Page 1

Back Bar Bottle Coolers

Models BD-CN-0007-S, 0019-S, 0023-D, 0032-D, BB-CN-0012-D, 0016-D, 0020-D

Items 42941, 38008, 42942, 38009, 42943, 38010, 42944

Instruction Manual

Revised - 02/24/2017

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model BD-CN-0007-S / Model BB-CN-0012-D / Model BD-CN-0019-S

Model BB-CN-0016-D / Model BD-CN-0023-D / Model BB-CN-0020-D

Model BD-CN-0032-D

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Cleaning and Maintenance

-------------------------------------------------------------------------------------- 8 - 10

------------------------------------------------------------------------------------- 10 - 13

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 6

-------------------------------------------------------------------------- 7

Page

--------------------------------------------------------------- 13 - 16

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

------------------------------------------------------------------------------------------------- 38

---------------------------------------------------------------------------- 17 - 30

---------------------------------------------------------------------- 31 - 37

---------------------------------------------------------------------------- 39

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

When using electrical appliances basic safety precautions should be followed:

• This cooler must be properly installed and located in accordance with the installation service

representative.

• Do not allow children to climb, stand or hang on the shelves in the cooler. They could damage the unit and

seriously injure themselves.

• Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or any other

appliance.

4

Page 5

Safety and Warranty

• Unplug the unit from the electrical outlet before cleaning or making repairs.

• Setting the temperature controls to the 0 (zero) position does not remove power to the light circuit,

perimeter heaters or evaporator fans.

NOTE: It is strongly recommended that any servicing be performed by an authorized instructions before it is

used.

ELECTRICAL SAFETY

Do not under any circumstances cut or remove the grounding prong from the power cord. For safety this

appliance must be properly grounded at all times.

• The power cord of this cooler is equipped with a grounding plug which mates with a standard grounding

wall outlet to minimize the possibility of electric shock hazard.

• If the outlet is a standard 2-prong outlet, it must be replaced with the properly grounded wall outlet. NEVER

USE AN ADAPTER PLUG!

• Have the wall outlet and circuit checked by a qualied electrician to make sure the outlet is properly

grounded. Check the incoming voltage with a voltmeter.

• DO NOT USE EXTENSION CORDS. The use of extension cords to connect the cooler will void warranty.

The unit must be close enough to the electrical supply so that extension cords are never used.

• The cooler should always be plugged into its own dedicated circuit with a voltage rating that matches the

rating plate. This provides the best performance and also prevents overloading wiring circuits which could

become a re hazard from overheated wires.

• Never unplug your cooler by pulling on the power cord. Always grip the plug rmly and pull straight out from

the outlet.

• Repair or replace immediately all power cords that have become frayed or otherwise damaged. Do not use

a power cord that has cracks or abrasion damage along its length or at either of its ends.

• When removing the cooler away from the wall be careful not to run over or damage the power cord.

• When the cooler is installed or used,all the packaging (including carton and plastic wrap) should be

removed.

• Keep the cooler stable to avoid vibration and noise.

• The cooler should be installed in a place with good ventilation and a space of at least 4” should be allowed

between the surrounding walls and the cabinet wall for air circulation.

• Unit should be placed far from any heating source to avoid decrease of refrigeration efciency.

• Install the cooler in a dry place to prevent rust from forming on the compartment body, which may affect the

electrical insulation.

It is strongly recommended that any servicing be performed by an authorized service representative.

NOTE: Wiring diagram can be referenced by removing the front louvered grill, and looking on the inside

cabinet wall electrical supply so that extension cords are never used.

CAUTION

• The cooler must be grounded correctly, never with a heating pipe and coal gas pipe.

• In case of damage to electrical cord and plug, please contact after sale service and never do it yourself.

5

Page 6

Safety and Warranty

• When unplugging unit, please grasp by the plug, not the cord.

• If the voltage is unstable, please select a suitable automatic voltage regulator.

• If the power cuts off, you should wait for at least 5 minutes before turning on the unit again to avoid

damage to the compressor.

• Never store any ammable, explosive or corrosive liquid or gas in or near the cooler.

PROPER DISPOSAL OF EQUIPMENT; DANGER! RISK OF CHILD ENTRAPMENT

Child entrapment and suffocation are not problems of the past. Junked or abandoned refrigerators are still

dangerous, even if they will sit for “just a few days.” If you are getting rid of an old refrigerator, please follow the

below instructions to help prevent a terrible accident.

• Remove the doors.

• Leave shelves in place to prevent children from easily climbing inside.

REFRIGERANT DISPOSAL

Your old refrigerator may have a cooling system that used “ozone depleting” chemicals. If you are throwing

away your old refrigerator, be sure the refrigerant is removed for proper disposal by a qualied service

technician. If you intentionally release any refrigerants you can be subject to nes and imprisonment under the

provisions of the environmental regulations.

1 YEAR PARTS AND LABOUR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see www.omcan.com/warranty.html for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

6

Page 7

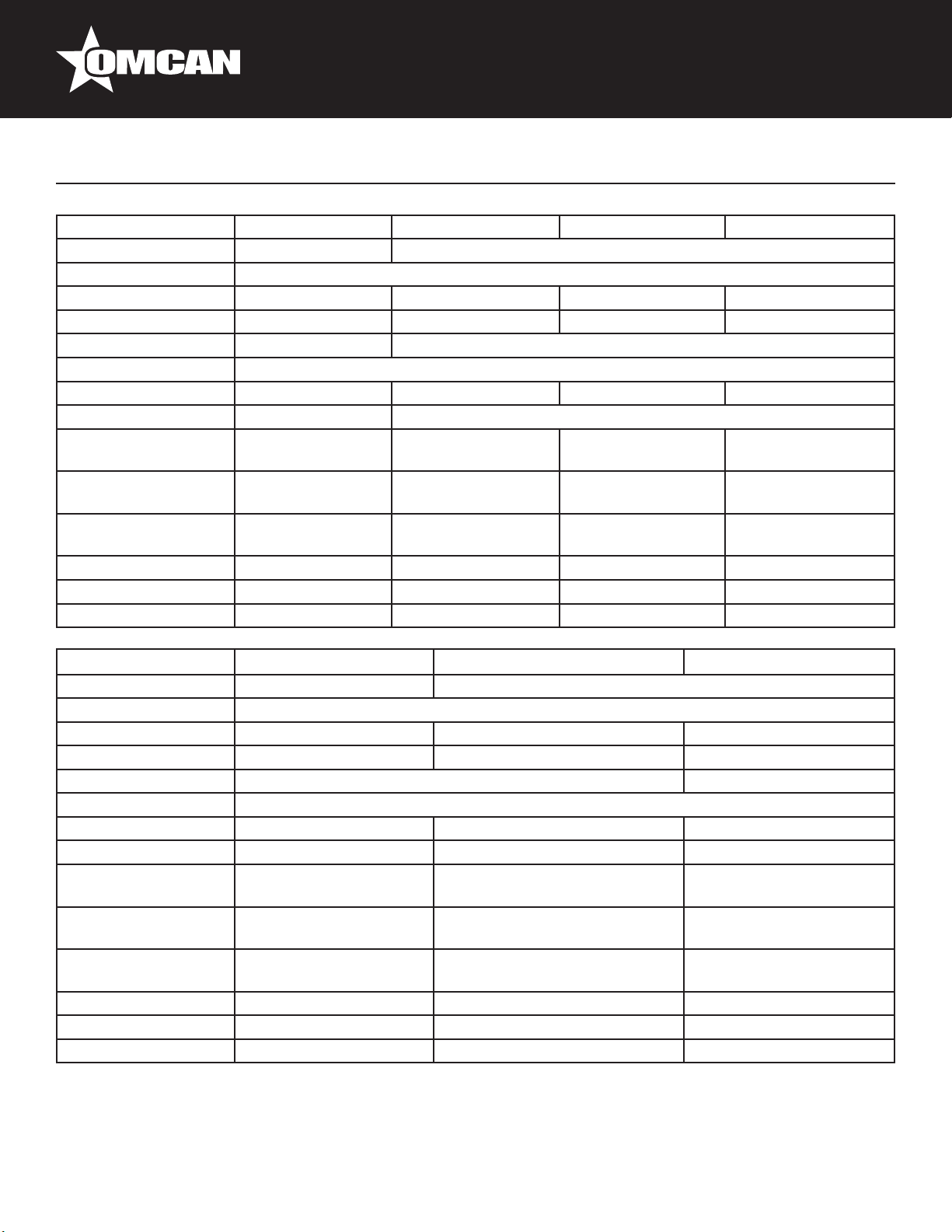

Technical Specications

Model BD-CN-0007-S BB-CN-0012-D BD-CN-0019-S BB-CN-0016-D

Number of Doors 1 2

Temperature Range 33 - 41°F / 0 - 5°C

Capacity 6.5 cu.ft. / 186 L 11.8 cu.ft. / 335 L 19 cu.ft. / 546 L 15.8 cu.ft. / 446 L

Number of Shelves - 4 2 4

Compressor HP 1/6+ 1/3+

Voltage 115V / 60Hz

Power 0.18 kW 0.44 kW 0.42 kW 0.46 kW

Amps 1.8A 6.4A

Dimensions (DWH)

Interior Dimensions

(DWH)

Packaging

Dimensions (DWH)

Weight 150 lbs. / 68 kg. 271 lbs. / 123 kg. 293 lb / 133 kg 326 lbs. / 148 kg.

Packaging Weight 187 lbs. / 85 kg. 315 lbs. / 143 kg. 337 lb / 153 kg 380 lbs. / 173 kg.

Item Number 42941 38008 42942 38009

772 x 597 x 984mm

30.4” x 23.5” x 38.8”

464 x 495 x 768mm

18.3” x 19.5” x 30.3”

826 x 654 x 1140mm

32.5” x 25.8” x 44.9”

620 x 1240 x 919mm

24.4” x 48.8” x 36.2”

508 x 919 x 787mm

20” x 36.2” x 31”

701 x 1300 x 1074mm

27.6” x 51.2” x 42.3”

705 x 1495 x 921mm

27.8” x 58.9” x 36.3”

594 x 1181 x 787mm

23.4” x 46.5” x 31”

775 x 1559 x 1060mm

30.5” x 61.4” x 41.8”

620 x 1544 x 919mm

24.4” x 60.8” x 36.2”

508 x 1224 x 787mm

20” x 48.2” x 31”

701 x 1610 x 1074mm

27.6” x 63.4” x 42.3”

Model BD-CN-0023-D BB-CN-0020-D BD-CN-0032-D

Number of Doors 2 3

Temperature Range 33 - 41°F / 0 - 5°C

Capacity 23.3 cu.ft. / 666 L 19.6 cu.ft. / 556 L 32 cu.ft. / 916 L

Number of Shelves 2 6 2

Compressor HP 1/3+ 3/4-

Voltage 115V / 60Hz

Power 0.54 kW 0.5 kW 0.64 kW

Amps 7.3A 7.4A 7.5A

Dimensions (DWH)

Interior Dimensions

(DWH)

Packaging

Dimensions (DWH)

Weight 348 lb / 158 kg 355 lbs. / 161 kg. 375 lb / 170 kg

Packaging Weight 331 lb / 150.1 kg 410 lbs. / 186 kg. 419 lb / 190 kg

Item Number 42943 38010 42944

705 x 1756 x 921mm

27.8” x 69.1” x 36.3”

594 x 1435 x 787mm

23.4” x 56.5” x 31”

787 x 1829 x 1067mm

31” x 72” x 42”

620 x 1849 x 919mm

24.4” x 72.8” x 36.2”

508 x 1529 x 787mm

20” x 60.2” x 31”

701 x 1910 x 1074mm

27.6” x 75.2” x 42.3”

705 x 2296 x 921mm

27.8” x 90.4” x 36.3”

594 x 1975 x 787mm

23.4” x 77.8” x 31”

775 x 2330 x 1060mm

30.5” x 91.8” x 41.8”

7

Page 8

Installation

Tools required: Phillips screw driver.

• Use a Phillips screw driver to remove the four (4) screws from the L-bracket connecting the unit to the

wood skid. Then remove the L-bracket from the unit.

• Remove skid by unscrewing all base rail anchor brackets. Place skid to the side.

• Carefully upright cabinet.

When lifting unit do not use the counter top as a lifting point. Also remember to leave cabinet upright

for 24-hours before plugging into power source.

• Set unit in its nal location. Make sure there is adequate ventilation in this location. Under extreme heat

conditions (+100°F / +38°C) an exhaust fan may be necessary.

• Proper leveling of the unit is critical to operating success (for non-mobile models). Effective condensate

removal and door operation will be affected by leveling.

• The cooler should be leveled front to back and side to side with a level.

Warning: Installation without proper ventilation will void the manufacturer’s warranty.

SEALING CABINET TO FLOOR

Step 1 - Position Cabinet

Allow one (1) inch between the wall and rear of the refrigerated bar equipment to assure proper ventilation.

Step 2 - Level Cabinet

Cabinet should be level side to side and front to back. Place a carpenter’s level in the interior cabinet oor in

four places:

A Position level in the inside oor of the unit near the door. Level should be parallel to cabinet front.

B Position level at the inside rear of cabinet. Level should be placed parallel to cabinet back.

C Perform similar procedures to steps A and B by placing the level on inside oor left and right sides parallel to

the depth of the cooler. Level cabinet.

Step 3 - Applying Sealant

• Draw an outline on the base of the oor.

• Raise and block the front side of the cabinet.

• Apply a bead of NSF Approved Sealant (see list below) to oor half an inch inside the outline drawn. The

bead must be heavy enough to seal the entire cabinet surface when it set down on the sealant.

• Raise and block the rear of the cabinet.

• Apply sealant on oor as outlined above on other 3 sides.

• Examine to see that the cabinet is sealed to oor around entire perimeter.

NSF APPROVED SEALANTS:

• Minnesota Mining #ECU800 Caulk.

• Minnesota Mining #ECU2185 Caulk.

8

Page 9

Installation

• Minnesota Mining #ECU1055 Bead.

• Minnesota Mining #ECU1202 Bead.

• Armstrong Cork - Rubber Caulk.

• Products Research Co #5000 Rubber Caulk.

• GE Silicone Sealer.

• Dow Corning Silicone Sealer.

NOTE: Asphalt oors are very susceptible to chemical

attack. A layer of tape on the oor prior to applying the

sealant will protect the oor.

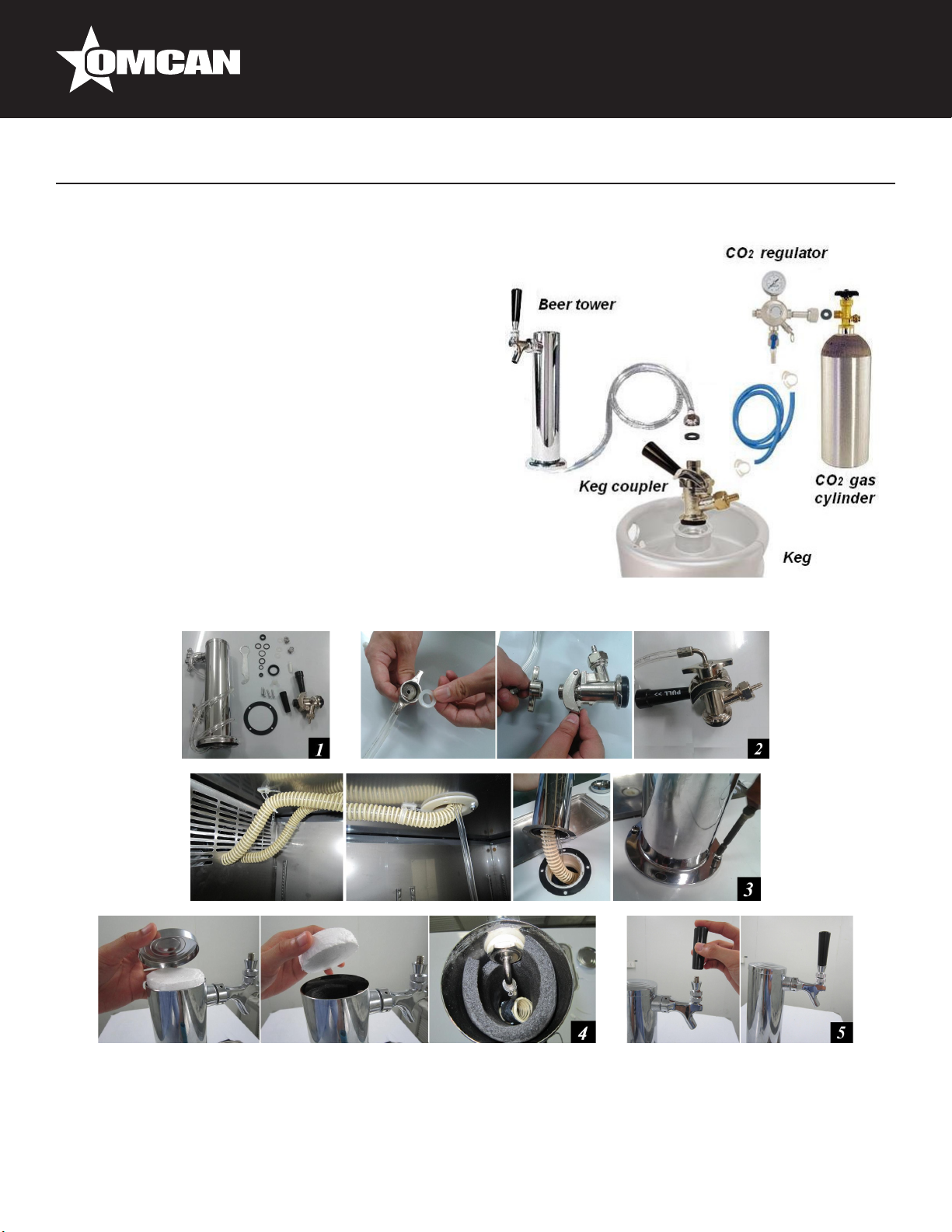

BEER DISPENSING SYSTEM

DRAFT BEER TOWER INSTALLATION

1. Beer tower contents.

2. Thread the beer line connector to the keg coupler.

3. Insert an air hose into the beer tower and secure the

beer tower to cabinet with the gasket under the beer

tower.

4. Make sure the air hose closes at the top of beer tower at all times. This is to keep the beer faucet cold.

5. Secure the handle onto beer faucet.

9

Page 10

Installation

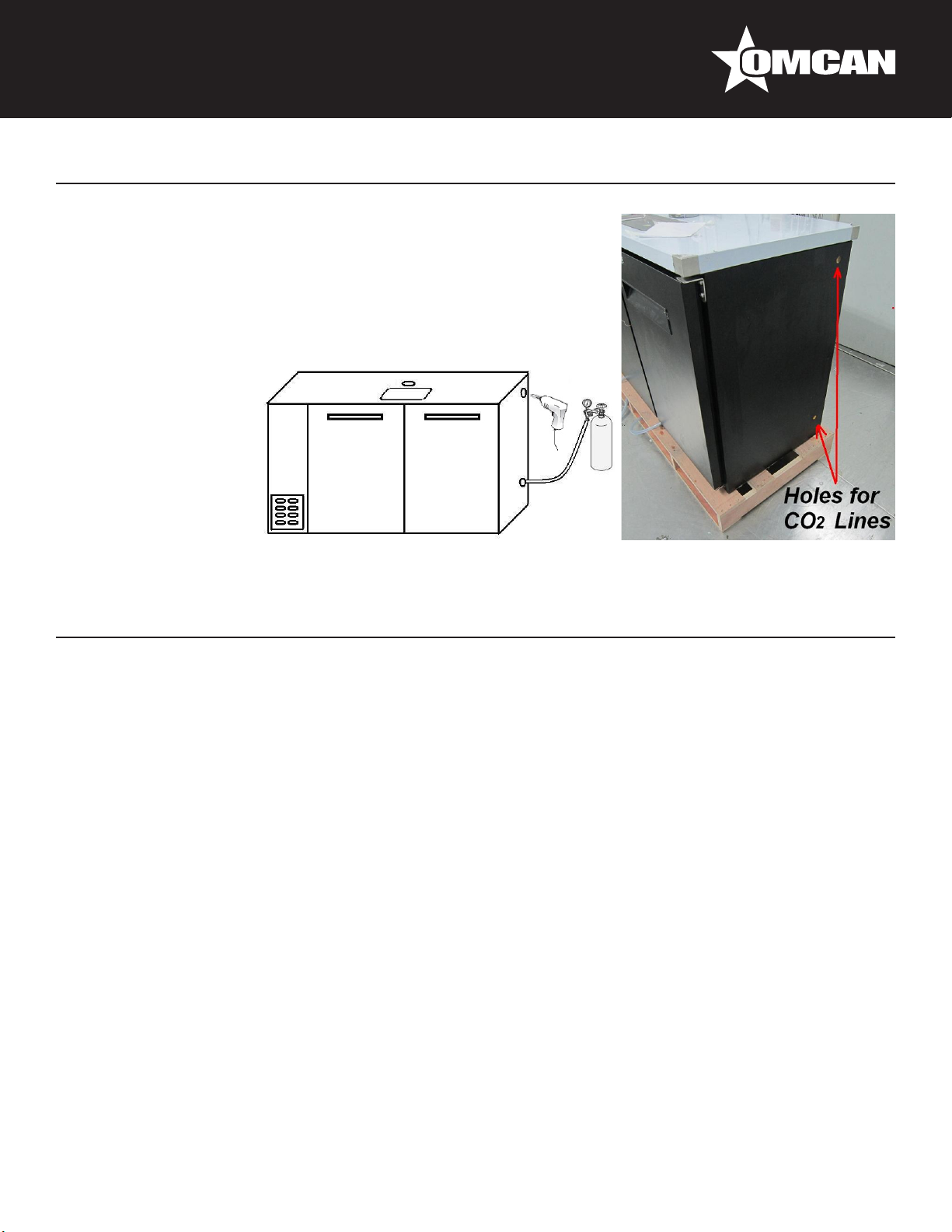

REMOTE CO2 GAS CYLINDER INSTALLATION

1. Remove the plug on the right wall of the machine with a pair of pliers.

2. Drill and make hole through the wall. Holes can be located in two

different areas. Reference above pictures for the position of the holes.

3. Insert the CO2 line through the hole.

4. Seal the hole around CO2 line with silicone sealer to prevent leakage

of cold air.

Operation

START UP

Plug in the cooler and the compressor is ready to operate.

• Temperature control set at #4 position gives the cooler an approximate temperature of 35°F. Allow unit to

function several hours, completely cooling cabinet before changing the control setting.

• Excessive tampering with the control could lead to service difculties. Should it ever become necessary to

replace the temperature control it should be ordered from your dealer or recommended service agent.

• Good air ow in your cooler is critical. Be careful to load product so that it neither presses against the back

wall nor comes within four (4) inches of the evaporator housing. Refrigerated air off the coil must circulate

down the back wall.

LIGHT SWITCH LOCATION:

The switch is located on the front of the evaporator housing toward the right of the cabinet. Open the front

door.

NOTE: If the unit is disconnected or shut off, wait ve (5) minutes before re-starting unit.

RECOMMENDATION

Before loading product the unit should be run for 2 to 3 days. This allows conrmation that the electrical wiring

and installation are correct and no shipping damage has occurred. Remember that the factory warranty does

10

Page 11

Operation

not cover product loss.

REPLACEMENT PARTS

We maintains a record of the cabinet model number and serial number for your cooler. If at any time during

the life of your cooler a replacement part is needed, call the factory ofce with the model number and serial

number of your unit to place an order for the part.

CONTROLLER INSTRUCTIONS

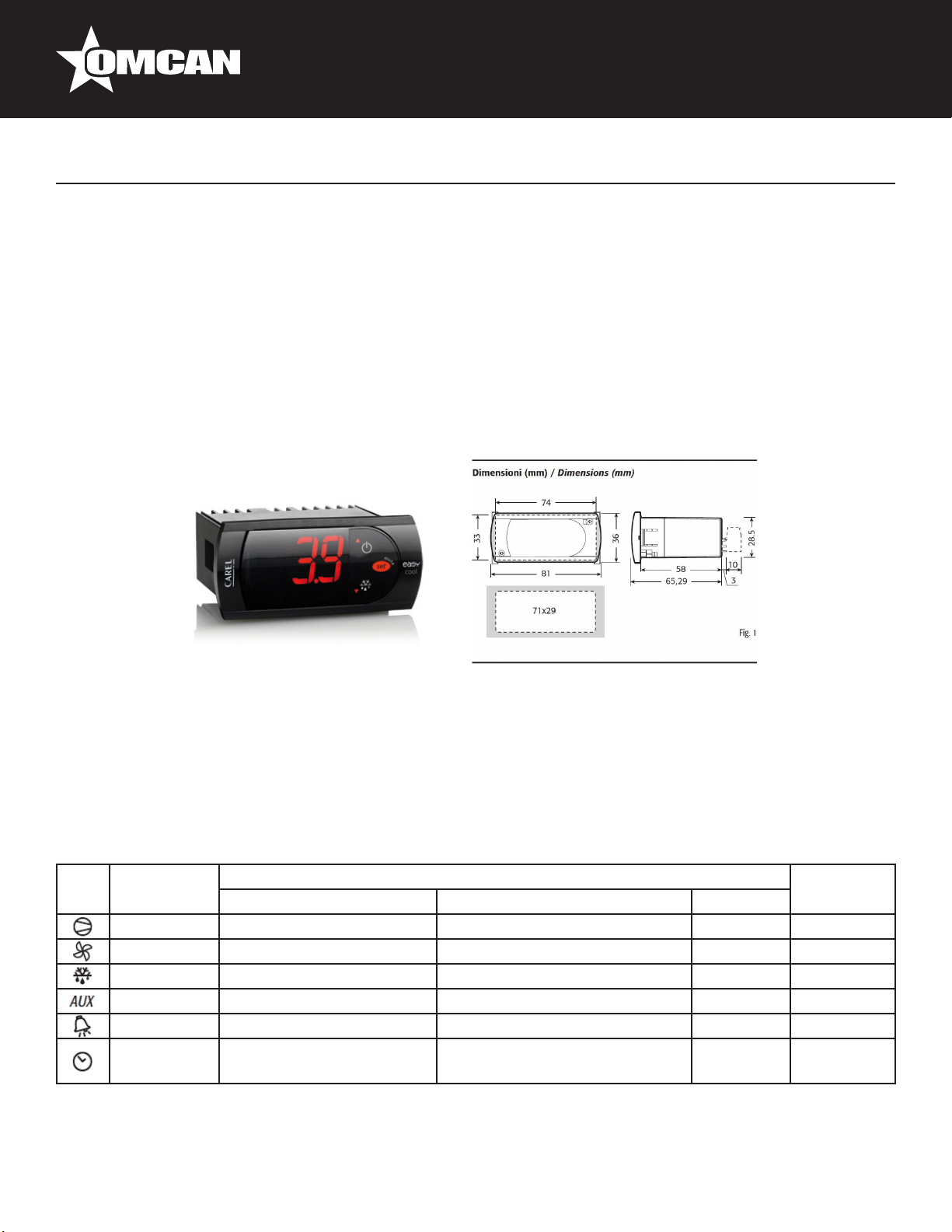

DIGITAL CONTROLLER MODEL: PJEZ FOR COOLER

DISPLAY AND FUNCTIONS

During normal operation, the controller displays the value of the probe set using parameter/4(=1 ambient

probe, default, = 2 second probe, = 3 third probe).In addition, the display has LEDs that indicate the activation

of the control functions (see Table 1),while the 3 buttons can be used to activate/deactivate some of the

functions(see Table 2).

LED’s and Associated Functions (Table 1)

Icon Function Normal Operation Start Up

ON OFF Blink

Compressor On Off Request ON

Fan On Off Request ON

Defrost On Off Request ON

Aux Output On Output Off - ON

Alarm All No Alarm - ON

Clock RTC tted and enabled, at

least 1 time band set

RTC not tted or disabled, not

even 1 time band set

- ON if RTC

tted

11

Page 12

Operation

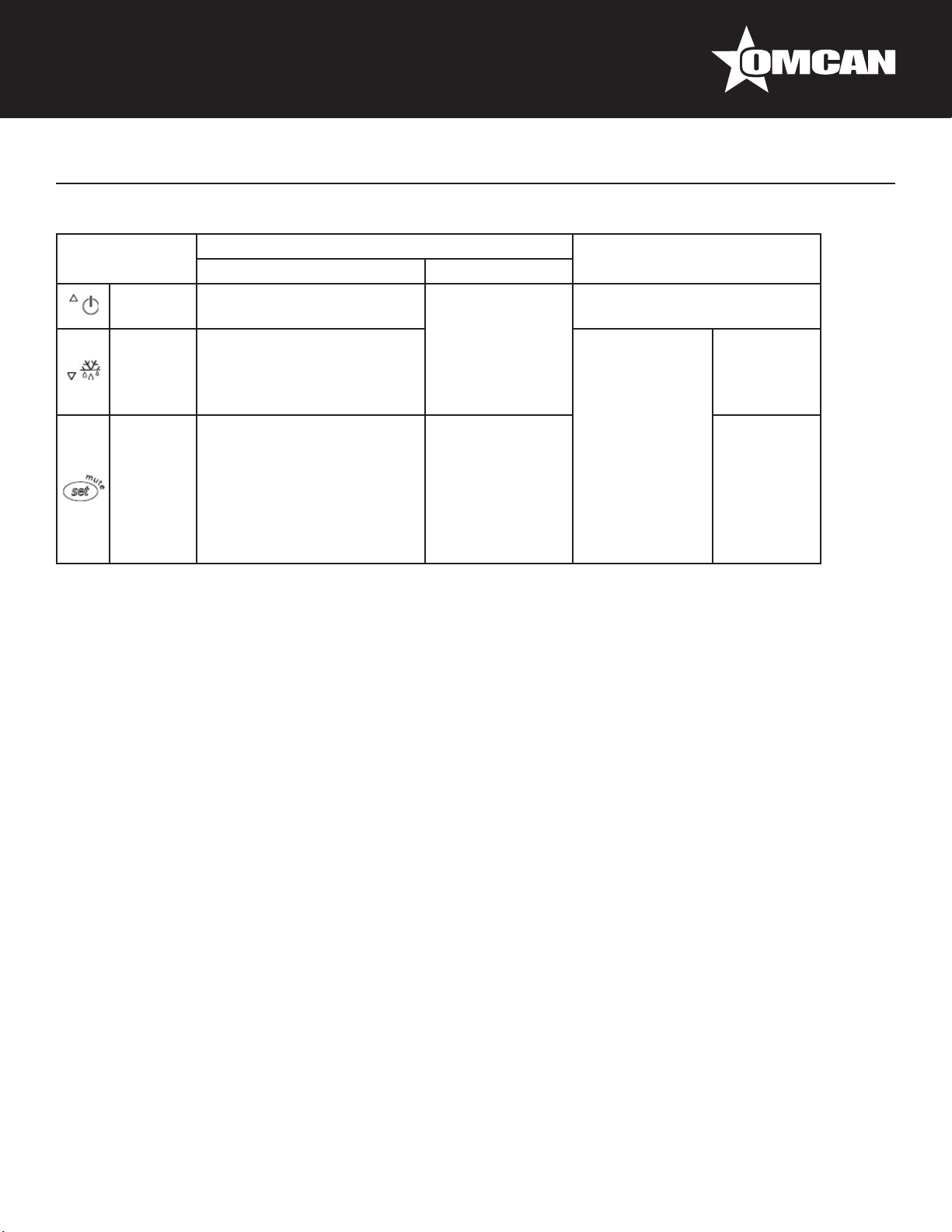

Table of Functions activated by the buttons - Models S, X, Y, C (Table 2)

Button Normal Operation Start Up

Pressing the Button Alone Pressed Together

Up

ON/OFF

Down

Defrost

Set Mute - 1 sec.: display/set the set

SETTING THE SET POINT (DESIRED TEMPERATURE)

More than 3 sec: toggle ON/

OFF

More than 3 sec: start/stop

defrost

point.

- more than 3 secs.: access

parameter setting menu

(enter password )

- mute audible alarm

(buzzer)

Start/Stop

continuous cycle

- For 1 sec.

-

Pressed

together

Start parameter

reset procedure

For 1 sec.

display

rmware

vers. code

RESET current EZY set

• Press SET for 1 sec, the set value will start ashing after a few moments.

• Increase or decrease the value using UP or DOWN.

• Press SET to conrm the new value.

SWITCHING THE DEVICE ON/OFF

Press UP for more than 3 sec. The control and defrost algorithms are now disabled and the Instrument

displays the message “OFF” alternating with the temperature read by the set probe.

MANUAL DEFROST

Press for DOWN more than 3 sec (the defrost starts only the temperature conditions are valid).

CONTINUOUS CYCLE

Press UP and DOWN together for more than 3 sec.

ACCESS AND SETTING TYPE F (FREQUENT) AND TYPE C (CONFIGURATION)

PARAMETERS

1. Press SET for 3 sec (the display will show “PS”).

2. • To access the type F and C parameter menu, enter the password “22” using UP/DOWN, press SET to

conrm.

• To access the F parameter menu only, press SET (without entering the password).

12

Page 13

Operation

3. Scroll inside the parameter menu using UP/DOWN.

• To display/set the values of the parameter displayed, press SET, then UP/DOWN and nally SET to

conrm the changes (returning to the parameter menu).

To save all the new values and exit the parameter menu, press SET for 3 sec.

To exit the menu without saving the changed values (exit by timeout) do not press any button for at least 60

sec.

MECHANICAL CONTROLLER INSTRUCTIONS

OFF: shut the compressor off.

Temperature range from 7 (coldest) to 1 (warmest).

CAUTION: Setting the temperature control to the coldest setting may cause the

evaporator coil to freeze and ice up. This will eventually result in a warmer cabinet

temperature.

Cleaning and Maintenance

Condensers accumulate dirt and dust and require cleaning every 30 days. Dirty condensers result in

compressor failure, product loss, and lost sales -- which are not covered by warranty.

Air is pulled through the condenser continuously along with dust, lint, grease, etc. If you keep the condenser

clean you will minimize your service expense and lower your electrical costs. The condenser requires

scheduled cleaning every days or as needed. A dirty condenser can result in non-warranted part and

compressor failures and product loss.

Proper cleaning involves removing debris from the condenser by using a soft brush or vacuuming the

condenser with a shop vac or using Co2, nitrogen or pressurized air.

If you cannot remove the debris adequately please call you refrigeration service company.

On most of the reach-in units the condenser is accessible at the rear of the unit. You must remove the cabinet

grill to expose the condenser. The condenser looks like a group of vertical ns. You need to be able to see

through the condenser for the unit to function at maximum capacity. Do not place lter material in front of

condensing coil. This material blocks air ow to the coil which is similar to having a dirty coil.

13

Page 14

Cleaning and Maintenance

CLEANING THE CONDENSER COIL

Required Tools:

• Phillips screwdriver.

• Stiff bristle brush.

• Adjustable wrench

When using electrical appliances basic safety precautions should be followed:

• Disconnect power to unit.

• Take off lower grill assembly by removing all screws.

• Remove bolts anchoring compressor assembly to frame rails and carefully slide out -- tube connections are

exible.

• Clean off accumulated dirt from condensing coil with the stiff bristle brush.

• Lift cardboard cover above fan at plastic plugs and carefully clean condenser coil and fan blades.

• After brushing condenser coil, vacuum dirt from coil and interior oor.

• Replace cardboard cover, carefully slide compressor assembly back into position and replace bolts.

• Reinstall louver assembly onto unit with appropriate fasteners and clips. Tighten all screws.

• Connect unit to power and check to see if condenser is running.

STAINLESS STEEL CARE AND CLEANING

Recommended cleaners for stainless steel

• Soap,ammonia and detergent medallion applied with a soft cloth or sponge for routine cleaning.

• Arcal 20,Loc-O-Nu Ecoshine provide a barrier lm for ngerprints and smears.

• Cameo, Talc, Zud First lmpression is for stubborn stains and discoloration. Rub in direction of polish lines.

• Easy-off and De-Grease It oven aid are excellent for removals on all nishes for grease-fatty acids,blood

and burnt-on foods.

• Any good commercial detergent can be applied with a sponge or soft cloth to remove grease and oil.

• Benet,Super Sheen,Sheila Shine are good for restoration/passiveness.

CAUTION: Do not use any steel wool, abrasive or chlorine based products to clean stainless steel surfaces.

Stainless Steel Enemies

There are three basic items that can break down stainless steel’s passivity layer and allow corrosion to occur.

1. Scratches from wire brushes, metal scrapers and steel pads are just a few examples of items that can be

abrasive to stainless steel’s surface.

2. Deposits left on stainless steel can leave spots. Hard water can leave spots. Hard water that is heated can

leave deposits if left to sit for too long. These deposits can cause the passive layer to break down and rust

stainless steel. All deposits left from food prep or service should be removed as quickly as possible.

3. Chlorides are present in table salt, food and water. Household and industrial cleaners are the worst type of

chlorides to use.

14

Page 15

Cleaning and Maintenance

8 Steps that can help prevent rust on stainless steel

1. Use the correct cleaning tools. Use non-abrasive tools when cleaning your stainless steel products. The

stainless steel’s passive layer will not be harmed by soft cloths and plastic scouring pads.

2. Clean along the polish lines. Polish lines or grain are visible on some stainless steel. Always scrub parallel

to visible lines. Use a plastic scouring pad or soft cloth when grain is not visible.

3. Use alkaline, alkaline chlorinated or non-chloride containing cleaners. While many traditional cleaners are

loaded with chlorides, the industry is providing an ever increasing choice of non-chloride cleaners. If unsure

of chloride content contact the cleaner supplier. If present cleaner contains chlorides, ask for an alternative.

Avoid cleaners containing quaternary salts as they can attack stainless steel causing pitting and rusting.

4. Water treatment. To reduce deposits, use soft water whenever possible. Installation of certain lters can be

an advantage. Contact a treatment specialist about proper water treatment.

5. Maintain cleanliness of food equipment. Use cleaners at recommended strength(alkaline, alkaline

chlorinated or non-chloride). Avoid buildup of hard stains by cleaning frequently.

6. When using chlorinated cleaners you must rinse and wipe dry immediately. It is better to wipe standing

cleaning agents and water as soon as possible. All stainless steel equipment to air dry. Oxygen helps

maintain the passivity lm on stainless steel.

7. Hydrochloric acid (muriatic acid) should never be used on stainless steel.

8. Regularly restore/clean stainless steel.

KEG BEER LINE CLEANING

1. Tools needed.

2. Pour cleaning solution and water into the pump bottle and connect it to the beer line.

3. Place a bucket under the faucet and open the beer faucet. Pump to remove the cleaning solution and

water. Continue to pump until all cleaning solution has exited. You can also ll the line and let it soak then

run through the line. After you have run the cleaning solution through, open the bottle and ll with water.

Repeat water rinsing until the line is free of cleaning chemicals.

15

Page 16

Cleaning and Maintenance

REFERENCE

Item Number Model Number Description Manufacturer Model Number

Beer Dispenser Single Solid Door with

42941 BD-CN-0007-S

38008 BD-CN-0012-D

42942 BD-CN-0019-S

38009 BD-CN-0016-D

42943 BD-CN-0023-D

38010 BD-CN-0020-D

42944 BD-CN-0032-D

One Tap 6.5 cu ft / 186 L Capacity

110V/60HZ ETL cETLus INTERTEK

Cooler Back Bar 11.8 cu ft Capacity Solid

Door with Beer Dispenser 115V/60/1 NSF

ETL cETLus INTERTEK

Beer Dispenser Double Solid Doors

with One Tap 19 cu ft / 546 L Capacity

110V/60HZ ETL cETLus INTERTEK

Cooler Back Bar 15.8 cu ft Capacity Solid

Door with Beer Dispenser 115V/60/1 NSF

ETL cETLus INTERTEK

Beer Dispenser Double Solid Doors with

Two Taps 23.3 cu ft / 666 L Capacity

110V/60HZ ETL cETLus INTERTEK

Cooler Back Bar 19.6 cu ft Capacity Solid

Door with Beer Dispenser 115V/60/1 NSF

ETL cETLus INTERTEK

Beer Dispenser Three Solid Doors with

Two Taps 32 cu ft / 916 L Capacity

110V/60HZ ETL cETLus INTERTEK

UDD-1

UDD-24-48

UDD-2

UDD-24-60

UDD-3

UDD-24-72

UDD-4

16

Page 17

Model BD-CN-0007-S 42941

Parts Breakdown

17

Page 18

Parts Breakdown

Model BD-CN-0007-S 42941

Item No. Description Position Item No. Description Position Item No. Description Position

71725 Cabinet for UDD1 1 71733 Back Cover for UDD1 18 71745

71726 Top Board for UDD1 2 26246 Front Castor for UDD1 19 71746 Rear Castor for UDD1 36

71727 Counter Top Tray for UDD1 3 71734 Solid Door for UDD1 20 71747 Counter Top Railing for UDD1 37

71843 Beer Tower for UDD1 4 26164 Spring Hinge of Solid Door for UDD1 21 71748 Exterior Water Tray for UDD1 38

71844 Cover of Top Tray for UDD1 5 26760 Axis Sleeve for UDD1 22 71749 Plastic Bottle for UDD1 39

71728

71851

73071 Drain Connector of Top Tray for UDD1 8 71736 Fan Motor Installation Panel for UDD1 25 71752 Tape of Plastic Bottle for UDD1 42

71847 Drain Hose of Top Tray for UDD1 9 71737 Evaporator Fan Motor Bracket for UDD1 26 71753 Door Seal for UDD1 43

37735 Fixed Block of Top Board for UDD1 10 71738 Evaporator Fan Motor for UDD1 27 26198 Door Lock for UDD1 44

37728 Bottom Right Hinge of Door for UDD1 11 71795 Blade of Evaporator Fan Motor for UDD1 28 71754 Air Tube of Beer Tower for UDD1 45

37734 Plate of Lock for UDD1 12 71739 Left Plate of Evaporator for UDD1 29 37694

71729 Bottom Plate of Machine Room for UDD1 13 71740 Right Plate of Evaporator for UDD1 30 37693

71730

71731 Condenser for UDD1 15 71742 Cover of Copper Pipe for UDD1 32 73072 Defrost Timer for UDD1 49

71732 Compressor for UDD1 16 71743 Cover of Inner Drain Hose for UDD1 33

37705 Condenser Fan Motor for UDD1 17 71744 Bracket of Defrost Timer for UDD1 34

Plastic Mounting Plate of Beer Tower

for UDD1

Drain Connector Nut of Top Tray for

UDD1

Compressor Unit Installation Board for

UDD1

6 37731 Upper Right Hinge for UDD1 23 71750 Plastic Pipe of CO2 Line for UDD1 40

7 71735 Evaporator for UDD1 24 71751

14 71741 Evaporator Cover for UDD1 31 37696

Reinforcing Plate of Interior Floor for

UDD1

Rubber Cover of Plastic Pipe of CO2

Line for UDD1

Mechanical Temperature Controller

for UDD1

Panel of Temperature Controller for

UDD1

Knob of Temperature Controller for

UDD1

35

41

46

47

48

18

Page 19

Model BB-CN-0012-D 38008

Parts Breakdown

19

Page 20

Parts Breakdown

Model BB-CN-0012-D 38008

Item No. Description Position Item No. Description Position Item No. Description Position

71788 Cabinet for UDD48 1 71810 Outer Drain Pan for UDD48 23 71832 Adjusted Feet for UDD48 45

71789 Top Board for UDD48 2 71811 Filter Fixer for UDD48 24 71833

71790 Inner Drain Pan for UDD48 3 71812 Filter for UDD48 25 71834 K Strip-2 Holes for UDD48 47

71791 Evaporator for UDD48 4 71813

71792 Fan Motor Installation Panel for UDD48 5 71814 Front Cover of Machine Room for UDD48 27 71836 Ballast of Light for UDD48 49

71793 Evaporator Fan Motor for UDD48 6 71815 Left Solid Door for UDD48 28 71837 Condenser Bracket for UDD48 50

71794 Evaporator Fan Motor Holder for UDD48 7 71816 Solid Door Gasket for UDD48 29 71838 Temperature Display for UDD48 51

71795

71796 Evaporator Cover for UDD48 9 71818 Axis Sleeve for UDD48 31 71840

71797 Temperature Control Panel for UDD48 10 71819 Bottom Right Hinge for UDD48 32 71841

71798 Mechanical Thermostat for UDD48 11 71820 Bottom Left Hinge for UDD48 33 71842 Spring Hinge for UDD48 55

71799 Temperature Control Knob for UDD48 12 71821 Upper Right Hinge for UDD48 34 71843 Beer Tower for UDD48 56

71800 Light Switch for UDD48 13 71822 Upper Left Hinge for UDD48 35 71844 Cover of Top Tray for UDD48 57

71801 Bracket of Lateral Cover for UDD48 14 71823 Plate of Lock for Right Door for UDD48 36 71845 Cover of CO2 Line for UDD48 58

71802

71803 Condenser for UDD48 16 71825 Fixed Block for Worktop for UDD48 38 71847 Drain Hose of Top Tray for UDD48 60

71804 Compressor for UDD48 17 71826 K Strip-4 Holes for UDD48 39 71848 L Shape Connector for UDD48 61

71805 Wiring Box of Compressor for UDD48 18 71827 K Clip for UDD48 40 71849 Rubber Pad for UDD48 62

71806 Start Capacitor for UDD48 19 71828 Shelf for UDD48 41 71850 Drain Connector of Top Tray for UDD48 63

71807 Overload Protector for UDD48 20 71829 LED Light for UDD48 42 71851

71808 Starter for UDD48 21 71830 Drain Hose for UDD48 43 71852 Air Tube for UDD48 65

71809 Condenser Fan Motor for UDD48 22 71831 Power Cord for UDD48 44

Blade of Evaporator Fan Motor for

UDD48

Compressor Unit Installation Board for

UDD48

8 71817 Right Solid Door for UDD48 30 71839

15 71824 Bottom Gasket of Compressor for UDD48 37 71846 Cover of L Shape Connector for UDD48 59

Lateral Cover of Machine Room for

UDD48

26 71835

Stop Block of Compressor Unit

Installation Board for UDD48

Handle of Compressor Unit Installation

Board for UDD48

Transformer of Temperature Display

for UDD48

Transformer Bracket of Temperature

Display for UDD48

Sensor of Temperature Display for

UDD48

Drain Connector Nut of Top Tray for

UDD48

46

48

52

53

54

64

20

Page 21

Model BD-CN-0019-S 42942

Parts Breakdown

21

Page 22

Parts Breakdown

Model BD-CN-0019-S 42942

Item No. Description Position Item No. Description Position Item No. Description Position

71755 Cabinet for UDD2 1 26188 Filter Base D25 for UDD2 24 28311

71756 Top Board for UDD2 2 26189 Filter D25x140 for UDD2 25 71834 K Strip 2 Holes for UDD2 47

37685 Inner Drain Pan for UDD2 3 71761 Lateral Cover for UDD2 26 71835

71757 Evaporator for UDD2 4 37708 Front Cover of Machine Room for UDD2 27 71836 Ballast for UDD2 49

71758 Fan Motor Installation Panel for UDD2 5 71762 Left Door (Solid) for UDD2 28 71837 Condenser Installation Board for UDD2 50

37688 Evaporator Fan Motor for UDD2 6 71763 Door Gasket (Solid) for UDD2 29 71838 Temp Display for UDD2 51

37689 Evaporator Fan Motor Holder for UDD2 7 71764 Right Door (Solid) for UDD2 30 71839 Transformer for Temp Display for UDD2 52

37690 Evaporator Fan Motor Blade for UDD2 8 26760 Axis Sleeve for UDD2 31 71840

71759 Evaporator Cover for UDD2 9 37728 Lower Right Hinge for UDD2 32 71841 Temp Sensor for Temp Display for UDD2 54

37693 Temperature Control Panel for UDD2 10 37730 Lower Left Hinge for UDD2 33 26164 Spring Hinge for UDD2 55

37694 Temperature Controller for UDD2 11 37731 Upper Right Hinge for UDD2 34 71843 Beer Tower for UDD2 56

37697 Lamp Switch for UDD2 13 37732 Upper Left Hinge for UDD2 35 71844 Cover of Top Tray for UDD2 57

71760 Bracket of Lateral Cover for UDD2 14 37734 Plate of Lock for UDD2 36 71845 CO2 Pipe Hole Cover for UDD2 58

37699

37700 Condenser 4R11K150L for UDD2 16 37735 Fixed Block of Top Board for UDD2 38 71847 Drain Hose of Top Tray for UDD2 60

26183 Compressor NE6187Z for UDD2 17 37736 K Strip 4 Holes for UDD2 39 71848 L Shape Connector for UDD2 61

37701 Splice Box for UDD2 18 26884 K Clip for UDD2 40 71766 Rubber Pad for UDD2 62

37702 Start Capacitor for UDD2 19 71774 Shelf (Left & Right) for UDD2 41 73075 Beer Tray Drain Plug for UDD2 63

37703 Overload Protector for UDD2 20 37741 LED Bulb for UDD2 42 73076 Beer Tray Drain Plug Nut for UDD2 64

37704 Starter for UDD2 21 26203 Drain Hose φ16 for UDD2 43 71767 Air Pipe for UDD2 65

37705

37706 Outer Drain Pan for UDD2 23 28236 Adjustable Feet M12x45 for UDD2 45

Compressor Unit Installation Board for

UDD2

Condenser Fan Motor RAM4715 for

UDD2

15 73073 Rubber Base of Compressor for UDD2 37 73074 Bottom Drain Plug Cover for UDD2 59

22 26205 Power Cord 16 AWG for UDD2 44 71768 Middle Beam Cover for UDD2 66

Installation Board Limited Block for

UDD2

Handle of Compressor Unit Installation

Board for UDD2

Temp Display Transformer Holder for

UDD2

46

48

53

22

Page 23

Model BB-CN-0016-D 38009

Parts Breakdown

23

Page 24

Parts Breakdown

Model BB-CN-0016-D 38009

Item No. Description Position Item No. Description Position Item No. Description Position

71853 Cabinet for UDD60 1 71876 Filter Fixer for UDD60 24 71899 K Strip-2 Holes for UDD60 47

71854 Top Board for UDD60 2 71877 Filter for UDD60 25 71900

71855 Inner Drain Pan for UDD60 3 71878

71856 Evaporator for UDD60 4 71879 Front Cover of Machine Room for UDD60 27 71902 Condenser Bracket for UDD60 50

71857 Fan Motor Installation Panel for UDD60 5 71880 Left Solid Door for UDD60 28 71903 Temperature Display for UDD60 51

71858 Evaporator Fan Motor for UDD60 6 71881 Solid Door Gasket for UDD60 29 71904

71859 Evaporator Fan Motor Holder for UDD60 7 71882 Right Solid Door for UDD60 30 71905

71860

71861 Evaporator Cover for UDD60 9 71884 Bottom Right Hinge for UDD60 32 71907 Spring Hinge for UDD60 55

71862 Temperature Control Panel for UDD60 10 71885 Bottom Left Hinge for UDD60 33 71908 Beer Tower for UDD60 56

71863 Mechanical Thermostat for UDD60 11 71886 Upper Right Hinge for UDD60 34 71909 Cover of Top Tray for UDD60 57

71864 Temperature Control Knob for UDD60 12 71887 Upper Left Hinge for UDD60 35 71910 Cover of CO2 Line for UDD60 58

71865 Light Switch for UDD60 13 71888 Plate of Lock for Right Door for UDD60 36 71911 Cover of L Shape Connector for UDD60 59

71866 Bracket of Lateral Cover for UDD60 14 71889 Bottom Gasket of Compressor for UDD60 37 71912 Drain Hose of Top Tray for UDD60 60

71867

71868 Condenser for UDD60 16 71891 K Strip-4 Holes for UDD60 39 71914 Rubber Pad for UDD60 62

71869 Compressor for UDD60 17 71892 K Clip for UDD60 40 71915 Drain Connector of Top Tray for UDD60 63

71870 Wiring Box of Compressor for UDD60 18 71893 Shelf for UDD60 41 71916

71871 Start Capacitor for UDD60 19 71894 LED Light for UDD60 42 71917 Air Tube of Left Beer Tower for UDD60 65

71872 Overload Protector for UDD60 20 71895 Drain Hose for UDD60 43 71918 Air Tube of Right Beer Tower for UDD60 66

71873 Starter for UDD60 21 71896 Power Cord for UDD60 44 71778 Short Drain Hose of Top Tray for UDD60 67

71874 Condenser Fan Motor for UDD60 22 71897 Adjusted Feet for UDD60 45 71779 T Shape Connector for UDD60 68

71875 Outer Drain Pan for UDD60 23 71898

Blade of Evaporator Fan Motor for

UDD60

Compressor Unit Installation Board for

UDD60

8 71883 Axis Sleeve for UDD60 31 71906

15 71890 Fixed Block for Worktop for UDD60 38 71913 L Shape Connector for UDD60 61

Lateral Cover of Machine Room for

UDD60

Stop Block of Compressor Unit

Installation Board for UDD60

26 71901 Ballast of Light for UDD60 49

46

Handle of Compressor Unit Installation

Board for UDD60

Transformer of Temperature Display

for UDD60

Transformer Bracket of Temperature

Display for UDD60

Sensor of Temperature Display for

UDD60

Drain Connector Nut of Top Tray for

UDD60

48

52

53

54

64

24

Page 25

Model BD-CN-0023-D 42943

Parts Breakdown

25

Page 26

Parts Breakdown

Model BD-CN-0023-D 42943

Item No. Description Position Item No. Description Position Item No. Description Position

71769 Cabinet for UDD3 1 26189 Filter D25x140 for UDD3 25 71835

71770 Top Board for UDD3 2 71761 Lateral Cover for UDD3 26 71836 Ballast for UDD3 49

37685 Inner Drain Pan for UDD3 3 37708 Front Cover of Machine Room for UDD3 27 71837 Condenser Installation Board for UDD3 50

71757 Evaporator for UDD3 4 71762 Left Door (Solid) for UDD3 28 27067 Temp Display for UDD3 51

71771 Fan Motor Installation Panel for UDD3 5 71763 Door Gasket (Solid) for UDD3 29 71839 Transformer for Temp Display for UDD3 52

37688 Evaporator Fan Motor for UDD3 6 71764 Right Door (Solid) for UDD3 30 71840

37689 Evaporator Fan Motor Holder for UDD3 7 26760 Axis Sleeve for UDD3 31 71841 Temp Sensor for Temp Display for UDD3 54

37690 Evaporator Fan Motor Blade for UDD3 8 37728 Lower Right Hinge for UDD3 32 26164 Spring Hinge for UDD3 55

71772 Evaporator Cover for UDD3 9 37730 Lower Left Hinge for UDD3 33 71843 Beer Tower for UDD3 56

37693 Temperature Control Panel for UDD3 10 37731 Upper Right Hinge for UDD3 34 71844 Cover of Top Tray for UDD3 57

37694 Temperature Controller for UDD3 11 37732 Upper Left Hinge for UDD3 35 71845 CO2 Pipe Hole Cover for UDD3 58

37697 Lamp Switch for UDD3 13 37734 Plate of Lock for UDD3 36 73078 Bottom Drain Plug Cover for UDD3 59

71760 Bracket of Lateral Cover for UDD3 14 73077 Rubber Base of Compressor for UDD3 37 71847 Drain Hose of Top Tray (Long) for UDD3 60

37699

37700 Condenser 4R11K150L for UDD3 16 37736 K Strip 4 Holes for UDD3 39 71775 Rubber Pad for UDD3 62

26183 Compressor NE6187Z for UDD3 17 26884 K Clip for UDD3 40 73079 Beer Tray Drain Plug for UDD3 63

37701 Splice Box for UDD3 18 71774 Shelf (Left & Right) for UDD3 41 73080 Beer Tray Drain Plug Nut for UDD3 64

37702 Start Capacitor for UDD3 19 37741 LED Bulb for UDD3 42 71776 Air Pipe (Short) for UDD3 65

37703 Overload Protector for UDD3 20 26203 Drain Hose φ16 for UDD3 43 71777 Air Pipe (Long) for UDD3 66

37704 Starter for UDD3 21 26205 Power Cord 16AWG for UDD3 44 71778 Drain Hose of Top Tray (Short) for UDD3 67

37705

37706 Outer Drain Pan for UDD3 23 37754 Installation Board Limited Block for UDD3 46 71780 Middle Beam Cover for UDD3 69

26188 Filter Base D25 for UDD3 24 71834 K Strip 2 Holes for UDD3 47

Compressor Unit Installation Board for

UDD3

Condenser Fan Motor RAM4715 for

UDD3

15

22 28236 Adjustable Feet M12x45 for UDD3 45 71779 T Shape Connector for UDD3 68

37735 Fixed Block of Top Board for UDD3 38 71848 L Shape Connector for UDD3 61

Handle of Compressor Unit Installation

Board for UDD3

Temp Display Transformer Holder for

UDD3

48

53

26

Page 27

Model BB-CN-0020-D 38010

Parts Breakdown

27

Page 28

Parts Breakdown

Model BB-CN-0020-D 38010

Item No. Description Position Item No. Description Position Item No. Description Position

71919 Cabinet for UDD72 1 71942 Filter Fixer for UDD72 24 71965 K Strip-2 Holes for UDD72 47

71920 Top Board for UDD72 2 71943 Filter for UDD72 25 71966

71921 Inner Drain Pan for UDD72 3 71944

71922 Evaporator for UDD72 4 71945 Front Cover of Machine Room for UDD72 27 71968 Condenser Bracket for UDD72 50

71923 Fan Motor Installation Panel for UDD72 5 71946 Left Solid Door for UDD72 28 71969 Temperature Display for UDD72 51

71924 Evaporator Fan Motor for UDD72 6 71947 Solid Door Gasket for UDD72 29 71970

71925 Evaporator Fan Motor Holder for UDD72 7 71948 Right Solid Door for UDD72 30 71971

71926

71927 Evaporator Cover for UDD72 9 71950 Bottom Right Hinge for UDD72 32 71973 Spring Hinge for UDD72 55

71928 Temperature Control Panel for UDD72 10 71951 Bottom Left Hinge for UDD72 33 71974 Beer Tower for UDD72 56

71929 Mechanical Thermostat for UDD72 11 71952 Upper Right Hinge for UDD72 34 71975 Cover of Top Tray for UDD72 57

71930 Temperature Control Knob for UDD72 12 71953 Upper Left Hinge for UDD72 35 71976 Cover of CO2 Line for UDD72 58

71931 Light Switch for UDD72 13 71954 Plate of Lock for Right Door for UDD72 36 71977 Cover of L Shape Connector for UDD72 59

71932 Bracket of Lateral Cover for UDD72 14 71955 Bottom Gasket of Compressor for UDD72 37 71978 Drain Hose of Top Tray for UDD72 60

71933

71934 Condenser for UDD72 16 71957 K Strip-4 Holes for UDD72 39 71980 Rubber Pad for UDD72 62

71935 Compressor for UDD72 17 71958 K Clip for UDD72 40 71981 Drain Connector of Top Tray for UDD72 63

71936 Wiring Box of Compressor for UDD72 18 71959 Shelf for UDD72 41 71982

71937 Start Capacitor for UDD72 19 71960 LED Light for UDD72 42 71983 Air Tube of Left Beer Tower for UDD72 65

71938 Overload Protector for UDD72 20 71961 Drain Hose for UDD72 43 71984 Air Tube of Right Beer Tower for UDD72 66

71939 Starter for UDD72 21 71962 Power Cord for UDD72 44 71985 Middle Shelf for UDD72 67

71940 Condenser Fan Motor for UDD72 22 71963 Adjusted Feet for UDD72 45

71941 Outer Drain Pan for UDD72 23 71964

Blade of Evaporator Fan Motor for

UDD72

Compressor Unit Installation Board for

UDD72

8 71949 Axis Sleeve for UDD72 31 71972

15 71956 Fixed Block for Worktop for UDD72 38 71979 L Shape Connector for UDD72 61

Lateral Cover of Machine Room for

UDD72

Stop Block of Compressor Unit

Installation Board for UDD72

26 71967 Ballast of Light for UDD72 49

46

Handle of Compressor Unit Installation

Board for UDD72

Transformer of Temperature Display

for UDD72

Transformer Bracket of Temperature

Display for UDD72

Sensor of Temperature Display for

UDD72

Drain Connector Nut of Top Tray for

UDD72

48

52

53

54

64

28

Page 29

Model BD-CN-0032-D 42944

Parts Breakdown

29

Page 30

Parts Breakdown

Model BD-CN-0032-D 42944

Item No. Description Position Item No. Description Position Item No. Description Position

71781 Cabinet for UDD4 1 26189 Filter D25x140 for UDD4 25 71835

71782 Top Board for UDD4 2 71761 Lateral Cover for UDD4 26 71836 Ballast for UDD4 49

37685 Inner Drain Pan for UDD4 3 37708 Front Cover of Machine Room for UDD4 27 71837 Condenser Installation Board for UDD4 50

71757 Evaporator for UDD4 4 71762 Left Door (Solid) for UDD4 28 27067 Temp Display for UDD4 51

71758 Fan Motor Installation Panel for UDD4 5 71763 Door Gasket (Solid) for UDD4 29 71839 Transformer for Temp Display for UDD4 52

37688 Evaporator Fan Motor for UDD4 6 71764 Right Door (Solid) for UDD4 30 71840

37689 Evaporator Fan Motor Holder for UDD4 7 26760 Axis Sleeve for UDD4 31 71841 Temp Sensor for Temp Display for UDD4 54

37690 Evaporator Fan Motor Blade for UDD4 8 37728 Lower Right Hinge for UDD4 32 26164 Spring Hinge for UDD4 55

71759 Evaporator Cover for UDD4 9 37730 Lower Left Hinge for UDD4 33 71843 Beer Tower for UDD4 56

37693 Temperature Control Panel for UDD4 10 37731 Upper Right Hinge for UDD4 34 71844 Cover of Top Tray for UDD4 57

37694 Temperature Controller for UDD4 11 37732 Upper Left Hinge for UDD4 35 71845 CO2 Pipe Hole Cover for UDD4 58

37697 Lamp Switch for UDD4 13 37734 Plate of Lock for UDD4 36 73082 Bottom Drain Plug Cover for UDD4 59

71760 Bracket of Lateral Cover for UDD4 14 73081 Rubber Base of Compressor for UDD4 37 73085 Drain Hose of Top Tray (Long) for UDD4 60

37699

37700 Condenser 4R11K150L for UDD4 16 37736 K Strip 4 Holes for UDD4 39 71784 Rubber Pad for UDD4 62

26280 Compressor NEK6214Z for UDD4 17 26884 K Clip for UDD4 40 73083 Beer Tray Drain Plug for UDD4 63

37701 Splice Box for UDD4 18 71783 Shelf (Left & Right) for UDD4 41 73084 Beer Tray Drain Plug Nut for UDD4 64

37702 Start Capacitor for UDD4 19 37741 LED Bulb for UDD4 42 71785 Air Pipe (Short) for UDD4 65

37703 Overload Protector for UDD4 20 26203 Drain Hose φ16 for UDD4 43 71786 Air Pipe (Long) for UDD4 66

37704 Starter for UDD4 21 26205 Power Cord 16AWG for UDD4 44 71847 Drain Hose of Top Tray (Short) for UDD4 67

37705

37706 Outer Drain Pan for UDD4 23 28311 Installation Board Limited Block for UDD4 46 71787 Middle Beam Cover for UDD4 69

26188 Filter Base D25 for UDD4 24 71834 K Strip 2 Holes for UDD4 47

Compressor Unit Installation Board for

UDD4

Condenser Fan Motor RAM4715 for

UDD4

15

22 28236 Adjustable Feet M12x45 for UDD4 45 73086 T Shape Connector for UDD4 68

37735 Fixed Block of Top Board for UDD4 38 71848 L Shape Connector for UDD4 61

Handle of Compressor Unit Installation

Board for UDD4

Temp Display Transformer Holder for

UDD4

48

53

30

Page 31

Model BD-CN-0007-S 42941

Electrical Schematics

31

Page 32

Electrical Schematics

Model BB-CN-0012-D 38008

32

Page 33

Model BD-CN-0019-S 42942

Electrical Schematics

33

Page 34

Electrical Schematics

Model BB-CN-0016-D 38009

34

Page 35

Model BD-CN-0023-D 42943

Electrical Schematics

35

Page 36

Electrical Schematics

Model BB-CN-0020-D 38010

36

Page 37

Model BD-CN-0032-D 42944

Electrical Schematics

37

Page 38

Notes

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

38

Page 39

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

www.omcan.com/warrantyregistration.html

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

39

Page 40

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 3,500 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 3500

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 3,500 productos con origen a nivel mundial.

Loading...

Loading...