Page 1

Olivetti 3D S2

Printer

SERVICE MANUAL

Code: Y118040-3

Page 2

PUBLICATION ISSUED BY:

Olivetti S.p.A.

Telecom Italy Group

Via Jervis, 77 - 10015 Ivrea (TO)

Italy

Copyright © 2016 Olivetti

All rights reserved

Page 3

Y118040-3 Service Manual iii

PREFACE

This document is intended to be used by technicians responsible for installing and servicing the Olivetti 3D S2 printer.

The aim of the manual is to supply all the information necessary for installing and maintaining the product

correctly.

CONTENTS

This manual comprises of 7 Chapters and an Appendix:

Chapter 1 – Provides a general introduction to the Olivetti 3D S2 printer

Chapter 2 – Provides an illustrated description of the printed circuit boards

Chapter 3 – Provides an illustrated description of installation procedures and printing tests

Chapter 4 – Describes the disassembly/reassembly procedures necessary for printer servicing

Chapter 5 – Provides the planned maintenance procedures

Chapter 6 – Describes the firmware and firmware updating

Chapter 7 – Describes the troubleshooting procedures

Appendix A – Provides a description of the printer accessories

This Manual is completed by a number of video clips, listed below, which can be accessed directly from within

the associated chapters. For this to be possible, the Service Manual and all the video clips must be copied to

the same folder.

Video clip ”Plastic layer bobbin and plastic layer settings”

Video clip “Plastic layer – hot-end group insertion”

Video clip ”Soft glue application method”

Video clip “Nozzle-print plate calibration procedures”

Video clip “Y axis belt replacement”

Video clip ”X axis belt replacement”

Video clip “Print plate calibration”

All the .gcode format files related to the tools and templates referred to in this Manual are available both on the

technical info site www.olinet.biz and on the SD Card supplied with the printer.

PRE-REQUIREMENTS

The approach adopted to the various subjects covered in this manual presumes that the reader has previous

knowledge of similar products.

REFERENCES

Spare Parts Catalogue – code Y117900-2

Product Support Plan – code 808795-00

User Manual German version code 589802

Spanish version code 589701

French version code 589600

Italian version code 589303

English version code 589402

DISTRIBUTION: General

FIRST EDITION: June 2016

Page 4

vi Service Manual Y118040-3

This page is intentionally left blank

Page 5

Y118040-3 Service Manual iii

CONTENTS

PREFACE ..................................................................................................................................................iii

CHAPTER 1 – OVERVIEW .................................................................................................................... 1-1

PRODUCT DESCRIPTION .................................................................................................................... 1-1

MAIN TECHNICAL FEATURES ............................................................................................................. 1-2

TECHNICAL SPECIFICATIONS ............................................................................................................ 1-9

CHAPTER 2 – PCB ASSEMBLY DESCRIPTION ................................................................................. 2-1

DESCRIPTION OF PRINTED CIRCUIT BOARD ASSEMBLIES ........................................................... 2-1

POWER UNIT ......................................................................................................................................... 2-2

ARDUINO PCB ASSEMBLY .................................................................................................................. 2-2

RAMPS PCB ASSEMBLIES ................................................................................................................... 2-3

DISPLAY UNIT ....................................................................................................................................... 2-5

SAFETY SWITCHES ............................................................................................................................. 2--5

CHAPTER 3 – INSTALLATION AND RUNNING THE PRINTING TEST ............................................. 3-1

PACKAGE CONTENTS .......................................................................................................................... 3-1

UNPACKING AND RECOMMENDED OPERATIONS WHEN INSTALLING PRINTER

ON WORK TABLE .................................................................................................................................. 3-3

PRINTER PREPARATION ..................................................................................................................... 3-6

MENUS AND NAVIGATION ................................................................................................................... 3-7

MAIN MENU ....................................................................................................................................... 3-8

PREPARE MENU ............................................................................................................................... 3-9

CONTROL MENU .............................................................................................................................3-11

SD CARD MENU .............................................................................................................................. 3-13

LOADING THE BOBBINS WITH FILAMENTS ..................................................................................... 3-14

PRINTING A TEST PIECE ................................................................................................................... 3-15

CALIBRATING THE EXTRUDER OFFSET ......................................................................................... 3-20

CHAPTER 4 – DISASSEMBLING PARTS AND MAINTENANCE ....................................................... 4-1

TOOL KIT AND TEMPLATES ................................................................................................................ 4-1

REPLACING THE BAKELITE BLOCKS ................................................................................................. 4-3

REPLACING THE NOZZLES ................................................................................................................. 4-7

NOZZLE - PRINT PLATE CALIBRATION PROCEDURE .................................................................... 4-10

CLEANING AND LUBRICATING THE GUIDE RAILS OF THE X AND Y AXES ................................. 4-13

CLEANING THE FOUR COOLING FANS OF THE EXTRUDER BLOCK ........................................... 4-13

VERIFYING AND ADJUSTING THE DRIVER VOLTAGES ................................................................. 4-14

CHECKING THE WIRING OF THE EXTRUDER BLOCK AND HOT-END MOTORS ......................... 4-17

CHECKING THAT HEATING ELEMENTS MAINTAIN OPERATING TEMPERATURE ...................... 4-18

UNMOUNTING THE UPPER BODY AND PANELS ............................................................................ 4-19

Y AXIS BELT REPLACEMENT ............................................................................................................ 4-22

REPLACING THE Y AXIS MOTOR AND IDLE PULLEY ..................................................................... 4-23

X AXIS BELT REPLACEMENT ............................................................................................................ 4-27

REPLACING THE X AXIS MOTOR AND IDLE PULLEY ..................................................................... 4-28

UNMOUNTING THE EXTRUDER BLOCK MOTORS .......................................................................... 4-32

UNMOUNTING THE Z AXIS MOTOR .................................................................................................. 4-36

UNMOUNTING THE PRINTING PLATE .............................................................................................. 4-38

UNMOUNTING THE END-OF-TRAVEL SENSORS ............................................................................ 4-43

UNMOUNTING THE SAFETY MAT ..................................................................................................... 4-44

CLEANING THE HOT-END GROUP ................................................................................................... 4-46

Page 6

vi Service Manual Y118040-3

CHAPTER 5 – PLANNED MAINTENANCE .......................................................................................... 5-1

GENERAL CLEANING ........................................................................................................................... 5-1

PLANNED MAINTENANCE EVERY 6 MONTHS OR EVERY 1000 HOURS OF OPERATION ........... 5-1

PLANNED MAINTENANCE EVERY 2 YEARS OR 4000 HOURS OF OPERATION ............................ 5-1

CHAPTER 6 – FIRMWARE .................................................................................................................... 6-1

UPDATING THE FIRMWARE ................................................................................................................ 6-1

CHAPTER 7 – TROUBLESHOOTING ................................................................................................... 7-1

ERROR MESSAGES .............................................................................................................................. 7-1

TROUBLESHOOTING ............................................................................................................................ 7-1

FAULT CATEGORIES ............................................................................................................................ 7-2

DIAGNOSTIC MESSAGES .................................................................................................................... 7-3

APPENDIX A ACCESSORIES ............................................................................................................ A-1

FILAMENT BOBBIN TYPES ................................................................................................................... A-1

Page 7

Y118040-3 Service Manual 1-1

Chapter 1 – OVERVIEW

PRODUCT DESCRIPTION

The Olivetti 3D S2 printer exploits the Fused Filament Fabrication (FFF) deposition technology to create threedimensional objects by sequentially depositing layers of material in 2-D.

The Olivetti 3D S2 printer is specially designed for small to medium-sized businesses on a digital

transformation path.

In this Chapter the printer components are described and the terminology used in the manual is introduced.

Page 8

1-2 Service Manual Y118040-3

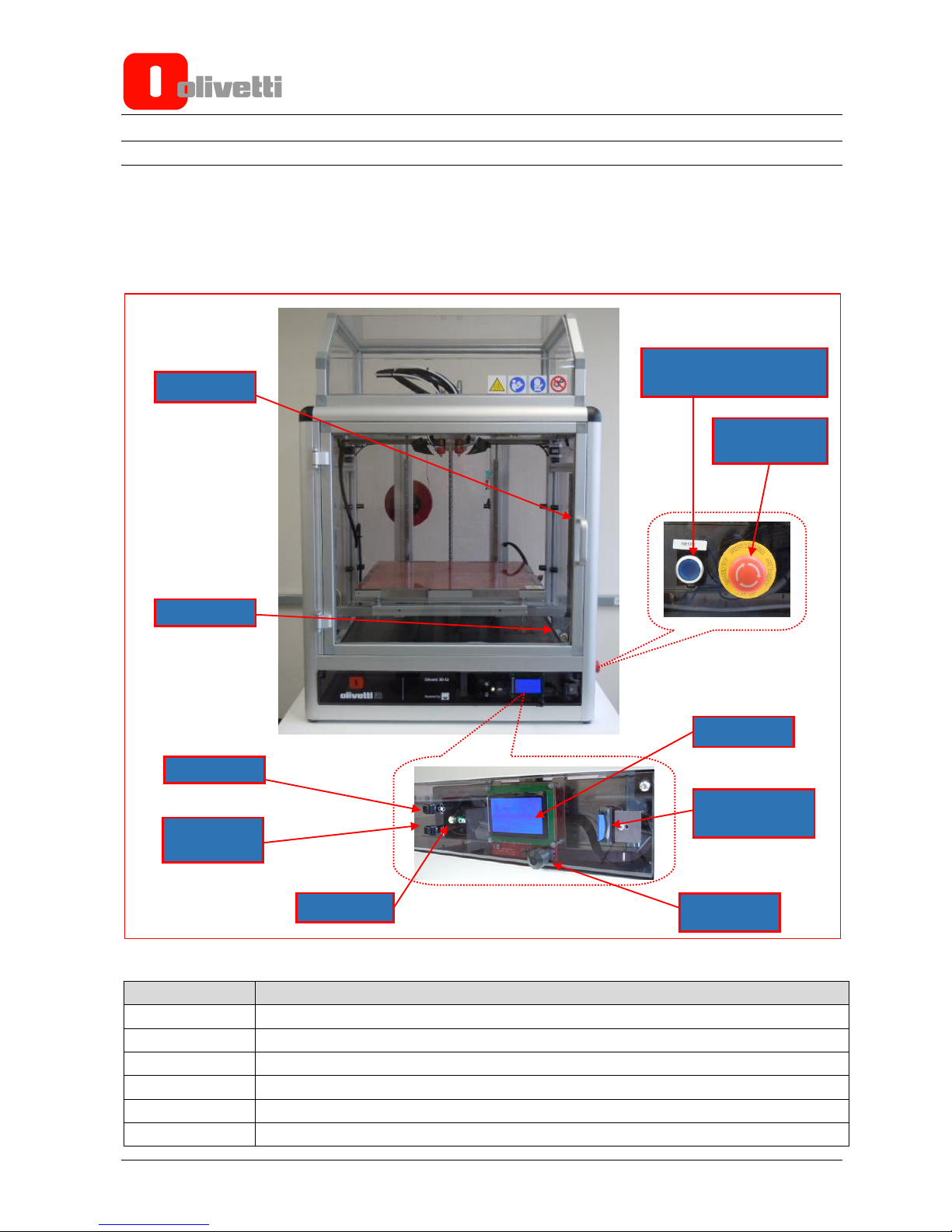

MAIN TECHNICAL FEATURES

Printer design

The main machine controls are located on the front of the printer where there is also a door for accessing the

inside of the printer.

The safety keys are located on the left side of the printer.

Figure 1-1

REFERENCE

DESCRIPTION

1

LCD Display

2

Jog Dialer

3

SD Card slot

4

Access door

5

Access door lock

6

Switch for fan for cooling material

6-Fan switch

7-Internal light

switch

8 - ON Led

1-LCD

3-SD Card Slot

2-Jog dialer

4-Access door

5-Lock

9-Emergency

stop key

10-Safety mat reset key

Page 9

Y118040-3 Service Manual 1-3

7

Internal light switch

8

Printer power on LED

9

Emergency stop push-button

10

Reset key for safety sensitive mat after activation.

On opening the front door, the hot-end group comprising of extruder 1 and extruder 2 is clearly visible.

Figure 1-2 Hot-end group

REFERENCE

DESCRIPTION

1

Extruder 1

2

Extruder 2

3

Extruder 1 cooling fan

4

Extruder 2 cooling fan

5

Cooling fan for material being printed by Extruder 1

6

Cooling fan for material being printed by Extruder 2

7

Printing plate in tempered glass

4 – Extruder 2

Cooling Fan

2 – Extruder 2

6 – Cooling Fan for

material printed by

Extruder 2

7 – Tempered glass

plate

5 – Cooling Fan for

material printed by

Extruder 1

1 – Extruder 1

3 – Extruder 1

Cooling Fan

Page 10

1-4 Service Manual Y118040-3

Figure 1-3 Hot-end group detail

REFERENCE

DESCRIPTION

1

Nozzle

2

Hot-end

3

Hot-end unlocking setscrew

4

Filament feeder unit

1 - Nozzle

2 – Hot-end

3 – Setscrew di blocco hot-

4 – Gruppo di trascinamento

filament

4 – Filament Feeder Assembly

3 – Hot-end Unlocking Setscrew

Page 11

Y118040-3 Service Manual 1-5

Figure 1-4 Feeder assembly terminals and pressure adjustment screw

REFERENCE

DESCRIPTION

1

Bowden quick release couplings

2

Filament pressure adjustment screw

The bobbins with the filament are installed at the rear of the machine, where there is also the power switch,

power socket and USB port.

1 – Bowden Quick

Release Couplings

2 – Filament Pressure

Adjustment Screws

Page 12

1-6 Service Manual Y118040-3

Figure 1-5 Rear View

Figure 1-6 Rear view detail

REFERENCE

DESCRIPTION

1

Bobbin holders

2

Feeder

3

Power Switch

4

Power Socket

5

USB Port

1-Bobbin Holders

2-Feeder

5-USB Port

3-Power Switch

4-Power Socket

Page 13

Y118040-3 Service Manual 1-7

IMPORTANT: Labels are displayed on some parts of the printer with hazard symbols. The meaning

of these symbols is described in the paragraph “Label positions and meanings”.

Printer axes orientation

The printer moves along three axes: X, Y and Z.

The hot-end group moves in the X and Y axes directions, while the printing plate moves in the Z axis direction.

The origin of the printer axes, known as the extruder Home position, is located at the front left corner of the

printing plate.

Figure 1-7 Orientation of Olivetti 3D S2 printer axes

Starting from the origin, the X axis is oriented from left to right of the work table, the abscissa increasing in this

direction. The positive direction of the Y ordinate axis, starting from the front door, is towards the rear of the

machine, while the positive direction of the Z axis – oriented vertically with respect to the printing plate – is

downwards.

X axis

Z axis

Y axis

Extruder Home Position

Page 14

1-8 Service Manual Y118040-3

Label positions and meanings

On the front top part of the printer the following labels can be seen displayed. The meaning of these symbols is

given in the table below.

Figure 1-8 Labels on front of printer

SYMBOL

COLOUR

WARNING

MEANING

TRIANGLE

YELLOW

DANGER

HOT SURFACES

CIRCLE

BLUE

REGULATIONS APPLY

READ INSTRUCTIONS

CIRCLE

BLUE

REGULATIONS APPLY

USE GLOVES

BARRED CIRCLE

RED

PROHIBITED

DO NOT REMOVE GUARDS

Inside the printer, on the safety sensitive mat, the following labels are displayed. For the meaning of these

symbols see the table below.

Figure 1-9 Internal labels on lower side

SYMBOL

COLOUR

WARNING

MEANING

TRIANGLE

YELLOW

DANGER

CRUSHING

TRIANGLE

YELLOW

DANGER

MOVING PARTS

At the back of the printer, near the on/off switch, the following label is displayed. See the table below for its

meaning.

Figure 1-10 Label on external switch on printer rear

SYMBOL

COLOUR

WARNING

MEANING

TRIANGLE

YELLOW

DANGER

HIGH VOLTAGE

The following label is displayed on the printing plate glass and on the extruder block. For the meaning of this

symbol see the table below.

Figure 1-11 Label on internal heated plate

SYMBOL

COLOUR

WARNING

MEANING

TRIANGLE

YELLOW

DANGER

HOT SURFACE

Page 15

Y118040-3 Service Manual 1-9

TECHNICAL SPECIFICATIONS

Case: Radiused anodised aluminium 45 x 45 with methacrylate panels

Power supply: input 100-240V 50-60 Hz 125-250V / 2.8A

output 12V 8.34A 100W

Display: Front LCD 128 x 64 dot matrix.

Printing plate: 5 mm tempered glass, heated. Maximum temperature 120°C.

Extruders: 2 extruders. Maximum temperature 280°C.

Filament: ø 1.75 mm

Print mode: Cartesian, horizontal dimension along X and Y axes,

Vertical, vertical dimension along Z axis.

Maximum printing speed: 150 mm/sec.

Min layer thickness: 0.05 mm (50 micron).

Min. thicknesses with different nozzles:

Nozzle diameter 0.30 mm min. layer thickness 0.05 mm recommended layer thickness 0.10

mm

Nozzle diameter 0.40 mm min. layer thickness 0.10 mm recommended layer thickness 0.20

mm

Nozzle diameter 0.80 mm min. layer thickness 0.20 mm recommended layer thickness 0.40

mm

N.B.: Nozzles with a diameter of 0.50 mm are mounted on the machine, while nozzles of diameters 0.30,

0.4, 0.50, 0.60 and 0.80 mm can be purchased separately.

Precision tolerance: 0.08 mm (80 microns) on X/Y axes.

0.01 mm (10 microns) on Z axis.

Max. printing volume: 400x400x400 mm

Firmware: Marlin Open source.

Machine code: Movement and printing operations are executed by GCODE machine

code.

Software: Compatible with the most popular printing software that supports

Marlin firmware such as: Repetier-Host, Simpllify3D, Cura, Slic3r, Kisslicer, for

generating GCODE machine code.

Safety devices: Emergency stop key.

Safety mat on bottom floor of printer.

Safety mat reset key.

Page 16

1-10 Service Manual Y118040-3

This page is intentionally left blank

Page 17

Y118040-3 Service Manual 2-1

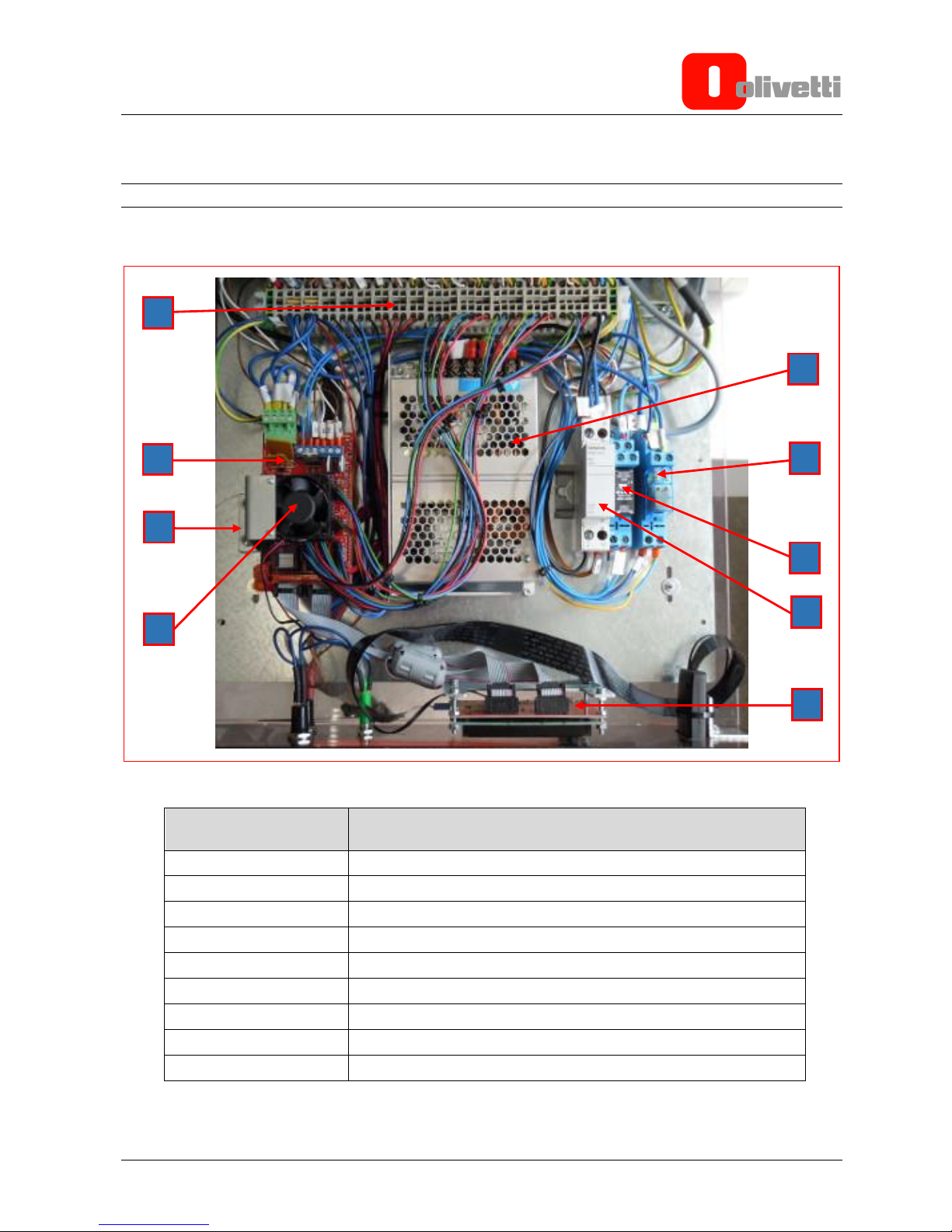

Chapter 2 – PCB ASSEMBLY DESCRIPTION

DESCRIPTION OF PRINTED CIRCUIT BOARD ASSEMBLIES

The figure below shows the metal plate with the electronic components of the printer:

Figure 2-1

REFERENCE

DESCRIPTION

A

Input/output wire terminals

B

RAMPS Card

C

Arduino MEGA 2560 Card (positioned under the RAMPS card)

D

Cooling fan for RAMPS card

E

SD Card connector and display card

F

Fuse holder

G

Emergency stop key relay

H

Safety mat relay

I

Power unit

I G A B C F H E D

Page 18

2-2 Service Manual Y118040-3

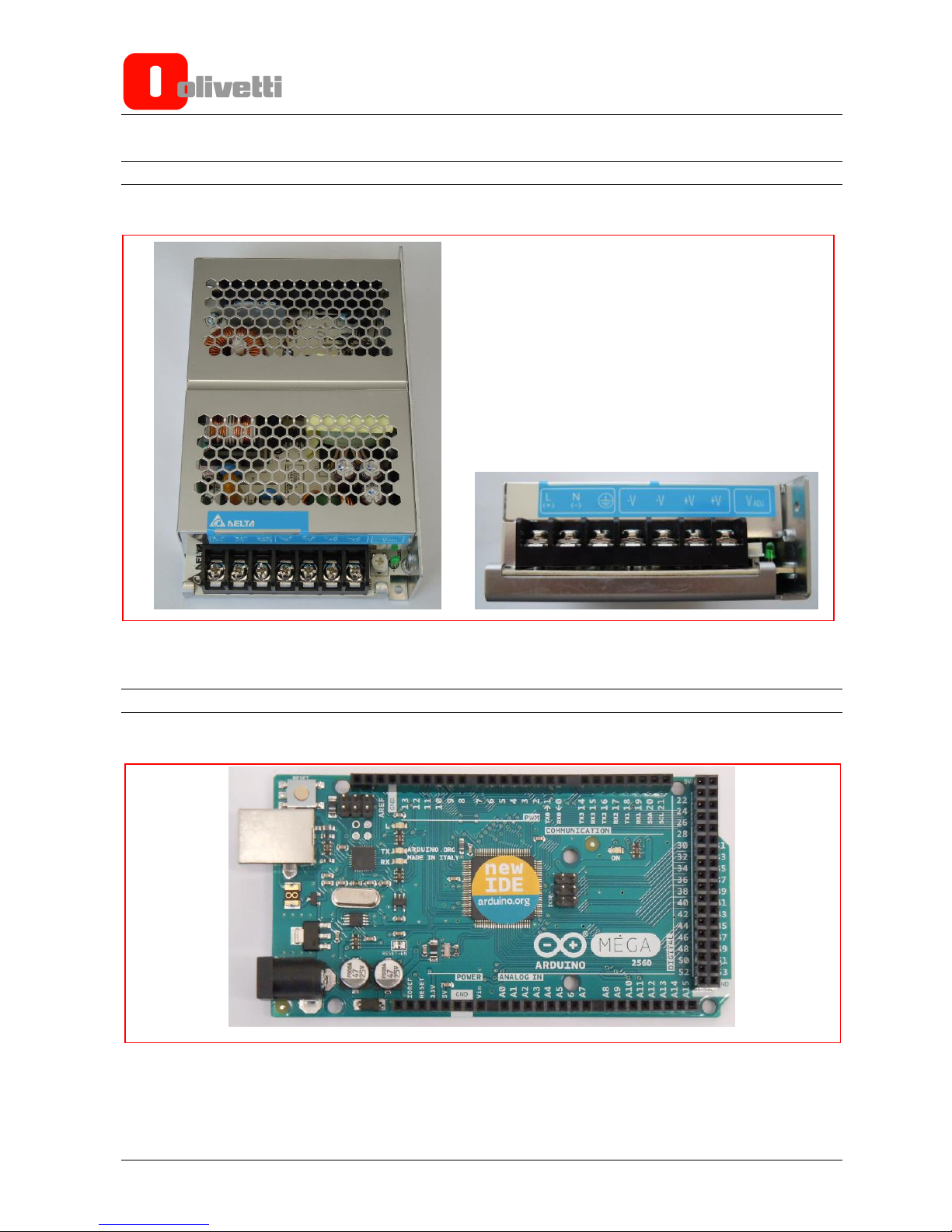

POWER UNIT

The figure below shows the power unit and the terminal board for the wire connections.

Figure 2-2

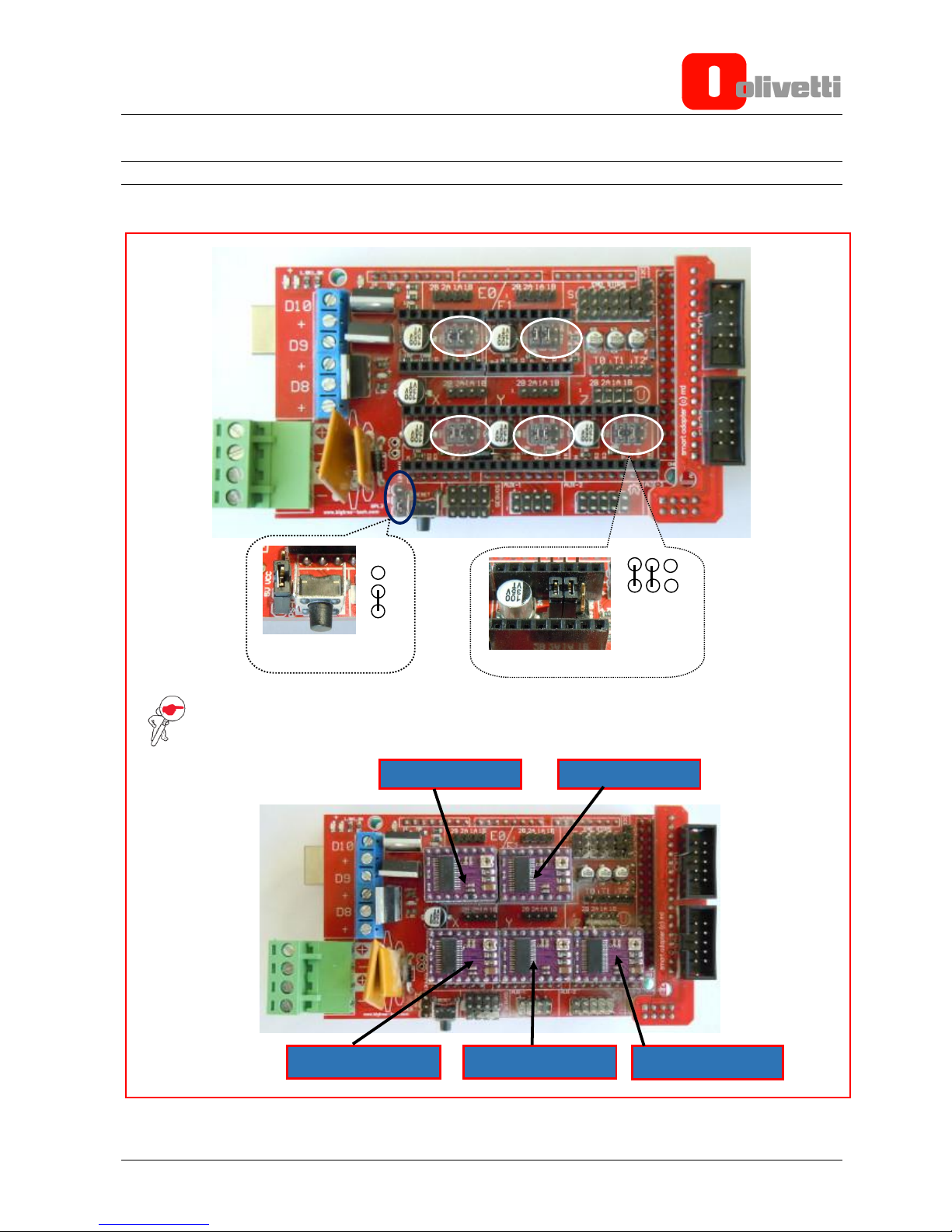

ARDUINO PCB ASSEMBLY

The illustration below shows the A side of the Arduino card.

Figure 2-3

Page 19

Y118040-3 Service Manual 2-3

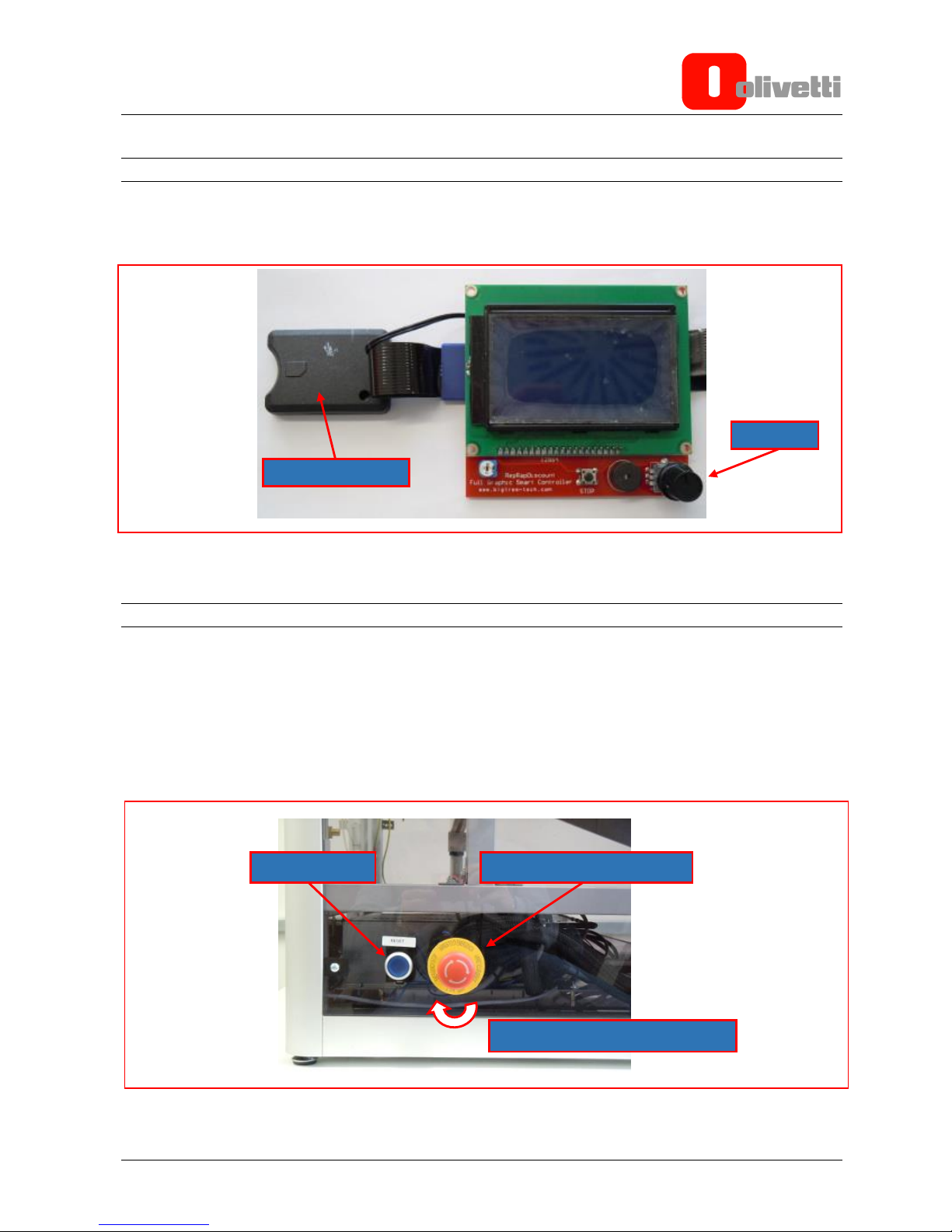

RAMPS PCB ASSEMBLIES

In the illustrations below can be seen the A side of the RAMPS card and its related block diagram.

NOTE: The two enlarged views show the jumpers located under the five driver chips

(circled in white) - all of which must have the same setting - and the power selection jumper

(circled in dark blue).

Figure 2-4

Extruder 1 Driver

Extruder 2 Driver

Y Axis Motor Driver

X Axis Motor Driver

Z Axis Motor Driver

Power selection

jumper

Jumpers under driver IC

Page 20

2-4 Service Manual Y118040-3

The figure below shows one of the five Driver chips mounted on the RAMPS card.

Figure 2-5

Figure 2-6

Page 21

Y118040-3 Service Manual 2-5

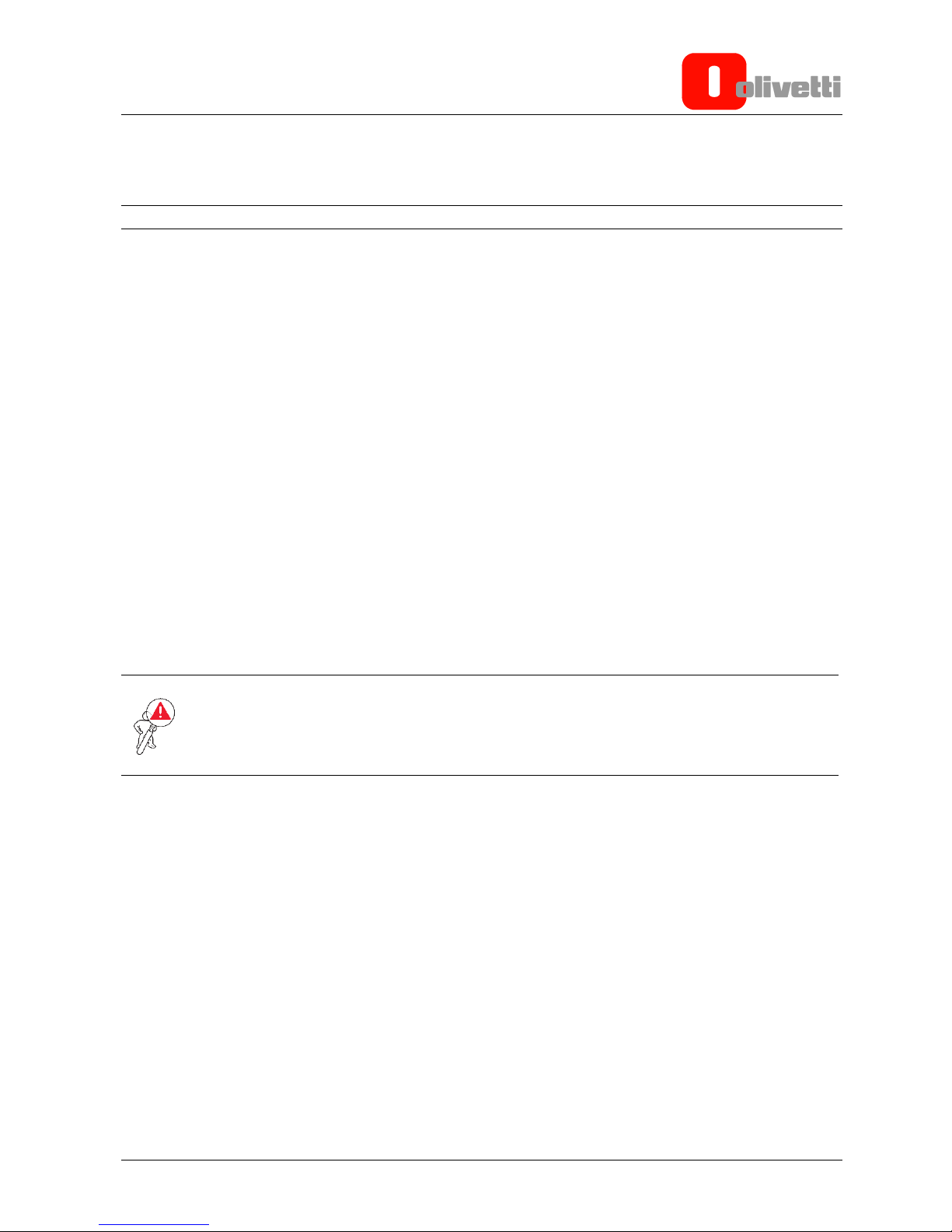

DISPLAY UNIT

The figure below shows the display unit comprised of the jog dialer and the connector for the SD Card device

mounted on the printer side.

Figure 2-7

SAFETY SWITCHES

The printer is equipped with two safety switches.

1. The Emergency Stop key – this key can be activated whenever a dangerous situation arises.

After the Emergency Stop key is activated it must be reset by rotating it in the direction indicated by the

arrows.

2. The Reset key – this key must be pressed after a machine shutdown caused by abnormal pressure being

applied to the safety mat which blocks printer operation.

Figure 2-8

SD Card connector

Jog dialer

Emergency Stop key

Reset key

Direction to turn key for reset

Page 22

2-6 Service Manual Y118040-3

This page is intentionally left blank

Page 23

Y118040-3 Service Manual 3-1

Chapter 3 – INSTALLATION AND PRINT TEST

PACKAGE CONTENTS

The following items are contained in the Olivetti 3D S2 printer package:

- 1 3D S2 Printer

- 1 Printer Door Key

- 1 USB Cable. Type A-B

- 1 AC Power Cord

- 1 SD Card of 4GB or more

- 3 Allen Keys (1.5 mm, 2.5 mm and 5 mm)

- 3 Hex Wrenches, sizes 8, 10 and 12

- 1 PLA Bobbin, diameter 1.75 mm, weight 1 Kg

- 1 Feeler Gauge, 0.08 mm

- 1 Spatula for removing printed pieces

- 1 EC, WEEE and Safety Declarations Leaflet

General instructions for installation

To guarantee top printer operation and avoid the need for servicing operations - other than those necessary as

a result of product defects - adhere to the following instructions:

Electrical Power

Make sure that the socket to which the printer is connected is earthed and that it supplies the power level

required by the printer.

WARNING: an unearthed socket may cause faulty operation and create safety-related issues.

Do not connect the printer to power supply lines used in common with other types of apparatus that could

create electrical disturbances and excessive voltage variations (air conditioning systems and fans,

photocopiers, motors of goods lifts or person lifts, radio and TV transmitters and signal generators, high

frequency security devices, etc.).

Environmental conditions

The environmental conditions under which the product can be kept for an unlimited period of time are those

indicated by the AB quality objectives for a normal, air-conditioned, office environment (ambient temperature

15-35 °C, relative humidity 35-85% HU). During both storage and operation, it is necessary to prevent

variations in environmental conditions which could give rise to condensation phenomena. Dust, dirt, smoke

and excessive humidity can lead to excessive wear of moving parts, short circuits and read/write errors while

the printer is executing the different operations. High temperatures and low humidity levels can lead to static

electricity problems.

Printer location

The printer must be installed on a flat, vibration-free, surface.

Do not position the printer very close to air ventilation systems or heat sources, or in positions where it will be

exposed to direct sunshine. Install the printer in a position that is convenient and easy to reach for servicing

and removal operations.

Page 24

3-2 Service Manual Y118040-3

Operator Information

At the end of the installation, the Field Engineer must ensure that the Operator is in possession of all the

information necessary for operating the printer correctly, and is capable of carrying out the operations for

replacing the bobbin and printing nozzles, and for clearing clogging caused by the filament.

For this purpose, it is recommended that you provide a practical demonstration on how to perform the following

operations:

- Use of the console. Interpretation of error messages and, where possible, operations for removing a printer

jam.

- Illustration of methods for inserting and managing filaments.

- Bobbin replacement.

- Removal of filament clogging printer.

- Printing nozzle replacement.

- Printing of test file.

- Manual printer cleaning.

Make the Operator aware of the importance of environmental conditions when choosing the location for

installing and operating the printer.

Remember that the printer will function reliably over time if used correctly. In the case of any faults, contact

Technical Support immediately.

Page 25

Y118040-3 Service Manual 3-3

UNPACKING AND RECOMMENDED OPERATIONS FOR PRINTER INSTALLATION ON WORK TABLE

1. With the printer resting on the ground (Figure 3-1) remove the top outer cover (Figure 3-2).

Figure 3-1 Figure 3-2

2. Remove the two pieces of protective padding (Figure 3-3) lifting them out (Figure 3-4).

Figure 3-3 Figure 3-4

Page 26

3-4 Service Manual Y118040-3

3. Remove the external cardboard packaging by lifting it upwards (Figure 3-5).

On the left side of the printer there are two boxes containing the printer accessories (Figure 3-6).

Figure 3-5 Figure 3-6

4. For the best, most ergonomic, use of the printer, choose a surface with a good level of staticity and

meeting the following specifications:

Work table height: ≥ 80 cm

Work table area: 100 cm x 100 cm

load resistance: ≥ 150 Kg

5. To place the printer on the work table, use a forklift truck of sufficient capacity to lift the printer up to the

height of the work table surface.

Page 27

Y118040-3 Service Manual 3-5

It is recommended that two persons carry out this operation, proceeding as follows:

6. Unpack the printer, load it onto the forklift truck and lift it up to the height of the work table.

Figure 3-7

7. Lift the printer to the height of the work table (arrow 1) and manually rest it on the surface (arrow 2).

NOTE: The printer bottom must rest entirely on the surface

Figure 3-8

8. Move the forklift truck away.

Figure 3-9

1

2

Page 28

3-6 Service Manual Y118040-3

9. With a spirit level, ensure that the printer is level in the X axis (Figure 3-10) and Y axis (Figure 3-11) directions.

Figure 3-10 Figure 3-11

PRINTER PREPARATION

This Chapter describes the procedures necessary for correctly configuring and preparing the Olivetti

3D-S2 printer for printing.

Unblocking the hot-end group

To protect the printer during shipping, the hot-end group is anchored to the centre of the Z axis (at the machine

rear) using two packing straps. Before attempting to use the printer you must therefore unblock the hot-end

group by removing these straps.

Figure 3-12

Powering on the printer

Connect the printer to a 220V electrical outlet using the power cord provided and power it on at the power switch.

LCD Display

When the printer is powered on, the LCD display illuminates.

On the display is shown the most important printer status information.

Loading the filament bobbins

See the Chapter ”Loading the Bobbins with Filaments”.

Cut packing straps

Page 29

Y118040-3 Service Manual 3-7

MENUS AND NAVIGATION

The User Interface of the Olivetti 3D S2 printer provides the commands for carrying out the calibration,

maintenance and printing operations. On powering on the printer, an initialisation screen is displayed for a few

seconds giving the firmware release version, date and time.

Figure 3-13 Initialisation page

This is followed by an information page with the following details:

Target temperature setting for extruders and printing plate (A).

Actual temperature of extruders and printing plate (B).

Position of extruders with respect to the three axes X, Y and Z (C).

Printing speed (D).

Information on insertion of SD Card (E).

Tool bar indicating percentage of work performed (F).

Time since printing began (G).

Figure 3-14 Start page

Figure 3-15 Jog dialer

To navigate between the menus, turn the jog dialer either in the clockwise or anti-clockwise direction.

To select a given command or menu, press the jog dialer.

A B C D G F E

Page 30

3-8 Service Manual Y118040-3

MAIN MENU

To access the main menu, press the jog dialer once when the printer is in rest mode with the Start page

displayed.

Figure 3-16 Main menu

From the Main menu you can return to the Start page by moving to the Info screen option using the jog dialer

and then pressing the jog dialer to confirm.

In any case, if the printer remains inactive for about 20 seconds, it returns automatically to the Start page.

From the main menu you can access the following submenus:

Prepare

Control

Print from SD

Page 31

Y118040-3 Service Manual 3-9

PREPARE MENU

From the Prepare menu you can carry out the principal machine calibrations. From this menu the following

submenus can be accessed:

Figure 3-17 Prepare menu submenus

Auto Home

Bed Setting

Move axis

Disable Steppers

Auto Home:

Positioning on the Auto Home command using the jog dialer and pressing to confirm, the printer moves the

extruders and the printing plate to the rest position (positioning the extruders at the front left corner of the

printing plate).

Bed Setting:

This command can be used to modify the distance of the nozzles from the printing plate. When this command

is given, the extruders are positioned at the four corners of the printing plate, approximately 20 cm from the

vertices. As the final position, the extruders are positioned at the centre of the plate.

Move axis:

This command can be used to move the printer axes.

Two types of movement are possible: rapid (10 mm) and slow (1 mm).

Figure 3-18 Axis setting commands

Page 32

3-10 Service Manual Y118040-3

Selecting the Move 10 mm submenu allows you to move the printhead rapidly along the X and Y axes (the

example in the figures below shows how to move 160 mm in the positive direction along the x axis).

Figure 3-19 Rapid settings menu

Selecting the Move 1 mm submenu, you can move both the X and Y axes and the Z axis (printing plate) as

well as the motors for feeding the filaments of Extruder 1 and Extruder 2 (N.B. to move the filaments, set the

Extruder temperature to the melting point of the material used).

Figure 3-20 Intermediate settings menu

Disable steppers:

If you need to move the X and Y axes manually, use this command to disable the motors controlling the

movement of these axes. To disable the motors, move to Disable steppers and press the jog dialer. The

motors are enabled again on receiving the first command from the printer,.

Figure 3-21 Disable steppers

WARNING: move the hot-end group slowly and carefully along the X and Y axes to avoid

inadvertently generating surplus currents which could cause damage to the electronic components.

Page 33

Y118040-3 Service Manual 3-11

CONTROL MENU

The Control menu gives you access to all printer parameter settings, allowing you to modify each one singly

as you need. From this menu you can access the following submenus:

Figure 3-22 Control menu and related submenus

Temperature

Motion

Restore failsafe

Temperature:

Accessing the Temperature menu you can adjust the temperature of Nozzle 1.

To do this, use the jog dialer to move to the Nozzle command then confirm by pressing the dialer.

Rotate the jog dialer to set the temperature to the desired level then press to confirm; in this way the machine

will heat the nozzle to the temperature value set.

Similarly, by selecting Nozzle 2, you can set the temperature for the second nozzle.

Figure 3-23

To set the temperature of the printing plate, select Bed then rotate the jog dialer to the required value.

Figure 3-24

Page 34

3-12 Service Manual Y118040-3

Selecting Fan speed you can vary the rotating speed of the two fans mounted on each of the two extruders.

Figure 3-25

Motion:

When you select this command, the acceleration speed of the motors of the X and Y axes is displayed.

NOTE: currently there is no need to modify this parameter.

Selecting Endstop abort you can enable or disable interruption of printing when an abnormal position is

assumed at end-of-travel (either by the extruder heads or the printing plate).

Figure 3-26

Page 35

Y118040-3 Service Manual 3-13

By selecting Restore failsafe and confirming, you can reload the default parameter values set in the factory.

Figure 3-27

SD CARD MENU

Selecting Print from SD using the jog dialer and confirming, you can display the contents of the SD Card

inserted, navigate between the files saved on it, select and print a file.

Figure 3-28

Page 36

3-14 Service Manual Y118040-3

LOADING THE BOBBINS WITH FILAMENTS

1. Position the bobbin on its holder and insert the filament inside the feeder as shown in the video clip ”Plastic

layer bobbin and plastic layer settings”.

2. Regulate the temperature of the hot-end to the appropriate operating value for the type of filament loaded

(for example, 200°C for PLA), proceeding as described below:

Switch on the printer by setting the power switch to the ON position. The Menu Start page is shown on

the display.

NOTE: you can navigate between the menus by turning the jog dialer in either the clockwise or anticlockwise direction. To select a given command or menu press once on the jog dialer.

Select the Control menu.

Position on the Temperature menu and select it.

To modify the temperature of Extruder 1 select Nozzle, to modify the temperature of Extruder 2 select

Nozzle 2.

Rotate the jog dialer to set the required temperature value depending on the type of filament installed

(refer to the “OPERATING TEMPERATURE” table).

Press the jog dialer repeatedly to confirm and return to the Start page where the temperature value

setting and actual nozzle temperature are both displayed.

Wait the time necessary for the nozzle to reach the temperature value set.

Figure 3-29 Command sequence for setting the temperature

Insert the filament inside the feeder unit as shown in the video clip “Plastic layer-hot end group insertion” .

Page 37

Y118040-3 Service Manual 3-15

WARNING: on the first manual extrusion you may find residues of previously printed material; this is

completely normal because the machine is subjected to testing before being packaged.

NOTE: should the filament not flow out smoothly, repeat the previous steps because either the

operating temperature is incorrect for the type of filament loaded or a duct must still be obstructed with

Teflon tape.

PRINTING A TEST PIECE

On the SD Card supplied in the package there is a file that can be used for running a printing test, so that you

can gain confidence using the printer.

To ensure good bonding between the first layer printed and the printing plate, spray a thin adhesive solution

on the plate, as shown in the video clip ”Soft glue application method” . To print the test piece proceed as

described below:

1. Insert the SD Card supplied in the package into the slot at the front of the printer.

Select Print from SD to access the file manager.

Select the file to print (for example: Test cube.gcode) by rotating the jog dialer and pressing to

confirm.

Figure 3-30 Command sequence for printing a piece

2. Launch printing. The printer carries out the following procedures:

Homing of all axes.

Heating of hot-end and plate (if necessary) until the temperature required is reached.

Extrusion of a length of material for loading into the extrusion chamber.

Movement in the printing area and start of printing procedure for each successive layer.

On terminating printing, the machine executes the Homing procedure for the carriage and switches off

the heaters to allow the extruders to return to ambient temperature.

All printing processes can be monitored from the printer display’s Start screen.

NOTE: The printing format supported by the Olivetti 3D S2 printer has the extension .gcode.

Page 38

3-16 Service Manual Y118040-3

Creating a printable file using the Olivetti 3D S2 printer

The steps necessary for producing your own printable .gcode files using the Olivetti 3D S2 printer are

described in this paragraph.

Creating a 3D model

The first step is to create a three-dimensional model of the object you want to print.

To create the model, you can either use a commercially-available 3D CAD design software or free software,

such as, OpenSCAD, Blender, SketchUp and FreeCAD.

Alternatively, you can also download ready-to-use 3D models available for free on internet sites, such as

Thingiverse and GrabCAD.

3D models come in different file formats however you are advised to generate or download models in .STL

format (STereoLithography), this being the most commonly used and easily managed by the programs that

will be used subsequently for generating the .gcode file for printing in 3D.

Creating a GCODE from a 3D model

Once the 3D model in STL format is ready, it must be further processed to transform it into GCODE so that it

is printable. The transformation from a 3D model to gcode is achieved using dedicated software applications

known as Slicers. These programs subdivide the 3D model into sections that the 3D printer can deposit on the

printing table.

Many different types of slicer exist, among which we particularly recommend Slic3r and Cura or the Repetier

Host environment. The latter - apart from having its own slicing software - also provides useful tools for

redimensioning, copying and repositioning the model on the printing plate.

Figure 3-31 3D model during conversion phase of Repetier Host

After having generated the GCODE file using the slicer, copy it onto the SD card that will be used for printing

after insertion into the Olivetti 3D S2 printer.

Page 39

Y118040-3 Service Manual 3-17

GCODE Printing

Now to print your GCODE, proceed as explained in the paragraph ”PRINTING A TEST PIECE”.

Overhang and generation of support material

Overhang is the term used to describe those portions of model that cannot be printed using the FFF printing

process without the help of suitable support underneath.

The FFF technology, in fact, assumes that layers will be deposited successively, one on top of the other. The

presumption is therefore that every layer has a supporting layer underneath.

If your 3D model has planes or surfaces that rise upwards from the bottom with a tilt in excess of about 50°

with respect to the vertical plane (40° from the surface), the layer deposited may not have a suitable support

surface underneath, and may therefore cede compromising the quality of the printed work piece.

To avoid problems related to overhang, the slicing software automatically generates material supports

whenever necessary (based on user-configurable parameters).

This additional material must therefore be removed manually after printing is terminated.

Suspending and interrupting printing

Using the menu you can suspend or cancel printing after it has been launched.

To suspend printing, press the jog dialer and enter the menu. Rotate the dialer to the Pause print command

then press to confirm.

Printing will be suspended and on the menu Start page the Pause print status is displayed.

Figure 3-32 Command sequence for suspending printing of a piece

Page 40

3-18 Service Manual Y118040-3

To restart printing just press the jog dialer.

Figure 3-33 Restarting printing

NOTE: when printing is suspended, the high nozzle temperature may result in material continuing to

flow, resulting in distortions in the piece printed.

To cancel printing, access the menu and move to Stop Print using the jog dialer, then confirm by pressing the

jog dialer. Printing is cancelled.

Figure 3-34 Stop print

Note that the hot-end group will remain frozen at the last position assumed before printing was cancelled. To

return it to its Home position you can either move it manually using the menu commands or execute a Homing

procedure.

Page 41

Y118040-3 Service Manual 3-19

Removing printed pieces

You may find that the printed piece is very strongly bonded to the glass printing plate. This is due to use of

the bonding solution to create good adhesion of the first layer to the plate, creating a "vacuum" effect which

literally glues the piece to the glass.

WARNING: Exercise the greatest care when removing printed pieces from the glass using sharp or

pointed objects. In fact you are strongly advised not to use either knives or cutters for removing

pieces from the glass, even of small dimensions. Although the glass is tempered it is also fragile,

therefore use the utmost care when touching and handling it.

Remove the printed piece from the glass only after having waited the time necessary for it to cool

(when the heated surface has been used). Always check the temperature on the display before

accessing the printing area because some parts may still be very hot, even after printing has

finished.

Never apply force to lever off the printing plate glass.

Do not apply excessive or direct force to the piece using heavy objects such as hammers etc.

The simplest way to detach a piece is to leave it to cool on the printing plate until 35°C; as plastic and glass

have different dilatation coefficients, the tensions created during cooling are conducive to detaching the

bottom layer of plastic from the plate.

Using the spatula supplied with the printer to help you, insert its metal edge under the border of the work

piece and twist slightly. This will cause the piece to come free. Another trick for removing small pieces is to

tap them with the handle of the spatula at a chosen point and taking care not to damage them. Do not use

excessive force, light tapping should cause the bottom to come free from the glass. The spatula is very

useful for removing any pre-printing flushing residues, known as “skirt”.

Page 42

3-20 Service Manual Y118040-3

CALIBRATING THE EXTRUDER OFFSETS

To be able to print with the dual extruder you must calibrate the offsets of the two printheads.

Before proceeding with the offset calibration, adjust the nozzle height as described in the Chapter NOZZLE

PRINT PLATE CALIBRATION PROCEDURE and REPLACING THE NOZZLES”.

The two hot-ends are kept in position by a block of aluminium. Their nominal alignment should be, on the

horizontal surface, X = 55 and Y = 0. However it is possible, due to small tolerances of the parts, that the

two heads are not aligned at this value. In this case it is necessary to carry out a calibration operation using

a test piece to allow any appropriate offset values to be set in the slicing software.

You are advised to carry out this operation whenever the heads are adjusted, changed, etc., or when

operations are carried out on the bakelites or on the nozzles.

The part to print for offset calibration is located in the following subfolder of the SD Card:

\GCODE\CALIBRATION\DUAL_HEAD\calibration_test.gcode

If the horizontal and vertical lines in each of the two colours are not aligned, you must “compensate” for the

excess in the X and Y elements by measuring the piece printed on the plate, as follows:

Figure 3-35

The misalignments measured on the printed piece, as shown in the illustration, allow you to set the

compensation for the slicer offset parameter as follows:

ΔX+ Insert the X axis offset obtained from the measurement as a positive value

ΔX- Insert the X axis offset obtained from the measurement as a negative value

ΔY+ Insert the Y axis offset obtained from the measurement as a positive value

ΔY- Insert the Y axis offset obtained from the measurement as a negative value

Horizontal

Alignment

[Y]

Horizontal

Alignment

[X]

Page 43

Y118040-3 Service Manual 4-1

Chapter 4 – DISASSEMBLING PARTS AND MAINTENANCE

To ensure maximum safety conditions and a successful outcome of operations, observe the following

instructions:

- For all disassembly and reassembly operations, switch off and disconnect the printer from the mains power supply.

- Carry out all operations in areas that are clean and free from obstacles.

- Follow procedures scrupulously; do not unscrew parts that must not be disassembled. Conserve parts in a

clean place, where they will not get lost.

- After replacing parts, check that they have not been deformed during assembly; if necessary correct.

- Operations for reassembling parts, unless otherwise indicated, must be carried out using the reverse

sequence of operations to that used for disassembly.

- Ensure that all connectors are connected correctly. After interventions, relubricate as indicated in the

specifications.

- At the end of operations, perform a test to check that the printer functions correctly without any problems.

TOOL KIT AND TEMPLATES

Certain technical interventions on the printer require mechanical adjustments to be carried out.

To allow these adjustments to be carried out correctly, a tool kit and templates are provided, which must form

part of the equipment used by the Technician when operating on the machine.

The following images show the kit composition together with a description of how each tool and template must be

used:

Kit for adjusting the tension of the X and Y axes belts.

Figure 4-1

REFERENCE

TOOL USE

1

HOOK * FOR ADJUSTING THE TENSION OF THE X AND Y AXES BELTS

2

BRACKET FOR ADJUSTING THE TENSION OF THE X AXIS BELT

3

BRACKET FOR ADJUSTING THE TENSION OF THE Y AXES BELT

* To adjust the tension, a downward force of 1300 g must be applied to the hook. This is possible by simply

tying an appropriate weight to the hook strap.

2

1

3

Page 44

4-2 Service Manual Y118040-3

Kit for adjusting the pulley heights and the position of the Y axis motor.

Figure 4-2

REFERENCE

TOOL USE

1

TEMPLATE FOR ADJUSTING THE HEIGHT OF THE IDLE PULLEY OF THE Y AXIS

2

SHIM (2.9 mm) FOR ADJUSTING THE DISTANCE OF Y AXIS MOTORS

3

SHIM (1.5 mm) FOR ADJUSTING THE HEIGHT OF THE X AXIS PULLEYS

4

TEMPLATE FOR ADJUSTING THE HEIGHT OF THE Z AXIS MOTOR PULLEY

All files in .gcode format for the parts composing the kit are provided on the SD Card supplied with the product.

This allows you to create these tools and templates autonomously, using the Olivetti 3D S2 printer .

1

4 3 2

Page 45

Y118040-3 Service Manual 4-3

REPLACING THE BAKELITE BLOCKS

Preventive and maintenance inspections are advised every 6 months or every 1000 hours of operation. The

photo below shows the two hot-ends of the extruder block with the cooling fans rotated upwards.

Figure 4-3

1. In most cases, the block arrives with the filament already inserted inside. To remove it and proceed with

operations, you must heat the extruder as described in the paragraph “Setting the temperature of the hot-

end”.

Bring the extruder to the temperature necessary for the type of filament installed, referring to the filament

temperature table.

When the temperature is reached, enter the Prepare menu

Position on and select the Move Axis menu.

Enter the menu Move 1 mm and select the nozzle desired (in this example Extruder 1).

Now turn the control knob anti-clockwise so that 3 or 4 cm of filament extrudes, then immediately turn

the knob clockwise 9 or 10 cm.

NOTE: the filament can also be inserted into the hot-end by turning the knob in this manner, using the

same sequence.

Bakelite Blocks

Hot-ends

Nozzles

Hot-end Setscrew

Page 46

4-4 Service Manual Y118040-3

Figure 4-4 Command sequence for inserting/extracting the filament from the extruder

3. The internal software saves your work in memory, the printer then extrudes and retracts the filament,

according to an automatic sequence, so that you will find the filament extruding out of the thrust gear

block.

4. Once the filament is extruded from the hot extruder, lower the temperature to 140°C as described in the

paragraph “Setting the temperature of the hot-end”.

WARNING: for the operations described below you are advised to wear heat-resistant gloves as a

protection from burns that could be caused by the operating temperature of the extruder block.

5. Using a 2.5 mm Allen key, unscrew the setscrew of the hot-end group to be unmounted.

Figure 4-5

Hot-end 1 Setscrew

Hot-end 2 Setscrew

Page 47

Y118040-3 Service Manual 4-5

6. Extract the hot-end group from its conduit.

Figure 4-6

7. With the hot-end group released, use the 12 mm hex wrench to unscrew the bakelite block.

NOTE: To make this operation easier, the wrench supplied with the printer has a low profile.

Figure 4-7

8. Before mounting the new bakelite block, you are advised to pass a metal wire of diameter 1.2 mm through

the hole in the Teflon lining to remove any impurities (for this operation a drill bit also can be used).

12 mm Hex Wrench

12 mm Hex Wrench

Page 48

4-6 Service Manual Y118040-3

Figure 4-8

9. Still with the hot-end hot, take the new block of bakelite and wind Teflon tape 4 times around the thread,

being careful not obstruct the hole. Now manually screw the bakelite back onto the hot-end block until the

end, then give it a further half-turn with the 12 mm hex wrench to tighten the group perfectly.

Figure 4-9

10. Put the whole hot-end group back into position in its conduit, pushing it in up against the thrust gear.

Figure 4-10

Thrust Gear

Page 49

Y118040-3 Service Manual 4-7

11. Screw the setscrew on again, tightening moderately, to fasten the hot-end group.

12. Move the cooling fan back to its operating position.

13. Adjust the nozzle–printing plate distance as described in the next Chapter NOZZLE PRINT PLATE

CALIBRATION PROCEDURE” and ”REPLACING THE NOZZLES”.

When two extruders are used, you are advised to check the offset setting, as described in the Chapter

”CALIBRATING THE EXTRUDER OFF-SETS”.

14. Bring the hot-end to the working temperature as described in the paragraph “Setting the temperature of the

hot-end”.

15. Insert the filament into the hot-end from the menus as described in Figure 4-4 Command sequence for

inserting/extracting the filament from the extruder.

REPLACING THE NOZZLES

To avoid the hot-end block getting jammed due to the use of different mixtures, you are advised to replace the

nozzle every time you change the type of material used as the filament, or whenever a jam occurs.

WARNING: for the operations described in the video clip, you are advised to use heat-resistant

gloves to avoid burns caused by the operating temperature of the extruder block.

1. As described in Figure 3-29 Command sequence for setting the temperature, set the temperature of the

hot-end for which the nozzle to be replaced (refer to the temperature table for the various materials).

2. Lower the printing plate by about 100 mm to work more comfortably.

Page 50

4-8 Service Manual Y118040-3

In order to select a given command or menu you must press the jog dialer.

From the Menu Start page select the Prepare menu.

Position on and select the Move Axis menu.

Select Move 1 mm.

Select Move Z then rotate the jog dialer anti-clockwise to move the printing plate downwards.

Figure 4-11 Command sequence for lowering the printing plate

3. Using the 12 mm hex wrench hold the hot-end block still while unscrewing the nozzle using the 10 mm hex

wrench.

Figure 4-12

10 mm Wrench

12 mm Wrench

Page 51

Y118040-3 Service Manual 4-9

4. Apply 3 windings of Teflon tape to the nozzle thread taking care not to cover the hole.

Figure 4-13

5. After have remounted the nozzle, perform the “NOZZLE – PRINT PLATE ADJUSTMENT PROCEDURE”.

6. At the end of these operations, carry out the printing test. Should you need to adjust the printing plate,

proceed from step 6 in the Chapter ”UNMOUNTING THE PRINTING PLATE”.

7. When two extruders are used, you are advised to check the offsets proceeding as described in the

Chapter ”CALIBRATING THE EXTRUDER OFFSETS”.

Page 52

4-10 Service Manual Y118040-3

NOZZLE - PRINT PLATE CALIBRATION PROCEDURE

This operation must be executed on a periodic basis or every time you carry out operations on the nozzle or on

the bakelite block.

1. Put the printer into operation by moving the power switch to the On position. The Menu Start page appears

on the display.

2. To work in the best conditions, you are advised to extract the filament from the extruder. To do this heat the

extruder as described in Figure 3-29 Command sequence for setting the temperature”, then extract the filament

as described in Figure 4-4 Command sequence for inserting/extracting the filament from the extruder.

Before continuing, lower the temperature of the nozzle to about 140°.

3. Bring the nozzles to the zero position using the procedure in the Auto Home menu.

WARNING: before carrying out the procedure, check that the four fans are in the operating positions

as shown in the figure below. Note that if the cone fan on the left is incorrectly positioned it will not be

possible to position the extruders at the zero point.

Figure 4-14

Correct Position

Page 53

Y118040-3 Service Manual 4-11

4. The image below shows the hot-end group in the Auto Home position.

Figure 4-15

5. Once you have found the zero point, from the Prepare menu click on Disable steppers. This will allow

you to move the extruders manually along the X-Y axes.

Figure 4-16 Command sequence for Auto Home and Disable steppers

6. The calibration must be repeated at five different points of the printing plate. The first with the nozzles

positioned at the centre of the plate, the other four at a distance of approximately 20 cm from the centre

towards the four corners of the plate. The photos and the diagram indicate the five points at which to

position the nozzles for the calibration.

NOTE: The Bed Setting function automatically carries the hot-end group to the 5 points that must be

used for calibration.

Zero point

Page 54

4-12 Service Manual Y118040-3

Position 1 Centre Position 2 front left Position 3 front right

Position 4 rear right Position 5 rear left

Figure 4-17

Figure 4-18

Pos.5

Pos.4

Pos.3

Pos.2

Pos.1

Page 55

Y118040-3 Service Manual 4-13

7. Carry out the calibration as illustrated in the video clip “Nozzle print plate calibration procedure”.

WARNING: for the operations described in the video clip, you are advised to use heat-resistant

gloves to avoid burns caused by the operating temperature of the extruder block.

NOTE: the operations described up to here must be carried out on both extruders.

8. At the end of the operations, bring the extruder to the working temperature, insert the filament into the

extruder and perform a printing test.

9. Should it be necessary to adjust the planarity of the printing plate, proceed as described from step 6 in

Chapter ”UNMOUNTING THE PRINTING PLATE”.

CLEANING AND LUBRICATING THE GUIDE RAILS OF THE X AND Y AXES

Preventive and maintenance inspections are recommended every 6 months or every 1000 hours of operation.

Clean the guides along their whole length using a dry cotton cloth. After cleaning, grease all surfaces of the

guides, applying 3 lentil-sized drops of grease per guide.

CLEANING THE FOUR COOLING FANS OF THE EXTRUDER BLOCK

Preventive and maintenance inspections are recommended every 6 months or every 1000 hours of operation.

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

1. Hot-end group cooling fans: rotate the two fans and blow air on them from the inside of the printer

outwards.

2. Cone cooling fans: blow air from inside the air convector towards the fans.

NOTE: To carry out this operation you can use industrial compressed air.

Page 56

4-14 Service Manual Y118040-3

VERIFYING AND ADJUSTING THE DRIVER VOLTAGES

Preventive and maintenance inspections are recommended every 6 months or every 1000 hours of operation.

1. Unscrew the screws at the side of the printer console (A).

2. Extract the console with all its electronic parts.

Figure 4-19

3. Unscrew and remove the screw (B) (3 mm hex), loosen screw (C) and rotate the fan anti-clockwise. After

doing this you will be able to access the drivers mounted on the RAMPS card.

Figure 4-20

RAMPS Card

A

C

B

Page 57

Y118040-3 Service Manual 4-15

4. On the RAMPS card, the drivers of the three axes and of the extruders are positioned as shown below.

Figure 4-21

X Axis

Y Axis

Z Axis

Extruder1

Extruder 2

Page 58

4-16 Service Manual Y118040-3

5. To check the driver voltage, with the machine powered on place the positive (red) test lead of the tester on

the driver trimmer and the negative (black) test lead on the first screw, furthest to the left, of the green

connector on the RAMPS card.

Figure 4-22

The nominal values and tolerances for the driver voltages are as follows:

X axis = 0.80V tolerance -0 - +0.05V

Y axis = 1.35V tolerance -0 - +0.05V

Z axis = 1.00V tolerance -0 - +0.05V

Extruder 1 = 1.10V tolerance -0 - +0.05V

Extruder 2 = 1.10V tolerance -0 - +0.05V

If the voltage value measured is low, work on the trimmer using small slotted screwdriver to bring the voltage to

the nominal value.

If it is not possible to reach the nominal voltage value working on the trimmer, you must replace the driver after

having first switched off and disconnected the printer from electrical outlet.

After replacing and/or adjusting the driver, check that the related axis still moves correctly by executing the test

file cubo_test.gcode (during the test, check that the axes movement is regular and continuous).

Trimmer for Adjusting

Driver Voltages

Black Test Lead

Red Test Lead

Page 59

Y118040-3 Service Manual 4-17

CHECKING THE WIRING OF THE EXTRUDER BLOCK AND HOT-END MOTORS

Preventive and maintenance inspections are recommended every 6 months or every 1000 hours of operation.

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

1. Cut the two straps and lift the sheath so as to have unobstructed access to the motor wires.

Figure 4-23

2. Ensure that the connectors are well inserted and that the wires are intact.

Figure 4-24

3. If the wires are not intact, replace any that are damaged.

4. Ensure that the hot-ends are intact and that the insulation and wires show no signs of overheating.

Extruder Block

Motor Connectors

Page 60

4-18 Service Manual Y118040-3

Figure 4-25

5. If this is not true replace the damaged hot-end(s).

CHECKING THAT HEATING ELEMENTS MAINTAIN OPERATING TEMPERATURE

Preventive and maintenance inspections are recommended every 6 months or every 1000 hours of operation.

These inspections relate to the heating elements and the thermo-sensors of the hot-end groups and work table.

1. Using the LCD panel as shown in Figure 3-29 Command sequence for setting the temperature, set the

following temperatures:

Nozzle 220° C

Nozzle 2 220° C

Surface 60° C

2. Wait for the length of time necessary for the elements to reach the temperature values set.

3. From the LCD panel, ensure that the temperatures of the hot-end group are maintained constant, with a

maximum divergence of 3-4°C.

4. Using an infrared thermometer (for example, the Fluke 62 Max model) and taking as reference points the 4

near-central points on the printing table, make sure that the temperature divergence from the value set is a

maximum of 4-5°C.

Hot-end Wires

Page 61

Y118040-3 Service Manual 4-19

UNMOUNTING THE UPPER BODY AND PANELS

1. Release the two bowdens by pressing on the black ring nuts in the directions indicated by the arrows and

extract the Teflon cannula through which the filament passes.

Figure 4-26

2. Extract the cannulas from the passthroughs on the upper body.

Figure 4-27

3. Undo the screws on the upper part of the three brackets fixing the upper body to the printer chassis.

The figure below shows the fore-mentioned screw on one of the three brackets.

Figure 4-28

Page 62

4-20 Service Manual Y118040-3

4. To remove the three rear panels, remove first the retainer and then the two bobbin holders. Unscrew all the

fixing screws highlighted.

NOTE: for technical servicing operations it is sufficient to remove only the centre panel.

Figure 4-29

5. To remove the right side panel, unscrew all the fixing screws highlighted.

Figure 4-30

Bobbin Holder and Retainer

Page 63

Y118040-3 Service Manual 4-21

6. Rotate the panel paying due attention to the safety switch wires. Using a flathead screwdriver apply a light

force to the snap hooks to release the two switches. At this point, separate altogether the side panel.

Figure 4-31

7. To remove the left side panel unscrew all the fixing screws highlighted.

Figure 4-32

8. To reassemble follow the same procedures described above but in reverse order.

Page 64

4-22 Service Manual Y118040-3

Y AXIS BELT REPLACEMENT

Preventive and maintenance inspections are recommended after 2 years or 4000 hours of operation.

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

1. Movement of the Y axis is provided by a dual belt transmission (on the right side, mirrored on the left), with

a toothed pulley, one belt being fitted onto the motor, the other idle.

The procedures for replacing the components of the right or left transmissions are identical.

The images shown in this Chapter relate to the right transmission.

Figure 4-33

2. Unmount the upper body and the right or left side panel as described in the Chapter ”UNMOUNTING THE

UPPER BODY AND PANELS”, depending on which transmission you want to replace.

3. Replace the belt and adjust its tension as shown in the video clip ”Y axis belt replacement”.

Belt Tensioner with Adjusting Screw

Belt

Motor with Pulley

Belt Fixing Screws

Idle Pulley

Page 65

Y118040-3 Service Manual 4-23

REPLACING THE Y AXIS MOTOR AND IDLE PULLEY

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

1. Unmount the upper body and the right or left side panel as described in the Chapter

”UNMOUNTING THE UPPER BODY AND PANELS” depending on which side of the printer you need to

work.

2. Unmount the belt of the Y axis as shown in the video clip ”Y axis belt replacement”.

3. Unscrew the Allen screw (5 mm) fastening the idle pulley assembly.

Figure 4-34

4. Unscrew and disconnect the motor wire quick connector. Undo the Allen screws (5 mm) and remove the

motor and its spacer.

Figure 4-35

Idle Pulley Assy Screw

Motor Wire Connector

Hex Screws

Page 66

4-24 Service Manual Y118040-3

The image below shows all the unmounted parts.

Figure 4-36

5. Working on the setscrew (1) with a hex key (2 mm) remove the pulley from the motor.

Now unscrew the cross-head screws (2), so as to separate the motor from its metal mounting.

Figure 4-37

1

2

Page 67

Y118040-3 Service Manual 4-25

6. After have screwed the motor back onto its metal mounting, mount the pulley regulating it as follows: place

a 2.9 mm shim on top of the motor, then insert the pulley onto the shaft, pushing it against the shim and

tighten the setscrew (3). To finish, extract the shim that must feel slightly gripped.

Figure 4-38

7. During the reassembly phase, insert a shim of 2.9 mm between the motor and the printer’s metal frame,

push the motor right up against the shim and tighten the two Allen screws (5 mm) shown in Figure 4-33.

Figure 4-39

8. On completing reassembly of the motor and belt, adjust the tension of the belt as illustrated in the “Y axis

belt replacement” video clip.

2.9 mm Spacer

3

Page 68

4-26 Service Manual Y118040-3

9. To unmount the idle pulley, loosen the nut (1) and unscrew the slotted screw (2) on the pulley.

Figure 4-40

10. When assembling the pulley, adjust as follows: screw the pulley onto the metal support up to the height

indicated by the C-shaped template. The idle pulley assembly must be the same height as the internal

profile of the template. At this point tighten the nut (1) to fix the pulley in the correct position.

Figure 4-41

11. On completing reassembly of the idle pulley and belt, adjust the belt tension as illustrated in the “Y axis belt

replacement” video clip.

1

2

Height Setting

Page 69

Y118040-3 Service Manual 4-27

X AXIS BELT REPLACEMENT

Preventive and maintenance inspections are recommended after 2 years or 4000 hours of operation.

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

1. Movement of the X axis is provided by a belt transmission with toothed pulleys, one belt being fitted onto

the motor, the other idle. The photos below show the components making up the mechanical transmission.

Figure 4-42

2. Unmount the upper body and the left side panel as described in the Chapter ”UNMOUNTING THE UPPER

BODY AND PANELS”.

3. Replace the belt and calibrate its tension as shown in the ”X axis belt replacement” video clip.

Idle pulley

Belt fixing screws

Belt

Belt tensioner

Motor with pulley

Page 70

4-28 Service Manual Y118040-3

REPLACING THE X AXIS MOTOR AND IDLE PULLEY

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

1. Unmount the upper body and the right or left side panel as described in the Chapter ”UNMOUNTING THE

UPPER BODY AND PANELS” depending on which side of the printer you need to work.

2. Unmount the belt of the X axis as shown in the ”X axis belt replacement” video clip.

3. Unscrew the two hex screws (4 mm) fastening the idle pulley assembly.

Figure 4-43

4. Cut the strap and extract the quick connector of the motor from its sheath. Unscrew and disconnect the

motor wire.

Figure 4-44

5. Working on the setscrew with a (2 mm) Allen key, remove the pulley of the motor.

Screws of Idle Pulley Assembly

Strap

Motor Wire Connector

Page 71

Y118040-3 Service Manual 4-29

6. Unscrew the four Allen screws (2.5 mm) and remove the motor.

Figure 4-45

The photo in the figure below shows all the unmounted parts.

Figure 4-46

Pulley Setscrew

Motor Hex Screws

Page 72

4-30 Service Manual Y118040-3

7. Remount the pulley of the motor with the following adjustments: insert a 1.5 mm shim between the pulley

and the motor mounting, push the pulley up against the shim and close the setscrew. At the end, remove

the shim that must be slightly clinched.

Figure 4-47

8. Remount the idle pulley following the indications given in the steps below.

9. Loosen the two nuts (10 mm) fixing the slotted screw under the pulley.

Figure 4-48

Shim of 1.5 mm

Lock Nuts

Setscrew

Slotted Screw

Page 73

Y118040-3 Service Manual 4-31

10. Between the pulley and the hot-end group guide support, insert a 1.5 mm shim as shown in the two photos.

Figure 4-49

11. Adjust the pulley in height working on the screw using a flathead screwdriver. When the correct height is

achieved, tighten the two nuts while holding the screw still. At the end, remove the shim that should feel

slightly clinched.

Figure 4-50

Positioning shim of 1.5 mm

Nuts to be tightened

Page 74

4-32 Service Manual Y118040-3

UNMOUNTING THE EXTRUDER BLOCK MOTORS

Preventive and maintenance inspections are recommended after 2 years or 4000 hours of operation.

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

The procedures for replacing the motors of Extruder 1 and 2 are identical. The photos shown in this Chapter

refer to the Extruder 1 motor.

1. Unmount the body as described in the Chapter ”UNMOUNTING THE UPPER BODY AND PANELS” .

2. Cut the strap and disconnect the motor wire connector.

Figure 4-51

3. Unscrew the Allen screw (2.5 mm) indicated and unmount the fan from the extruder blocks.

Figure 4-52

Motor Wire Connector

Strap

Page 75

Y118040-3 Service Manual 4-33

4. Release the bowden and remove the cannula as shown in the video clip ”Plastic layer bobbin and plastic

layer settings”. Unscrew the Allen screws (2.5 mm), highlighted below with circles, that fix the motor to the

extruder block.

Figure 4-53

5. Unscrew the Allen screw (1) (5 mm) so as to separate the bowden from the motor assy.

Unscrew the Allen screws (2) (2.5 mm) so as to separate the feeder unit from the motor.

Figure 4-54

Bowden released and cannula removed

1

2

Page 76

4-34 Service Manual Y118040-3

6. Unscrew the (5 mm) Allen screw (3) to unmount the thrust block. The image on the right shows the thrust

assy components.

Figure 4-55

7. Unscrew the setscrew (3) (1.5 mm) and remove the gear mounted on the motor shaft.

Figure 4-56

8. Reassemble following the procedures just described but in reverse order.

3

3

Page 77

Y118040-3 Service Manual 4-35

During reassembly pay particular attention to the following points.

8. The setscrew of the gear must be inserted into the flat side of the shaft (4). Align the gear with the shaft

head (5) and tighten the setscrew.

Figure 4-57

10. With the hex screw (6) torque tightened, position the bowden with the holes for the filament centred on

each other (on the same vertical axis).

Figure 4-58

11. Torque tighten the hex screw (7) against the thrust spring (8) of the feeder assy wheel (9). Give the screw

(7) a further half turn and then tighten the (9.5 mm) nut (10).

Figure 4-59

4

5

6

7

9

10

8

Page 78

4-36 Service Manual Y118040-3

UNMOUNTING THE Z AXIS MOTOR

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

1. Unmount the rear centre panel as described in the Chapter ”UNMOUNTING THE UPPER BODY AND

PANELS”.

2. Unscrew the two Allen screws (5 mm) fastening the motor mounting to the printer body. Disconnect the

motor quick connector.

Figure 4-60

3. Undo the (1.5 mm) setscrew (1) and remove the gear mounted on the motor shaft. Unscrew the four (3

mm) hex screws (2) so as to separate the motor from its mounting (in the figure the two screws on the

connector side are shown).

Figure 4-61

4. To reassemble follow the same procedures described above but in reverse order.

Hex Screws

Motor Fast Connector

1

2

Page 79

Y118040-3 Service Manual 4-37

During reassembly follow the next step carefully.

5. After have remounted the motor mounting, position the pulley so that the distance between its outer part

and the base is 17.3 mm. (To make this operation easier use the template supplied).

Figure 4-62

Page 80

4-38 Service Manual Y118040-3

UNMOUNTING THE PRINTING PLATE

Before attempting any of the operations described in this Chapter, first power off the machine and disconnect it

from the electrical outlet.

1. To work more comfortably you are advised to unmount both the side panel and the rear centre panel as

described in the Chapter ”UNMOUNTING THE UPPER BODY AND PANELS”.

2. Remove the sleeve from the conduit in the metal plate which supports the printing plate. Cut the strap and

unscrew the earth wire.

Figure 4-63

3. Slide the sleeve so as to be able to access the wire connections. Disconnect the connector and the two

quick connect terminals.

Figure 4-64

Sleeve conduit

Strap

Earth wire

Page 81

Y118040-3 Service Manual 4-39

4. Remove the eight brackets fastening the glass with its resistance to the metal frame of the printing table.

Figure 4-65

5. Using a spatula or similar tool, and working very gently, lever lightly between the metal frame of the table

and the glass with its resistance. This operation serves to separate the two parts when the rubbery material

of the resistance adheres too strongly to the metal frame of the table.

Figure 4-66

Anchoring brackets

Metal frame without the printing plate

Page 82

4-40 Service Manual Y118040-3

6. The image below shows the glass with its resistance. The detail shows a portion of the resistance that

covers entirely the underside of the glass.

Figure 4-67

7. After replacing the glass and resistance assembly, you must regulate four points on the printing plate.

Imagining a 20 cm square positioned at the centre of the table, the four corners are the points at which

Extruder 1 is at a distance of 0.08 mm from the glass. Verify also the adjustment of Extruder 2. The figure

below shows the ideal positions and the corners of the square.

Figure 4-68

Portion of resistance

Page 83

Y118040-3 Service Manual 4-41

8. Bring the nozzles to the zero point using the Auto Home procedures in the menu as described in

Figure 4-16 Command Sequence for Auto Home and Disable Motors

WARNING: to avoid reverse currents produced by the motors damaging the electronic parts, move

the extruders very gently and using small limited movements.

NOTE: The Bed Setting function automatically moves the hot-end group to the 5 points necessary for

regulating.

9. Perform the adjustment as shown in the video clip “Print plate calibration”.

If the height adjustment is not carried out correctly, bad printing quality might result. In extreme cases it

could cause a collision between the hot-end and the printing plate, damaging the machine.

NOTE: the first layer printed is normally deposited with a greater thickness than the other layers (by

appropriate setting of the slicing software). This precaution can compensate for any small

misalignments.

The tempered glass does not have a planarity with centesimal resolution, therefore the first printed

layer of the material may not be deposited uniformly. It is therefore very important to ensure that the

outer lines are uniform so as to guarantee good adhesion. The centesimal differences in height are

compensated for in the 2-3 successive layers.

Page 84

4-42 Service Manual Y118040-3

UNMOUNTING THE DISPLAY

1. Undo the screws on the side of the printer console (A).

2. Undo the setscrew of the jog dialer (B).

3. Extract the console so as to be able to access the electronic parts.

4. Undo the four locking screws (C).

Figure 4-69

5. Disconnect the flat cable (D) from the console.

6. Disconnect the flat cable of the SD Card from the display (E).