Page 1

Sausage Stuffers

Models SS-ES-0015, 0020, 0026, 0031, 0042, 0052

Items *13743, *13744, 41708, *13745, 13746, *13750, 13752, *13751,

*13753, *41709, *13755, 13756, 13757, 13758, 13759, 17146

Instruction Manual

Revised - 12/07/2017

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

*

Page 2

Table of Contents

Model SS-ES-0015-PA / Model SS-ES-0015-PAM / Model SS-ES-0020-PA

Model SS-ES-0020-PAM / Model SS-ES-0026-PA / Model SS-ES-0026-PAM

Model SS-ES-0026-PAS / Model SS-ES-0026-PASM / Model SS-ES-0031-PAS

Model SS-ES-0031-PASM / Model SS-ES-0042-PAS / Model SS-ES-0042-PASM

Model SS-ES-0052-PAS / Model SS-ES-0052-PASM

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

----------------------------------------------------------------------------------------------------- 7 - 9

----------------------------------------------------------------------------------------------------- 9 - 10

----------------------------------------------------------------------------------------------- 11 - 15

----------------------------------------------------------------------------------------- 3 - 4

---------------------------------------------------------------------------------------- 4 - 6

------------------------------------------------------------------------------------------- 15 - 16

Page

---------------------------------------------------------------------------------------- 7

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

-------------------------------------------------------------------------------------------------------------- 26

----------------------------------------------------------------------------------------- 17 - 23

------------------------------------------------------------------------------------ 24 - 25

----------------------------------------------------------------------------------------- 27

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

This machine has moving mechanical parts and uses voltages that are potentially hazardous. Severe, even

life-threatening, personal injury could result if the instructions contained in this manual are not followed.

Before operating the unit, please read this manual thoroughly. This manual should be kept for future reference

and given to every user of the machine. The following clauses limit the liability of the manufacturer and its

representatives:

• This machine should only be installed by a qualied electrician. Once installed, do not tamper with the

4

Page 5

Safety and Warranty

electrical wiring or components of the machine.

• Do not use the machine without having received previous instructions about its use, maintenance and

safety devices from an experienced operator.

• Read the instruction manual carefully before using the machine.

• Do not use the machine without the personal safety equipment required by law.

• Do not tamper with the xed guards, the safety interlock electrical switches or any other safety devices.

• Always keep hands at a safe distance from the moving parts of the machine.

• Do not leave machine unattended while switched on or in operation.

• Always disconnect the power supply before removing shrouds, removable guards, covers, doors, fences,

panels, etc. for servicing, cleaning, or repairs.

• Do not open the machine or tamper with its internal parts. There are no internal components that require

adjustment or maintenance on the part of the user.

• Should the machine malfunction, turn it off immediately and notify the supervisor.

• Installation must be in accordance with the operating instructions and with local and state hygiene

standards and safety codes. Compliance with codes is the responsibility of the Owner and Installer.

• Before operating the machine, make sure that it is properly grounded and/or connected to a circuit leakage

breaker and thermal switch. Failure to do so could result in electric shock.

• Make sure the safety signs and stickers are rmly afxed to the machine, that they are legible, and that

they have not been blurred or erased after the machine is cleaned. If they become damaged or lost, ask

your dealer for new ones and replace them.

• Keep your work area well lit and free of obstacles.

• When operating the machine never wear loose clothing or jewelry that could get caught in the moving

parts.

• Disconnect power.

• Keep children and on-lookers at a safe distance.

• Do not pull on the cord to remove the electrical plug from the socket.

• To avoid damaging the electrical cord, keep it out of areas where it can be stepped on.

• Do not alter or modify the machine’s original design in any way.

• Should the machine need repairs, consult the ofcial dealer where the machine was purchased.

• Use only genuine TALSA parts and accessories and have them properly installed by a qualied technician.

• This machine has been designed exclusively for meat processing. Any other use of this machine is not

in accordance with its intended application. The manufacturer assumes no responsibility for any possible

damage or injury resulting from improper use of this machine.

Additional operating instruction manuals are available from your dealer. Your local dealer will be happy to

answer any further questions you may have.

LIST OF POSSIBLE OPERATING HAZARDS

Read and review thoroughly the following operating hazards.

MECHANICAL HAZARDS

• Crushing hands, ngers etc. on the barrel when closing the lid.

• Crushing hands, ngers etc. between the lid and the piston while the latter is being raised, especially when

the lid is not completely open.

5

Page 6

Safety and Warranty

• Crushing hands, ngers etc. between the piston and the upper part of the base during the dismantling of

the removable barrel on E models.

• Personal injury should the machine tip over if it is raised too high while being moved (since the llers are on

wheels, this is an important hazard).

• Foot injuries should the piston fall during dismantling or cleaning.

ELECTRICAL HAZARDS

• Electric shock due to direct or indirect contact with electrical current.

• Electric shock due to defective electrical parts.

NOISE HAZARDS

• Hearing damage should any modication of the machine’s original design raise noise emission levels

above 85 dB(A).

PERSONAL HEALTH HAZARDS

• Changes in the nature of the food mixture if hygiene and cleaning instructions have not been followed.

1 YEAR PARTS AND LABOR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see www.omcan.com/warranty.html for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

6

Page 7

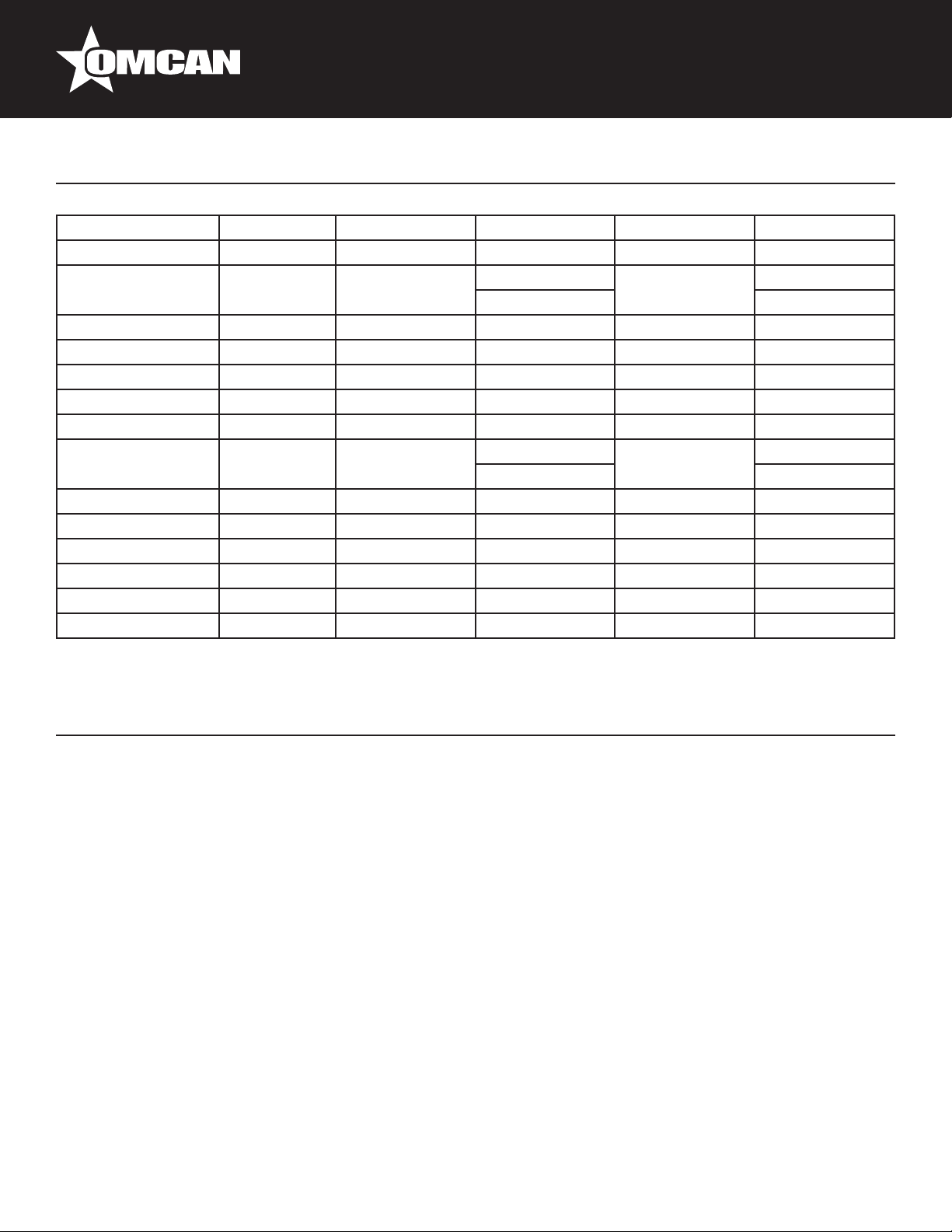

Technical Specications

Model HP Capacity Electrical Weight Item Number

SS-ES-0015-PA 0.75 HP 33 lbs. 208V/60/3 223 lbs. 13743

SS-ES-0015-PAM 1.75 HP 33 lbs.

SS-ES-0020-PA 0.75 HP 44 lbs. 208V/60/3 231.5 lbs. 13745

SS-ES-0020-PAM 1.75HP 44 lbs. 220V/60/1 231.5 lbs. 13746

SS-ES-0026-PA 1.5 HP 57 lbs. 208V/60/3 289 lbs. 13750

SS-ES-0026-PAS 1.5 HP 57 lbs. 208V/60/3 289 lbs. 13752

SS-ES-0026-PAM 2.25 HP 57 lbs. 220V/60/1 289 lbs. 13751

SS-ES-0026-PASM 2.25 HP 57 lbs.

SS-ES-0031-PAS 2 HP 68 lbs. 220V/60/3 315.25 lbs. 13755

SS-ES-0031-PASM 2.25 HP 68 lbs. 220V/60/1 315.25 lbs. 13756

SS-ES-0042-PAS 2.5 HP 92 lbs. 220V/60/3 527 lbs. 13757

SS-ES-0042-PASM 2.5 HP 92 lbs. 220V/60/1 527 lbs. 13758

SS-ES-0052-PAS 2.5 HP 114 lbs. 220V/60/3 610.7 lbs. 13759

SS-IT-0052-PASM 2.5 HP 114 lbs. 220V/60/1 610.7 lbs. 17146

220V/60/1

223 lbs.

110V/60/1 41708

220V/60/1

289 lbs.

110V/60/1 41709

13744

13753

Installation

(Machine should only be installed by a qualied technician and in compliance with local codes).

The electrical installation of the workplace should be equipped with power surge full protection, which should

then be adjusted to the technical specications of your particular unit (see below).

UNPACKING AND POSITIONING

Always keep the machine in a vertical position. Take the machine out of its box. Remove the knee lever (and

the upper lid screws for E models) from the inside of the barrel and set them in their proper positions. Do not

use the knee lever to move the machine. The machine comes with two xed (non-castor) wheels in the front

and two plastic anti-vibration legs in the back; lift the back part of the machine using the transport handle and

move the machine to the desired location (two people are necessary for moving the heavier H42 and H52

models). Do not raise the ller/stuffer too high when moving it since it could tip over, causing personal injury.

Place the machine on a level surface. Should the machine wobble, adjust the anti-vibration legs until it is

perfectly stable and level. The machine should be placed so that the plug is easily accessible.

IMPORTANT: Remove the protective transport cap on the oil inlet (marked OIL) and replace it with the

depressurized oil cap/dipstick enclosed with the machine. Also make sure that the air holes located at the base

7

Page 8

Installation

of the barrel are totally clear; if not, the piston will not function properly.

CONNECTING THE MACHINE

Make sure the electrical characteristics of the machine (connection, voltage, and frequency) are suited to your

power source. (These specications are given in detail on the technical specications sticker afxed to the

machine itself; there is a tolerance of ±10% for voltage and of ±2% for frequency). If the specications are

compatible with your power source, refer to the OPERATING INSTRUCTIONS section below. If the electrical

features of the machine are not compatible with your power source and your machine is a dual voltage, three-

phase unit, adjust the voltage as described below in the CHANGING VOLTAGE section. Once the machine has

been installed and the oil level inside the reservoir has been checked using the dipstick attached to the oil inlet

screw, check the turning direction of the three-phase motor. If the phases are correctly adjusted, the piston will

rise and fall when the knee pedal is pushed. If the phases are incorrect, the pump will not work properly; the

motor will make noise, but the piston will not move. Stop immediately and interchange two of the three phases

in the plug. Make sure that the plug and outlet are appropriate for the machine.

IMPORTANT: the wiring in the electrical cord is normally assigned as follows: Phase(s): • Black, Brown,

Gray • Ground wire: Two-colored Yellow/Green or Green. Check the wiring before connecting; call a qualied

electrician if the electrical specications do not correspond with your power source.

HYDRAULIC OIL FILLING

The H ller/stuffer is delivered with hydraulic oil already in the internal reservoir; therefore, the initial addition of

oil to the hydraulic system is usually unnecessary. In the exceptional case that a machine is delivered without

hydraulic oil in the reservoir, do not turn it on. Fill the reservoir as follows:

• Remove the oil reservoir screw (marked OIL) located in the upper part of the base.

• Check that the correct level of oil is inside the reservoir by using the dipstick (with max./min. marks)

attached to the oil reservoir cap.

• Using a funnel, pour the hydraulic oil into the tank. Do not ll the reservoir to the top since a certain

amount of air must remain in the reservoir to allow for expansion. Use oils for medium pressure hydraulic

assemblages (approx. 100 bar), and of a viscosity of approximately 5º Engler (equivalent to IS03498: cat

HL VG46 or DIN8659: HL-46). After lling the reservoir, raise and lower the piston several times to purge

any remaining air from the hydraulic circuit.

Always ll the reservoir to the maximum level without exceeding it since the more oil there is in the reservoir,

the more effectively the heat given off by the hydraulic assemblage will be cooled. This helps lengthen the life

of the oil. Because there should be no loss of oil or oil vapors, an adequate level of hydraulic oil should last

several years (between 2500 and 5000 hours of use), making it unnecessary to check the oil level as long as

the machine is functioning well. For more information, see the MAINTENANCE section below.

CHANGING THE VOLTAGE

IMPORTANT: Only for three-phase machines with dual voltage motor 380/220 Volt (400/230 Volt for EU), etc.

This operation should only be carried out by a qualied electrician. Do not connect the machine to the power

source. If already plugged in, unplug it and leave it disconnected for the entire process. Remove the screws

from the steel lid on the base. Remove the lid.

8

Page 9

Installation

CHANGING THE VOLTAGE ON A MODELS (AUTOMATIC-CONTACTOR)

MOTOR: Open the connection terminal box of the motor by unscrewing the four screws. Loosen the six small

nuts on the connection terminals and place the plates in the correct position.

CONTACTOR: will need to be replaced by a qualied technician to a new one of same voltage than power

supply.

CHANGING THE VOLTAGE ON “I” MODELS (SWITCH)

MOTOR: Open the connection terminal box of the motor by unscrewing the four screws. Loosen the six small

nuts on the connection terminals and place the plates in the correct position.

Operation

IMPORTANT: Before operating the unit, read this manual thoroughly. Test the machine when it is empty before

using it on food.

HANDLING STEPS

• Loosen the screws on the upper lid (only for E models) and open the lid with a slight upward motion to

reduce friction.

• Wash the meat barrel, the underside of the lid, and the appropriate nozzle with hot water.

• Lower the pressure of the machine to the minimum by turning the red knob that regulates the lling speed

counter-clockwise.

• Plug the machine in.

• Turn the gray switch located on the right of the machine to the “I” (start) position (I models only).

• Turn the machine on by pushing the knee lever.

• Push the knee lever all the way back to lower the piston enough to make room for the desired amount of

mixture.

• Place the mixture in the meat barrel, pressing each new load of mixture down to avoid the formation of air

pockets which could break the casing during the lling process.

• Put the green lid gasket in place.

• Using the knee pedal, raise the piston until the mixture reaches the top of the barrel.

• Using food fat or another USDA approved shortening, grease the upper part of the lid gasket and the

underside of the lid.

• Carefully close the lid with a light lifting movement to avoid friction, taking care not to pinch or crimp the

cover gasket in the process.

To close the lid, use only the lever incorporated in the lid itself; do not use the nozzle. Take extreme care not to

trap or pinch your hands while closing the lid.

• After putting the screws back on the upper lid (E models only), place the optimum-size nozzle (largest

9

Page 10

Operation

diameter and shortest length possible) on the lid, locking it in place by turning the triangular nozzle nut.

Prepare the proper amount of casing.

• Push the knee lever all the way forward to the piston raising position. Always push the knee lever rmly; do

not use it as a speed control regulator.

• Carefully raise the pressure by slowly turning the pressure control knob clockwise. Do not raise the

pressure suddenly, as this could cause the mixture to come out of the nozzle too quickly.

• Note how the piston will begin to rise and air will come out of the nozzle.

• Once the mixture begins to come out of the nozzle, release the pressure and place the casing on the

nozzle. Adjust the red pressure control knob to select the optimum speed.

• Once the casing has been lled, push the knee lever back to the piston lowering position until the piston is

at its lowest level in the barrel.

• To stop the hydraulic assemblage, bring the knee pedal to the central position.

• Turn the gray switch located on the right of the machine to the “O” (stop) position (I models only).

• When nished using the machine, clean it, lower the piston to its lowest position in the barrel, unplug the

machine and make sure that the machine cannot roll.

USEFUL TIPS

• Do not use the machine without having received previous instructions from an experienced operator.

• This instruction manual should be read carefully and fully understood before using the machine.

• Test the machine when it is empty before using it on food.

Observe all the appropriate hygiene measures when handling food products; use adequate protective

equipment and procedures (washing, gloves, cap, apron, etc.). To produce sausage with a better appearance

and less smearing, as well as for more uniform mixture and less wear and tear on the machine, we recommend

the use of:

• Horn with the largest diameter and shortest length possible.

• Finely chopped mixtures at the least coldest temperature possible.

Consequently, we recommend avoiding very long nozzles or nozzles with small diameters when using roughly

chopped or very cold mixtures. If nozzles of special dimensions are needed, order them from your dealer.

Never use the nozzle to close the lid since the rim could break. Close the lid with the lid lever only. Do not

open or close the lid without the green gasket in place since this could lead to scratches on the lid and clamp.

The barrel lid cannot be opened without rst slightly lowering the piston by placing the knee pedal in the down

position. This will stop the mixture from blocking the opening. Place the machine as close to the work surface

as possible. The locations of the nozzle and knee lever allow the nozzle to be located completely over the work

surface, thus guaranteeing that no liquid falls onto the oor or the operator. In order to prevent overheating in i

models, turn the machine off after use. Turn the motor on only when in use.

Work at a reasonable pace, thus avoiding constant stopping and restarting of the hydraulic assemblage.

This machine is not designed to withstand permanent, uninterrupted use at high pressure, but rather to run

intermittently with pauses to allow for the dissipation of the heat generated, the amount of which depends on

the consistency of the mixture. Because of the pressure transmitted by the pump, after prolonged periods of

use the hydraulic oil may reach temperatures of up to 60ºC (140ºF) and the base side panel may become

warm to the touch.

10

Page 11

Maintenance

CLEANING

IMPORTANT: In order to avoid mechanical hazards during cleaning operations and piston dismantling, always

open the lid completely when raising the piston.

CLEANING INSTRUCTIONS

To clean the outside of the machine use hot water and a mild cleanser. Do not use any abrasive products,

especially those that could scratch warning stickers and labels. Never wet or dampen the electrical elements

of the machine (switches, cables, etc.). Never use a jet of water to clean any part of the machine, especially

the air holes on the side of the oil tank cap. At the end of each workday, the underside of the lid (the mixture

exit hole), as well as the nozzle(s) and the nozzle nut should be cleaned thoroughly. If necessary, clean the

inside of the nozzles with a round brush. Do not open or close the lid without the green gasket in place since

this could scratch the lid and clamp. Using hot water only, rinse the lid bolt and bearing to eliminate any residue

that could crystallize (salts, spices, etc.) and thus impede the proper functioning of the lid. The upper part of

the black piston gasket should also be cleaned daily, following these steps:

• Open the lid completely and remove the green lid gasket.

• Press the knee lever until the piston rises to its uppermost position. Part of the black piston gasket will now

be accessible via the upper part of the barrel. Clean it with a damp cloth.

We recommend that you periodically clean the piston and barrel interior thoroughly:

• Loosen the screws on the upper lid (E models only), open the lid completely and remove the green lid

gasket.

• Press the knee lever until the piston rises to its uppermost position.

• With the piston at its highest position, simultaneously push the knee lever and, with the aid of the two pivots

of the wrench supplied, unscrew the piston-locking bolt (two turns) located in the center of the piston.

• Screw the wrench completely into the piston hole. The piston will rise above the rim of the barrel.

• Pull the wrench up to remove the piston from the barrel.

• Unplug the machine.

• Clean the inside of the cylinder. Make sure that the bottom of the cylinder is completely DRY to avoid the

formation of water droplets, which could eventually lead to the formation of rust on the upper part of the

base.

IMPORTANT: Piston and barrel cleaning can also be done by dismantling the removable barrel (E models

only); however, to avoid mechanical hazards as well as damage to the piston gaskets, we advise removal of

the piston only.

CLEANING PRECAUTIONS

Because of the weight of the piston, use caution when moving it. Clean the piston and the black piston gaskets

(1 or 2, depending on the model). To avoid damaging the gaskets, never use sharp or pointed tools (knives,

screwdrivers) to remove them. To reduce the noise caused by the movement of the piston, grease the piston

gaskets with food fat or another USDA approved shortening before putting them back into the barrel. Never

introduce water inside the barrel since it could lter down to the base of the machine and affect the electrical

and mechanical components. The holes in the bottom of the barrel are vents for air only.

To reassemble the piston, make sure that the bottom of the barrel is completely dry, then place the piston in the

11

Page 12

Maintenance

barrel and screw the piston-locking bolt tight, making sure that the smaller gasket is properly placed. Raise and

lower the piston, and tighten the piston locking bolt again, making sure it does not bend against the pressure of

the lid. Grease the thread of the piston-locking bolt before replacing it; this will make future dismantling easier.

When the machine is not in use, leave the piston head at the bottom of cylinder, where it will be submerged in

hydraulic oil. This will lengthen the life of the ram and the gaskets.

GENERAL CLEANING ADVICE

Cleaning steps Products Method Tools Notes

Supercial cleaning Manual Spatula Remove all residue directly after use,

removing smaller machine parts if

necessary.

Extensive cleaning Mild detergent Manual Brush, bucket Leave product to work ± 15 minutes.

Rinsing Warm water Manual Sponge, bucket Warm water 40/50 º C - 100/120 º F.

Inspection Check critical points and problematic

parts.

Disinfecting Disinfectant

products

Rinsing Drinking water Manual Sponge, bucket

Drying Cleaning cloth

Maintenance Lubricating oil Manual Cleaning cloth External machine parts.

Manual Sponge, cleaning

cloth

After completing all other cleaning

operations.

SPECIFIC CLEANING ADVICE

Interval Cleaning area Method Products Tools Notes

Daily Underside of the lid, lid

gasket, inside of the

barrel and piston bolt

retaining screw

Bi-Weekly Piston, piston gaskets

and gasket of piston bolt

retaining screw

These cleaning instructions have been elaborated for companies with just one shift; shorter intervals should be

observed in companies with many work groups.

IMPORTANT: Among the parts which should be cleaned daily (see “SPECIFIC CLEAN ADVICE” above),

the piston bolt retaining screw must be cleaned thoroughly by dismantling it. In E models, the following parts

should also be dismantled for better cleaning: lid closing nuts, lid, barrel. Piston removal: See above.

Manual Mild detergent,

warm water

Manual Mild detergent,

warm water

Sponge,

cleaning cloth

Sponge,

cleaning cloth

Eliminate dirt from retaining

screw using a brush if

necessary. Avoid build up of

residues.

To remove the piston, follow

the instructions above.

MAINTENANCE

IMPORTANT: Unplug the machine before proceeding with maintenance and inspection.

12

Page 13

Maintenance

During maintenance and inspection operations always follow the safety instructions in this manual. Mechanical

breakdowns caused by inadequate or improper maintenance can lead to high repair costs as well as

work stoppages; therefore, regular and adequate maintenance is indispensable. The safety and life of the

machine depend on many factors, including proper maintenance. Because different companies have different

shift schedules, it is impossible to prescribe in advance how often you should proceed with inspections,

maintenance or replacement. Adjust your inspection routine to the number of work groups you have in

your company. Our local dealer will be delighted to give you further information. The table below contains

information about maintenance and inspection (control intervals, critical points, etc.) for a machine under

normal use.

MAINTENANCE AND INSPECTION SCHEDULES

After reading the following, consult the MAINTENANCE AND INSPECTION TIPS section for more details.

Control interval Critical points / Maintenance information

Daily Check green lid gasket and replace it if necessary.

Check the two black piston gaskets and replace them if necessary.

Check the air holes located at the base of the barrel and clear them of any

obstruction.

Monthly Check the lid closure and tighten if necessary by regulating the lid xing

bolts (P models only).

Yearly Check hydraulic oil level and rell the reservoir if necessary.

Every 2500-5000 service hours Change hydraulic oil.

Check oil lter and replace it if necessary.

MAINTENANCE AND INSPECTION TIPS

Green lid gasket: Replace if damaged or if leaks are observed. This gasket is reversible, i.e. it can be used

with either side facing up. A spare gasket comes with the machine. The gasket is made from a non-toxic

material that is safe for alimentary use. Place the glued joint of the gasket under the lid bolt. To reduce lid

friction and extend lid gasket life, before closing always grease the green gasket and the lower part of the lid

with animal fat or another USDA approved.

Black piston gasket: Replace if damaged or if leaks are observed. To reduce noise caused by the movement

of the piston, grease this gasket with animal fat or another USDA approved shortening before placing it in the

barrel.

Hydraulic oil level: The oil level can be tested with the dipstick provided on the oil inlet screw. Always ll the

reservoir to the maximum level marked without exceeding it since the more oil there is in the reservoir, the

more effectively the heat given off by the hydraulic assemblage will be cooled. This helps lengthen the life of

the oil.

Hydraulic oil duration: The life of hydraulic oil varies depending on many factors, e.g. temperature and

13

Page 14

Maintenance

pressure at which the machine is run, the presence of humidity or residual water, etc. Normally it can last

between 2.500 and 5.000 hours of service. If the oil loses viscosity, becomes impure, or turns a whitish color

from having had water pumped into it, drain the oil by emptying the housing via the plug located at the bottom

of the machine. Rell the oil following the instructions found in the INSTALLATION section above. Because

there is no natural loss of oil or oil vapors, an adequate level of hydraulic oil should last several years, making

it unnecessary to check the oil level regularly. If the oil level is insufcient, the piston will not move smoothly,

since air will be entering the circuit.

Changing the hydraulic oil: Remove the oil outlet plug located at the bottom of the base and drain the

reservoir, emptying the oil into an appropriate recipient (please recycle used oil). Replace the plug and seal

the oil outlet site hermetically. Using a funnel, ll the reservoir with 10 liters (for H15/H20 models), 15 liters

(for H26/H31 models) or 25 liters (for H42/H52 models) of hydraulic oil via the tank opening. Do not ll the

reservoir to the top since a certain amount of air must be present to allow for expansion. Use oils for medium

pressure hydraulic assemblages (approx. 100 bar), and of a viscosity of approximately 5º Engler (equivalent to

IS03498: cat HL VG46 or DIN8659: HL-46). After lling the reservoir, raise and lower the piston several times

to eliminate air pockets from the hydraulic circuit.

Oil lter: Located inside the oil reservoir, the oil lter is not accessible to the user and should only be replaced

by a qualied technician. To remove the oil lter remove the two screws that attach the closing clamp to the

lter and pull the lter outward. Normally, the lter should not become dirty or present any abnormality. If

the lter must be changed, use a similar lter with a thread of 3/8” BSP and a ltering capacity of 10 liters

per minute, (5 liters per minute for H15/H20). After reassembling the unit, the closing clamp must be sealed

hermetically.

Oil temperature: Because of the pressure transmitted by the pump, after prolonged periods of use the

hydraulic oil may reach temperatures of up to 60ºC (140ºF) and the base side panel may become warm to the

touch. This machine is not designed to withstand permanent, uninterrupted use at high pressure, but rather to

run intermittently with pauses to allow for the dissipation of the heat generated, the amount of which depends

on the consistency of the mixture.

Cylinder ram: In order to lengthen the life of the hydraulic cylinder ram, leave the piston head at the bottom of

the cylinder when the machine is not in use. The ram will thus be completely submerged in hydraulic oil.

Lid closure: The lid of the barrel can be shut more or less tightly depending on how watertight the closure

should be. If the mixture is customarily dry, the closure can be loosened, making it easier to close the lid. If,

however, the mixture contains more liquid, the closure should be tighter to avoid leaks. To loosen the lid in E

models, loosen the upper lid screws until the desired seal is obtained. For P models, loosen the nuts located

beneath the clamp and either loosen or tighten the 2 lid xing bolts. Then retighten the 2 lock nuts completely.

To keep crystallized residue (from salts, spices, etc.) from impeding the proper closure of the lid, remember to

rinse the lid bolt and bearing with hot water after using the machine.

Lack of power: If the machine seems to lack power, notify the service department of the dealer where the

machine was purchased. They should verify the following points: that the air holes located at the base of the

barrel are completely free of obstruction, that the piston and the piston gaskets are perfectly clean and free

of residue which could inhibit the movement of the piston, that the voltage of the power source is compatible

14

Page 15

Maintenance

with that selected for the motor, that the motor is not functioning with only two phases, that there is enough

hydraulic oil, that there is no oil leakage from the hydraulic screws or pipes, and that the oil lter is clean and

unobstructed.

Electrical cord: If the electrical cord becomes damaged, have it replaced immediately with a cord of identical

technical characteristics (your local distributor can supply you with one).

Spare parts: To order spare parts, contact the dealer where the machine was purchased. Be sure to give full

details when identifying the machine (model, serial number, year of manufacture, power, voltage, frequency,

etc.). This data can be found on the technical specications plate located on the machine itself.

Troubleshooting

Problems Possible Causes Solutions

Machine does not work. Machine is unplugged. Plug the machine in.

Electric motor runs, but the piston

does not move up or down.

Machine connected to a lower

voltage.

No voltage in one or more phases. Check fuses, plugs, and switches.

Switch located on the right of the

machine is in 0-stop position (I

models only).

0-1 switch (I models only) is

defective.

Internal on/off microswitch in knee

lever is defective or not properly

adjusted (A models only).

Speed regulator on minimum. Turn speed regulator knob

Motor is turning in the wrong

direction.

Change machine voltage.

Turn the switch to 1-start position.

Call an electrician.

Call an electrician to replace or

adjust the microswitch.

clockwise.

Interchange two of the three

phases in the plug.

15

Page 16

Troubleshooting

Piston moves up and down but

machine seems to lack power.

The air holes located at the base

of the barrel are obstructed.

Piston and piston gaskets are dirty. Clean piston and piston gaskets.

Voltage of power source is not

compatible with voltage selected

for the motor.

Three-phase motor (if available) is

only functioning with two phases.

Lack of hydraulic oil. Fill the oil reservoir to the “MAX.”

Oil leakage from hydraulic screws

or pipes.

Oil lter is dirty. Call your local dealer to replace it.

Clean air holes.

Call an electrician to change motor

voltage.

Adjust phases at the power source.

mark.

Call your local dealer.

16

Page 17

Parts Breakdown

Model SS-ES-0015-PA 13743

Model SS-ES-0015-PAM 13744

Model SS-ES-0015-PAM 41708

Model SS-ES-0020-PA 13745

Model SS-ES-0020-PAM 13746

Model SS-ES-0026-PA 13750

Model SS-ES-0026-PAM 13751

Model SS-ES-0026-PAS 13752

Model SS-ES-0026-PASM 13753

Model SS-ES-0026-PASM 41709

Model SS-ES-0031-PAS 13755

Model SS-ES-0031-PASM 13756

Model SS-ES-0042-PAS 13757

Model SS-ES-0042-PASM 13758

Model SS-ES-0052-PAS 13759

Model SS-ES-0052-PASM 17146

17

Page 18

Parts Breakdown

Model SS-ES-0015-PA 13743

Model SS-ES-0015-PAM 13744/41708

Item No. Description Position Item No. Description Position Item No. Description Position

36005 Aluminum Lid for H15 H200 19253

36005 Aluminum Lid for H15 H200 64313 Hydraulic Pump for H15 H223 36064 Piston Locking Bolt O-Ring for H15 H245

36 111

36013

16542

76770 Horn/Nozzle, all Stainless Steel for H15 H203 76773 Machine Frame for H15 H227 36061 Lid Closing Nut (only E Models) for H15 H249

36034

36035

16539

16517

19238 Green Rubber Knee Lever for H15 H207 36074 Plastic Pressure Control Label for H15 H232 16547 Knee Lever Bar for H15 H254

16549

16550

16551 Knee Lever Bronze Bearing for H15 H209 16527 Green Plastic Oil Input Tube for H15 H235 16525 Pressure Gauge P for H15 H258

19239 Knee Lever Bronze Bearing for H15 H209 16526

36093 Green Rubber Gasket Panel for H15 H210 36080

16524

16523 Oil Filter for H15 H212 36023 Fixed P Meat Barrel for H15 H239 36106

23808 Oil Filter Cover for H15 H213 36075 Removable E Meat Barrel for H15 H239 23809

19416 Green Plastic Wheel for H15 H214 36008

36042 Plastic Electric Switchboard Box for H15 H215 36032

76771 Contactor Telemecanique for H15 H217 31223 Stainless Steel Fixing Screw for H15 H241 36037

39059 Air Extraction Fan for H15 H219 16530

36038 Complete Hydraulic Cylinder for H15 H220 36067

27879 Green Rubber Anti-Vibration Foot for H15 H221 36077

Plastic Bearing for Aluminum Lid E Removable Barrel Model for H15

Bronze Bearing for Aluminum Lid P-Fixed

Barrel Model for H15

Aluminum Horn/Nozzle Locking Nut,

Open Slot for H15

Stainless Steel Horseshoe for Aluminum

Lid E Model for H15

Stainless Steel Horseshoe for Aluminum

Lid P Model for H15

Lid Lever without Green Plastic Knob

for H15

Green Plastic Ital Knob for Lid Lever

for H15

Vertical Knee Lever Shaft P-Model,

Stainless Steel for H15

Vertical Knee Lever Shaft E Stainless

Steel for H15

Internal Crouzet Micro-Switch (only

A-Automatic Models) for H15

H201 31221 Motor-Pump Gasket for H15 H224 16538 Piston Lock Bolt Screw for H15 H246

H201 31222 Motor-Pump Coupling for H15 H225 16543

H202 76772 Electric Motor for H15 H226 16533

H204 31219

H204 36030 Supply Cord Grommet for H15 H229 19237

H205 36044 Grommet Nut for H15 H230 36100

H206 36031 Stainless Steel Transport Handle for H15 H231 16548 Fork Knee Lever for H15 H253

H208 16522

H208 36022 Oil Input Label for H15 H234 19415 Hydraulic Control Action Bar for H15 H256

H211 36107

Black Rubber Anti-Vibration Motor

Support for H15

Red Knob and Shaft Only (Pressure

Control) for H15

Complete Hydraulic Direct Control Valve

for H15

Plastic Oil Drain Plug with Level Bar

for H15

Stainless Steel Hex Nut for Lid Bolt (P

Models only) for H15

Stainless Steel Washer for Lid Bolt (P

Models only) for H15

Stainless Steel Barrel Bottom Protection

Disc (P Models only) for H15

Stainless Steel Barrel Bottom Protection

Hat (E Models only) for H15

Lid Gasket for P Models Barrel only

(Package of 3) for H15

Green Rubber Rectangular Lid Gasket

for E Models Removable Barrel only

(Package of 3) for H15

Stainless Steel Lid Bolt Models HP

for H15

H222 36068 Aluminum Piston for H15 H244

Piston Removing Wrench with Screw

for H15

Piston O-Ring (Package of 4/2 Units)

for H15

H228 36098

H233 36101 Knee Lever Thread M8 for H15 H255

H236 36036 Pressure Gauge Hose for H15 H259

H237 36043

H238 36018

H240 23810

H240 36062 Oil Emptying Plug for H15 H266

H242 21584 Ring, Threaded Aluminum Piston for H15 H268

H242

H243

Lateral Barrel Bar (only E Models)

for H15

Horizontal Stainless Steel Knee Lever

Axle for H15

Manual Switch 0-1 with Black Knob (only

I Models) for H15

Lid Closing Nut Lever without Green

Knob, E Models only for H15

Inferior Circular Barrel Rubber Gasket

Green (only for P Models) for H15

Hydraulic Metal-Plastic Washer 3/8”,

Emptying for H15

Plane Black Rubber Washer, Emptying

for H15

Special Plane Stainless Steel Rubber,

Emptying for H15

Micro Switch Holder (only for P Models)

for H15

H247

H248

H250

H251

H252

H260

H261

H263

H264

H265

H267

18

Page 19

Parts Breakdown

Model SS-ES-0020-PA 13745

Model SS-ES-0020-PAM 13746

Item No. Description Position Item No. Description Position Item No. Description Position

36005 Aluminum Lid (only P Models) for H20 H200 64314 Hydraulic Pump for H20 H223 36068 Aluminum Piston for H20 H244

36013

16542

76776 Horn/Nozzle, all Stainless Steel for H20 H203 76781 Electric Motor for H20 H226 16543

36035

16539

16517

19238 Green Rubber Knee Lever for H20 H207 36044 Grommet Nut for H20 H230 16548 Fork Knee Lever for H20 H253

16549

16551 Knee Lever Bronze Bearing for H20 H209 36074 Plastic Pressure Control Label for H20 H232 36101 Knee Lever Thread M8 for H20 H255

36094 Green Rubber Gasket Panel for H20 H210 16522

16524

16523 Oil Filter for H20 H212 16527

23808 Oil Filter Cover for H20 H213 16526

19416 Green Plastic Wheel for H20 H214 36080

36042 Plastic Electric Switchboard Box for H20 H215 36107

76778 Contactor Telemecanique for H20 H217 36024 Fixed P Meat Barrel for H20 H239 23810

76779 Air Extraction Fan for H20 H219 36008

36039 Complete Hydraulic Cylinder for H20 H220 31223 Stainless Steel Fixing Screw for H20 H241 36037

27879 Green Rubber Anti-Vibration Foot for H20 H221 16530

19253

Bronze Bearing for Aluminum Lid P-Fixed

Barrel Model for H20

Aluminum Horn/Nozzle Locking Nut,

Open Slot for H20

Stainless Steel Horseshoe for Aluminum

Lid P Model for H20

Lid Lever without Green Plastic Knob

for H20

Green Plastic Ital Knob for Lid Lever

for H20

Vertical Knee Lever Shaft P-Model,

Stainless Steel for H20

Internal Crouzet Micro-Switch (only

A-Automatic Models) for H20

Black Rubber Anti-Vibration Motor

Support for H20

H201 31221 Motor-Pump Gasket for H20 H224 36064 Piston Locking Bolt O-Ring for H20 H245

H202 31222 Motor-Pump Coupling for H20 H225 16538 Piston Lock Bolt Screw for H20 H246

Piston Removing Wrench with Screw

for H20

H204 76782 Machine Frame for H20 H227 16533

H205 31219

H206 36030 Supply Cord Grommet for H20 H229 36100

H208 36031 Stainless Steel Transport Handle for H20 H231 16547 Knee Lever Bar for H20 H254

H211 36022 Oil Input Label for H20 H234 16525 Pressure Gauge P for H20 H258

H222 36077

Red Knob and Shaft Only (Pressure

Control) for H20

Complete Hydraulic Direct Control Valve

for H20

Green Plastic Oil Input Tube for H20 H235 36036 Pressure Gauge Hose for H20 H259

Plastic Oil Drain Plug with Level Bar

for H20

Stainless Steel Hex Nut for Lid Bolt (P

Models only) for H20

Stainless Steel Washer for Lid Bolt (P

Models only) for H20

Stainless Steel Barrel Bottom Protection

Disc (P Models only) for H20

Lid Gasket for P Models Barrel only

(Package of 3) for H20

Stainless Steel Lid Bolt Models HP

for H20

H228 19237

H233 19415 Hydraulic Control Action Bar for H20 H256

H236 36018

H237 36106

H238 23809

H240 36062 Oil Emptying Plug for H20 H266

H242 21584 Ring, Threaded Aluminum Piston for H20 H268

H243

Piston O-Ring (Package of 4/2 Units)

for H20

Horizontal Stainless Steel Knee Lever

Axle for H20

Manual Switch 0-1 with Black Knob (only

I Models) for H20

Inferior Circular Barrel Rubber Gasket

Green (only for P Models) for H20

Hydraulic Metal-Plastic Washer 3/8”,

Emptying for H20

Plane Black Rubber Washer, Emptying

for H20

Special Plane Stainless Steel Rubber,

Emptying for H20

Micro Switch Holder (only for P Models)

for H20

H247

H248

H251

H252

H261

H263

H264

H265

H267

19

Page 20

Parts Breakdown

Model SS-ES-0026-PA 13750

Model SS-ES-0026-PAM 13751

Item No. Description Position Item No. Description Position Item No. Description Position

16536 Aluminum Lid (only P Models) for H26 H200 76787 Complete Hydraulic Cylinder for H26 H220

36003 Aluminum Lid (only E Models) for H26 H200 27879 Green Rubber Anti-Vibration Foot for H26 H221 31263 Aluminum Piston for H26 H244

36084 Stainless Steel Lid for H26 H200 19253

19414

19409

36014

16542

31460

76784 Horn/Nozzle, all Stainless Steel for H26 H203 31219

36034

36035

16539

16517

19238 Green Rubber Knee Lever for H26 H207 16522

16549

16550

16551 Knee Lever Bronze Bearing for H26 H209 16526

19239 Knee Lever Bronze Bearing for H26 H209 36081

31220 Green Rubber Gasket Panel for H26 H210 36108

16524

19411 Oil Filter for H26 H212 36076 Removable E Meat Barrel for H26 H239 23809

23808 Oil Filter Cover for H26 H213 36009

19416 Green Plastic Wheel for H26 H214 36033

36042 Plastic Electric Switchboard Box for H26 H215 31223 Stainless Steel Fixing Screw for H26 H241 36037

76786 Contactor Telemecanique for H26 H217 36090

39059 Air Extraction Fan for H26 H219 36090

Plastic Bearing for Aluminum Lid E Removable Barrel Model for H26

Bronze Bearing for Aluminum Lid P-Fixed

Barrel Model for H26

Bronze Bearing for Stainless Steel Lid

P - Fixed Barrel Model for H26

Aluminum Horn/Nozzle Locking Nut,

Open Slot for H26

Stainless Steel Horn/Nozzle Locking Nut,

without Slot for H26

Stainless Steel Horseshoe for Aluminum

Lid E Model for H26

Stainless Steel Horseshoe for Aluminum

Lid P Model for H26

Lid Lever without Green Plastic Knob

for H26

Green Plastic Ital Knob for Lid Lever

for H26

Vertical Knee Lever Shaft P-Model,

Stainless Steel for H26

Vertical Knee Lever Shaft E Stainless

Steel for H26

Internal Crouzet Micro-Switch (only

A-Automatic Models) for H26

H201 18285 Hydraulic Pump for H26 H223 36064 Piston Locking Bolt O-Ring for H26 H245

H201 31221 Motor-Pump Gasket for H26 H224 16538 Piston Lock Bolt Screw for H26 H246

H201 31222 Motor-Pump Coupling for H26 H225 16543

H202 76788 Electric Motor for H26 H226 16534

H202 76789 Machine Frame for H26 H227 36061 Lid Closing Nut (only E Models) for H26 H249

H204 36030 Supply Cord Grommet for H26 H229 19237

H204 36044 Grommet Nut for H26 H230 36100

H205 36031 Stainless Steel Transport Handle for H26 H231 16548 Fork Knee Lever for H26 H253

H206 36074 Plastic Pressure Control Label for H26 H232 16547 Knee Lever Bar for H26 H254

H208 36022 Oil Input Label for H26 H234 19415 Hydraulic Control Action Bar for H26 H256

H208 16527 Green Plastic Oil Input Tube for H26 H235 16525 Pressure Gauge P for H26 H258

H211 27876 Fixed P Meat Barrel for H26 H239 36106

Black Rubber Anti-Vibration Motor

Support for H26

Red Knob and Shaft Only (Pressure

Control) for H26

Complete Hydraulic Direct Control Valve

for H26

Plastic Oil Drain Plug with Level Bar

for H26

Stainless Steel Hex Nut for Lid Bolt (P

Models only) for H26

Stainless Steel Washer for Lid Bolt (P

Models only) for H26

Stainless Steel Barrel Bottom Protection

Disc (P Models only) for H26

Stainless Steel Barrel Bottom Protection

Hat (E Models only) for H26

Lid Gasket for P Models Barrel only

(Package of 3) for H26

Green Rubber Rectangular Lid Gasket

for E Models Removable Barrel only

(Package of 3) for H26

Model SS-ES-0026-PAS 13752

Model SS-ES-0026-PASM 13753/41709

36078

16540

H222 36069 Stainless Steel Piston for H26 H244

H228 36099

H233 36102 Knee Lever Thread M8 for H26 H255

H236 36036 Pressure Gauge Hose for H26 H259

H237 36043

H238 18230

H240 23810

H240 36062 Oil Emptying Plug for H26 H266

H242 21584 Ring, Threaded Aluminum Piston for H26 H268

H242

Stainless Steel Lid Bolt Models HP

for H26

Piston Removing Wrench with Screw

for H26

Piston O-Ring (Package of 4/2 Units)

for H26

Lateral Barrel Bar (only E Models)

for H26

Horizontal Stainless Steel Knee Lever

Axle for H26

Manual Switch 0-1 with Black Knob (only

I Models) for H26

Lid Closing Nut Lever without Green

Knob, E Models only for H26

Inferior Circular Barrel Rubber Gasket

Green (only for P Models) for H26

Hydraulic Metal-Plastic Washer 3/8”,

Emptying for H26

Plane Black Rubber Washer, Emptying

for H26

Special Plane Stainless Steel Rubber,

Emptying for H26

Micro Switch Holder (only for P Models)

for H26

H243

H247

H248

H250

H251

H252

H260

H261

H263

H264

H265

H267

20

Page 21

Parts Breakdown

Model SS-ES-0031-PAS 13755

Model SS-ES-0031-PASM 13756

Item No. Description Position Item No. Description Position Item No. Description Position

36085 Stainless Steel Lid for H31 H200 18285 Hydraulic Pump for H31 H223 16540

36015

31460

76791 Horn/Nozzle, all Stainless Steel for H31 H203 76796 Electric Motor for H31 H226 16538 Piston Lock Bolt Screw for H31 H246

16539

16517

19238 Green Rubber Knee Lever for H31 H207 36030 Supply Cord Grommet for H31 H229 19237

16549

16551 Knee Lever Bronze Bearing for H31 H209 36031 Stainless Steel Transport Handle for H31 H231 16548 Fork Knee Lever for H31 H253

31220 Green Rubber Gasket Panel for H31 H210 36074 Plastic Pressure Control Label for H31 H232 16547 Knee Lever Bar for H31 H254

16524

19411 Oil Filter for H31 H212 36022 Oil Input Label for H31 H234 19415 Hydraulic Control Action Bar for H31 H256

23808 Oil Filter Cover for H31 H213

19416 Green Plastic Wheel for H31 H214 16526

36042 Plastic Electric Switchboard Box for H31 H215 36081

76794 Contactor Telemecanique for H31 H217 36108

39059 Air Extraction Fan for H31 H219 36025 Fixed P Meat Barrel for H31 H239 23809

76795 Complete Hydraulic Cylinder for H31 H220 36010

27879 Green Rubber Anti-Vibration Foot for H31 H221 31223 Stainless Steel Fixing Screw for H31 H241 36062 Oil Emptying Plug for H31 H266

19253

Bronze Bearing for Stainless Steel Lid

P - Fixed Barrel Model for H31

Stainless Steel Horn/Nozzle Locking Nut,

without Slot for H31

Lid Lever without Green Plastic Knob

for H31

Green Plastic Ital Knob for Lid Lever

for H31

Vertical Knee Lever Shaft P-Model, Stainless Steel for H31

Internal Crouzet Micro-Switch (only

A-Automatic Models) for H31

Black Rubber Anti-Vibration Motor Support for H31

H201 31221 Motor-Pump Gasket for H31 H224 36070 Stainless Steel Piston for H31 H244

H202 31222 Motor-Pump Coupling for H31 H225 36064 Piston Locking Bolt O-Ring for H31 H245

H205 76797 Machine Frame for H31 H227 16543

H206 31219

H208 36044 Grommet Nut for H31 H230 36100

H211 16522

16527 Green Plastic Oil Input Tube for H31 H235 16525 Pressure Gauge P for H31 H258

H222 16529

Red Knob and Shaft Only (Pressure

Control) for H31

Complete Hydraulic Direct Control Valve

for H31

Plastic Oil Drain Plug with Level Bar

for H31

Stainless Steel Hex Nut for Lid Bolt (P

Models only) for H31

Stainless Steel Washer for Lid Bolt (P

Models only) for H31

Stainless Steel Barrel Bottom Protection

Disc (P Models only) for H31

Lid Gasket for P Models Barrel only

(Package of 3) for H31

H228 16528

H233 36102 Knee Lever Thread M8 for H31 H255

H236 36036 Pressure Gauge Hose for H31 H259

H237 36019

H238 36106

H240 23810

H242 36037

Stainless Steel Lid Bolt Models HP

for H31

Piston Removing Wrench with Screw

for H31

Piston O-Ring (Package of 4/2 Units)

for H31

Horizontal Stainless Steel Knee Lever

Axle for H31

Manual Switch 0-1 with Black Knob (only

I Models) for H31

Inferior Circular Barrel Rubber Gasket

Green (only for P Models) for H31

Hydraulic Metal-Plastic Washer 3/8”,

Emptying for H31

Plane Black Rubber Washer, Emptying

for H31

Special Plane Stainless Steel Rubber,

Emptying for H31

Micro Switch Holder (only for P Models)

for H31

H243

H247

H248

H251

H252

H261

H263

H264

H265

H267

21

Page 22

Parts Breakdown

Model SS-ES-0042-PAS 13757

Model SS-ES-0042-PASM 13758

Item No. Description Position Item No. Description Position Item No. Description Position

36086 Stainless Steel Lid for H42 H200 76803 Hydraulic Pump for H42 H223 36079

36016

31460

76800 Horn/Nozzle, all Stainless Steel for H42 H203 76804 Electric Motor for H42 H226 16538 Piston Lock Bolt Screw for H42 H246

16539

16517

19238 Green Rubber Knee Lever for H42 H207 36030 Supply Cord Grommet for H42 H229 19237

16550

19239 Knee Lever Bronze Bearing for H42 H209 36088 Stainless Steel Transport Handle for H42 H231 16548 Fork Knee Lever for H42 H253

36095 Green Rubber Gasket Panel for H42 H210 36074 Plastic Pressure Control Label for H42 H232 16547 Knee Lever Bar for H42 H254

16524

19411 Oil Filter for H42 H212 36022 Oil Input Label for H42 H234 19415 Hydraulic Control Action Bar for H42 H256

23808 Oil Filter Cover for H42 H213 16527

36110 Green Plastic Wheel for H42 H214 16526

36042 Plastic Electric Switchboard Box for H42 H215 36082

76802 Contactor Telemecanique for H42 H217 36109

39059 Air Extraction Fan for H42 H219 36026 Fixed P Meat Barrel for H42 H239 23809

36040 Complete Hydraulic Cylinder for H42 H220 64316

27880 Green Rubber Anti-Vibration Foot for H42 H221 36083 Stainless Steel Fixing Screw for H42 H241 36062 Oil Emptying Plug for H42 H266

19253

Bronze Bearing for Stainless Steel Lid

P - Fixed Barrel Model for H42

Stainless Steel Horn/Nozzle Locking Nut,

without Slot for H42

Lid Lever without Green Plastic Knob

for H42

Green Plastic Ital Knob for Lid Lever

for H42

Vertical Knee Lever Shaft E Stainless

Steel for H42

Internal Crouzet Micro-Switch (only

A-Automatic Models) for H42

Black Rubber Anti-Vibration Motor Support for H42

H201 31221 Motor-Pump Gasket for H42 H224 36071 Stainless Steel Piston for H42 H244

H202 31222 Motor-Pump Coupling for H42 H225 36064 Piston Locking Bolt O-Ring for H42 H245

H205 76805 Machine Frame for H42 H227 16543

H206 31219

H208 36044 Grommet Nut for H42 H230 36100

H211 16522

H222 16532

Red Knob and Shaft Only (Pressure

Control) for H42

Complete Hydraulic Direct Control Valve

for H42

Green Plastic Oil Input Tube for H42 H235 16525 Pressure Gauge P for H42 H258

Plastic Oil Drain Plug with Level Bar

for H42

Stainless Steel Hex Nut for Lid Bolt (P

Models only) for H42

Stainless Steel Washer for Lid Bolt (P

Models only) for H42

Stainless Steel Barrel Bottom Protection

Disc (P Models only) for H42

Lid Gasket for P Models Barrel only

(Package of 3) for H42

H228 16535

H233 36104 Knee Lever Thread M8 for H42 H255

H236 36036 Pressure Gauge Hose for H42 H259

H237 36020

H238 36106

H240 23810

H242 36037

Stainless Steel Lid Bolt Models HP

for H42

Piston Removing Wrench with Screw

for H42

Piston O-Ring (Package of 4/2 Units)

for H42

Horizontal Stainless Steel Knee Lever

Axle for H42

Manual Switch 0-1 with Black Knob (only

I Models) for H42

Inferior Circular Barrel Rubber Gasket

Green (only for P Models) for H42

Hydraulic Metal-Plastic Washer 3/8”,

Emptying for H42

Plane Black Rubber Washer, Emptying

for H42

Special Plane Stainless Steel Rubber,

Emptying for H42

Micro Switch Holder (only for P Models)

for H42

H243

H247

H248

H251

H252

H261

H263

H264

H265

H267

22

Page 23

Parts Breakdown

Model SS-ES-0052-PAS 13759

Model SS-ES-0052-PASM 17146

Item No. Description Position Item No. Description Position Item No. Description Position

36087 Stainless Steel Lid for H52 H200 64315 Hydraulic Pump for H52 H223 36079

36017

31460

76807 Horn/Nozzle, all Stainless Steel for H52 H203 76810 Electric Motor for H52 H226 16538 Piston Lock Bolt Screw for H52 H246

16539

16517

19238 Green Rubber Knee Lever for H52 H207 36030 Supply Cord Grommet for H52 H229 19237

16550

19239 Knee Lever Bronze Bearing for H52 H209 36088 Stainless Steel Transport Handle for H52 H231 16548 Fork Knee Lever for H52 H253

36092 Green Rubber Gasket Panel for H52 H210 36074 Plastic Pressure Control Label for H52 H232 16547 Knee Lever Bar for H52 H254

16524

19411 Oil Filter for H52 H212 36022 Oil Input Label for H52 H234 19415 Hydraulic Control Action Bar for H52 H256

23808 Oil Filter Cover for H52 H213 16527

36110 Green Plastic Wheel for H52 H214 16526

36042 Plastic Electric Switchboard Box for H52 H215 36082

76809 Contactor Telemecanique for H52 H217 36109

39059 Air Extraction Fan for H52 H219 36027 Fixed P Meat Barrel for H52 H239 23809

36040 Complete Hydraulic Cylinder for H52 H220 36012

27880 Green Rubber Anti-Vibration Foot for H52 H221 36083 Stainless Steel Fixing Screw for H52 H241 36062 Oil Emptying Plug for H52 H266

19253

Bronze Bearing for Stainless Steel Lid

P - Fixed Barrel Model for H52

Stainless Steel Horn/Nozzle Locking Nut,

without Slot for H52

Lid Lever without Green Plastic Knob

for H52

Green Plastic Ital Knob for Lid Lever

for H52

Vertical Knee Lever Shaft E Stainless

Steel for H52

Internal Crouzet Micro-Switch (only

A-Automatic Models) for H52

Black Rubber Anti-Vibration Motor Support for H52

H201 31221 Motor-Pump Gasket for H52 H224 36072 Stainless Steel Piston for H52 H244

H202 31222 Motor-Pump Coupling for H52 H225 36064 Piston Locking Bolt O-Ring for H52 H245

H205 76811 Machine Frame for H52 H227 16543

H206 31219

H208 36044 Grommet Nut for H52 H230 36100

H211 16522

H222 19153

Red Knob and Shaft Only (Pressure

Control) for H52

Complete Hydraulic Direct Control Valve

for H52

Green Plastic Oil Input Tube for H52 H235 16525 Pressure Gauge P for H52 H258

Plastic Oil Drain Plug with Level Bar

for H52

Stainless Steel Hex Nut for Lid Bolt (P

Models only) for H52

Stainless Steel Washer for Lid Bolt (P

Models only) for H52

Stainless Steel Barrel Bottom Protection

Disc (P Models only) for H52

Lid Gasket for P Models Barrel only

(Package of 3) for H52

H228 19156

H233 36103 Knee Lever Thread M8 for H52 H255

H236 36036 Pressure Gauge Hose for H52 H259

H237 36021

H238 36106

H240 23810

H242 36037

Stainless Steel Lid Bolt Models HP

for H52

Piston Removing Wrench with Screw

for H52

Piston O-Ring (Package of 4/2 Units)

for H52

Horizontal Stainless Steel Knee Lever

Axle for H52

Manual Switch 0-1 with Black Knob (only

I Models) for H52

Inferior Circular Barrel Rubber Gasket

Green (only for P Models) for H52

Hydraulic Metal-Plastic Washer 3/8”,

Emptying for H52

Plane Black Rubber Washer, Emptying

for H52

Special Plane Stainless Steel Rubber,

Emptying for H52

Micro Switch Holder (only for P Models)

for H52

H243

H247

H248

H251

H252

H261

H263

H264

H265

H267

23

Page 24

Electrical Schematics

Model SS-ES-0015-PA 13743

Model SS-ES-0020-PA 13745

Model SS-ES-0026-PA 13750

Model SS-ES-0026-PAS 13752

Model SS-ES-0031-PAS 13755

Model SS-ES-0042-PAS 13757

Model SS-ES-0052-PAS 13759

24

Page 25

Electrical Schematics

Model SS-ES-0015-PAM 13744/41708

Model SS-ES-0020-PAM 13746

Model SS-ES-0026-PAM 13751

Model SS-ES-0026-PASM 13753/41709

Model SS-ES-0031-PASM 13756

Model SS-ES-0042-PASM 13758

Model SS-ES-0052-PASM 17146

25

Page 26

Notes

26

Page 27

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

www.omcan.com/warrantyregistration.html

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

27

Page 28

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 3, 500 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 3500

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 3, 500 productos con origen a nivel mundial.

Loading...

Loading...