Page 1

Juice Extractor

Model J-110

Instruction Manual

3115 Pepper Mill Court, Mississauga, ON, L5L 4X5

4450 Witmer Industrial Estates, Unit 4, Niagara Falls, NY, 14305

Version 1.1

1-800-465-0234

www.omcan.com

Page 2

Table of Contents

Model J-110

Section

General Instructions

Assembly and Disassembly

Operation

Maintenance

Troubleshooting

Warranty

----------------------------------------------------------------------------------------- 6 - 8

----------------------------------------------------------------------------------- 8 - 10

--------------------------------------------------------------------------------------------- 12

--------------------------------------------------------------------------- 3 - 5

----------------------------------------------------------------------------- 10 - 11

Page

----------------------------------------------------------------- 5 - 6

Parts Breakdowns

Electrical Schematics

Warranty Registration

-------------------------------------------------------------------------- 13 - 14

---------------------------------------------------------------------------- 15

---------------------------------------------------------------------------- 17

Page 3

General Instructions

Omcan Manufacturing And Distributing Company Inc. and Food Machinery Of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

ATTENTION: Thank you for purchasing this product from Omcan Inc. With the proper care and maintenance,

this product will provide you with a long service life. Please be advised that the J-110 Juicer has been designed

as a production juicer; meaning that it is not suitable for single glass portions. It is designed to produce 3 to

4 quarts of juice at a time. The centrifugal ejection of the pulp requires some mass (weight), in order to be

expelled from the basket. It is normal not to see pulp being expelled at the beginning of the juicing process.

Continue to feed the juicer with product and when enough mass has been collected in the basket, the

centrifugal force of the spinning basket will expel the pulp. Failure to properly clean the basket after every

production will cause the left over pulp to harden onto the screen and juice production will be compromised.

NOTICE: All users of this juicer must understand the IMPORTANT SAFEGUARDS section and the contents of

this manual. This manual needs to be located in an accessible location for all users.

Thank you for purchasing the Omcan Juice Extractor. This juicer has been engineered to extract juice from

fruits and vegetables. Crafted with from quality materials, the high rotation cutting blades and centrifugal

system provide optimal juice extraction. The J-110 Juicer has been designed as a production juicer; meaning

that it is not suitable for single glass portions. It is designed to produce 3 to 4 quarts of juice at a time. With the

proper care and maintenance, this product will provide you with a long service life.

Inspect your Juicer for shipping damages.

When you receive your juicer, please inspect the shipping carton for damage. Open the carton from the top

and check for any visible damage to the machine that may have occurred during transport. If any visual or

concealed damage is noted, le a claim immediately with the delivering carrier. Claims must be led within

3 days of receipt. Failure to promptly le a claim may cause you a loss. Omcan cannot be responsible for

products damaged in shipping if the customer has failed to initiate a claim with the shipping company.

Check Contents

Ensure that the following items are present. If anything is missing, contact Omcan Inc. immediately at

1-800-465-0234.

1. User’s Manual.

2. Machine.

3. Wrench.

4. Food Pusher.

5. Pulp Pipe.

3

Page 4

General Instructions

Please clean before use

Before using your juicer, please follow the disassembly and cleaning instructions in this manual. Please wash

the cover thoroughly in hot, soapy water and sponge off the rest of the juicer to remove any dust or particles

that may have settled during manufacturing or shipping.

TRAINING USERS

1. It is the owner’s responsibility to ensure that all operators of this machine understand the IMPORTANT

SAFEGUARDS section and the contents of this manual. Please contact us if you have any questions.

2. Before removing the top of the machine, always turn the switch OFF, and UNPLUG the machine.

3. The machine should be located at a height that is ergonomic for the users.

4. The ON/OFF power switch is to be located in direct view of the users.

5. The electrical outlet for this machine must always be accessible so that the users can easily UNPLUG the

machine for cleaning, moving, and/or servicing.

6. NEVER leave the wrench on the blade nut unattended, nor attempt to operate the machine with the wrench

in place on the blade nut.

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should always be followed including the following:

• READ ALL INSTRUCTIONS.

• Close supervision is necessary when any appliance is used by or near children.

• Avoid contacting moving parts.

• The use of attachments not recommended or sold by the manufacturer may cause re, electric shock or

injury. Do not use outdoors.

• NEVER Remove, Destroy, or Alter any of the Product Warnings or Guards. Do not operate the machine if

the switch guard is not in place protecting the power switch.

• Always turn OFF and UNPLUG your juicer before disassembly. Make sure the motor and cutter plate has

completely stopped moving before assembling, disassembling or cleaning your juicer.

• The motor and electrical parts of the machine are not waterproof. To protect against risk of electrical

shock, do not put the motor base into water or other liquids. Water contact will seriously damage the motor,

bearings and electrical system.

• Be sure to turn switch to OFF position after each use of your juicer. Make sure the motor stops completely

before disassembling.

• Use a dedicated 20 AMP circuit. If your outlet has no ground provision, replace the socket portion of the

outlet to provide a safety ground.

• NEVER alter or disable the interlock switch.

• NEVER attempt to remove the blade nut with the power cord plugged in. NEVER leave the wrench on the

blade nut unattended. NEVER attempt to switch ON the machine with the wrench placed on the blade nut.

• Use the power cord carefully. Do not let the power cord hand over the edge of a counter or table.

• NEVER operate any machine with a damaged cord. Do not alter the power cord by clipping off the ground

lead.

4

Page 5

General Instructions

• Always make sure juicer cover is latched securely in place before motor is turned on. Do not unfasten the

latches while the juicer is in operation, or when the cutter plate is turning.

• NEVER use a damaged machine.

• Do not continue operation if your juicer malfunctions or is dropped or damaged in any manner. Call Omcan

Inc. at 1-800-465-0234 for assistance.

• NEVER return your juicer without authorization from a Omcan representative.

• Do not put your ngers or other objects into the juicer opening while it is in operation.

• If food becomes lodged in the opening, use the good pusher or another piece of fruit or vegetable to push

it down. When this method is not possible, turn the machine OFF, UNPLUG, and disassemble the juicer.

Remove remaining produce and clean the cutter plate and lter.

• SAVE THESE INSTRUCTIONS.

Assembly and Disassembly

ASSEMBLING YOUR OMCAN COMMERCIAL JUICE EXTRACTOR

1. Prepare / use a certied sanitation solution that is food grade compliant. Always follow the directions on the

container.

2. Install the juice pan by placing the spout through an opening in the tower. Point the spout in the direction

you wish your juice to be served. Do not touch the inside of the juice pan.

3. Install the lter and cutter plate. Place the cutter plate inside the lter. Align the center hole over the center

hub, and lower the parts into the juice pan. Make sure both parts are seated properly on the hub.

4. Make sure the motor shaft is dry, and hand tighten the blade nut on the motor shaft. Hold the screen

lter and use the wrench to tighten the blade nut an additional ¼ turn clockwise, securing the blade/lter

assembly. Do not store the blade nut on a wet motor shaft over night.

5. Store the wrench. Clean the wrench and return it to its storage place near the juicer. This wrench is

specially designed to be used with your Omcan.

6. Wrap a dry dish towel around the base to cover the power switch and power cord. Set a waste container

under the juice pan spout. Spray approximately 1 pint of the sanitizing solution around the perimeter of the

lter screen, inside the lter screen, and onto the cutter plate and blade nut. Once done, remove the dish

towel and thoroughly dry the base.

7. Replace the top. Hold the top over the lter and align the latch strikes with the latches on the tower of the

juicer. Carefully lower the top onto the juicer body until it is resting on the tower.

8. Lock the latches. Hook the inner latch attached to the tower over the latch strike on the top. Assure proper

alignment of the latch to latch strike. Lift both the outer latch arms together until the latches lock in place.

Ensure even tension on both latches. You should hear an audible SNAP sound when properly adjusted.

9. Insert the pulp pipe into the pulp spout of the lid. The pulp pipe is held in by a thumb screw. Use your hand

to adjust the screw, it should be adjusted so that the pipe can stay in rmly in place.

10. With receptacles under the juice spout and pulp pipe, spray 1 quart of sanitizing solution down the feed

chute while the juicer is running. Follow by rinsing the sanitizing solution from the juicer by spraying one

quart tap or distilled water into the feed chute while the motor is running. Allow the juice pan to drain.

Dispose of the waste solution.

5

Page 6

Assembly and Disassembly

11. Clean the pusher with sanitizing solution and rinse thoroughly. The juicer is now ready for operation.

12. Test before use. Before use, check to make sure all parts are in proper alignment. Plug your juicer into a

grounded electrical outlet and test before use.

DO NOT PLUG MACHINE INTO AN ELECTRICAL OUTLET UNTIL ASSEMBLY IS COMPLETE. Wear vinyl

gloves (as used in food handling) during operation.

DISASSEMBLING YOUR OMCAN COMMERCIAL JUICER EXTRACTOR

1. TURN OFF AND UNPLUG JUICER. Make sure the motor and cutter plate have completely stopped before

disassembling. Disconnect the pulp ejection pipe and remove the food pusher.

2. UNLATCH AND REMOVE TOP. Release the top latches by pulling them away from the machine. Make

sure to release both latches at the same time to maintain equal tension. Carefully lift the top straight up. Be

sure it does not touch the screen lter. Place the top upside-down on a at, stable counter top.

3. STABILIZE THE FILTER. Place your left arm across the top of the lter, and grip the far side of the lter rim

with your ngers. Hold the lter steady by applying equal pressure with your forearm and hand.

4. UNSCREW AND REMOVE THE BLADE NUT. With your right hand, place the head of the wrench on the

blade nut. Turn the blade nut counter-clockwise while holding the lter steady with your left arm. To remove

the blade nut, use only the special wrench provided with your unit. Always wash the wrench between uses.

NEVER leave the wrench on the blade nut unattended.

5. REMOVE JUICING PARTS. With both hands, carefully lift the lter and cutter plate from the juice pan.

Carefully insert your index nger into the center hole of the cutter plate, and lift it out of the lter. The cutter

plate blades are sharp, so handle carefully. EXTRA CARE MUST BE TAKEN SO THE FILTER IS NOT

DAMAGED WHEN DISASSEMBLING OR REASSEMBLING THE MACHINE.

6. REMOVE THE JUICE PAN. With both hands, lift the juice pan out of the tower and set it upside-down on a

at, stable counter top.

Operation

1. Ensure the machine is fully assembled.

2. Plug it in.

3. Place the juicing container below the juice pan spout.

4. Make sure there is a receptacle for pulp waste under pulp pipe.

5. Turn ON the machine.

6. Insert prepared produce in the feed pipe.

7. Use the Food Pusher to guide produce through the feed pipe. Do not force. While juicing, make sure pulp

is being ejected through the pulp pipe.

Note: (Please be advised that the J-110 Juicer has been designed as a production juicer; meaning that it is

not suitable for single glass portions. It is designed to produce 3 to 4 quarts of juice at a time. The centrifugal

ejection of the pulp requires some mass (weight), in order to be expelled from the lter. It is normal not to see

pulp being expelled at the beginning of the juicing process. Continue to feed the juicer with product and when

6

Page 7

Operation

enough mass has been collected in the lter, the centrifugal force of the spinning lter will expel the pulp.)

8. Turn OFF the machine when not in use. (If the juicer runs continuously for 30 minutes (not typical) turn the

machine OFF and allow 15 minutes for the motor to cool-down.)

9. If not in use for more than 30 minutes, UNPLUG, disassemble and rinse the lter under hot water to

remove any pulp residue.

HOW IT WORKS

The juicer works by centrifugal force. The motor turns the lter and cutter plate at 3,450 rpm. This causes

air to be drawn through the holes in the top and bottom of the machine, forcing air out of the pulp ejection

pipe. When the produce is pushed through the hopper, the cutter plate works with the mating plate to cut the

produce. The rotation forces the pulp onto the lter screen; then the airow and rotation passes the pulp across

the screen. While the pulp is moving across the screen, the juice is being forced through the holes of the lter

into the juice pan and out of the spout. At the same time, the waste pulp is blown out of the pulp ejection pipe.

The lter and cutter plate are the critical components in the operation and efciency of your machine.

Therefore, great care must be taken in the handling and cleaning of these parts. A dented or badly stained lter

will cause a drop in efciency of the machine, and if problems aren’t corrected promptly, more damage could

occur.

YIELD

Juice yield is governed by a number of things:

1. Freshness of produce.

2. Produce in or out of season.

3. Organic vs. non-organic produce.

If you start noticing drops in yield or performance of the machine, ask yourself the following questions:

1. Have I changed my produce supplier?

2. Is the produce in or out of season?

3. Is produce as fresh as usual?

TIPS ON JUICING

The safe handling, cleaning, and processing of fruit/vegetable, and the proper cleaning and sanitizing of

equipment are essential to help reduce the risk of food borne illness. Consult your local health department to

determine the adequate methods of cleaning and storing the produce prior to juicing, and storing your juices

after juicing. Following are some recommendations to reduce risk.

1. You need to wash all fruit/vegetables in clean fresh water. You may wish to dip fruits and vegetables in a

chlorine bleach solution for 3-5 minutes and then rinse them off. Use on teaspoonful of bleach per gallon

of cool water. Rinse off fruit/vegetables after dipping in bleach. Items such as carrots and other root

vegetables can be peeled as a precautionary measure.

7

Page 8

Operation

2. Wash your hands thoroughly before handling clean fruit/vegetables.

3. You need to wash, rinse, and sanitize utensils/knives before cutting fruit/vegetables. Separate cutting

boards for fruits and vegetables are needed unless cleaning/sanitizing occurs between each use.

4. If you do not drink the juice immediately, put it in the refrigerator or in ice.

5. Thoroughly clean juice machines according to the instructions in this manual.

6. Store juice at 45 degrees F. Or below during refrigerated storage or iced storage. Replenish ice as it melts.

To keep the produce cold the level of ice must be within 1 inch of the top of the container.

• Wear gloves suitable for produce handling during preparation and juicing.

• Citrus fruit should be cut just a little larger than the feed hole so food can be wedged in and then pushed

through with a plunger.

• All other produce should be cleaned and cut to t the hopper. The larger the better; less prep = higher

efciency.

• On mixed drinks, alternate produce going through the hopper. Firmer vegetables should follow leafy

greens, apples, and stringy vegetables such as celery.

• Always end with rmest produce, and push through fast and hard. This helps in the pulp extraction.

• The motor in the n450 is a heavy-duty industrial motor. It is difcult to overload it in the juicing application,

so push food through fast. Not only does this help in extraction, it increases efciency.

• Bunch up leafy greens and push through using a carrot or other hard vegetable. This helps to increase the

yield.

• Limes are very bitter, so we suggest you squeeze lime into your drinks, rather than juicing it whole.

• Oranges and grapefruit: peel off the bitter tasting zest, leaving the white pithy part on. The pith contains

bioavonoids and vitamin C.

• Tropical fruits such as kiwi and papaya should be peeled. They are often grown in foreign countries where

certain fertilizers, illegal in the US, are still being used.

• Pineapples - just screw off top, slice remainder into long strips, leaving husk on. Always juice the harder

core of the pineapple last. This helps in the pulp ejection. The skin of pineapple contains the enzyme

bromelain, which is reported to help in the digestion of protein (good for people who overindulge in meat

and dairy foods), and may also help to reduce swelling and joint pain.

Maintenance

INITIAL CLEANING

To remove miscellaneous residue, disassemble and wash juicer prior to initial use. The machine must be

disconnected from the power source and disassembled following the disassembly instructions on page #6.

Wash the juice pan, screen lter, cutter plate, blade nut, wrench, and food pusher in hot soapy water and rinse

thoroughly.

DAILY SANITIZING PROCEDURE

THIS PROCEDURE SHOULD BE CARRIED OUT AT THE START OF EACH DAY. BE SURE TO WEAR

VINYL GLOVES, AS USED FOR FOOD HANDLING, DURING THIS OPERATION.

8

Page 9

Maintenance

1. ALWAYS TURN OFF AND UNPLUG YOUR JUICER BEFORE SANITIZING.

2. Prepare / use a certied sanitation solution that is food grade compliant. Always follow the directions on the

container.

3. Assemble the machine, leaving the top off. Make sure the blade nut is tightened.

4. Wrap the base in plastic wrap cover the power switch and power cord. Set waste container under the juice

pan spout. Spray approximately 1 pint of the sanitizing solution around the perimeter of the lter screen,

inside the lter screen, and onto the cutter plate and blade nut. Once done, remove the plastic wrap and

thoroughly dry the base.

5. Thoroughly clean latch assembly, with particular attention to the adjustment thread.

6. Replace the top. Lock latches. You should hear an audible SNAP sound when properly adjusted.

7. Insert the pulp pipe into the pulp spout of the lid.

8. With receptacles under the juice spout and pulp pipe, spray 1 quart of sanitizing solution down the feed

chute while the juicer is running. Follow by rinsing the sanitizing solution from the juicer by spraying one

quart of clean water into the feed chute while the motor is running. Allow the juice pan to drain. Dispose of

the waste solution.

9. Clean the pusher with sanitizing solution and rinse thoroughly.

10. Test before use. Before use, check to make sure all the parts are in proper alignment. Plug your juicer into

an electrical outlet and test before use. The juicer is now ready for operation.

NIGHTLY CLEANING

Scrub the lter with steel wool to remove any loose pulp before washing the parts with hot soapy water. Make

sure the screen holes in the lter are clear before assembly, if not, scrub again with soap and steel wool pad,

rinse and assemble as instructed on page #5.

ATTENTION: IMMERSING, SPRAYING, OR HOSING THE POWER UNIT WILL VOID YOUR WARRANTY.

Do not immerse or spray the base and tower sections of the unit with water or other liquids. The base, motor

housing, and tower sections should only be cleaned with a damp cloth or sponge. It is important that the rims

of the tower and top be wiped thoroughly before assembly. Never spray or wash the exposed shaft of the

machine. The motor and electrical parts of the machine are not waterproof. Contact with water or other liquids

will damage the motor, bearings, and electrical system.

MAINTENANCE CLEANING DURING THE DAY

If you are using the juicer intermittently, pulp residue may collect and dry on the lter. This may cause

vibration during use. To prevent this vibration, remove the lter after more than one half-hour of idle time, and

rinse it under hot water. Before reassembling, make sure all holes are free of any pulp residue. PROPER

CARE OF YOUR FILTER IS ESSENTIAL. Your lter is engineered to provide the nest juice possible. It is

constructed with very ne stainless steel, and has been precisely balanced to provide vibration free operation.

Proper cleaning and handling are necessary to ensure the best possible operation of your juicer. LATCH

ADJUSTMENT. The threaded latches on your machine may need future adjustment. The latches should

require some pressure when putting the lid on the machine. You should hear an audible SNAP when properly

adjusted.

9

Page 10

Maintenance

The 16 blade cutter plate will need replacing periodically. The indications of a dull cutter plate are:

1. Reduction in juice yield (more produce than usual to make a drink).

2. Vibration during juicing (if lter is clean).

3. Pulp that is much wetter than usual.

Omcan sells replacement parts. Please feel free to call if you have any questions about when and how

to get a new cutter plate.

Troubleshooting

TROUBLESHOOTING GUIDE

Many potential problems can be avoided through proper care and maintenance. If you do experience machine

vibration or other problems, consult this guide before calling for service.

Trouble Possible Cause Solution

Machine won’t start. No power to machine. Turn OFF and UNPLUG.

Check circuit breaker.

Check plug at outlet (Check the

outlet by plugging something else

into it).

Manual overload protection

tripped.

Damaged electrical cord. Turn OFF and UNPLUG. Check

Loose electrical wires at switch or

switch damaged (if switch is in the

ON position and light is off).

Turn OFF and UNPLUG. Let

machine cool down.

Reset manual overload button.

electrical cord for any breaks in

the insulation or open circuits. If

problem found call Omcan.

Turn OFF and UNPLUG. Check

wiring at switch. Call Omcan.

10

Page 11

Troubleshooting

Motor stops while juicing. Loss of power to machine. Turn OFF and UNPLUG.

Check circuit breaker.

Check plug at outlet. (Check the

outlet by plugging something else

into it).

Overheating (if switch is in the ON

position and light is on).

Switch damaged. Turn OFF and UNPLUG.

Excessive vibration. Pulp sticking to lter. Filter dented or damaged, replace

Cover rattles or latches come

undone.

Pulp is too wet. Holes in lter are clogged. Clean lter (see instructions for

Pulp does not exhaust, but no

vibration problems.

Loose latches. Adjust and or tighten latch arms.

Dull cutter plate. Sharpen cutter plate.

Clogged discharge opening. Clean out pulp discharge pipe.

Turn OFF and UNPLUG. Reset

manual overload button after

machine cools.

Call Omcan for replacement

switch.

lter.

Filter Discolored (brown color),

clean lter thoroughly, soak

overnight in Clean Cut solution.

Latches loose, tighten latches by

turning clockwise. Ensure even

tension on both sides.

Latch tension uneven; adjust to

ensure even tension on both sides.

Dull cutter plate, needs

sharpening.

Clean Cut).

MOTOR RESET PROCEDURE

The motor has an automatic safety shut-off to avoid overheating. When it detects an overload, it automatically

cuts off the power. It will not reset itself. There is a manual reset push button on the base of the motor. If your

machine turns off while in use, allow the machine 15 minutes to cool. To reset, switch OFF the machine and

UNPLUG cord from outlet. Disassemble machine per instructions on page 6. Turn the machine upside down so

it is sitting on the tower. The red reset switch on the bottom of the motor is accessible through the hole on the

base screen. Firmly push on the red switch (you may hear an audible CLICK sound. Turn the machine upright

and reassemble per instructions on page 5. If the machine stalls again, contact Omcan at 1-800-465-0234.

11

Page 12

Warranty

PRODUCT LABEL LOCATIONS

CAUTION – Sharp moving parts within. Turn off the machine and unplug before removing lid. (Located

underneath, on Base Screen Enclosure) SWITCH GUARD and SPLASH GUARD IN PLACE. IF THE

SWITCH GUARD OR SPLASH GUARD IS MISSING OR DAMAGED, PLEASE CONTACT OMCAN FOR

REPLACEMENT. IF ANY LABELS ARE MISSING OR ILLEGIBLE, PLEASE CONTACT OMCAN FOR

REPLACEMENT LABELS.

ONE YEAR LIMITED WARRANTY

Call Us for Help, Repair or Replacement 1-800-465-0234

Omcan Inc.’s Juice Extractor warranty policy for the J-110 Commercial Juice Extractor covers one year

on parts, and 90 days on labor. For one year from the date of purchase, Omcan warrants your machine

against defects in parts and workmanship, and will, at its option, replace parts at no charge. During the rst

three months of this limited warranty period, Omcan Inc. will, at its option, repair or replace this product with

no charge for labor or parts. Cost of round trip shipping to Omcan Inc. is not included. This limited warranty

excludes normal wear and tear on the cutter plate and pulp pipe.

This warranty extends only to the original purchaser, and is not valid outside the United States.

Most often, operational questions can be addressed over the telephone; please call Commercial Operations

for assistance. If appropriate, we may authorize you to return the machine for our review. You must receive

a Return Authorization Number before returning the juicer, postage-paid and insured, to Omcan Inc. Upon

review, we may repair your used machine or replace it with a comparable, reconditioned juicer. Please note:

You must pay the shipping costs to return the juicer to Omcan Inc. We will cover the expense for returning the

repaired or replaced juicer to you.

THE FINE PRINT (LIMITATIONS)

Follow directions and use the juicer properly - failure to do so will void your warranty. Your warranties do not

apply if your juicer is found to have been abused, mishandled, damaged from service by non-authorized repair

services, tampered with, or damaged by your negligence, accident or misuse. Your warranty does not cover

damages incurred in transit to us; please use adequate packaging and insure your shipment to protect against

loss. Under no circumstances shall Omcan Inc. be liable for any loss or damage (direct, indirect, incidental,

special, consequential, or punitive) arising out of or in connection with the use of this product. Omcan Inc.’s

liability shall not exceed the purchase price paid. The warranty terms and remedies are in lieu of any and

all other warranties, express or implied, including warranties of merchantability and tness for a particular

purpose. (Some states do not allow the limitation or exclusion of incidental or consequential damages, so the

above limitation or exclusion may not apply to you).

12

Page 13

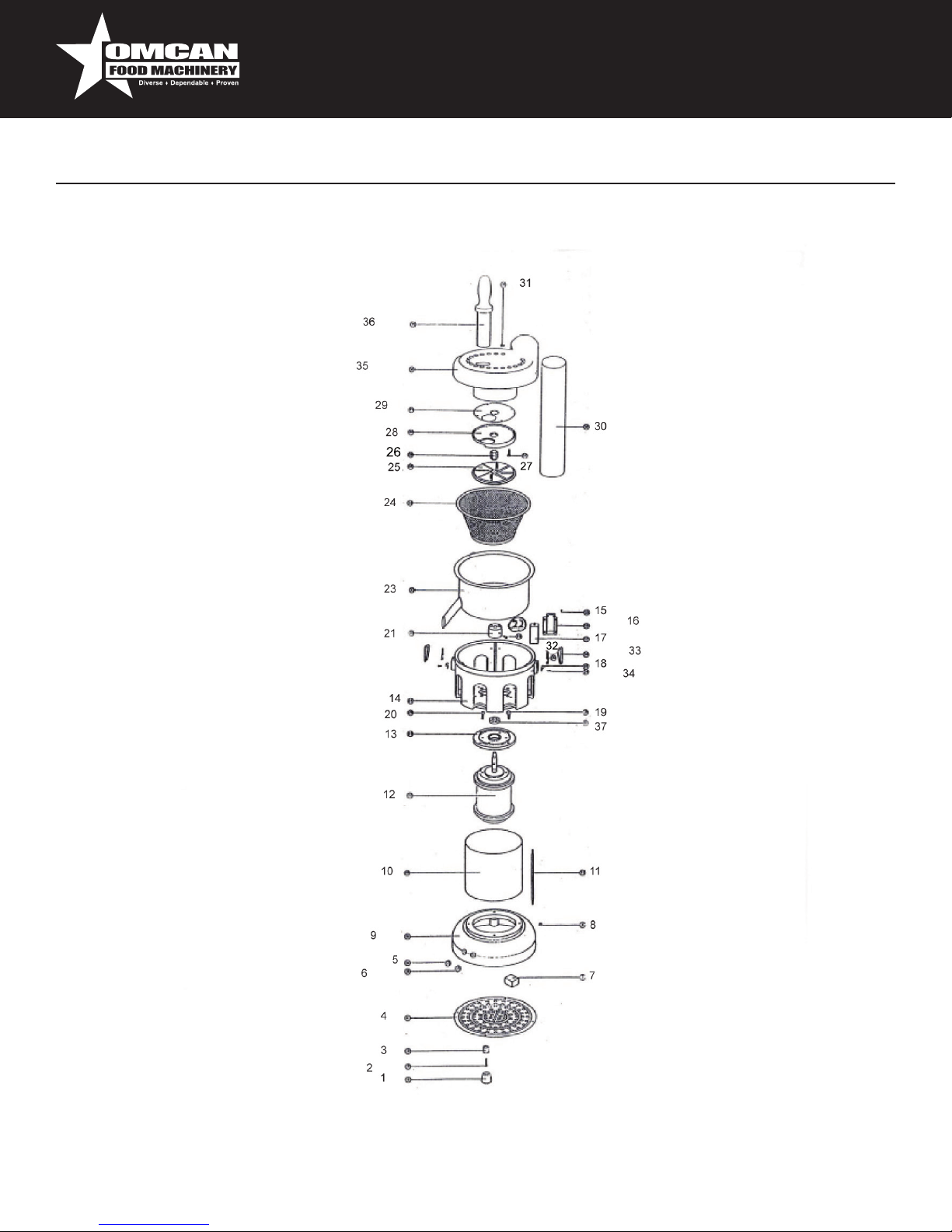

Model J-110 21634

Parts Breakdown

13

Page 14

Parts Breakdown

Model J-110 21634

Item

Description Position

No.

15601 Rubber Foot Cap 1 15615 Screw 15 15629 Seal 29

15602 Foot Fixing Screw 2 15616 Limit Switch Cover 16 15630 Pulp Ejection Pipe 30

15603 Aluminum Foot 3 15617 Limit Switch 17 15631 Screw 31

15604 Base Protection Plate 4 15618 Clip Hook 18 15632 Clip Adjuster Complete 32

15605 Push Button Start 5 15619 Screw 19 15633 Clip Cover 33

15606 Push Button Stop 6 15620 Screw 20 15634 Screw 34

15607 Contactor 7 15621 Connecting Axle 21 15635 Cover 35

15608 Nut 8 15622 Screw 22 15636 Feed Rod 36

15609 Base 9 15623 Juice Container 23 15637 Rubber Sealing Ring 37

15610 Centre Housing 10 15624 Filter 24 15638 Electric Outlet 38

15611 Connecting Screw Rod 11 15625 Movable Cutting Knife 25 15639 Clip and Two Screws

15612 Electric Motor 12 15626 Fasten Nut 26 25206 Overload Contactor

15613 Flange 13 15627 Screw 27 16892 Wrench Kit

15614 Upper Housing 14 15628 Fixed Cutting Knife 28

Item

Description Position

No.

Item

Description Position

No.

14

Page 15

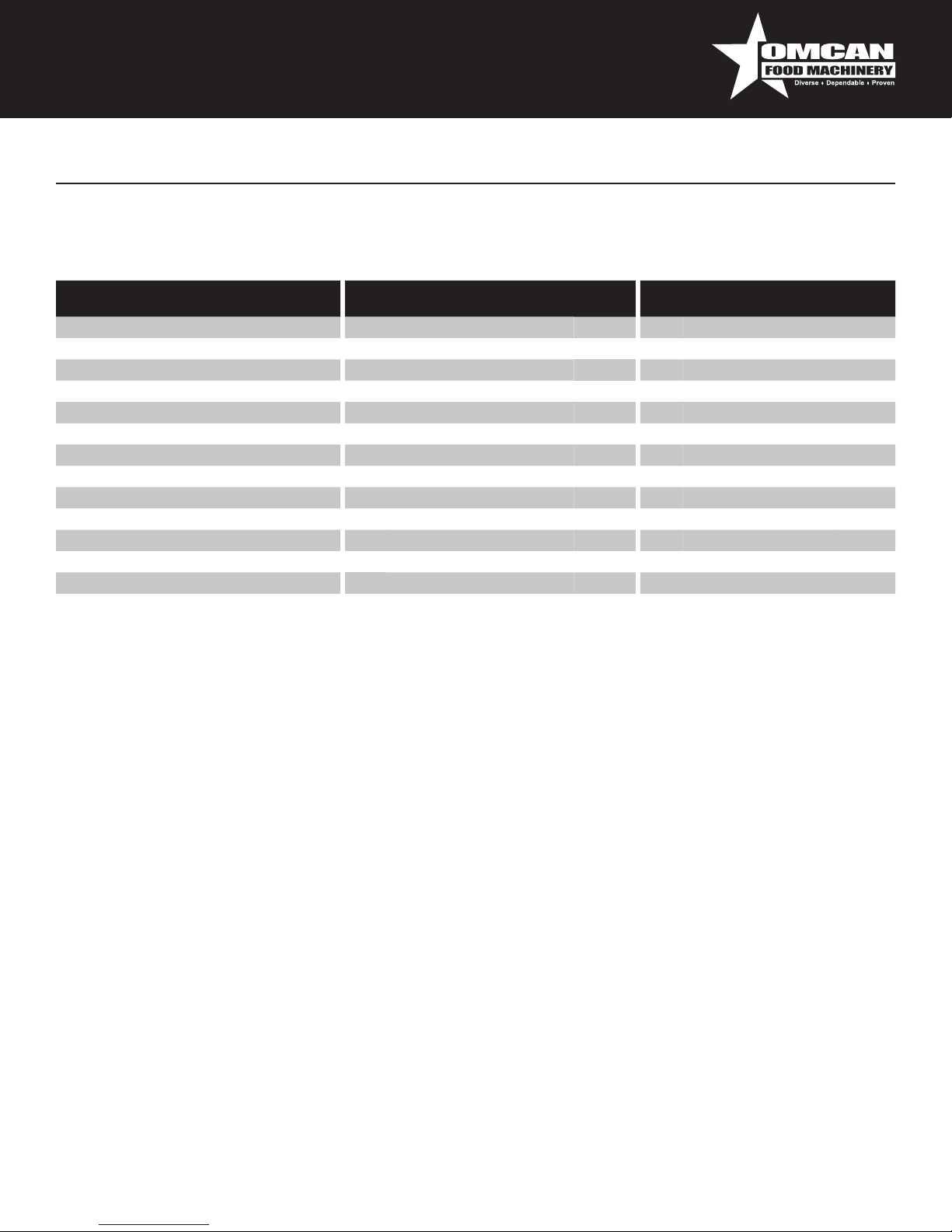

Model J-110 21634

Electrical Schematics

15

Page 16

16

Page 17

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

www.omcan.com/warrantyregistration.html

For mailing in Canada For mailing in the US

OMCAN INC.

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

1889 Maryland Avenue,

Niagara Falls, New York

OMCAN

USA, 14305

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Thank you for choosing Omcan

17

Page 18

Page 19

Page 20

Over the last 60 years, Omcan has grown to become a leading supplier to the food

service industry in Canada and the USA. Our success over these many years is

directly attributed to our established relationships with all of our valued customers

and through providing them with Diverse, Dependable and Proven products.

Omcan continues to help our customers remain competitive.

With associates in North America, Europe, and Asia, our global footprint continues

to expand as we hold to the principle that clients benet from the accessibility

and familiarity of our sales team. In 2013 as our geography and brand recognition

continued to grow, we changed to one name Omcan Food Machinery.

In over 200,000 sq ft of warehouse space we stock over 2,500 quality food

equipment and supplies for the food preparation market.

Loading...

Loading...