Page 1

OLY MPUS POLARIZING MICROSCOPE

I

MODELS

BHA

-P&B;H.-P

ATTACHMENT

Page 2

This

i

>

!

instruction rnancral has been written for the use

Modcl

manual carefully in order to familiarize yourself fully

polarizing attachment so

CHA-P

and Polarizirl!j Attach~nent Model

lhal

you

can

ob~an

IMPORTANT

the

of

131-I-P.

with

best

performance

the Olyn~pus Polarizing Microscope

It

is

recommended

the use

of

Ihe microscope on the

and

~ffectiveness.

to

r-ead

the

!,

I

t

Observe

the

following points carefully:

Operation

1.

Always

2.

Avoid exposure of

3.

Only

Do

ously, which

4.

Ascertain that

local mains voltage.

5.

Disconnect

Maintenance

1.

Lenses

wiped off by means

prints deposited

xylene, alcohol or ether.

2.

Do

parts, especially, should

handle

use

the

not twist the two coarse adjustment

must

not use organic solutions

the microscope

the

microscope

tension adjustment ring for altering the tension

might

cause damage.

the

voltage selector switch on the base plate is set

the

line cord frorn

always

on

be

of

the

with

the

care

it

deserves, and avoid abrupt motions.

to

direct sunlight.

knobs

in

the

AC

power outlet for fuse replacement.

kept

clean. Fine dust

an air blower

lens

surfaces

be

cleaned with a neutral detergent.

lo

or

wipe

a

with

on

clean

brush.

yaclzs moistened

the surfaces of various components.

dust

the

lens

and vibration.

of

the coarse adjustment.

opposite directions sirnultane-

to

conform wit11

surfaces

Carefi~lly wipe off oil

should

with

be

blown or

or

a

small amount

finger-

Plastic

the

of

3.

Never disassemble the rnicroscope for repair

4.

The microscope should

possible, it slioi~ld

eyepieces in

5.

Disconnect the line cord

a

desiccator, containing cjcsiccants.

be

stored

be

covered with

frorn

the

in

AC

its container immediately aftel- use. li this

ti

vinyl dust cover.

power

soirrce before

It

is best

fuse

to

kcap

objectives and

replacement.

is

not

Page 3

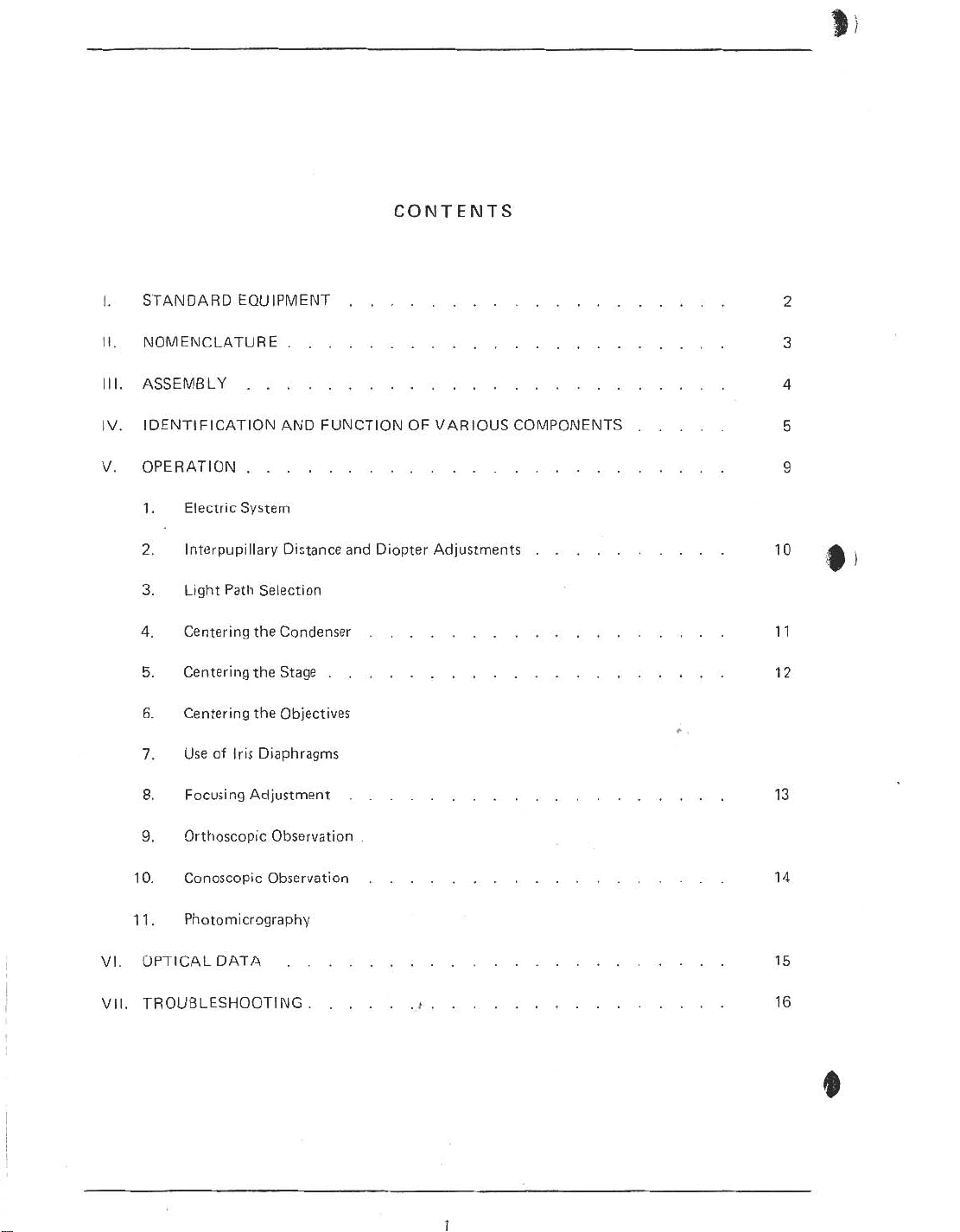

CONTENTS

t.

STANDARD

it.

NOMENCLATURE

I1

I. ASSEMBLY

1V.

IDENTIFICATION AND FUNCTION OF VARIOUS

EQUIPMENT

.

.

.

.

.

.

.

. .

. . .

.

.

.

. . . .

. . . . . . . . . .

.

. . .

.

. . .

.

. . . . . . .

. .

. . . . .

COMPONENTS

.

.

.

. . .

.

. .

.

.

.

.

.

V. OPERATION

1.

Electric System

2,

lnterpupillary Distance

3.

Light Path Selection

4.

Centering

5.

Centering

6.

Centering

7.

Use of

8.

Focusing Adjustment

9.

Orthoscopic Observation

10.

Conoscopic Observation

11.

Photomicrography

VI. OPTICAL

DATA

.

.

. . . . .

the Condenser

the

Stage

the

Objectives

Iris

Diaphragms

.

.

. . .

and

Diopter

.

.

.

. . .

. . .

. . . .

. .

.

,

. .

.

.

. . . . .

Adjustments

.

.

.

.

.

.

. . .

.

.

. .

. . . . . . . . .

. . . . .

.

. . . . . . . . .

.

.

. . .

.

. . . . . . .

.

. .

.

.

.

.

.

.

. . .

,

.

. . .

. .

. . .

.

.

.

.

.

. . .

. . . . .

.

.

VII. TROUBLESHOOTING.

. . . . . t . . . .

.

.

.

.

.

.

. .

.

Page 4

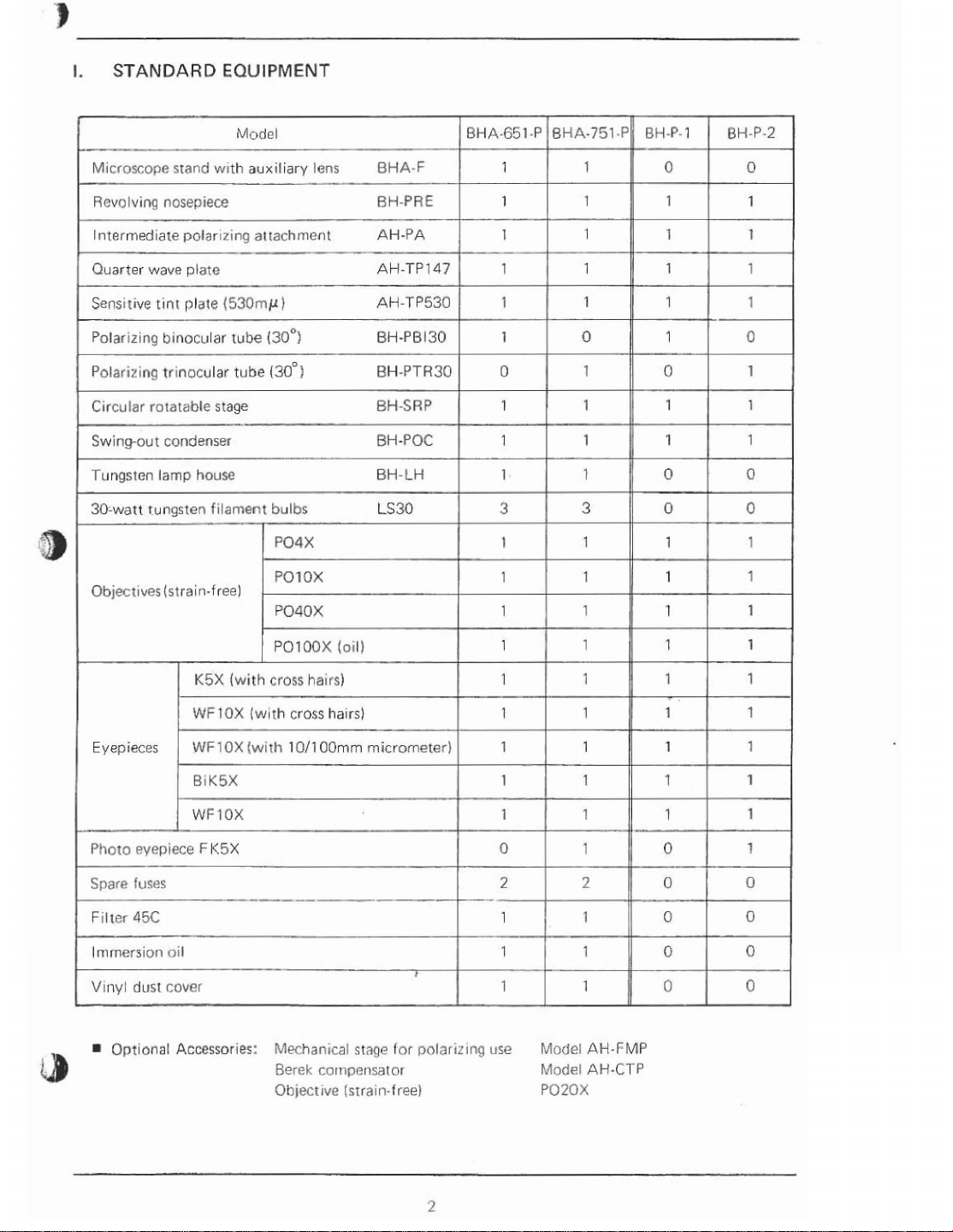

1.

STANDARD

-

EQUIPMENT

Microscope

Rcvo

l~itermediate

Quarter

Sensrt~ve

Polarlztng

Polari~lnq

Circular

Swing-out

Tungsten

30-watt

Objecrrves

lving

nosepiece

wave

tint

b~necular

tr~nocular

rotatable

condenser

lamp

tungsten

(strain-free)

stand

Model

wrth

polarizing

plate

plate

(53OrnpCI)

tube

tube

stage

house

filament

aux~lrary

a~tachmenl

lens

(30~)

(30~1

bulbs

PO4

X

POIOX

P040X

BHA-F

RH-PRE

AH-PA

AH-TPI47

AH-TP530

BH-PB

130

BH-PTH30

BH-SRP

BH

-POC

BH-LH

LS30

BHA-651-P

1

1

1

1

pp

1

1

0

1

1

1

3

1

'

1

1

BHA-751-P

J

1

1

BH-P-1

I

I

0

1

1

1

1

0

1

1

111

1

3

1

1

1

1

0

1

0

0

1

1

1

BH-P-2

0

1

1

0

1

1

1

0

0

1

1

1

Eyepieces

Photo

Spare

F~lter

Immersion

V~nyt

-

Optional

K5X

WFlOX

WF1

BIKSX

WFlOX

~yep~ece

fuses

F

45C

nil

dust

cover

Accessories:

(with

OX

K5X

PO1

cross

(with

(with

Mechanical

Berek

Qhjectivc

00X

Iollj

hatrs)

cross

ha~rs}

1011

00mm

cornpensalor

(srrain-free)

micrometer)

stage

for

-

I

polarizing

1

1

1

1

1

1

0

2

1

1

1

use Model

Modsl

P020X

1

1-1

1

1

1

1

2

1

'

1

t

1

1

7

1

1

11

10

-

0

I

I0

1

0

,!

\

0

1

1

1

0

0

0

0

AH-FMP

AH-CTP

Page 5

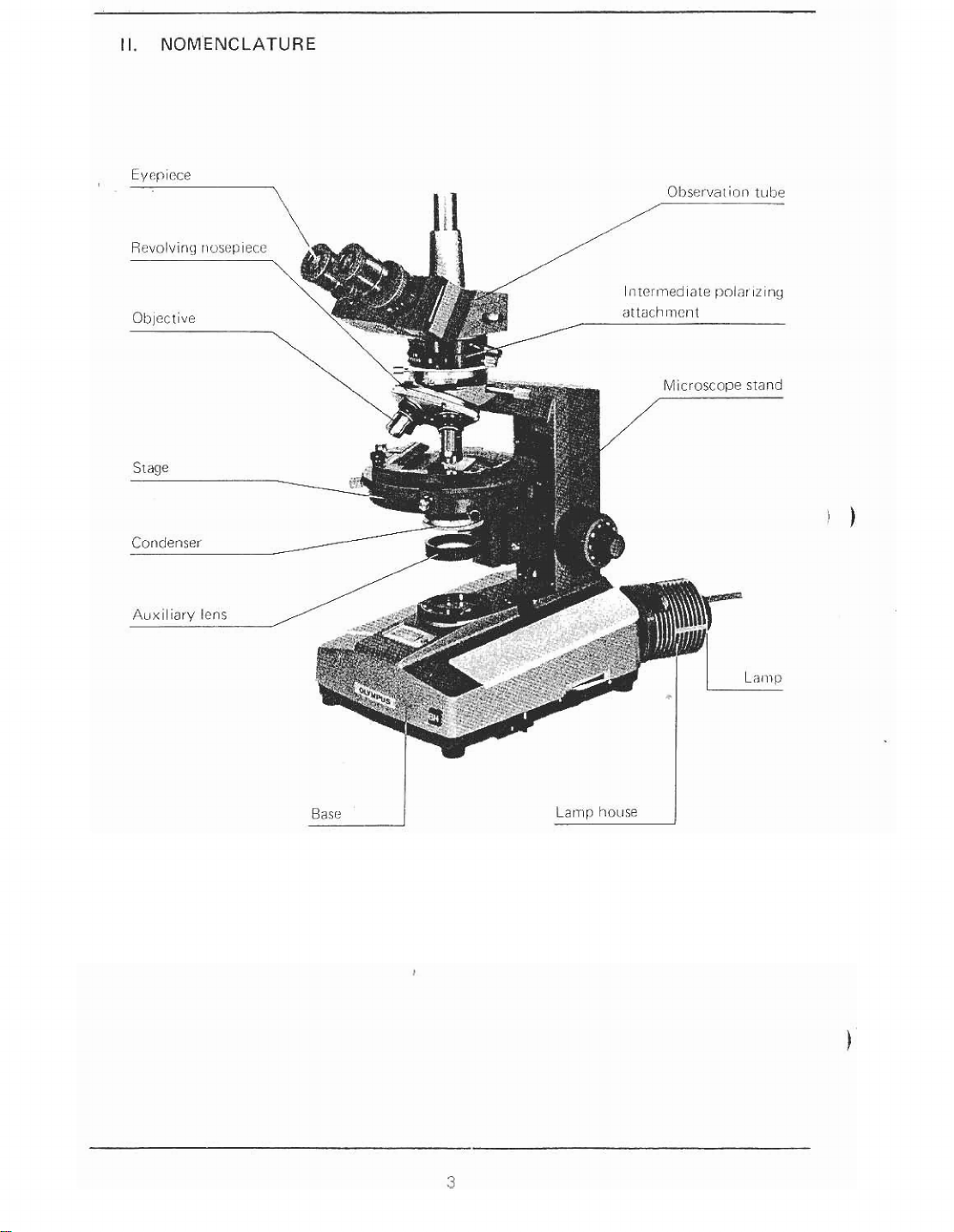

II.

NOMENCLATURE

Base

1

Page 6

Insert

the

piece.

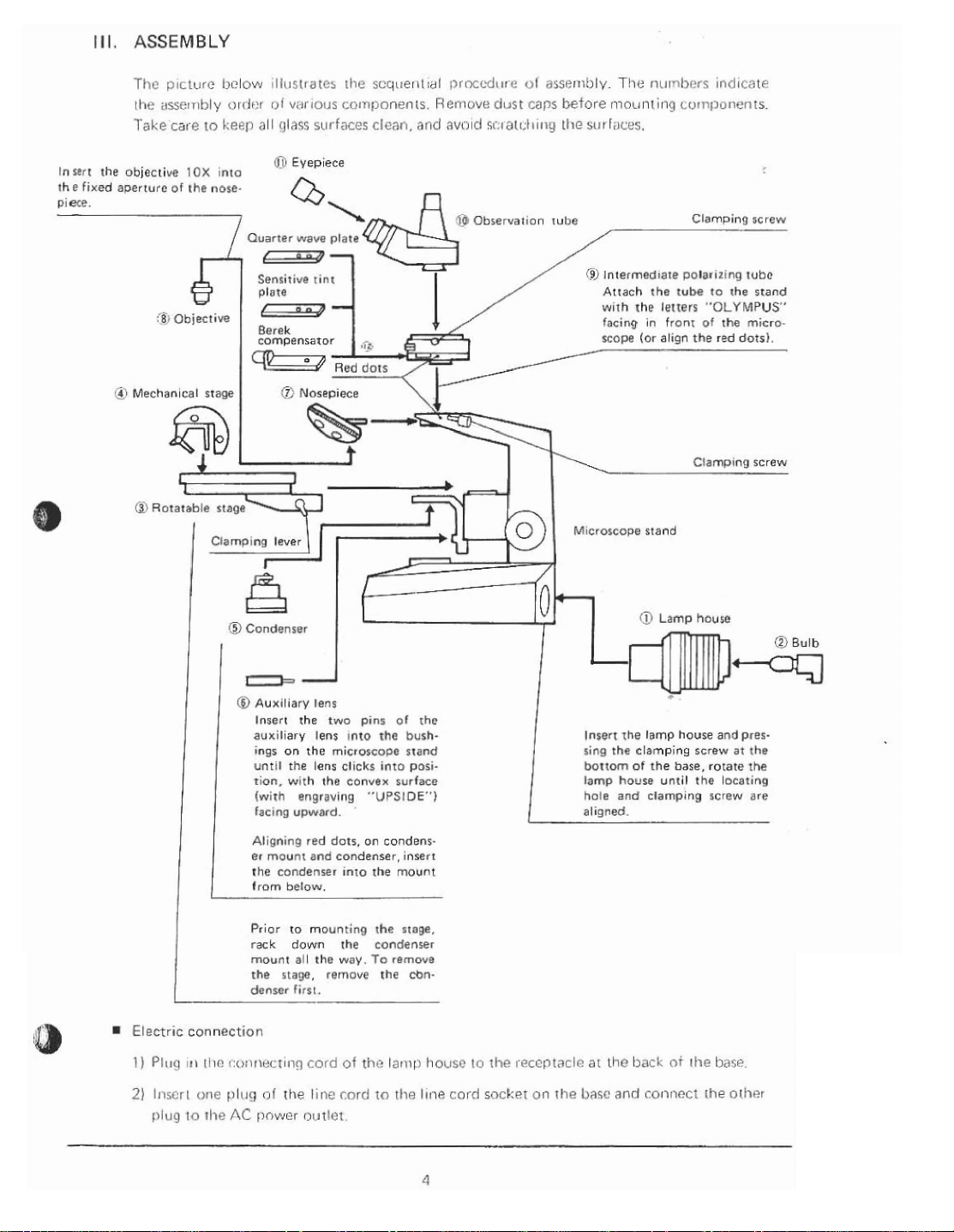

Ill.

the

fixed

objective

aperture

(TI

ASSEMBLY

Tfic

141ctl1re

the

assembly

Take

cars

of

$1

i~clow 11111~t~atCs the

cjrrlnr

lo

Ireep

10X

inlo

the

nose-

Objective

"I

Mechanical

stage

ol

all

glaqs

0

Quarter

Sensitive

plate

vilrlous

colnponenls. Rel~iove

surfaces cleat),

Eyepiece

wave

plate

rint

--

Berek

compensator

I

0

Nosepiece

scq~leritidl

and

\

k---

~prncodr~r

dust

avalcl

si.4

al~4t111g

@

Qbservat~on

1%

ol

caps

assernbly

T!ie

before mounting

tlie

srrr

faces.

tu11e

@j

lntermedrate Dolarizing

Attach

wrth

rhe

facing

scope

nt~nhrvc

Lurnpunents.

the

tube

letters

in front

(or

align

~ndtcrlt~

Clamping

tube

to

the

"OLYMPUS"

of

the

red

micro-

dots).

the

screw

stand

Rotatable

stage

Insert

aux~liary

rng5 on

unt~l

the

tion.

w~th

(with

engraving

tac~ng

upward.

Align~ng

er

mount

the

condenser

Prior

to

rack

down

mount

all

the

stage,

denser

firs[.

the

two

lens ~nto

the

microscoae

lens

clicks

the

red dots,

and

condenser,

inro

mounting

the

the

way.

(*move

pins

the

into

convex

"UPS1DE")

on

condens-

the

the

condenser

To

rhe

01

the

bush.

stand

posi-

surface

Insert

mount

stage.

rernwe

cbn-

M~croscops

@

Insert

the

sing

the clamping

bottom

of

lamp

house

hole

and

al~sned.

stand

Lamp

lamp

house

the

base,

until

clamplng

house

and

screw

rotate

the

screw

pres-

at

the

he

locating

are

,

Electr~c

1)

Pluq 111

2)

Inscr

or lug

connection

11i(!

t:o~hnr?ct~ng

i

onc

plz~g

to

rhe

AC

ol

the

[lnwer

cord

of

linc

cord

outlet.

th~

lari~p

to

the

hocrsc

Illis

cord

10

socket

~hc

r~ccptactr:

on

rhe

llasc

at

tho

and

back

coiincct

of

the

the

bds~

orher

Page 7

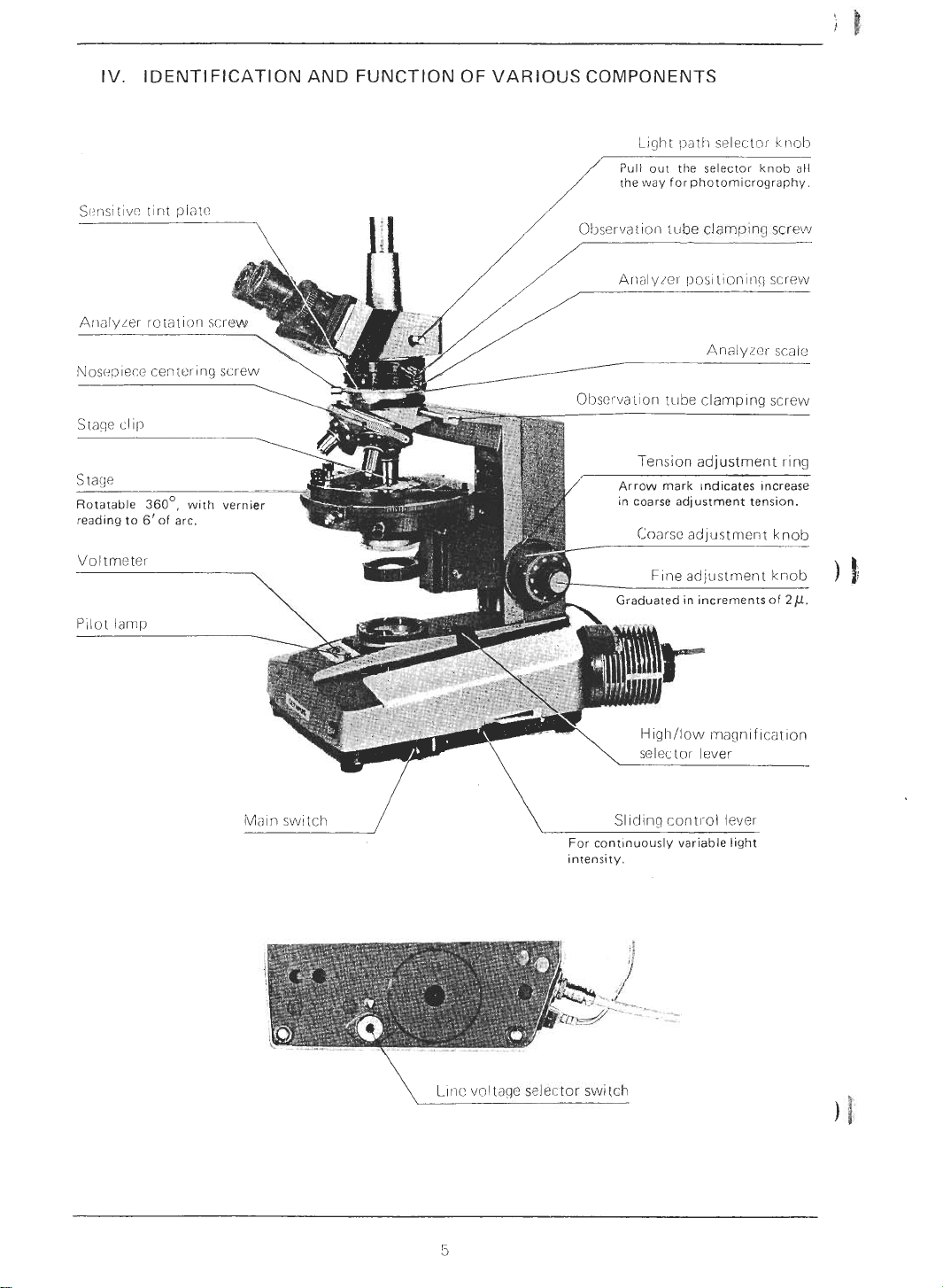

IV. IDENTIFICATION AND FUNCTION OF VARIOUS COMPONENTS

L~ght

path

Pull out the selector knob all

/

the way for photomicrography.

Tension adjustment ring

Arrow mark ~ndicates Increase

in coarse adjustment tension.

selector

Analyicl- scaic

kr~ol)

;

)

Voltmeter

\

SIlcIinq cont~~ol lever

For cont~nuously variable light

intensity.

\

L~ic vol~~g~

selector

switch

Page 8

Mer.lianical tube length

adjust-

Clarnping screw for

mechanical stage

45'

click stop lever

Polarizer scale

Reading to

5'.

ngraved letters "IN" for in-

of

sertion

the light path;

removal of the Bertrand lens

from the light

Clamping screw for

uated.

Bertrand lens into

"OUT"

path.

for

stage

Filter mount

Field iris diaphragm ring

Polarirer rotation ring

Rheostat trimmer screw

screwdriver until the

with the slid~ng control lever positioned

closest to vou (low voltage).

voltmeter

Larnp house clamping screw

indicates IV,

Page 9

Automatic

Nosepiece

clamping

the cap

of

replace the defective fuse with

a

replacement fuse.

(Disconnect BEFORE RE-

PLACEMENT.)

the fuse holder, and

Page 10

Summary of Putting the Microscope in Operation

Model BHA-P

A. Match the line voltage selector switch to local mains voltage (see page

Switch on the light source.

B.

Rotate the trimmer screw until the voltmeter indicates

C.

Place a specirnen slide on the mechanical stage.

D.

Remove the Bertrand lens and analyzer from the ligh! path.

E.

10X

Coarse focc~s with the

F.

Make interpirpillary and diopter adjustments (page

G.

Center the condenser (page

H.

Center the stage (page 12).

I.

Center objectives other than

J.

Swing in the desired objective.

K.

L.

Set the condenser, analyzer and Bertrand lens correctly according to your microscopic

purpose (pages 13 and 14).

M.

Adjust illumination system.

N. Adjust light intensity.

0.

Fine focus.

objective.

10)

10X

(page 12)

10)

1V

(page

6).

9)

Adjust aperture iris diaphragm and field iris diaphragm (page

P.

(

Adjustment of illumination system

Intermediate

polarizing at-

tachment

OUT

IN

"H"

positior? for

put

~t on the wall near the microscope for

r

4X

Objective

4X

20X

and

lox,

to

to

100X

100X

aricl the

Microscopic

Orthoscopic

observation

Conoscopic

observation

For biological use ol the Moclel BHA-P, however, remove the analyzer, Bertrand lens

sensitive tint plates, and place the high/low magnification selector lever into the

tion lor

Cut

off this page at dotted line and

*

microscopic procedure.

Conder~ser

top lens

OUT

IN

20X. 40X

and

12).

I

Highllow magnification selector lever

100X

object~ves.

use

L

H

"L"

as a reminder of

and

posi-

Page 11

V.

OPERATION

1.

Electric System

1)

Adjustment of Light Intensity

The rninimum voltage required for the light source can be adjusted with the rheostat

trimmer screw at the bottorri of the microscope base in accordance with the line voltage

and frequency.

control. The

@

@

@

2)

Adjustment of Minimum Line Voltage

@

(3

A

silicon controlled rectifier (SCR)

SCR

has the following advantages over conventional rheostat cor-itrols.

Extremely fine adjustment of light intensity can be easily achieved

Flickering of the bulb filament is elirninated and light intensity is stabilized.

Increased life expectancy of the bulb.

Ascertain that the voltage selector switch is set to conform with the local mains

voltage. (This switch can be

voltages: 100V-110V-I 20V or 220V-240V.)

Ascertain that the sliding control lever is positioned closest to you (low voltage), and

then activate the main switch. The pilot lan-ip lights up.

turned with a coin, and can be set to the following

is

provided lor output voltage

@

If the bulb is dimnily lit, and the voltmeter indicates about IV, the secondary voltage

is correct, and you have only to push the sliding control lever forward in order to

obtain optimum light intensity.

@

If the bulb does not light or lights up brightly immediately after switching on, rotate

the rheostat trimmer screw gradually w~th a coin, until the voltmeter indicates

about 1V.

3)

Light Source

The standard light source incorporates a 30W pre-centered tungsten filament bulb,

provided with a socket for positive contact, eliminating the problems of defective

contact and over-heating.

of

When used at the rated voltage 6V. the aver-age lrfe

than 200 hours. This is,.however, greatly reduced, if the bulb is used at higher voltage; for

instance, the bulb life is reduced to 1/50 at 8V. Therefore, it is advisable to avoid

prolonged use at readings over 6V (in the red rorie).

If the light source should be used at high voltage constantly, it is reconirnended to usea

high intensity halogen bulb.

*

Do not switch the tungsten bulb on &ith the sliding control lever at high intensity posi-

tion (away from the user). It reduces bulb life.

the tungsten bulb LS30 is longer

Page 12

2.

lnterpupillary Distance and Diopter Adjustments

Insert the eyepiece v~ith cross hairs of your choice into

1)

tile right eyepiece tube, align~ng the positioning slot

and position~ng pi11

*

When the eyepiece positioning pin is inserted into the

lower slot on the tube, the cross lines in the eyepiece

coincide with the vibration direction of polarizer and

analyzer at

slot, the cross lines are at

vibration.

2)

Looking through the iight eyepiece (with cross hairs)

with your right eye, rotate the d~opter adjustment ring

@

until the cross hairs are sharpty focused. (Fig.

3)

Looking through the both eyepieces with both eyes,

adjust the interpupillary distance, sliding the knurled

dovetail slides

cintil perfect binocular vis~on is obtained.

4)

Memorize your interpupillary distance setting by means of the scale

5)

Rotate the tube length adjustment ring @ on the right eyepiece tube

interpupillary distance setting which you obtained from the scale

@

.

(Fig.

1)

0

settings. When inserted into the other

45O

to the direction of

@

of the right and left eyepiece tubes,

@

2)

@

Fig.

2

to

match your

,

))!{

6)

Look at the image through the right eyepiece with your right eyepiece v~ith your right

eye and focc~s on the specimen with the coarse and fine adjustment knobs.

7) Look at the image through the left eyepiece with yocrr left eye and rotate the tube length

@)

adjustment ring

ment knobs.

3.

Light Path Selection

The trinoc~.llar tcrbe is provided with a light path selector knob to direct the light to the

observation tube or to the phototube.

Knob position

Pushed in all the way.

Pulled out all the way.

to focus on the specimen without using the coarse and fine adjust-

Amount of light

100%

into binocc~lar tub:!

20%

into binocular tube

80%

into phototube

Application

Observation

Photomicrography

Page 13

4.

Condenser Centration

1)

Br~ng the

*

If a specimen

without

the peripheries of the specimen with the stage clips

provided to the circular stage.

Swing in the condenser top lens, and br~ng the specimen

into focus.

objective

a

mechanical stage it is recommended to hold

10X

into the light path.

is

placed on the circular rotatable stage

Stop down the field iris diaphrag~n w~tli knurled ring

A

slightly blurred image of the field diaphragm can now

be seen in the eyepiece.

4) Move the condenser up and down to locus on the image of the field diaphragm.

*

If the specimen slide is too thick, it is sometimes impossible to obtain a sharply-focused

image.

5)

While widening the diameter of the field progressively,

(3)

screws

6)

Push the analyzer @ into the light path, and make sure

that both polarizer and analyzer are set at position

to attain the "Crossed filter" position. Then loosen the

clamping screw

to bring the diaphragm iniage Into the center of view. (Fig.

(2)

(Fig.

3)

of the condenser.

(Fig,

4)

a.

"0"

Flg.

3

iise

the condenser centering

3)

7)

Remove

transparent area comes into the light path. Keeping the

polarizer at the

tion ring @ until the optimum extinction is obtained,

then clamp the ring. (Fig.

the speclmen o~~t of the light path so that a

"0"

position, rotate the polarirer rota-

4)

.

I++-&:

/--:,

Fig.

.,

4

.

,

,--

j,i

Page 14

5.

Centering the Stage

I)

Looking througlk llic eyeplece ancl objective

In

you like,

hairs of the eyepiece.

the specimen irnage and coincidii thrs point with

10X,

cleter~nine solme particular point, as

thc

center of the cross

2)

Rotating the stage, coincide the center of

the rotation oi the specimen's point g~ith

the center of the cross hairs by means of

two centering screws

stage. (Fig.

*

Repeat this procedure until the centration

6.

Centering the Objectives

This centration

the pre-centered objective

1)

Connect a centering knob 9 to each centering screw

the circular rotatable stage. (Fig.

21

By means

centers of the cross hairs and the rotation of the

specimen.

3)

After complete centration, remove the centering knobs.

7.

Use of Iris Diaphragms

1

)

Aperture iris diaphragm

Adjust the opening of the aperture iris diaphragm

according to the various conditions scrch as the numerical aperture of the objective, irnage contrast, depth of

focus, and flatness of field. Generally it is often preferable to stop do\nln the aperture iris diaphragm to the

or

80%

After the eyepiece is removed from the observation

tube, if necessary, look through the observation tube

and check the opening of the aperture diaphragm at the

objective pupil.

51

is

secured.

is

of

these two centering screws, coincide the

of the N.A. of the objective.

[I?

provided on tlie

necessary to all the

POlOX.

6)

PO

objectives except

of

70%

11111

I--

>--

-

--

Fig.

6

-

2)

Field iris diaphragm

The field [!-is diaphl-agm controls the diarnetellneri s~~rface and thus increases irriage definition.

Generally, it is prefel-able to slightly increase the diameter of the field iris diaphragm until

it is just outside the field of view.

!

of

tlie ray bcrndle ~nlpinging on the speci-

Page 15

8.

Focusing Adjcistment

1)

Tension adjustment of coarse adjustment ltnobs

A

tension adjustment ring

riqlit hand coarse adjustment

terisior) of the coarse adjustment is freely adjustable

eittier- heavy oi liclti t movement rfependincl or1 opcrator

01-eference.

Iiowever, do not loosen thc: tension adjustrnent rlny too

rnoch, because the stage clrops, or the

knobs sl111 eas~ly. Fig.

*

Be careful not to rotate the right and left coarse adjustment knobs

2)

Pre-focusing lever

This levci.

accomplished. It prevents further ~ipward travel of the

stage by nienns of the coarse adjustrnent knobs, and

autoniatically provides a liiniting stop if the stage is

lowered and then raised agaln. (Fig.

9.

Orthoscopic Observation

1)

Swing out tile top eris

In

principle, polarizided light enters the light path, parallel to the optical axis, to enable

observalion of the optical characler~st~cs of the specirnen. However, this method will

darken the field of view and lower the resolving power

fore, swing out the top lens of the condenser, using only the lower aperture of the lower

condenser lens.

in

the opposite directions sim~iltaneously.

3)

is locked after coarse focirs has been

of

IS

provided nc!xt to the

knob.

With this clevice the

8)

the condensel

fine

adjustrncnt

lo^.

7

FI~.

8

of

the objective extremely. There-

2)

Insert the analy~er into the light path, and attain the crossed filter position with analyzer

0

and polari7er at

direction, and the analyzer vibration in the east-west d~rection. To open the filter position, pull out the analyrer rotation screw.

3)

Rotatc the stage until the extinction of the image is

attaned, and n)ove tlic

the operator.

Frorn this position, it is easy to rotate the stage in

45'

Increments without having to ircfer to

scale, and the stage clicks at the clla~onal position, at

\vliicii position. the retardation angle

relcase the

lever.

45O

setting.

(Fig,

cl~ck stops, push back the

At this pos~tori, the polari~er vibra~i

45'

click stop lever $ toward

9)

the

angular

is

measured. To

45"

click slop

I

In

is in the north-south

Fig.

9

Page 16

4)

Insel-t the quarter \Nave pltite or sensitive tint plate into tlie slot in

l)oIarr?in(j lul~e,

*

A

Berek compensator

is

optionally available to measure the birefringence of a specimen.

:he

intcrmccliato

Sensit~ve tint plate Quarter

10.

Conoscopic Observation

1)

Swing in the top lens of the condenser, and illornrnate the specimen with no need to

immerse between the condenser and specimen slicle,

2)

Bring the specimen into foccrs, rotate the Bertrand lens tcrrrent ring into the

3)

Focus on the interference

20X

ro

100X.

The pinhole cap provided may be ~~sed in place of the eyepiece to directly view the

interference figure mentioned above. In this case, the Bertrdncl lens is disengaged.

11.

Photomicrography

1)

Photomicrographic equipment

Photomicrography i~ith the h4odel

the photomicrograpliic system camera, exposure meter, photo eyepiece, etc. Read the

lnsiruction manuals for each equipment, and follow the steps below:

a

It

is

recommended to use a low power photo eyepiece

@

Photor~iicrographic magnification 1s same as witl-1 the standard optrcal tube length,

although the optical tube length for- this use

polariilng tube.

(I~LI~C

wave

plate

formed at the back focal plane of the objective frorn

BHA-P

requires photomicrographic equipment such as

is

prolonged because of the

Berek

FK2.5X.

compensator

IN

position.

intermediate

0.

)

I

Page 17

VII.

OPTICAL

DATA

[

WFlOX

-

-

PO20X

0.40

1.58

3

8.1

0.84

1 OOX

15.56

1.05

200X

9.19

0.9

P040X

0.65

1

0.6

4.33

0.52

(Spring

loaded)

200X

4.99

0.53

400X

3.03

0.45

is

used at the full

Objective Magnification

K5X

r::ber

11 81

-

2 1

)

)ecW(mm)-

N.A.

W.D.

imml

Focal length

Resolving power

Total magnification

Focal depth

f

otal magnification

Focal depth

Field of view (mm)

(mrn)

--

(

I*)

(

,U

Immersion objective. Resolving power

P04X

0.1 0

18.77

28.45

(

P

3.4

)

20X

300.0

5.25

40X

172.5

4.5

POlOX

0.25

6.78

16.08

'

1.3

50X

48.0

2.1

1 OOX

27.60

1.8

is

obtained when the objective

aperture diaphragm.

The eyepieces

K5X

and WFlOX incorporate a sliding eye shield. This eye shield can be

pulled out to prevent glare and loss of contrast caused by arnbient light hitting the eye lens.

0

W.D.

(Working distance):

The distance between the specimen orcover- glass and the nearest point of the objective.

A

POlOOX

1.30

0.1

1.81

.-

0.26

(Spring

loaded)

500X

1.05

--

0.21

1,OOOX

0.66

0.18

1

9

0

N.A. (Numerical aperture):

a

The n~~merical aperture represents

the relative aperture (f-number) of a camera lens.

perforrnance number whlch cocrld he compared to

N.A. values can be usecl for directly

comparing the resolving powers of all types of objectives. The larger

resolving power.

0

Resolving power:

a

The abllily of

lens to register small details. The resolving power of a lens

its ability to separate two points.

0

Focal depth:

The

disrance between the upper and lower limits of sharpness in the image formed by an

optical system.

0

Field number:

A

number that repl-esents the diameter in

formed bv the lens

0

Field of view diameter: the actual six of the field

~ri

front of it.

t

lnln

of the image of

of

view in mnl.

N.A..

the higher the

IS

measured by

the

field diapliragnl that is

Page 18

VI II. TROUBLESHOOTING

I

I

1.

'

(a) With the illuminator The highllow magnification selector Place the lever in correct position.

I

Troubles

Optical System

switched on, the field of lever is not correctly positioned.

view cannot be seen.

The condenser is lowered exces- Raise the condenser to the upper

Causes

I

Remedies

i-I

(b)The field of view is cut off

or illuminated irregularly.

Analyzer and polarizer are in the

"crossed filter" position

The light path selector lever is stopped midway.

The highllow magnification selector

lever is not correctly positioned.

The auxiliary lens is not correctly

attached.

The nosepiece is not click stopped. Slightly rotate the nosepiece until

The nosepiece is not correctly at- Insert the sliding dovetail mount

tached to the stand.

("0:O").

Sei them at the position

"90:O".

Push the lever all the way.

Place the lever all the way.

Correct the lens position.

1

clicks into position.

lnto the stand all the way, until it

stops, then lock.

"0:90"

-

I

or

(c) Dust or dirt

the field of view.

is

visible in

The condenser is not correctly

mounted on the ring mount.

The sensitive tint plate is stopped

midway.

In case of orthoscopic observation,

the condenser top lens stays in the

light path or stops midway.

is

The field iris diaphragm

down excessive1 y.

The lamp is not correctly attached.

Dust or dirt on the glass surface at

the light exit on the base.

Dust on condeqser top lens.

Dirty specimens.

I

Dust on eyepiece.

stopped

Re-insert the condenser all the way.

Push the plate all the way until

clicks.

Swing it out of the light path.

Open the diaphragm fully.

Re-insert the lamp correctly.

Clean off the dust or dirt.

I

it

Page 19

Troubles

(cl

)Excessive irnage contrast.

The condenser

sivel y.

Causes

IS

lowered exces-

Remedies

Raise the condenser.

The aperture irls diaphragm is stoppet1 down excessive1

The auxiliary lens is not mounted.

The high/low magnification selector

lever is not correctly positioned.

(e) Pesolution problems:

0

1

fiage is not sharp.

0

lrscrfficient contrast.

lrnage

details

tron.

lack

defini-

D

The nosepiece

tached.

The objective is not correctly positioned in the light path.

Dirt on objective front lens.

The immersion objective

without immersion oil.

Birbbles in the

The Olympcrs designted oil

used.

Dirty specimen.

Dirt on condenser lens.

The specirnen is not properly il-

luminated.

y.

is

not correctly at-

immersion

oil.

is

IS

used

not

Operi tile diaphragm.

Mount the auxiliary lens.

Place the lever in correct position.

Insert the sliding dovetail mount all

the way, until it stops, then lock.

Slightly rotate the nosepiece until

it clicks into

Clean the objective.

Apply immersion oil.

Remove bubbles.

Use the designated oil.

Clean.

Adjust the illumination.

position.

(f) The field of view

ly out of focus.

(g) The image goes out

focus cccentr~cally.

is

partial-

The nosepiece is not correctly attached.

IS

The objective

tioned in the light path.

The specimen is not correctly positioned on the stage.

The nosepiece is not correctly at-

of

tached.

The objective

tioned in the light path.

The condenser

The auxiliary lens is not correctly

rnoc~n tecl.

The higti/low rnagnlfication selector

lever is stopped midway.

not correctly posi-

is

not correctly posi-

is

out of center.

Insert the sliding dovetail mount

all

into the stand

lock.

Slightly rotate the nosepiece until

it clicks into position.

Place the specirnen on the stage and

secure it with the specimen clips.

Insert the sliding dovetail mount all

the way, until it stops, then lock.

Slightly rotate the nosepiece until

it clicks inlo posilion.

Cenler the condenser.

Mocrnt the lens correctly.

Place the lever in correct position.

the way, then

Page 20

Troubles

-

--

!h)Wlien objectives are

changed, they are not parfocal.

-

-

-

- - -

Causes

.-

The mechanical tube length is not

correctly adjusted.

Remedies

Adjiist with the tube length adjustment rings on the observation tube.

(i) Light intensity does no1

increase although the volt-

age is raised.

(1)

The condenser does not

come to the correct position for optimum extinction.

(k)No conoscopic image can

be seen.

(I) The crossed filter position

is

not atte~ned.

2.

Electric System

la)The illuminator

is

too

bright (or too dark).

The condenser is not correctly centered.

is

The condenser

lowered exces-

sively.

The observation tube and condens-

er are not correctly mounted.

The condenser top lens is not in

the light path.

The analyzer is out of the light

I

path.

The rheostat trimmer screw is not

matched to the mains voltage.

-

The mains voltage is too high (or

too low).

The rheostat trimmer screw is not

correctly adjusted.

Center the condenser.

Raise the condenser.

Re-mo~lnt them correctly.

Swing it in.

Push it in.

Adjust the trimmer screw to match.-B

the mains voltage.

Adjust the mains voltage with

a

variable voltage transformer.

Adjust the trimmer screw until the

1

voltmeter indicates

V.

(b)Output voltage for the il-

luminator cannot be regulated.

The voltage selector switch is not

matched to the mains voltage.

The mains voltage is too low or too

high.

(c) The light flickers and the

intensity is unstable.

The mains voltage is unstable.

The filament of the bulb is likely

to bi.rrn out.

Loose electrical con1 ~ection.

(d)Fuse burns out too often.

The fuse

The voltage selector switch is not

matched to the mains voltage.

(e) The pilot I;~mp l~glits b~~t

the bull2

docs

not.

The bulb

Loose electrical connection.

IS

not a standard fuse.

IS

burned out.

Adjust the mains voltage selector

switch to the mains voltage.

Adjust the mains voltage with

variable voltage transformer.

Use a variable voltage transformer.

Replace the bulb.

Secure the connection.

Use a standard fuse.

Match the swilch to the mains

voltage.

Replace the b1.115,

Secure the connection.

a

Page 21

Troubles

(f)

Reduced bulb life.

Causes

The voltage selector switch is not

matched to the mains voltage.

Remedies

.

Match the selector switch to the

mains voltage.

3.

Focusing

(a) Coarse adjustment is too

tight.

(b)The stage drops and the

specimen goes out of focus.

(c)

The stage cannot be raised

to

the upper limit.

(d)The stage cannot be lower-

ed

to the lower limit of

the working range.

The bulb is not a standard bulb.

Mains voltage is too high.

Tension adjustment ring is tightened too much.

The user is trying to raise the stage

passing over the upper focusing

limit imposed by the engaged prefocusing lever.

The tension adjustment ring is too

loose.

Automatic pre-focusing lever is engaged in lower than focusing position.

The condenser mount is lowered

too much.

Use a standard bulb.

Use the tungsten bulb under

well as possible, or use a high

intensity bulb, such as a halogen

bulb.

Loosen the tension adjustment ring

properly.

Unlock the pre-focusing lever.

Tighten the ring properly.

Unlock the pre-focusing lever.

Raise the condenser mount.

6V

as

(e)The objective front lens

hits against the specimen,

4.

Observation Tube

(a) l ncomplete binocular vi-

sion.

5.

Stage

(a)

The image easily goes out

of focus when you touch

-B

the stage.

(b)The specimen stops mid-

way on the east-west trav-

erse.

The specimen is mounted on the

stage upside down.

lnterpupillary distance is not correctly adjusted.

Diopter adjustment is incomplete.

Right and left eyepieces are not

matched.

The user is unaccustomed with a

binocular vision.

The stage is not correctly clamped.

The specimen is not correctly posi-

tioned on the stage.

Reverse the specimen.

Correct the interpupillary distance

Complete the diopter adjustment.

Use a pair of matched eyepieces.

Prior to looking at the image of the

specimen, try to look the entire

field of view, or look at a far away

object before resuming microscopic

observation.

Clamp the stage securely.

Adjust the specimen position.

Loading...

Loading...