Omcan Food Machinery PE-CN-0015 Installation Manual

Potato Peeler

Model PE-CN-0015

Instruction Manual

Revised - 12/23/2014

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: sales@omcan.com

www.omcan.com

Table of Contents

Model PE-CN-0015

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

French Instructions

------------------------------------------------------------------------------------------------------ 7

--------------------------------------------------------------------------------------------------- 7 - 8

---------------------------------------------------------------------------------------------- 8 - 9

------------------------------------------------------------------------------------- 3 - 4

------------------------------------------------------------------------------------- 4 - 5

------------------------------------------------------------------------------------- 9 - 15

Page

-------------------------------------------------------------------------------- 5 - 6

Spanish Instructions

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

----------------------------------------------------------------------------------------------------- 25 - 26

-------------------------------------------------------------------------------------- 22 - 23

--------------------------------------------------------------------------------- 15 - 21

-------------------------------------------------------------------------------------- 24

-------------------------------------------------------------------------------------- 27

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Omcan Fabrication et distribution Companie Limité et Food Machinery d’ Amerique, dba Omcan ne

sont pas responsables de tout dommage ou blessure causé du fait que toute personne ait utilisé

cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de plus de 18

ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour utiliser

cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication de la

machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine ou

des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan no son responsables de ningun daño o perjuicío causado por cualquier persona inadecuada o

el uso descuidado de este equipo. El producto solo podra ser operado por una persona mayor de 18

años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido entrenado

en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada. Cualquier

modicación a la máquina anúla la garantía y puede causar daños a las personas usando la máquina

mientras esta en el funcionamiento.

3

General Information

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Safety and Warranty

GENERAL PRECAUTIONS

• The machine must only be used by trained personnel who are perfectly aware of the safety norms

contained in this manual.

• If there is a turnover of staff, promptly provide proper training for new personnel.

• Even if safety devices are installed on the machine do not place hands near moving parts and avoid

touching the machine with wet or damp hands.

• Before carrying out any type of maintenance or cleaning, disconnect the machine plug from the electrical

outlet.

• When intervening for maintenance or cleaning purposes (therefore the protections are removed) carefully

evaluate residual risks.

• During maintenance or cleaning always concentrate on the operation in progress.

• Regularly check the state of the feeding cable(completely unwinding the cable, avoiding twisting it, is

advisable to avoid potential risks); a worn or broken cable can present serious danger of the electrical kind;

avoid compressing the wire with weights, leaving it in contact with hot or sharp surfaces and pulling on it to

unplug it from the outlet.

• If the machine shows signs of malfunctioning or does not work, do not use it or try to repair it; contact

Omcan.

• The OUT push button must only be used for unloading the worked product.

The manufacturer is not responsible in the following cases:

• If the machine is mishandled or the safety devices are installed by unauthorized personnel.

• If components are replaced with unoriginal parts.

• If the instructions in this manual are not followed carefully.

• If the machine surfaces are treated with inappropriate products (inammable, corrosive or harmful

substances).

4

Safety and Warranty

1 YEAR PARTS AND LABOUR WARRANTY

WITHIN THE WARRANTY PERIOD, CONTACT OMCAN INC. AT 1-800-465-0234 TO SCHEDULE AN

OMCAN AUTHORIZED SERVICE TECHNICIAN TO REPAIR THE EQUIPMENT LOCALLY.

UNAUTHORIZED MAINTENANCE WILL VOID THE WARRANTY. WARRANTY COVERS ELECTRICAL

AND PART FAILURES NOT IMPROPER USE.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

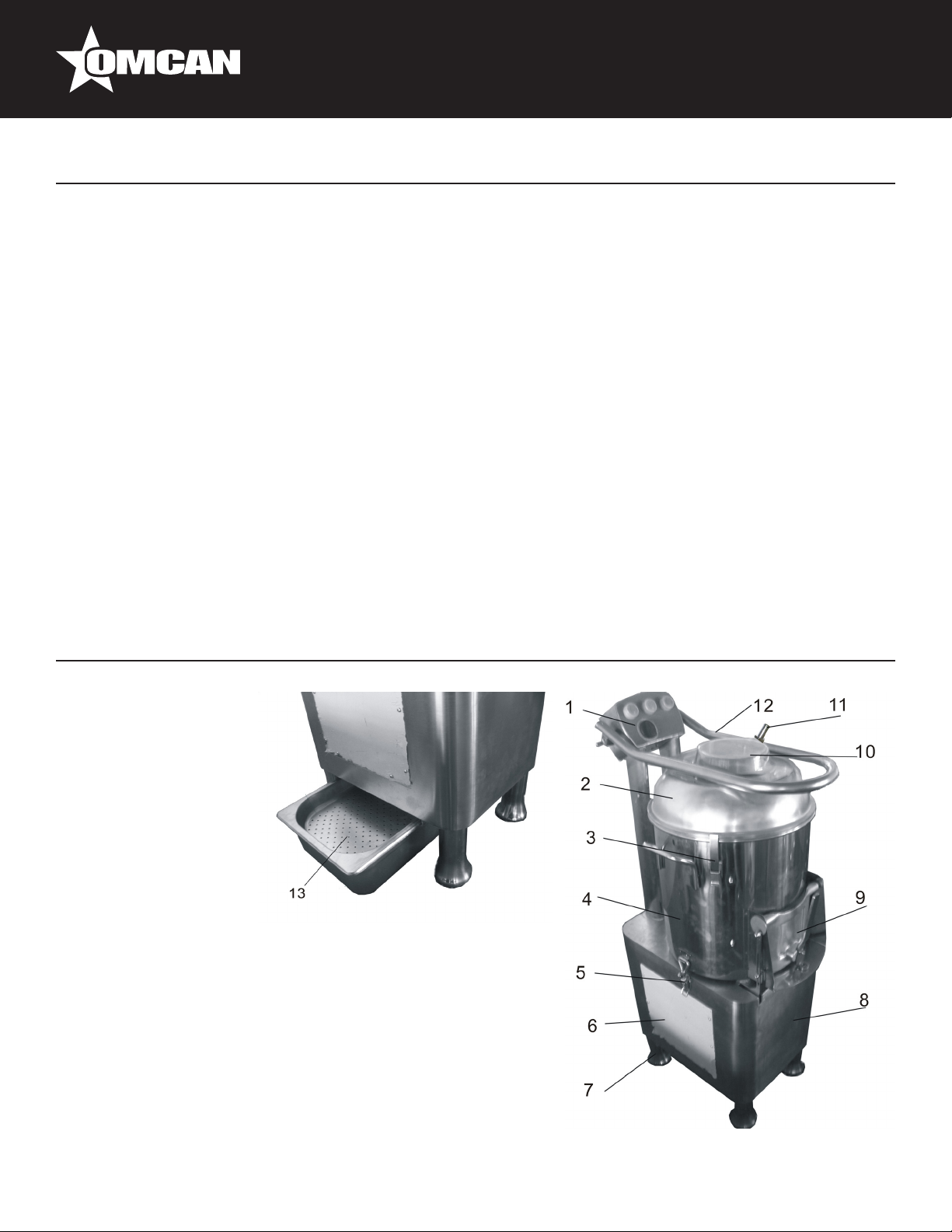

1. Push Button Strip.

2. Hopper.

3. Cover Block Hinge.

4. Pan.

5. Pan Block Hinge.

6. Maintenance Door.

7. Feet.

8. Structure.

9. Discharge Door.

10. Cover.

11. Feeding Tap.

12. Handle.

13. Stand.

There is the possibility of adding the sieve to the stand to

collect waste.

5

Technical Specications

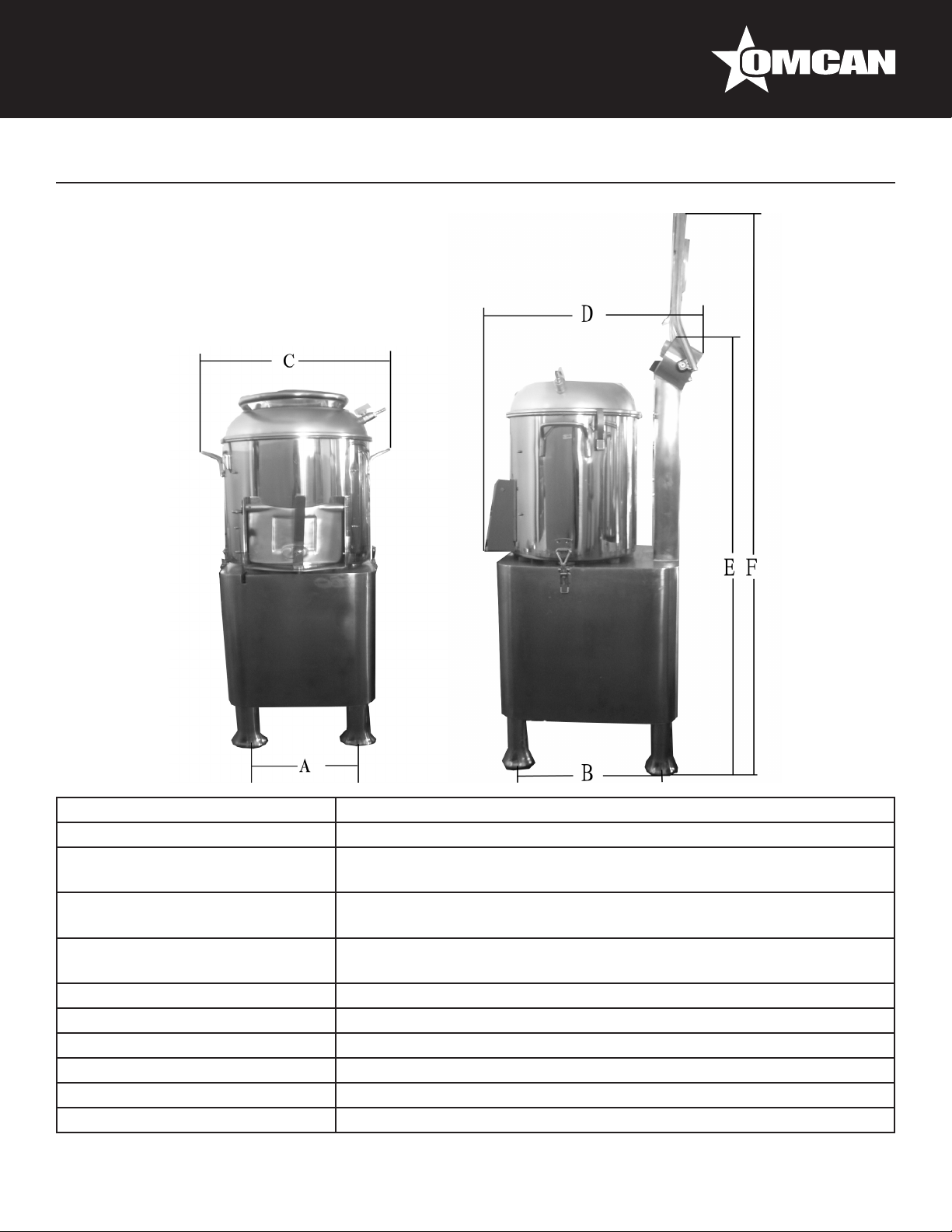

Model PE-CN-0015

Electrical 110V / 60 / 1

Dimensions (A x B) 11.4” x 14.6”

290 x 370mm

Dimensions (C x D x E) 18.1” x 23.2” x 43.3”

460 x 590 x 1100mm

Dimensions (F) 59.8”

1520mm

Capacity 20 kg. / 44.1 lbs.

Output/h. 225 kg. / 496 lbs.

Motor 1 HP

Power 1100 W

Net Weight 68 kg. / 149.9 lbs.

Noise Level ≤75 dB

6

Installation

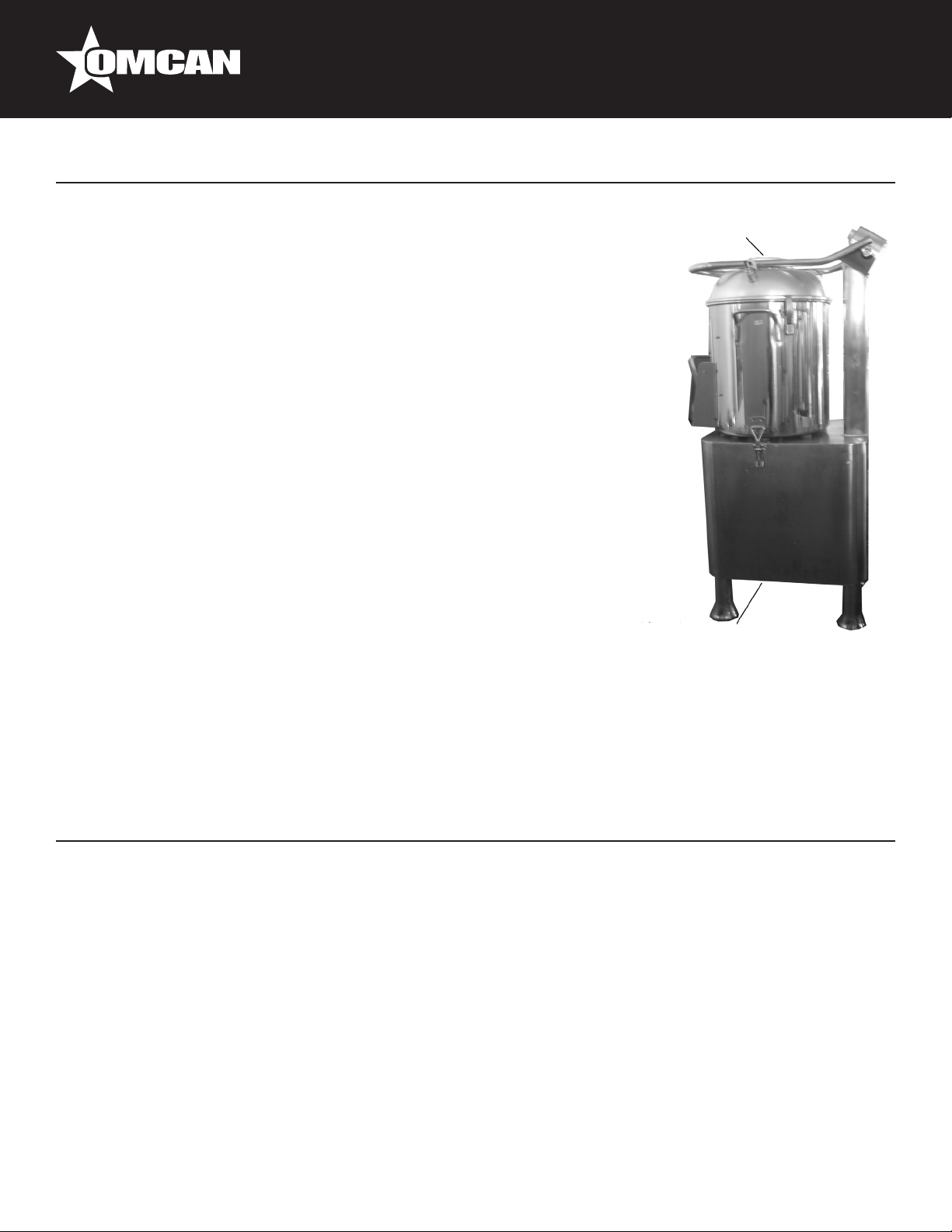

MACHINE PLACEMENT

When choosing the plane the machine will be placed on the dimensions

shown (based on model), therefore the surfaces must be wide enough to

hold it, and it must be well-levelled and dry. Prearrange a discharge tube

(φ60mm.) under the machine and a drain trap on the oor, or a oor grate

to collect the water or other waste material. Furthermore the machine must

be placed as near as possible to a faucet (φ12mm.), which enables the

feeding tube to be easily and safely attached. Once the machine is placed

proceed to blocking it by fastening it to the oor with the set screws on the

anged feet. Furthermore the machine must be placed in an environment

with a maximum humidity of 75%, which is not salty and has a temperature

between +5°C and +25°C; in any case in environments which do not bring

about its malfunctioning.

ELECTRICAL CONNECTIONS

The machine is outtted with a feeding cable with a cross section area of 3

x 1.5mm2/0.06”2, length 1.5m/4.9 ft. Connect the machine to 230V / 50Hz.

Furthermore check that the data shown on the serial number/technical plate

corresponds to the data on the delivery notes.

load φ 12mm

faucet

discharge

Before nally connecting the machine to the three phase feeder line, check the direction of rotation of the cap

by pressing the START push button then immediately stop it by pressing the STOP push button. The direction

of rotation of the cap seen from the discharge outlet must be counterclockwise; if the direction of rotation is not

exact, invert two of the three feeding wires in the plug or outlet.

Operation

OPERATIONAL CHECK

Before proceeding to testing make sure the upper cover and the discharge door are well-blocked, then check

the running of the machine with the following procedure:

1. Check that the upper cover and the discharge door are closed well.

2. Press the START push button and then the STOP one.

3. Repeat the same operation, checking that the cap rotates in a counter clockwise direction through the

closed transparent upper cover.

4. Check if the machine stops when running by opening the cover or discharge door, and once it is closed if

the machine restarts by pushing the START push button.

5. To discharge the material open the discharge door, keeping it open with your right hand and at the same

time pushing the OUT and START buttons on the push button strip with your left hand; the machine will

start by unloading the potatoes by centrifugal force.

7

Operation

LOADING AND WORKING THE PRODUCT

Note: The goods to be worked are loaded gradually on the cap from the upper cover when the motor is

off.

Adhere to the following procedure:

1. Load the product from the upper cover, making sure that the discharge door is closed well.

2. Check that the machine is not too full and that the level of the product does not go over the abrasive band

inside the machine.

3. Close the upper cover.

4. Open the water ow using the faucet on the hopper.

Running:

1. Set the desired work time with the timer (maximum time 5 minutes).

2. Then start the machine by pressing the START push button.

3. If the cover and/or discharge door are accidentally opened or moved while the machine is running, the

machine will stop; when closed press the START button.

4. Open the water ow using the faucet on the hopper.

5. If the machine is outtted with a stand with sieve, repeatedly unload the slag tray, to avoid the water

dripping.

Unloading the worked product:

1. Close the water faucet and put a big container near the discharge outlet.

2. To unload the material open the discharge door keeping it open with your right hand; press the OUT and

START push button at the same time with OUT your left hand; the machine will start unloading the product

by centrifugal force.

3. Once the unloading is complete the machine will stop by releasing the push buttons and the discharge

door.

Note: Avoid making an empty machine turn.

Maintenance

ROUTINE CLEANING

ATTENTION: Never put hands inside the moving machine.

Cleaning and maintenance operations are carried out only when the machine is off and the feeding cable is

unplugged.

Before cleaning the machine the feeding plug must be disconnected from the network to completely isolate the

machine.

• The machine must be cleaned at the end of every work day and all the parts of the machine (completely

8

Maintenance

removable) which come into direct or indirect contact with the worked food stuff must be carefully cared for.

• Both the inside and the outside of the machine must be cleaned because the residual waste can be

seriously damaging.

• The machine must not be cleaned with water cleaners, high-pressure jets of water, brushes, and anything

else which can damage it on the surface. Acidic, corrosive or inammable substances must not be used.

• If the machine has a stand with a sieve repeatedly empty the slag tray to avoid the water dripping.

Before carrying out any maintenance activity it is necessary to:

Disconnect the plug from the electrical outlet to completely isolate the machine from the rest of the system.

BELT

The belt does not need any adjustments. Usually, after 3/4 years it must be replaced, in this case call Omcan.

FEET

The feet could deteriorate with time, thus reducing the stability of the machine. Therefore they must be

replaced.

FEEDING CABLE

Periodically check the wear of the cable and call Omcan to replace it.

ATTENTION: When cleaning machine, please don’t damaged parts. If damaged please return

maintenance

DISMANTLING

PUTTING IT OUT OF WORK

If for some reason it is decided to put the machine out of work make sure that it cannot be used by anyone:

unplug the electrical connections.

DISPOSAL

Once it has been put out of work the machine can be eliminated. To correctly dispose of the machine get

information from any company responsible for such a service and take careful note of the material used for the

various components.

French Instructions

SÉCURITÉ ET GARANTIE

PRÉCAUTIONS GÉNÉRALES

• La machine ne doit être utilisé par un personnel qualié qui sont parfaitement au courant des normes de

sécurité contenues dans ce manuel.

9

Loading...

Loading...