Page 1

Starting with Serial No. 2321 (Screw Lock Bowl)

Starting with Serial No. 8151 (Removable Tray Assembly)

Starting with Serial No. 9340 (IDEC Pushbuttons, DIN Size Magnetic Starter)

PTCT

6642

047-11-04-25

+

IMPORTANT SAFETY NOTICE

+

This Manual contains important

safety instructions which must

be strictly followed when using

this equipment.

BIRO GRINDER PARTS LIST

STAINLESS MODEL 6642

047-7-07-27

Page 2

TABLE OF CONTENTS

Page

NOTICETOOWNERSANDOPERATORS......................................... 1

SAFETYTIPS............................................................... 2

INSTALLATION ............................................................. 3

UNCRATINGANDSETUP ................................................... 3

MOTOR WIRING AND ELECTRICAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MOTORSPECIFICATIONS................................................... 5

WARNINGLABELSANDLOCATIONSONGRINDER................................. 5

PARTS DIAGRAMS, PARTS ORDERING BASIC MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTRUCTIONS: REMOVINGTRAYASSEMBLY.................................... 7

INSTRUCTIONS: ASSEMBLING GRINDING BOWL, REMOVING GRINDING BOWL . . . . . . . . . 7

OPERATION................................................................ 8

TOPROCESSPRODUCT.................................................... 8

CLEANING................................................................. 9

MAINTENANCE .............................................................10

GRINDINGBOWLINSTALLATION.............................................10

GEARBOXLUBRICATION...................................................10

GEAR BOX ASSEMBLY PARTS DIAGRAMS AND PARTS ORDERING. . . . . . . . . . . . . . . . . . . . . 11

MAGNETIC SWITCH SYSTEMS PARTS DIAGRAMS AND PARTS ORDERING . . . . . . . . . . . . . . 12

WIRINGDIAGRAMS ..........................................................13

PARTS LISTS/ORDERING FOR GRINDERS PRIOR TO SERIAL NO. 9340 . . . . . . . . . . . . . . . . . 14

OPERATOR'SSIGNATUREPAGE................................................15

LIMITEDWARRANTY.........................................................16

Page 3

BIRO’s products are designed to process food products safely and efficiently. Unless the operator is properly trained and supervised, however, there is the possibility of a serious injury. It is the

responsibility of the owner to assure that this machine is used properly and safely, strictly following

the instructions contained in this Manual and any requirements of local law.

No one should use or service this machine without proper training and supervision. All operators should be thoroughly familiar with the procedures contained in this Manual. Even so BIRO

cannot anticipate every circumstance or environment in which its products will be used. You, the

owner and operator, must remain alert to the hazards posed by the function of this equipment –

particularly the ROTATING GRINDING WORM, which can severely injure an inattentive operator

amputating fingers and limbs. No one under eighteen (18) years of age should operate this equipment. If you are uncertain about a particular task, ask your supervisor.

This Manual contains a number of safe practices in the SAFETY TIP section. Additional warnings are placed throughout the Manual. Warnings related to your personal safety are indicated by:

Warnings related to possible damage to the equipment are indicated by:

BIRO also has provided warning labels on the equipment. If any warning label or Manual becomes misplaced, damaged, or illegible, please contact your nearest Distributor or BIRO directly

for a replacement.

Remember, however, this Manual or the warning labels do not replace the need to be alert and

to use your common sense when using this equipment.

This Manual applies to machines with Serial Number 2321 and higher.

1

NOTICE TO OWNERS AND OPERATORS

OR

- NOTE -

“A copy of this manual is included with each Model 6642 Grinder”

“The descriptions and illustrations contained in this manual

are not binding. The manufacturer reserves the right to

introduce any modification without updating the manual.”

Page 4

SAFETY TIPS

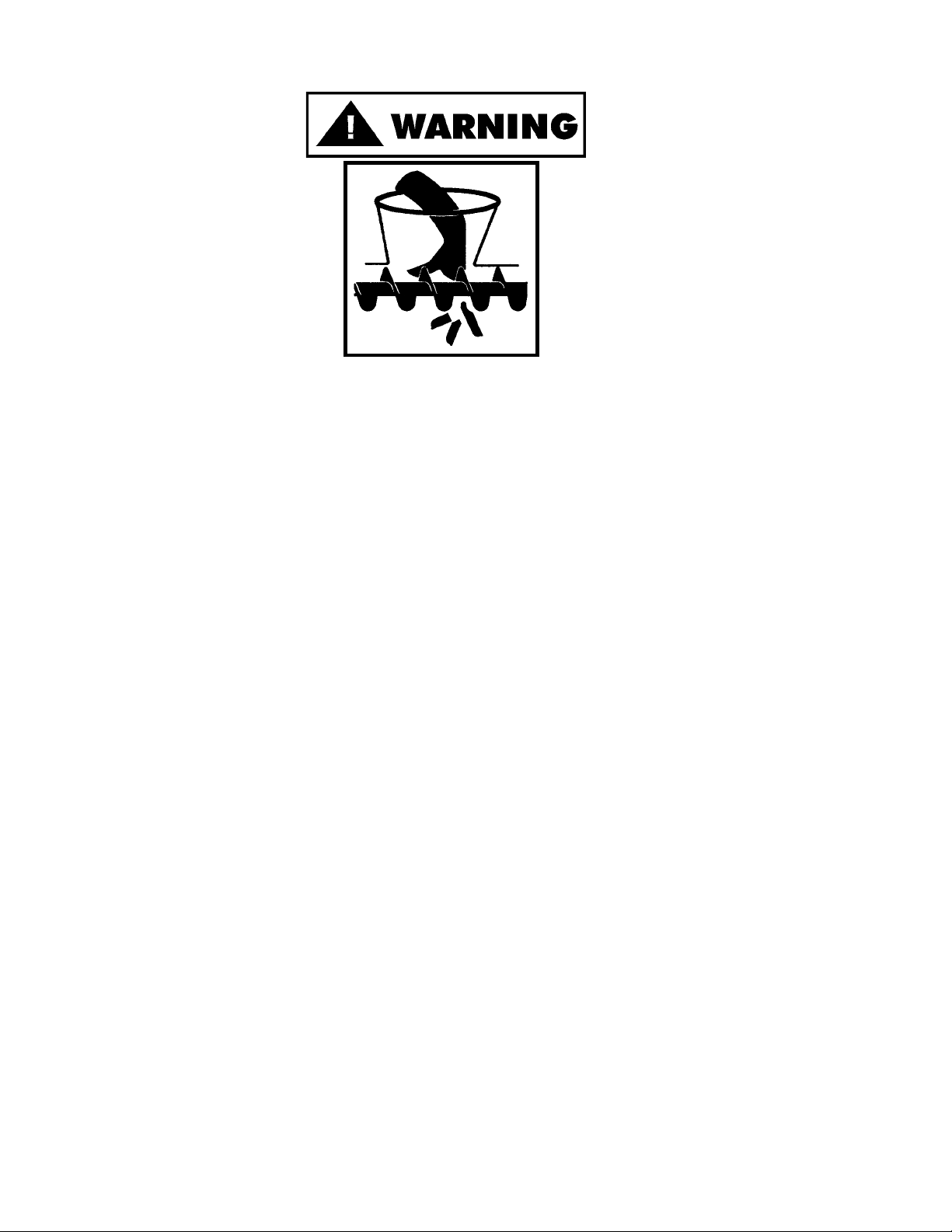

ROTATING GRINDING WORM

TO AVOID SERIOUS PERSONAL INJURY

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

NEVER Place Hands Into Machine Input or Output Openings.

NEVER Open Machine During Operation.

ONLY Use a Qualified Electrician to Install According to Local Building Codes: Machine MUST

Be Properly Grounded.

ALWAYS Connect to Proper Voltage & Phase.

ONLY Install on Level, Non-Skid Surface in a Clean, Well-Lighted Work Area Away From

Children and Visitors.

NEVER Use This Machine For Non-Food Products.

NEVER Operate Machine With Tray And/Or TrayGuard Removed or Magnetic Safety Swtich

By-Passed.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Attempting to Unjam or Unclog, Cleaning or Servicing.

NEVER Leave Machine Unattended While Operating.

NEVER Alter This Machine From its Original Form as Shipped From Factory. DO NOT Operate

Machine With Parts Missing.

PROMPTLY REPLACE Any Worn or Illegible Warning Labels.

ALWAYS Read Operation and Service Manual BEFORE Operating, Cleaning or Servicing.

USE ONLY BIRO Parts and Accessories Properly Installed.

2

Page 5

INSTALLATION

TO AVOID SERIOUS PERSONAL INJURY

PROPERLY INSTALL EQUIPMENT IN ADEQUATE WORK AREA

ALWAYS Use Qualified Technician and Electrician for Installation.

ALWAYS Connect to Proper Voltage & Phase.

ALWAYS Install Equipment in Work Area with Adequate Light and Space Away From Children

and Visitors.

ONLY Operate on a Solid, Level, Non-Skid Surface.

NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

NEVER Operate With Tray And/Or Tray Guard Removed or Magnetic Safety Switch By-Passed.

NEVER Operate Without all Warning Labels Attached and Owner/Operator Manual Available to

the Operator.

UNCRATING AND SET UP

1. Read this Manual thoroughly before installation and operation. Do not proceed with installation and operation if

you have any questions or do not understand anything in this Manual. Contact your local Distributor, or BIRO

first.

2. Install machine on a level, solid, non-skid surface in a well-lighted work area away from children and visitors.

3. After installing machine in operational area, it is imperative that the four adjusting legs be adjusted to level the

machine and also eliminate rocking.

4. This machine is complete except for a knife and plate. There is a bowl shipping plug (stamped steel) placed in

the output end of the grinding bowl to retain the grinding worm during shipment. REMOVE THE BOWL

SHIPPING PLUG AND THE GRINDING WORM.

5. After checking and making sure the power supply is correct, plug in your machine. NEVER OPERATE

MACHINE WITHOUT TRAY AND GUARD INSTALLED. (Machine will not run with tray removed.)

3

ALWAYS LEVEL MACHINE BEFORE USING

Page 6

6. Machine must be properly grounded. Use qualified electrician to install according to building codes.

MOTOR WIRING AND ELECTRICAL REQUIREMENTS

(A) Interchange of current is made in motor outlet box. Leads are properly marked. Changing instructions are

on the motor plate or motor outlet box.

(B) All grinders are wired 220 volts unless otherwise specified. Be sure motor specifications (voltage, cycle,

phase) match power supply line. Be sure line voltage is up to specification.

(C) Electrical connections to be in accordance with safety codes and National Electrical Code.

(D) Rated voltage of the unit shall be identical with full supply voltage.

(E) Voltage drop on the supply line shall not exceed 10% of full supply voltage.

(F) The feederline conductor size in the raceway from the branch circuit to the unit must be correct to assure

adequate voltage under heavy starting and short overload conditions.

(G) The feederline conductor shall only be used for the supply of one unit of the relevant horsepower. For

connections of more than one unit on the same feederline, a local electrician will have to be consulted to

determine the proper conductor size.

(H) The size of the electrical wiring required from the power source to the grinder for 208/220/230/440/550 Volts

is a MINIMUM of No. 12 AWG. For 110/115 Volts is a MINIMUM of No. 10 AWG.

(I) The BIRO Manufacturing Company is not responsible for permanent wiring, connection or installation.

MOTOR

HP VOLTS HZ PH AMPS

2 104 60 1 31

2 115 60 1 28

2 208 60 1 15.5

2 230 60 1 14

2 208 dedicated 60 3 5.0

2 208/220 50/60 3 6.2/6.0

2 440 50/60 3 3.0

2 550 60 3 2.24

4

NOTE TO OWNER AND ELECTRICIAN: IF THIS MACHINE IS NOT CORD

AND PLUG CONNECTED TO THE ELECTRICAL SUPPLY SOURCE, THEN IT

SHOULD BE EQUIPPED WITH, OR CONNECTED TO, A LOCKABLE,

MANUALLY-OPERATED DISCONNECT SWITCH (OSHA 1010.147).

Page 7

7. Pushbuttons that activate the internal on/off switch are located on the side of the machine. The interlock safety

switch is mounted inside the machine case toward the front and will break contact with the magnetic starter

should the tray be removed.

8. Push the green “ON” button. CHECK THE ROTATION OF THE WORM DRIVE SHAFT. ROTATION MUST

BE COUNTER-CLOCKWISE as indicated by the rotation decal affixed to the grinding bowl. ROTATION MUST

ONLY BE CHECKED WITH THE GRINDING WORM REMOVED, otherwise serious irreparable damage may

occur to grinding components. Push red “STOP” button.

9. If machine runs clockwise (backwards), it must be rewired to correct rotation, otherwise serious irreparable

damage may occur to grinding components.

10. Insert worm assembly into grinding bowl, place knife (sharp edges out) onto the square end of the worm

assembly. The breaker plate slides over the worm knife drive pin, and is held from rotating by pins in the grinding

bowl. Install on the retaining ring.

ONLY HAND TIGHTEN RETAINING RING

For best results, use knife and plate as a set. Do not operate machine for any period of time without product

in the grinding bowl. This will cause heating and dulling of the knife and plate.

11. Check placement of all warning labels and Manual. Machine is now ready for trained operators to process

product.

12. Use meat deflector attached to tray to eliminate meat splatter.

13. Contact your local Distributor or BIRO directly if you have any questions or problems with the installation or

operation of this machine.

WARNING LABELS & LOCATIONS ON GRINDER

5

Page 8

Page 9

7

TO REMOVE TRAY ASSEMBLY

1. Unplug grinder from power source, perform

lockout/tagout procedures.

2. Unlock Tray Hold Down Latches.

3. Lift front of tray enough for magnet to clear the

case top, slide Tray Assembly toward back of

grinder and lift off.

TO ASSEMBLE BOWL

1. Make certain the Bowl Lock Screw is unscrewed

sufficiently to alllow free entry of Grinding Bowl.

2. With End Retaining Ring, Knife, Breaker Plate and

Grinding Worm removed, insert the Grinding

Bowl fully into the gear box housing, making sure

that the rear end of the Grinding Bowl is flush with

the gear box housing.

3. Tighten the Bowl Lock Screw.

4. Insert the Grinding Worm and fully seat square

drive.

5. Install the Knife (sharp side out) and Breaker

Plate.

6. Install End Retaining Ring.

HAND TIGHTEN ONLY.

TO REMOVE GRINDING BOWL

1. Unplug grinder from power source, perform

lockout/tagout procedures.

2. Remove End Retaining Ring, Knife, Breaker Plate,

and Grinding Worm.

3. Loosen Bowl Lock Screw (counterclockwise).

4. Remove Grinding Bowl.

MOTORS FOR MODEL 6642 GRINDER

Item No. Description

42MC-10-4U Motor, 2HP, 550-60-3, U.S. G57892

42MC-10-5U Motor, 2HP, 104/208-60-1, U.S.

G57328

42MC-10-6U Motor, 2HP, 115/230-60-1, U.S.

G54314

42MC-10-7U Motor, 2HP, 208/230/460-50/60-3,

U.S. 57893

42MC-10-8U Motor, 2HP, 115/230-50-1, U.S.

G57901

42MC-10-9U Motor, 2HP, 208-60-3, U.S. G57890

Page 10

OPERATION

ROTATING GRINDING WORM

TO AVOID SERIOUS PERSONAL INJURY

ONLY Properly Trained Personnel Should Use This Equipment.

NEVER Place Hands Into Machine Input or Output Openings.

NEVER Open Machine During Operation.

DO NOT Wear Gloves While Operating.

DO NOT Tamper With, Bypass, Alter, or Modify This Equipment in Any Way From Its Original

Condition.

NEVER Operate Machine With Tray And/Or Tray Guard Removed or Magnetic Safety Switch

By-Passed.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine Before Unjamming, Unclogging, Cleaning or Servicing.

NEVER Leave Unattended While Operating.

NEVER Operate Without All Warning Labels Attached and Owner/Operator Manual Available to

the Operator.

A. TO PROCESS PRODUCT

1. Before starting grinder, have meat stomper within easy reach and a container for receiving ground product at

the output end of grinding bowl.

2. Push the green “ON” button. Look down grinder bowl and make certain grinding worm is turning in the

proper direction (counter-clockwise).

3. Carefully push unground product to top opening of grinding bowl and let drop onto the grinding worm.

Product will then be ground out.

DO NOT REACH DOWN BOWL OPENING

4. Use meat stomper to assist any product that should “bridge up” in grinding bowl opening.

5. When finished grinding, push the red “OFF” position and unplug grinder from power source and perform

lockout/tagout procedures.

8

Page 11

CLEANING

ROTATING GRINDING WORM

TO AVOID PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Cleaning or Servicing.

ONLY Use Recommended Cleaning Equipment, Materials and Procedures.

NEVER Spray Water or Other Liquid Substances Directly at Motor, Power Switch or any Other

Electrical Components.

ALWAYS Thoroughly Clean Equipment at Least Daily.

CLEANING THE BIRO MODEL 6642 GRINDER

1. Disconnect grinder from power source and perform lockout/tagout procedures.

2. Remove the feed tray.

3. Remove grinding bowl end ring, breaker plate, knife and grinding worm and the grinding bowl.

DO NOT SPRAY DIRECTLY AT ELECTRICAL COMPONENTS

4. Machine is now ready to be cleaned using warm soapy water and rinsed with clean water. Machine may be

cleaned by power spray washing, taking care to not spray directly at any electrical controls.

5. After machine has been cleaned and allowed to dry, all exposed metal surfaces should be coated with a good

food grade light oil or grease.

9

DO’s

•

Always keep knife & plate as matched set.

•

Always keep the knife & plate sharp.

•

Always check for levelness by laying the knife on the

plate before inserting in machine.

• Always install the knife & plate in correct sequence,

knife 1st, then plate.

• Always keep knives & plates lubricated in storage and

when starting up machine.

• Always use coolant when sharpening plates.

• Always inspect the plates making sure all holes are

clear – that there are no cracks.

DON’Ts

•

Never, never mix different knives to different plates.

•

Never, never over tighten the bowl retaining ring on

the machine.

•

Never, never run the grinder/mincer without product.

Product is a natural lubricant. Heat can build up so

fast that cold product could crack the plate.

• Never, never hit the plate against anything to clean

the holes.

• Never, never throw the knives & plates.

Page 12

10

MAINTENANCE

ROTATING GRINDING WORM

TO AVOID SERIOUS PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Servicing.

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

NEVER Place Hands Into Machine Input or Output Openings.

NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

PROMPTLY REPLACE Any Worn or Illegible Labels.

USE ONLY GENUINE BIRO Parts and Accessories Properly Installed.

A. GRINDING BOWL INSTALLATION

1. Mount the grinding bowl in the gear box opening. Insert screw lock under the grinding bowl and hand

tighten fully seating the bowl.

2. Place the grinding worm in the grinding bowl and fully seat rear drive tang into worm drive shaft.

3. Install knife, breaker plate and end retaining ring.

ONLY HAND TIGHTEN RETAINING RING

4. When the bowl assembly is mounted and tight, there should be approximately

1

8

" gap between the back

inside wall of the bowl and the back of the worm. The bowl ring wrench which is provided with each grinder

is used only for REMOVAL of the end retaining ring for cleaning purposes or for changing knife and breaker

plate.

B. GEAR BOX LUBRICATION

1. The gear box lubricant should be changed after the first four (4) weeks of operation to remove any metal

particles that may be generated during the initial mating of the gears.

2. Thereafter at one (1) year intervals.

3. There is a drain plug on the underside of the gear box.

4. Refill with a measured one (1) pint of LUBRIPLATE #APG-140 gear oil or equivalent.

CLEANING THE BOWL - RING AND WORM

CARE OF TIN COATED PRODUCTS

(DO’S AND DON’TS)

1. Do not use abrasive cleaning materials, such as brillo pads or metal scrapers. Tin is a soft metal and should be cleaned with a

soft cloth and dried.

2. Do not use a cleaning agent containing a high percentage of free alkali or acid.

3. Do not use a detergent containing a high percentage of tri-sodium phosphate or meta-silicate. Tin is reactive to both.

4. Rinse well and dry throughly after washing to remove agents that may be reactive to tin.

5. If sterilizing agent containing chlorine is used, the tinned surface must be throughly rinsed. Chlorine is corrosive to tin.

6. Dry throughly after rinsing and store in a dry environment.

7. If water is exceptionally hard, drying will be necessary to prevent spotting.

Page 13

MODEL 6642 GEAR BOX ASSEMBLY

PARTS LIST

11

Item No. Description

FW12S Flat washer,

3

8

,SS

HHS045 Hex head screw,

1

4

-20

´

7

8

HHS070S Hex head screw,

3

8

-16´1, SS

LW10 Lock washer,

1

4

LW25S Lock washer,

3

8

,SS

LW30 Lock washer,

1

2

MC-1Z Gear box only

MC-10D Motor shaft slottet nut

MC-10E Cotter key,

1

8

´

1

MC-105 Motor seal, lip type

MC-11Z Lower shaft washer

MC-12 Gear box motor bolt, short

MC-12A Gear box motor bolt, long

MC-13Z Lower shaft bearing adj. cap

MC-2BL Bowl locator pin, dowel

MC26ZAZ Idler bearing cup/cone

MC-27ZAZ Rear thrust bearing cup/cone

MC-29 Upper shaft oil seal

MC-30A Uper brg. cap set screw, long

MC-31 Adjusting cup & seal housing

MC-34 Woodruff gear key, #91

MC-35 Gear box cover locator pin

MC-39 Oil plug,

1

8

´

3

8

MC-40 NPT vented plug,

1

8

Item No. Description

MC-5Z1 Upper shaft spacer

MC-51L Gear box lubricant, 1 pint

MC-6A Motor pinion gear

MC-7A Idler gear

MC-8 Idler pinion gear

MC-9 Drive gear

SSS13 Set screw,

1

4

-20

´

3

8

300 Lower shaft woodruff key

42MC-110 Gear box O-ring seal, #8493 on

42MC-115 Gear box cover gasket

42MC-2R Gear box cover only, #2321 on

42MC-2R1 Heli-coil insert, SS, #3663 on

42MC-3Z Up. shaft, hollow sq. end, #2321 on

42MC-4Z Lower shaft

ASSEMBLIES FOR GEAR BOX

Item No. Description

A227 Upper bearing cup/cone assembly

B42MC-2R Gear box cover assembly, #2321 on

BMC-1Z-1 Gear box assembly, #2321 on

w/motor seal

BMC-Y21R-3 Bowl lock assembly, #2321 on

MC-26ZAZ Idler bearing cup/cone assembly

MC-27ZAZ Rear thrust bearing cup/cone

assembly

Page 14

MODEL 6642 MAGNETIC SWITCH SYSTEM

WITH SAFETY INTERLOCK SWITCH STARTING WITH SERIAL NO. 9340

CONTACTOR COIL VOLTAGE MUST BE SAME AS POWER SUPPLY VOLTAGE

12

Item No. Description

42MC-Y20-8 Magnet, S/N 5796 to 8150

42MC-Y60 Safety interlock switch bracket, S/N

5796 to 8151

42MC-AE79K AEG contactor, 2HP, 1 & 3PH

(208/220/230V), 50/60Hz with din

rail, fasteners and clips

42MC-AE80K AEG contactor, 2HP, 3PH, (440V),

60Hz with din rail, fasteners, and clips

42MC-AE81K AEG contactor, 2HP, 3PH (380-415V)

50Hz with din rail, fasteners and clips

Item No. Description

42MC-AE82K AEG contactor, 2HP, 3PH (550V)

60Hz with din rail, fasteners and clips

42MC-AE84K AEG contactor, 2HP, 1PH (110/120V)

60Hz with din rail, fasteners and clips

6808-G Toggle Switch (1PH) to S/N 5796

7810-G Toggle Switch (3PH) to S/N 5796

800S-2ASQ GP Push button station – flush

mount, S/N 5796 to 9339

Item No. Description

42MC-Y20-8A Magnet S/N 8151 on

42MC-Y64 Magnet safety interlock switch,

SN5796 on (up to 250V)

H442-1 Magnetic safety interlock switch

(250V and up)

42MC-Y67 Flange spade crimp-on connector

42MC-Y70 Safety switch bracket

42MC-Y73 Green start button

42MC-Y74 Red stop button

42MC-Y75 “Start” legend plate

42MC-Y76 “Stop” legend plate

42MC-Y77 Switch hole cap plug

42MC-AE79 AEG contactor, 2HP, 1 & 3PH,

(208/220/230V), 50/60Hz

42MC-AE79A AEG contactor & overload 2HP, 1 &

3 PH (208/230V) 50/60Hz

Item No. Description

42MC-AE79-CL Coil, 220V

42MC-AE0L08L AEG overload 2HP, 1 & 3PH

(208/230V) 5.6-8 amp

42MC-AE80 AEG contactor, 2HP, 3PH (440V), 60Hz

42MC-AE81 AEG contactor, 2HP, 3PH,

(380/415V) 50Hz

42MC-AE82 AEG contactor, 2HP, 3PH, (550V) 60Hz

42MC-AE83 AEG contactor 2HP, 3PH (24V)

50/60Hz

42MC-AE84 AEG contactor, 2HP, 1PH,

(110/120V) 60Hz

42MC-AE87 3.5" long din rail

BLK323 End barrier

HHS010S Hex head screw, 10-32

´

3

8

"SS

HN10S Hex nut, 10-32 SS

Item No. Description

42MC-Y20-8A Magnet S/N 8151 on

42MC-Y64 Magnet safety interlock switch,

H442-1 Magnetic safety interlock switch

42MC-Y67 Flange spade crimp-on connector

42MC-Y70 Safety switch bracket

42MC-Y73 Green start button

42MC-Y74 Red stop button

42MC-Y75 “Start” legend plate

42MC-Y76 “Stop” legend plate

42MC-Y77 Switch hole cap plug

226EE-CO11K AEG contactor, 2HP, 1 & 3PH,

42MC-EE79A AEG contactor & overload 2HP, 1 &

SN5796 on (up to 250V)

(250V and up)

(208/220/230V), 50/60Hz

3 PH (208/230V) 50/60Hz

Item No. Description

42MC-Y20-8 Magnet, S/N 5796 to 8150

42MC-Y60 S

42MC-EE79K AEG contactor, 2HP, 1 & 3PH

42MC-EE80K AEG contactor, 2HP, 3PH, (440V),

42MC-EE81K AEG contactor, 2HP, 3PH (380-415V )

afety interlock switch bracket, S/N

5796 to 8151

(208/220/230V), 50/60Hz with din

rail, fasteners and clips

60Hz with din rail, fasteners, and clips

50Hz with din rail, fasteners and clips

Item No. Description

42MC-AE79-CL Coil, 220V

226EE-0L08.5L AEG overload 2HP, 1 & 3PH

226EE-EO11K AEG contactor, 2HP, 3PH (440V), 60Hz

226EE-EO11K AEG contactor, 2HP, 3PH, same/coil

226EE-FO11K AEG contactor, 2HP, 3PH, (550V) 60Hz

226EE-GO11K AEG contactor 2HP, 3PH (24V)

226EE-AO15K AEG contactor, 2HP, 1PH,

42MC-AE87 3.5" long din rail

BLK323 End barrier

HHS010S Hex head screw, 10-32 3/8" SS

HN10S Hex nut, 10-32 SS

(208/230V) 5.5-8.5 amp

rated 400V (380/415V) 50Hz

50/60Hz

(110/120V) 60Hz

Item No

42MC-EE82K AEG contactor, 2HP, 3PH (550V)

42MC-EE84K AEG contactor, 2HP, 1PH (110/120V )

6808-G Toggle Switch (1PH) to S/N 5796

7810-G Toggle Switch (3PH) to S/N 5796

800S-2ASQ GP Push button station – flush

. Description

60Hz with din rail, fasteners and clips

60Hz with din rail, fasteners and clips

mount, S/N 5796 to 9339

Page 15

Page 16

IMPORTANT:

PLEASE SPECIFY SERIAL NUMBER WHEN

ORDERING REPLACEMENT PARTS.

PARTS LIST SPECIFIC TO MACHINES PRIOR TO SERIAL NO. 9340

Item No. Description

M99-2-17 Sta. switch, 2HP, 50Hz, Baldor mtr.

M99-2-17A Rot. switch, 2HP, 500/60Hz Baldor

mtr.

MC-100 Motor seal, ORDER MC105

MC-25B Model plate switch slot

MC-25B1 Name plate self-tap screw

MC-25C Model plate case screw

MC-25D Sw. to model plate screw 6-32

´

3

8

42MC-Y25B Case, SS, 18 inch, #5796 to #8150

42MC-Y25B5 Adapter plate, sw. to new case

42MC-Y49-1 Drive screw for ali. guard, #14

´

5

8

42MC-49SFT Tray guard, ali, #4800 to #8272

Item No. Description

BMC-Y21R-1 Bowl lock assembly,

1

2

", to #3663

B42MC-L20 Large tray w/guard safety kit, to

#2000

B42MC-Y20A-OS

Tray w/guard & safety kit, #2000 to

#4799

B42MC-Y20A1 Tray assembly w/guard & magnet

#5796 to #8151

B42MC-Y25C SS case assembly w/model plate and

decals, #8151 to #9339

B42MC-Y25E SS case assembly, 18 inch, #4800 to

#5795

B42MC-Y25F SS case assembly, 18 inch, #2000 to

#4800

Page 17

OPERATOR’S SIGNATURE PAGE

MY SIGNATURE ATTESTS THAT I HAVE COMPLETELY READ AND UNDERSTAND THIS

MANUAL. I REALIZE THAT THIS MACHINE, IF OPERATED CARELESSLY, CAN CAUSE SERIOUS INJURY TO MYSELF AND OTHERS.

NAME (PRINT) SIGNATURE

SUPERVISOR’S

INITIALS

DATE

Page 18

LIMITED WARRANTY

WARRANTY: The BIRO Manufacturing Company warrants that the BIRO Model 6642 Grinder will

be free from defects in material and workmanship under normal use and with recommended service. BIRO will replace defective parts, which are covered by this limited warranty, provided that

the defective parts are authorized for return, shipping charges prepaid, to a designated factory for

inspection and/or testing.

DURATION OF WARRANTY: The warranty period for all parts covered by this limited warranty is

one (1) year from date of inspection/demonstration as advised on the returned warranty registration card, or eighteen (18) months from original factory shipping date, whichever date occurs first,

except as noted below.

PARTS NOT COVERED BY WARRANTY: The following are not covered by this limited warranty:

wearable parts in the grinding system such as bowl, worm drive shaft, ring, worm, and knife drive

pin. This limited warranty does not apply to machines sold as used, rebuilt, modified, or altered

from the original construction in which the machine was shipped from the factory. Water contaminated electrical components are not covered under this limited warranty. BIRO is not responsible

for electrical connection of equipment, adjustments to switch components or any other electrical

requirements, which must be performed only by a certified electrician. BIRO is not responsible for

service charges or labor required to replace any part covered by this limited warranty or for any

damages resulting from misuse, abuse, lack of proper or recommended service.

EXCLUSION OF WARRANTIES AND LIMITATION OF REMEDIES: BIRO gives no warranties

other than those expressly stated in this limited warranty. THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR PROCESSING OF FOOD PRODUCTS, AND ALL OTHER IMPLIED WARRANTIES ARE SPECIFICALLY EXCLUDED. BIRO IS NOT

LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, EXPENSES, OR LOSSES. THE

REMEDIES PROVIDED IN THIS BIRO LIMITED WARRANTY ARE PURCHASER’S SOLE AND EXCLUSIVE REMEDIES AGAINST BIRO.

REGISTRATION CARDS: You must sign, date and complete the warranty registration card supplied with each machine. The warranty registration card must be returned to The Biro Manufacturing Company for proper registration. If no warranty registration card is returned to BIRO, the

warranty period will begin from the date the machine was originally shipped from the factory.

HOW TO GET SERVICE:

1. Contact the agency from whom you purchased the machine; or

2. Consult the yellow pages of the phone directory for the nearest authorized dealer; or

3. Contact Biro Mfg. Company for the nearest authorized service entity (250 plus worldwide) in

your area.

THE BIRO MANUFACTURING COMPANY

1114 Main Street

Marblehead, Ohio 43440-2099

Ph. 419-798-4451

Fax 419-798-9106

E-mail: service@birosaw.com

Web: http://www.birosaw.com

16

ITEM NUMBER 42MC-Y53-047

PTCT 6642-047-11-04-25 COMM.

ITEM NO. 42MC-Y53-047

PTCT 6642-047 7-07-27 ACME

Loading...

Loading...