 1 & Output 2. Analog Out

available only if Analog Output Option board is factory installed.

If Analog Output Option is installed, the controller will skip Alarm 1 Menu

item to Analog Output.

Alarm must be DISABLED if Ramp is ENABLED.

Figure 3.5 Flow Chart for Alarm 1

ENTER ALARM 1 MENU:

Press a 1) Press a, if necessary, until

CNFG

prompt appears.

Press d 2) Display advances to

INPT

Input Menu.

Press a 3) Press a, if necessary, until Display advances to

ALR1

Alarm 1

Menu.

Press d 4) Display advances to Alarm 1

ENBL

Enable or

DSBL

Disable

Submenu and flashes the previous selection.

Page 30

26

ALARM 1 ENABLE/DISABLE SUBMENU:

Press b 5) Scroll though the available selection until

ENBL

displays to

use Alarm 1.

Press d 6) Display shows

STRD

stored message momentarily and then

advances to

ABSo

only if it was changed, otherwise press a to

advance to

ABSo

Alarm 1 Absolute/Deviation Submenu.

If

DSBL

Alarm 1 Disabled was selected, all submenus of Alarm

1 Menu will be skipped and meter advances to

ALR2

Alarm 2

Menu. If

ENBL

Alarm 1 Enabled was selected, Output 1 would

be automatically Disabled, and reassigned as Alarm 1.

ALARM 1 ABSOLUTE/DEVIATION SUBMENU:

Press

d

7)

Display flashes previous selection. Press bto

ABSo

Absolute or

_DEV

Deviation.

Press

d

8) Display shows

STRD

stored message momentarily and then

advances to

LTçH

only if it was changed, otherwise press a to

advance to

LTçH

Alarm 1 Latch/Unlatch Submenu.

Absolute Mode allows Alarm 1 to function independently from Setpoint 1. If the

process being monitored does not change often, then "Absolute" Mode is

recommended.

Deviation Mode allows changes to Setpoint 1 to be made automatically to

Alarm 1. Deviation mode is typically the ideal mode if the process temperature

changes often. In Deviation Mode, set Alarm 1 a certain number of degrees or

counts away from Setpoint 1 — this relation remains fixed even if Setpoint 1 is

changed.

ALARM 1 LATCH/UNLATCH SUBMENU:

Press

d

9) Display flashes previous selection. Press bto

LTçH

Latched or

UNLT

Unlatched.

Press

d

10) Display shows

STRD

stored message momentarily and then

advances to

CT.CL

only, if it was changed, otherwise press a to

advance to

CT.CL

Contact Closure Submenu.

Latched Mode: Relay remains "latched" until reset. To reset already latched

alarm, select Alarm Latch and press Max twice (i.e. Unlatch and then back to

Latch) or from a Run Mode, push dtwice to put the controller in Standby Mode

and then push done more time to return to the Run Mode.

Unlatched Mode: Relay remains latched only as long as the alarm condition is

true.

Page 31

27

CONTACT CLOSURE SUBMENU:

Press

d

11) Display flashes previous selection. Press b to

N.ç.

Normally

Closed or

N.o.

Normally Open.

Press

d

12) Display shows

STRD

stored message momentarily and then

advances to

AçTV

only if it was changed, otherwise press ato

advance to

AçTV

Active Submenu.

Normally Open: If this feature is selected, then the relay is "energized" only

when an alarm condition occurs.

Normally Closed: "Fail Safe" Mode. Relay is energized under "normal"

conditions and becomes de-energized during alarm or power failure.

ACTIVE SUBMENU:

Press

d

13) Display flashes previous selection. Press bto scroll through

the available selections:

ABoV

Above,

BELo

Below,

HI.Lo

HI/Low and

BAND

Band. (Band is active if

_DEV

Deviation was

selected).

Press

d

14) Display shows

STRD

stored message momentarily and then

advances to

A.P.oN

only if it was changed, otherwise press a to

advance to

A.P.oN

Alarm Enable/Disable at Power On

Submenu.

Above: Alarm 1 condition triggered when the process variable is greater than the

Alarm Hi Value (Low value ignored).

Below: Alarm 1 condition triggered when the process variable is less than the

Alarm Low Value (Hi value ignored).

Hi/Low: Alarm 1 condition triggered when the process variable is less than the

Alarm Low Value or above the Hi Value.

Band: Alarm 1 condition triggered when the process variable is above or below

the "band" set around Setpoint 1. Band equals Hi Value (Low Value ignored). A

"band" is set around the Setpoint by the instrument only in the "Deviation" Mode.

The Band for the AL 1 would be following the Setpoint 1 value

The Band for the AL 2 would be following the Setpoint 2 value.

The Band or the Deviation Value should be entered under:

AL1 High (if they want Alarm 1)

AL2 High (if they want Alarm 2)

AL Low value is ignored in the Band mode.

Example: if customer requires a Deviation Value of ±10 degrees around a

setpoint (using Output 2 as alarm)

Output 2: disabled (this enables the Alarm 2)

Alarm 2: - Deviation

Contact Closure type: Deviation---Band

AL2 High: 10 (Band they want around Setpoint 2)

Then the Band Value is to be entered under AL2 HI: 10 not 80+10 = 90

Page 32

28

ALARM ENABLE/DISABLE AT POWER ON:

Press

d

15) Display flashes previous selection. Press bto

ENBL

enable

or

DSBL

disable.

Press d 16)

Display shows

STRD

stored message. momentarily and then

advances to

ALR.L

only if it was changed, otherwise press ato

advance to the

ALR.L

Alarm 1 Low Value Submenu.

If the alarm is enabled at Power On, the alarm will be active right after

reset. If the alarm is disabled at Power On, the alarm will become

enabled when the process value enters the non alarm area. The alarm is

not active while the process value is approaching Setpoint 1.

ALARM 1 LOW VALUE SUBMENU:

Press

d

17) Display flashes 1stdigit of previous value. Use band cto

enter new value.

Press b& c18) Use band cto enter Alarm 1 Low Value.

Press

d

19) Display shows

STRD

storage message momentarily and

then advances to

ALR.H

only, if it was changed, otherwise press

a to advance to

ALR.H

Alarm 1 Hi Value Submenu.

ALARM 1 HI VALUE SUBMENU:

Press

d

20) Display flashes 1stdigit of previous value. Use band cto

enter new value.

Press b& c21) Use band cto enter Alarm1 Hi Value.

Press

d

22) Display shows

STRD

stored message momentarily and then

advances to the next menu only, if it was changed, otherwise

press ato advance to the next menu.

Page 33

29

3.2.7 Analog Output (Retransmission)

Analog Output can be configured as Retransmission or Control outputs.

In this section we will discuss Retransmission Output.

This unit is equipped with two physical outputs that can only be configured as

follows: Alarm 1 & Alarm 2, Alarm 1 & Output 2, Output 1 & Alarm 2, Output

1 & Output 2, Analog Out 1 & Alarm 2, Analog Out 1 & Output 2. Analog

Output is available only, if Analog Output Option board is factory installed.

If Analog Output Option is not installed, the instrument will skip to Alarm 2 Menu.

Figure 3.6 Flow Chart for Analog Output (Retransmission)

ENTER ANALOG OUTPUT MENU:

Press

a

1) Press a, if necessary, until

CNFG

prompt appears.

Press

d

2) Display advances to

INPT

Input Menu.

Press

a

3) Press a, if necessary, until Display advances to

ANLG

Analog Output Menu.

Press

d

4) Display advances to Analog Output

ENBL

Enable or

DSBL

Disable Submenu and flashes the previous selection.

Page 34

30

ANALOG OUTPUT ENABLE/DISABLE SUBMENU:

Press

b

5) Scroll though the available selection until

ENBL

displays to

use Analog Output Retransmission (output proportional to the

input signal).

Press

d

6) Display shows

STRD

stored message momentarily and then

advances to

CURR

or

VoLT

Submenu only if it was changed,

otherwise press a to advance to

CURR

or

VoLT

Current/Voltage Submenu.

If

DSBL

Analog Output Disabled was selected, all submenus of Analog

Output Menu will be skipped and the meter will advance to

ALR2

Alarm 2

Menu. If

ENBL

Analog Output Enabled was selected, Output 1 would be

automatically Disabled, and reassigned as Analog Output.

CURRENT/VOLTAGE SUBMENU:

Press

d

7) Display flashes

CURR

Current or

VoLT

Voltage.

Press

b

8) Scroll through the available selection: Current or Voltage

(Example

VoLT

).

Press

d

9) Display shows

STRD

stored message momentarily and then

advances to

RD1

Submenu only if it was changed, otherwise

press ato advance to

RD1

Reading 1 Submenu.

READING 1:

Press

d

10) Display flashes 1

st

digit of previous “Reading 1” value.

Press b& c11) Enter “Reading 1” value. (Example 0000)

Press

d

12) Display advances to

OUT.1

Out 1 Submenu.

OUT 1:

Press d 13) Display flashes 1

st

digit of previous “Out 1” value.

Press b & c 14) Enter “Out 1” value. (Example 00.00)

Press d 15) Display advances to RD!2 Reading 2 Submenu.

READING 2:

Press

d

16) Display flashes 1

st

digit of previous “Reading 2” value.

Press b& c17) Enter “Reading 2” value. (Example 9999)

Press

d

18) Display advances to

OUT.2

Out 2 Submenu.

OUT 2:

Press

d

19) Display flashes 1

st

t

digit of previous “Out 2” value.

Press b& c20) Enter “Out 2” value. (Example 10.00)

Press

d

21) Display advances to the

ALR2

Alarm 2 Menu.

The above example is for 0-10 V of the entire range of the Process Input

and Analog Output. For 0-20 mA output you need to set “Analog Type” to

Current and OUT 2 to 20.00.

Page 35

31

Accuracy of Analog Output board is +/-1% of FS (Full Scale) when following

conditions are satisfied:

1. The input is not scaled below 1% of Input FS (10 mV @ 1 V or 0.2 mA @

20 mA input ranges).

2. Analog Output is not scaled below 3% of Output FS (300 mV @ 10 V or

0.6 mA @ 20 mA output ranges).

Otherwise certain corrections need to be applied.

For example:

For entire range of process input, the Analog Output on 10 V FS scaled for

300 mV output range:

Rd1 = 0000, Out1 = 00.00

RD2 = 9999, Out2 = 00.30

The measured output will be as follows:

Rd1 = 0000, Out1 = -0.07 V

Rd2 = 9999, Out2 = 0.23 V

This means that for 300 mV output range we have -70 mV offset at zero and at

full scale. In order to compensate this 70 mV offset the correct scaling will be

as follows:

Rd1 = 0000, Out1 = 00.07

Rd2 = 9999, Out2 = 00.37

The above corrections need to be applied only for Input scaled below 1% of FS

and Output scaled below 3% of FS or if you need the Analog Output

accuracy to be better than 1% of FS.

Page 36

32

3.2.8 Alarm 2

This unit is equipped with two physical outputs that can only be configured as

follows: Alarm 1 & Alarm 2, Alarm 1 & Output 2, Output 1 & Alarm 2, Output 1

& Output 2, Analog Out 1 & Alarm 2, Analog Out 1 & Output 2. Analog Out

available only if Analog Output Option board is factory installed.

Alarm must be DISABLED if Ramp is ENABLED.

Figure 3.7 Flow Chart for Alarm 2

ENTER ALARM 2 MENU:

Press

a

1) Press a, if necessary, until

CNFG

prompt appears.

Press

d

2) Display advances to

INPT

Input Menu.

Press

a

3)

Press a, if necessary, until Display advances to

ALR2

Alarm 2 Menu.

Press

d

4)

Display advances to Alarm 2

ENBL

Enable or

DSBL

Disable

Submenu.

ALARM 2 ENABLE/DISABLE SUBMENU:

Press

d

5) Display flashes previous selection. Press buntil

ENBL

displays

to use Alarm 2.

Press

d

6) Display shows

STRD

stored message momentarily and then

advances to

ABSo

only if it was changed, otherwise press ato

advance to

ABSo

Absolute/Deviation Submenu.

If

DSBL

Alarm 2 Disabled was selected, all submenus of Alarm 2 will

be skipped and meter advances to

LOOP

Loop Break Time Menu. If

ENBL

Alarm 2 Enabled was selected, Output 2 will automatically

Disabled, and reassigned as Alarm 2.

The remaining Alarm 2 menu items are identical to Alarm 1 Menu. Modifying

Alarm Settings will not reset the instrument.

Page 37

33

3.2.9 Loop Break Time/Field Calibration

Figure 3.8 Flow Chart for Loop Break Time/Field Calibration

ENTER LOOP BREAK TIME MENU:

Press

a

1) Press a, if necessary, until

CNFG

prompt appears.

Press

d

2) Display advances to

INPT

Input Menu.

Press

a

3) Press a, if necessary, until Display advances to

LOOP

Loop

Break Time Menu.

Press

d

4) Display advances to Loop Break Time

ENBL

Enable or

DSBL

Disable Submenu and flashes the previous selection.

LOOP BREAK ENABLE/DISABLE SUBMENU:

Press b 5) Scroll through the available selections:

ENBL

or

DSBL

.

Press

d

6) Display shows

STRD

stored message momentarily and then

advances to

B.TIM

Loop Break Time Value Submenu.

Loop Break is an additional safety feature intended to monitor the rate of change of the

process value, while approaching the SP1. It is strictly intended as an additional warning

system, therefore its use is entirely optional. An active Loop Break will cause the Process

Value digits to blink in a rotating pattern. If the process value reaches the set point the

blinking will stop and

B.TIM

is completed successfully, otherwise

BR.AL

Break Alarm

warning will flash, and Output 1 will be turned off.

LOOP BREAK TIME VALUE SUBMENU:

Press

d

7) Display flashes 1stdigit of previous Loop Value.

Press b& c8)

Press band cbuttons to enter a new Loop Value (0 to 99.59).

Press

d

9) Display shows

STRD

stored message momentarily and then

advances to

R.ADJ

Reading Adjust Submenu.

Loop Break Time Value allows the user to determine the time interval in MM:SS (from

zero to 99 minutes and 59 seconds) that the Process Value changes at least 10 counts or

if the Input Type is either RTD or Thermocouple, the value changes 4° Fahrenheit or 2°

Celsius. At the specified time interval, if the process value change is less than the stated

rate, flashing

B.TIM

will be displayed, the output 1 will be de-energized, and Alarm 1

energized. Loop break time will be disabled when the Process Value (PV) enters the

control band.

READING ADJUST SUBMENU:

Press

d

10) Display flashes 1stdigit of previous Reading Adjust value.

Press b& c11) Press band cbuttons to enter a new Reading Adjust value

(-1999 to 9999).

Press

d

12) Display shows

STRD

stored message momentarily and then

advances to

SP.DV

Setpoint Deviation Menu.

It is required

that you put

the controller

in the Standby Mode

for any configuration

change other than Set

Points & Alarms.

Page 38

34

3.2.9 Loop Break Time/Field Calibration (continued)

Reading Offset Adjust allows the user to fine tune a minor error of the transducer,

however some applications may require a large offset adjust.

(Displayed Process Value = Measured Process Value ± R.ADJ).

Reading Adjust is adjustable between -1999 to 9999. For Temperature Reading only,

not Process

SETPOINT DEVIATION ENABLE/DISABLE SUBMENU:

Press

d

13) Display advances to Setpoint Deviation

ENBL

Enable or

DSBL

Disable Submenu and flashes the previous selection.

Press

b

14) Scroll through the available selections:

ENBL

or

DSBL

.

Press

d

15) Display shows

STRD

stored message momentarily and then

advances to

CAL1

Menu.

Setpoint Deviation Submenu, if “enabled”, allows changes to Setpoint 1 to be made

automatically to Setpoint 2. This mode is very helpful if the Process Value changes often.

In Setpoint Deviation Mode, set SP2 a certain number of degrees or counts away from

SP1 - this relation remains fixed when SP1 is changed. For instance: Setting SP1=200

and SP2=20 and enabling

SP.DV

means that the absolute value of SP2=220. Moving

SP1 to 300, the absolute value of SP2 becomes 320.

THERMOCOUPLE FIELD CALIBRATION SUBMENU:

RTD and Process are perfectly calibrated. This section is applicable to

Thermocouple (TC) calibration only.

Be sure that the TC being used to calibrate the meter is of the type

selected in the TC submenu. Place the TC in an ice-bath (or other

0°C / 32°F environment). In ambient temperature conditions: connect the

TC to the meter, apply power to the meter.

CAUTION: Do not proceed with TC calibration unless the above

conditions have been in effect for at least one hour.

Press

a

7) Display shows

CAL1

.

Press

d

8) Display shows flashing

0000

.

Press a * 9) Display will still show flashing

0000

.

Press d * 10) Display shows

OUT1

(meaning Calibration is complete)

* If you accidently engage the flashing

0000

(CAL° alert) simply re-press

the last button you pressed, to avoid unintentionally mis-calibrating your

meter.

°°

CAUTION: Do not perform the following steps until you fully

understand this entire section.

°°

Page 39

35

3.2.10 Output 1

Alarm 1 and Output 1 or Analog Output (Retransmission) share the same contacts

on the rear panel connector. If Alarm 1 or Analog Output (Retransmission) is

Enabled, Output 1 is automatically Disabled.

Figure 3.9 Flow Chart for Output 1

It is required that you put

the controller in the

Standby Mode for any

configuration change other

than Set Points & Alarms.

Page 40

36

ENTER OUTPUT 1 MENU:

Press

a

1) Press a, if necessary, until

CNFG

prompt appears.

Press

d

2) Display advances to

INPT

Input Menu.

Press

a

3) Press a, if necessary, until Display advances to

OUT1

Output

1 Menu.

Press

d

4) Display advances to

SELF

Self Submenu.

SELF SUBMENU:

The Self Option allows the output of the instrument to be controlled manually

from the front panel.

Press

d

5) Display flashes the current setting of Self,

ENBL

Enabled or

DSBL

Disabled.

Press

b

6) Press the bbutton to select between Enable and Disable.

Press

d

7) If Self

ENBL

Enabled was selected, display shows

STRD

stored message momentarily and then advances to the next

menu (Output 1 setting is completed).

The output is now under the direct control of the operator and

can be adjusted in the Run Mode (

M00.0

to

M99.9

), by pressing

the band cbuttons, where M calls for the Manual (Self)

Control. For example, setting of

M50.0

of an Analog Output of 0

to 10 Vdc would produce roughly 5 Vdc at the output.

8) If Self

DSBL

Disabled was selected, display shows

STRD

stored message momentarily and then advances to

oPLO

Minimum/Percent Low Submenu of Output 1 Menu.

There is a shorter way to Enable or Disable Self Mode. From a Run

Mode, press dand then press a. Self Mode is Enabled now. Press bor

c

to display MXX.X. To disable Self, press dand then press a. Display

goes to the Run Mode. Self Mode is Disabled now.

MINIMUM/PERCENT LOW SUBMENU:

Specify in percent, the minimum value (0000) for control output. If the output is

analog proportional (Current or Voltage), then the minimum voltage or current, in

percent, is specified. If the output is time proportional (Relay, SSR or Pulse),

then the minimum duty-cycle, in percent, is specified.

Press

d

9) Display flashes 1st digit of previous “Percent Low” setting.

Press b& c10) Use band cbuttons to enter a new value for “Percent Low”.

Press

d

11) Display shows

STRD

stored message momentarily and then

advances to

oPHI

Maximum/Percent High Submenu.

Page 41

37

MAXIMUM/PERCENT HIGH SUBMENU:

Specify in percent, the maximum value (99) for control output. If the output is

analog proportional (Current or Voltage), then the maximum voltage or current, in

percent, is specified. If the output is time proportional (Relay, SSR, or Pulse),

then the maximum duty-cycle, in percent, is specified.

Press

d

12) Display flashes 1

st

digit of previous “Percent High” setting.

Press b& c13) Use band cbuttons to enter a new value for “Percent High”.

Press

d

14) Display shows

STRD

stored message momentarily and then

advances to

CTRL

Control Type Submenu.

Example: On an Analog Output of 0~10 Vdc, a setting of %LO = 10 and %HI = 90,

cause the minimum on the control output to be 1 V and the maximum on the

control output to be 9 V. The same setting on a time proportional output, will

cause 10% duty cycle for the minimum control output and 90% duty cycle for

maximum control output. To disable %LO/HI, set LO to 00 and HI to 99. If

%LO/HI

is at other values than the default (%LO = 00, %HI = 99),

SOAK

is disabled.

*CONTROL TYPE OUTPUT:

(Relay, SSR, Pulse or Analog)

Press

d

15) Display flashes

ON.OF

On/Off or

PID

Proportional, Integral,

Derivative.

Press

b

16) Scroll through the available selections: “ON/OFF” or “PID”.

Press

d

17) Display flashes

STRD

stored message momentarily and

then advances to

AçTN

only, if it was changed, otherwise press

a to advance to

AçTN

Action Type Submenu.

The ON/OFF control is a coarse way of controlling the process. The “Dead

Band” improves the cycling associated with the On/Off control. The PID control is

best for processes where the Setpoint is continuously changing and/or a tight

control of the process variable is required. PID control requires tuning and

adjustment of the "Proportional", "Integral or Reset" and "Derivative or Rate"

terms by a trial-and-error method. The instrument provides an "Auto Tuning"

feature making the tuning process automatic, possibly optimum.

* If Analog Output (Current/Voltage) is your control Output 1, this menu i.e.

CTRL

type will not appear, instead

4-20

Current will be displayed. Select

ENBL

for a

4-20 mA current (2-10 V Voltage) outputs or

DSBL

for a 0-20 mA current (0-10 V

Voltage) outputs. If 4-20 mA is enabled, %HI/LO setting will have no effect.

Both Current and Voltage control outputs are active simultaneously.

Page 42

38

ACTION TYPE SUBMENU:

The error that results from the measurement of the Process Variable may be

positive or negative since it may be greater or smaller than the Setpoint. If a

positive error should cause the instrument output to increase (i.e. cooling), it would

be called Direct Acting. If a negative error should cause the output to increase

(i.e. heating), it would be called Reverse Acting.

Press

d

18) Display flashes

DRçT

Direct or

RVRS

Reverse.

Press

b

19) Scroll through the available selections: “Direct” or “Reverse”.

Press

d

20) Display shows

STRD

stored message momentarily and then

advances to

AUTo

only, if it was changed, otherwise press ato

advance to

AUTo

Auto PID Submenu (if PID Control Type was

selected).

If “ON/OFF” was selected in the Control Type, the display skips

to the Dead Band Submenu.

AUTO PID SUBMENU:

Press

d

21) Display flashes

ENBL

or

DSBL

.

Press

b

22) Scroll through the available selections: “Enable” or

“Disable”.

Press

d

23) Display shows

STRD

stored message momentarily and then

advances to

ANTL

only, if it was changed, otherwise press ato

advance to

ANTL

Anti Integral Submenu.

If “Enabled”, the controller can determine, by enabling Start PID, the

optimum values for the three adjustments — Proportional, Reset and

Rate corresponding to P, I, and D. These values may be changed once

the auto tuning is complete.

If “Disabled” is selected, the user will manually enter these three

adjustment values. If you want the instrument to do the auto PID and the

P , PI or PID, first select auto disable and enter 0000 for unwanted

parameter. i.e. for PI enter 0000 for the rate.

ANTI INTEGRAL SUBMENU:

Press

d

24) Display flashes

ENBL

or

DSBL

.

Press

b

25) Scroll through the available selections: “Enable” or “Disable”.

Press

d

26) Display shows

STRD

stored message momentarily and then

advances to

STRT

only, if it was changed, otherwise press ato

advance to

STRT

to Start Auto Tune PID Submenu (If auto PID

was Enabled).

If Auto PID was disabled display advances to

PRoP

Proportional Band Submenu.

Page 43

39

If Anti Integral (Anti Windup) Submenu “Enabled”, this feature allows

the error term outside the proportional band to be calculated and

accumulated for integration. This may be an important feature in

applications where fast response time is desirable.

START AUTO TUNE PID:

Press

d

27) Display flashes

ENBL

or

DSBL

.

Press

b

28) Scroll through the available selections: “Enable” or “Disable”.

Press

d

29) Display shows

STRD

stored message momentarily and then

advances to

CYCL

only, if it was changed, otherwise press ato

advance to

CYCL

Cycle Time Submenu.

If “Enabled”, the controller is ready to calculate P, PI or PID parameters.

The instrument performs this by activating the output and observing the

delay and rate at which the Process Value changes. The setpoints must

be at least 18°F or 10°C above the (PV) Process Value in order to

perform Auto Tune, otherwise an error message will be displayed.

To start Auto Tune PlD select PID, enable Auto PID and enable Start PID.

Sometimes Auto PID parameter needs fine tuning i.e. for each 5°F over

shoot increase the Proportional Band (PB) by 15% and for each ±1°F

fluctuation at the Setpoint (SP) increase reset by 20%.

Once started, display shows A.TUN with letters blinking in the rotating

pattern. When auto tune stops, display will show process value. Do not

perform any operations or settings before first stopping Auto Tune. Any

alarms or other output is disabled during Auto Tune.

If “AUTO PID” was “DISABLED”, the display will show the following

three submenus. This allows the user to manually enter values for

Proportional, Reset and Rate terms corresponding to P, I, and D. It also

can be used for auto PID for disabling unwanted parameter i.e. PI enter

0000 for rate.

PROPORTIONAL BAND SUBMENU:

Press

d

30) Display flashes 1stdigit of the previous P

PRoP

Proportional

band value.

Press b& c31) Press band cbuttons to enter a new “Proportional Band”

value.

Press

d

32) Display shows

STRD

stored message momentarily and then

advances to

REST

only, if it was changed, otherwise press ato

advance to

REST

Reset Setup Submenu.

Proportional band is in degrees of temperature or counts of process. Proportional

band is defined, as the change in the instrument input to cause a 100% change in

the controller output.

Page 44

40

RESET SETUP SUBMENU:

Press

d

33) Display flashes 1stdigit of the previous I

REST

Reset value.

Press b& c34) Press band cbuttons to enter a new “Reset” value.

Press

d

35) Display shows

STRD

stored message momentarily and then

advances to

RATE

only, if it was changed, otherwise press ato

advance to

RATE

Rate Setup Submenu.

Reset unit is in seconds 0-3999.

RATE SETUP SUBMENU:

Press

d

36) Display flashes 1stdigit of previous D

RATE

Rate value.

Press b& c37) Press band cbuttons to enter a new

RATE

value.

Press

d

38) Display shows

STRD

stored message momentarily and then

advances to the

CYCL

only, if it was changed, otherwise press

a

to advance to

CYCL

Cycle Time submenu for RTD and

Thermocouple types.

Rate unit is in seconds 000.0-399.9.

If the Output 1 is Analog Option the display skips to Damping

Factor.

CYCLE TIME SUBMENU:

Press

d

39) Display flashes 1stdigit of the previous

CYCL

Cycle Time

value.

Press b& c40) Press band cbuttons to enter a new “Cycle Time” value.

(1 to 199 seconds)

Press

d

41) Display shows

STRD

stored message momentarily and then

advances to

DPNG

only, if it was changed, otherwise press ato

advance to

DPNG

Damping Factor Submenu.

A Cycle Time selected between 1 and 199 seconds determines the total On/Off

time of each proportional cycle. For example, a 15 second cycle time means that

every 15 seconds the output will turn on for part or all of the cycle. For Relay

control outputs, do not select a cycle time of less than 7 seconds or the relays’

lifetime will be shortened. For a cycle time of less than 7 seconds select SSR or

DC pulse. Use an external SSR with the DC pulse option for higher currents

(higher than 1 Amp).

Page 45

41

DAMPING FACTOR SUBMENU:

Press

d

42) Display flashes the previous “Damping Factor” selection.

Press

b

43) Scroll through the available selections:

0000,0001,0002

,

0003,0004,0005,0006,0007

.

Press

d

44) Display flashes

STRD

stored message and then advances

to

OUT2

only, if it was changed, otherwise press ato advance

to

OUT2

Output 2 Menu.

Damping Factor is a measure of speed, overshoot, and undershoot in which the

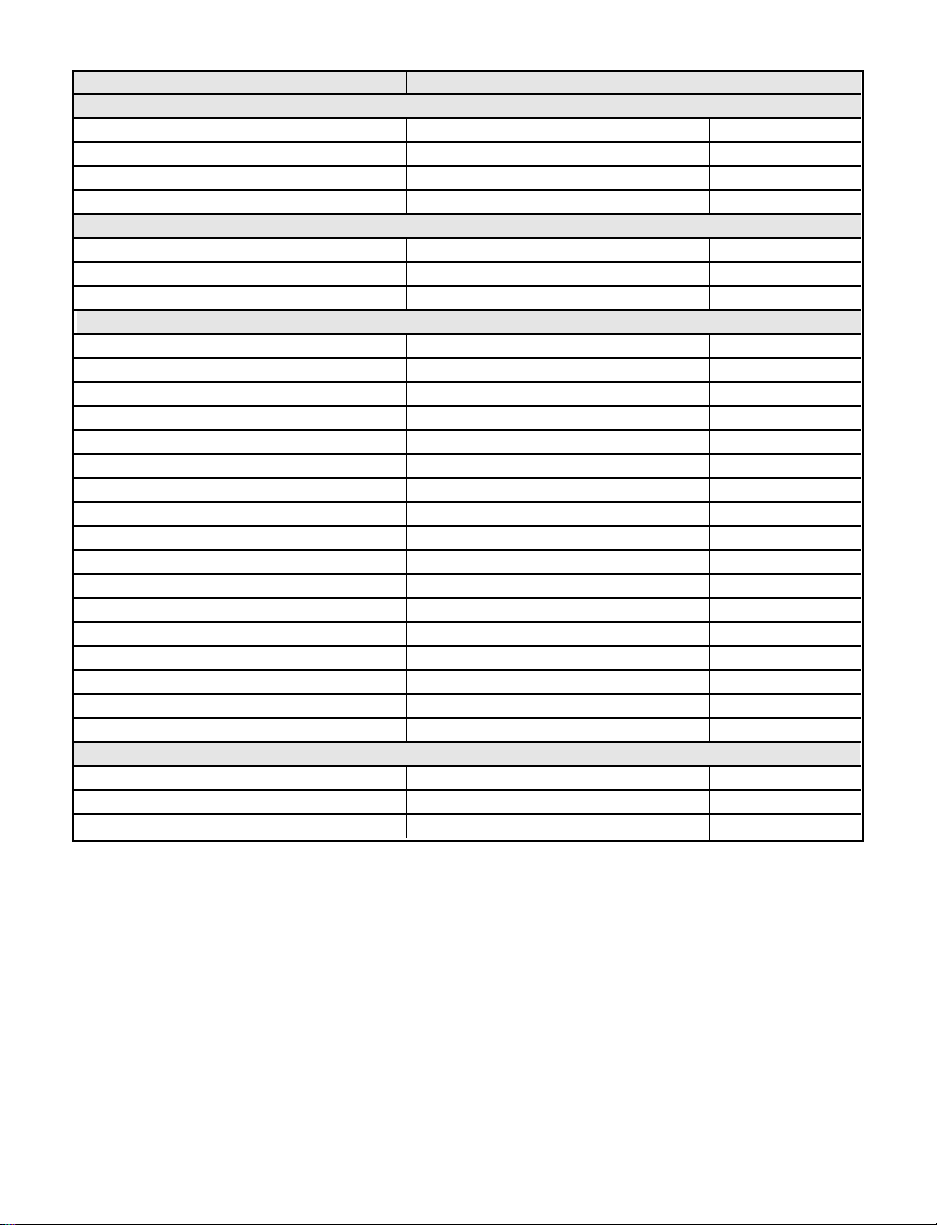

process variable responds to the output changes of the instrument, which were