Omcan Food Machinery PE-IT-0049-D Installation Manual

Pizza Ovens

Models PE-IT-0024-S, 0048-D, 0049-D, 0049-DD

Instruction Manual

Revised - 11/14/2014

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: sales@omcan.com

www.omcan.com

Table of Contents

Model PE-IT-0024-S / Model PE-IT-0048-D

Model PE-IT-0049-D / Model PE-IT-0049-DD

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

French Instructions

------------------------------------------------------------------------------------------------------------------ 6

------------------------------------------------------------------------------------------------------------- 7 - 13

------------------------------------------------------------------------------------------------------------- 14

------------------------------------------------------------------------------------------------- 3 - 4

------------------------------------------------------------------------------------------------- 4 - 5

--------------------------------------------------------------------------------------------------- 15 - 16

----------------------------------------------------------------------------------------------- 16 - 29

Page

------------------------------------------------------------------------------------------------ 5

Spanish Instructions

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

----------------------------------------------------------------------------------------------------------------------- 58

-------------------------------------------------------------------------------------------------- 44 - 53

--------------------------------------------------------------------------------------------- 30 - 43

-------------------------------------------------------------------------------------------- 54 - 57

-------------------------------------------------------------------------------------------------- 59

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan ne

sont pas responsables de tout dommage ou blessure causé du fait que toute personne ait utilisé

cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de plus de 18

ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour utiliser

cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication de la

machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine ou

des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan no son responsables de ningun daño o perjuicío causado por cualquier persona inadecuada o

el uso descuidado de este equipo. El producto solo podra ser operado por una persona mayor de 18

años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido entrenado

en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada. Cualquier

modicación a la máquina anúla la garantía y puede causar daños a las personas usando la máquina

mientras esta en el funcionamiento.

3

General Information

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Safety and Warranty

WARNINGS FOR THE INSTALLER

Check that the location of the oven is in compliance with local and national regulations.

• Adhere to the instructions in this manual.

• Do not execute electrical connections using temporary or uninsulated cables.

• Check that the ground connection of the electrical system is functioning properly.

• Always use individual safety devices and other means of protection in compliance with the law.

WARNING FOR THE USER

The conditions in the surrounding area where the machine will be installed must have the following

characteristics:

• The area must be dry.

• The area must have water and heat sources at an adequate distance.

• Ventilation and lighting must be suitable and comply with the hygiene and safety standards foreseen by

current laws.

• The oor must be at and compact to facilitate thorough cleaning.

• There must be no obstacles of any kind in the immediate vicinity of the machine that could effect the

machine’s normal ventilation.

In addition, the user must:

• Make certain to keep children away from the machine when it is operating.

• Adhere to the instructions in this manual.

• Not remove or tamper with the safety devices on the machine.

• Always pay careful attention to the work at hand and not use the machine when in a distracted state.

• Perform all operations with maximum safety and calm.

• Respect the instructions and warnings displayed on the machine labels.

The labels are accident prevention devices, and therefore must always be perfectly legible. If these should be

4

Safety and Warranty

damaged and illegible, it is mandatory to replace them by requesting replacements from the Manufacturer.

• At the end of each working shift, before cleaning, maintenance or transfer operations, disconnect electrical

power.

WARNINGS FOR THE MAINTENANCE OPERATOR

Observe the instructions indicated in this manual.

• Always use individual safety devices and other protection means.

• Before starting any maintenance operations, make sure that the oven, it was used, is cooled down.

• If any of the safety devices is worn or faulty, the oven is also considered faulty and not to be used.

• Disconnect electrical power before intervening on electrical or electronic parts and connectors.

1 YEAR WARRANTY

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

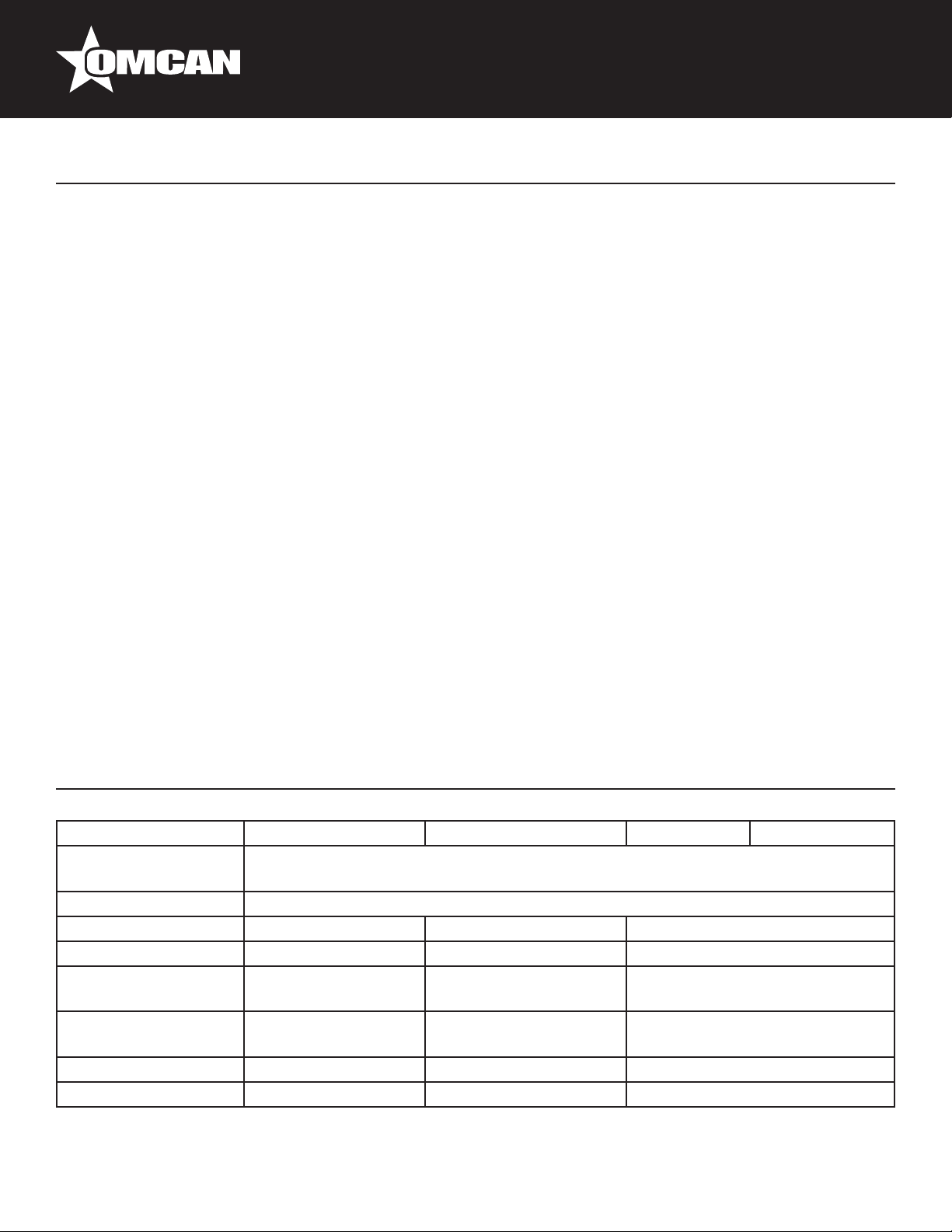

Technical Specications

Model PE-IT-0024-S PE-IT-0048-D PE-IT-0049-D PE-IT-0049-DD

Maximum

Temperature

Electrical 220V/60/3

Power 6.6 kW 13.2 kW 18 kW

Volume 23.7 Cu. Ft. 36.7 Cu. Ft. 48.7 Cu. Ft.

Chamber Dimensions

External Dimensions

Net Weight 115 kg. / 253 lbs. 183 kg. / 403.4 lbs. 231 kg. / 509 lbs.

Gross Weight 132 kg. / 291 lbs. 201 kg. / 443 lbs. 254 kg. / 560 lbs.

27.6” x 27.6” x 5.9”

701 x 701 x 150mm

43” x 39.8” x 16.9”

1092 x 1011 x 429mm

(27.6” x 27.6” x 5.9”) x 2

(701 x 701 x 150mm) x 2

43” x 39.8” x 29.5”

1092 x 1011 x 749mm

842°F / 450°C

(41.3” x 27.6” x 5.9”) x 2

(1049 x 701 x 150mm) x 2

56.9” x 39.8” x 29.5”

1445 x 1011 x 749mm

5

Installation

Installation must be executed by qualied personnel in compliance with local and national regulations.

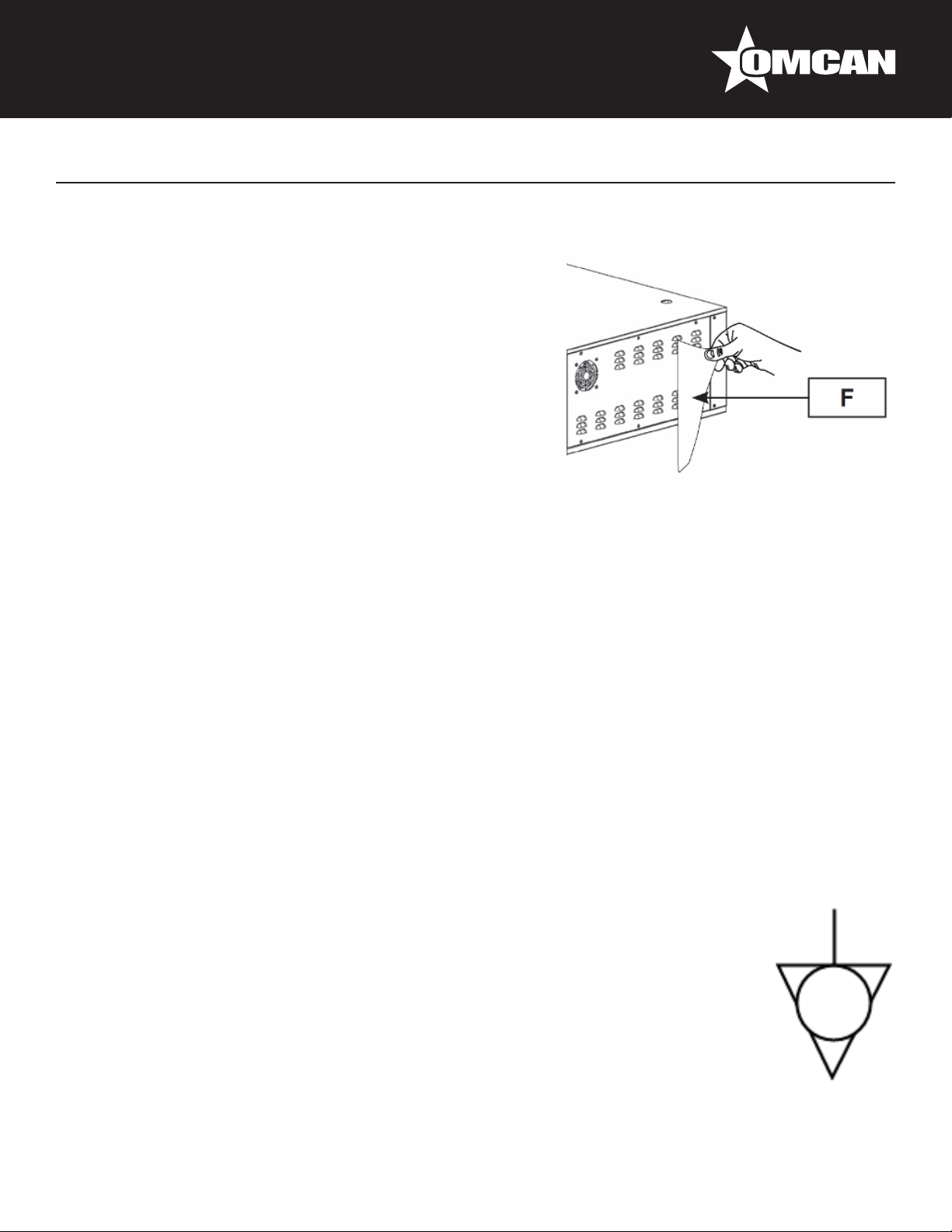

OVEN POSITIONING

Ensure that the oven is put on a stand with the suitable carrying

capacity and that is at.

After unpacking the oven from its packing, position it in prepared

location, taking into account the minimum distances.

Remove possible protections in polystyrene and take off the

protecting lm (F) avoiding to use tools which can damage the

surfaces.

EQUIPMENT HOOK-UP

Electrical connection

The oven is not provided with power supply cable. When connecting the appliance electrically, an automatic

RCD must be interposed with an opening distance between contacts of at least 3 mm. To connect the

appliance electrically it is essential to proceed in the following way:

• Remove the right side panel.

• Connect to the terminal block the power cable.

The power supply cable must be of H07-RNF type, with approved minimum cross section as prescribed by the

specic directive.

The electrical outlet must be easy to access, no moving should be necessary.

The electrical connection (plug) must be easily accessible, also following oven installation.

The distance between the machine and the socket must be adequate to not cause tension in the power supply

cable. In addition, the cable must not be located beneath the machine support base.

If the electrical power supply cable is damaged, it must be replaced by the technical assistance service

or by a qualied technician to prevent any risks.

GROUND CONNECTION

It is mandatory that the electrical system is equipped with a ground connection.

The appliance must be part of an equipotential system. The connection is done on terminal

marked with symbol which you will nd near the cable clamp. The section of the equipotential

wire must be at least 10mm2. The equipotential symbol is showed in the following gure.

6

DIGITAL OVEN START UP AND USE

COMMAND PANEL DESCRIPTION

Operation

Digital control panel

Main switch

The digital control panel allows the separate setting of top heating’s elements and bottom heating’s elements,

furnishing in real time the information on the temperatures. It also allows the activation and set point of the

timer, and the delay of lighting.

Cooking chamber light switch

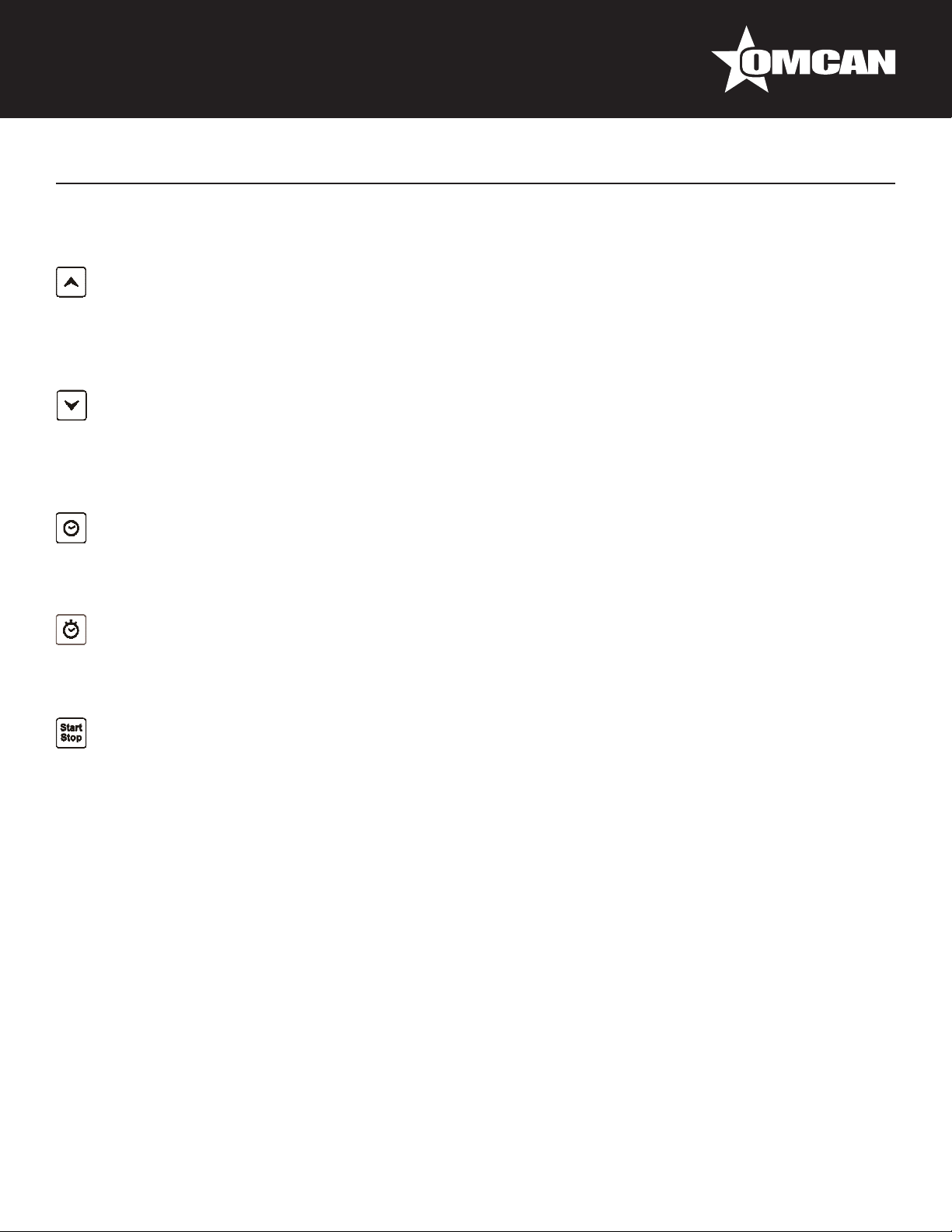

FUNCTION OF THE KEYS

ON/OFF KEY

When the digital control panel is in position Off (switched off) one push enables the switch on of the same.

When the digital control panel is “on”, the continuous push for three seconds enables shifting into “Off”

(switched off).

TOP KEY / P1 PROGRAM

When the digital control panel is active (and the display shows the average baking chamber temperature),

pushing once the touch programme 1 is taken back and signal “P1” is shown. A minimum three seconds lasting

push enables the modication of top temperature set (of the selected programme).

BOTTOM KEY / P2 PROGRAM

When the digital control panel is active (and the display shows the average baking chamber temperature), by

7

Operation

pushing once the touch Programme 2 is taken back and “P2” is shown. A minimum three seconds lasting push

enables the modication of the bottom temperature (of the selected programme).

INCREMENT VALUE KEY / VISUALIZATION TOP TEMPERATURE

When the display shows the average baking chamber temperature, pushing once the touch top temperature is

shown. When programme modalities (p1 or p2) or other modalities active, same touch enables the increase of

the selected value.

DECREMENT VALUE KEY / VISUALIZATION BOTTOM TEMPERATURE

When the display shows the average baking chamber temperature, pushing once the touch bottom

temperature is shown. When programme modalities (p1 or p2) or other modalities, same touch enables

decrease of the selected value.

CLOCK KEY / DELAY TIME

When the digital control panel is active, three seconds continuous push enables to modify the switch on delay

(clock signal blinks)

COOKING TIMER KEY

When the digital control panel is active, a three seconds continuous push enables to modify the baking time

(timer signal blinks).

START/STOP KEY

When the digital control panel is active:

• After setting the delayed switch-on, the single push of start/stop touch enables the countdown of the

delayed switch on.

• When the delayed switch on countdown is under process, a three seconds lasting push of the start/stop

touch enables to disconnect the same.

• After setting the baking timer the single push of start/stop touch enables the baking timer countdown.

• When the baking timer countdown is under process a single push of start/stop enables to stop counting. A

further single push enables to activate again the counting.

• When the baking timer countdown is working, the three seconds lasting start/stop push enables to

deactivate the timer.

MEANING OF DISPLAY ICONS

°C

CELSIUS ICON: It is active when the temperature is set in Celsius.

FAHRENHEIT ICON: It is active when the temperature is set in Fahrenheit.

°F

8

Operation

TOP TEMPERATURE ICON: It is active when the top probe temperature is showed on the display. This

icon ashes during the variation of the top temperature set point.

BOTTOM TEMPERATURE ICON: It is active when the bottom probe temperature is showed on the

display. This icon ashes during the variation of the bottom temperature set-point.

TIMER ICON: It is active during the timer countdown. This icon ashes during the timer set-point.

CLOCK ICON: It is active during the delay time countdown. This icon ashes during the delay time set-

point.

TOP HEATING ELEMENTS ICON: It is active when the top heating elements are turned on.

BOTTOM HEATING ELEMENTS ICON: It is active when the bottom heating elements are turned on.

FIRST LIGHTING OF THE OVEN

At the rst use of the appliance it is advisable to heat the empty oven to eliminate bad smells caused by the

refractory stones evaporation and the inner metallic parts.

Procedure:

• Fully open the exhauster valve.

• Set the main switch in the position “1” after checking that the oven is connected with the power supply.

• Heat up the heating elements by pushing the on/off switch on the digital control panel.

• Leave the oven working (empty) for at least 8 hours at the temperature of 300° C before proceeding to the

rst baking.

START UP PHASE

After connecting the oven to the electric net rotate the main switch in position “1”. The digital control panel light

on and the word off is shown on the display. At this stage it is possible to start heating the oven by pushing the

on/off touch, with the consequent the heating elements start-up (top and bottom) of the baking chamber. By

pushing the on/off touch a short lamp-test takes place, after that for roughly 5 seconds the programme under

process is shown (p1 or p2). At this stage the display shows the average baking chamber temperature and

the thermostat setting takes place. This operation consists of the electronic and automatic use of the heating

elements to reach and maintain the temperatures set in the used programme (p1 or p2).

FUNCTION OF DIGITAL CONTROL PANEL

The main functions of the digital control panel are:

• Visualization of the baking chamber temperatures (average top and bottom).

• Top and bottom temperatures setting of baking programmes p1 or p2 (see ex. nr.1).

• Baking timer setting and activation (see ex. nr 2).

• Delayed switch-on setting and activation (see ex. nr 3).

9

Operation

GENERAL INDICATIONS FOR A GOOD COOKING

Generally for the food products it is not advisable to give precise temperature and baking time, because of their

different characteristics. Particularly, regarding pizza and similar products, time and temperatures depend on

the shape and thickness of the dough, as well as on the quantity and typology of the additional ingredients.

For those reasons it is always advisable to carry out previously some baking tests, (particularly when it is an

absolute new oven), with the aim of understanding as much as possible the characteristics and the functioning

of the oven.

Ideal time and temperature choice is determinant for a right pizza baking; mostly they depend on the

operator’s experience.

WORKING PHASE

While working, at any time the oven can be modied in its temperature parameters and programs; in addition,

pizza baking operation can be veried by inner chamber light. Once the oven has reached the set temperature

(visible on the display), it is possible to put in the pizza/s for baking, proceeding as follows:

• Open the door of the oven by the suitable handles.

• To light the inner chamber, set the lighting button (B) in the position “1”.

• Put in the oven the pizza/s to bake with suitable instruments for said use.

• Close the door again by the suitable handles and check the baking through the door glass. If wished, it is

possible to set the baking timer, which will warn with an acoustic signal the set baking time expiry.

• At baking over, open the door by the suitable handles and take out the pizza/s by suitable instruments for

said use.

When opening the door while the oven is on, it is important to stay at the right distance, to avoid being

invested by the heat coming out from the chamber.

Use suitable instruments to bake in and displace the pizzas in the baking chamber, to avoid burns.

When opening the door to bake the pizza/s, do not leave it opened for long time, to avoid heat

dispersion and consequently chamber temperature drop.

Avoid oil and fats to drop on bottom; if brought at high temperature can burn.

QUICK PROGRAM ACCESS

Press the TOP key to access the temperature setpoints related to program 1 (parameters P3 and P4), press

instead the BOTTOM key to access the temperature setpoints related to program 2 (parameters P5 and P6).

When pressing the TOP or BOTTOM key, the display shows the selected program for 5 seconds (Pr 1 in green

or Pr 2 in red). The setpoints are updated when the label disappears. If while Pr 1 or Pr 2 is displayed the TOP

or BOTTOM key is pressed, this display will disappear and the setpoints are updated. With the card ON, press

the TOP and BOTTOM keys for 3 seconds to display the program in use for 5 seconds. The selected program

is maintained also if the card is set to OFF or if the power is interrupted.

10

Operation

SETTING THE DATE AND TIME

The date and time must be set when the expansion with RTC is used for delayed start (parameter P20 = 2).

With the card OFF, press the CLOCK key for 3 seconds, and the display will show the label dd followed by the

day of the week from 1 to 7 (1= Monday, 7 = Sunday). Use the UP and DOWN keys to set the day of the week

and conrm by pressing the CLOCK key. Set the hours (label hh) and minutes (label mm) in the same way.

After conrming the minutes with the CLOCK key, the card will return to OFF.

NOTE: if P20=2, but the correct expansion is not installed (with RTC) an error is displayed (RTC label

ashing) at the end of the date and time setting procedure.

SETTING DELAYED START

The delayed start can be set only when the card is on and the timer is not being used for counting. Delayed

start can be set for the same day and for the following 6 days (for example, on Wednesday it is possible to

set the programmed start until maximum next Tuesday). From the day on which the rst delayed start is set,

the card will turn on EVERY DAY at the set time until the delayed start is turned off. Press the CLOCK key for

3 seconds, the display will show the ashing dd label followed by the day of the week from 0 to 7 (0=delayed

start off, 1=Monday, 7=Sunday). Use the UP and DOWN keys to set the day of the week and conrm by

pressing the CLOCK key. Set the hours (ashing hh label) and minutes (ashing mm label) in the same way.

After conrming the minutes with the CLOCK key, the card will turn OFF and with the clock icon on and the

central dotpoints ashing. To display the programmed start date, press the CLOCK key and the day of the

week, time and minutes of the programmed start time will be displayed. The card can be used by pressing the

ON/OFF key and setting it to the on status. If the card is turned off, the indication of the delayed start will be

redisplayed (ashing dotpoints and clock icon on). To disable the programmed start, turn on the card, access

the delayed start setting and disable it by setting dd to zero.

NOTE: If the card turns on in error because the user forgot to turn off the daily delayed start, the oven

will turn off automatically after P23 hours after starting if no key is pressed. Set P23=0 to disable this

function.

USE OF EXAUSTER VALVE

By the exhauster valve the operator can regulate the baking steams and fumes ow out from the baking

chamber, while in the same the heat is kept. It is advisable to keep the valve fully closed when the oven is

under heating; so, the set temperature is reached in shortest possible time. While baking regulate the valve

according to the exigencies.

SHUT DOWN PHASE

To shut down the oven, press the power button on the digital control panel and then turn the main switch to the

position “0”.

11

Operation

MECHANICAL OVEN START UP AND USE

COMMAND PANEL DESCRIPTION

Top heating elements

function pilot light

Bottom heating elements

function pilot light

Main switch

Thermostat for the regulation

of top temperatures

Digital control thermometer

Thermostat for the regulation

of bottom temperatures

Cooking chamber light switch

FIRST LIGHTING OF THE OVEN

At the rst use of the appliance it is advisable to heat the empty oven to eliminate bad smells caused by the

refractory stones evaporation and the inner metallic parts.

Procedure:

• Fully open the exhauster valve.

• Set the main switch in the position “1” after checking that the oven is connected with the power supply.

• Leave the oven working (empty) for at least 8 hours at the temperature of 300° before proceeding to the

rst baking.

START UP PHASE

After connecting the oven to the electric net rotate the main switch in position “1”. The digital thermometer

display shows the actual average temperature of the baking chamber. Rotate the thermostat knobs and until

the expected temperature. In this way top and bottom heating elements are under working and the relevant

light signals switch on.

GENERAL INDICATIONS FOR A GOOD COOKING

Generally for the food products it is not advisable to give precise temperature and baking time, because of their

different characteristics. Particularly, regarding pizza and similar products, time and temperatures depend on

12

Operation

the shape and thickness of the dough, as well as on the quantity and typology of the additional ingredients.

For those reasons it is always advisable to carry out previously some baking tests, (particularly when it is an

absolute new oven), with the aim of understanding as much as possible the characteristics and the functioning

of the oven.

Ideal Time and temperature choice is determinant for a right pizza baking; mostly they depend on the

operator’s experience.

WORKING PHASE

While working, at any time the oven can be modied in its temperature parameters; in addition, pizza baking

operation can be veried by inner chamber light. Once the oven has reached the set temperature (visible on

the display), it is possible to put in the pizza/s for baking, proceeding as follows:

• Open the door of the oven by the suitable handles.

• To light the inner chamber, set the lighting button (B) in the position “1”.

• Put in the oven the pizza/s to bake with suitable instruments for said use.

• Close the door again by the suitable handles and check the baking through the door glass.

• At baking over, open the door by the suitable handles and take out the pizza/s by suitable instruments for

said use.

When opening the door while the oven is on, it is important to stay at the right distance, to avoid being

invested by the heat coming out from the chamber.

Use suitable instruments to bake in and displace the pizzas in the baking chamber, to avoid burns.

When opening the door to bake the pizza/s, do not leave it opened for long time, to avoid heat

dispersion and consequently chamber temperature drop.

Avoid oil and fats to drop on bottom; if brought at high temperature can burn.

USE OF EXHAUSTER VALVE

While baking regulate the valve according to the exigencies. Oven is under heating; so, the set temperature

is reached in shortest possible time. By the exhauster valve the operator can regulate the baking steams and

fumes ow out from the baking chamber, while in the same the heat is kept.

SHUT DOWN PHASE

To shut down the oven turn the main switch to the position “0”.

13

Maintenance

Before performing any maintenance operations, including cleaning, take the following precautions:

• Ensure that the oven is not working end completely cold.

• Ensure that the electrical power is not present.

• Make certain that the electrical power cannot be accidentally reinserted. Disconnect the plug from the

electrical power socket.

• Use individual protection devices in compliance with the directive 89/391/CEE.

• Always operate using appropriate maintenance tools.

• Once maintenance and repairs are nished, before starting up the oven, reinstall all of the protection

devices and reactivate all of the safety devices.

ORDINARY MAINTENANCE FOR THE USER

As any equipment also our ovens requires simple, frequent and careful cleaning to ensure efcient, regular

functioning.

It is recommended to never use chemical products which are not specic for food preparation areas,

abrasives or corrosives for any reason. Avoid by all means using water jets, tools, rough or abrasive

instruments, such as steel wool, brillo sponges or any other item which could damage the surface of

the machine, and especially those that could compromise health safety.

CLEANING OF REFRACTORY PLAN

The oven must be cleaned at the end of each use, in compliance with the hygiene regulations and to safeguard

machine operation. Before proceeding the oven temperature must be at 350° C for roughly 60 minutes (setting

350° on the top and on the bottom as well), for an easy baking scoriae carbonization. Once reached the

temperature, switch off the oven and wait until the temperature drops until roughly 100°C (the best temperature

for cleaning). At this stage disconnect the electric power supply. After dressing in gloves and suitable dresses

as protection from burns, open the door and by a brush in natural ber with a long handle, proceed to a rst

removal of baking fragments from the refractory stones, then take them out by a suitable vacuum cleaner. At

the end, clean the refractory stone with an humid cloth.

EXTERNAL CLEANING OF THE OVEN

Oven external areas cleaning, external parts in stainless steel, door glass, and switch panel, must be carried

out at cold oven and at disconnected electric power supply. Use a sponge or a soft cloth, not abrasive, slightly

humidied with water or possibly with a neutral detergent not corrosive. In any case, do not use water jets

which can penetrate through the electric parts and heavily damage them, as well as bring a possible danger for

people.

14

Troubleshooting

WORKING ERRORS

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

The oven does not switch on. No electric Energy in the net. Check the general contactor, the

socket, the plug, and the supply

cable.

Main switch off (positioned on "0"). Rotate the main switch to position

"1".

The display is off in spite of the

main switch being on position 1

and the electric supply is in order.

Inner light bulb does not switch on. Burned inner light bulb. Replace inner light bulb.

The door is closed, but fume

comes out.

The baking chamber does not heat

suitably.

The baking chamber does not heat

suitably in spite of the temperature

being set rightly.

The temperature continues going

up over the set by thermo/timer.

Digital thermo/timer defective. Replace the digital thermo/timer.

Inner light bulb switch defected. Replace light bulb switch.

No electric supply power on the

light bulb.

Exhauster buttery valve closed. Open more the valve and check

The set temperature are too low. Set the right temperature.

One or more heating elements are

defected.

Power card contactors contacts

blocked (heating elements always

supplied).

Thermo/timer contacts defective. Check and if necessary replace the

Check electric connection with the

light bulb.

the right functioning.

Replace the defective heating

elements.

Check and, if necessary, replace

contactors card.

thermo/timer.

CONTROLLER ERRORS

DISPLAY ALARMS ALARMS MEANING POSSIBLE CAUSES EFFECT SOLUTIONS

ER1 Top probe damage

or probe connection

anomaly.

ER2 Bottom probe

damage or probe

connection anomaly.

Top probe defective

or anomaly probe

connection.

Bottom probe

damaged or probe

connection anomaly.

Top heating

elements

disconnection and

intermittent buzzer

sound.

Bottom heating

elements

disconnection and

buzzer intermittent

sound.

Connect again

and/or replace the

top probe.

Connect again

and/or replace the

bottom probe.

15

Troubleshooting

ERR Card probe damage. Card probe damage. All heating

elements

disconnection (top

and bottom) and

buzzer intermittent

sound.

HIT Probe temperature

too high.

Insufcient oven air

circulation due to

non respect of the

minimum distances

from surrounding

walls.

Power card contactor

contacts blocked

(heating elements

always power

supplied).

Switch panel cooling

fan damage (the

fan is tted in some

models only).

Disconnection

of all heating

elements (top

and bottom) and

intermittent buzzer

sound.

Disconnection

of all heating

elements (top

and bottom) and

intermittent buzzer

sound.

Disconnection

of all heating

elements (top

and bottom) and

intermittent buzzer

sound.

Replace the card

probe.

Wait until the

temperature of

the switch panel

area decreases

below the security

temperature and

check the causes

of the overheating.

French Instructions

SÉCURITÉ ET GARANTIE

AVERTISSEMENTS POUR L’INSTALLATEUR

Vériez que l’emplacement du four est en conformité avec les réglementations locales et nationales.

• Respecter les instructions de ce manuel.

• Ne pas exécuter les connexions électriques à l’aide de câbles temporaires ou non isolés.

• Vériez que la connexion à la terre du système électrique fonctionne correctement.

• Toujours utiliser les dispositifs de sécurité individuels et autres moyens de protection en conformité avec la

loi.

AVERTISSEMENT DE L’UTILISATEUR

Les conditions dans les environs où la machine sera installée doivent avoir les caractéristiques suivantes:

16

French Instructions

• La zone doit être sec.

• La zone doit disposer de sources d’eau et de chaleur à une distance sufsante.

• Ventilation et l’éclairage doivent être adaptés et conformes aux normes d’hygiène et de sécurité prévues

par les lois en vigueur.

• Le sol doit être plat et compact pour faciliter le nettoyage en profondeur.

• Il doit y avoir aucun obstacle d’aucune sorte dans le voisinage immédiat de la machine pouvant affecter la

ventilation normale de la machine.

En outre, l’utilisateur doit:

• Assurez-vous de garder les enfants loin de la machine quand elle est en marche.

• Respecter les instructions de ce manuel.

• Pas supprimer ou altérer les dispositifs de sécurité sur la machine.

• Faites toujours attention aux travaux à portée de main et ne pas utiliser la machine lorsque dans un état

distrait.

• Effectuer toutes les opérations avec un maximum de sécurité et de calme.

• Respecter les instructions et les avertissements afchés sur les étiquettes de la machine.

Les étiquettes sont des dispositifs de prévention des accidents, et doivent donc toujours être parfaitement

lisible. Si ceux-ci devraient être endommagés et illisibles, il est obligatoire de les remplacer en demandant le

remplacement du fabricant.

• A la n de chaque quart de travail, avant les opérations de nettoyage, d’entretien ou de transfert,

débrancher l’alimentation électrique.

AVERTISSEMENTS POUR L’OPÉRATEUR DE MAINTENANCE

Respectez les instructions indiquées dans ce manuel.

• Toujours utiliser les dispositifs de sécurité individuels et d’autres moyens de protection.

• Avant de commencer toute opération de maintenance, assurez-vous que le four, il a été utilisé, est refroidi.

• Si l’un des dispositifs de sécurité est usée ou défectueuse, le four est également considéré comme

défectueux et ne pas être utilisé.

• Coupez l’alimentation électrique avant d’intervenir sur les pièces et les connecteurs électriques ou

électroniques.

GARANTIE 1 AN

AVERTISSEMENT:

Les matériaux d’emballage sont considérés comme des déchets solides urbains normale et peuvent donc être

éliminés sans difculté.

En tout cas, pour le recyclage approprié, nous suggérons au rebut des produits séparément (type de

déchets) selon les normes en vigueur.

NE PAS JETER LES EMBALLAGES DANS L’ENVIRONNEMENT!

17

French Instructions19French Instructions

SPÉCIFICATIONS TECHNIQUES

Modèle PE-IT-0024-S PE-IT-0048-D PE-IT-0049-D PE-IT-0049-DD

Température

Maximale

Électrique 220V/60/3

Puissance 6.6 kW 13.2 kW 18 kW

Volume 23.7 Cu. Ft. 36.7 Cu. Ft. 48.7 Cu. Ft.

Dimensions de la

Chambre

Dimensions

Extérieures

Poids Net 115 kg. / 253 lbs. 183 kg. / 403.4 lbs. 231 kg. / 509 lbs.

Poids Brut 132 kg. / 291 lbs. 201 kg. / 443 lbs. 254 kg. / 560 lbs.

27.6” x 27.6” x 5.9”

701 x 701 x 150mm

43” x 39.8” x 16.9”

1092 x 1011 x 429mm

(27.6” x 27.6” x 5.9”) x 2

(701 x 701 x 150mm) x 2

43” x 39.8” x 29.5”

1092 x 1011 x 749mm

INSTALLATION

842°F / 450°C

(41.3” x 27.6” x 5.9”) x 2

(1049 x 701 x 150mm) x 2

56.9” x 39.8” x 29.5”

1445 x 1011 x 749mm

L’installation doit être exécutée par du personnel qualié dans le respect des réglementations locales et

nationales.

POSITIONNEMENT DU FOUR

Assurez-vous que le four est placé sur un support avec la

capacité de charge et qui est adapté à plat.

Après avoir déballé le four de son emballage, placez-le dans

l’emplacement préparé, en tenant compte des distances

minimales.

Retirez les protections possibles dans le polystyrène et enlever

le lm de protection (F) en évitant d’utiliser des outils qui peuvent

endommager les surfaces.

ÉQUIPEMENT HOOK-UP

Raccordement électrique

Le four est pas fourni avec un câble d’alimentation. Lors du raccordement électrique, un disjoncteur différentiel

automatique doit être interposé avec une distance d’ouverture entre les contacts d’au moins 3 mm. Pour

connecter l’appareil électrique, il est indispensable de procéder de la manière suivante:

• Retirez le panneau latéral droit.

• Connectez à la borne bloquer le câble d’alimentation.

Le câble d’alimentation doit être de type H07-RNF, avec une section minimale approuvé tel que prescrit par la

directive spécique.

La prise électrique doit être facile d’accès, pas de mouvement devrait être nécessaire.

18

Loading...

Loading...