Page 1

CN8240 & CN8260 Series Communications & Options

omega.com

®

®

TM

www.omega.com

e-mail: info@omega.com

CN8240 &

CN8260

SERIES

Communications &

Options Guide

User’s Guide

Page 2

CN8240 & CN8260 Series Communications & Options

omega.com

®

®

TM

OMEGAnet®On-Line Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: ISO 9001 Certified

One Omega Drive, Box 4047

Stamford CT 06907-0047

Tel: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

For immediate technical or application assistance:

USA and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

®

Servicing Europe:

Benelux:

Postbus 8034, 1180 LA Amstelveen

The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic:

Rudé armády 1868, 733 01 Karviná 8

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France:

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Canada:

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

Mexico:

Tel: (001) 800-826-6342

FAX: (001) 203-359-7807

®

En Espan~ol: (001) 203-359-7803

e-mail: espanol@omega.com

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0800 TC-OMEGA

e-mail: germany@omega.com

United Kingdom: ISO 9002 Certified

One Omega Drive

River Bend Technology Centre

Northbank, Irlam

Manchester M44 5EX England

Tel: +44 (0)161 777 6611

FAX: +44 (0)161 777 6622

Freephone: 0800-488-488

e-mail: sales@omega.co.uk

SM

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification

of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains,

and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

i

Page 3

CN8240 & CN8260 Series Communications & Options

Table of Contents

For information and instructions related to basic operations, refer to the CN8240/CN8260

operator’s manual supplied with your controller.

Option Wiring Diagrams

Alarm Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

24 Volt DC Alarm Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Relay, N.O. Alarm Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

RS-232 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

RS-485 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Transducer Excitation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Auxiliary Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Remote Analog Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Guide to Digital Communications

Remote Communications Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Omega+ Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• Message Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

• Sample Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9, 10

• Request Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

• Response Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

• Communications Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-21

• Auxiliary Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22, 23

• Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26

ii

Page 4

1

2

3

1

1

12

13

23

24

RCV

B(-)

XMT

A(+)

SIG GND

SIG GND

RS 232

RS 485

Relay, N.O.

OUTPUT 2

N.O.

C

N.O.

2

3

12

13

14

15

16

17

18

23

24

8

9

1

0

19

2

0

21 22

4

5

6

7

N.O.

C

N.O.

C

ALARM 1

L1

L2

ALARM 2

120-250 V

50-60 Hz

+

–

+

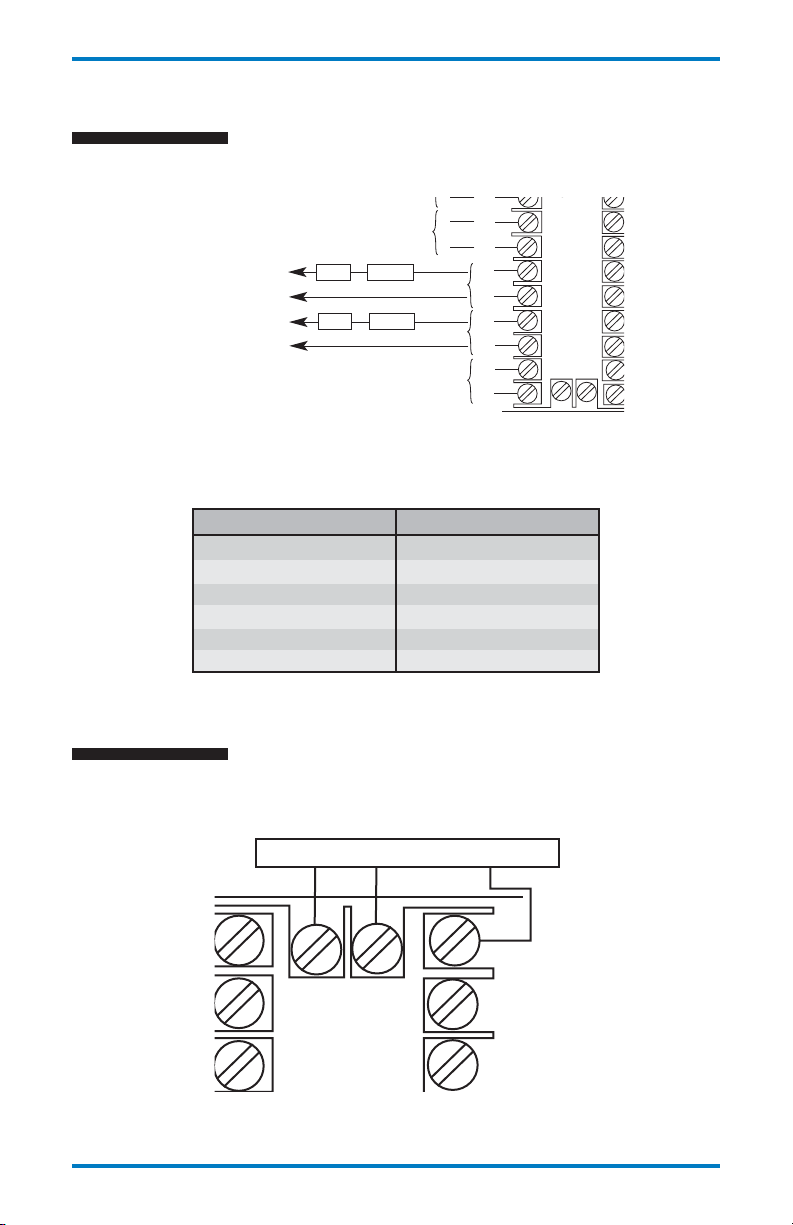

Alarm Output

Option -AL1, -AL2: Relay, N.O. Alarm Output

CN8240 & CN8260 Series Communications & Options

Supply voltage*

Supply voltage*

Load 5 amp fuse

Load 5 amp fuse

Option Description: NO (Normally open) relay contact is closed when either alarm is active. The relay life is greater

than 100,000 operations at 5 operations per second switching full load.

*Connect load and supply voltage per the following table:

Load Type 5 A Voltage Limit

Resistive dc 30 Vdc

Inductive ac (L/R = 7 ms) 20 Vdc

Resistive ac 250 Vac

Inductive ac (pF = 0.4) 150 Vac

Motor, ac, 1/6 hp 250 Vac

Tungsten Lamp, 360 W 120 Vac

RS-232

Communications

Option -C2: RS-232 (one-to-one) Communications

RCV XMT SIG GND

Option Description: Provides a one-to-one connection between the controller and an RS-232 port. Computers,

PLCs, or dumb terminals may be used to set and access controller data.

1

Page 5

CN8240 & CN8260 Series Communications & Options

1

2

3

1

1

12

13

23

24

RCV

B(-)

XMT

A(+)

SIG GND

SIG GND

RS 232

RS 485

+

–

NOTE: FOR 2 WIRE RTD

JUMPER 18 & 20

3

12

13

14

15

16

17

18

8

9

1

0

19

2

0

21 22

4

5

6

7

T/C

+

–

RTD

MA

MV

V

SENSOR

INPUT

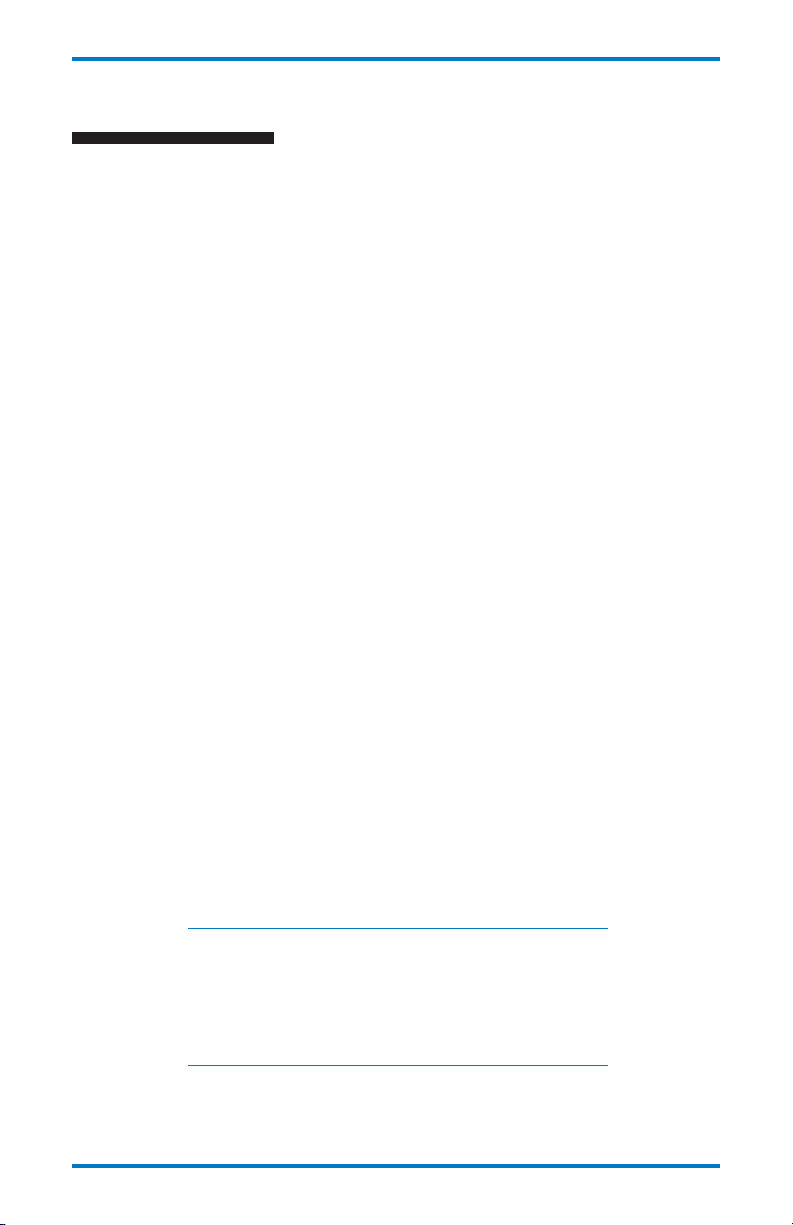

RS-485

Communications

Option -C4: RS-485 (one-to-many) Communications

B(-) A(+) SIG GND

JMP 1

Option Description: Provides one-to-many communications.

Terminate the controller furthest from the computer by either connecting a 120-ohm, 1/4-watt resistor between terminals 23 and 24 or using jumper 1 located on the underside of the communications board as shown above.

Transducer

Power Supply

Options -XP1, -XP2, -XP3, -XP4: Transducer Power Supply

0 to1 volt out = 0 to100% RH

(6 to 30 Vdc input)

Option Description: The transducer power supply option provides power to remote transducers. The transducer

outputs, in turn, provide a signal to the controller input which can be scaled in the appropriate engineering units.

Option -XP1: 15 Vdc

Option -XP2: 12 Vdc

Option -XP3: 10 Vdc

Option -XP4: 5 Vdc

All options will provide at least 20 mA. The transducer circuitry is thermally protected from short circuits.

2

Page 6

CN8240 & CN8260 Series Communications & Options

+

–

NOTE: FOR 2 WIRE RTD

JUMPER 18 & 20

2

3

12

13

14

15

16

17

18

23

24

8

9

1

0

19

2

0

21 22

4

5

6

7

T/C

+

–

RTD

MA

MV

V

SENSOR

INPUT

–

14

15

16

17

18

8

9

19

21 22

4

5

6

7

T/C–RTD

MA

MV

SENSOR

INPUT

1

12

13

14

15

16

17

24

1

12

13

14

15

16

17

24

Process Output

Options -PVSV1, -PVSV2: Process Output

Connect jumper between pins 16 and

17 for option -PVSV2

Option PVSV2

(0-5 V)

Option -PVSV1

(4-20 mA)

Option Description: The Setpoint Variable or Process Variable is transmitted to a remote device (chart recorders,

indicators, data recorders, computers, process controllers, etc.) with 1 of 2 different interfaces:

Option -PVSV1: 4-20 mA

Option -PVSV2: 0-5 V

The output signal is scalable in the Auxiliary Output Menu. Multiple remote indicators may be driven by the controller.

For current (mA) options, the remote indicators are connected in series. The sum of the input resistance for all

remote indicators must be less than 400 ohms. For voltage options, the remote indicators are connected in parallel.

The sum of the currents for all remote indicators must be less than 10 mA.

Remote

Setpoint Options

Options -DIC, -RSP4, -RSP5, -RSP6, -RSP7: Remote Setpoint

Options -RSP4, -RSP5, -RSP6, -RSP7

0-5 V/1-5 V/0-10 V

0-20 mA/4-20 mA

}

Enable

Switch

→

10K

CW

Remote analog setpoint

(voltage/current input)

(potentiometer with

enable switch)

Option Description: Remote setpoints use either voltage or current inputs, depending on the specified option:

Option -DIC: Switch Input Closed

Option -RSP4: 0-5 Vdc

Option -RSP5: 1-5 Vdc

Option -RSP6: 0-20 mA

Option -RSP7: 4-20 mA

The input signal is scalable in the Remote Analog Setpoint Menu. Activation of the analog setpoint causes the F1

indicator to illuminate. For current (mA) options, the input resistance is 255 ohms. For voltage input options, the

input resistance is greater than 10K ohms.

input option menu controls the programming of this switch.

*Ground shield at one end, taking care not to run wires next to power circuitry. Maximum length will be determined

by noise performance.

Note: Switch input option -DIC is active when switch is closed. The digital

3

Option -DIC

Switch input onlyRemote analog setpoint

Enable

Switch

Page 7

CN8240 & CN8260 Series Communications & Options

omega.com

®

®

CN8240/CN8260 Series

Controllers

with

Digital

Communications

Option

4

Page 8

CN8240 & CN8260 Series Communications & Options

1

2

3

1

1

12

13

14

15

16

23

24

4

5

6

RCV

B(-)

XMT

A(+)

SIG GND

SIG GND

RS 232

RS 485

DIGITAL COMMUNICATIONS

Digital

Communications Option

Remote Communications Options

RS-232

This method allows bidirectional data transfer via a three-conductor cable consisting of signal ground, receive input

and transmit output. It is recommended for communication distances less than 50 feet between the computer terminal and the instrument. Note: Multiple instruments cannot be connected to the same port.

The RS232 port is optically isolated to eliminate ground loop problems. Typically, “Data Out” of the computer/

terminal connects to the “RCV” terminal. “Data In” connects to the “XMT” terminal. If shielded cable is used, it

should be connected to the frame ground at one end only. Signal ground is to be connected at appropriate ground

terminals (refer to wiring diagram on bottom of this page).

RS-485

The RS485 multipoint capability allows up to 32 controllers to be connected together in a half-duplex network or up

to 100 controllers with an appropriate communications repeater.

This method allows bidirectional data transfer over a twisted pair cable. The twisted pair cable is a transmission line;

therefore, terminating resistors are required at the most distant ends of the line to minimize reflections (typically 120

ohms at each end). The RS485 circuit is fully optically isolated, eliminating ground loop problems. Parallel drops

from the transmission lines should be kept as short as possible; however, the line may be daisy-chained at each

controller. The polarity of the line is important and each device will specify an “A” (+) and “B” (-) connection.

Figure 1. Wiring diagram for digital communications.

Three remote communications options are available for the CN8240/CN8260 which allow interfacing to remote

devices utilizing the most common industry standards: RS232 and RS485.

Call factory for a recommended RS485 converter.

5

Page 9

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Omega+ Protocol

The Omega+ Protocol provides an easy way to query and modify controller parameters using a personal computer

and the optional digital communications option of the 18C/25C.

In this manual, the word “host” refers to the personal computer that’s communicating with the controllers in the

serial link, and the word “slave” refers to the controllers themselves.

All transactions between the host and the slaves are done with messages consisting of only printable ASCII characters. There are only two primary types of messages: Requests and Responses. Messages coming from the host are

called requests and messages coming from the slaves are called responses.

With the exception of a broadcast request, for every request sent from the host, the slave will send back a response.

If a slave does not respond within 100 milliseconds, then the request can be considered lost.

A broadcast request is a request having an ID of ‘00’ (see Message Formats below). It is used to address all slaves

on the network. All slaves on the network will perform the actions requested in a broadcast message. However, a

response message will not be returned. Therefore, the host can only broadcast Write or Auxiliary Command

Requests. All slaves will ignore all Read Broadcast Requests.

Message Formats

All Omega+ messages adhere to the general format of:

[START CHAR][ID][ZONE][TYPE][PARAM][ERROR][DATA][CHKSUM][END CHAR]

START CHAR

This is a single character which designates the start of the message. For a Request message, this character is the

ASCII ‘$’ and for a Response message, this character is the ASCII ‘%’.

ID

This is a two-character ID identifying the receiving controller. Controller IDs go from 1-255 inclusively and all slaves

in the network must have unique IDs. The ID number of ‘00’, when used in a request, designates a broadcast message that is used to address all controllers in the network. See the section Request Message for an explanation of the

broadcast message.

In order to represent 255 with just two ASCII characters, a number system known as the Message Code Numbering

System is used. In this system, the most significant digit is represented with the numbers 0-9 and the letters A-Z

and the least significant digit is represented with the numbers 0-9.

The numbers 0-9 have the same values as their decimal counterparts and the letters A-Z have the values of 100 - 50

inclusively in increments of 10.

Example:

Message Code Value = Decimal Value

00 0 + 0 = 00

99 90 + 9 = 99

A0 100 + 0 = 100

A2 100 + 2 = 102

B8 110 + 8 = 118

P5 250 + 5 = 255

Zone

This is a two character ID identifying the Zone number in multi-zone capable controllers. For the 18C/25C, this number must be 01.

6

Page 10

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Type

This is a single character identifying the type of message. The following table lists the type characters for all messages.

TYPE character Message Type

R Read Request or Read

r Read Response Returning a Negative Result

W Write Positive Value Request and Response

w Write Negative Value Request and Response

A Auxiliary Command

For further information, see following sections on the different message types.

This is a two character, message specific, parameter ID. For a Read/Write Request or Response message, this

ID identifies the controller parameter. For an Auxiliary Command Request or Response message, this ID specifies

the command.

Code Description

0 No error.

1 Framing error.

2 Hardware error.

3 Parity error.

4 Bad character in the TYPE field.

5 Bad message. Message cannot be understood.

6 Bad checksum. The checksum received

7 Bad zone ID.

8 Bad auxiliary command ID. The auxiliary

9 Bad parameter ID. The parameter is not

A Bad data. Bad representation in the data field

B Attempt to write to a read only parameter.

C Cannot write to a parameter because it’s in use.

Response Returning a Positive Result

PARAM

ERROR

did not match the checksum of the message.

command is not supported in this controller.

supported in this controller.

or data is out of range.

7

Page 11

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Examples of valid numeric representations for a 6 character data field:

Numeric Value ASCII Representation

3 3.0000

100 100.00

3.2 003.20

000003

003.00

0100.0

000100

0003.2

Examples of invalid numeric representations for 6 character data field:

Numeric Value Bad ASCII Representation Why?

3 BBBBB3 Leading blanks

3.2 -3.20000 ‘-’ is not allowed.

(B represents a blank, or a space, character)

are not allowed.

3.0BBBB Trailing blanks

are not allowed.

CHKSUM

This is a two character Message Code Numbering System, representing the sum of all the ASCII values of all the

characters (excluding the START, CHAR, the END CHAR, and the CHKSM themselves) in the message. The sum

is computed using the following formula:

CHKSM = SUM(All Message Characters)%256

% represents the modulus operator.

END CHAR

This is a single character designating the end of the message. For all messages, the character used is <CR>, the

carriage return.

8

Page 12

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

READ COMMAND TO CONTROLLER

Controller ID

Start of Message

READ RESPONSE FROM CONTROLLER

Read Command

Checksum

$0101R01B7<CR>

End of Message

Parameter Number

Zone Number

Read Command

Controller ID

Data

Checksum

%0101R0502.0000J7<CR>

Start of Message

Parameter Number

Zone Number

End of Message

WRITE COMMAND TO CONTROLLER

Write Command

Controller ID

Checksum

Data

$0101W1025.000G7<CR>

Start of Message

Parameter Number

Zone Number

End of Message

9

Page 13

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

WRITE RESPONSE FROM CONTROLLER

Controller ID

Write Command

No Error

Checksum

%0101W090H8<CR>

Start of Message

Parameter Number

Zone Number

End of Message

AUXILIARY COMMAND TO CONTROLLER

Auxiliary

Controller ID

Command

Data

Checksum

$0101A020.0000000067<CR>

Start of Message

Parameter Number

Zone Number

End of Message

AUXILIARY RESPONSE FROM CONTROLLER

Auxiliary

Controller ID

Command

No Error

Checksum

%0101A020E9<CR>

Start of Message

Parameter Number

Zone Number

10

End of Message

Page 14

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

The Read Request:

The Read Request is used to query parameter values and it has the following message format:

[START CHAR][ID][ZONE][TYPE][PARAM][CHKSUM][END CHAR]

Field Description: TYPE Must contain the uppercase letter ‘R’.

Request Message Description

$Ø1Ø1RØ5C1<CR> Queries the value of the Process Variable

$Ø1Ø1RØ9C5<CR> Queries the value of the EEPROM

$Ø2Ø1RØ9C6<CR> Queries the value of the EEPROM

Request Messages are sent from the host to the slaves. Each request will have an ID identifying the intended

recipient of the request. If the ID is ‘00’ (zero), then the request is a broadcast message.

All slaves will perform the action requested in the broadcast request. However, a response message will not be

returned. Therefore, it only makes sense to send Write or Auxiliary Command Requests as broadcast requests.

There are three types of Request Messages: Read, Write, and Auxiliary Commands.

of Controller #1.

Setpoint 1 of Controller #1

Setpoint 1 of Controller #2.

END CHAR

CHKSUM

PARAM

TYPE

ZONE

ID

START CHAR

*Examples of the responses to these requests are given in later sections on Response Messages.

11

Page 15

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

The Write Request:

The Write Request is used to modify parameter values and it has the following message format: [START

CHAR][ID][ZONE] [TYPE][PARAM][DATA][CHKSUM][END CHAR]

Field Description: TYPE This field must contain one of the following

Request Message Description

$Ø1Ø1WØ91Ø.123G7<CR> Change both the RAM and EEPROM

$Ø1Ø1w1Ø1Ø.123J1<CR> Change only the RAM copy of setpoint #1

two characters.

W – Value in DATA is a positive value.

w – Value in DATA is a negative value.

DATA A six-character ASCII representation of a numeric value.

copies of Setpoint #1 in controller #1

to the value of 10.123

in controller #1 to the value of -10.123

(notice the lowercase ‘w’).

END CHAR

CHKSUM

DATA

PARAM

TYPE

ZONE

ID

START CHAR

12

Page 16

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

The Auxiliary Command Request:

The Auxiliary Command Request is used to issue commands to the controllers and it has the following message format:

Field Description: TYPE This field must contain the uppercase letter ‘A’

DATA A ten-character ASCII representation of a numeric value or

10 alphanumeric ASCII characters.

Request Message Description

$Ø1Ø1AØ1XXXXXXXXXXL2<CR> Tell controller #1 to load all

$Ш2Ш1AШ2ШШШ1.ШШШШШ69<CR> Tell controller #2 to perform a low

parameters with their defaults.

The 10 X’s are padding characters.

RTD calibration.

END CHAR

CHKSUM

DATA

PARAM

TYPE

ZONE

ID

START CHAR

Response Messages:

Response Messages are replies to the requests sent from the host. For each

request received, the slave will reply back with a response.

For all requests, the Omega+ Protocol specifies a maximum response time

of 100 milliseconds. If the controller does not start responding within 100

milliseconds after the last request character is received, that request can be

considered lost. See Figure 2 below.

There are three types of Response Messages:

Read, Write, and Auxiliary Commands.

Figure 2. Maximum Time Interval Between Host Request and

Slave (Controller) Response.

100 ms max.

Request Message

13

Response Message

Page 17

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

The Read Response:

The Read Response will be sent in response to a Read Request. Some examples:

Request Message Description

%Ø1Ø1RØ5Ø21.123K8<CR> The value of the Process

%Ø2Ø1R1Ø1G7<CR> A serial transmission has occurred:

%Ø1Ø1rØ9Ø21.ØØØN8<CR> The value of the EEPROM setpoint #1 is

Variable is 21.123 Degrees C.

Framing Error

-21 Degrees C (notice the lowercase ‘r’).

END CHAR

CHKSUM

DATA

STATUS

PARAM

TYPE

ZONE

ID

START CHAR

The Write Response:

The Write Response will be sent in response to a Write Request. Some examples:

Request Message Description

%Ø1Ø1WØ93I1<CR> A serial transmission error has occurred:

%Ø1Ø1w1ØØK2<CR> RAM copy of setpoint #1

Parity error. Write failed.

modified successfully.

END CHAR

CHKSUM

STATUS

PARAM

TYPE

ZONE

ID

START CHAR

14

Page 18

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

The Auxiliary Command Response:

The Auxiliary Command Response will be sent in response to an Auxiliary Command Request. Some examples are:

Request Message Description

%Ø1Ø1AØ1ØXXXXXXXXXXØ4<CR> Default load all parameters

%Ш2Ш1AШ2ШШ.ШШШШШШШШB6<CR> RTD low calibration on controller

has started.

#2 has started.

END CHAR

CHKSUM

DATA

STATUS

PARAM

TYPE

ZONE

ID

START CHAR

Table 1. Communications Parameter List (Omega+ Protocol)

Number Name Read Write Data Field Value

1 Controller Type X 0 3

2 Software Version X 0

3 Communications Version X 0

4 Status Byte X 0 This field contains the ASCII

CN8240/CN8260 Parameter Codes

“X”s mark parameters that are supported by

the CN8240 and CN8260 and “O”s indicate

parameters that are not supported.

representation of an 8-bit value

in which the bit assignments are as follows (starting

from the least significant bit):

X Process Input Error

X RAS Error

0 Always Zero

X Loop Break

X Alarm 1 Active

X Alarm 2 Active

0 Always Zero

0 Always Zero

If a bit at a location marked as “X”

is set, then the condition is TRUE.

For example, a “48.000” in the data field means that

both alarm 1 and alarm 2 are active and everything

else is FALSE.

15

Page 19

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Table 1. Continued

Number Name Read Write Data Field Value

5 Process Value X 0

6 Operating Mode X X 1 - Manual

7 Access Level X X 1 - Lockout

8 Contact/Digital Input State X 0 0 - Switch Open

9 Setpoint, RAM, EEPROM X X

10 Setpoint, RAM Only X X

11 Second Setpoint,

RAM, EEPROM X X

12 Second Setpoint,

RAM only X X

13 Remote Analog Setpoint X 0

14 Recipe Setpoint X 0

16 Output 1 Percentage X 0

17 Output 2 Percentage X 0

18 Manual Control

Output 1 Percentage X X

19 Manual Control

Output 2 Percentage X X

20 Output 1 Deadband X X

21 Output 1 Hysteresis X X

22 Output 1 Proportional X X

Band

23 Output 2 Proportional X X

Band

30 Rate (Derivative) Value X X

32 Reset (Integral) Value X X

34 Manual Reset X X

(Integral) Value

37 Output 2 Deadband X X

38 Output 2 Hysteresis X X

2 - Standby

3 - Normal (automatic)

4 - Initiate Autotune

5 - Recipe Run

6 - Recipe Hold

2 - Setpoint

3 - Setpoint Plus

4 - User

5 - Configuration

6 - Factory

1 - Switch Closed

16

Page 20

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Table 1. Continued

Number Name Read Write Data Field Value

39 Autotune Damping X X 1 - Low

40 Recipe Option X X 0 - Disabled

X X 1 - Single Step

X X 2 - Multi-Step

41 Single-Setpoint X X

Ramp Time

42-49 Ramp Times 1-8 X X

50-57 Ramp Events 1-8 X X 0 - Disabled

58-65 Soak Levels 1-8 X X

66-73 Soak Times 1-8 X X

74-81 Soak Events 1-8 X X 0 - Disabled

82 Recycle Number X X

83 Holdback Band X X

84 Termination State X X 0 - Last Setpoint

85 Power Fail Resume X X 1 - Resume Off

Enable 2 - Resume On

86 Input Bias X X

87 Input Low Scale X X

88 Input High Scale X X

89 Lower Setpoint Limit X X

90 Upper Setpoint Limit X X

91 Input Filter X X

2 - Normal

3 - High

1 - Event 1 On

2 - Event 1 Off

3 - Event 2 On

4 - Event 2 Off

1 - Event 1 On

2 - Event 1 Off

3 - Event 2 On

4 - Event 2 Off

1 - Default Setpoint

2 - Recipe to Standby Mode

17

Page 21

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Table 1. Continued

Number Name Read Write Data Field Value

92 Input Type X X 0 - B Thermocouple

94 Output 1 Type X X 1 - Inactive/Disabled

1 - C Thermocouple

2 - E Thermocouple

3 - J Thermocouple

4 - K Thermocouple

5 - N Thermocouple

6 - NNM Thermocouple

7 - R Thermocouple

8 - S Thermocouple

9 - T Thermocouple

10 - Platinel II Thermocouple

11 - RTD (Integer)

12 - RTD (Decimal)

13 - 0-20 mA

14 - 4-20 mA

15 - 0-10 mV

16 - 0-50 mV

17 - 0-100 mV

18 - 10-50 mV

19 - 0-1 V

20 - 0-5 V

21 - 0-10 V

22 - 1-5 V

2 - PID

4 - On/Off

95 Output 1 Action X X 1 - Direct

2 - Reverse

18

Page 22

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Table 1. Continued

Number Name Read Write Data Field Value

A2 Output 1 Cycle Time X X

A3 Output 1 Low Limit X X

A4 Output 1 High Limit X X

A5 Output 2 Type X X 1 - Inactive/Disabled

2 - PID

4 - On/Off

A6 Output 2 Action X X 1 - Direct

B3 Output 2 Cycle Time X X

B4 Output 2 Low Limit X X

B5 Output 2 High Limit X X

B6 TC/RTD Decimal Position X X

B7 Linear Decimal Position X X

B8 Display Filter X X

B9 Display Units X X 1 - Fahrenheit

C1 Display Blanking X X

C2 Alarm 1 Action 1- Off

C3 Alarm 1 Operation X X 1- Process High

C4 Alarm 1 Delay X X

C5 Alarm 1 Inhibit X X

C6 Alarm 1 Process Setpoint X X

C7 Alarm 1 Deviation Setpoint X X

C8 Alarm 2 Action X X 1 - Off

C9 Alarm 2 Operation X X 1 - Process High

2 - Reverse

2 - Celsius

3 - Kelvin

2 - Normal

3 - Latched

4 - Event

2 - Process Low

3 - Deviation High

4 - Deviation Low

5 - Normal Band

6 - Inverse Band

2 - Normal

3 - Latched

4 - Event

2 - Process Low

3 - Deviation High

4 - Deviation Low

5 - Normal Band

6 - Inverse Band

19

Page 23

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Table 1. Continued

Number Name Read Write Data Field Value

D0 Alarm 2 Delay X X

D1 Alarm 2 Inhibit X X

D2 Alarm 2 Process Setpoint X X

D3 Alarm 2 Deviation Setpoint X X

D4 Communications Protocol X 0 1 - Omega +

D5 Communications ID X X

D6 Baud Rate X X 0 - 75

D7 Data Format X X 0 - 7-0-1

D8 Communications

Transmit Delay X X

E1 Output 1 Failsafe % X X

E2 Output 2 Failsafe % X X

E3 Loop Break Time X X

E4 Highest Reading X X

E5 Lowest Reading X X

E8 Option Selection X 0 1 - Comm Option

E9 TC Zero Calibration X X

F0 TC Span Calibration X X

F1 RTD Zero Calibration X X

F2 RTD Span Calibration X X

F3 Low-Voltage Zero

Calibration X X

F4 Low-Voltage Span

Calibration X X

F5 High-Voltage Zero

Calibration X X

1 - 150

2 - 300

3 - 600

4 - 1200

5 - 2400

6 - 4800

7 - 9600

1 - 7-E-1

2 - 7-N-2

3 - 7-0-2

4 - 7-E-2

5 - 8-N-1

6 - 8-0-1

7 - 8-E-1

8 - 8-N-2

20

Page 24

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Table 1. Continued

Number Name Read Write Data Field Value

F6 High-Voltage Span

F7 Current Zero Calibration X X

F8 Current Span Calibration X X

G1 Auxiliary Output Variable X X

G2 Auxiliary Output Scale Low X X

G3 Auxiliary Output Scale High X X

G5 RAS Scale Low X X

G6 RAS Scale High X X

G7 Contact/Digital Switch X X 1 - Disabled

H2 Autotune State X 0 0 - Success

H3 Recipe State X 0

H5 Current Recipe Statement X 0

H6 Active Setpoint X X

H7 Resume Exhaustion Flag X 0

H8 LED Status Indicator X 0

H9 RTD Decimal Zero

I0 RTD Decimal Span

I1 1-5 V, 0-10 V

I2 1-5 V, 0-10 V

I3 10-050 mV, 0-100 mV

I4 10-50 mV, 0-100 mV

Calibration X X

2 - Second Setpoint Select

3 - Standby Select

4 - Run/Hold Switch

1 - Aborted

2 - Error: No PID Output

3 - Error: No Deviation

4 - Error: No Output

5 - Error: Timed out

6 - Error: Bad Tune

7 - Waiting for PV to settle

8 - Reverse Tune In Progress

9 - Direct Tune In Progress

Calibration X X

Calibration X X

Zero Calibration X X

Span Calibration. X X

Zero Calibration X X

Span Calibration X X

21

Page 25

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Auxiliary Commands:

Command: Load Parameter Defaults

Parameter #: 01

Description Restore all menu parameters to their default values.

Request Data Field: Ignored.

Response Data Field: Ignored.

Command: Perform Process Low Calibration

Parameter #: 02

Description: Performs a Low Calibration. The data field in the request

message specifies the process. Make sure the prerequisite

for the calibration is satisfied before issuing a calibration

command. For instance, the RTD calibration command must

only be used when the input sensor type is chosen as RTD

or RTD w/ Decimal.

22

Page 26

CN8240 & CN8260 Series Communications & Options

Digital

Communications Option

Request Data Fields: A 10-character ASCII representation of a numeric value

Response Data Field: Ignored.

Command: Perform Process High Calibration

Parameter #: 03

Description: Performs a High Calibration. The data field in the request

Request Data Field: A 10-character ASCII representation of a numeric value

Command: Retrieve Display

Parameter #: 05

Description: Retrieves the string currently displayed on the slave’s display.

Request Data Field: A 10 character ASCII representation of a numeric value

Response Data Field: The ASCII string.

Command: Clear Latched Alarms

Parameter #: 10

Description: Clear all latched alarms.

Request Data Field: Ignored.

Response Data Field: Ignored.

specifying what to calibrate.

0 - Thermocouple

1 - RTD, Resistive Thermal Device

2 - Linear

3 - RAS, Remote Analog Setpoint

message specifies the process. Make sure the prerequisite

for the calibration is satisfied before issuing a calibration

command. For instance, the RTD calibration command must

only be used when the input sensor type is chosen as RTD

or RTD w/ Decimal.

specifying what to calibrate.

0 - Thermocouple

1 - RTD, Resistive Thermal Device

2 - Linear

3 - RAS, Remote Analog Setpoint

The data field in the request message specifies which display

and the data field in the response message contains the string.

specifying which display to retrieve data from.

0 - Lower Display

1 - Upper Display

23

Page 27

Notes

CN8240 & CN8260 Series Communications & Options

24

Page 28

Notes

CN8240 & CN8260 Series Communications & Options

25

Page 29

Notes

CN8240 & CN8260 Series Communications & Options

26

Page 30

OMEGA ENGINEERING, INC. warran ts this uni t to be free of defects in materials and workmanship for a period of 25

WARRANTY/ DISCLAIMER

months from date of purchase. OMEGA's Warranty adds an additional one (1) month grace pe riod to the normal two (2)

year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum cover-

age on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an

Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be

defective it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the

purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or

unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of

having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its

products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only

that the pa rts manufac tured by it will be as spe cifi ed and free of defects . OM EGA MAKES NO OT HER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS

FOR A PART ICU LA R PURPOS E AR E H ERE BY DISCLA IME D. LIMITATION OF L IAB ILI TY: The re med ies o f

purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether

based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the

purchas e price of the com pone nt upon whi ch li abili ty is base d. In n o event shal l OM EGA be lia ble for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under

10 CFR 21 ( NRC), used in or with any nuclear installation or activity; or (2 ) in medical applications or used on humans.

Should any Pro duct(s) be used in or with any nucle ar installation or acti vity, medical ap plication, used on humans, or

misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language, and,

additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising

out of the use of the Product(s) in such a manner.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY

PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FR OM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROC ESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE contacting

OMEGA:

1. Purchase Order number under which the

product was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to mak e running changes, not model changes, whenever an improvement is possible. This affords our customers the

latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2008 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

RETURN REQUESTS/ INQUIRIES

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

Page 31

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

– Thermocouple, RTD & Thermistor Probes, Connectors,

Panels & Assemblies

– Wire: Thermocouple, RTD & Thermistor

– Calibrators & Ice Point References

– Recorders, Controllers & Process Monitors

– Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

– Transducers & Strain Gages

– Load Cells & Pressure Gages

– Displacement Transducers

– Instrumentation & Accessories

FLOW/LEVEL

– Rotameters, Gas Mass Flowmeters & Flow Computers

– Air Velocity Indicators

– Turbine/Paddlewheel Systems

– Totalizers & Batch Controllers

pH/CONDUCTIVITY

– pH Electrodes, Testers & Accessories

– Benchtop/Laboratory Meters

– Controllers, Calibrators, Simulators & Pumps

– Industrial pH & Conductivity Equipment

DATA ACQUISITION

– Data Acquisition & Engineering Software

– Communications-Based Acquisition Systems

– Plug-in Cards for Apple, IBM & Compatibles

– Datalogging Systems

– Recorders, Printers & Plotters

HEATERS

– Heating Cable

– Cartridge & Strip Heaters

– Immersion & Band Heaters

– Flexible Heaters

– Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

– Metering & Control Instrumentation

– Refractometers

– Pumps & Tubing

– Air, Soil & Water Monitors

– Industrial Water & Wastewater Treatment

– pH, Conductivity & Dissolved Oxygen Instruments

900M124U00B

Loading...

Loading...