Page 1

Ice Maker

Model IC-CN-0040

Item 27936

Instruction Manual

Revised - 07/31/2017

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

UL

approved

Page 2

Table of Contents

Model IC-CN-0040

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

----------------------------------------------------------------------------------------------------- 5 - 6

------------------------------------------------------------------------------------------------------ 7 - 9

------------------------------------------------------------------------------------------------- 9 - 12

----------------------------------------------------------------------------------------- 3 - 4

---------------------------------------------------------------------------------------- 4 - 5

------------------------------------------------------------------------------------------- 12 - 18

Page

---------------------------------------------------------------------------------------- 5

Instructions Français

Instrucciones en Español

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

-------------------------------------------------------------------------------------------------------- 53 - 54

------------------------------------------------------------------------------------ 19 - 33

----------------------------------------------------------------------------------------- 50 - 51

------------------------------------------------------------------------------------------ 52

----------------------------------------------------------------------------------------- 55

------------------------------------------------------------------------------- 34 - 49

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

• Turn the unit off and unplug before performing any cleaning, maintenance or repairs.

• Do not operate the unit with a damaged power cord. If a damaged power cord is found, immediately turn

the unit off and unplug it. Do not operate again until trained personnel has xed the problem.

• Only operate the unit in a at, level ground. Do not place the unit near any heat sources.

• Only use original spare parts for repairs.

1 YEAR PARTS AND LABOUR WARRANTY

4

Page 5

Safety and Warranty

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see www.omcan.com/warranty.html for complete info.

WARNING:

The packaging components (cardboard, polyethylene, and others) are classied as normal solid urban waste

and can therefore be disposed of without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

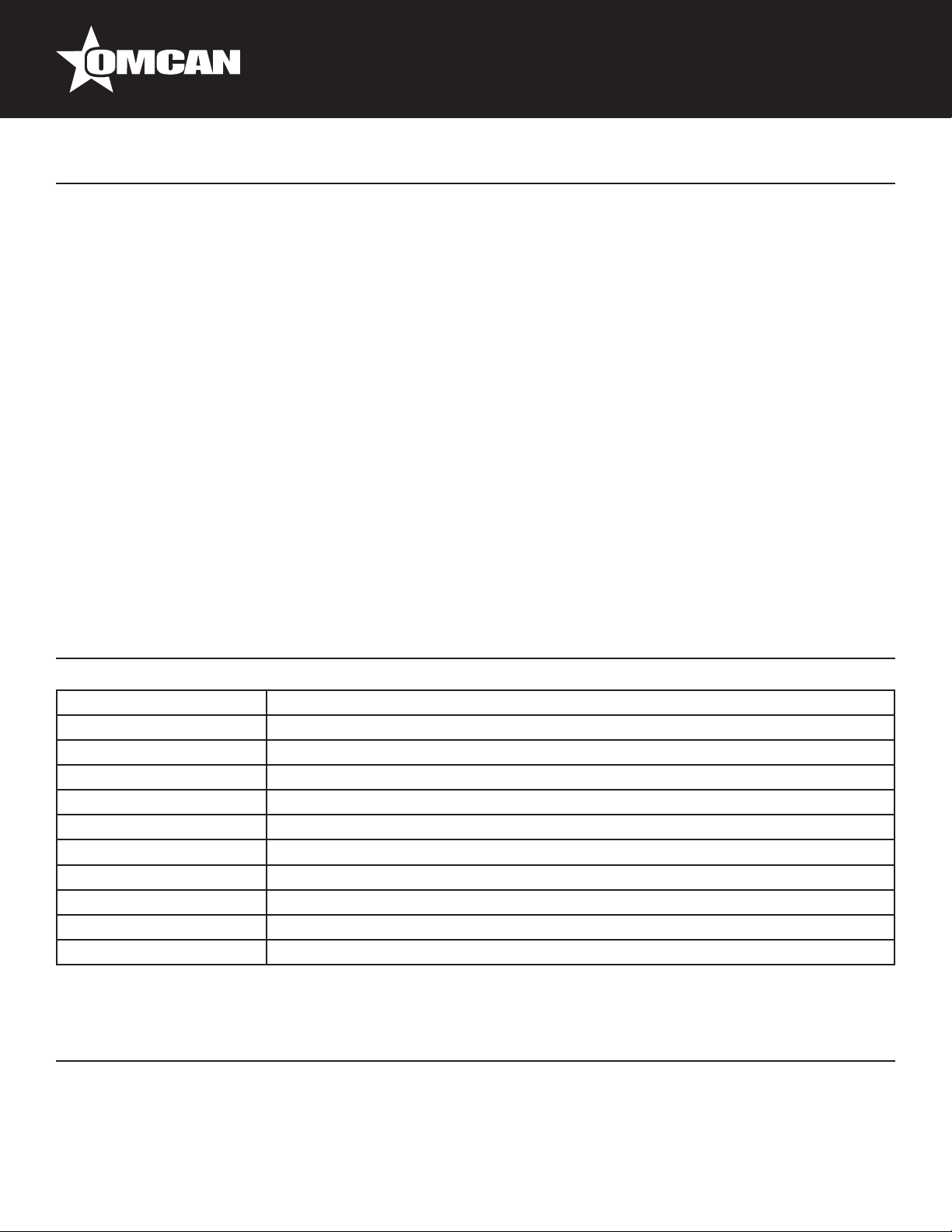

Technical Specications

Model IC-CN-0040

Production 200 lbs./day (90.7 kg./day)

Capacity 88.2 lbs. / 40 kg.

Electrical 115V / 60Hz / 1

Current 9.2A - 12A

Refrigerant R404a, 650g

Weight 123.5 lbs. / 56 kgs.

Packaging Weight 136.7 lbs. / 62 kgs.

Dimensions 24” x 24” x 39” / 610 x 610 x 990mm

Packaging Dimensions 26.2” x 26.2” x 39.4” / 665 x 665 x 1000mm

Item # 27936

Installation

Note: Installation should be performed by a trained Service Technician. For proper operation of the ice

machine, the following installation guidelines must be followed. Failure to do so may result in loss of production

5

Page 6

Installation

capability, premature part failure, and may void any warranties.

AMBIENT OPERATING TEMPERATURES

Minimum Operating Temperature: 50°F (10°C).

Maximum Operating Temperature: 100°F (38°C).

Note: The unit is not designed for outdoor use.

INCOMING WATER SUPPLY

Minimum incoming water temperature: 40°F (5°C).

Maximum incoming water temperature: 90°F (32°C).

Minimum incoming water pressure: 15 psig.

Maximum incoming water pressure: 80 psig.

Note: If water pressure exceeds 80 psig, a water pressure regulator must be installed.

DRAINS

Route bin drain, purge drain and water condenser drain must be individually connected to a oor drain. The

use of condensation pumps for draining water on equipment should not produce over 200 lbs./day. Omcan

assumes no responsibility for improperly installed equipment.

WATER FILTRATION

A water lter system should be installed with the ice machine.

CLEARANCE REQUIREMENTS

The unit must have a minimum of 6 inches (15 cm) of clearance at the rear, top, and sides of the ice machine

for proper air circulation. When using models which are located under the counter, circulation occurs from the

front. Top and side clearances are minimal.

STACKING

Omcan does not recommend stacking the unit.

DISPENSER APPLICATION

A thermostatic bin control kit must be installed if the ice machine is placed on a dispenser. A bin top may or

may not be required.

6

Page 7

Operation

There are 3 systems: the Cooling System, the Water System and the Electrical System.

During the ice-making stage, the hot gas valve is closed. The hot refrigerant gas is pumped out of the

compressor to the condenser. The hot gas is cooled by a fan after passing through the condenser. The drier

and lter will reduce possible dirt and moisture in the refrigerant. The refrigerant expands in the evaporator

cooling so water will freeze. The low pressure refrigerant gas returns to the compressor from the evaporator

where the cycle continues. During the ice harvest stage, the valve is open. The hot refrigerant gas is pumped

out of the compressor to the evaporator through the hot gas valve. Since the hot gas i not cooled by the

condenser, the refrigerant warms the evaporator. Ice in contact with the evaporator begins to melt on the back

side. The ice gradually ice slides off of the evaporator and drops to the storage bin. When the water inlet is

connected with the main water supply, water will ll the trough through the oat valve until the water level

in the trough closes the valve. During the ice-making stage, water is pumped from the water trough to the

water distribution tube. The distributed water ows over the surface of the cold evaporator where the water is

converted to ice. The unfrozen water will return to the trough. At the end of the freeze cycle and during harvest,

the water dump valve is opened and the remaining water is pumped down the drain.

CIRCUIT DESCRIPTION

1. First time usage: The ice-maker must be properly installed. Switch the water tap on, let the water trough

ll, then turn the power switch to the ON position on the back panel. The ice-maker will start working

automatically. In this stage, the time is xed about 3 minutes. At this status, the White, Green, Yellow and

Red LEDs are light together.

2. Ice-making Status: The compressor, motor fan and pump are on. The hot gas valve is off. When the green

LED is lit, the unit is working in the ice making mode controlled by a temperature probe on the evaporator.

When the green LED is ashing, the unit is working in the ice making mode controlled by a xed timer. The

fan motor is also controlled by the condenser sensor. When the ambient temperature is too low, the motor

fan stops working.

3. Ice Harvest Status: The pump is off. The hot gas valve, compressor and motor fan are on. The fan motor

is also controlled by the condenser sensor. When the ambient temperature is too low, the motor fan stops

working. The Yellow LED indicates the ice harvest status.

4. Ice Full Status And Cold Preservation Stage: If the ice bin is lled with ice, the machine stops making

ice and turns to the cold preservation stage automatically. In this stage, the compressor works regularly

to keep the low temperatures so ice does not melt. The rest of the electric components are off. The

WHITE LED indicates the ice full status and the GREEN AND YELLOW LEDs together indicates the cold

preservation status.

5. Cleaning Status: Turn the machine’s CLEAN SWITCH to CLEAN for 3 minutes after the POWER SWITCH

is turned on. At this stage, the pump is on. Compressor, motor fan and are off. The GREEN and YELLOW

LEDs are ashing together. To stop the cleaning mode, turn the machine “OFF” or the unit will turn off

automatically after 30 minutes. NOTE: In order to start the Clean Status the unit must be on. The CLEAN

switch must be turned on within 3 minutes before the COMPRESSOR starts. Do not turn the CLEAN switch

on when machine is in ice-making status or ice-harvest status.

CONTROLLER BOX

Instructions for LEDs and buttons:

7

Page 8

Operation

1. White LED: Ice full indicator light. When this LED is lit, the ice storage bin is full of ice or there is something

between the ice-full sensor and the evaporator. The unit will stop making ice. When ice cubes are taken out

of the ice storage bin making the ice-full probe free, the white LED will ash for 3 minutes. Then the unit will

restart and return to the ice making mode.

2. Green LED: Ice making indicator light. When this LED is lit, the unit is working in the ice making mode

controlled by a temperature probe on the evaporator. When the green LED is ashing, the unit is working in

the ice making mode controlled by a xed timer.

3. Yellow LED: Ice harvest indicator light. When this LED is lit, the unit is working in the ice harvest mode

controlled by ice-full probe. When green LED and yellow LED is lit, it means the unit is working in the cold

preservation stage.

4. Red LED: power indicator light. The unit is on when the red LED is lit.

5. Mode button: Mainly for service. When this button is pressed, it can change from ice making mode to ice

harvest mode, or from ice harvest mode to ice making mode. You can see the change of the mode from the

status of the green and yellow LEDs.

NOTE: If during the ice size adjustment, the “BIN FULL”, “ICE” and “HARVEST” LEDS blink all at once, this

indicates that the unit is in the default factory setting of the ice size adjustment.

CONTROL BOARD CHECKS

Timer Initiate

The timer initiate is a temperature sensor mounted on the liquid line to the evaporator. When the sensor

detects the correct low temperature, the freeze timer starts and the machine enters the timed portion of the

freeze cycle. When the freeze timer starts, the machine is in the timed portion of the freeze cycle. When

the machine enters harvest, the temperature rises, but the amount of time the machine is in harvest is

predetermined and is controlled by the Controller Board. Once the time has passed, the machine will enter the

harvest cycle. The timer is not adjustable, but the temperature at which the timer is initiated is adjustable.

ICE SIZE ADJUSTMENT

1. Press and hold the “Clean” button and the “Mode” button together for at least 3 seconds. The unit will

enter the Ice Size Adjustment mode. The GREEN LED will be blinking continuously during the ice size

adjustment.

2. While in the Ice Size Adjustment mode, press the “Clean” button or the “Mode” button for the desired ice

size.

Smaller ice setting: By pressing the “Clean” button, you can decrease the size of the ice cubes. The RED LED

will ash as you lower the ice size and will nally be blinking at the setting of smallest ice size.

Larger ice setting: By pressing the “Mode” button, you can increase the size of the ice cubes. The YELLOW

LED will ash as the larger size is set and will blink when the setting of largest ice size has been reached. After

10 seconds without any operation, the unit will automatically memorize the current setting and return to the

previous mode.

8

Page 9

Operation

BIN CONTROL OPERATION

The bin control is used to shut the machine off when the bin lls with ice. The bin control must be checked

upon installation or initial startup and

when performing maintenance. There

is one bin switch for each evaporator.

The actuator arm of the bin switch

comes in contact with the splash

curtain. When the bin is full of ice,

the splash curtain is held open when

ice drops off of the evaporator. This

releases the pressure of the bin switch

actuator arm allowing the switch to

open. Units placed under counters

and machines without curtains: An ice slide at the bottom of the evaporator is used on all under the counter

units and some modular units. The slideway swivels up and down and has a magnetic reed switch which

detects its position. When ice is sitting on the control, the slideway faces down indicating that ice is present

(and disconnecting the circuit from the reed switch). When the ice is removed, the slideway swivels up and the

connection is completed allowing the machine to begin producing ice again.

BIN CONTROL ADJUSTMENT

All Models (except those without curtains): Check the bin switch for proper adjustment by swinging the bottom

of the curtain away from the evaporator. Slowly bring the curtain towards the evaporator. The switch should

close when the bottom edge of the curtain is even with the outer edge of the water trough. Adjust the switch

by loosening the screws which hold the switch in place. Move the switch to the proper position and retighten

the screws. Recheck the adjustment. Under the counter models or those without curtains: There are no

adjustments needed for the bin (magnetic reed) switch.

Maintenance

ELECTRICAL SHOCK HAZARD

Disconnect electrical power before

beginning removal of parts

Before Maintenance:

1. Ensure the electrical supply is 115 VAC, 60Hz, 15A and is properly grounded to protect maintenance

personnel.

9

Page 10

Maintenance

2. If any electrical parts are loose or if there is a danger of short circuiting, disconnect the power immediately.

MAINTENANCE PROCEDURE

1. Cleaning should be performed at least every 6 months. Local water conditions may require that cleaning be

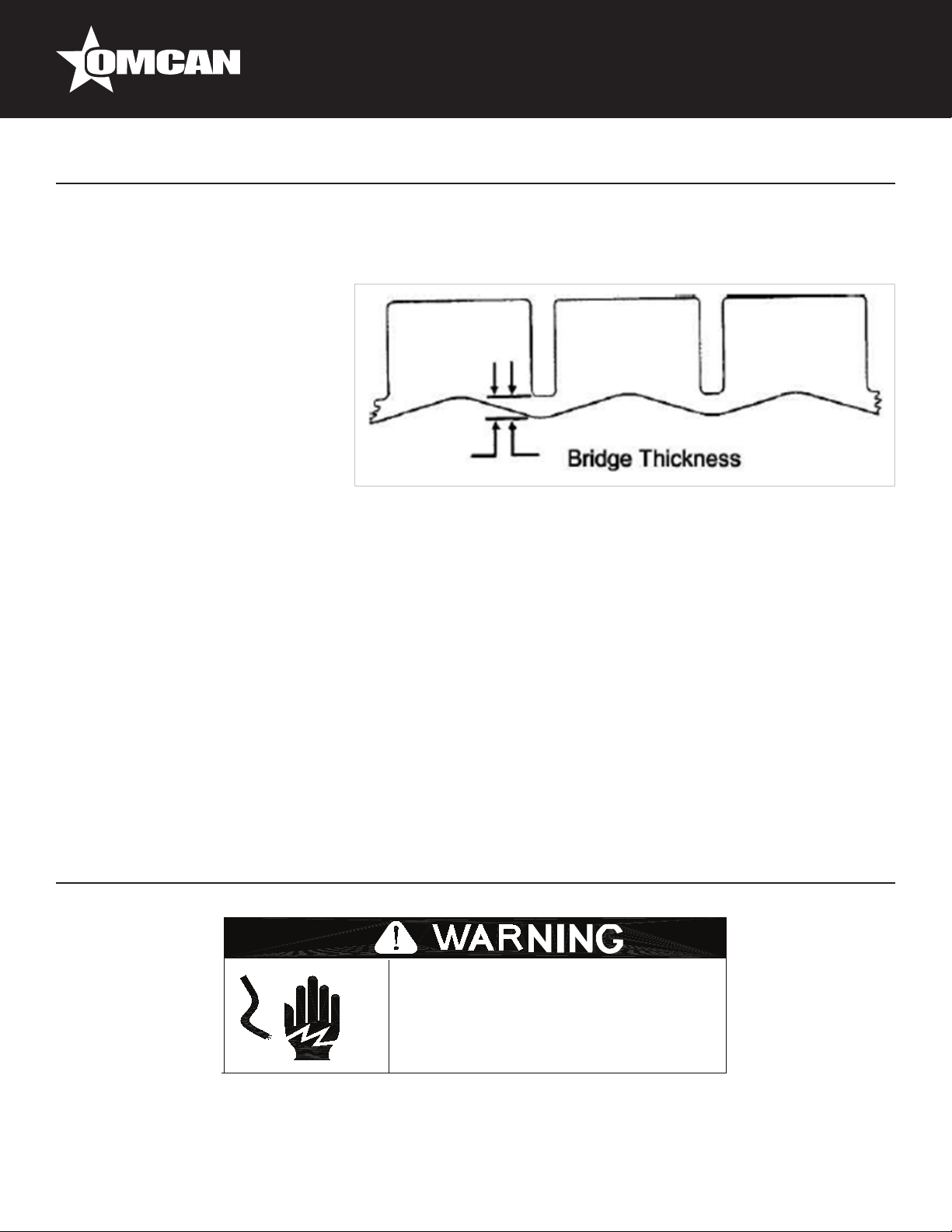

performed more often.

2. Check the ice bridge thickness. The thickness should be between 1/16-1/8’’.

3. Check the water level in trough. Check for proper water level and adjustment and troubleshoot if there is an

incorrect level.

4. Clean the condenser to ensure proper air ow.

5. Check for leaks of any kind: Water, Refrigerant, Oil, Etc.

6. Check the bin switch for proper adjustment.

7. Check all electrical connections.

8. Check the oil of the fan motor if applicable.

CLEANING AND SANITIZING

Problems may occur if the following procedures are not performed every 6 months:

1. Remove the front panel.

2. Make sure that there is no ice on the evaporator. If there is, wait until operation is nished and turn the

machine “OFF”.

3. Remove or melt all ice in the storage bin.

4. Add the recommended amount of approved cleaner to the water trough according to label instructions on

the container.

5. Initiate the clean cycle at the controller board switch by turning the machine on and switching to the

“CLEAN” setting. Note: This must be done within 3 minutes of turning the machine “ON”. Allow the cleaner

to circulate for approximately 15 minutes to remove mineral deposits.

6. After 15 minutes (or 30 minutes automatically), stop the process and drain. Rell with clean water and run

for another 5 minutes, then drain again. Fill the trough with fresh incoming water.

7. Stop the wash cycle by positioning the switch to the “OFF” position. Remove the splash curtain (if

applicable) and inspect the evaporator and water spillway (the plastic top of the evaporator) to assure all

mineral residue has been removed.

8. If necessary, wipe the evaporator, spillway and other surfaces with a clean soft cloth to remove any

remaining residue. If necessary, remove the water distribution tube, disassemble and clean with a

bottlebrush. Reassemble all components and repeat steps 4 through 7 as required to remove residue.

9. Turn the unit OFF and clean the water trough thoroughly to remove all scale or slime buildup. If necessary,

remove the water trough to reach all splash areas.

10. Prepare 1½ to 2 gallons (5.7 to 7.5 liters) of approved (EPA/FDA) sodium hypochloride food equipment

sanitizer to form a solution with 100 to 200 ppm free chlorine yield.

11. Add enough sanitizing solution to ll the water trough to overowing and activate the switch to the “CLEAN”

position and allow circulation to occur for 10 minutes and inspect all disassembled ttings for leaks. During

this time, wipe down all other ice machine splash areas and the interior surfaces of the bin, deector

and door with the remaining sanitizing solution. Inspect to make sure that all functional parts, fasteners,

thermostat bulbs (if used), etc. are in place.

12. After 3 minutes, stop the process and drain. Rell with clean water run another 5 minutes and drain again.

10

Page 11

Maintenance

Fill the trough with fresh incoming water.

13. Place the switch to the “ON” position and replace or close the panel. Discard the rst two ice harvests.

REPLACING CONTROL BOX AND TEMPERATURE SENSOR

• Remove the rear cover and the front or side panel.

• Locate the electronic control box in the unit.

• Carefully pull out the temperature sensors (one at the evaporator, another at the condenser).

• Loosen the screws holding the control box and replace. Reverse the previous steps to reassemble.

• If you need to replace a temperature sensor, pull out the sensor, open the panel of the control box, pull out

the other end of the sensor and replace. Reverse these steps to reassemble.

REPLACING THE WATER PUMP

• Turn the unit off and unplug it from the socket.

• Remove the front cover.

• Unplug the lines connected with the water pump, including the water outlet tube.

• Loosen the screws. Replace the pump with a new one.

• Reverse the above steps to reassemble.

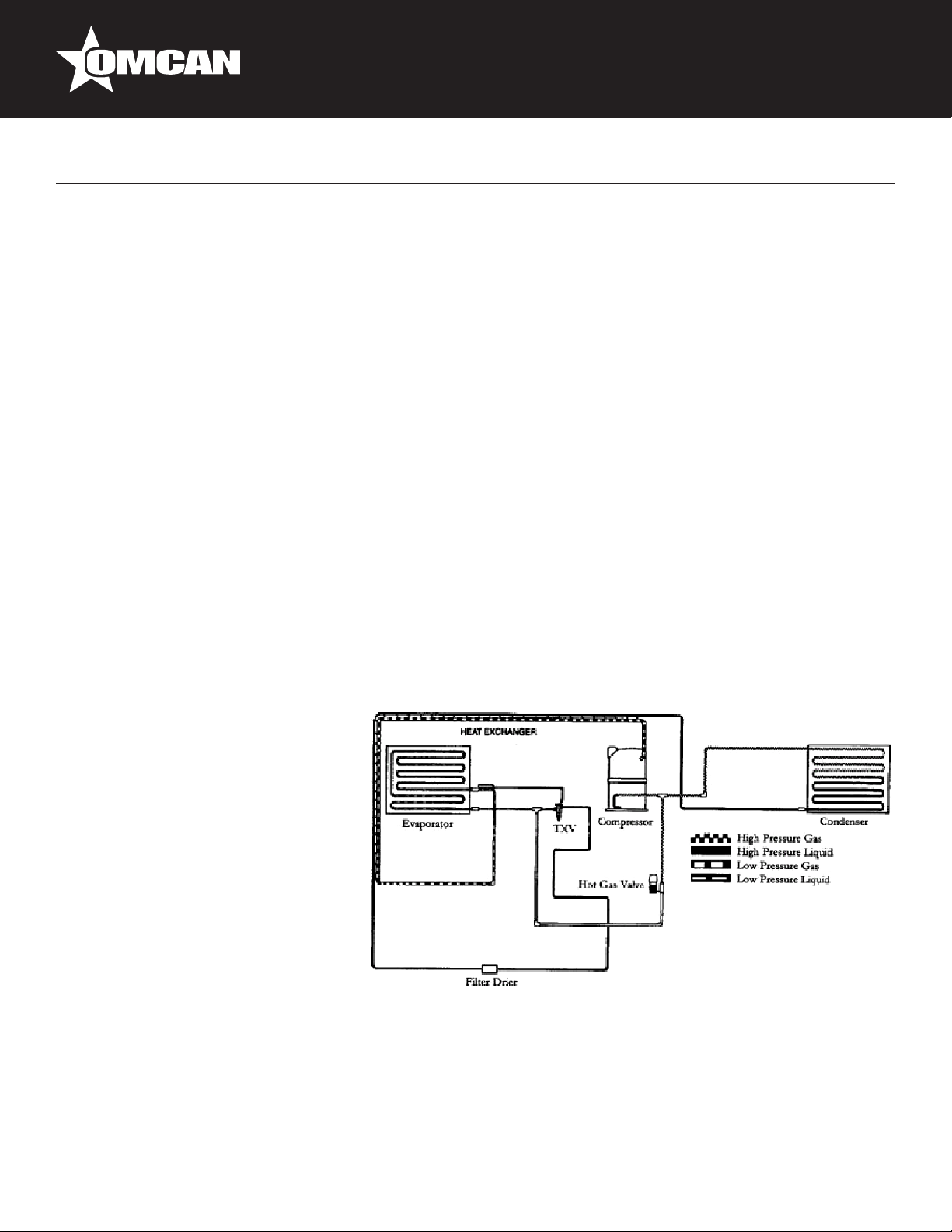

REPLACING THE COOLING SYSTEM COMPONENTS

To replace the condensing components, see the Cooling System gure.

• Remove the top panel and left

panel, locate the compressor, take

off the clip and replace the defective

components.

• Reverse the above steps to

reassemble.

ELECTRICAL SHOCK HAZARD

• Turn the unit off and unplug it form

the socket.

• If the compressor needs to be

replaced, remove the top cover and

locate the compressor.

• Unplug the lines and remove the

ground line, open the Process/Suction, remove the refrigerant, take out the compressor and replace it.

• Reverse the above steps to reassemble.

REPLACING THE FAN MOTOR AND FAN BLADE

• Remove the top and right panels.

11

Page 12

Maintenance

• Locate the fan motor, unplug the lines connected with the fan motor, loosen the screws of the holding

bracket and fan motor bracket, remove the damaged unit and replace with a new one.

• Reverse the above steps to reassemble.

REPLACING THE HOT GAS VALVE, DRIER AND EVAPORATOR

• Remove the top panel.

• Remove the refrigerant. Locate the drier and hot gas valve, open weld, replace the drier and hot gas valve,

and weld. Replace the refrigerant.

• Reverse the above steps to reassemble.

• If needed, replace the evaporator.

• Remove the refrigerant. Remove the front and top panels, locate the evaporator, open the Process/Suction,

open the two welds, replace with a new evaporator. Replace the refrigerant.

Reverse the above steps to reassemble.

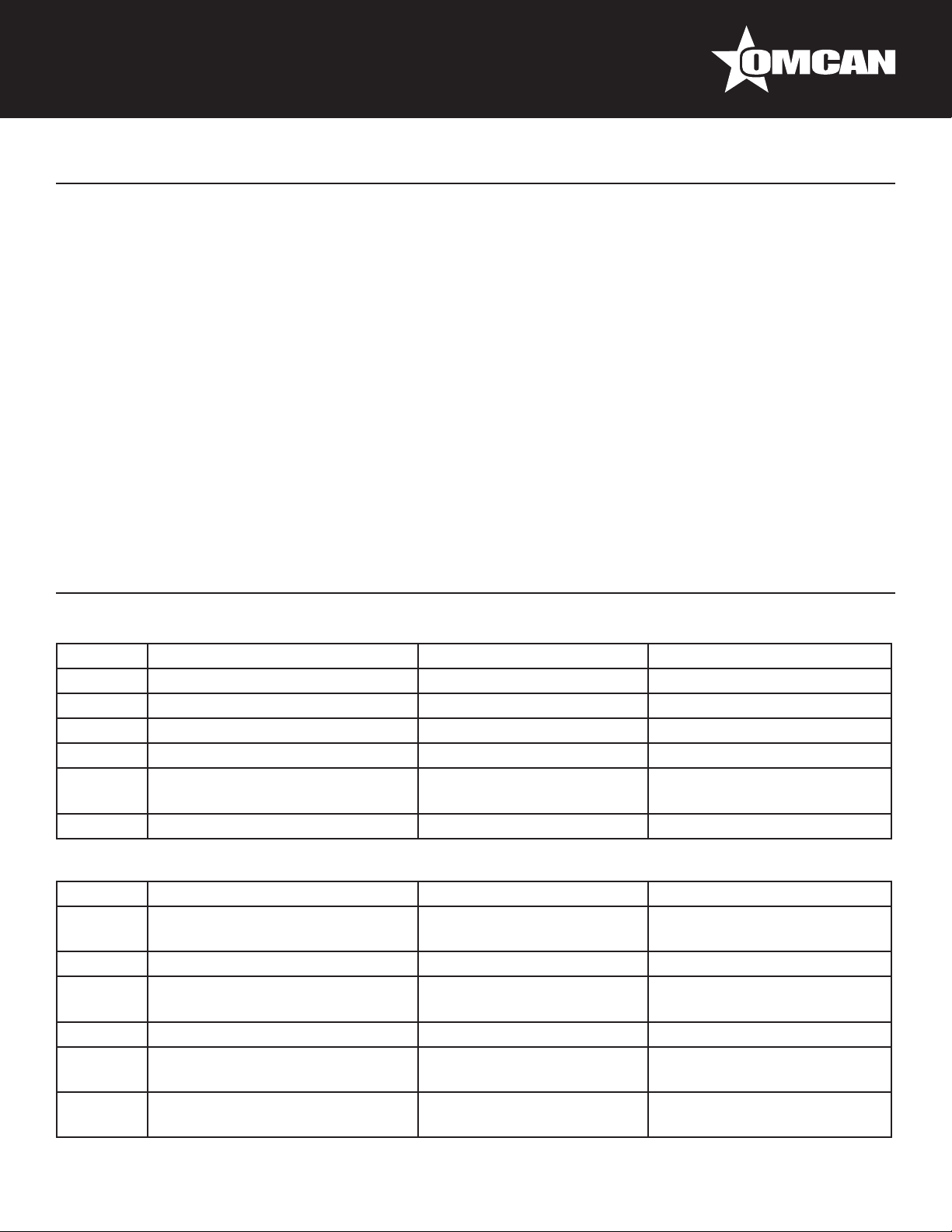

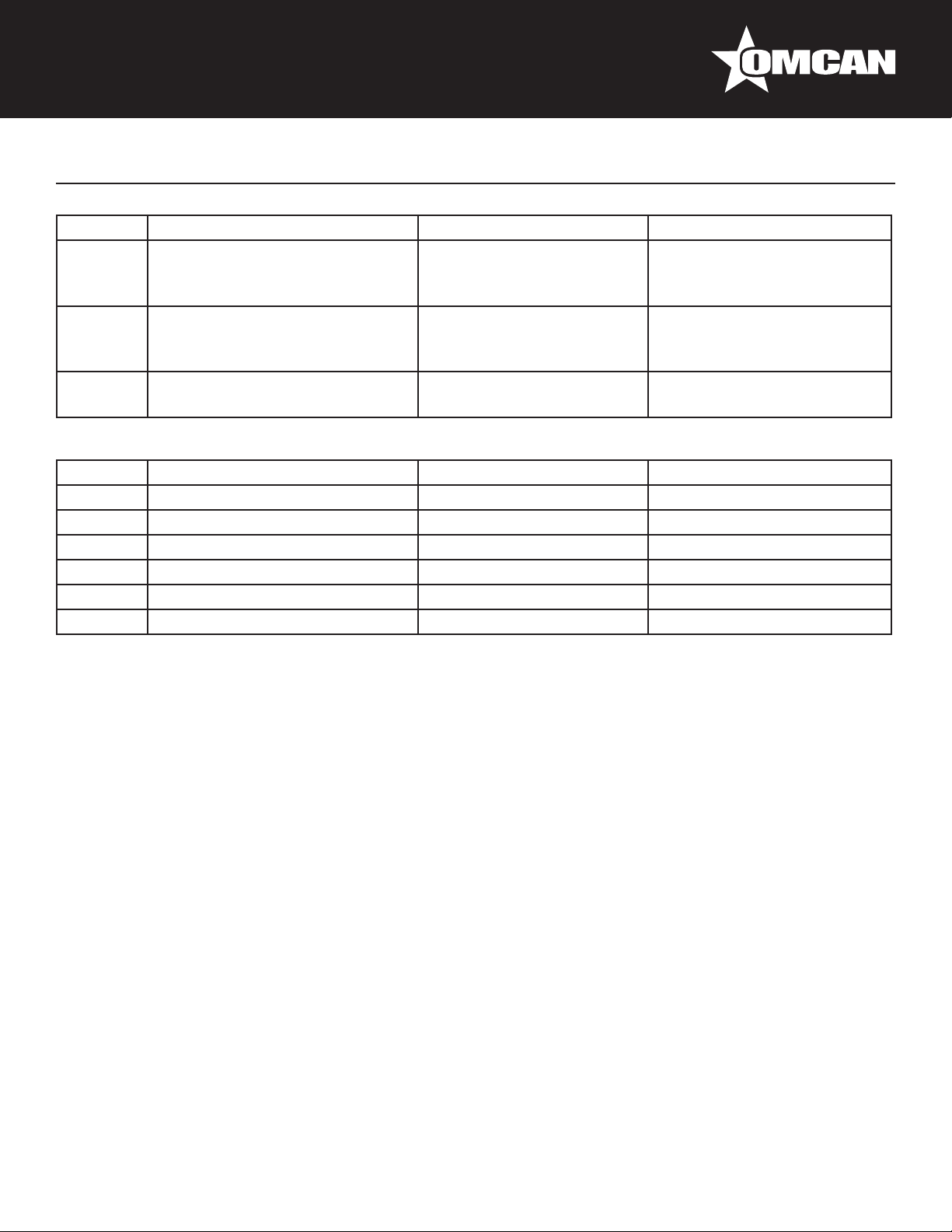

Troubleshooting

Machine does not run.

Step Check If yes, proceed to If no, proceed to

A1 Is the switched turned to on? Turn on A2

A2 Is there power to the machine? Rewire A3

A3 Is the bin full? A4 Take ice out

A4 Is the bin control adjusted? Adjust A5

A5 Is the high pressure safety switch

tripped?

A6 Is the selector switch out? Replace

Machine runs but does not produce ice.

Step Check If yes, proceed to If no, proceed to

B1 Is water running over the

evaporator?

B2 Is the compressor running? B5 B3

B3 Is there power to the

compressor?

B4 Is the switch defective? Replace

B5 Is there water leaking from the

trough?

B6 Is the refrigerant pressure high? Clean the condenser or

A6 Reset clean condenser

The following

troubleshooting chart.

Repair the leak B6

check HGV

B2

Check for bad connection or

starting components

B7

12

Page 13

Troubleshooting

B7 Is the refrigerant pressure low? Check for leaks B8

B8 Is there a low side restriction? Repair TXV is defective

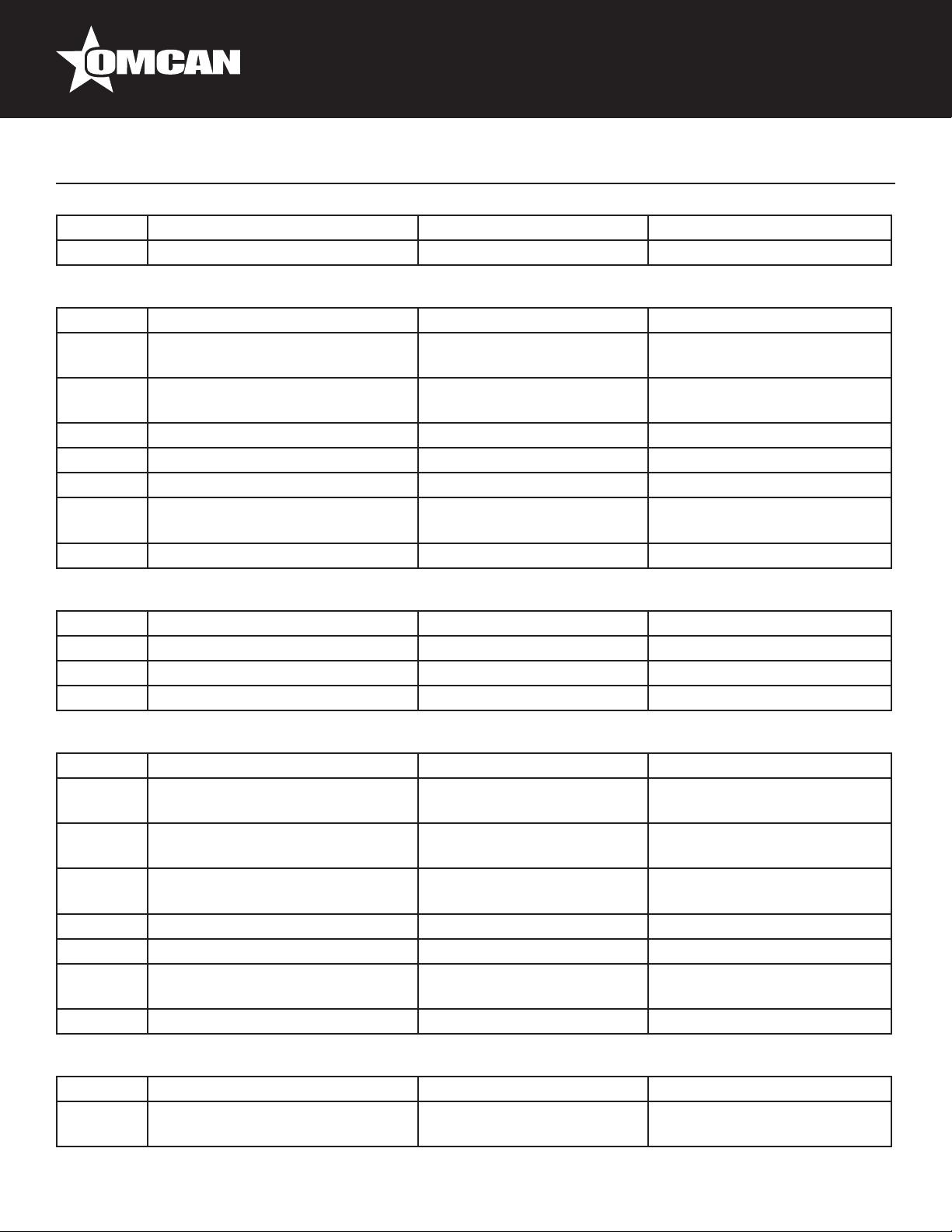

Machine produces cloudy or incomplete cubes.

Step Check If yes, proceed to If no, proceed to

C1 Is water running over the

evaporator?

C2 Is the machine level? The incoming water quality

C3 Is the trough water level correct? C6 C4

C4 Is the supply pressure correct? C5 Correct deciency

C5 Is there a water leak? Repair the leak Adjust oat valve

C6 Is the water distribution tube

plugged correctly?

C7 Is the water pump damaged? Replace/Repair pump Clean evaporator spillway

Produces proper cubes but is slow in production.

Step Check If yes, proceed to If no, proceed to

D1 Is the unit installed correctly? D2 Correctly install the unit

D2 Is the head pressure too high? D3 Check refrigeration system

D3 Is the condenser clean? Check refrigeration system Clean

C2 C3

Level the unit

is poor.

Clean/replace C7

Cubes are hollow.

Step Check If yes, proceed to If no, proceed to

E1 Is the water temperature above

100°F?

E2 Is there good ow over the

evaporator?

E3 Is there water leaking from the

purge?

E4 Does the cube adjuster work? Reset cube size E5

E5 Is the evaporator sensor loose? Tighten E6

E6 Is the evaporator sensor wire

tight?

E7 Is the controller damaged? Replace

Bridge thickness is uneven.

Step Check If yes, proceed to If no, proceed to

F1 Is the water temperature above

100°F?

Correct the temperature E2

E3 Go to section C

Replace valve E4

E7 Tight the spade connection to

the board

Correct the temperature F2

13

Page 14

Troubleshooting

F2 Is the water running into the bin? Check sections C,D, E or

check trough for leak

F3 Is water leaking from the purge? Replace the valve F4

F4 Is the suction pressure high? Check the hot gas valve Recharge and/or check the

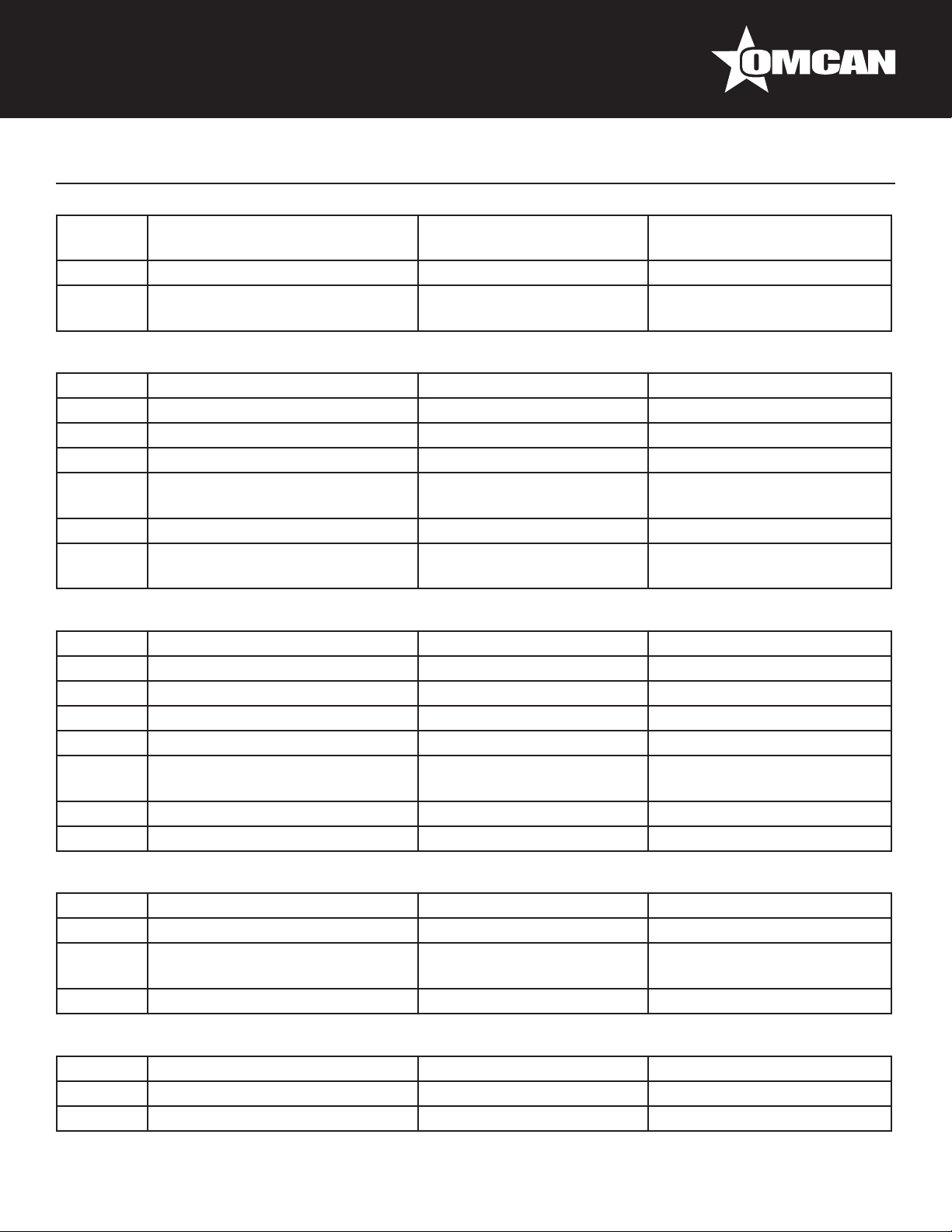

Bridge thickness varies with each cycle.

Step Check If yes, proceed to If no, proceed to

G1 Is the water temperature proper? Correctly adjust temperature G2

G2 Is the purge valve leaking? Replace valve G3

G3 Is the hot gas valve damaged? Replace G4

G4 Are sensors connected to the

board?

G5 Is the controller damaged? Replace G6

G6 Is the thermal expansion valve

damaged?

Machine does not start producing ice cubes.

Step Check If yes, proceed to If no, proceed to

H1 Does the purge valve work? H6 H2

H2 Is the freeze pattern even? H3 H2

H3 Is the purge valve leaking? Replace H3

H4 Is the compressor failing? Replace H4

H5 Is the system supplied with too

much voltage?

H6 Is the relay defective? Replace H7

H7 Is the board defective? Replace

G5 Tighten spade connections

Replace

Adjust the voltage Replace TXV

F3

TXV

Machine harvests but returns to ice-making prematurely.

Step Check If yes, proceed to If no, proceed to

I1 Is the manual purge open? Replace purge valve I2

I2 Is the high temperature safety

switch open?

I3 Is the relay damaged? Replace

Length of harvest is excessive.

Step Check If yes, proceed to If no, proceed to

J1 Is the machine installed correctly? J2 Correct

J2 Is ice forming correctly? J3 Low charge - recharge

Replace I3

14

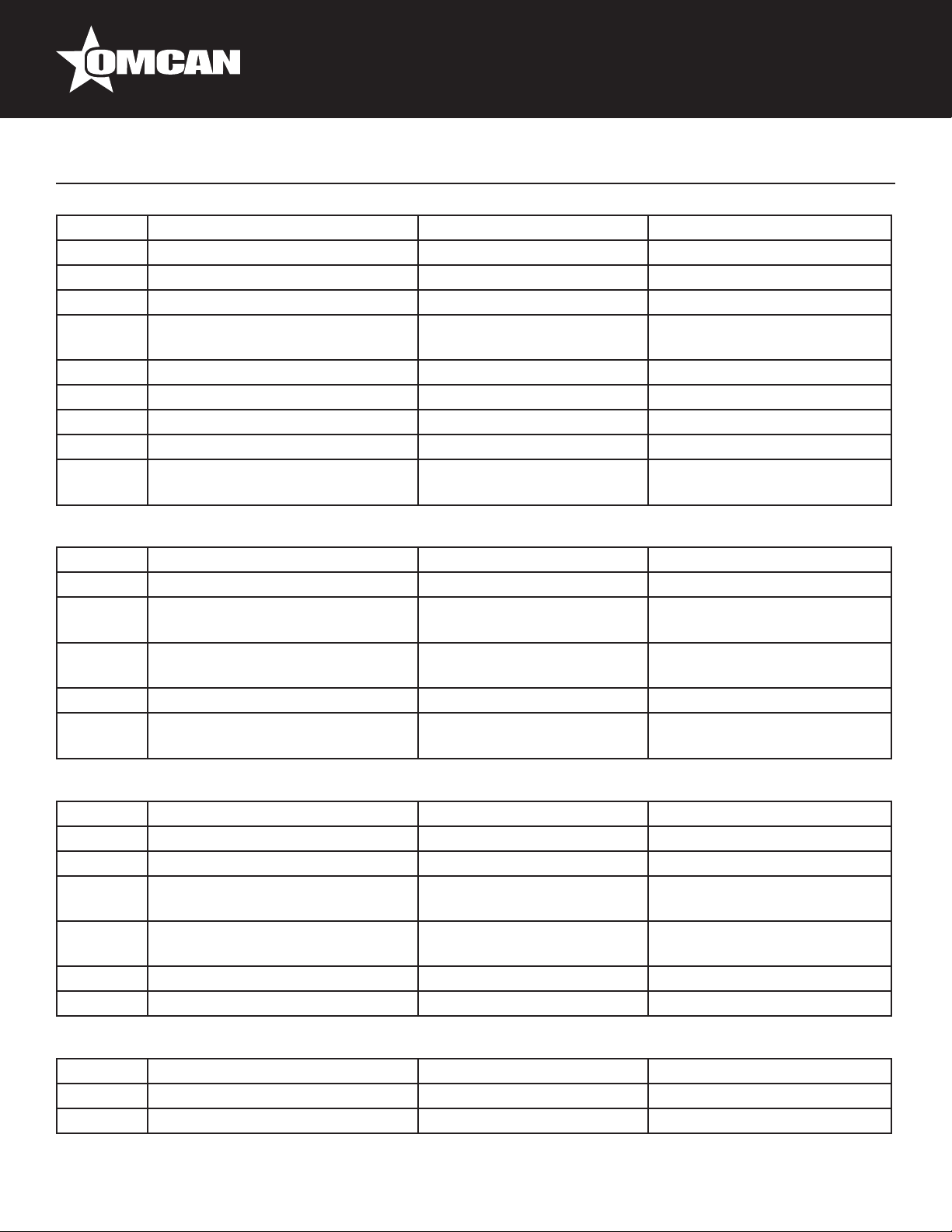

Page 15

Troubleshooting

J3 Is the suction pressure too low? Replace the hot gas valve J4

J4 Is the evaporator clean? J5 Clean accordingly

J5 Is the ice bridge correct? J6 Go to F or G sections

J6 Is the machine level? J7 Level the unit

J7 Does water run over the

evaporator during harvest?

J8 Is the purge valve leaking? Replace J9

J9 Is the relay damaged? Replace J10

J10 Is the selector switch damaged? Replace

J11 Is the suction pressure damaged? Replace evaporator J12

J12 Is the discharge pressure low

during freezing?

Evaporator gets hot.

Step Check If yes, proceed to If no, proceed to

K1 Is the unit installed correctly? K2 Correctly install the unit

K2 Is the condenser fan turning? K3 Tighten the blade, check the

K3 Are the hot gas valve connections

loose?

K4 Is the machine charged correctly? K5 Charge correctly

K5 Is the controller operating

correctly?

Clean or J11 J8

Ambient temperature is too

low

Tighten all wiring

connections

Replace the hot gas valve Replace the controller board.

Replace the hot gas valve

wires or replace the motor

K4

The compressor does not start.

Step Check If yes, proceed to If no, proceed to

L1 Is the condenser dirty? Clean L2

L2 Has the fan stopped or is dirty? Repair/clean L3

L3 Are the wires tight on the

controller?

L4 Are the compressor starting

components damaged?

L5 Is the controller board damaged? Replace L6

L6 Is the compressor damaged? Replace

Compressor runs but no ice is produced.

Step Check If yes, proceed to If no, proceed to

M1 Is the air vent obstructed? Clear the path M2

M2 Is the condenser dirty? Clean M3

L4 Tighten all spade connections.

Replace components L5

15

Page 16

Troubleshooting

M3 Is the fan turning? M4 Replace fan motor

M4 Is there a refrigerant leak? Add the valve, clean the

refrigerant, x and charge

(replace lter)

M5 Is the TXV or cap tube operating

normally?

M6 Does the ice making mode

convert to harvest?

Machine makes excessive noise.

Step Check If yes, proceed to If no, proceed to

N1 Are the panels loose? Tighten all the screws N2

N2 Is the fan hitting the shroud? Realign N3

N3 Is the fan blade loose? Tighten N4

N4 Is the pump noisy? N5 N6

N5 Is there an object in the propeller? Remove the object Replace the pump

N6 Is the noise from the compressor? Replace the compressor

M6 Add the valve, clean the

M5

refrigerant, x and charge

(replace lter)

Replace the controller board

ADVANCED COMPONENT TROUBLESHOOTING TECHNIQUES

Refrigerant Cycle and Components

Before diagnosing the refrigeration system, it is very important that the refrigeration charge is correct.

Whenever the refrigeration system has been opened, the lter drier must be replaced and the proper

refrigerant charge must be weighed in.

Refrigerant Pressures

The suction pressure at the beginning of the freeze cycle can vary +/10 psi (.7 bar) depending on operating

conditions. Pressures less than this may indicate an undercharge. The discharge pressure on air cooled units

will vary with ambient conditions. Refrigerant in a gas state is pumped throughout the refrigeration system by

a hermetic compressor to the condenser. Heat is removed from the refrigerant either by forced air movement

through an air cooled condenser or transferring heat from the refrigerant to water through a water cooled

condenser. The refrigerant changes to a liquid when cooled. The refrigerant in a liquid state passes through a

lter drier. The lter drier traps small amounts of moisture and foreign particles from the system. The lter drier

must be replaced whenever the refrigeration system is opened or if the refrigerant has been completely lost.

Compressor

The compressor runs during the entire cycle. If the valves in the compressor are damaged, the compressor

will be unable to pump refrigerant efciently. Damaged valves may be the result of another problem in the

16

Page 17

Troubleshooting

refrigeration system. When a compressor is replaced it is important that the refrigeration charge be weighed

in and the system checked for proper operation to prevent a repeat failure. An inefcient compressor will

usually have a higher than normal suction pressure at the end of the cycle. The freeze cycle will be longer

than normal and/or the harvest cycle may be excessively long. Check the compressor’s amps 5 minutes into

the freeze cycle. If the amps is less than 70% of rated full amount, the compressor may be inefcient. These

symptoms may also be caused by other problems, therefore it is important to use the troubleshooting charts

when diagnosing a problem. The air condenser is located in the back of the cabinet. Air is pulled through the

condenser by a fan motor and released through the right hand side panel. Under the counter models intake

and discharge air through the front panel. Do not block airow as it will cause premature failure of the machine

and will void the warranty.

Compressor and Start Components

The compressor should run during the entire cycle. If the machine is in the ON position but the compressor is

not running, check the compressor contactor to see if it is connected properly. If the contactor is not connected,

the problem is not with the compressor or the compressor start components. If the contactor is engaged and

there is correct voltage through the contactor, there could be a problem with one of the starting components or

the compressor. It is recommended that the compressor starting components be replaced when replacing the

compressor.

DISCONNECT POWER BEFORE SERVICING!

If the compressor uses an internal overload, be certain that the compressor has cooled and the overload

has reset before diagnosing the compressor. If the compressor is cool and is still not running, check the

compressor motor windings by rst removing the wires at the compressor terminals. With an ohmmeter, check

for continuity between all three terminals, if an open circuit exists between any of the terminals, the compressor

may need to be replaced. Check for continuity from each terminal to the compressor body, if continuity is found

from any terminal to the compressor body, the compressor windings are shorted to ground and the compressor

will need to be replaced. If the compressor appears to be good at this point, it is advisable to use a compressor

analyzer to isolate the compressor from the start components while checking for a locked rotor. If it is not

available, the compressor starting components must be checked. If all starting components are working, check

the amp rating from the terminal of the compressor, making sure proper voltage is supplied to the compressor

and all wiring is properly connected. If the compressor does not start and there is excessive amp rating, (see

locked rotor amps on compressor tag) the compressor has a locked rotor and should be replaced.

Overload (External)

If there is no amperage draw check the compressor overload. The compressor overload can be checked for

continuity after removing it from the compressor and letting it cool to room temperature. If there is no continuity

between the two terminals, replace the overload. If the overload is suspected of opening prematurely, it should

be replaced with an overload.

Capacitors

The start capacitor is an electrical storage device used to provide starting torque to the compressor. If a start

17

Page 18

Troubleshooting

capacitor is defective, the compressor will not start properly. The run capacitor is an electrical storage device

used to improve the productivity and efciency of the compressor. Before checking a capacitor, it should be

discharged by shorting across the terminals. If a run or start capacitor is cracked, leaking or bulging it should

be replaced. If a capacitor is suspected of being defective, it can easily be checked by replacing it with a

capacitor of the correct size, which is known to be working. If the compressor starts and runs properly, replace

the original capacitor. A capacitor tester can also be used.

Start Relay

The start relay breaks the electrical circuit to the start windings when the compressor motor speed increases. If

the relay is defective, the compressor will not start or it may start but will run for a very short time.

A compressor relay can be checked by removing the relay and checking the relay contacts for damage and

check for continuity across the closed relay points. Check the relay coil with an ohmmeter. If no continuity is

read, replace the relay.

Thermostatic Expansion Valve (TXV)

The thermostatic expansion valve measures the ow of refrigerant into the evaporator changing its state

from a high pressure liquid to a low pressure liquid. This drop in pressure causes the refrigerant to cool. The

cooled refrigerant absorbs heat from the water circulating over the evaporator. As the evaporator lls with

liquid refrigerant, the evaporator becomes colder. The ow of refrigerant into the evaporator is controlled by the

temperature at the outlet of the evaporator. The expansion valve bulb, mounted to the top of the suction line,

senses the evaporator outlet temperature causing the expansion valve to open or close. As ice forms on the

evaporator, the temperature drops and the ow of refrigerant into the evaporator decreases, resulting in a drop

in suction pressure. The evaporator should become completely ooded (lled with liquid refrigerant) during

the freeze cycle. A completely ooded evaporator will have a uniform freeze pattern (ice formation across the

evaporator). A starved evaporator (not enough liquid refrigerant) will have poor or no ice formation at the top of

the evaporator, and the tube(s) exiting the evaporator will not frost. All tubes should be frosted approximately

5 minutes from the start of the freeze cycle. An expansion valve that is restricted or not opening properly will

starve the evaporator resulting in lower than normal suction pressure. A low refrigerant charge will also starve

the evaporator and cause low suction and discharge pressures. If not sure of the amount of charge in the

system, the refrigerant should be recovered and the correct charge be weighed in before a defective valve can

be diagnosed. If the evaporator is starved but the suction pressure is higher than normal, the TXV is not the

problem, refer to the above charts. If the TXV sticks open or if the thermal bulb is not making good contact with

the suction line, the ow of refrigerant into the evaporator will be too great and liquid refrigerant will ood the

compressor. The suction pressure will remain higher than normal and the machine will remain in an extended

freeze cycle. Ice will build evenly but will be very thick.

REFERENCE

Item Number Model Number Description Manufacturer Model Number

27936 IC-CN-0040

Ice Maker 88 lbs. / 40 kgs. Capacity

115V/60/1 UL cUL

AZ-120L

18

Page 19

Instructions Français

SÉCURITÉ ET GARANTIE

• Eteignez l’appareil et le débrancher avant toute opération de nettoyage, d’entretien ou de réparation.

• Ne pas faire fonctionner l’appareil avec un cordon d’alimentation endommagé. Si un cordon d’alimentation

endommagé se trouve, mettez immédiatement l’appareil hors tension et débranchez-le. Ne pas faire

fonctionner à nouveau jusqu’à ce personnel qualié a résolu le problème.

• Ne faire fonctionner l’unité dans un sol plane. Ne pas placer l’appareil près de sources de chaleur.

• Utiliser uniquement des pièces de rechange d’origine pour les réparations.

1 AN PIÈCES ET GARANTIE DU TRAVAIL

Dans la période de garantie, contacter Omcan Inc. au 1-800-465-0234 pour planier une Omcan

technicien autorisé à réparer l’équipement localement.

Entretien non autorisée annulera la garantie. La garantie couvre les pannes électriques et une partie

pas une mauvaise utilisation.

S’il vous plaît voir www.omcan.com/warranty.html pour info complète.

AVERTISSEMENT:

Les matériaux d’emballage (carton, de polyéthylène et autres) sont classés comme déchets solides urbains

normale et peuvent donc être éliminés sans difculté.

En tout cas, pour le recyclage approprié, nous suggérons tranchent des produits séparément

(différenciée des déchets) selon les normes actuelles.

NE PAS JETER LES EMBALLAGES DANS L’ENVIRONNEMENT!

SPÉCIFICATIONS TECHNIQUES

Modèle IC-CN-0040

Production 200 lbs./jour (90.7 kgs./jour)

Capacité 88.2 lbs. / 40 kgs.

Électrique 115V / 60Hz / 1

Courant 9.2A - 12A

Réfrigérant R404a, 650g

Poids 123.5 lbs. / 56 kgs.

Emballage Poids 136.7 lbs. / 62 kgs.

Dimensions 24” x 24” x 39” / 610 x 610 x 990mm

Conditionnement Dimensions 26.2” x 26.2” x 39.4” / 665 x 665 x 1000mm

Item # 27936

19

Page 20

Instructions Français

INSTALLATION

Remarque: L’installation doit être effectuée par un technicien qualié. Pour un bon fonctionnement de la

machine à glace, les directives d’installation suivantes doivent être suivies. Ne pas le faire peut entraîner

une perte de la capacité de production, une défaillance prématurée de la pièce, et peut annuler toutes les

garanties.

LES TEMPÉRATURES AMBIANTES

Minimum Température de fonctionnement: 50 ° F (10 ° C).

Température de fonctionnement: 100 ° F (38 ° C).

Remarque: L’appareil ne est pas conçu pour une utilisation extérieure.

ENTRANT ALIMENTATION EN EAU

Température minimale d’arrivée d’eau: 40 ° F (5 ° C).

Température maximale de l’eau entrant: 90 ° F (32 ° C).

Pression de l’eau entrant minimum: 15 psi.

Pression de l’eau entrante maximale: 80 psi.

Remarque: Si la pression de l’eau dépasse 80 psig, un régulateur de pression d’eau doit être installé.

DRAINS

Route bin vidange, vidange de purge et le drain de condensation de l’eau doivent être connectés

individuellement à un drain de plancher. L’utilisation de pompes de condensation pour drainer l’eau de

l’équipement ne doit pas produire plus de £ 200. / Jour. Omcan ne assume aucune responsabilité pour les

équipements mal installé.

FILTRATION

Système de ltre à eau doit être installé avec la machine à glace.

EXIGENCES DE LIQUIDATION

L’unité doit avoir un minimum de 6 pouces (15 cm) d’espace libre à l’arrière, en haut et sur les côtés de la

machine à glace pour la circulation de l’air. Lors de l’utilisation de modèles qui sont situés sous le comptoir, la

circulation se produit à partir de l’avant. Latérales et supérieures dégagements sont minimes.

EMPILAGE

Si les machines à glace doivent être empilés, reportez-vous aux instructions décrites plus loin dans ce manuel.

Omcan déconseille d’empiler l’unité.

20

Page 21

Instructions Français

DISTRIBUTEUR APPLICATION

Un kit de commande bin thermostatique doit être installé si la machine à glace est placé sur un distributeur. Un

top bin peut ou peut ne pas être nécessaire.

OPÉRATION

Il ya trois systèmes: le système de refroidissement, le système d’eau et le système électrique.

Au cours de l’étape de fabrication de glace, la soupape de gaz chaud est fermée. Le gaz réfrigérant chaud

est pompé hors du compresseur vers le condenseur. Le gaz chaud est refroidi par un ventilateur après

passage dans le condenseur. Le sécheur et le ltre réduiront possible saleté et l’humidité dans le réfrigérant.

Le réfrigérant se dilate dans l’évaporateur de refroidissement an que l’eau gèle. Le gaz réfrigérant à basse

pression retourne au compresseur depuis l’évaporateur où le cycle continue. Pendant la phase de récolte de

la glace, la vanne est ouverte. Le gaz réfrigérant chaud est pompé hors du compresseur vers l’évaporateur à

travers la soupape de gaz chaud. Etant donné que le gaz chaud i pas refroidi par le condenseur, le réfrigérant

se réchauffe l’évaporateur. Glace en contact avec l’évaporateur commence à fondre sur la face arrière. La

glace progressivement diapositives de glace au large de l’évaporateur et les gouttes vers le bac de stockage.

Lorsque l’arrivée d’eau est relié à l’alimentation principale en eau, l’eau se remplir la cuve à travers la vanne à

otteur jusqu’à ce que le niveau d’eau dans la cuve se ferme la soupape. Au cours de l’étape de fabrication de

glace, l’eau est pompée à partir du bac à eau sur le tube de distribution d’eau. L’eau distribuée se écoule sur

la surface de l’évaporateur froid où l’eau est convertie en glace. L’eau non gelée sera de retour à l’auge. A la

n du cycle de congélation et pendant la récolte, la valve d’évacuation d’eau est ouverte et l’eau restante est

pompée dans le drain.

DESCRIPTION DU CIRCUIT

1. Première utilisation du temps: La machine à glaçons doit être correctement installé. Mettez le robinet

d’eau, laisser le remplissage de cuve d’eau, puis tourner l’interrupteur d’alimentation en position ON sur

le panneau arrière. La machine à glaçons va commencer à travailler automatiquement. Dans cette étape,

le temps est xé à environ 3 minutes. A cet état, le blanc, vert, jaune et les voyants rouges sont la lumière

ensemble.

2. Fabrication de glace État: Le compresseur, ventilateur de moteur et la pompe sont allumés. La vanne de

gaz chaud est éteint. Lorsque le voyant vert est allumé, l’appareil fonctionne dans le mode de fabrication

de glace contrôlé par une sonde de température sur l’évaporateur. Lorsque le voyant vert clignote,

l’appareil fonctionne dans le mode de fabrication de glace contrôlé par une minuterie xe. Le moteur du

ventilateur est également contrôlé par le capteur de condenseur. Lorsque la température ambiante est trop

basse, le ventilateur du moteur se arrête de fonctionner.

3. Ice récolte Statut: La pompe est éteint. La vanne de gaz chaud, compresseur et du ventilateur du moteur

sont allumés. Le moteur du ventilateur est également contrôlé par le capteur de condenseur. Lorsque

la température ambiante est trop basse, le ventilateur du moteur se arrête de fonctionner. La LED jaune

indique l’état de la récolte de la glace.

4. Ice statut complet et froide préservation étape: Si le bac à glaçons est rempli de glace, la machine se

arrête faire de la glace et se tourne vers l’étape de la conservation par le froid automatiquement. Dans

cette étape, le compresseur fonctionne régulièrement pour garder les basses températures an glace ne

21

Page 22

Instructions Français

fond pas. Le reste des composants électriques sont coupés. La Led blanche indique l’état complet de la

glace et de la LED verte et jaune indique ainsi que l’état de conservation par le froid.

5. Nettoyage Statut: Tourner le commutateur CLEAN de la machine pour nettoyer pendant 3 minutes après

l’interrupteur d’alimentation est allumé. A ce stade, la pompe est en marche. Compresseur, ventilateur de

moteur et sont éteints. La LED verte et jaune clignotent ensemble. Pour arrêter le mode de nettoyage,

tourner la machine «OFF» ou l’appareil se éteint automatiquement après 30 minutes. NOTE: An de

commencer le statut Nettoyez l’appareil doit être allumé. Le commutateur CLEAN doit être activée dans

les 3 minutes avant le démarrage du compresseur. Ne tournez pas le commutateur sur CLEAN lorsque la

machine est en état ou de la glace récolte état de fabrication de glace..

CONTRÔLEUR BOX

Instructions pour LED et boutons:

1. LED blanche: Ice pleine lumière de l’indicateur. Lorsque ce voyant est allumé, le bac de stockage de glace

est plein de glace ou il ya quelque chose entre le capteur de glace complète et l’évaporateur. L’appareil

se arrête faire de la glace. Lorsque les glaçons sont retirés du bac de stockage de glace faisant la sonde

de glace en totale franchise, la LED blanche clignote pendant 3 minutes. Puis l’appareil va redémarrer et

revenir au mode de fabrication de glace.

2. LED verte: fabrication de glace voyant. Lorsque ce voyant est allumé, l’appareil fonctionne dans le mode

de fabrication de glace contrôlé par une sonde de température sur l’évaporateur. Lorsque le voyant vert

clignote, l’appareil fonctionne dans le mode de fabrication de glace contrôlé par une minuterie xe.

3. LED jaune: récolte de glace voyant. Lorsque ce voyant est allumé, l’appareil fonctionne en mode de récolte

de glaçons contrôlée par la sonde de glace complet. Lorsque la LED verte et LED jaune est allumée, cela

signie que l’appareil fonctionne à l’étape de conservation par le froid.

4. LED rouge: alimentation voyant. L’appareil est allumé lorsque le voyant rouge se est allumée

5. Bouton Mode: Principalement pour le service. Lorsque ce bouton est pressé, il peut passer du mode

de fabrication de glace en mode de récolte de la glace ou du mode de récolte de glaçons en mode de

fabrication de glace. Vous pouvez voir le changement de mode de l’état des DEL verte et jaune.

REMARQUE: Si pendant le réglage de la taille de la glace, le «BIN FULL», «ICE» et «LEDS de moisson»

clignotent tout à la fois, ce qui indique que l’appareil est dans le réglage d’usine par défaut de l’ajustement de

la taille de la glace.

CONTRÔLE CONSEIL VÉRIFIE

Initié minuterie

La minuterie est initier un capteur de température monté sur la conduite de liquide de l’évaporateur. Lorsque le

capteur détecte la faible température correcte, le gel chronomètre démarre et la machine entre dans la partie

chronométrée du cycle de congélation. Lorsque la minuterie de congélation démarre, la machine se trouve

dans la partie synchronisée du cycle de congélation. Lorsque la machine entre dans la récolte, la température

se élève, mais la quantité de temps la machine est en récolte est prédéterminé et est contrôlée par la carte

contrôleur. Une fois que le temps a passé, la machine va entrer dans le cycle de récolte. La minuterie ne est

pas réglable, mais la température à laquelle le temporisateur est lancé est réglable.

22

Page 23

Instructions Français

RÉGLAGE DE LA TAILLE DE L’ICE

1. Appuyez et maintenez ainsi le bouton «Clean» et le bouton «Mode» pendant au moins 3 secondes. L’unité

entrera en mode Ice Réglage de la taille. La LED verte clignote en permanence pendant le réglage de la

taille de la glace.

2. Alors que dans le mode de réglage Ice Taille, appuyez sur le bouton «Clean» ou sur le bouton «Mode»

pour la taille de glace désiré.

Réglage de la glace plus petit: En appuyant sur le bouton «Clean», vous pouvez diminuer la taille des cubes

de glace. La LED rouge clignote lorsque vous abaissez la taille de la glace et sera nalement à clignoter au

réglage de la plus petite taille de la glace.

Réglage de la glace plus grande: En appuyant sur le bouton «Mode», vous pouvez augmenter la taille des

cubes de glace. La LED jaune clignote pendant la plus grande taille est dénie et clignote lorsque le réglage

de la plus grande taille de la glace a été atteint. Après 10 secondes sans aucune opération, l’appareil se met

automatiquement mémoriser le réglage actuel et revenir au mode précédent.

BIN FONCTIONNEMENT DE COMMANDE

Le contrôle bin est utilisé pour arrêter la machine lorsque le bac se remplit avec de la glace. Le contrôle de la

poubelle doit être vérié lors de l’installation ou le démarrage initial et lors de l’entretien. Il ya un interrupteur

de bac pour chaque évaporateur. Le bras de l’actionneur de l’interrupteur de bac entre en contact avec le

rideau de démarrage. Lorsque le bac est plein de glace, le rideau de démarrage est maintenue ouverte

lorsque la glace tombe de l’évaporateur. Ceci libère la pression du bras d’actionnement de l’interrupteur de

bac permettant d’ouvrir l’interrupteur. Unités placées sous les comptoirs et les machines sans rideaux: Une

glissade de glace au fond de l’évaporateur est utilisé sur tous sous le comptoir unités et certaines unités

modulaires. La glissière pivote de haut en bas et dispose d’un interrupteur magnétique qui détecte sa position.

Lorsque la glace est assis sur le contrôle, la glissière orientée vers le bas ce qui indique que la glace est

présente (et déconnecter le circuit de l’interrupteur Reed). Lorsque la glace est retiré, la glissière pivote et la

connexion est terminée permettant à la machine de commencer à produire à nouveau la glace.

AJUSTEMENT BIN CONTRÔLE

Tous les modèles (sauf ceux sans rideaux): Vérier que l’interrupteur de bac pour un réglage correct en

balançant le bas du rideau loin de l’évaporateur. Porter lentement le rideau vers l’évaporateur. Le commutateur

doit fermer quand le bord inférieur du rideau est aligné sur le bord externe du bac à eau. Réglez le

commutateur en desserrant les vis qui maintiennent le commutateur en place. Déplacer l’interrupteur sur la

position correcte et resserrer les vis. Vériez à nouveau le réglage. Selon les modèles de compteur ou ceux

sans rideaux: Il n’y a pas les ajustements nécessaires pour le bac de commutateur (Reed magnétiques).

23

Page 24

Instructions Français

ENTRETIEN

RISQUE DE CHOC ÉLECTRIQUE

Coupez l’alimentation électrique avant

de commencer le retrait des pièces.

Avant Entretien:

1. Soyez sûr l’alimentation électrique est de 115 VAC, 60Hz, 15A et est correctement mise à la terre pour

protéger le personnel de maintenance.

2. Si des pièces électriques sont lâches ou se il ya un risque de court-circuit, débranchez immédiatement le

pouvoir.

PROCÉDURE DE MAINTENANCE

1. Le nettoyage doit être effectué au moins tous les six mois. Conditions d’eau locales peuvent exiger que le

nettoyage être effectué plus souvent.

2. Vériez l’épaisseur de pont de glace. L’épaisseur doit être comprise entre 1 / 16-1 / 8 ‘’.

3. Vériez le niveau d’eau dans auge. Vérier le niveau adéquat de l’eau et de l’ajustement et dépanner se il

ya un niveau incorrect.

4. Nettoyer le condenseur pour assurer l’écoulement de l’air.

5. Vérier les fuites de toute nature: l’eau, réfrigérant, huile, etc.

6. Vériez l’interrupteur bin pour un réglage correct.

7. Vériez toutes les connexions électriques.

8. Vérier l’huile du moteur du ventilateur le cas échéant.

NETTOYAGE ET ASSAINISSEMENT

Des problèmes peuvent se produire si les procédures suivantes ne sont pas effectuées tous les 6 mois:

1. Retirez le panneau avant.

2. Assurez-vous qu’il n’y a pas de glace sur l’évaporateur. Se il est, attendre opération est terminée et tourner

la machine «OFF».

3. Retirer ou faire fondre toute la glace dans le bac de stockage.

4. Ajouter la quantité recommandée de détergent autorisé à l’auge de l’eau conformément aux instructions

sur l’étiquette sur le contenant.

5. Initier le cycle de nettoyage au niveau du commutateur de la carte contrôleur en tournant la machine et de

passer à la mise en «CLEAN». Note: Ceci doit être fait dans les trois minutes de tourner la machine «ON».

Laisser agir le nettoyant circuler pendant environ 15 minutes pour enlever les dépôts de minéraux.

6. Après 15 minutes (ou 30 minutes automatiquement), arrêter le processus et les égoutter. Remplir avec de

l’eau propre et de fonctionner pendant encore cinq minutes, puis égouttez à nouveau. Remplissez la cuve

avec de l’eau frais entrant.

24

Page 25

Instructions Français

7. Arrêtez le cycle de lavage en positionnant le sélecteur sur la position «OFF». Retirer le rideau de

démarrage (le cas échéant) et inspecter l’évaporateur et du déversoir de l’eau (de haut en plastique de

l’évaporateur) pour assurer tous les résidus de minéraux a été supprimé.

8. Si nécessaire, essuyez l’évaporateur, l’évacuateur de crues et d’autres surfaces avec un chiffon doux et

propre pour enlever tout résidu restant. Si nécessaire, retirer le tube de distribution d’eau, démonter et

nettoyer avec un goupillon. Remonter tous les composants et répétez les étapes 4 à 7 selon les besoins

pour enlever les résidus.

9. Eteignez l’appareil et nettoyer le bac à eau pour éliminer toutes les dimensions ou la boue accumulation. Si

nécessaire, retirez le bac à eau pour atteindre toutes les zones de boue.

10. Préparer 1½ à 2 gallons (5.7 à 7.5 litres) de l’équipement alimentaire approuvé d’hypochlorite (EPA / FDA)

désinfectant sodium pour former une solution avec un rendement en chlore libre de 100 à 200 ppm.

11. Ajouter solution désinfectante assez pour remplir l’abreuvoir à craquer et activer l’interrupteur à la position

«propre» et permettre la circulation de se produire pendant 10 minutes et inspecter tous les raccords

démontés pour les fuites. Pendant ce temps, essuyez tous les autres domaines de démarrage de la

machine de glace et les surfaces intérieures du bac, déecteur et porte avec la solution désinfectante

restant. Inspectez pour se assurer que toutes les pièces, attaches, bulbes des thermostats fonctionnels (si

utilisé), etc., sont en place.

12. Après trois minutes, arrêter le processus et les égoutter. Remplir avec de l’eau propre de fonctionner

encore 5 minutes et égoutter de nouveau. Remplissez la cuve avec de l’eau frais entrant.

13. Placez l’interrupteur sur la position «ON» et remplacer ou fermer le panneau. Jeter les deux premières

récoltes de glace.

REMPLACEMENT BOÎTE DE CONTRÔLE ET CAPTEUR DE TEMPERATURE

• Retirez le couvercle arrière et le panneau avant ou sur le côté.

• Repérez le boîtier de contrôle électronique de l’appareil.

• Retirez délicatement les capteurs de température (une à l’évaporateur, un autre au niveau du condenseur).

• Desserrez les vis de xation de la boîte de contrôle et à remplacer. Inversez les étapes précédentes pour

remonter.

• Si vous devez remplacer un capteur de température, retirer le capteur, ouvrez le panneau de la boîte de

contrôle, tirez l’autre extrémité de la sonde et remplacer. Inverser ces étapes pour remonter.

REMPLACEMENT DE LA POMPE A EAU

• Eteignez l’appareil et débranchez-le de la prise.

• Retirer le capot avant.

• Débrancher les lignes raccordées à la pompe à eau, y compris le tube de sortie d’eau.

• Desserrer les vis. Remplacer la pompe par une nouvelle.

• Inversez les étapes ci-dessus pour remonter.

REMPLACEMENT DES COMPOSANTS DU SYSTÈME DE REFROIDISSEMENT

• Retirez le panneau supérieur et panneau de gauche, recherchez le compresseur, enlever le clip et

remplacer les composants défectueux.

25

Page 26

Instructions Français

• Inversez les étapes ci-dessus pour remonter.

RISQUE DE CHOC ÉLECTRIQUE

• Eteignez l’appareil et débranchez-le former la prise.

• Si le compresseur doit être remplacé, retirez le couvercle supérieur et de localiser le compresseur.

• Débranchez les lignes et supprimer la ligne du sol, ouvrir le processus / aspiration, retirer le réfrigérant,

prendre le compresseur et le remplacer.

• Inversez les étapes ci-dessus pour remonter.

REMPLACEMENT DU MOTEUR VENTILATEUR ET BLADE

• Retirer les panneaux supérieur et droite.

• Localisez le moteur du ventilateur, débranchez les lignes connectées avec le moteur du ventilateur,

desserrez les vis du support de support de xation et le moteur du ventilateur, retirez l’unité endommagée

et la remplacer par une nouvelle.

• Inversez les étapes ci-dessus pour remonter.

REMPLACEMENT DE LA VANNE DE GAZ CHAUD, PLUS SEC ET EVAPORATOR

• Retirez le panneau supérieur.

• Retirer le réfrigérant. Localisez le plus sec et la vanne de gaz chaud, soudure ouverte, remplacer la vanne

sèche et chaude gaz et soudure. Remplacer le réfrigérant.

• Inversez les étapes ci-dessus pour remonter.

• Si nécessaire, remplacer l’évaporateur.

• Retirer le réfrigérant. Retirez le haut des panneaux avant et, de localiser l’évaporateur, ouvrir le processus /

aspiration, ouvrir les deux soudures, le remplacer par un nouvel évaporateur. Remplacer le réfrigérant.

• Inversez les étapes ci-dessus pour remonter.

DÉPANNAGE

La machine ne fonctionne pas.

Étape Chèque Si oui, passez à Si non, passez à

A1 Est l’interrupteur et se sont

tournés vers le?

A2 Y at-il le pouvoir de la machine? Refaire l’installation

A3 Est le bac plein? A4 Prenez glace sur

A4 Est le contrôle bin ajusté? Ajuster A5

A5 Est l’interrupteur de sécurité à

haute pression déclenché?

A6 Est le commutateur de sélection

sur?

Allumer A2

A3

électrique

A6 Réinitialiser condenseur

propre

Remplacer

26

Page 27

Instructions Français

Pistes de machine, mais ne produit pas de glace.

Étape Chèque Si oui, passez à Si non, passez à

B1 L’eau courante sur l’évaporateur? Le tableau de dépannage

suivant.

B2 Est le compresseur fonctionne? B5 B3

B3 Y at-il le pouvoir de le

compresseur?

B4 Le commutateur défectueux? Remplacer

B5 Y at-il des fuites d’eau de la

cuve?

B6 Est la pression du réfrigérant

haute?

B7 Est la pression de réfrigérant

bas?

B8 Y at-il une restriction du côté bas? Réparation TXV est défectueux

Machine produit cubes nuageux ou incomplètes.

Étape Chèque Si oui, passez à Si non, passez à

C1 L’eau courante sur l’évaporateur? C2 C3

C2 Le niveau de la machine? La qualité de l’eau entrant

C3 Le niveau de l’eau de pénétration

correcte?

C4 Est la pression d’alimentation

correcte?

C5 Y at-il une fuite d’eau? Réparer la fuite Ajuster robinet à otteur

C6 Est le tube de distribution d’eau

branché correctement?

C7 Est la pompe à eau

endommagée?

Réparer la fuite B6

Nettoyer le condenseur ou

consulter les poids lourds

Vérier les fuites B8

est pauvre.

C6 C4

C5 Corriger la carence

Nettoyer / remplacer C7

Remplacer / Réparer la

pompe

B2

Vériez mauvaise connexion

ou composants de départ

B7

Niveler l’unité

Nettoyer l’évaporateur

déversoir

Produit cubes appropriés mais est lente dans la production.

Étape Chèque Si oui, passez à Si non, passez à

D1 L’appareil est installé

correctement?

D2 Est la pression de la tête trop

élevé?

D3 Le condenseur est propre? Vériez le système de

D2 Installez correctement l’unité

D3 Vériez le système de

réfrigération

Propre

réfrigération

27

Page 28

Instructions Français

Cubes sont creux.

Étape Chèque Si oui, passez à Si non, passez à

E1 Est la température de l’eau

supérieure à 100 ° F?

E2 Y at-il une bonne circulation sur

l’évaporateur?

E3 Y at-il des fuites d’eau de la

purge?

E4 Fonctionne le réglage du cube? La taille des glaçons

E5 Le capteur de l’évaporateur

lâche?

E6 Est le l tendu de la sonde

évaporateur?

E7 Est le contrôleur endommagé? Remplacer

Épaisseur de pont est inégale.

Étape Chèque Si oui, passez à Si non, passez à

F1 Est la température de l’eau

supérieure à 100 ° F?

F2 L’eau est en cours d’exécution

dans le bac?

F3 L’eau se échappe de la purge? Remplacer la soupape F4

F4 Est la pression d’aspiration

élevée?

Corrigez la température E2

E3 Passez à la section C

Remplacer la vanne E4

E5

Réinitialiser

Serrer E6

E7 Serrer la connexion de bêche

pour le conseil

Corrigez la température F2

Consultez les sections C, D,

E ou vérier goulotte de fuite

Vériez la vanne de gaz

chaud

F3

Rechargez et / ou vérier la

TXV

Épaisseur de pont varie avec chaque cycle.

Étape Chèque Si oui, passez à Si non, passez à

G1 Est la température de l’eau? Réglez correctement la

température

G2 Est la vanne de purge fuit? Remplacer la vanne G3

G3 Est la vanne de gaz chaud

endommagé?

G4 Sont des capteurs connectés à la

carte?

G5 Est le contrôleur endommagé? Remplacer G6

G6 Est-ce que la soupape de

dilatation thermique endommagé?

Remplacer G4

G5 Serrer les connexions à

Remplacer

G2

fourche

28

Page 29

Instructions Français

La machine ne démarre pas produire des cubes de glace.

Étape Chèque Si oui, passez à Si non, passez à

H1 Ne fonctionne la vanne de purge? H6 H2

H2 Est le modèle de gel même? H3 H2

H3 Est la vanne de purge fuit? Remplacer H3

H4 Le compresseur est défaillant? Remplacer H4

H5 Le système est fourni avec trop

de tension?

H6 Est le relais défectueux? Remplacer H7

H7 Est la carte défectueuse? Remplacer

Récoltes de machine, mais revient à fabrication de la glace prématurément.

Étape Chèque Si oui, passez à Si non, passez à

I1 Est la purge manuelle ouverte? Remplacer la vanne de

I2 Est l’interrupteur de sécurité à

haute température ouverte?

I3 Est le relais endommagé? Remplacer

Régler la tension Remplacer TXV

I2

purge

Remplacer I3

Longueur de la récolte est excessive.

Étape Chèque Si oui, passez à Si non, passez à

J1 La machine est correctement

installé?

J2 Est la formation de glace

correctement?

J3 Est la pression d’aspiration trop

faible?

J4 L’évaporateur est propre? J5 Clean conséquence

J5 Est le pont de glace correcte? J6 Aller au sections F ou G

J6 Le niveau de la machine? J7 Niveler l’unité

J7 Est-eau couler sur l’évaporateur

pendant la récolte?

J8 Est la vanne de purge fuit? Remplacer J9

J9 Est le relais endommagé? Remplacer J10

J10 Est le sélecteur endommagé? Remplacer

J11 Est la pression d’aspiration

endommagé?

J12 Est la pression de refoulement

faible pendant la congélation?

J2 Correct

J3 Charge faible - Recharge

Remplacer la vanne de gaz

chaud

Nettoyer ou J11 J8

Remplacer évaporateur J12

La température ambiante

est trop faible

J4

Remplacer la vanne de gaz

chaud

29

Page 30

Instructions Français

Évaporateur devient chaud.

Étape Chèque Si oui, passez à Si non, passez à

K1 L’appareil est installé

correctement?

K2 Est le ventilateur du condenseur

tourne?

K3 Les connexions à chaud de la

vanne de gaz sont-ils lâches?

K4 La machine est chargée

correctement?

K5 Est le contrôleur fonctionne

correctement?

Le compresseur ne démarre pas.

Étape Chèque Si oui, passez à Si non, passez à

L1 Le condenseur est sale? Propre L2

L2 Possède un ventilateur arrêté ou

est sale?

L3 Les ls sont serrés sur le

contrôleur?

L4 Sont le compresseur commence

composants endommagé?

L5 Est la carte contrôleur

endommagé?

L6 Le compresseur est

endommagé?

K2 Installez correctement l’unité

K3 Serrer la lame, vérier les ls

ou remplacer le moteur

Serrer toutes les connexions

de câblage

K5 Chargez correctement

Remplacer la vanne de gaz

chaud

Réparation / clean L3

L4 Serrer tous les raccords

Remplacer les composants L5

Remplacer L6

Remplacer

K4

Remplacer la carte contrôleur.

bêche.

Le compresseur fonctionne mais pas de glace est produite.

Étape Chèque Si oui, passez à Si non, passez à

M1 Le conduit d’air obstrué? Dégagez le chemin M2

M2 Le condenseur est sale? Propre M3

M3 Le ventilateur tourne? M4 Remplacer le moteur du

ventilateur

M4 Y at-il une fuite de uide

frigorigène?

M5 Est le tube de TXV ou casquette

fonctionne normalement?

M6 Est-ce que le mode de fabrication

de glace se convertir à récolter?

Ajouter la vanne, nettoyer le

réfrigérant, xer et charge

(remplacer le ltre)

M6 Ajouter la vanne, nettoyer le

M5

réfrigérant, xer et charge

(remplacer le ltre)

Remplacer la carte contrôleur

30

Page 31

Instructions Français

Machine fait un bruit excessif.

Étape Chèque Si oui, passez à Si non, passez à

N1 Les panneaux sont lâches? Serrer toutes les vis N2

N2 Le ventilateur de frapper le

capot?

N3 Est la pale de ventilateur perdre? Serrer N4

N4 La pompe est bruyante? N5 N6

N5 Y at-il un objet dans l’hélice? Retirez l’objet Remplacer la pompe

N6 Est le bruit du compresseur? Remplacer le compresseur

ADVANCED COMPOSANTS TECHNIQUES DE DÉPANNAGE

Refrigerant Cycle et Composants

Avant de diagnostiquer le système de réfrigération, il est très important que la charge de réfrigération est

correcte. Chaque fois que le système de réfrigération a été ouvert, le ltre déshydrateur doit être remplacée et

la charge de réfrigérant approprié doit être pesé dans.

Réaligner N3

Pressions de réfrigérant

La pression d’aspiration au début du cycle de congélation peut varier de + / 10 psi (0,7 bar de) en fonction

de conditions de fonctionnement. Des pressions inférieures à ce qui peut indiquer une charge insufsante.

La pression de décharge sur l’air refroidi unités varient en fonction des conditions ambiantes. Le réfrigérant à

l’état gazeux est pompé à travers le système de réfrigération par un compresseur hermétique au condenseur.

La chaleur est retirée du réfrigérant, soit par la circulation d’air forcé à travers un condenseur refroidi par

air ou transférer la chaleur du réfrigérant à l’eau à travers un condenseur refroidi à l’eau. Les modications

apportées à un réfrigérant liquide lorsque refroidis. Le uide frigorigène à l’état liquide passe à travers un ltre

déshydrateur. Le ltre pièges les plus sèches de faibles quantités de l’humidité et les particules étrangères du

système. Le ltre déshydrateur doit être remplacée chaque fois que le système de réfrigération est ouvert ou si

le réfrigérant a été complètement perdue.

Compresseur

Le compresseur fonctionne pendant tout le cycle. Si les vannes du compresseur sont endommagés, le

compresseur sera incapable de pomper le uide frigorigène efcacement. Valves endommagées peuvent être

le résultat d’un autre problème dans le système de réfrigération. Lorsqu’un compresseur est remplacé, il est

important que la charge de réfrigération être pesé dans le système et vérier le fonctionnement pour empêcher

une défaillance de la répétition. Un compresseur inefcace aura généralement une pression d’aspiration

supérieure à la normale à la n du cycle. Le cycle de congélation sera plus long que la normale et / ou le cycle

de récolte peut être excessivement long. Vériez les ampères du compresseur 5 minutes dans le cycle de

congélation. Si les ampères est inférieur à 70% du montant total évalué, le compresseur peut être inefcace.

Ces symptômes peuvent aussi être causés par d’autres problèmes, il est donc important d’utiliser les tableaux

de dépannage pour diagnostiquer un problème. Le condenseur à air est situé à l’arrière de l’armoire. L’air est

31

Page 32

Instructions Français

aspiré à travers le condenseur par un moteur de ventilateur et libéré via le panneau de droite. En vertu de

la contre-modèles de consommation et de l’air de décharge à travers le panneau avant. Ne pas bloquer la

circulation d’air, car cela fera une défaillance prématurée de la machine et annulera la garantie.

Compresseur et démarrer les composants

Le compresseur doit fonctionner pendant tout le cycle. Si la machine est en position ON mais le compresseur

ne fonctionne pas, vériez le contacteur du compresseur pour voir si elle est correctement connecté. Si

le contacteur ne est pas connecté, le problème ne est pas avec le compresseur ou les composants de

démarrage du compresseur. Si le contacteur est activé et la tension est correcte à travers le contacteur, il

pourrait y avoir un problème avec l’un des composants de départ ou le compresseur. Il est recommandé que le

compresseur est remplacé composants de départ lors du remplacement du compresseur.

DÉBRANCHEZ AVANT ENTRETIEN!

Si le compresseur utilise une surcharge interne, être certain que le compresseur a refroidi et la surcharge a été

réinitialisé avant de diagnostiquer le compresseur. Si le compresseur est cool et ne fonctionne toujours pas,

vériez les enroulements du moteur du compresseur en retirant d’abord les ls aux bornes du compresseur.

Avec un ohmmètre, vérier la continuité entre les trois terminaux, si un circuit ouvert existe entre l’une des

bornes, le compresseur peut avoir besoin d’être remplacé. Vérier la continuité de chaque terminal au corps de

compresseur, si la continuité se trouve de ne importe quel terminal au corps de compresseur, les enroulements

de compresseur sont mis à la masse et le compresseur devront être remplacés. Si le compresseur semble être

bon à ce point, il est conseillé d’utiliser un analyseur de compresseur pour isoler le compresseur à partir des

composants de départ lors de la vérication d’un rotor bloqué. Si elle ne est pas disponible, le compresseur

composants de départ doit être vériée. Si tous les composants de départ travaillent, vérier l’ampérage de

la borne du compresseur, en veillant à la bonne tension est fournie au compresseur et tout le câblage est

correctement connecté. Si le compresseur ne démarre pas et il est ampérage excessive, (voir ampères de

rotor bloqué sur le compresseur tag) le compresseur a un rotor bloqué et doit être remplacé.

Surcharge (externe)

Si il n’y a pas ampérage vérier la surcharge du compresseur. La surcharge du compresseur peut être

contrôlée pour assurer la continuité après l’avoir sortie du compresseur et le laisser refroidir à température