Olympus 45MG User Manual

45MG

Ultrasonic Thickness Gage

User’s Manual

DMTA-10022-01EN — Rev. C

January 2015

This instruction manual contains essential information on how to use this Olympus product safely and effectively.

Before using this product, thoroughly review this instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Olympus Scientific Solutions Americas, 48 Woerd Avenue, Waltham, MA 02453,

USA

Copyright © 2012, 2013, 2015 by Olympus. All rights reserved. No part of this

publication may be reproduced, translated, or distributed without the express

written permission of Olympus.

This document was prepared with particular attention to usage to ensure the

accuracy of the information contained therein, and corresponds to the version of

the product manufactured prior to the date appearing on the title page. There

could, however, be some differences between the manual and the product if the

product was modified thereafter.

The information contained in this document is subject to change without notice.

Part number: DMTA-10022-01EN

Rev. C

January 2015

Printed in the United States of America

All brands are trademarks or registered trademarks of their respective owners and

third party entities.

DMTA-10022-01EN, Rev. C, January 2015

Table of Contents

List of Abbreviations ....................................................................................... ix

Labels and Symbols ........................................................................................... 1

Important Information — Please Read Before Use ..................................... 5

Intended Use .......................................................................................................................... 5

Instruction Manual ................................................................................................................ 5

Instrument Compatibility ..................................................................................................... 6

Repair and Modification ....................................................................................................... 7

Safety Symbols ....................................................................................................................... 7

Safety Signal Words ............................................................................................................... 8

Note Signal Words ................................................................................................................. 8

Safety ....................................................................................................................................... 9

Warnings ................................................................................................................................. 9

Battery Precautions .............................................................................................................. 10

Equipment Disposal ............................................................................................................ 11

WEEE Directive .................................................................................................................... 11

China RoHS .......................................................................................................................... 11

EMC Directive Compliance ................................................................................................ 12

FCC (USA) Compliance ...................................................................................................... 12

ICES-001 (Canada) Compliance ........................................................................................ 12

Regulatory Information ...................................................................................................... 13

Warranty Information ......................................................................................................... 13

Technical Support ................................................................................................................ 14

Introduction ...................................................................................................... 15

1. Instrument Description ............................................................................. 17

1.1 Product Description .................................................................................................. 17

Table of Contents iii

DMTA-10022-01EN, Rev. C, January 2015

1.2 Environmental Ratings ............................................................................................. 19

1.3 Instrument Hardware Components ....................................................................... 19

1.4 Connectors ................................................................................................................. 20

1.5 Keypad Functions ..................................................................................................... 22

2. Powering the 45MG ................................................................................... 27

2.1 Power Indicator ......................................................................................................... 27

2.2 Battery Power ............................................................................................................ 28

2.2.1 Battery Operating Time ................................................................................. 28

2.2.2 Battery Level and Storage ............................................................................. 29

2.2.3 Replacing the Batteries .................................................................................. 29

3. Software User Interface Elements ........................................................... 33

3.1 Measurement Screen ................................................................................................ 33

3.2 Menus and Submenus .............................................................................................. 37

3.3 Parameter Screens ..................................................................................................... 38

3.4 Selecting the Text Edit Mode ................................................................................... 39

3.4.1 Editing Text Parameters Using the Virtual Keyboard .............................. 39

3.4.2 Editing Text Parameters Using the Traditional Method ........................... 41

4. Initial Setup ................................................................................................ 43

4.1 Setting the User Interface Language and Other System Options ...................... 43

4.2 Selecting the Measurement Units ........................................................................... 44

4.3 Setting the Clock ....................................................................................................... 44

4.4 Changing Display Settings ...................................................................................... 45

4.4.1 Color Schemes ................................................................................................ 47

4.4.2 Display Brightness ......................................................................................... 48

4.5 Adjusting the Measurement Update Rate ............................................................. 48

4.6 Changing the Thickness Resolution ....................................................................... 50

5. Basic Operation .......................................................................................... 51

5.1 Setting Up the Transducer ....................................................................................... 51

5.2 Calibration .................................................................................................................. 54

5.2.1 Calibrating the Instrument ........................................................................... 55

5.2.2 Test Blocks ....................................................................................................... 58

5.2.3 Transducer Zero Compensation ................................................................... 58

5.2.4 Material Sound Velocity and the Zero Calibrations .................................. 59

5.2.5 Entering a Known Material Sound Velocity ............................................... 60

5.2.6 Locked Calibrations ....................................................................................... 60

5.2.7 Factors Affecting Performance and Accuracy ............................................ 61

5.3 Measuring Thicknesses ............................................................................................ 63

Table of Contents

iv

DMTA-10022-01EN, Rev. C, January 2015

5.4 Saving Data ................................................................................................................ 65

6. Software Options ....................................................................................... 67

6.1 Activating Software Options ................................................................................... 68

6.2 Echo Detection Modes with Dual Element Transducers ..................................... 70

6.2.1 Blanking Adjustments in Manual Echo-to-Echo Detection Mode .......... 73

6.2.2 Dual Element Transducer Selection in Echo-to-Echo Modes .................. 74

6.3 Measurements with Optional THRU-COAT, D7906, and D7908 Transducers 76

6.3.1 Enabling the THRU-COAT Function .......................................................... 76

6.3.2 Performing a THRU-COAT Calibration ..................................................... 77

6.4 Waveform Software Option ..................................................................................... 78

6.4.1 Waveform Rectification ................................................................................. 80

6.4.2 Waveform Trace .............................................................................................. 82

6.4.3 Range of the Waveform Display .................................................................. 82

6.4.3.1 Selecting the Range Value .................................................................. 83

6.4.3.2 Adjusting the Delay Value ................................................................. 84

6.4.3.3 Activating the Zoom Function (Available Only with the

Waveform Option) .............................................................................. 84

6.5 Single Element and High Resolution Option ....................................................... 86

6.5.1 Recalling Single Element Transducer Setups ............................................. 87

6.5.2 Creating Custom Single Element Transducer Setups ............................... 87

6.5.3 High-Resolution Thickness .......................................................................... 87

6.6 High-Penetration Software Option ........................................................................ 88

6.7 Datalogger Option .................................................................................................... 88

6.7.1 Datalogger ....................................................................................................... 89

6.7.2 Creating a Data File ....................................................................................... 92

6.7.2.1 Data File Types .................................................................................... 93

6.7.2.2 Incremental Data File Type ................................................................ 94

6.7.2.3 Sequential Data File Type ................................................................... 96

6.7.2.4 Sequential with Custom Point Data File Type ................................ 97

6.7.2.5 2-D Grid Data File Type ..................................................................... 98

6.7.2.6 Boiler Data File Type ......................................................................... 102

6.7.3 File Data Modes ............................................................................................ 104

6.7.4 Performing File Operations ........................................................................ 105

6.7.4.1 Opening a File .................................................................................... 106

6.7.4.2 Reviewing a File ................................................................................ 107

6.7.4.3 Copying a File .................................................................................... 107

6.7.4.4 Editing a File ...................................................................................... 108

6.7.4.5 Deleting a File or Its Contents ......................................................... 111

6.7.4.6 Deleting a Range of IDs .................................................................... 112

6.7.4.7 Deleting All Data Files ...................................................................... 113

6.7.4.8 Viewing the Memory Status ............................................................ 114

Table of Contents

v

DMTA-10022-01EN, Rev. C, January 2015

6.7.5 Setting the ID Overwrite Protection .......................................................... 115

6.7.6 ID Review Screen ......................................................................................... 115

6.7.6.1 Reviewing Stored Data and Changing the Active ID .................. 117

6.7.6.2 Editing the ID ..................................................................................... 117

6.7.6.3 Erasing Data in the Active File ........................................................ 119

6.7.7 Generating Reports ...................................................................................... 120

7. Using Special Functions ......................................................................... 127

7.1 Activating and Configuring a Differential Mode ............................................... 127

7.2 Using the Minimum, Maximum, or Min/Max Thickness Mode ...................... 129

7.3 Preventing False Minimum/Maximum Thickness Readings ........................... 131

7.4 Using Alarms ........................................................................................................... 131

7.5 Locking the Instrument .......................................................................................... 136

7.6 Freezing the Measurement or Optional Waveform ........................................... 138

8. Configuring the Instrument ................................................................... 141

8.1 Configuring Measurement Parameters ................................................................ 141

8.2 Configuring System Parameters ........................................................................... 144

8.3 Configuring Communications .............................................................................. 145

9. Using Advanced Gaging Features ........................................................ 149

9.1 Adjusting the Gain with Dual Element Transducers ......................................... 149

9.2 Adjusting the Extended Blank with Dual Element Transducers ..................... 151

9.3 B-Scan ........................................................................................................................ 153

9.3.1 Using the B-Scan ........................................................................................... 156

9.3.2 Using the B-Scan Alarm Mode ................................................................... 157

9.3.3 Saving B-Scans or Thickness Readings (Optional Datalogger) ............. 157

9.4 DB Grid ..................................................................................................................... 159

9.4.1 Activating and Configuring the DB Grid ................................................. 160

9.4.2 Changing the Highlighted Cell in the DB Grid ....................................... 162

9.4.3 Saving Thickness Readings in the DB Grid .............................................. 163

9.4.4 Viewing an Inserted or an Appended Cell in the DB Grid .................... 163

10. Custom Setups for Single Element Transducers ............................... 165

10.1 Creating a Custom Setup for a Single Element Transducer .............................. 165

10.2 Quickly Adjusting Waveform Parameters For Single Element Transducers . 168

10.3 Detection Modes ..................................................................................................... 169

10.4 First Peak .................................................................................................................. 171

10.5 Pulser Power ............................................................................................................ 172

10.6 Time-Dependent Gain Curve ................................................................................ 173

10.6.1 Maximum Gain ............................................................................................. 174

Table of Contents

vi

DMTA-10022-01EN, Rev. C, January 2015

10.6.2 Initial Gain .................................................................................................... 175

10.6.3 TDG Slope ..................................................................................................... 175

10.7 Main Bang Blank ..................................................................................................... 175

10.8 Echo Window .......................................................................................................... 177

10.8.1 Detection of Echo 1 and Echo 2 .................................................................. 179

10.8.2 Interface Blank .............................................................................................. 180

10.8.3 Mode 3 Echo Blank ...................................................................................... 182

10.9 Saving Setup Parameters ....................................................................................... 183

10.10 Quickly Recalling a Custom Setup for Single Element Transducers .............. 184

11. Managing Communications and Data Transfer ................................. 187

11.1 GageView ................................................................................................................. 187

11.2 Setting Up USB Communication .......................................................................... 187

11.3 Exchanging Data with a Remote Device ............................................................. 189

11.3.1 Exporting a File to the Memory Card (Datalogger Option Only) ........ 189

11.3.2 Importing Survey Files from the External Memory Card ...................... 190

11.3.3 Receiving Files from a Computer .............................................................. 192

11.4 Capturing Screen Images ....................................................................................... 193

11.4.1 Sending a Screen Capture to GageView ................................................... 193

11.4.2 Sending a Screen Capture to the External microSD Card ...................... 195

11.5 Resetting the Communication Parameters .......................................................... 196

12. Maintaining and Troubleshooting the 45MG .................................... 199

12.1 Routine Gage Handling ......................................................................................... 199

12.2 Cleaning the Instrument ........................................................................................ 200

12.3 Maintaining Transducers ....................................................................................... 200

12.4 Using Instrument Resets ........................................................................................ 200

12.5 Performing Hardware Diagnostic Tests .............................................................. 203

12.6 Performing the Software Diagnostic Test ............................................................ 205

12.7 Viewing the Instrument Status ............................................................................. 206

12.8 Understanding Error Messages ............................................................................ 207

12.9 Resolving Battery Problems .................................................................................. 207

12.10 Resolving Measurement Problems ....................................................................... 208

Appendix A: Technical Specifications ....................................................... 209

Appendix B: Sound Velocities ..................................................................... 217

Appendix C: Accessories and Replacement Parts .................................... 219

List of Figures ................................................................................................. 223

Table of Contents vii

DMTA-10022-01EN, Rev. C, January 2015

List of Tables ................................................................................................... 227

Index ................................................................................................................. 229

Table of Contents

viii

DMTA-10022-01EN, Rev. C, January 2015

List of Abbreviations

2-D two-dimensional

AEtoE automatic Echo-to-Echo

AGC automatic gain control

CSV comma separated variables

DB database

DIAG diagnostic

DIFF differential

EFUP environment-friendly use period

ESS electronic stress screening

EXT extended

FRP fiber-reinforced polymer

GB gigabytes

GRN green

HDPE high-density polyethylene

HI high

ID identification

LDPE low-density polyethylene

LOS loss-of-signal

MAX maximum

MB main bang

MEtoE manual Echo-to-Echo

MIL military

MIN minimum

NiMH nickel-metal hydride

List of Abbreviations ix

DMTA-10022-01EN, Rev. C, January 2015

PDF portable document format

PRF pulse repetition frequency

PVC polyvinyl chloride

RoHS restriction of hazardous substances

SE single element

STD standard

SW software

TDG time-dependent gain

TFT thin-film transistor (liquid crystal display technology)

TOF time-of-flight

USB universal serial bus

WEEE waste electrical and electronics equipment

YEL yellow

List of Abbreviations

x

DMTA-10022-01EN, Rev. C, January 2015

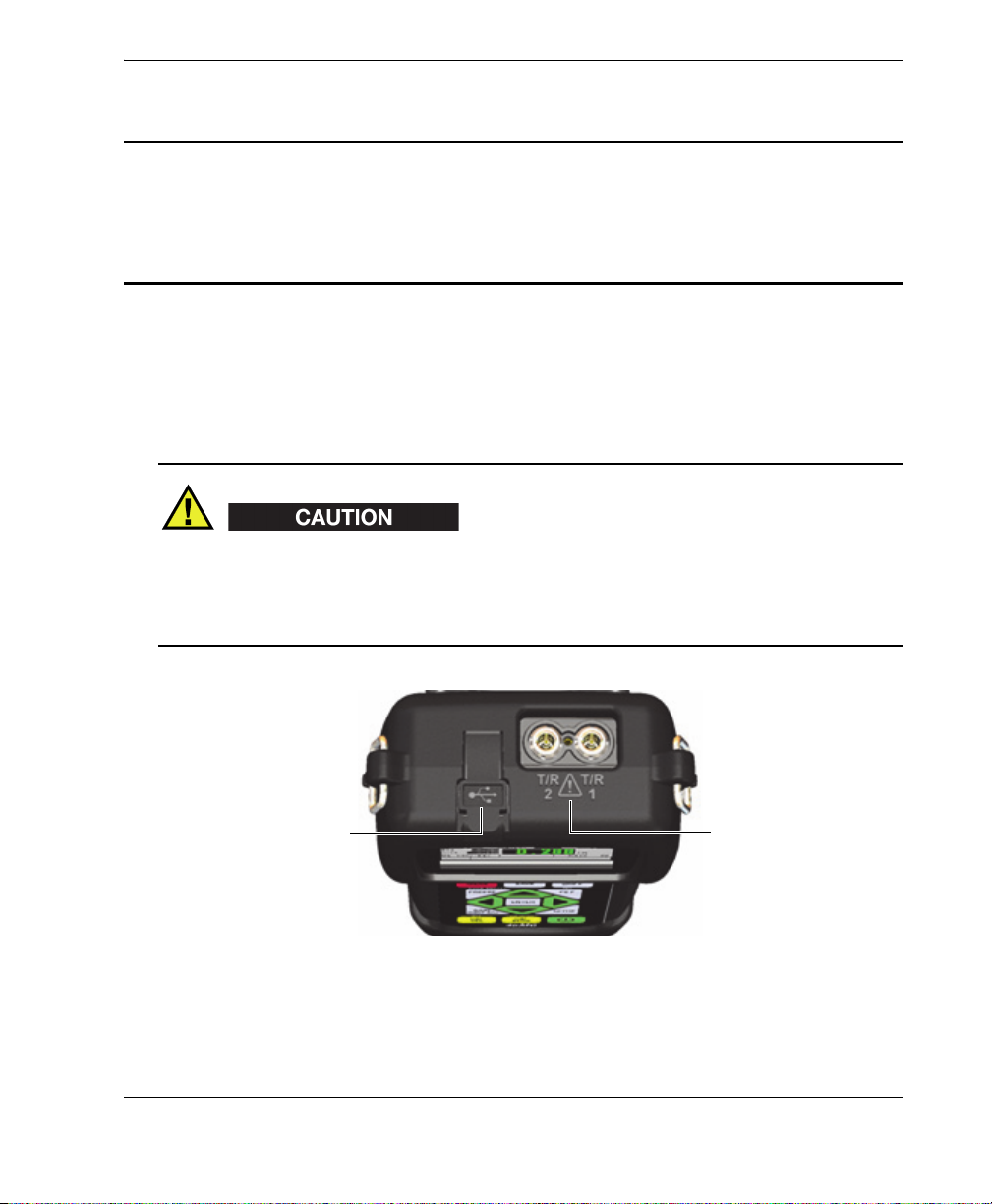

CAUTION

Warning symbol

USB symbol

Labels and Symbols

Safety-related labels and symbols are attached to the instrument at the locations

shown in Figure i-1 on page 1 and Figure i-2 on page 2. If any or all of the labels or

symbols are missing or illegible, please contact Olympus.

To avoid the risk of electric shock, do not touch the inner conductor of the T/R 1 and

T/R 2 connectors. Up to 200 V can be present on the inner conductor. The warning

symbol between the Transmit/Receive (T/R) connector markings warns of this electric

shock risk.

Figure i-1 The symbols on the top of the 45MG

Labels and Symbols

1

DMTA-10022-01EN, Rev. C, January 2015

Instruction label

(see Table 1 on page 3)

Serial number labels

(two locations)

Labels and Symbols

2

Figure i-2 Labels attached to the back of the instrument

Serial number

yynnnnnmm

label

Instruction label

DMTA-10022-01EN, Rev. C, January 2015

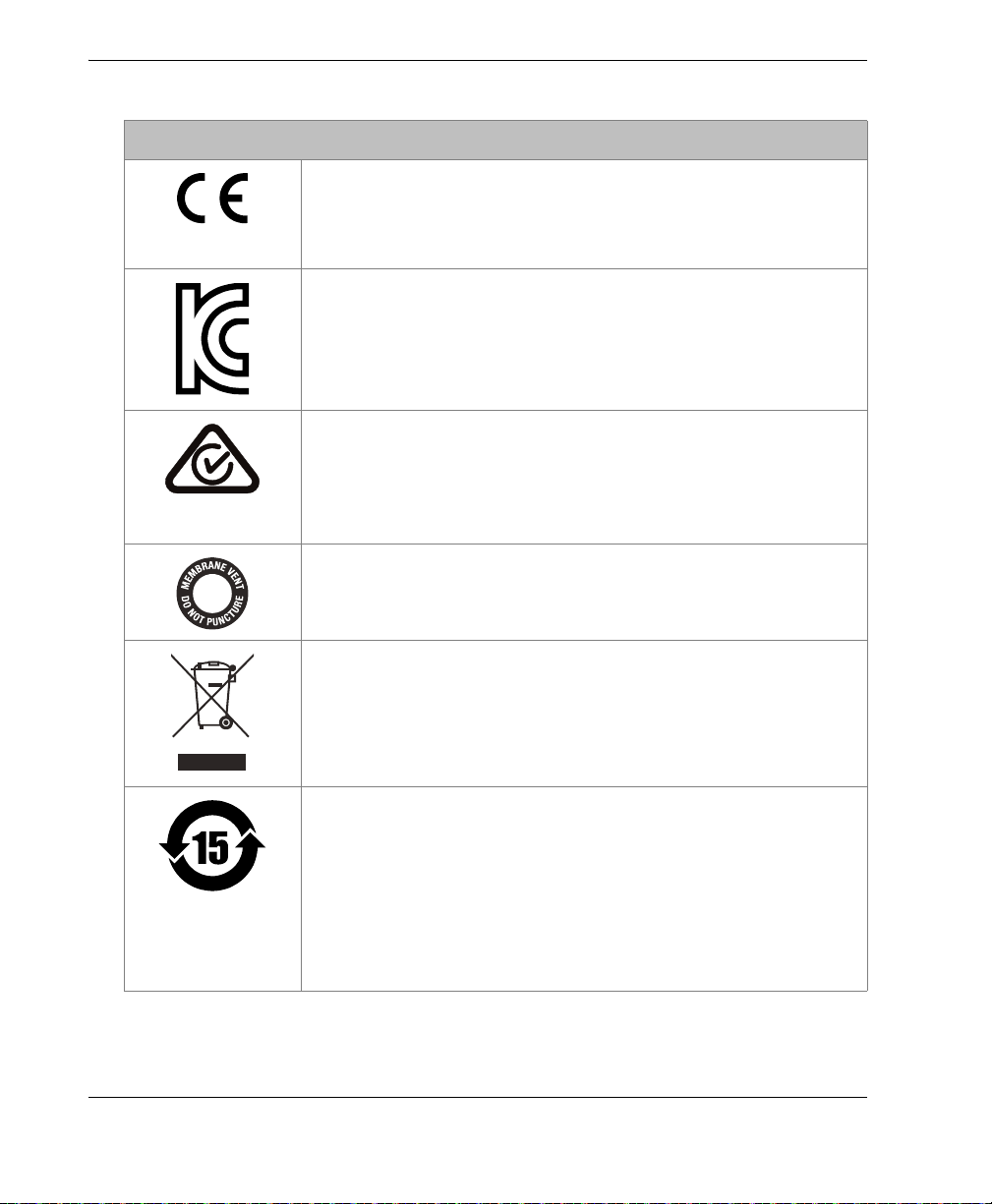

Table 1 Label contents

Where:

yy: last two digits of the production year

nnnnn: five-digit non-duplicated incrementing number

representing the n

th

production unit of this product

mm: production month

Labels and Symbols

3

DMTA-10022-01EN, Rev. C, January 2015

Table 1 Label contents(continued)

The CE marking is a declaration that this product conforms to

all the applicable directives of the European Community. See

the Declaration of Conformity for details. Contact your Olympus

representative for more information.

Seller and user shall be noticed that this equipment is suitable

for electromagnetic equipment for office work (class A) and it

can be used outside home. The MSIP code for the 45MG is the

following: MSIP-REM-OYN-45MG.

The regulatory compliance mark (RCM) label indicates that

the product complies with all applicable standards, and has

been registered with the Australian Communications and

Media Authority (ACMA) for placement on the Australian

market.

This symbol indicates the location of the membrane vent.

Content

Labels and Symbols

4

The WEEE symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be

collected separately.

The China RoHS mark indicates the product’s EnvironmentFriendly Use Period (EFUP). The EFUP is defined as the

number of years for which listed controlled substances will not

leak or chemically deteriorate while in the product. The EFUP

for the 45MG has been determined to be 15 years. Note: The

Environment-Friendly Use Period (EFUP) is not meant to be

interpreted as the period assuring functionality and product

performance.

DMTA-10022-01EN, Rev. C, January 2015

WARNING

Important Information — Please Read Before Use

Intended Use

The 45MG instrument is designed to measure thicknesses of industrial and

commercial materials.

Do not use the 45MG for any purpose other than its intended use. It must never be

used to inspect or examine human or animal body parts.

Instruction Manual

This instruction manual contains essential information on how to use this Olympus

product safely and effectively. Before using this product, thoroughly review this

instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Important Information — Please Read Before Use

5

DMTA-10022-01EN, Rev. C, January 2015

IMPORTANT

CAUTION

Some of the details of components illustrated in this manual may differ from the

components installed on your instrument. However, the operating principles remain

the same.

The 45MG documents are:

45MG Ultrasonic Thickness Gage — Getting Started (P/N: DMTA-10024-01EN

[U8778520])

A short leaflet containing essential information for quick start-up of the 45MG

instrument.

45MG Ultrasonic Thickness Gage — User’s Manual (P/N: DMTA-10022-01EN)

This document is in PDF format, and contains a detailed description of the

instrument, in addition to the setup and operating procedures for all the

instrument features. The PDF file is available on the documentation CD (P/N:

45MG-MAN-CD [U8147024]) that is shipped with the 45MG, and can also be

downloaded at www.olympus-ims.com.

GageView Interface Program — User’s Manual (P/N: 910-259-EN [U8778347])

The 45MG also works with the GageView interface program. Refer to this

document for detailed information on GageView. The document is available in

PDF format on the GageView CD, and as online help within GageView.

Instrument Compatibility

Refer to “Accessories and Replacement Parts” on page 219 for information on

accessories that are compatible with the 45MG.

Always use equipment and accessories that meet Olympus specifications. Using

incompatible equipment could cause equipment malfunction and/or damage, or

human injury.

Important Information — Please Read Before Use

6

DMTA-10022-01EN, Rev. C, January 2015

CAUTION

Repair and Modification

Apart from the batteries, the 45MG instrument does not contain any user-serviceable

parts.

In order to prevent human injury and/or equipment damage, do not disassemble,

modify, or attempt to repair the instrument.

Safety Symbols

The following safety symbols might appear on the instrument and in the instruction

manual:

General warning symbol

This symbol is used to alert the user to potential hazards. All safety messages that

follow this symbol shall be obeyed to avoid possible harm or material damage.

High voltage warning symbol

This symbol is used to alert the user to potential electric shock hazards greater

than 1000 volts. All safety messages that follow this symbol shall be obeyed to

avoid possible harm.

Important Information — Please Read Before Use

7

DMTA-10022-01EN, Rev. C, January 2015

DANGER

WARNING

CAUTION

IMPORTANT

Safety Signal Words

The following safety symbols might appear in the documentation of the instrument:

The DANGER signal word indicates an imminently hazardous situation. It calls

attention to a procedure, practice, or the like, which, if not correctly performed or

adhered to, will result in death or serious personal injury. Do not proceed beyond a

DANGER signal word until the indicated conditions are fully understood and met.

The WARNING signal word indicates a potentially hazardous situation. It calls

attention to a procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in death or serious personal injury. Do not proceed beyond a

WARNING signal word until the indicated conditions are fully understood and met.

The CAUTION signal word indicates a potentially hazardous situation. It calls

attention to an operating procedure, practice, or the like, which, if not correctly

performed or adhered to, may result in minor or moderate personal injury, material

damage, particularly to the product, destruction of part or all of the product, or loss of

data. Do not proceed beyond a CAUTION signal word until the indicated conditions

are fully understood and met.

Note Signal Words

The following safety symbols could appear in the documentation of the instrument:

The IMPORTANT signal word calls attention to a note that provides important

information, or information essential to the completion of a task.

Important Information — Please Read Before Use

8

DMTA-10022-01EN, Rev. C, January 2015

NOTE

TIP

WARNING

The NOTE signal word calls attention to an operating procedure, practice, or the like,

which requires special attention. A note also denotes related parenthetical

information that is useful, but not imperative.

The TIP signal word calls attention to a type of note that helps you apply the

techniques and procedures described in the manual to your specific needs, or

provides hints on how to effectively use the capabilities of the product.

Safety

This instrument has been tested according to IEC Publication 61010: Safety

Requirements for Electronic Measuring Apparatus. This instruction manual contains

warnings and safety rules that must be observed by the user to ensure safe operation

of the instrument, and maintain it in safe condition. Please read through these

operating instructions before using the instrument.

Before turning on the instrument, verify that the correct safety precautions have been

taken (see the following warnings). In addition, note the external markings on the

instrument, which are described under “Safety Symbols.”

Warnings

General Warnings

• Carefully read the instructions contained in this instruction manual prior to

turning on the instrument.

• Keep this instruction manual in a safe place for further reference.

• Follow the installation and operation procedures.

• It is imperative to respect the safety warnings on the instrument and in this

instruction manual.

Important Information — Please Read Before Use

9

DMTA-10022-01EN, Rev. C, January 2015

CAUTION

• If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment could be impaired.

• Do not install substitute parts or perform any unauthorized modification to the

instrument.

• Service instructions, when applicable, are for trained service personnel. To avoid

the risk of electric shock, do not perform any work on the instrument unless

qualified to do so. For any problem or question regarding this instrument, contact

Olympus or an authorized Olympus representative.

• Do not touch the connectors directly by hand. Otherwise, a malfunction or electric

shock may result.

• Do not allow metallic or foreign objects to enter the device through connectors or

any other openings. Otherwise, a malfunction or electric shock may result.

Battery Precautions

• Before disposing of a battery, check your local laws, rules, and regulations, and

follow them accordingly.

• When lithium-metal batteries are used, transportation of the batteries is regulated

by the United Nations under the United Nations Recommendations on the

Transport of Dangerous Goods. It is expected that governments,

intergovernmental organizations, and other international organizations shall

conform to the principles laid down in these regulations, thus contributing to

worldwide harmonization in this field. These international organizations include

the International Civil Aviation organization (ICAO), the International Air

Transport Association (IATA), the International Maritime Organization (IMO), the

US Department of Transportation (USDOT), Transport Canada (TC), and others.

Please contact the transporter and confirm current regulations before

transportation of lithium-ion batteries.

• Do not open, crush, or perforate batteries; doing so could cause injury.

• Do not incinerate batteries. Keep batteries away from fire and other sources of

extreme heat. Exposing batteries to extreme heat (over 80 °C) could result in an

explosion or personal injury.

• Do not drop, hit, or otherwise abuse a battery, as doing so could expose the cell

contents, which are corrosive and explosive.

Important Information — Please Read Before Use

10

DMTA-10022-01EN, Rev. C, January 2015

• Do not short-circuit the battery terminals. A short circuit could cause injury and

severe damage to a battery making it unusable.

• Do not expose a battery to moisture or rain; doing so could cause an electric

shock.

• Do not leave batteries in the 45MG unit during instrument storage.

Equipment Disposal

Before disposing of the 45MG, check your local laws, rules, and regulations, and

follow them accordingly.

WEEE Directive

In accordance with European Directive 2012/19/EU on Waste Electrical

and Electronic Equipment (WEEE), this symbol indicates that the

product must not be disposed of as unsorted municipal waste, but

should be collected separately. Refer to your local Olympus distributor

for return and/or collection systems available in your country.

China RoHS

China RoHS is the term used by industry generally to describe legislation

implemented by the Ministry of Information Industry (MII) in the People’s Republic

of China for the control of pollution by electronic information products (EIP).

The China RoHS mark indicates the product’s EnvironmentFriendly Use Period (EFUP). The EFUP is defined as the number of

years for which listed controlled substances will not leak or

chemically deteriorate while in the product. The EFUP for the

45MG has been determined to be 15 years.

Note: The Environment-Friendly Use Period (EFUP) is not meant

to be interpreted as the period assuring functionality and product

performance.

Important Information — Please Read Before Use 11

DMTA-10022-01EN, Rev. C, January 2015

EMC Directive Compliance

This equipment generates and uses radio-frequency energy and, if not installed and

used properly (that is, in strict accordance with the manufacturer’s instructions), may

cause interference. The 45MG has been tested and found to comply with the limits for

an industrial device in accordance with the specifications of the EMC directive.

FCC (USA) Compliance

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that

may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy, and if not installed and used in accordance with the

instruction manual, might cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case you will be required to correct the interference at your own

expense.

ICES-001 (Canada) Compliance

This Class A digital apparatus complies with Canadian ICES-001.

Cet appareil numérique de la classe A est conforme à la norme NMB-001 du Canada.

Important Information — Please Read Before Use

12

DMTA-10022-01EN, Rev. C, January 2015

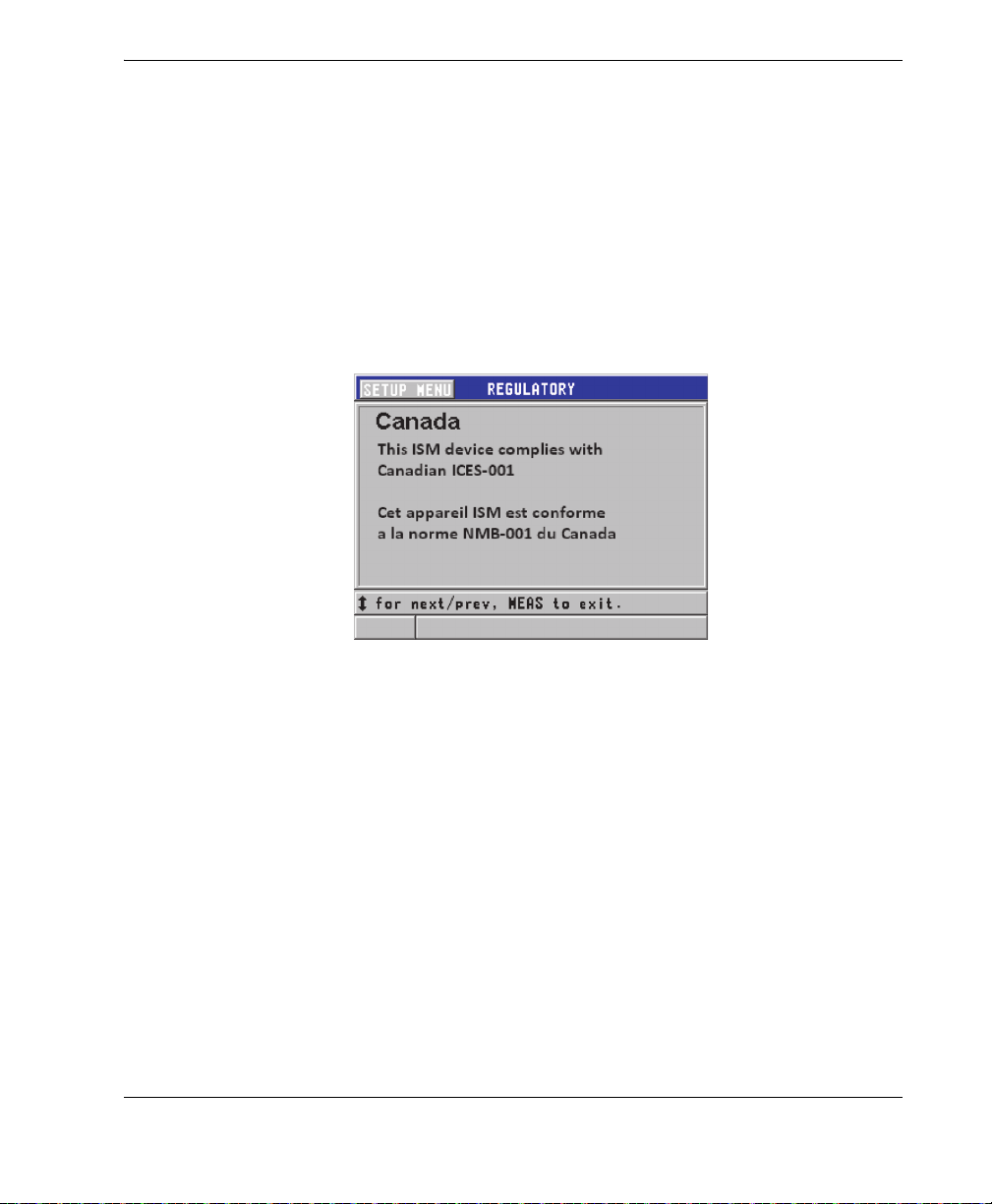

Regulatory Information

The 45MG may display a regulatory screen that lists the specific regulation with

which it complies.

To view the REGULATORY screen

1. In the measurement screen, press [SETUP], and then select SP MENU.

2. In the SP MENU (see Figure 4-2 on page 45), select REGULATORY to display the

REGULATORY screen (see Figure i-3 on page 13).

Figure i-3 The REGULATORY screen

3. Use the up and down arrow keys to scroll through the different REGULATORY

screens.

4. Press [MEAS] to return to the measurement screen.

Warranty Information

Olympus guarantees your Olympus product to be free from defects in materials and

workmanship for a specific period, and in accordance with conditions specified in the

Olympus Scientific Solutions Americas Inc. Terms and Conditions available at

http://www.olympus-ims.com/en/terms/.

Important Information — Please Read Before Use 13

DMTA-10022-01EN, Rev. C, January 2015

The Olympus warranty only covers equipment that has been used in a proper

manner, as described in this instruction manual, and that has not been subjected to

excessive abuse, attempted unauthorized repair, or modification.

Inspect materials thoroughly on receipt for evidence of external or internal damage

that might have occurred during shipment. Immediately notify the carrier making the

delivery of any damage, because the carrier is normally liable for damage during

shipment. Retain packing materials, waybills, and other shipping documentation

needed in order to file a damage claim. After notifying the carrier, contact Olympus

for assistance with the damage claim and equipment replacement, if necessary.

This instruction manual explains the proper operation of your Olympus product. The

information contained herein is intended solely as a teaching aid, and shall not be

used in any particular application without independent testing and/or verification by

the operator or the supervisor. Such independent verification of procedures becomes

increasingly important as the criticality of the application increases. For this reason,

Olympus makes no warranty, expressed or implied, that the techniques, examples, or

procedures described herein are consistent with industry standards, nor that they

meet the requirements of any particular application.

Olympus reserves the right to modify any product without incurring the

responsibility for modifying previously manufactured products.

Technical Support

Olympus is firmly committed to providing the highest level of customer service and

product support. If you experience any difficulties when using our product, or if it

fails to operate as described in the documentation, first consult the user’s manual, and

then, if you are still in need of assistance, contact our After-Sales Service. To locate the

nearest service center, visit the Service Centers page at: http://www.olympusims.com.

Important Information — Please Read Before Use

14

DMTA-10022-01EN, Rev. C, January 2015

IMPORTANT

Introduction

This user’s manual provides operating instruction for the 45MG ultrasonic thickness

gage. The information in this manual is organized to explain the technology, safety

details, hardware, and software. Practical measurement examples help the user

become familiar with the instrument’s capabilities.

This manual describes how to use the 45MG instrument’s advanced features,

including the use of special transducers, management of custom transducer setups,

software options, the datalogger, and communication with external devices.

The PDF file for this manual is included on the documentation CD

(P/N: 45MG-MAN-CD [U8147024]) that is shipped with the 45MG.

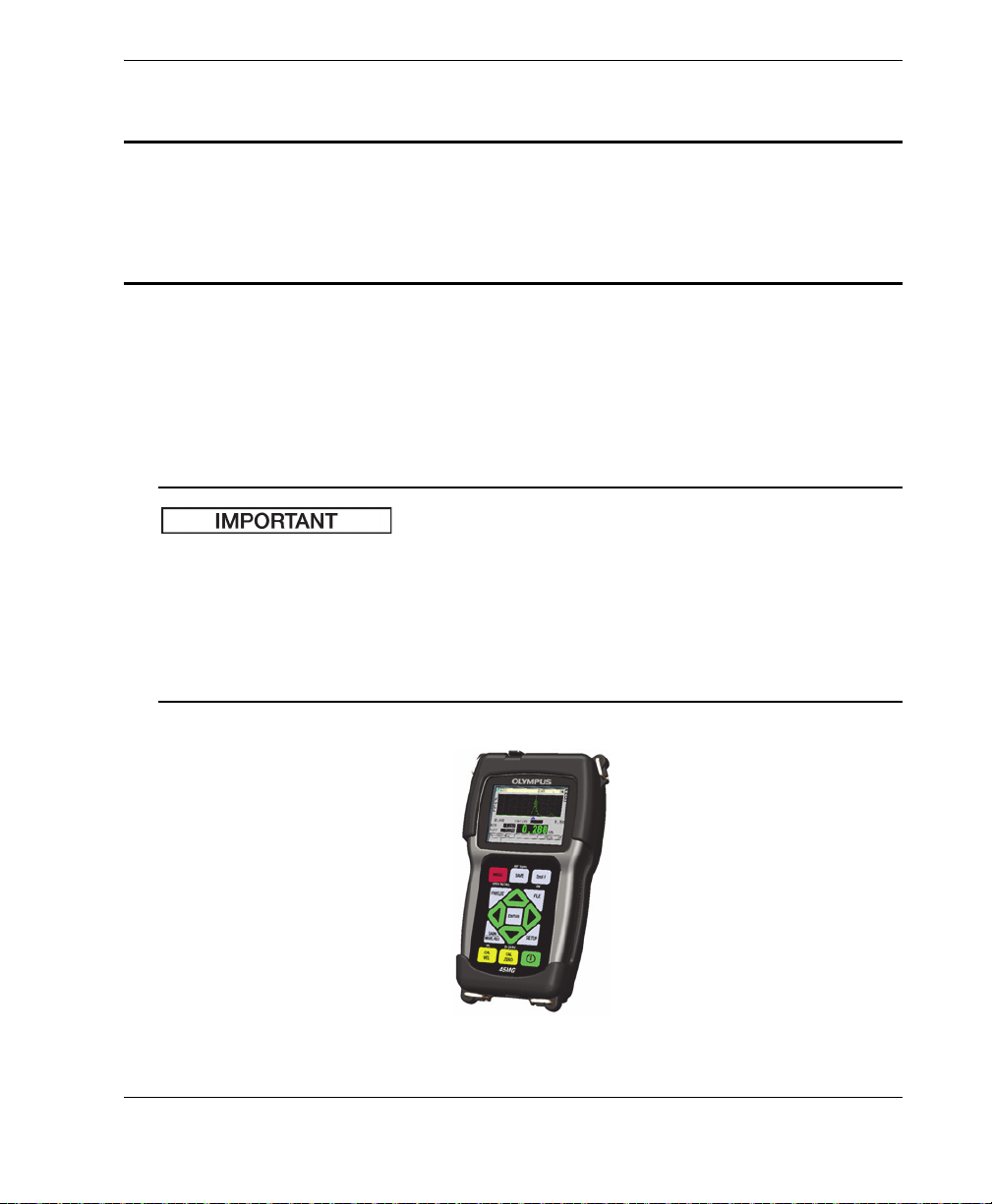

Figure i-4 The 45MG instrument

Introduction 15

DMTA-10022-01EN, Rev. C, January 2015

16

Introduction

DMTA-10022-01EN, Rev. C, January 2015

1. Instrument Description

This chapter describes the main features and hardware components of the 45MG

instrument.

1.1 Product Description

The 45MG by Olympus is a handheld ultrasonic thickness gage designed for a wide

variety of thickness-measurement applications. With the 45MG, you only need access

to one side of a part in order to obtain nondestructive measurements of the thickness

of corroded, pitted, scaled, granular, and other difficult materials.

The 45MG displays a thickness readout and offers an optional A-scan view for

waveform verification. The microprocessor of the 45MG continuously adjusts the

receiver setup so that every measurement is optimized for reliability, range,

sensitivity, and accuracy. An optional advanced internal datalogger can store up to

475000 thickness measurements and 20000 waveforms.

With the Single Element option, the 45MG operates with a full line of single element

transducers. Operation with dual element transducers is a standard feature.

Depending on the software options, the 45MG is capable of measuring material

thicknesses between 0.08 mm and 635.0 mm (0.003 in. and 25.0 in.). The temperature

range of measured materials may vary between

depending on the material characteristics, the transducer, and the measurement

mode.

−20 °C and 500 °C (−4°F and 932°F),

Basic features

• Measurement-related status flags and alarms

• Quarter VGA color transflective LED back-lite display

Instrument Description 17

DMTA-10022-01EN, Rev. C, January 2015

• Automatic probe recognition for the standard D79X and MTD705 series

transducers

• Warning against calibration doubling (for dual element transducers)

• Calibration for unknown material sound velocity and/or transducer zero

• Fast scan mode with 20 readings per second

• Hold or blank thickness display during loss-of-signal (LOS) conditions

• Hold minimum and maximum functions

• Differential thickness display relative to the set point in absolute values or

percentage ratios

• Selection of password-protected lockout functions

• Selectable resolution: low of 0.1 mm (0.01 in.), standard of 0.01 mm (0.001 in.), or

high (optional) of 0.001 mm (0.0001 in.); [option not available for all transducers]

Optional features

• Single element transducers

• Echo-to-Echo and THRU-COAT measurements

• High Penetration software for low-frequency single element transducers

• A-scan or waveform display

— Real-time A-scan waveform display for verification of critical measurements

— Manual freeze mode with post processing

— Manual zoom and range control of waveform display

— Auto hold on loss of signal (LOS) and auto zoom (measured echo centering)

— Extended blank

— Blank after first received echo in Echo-to-Echo mode

— Receiver gain readout

— Ability to capture and display waveform associated with minimum thickness

during scanned measurements

— Display of stored and downloaded waveforms (Datalogger option only)

— Manual gain adjustment in 1-dB steps

• Internal datalogger functions

— Internal data storage and possibility to export data to a removable microSD

memory card

— Capacity to store 475000 fully-documented thickness readings or

20000 waveforms with thickness readings

18

Chapter 1

DMTA-10022-01EN, Rev. C, January 2015

CAUTION

— Database enhancements include 32-character file naming and 20-character ID

naming

— Automatic ID number increments following a preset sequence, or manual ID

numbering using the keypad

— Save reading/waveform to an ID number

— Ability to simultaneously display ID number and stored reference thickness

while displaying active thickness and waveform

— Five file formats available

— Erase selected data or all stored data

— Standard USB directional communication

1.2 Environmental Ratings

The 45MG is a rugged and durable instrument that can be used in harsh

environments. The 45MG was designed to meet the requirement of the IP67 rating

(Ingress Protection rating).

Olympus cannot guarantee any level of ingress protection rating once the instrument

seals have been manipulated. You must use sound judgment, and take proper

precautions before exposing the instrument to harsh environments.

To maintain the original level of ingress protection, you are responsible for the proper

care of all routinely exposed membrane seals. Additionally, you are responsible for

returning the instrument to an authorized Olympus service center on an annual basis

to ensure that the instrument seals are properly maintained.

1.3 Instrument Hardware Components

The 45MG front panel features a color display and a keypad. The instrument comes

with a wrist strap. An optional protective rubber boot includes a dust flap seal for the

USB communication connector, strap rings at the four corners, and a stand at the back

of the instrument (see Figure 1-1 on page 20).

Instrument Description 19

DMTA-10022-01EN, Rev. C, January 2015

Protective rubber

boot

Stand

Strap rings (at the

four corners)

Color display

Keypad

I/O door protecting USB

connector

Transducer

connectors

Power key

USB connector

Transducer

microSD memory

card

Figure 1-1 The 45MG hardware components — Front, top, and side views

1.4 Connectors

20

Figure 1-2 on page 20 illustrates the possible connections between the 45MG and

external devices.

Figure 1-2 The 45MG connections

Chapter 1

Loading...

Loading...