Omcan Food Machinery PE-IT-0019-S Installation Manual

Pizza Ovens

Models PE-IT-0019-S, 0038-D

Instruction Manual

Revised - 11/11/2014

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: sales@omcan.com

www.omcan.com

Table of Contents

Model PE-IT-0019-S / Model PE-IT-0038-D

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

---------------------------------------------------------------------------------------------------------- 6

------------------------------------------------------------------------------------------------------ 7 - 8

------------------------------------------------------------------------------------------------------- 8

----------------------------------------------------------------------------------------- 3 - 4

---------------------------------------------------------------------------------------- 4 - 5

---------------------------------------------------------------------------------------------- 8 - 9

Page

------------------------------------------------------------------------------------ 5 - 6

French Instructions

Spanish Instructions

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

-------------------------------------------------------------------------------------------------------------- 26

----------------------------------------------------------------------------------------- 20 - 23

---------------------------------------------------------------------------------------- 9 - 14

------------------------------------------------------------------------------------- 14 - 19

------------------------------------------------------------------------------------ 24 - 25

----------------------------------------------------------------------------------------- 27

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan ne

sont pas responsables de tout dommage ou blessure causé du fait que toute personne ait utilisé

cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de plus de 18

ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour utiliser

cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication de la

machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine ou

des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan no son responsables de ningun daño o perjuicío causado por cualquier persona inadecuada o

el uso descuidado de este equipo. El producto solo podra ser operado por una persona mayor de 18

años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido entrenado

en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada. Cualquier

modicación a la máquina anúla la garantía y puede causar daños a las personas usando la máquina

mientras esta en el funcionamiento.

3

General Information

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Safety and Warranty

WARNINGS FOR THE INSTALLER

Check that the location of the oven is in compliance with local regulations.

• Adhere to the instructions in this manual.

• Do not execute electrical connections using temporary or uninsulated cables.

• Check that the ground connection of the electrical system is functioning properly.

• Always use individual safety devices and other means of protection in compliance with the law.

WARNING FOR THE USER

The conditions in the surrounding area where the machine will be installed must have the following

characteristics:

• The area must be dry.

• The area must have water and heat sources at an adequate distance.

• Ventilation and lighting must be suitable and comply with the hygiene and safety standards foreseen by

current laws.

• The oor must be at and compact to facilitate thorough cleaning.

• There must be no obstacles of any kind in the immediate vicinity of the machine that could effect the

machine’s normal ventilation.

In addition, the user must:

• Make certain to keep children away from the machine when it is operating.

• Adhere to the instructions in this manual.

• Not remove or tamper with the safety devices on the machine.

• Always pay careful attention to the work at hand and not use the machine when in a distracted state.

• Perform all operations with maximum safety and calm.

• Respect the instructions and warnings displayed on the machine labels.

The labels are accident prevention devices, and therefore must always be perfectly legible. If these should be

4

Safety and Warranty

damaged and illegible, it is mandatory to replace them by requesting replacements from the Manufacturer.

• At the end of each working shift, before cleaning, maintenance or transfer operations, disconnect electrical

power.

WARNINGS FOR THE MAINTENANCE OPERATOR

Observe the instructions indicated in this manual.

• Always use individual safety devices and other protection means.

• Before starting any maintenance operations, make sure that the oven, it was used, is cooled down.

• If any of the safety devices is worn or faulty, the oven is also considered faulty and not to be used.

• Disconnect electrical power before intervening on electrical or electronic parts and connectors.

1 YEAR WARRANTY

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

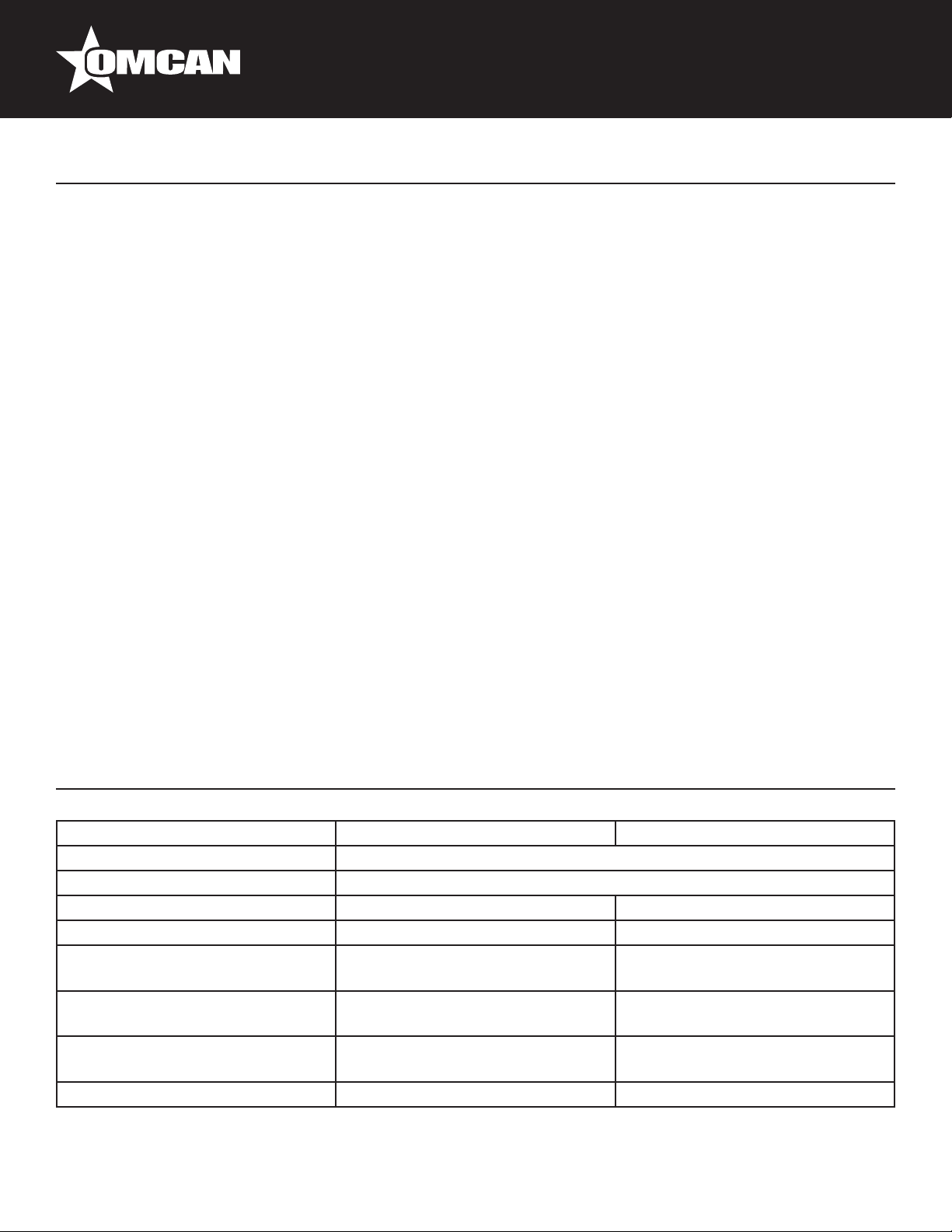

Technical Specications

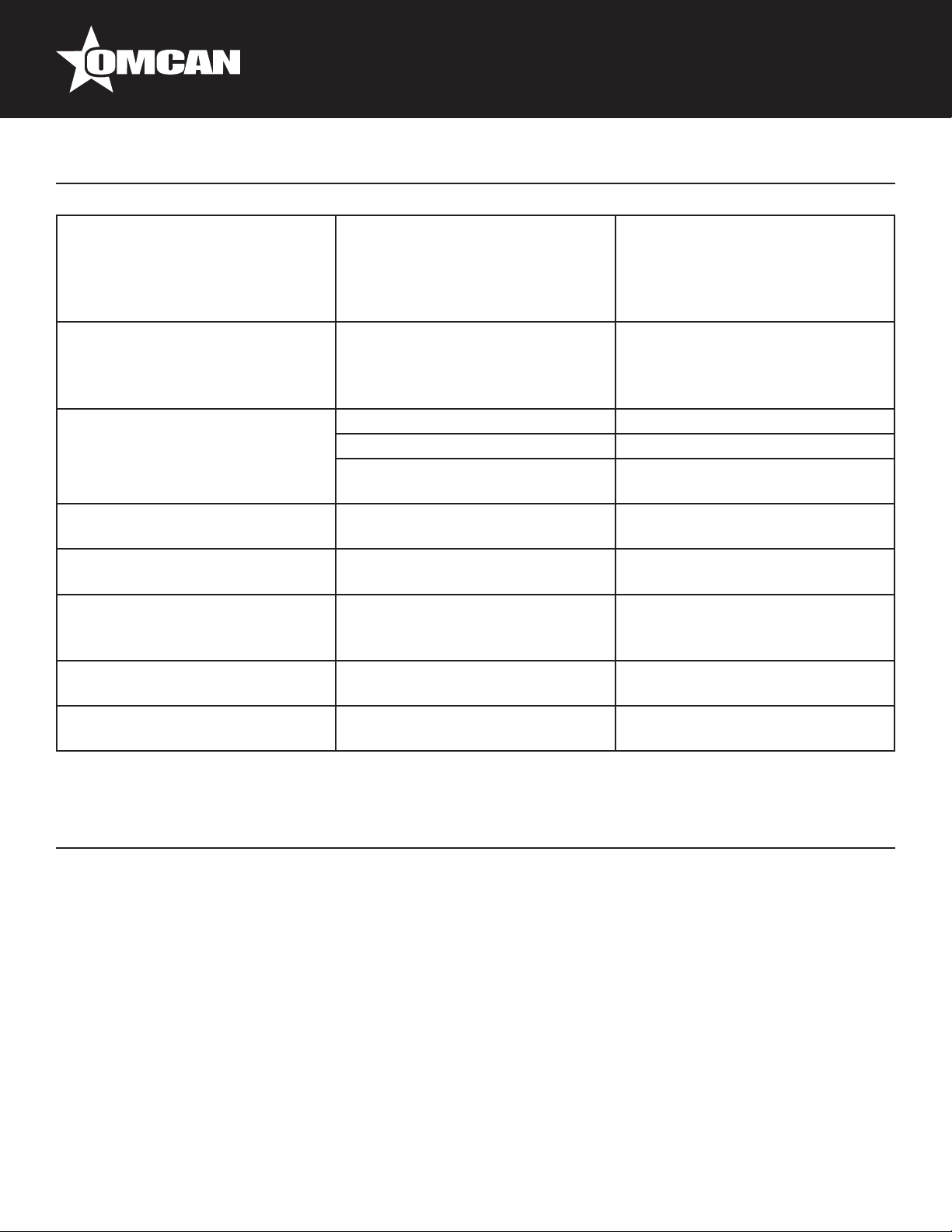

Model PE-IT-0019-S PE-IT-0038-D

Maximum Temperature 842°F / 450°C

Electrical 220V/60/3

Power 5.56 kW 11.2 kW

Volume 19.1 Cu. Ft. 29.3 Cu. Ft.

Chamber Dimensions

Chamber Dimensions

(Full Refractory Stone)

External Dimensions

Net Weight 74 kg. / 163 lbs. 149 kg. / 328.5 lbs.

27.6” x 27.6” x 5.9”

701 x 701 x 150mm

26.4” x 27” x 5.31”

671 x 686 x 135mm

39” x 36” x 15”

991 x 914 x 381mm

(27.6” x 27.6” x 5.9”) x 2

(701 x 701 x 150mm) x 2

(26.4” x 27” x 5.31”) x 2

(671 x 686 x 135mm) x 2

39” x 36” x 26.7”

991 x 914 x 678mm

5

Technical Specications

Net Weight

(Full Refractory Stone)

Gross Weight 88 kg. / 194 lbs. 165 kg. / 363 lbs.

Gross Weight

(Full Refractory Stone)

96 kg. / 211 lbs. 193 kg. / 425 lbs.

110 kg. / 242 lbs. 209 kg. / 460 lbs.

Installation

Installation must be executed by qualied personnel in compliance with local regulations.

EQUIPMENT HOOK-UP

The oven is not provided with power supply cable. When connecting the appliance electrically, an automatic

RCD must be interposed with an opening distance between contacts of at least 3 mm. To connect the

appliance electrically it is essential to proceed in the following way:

• Raise the cover of the terminal block.

• Connect to the terminal block the power cable.

The power supply cable must be of H07-RNF type, with approved minimum cross section as prescribed by the

specic directive.

The electrical outlet must be easy to access, no moving should be necessary.

It is mandatory that the electrical system is equipped with a ground connection.

The appliance must be part of an equipotential system. The connection is done on terminal

marked with symbol which you will nd near the cable clamp. The section of the equipotential

wire must be at least 10 mm2.

The equipotential symbol is showed in the following gure.

6

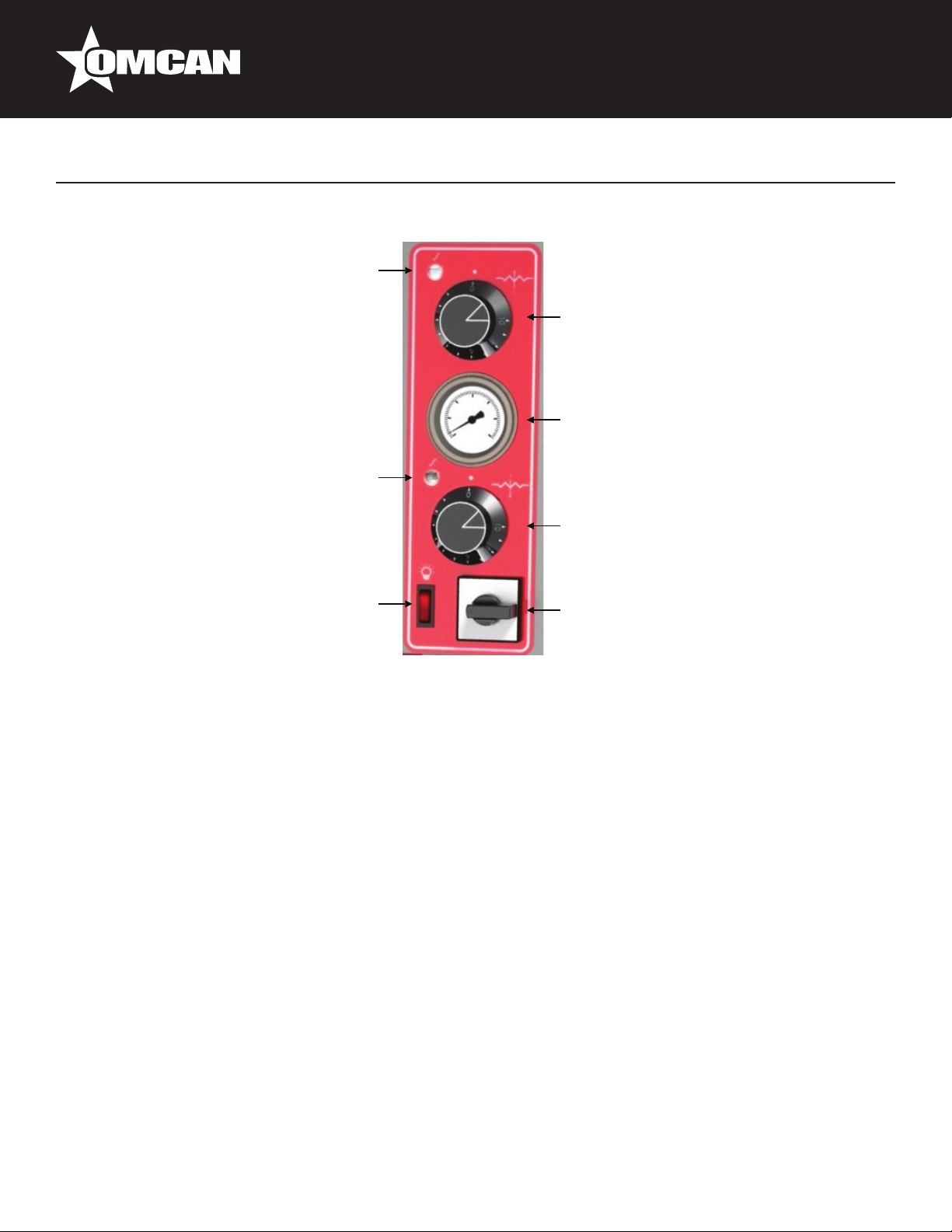

COMMAND PANEL DESCRIPTION

Pilot Light

Top

Pilot Light

Bottom

Operation

Thermostat for the

Regulation Top

Analogic Control

Thermometer

Thermostat for the

Regulation Bottom

Cooking Chamber

Light Switch

Main Switch

FIRST LIGHTING OF THE OVEN

At the rst use of the appliance it is advisable to heat the empty oven to eliminate bad smells caused by the

refractory stones evaporation and the inner metallic parts.

Procedure:

• Fully open the exhauster valve.

• Turn the main switch in position “1”.

• Leave the oven working (empty) for at least 8 hours at the temperature of 300° before proceeding to the

rst baking.

START UP PHASE

The analogical thermometer display shows the actual average temperature of the baking chamber. Rotate the

thermostat knobs and until the expected temperature. In this way top and bottom heating elements are under

working and the relevant light signals switch on.

USE OF EXHAUSTER VALVE

While baking regulate the valve according to the exigencies. Oven is under heating; so, the set temperature

is reached in shortest possible time. By the exhauster valve the operator can regulate the baking steams and

fumes ow out from the baking chamber, while in the same the heat is kept.

7

Operation

SHUT DOWN PHASE

To shut down the oven turn the thermostat to the position “0”.

Maintenance

SAFETY PRECAUTIONS

Before performing any maintenance operations, including cleaning, take the following precautions:

• Ensure that the oven is not working end completely cold.

• Ensure that the electrical power is not present.

• Make certain that the electrical power cannot be accidentally reinserted. Disconnect the plug from the

electrical power socket.

• Use individual protection devices in compliance with the directive 89/391/CEE.

• Always operate using appropriate maintenance tools.

• Once maintenance and repairs are nished, before starting up the oven, reinstall all of the protection

devices and reactivate all of the safety devices.

ORDINARY MAINTENANCE FOR THE USER

As any equipment also our ovens requires simple, frequent and careful cleaning to ensure efcient, regular

functioning. It is recommended to never use chemical products which are not specic for food preparation

areas, abrasives or corrosives for any reason. Avoid by all means using water jets, tools, rough or abrasive

instruments, such as steel wool, brillo sponges or any other item which could damage the surface of the

machine, and especially those that could compromise health safety. Oven external areas cleaning, external

parts in stainless steel, door glass, and switch panel, must be carried out at cold oven and at disconnected

electric power supply. Use a sponge or a soft cloth, not abrasive, slightly humidied with water or possibly with

a neutral detergent not corrosive. In any case, do not use water jets which can penetrate through the electric

parts and heavily damage them, as well as bring a possible danger for people.

Troubleshooting

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

The oven does not heat even

though the temperatures are set

correctly. The pilot lights are off.

Main switch in position “0”. Turn the main switch in position

“1”.

8

Troubleshooting

The oven doesn’t heat despite the

main switch is on (position 1) and

the temperatures are correctly

set. The function pilot lights of the

heating elements are off.

The analogical thermometer

doesn’t notice the increase of the

temperature despite the heating

elements are correctly functioning.

Inner light bulb does not switch on. Burned inner light bulb. Replace inner light bulb.

The door is closed, but fume

comes out.

The baking chamber does not heat

suitably.

The baking chamber does not heat

suitably in spite of the temperature

being set rightly.

The temperature continues going

up over the set by thermostats.

The door does not keep right

closed.

No electric Energy in the net. Check the general contactor, the

socket, the plug, and the supply

cable.

Analogical thermometer defect. Check and if necessary replace the

thermometer.

Inner light bulb switch defected. Replace light bulb switch.

No electric supply power on the

light bulb.

Exhauster buttery valve closed. Open more the valve and check

The set temperature are too low. Set the right temperature.

One or more heating elements are

defected.

Thermostat probe or thermostat

contacts defected.

The door closing spring has

subsiding.

Check electric connection with the

light bulb.

the right functioning.

Replace the defecate heating

elements.

Check and if necessary replace the

thermostats.

Disassemble the left side panel

and replace the spring.

French Instructions

SÉCURITÉ ET GARANTIE

À L’ATTENTION DE L’INSTALLATEUR

Vériez que l’emplacement du four est en conformité avec les réglementations locales.

• Veuillez observer les consignes indiquées dans le manuel.

• N’utilisez pas de branchement électrique de type “volant” basé sur des câbles provisoires ou non isolés.

• Verriez que la mise à la terre de l’installation électrique soit bien fonctionnant.

• Utilisez toujours les dispositifs de sécurité individuelle et tout autre moyen de protection prévus par la loi.

9

Loading...

Loading...