Page 1

Rev 2, 18.06.19

Maturmeat

®

Manual

1

Page 2

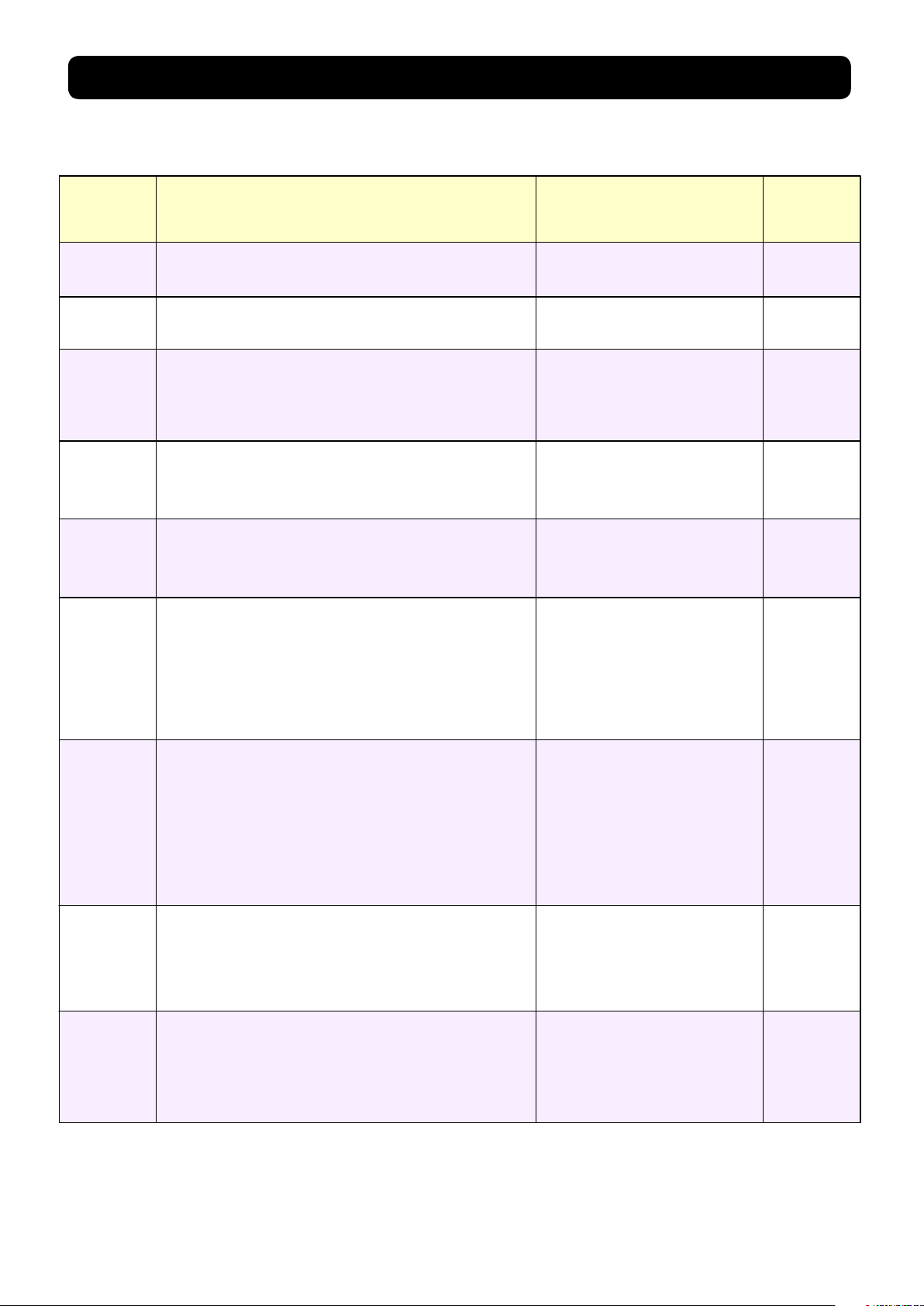

MATURMEAT®

Pag. 3 1.1 General Safety Warnings

Pag. 4 1.2 Identication Data & Data Plate

Pag. 4 1.3 Standard Accessories

Pag. 5 1.4 Maturmeat® Diagram

Pag. 6 1.5 Receipt Inspection

Pag. 6 1.6 Installation

INDEX

SICUR FOOD CONTROL

Pag. 8 2.1 Using Sicur Food Control® For The First Time

Pag. 9 2.2 Starting The Test Recipe

Pag. 10 2.3 Recipe Screen Dened

Pag. 12 2.4 Starting a Default Climatic Recipe

Pag. 12 2.5 Moding Recipe Parameters

Pag. 13 2.6 Checking HACCP-Performance as Line Data

Pag. 14 2.7 Checking HACCP-Performance as a Graph

Pag. 15 2.8 New Recipe Parameters Dened

Pag. 16 2.9 Creating and Saving New Recipes

Pag. 18 2.10 Starting a Saved Recipe

Pag. 18 2.11 Forcing Aroma

MAINTANENCE

Pag. 19 3.1 Calibrating Standard Probes

Pag. 20 3.2 Changing HACCP Recording Frequency

Pag. 20 3.3 Changing From Celcius To Farenheit

Pag. 21 3.4 Setting The Screen Lock

Pag. 22 3.5 Calibrating pH Probe

Pag. 24 3.6 Fumotic’s supply tanks

Pag. 24 3.7 Water Filter

Pag. 25 3.8 Fumotic® Rear View

Pag. 25 3.9 Fumotic® Front View

Pag. 26 3.10 How to connect direct waterline to Fumotic

Pag. 26 3.11 Scale Formation Inside Fumotic

®

Pag. 27 3.12 Cleaning Maturmeat®

Pag. 28 3.13 Empting drain tray

Pag. 29 3.14 Temperature Maintenance

Pag. 30 3.15 Humidity Maintenance

Pag. 31 3.16 Firmware Update Sicur Food Control

®

Pag. 32 3.17 Firmware Update PLC’s

Pag. 33 3.18 Network Connection

Pag. 34 3.19 Troubleshooting

®

®

TECHNICAL INFORMATION & DATA

Pag. 36 4.1 System Variables

Pag. 43 4.2 Maturmeat® Specications

Pag. 43 4.3 Sicur Food Control® Specications

Pag. 44 4.4 Functions Managed By Sicur Food Control

Pag. 45 4.5 PLC A Specications

Pag. 45 4.6 PLC B Specications

Pag. 47 4.7 Electrical Schematic 60/100kg

Pag. 48 4.8 Electrical Schematic 150kg

Pag. 49 4.9 Electrical Schematic 200kg

Pag. 50 4.10 Electrical Schematic Twin 100+100kg Table 1

Pag. 51 4.11 Electrical Schematic Twin 100+100kg Table 2

Pag. 52 4.12 Electrical Schematic Fumotic® 60/100/150/200kg

Pag. 53 4.13 Electrical Schematic Fumotic® Twin 100+100kg

WARRANTY & DISPOSAL

Pag. 54 5.1 Limited Warranty

Pag. 55 5.2 Proper Disposal

2

Rev 2, 18.06.19

®

Page 3

1.1

GENERAL SAFETY WARNINGS

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and the word

“Danger.” This word mean:

You can be killed or seriously injured if you don’t follow

DANGER

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury,

and tell you what can happen if the instructions are not followed.

instructions.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of re, electric shock, or injury when using your Maturmeat®,

follow these basic precautions:

■ After unpacking, make sure the machine is

complete and free from damage. If in doubt,

do not use and contact a qualied technician.

■ Check that the information on data plate

corresponds with the main power supply.

■ This appliance must be used exclusively for

the purpose for which it was made. Any other

use is considered improper and therefore dan-

gerous.

■ The machine must be handled only by trained

personnel.

■ For any eventual repairs please contact an

authorized dealer and/or technician, use only

original replacement parts.

■ Do not wash the machine with high pressure

water jets.

■ Fumotic

and humidity probes are not to be used below –3°C (minus three degrees centigrate),

and are excluded from operation and consequently unusable and unreilable, the manufacture is not liable for programming differing

from the aforementioned

®

avoring/humidication processes

■ All working parameters described in bro-

chures, price lists, refer to programming and/

or functionality to achieve a single process

separately, and not connected or linked.

SAVE THESE INSTRUCTIONS

■ Arredo Inox Srl assumes no responsibility for

any errors that may appear in this document.

In no event shall Arredo Inox Srl be liable for

incidental or consequential damages arising

from use of this document or the software and

hardware described in this document.

■ The information contained within the user

manual is subject to change without notice

and should not be construed as a commitment by Arredo Inox Srl.

■ The default climatic recipes programmed

in your Maturmeat® are suggested and are

modiable by the user, they are meant to be

used a guide.

■ Always shut down power to the unit before

attempting any work on the unit, other than

the exclusive purpose for which it was made.

■ Do not store explosive substances such as

containers with explosive propellants in side

your Maturmeat®

■ Not respecting any of the aforementioned

points may compromise the safety of the

machine and or the user.

This manual replaces all previous versions, and contains up to date information on procedures and settings, with the

exception of electrical drawings (nd production dates on each drawing)

This document and parts thereof must not be reproduced or copied without Arredo Inox Srl’s written permission, and

contents thereof must not be imparted to a third party nor be used for any unauthorized purpose. Contravention will

be prosecuted.

Rev 2, 18.06.19

3

Page 4

1.2

Modello/Model: STGXXXXXX

Matricola/Serial No: 51XXX

Lotto Produzione/ Lot No: STGXXXXXXXXXXXXXXXXXXXX

Tensione/Voltage: 230 V

Frequenza/Frequency: 60Hz

Assorbimento Max/Max Power: 3420W - 14A

Assorbimento Nominale/Rated Power: 2100W - 9.3A

Illuminazione/Lighting 30W - 0.3A

Riscaldamento/Heaters: 1500W - 6.2A

Ricambio Aria/Air Recycling: 40W - 0.5A

Raffreddamento/Cooling: 670W - 4A

Umidificazione/Humidification: 1250W - 6A

Deumidificazione/Dehumidification: 2100W - 9.4A

Aromatizzazione/Aromatization: 1250W - 6A

Sbrinamento/Defrost: 770W - 4A

Gas Refrigerante/Refrigerant Type: R 404 A

Quantità Refrigerante/Refrigerant Quantity: 400g

Classe Climatica/Ambient Temperature: ST

Max Corr. Operativa (MRA)/Max Operating Curr. (MRA) 2.8A

Compressore (RLA)/Compressor (RLA) 16.5A

Arredo Inox s.r.l. Zona Industriale

loc. Zigari 88900 Crotone Italy

MADE IN ITALY

™

Modello/Model: STGXXXXXX

Matricola/Serial No: 51XXX

Lotto Produzione/ Lot No: STGXXXXXXXXXXXXXXXXXXXX

Tensione/Voltage: 230 V

Frequenza/Frequency: 60Hz

Assorbimento Max/Max Power: 3420W - 14A

Assorbimento Nominale/Rated Power: 2100W - 9.3A

Illuminazione/Lighting 30W - 0.3A

Riscaldamento/Heaters: 1500W - 6.2A

Ricambio Aria/Air Recycling: 40W - 0.5A

Raffreddamento/Cooling: 670W - 4A

Umidificazione/Humidification: 1250W - 6A

Deumidificazione/Dehumidification: 2100W - 9.4A

Aromatizzazione/Aromatization: 1250W - 6A

Sbrinamento/Defrost: 770W - 4A

Gas Refrigerante/Refrigerant Type: R 404 A

Quantità Refrigerante/Refrigerant Quantity: 400g

Classe Climatica/Ambient Temperature: ST

Max Corr. Operativa (MRA)/Max Operating Curr. (MRA) 2.8A

Compressore (RLA)/Compressor (RLA) 16.5A

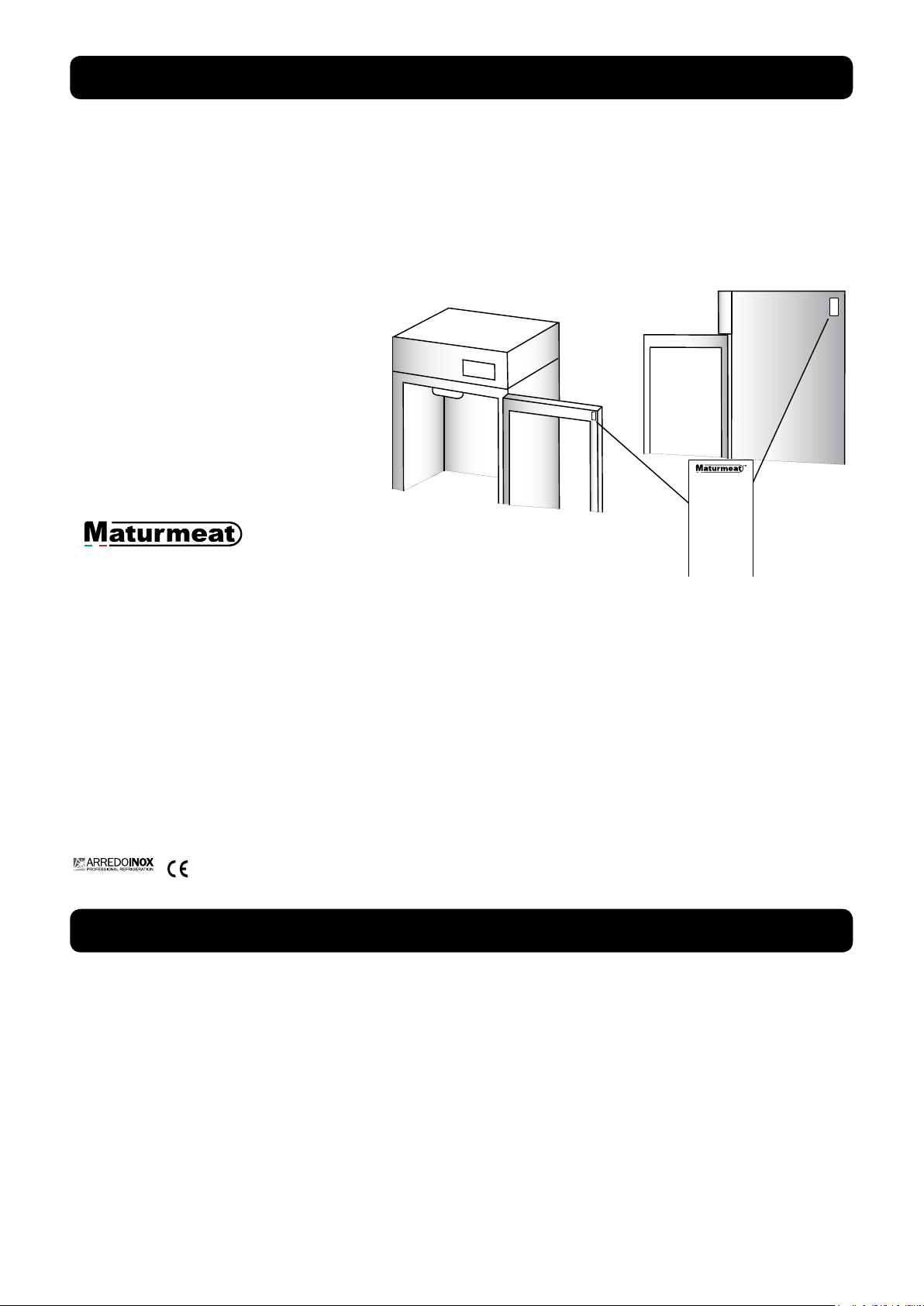

IDENTIFICATION DATA & DATA PLATE

The serial tag is a permanently afxed sticker on which is recorded vital electrical and refrigeration data about your Maturmeat® product, as well as the model and serial number. There are

two data plates on each unit, they can be found on the inside top corner of the doorframe

and on the top corner on the right hand side of the body. When contacting the manufacturer,

please provide the serial number and production lot number found on your cabinet or on the

conformance certicate.

1) Brand

2) Model

3) Serial number

4) Production lot number

5) Voltage

6) Frquency

7) Max Power

8) Nominal Power

9) Power usage for lighting

10) Power usage during heating

11) Power usage during air cycling

12) Power usage during cooling

13) Power usage during humidication

14) Power usage during dehumidication

15) Power usage during avouring

16) Power usage during defrosting

17) Refrigerant type

18) Refrigerant quantity

19) Climatic class

20) Max operating current

21) Compressor Rated load Amps

22) Manufacturer

23) Certication

24) Country of Origin

1.3

The following items are included with your Maturmeat®. Contact your dealer should any of the

following be missing

No. 3 temperature probes;

No. 1 humidity probe;

No. 1 closed loop connector (for direct waterline see page 25);

No. 1 replacement tubes for aroma pump (2 for Twin 100+100);

No. 1 user manual;

No. 1 warranty registration card;

No. 1 drain tray (except 60);

No. 1 drain hose;

No. 5 guide sets (L&R); (10 for 200 & Twin 100+100)

No. 5 stainless steel shelves (10 for 200 & Twin 100+100)

4

STANDARD ACCESSORIES

Rev 2, 18.06.19

Page 5

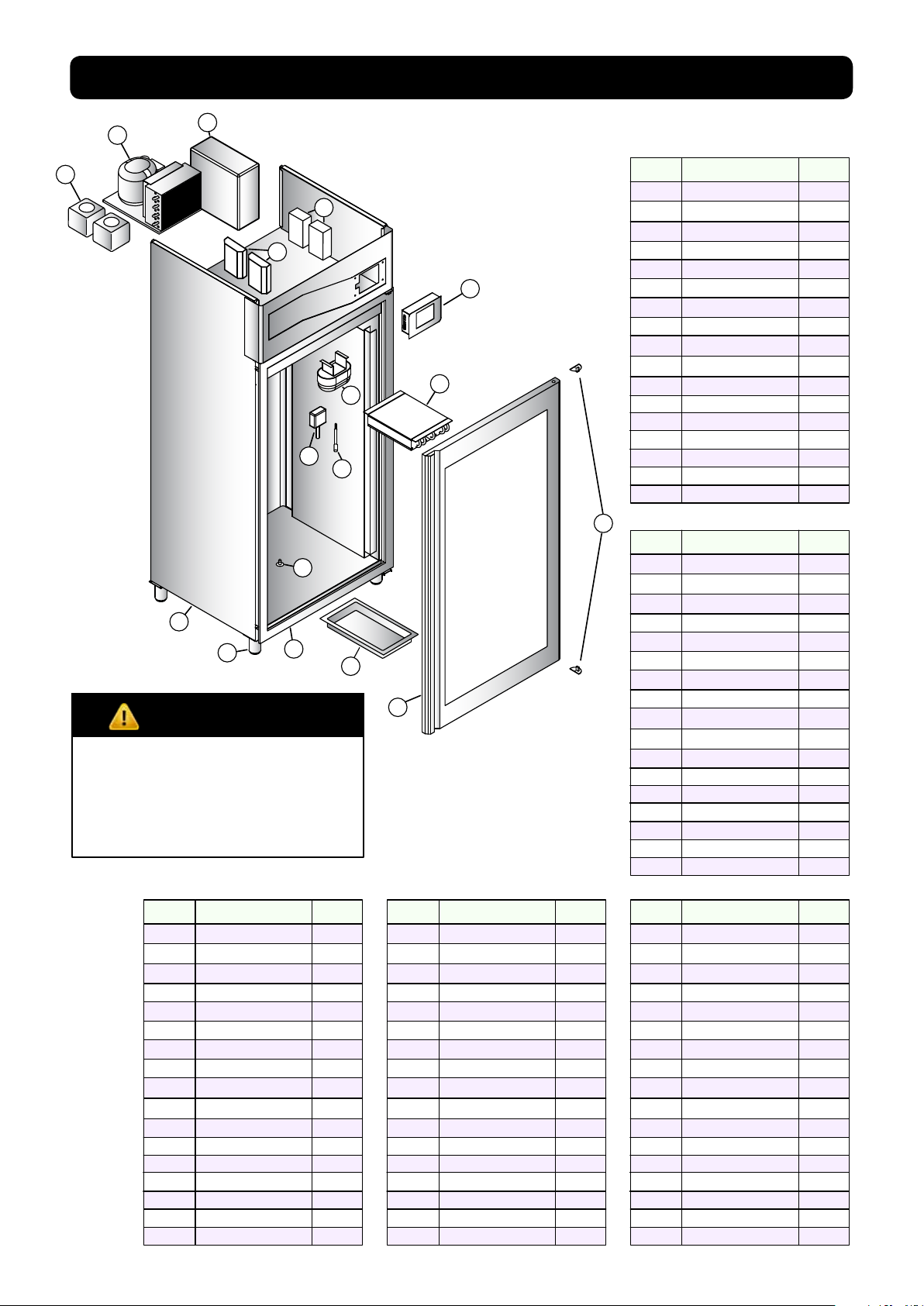

1.4

MODEL 60

MATURMEAT® DIAGRAM

2

3

1

5

9

11

12

13

14

DANGER

Gas Exposure

Do not damage the cooling system as it contains R404a refrigerant, which can cause injury, burns

and frostbite.

MODEL 150 MODEL 200 MODEL TWIN100+100

Number Description Quantity

1

Tanks water/aroma

2

Condensing Unit

3

Fumotic®

4

Transformer

5

PLC

6

Touch Controller

7

Evaporator

8

Internal Light

9

Humidity Probe

10

Ambient Probe

11

Steam Output

12

Unibody Frame

13

Adjustable Legs

14

Molding w/Heating

15

Drain Tray

16

Door w/Resistance

17

Door Hinge

Number Description Quantity

1

Tanks water/aroma

4

6

8

7

10

15

16

Number Description Quantity

2

1

1

2

2

1

2

1

1

1

1

1

4

1

1

1

2

1

Tanks water/aroma

2

Condensing Unit

3

Fumotic®

4

Transformer

5

PLC

6

Touch Controller

7

Evaporator

8

Internal Light

9

Humidity Probe

10

Ambient Probe

11

Steam Output

12

Unibody Frame

13

Adjustable Legs

14

Molding w/Heating

15

Drain Tray

16

Door w/Resistance

17

Door Hinge

17

2

1

1

2

2

1

2

1

1

1

2

1

4

1

1

2

4

2

Condensing Unit

3

Fumotic®

4

Transformer

5

PLC

6

Touch Controller

7

Evaporator

8

Internal Light

9

Humidity Probe

10

Ambient Probe

11

Steam Output

12

Unibody Frame

13

Adjustable Legs

14

Molding w/Heating

15

Drain Tray

16

Door w/Resistance

17

Door Hinge

MODEL 100

Number Description Quantity

1

Tanks water/aroma

2

Condensing Unit

3

Fumotic®

4

Transformer

5

PLC

6

Touch Controller

7

Evaporator

8

Internal Light

9

Humidity Probe

10

Ambient Probe

11

Steam Output

12

Unibody Frame

13

Adjustable Legs

14

Molding w/Heating

15

Drain Tray

16

Door w/Resistance

17

Door Hinge

Number Description Quantity

1

Tanks water/aroma

2

Condensing Unit

3

Fumotic®

4

Transformer

5

PLC

6

Touch Controller

7

Evaporator

8

Internal Light

9

Humidity Probe

10

Ambient Probe

11

Steam Output

12

Unibody Frame

13

Adjustable Legs

14

Molding w/Heating

15

Drain Tray

16

Door w/Resistance

17

Door Hinge

2

1

1

2

2

1

1

1

1

1

1

1

4

1

1

2

4

2

1

1

2

2

1

1

1

1

1

1

1

4

1

1

1

2

2

2

1

4

4

2

2

1

2

2

2

1

4

1

1

2

4

5

Rev 2, 18.06.19

Page 6

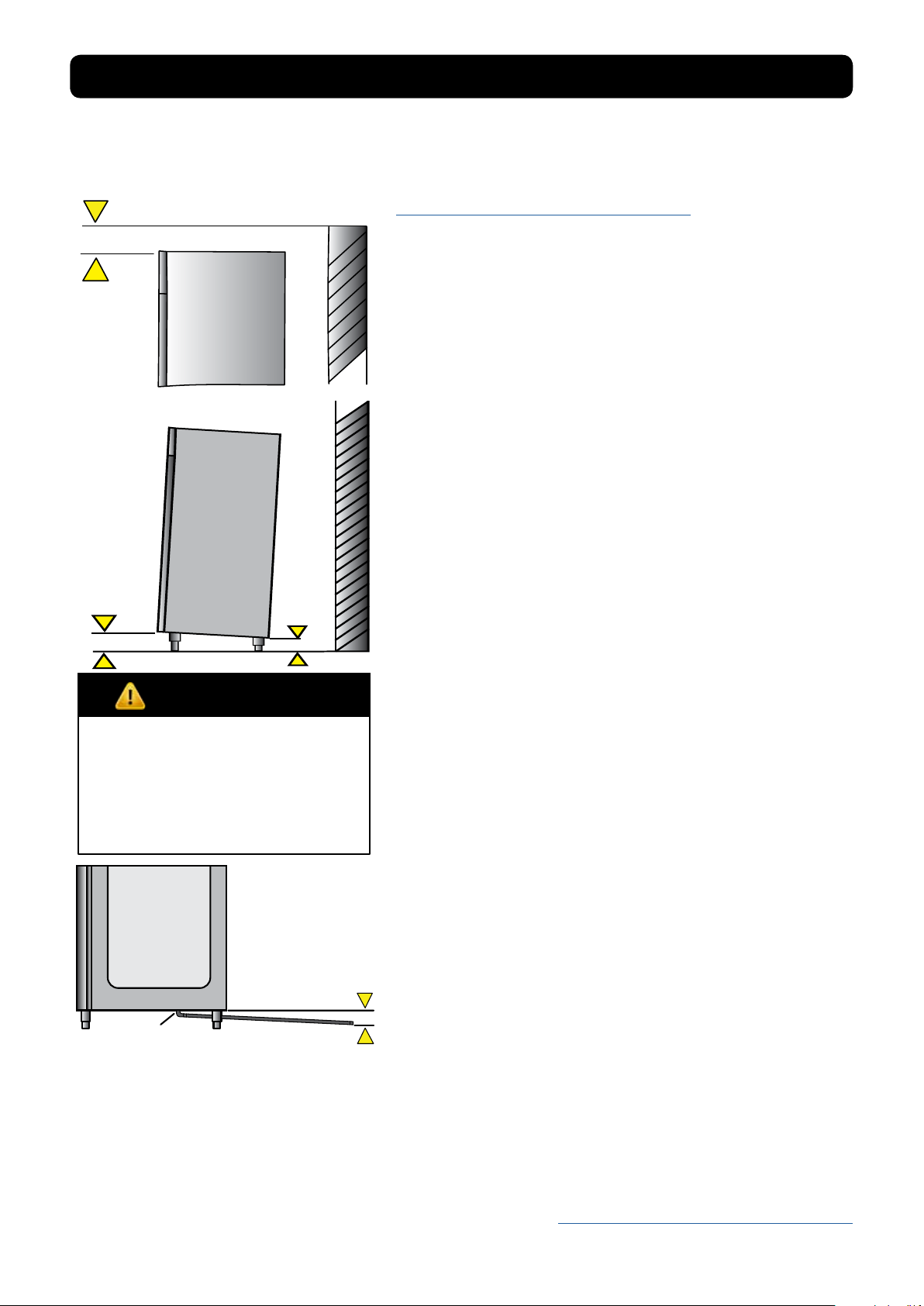

1.5

All Maturmeat® units are factory tested for performance and are free from defects when

shipped. The utmost care has been taken in crating this product to protect against damage in

transit.

You should carefully inspect your Maturmeat® unit for damage during delivery, even if the crate

is free from damage. If damage is detected, you should save all the crating materials and make

note on the carrier’s Bill Of Lading describing this. A freight claim should be led immediately. If

damage is subsequently noted during or immediately after installation, contact the respective

carrier and le a freight claim. Under no condition may a damaged unit be returned without rst

obtaining written permission (return authorization).

RECEIPT INSPECTION

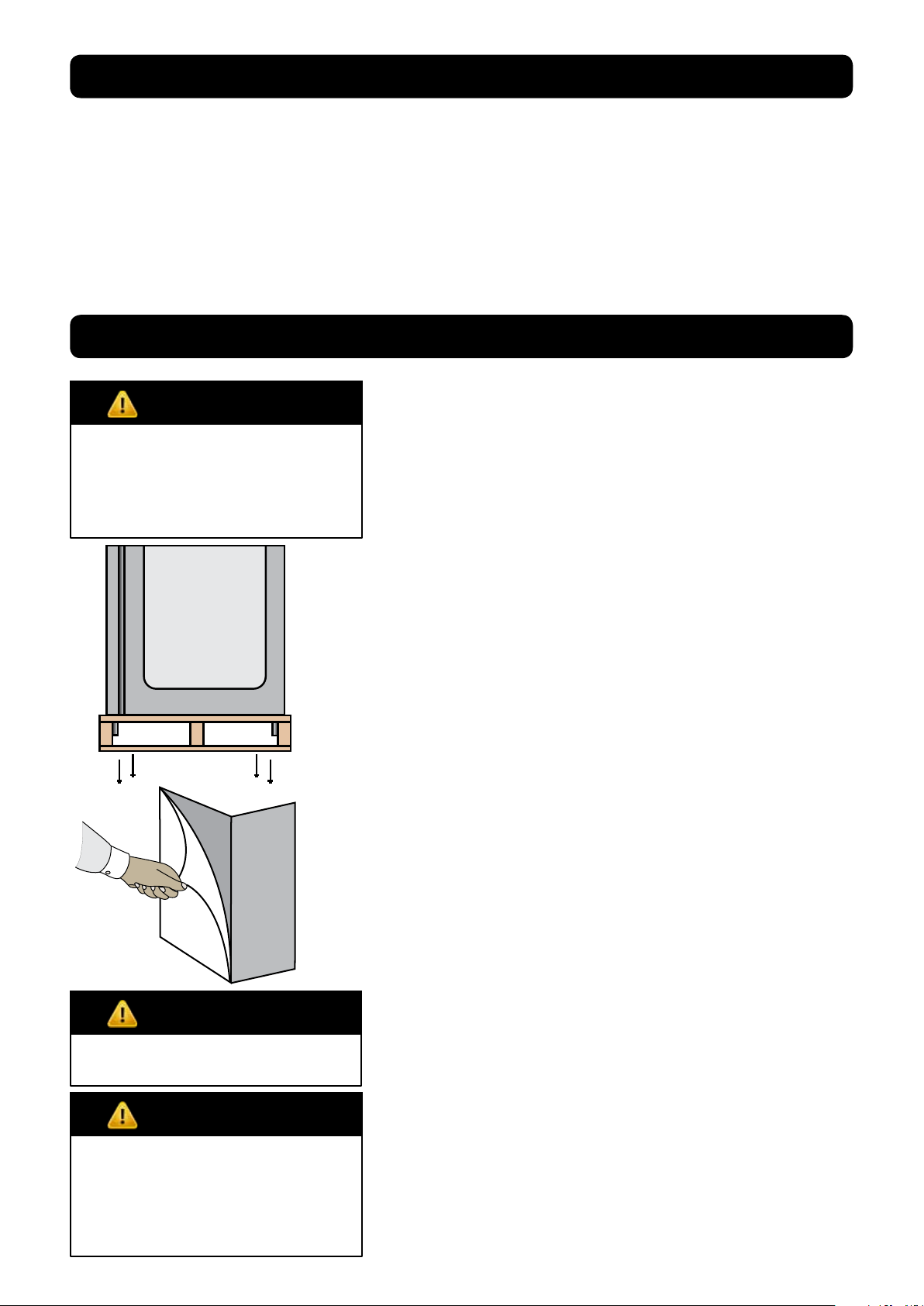

1.6

DANGER

Excessive Weight Hazard

Use two or more people to move

and install your Maturmeat®.

Failure to do so can result in back

or other injury.

INSTALLATION

LOCATION:

Select a proper location away from extreme heat or

cold. Space above the unit should allow for breathability to the condensing unit and access to the Water/

Aroma tanks. Allow enough clearance between the

unit and the side wall in order to allow the doors to fully

open.

PACKAGING:

The unit is shipped from the factory strapped to a sturdy wooden pallet and protected by MDF crating. The

crating is attached to the pallet with nails and several

screws. These should rst be removed to avoid scratching the unit when lifting off the crating. To remove the

Maturmeat® from the wooden pallet start by cutting

free the nylon bands. There are 4 bolts connecting the

Maturmeat® to the pallet, remove them to release the

Maturmeat® from the pallet.

Most exterior surfaces have a protective vinyl covering

to prevent scratching during manufacturing, shipping,

and installation, remove after installation and discard.

DANGER

Keep all packaging away from

children

DANGER

Electrical Hazard

Never connect power to unit

via extension cord or adapter,

this can cause damage to the

system and/or start a re.

6

NOTE: DO NOT LAY THE UNIT ON ITS SIDE/BACK/FRONT

DURING TRANSPORTATION OR INSTALLATION.

POWER CORD:

An attached power cord is provided without plug,

shipped coiled inside the compressor compartment.

For your safety and protection, have the installer connect the proper plug for your country by checking with

the information on the data plate. Connect only to an

appropriate dedicated 20 amp outlet.

POWER SUPPLY:

The supply voltage should be checked prior to connection to be certain that proper voltage for the cabinet

wiring is available (refer to the data plate for the correct

unit voltage). Make connections in accordance with local electrical codes. Use qualied electricians.

Use of a separate, dedicated circuit is required.

Size wiring to handle indicated load and provide necessary overcurrent protector in circuit (see amp requirements on the unit’s data plate).

Rev 2, 18.06.19

Page 7

INSTALLATION continued

Connection

Point

ELECTRICAL SCHEMATICS:

Refer to the electrical schematics on page 46-52 for any

service work performed on the unit. Should you require

a new one, please contact Maturmeat® Service at

ufcioqualita@stagionellostore.com, and provide serial

number of the unit involved.

CLEARANCE:

To assure optimum performance of your Maturmeat®

the condensing unit MUST have an adequate supply of

air for cooling purposes. The operating location must

have 45 cm (18”) minimum clearance from the top of

the Maturmeat® to the ceiling.

Select a working location away from extreme heat or

cold. The Maturmeat® is designed to operate in temps

of 32°C (89°F) or less. Locate the unit so that air drafts

(such as heat, A/C or ventilation) do not blow on or over

the top of the Maturmeat®.

ADJUSTING LEGS:

Unit includes 4 factory installed (except 100kg model).

The ideal position for the unit should be that it leans

towards the back, to allow for proper door closure.

Adjust the leg by turning the lower portion of the leg.

MATC100TF units will include 4 legs and 16 bolts packed

inside the unit, these will need to be mounted and then

adjusted.

VISUAL TEST:

DANGER

Electrical Shock Hazzard

if any damage to wiring is found,

do not touch and contact your

local service point. Failure to do

so can result in serious injury or

death.

REGISTER YOUR UNIT:

Once your Maturmeat® has been installed by an authorized technician, validate the

warranty by sending an e-mail to the following address ufcioqualita@stagionellostore.com

enclosing the installation worksheet.

Check the top of the unit making sure nothing has

moved, shifted or loosened during transport. Check that

all wires to PLC’s are rmly connected, check lines on

the condensing unit, check Fumotic® and lines to tanks.

Disconnect power to unit before performing visual test

PREPARE UNIT:

Fill the water tank with water to avoid false alarm. Slide

the drain tray on the tracks underneath the unit, or set up

the drain hose to connect to a oor or dedicated drainage system. Make sure that the end of the drain hose

is a minimum of 5cm lower than the connection point.

Before starting the test recipe, wipe down the inside of

the unit in contact with food using a cloth or sponge,

water and a non aggressive/non abrasive cleaner (for

more information on cleaning, refer to page 26).

TEST RECIPE:

Maturmeat® has a test recipe programmed under the

My Recipe category. The test recipe must be run to ensure the Maturmeat® performs all its functions. This is to

prevent loss of product on rst use. To set test recipe see

page 9

Rev 2, 18.06.19

7

Page 8

®

®

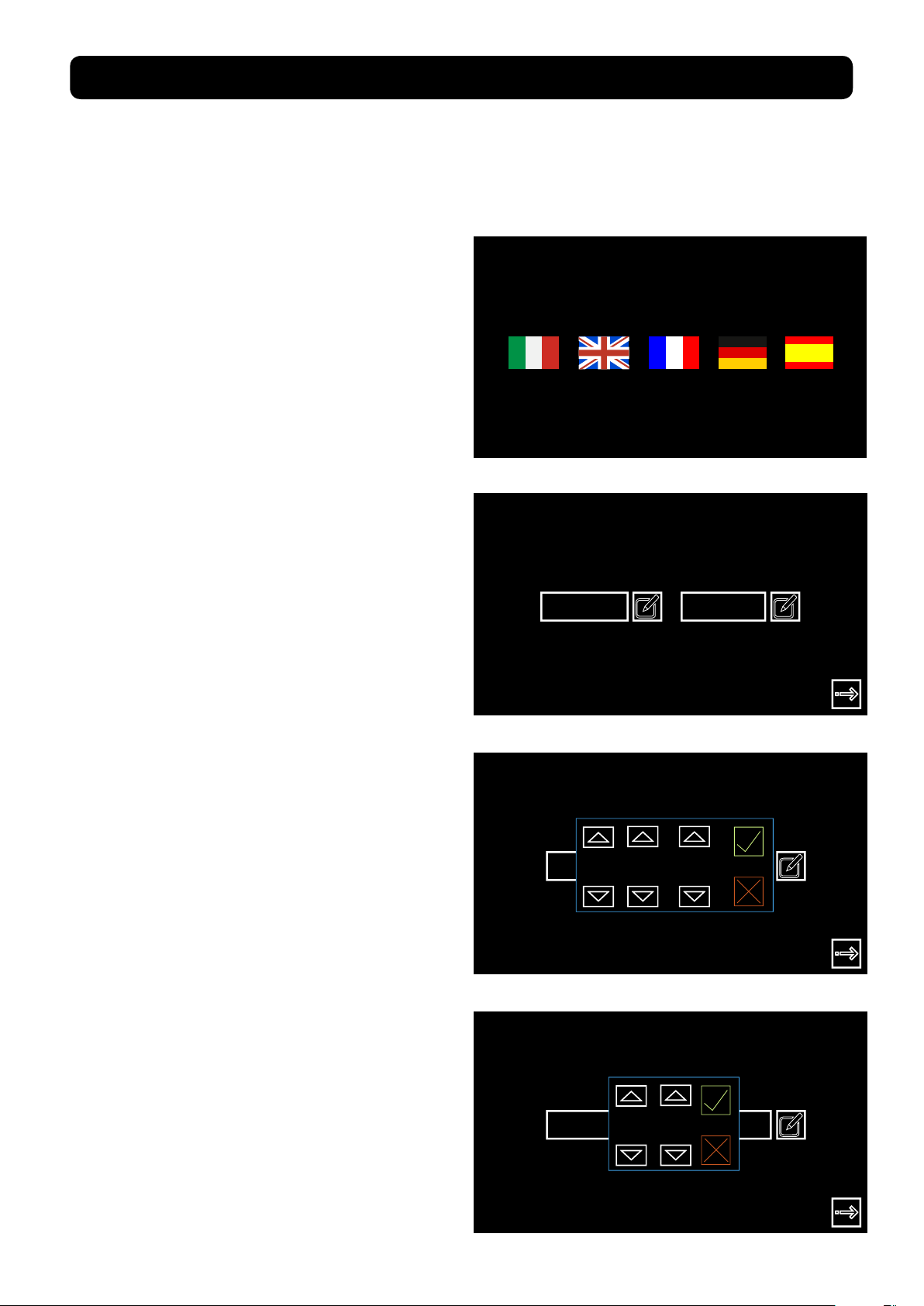

2.1

USING SICUR FOOD CONTROL

FOR THE FIRST TIME

After a successful installation and with power to your Maturmeat®, the Sicur Food Control® controller will start up automatically on the Welcome page.

The Welcome page allows you to select the language, and displays Firmware version installed.

Note: Information may be displayed in Italian for the rst time

From this screen, select the language

you would like to use. You can change

language at anytime by pressing the

Welcome

24/03/2018 12:35

backward arrow from the Home page.

If needed, come back to the welcome

page to check your rmware version,

which can be found in the bottom left

corner of the screen.

Serial

10002156, FW.1.13, PLC-A1.37, PLC-B1.37

Patent #1395586 - Climatouch

After selecting your language, you

will land on the date and time page,

where you can adjust the data should

you need to.

To adjust the date or time, press the Set

icon beside the corresponding eld.

Use the up and down arrows above

and below the numbers to adjust the

month, day and year. Press the check

mark to save and exit.

24/03/2018

24/03/2018

24 03 2018

12:35

12:35

Use the up and down arrows above

and below the numbers to adjust the

hour and minute. Press the check mark

to save and exit.

24/03/2018

12 35

12:35

8

Rev 2, 18.06.19

Page 9

2.2

STARTING THE TEST RECIPE

24/03/2018

12:35

1. After setting date & time,

press forward arrow.

Customer Dealer Producer

2. This is the Home page, here

you have 3 options to choose

from:

i. Customer,

ii. Dealer,

iii. Producer,

Select Customer to proceed.

Recipe list Recipe list

3. In the customer area, you

have 4 options to choose from:

i. Climatic Recipes

ii. HACCP-Performance

iii. pH calbr.

iiii. Variables

Select Climatic Recipes.

Climatic recipes

pH calibr.

HACCP-Perf

Variable

My recipe Def. recipes Create a recipe

4. On the recipes page

you can access all recipes;

here you have 3 options to

choose from:

i. My Recipes

ii. Default Recipes

iii. Create a Recipe

Select My recipes.

7. The test recipe should

automatically start. Look at

the start/pause button to

make sure itsn’t ashing.

Test Recipe

5. The test recipe is found at

the bottom of the list; press

the downward arrow until

you see the recipe.

Current Recipe

Test Recipe

TOTAL TIME

12 Hrs

REMAING TIME

TEMPERATURE

TOTAL TIME2REMAING TIME

11 Hrs

PHASE 1 OF 1

Heat

HUMIDITY

Ongoing recipe !

Start new ?

Test Recipe

6. With the test recipe

Highlighted, press the start

button. A message will

appear, press the check

mark button to proceed.

PH

5.8

1

SET

POINT

5.0

21.1˚C

SET

POINT

12:35 24/03/2018

25.0˚C

Rev 2, 18.06.19

SET

POINT

18

5%

%

9

Page 10

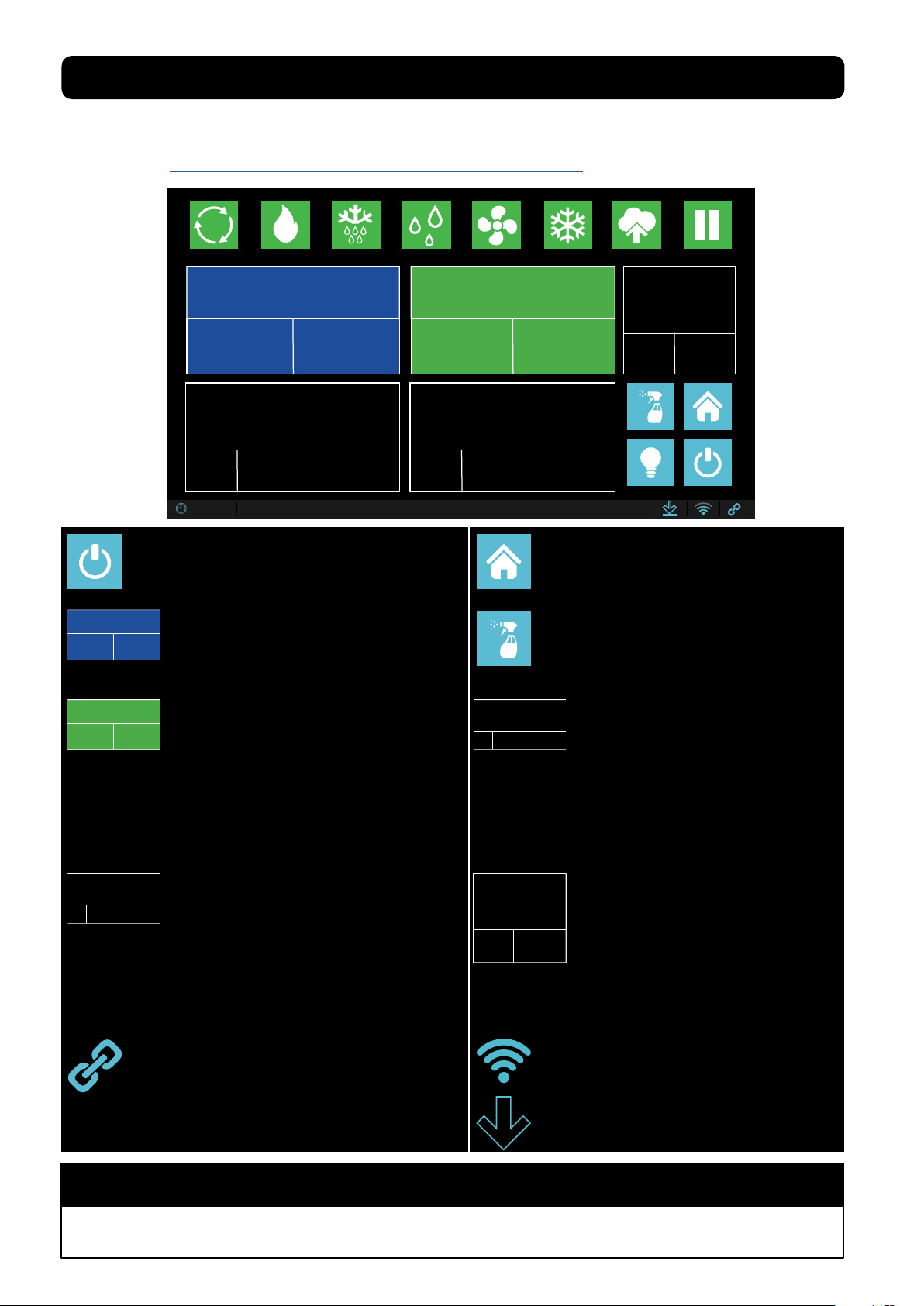

2.3

81%

5.8

1.0˚C

RECIPE SCREEN DEFINED

The following is an explaination of the recipe screen to help you understand the parameters you

will be interacting with daily on the Maturmeat® controller. Alternatively, use the link to see the

video online https://www.youtube.com/watch?v=AfhtshDWTdI

Current Recipe

AGED BEEF

TOTAL TIME

999 Hrs

TEMPERATURE

REMAING TIME

999 Hrs

TOTAL TIME

999

1.3˚C

SET

POINT

12:35 24/03/2018

Start/Pause Recipe:

Icon Light Blue = recipe is working.

Icon Grey = recipe is paused.

Current Recipe

AGED BEEF

TOTAL TIME

999 Hrs

PHASE 1 OF 1

MATURING

TOTAL TIME

999

Note: set yellow value to 0 to skip phase when necessary.

Recipe name currently in use.

REMAING TIME

Total time of the current recipe in use.

999 Hrs

Remaining time of the recipe in use.

Recipe phase currently preforming

REMAING TIME

WHITE VALUE: displays time remaining

999

in current phase.

YELLOW VALUE: displays total time in

current phase.

1.0˚C

SET

POINT

PHASE 1 OF 1

PH

MATURING

REMAING TIME

HUMIDITY

75

999

%

5.6

SET

POINT

5.8

81%

Home icon: has 2 functions, exit recipe

(when recipe is paused), check VTE/VTC

values (while recipe is working).

Cleaning In Place (C.I.P.): a 2 stage

recipe for internal washing and drying of

the chamber.

Note: remove all foodstuff before starting.

TEMPERATURE

1.3˚C

SET

Note: There is +/- 2 range. Temp must be achieved

before any other functions will work. It is normal to see

humidity go out of range during cooling/heating.

Temperature for current phase

WHITE VALUE: displays current temp

inside unit.

YELLOW VALUE: displays temp set

point needed to be reached.

HUMIDITY

75

SET

Note: There is +/- 7 range. Temp must be achieved before

any other functions will work. It is normal to see humidity go

out of range during cooling/heating.

Note: In order for the Link icon to be active, you must add

a GSM sim card to the controller.

Relative Humidity for current phase

%

WHITE VALUE: displays current humidity

inside unit.

YELLOW VALUE: displays humidity set

point needed to be reached.

Link turns blue only when a live connection

exists between controller and our server,

otherwise icon will be grey.

PH

5.6

SET

POINT

*This value can only be read when pH probe has been

purchased and connected.

pH for current phase (guide only)

*WHITE VALUE: displays current pH

value inside unit.

YELLOW VALUE: displays ideal value

to be reached.

Shows GSM connection strength in blue,

icon will be grey without connection.

Turnes blue when downloading

rmware, otherwise icon will be grey.

NOTE

Yellow value can be changed for the duration of the phase only, default values will reset once recipe

advances into the next phase, if recipe is exited and re-entered, or if power loss occurs.

10

Rev 2, 18.06.19

Page 11

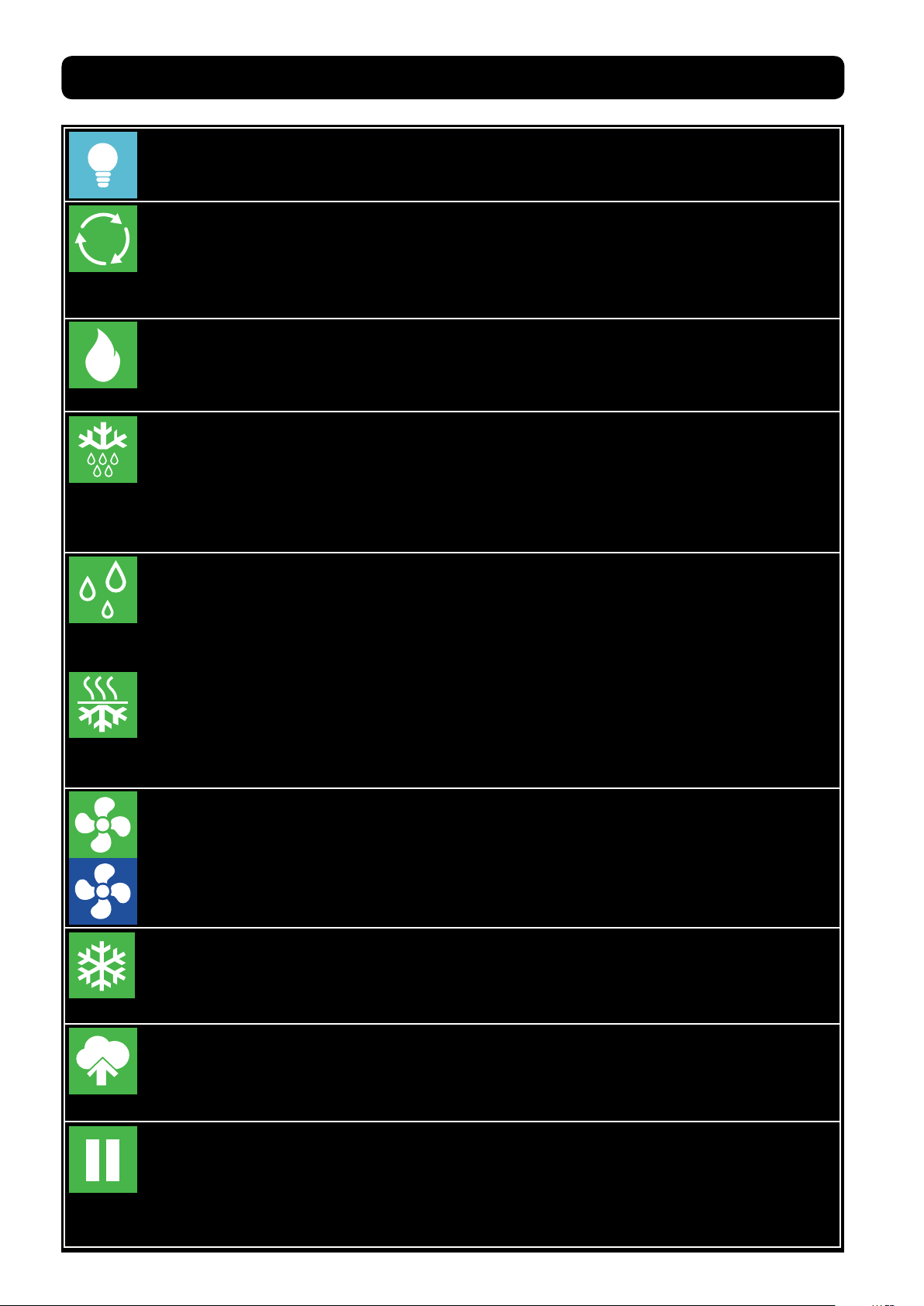

RECIPE SCREEN DEFINED continued

Internal Light:

If the icon is light blue and the frame ashing, this indicates the light inside the unit is

switched on.

Air Cycling:

If the icon is green and the frame ashing, this indicates that the air inside the unit is

being equalized to reduce cool/warm spots. All functions will be disabled for a set

period of time. It is normal for the temp and humidity to go out of range during this

time. The same key gives you the possibility of disabling or forcing an air cycle.

Heating:

If the icon is green and the frame ashing, this indicates that the heating system is

working to bring the temp up to the set point. The same key gives you the possibility

of disabling or forcing the action.

Defrost:

If the icon is green and the frame ashing, this indicates that the evaporator probe

has detected a temp (set in the system variables) and has triggered a defrost. All

functions will be disabled during the defrost period. It is normal for the temp and

humidity to go out of range during this time. The same key gives you the possibility of

disabling or forcing the action.

Humidication:

If the icon is green and the frame ashing, this indicates that humidication system is

working to bring the RH up to the set point. The same key gives you the possibility of

disabling humidication. Note when the unit needs to dehumidify, the humidication

icon will change to the dehumidication icon.

Dehumidication:

If the icon is green and the frame ashing, this indicates that dehumidication system

is working to bring the RH down to the set point. The same key gives you the possibility

of disabling dehumidication. Note when the unit needs to humidify, the dehumidi-

cation icon will change to the humidication icon.

Fan low/high speed:

If this icon is green with the green frame ashing, this indicates that the fan is working

at a low speed; if the icon is blue with blue ashing frame, this indicates that the fan is

working at a high speed. Note you can toggle between high and low speed setting

simply by pressing the fan icon.

Cooling:

If the icon is green and the frame ashing, this indicates that cooling system is

working to bring the temp down to the set point. The same key gives you the

possibility of disabling or forcing the action.

Aroma:

If the icon is green and the frame ashing, this indicates that liquid is drawn out of the

®

aroma tank by the Fumotic

you the possibility of disabling or forcing the action.

, nubulized and sprayed into the unit. The same key gives

Rest/Recovery:

If the icon is green and the frame ashing, this indicates that the Maturmeat® has

disabled all functions for a set period of time to allow the product inside to rest. It is

normal for the temp and humidity to go out of range during this time. The same key

gives you the possibility of disabling or forcing the action.

Rev 2, 18.06.19

11

Page 12

2.4

81%

STARTING A DEFAULT CLIMATIC RECIPE

Follow the steps below to start a default climatic recipe. Alternatively, use the link to see the

video online https://www.youtube.com/watch?v=TPEB3mqgs7M

Customer Dealer Producer

1. From the Home page,

Select Customer to proceed.

Recipe list

Aged Beef

Aged Game

Aged Deer

Aged Horse

R.Mortis

4. On this page you will nd

a list of 5 preset climatic

recipes. Press the recipe

name or use the down icon

until you see the recipe you

want to use.

Climatic recipes

pH calibr.

HACCP-Perf

Variable

2. Select Climatic Recipes.

Recipe list

Aged Beef

Aged Game

Aged Deer

Aged Horse

R.Mortis

Ongoing recipe !

Start new ?

5 . W i t h y o u r r e c i p e

highlighted, press the start

button, a message will

apear, press the check

mark button to proceed.

My recipe Def. recipes Create a recipe

3. Select Default Recipes

Current Recipe

AGED BEEF

TOTAL TIME

999 Hrs

TEMPERATURE

1.3˚C

SET

POINT

12:35 24/03/2018

REMAING TIME

999 Hrs

1.0˚C

TOTAL TIME

SET

POINT

999

PHASE 1 OF 1

MATURING

REMAING TIME

HUMIDITY

75

81%

999

%

5.6

SET

POINT

6. Your selected recipe

should automatically start.

Look at the start / pause

button to make sure its light

blue and ashing.

PH

5.8

2.5

MODIFING RECIPE PARAMETERS

Your production should be monitored daily, you may need and probably will have to, modify a

recipe at some point, this could be due to several factors (meat type, meat quality, etc.). Follow

the steps below to modify Time, Temp and Humidity parameters.

Modications to default/saved recipes while in course are temporary and will last until the end

of the phase, once the phase changes the parameters are returned to their preset value.

78

HUMIDITY

75

%

SET

POINT

1. To change a set point,

press the number in Yellow.

Current Recipe

AGED BEEF

TOTAL TIME

REMAING TIME

999 Hrs

SET

POINT

12:35 24/03/2018

999 Hrs

TEMPERATURE

1.3˚C

1.0˚C

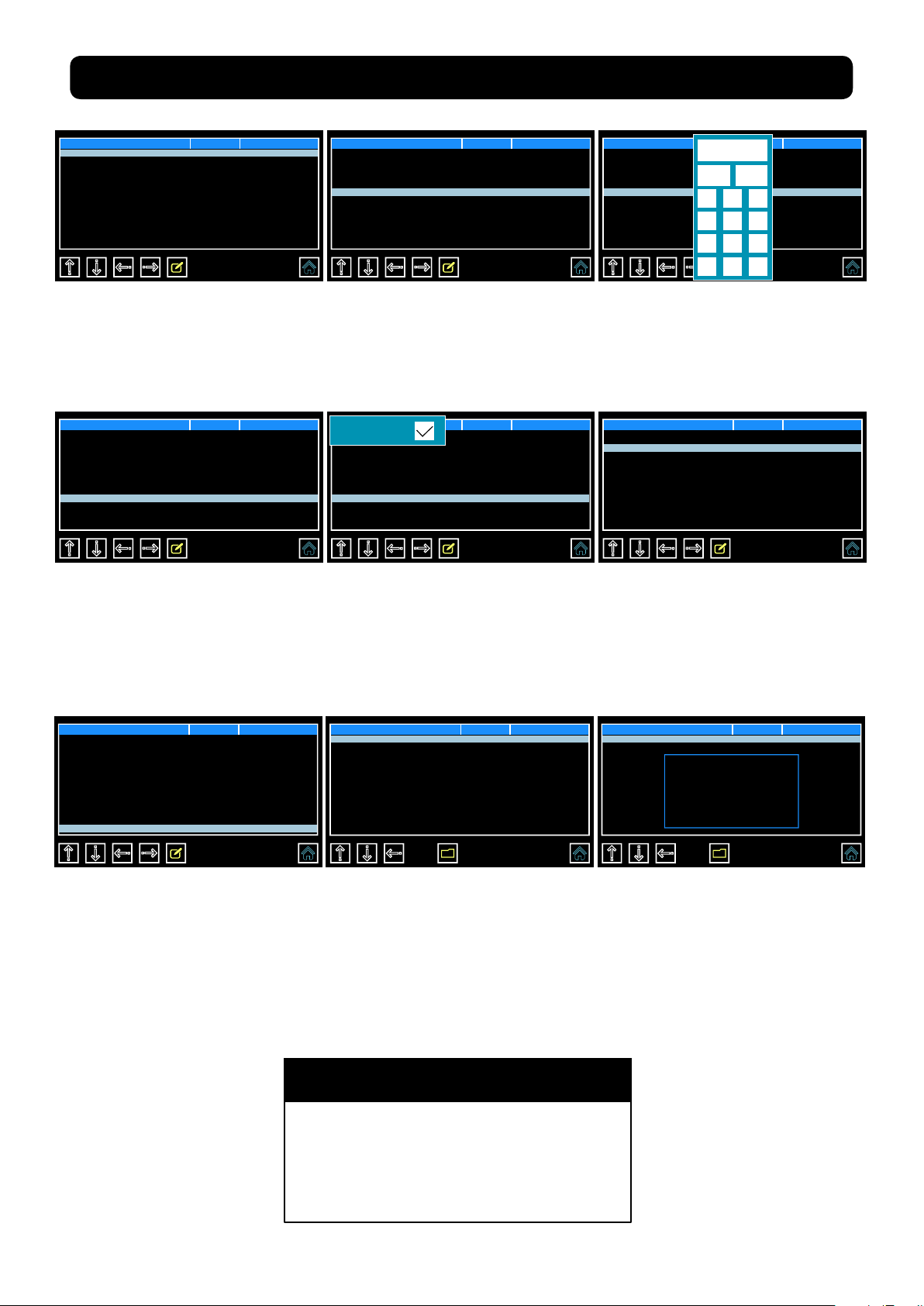

2. The keypad will appear,

enter your value and press

OK to temporarily save.

Esc

1

4

7

-

.

TOTAL TIME

SET

POINT

999

PHASE 1 OF 1

OK

MATURING

2 3

5 6

HUMIDITY

75

8 9

81%

0 C

REMAING TIME

999

%

5.6

SET

POINT

PH

5.8

Current Recipe

AGED BEEF

TOTAL TIME

999 Hrs

TEMPERATURE

1.3˚C

SET

POINT

12:35 24/03/2018

REMAING TIME

999 Hrs

1.0˚C

TOTAL TIME

SET

POINT

999

PHASE 1 OF 1

MATURING

REMAING TIME

HUMIDITY

75

78%

999

%

5.6

SET

POINT

PH

5.8

3. The recipe will continue

with the new modied value

until the end of the phase.

12

Rev 2, 18.06.19

Page 13

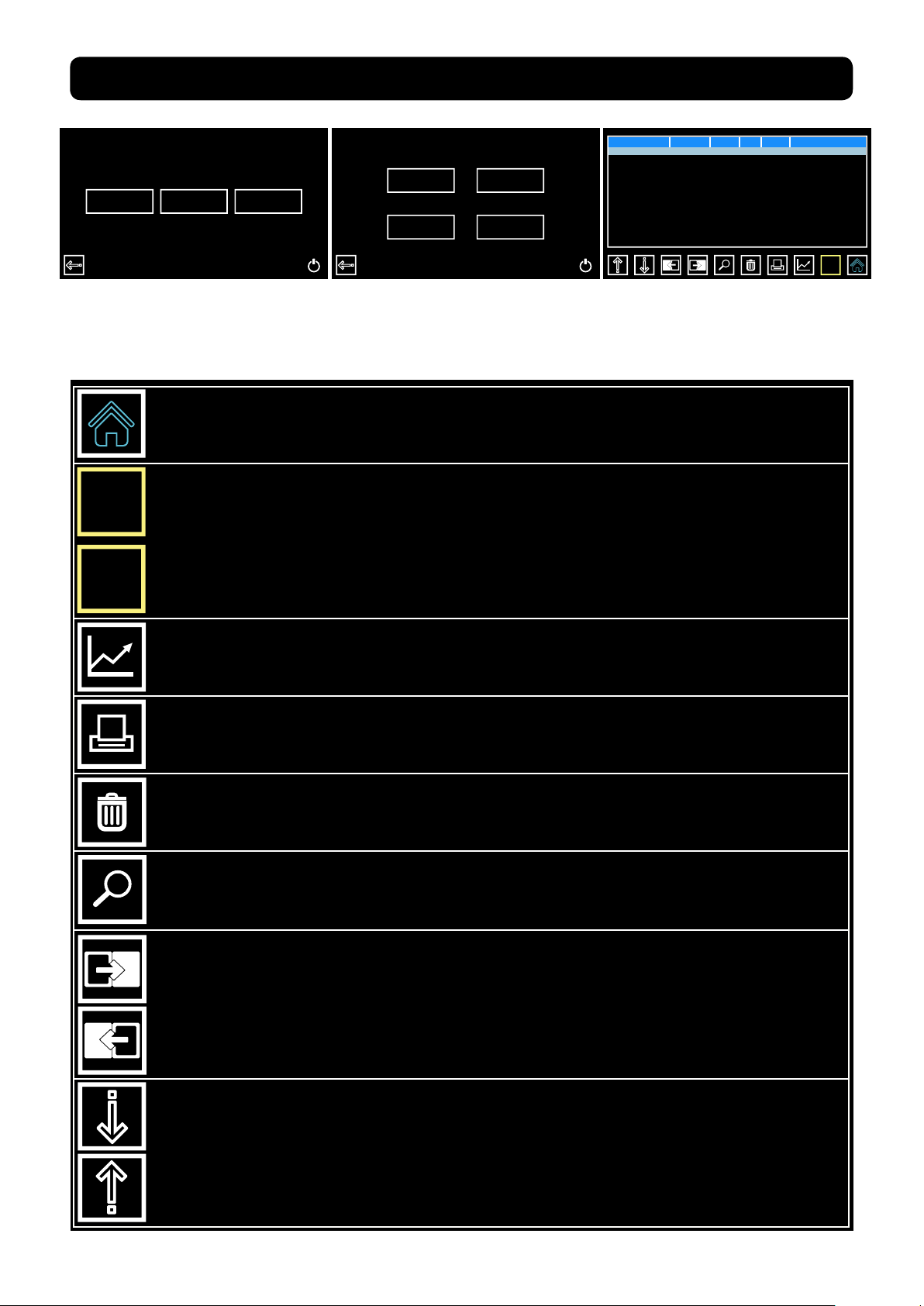

2.6

H

CHECKING HACCP-PERFORMANCE AS LINE DATA

Customer Dealer Producer

1. From the Home page,

Select Customer to proceed.

Home Icon:

Pressing the home icon exits the HACCP-Performance page and returns you to the

home page

R Icon:

R

Displays production data in line form. Press the R and it turns to an H.

Note: while in R mode you cannot access the graphs, for this you must be in H mode

H Icon:

Displays the same production data (in green font), this data cannot be printed. At

this point you can press graph icon to change to graph view.

Climatic recipes

pH calibr.

HACCP-Perf

Variable

2. Select HACCP-Pref.

Date Time

10/06/2018

10/06/2018

10/06/2018

10/06/2018

11/06/2018

11/06/2018

11/06/2018

11/06/2018

11/06/2018

11/06/2018

12/06/2018

10:32

14:32

18:32

22:32

02:32

06:32

10:32

14:32

18:32

22:32

02:32

C RH

˚

1.5

2.3

3.4

2.9

2.4

1.1

1.9

1.7

2.3

3.1

1.2

pH

5.9

˚C

76

6.0

75

6.0

78

6.0

80

6.1

78

6.1

81

6.1

76

6.1

88

6.2

79

6.2

75

6.2

R

3. Here you can search, view

and print production data.

Graph Icon:

Graph layout of line data can be viewed here, if your contoller is connect to our

cloud, this data can be downloaded.

Print Icon:

Line data can be printed via a specialized handheld printer purchased through your

Stagionello™/Maturmeat® distributor.

Trash Icon:

Delete line data.

Search Icon:

Line data can accumulate quickly, use the search icon to advance to a specic

date.

Page Down Icon:

Quickly scroll down page by page.

Page Up Icon:

Quickly scroll up page by page.

Down Icon:

Scroll down one line at a time.

Up Icon:

Scroll up one line at a time.

13

Rev 2, 18.06.19

Page 14

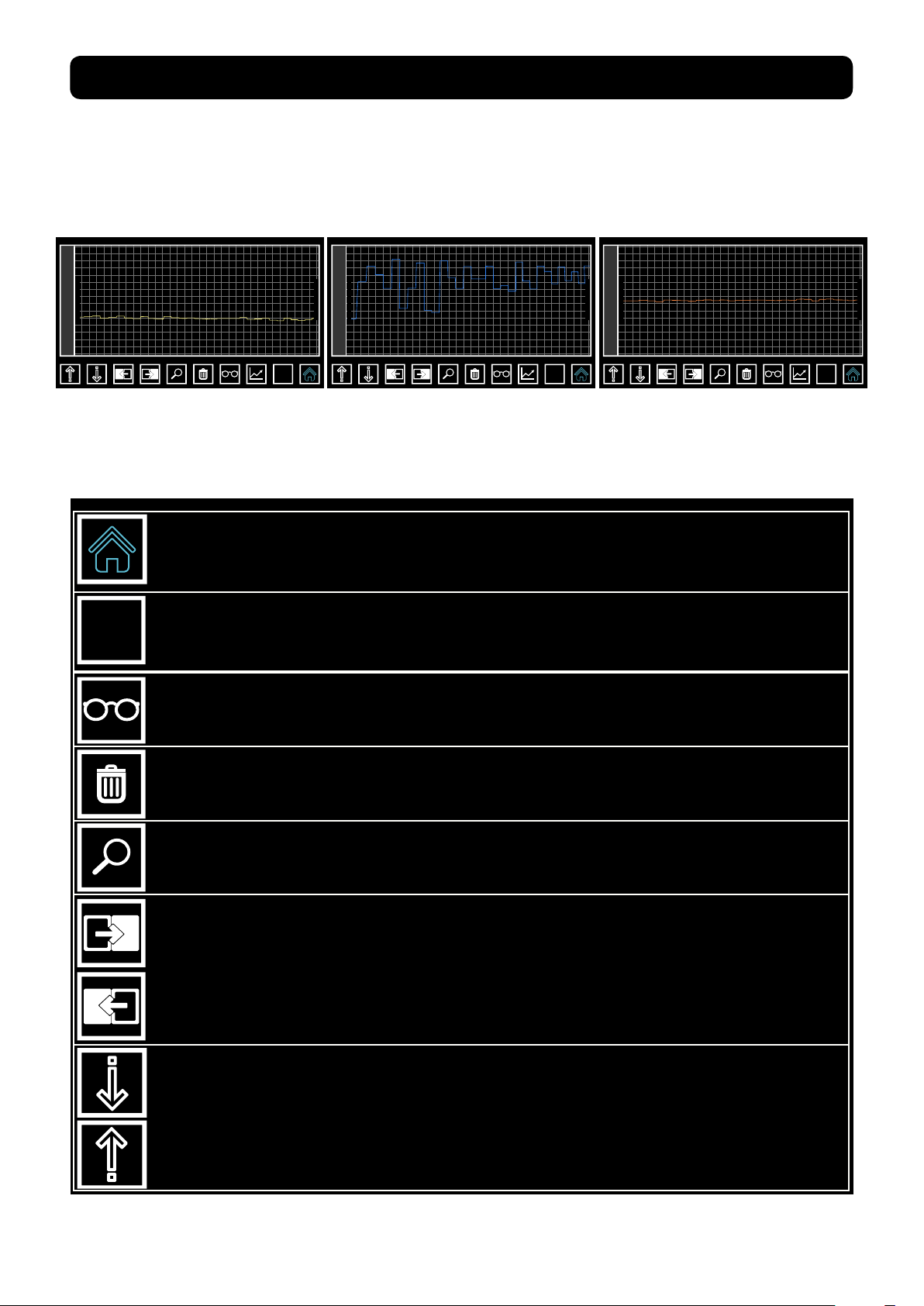

2.7

CHECKING HACCP-PERFROMANCE AS A GRAPH

Graph View:

After switching to H mode, you can now access your production data in the form of a graph by

pressing the graph icon. Temperature, Humidity and pH can be viewed here. You will notice that

the print icon has been replaced by an Eye icon, this will allow you to toggle between 3 graphs.

99

Temperature

12/04/2018 10:32

90

80

70

60

50

40

30

20

10

0

-10

-20

-30

-40

-50

Temperature

15/05/2018 14:32

12/04/2018 10:32

H

92

82

71

61

50

40

30

20

10

0

pH

15/05/2018 14:32

12/04/2018 10:32

H

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

H

15/05/2018 14:32

Temperature Graph

Home Icon:

Pressing the home icon exits the HACCP-Performance page and returns you to the

home page

H Icon:

H

While in graph view, pressing H will exit graph view and return you to R mode (line

data).

Eye Icon:

While in graph view, press the eye icon to toggle through the 3 graphs (Temp, Humidity, pH).

Trash Icon:

Delete data.

Search Icon:

Graph data can accumulate quickly, use the search icon to advance to a specic

date.

Humidity Graph

pH Graph

14

Forward Icon:

Advance forward to the next section data.

Backward Icon:

Move backward to the next section data.

Down Icon:

Has no functionality on graph view.

Up Icon:

Has no functionality on graph view.

Rev 2, 18.06.19

Page 15

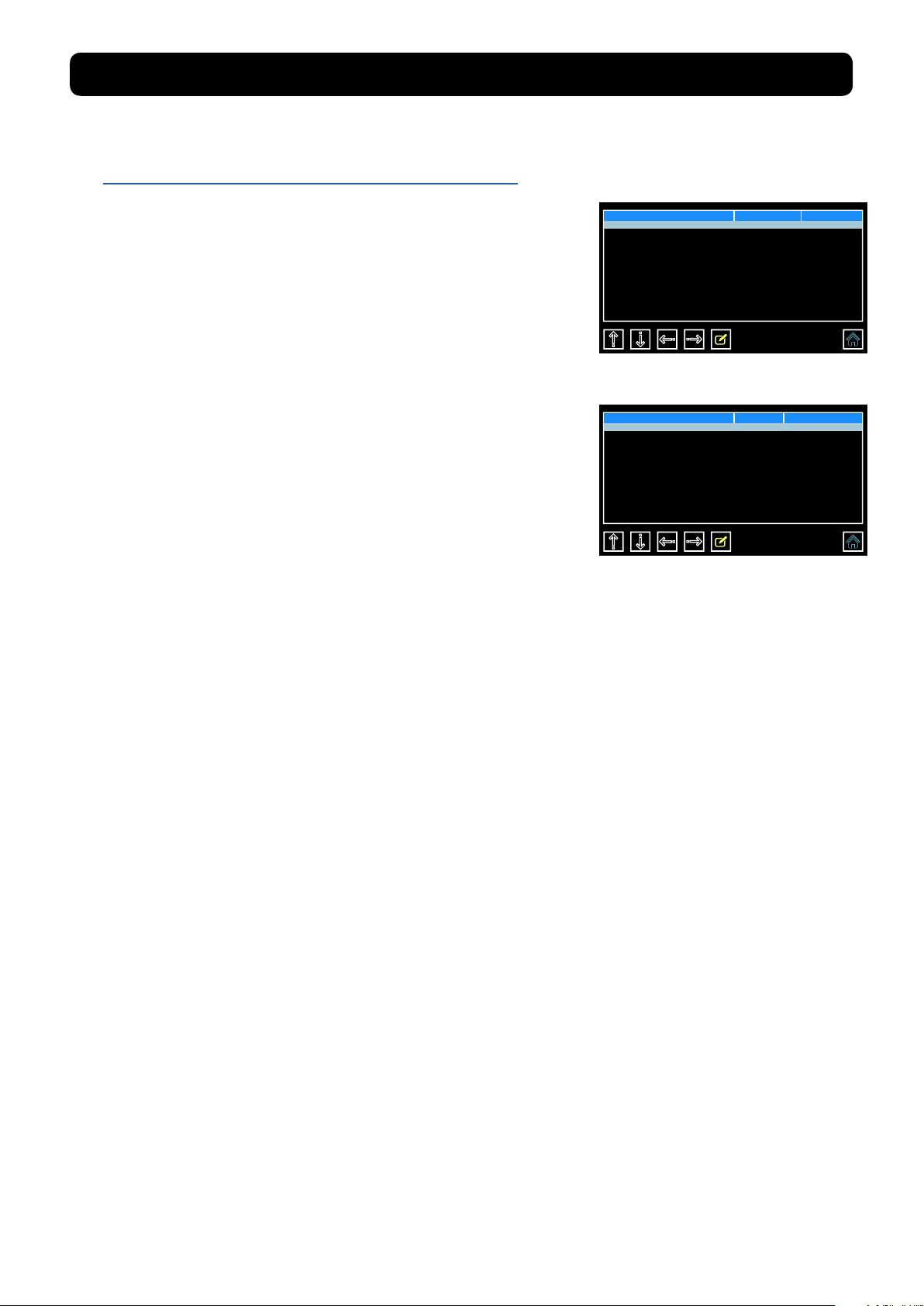

2.8

NEW RECIPE PARAMETERS DEFINED

The following is an explanation to help you understand the parameters involved in creating a

new recipe on the Sicur Food Control® controller. Alternatively, use the link to see the video on-

line https://www.youtube.com/watch?v=-HKpifRFNWE

Create a recipe

Create Recipe Page 1.

Name

StageNbrs

Nuova Ricetta

8

On this page there are 2 sections to ll in:

1. Recipe Name

2. Number of sequential stages

Create Recipe Page 2.

There are 16 recipe variables to create:

1. Name: Phase Name.

2. Time: Number of hours this phase should last.

3. Temp(ºC): The average temperature that should be main-

Create a recipe Stage 1

Name

Time

Temperature(˚) 20.0

Humidity(Rh) 50

PH 7.0

Ventilation H 0

Aroma Length(m) 0

Per.Aroma(h) 0

Phase 1

10

tained during this phase.

4. Humidity: The average humidity that should be maintained

during this phase.

5. Ventilation: Fan speed 0 = low speed, 1 = high speed.

6. PH: by setting a value here, you are creating a guideline. Note: in order for the Sicur Food Control®

to read pH data in your product, the optional pH probe must be connected to the Maturmeat®.

7. Aroma length(m): by setting a value here, the liquid in the aroma tank will be drawn into the Fumotic® and will be nebulized and sprayed into the unit for the length of time (in minutes) set by you.

8. Per.Aroma(h): by setting a value here, you are setting the number of hours between each aroma

activation.

9. Recovery length(m): all functionality is shut down to allow the product inside time to rest, this variable represents the amount of time in minutes that the rest/recovery will last.

10. Recovery period(h): this variable sets the number of hours between each rest/recovery period.

11. Recycle length(s): all functionality is shut down and the air inside is cycled in an attempt to

equalize the climate, this variable represents the amount of time in seconds that the air cycle will

last.

12. Recycle period(m): this variable sets the number of minutes between each air cycling period.

13. Airenew length(m): all functionality is shut down and the air inside is ushed out and fresh air is in-

troduced into the unit, this variable represents the amount of time in minutes that the air exchange

will last.

14. Airenew period(h): this variable sets the number of hours between each air exchange period.

15. Overtime(h): this variable extents the phase in case extra time is needed.

Rev 2, 18.06.19

15

Page 16

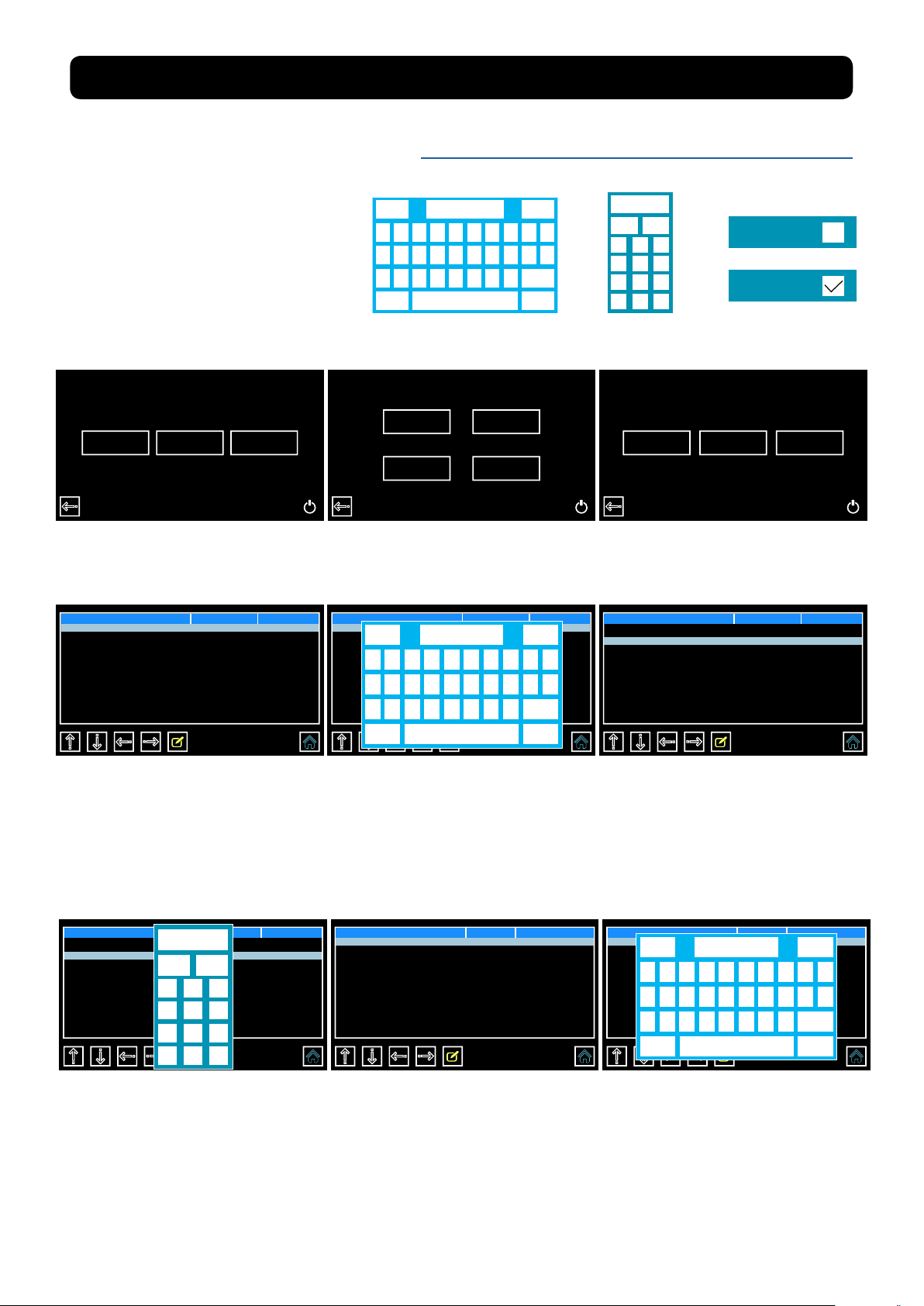

2.9

CREATING AND SAVING NEW RECIPES

This guide will help walk you through the process of creating and saving your own recipe. Alternatively, use the link to see the video online https://www.youtube.com/watch?v=FQfpGkWbeNs

The 3 tools you will use to

modify the recipe parameters

are:

Customer Dealer Producer

1. From the Home page,

Select Customer to proceed.

Create a recipe

Name

StageNbrs

Nuova Ricetta

8

Nuova Ricetta OKEsc

iuytrewq

kjhgfdsa

Del><mnbvcx

Shift Num

Shift

Keyboard Keypad Check box

Climatic recipes

pH calibr.

HACCP-Perf

Variable

2. Select Climatic Recipes.

Create a recipe

Name

StageNbrs

Shift Num

Shift

Nuova Ricetta

My Dry Aged OKEsc

8

iuytrewq

kjhgfdsa

Del><mnbvcx

78

OK

po

zl

Esc

1

2 3

4

5 6

7

8 9

-

.

0 C

My recipe Def. recipes Create a recipe

Ventilation H

Ventilation H

3. Select Create a Recipe

Create a recipe

Name

StageNbrs

po

zl

My Dry Aged

8

4. With the name eld

higlighted in red, Press the

pencil icon to activate the

onscreen keyboard and set

your recipe name.

Create a recipe

Name

StageNbrs

Esc

1

4

7

-

.

My Dry Aged

8

OK

2 3

5 6

8 9

0 C

1

7. Enter the number of stages

you want to your new recipe

to have and press OK. If all

the information you have

entered is correct press the

forward arrow to advance to

the next page.

16

5. Use delete key to empty the

eld, type the name of your

new recipe and press OK.

Create a recipe Stage 1

Name

Time

Temperature(˚) 20.0

Humidity(Rh) 50

PH 7.0

Ventilation H 0

Aroma Length(m) 0

Per.Aroma(h) 0

Phase 1

10

8. On this page you have *16

elds that can be modied

(*with the exception of Free

Variable this should be left 0).

With the name eld highlighted in red, press the pencil icon

to activate the keyboard and

set the name for this stage.

Rev 2, 18.06.19

6. Use the down arrow to

highlight the next eld, press

the pencil icon to activate

the keypad to select the

number of stages you want

your recipe to have.

Create a recipe Stage 1

Name

Time

Temperature(˚) 20.0

Humidity(Rh) 50

PH 7.0

Ventilation H 0

Aroma Length(m) 0

Per.Aroma(h) 0

Shift Num

Shift

Phase 1

Maturing OKEsc

10

iuytrewq

po

kjhgfdsa

zl

Del><mnbvcx

9. Use delete key to empty

the eld, type the name of

this stage and press OK.

Page 17

CREATING AND SAVING NEW RECIPES continued

Create a recipe Stage 1

Name

Time

Temperature(˚) 20.0

Humidity(Rh) 50

PH 7.0

Ventilation H 0

Aroma Length(m) 0

Per.Aroma(h) 0

Maturing

10

10. Use the down arrow to

scroll through the recipe

parameters, one by one,

and adjust according to your

needs.

Create a recipe Stage 1

Name

Time

Temperature(˚) 1.5

Humidity(Rh) 75

PH 7.0

Ventilation H 0

Aroma Length(m) 0

Per.Aroma(h) 0

Maturing

999

13. The ventilation or fan

speed has 2 settings:

0 = low speed

1 = high speed

Press the pencil icon to

activate the check box.

Create a recipe Stage 1

Name

Time

Temperature(˚) 1.5

Humidity(Rh) 50

PH 7.0

Ventilation H 0

Aroma Length(m) 0

Per.Aroma(h) 0

Maturing

999

11. You can skip ahead

somewhat by pressing on the

parameter to highlight it.

Create a recipe Stage 1

Ventilation H

Name

Time

Temperature(˚) 1.5

Humidity(Rh) 75

PH 7.0

Ventilation H 0

Aroma Length(m) 0

Per.Aroma(h) 0

Maturing

999

14. By pressing on the empty

box you will place a check

mark inside, setting the fan on

high-speed for this stage when

needed.

Create a recipe Stage 1

Name

Time

Temperature(˚) 1.5

Humidity(Rh) 50

PH 7.0

Ventilation H 0

Aroma Length(m) 0

Per.Aroma(h) 0

Esc

1

4

7

75

Maturing

999

OK

2 3

5 6

8 9

-

.

0 C

12. For the majority of the

parameters, you will be

working with the keypad to

modify its value.

Create a recipe Stage 1

Per.Aroma(h)

Recov. length(m)

Recov. period(h) 2

Recov. length(s) 300

Recov. period(m) 120

Recov. length(m) 5

Recov. period(h) 12

Overtime(h) 0

0

30

15. The following Parameters

can be left as is:

Recov

Recycl

Airenew

Create a recipe Stage 1

Per.Aroma(h)

Recov. length(m)

Recov. period(h) 2

Recov. length(s) 300

Recov. period(m) 120

Recov. length(m) 5

Recov. period(h) 12

Overtime(h) 0

0

30

16. Once nished the current

page, press the forward

arrow to advance to the

next page and repeat steps

8 - 15. Once you have lled

in all parameters for all stages

press the forward arrow to

advance.

Save recipe Position

...

...

... 3

... 4

... 5

... 6

... 7

... 8

1

2

17. Once on the save recipe

page, select the position to

place your recipe and press

the disk button to save.

Save recipe Position

...

...

... 3

... 4

... 5

... 6

... 7

... 8

18. A save in progress message will appear onscreen

and may last a short while.

Once save is complete you

will automatically be returned

to the Home page.

NOTE

The Aroma parameters are connected

®

directly to the Fumotic

tank, if you do not use liquid avoring (ie.

Natural liquid smoke) in your recipe set

the values to 0 to avoid false alarms.

and the aroma

1

2

Please wait

Save in progress

Rev 2, 18.06.19

17

Page 18

2.10

STARTING A SAVED RECIPE

Follow the steps below to start a recipe that you have previously created and saved.

Customer Dealer Producer

1. From the Home page,

Select Customer to proceed.

Recipe List

My Dry Aged

...

...

...

...

...

...

...

4. Depending on how many

recipes you’ve created and

saved, you may have to use

the down arrow to select the

recipe you want.

Climatic recipes

pH calibr.

HACCP-Perf

Variable

2. Select Climatic Recipes

Recipe List

My Dry Aged

...

...

...

...

...

...

...

Ongoing recipe !

Start new ?

5. With your recipe highlighted

in red, press the start button,

a message will appear, press

the check mark button to

proceed.

My recipe Def. recipes Create a recipe

3. Select My Recipes

Current Recipe

My Dry Aged

TOTAL TIME

999 Hrs

TEMPERATURE

1.8˚C

SET

POINT

12:35 24/03/2018

REMAING TIME

999 Hrs

1.5˚C

TOTAL TIME

SET

POINT

Maturing

999

PHASE 1 OF 1

HUMIDITY

73

75%

REMAING TIME

999

%

6.4

SET

POINT

PH

6. Your selected recipe

should automatically start.

Look at the start / pause

button to make sure its

green.

7.0

2.11

FORCING AROMA

Follow the steps below to force aroma anytime during a default climatic recipe or a recipe that

you have previously created and saved.

Current Recipe

My Dry Aged

TOTAL TIME

999 Hrs

TEMPERATURE

1.8˚C

SET

POINT

12:35 24/03/2018

REMAING TIME

999 Hrs

1.5˚C

TOTAL TIME

SET

POINT

Maturing

999

PHASE 1 OF 1

HUMIDITY

73

75%

REMAING TIME

999

%

6.4

SET

POINT

PH

7.0

1. With your recipe running,

press the aroma icon, the time

selection box will appear

onscreen.

Current Recipe

My Dry Aged

TOTAL TIME

999 Hrs

SET

POINT

12:35 24/03/2018

REMAING TIME

999 Hrs

TEMPERATURE

1.8˚C

1.5˚C

12 35

2. Using the up and down

arrows, select the hours and/

or minutes that you want

liquid from the aroma /

Force Aroma

Maturing

TOTAL TIME

999

SET

POINT

PHASE 1 OF 1

HUMIDITY

73

75%

REMAING TIME

999

%

6.4

SET

POINT

PH

7.0

avor tank to be nebulized

®

by Fumotic

and sprayed

into the unit.

18

Rev 2, 18.06.19

Page 19

3.1

CALIBRATING STANDARD PROBES

Your Maturmeat® has 3 standard probes that can be calibrated by you or by a technician. The probes are checked thoroughly before your Maturmeat® leaves the factory.

A certied instrument to measure either humidity and/or temperature must be used to calibrate the probes on your Maturmeat®. Follow the steps below to access the variables

p a g e t o b e g i n c a l i b r a t i n g t h e p r o b e s , a l t e r n a t i v e l y , u s e t h e l i n k t o s e e t h e v i d e o o n l i n e

https://www.youtube.com/watch?v=TmPLBJ2aC4Q

Customer Dealer Producer

1. From the Home page,

Select Customer to proceed.

Var. Meaning

CORR. SONDA AMB.

CSA

CORR. SONDA U.

CSU

CORR. SONDA C.D

CSC

F.ZA MEM.HACCP

HACF

FAHRENHEIT

FAHR

ESCL.PSW USER

EPSU

PASSWD USER

PSWU

Esc

1

4

7

-

.

0.0

0

OK

0.0

240

2 3

0

0

5 6

1234

8 9

0 C

-3

˚C

Hg

˚C

m

D

D

*

4. Use the keypad to enter

the new value. The range of

values that can be set are

between -20…0…+20. Once

value is set press OK. Press the

folder / left facing arrow icon

to save and exit the variables

page.

Climatic recipes

pH calibr.

HACCP-Perf

Variable

2. Select Variables

Climatic recipes

pH calibr.

HACCP-Perf

Variable

5. Press the start icon to get

back to your recipe. Continue to take readings with the

two probes (Certied probe

and built-in Maturmeat®

probe) until both probes read

the same.

Var. Meaning

CORR. SONDA AMB.

CSA

CORR. SONDA U.

CSU

CORR. SONDA C.D

CSC

F.ZA MEM.HACCP

HACF

FAHRENHEIT

FAHR

ESCL.PSW USER

EPSU

PASSWD USER

PSWU

0.0

0

0.0

240

0

0

1234

˚C

Hg

˚C

m

D

D

*

3. On the variables page you

will nd 3 editable items:

i. CSA - Ambient temp probe

ii. CSU - Humidity probe

iii. CSC - Condenser probe

Highlight the variable and

press the pencil icon to

activate the keypad to select

the corrected value.

NOTE

Comparison readings should

be taken with the fan running

and with the fan on pause.

Take readings over a period

of 5-10min.

NOTE

Rev 2, 18.06.19

If you do not have a certied

or professionally calibrated

probe, please consult with a

professional for assistance.

19

Page 20

3.2

CHANGING HACCP RECORDING FREQUENCY

Your Maturmeat® can be modied in the to adjust to your needs. The HACCP recording

frequeny can be modied to allow you to validate your production.

Customer Dealer Producer

1. From the Home page,

Select Customer to proceed.

Var. Meaning

CORR. SONDA AMB.

CSA

CORR. SONDA U.

CSU

CORR. SONDA C.D

CSC

F.ZA MEM.HACCP

HACF

FAHRENHEIT

FAHR

ESCL.PSW USER

EPSU

PASSWD USER

PSWU

Esc

1

4

7

-

.

120

0.0

0

OK

0.0

240

2 3

0

0

5 6

1234

8 9

0 C

˚C

Hg

˚C

m

D

D

*

Climatic recipes

pH calibr.

2. Select Variables

Climatic recipes

pH calibr.

HACCP-Perf

Variable

HACCP-Perf

Variable

Var. Meaning

CORR. SONDA AMB.

CSA

CSU

CORR. SONDA U.

CSC

CORR. SONDA C.D

HACF

F.ZA MEM.HACCP

FAHRENHEIT

FAHR

ESCL.PSW USER

EPSU

PASSWD USER

PSWU

0.0

0

0.0

240

0

0

1234

˚C

Hg

˚C

m

D

D

*

3. On the variables page you

must look for HACF. Highlight

the variable and press the

pencil icon to activate the

keypad.

4. Use the keypad to enter

the new value. The range

5. Press the start icon to get

back to your recipe.

of values that can be set

are between 1……240 minutes (m). Once value is set

press OK. Press the folder/left

facing arrow icon to save

and exit the variables page.

3.3

CHANGING FROM CELCIUS TO FARENHEIT

Your Maturmeat® can be modied in the to adjust to your needs. You can simply and quickly

change from celcius to farenheit, by following the steps below.

Customer Dealer Producer

Climatic recipes

pH calibr.

HACCP-Perf

Variable

Var. Meaning

CORR. SONDA AMB.

CSA

CSU

CORR. SONDA U.

CSC

CORR. SONDA C.D

HACF

F.ZA MEM.HACCP

FAHRENHEIT

FAHR

ESCL.PSW USER

EPSU

PASSWD USER

PSWU

0.0

0

0.0

240

0

0

1234

˚C

Hg

˚C

m

D

D

*

1. From the Home page,

Select Customer to proceed.

20

2. Select Variables

Rev 2, 18.06.19

3. On the variables page you

must look for FAHR. Highlight

the variable and press the

pencil icon to activate the

check box.

Page 21

Var. Meaning

FAHR

CORR. SONDA AMB.

CSA

CORR. SONDA U.

CSU

CORR. SONDA C.D

CSC

F.ZA MEM.HACCP

HACF

FAHRENHEIT

FAHR

ESCL.PSW USER

EPSU

PASSWD USER

PSWU

CHANGING FROM CELCIUS TO FARENHEIT

0.0

0

0.0

240

1

0

1234

˚C

Hg

˚C

m

D

D

*

Climatic recipes

pH calibr.

HACCP-Perf

Variable

continued

4. By pressing on the empty

box you will place a check

5. Press the start icon to get

back to your recipe.

mark inside, locking in

Farenheit as the new unit of

measurement. Press the folder/left facing arrow icon to

save and exit the variables

page.

3.4

SETTING THE SCREEN LOCK

Whether your Maturmeat® is placed in an area where the public can touch it, or it may be you

don’t want any other staff member/s to be able to manipulate your Sicur Food Control® controller, you can protect your product and settings by setting a passcode protected screen lock.

Customer Dealer Producer

Climatic recipes

pH calibr.

HACCP-Perf

Variable

Var. Meaning

CORR. SONDA AMB.

CSA

CSU

CORR. SONDA U.

CSC

CORR. SONDA C.D

HACF

F.ZA MEM.HACCP

FAHRENHEIT

FAHR

ESCL.PSW USER

EPSU

PASSWD USER

PSWU

0.0

0

0.0

240

0

0

1234

˚C

Hg

˚C

m

D

D

*

1. From the Home page,

Select Customer to proceed.

Var. Meaning

EPSU

CSA

CSU

CSC

HACF

FAHR

EPSU

PSWU

CORR. SONDA AMB.

CORR. SONDA U.

CORR. SONDA C.D

F.ZA MEM.HACCP

FAHRENHEIT

ESCL.PSW USER

PASSWD USER

0.0

0

0.0

240

0

1

1234

˚C

Hg

˚C

m

D

D

*

4. By pressing on the empty

box you will place a check

mark inside, activating the

screen lock. Press the folder/

left facing arrow icon to save

and exit the variables page.

2. Select Variables

Climatic recipes

pH calibr.

HACCP-Perf

Variable

5. Press the start icon to get

back to your recipe.

3. On the variables page you

must look for EPSU. Highlight

the variable and press the

pencil icon to activate the

check box.

NOTE

The lock will reactive every 5

min after the last touch of the

screen.

NOTE

To set a custom passcode,

follow the same steps

highlighting PSWU instead.

The default passcode is 1234.

Rev 2, 18.06.19

21

Page 22

3.5

CALIBRATING pH PROBE

Your Maturmeat® has an optional pH probe that can be purchased. The probe is checked

thoroughly before your Maturmeat® leaves the factory. A calibration system has been

programmed into Sicur Food Control® allowing you the possibility to calibrate your pH probe

anytime. Follow the steps below to successfully calibrate your probe, alternatively, use the link

to see the video online https://www.youtube.com/watch?v=AkLgjoDq-G0

Here is what you will

need to calibrate the

pH probe

1. pH probe

2. Buffer solution 4.01

3. Buffer solution 7.01

4. Water (small amount)

5. Container x 3 (ie.cups)

6. Paper towel/Napkins

7. Marker to label cups

Because all of

the uids look

alike it is best to

pH 4 pH 7

label the cups to

avoid confusion

later on. Use the

marker and write

pH 4 or just 4 on

the 1st cup.

Buer

Solution

pH 4.01

On the 2nd cup,

use the marker

and write pH 7 or

just 7.

pH 4 pH 7 water

Buer

Solution

pH 7.01

On the 3rd cup,

use the marker

and write water or

just W. The water

will act as a rinse

between solutions.

water

NOTE

Rinse probe with water

between each recording of

buffer solutions. Use paper

towel/napkins with extreme

care when drying probe,

as probe’s surface can

easily scratch and become

damaged producing false

readings.

22

Customer Dealer Producer

1. From the Home page,

Select Customer to proceed.

Rev 2, 18.06.19

Climatic recipes

pH calibr.

2. Select pH calibr.

HACCP-Perf

Variable

Page 23

CALIBRATING pH PROBE continued

1338

PH4 PH7

- - - -

pH 4

3. With the pH 4 eld highlighted in yellow,

Place the pH probe into the cup with the

4.01 solution, be sure to hold the probe so

that it does not touch the bottom/sides of

the cup. The correct pH 4 value will sit in

the 1300 -1500 range. Once the value has

stabilized press the pH 4 button to save and

continue.

1338

2031

pH 7

Water

4. After recording in pH solution

it is necessary to rinse the probe

in water and gently dry with a

napkin to reduce the chance of

introducing pH 4.01 solution or

water into the pH 7.01 solution.

Water

PH4 PH7

5. With the pH 7 eld highlighted in yellow,

Place the pH probe into the cup with the

7.01 solution, be sure to hold the probe so

that it does not touch the bottom/sides of

the cup. The correct pH 7 value will sit in

the 1900 -2300 range. Once the value has

stabilized press the pH 7 button to save.

1338

PH4 PH7

2031

7. With both values saved, press the check

mark icon to save and exit.

6. After recording in pH 7 solution,

rinse the pH probe in water one

last time before placing it back

into it’s protective housing. Rinse

out and partially ll pH probe’s

protective housing with fresh 4.01

buffer solution.

NOTE

Calibration of the optional pH

probe is highly recommended

each time a new production lot

is started to ensure accuracy.

If the probe has been sitting in

its protective housing unused

for 3 weeks or longer, it is highly

recommended to calibrate the

pH probe.

Rev 2, 18.06.19

23

Page 24

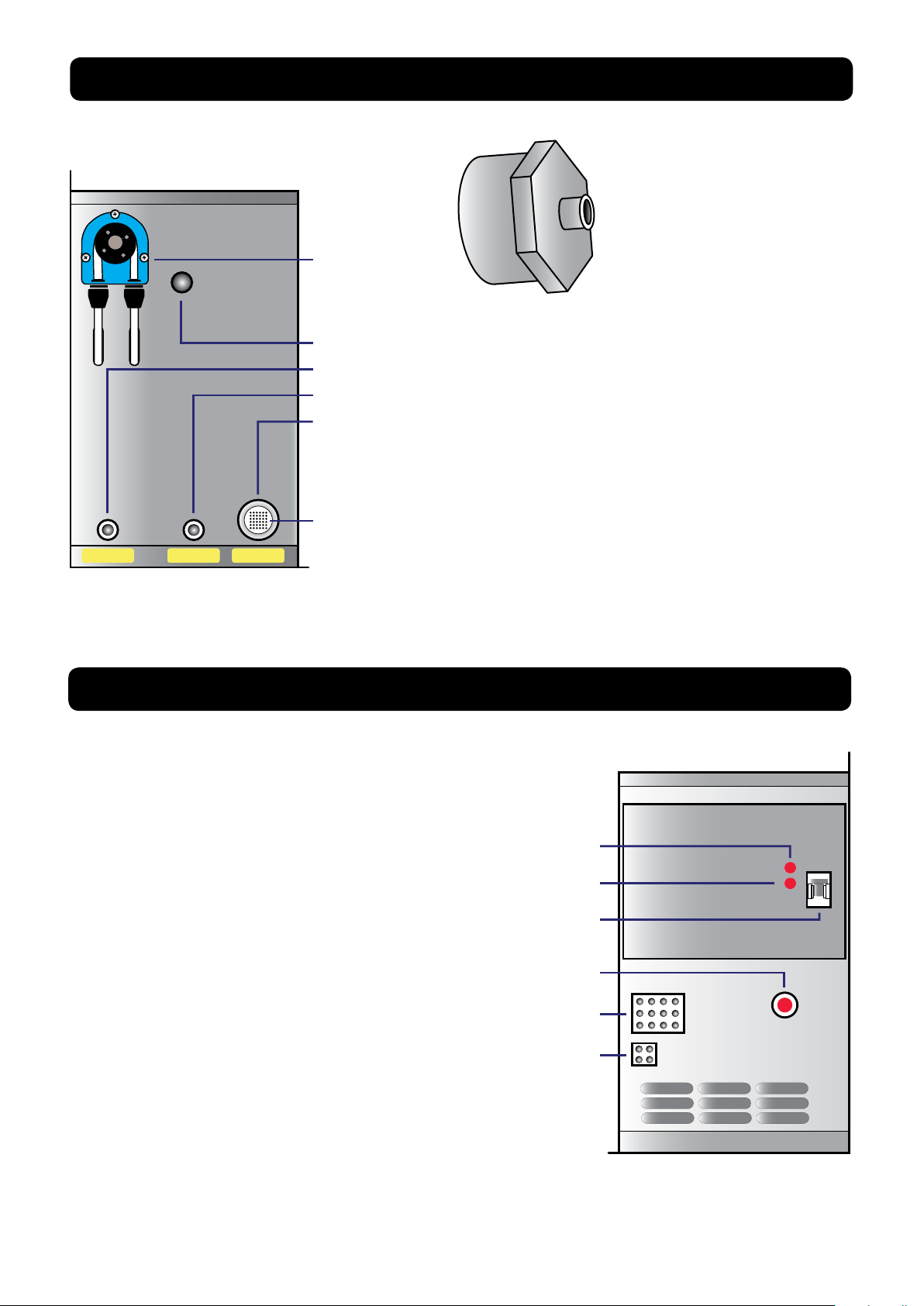

3.6

The Fumotic® is our patented system that enables you to introduce humidity when necessary.

The water is drawn out of a tank situated on top of your Maturmeat® and fed directly into the

Fumotic®. The tank needs to be lled periodically, and should be checked daily, specically

before the end of the business day, or at any time when you will be away from the Maturmeat®

for an extended period of time. Doing this will help avoid triggering H20/Flavour level alarms.

The aroma tank works on the same principal but uses a avoring liquid instead of water to

introduce into your recipe, this can be added manually during a default climatic recipe or

preprogrammed into a custom made recipe.

DANGER

System Damage

Use zero solid residue liquids only, do

not use corrosive or explosive liquids;

do not use liquids that increase in

volume when heated. Failure to do

so can cause damage to the unit

and /or the user.

FUMOTIC® DESCRIPTION AND SUPPLY TANKS

Water Filter

Water Line

Level Arm with

electric sensor

Connection to

PLC

Liquid Level Sensor:

Introduced in late 2013 is the

electronic leveling system, this innovation allows for simpler connection

to the Fumotic® and a higher degree

of accuracy when reading water

levels.

3.7

°fH

ppm, mg/L

This chart shows

the maxium duration of the lter’s

life based on the

Hardness of water

passing through

it.

9

18

27

36

45

0.9

1.8

2.7

3.6

4.5

WATER FILTER

dGH, °dH

16.07

32.13

48.20

64.26

80.33

gpg

15.41

30.82

46.22

61.63

77.04

°e, °Clark

12.83

25.65

38.48

51.30

64.13

Fumotic®

November 2013 - Present

Max.Duration

220L

110L

80L

60L

50L

Water Filter:

The contents of the lter and bacteriostatic housing itself meets the most stringent quality standards certied by the

FOOD AND DRUG ADMINISTRATION ( title 21, section 173.25, paragraph A, sub-paragraph 1). The lter’s nylon

fabric with a ltration level of 150 microns complies with directive EEC 128/1990 and certied to FDA standards

(title 21, paragraph 177). The homopolymer polypropylene structure is also FDA certied.

NOTE

The water used in conjuction with the Fumotic® should have a low mineral content to prevent

calcium build up inside the Fumotic®. Calcium buildup inside the Fumotic® can create many

problems, please contact a local Maturmeat® service point for assistance.

24

Rev 2, 18.06.19

Page 25

Vapor out

Drain out Aroma in Water in

3.8

FUMOTIC® REAR VEIW

Reducer:

This adapter is connected on

your Fumotic® to allow for the

waterline from the Water tank

Aroma Pump

Vapor out: connects inside the unit to add humidity or aroma/avor

Drain out: expels any overow from Fumotic®

Aroma In: connects directly to aroma/avor tank

Water In: connects directly to water tank, dual purpose connection

can be connected to direct waterline

Screen: prevents large particles from entering the fumotic, this is not

a substitute for a lter.

to be connected.

Direct Connect:

The waterline connected to the Fumotic® is dual purpose. From the factory, the

water tank is connected, but this can be removed and connected directly to a

dedicated waterline. See page 23 for instructions.

3.9

FUMOTIC® FRONT VEIW

Level probe sensitivity adjustment: This should not be touched

Level probe inverter: This should not be touched

Breaker switch: A safety measure to prevent overloading of the

circuit, can also be used to manually shut off the Fumotic®

Vapor discharge: manual discharge of vapor

12 Point connection: (12 pin twin model, 9 pin all other models)

4 point connection: Connector for tank level system

25

Rev 2, 18.06.19

Page 26

3.10

HOW TO CONNECT DIRECT WATERLINE TO FUMOTIC®

It is very imorprtant to note that there must be no more then 2.5 bar (35 psi) of pressure at any

time in the water line bieng connected to the Fumotic®

1. Push on ring around water

tube and pull hose.

WA

T

E

R

Connection

Point

4. From water tank, follow

level sensor wire until you

reach the wiring duct. Open

wiring duct and locate connection point.

2. Unscrew and remove

reducer.

5. Disconnect line and insert

the closed loop.

3. Connect using a standard

water hose connection

3/4”, do not over tighten

DANGER

Electrical Shock Hazard

Unplug/Disconnect power

before touching wiring of

any kind. Failure to do so

can result electric shock or

death.

6. Place wiring neatly back

in wiring duct

7. Turn on water supply, and

check for leaks.

8. Turn power back on to

unit.

3.11

SCALE FORMATION INSIDE FUMOTIC®

Scale build up is caused by the high mineral content in your water also know as “Hard

water”. Scale build up inside the Fumotic

®

will reduce performance and cause severe

damage. Should scale build up inside your Fumotic® contact your local Maturmeat® service

point for assistance, the process to remove scale from the system requires removal of the

Fumotic® and the use of solutions to dissolve the scale and uids to clean and purify the system

rendering it safe for use with food. Be advised that the manufacturers warranty is voided when

scale/calcium is found anywhere in the humidication system from the tanks leading into the

Fumotic® to inside of the Maturmeat® itself.

26

Rev 2, 18.06.19

Page 27

3.12

CLEANING MATURMEAT®

Cleaning Maintenance:

Cleaning your Maturmeat® should be done as often as needed or part of your HACCP program.

AISI 304 stainless steel has a layer of oxide preventing rust. Using abrasive and/or corrosive deter-

gents can deteriorate this layer. Follow the steps below for an efcent and thorough cleaning.

Before beginning, be sure to remove all food product and Maturmeat® accessories, such as

guides, grills/shelves, and hanging rods. Using a mild detergent, spray all internal surfaces including vent holes, corners, steam output valve, door/s and glass panel/s. Never spray Humidity

probe directly.

Current Recipe

AGED BEEF

TOTAL TIME

999 Hrs

TEMPERATURE

1.3˚C

SET

POINT

12:35 24/03/2018

1.0˚C

REMAING TIME

999 Hrs

SET

POINT

MATURING

TOTAL TIME

999

PHASE 1 OF 1

REMAING TIME

999

HUMIDITY

75%

81%

5.6

SET

POINT

PH

5.8

From the recipe screen, press the C.I.P.

Icon and conrm, this will start a 2 stage,

2 hour cleaning in place recipe that will

use Maturmeat® highest temperature,

and humidity settings to clean and nish off with a low humidity environment

designed to dry all internal surfaces.

Using paper towel, wipe down

all internal sufaces that may

have residual moisture. Thoroughly drying your Maturmeat®

will ensure its proper functionality and hygenic state.

Rev 2, 18.06.19

27

Page 28

CLEANING MATURMEAT® continued

Condensing Unit:

All condensing units require regular maintenance. The purpose of the condenser

is to release absorbed heat; If the condenser coils are clogged with dirt or the

ns are bent it restricts or block air ow

through the coils and interferes with the

heat exchange. This causes the system to

work harder and shortens the life of your

compressor. Please check your condensing unit regularly. Please unplug the unit’s

power or shut down power to the unit if

connected directly to an electrical panel

before attempting to clean. You can use

compressed air to clear away and loose

dirt or dust that may impair normal use.

NOTE

A general preventative maintenance schedule must be established to protect your Maturmeat®. A copy of the general preventative maintenance schedule (MOD_001 ENG) can be found

inside the unit along with this user manual. Based on tests performed at a factory level, It is highly

recommend that this maintenance occur at regular intervals once every 3 months, annually.

DANGER

Shock Hazzard

Before attempting to clean any part the unit, unplug the unit’s power or shut down power to

the unit if connected directly to an electrical panel, failure to do so can result in serious injury or

death.

3.13

EMPTYING THE DRAIN TRAY

DANGER

Slip Hazzard

Overow from the drain tray as a result

of neglecting to empty it can result in

serious injury or death.

Your Maturmeat® has a tray, which collects excess water moisture. The tray

should be emptied daily to avoid overowing onto your oor creating the possibility of unsafe or unsanitary conditions

in your workplace.

28

Rev 2, 18.06.19

Page 29

3.14

TEMPERATURE MAINTENANCE

You can cross referance the follow variable codes with the list found on pages 36 - 41

Heating and cooling is managed in the neutral zone on the basis of the temperature set point

and the temperature differentials (parameters DTNC and DTNF). Cooling is activated when

the set point +(DTF value) is exceeded and remains enabled until the set point is reached

(with DTNF = 0). Heating is activated when the temperature goes below the set point -(DTNC

value) and remains enabled until the set point is reached (with DTNC = 0). It is possible to

set a “dead zone” with the parameters (DTNC) and (DTNF) which de-activates heating and

cooling when the temperature is between the set point -(DTNC) and the set point +(DTNF).

ºC

(SetºC)+DTF

Cold On

(SetºC)+DTNF

(SetºC)

(SetºC)+DTNC

(SetºC)+DTC

Dehumidication

Activated

Humidication

Activated

The parameter (TSF) creates a delay between the cooling system’s switch off and it’s

subsequent re-activation. Heating can be deactivated with the parameter CA (CA = 0

disables the heating relay under all conditions).

Cold Off

Neutral Zone

Heat Off

Heat On

Time(s)

1

0

Time(s)

1

0

Time(s)

Rev 2, 18.06.19

29

Page 30

3.15

HUMIDITY MAINTENANCE

You can cross reference the follow variable codes with the list found on pages 36 - 41

Humidication and dehumidication is managed in the neutral zone on the basis of the humidity set point and the humidity differentials (parameters DUU and DUD). Dehumidication

is activated when the set point +(DUD value) is exceeded and remains enabled until the set

point is reached (with DUNS = 0). Humidication is activated when the humidity value falls

below the set point -(DUU value) and remains enabled until the set point is reached (with

DUNI = 0). It is possible to set a “dead zone” with parameters (DUNS) and (DUNI) which deactivates humidication and dehumidication when the humidity is between the set point

-(DUNI) and the set point +(DUNS). Humidication and dehumidication management can

be excluded with the variables (U) and (DE). With the (HR) variable you can decide whether

to show the humidity value on the display or not.

There are three dehumidication modes found in parameter (DEU):

0. Dehumidify with cooling (cooling is activated to dehumidify, heating is activated only to

maintain the ambient temperature;

1. Dehumidify with heating (heating is activated to dehumidify, cooling is activated only to

maintain the ambient temperature;

2. Separate dehumidication (the dehumidication system is activated without the use of

heating and cooling, they will only be activated in the event of thermoregulation).

It is possible to set a limit on the dehumidication phase with parameter (LDE) by agging an

alarm.

It is possible to set a limit on the humidication phase with parameter (LUM) by agging an

alarm.

(Set RH%)+DUD

(Set RH%)+DUNS

(Set RH%)

(Set RH%)+DUNI

(Set RH%)+DUU

Dehumidication

Activated

Humidication

Activated

RH%

Dehumidication On

Dehumidication Off

Neutral Zone

Humidication Off

Humidication On

Time(s)

1

0

Time(s)

1

0

Time(s)

30

Rev 2, 18.06.19

Page 31

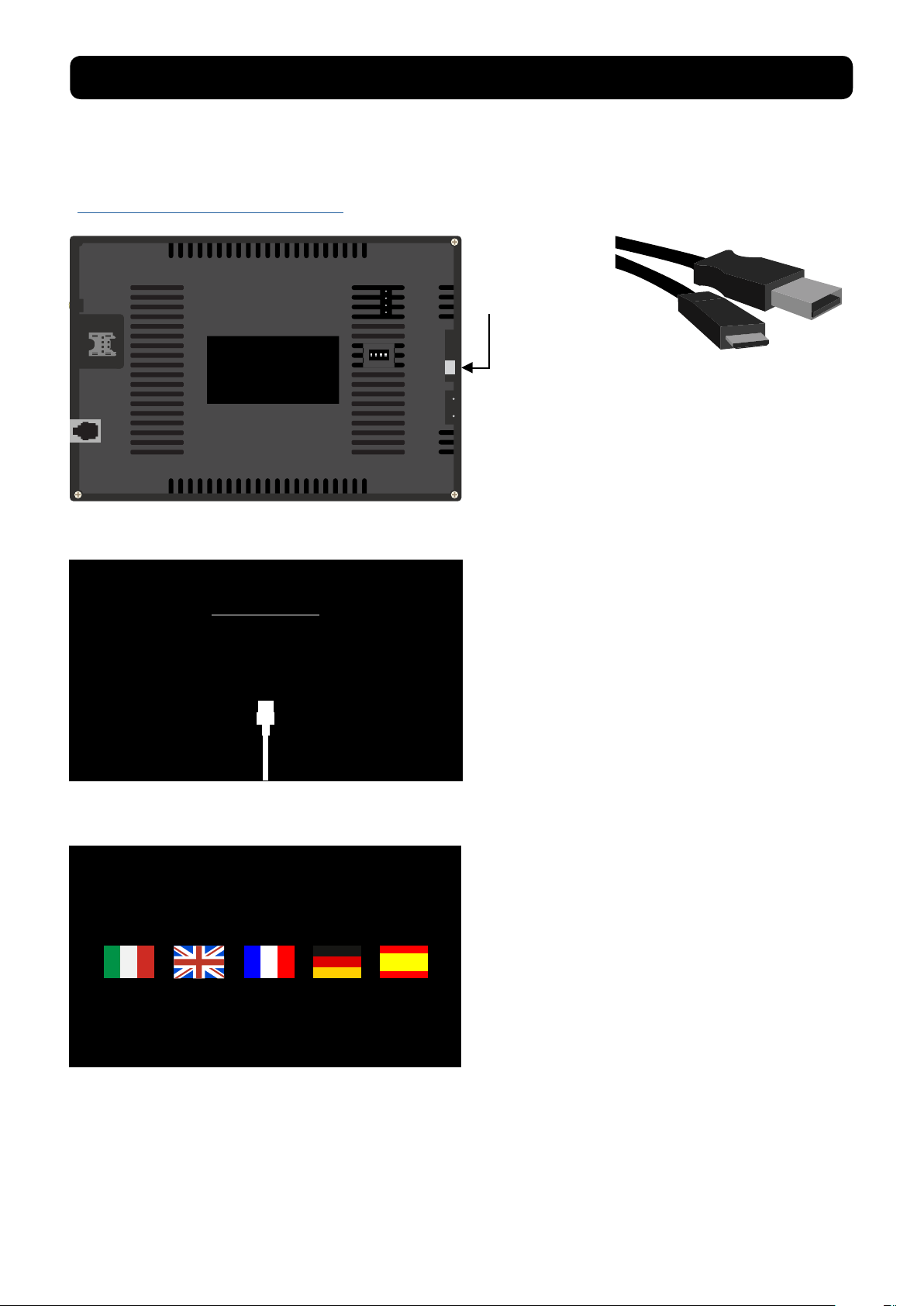

3.16

USB Drive Mode

Once finished, turn off power and disconnect the USB cable

®

FIRMWARE UPDATE Sicur Food Control®

Please follow these directions closely, failure to do can result in complete failure of the

device your trying to update, be sure to connect and disconnect cables when power is OFF, or unless otherwise directed. Alternatively, u s e t h e l i n k t o s e e t h e v i d e o o n l i n e

https://youtu.be/3aRbbZq-MOw

USB

Micro USB port

Micro USB

With your Maturmeat® powered down, connect your micro USB cable to the port on the

back side of the controller, and the USB to

your computer.

Welcome

24/03/2018 12:35

Once the 2 devices have been connected.

power up your Maturmeat®. Your controller

will now display the communication mode

screen, and a new window will open on your

computer. Copy/Cut the rmware le from

its current location and paste into newly

opened window. A small uploading window

will apear and will take several seconds

(depending on computer) to begin. Once

completed, power down your Maturmeat

and disconnect the micro USB cable from

the controller.

After powering back up, navigate to the

welcome screen. on the bottom lefthand

corner you will nd the updated rmware

version.

Serial

10002156, FW.1.15, PLC-A1.37, PLC-B1.37

Patent #1395586 - Climatouch

31

Rev 2, 18.06.19

Page 32

3.17

FIRMWARE UPDATE PLC’S

Please follow these directions closely, failure to do can result in complete failure of the device

your trying to update, be sure to connect and disconnect cables when power is OFF, or unless

otherwise directed.

Pins to connect bridge for communication mode

PLC A PLC B

Reset

Button

TTL connect

Step 1.

• With a computer connected to the internet, connect

the TTL Cable to install drivers.

• Open Flashloader.exe program or download form internet and install on your computer.

Reset

Button

Step 2.

• Before continuing stop any

running program on Maturmeat® and power down.

• With NO power to Maturmeat® connect the TTL cable to

the PLC.

TTL USB

Bridge

Step 3.

• Place the bridge on the 2

pins on the PLC to enable

communication made.

• After all connections

a r e m a d e p o w e r u p

Maturmeat®.

Step 4.

• Start Flashloader and begin

to congure the connection.

• Page 1 Select Com Port

Baud Rate: 115.200

Time Out (S): 5

Parity: Even

Echo: Disabled

32

Target is readable. Please click “Next” to proceed

Remove protection

Step 5.

• Page 2 The PLC will be

read quickly if successful the

Target Readable message will

appear in the window, if not

press the reset button on the

PLC just above the jumper.

Rev 2, 18.06.19

Please, select your device in the target list

Target

STM32_Connectivity-line_64K

STM32_Connectivity-line_128K