Page 1

Spiral Mixers

Models SM-IT-0053-F, 0053-R

Items 41548, 41549

Instruction Manual

Revised - 01/21/2020

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model SM-IT-0053-F / Model SM-IT-0053-R

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

---------------------------------------------------------------------------------------------------------- 7

------------------------------------------------------------------------------------------------------ 8 - 9

------------------------------------------------------------------------------------------------- 9 - 10

----------------------------------------------------------------------------------------- 3 - 4

---------------------------------------------------------------------------------------- 4 - 6

------------------------------------------------------------------------------------------------- 11

Page

---------------------------------------------------------------------------------------- 6

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

-------------------------------------------------------------------------------------------------------------- 26

----------------------------------------------------------------------------------------- 12 - 23

------------------------------------------------------------------------------------ 24 - 25

----------------------------------------------------------------------------------------- 27

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

WARNINGS FOR THE INSTALLER

• Check that the location of the kneading machine is in compliance with local, national and European

regulations.

• Adhere to the instructions in this manual.

• Do not execute electrical connections using temporary or non insulated cables.

• Check that the ground connection of the electrical system is functioning properly.

4

Page 5

Safety and Warranty

• Always use individual safety devices and other means of protection in compliance with the law.

WARNINGS FOR THE USER

The conditions in the surrounding area where the machine will be installed must have the following

characteristics:

• The area must be dry.

• The area must have water and heat sources at an adequate distance.

• Ventilation and lighting must be suitable and comply with the hygiene and safety standards foreseen by

current laws.

• The oor must be at and compact to facilitate thorough cleaning.

• There must be no obstacles of any kind in the immediate vicinity of the machine that could eect the

machine’s normal ventilation.

In addition, the user must:

• Make certain to keep children away from the machine when it is operating.

• Adhere to the instructions in this manual.

• Not remove or tamper with the safety devices on the machine.

• Always pay careful attention to the work at hand and not use the machine when in a distracted state.

• Perform all operations with maximum safety and calm.

• Respect the instructions and warnings displayed on the machine labels.

The labels are accident prevention devices, and therefore must always be perfectly legible. If these should be

damaged and illegible, it is mandatory to replace them by requesting replacements from Omcan.

• At the end of each working shift, before cleaning, maintenance or transfer operations, disconnect electrical

power.

WARNINGS FOR THE MAINTENANCE OPERATOR

• Observe the instructions indicated in this manual.

• Always use individual safety devices and other protection means.

• Before starting any maintenance operations, make sure that the kneading machine, it was used, is cooled

down (electric motor).

• If any of the safety devices is worn or faulty, the kneading machine is also considered faulty and not to be

used.

• Disconnect electrical power before intervening on electrical or electronic parts and connectors.

1 YEAR PARTS AND LABOUR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

5

Page 6

Safety and Warranty

Please see https://omcan.com/disclaimer for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without diculty.

In any case, for suitable recycling, we suggest disposing of the products separately (dierentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

Model SM-IT-0053-F SM-IT-0053-R

Power 2 HP / 1500 W

Bowl Speed 9 RPM

Shaft Speed 93 RPM

Bowl Capacity 53 L / 46 QT

Maximum Kneading Capacity 97 lbs. / 44 kgs.

Electrical 208V / 60Hz / 3Ph

Weight 243 lbs. / 110 kgs. 295 lbs. / 134 kgs.

Dimensions

Packaging Weight 297 lbs. / 135 kgs. 350 lbs. / 159 kgs.

Packaging Dimensions

Item Number 41548 41549

20.9” x 33.9” x 28.3”

531 x 861 x 719mm

23.6” x 37.8” x 36.6”

600 x 960 x 931mm

21.7” x 34.2” x 29.7”

551 x 869 x 754mm

23.6” x 37.8” x 34.6”

600 x 960 x 880mm

6

Page 7

Installation

Installation must be executed by qualied personnel in compliance with local, national and European

regulations.

KNEADING MACHINE LEVELLING

If the machine is unstable due to oor irregularity, adjust the support feet or wheels by inserting rubber pieces.

EQUIPMENT HOOK-UP

Electrical connection

It is sucient to connect the power supply cable to the electrical mains power supply. The electrical outlet must

be easy to access, no moving should be necessary.

The electrical connection (plug) must be easily accessible, also following kneading machine

installation.

The distance between the machine and the socket must be adequate to not cause tension in the power supply

cable. In addition, the cable must not be located beneath the machine support feet or wheel.

If the electrical power supply cable is damaged, it must be replaced by the technical assistance service

or by a qualied technician to prevent any risks.

GROUND CONNECTION

DANGER: It is mandatory that the electrical system is equipped with a ground connection and

dierential switch that comply with currently enforced laws.

7

Page 8

Operation

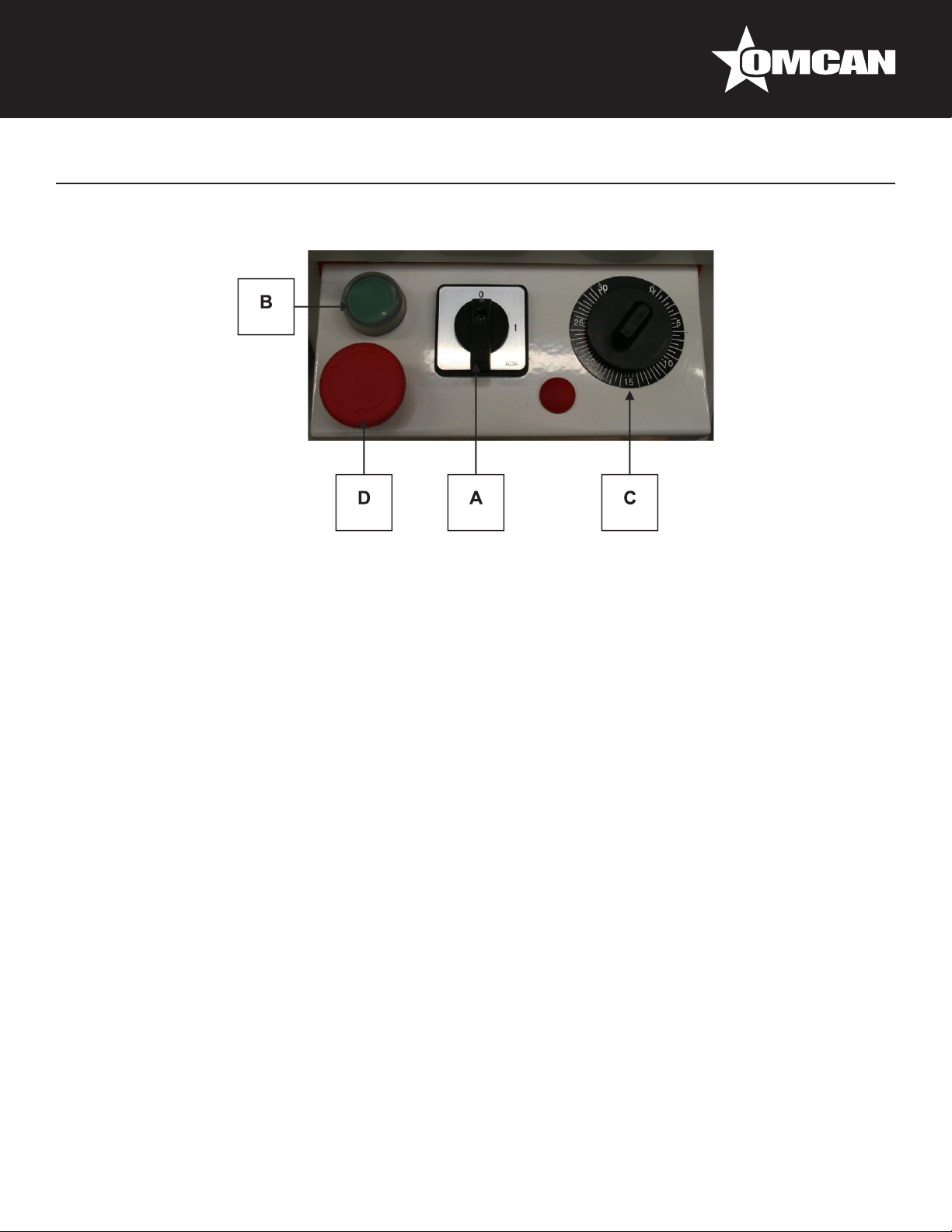

COMMAND PANEL DESCRIPTION

The panel consists of a main switch (A), a green start button (B), a timer (C), a red emergency stop button (D).

The panel permits start-up and stopping of the kneading machine, and regulates functioning and settings.

LEGEND:

A = Mainswitch (the 2V versions also allow speed selection)

B = Green start button

C = Timer

D = Red emergency stop button

START-UP PHASE

Connect the kneading machine to the electrical mains and turn the main switch A to the position “1”. Turn the

timer knob C to the desired time from 0 to 30 min. Press the green button B to start both the tank and the

spiral.

WORKING PHASE

Prior to starting each work cycle, make sure that the machine is perfectly clean, especially the surface of the

tank, the spiral and the dough breaker in contact with food products.

Whenever necessary, proceed with cleaning.

After having lifted the protection, pour the desired quantities of ingredients into the tank. Lower the protection,

set the timer C at a dened time and press the green start button B. The action created by the spiral,

synchronized with tank rotation, obtains a mixture of our, water, salt, yeast and other possible ingredients

in the desired consistency. If needed, to slightly modify the characteristics and/or consistency of the starter

dough, pour the ingredients from the tank through the protection grating. Once the work cycle is completed,

stop the machine by pressing the red emergency button D, lift the mobile protection to its maximum opening

8

Page 9

Operation

point, remove the dough from the tank and proceed with machine cleaning. If kneading machine operations

are stopped for any reason, wait at least 15 seconds before restarting. Even though it is functionally identical

to other versions, the machine with liftable head and removable tank is dierentiated for easier removal of

the dough at the end of the working cycle, as well as easier cleaning. To lift the head and extract the tank,

proceed as follows: stop the machine by pressing the red emergency button D; disconnect the plug from the

electrical power supply; completely remove the mobile protection; horizontally pull the pin using the handle

located on the right side of the machine until the head is released; lift the head using the lower piston; turn the

disc located under the tank in a clockwise direction and extract the tank to remove the dough. After nishing

machine cleaning, reassemble the tank by following the previously described steps in a backwards order,

making sure that the pins beneath the tank are correctly inserted into the holes on the machine.

Before removing the dough, always perform the shut-down steps

SAFETY DEVICES

The kneading machine is equipped with safety devices to protect the user, including a mobile protective grating

and a device that ensures the grating is lowered. The kneading machines with liftable heads and removable

tanks are also equipped with a device that checks whether the head is lifted or lowered, a blocking pin for the

head in a lowered position, a device that checks whether the tank is inserted or removed and a tank blocking

disc.

Before proceeding with working phases, check the status of the various safety devices. These are in a

good state when:

• The machine stops when the grating is lifted.

• The machine stops and will not start when the machine head is lifted.

• The machine stops and will not start when the tank is removed.

• When pulling the tank and the head slightly upwards, they remain blocked in their positions.

SHUT-DOWN PHASE

To shut down the kneading machine, press the red emergency button D and turn the main switch knob A to the

position “0”.

Maintenance

SAFETY PRECAUTIONS

Before performing any maintenance operations, including cleaning, take the following precautions:

• Make certain that the main switch is disconnected.

• Make certain that the electrical power cannot be accidentally reinserted. Disconnect the plug from the

electrical power socket.

• Use individual protection devices in compliance with the directive 89/391/CEE.

9

Page 10

Maintenance

• Always operate using appropriate maintenance tools.

• Once maintenance and repairs are nished, before starting up the kneading machine, reinstall all of the

protection devices and reactivate all of the safety devices.

ORDINARY MAINTENANCE FOR THE USER

The kneading machine requires simple, frequent and careful cleaning to ensure ecient, regular functioning.

General cleaning

The machine must be cleaned at the end of each use, in compliance with the hygiene regulations and to

safeguard machine operation. Using a wooden or plastic spatula, proceed by removing dough residues, and

then thoroughly clean the tank, spiral, dough breaker and mobile protection using a soft sponge and warm

water. Dry with paper towels, and then pass over all of the aforementioned parts and the entire machine with a

soft cloth and a disinfectant solution for use in food preparation areas.

It is recommended to never use chemical products which are not specic for food preparation areas,

abrasives or corrosives for any reason. Avoid by all means using water jets, tools, rough or abrasive

instruments, such as steel wool, brillo sponges or any other item which could damage the surface of

the machine, and especially those that could compromise health safety.

Upper chain tensioning

To maintain both performance and safety of the machine, it is indispensable to execute periodical controls of

the upper chain tension. The chain should be tensioned if these controls detect excessive loosening of the

chain, or if the spiral rotation is not constant. Unscrew the screws and disassemble the panel located above

the kneading machine head. Loosen the screws by a few turns that mount the spiral support and pull the spiral

support until the chain is tensioned. Block the spiral support by tightening the screws and then reassemble and

mount the panel.

Greasing the chains

Periodically grease the chains, one located in the upper interior of the head and the other located inside of

the machine body. Unscrew the screws and remove the panel over the head and the panel in the rear of the

machine. Deposit a reasonable quantity of suitable grease inside of the chain and make sure to lubricate all of

the chain links. Once nished, reassemble the two panel and tighten the screws.

10

Page 11

Troubleshooting

Fault Cause Remedy

The machine does not start. Lack of electrical energy. Check the main switch, socket,

plug and power supply cable.

The emergency stop button is

inserted.

The protection grating and/or the

head are lifted.

The main switch knob is in position

“0”.

The timer knob is in position “0”. Set the knob from 1 to 30 minutes.

The spiral turns sporadically. The chain is loose. Tighten the chain as stated in

Turn the button in the direction

indicated by the arrow.

Correctly lower both the protective

grating and the head.

Turn the knob to position “1”.

Maintenance.

11

Page 12

Parts Breakdown

Model SM-IT-0053-F 41548

12

Page 13

Model SM-IT-0053-F 41548

Parts Breakdown

13

Page 14

Parts Breakdown

Model SM-IT-0053-F 41548

14

Page 15

Model SM-IT-0053-F 41548

Parts Breakdown

15

Page 16

Parts Breakdown

Model SM-IT-0053-F 41548

16

Page 17

Parts Breakdown

Model SM-IT-0053-F 41548

Item No. Description Position Item No. Description Position Item No. Description Position

AC199 Safety Guard for IF53 1 AC222 Rod Breaking Dough for IF53 33 AC242 Spiral Chain 08B/69 for IF53 69

AC200 Bowl for IF53 2 AC223 Screw M10x25 for IF53 34 AC243 Chain Pinion Gear Z=29 08B for IF53 70

AC201 Snap Ring Diam. 25 for IF53 5 AC224 Side Safety Panel for IF53 39 AC244

AC202 Bearing 6205-2RS for IF53 6, 22 AC225 Steel Foot M12 for IF53 41 AC245 Stainless Steel Washer Ø 10 for IF53 72

AC203 Support Bowl Base for IF53 7 AC226 Insert for Plastic Foot for IF53 42 AC246

AC204 Bowl Spiral 06B/144 for IF53 8 AC227 Wheel with Brake M12 for IF53 43 AC247 Screw M10x35 for IF53 74

AC205 Crown Z=85 06B for IF53 9 AC228

AC206 Bowl Support Axle for IF53 10 AC229 Cover Red for IF53 45 46382 Chain Pinion Gear Z=16 06B for IF53 81

AC207 Screw M8x35 for IF53 11 AC230 Ring in Nylon for IF53 47 AC249 Transmission Shaft for IF53 83

AC208 Safety Guard Pin for IF53 13 AC231 Screw M4x30 for IF53 48 AC250 Key 8x7x35 for IF53 84

AC209 Cam for Safety Guard for IF53 14 AC232 Axis Cover for IF53 52 AC251 Micro-Switch for IF53 86

AC210 Screw M8x10 for IF53 15 AC233 Wheel without Brake M12 for IF53 54 AC252 Spiral Plate for IF53 93

AC211 Screw M8x25 for IF53 16 69417 Contactor CN-6/4A 24 V for IF53 55 AC253 O-Ring Diam. 20x2.5 for IF53 94

AC212

AC213 Stainless Steel Washer Ø8 for IF53 18 AC234 Ring Fixing Reduction Gear for IF53 58 AC255 Nut M5 ZN for IF53 98

AC214 Pinion Gear Z=15 08B for IF53 19 AC235 Screw M8x40 for IF53 60 AC256 Tensioner Base for IF53 99

AC215 Spiral Support for IF53 20 AC236

AC216 Screw M8x30 for IF53 21 AC237 Screw M5x10 for IF53 62 AC258 Nylon Block for IF53 101

AC217 Bearing 6006-2RS for IF53 22.01 AC238 Back Panel Red for IF53 63 AC259 Bowl Chain Tensioner Part for IF53 105

AC218 Key 6x6x35 for IF53 23 AC239 Transformer 380 V for IF53 64 AC260 Control Card 115/230/400 V for IF53 106

AC219 Axle for Spiral Base for IF53 24 AC240 Main Switch for IF53 65 AC261 Screw M8x100 for IF53 116

64154 Spiral for IF53 25 AC241 Front Oblique Switch Panel for IF53 66 AC262 Red Frame for IF53 123

AC220 Wire Clip for IF53 27 AC153 Starting Button for IF53 67

AC221 Supply Wire for IF53 28 67014 Timer 0-30 Min. for IF53 68

Stainless Steel Washer Grover Ø 8.5

for IF53

17 61375 Emergency Stop Switch for IF53 57 AC254 Nylon Block Base for IF53 97

Motor 400 V -1,5 kW - 50 Hz 90 B14

for IF53

Gear Box CM63 90 B14 1/30 FLS for

IF53

44 AC248 Key 6x6x30 for IF53 76

61 AC257 Screw TCEI M5x30 for IF53 100

Transmission Shaft Base UCF 205

for IF53

Stainless Steel Washer Spring Ø 10

for IF53

71

73

17

Page 18

Parts Breakdown

Model SM-IT-0053-R 41549

18

Page 19

Model SM-IT-0053-R 41549

Parts Breakdown

19

Page 20

Parts Breakdown

Model SM-IT-0053-R 41549

20

Page 21

Model SM-IT-0053-R 41549

Parts Breakdown

21

Page 22

Parts Breakdown

Model SM-IT-0053-R 41549

22

Page 23

Parts Breakdown

Model SM-IT-0053-R 41549

Item No. Description Position Item No. Description Position Item No. Description Position

AC199 Safety Guard for IR53 1 AC223 Screw M10x25 for IR53 34 AC243 Chain Pinion Gear Z=29 08B for IR53 70

AC200 Bowl for IR53 2 AC270 Head Closing Knob for IR53 35 AC279 Ball Bearing Base for IR53 71

AC263 Bowl Flange for IR53 3 AC271 Closing Handle Axle for IR53 36 AC245 Stainless Steel Washer Ø 10 for IR53 72

AC264 Plate Block Bowl for IR53 4 AC272 Spring Ø 1.5 x Ø 14 x 30/6 for IR53 37 AC246

AC201 Snap Ring Diam. 25 for IR53 5 AC273 Pin Diam. 3.2 for IR53 38 AC280 Screw TE M10x35 INOX for IR53 74

AC202 Bearing 6205-2RS for IR53 6, 22 AC274 Side Safety Panel for IR53 39 AC281 Connecting Shaft for IR53 75

AC203 Support Bowl Base for IR53 7 AC225 Steel Foot M12 for IR53 41 AC248 Key 6x6x30 for IR53 76, 82

AC204 Bowl Spiral 06B/144 for IR53 8 AC226 Insert for Plastic Foot for IR53 42 AC282 Connecting Pin Ø 10x50 for IR53 77

AC205 Crown Z=85 06B for IR53 9 AC227 Wheel with Brake M12 for IR53 43 69741 Transmission Joint for IR53 78

AC206 Bowl Support Axle for IR53 10 AC228

AC265 Screw M8x60 for IR53 11 AC229 Cover Red for IR53 45 AC244

AC266 Guard Ring for IR53 12 AC230 Ring in Nylon for IR53 47 46382 Chain Pinion Gear Z=16 06B for IR53 81

AC208 Safety Guard Pin for IR53 13 AC231 Screw M4x30 for IR53 48 AC284 Transmission Shaft for IR53 83

AC267 Cam for Safety Guard for IR53 14 69380 Gas Spring for IR53 49 AC250 Key 8x7x35 for IR53 84

AC210 Screw M8x10 for IR53 15 AC275 Micro-Switch for IR53 50 AC285 Bowls Peg for IR53 92

AC211 Screw M8x25 for IR53 16 AC276 Head Rotation Shaft for IR53 51 AC252 Spiral Plate for IR53 93

AC212

AC213 Stainless Steel Washer Ø8 for IR53 18 AC233 Wheel without Brake M12 for IR53 54 AC286 Proximity Micro L=75mm for IR53 95

AC214 Pinion Gear Z=15 08B for IR53 19 69417 Contactor CN-6/4A 24 V for IR53 55 AC287 Nut M12 ZN for IR53 96

AC215 Spiral Support for IR53 20 61375 Emergency Stop Switch for IR53 57 AC254 Nylon Block Base for IR53 97

AC216 Screw M8x30 for IR53 21 AC234 Ring Fixing Reduction Gear for IR53 58 AC255 Nut M5 ZN for IR53 98

AC217 Bearing 6006-2RS for IR53 22.01 AC235 Screw M8x40 for IR53 60 AC256 Tensioner Base for IR53 99

AC218 Key 6x6x35 for IR53 23 AC236

AC219 Axle for Spiral Base for IR53 24 AC237 Screw M5x10 for IR53 62 AC258 Nylon Block for IR53 101

64154 Spiral for IR53 25 AC277 Back Panel Red for IR53 63 AC288 Screw TCEI M10x25 for IR53 102

69999

AC220 Wire Clip for IR53 27 AC240 Main Switch for IR53 65 AC290 Nut M8 ZN for IR53 104

AC221 Supply Wire for IR53 28 AC241 Front Oblique Switch Panel for IR53 66 AC259 Bowl Chain Tensioner Part for IR53 105

AC268 Pivot for Fixing Spring for IR53 31 AC153 Starting Button for IR53 67 AC260 Control Card 115/230/400 V for IR53 106

AC269

AC222 Rod Breaking Dough for IR53 33 AC278 Spiral Chain 08B/76 for IR53 69

Stainless Steel Washer Grover Ø 8.5

for IR53

Distance Sensor with Two Cables "NO"

for IR53

Spring Diam. 1.2 x Diam. 8.5 x 20/13

for IR53

17 AC232 Axis Cover for IR53 52 AC253 O-Ring Diam. 20x2.5 for IR53 94

26 AC239 Transformer 380 V for IR53 64 AC289 Head Closing Hook for IR53 103

32 67014 Timer 0-30 Min. for IR53 68 AC262 Red Frame for IR53 123

Motor 400 V -1,5 kW - 50 Hz 90 B14

for IR53

Gear Box CM63 90 B14 1/30 FLS for

IR53

44 AC283 Nut M10 ZN for IR53 79

61 AC257 Screw TCEI M5x30 for IR53 100

Stainless Steel Washer Spring Ø 10

for IR53

Transmission Shaft Base UCF 205

for IR53

73

80

23

Page 24

Electrical Schematics

Model SM-IT-0053-F 41548

24

Page 25

Model SM-IT-0053-R 41549

Electrical Schematics

25

Page 26

Notes

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

26

Page 27

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear o the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

https://omcan.com/warranty-registration/

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

27

Page 28

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 5,000 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 5000

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 5,000 productos con origen a nivel mundial.

Loading...

Loading...