Omcan SS-ES-0095-FT Service Manual

Sausage Stuffers

Models SS-ES-0026-F, 0026-FT, 0026-FS, 0048-FS, 0048-FT, 0048-F,

0065-F, 0065-FS, 0065-FT, 0095-F, 0095-FS, 0095-FT

Items 45950, 46099, 46098, 45920*, 45869*, 45959*, 45870, 46101*,

46100*, 45951, 46102, 46103*

Instruction Manual

Revised - 12/10/2018

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

*

Table of Contents

Model SS-ES-0026-F / Model SS-ES-0026-FT / Model SS-ES-0026-FS

Model SS-ES-0048-FS / Model SS-ES-0048-FT / Model SS-ES-0048-F

Model SS-ES-0065-F / Model SS-ES-0065-FS / Model SS-ES-0065-FT

Model SS-ES-0095-F / Model SS-ES-0095-FS / Model SS-ES-0095-FT

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

-------------------------------------------------------------------------------------------------- 11 - 15

--------------------------------------------------------------------------------------------------- 15 - 17

----------------------------------------------------------------------------------------------- 18 - 23

----------------------------------------------------------------------------------------- 3 - 4

---------------------------------------------------------------------------------------- 4 - 8

------------------------------------------------------------------------------------------- 23 - 25

Page

---------------------------------------------------------------------------------- 9 - 10

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

-------------------------------------------------------------------------------------------------------- 44 - 46

----------------------------------------------------------------------------------------- 26 - 41

------------------------------------------------------------------------------------ 42 - 43

----------------------------------------------------------------------------------------- 47

2

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

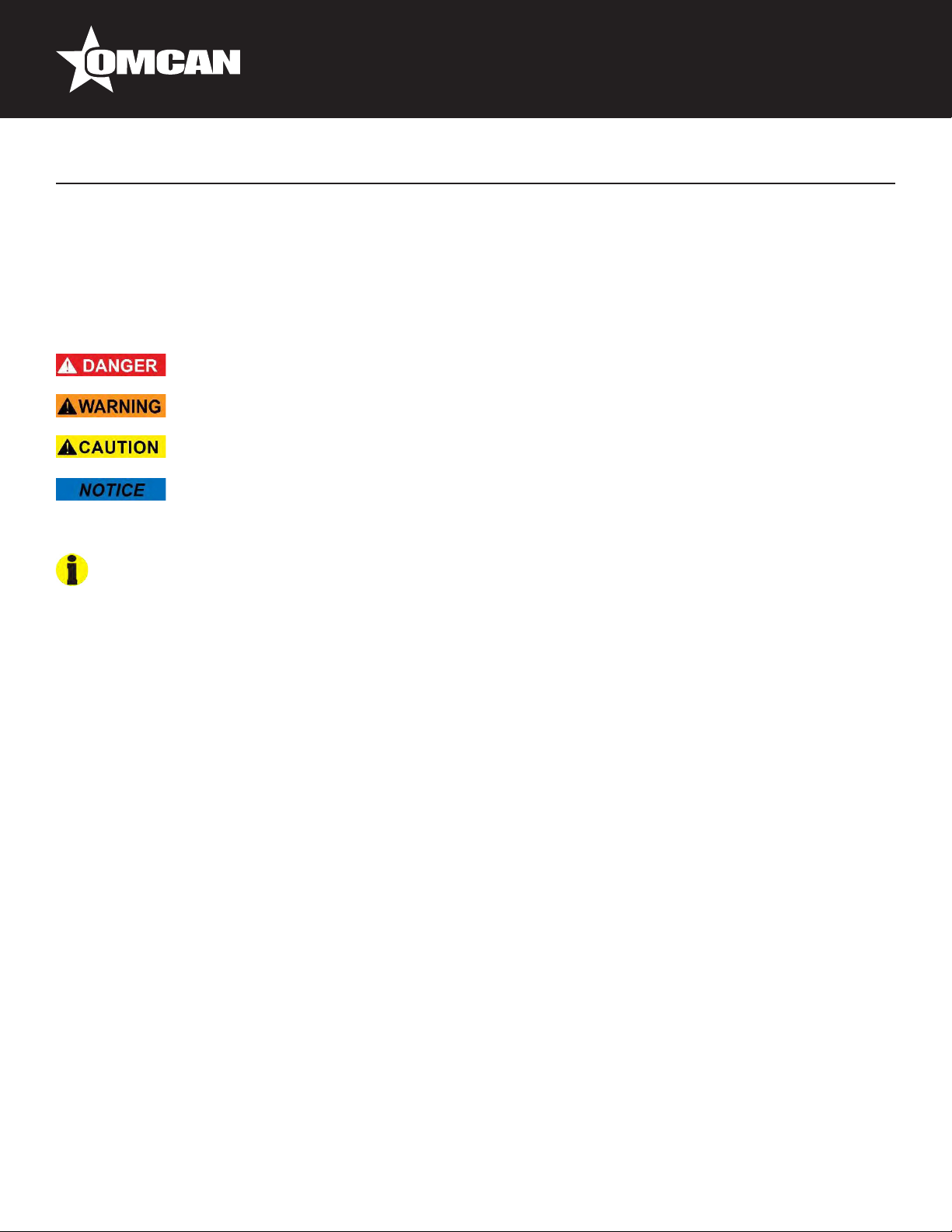

Safety and Warranty

DEFINITION OF WARNINGS AND SIGNAL WORDS

SAFETY WARNINGS AND SIGNAL WORDS USED IN THIS MANUAL

The safety instructions serve as indications and precautionary measures that must be taken into account or

adopted to avoid a dangerous situation.

This is the safety alert symbol. It is used to alert you to personal injury hazards. Obey all safety

4

Safety and Warranty

messages that follow this symbol to avoid possible injury or death.

Warnings can be classied according to the severity of the hazardous situation. The classication is based on

an assumption of probability of being exposed to a dangerous situation and what could happen in such a case.

There are four kinds of warnings:

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury.

Is used to address practices not related to personal injury.

IMPORTANT INFORMATION:

NOTE: provides additional information to clarify or simplify a procedure.

SAFETY WARNINGS ATTACHED TO THE MACHINES

The safety symbols warn of special hazards and are placed in the relevant places on the machine. Check

warning symbols daily:

• Are all security symbols present?

• Are all safety symbols recognizable and readable?

Ensure that the safety plates / adhesives are rmly attached to the machine, are easily readable and are not

erased during the cleaning process. Disconnect the machine and secure the main switch against reconnection

if a warning symbol is missing or no longer recognizable. Do not reconnect the machine until they are in place

and all safety symbols are recognizable. If they become damaged or lost, contact your authorized dealer.

INTENDED USE OF THE MACHINE

In general, the hydraulic piston llers/stuffers are used to prepare sausages made of minced meat. Other

applications include dough or paste of any type that can ow through a nozzle/horn of Ø10mm. Never use

hard masses or pastes that do not ow and could cause dangerous overpressure. The temperature of the

dough to be stuffed should be higher than 2ºC (35ºF).Do not process frozen or semi-frozen doughs. Working

environment conditions: temperature +5 to + 40ºC (+40 to + 100ºF), relative humidity: 20 to 90%. The

maximum operating pressure must not exceed 120 bar.

Any other use would conict with the machine’s characteristics, the manufacturer is not liable for any damages

that may occur as a result of improper use.

5

Safety and Warranty

MODIFICATIONS

DISCLAIMER OF LIABILITY

It is not allowed to modify the machine without the prior express authorization of Omcan, neither in its design

nor in its security systems. Omcan will not be liable for damages caused by arbitrary changes. When a user

makes essential modications to the machine, he assumes the manufacturer status. In such a case, he shall

be obliged to take all the measures incumbent on it legally as a manufacturer. The original manufacturer is

therefore released from its responsibility.

GENUINE PARTS

The machine is only allowed to be used with original Omcan accessories and spare parts. Omcan will not be

liable for damages caused by using tools, accessories or spare parts from other manufacturers.

IMPORTANT WARNINGS

Since the WARNINGS, CAUTIONS and INSTRUCTIONS in this manual cannot address all possible conditions

and situations that may arise, the operator MUST ALWAYS exercise common sense and due caution when

using this machine!

• DO NOT DISCARD THIS MANUAL; KEEP IT FOR FUTURE REFERENCE BY ALL USERS AND

MAINTENANCE PERSONNEL. PLEASE THOROUGHLY READ AND FULLY UNDERSTAND ALL THE

INSTRUCTIONS BEFORE SERVICING OR USING THE MACHINE.

• THIS MACHINE HAS MOVING PARTS AND USES VOLTAGES THAT ARE POTENTIALLY HAZARDOUS.

FAILURE TO FOLLOW THE INSTRUCTIONS CONTAINED IN THIS MANUAL COULD RESULT IN

SEVERE, POSSIBLY LIFE-THREATENING, PERSONAL INJURY.

• THIS MACHINE HAS BEEN DESIGNED EXCLUSIVELY FOR MEAT PROCESSING. USE OF THIS

MACHINE FOR ANYTHING OTHER THAN MEAT PROCESSING DOES NOT CONFORM TO ITS

INTENDED FUNCTION, IS STRICTLY PROHIBITED AND SHALL VOID Omcan’s WARRANTY. Omcan

ASSUMES NO RESPONSIBILITY FOR ANY DAMAGE OR INJURY RESULTING FROM IMPROPER USE

OF THIS MACHINE.

• DO NOT ALTER OR MODIFY THE MACHINE’S ORIGINAL DESIGN IN ANY WAY; DOING SO WILL VOID

Omcan’s WARRANTY AND MAY RESULT IN PERSONAL INJURY OR DAMAGE TO THE MACHINE.

• This machine MUST be installed ONLY by a qualied electrician in accordance with the instructions in this

manual and in compliance with all applicable national, regional and local electrical, safety and hygiene

standards and codes. Compliance with said standards and codes is the sole responsibility of the owner and

installer.

• DO NOT open the machine or tamper with its internal parts; none of the internal components requires

adjustment or maintenance by the user.

• DO NOT tamper with the machine’s mechanical or electrical safeguards.

• Use ONLY genuine Omcan parts or accessories and have them installed only by a qualied technician.

Use of unapproved parts and accessories voids Omcan’s warranty and may result in personal injury or

damage to the machine.

• NEVER attempt to repair the machine on your own. Should the machine require service, contact the

authorized dealer from whom you purchased the machine.

• Modications to the machine that raise noise emission levels above 85 dB(A) may result in hearing

6

Safety and Warranty

damage. ALWAYS wear appropriate hearing protection.

OPERATING HAZARDS

• PLEASE READ THIS MANUAL CAREFULLY AND FULLY UNDERSTAND ALL THE INSTRUCTIONS

BEFORE USING THE MACHINE.

• DO NOT OPERATE THE MACHINE WITHOUT HAVING FIRST BEEN INSTRUCTED ON ITS USE,

MAINTENANCE AND SAFEGUARDS FROM AN EXPERIENCED OPERATOR.

• ALWAYS keep hands and hair away from moving parts when the machine is in use. There is the danger of

crushing hands, ngers, etc. when closing the lid or when the piston is raised while the lid is not completely

open.

• NEVER wear loose clothing or jewellery that could get caught on moving parts when the machine is in use.

• DO NOT use the machine without wearing the protective gear required by law.

• DO NOT leave the machine unattended while it is switched on or plugged to an electrical outlet. ALWAYS

unplug the machine when it is not in use.

• ALWAYS keep your work area well-lit and free of obstacles.

• ALWAYS keep children, visitors and bystanders away from the machine while it is in use or plugged to an

electrical outlet. NEVER allow children to operate the machine.

• SHOULD THE MACHINE MALFUNCTION, PROMPTLY TURN IT OFF AND NOTIFY THE APPROPRIATE

PERSONNEL.

• ALWAYS follow the hygiene and cleaning instructions in this manual and the local sanitary codes in order to

avoid contaminating the food mixture.

• ALWAYS rmly grip both the transport handle (located at the machine’s base) and the lid handle when

moving the machine. DO NOT tilt the machine too far while it is balanced on its wheels since it is heavy

and there is a risk of personal injury or property damage if it tips over.

ELECTRICAL HAZARDS

• DO NOT TAMPER WITH THE MACHINE’S ELECTRIC SYSTEM. THIS MACHINE MUST BE INSTALLED

ONLY BY A QUALIFIED ELECTRICIAN AND IN COMPLIANCE WITH APPLICABLE NATIONAL,

REGIONAL AND LOCAL ELECTRICAL CODES.

• ALWAYS USE CAUTION WHEN WORKING ON THE MACHINE’S ELECTRICAL SYSTEM SINCE THERE

IS A RISK OF ELECTRIC SHOCK DUE TO:

- DIRECT OR INDIRECT CONTACT WITH ELECTRIC CURRENT.

- IMPROPERLY INSTALLED DEFECTIVE OR DAMAGED ELECTRICAL PARTS.

• BEFORE operating the machine, make sure that all phases are connected properly and that the machine is

properly grounded and/or connected to a circuit leakage breaker and thermal switch. Failure to do so could

result in electric shock!

• DO NOT tamper with the machine’s electrical wiring or components after installation.

• ALWAYS disconnect the machine from the electrical outlet before proceeding with cleaning, maintenance,

or repairs.

• To avoid damaging the power cord and possible injury, keep it away from areas where it may be stepped

on or tripped over. DO NOT pull on the power cord to disconnect the plug from the electrical outlet; always

pull on the plug.

7

Safety and Warranty

DISPOSAL

Risk of damage to people and environmental hazards. The machine is composed of different materials.

Observe local regulations on waste disposal. Instruct an authorized waste disposal company to dispose of

waste correctly.

1 YEAR PARTS AND LABOR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see https://omcan.com/disclaimer for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

8

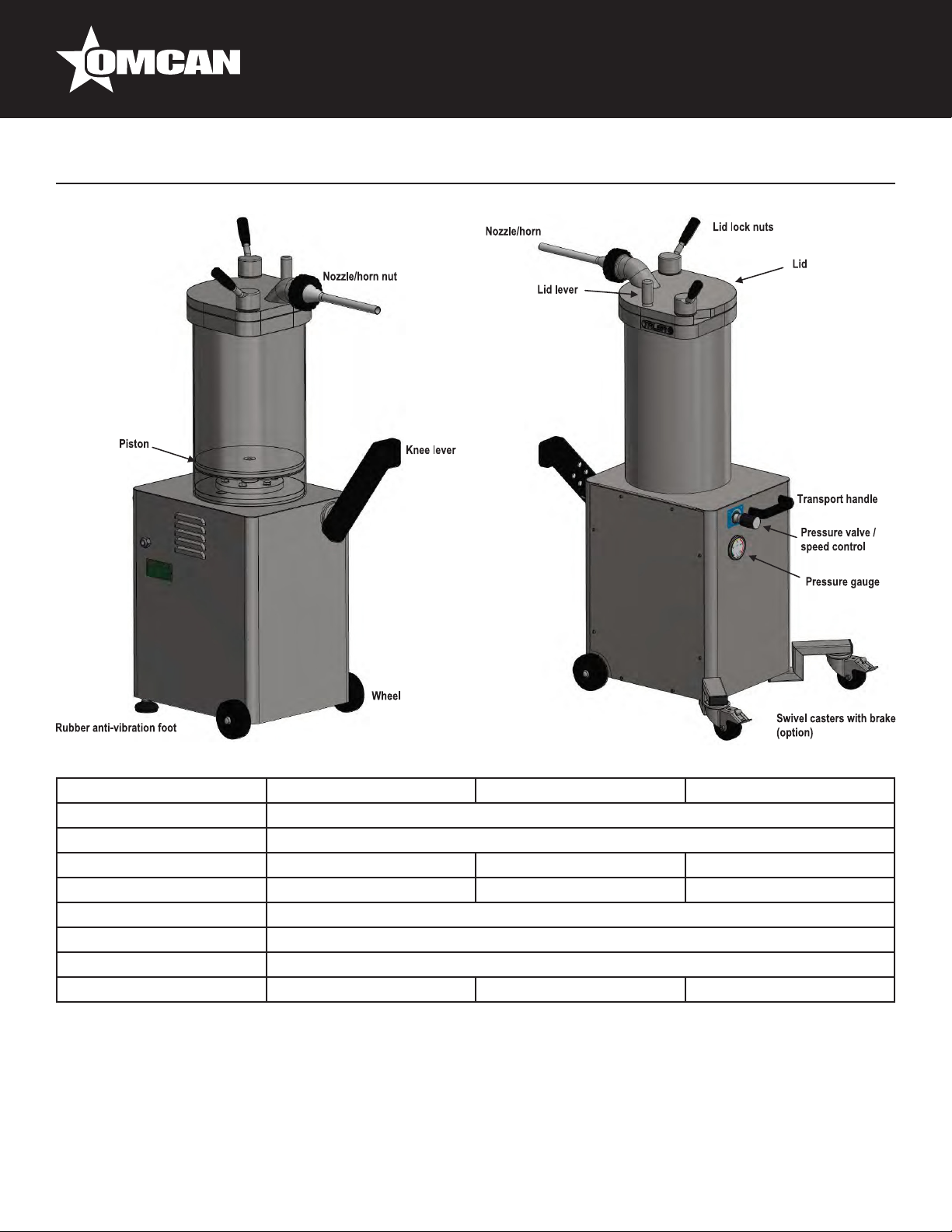

Technical Specications

14.2 L STUFFER

Model SS-ES-0026-F SS-ES-0026-FT SS-ES-0026-FS

Barrel Capacity 14.2 L / 3.7 Gal

Approx. Meat Capacity 26 lbs. / 11 kgs.

Power 1 HP / 0.75 kW 0.75 HP / 0.55 kW 1 HP / 0.75 kW

Electrical 110V / 60Hz / 1 208V / 60Hz / 3 220V / 60Hz / 1

Dimensions 19” x 21” x 49” / 483 x 533 x 1245mm

Weight 265 lbs. / 120 kgs.

Packaging Weight 310 lbs. / 140 kgs.

Item Number 45950 46099 46098

9

Technical Specications

25.2 L STUFFER

Model SS-ES-0048-FS SS-ES-0048-FT SS-ES-0048-F

Barrel Capacity 25.2 L / 6.6 Gal

Approx. Meat Capacity 48 lbs. / 20 kgs.

Power 1.75 HP / 1.3 kW 1.5 HP / 1.1 kW 1.75 HP / 1.3 kW

Electrical 110V / 60Hz / 1 208V / 60Hz / 3 220V / 60Hz / 1

Dimensions 21” x 23” x 49” / 533 x 584 x 1245mm

Weight 310 lbs. / 140 kgs.

Packaging Weight 350 lbs. / 160 kgs.

Item Number 45920 45869 45959

35.1 L STUFFER

Model SS-ES-0065-F SS-ES-0065-FS SS-ES-0065-FT

Barrel Capacity 35.1 L / 9.2 Gal

Approx. Meat Capacity 65 lbs. / 28 kgs.

Power 1.75 HP / 1.3 kW 1.5 HP / 1.1 kW

Electrical 110V / 60Hz / 3 220V / 60Hz / 1 220V / 60Hz / 3

Dimensions 21” x 23” x 49” / 533 x 584 x 1245mm

Weight 350 lbs. / 160 kgs.

Packaging Weight 400 lbs. / 180 kgs.

Item Number 45870 46101 46100

51 L STUFFER

Model SS-ES-0095-F SS-ES-0095-FS SS-ES-0095-FT

Barrel Capacity 51 L / 13 Gal

Approx. Meat Capacity 95 lbs. / 40 kgs.

Power 2.5 HP / 1.87 kW 2.5 HP / 1.9 kW

Electrical 110V / 60Hz / 1 220V / 60Hz / 1 220V / 60Hz / 3

Dimensions 26” x 25” x 64” / 660 x 635 x 1626mm

Weight 580 lbs. / 260 kgs.

Packaging Weight 660 lbs. / 300 kgs.

Item Number 45951 46102 46103

10

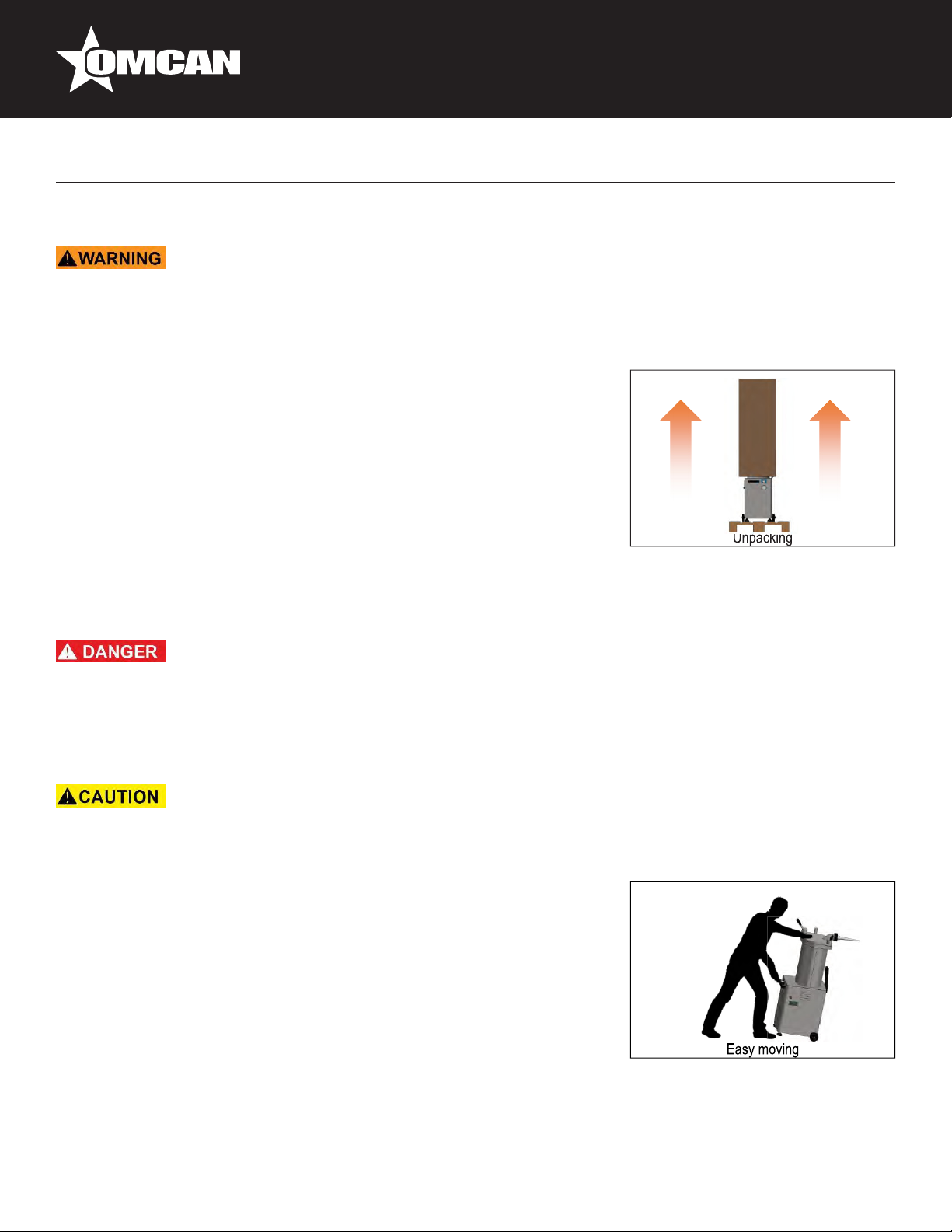

STORAGE, DELIVERY AND UNPACKING

• ALWAYS keep the machine upright, even while in its packaging.

• NEVER stack machines even if they are in their original packaging.

• NEVER place heavy objects on top of the machines or its packaging.

The machine is delivered on a pallet protected either by cardboard

packaging (F14/25/35) or wooden crate (F50). We use only recyclable

packaging and ask that you please recycle these materials.

Remove the packaging and thoroughly inspect the machine upon delivery.

Should you note any damage to the machine, retain all packing materials

and promptly notify the carrier. The transport company is solely responsible

for any damage to the machine during transit. If the machine is found to

be in satisfactory condition, follow the instructions in POSITIONING THE

MACHINE in order to safely convey it to a suitable work area. Your needs

will determine the most appropriate location for the machine.

Installation

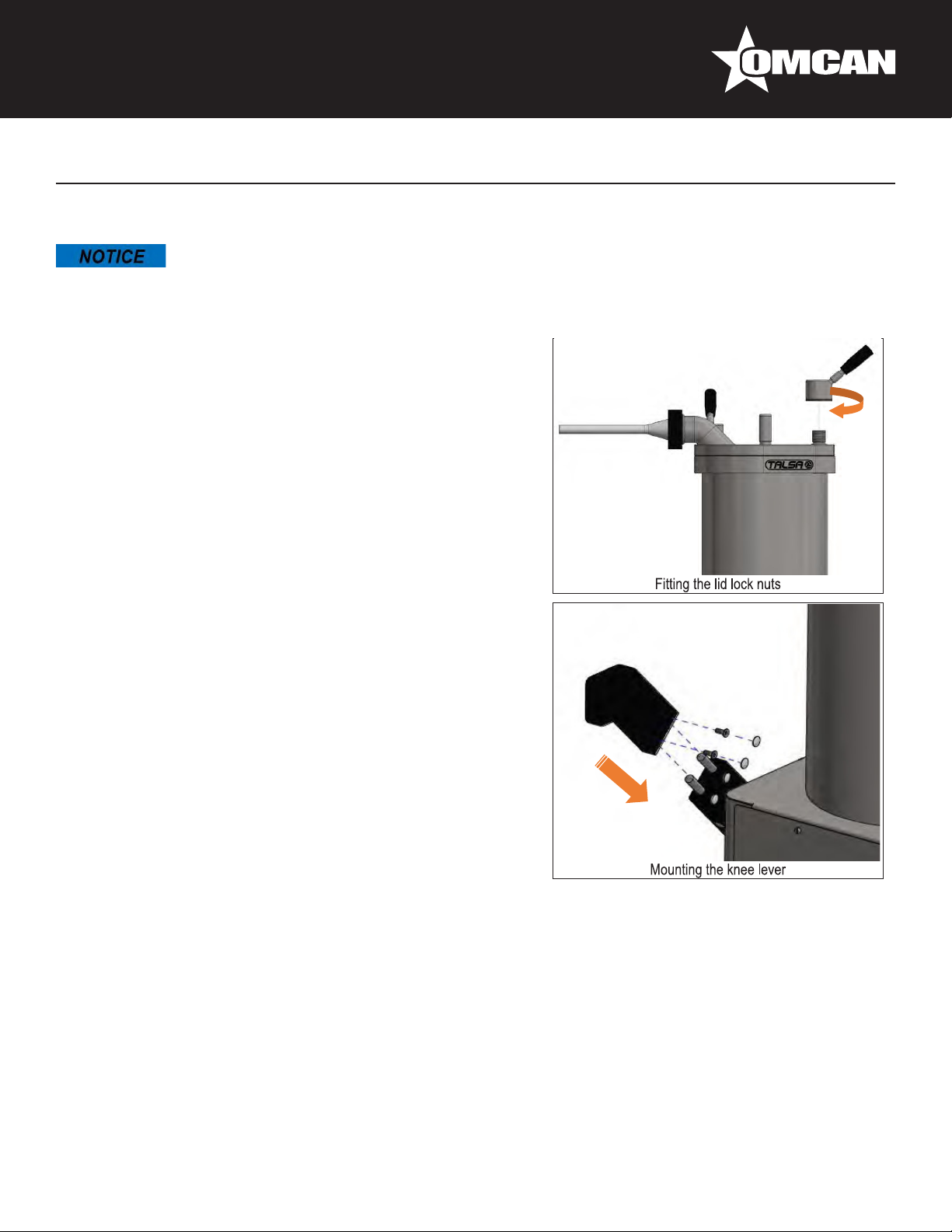

PLACEMENT

ELECTRICAL HAZARD!

• The electrical installation of the enclosure must provide a thermal protection device (MCB) and leakage

(differential), conforming to the specications of each machine. A qualied electrician must adjust these

safety devices to the specications of your particular machine.

• Do not use the machine in wet locations.

• Do not lift the machine more than necessary, it could collapse.

• In order to move the F50 model, two people are required.

The machine should be placed in the most appropriate place, according

to the demands and needs of use. For a good, prolonged operation, the

machine should be placed in a sufciently ventilated area, avoiding lack

of air circulation. The workplace should be clean, free from obstacles and

have a horizontal and anti-slip surface. Observe a passage area around

the machine of 1 meter to proceed to use, clean and maintenance thereof.

To move the machine to the desired location:

• ALWAYS rmly hold the carrying handle and the lid handle to move the

machine. NEVER use the knee lever to move the machine!

• Tilt the machine so that it is balanced on its wheels and may be rolled

into place.

• ALWAYS place the machine on a at, level surface. Should the machine wobble, adjust the anti-vibration

legs until it is perfectly level and stable.

11

Installation

• The machine should be positioned so that the power plug is easily accessible to the operator.

Do not store the machine in cold places (i.e. refrigerated storage house). Persistent low temperatures

can cause damages in the machine.

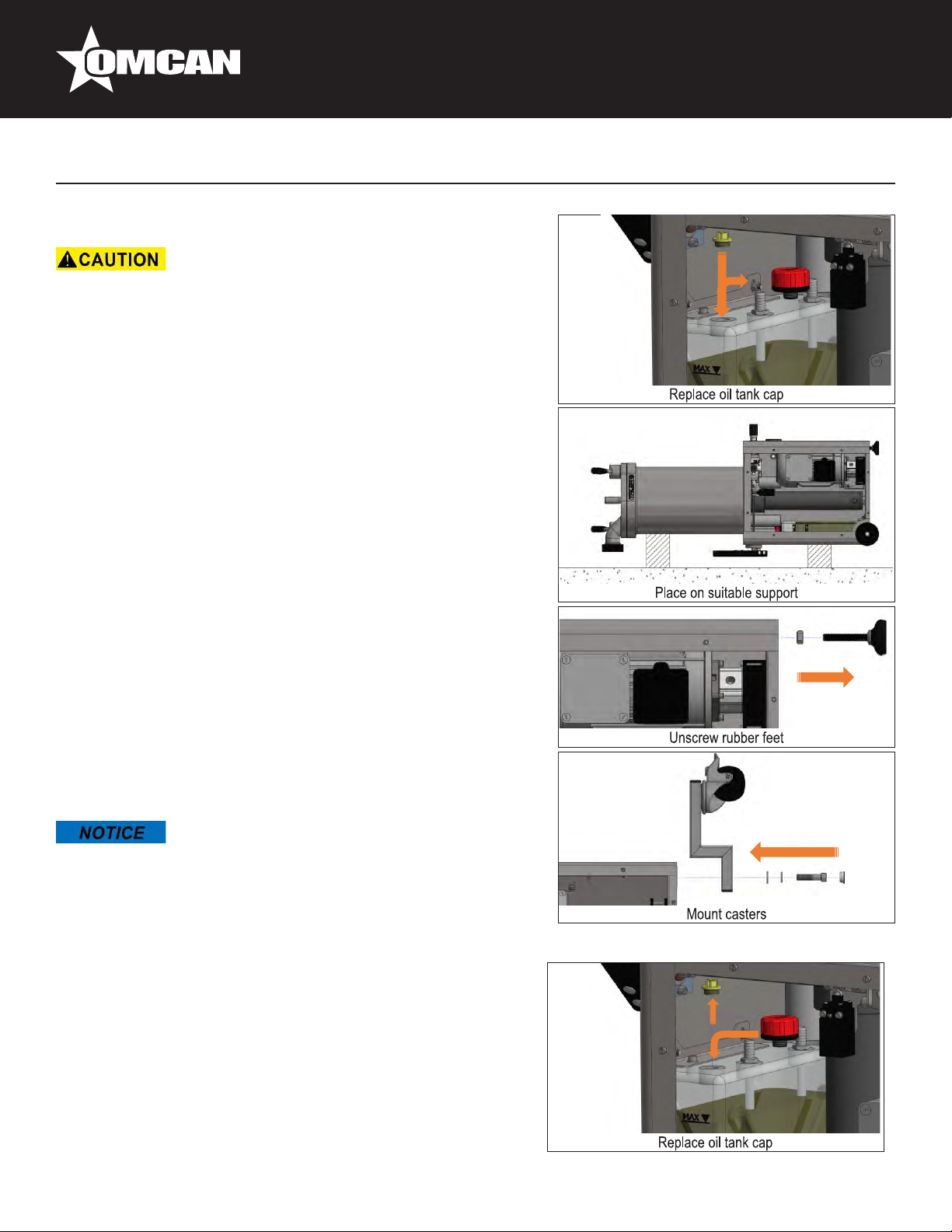

INSTALLATION OF THE LID LOCK NUTS AND

KNEE LEVER

Before using the stuffer it is necessary to assemble the lid lock

nuts and knee lever delivered with the machine.

• Screw the lid lock nuts on the threads projecting from the

lid. Do not overtighten, as this would hinder the opening and

closing of the lid.

• Place the knee lever at the anchor point.

• Attach the two screws with Allen wrench supplied with the

machine. Check the operation of the knee lever. It should

move with little effort and return to the center position when

released (in the lifting drive the piston).

• Place the two gray caps on the heads of the screws.

Knee lever position and action of the piston:

• When you push the toggle to the left, the piston must rise.

The knee lever automatically returns to the center position

when no pressure is applied thereon.

• When pushing the lever rightward the piston must descend.

In this position, the lever is automatically locked until

the piston reaches the lower position. The piston can be

stopped at any time by pushing the lever to the center

position.

It is possible to reverse the direction of drive knee lever / piston.

Consult your dealer where you purchased the stuffer.

12

INSTALLING CASTERS (OPTIONAL)

• To lay down and lift the machine at least two people are

needed.

• ALWAYS secure the position of the machine setting the brakes

on the castors (optional).

Optionally the stuffer is provided with two pivoting wheels with

brakes that facilitate the movement of the stuffer. To install these

wheels follow the instructions below:

• Unscrew and remove the screws that hold the panel to the

machine base, then withdraw it.

• Remove the evaporator cap (red) and replace it with the

transport cap (yellow). This cap closes the oil reservoir

hermetically, avoiding leakage of hydraulic oil for the following

steps.

• Lay the machine to the side of the knee lever, on a suitable

support to prevent damaging the lever. To lay down and lift the

machine at least two people are needed.

• Remove the anti-vibratory rubber feet unscrewing them from

the machine body.

• Attach the extensions and casters with the screw and washers

provided.

• Lift the machine (at least two people are required).

• Very important! Before operating the machine, replace the

evaporator cap (red) in the oil tank.

• Check the operation of the machine and close machine body

cover.

Installation

Before putting the machine into operation, make sure to

replace the transport cap (yellow) with the cap of the oil tank

(red). Operating the machine with the yellow transport cap

will damage the hydraulic system!

TRANSPORT CAP OF THE OIL TANK (MACHINES

SENT LYING)

Machines sent lying on a pallet (air shipment), have a transport

oil cap (yellow) closing the oil tank hermetically, to prevent

oil leakage during transport. Before operating the machine,

replace the transport oil cap by the depressurized oil cap (red)

delivered with the machine.

• Unscrew and remove the screws that hold the panel to the

13

Installation

machine base, then withdraw it.

• On the oil reservoir, replace the transport oil cap (yellow) by the depressurized oil cap (red).

• Check the oil level in the tank. It must be between the MAX and MIN marks on the tank. If necessary, add

enough oil to bring the level up to the maximum mark. Do not ll the tank completely, as a certain volume of

air for expansion of the oil is necessary.

• Replace the panel at the end of operations.

• Before putting the machine into operation, make sure to replace the transport cap (yellow) with the cap of

the oil tank (red). Operating the machine with the yellow transport cap will damage the hydraulic system!

• The llers are supplied from factory with the appropriate hydraulic oil level. Therefore, it is usually not

necessary to rell it. In the exceptional event that the new machine is delivered with a lack of hydraulic oil,

DO NOT connect it. Proceed to ll it before operation.

CONNECTING TO THE POWER SOURCE

ELECTRICAL HAZARD!

• This machine must be installed only by a qualied technician and in compliance with applicable national,

regional and local electrical codes.

• The machine MUST remain disconnected from the power supply throughout this procedure.

CHECK THE WIRING BEFORE CONNECTING THE MACHINE! Call a qualied electrician if the electrical

specications do not correspond with your power source: the wiring in the electrical cord is normally assigned

as follows: PHASE(S): Black, Brown or Gray. NEUTRAL: Blue (or White in some non CE/CEN/UE countries).

GROUND: Bi-coloured Yellow / Green (or Green in some non CE/CEN/UE countries).

• Ensure that the electrical characteristics of the stuffer, detailed in the plate xed to the machine (voltage,

frequency, Hz, phases), coincide with those of the mains. A tolerance of ± 10% in voltage and frequency ±

2% is accepted.

• If they match those of the network, have a qualied electrician connect a plug to the power cord.

• If the voltage of the machine does not match the network, and if dual voltage three-phase motor, it

appropriate to adjust the voltage thereof, as described in Voltage change and then have a qualied

electrician connect a plug to the power cord.

• It is mandatory the use of a standard plug for connecting the machine.

Once connected machine check the proper operation of the stuffer: push the brace rmly to the left (rising

piston).

• If the phases are correctly connected, the piston will rise and lower correctly when operating the knee lever.

• If the phases are not well connected, the pump will operate in reverse, the motor will make noise but

the piston will not move. Stop the machine immediately and switch it from the mains. Have a qualied

technician permute two of the three phases in the plug; NEVER inside the machine.

14

VOLTAGE CHANGE

ELECTRICAL HAZARD!

• This operation must only be carried out by a qualied electrician!

• The machine MUST remain disconnected from the power supply

throughout this procedure.

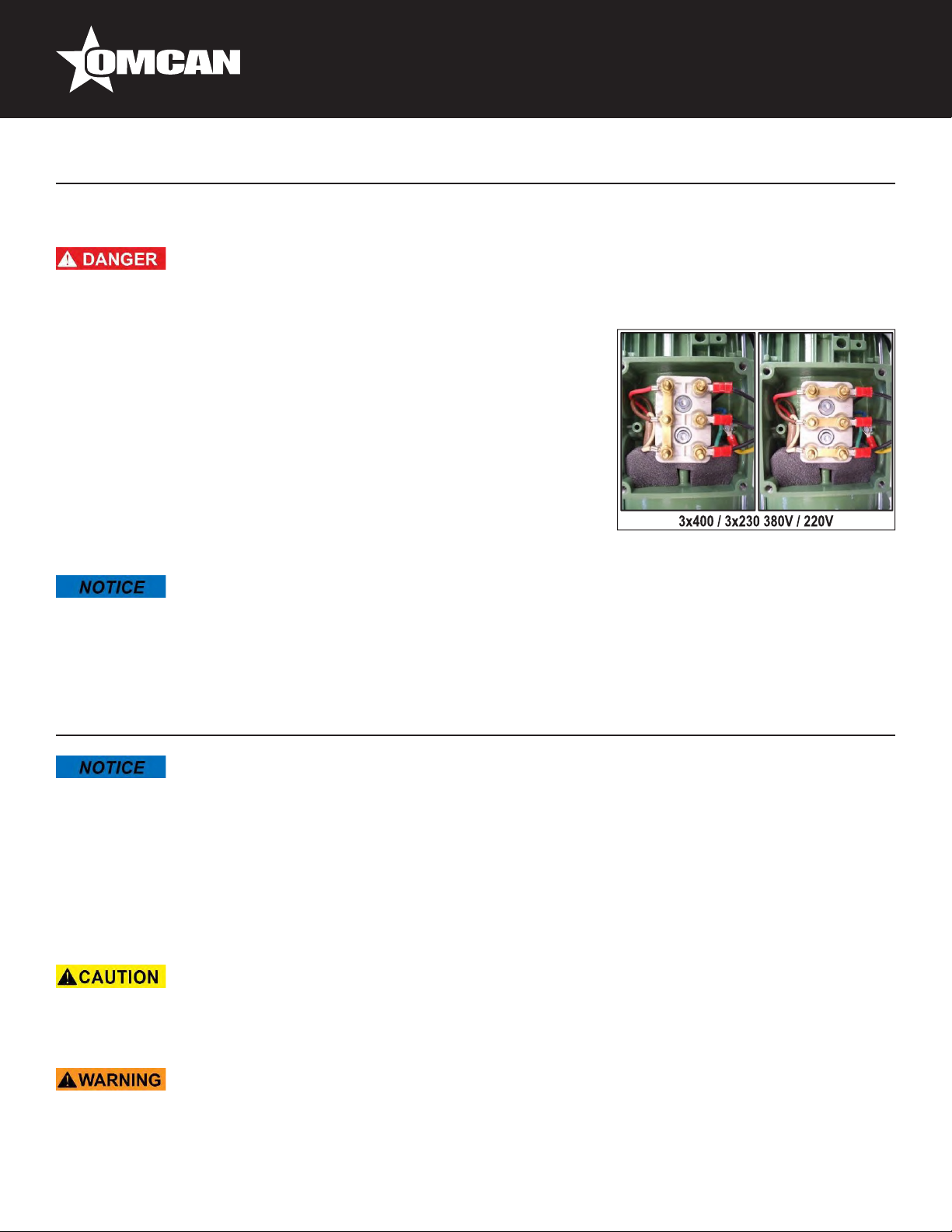

Only dual voltage three-phase machines powered 380 / 220V (400 /

230V EU) Unscrew and remove the screws that hold the panel to the

machine base, then withdraw it. Make the following changes in the

components:

• Open the terminal box by removing the screws 4 thereof.

• Release 6 locknuts small terminals.

• Put the plates in the correct position.

• Reseal the motor terminal box.

• Replace the panel at the end of operations.

Installation

The Qualied electrician in charge of changing the voltage of the machine should refer to the corresponding

wiring diagrams in this manual.

Operation

• BEFORE STARTING WORK, PLEASE READ AND UNDERSTAND THIS ENTIRE MANUAL AND SAFETY.

• DO NOT use the machine without having been instructed by an advanced user.

• Practice using the machine in vacuum before contacting mass.

• This machine is not designed to run in continuous operation uninterrupted at high pressures, but

intermittent operation stops dissipating the heat generated varies depending on the consistency of the

product.

STEPS TO FOLLOW

• If the phases are not well connected, power up the pump will operate in reverse, the engine make noise but

will not move the piston. In this case stop immediately and disconnect the machine from the mains.

• Have a qualied electrician permute two of the three phases in the plug.

• Observe all hygiene measures in food processing, using the necessary protection material (washing,

gloves, hat, apron, etc.)

15

Loading...

Loading...