Page 1

Olivetti 3D IoT

Printer

USER MANUAL

Code: 596806-02

Page 2

PUBLICATION ISSUED BY:

Olivetti S.p.A.

Telecom Italia Group

Via Jervis, 77 - 10015 Ivrea (TO)

Copyright © 2018 Olivetti

All rights reserved

Page 3

596806-02 User Manual iii

TABLE OF CONTENTS

TABLE OF CONTENTS ............................................................................................................................................ III

INTRODUCTION ....................................................................................................................................................... IV

GENERAL SAFETY PROVISIONS ........................................................................................................................................... v

SAFETY WARNINGS ............................................................................................................................................................... v

TRANSPORTATION AND INSTALLATION: ............................................................................................................................... vi

USE .......................................................................................................................................................................................... vi

MAINTENANCE OPERATIONS SAFETY STANDARDS ......................................................................................................... viii

PACKAGE CONTENTS ............................................................................................................................................ IX

CHAPTER 1 – INTRODUCTION................................................................................................................................ 1

PRODUCT OVERVIEW ............................................................................................................................................. 1

PRINTER DESIGN ..................................................................................................................................................... 2

PRINTER AXES ORIENTATION ............................................................................................................................... 8

CHAPTER 2 – PRINTER SETUP .............................................................................................................................. 1

PREPARING YOUR PRINTER .................................................................................................................................. 1

Unblocking the extruder assembly ........................................................................................................................ 1

Powering on the printer ......................................................................................................................................... 1

Touch Screen Display ........................................................................................................................................... 2

Aligning the printing table ...................................................................................................................................... 3

Adjusting the printing nozzle height ....................................................................................................................... 7

Loading the filament bobbins ................................................................................................................................ 8

Preparing the printing table ................................................................................................................................. 13

CHAPTER 3 – PRINTING WITH THE OLIVETTI 3D IOT .......................................................................................... 1

PRINTING WITH THE OLIVETTI 3D IOT PRINTER .................................................................................................. 1

Printing a test piece ............................................................................................................................................... 1

CREATING PRINTABLE FILES FOR THE OLIVETTI 3D IOT PRINTER .................................................................. 2

Creating a 3D model ............................................................................................................................................. 2

Creating GCODE starting from 3D model ............................................................................................................. 2

GCODE PRINTING .................................................................................................................................................... 4

Generating overhang supports .............................................................................................................................. 4

SUSPENDING AND INTERRUPTING PRINTING ..................................................................................................... 5

REMOVING PRINTED PIECES ............................................................................................................................... 10

MENUS AND NAVIGATION ..................................................................................................................................... 12

Main Menu .............................................................................................................................................................................. 13

Prepare Menu ......................................................................................................................................................................... 14

Control Menu .......................................................................................................................................................................... 16

SD Card Menu ........................................................................................................................................................................ 17

Info ......................................................................................................................................................................................... 18

CHAPTER 4 – WI-FI CONNECTIONS ....................................................................................................................... 1

SETTING AND USING WI-FI CONNECTIONS .......................................................................................................... 1

PRINTER CONTROL VIA WI-FI: FEATURES ........................................................................................................... 6

APPENDIX A – OLIVETTI 3D IOT LABELS ............................................................................................................. 1

Label positions and meanings ............................................................................................................................... 1

APPENDIX B – OLIVETTI 3D IOT PRINTER CARE AND MAINTENANCE ............................................................. 1

Cleaning the printing table ..................................................................................................................................... 1

Lubricating the axes and the spindle nut ............................................................................................................... 2

Cleaning the feeder ............................................................................................................................................... 3

Replacing and cleaning the printing nozzle ........................................................................................................... 4

APPENDIX C – ELECTRICAL DIAGRAM ................................................................................................................. 1

APPENDIX D - OLIVETTI 3D IOT PRINTER-COMPATIBLE MATERIALS .............................................................. 1

APPENDIX E - SD CARD CONTENTS ..................................................................................................................... 3

APPENDIX F EU DECLARATION OF CONFORMITY ........................................................................................... 1

APPENDIX G PRODUCT DISPOSAL INFORMATION .......................................................................................... 1

Page 4

vi User Manual 596806-02

This page is intentionally left blank

Page 5

596806-02 User Manual v

INTRODUCTION

GENERAL SAFETY PROVISIONS

Important safety-related provisions are provided in this section which must be observed when installing and

using the printer: read and follow attentively these instructions and all other information provided in this manual.

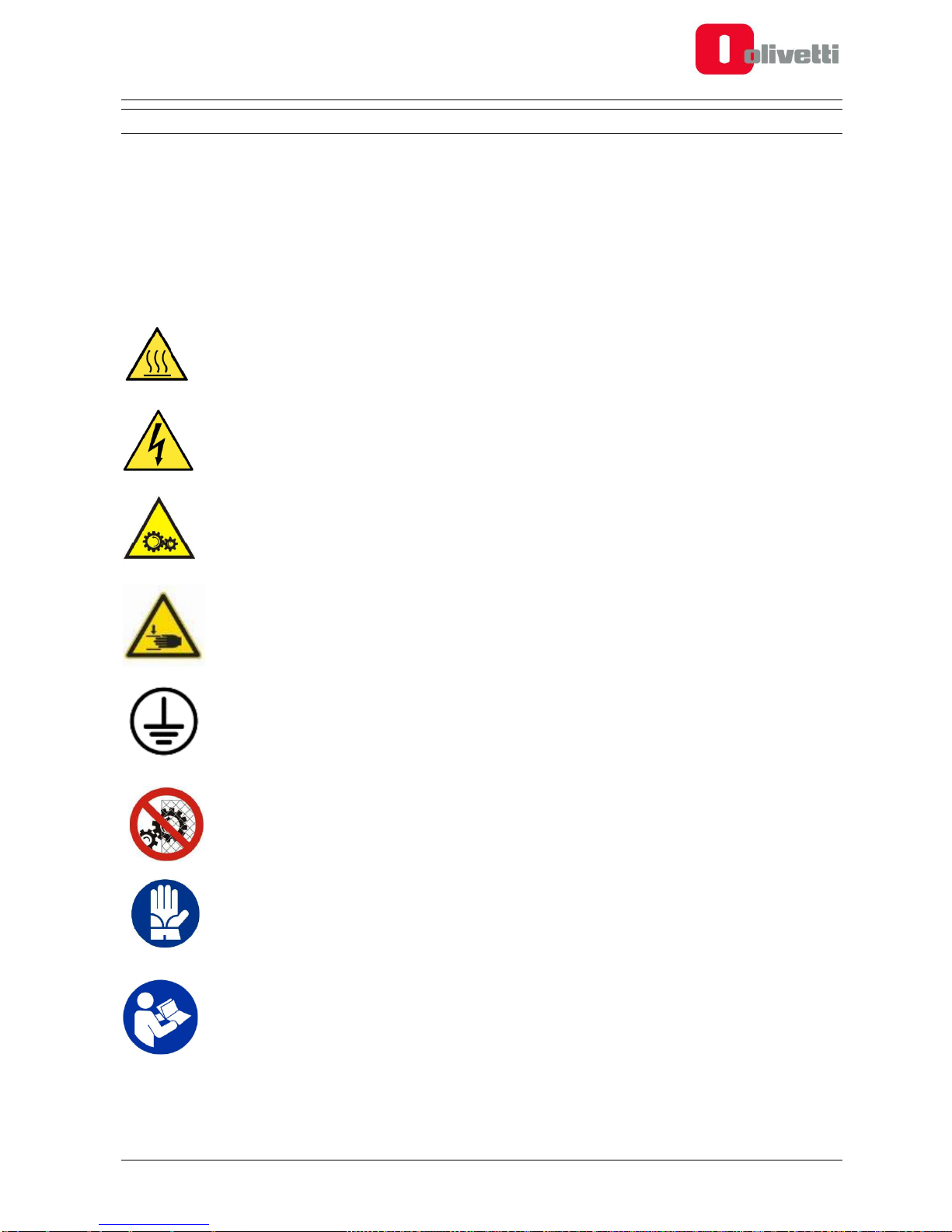

SAFETY WARNINGS

Pictograms are applied to certain parts of the printer as safety warnings, these warnings must be observed

attentively by anyone preparing to use the printer.

HOT SURFACES

The hot surfaces warning symbol warns of the presence of devices having high temperatures.

Always exercise great care and wear safety gloves when manipulating heated components

HIGH VOLTAGE HAZARD

Exercise great caution: live electrical equipment

MOVING PARTS

Moving parts present - approach with great care

CRUSHING/PINCHING HAZARD

Do not introduce your hands into the machine while it is functioning

GROUND TERMINAL

Equipment ground connection points

REMOVAL OF MECHANICAL GUARDS PROHIBITED

Do not open the front door during the printing process. Do not remove the protective bellows of

the worm screw.

GLOVES

When carrying out preparatory procedures for printing or maintenance routines, the device may

be hot therefore you must always wear gloves to avoid burns.

READ INSTRUCTIONS

For the correct operating instructions you must read the User Manual provided on the SD Card

supplied with the product.

Page 6

vi User Manual 596806-02

TRANSPORTATION AND INSTALLATION:

At least two persons are requested for transporting the 3D printer. The weight of the printer with packing is

approximately 31 Kg.

Personnel charged with handling the shipment must wear safety gloves.

When lifting or moving the 3D printer, or any of its parts, first make sure that the operating area is completely

clear, leaving also a sufficiently large safety area around it to avoid damaging persons or objects that could come

within the area for manoeuvring the load.

Note: conserve the original product packaging in case you will need it for shipping the product in the future.

Observe the following instructions:

the printer must be placed on a flat stable surface (not supplied with the printer) of sufficient load-bearing

capacity to support its weight, and at a minimum floor height of 60 cm.

fans are provided for cooling the electronic parts. Make sure there is sufficient free space around the printer

to allow adequate air circulation for ventilation. You must leave a distance of at least 60 cm from walls or

other objects.

do not position the printer near sources of heat, water or other freely moving liquids.

do not expose the printer to dust, rain, humidity or vapour.

the operating environment temperature must be maintained at 20°C approximately.

by law the equipment must be grounded; use exclusively the power cord provided with the product without

extension cords.

to protect the printer during transportation, the print carriage is locked into position with strapping tape: before

starting to print cut and remove this tape.

USE

The 3D IoT printer is not suitable for use by persons under 14 years of age, and anyway always under the

direct supervision of an adult. Make sure that children do not tamper or play with the equipment.

The printer is intended for use by operators who have received adequate training.

Use the power supply voltage indicated in the technical specifications. The power cord must never be pulled,

subjected to weights or brought into contact with sharp objects.

Do not touch the equipment with parts of the body that are wet; footwear must always be worn.

Do not smoke, use naked flames or create sparks in the vicinity of the printer.

If the printer malfunctions or fails, do not attempt to use it again until it has been repaired.

When the 3D IoT printer is functioning, certain parts generate high temperatures (printhead, heated table if

present); there are also moving parts which could cause injury if touched accidentally during operation. You

must therefore observe the following warnings carefully:

Whenever any operation is carried out on the printer - whether for installation or maintenance purposes

- always first switch off and disconnect the equipment from the electrical socket. Before proceeding,

wait for all parts that may have become heated during the previous operation to cool down.

The machine must be used exclusively with the front door closed; printing IS NOT interrupted

automatically when the front door is opened, therefore this instruction must be observed with maximum

attention.

The front door is fitted with a lock and key to prevent unauthorised access.

The key must be conserved in a safe place by those responsible for its safe-keeping.

Page 7

596806-02 User Manual vii

The heated parts must be left to cool for a certain length of time at the end of printing or when printing

is interrupted: leave the machine to cool down (approx. 5 minutes) before attempting to access the

printing area. It is good practice to check that the machine temperature shown on the front display (of

printhead and, if heated, table) is less than 40°C before attempting any interventions. Do not touch the

printhead as it may be very hot after use.

Do not wear rings, wristwatches, jewellery or loose/baggy clothing, such as scarves, unbuttoned jackets

or tops with open zips, that could become entangled in the moving parts. Keep hair tied back.

Do not insert your hands between the moving parts.

Do not use the printer for a different purpose to that for which it is designed, as specified in the User

Manual.

Do not attempt to clean the printer while it is in operation. Clean the outside of the printer only using a

soft cloth, without the use of corrosive chemical products, solvents or strong detergents, and only after

having disconnected the printer from all external power supplies and other cables.

It is advised not to leave the printer unsupervised during printing

Make sure that the room where the printer is installed is well ventilated.

Before launching a print job make sure that no objects or scrap materials are left inside the printer (such

as lacquer, rags, maintenance tools, materials removed manually,..).

Exercise the greatest care when removing the worked piece from the glass table using sharp or pointed

objects to avoid injuring yourself in the process. Use of knives or cutters for removing worked pieces

from the glass table is strongly discouraged, even in the case of small pieces.

Although the glass is tempered it is still fragile and great care must be taken when handling it.

If required, clean or change the print nozzle. The extruder must be hot to allow the residual material

inside the head to soften and not create an obstruction during replacement procedures : for all

operations always wear heat protection gloves.

Page 8

vi User Manual 596806-02

MAINTENANCE OPERATIONS SAFETY STANDARDS

Printer maintenance must be carried out exclusively by adequately trained personnel.

The principal rules to follow when carrying out maintenance operations on the printer are:

Before carrying out any interventions on the printer, make sure that it is in a safe condition.

Do not wear rings, wristwatches, jewellery or loose/baggy clothing, such as scarves, unbuttoned jackets or

tops with open zips, that could become entangled in the moving parts. Keep hair tied back.

Do not touch the equipment with wet body parts and never without shoes.

Do not use naked flames or pointed/sharp instruments for cleaning purposes.

Do not smoke.

Do not insert hands between moving parts.

When carrying out printer installation or maintenance operations, always switch off and disconnect the printer

from the electrical socket. Wait for all parts heated during the preceding operation to cool down. Leave the

machine to cool (approx. 5 minutes) before attempting to access the printing area. It is a good rule to check

that the machine temperature on the front display (of printhead and, if heated, the table) is under 40°C before

attempting any interventions. Do not touch the printhead as it could be very hot after operation.

If necessary, clean or replace the print nozzle. The extruder must be hot to allow the residual material inside

the head to soften and not create obstructions during replacement operations: when operating always

wear safety gloves for heat protection

Switch on the printer only when necessary and following the instructions in the Manual, remembering to

proceed always with maximum care

Do not attempt to clean the printer while it is functioning. Clean the outside of the printer with a soft cloth and

without using corrosive chemical products, solvents or other strong detergents. Before any cleaning

operation, disconnect the printer from all external power supplies and any connected cables.

Be very careful when attempting to remove the printed object from the glass table using sharp or pointed

objects to avoid injuring yourself in the process. Use of knives or cutters for removing items from the glass

table is strongly discouraged, even in the case of small objects.

Although the glass is tempered it is still fragile so always be very careful when handling it.

At the end of servicing operations, make sure that you remove any tools or rags used from inside the printer

and eliminate all accumulated residues

When you finish servicing operations, return the door key to the person responsible for its safe-keeping.

Page 9

596806-02 User Manual ix

PACKAGE CONTENTS

The following items are contained in the Olivetti 3D IoT printer package:

1 3D IoT Printer

2 Front door keys

1 SD Card, 4GB or greater

3 Allen Keys (1.5 mm, 2.5 mm, 5 mm)

1 Hex key, size 8

1 key, 12 mm

Washer, pin, sleeve and hex head screw for filament bobbin mount point

1 Spatula for removing printed pieces

1 AC Power Cord

1 PLA Bobbin, diameter 1.75 mm, weight 1 Kg

1 CE, WEEE, Safety Declarations leaflet

Page 10

vi User Manual 596806-02

This page is intentionally left blank

Page 11

596806-02 User Manual 1-1

Chapter 1 – INTRODUCTION

PRODUCT OVERVIEW

The Olivetti 3D IoT printer exploits Fused Filament Fabrication (FFF) technology to create 3-D objects through

layer upon layer deposition of material in 2-D.

This chapter describes the printer design and introduces the terminology that will be used in the rest of the

manual.

.

Page 12

1-2 User Manual 596806-02

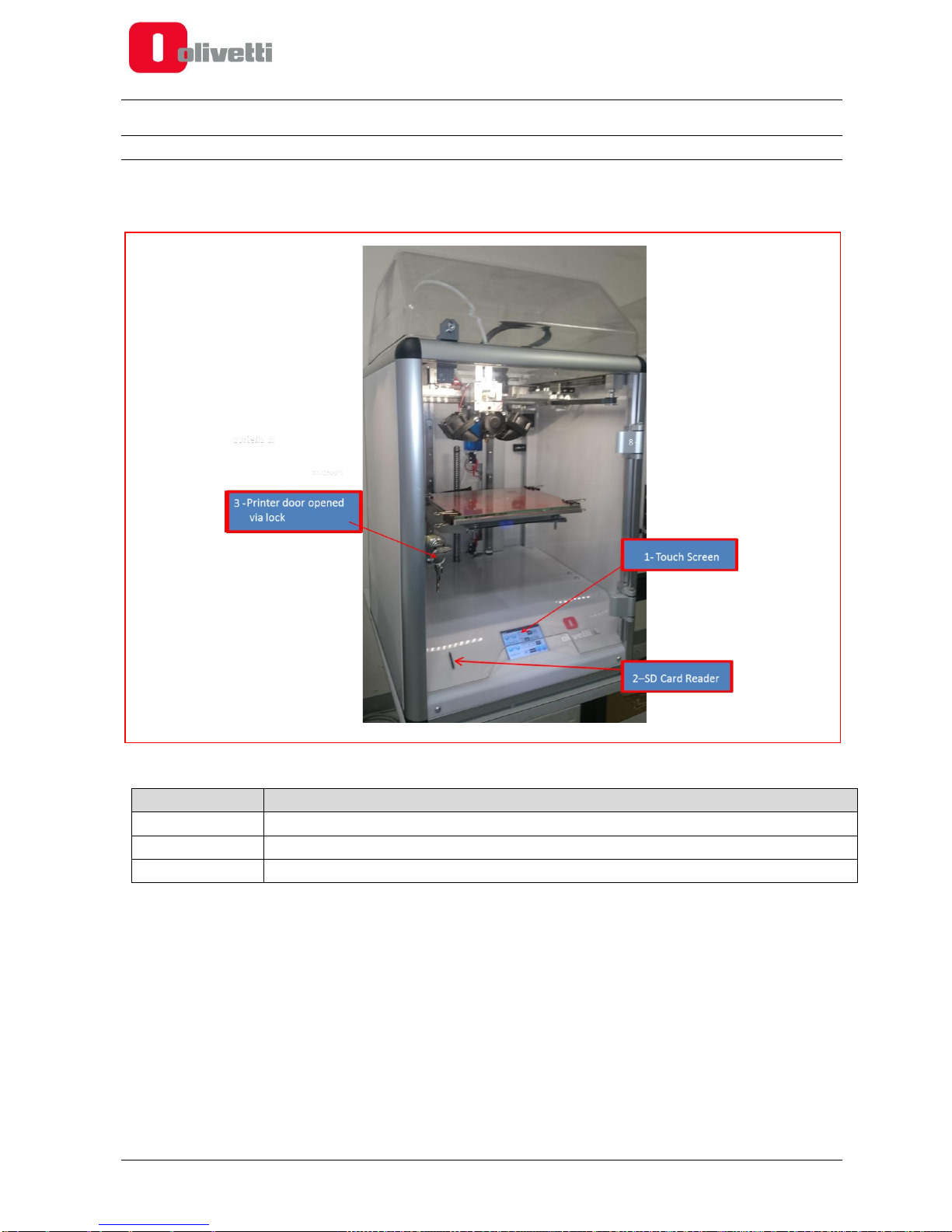

PRINTER DESIGN

The main printer controls are located at the front of the printer where there is also a door fitted with a lock

for accessing the inside of the printer.

Figure 1-1 Front view

REFERENCE

DESCRIPTION

1

Touch screen display

2

SD card reader

3

Printer door with lock

Page 13

596806-02 User Manual 1-3

The upper dome-shaped casing can be opened by releasing the catch from the inside, applying light pressure

on its lower part.

Figure 1-2 Internal catch for locking/unlocking the upper dome

Page 14

1-4 User Manual 596806-02

When the front door is opened, the extruder assembly can be seen clearly.

Figure 1-3 Extruder assembly

REFERENCE

DESCRIPTION

1

Extruder

2

Fans for cooling material being printed

3

Extruder cooling fan

Page 15

596806-02 User Manual 1-5

Figure 1-4 Hot-end close-up

REFERENCE

DESCRIPTION

1

Nozzle

2

Hot-end

3

Hot-end set screw

4

Filament feeder assembly

Page 16

1-6 User Manual 596806-02

Figure 1-5 Feeder assembly terminals and pressure adjustment screw

REFERENCE

DESCRIPTION

1

Bowden quick release coupling

2

Filament pressure adjustment screw

Page 17

596806-02 User Manual 1-7

At the rear of the machine, there is the housing for the bobbin containing the filament, the power switch and

power socket.

Figure 1-6 Rear view

REFERENCE

DESCRIPTION

1

Bobbin holder

2

Feeder

3

Power switch

4

Power socket

Page 18

1-8 User Manual 596806-02

PRINTER AXES ORIENTATION

The printer axes origin, known as the Home position, is the front left corner of the printing table.

Figure 1-7 Orienting the Olivetti 3D IoT printer axes

Starting from the origin, the positive direction of the X axis ordinate is from the left of the worktable to the right

side, the positive direction of the Y axis ordinate is from the front door towards the rear of the machine, while the

Z axis is oriented vertically, its ordinate increasing as the printing table descends from the top downwards.

Page 19

596806-02 User Manual 1-9

This page is intentionally left blank

Page 20

Page 21

596806-02 User Manual 2-1

Chapter 2 – PRINTER SETUP

PREPARING YOUR PRINTER

This chapter describes the procedures that must be followed to configure correctly the Olivetti 3D IoT printer and

prepare it for the successive printing phase.

Unblocking the extruder assembly

To protect the printer during transportation, the print carriage is fixed securely in position by plastic banding.

This banding must be removed before attempting to print.

Powering on the printer

Connect the printer to a 220V power supply socket using the power cord supplied in the kit. Switch on the printer

at the power switch at the back of the machine.

Figure 2-1 Power socket and power switch

Page 22

2-2 User Manual 596806-02

Touch Screen Display

When the printer is powered on, the main printer status information is displayed on the 3.5” Touch Screen.

Figure 2-2 Touch Screen Display in Rest mode (Desktop Menu)

Current Extruder

temperature setting

New Extruder

temperature setting

Current Printing Table

temperature setting

New Printing Table

temperature setting

Menu Key

Current Acceleration

setting (metres per

second squared)

Current Flow value

setting

New Flow value

setting

New Acceleration setting

Auto Home

Page 23

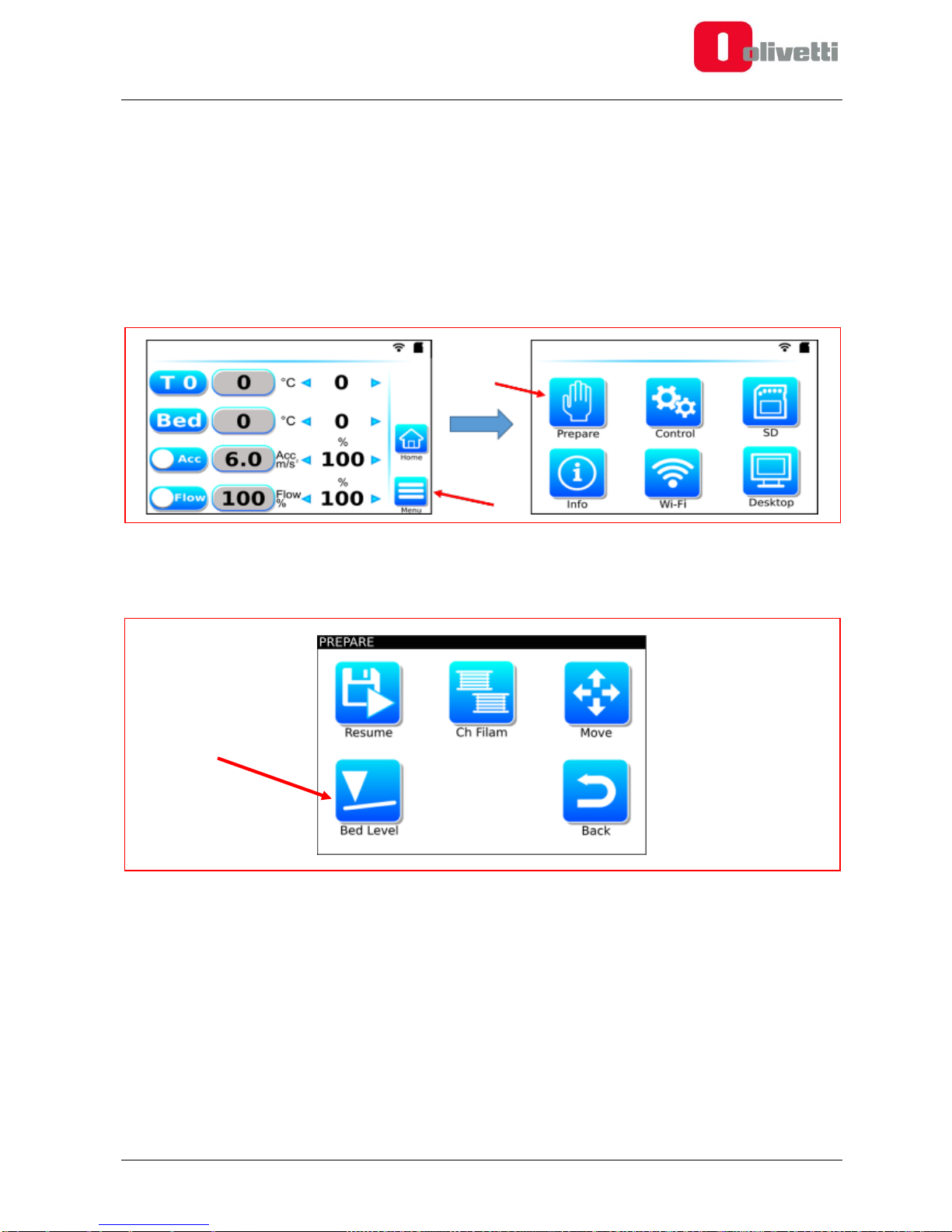

596806-02 User Manual 2-3

Aligning the printing table

To obtain good printing quality it is essential to ensure that the first layer deposited is distributed in a uniform

manner on the printing table.

To achieve this, you must ensure that the printing table is aligned correctly.

Although the printer has been set up correctly at the factory, it may have been subjected to vibrations during

transportation making it necessary to repeat this procedure.

To align the printing table:

1. Starting from the Desktop Menu, press the Menu key and then, in the next screen, press the Prepare key.

Figure 2-3 From the Desktop Menu, select Menu then Prepare

2. From the Prepare Menu, select the Bed Level command.

Figure 2-4 Prepare Menu with Bed Level command

Page 24

2-4 User Manual 596806-02

3. The Touch Screen displays the Bed Levelling message while the extruder assembly takes up the Home

position.

Figure 2-5 Bed Levelling Display

4. Touch the display at bottom left (Position 1 in Figure 2-5). The extruder assembly moves to this first

adjustment point.

5. Try to pass a normal sheet of paper, folded in two, between the extruder nozzle and the tempered glass

table (Figure 2-6).

If the paper moves freely between the nozzle and the glass, you need to concentrate on the self-locking nut

(Figure 2-7), turning it a few degrees in the clockwise direction to bring the table nearer to the nozzle

eliminating any space between the glass, the paper and the nozzle.

If the opposite is true, i.e. the nozzle is too near the glass (you cannot insert the sheet), then you must turn

the nut in the opposite direction (i.e. anticlockwise) so as to set the correct amount of space between the

nozzle and the printing table.

Figure 2-6 Use a sheet of paper to check the distance between the extruder nozzle and the tempered glass

1 2 3

4

5

Page 25

596806-02 User Manual 2-5

Figure 2-7 Adjustment nut locations

6. After having completed the first adjustment, touch the display this time at Position 2. The extruder assembly

moves to this second adjustment point.

7. Repeat the adjustment in the same way as illustrated in step 5, working on the related selflocking nut.

In all, there are 4 adjustment points for each of which you must carry out adjustments as described in step 5.

8. To conclude, check the distance between the extruder nozzle and the tempered glass at the centre part of

the glass, touching the display at Position 5.

9. Repeat the whole operation a second time, that is, as many times as necessary, until the distance between

the extruder nozzle and the tempered glass is correct for all positions.

10. After completing adjustments, press the “Back” key to conclude the adjustment procedures.

NOTE: The first layer printed is normally thicker than the subsequent layers (when set appropriately in

the Slicing software). This feature is able to compensate for any small misalignments.

NOTE: the tempered glass does not have centesimal planarity, therefore the material for the first layer

may not deposited in a perfectly uniform way. It is essential however to ensure that the outer lines are

uniform to ensure good adhesion with the table. The centesimal differences in height are compensated

for in the next 2-3 layers.

WARNING: If the height adjustment operation is not carried out correctly, print quality could be poor.

In extreme cases, it could also result in collisions between the hot-end and the printing table, with the

risk of damaging the machine.

Page 26

2-6 User Manual 596806-02

The table below provides some examples of problems caused by incorrect alignment of the printing table and

provides suggestions for how they can be resolved.

Problem

Reason

Solution

Nozzle touches the glass

Glass is too near the nozzle

Turn the nuts of the printing table a

few degrees in the anticlockwise

direction to increase the distance

between nozzle and printing table

Material is not able to flow out of the

nozzle correctly

Glass is too near the nozzle

Turn the nuts of the printing table a

few degrees in the anticlockwise

direction to increase the distance

between nozzle and printing table

The material flows out of the nozzle,

but the line printed for the first layer

is extremely narrow and too “spread

out” width-wise

Glass is too near the nozzle

Turn the nuts of the printing table a

few degrees in the anticlockwise

direction to increase the distance

between nozzle and printing table

The material flows out correctly, but

the “line” deposited is very narrow in

width and has a cylindrical section, it

comes away from the printing table

easily during successive printing

operations.

Glass is too far from the nozzle

Turn the nuts of the printing table a

few degrees in the clockwise

direction to deincrease the

distance between nozzle and

printing table

The material flows out correctly but

can be seen to “jump” slightly before

sticking to the printing table

Glass is too far from the nozzle

Turn the nuts of the printing table a

few degrees in the clockwise

direction to deincrease the

distance between nozzle and

printing table

On visual examination, the line

deposited for the first layer is

irregular varying in both thickness

and width

The glass has not been aligned

correctly: a line which is too thick

indicates that the distance

between the nozzle and printing

table is too small. A line which is

not thick enough indicates that

the distance between the printing

table and the nozzle is too great

Repeat the procedure for adjusting

the printing table, then adjust the

printing height.

Page 27

596806-02 User Manual 2-7

Adjusting the printing nozzle height

To ensure correct printer operation and optimise printing quality, apart from aligning the printing table, it might

be useful to adjust also the printing nozzle height.

Although this procedure has already been carried out at the factory, you may need to repeat it as the printer may

have been subjected to jolts during transportation.

To adjust the nozzle height, first unblock the hot-end unit by unscrewing the set screw on the extruder assembly

that can be found under the fans (use the 2.5 mm allen key supplied with the machine).

Figure 2-8 Hot-end assembly setscrew

With the set screw loosened the hot-end block is free to move; adjust the nozzle to a distance of 0.10mm from

the tempered glass table.

This adjustment can be achieved as described in the previous section, by placing a paper sheet folded in two

between the nozzle and the table. Rest the nozzle on the sheet and check that the distance between the

extruder nozzle and the tempered glass is correct, then tighten the setscrew again using the 2.5 mm allen key

to block the hot-end assembly again.

WARNING: If the height adjustment is not carried out correctly, printing quality could be poor or, in

the worst case, it could cause a collision between the hot-end and the printing table with damage to

the machine.

WARNING: The height adjustment procedure must be carried out with the nozzle in a clean

condition, free from plastic residues.

Page 28

2-8 User Manual 596806-02

Loading the filament bobbins

To correctly load the filaments containing the materials for printing, follow the procedure below:

1. Unscrew by hand the protection screw mounted at the rear of the printer.

2. Insert the washer and cylindrical tube onto the hexhead screw.

3. Tighten the screw by hand (do not use an allen key for tightening as you may tighten the screw too much).

Figure 2-9 Protective screw to remove

Figure 2-10 Bobbin with its holder components

Page 29

596806-02 User Manual 2-9

Figure 2-11 Putting bobbin with filament into position

4. Insert the bobbin with the filament onto the bobbin holder. With the end of the filament trailing to the bottom

left of the bobbin, feed the filament into the input slot to the feeder. This means that, looking at the machine

from the back, when the filament is pulled upwards the bobbin rotates in a clockwise direction.

5. To minimise the possibility of the bobbin shifting sideways during printing, a fork-like wedge can be inserted

onto the fixing nut, as shown in the figure below. The file for printing the wedge is stored on the SD Card

supplied in the printer package.

Figure 2-12 Inserting fork-like wedge (optional)

6. Cut the filament at an angle of approximately 45° and straighten out the first 5 centimetres. This makes

inserting the filament into the feeder and the end-of-filament sensor easier. Insert the filament into the lower

feeder slot and push it through, sliding it inside the feeder. When the filament enters the end-of-filament

sensor (mounted inside the printer) you may notice a certain amount of resistance impeding movement – in

this case push the filament with determination to overcome resistance.

Page 30

2-10 User Manual 596806-02

Figure 2-13 End-of-filament sensor (inside printer)

If an obstacle is perceived during the passage of the filament inside the sensor, it is advisable to withdraw

the filament downwards, push downwards the teflon tube inserted in the upper part of the sensor (see figure

2-14) , until the tube itself can not be pushed further down, and then try again to insert the filament.

Figure 2-14 Pushing downwards the teflon tube inserted in the upper part of the sensor

7. Continue pushing until the filament appears at the feeder unit located at the front of the machine inside the

extruder assembly. If the filament does not feed through easily, remove the filament duct from the feeder,

pressing the black gasket of the bowden lightly between two fingers of one hand, while pulling slowly the

white duct with the other hand.

Pull the filament out and insert it into the feeder unit. Pressing slightly, put the duct back into place.

Figure 2-15 Removing the feeder duct and passing through the filament

Page 31

596806-02 User Manual 2-11

8. Adjust the hot-end temperature to the correct operating value for the type of filament loaded (for example,

200°C for PLA).

To adjust the hot-end temperature:

from the Start menu, press on the RIGHT arrow of the T0 line until the required temperature value is

displayed.

Figure 2-16 Setting the temperature of the hot-end

9. Pass the filament inside the feeder unit and push it through for approximately 10 cm until it comes out of the

printing nozzle.

Figure 2-17 Inserting the filament into the hot-end

WARNING: During the first manual extrusion, you may find residual material from a preceding

printing process; this is normal because the machine is subjected to testing before being packaged.

Page 32

2-12 User Manual 596806-02

The following table gives some examples of error conditions that could be caused by incorrectly loading the

filament with possible solutions.

Problem

Reason

Solution

The filament is not fed through by

the feeder unit. Examining the

filament by eye it seems

unblemished without any

“notches” left by the gears.

Insufficient pressure as a result

of which the filament is not

pressed correctly against the

gear.

Increase the pressure of the feeder

unit by means of the adjusting grub

(see Figure 2-17), avoiding setting

too high a pressure that could

deform the filament

The filament is fed by the feeder

assembly, but occasionally

unexpected “slips” occur and

material is not extruded.

Examining the filament by eye it

can be seen to be deeply notched

or consumed by the gear.

Too much pressure resulting in

the filament being squeezed to

hard against the gear.

Decrease the feeder tightness by

means of the adjusting grub (see

Figure 2-17)

Figure 2-18 Adjusting grub of feeder unit

Page 33

596806-02 User Manual 2-13

Preparing the printing table

The last operation to accomplish before proceeding with printing is to prepare the printing table.

If you are going to use the table covered with PEI (polyetherimide) film - already mounted on the 3D IoT printer

- no preparatory steps in fact are needed for the table, nor to increase the adhesion of material to the

table.

SPECIAL CASES

when printing using technical materials such as ABS, ASA and Nylon-based materials (eg

Carbonium), it is advisable to improve adhesion by using a special 3D printing spray, such as the

Dimafix. For how to use the spray, see the instructions below for using lacquer.

when printing using flexible materials such as Rubber HS, it is advisable to print on the glass surface

instead of the PEI surface, by following the instructions below.

In situations where you want to use the tempered (4 mm) glass printing table WITHOUT the PEI film, you need

to be aware that, under normal conditions, plastic does not stick to glass. For this reason, to improve adhesion,

you are advised to use a special 3D printing spray or a common hairspray to create a “sticky” film to which the

plastic can adhere (Strong Hold hairspray is recommended). To prepare the table and make applying the film

of hairspray easier, you have to remove the glass from the printer.

To do this, proceed as follows:

1. lower the table following these steps:

I. Starting from the Desktop Menu, press the Menu key and then, from the next screen, the

Prepare key.

Figure 2-19 From the Desktop Menu, select Menu then Prepare

II. From the Prepare Menu, select the Move command

Figure 2-20 Prepare Menu with Move command

III. In the Move menu, set the following values for the movement parameters:

Page 34

2-14 User Manual 596806-02

DISTANCE (mm): 100.

SPEED (mm/sec): 500

ACCELERATION (mm/sec2): 12

IV. Press the RIGHT arrow on the Z row to lower the table:

Figure 2-21 Move command for Z axis

2. when the table has completed its movement, remove the four clamps by pressing lightly on their metal

wings.

3. after removing the clamps, lift the glass table, reverse it and place it gently on a flat surface.

4. spray on the glass the lacquer (strong/extra strong hold) from a distance of approximately 15 cm. The

best procedure is to spray across the table first horizontally and then perpendicularly. Be sure to carry

out this operation in a well ventilated room, far from inflammable objects and other objects that could

become covered with lacquer.

5. wait a few seconds until the lacquer dries (it is dry when no fingerprints are left) and proceed to remount

the table fixing it again with the four clamps.

To resume printing on the PEI surface, repeat the removal operation of the plate described above, clean the

glass surface removing the lacquer residues (using a degreaser) and replace the plate with the PEI surface

facing up.

WARNING: Although the glass is hardened it is still fragile, so you must always be very careful when

handling it.

Page 35

596806-02 User Manual 3-1

Chapter 3 – PRINTING WITH THE OLIVETTI 3D IOT

PRINTING WITH THE OLIVETTI 3D IOT PRINTER

After you have carried out the printer adjustments and loaded the bobbin with the filament, the printer is ready

to use.

Printing a test piece

On the SD card in the kit, you can find some files that can be used for executing a printing test to gain confidence

with using the printer.

WARNING: if the SD Card cannot be recognised / read, check the position of the lock switch on the

side of the card, making sure it is in the unlocked position (that is, enabled for reading and writing).

To print a test piece:

1. Insert the SD CARD into the slot at the front of the printer

2. Starting from the Desktop Menu, press the Menu key and then, in the next screen, the SD key

Figure 3-1 From the Desktop Menu, select Menu then SD

3. Select the file to print (e.g. Logoolivetti1.gcode)

4. The machine now starts the automatic printing procedure reading the GCODE file indicated, executing all

phases. You can follow the process from either the Info menu or, naturally, looking through transparent

door of the printer.

When printing is launched, the printer executes the following procedure:

1. Homes all axes,

2. Heats the extruder and table, until the temperature required is reached

3. Extrudes a small quantity of material for loading into the extrusion chamber

4. Moves to the printing area, and starts the procedure for printing layer on layer.

5. When printing completes, the machine sends the carriage to the Home position. It then switches off the

heaters to allow the machine to return to the normal environmental temperature.

NOTE: Files in the printing format supported by the Olivetti 3D IoT printer always have the

extension .GCODE.

Page 36

3-2 User Manual 596806-02

CREATING PRINTABLE FILES FOR THE OLIVETTI 3D IOT PRINTER

This section describes the steps necessary for producing GCODE files that can be printed using the Olivetti 3D

IoT printer.

Creating a 3D model

The first thing to do is create a three-dimensional model of the object you want to print.

To create the model you can use both commercially-available 3D CAD drawing software or free software, such

as OpenSCAD, Blender, SketchUp or FreeCAD.

Alternatively, you can also download ready-to-use 3D models, available for free on Internet sites such as

Thingiverse and GrabCAD.

There are various file formats for 3D models however .STL (STereoLithography) format is recommended for

generating and downloading models given that it is the most commonly used format. It will be easily managed

by the programs you will have to use afterwards for generating the GCODE for printing in 3D.

Creating GCODE starting from 3D model

Once the 3D model in STL format is ready, it must be further processed to make it printable through

transformation in GCODE.

Transformation from .STL to .GCODE using special SW called slicers.

Slicers are programs that divide up the 3D model into manageable sections that the 3D printer is able to deposit

on a work table.

Page 37

596806-02 User Manual 3-3

Many types of slicers exist, however the most recommended are Cura, and in particular, Simplify3D.

The sample files saved on the SD Card have been generated using Simplify3D. For the profiles provided by

Olivetti for simplifying slicing operations you must use Simplify 3D.

Figure 3-2 3D model being converted by Simplify3D

After generating the GCODE file using the slicer, copy it onto the SD card. Now insert the card into the Olivetti

3D IoT printer to print the model.

WARNING: if the SD Card cannot be recognised / read, check the position of the lock switch on the

side of the card, making sure it is in the unlocked position (that is, enabled for reading and writing).

Page 38

3-4 User Manual 596806-02

GCODE PRINTING

To print your GCODE, proceed as previously explained in the section related to test piece printing, that is:

1. Insert the SD CARD into the slot at the front of the printer

2. Starting from the Desktop Menu press the Menu key and then, in the next screen, the SD key

Figure 3-3 From the Desktop Menu, select Menu then SD

3. Select the file to print (e.g. Logoolivetti1.gcode)

4. The automatic printing procedure starts, reading the GCODE file indicated and executing all the phases.

You can follow the process from the Info menu or, naturally, observing it directly through the transparent

printer glass.

Generating overhang supports

Portions of a model that cannot be printed using the FFF printing process, without the provision of an

adequate support underneath, are defined as overhang.

As in FFF technology layers are deposited one on top of the other, each layer must have an adequate

support underneath.

If your 3D model has planes or surfaces that rise upwards with an inclination of over 50° approximately

with respect to the vertical plane (40° from the table), the layer deposited may not have sufficient support

underneath resulting in it collapsing downwards, compromising printing quality.

To resolve the problem of overhang, whenever required the slicing software is able to generate material

supports automatically (on the basis of user-defined parameters).

At the end of printing process this additional material must be removed manually.

Page 39

596806-02 User Manual 3-5

SUSPENDING AND INTERRUPTING PRINTING

1. Suspending printing manually

Using the menus you can suspend or cancel printing while it is in progress.

To suspend printing, select the “Pause” key from the Desktop Menu

Printing will be suspended and the extruder assembly moved to the “wait” position.

Figure 3-4 Suspending printing

After printing is suspended, the “Pause” screen appears on the display

Figure 3-5 “Pause” Screen

From this screen you can:

a. Restart printing by pressing “Restart”

b. Stop and save the print job in progress by pressing “Stop&Save”.

Printing can then be restarted in the following manner:

from the Desktop Menu, select Menu

from the next menu, select Prepare

from the next menu, select “Resume”. The printer:

heats the extruder and printing table to the appropriate temperature, at the end displaying this

screen:

Page 40

3-6 User Manual 596806-02

Figure 3-6 “Resume Saved Job”, with Restart command

now select the “Restart” command. The printer begins to extrude slowly, filling the nozzle to

the appropriate level.

During this phase, the screen below is shown on the display (Figure 3-7). Check that the

printer is extruding in a regular manner then confirm the restart operation by selecting

“Restart”.

To avoid imperfections in the printed object, you are advised to remove by hand the filament

that is extruded during the restart phase, that is before the nozzle and table come into contact

again. For this operation you must always wear protective heat-resistant gloves and pay

maximum attention to the nozzle, avoiding all contact with it.

Figure 3-7 “Pause” Screen showing Restart command

c. the third option in the “Pause” screen is Change Filament that is activated by selecting “Ch Filam”.

When this command is selected, the following screen appears on the display:

Figure 3-8 “Change Filament” screen

Page 41

596806-02 User Manual 3-7

The machine automatically heats the extruder to the appropriate temperature for this operation. Once the

temperature has been reached, proceed as follows:

I. using the down arrow, activate extrusion of a small quantity of material

II. use the up arrow to retract the filament to be replaced.

After removing the bobbin with the filament, proceed to load the new filament (see section

“Loading the filament bobbins” in Chapter 2).

On completing this operation, select the “Back” key then “Restart” in the next screen

Figure 3-9 “Pause” Screen with “Restart” key

Page 42

3-8 User Manual 596806-02

2. Suspending printing automatically

Printing can be suspended automatically under two conditions:

a. end-of-filament sensor detects filament is finished.

In this case, printing is suspended. The printer retracts any residual filament before moving to the

pause position, as indicated by these two screens:

Figure 3-10 End-of-filament screens

Select “Ch Filam” from the second screen, replace the empty bobbin, then restart printing following the

procedure outlined in the previous section.

Page 43

596806-02 User Manual 3-9

b. power supply failures

when the power supply is interrupted, the mini-UPS integrated in the printer comes into function:

printing is suspended, the printer retracts the residual filament and then switches off. During the save

procedure the screen below is shown on the display:

Figure 3-11 Screen that appears for power interruptions

Printing can be restarted following this sequence:

from the Desktop Menu, select Menu

from the next Menu, select Prepare

from the next Menu, select “Resume Saved”.

Figure 3-12 From the Desktop Menu, select Menu then Prepare

Figure 3-13 From the Prepare Menu, select the Resume command

From this moment, the printer performs the procedures described in the earlier section for restarting

printing after a manual suspension.

Page 44

3-10 User Manual 596806-02

REMOVING PRINTED PIECES

When printing concludes, wait until the printing table returns to the normal environmental temperature before

attempting to remove the printed part.

At this point, proceed as follows:

lower the table using this sequence:

1. Starting from the Desktop Menu, press the Menu key then, in the next screen, the Prepare key

Figure 3-14 From the Desktop Menu, select Menu then Prepare

2. From the Prepare Menu, select the Move command.

Figure 3-15 Prepare Menu with Move command

3. In the Move screen, set the following values for the movement parameters:

DISTANCE (mm): 100

SPEED (mm/sec): 500

ACCELERATION (mm/sec2): 12

Page 45

596806-02 User Manual 3-11

4. Press the RIGHT arrow on the Z row to lower the table:

Figure 3-16 Move Command for Z axis

when the table has stopped moving, proceed to remove the printed piece. If necessary use the spatula

supplied in the kit, taking care not to damage the PEI film covering the printing surface.

NOTE: The printing table is composed of 4 mm tempered glass. Although it is a safe heat-resistant material,

it is still fragile. You must therefore be very careful when handling it. For printing always use the special glass

supplied with the machine.

Page 46

3-12 User Manual 596806-02

MENUS AND NAVIGATION

From the Olivetti 3D IoT printer User Interface you can access all commands necessary for carrying out printer

adjustments, maintenance operations and printing itself.

From the Desktop Menu you can display and modify the principal parameters:

Figure 3-17 Touch Screen Display in rest mode (Desktop Menu)

You can modify the settings using the arrows present on each of the rows T0, Bed, Acc and Flow. Press

on the left arrow to decrease a value or on the right arrow to increase it.

The two right-hand keys perform the following functions:

Home key: the machine performs the auto homing manoeuvre, that is, it carries the printhead and the

printing table to the rest position

Menu key: provides access to the Main Menu

Current Extruder

temperature setting

New Extruder

temperature setting

Current Printing Table

temperature setting

New Printing Table

temperature setting

Menu Key

Current Acceleration

setting (metres per

second squared)

Current Flow value

setting

New Flow value

setting

New Acceleration setting

Auto Home

Page 47

596806-02 User Manual 3-13

MAIN MENU

The Main Menu can be accessed by pressing the Menu key that appears at the bottom right of the start

screen /Desktop Menu.

Figure 3-18 Main Menu

From the Main Menu you can select:

Prepare to access its related submenu

Control to access its related submenu

SD to access the contents of the SD Card

Info: to access information on the printer and its use

Wi-Fi: to access its related submenu

Desktop to return to the Desktop Menu

Page 48

3-14 User Manual 596806-02

PREPARE MENU

The Prepare Menu allows you to carry out the main machine adjustments. Select Prepare to access the

following submenu:

Figure 3-19 Prepare Submenus

Resume resumes the last saved job, as previously described in the section “Suspending and

interrupting printing”

Change FIlament procedures for changing the filament, as previously described in the section

“Suspending and interrupting printing”

Move movement of X, Y and Z axes

Bed Level procedures for levelling the printing table, as previously described in the section “Aligning

the printing table”

Back Returns you to the Main Menu

MOVE COMMAND

When you select the Move command, the following screen is displayed.

Figure 3-20 Move Submenu

The Distance, Speed and Acceleration parameters on the right of the display allow you to define the distance

and speed of movement of the Axes and of the Extruder:

DISTANCE (mm): you can set the movement from a minimum of 0.1 mm to a maximum of 100 mm.

SPEED (mm/sec): you can set the speed from a minimum of 10 mm/sec to a maximum of 500 mm/sec

ACCELERATION (mm/sec2): you can set the acceleration from a minimum of 3 mm/sec2 to a maximum

of 12 mm/sec2

Page 49

596806-02 User Manual 3-15

After adjusting the previously mentioned parameters, you can move the extruder assembly (X and Y) and

the printing table (Z), and turn the filament (E0) feeder gears by pressing the arrows on the X, Y and Z

rows:

X Row: press the left arrow to move the extruder assembly to the left or the right arrow to move it to

the right

Y Row: press the left arrow to move the extruder assembly towards the front door or press the right

arrow to move the extruder assembly towards the back of the printer

Z Row: press the left arrow to move the printing table upwards or the right arrow to move it downwards

E0: press the left arrow to turn the feed gears upwards (filament retraction) or the right arrow to move

the feed gears downwards (filament extrusion)

The Motor On/Off key allows you to enable or disable the motors: when you need to move the motors

manually select MotorOff to switch off the motors.

WARNING: move the axes slowly and carefully to avoid self-induction of currents that could damage

the axes controller boards.

Page 50

3-16 User Manual 596806-02

CONTROL MENU

The Control menu shows the basic printer adjustment parameters.

Given that this type of adjustment must be carried out exclusively by expert users, they can’t be modified

by the user.

Figure 3-21 Control Submenu

Page 51

596806-02 User Manual 3-17

SD CARD MENU

Selecting SD in the Main Menu, you can access the SD Card Menu and view the list of .GCODE files present in

memory.

Figure 3-22 Main Menu with SD key

Figure 3-23 Menu SD

To select a file and print it, scroll through the list using the arrows then confirm your selection by pressing the

OK key.

Press the Menu key to return to the Main Menu.

Page 52

3-18 User Manual 596806-02

INFO

Figure 3-24 Main Menu with Info key

When Info is selected in the Main Menu, the Olivetti3D access screen is displayed. Touching this screen you

can access printer information including usage data:

Figure 3-25 Access screen

Figure 3-26 Information

Information provided :

a. Firmware version

b. Printer Serial Number

c. Power-On time total number of hours powered on

d. Printing time total number of printing hours

e. Extruder 0 Filament: Number of metres of filament extruded

f. Parameter mode: Parameter profile set

Page 53

596806-02 User Manual 4-1

Chapter 4 – WI-FI CONNECTIONS

SETTING AND USING WI-FI CONNECTIONS

An Access Point is integrated in the 3D IoT printer, allowing wireless connections to be set up with devices such

as PCs, Tablets and smartphones (running either operating system, iOS or Android).

When the Wi-Fi key is selected from the Main Menu, the Wi-Fi Management menu appears:

Figure 4-1 Main Menu with Wi-Fi key

Figure 4-2 Wi-Fi menu

Pressing the “Off” key in the Wi-Fi Menu, the related function is activated.

In the lower half of the display the following messages appear in sequence :

Wi-Fi Module booting Wi-Fi module startup operations

SSID Scanning searching for the Service Set IDentifier, that is, the 32-character alphanumeric key

identifying univocally the wireless network generated by the Access Point integrated in the printer

Starting AP Mode starts the Wi-Fi Access Point functionality in Access Point (AP) mode.

At the end of these setup operations, the Wi-Fi module is ready.

Page 54

4-2 User Manual 596806-02

ACCESS POINT MODE

When the Wi-Fi module is powered on it activates Access Point mode.

In the lower half of the display, the “name” of the Wi-Fi network generated by the Access Point is shown.

To connect a device (PC, Smartphone, etc.) to the Wi-Fi network, from the list of Wi-Fi networks shown on

your device select the name of the Wi-Fi network generated by the Access Point. If your browser does not

load the printer startup page automatically, enter the address 192.168.1.1 directly into the browser search

field.

Unless differently set, the network logon password is the printer Serial Number. This can be found in

the “Info” submenu (see previous section), its position indicated by the arrow in the Figure here:

Figure 4-3 Info Submenu – Wi-Fi Password (Serial Number)

If the browser doesn’t show automatically the printer’s home page, digit in the browser address bar the

address olivetti3dportal.net or 192.168.1.1.

Once the connection is established, from the browser of your device you can select:

Wi-Fi: to configure/modify the Wi-Fi connection parameters

Moves: printer functionalities and commands, including:

o Verify and modify printing parameters

o Start printing

SD: reading and writing data to SD memory, including:

o Upload a print file (.GCODE) from the device to the SD memory

o Remove a print file (.GCODE) from the SD memory

Page 55

596806-02 User Manual 4-3

STATION MODE

To connect the printer to an existing Wi-Fi network, activate “Station Mode”.

To do this, select Wi-Fi from your browser screen then click on STA.

Figure 4-4 Selecting Station Mode (STA) in browser screen

In the “Station Configuration” screen, select the Wi-Fi network you want to connect the printer to and enter

its password. Now select DHCP mode or insert manually the IP addresses of the network.

Figure 4-5 Station Configuration in browser screen

Page 56

4-4 User Manual 596806-02

After completing the configuration, close the browser on your device and connect to the printer Wi-Fi network.

Open the browser again and enter the address:

If the Wi-Fi network addressing is managed manually, type in the browser the assigned address (in the

figure 4-5 sample, the IP Address is 192.168.0.52)

If the Wi-Fi network addressing is managed by DHCP type in the browser the address shown on the

printer display once connected to the network ((in the figure 4-6 sample, the address is STA IP

192.168.0.50)

Figura 4- Sample of IP address assigned by DHCP, shown on printer display

Page 57

596806-02 User Manual 4-5

CHANGING MODE FROM STATION MODE ACCESS POINT

To change the mode from Station Mode to Access Point, select Wi-Fi again from your browser screen and

click on AP.

Alternatively, you can use the “RESET” key in the printer Wi-Fi Menu to reset the original Access Point

setup.

Figure 4-7 Wi-Fi Menu with Reset key

Page 58

4-6 User Manual 596806-02

PRINTER CONTROL VIA WI-FI: FEATURES

Once the Wi-F connectivity is on, it’s possible to access the following features through the browser of the

personal device (PC, smartphone, etc.).

PRINTER DATA

The “home page” (accessible by clicking on the olivetti3D logo in the menu line) shows the main data of

the printer (Firmware Version, Wi-Fi Version, Serial Number) and other information regarding the use of

the printer (Power-on Time, Printing Time, meters of extruded filament).

Figure 4-8 Browser screen – Home Page

WI-FI MODE SELECTION

By clicking on the word "Wi-Fi" in the Menu line, the screen shows the selection of the Wi-Fi operating

mode (AP Access Point / STA Station Mode), for which please refer to the previous paragraphs.

Figura 4-9 Browser screen – Wi-Fi mode selection - Access Point (AP) / Station Mode (STA)

Page 59

596806-02 User Manual 4-7

PRINTER COMMANDS

By clicking on the word "Moves" in the Menu line, the screen shows the current parameters of the printer

(temperature of the extruder and bed, flow, speed, etc.), and further down the commands to move the

axes and to set the parameters.

The commands available are different depending on whether the printer is in stand-by or during printing:

commands available on standby:

o movement of the axes (auto-home and movement)

o parameter setting during stand-by (extruder and bed temperature, speed, flow, etc.)

Figura 4-10 Browser screen – “Moves” window during stand-by

Page 60

4-8 User Manual 596806-02

commands available during printing:

o set of the parameters related to the print (extruder and bed temperature, speed, flow, etc.)

Figura 4-11 Browser screen – “Moves” window during printing

Page 61

596806-02 User Manual 4-9

SD MENU

By clicking on the word “SD” in the Menu line, the screen shows the SD card contents.

Durting the stand-by, the available commands are the following:

a. select one of the gcode files saved on the SD card and start printing it, by clicking on the "print"

command (which appears once the file is selected)

b. upload a file to the SD card, using the "Select file" command or the "Drag & Drop" mode (ie by

dragging it from a PC folder)

c. delete a file by pressing the trash symbol next to the file name

Figura 4-11 Browser screen – “SD” window during stand-by

During printing, no command can be selected from this screen.

Page 62

4-10 User Manual 596806-02

This page is intentionally left blank

Page 63

596806-02 User Manual A-1

Appendix A – Olivetti 3D IoT Labels

Label positions and meanings

Figure A-1 Front labels

SYMBOL

COLOUR

MEANING

MEANING

TRIANGLE

YELLOW

DANGER

HOT SURFACES

CIRCLE

BLUE

FOLLOW

PROVISIONS

USE GLOVES

CIRCLE

BLUE

FOLLOW

PROVISIONS

READ INSTRUCTIONS

BARRED CIRCLE

RED

PROHIBITED

DO NOT REMOVE GUARDS

Page 64

A-2 User Manual 596806-02

Figure A-2 Internal labels lower side

SYMBOL

COLOUR

MEANING

MEANING

TRIANGLE

YELLOW

DANGER

PINCHING

TRIANGLE

YELLOW

DANGER

MOVING PARTS

Figure A-3 Extruder assembly label

SYMBOL

COLOUR

MEANING

MEANING

TRIANGLE

YELLOW

DANGER

HOT SURFACES

Page 65

596806-02 User Manual B-1

Appendix B – Olivetti 3D IoT printer care and maintenance

Cleaning the printing table

When printing completes and after removing the printed piece, you are advised to clean the printing table so as

to eliminate any lacquer or plastic residues that may be present.

To clean the table you can use household ethyl alcohol and a soft dry cloth.

The use of degreasers or similar liquids, which could alter the surface in PEI and compromise the adhesion of

the printed objects, is not recommended.

Alternatively, you can also clean the table after first removing the glass from the printer. To do this, follow these

steps:

lower the table using this sequence:

1. Starting from the Desktop screen, press the Menu key then the Prepare key in the next screen.

Figure B-1 From the Desktop Menu, select Menu then Prepare

2. From the Prepare Menu, select the Move command.

Figure B-2 Prepare Menu with Move command

3. In the Move menu, set the following values for the movement parameters:

DISTANCE (mm): 100

SPEED (mm/sec): 500

ACCELERATION (mm/sec2): 12

Page 66

B-2 User Manual 596806-02

4. Press the RIGHT arrow on the Z row to lower the table:

Figure B-3 Z axis Move command

when the table has completed its movement, detach the four clamps by pressing lightly on their metal

wings.

after removing the clamps, lift the glass table and remove it altogether from the printer. If the glass is

partially glued to the underlying resistance, lift with greater force, but taking care not to damage the

resistance

clean the top side of the table (PEI surface) using household ethyl alcohol and a soft dry cloth.

To clean the reverse side of the table (glass surface), it’s advisable to use a degreaser.

at the end, dry the table with a dry cloth and reinstall it on the printer, securing it with the special clamps

MAKE SURE NOT TO PUT THE TABLE BACK UPSIDE DOWN (ON THE TOP SIDE THERE IS A FILM IN

PEI THAT MUST NOT BE REMOVED)

NOTE: The printing table is made of tempered glass, 4 mm thick. While it is a safe heat-resistant material it

is still very fragile so you must be very careful when manipulating it. Always use exclusively the glass supplied

with your printer.

Lubricating the axes and the spindle nut

The linear guides are lubricated by the grease present in the recirculating ball slide guides.

The bearings can be injected with lithium-based machine grease through the hole on the side of the guide. In

this way, the grease penetrates inside the ball recirculation camera lubricating both the guide and the bar. You

are advised also to spread a little grease on the recesses at the sides of the guides using a clean dry cloth.

The operation of the spindle nut is based on a recirculating ball screw mechanism, which therefore assures long

resistance to wear over time. To maintain noise levels low and improve operating smoothness, apply a little

grease to the spindle nut using a clean dry cloth

WARNING: Use only lithium-based grease. Solid lubricants, such as those based on molybdenum

disulphide, must not be used.

Page 67

596806-02 User Manual B-3

Cleaning the feeder

The feeder normally does not need to be serviced, however, from time to time, it may be opportune to clean the

filament feeder assembly, removing the plastic residues that accumulate during printer operation.

To remove plastic dust residues, use a small brush starting from the front slot of the feeder.

A fast efficient method is to use a jet of compressed air either from an air compressor or compressed air can,

such as normally used for cleaning keyboards and electronic equipment.

Page 68

B-4 User Manual 596806-02

Replacing and cleaning the printing nozzle

Whenever you change the printing material it is advisable to replace the printing nozzle also.

To replace the nozzle the extruder must be hot - at its operating temperature - so that any residual material

within the head softens and does not obstruct the replacement operation.

WARNING: during operations always wearing safety gloves for heat protection.

To replace the printing nozzle:

1. Maintain the hot-end block still using a 12 mm hex wrench.

2. Unscrew the nozzle using the 10 mm hex wrench.

3. Wrap Teflon tape three times around the thread of the new nozzle taking care not to obstruct the hole

through which the filament must extrude.

4. Mount the new nozzle.

5. Perform the printing height calibration procedure as described in the section “Adjusting the printing nozzle

height”.

Figure B-4 Preparation the new printing nozzle

Under normal conditions nozzle cleaning is not normally required. However, should it become necessary, you

can unmount the nozzle as described previously and clean it using a pin having a diameter smaller than that of

the nozzle.

Page 69

596806-02 User Manual C-1

Appendix C – Electrical Diagram

Figure C-1 Electrical diagram

Page 70

C-2 User Manual 596806-02

This page is intentionally left blank

Page 71

596806-02 User Manual E-1

Appendix D - Olivetti 3D IoT printer-compatible materials

The Olivetti 3D IoT printer can be used for printing filaments composed of the materials below.

PLA

Polylactic Acid is a Biopolymer of vegetable origin, completely recyclable, with great versatility and good

mechanical and elastic properties.

Its shiny finish makes it ideal for producing stylish objects with a pleasant feel. Its excellent resistance to

ultraviolet light prevents variations in colour otherwise caused by fading. A simple material to print, it is also easy

to sand.

This very versatile material can be used in many fields of application, and is particularly suitable for

producing aesthetically attractive objects of precise dimensions with a glossy surface.

PLA RENEGADE

PLA Renegade is a filament in Loaded Polylactic Acid used in 3D printing. This very versatile Biopolymer of

vegetable origin has good mechanical and elastic properties, and can be used for producing objects with an

excellent printing quality.

Its shiny finish and natural properties render the superimposition of layers almost invisible, making it ideal for

producing objects with great aesthetic qualities and that are also pleasant to the touch.

Its optimal resistance to ultraviolet light prevents variations in colour. Simple to print it can also be sanded.

Unlike Standard PLA, PLA Renegade has excellent heat resistance combined with great mechanical

strength - comparable to those of ABS

PLA LAYER

Loaded Polylactic Acid is a very versatile Biopolymer of vegetable origin having good mechanical and elastic

properties.

With a shiny finish and natural properties able to render the superimposition of layers almost invisible, it is ideal

for producing aesthetically-pleasing objects that are pleasant to the touch.

Its optimal resistance to ultraviolet light prevents variations in colour. Simple to print it can also be sanded.

Different to standard PLA, PLA Layer has optimal heat resistance and greater mechanical strength.

PLA ENDURANCE

Loaded Polylactic Acid is a very versatile Biopolymer of vegetable origin having good mechanical and elastic

properties.

The PLA Endurance special formulation makes it especially fluid and smooth when printing, eliminating the risk

of nozzle clogging and retraction problems during high speed printing. Therefore PLA Endurance is a material

particularly useful for medium / long lasting prints and in all cases in which the printer is to be used at a particularly

high speed.

ABS-OL

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer, with good properties in impact resistance and

toughness, used largely for mechanical purposes

Thanks to its particular composition, the ABS-OL minimizes warping, optimizes the adhesion to the printing bed

and allows an excellent interlayer adhesion.

This is a versatile material that can be used in many fields of application, especially for producing strong objects

that require a high impact tolerance.

WOOD

Polylactic Acid contains 46% wood dust. This filament finds innumerable applications in differing fields of design.

Easily printable, it has a really wood feel, even its odour. Excellent workability post-printing.

CARBONIUM

Carbonium is a filament made of polyamide loaded with carbon microdust.

Carbon, apart from creating a fibre effect, also confers greater mechanical strength, resilience and elasticity with

higher resistance to mechanical fatigue.

Page 72

E-2 User Manual 596806-02

Ideal for anyone needing to produce pieces with mechanical strength. Post-printing workings are fast and

simple. An ideal material for use in the automotive sector to create application accessories featuring lightness

combined with resilience.

N.B.: the Ruby nozzle must be used for printing with Carbonium filament - to be ordered separately

RUBBER HS

Rubber HS Rubber HS is a high-quality elastomer supplied as a 3D filament, with optimal flexural

properties, great tensile strength and high-level aesthetic results.

It’s the ideal material for all industrial and design sectors which need a material that combines optimally

flexibility, resistance and aesthetic quality.

Rubber HS may come in contact with food, having been successfully tested according to Regulation

10/2011 / EU (on plastic materials and articles intended to come into contact with food).

More information on these materials can be found on the Olivetti 3D site (www.olivetti3d.com)

Page 73

596806-02 User Manual E-1

Appendix E - SD Card Contents

On the SD Card supplied with the printer, in addition to this User Manual, the following files are also provided:

PRINTING TEST FILES

3DBenchy, in .stl and .gcode formats

Cubo-test in .stl and .gcode formats

Gecko, in .stl and .gcode formats

Spiral-vase, in .stl and .gcode formats

Charles Darwin, in .stl e .gcode formats

Printable file description_3D IoT.pdf, short document which describes the above mentioned printing

files

.gcode files are especially profiled to be printed with the Blue PLA supplied with the 3D IoT printer

FILES FOR PRINTING ADDITIONAL COMPONENTS

“forcella.stl”, fork to print and insert (optionally) onto bobbin holder screw to reduce horizontal

movements of bobbin during printing operations (see figure 2-12)

SETUP FILES

Olivetti 3DIoT nz04 v1.0.fff”, default profile for Simplify 3D software.

Page 74

E-2 User Manual 596806-02

This page is intentionally left blank

Page 75

F-1 User Manual 596806-02

Appendix F EU Declaration of Conformity

Olivetti declares that the radio equipment 3D IoT Printer is in compliance with Directive

2014/53/EU.

The full text of the EU declaration of conformity is available at the following address:

https://www.olivetti.com/en/support/download-area

Transmitter module (Wi-Fi) Operating frequency : 2412 - 2472 MHz

Maximum output power : +16dBm

Page 76

F-2 User Manual 596806-02

This page is intentionally left blank

Page 77

596806-02 User Manual G-1

Appendix G Product disposal Information

Pursuant to Directive 2012/19/EU relating to the disposal of waste electrical and electronic equipment.

1. EUROPEAN UNION (EU) COUNTRIES

It is prohibited to dispose of any electrical or electronic equipment as solid urban waste: separate

collection methods must be used. Abandoning such equipment in locations that are not specifically

designed and authorised for this purpose can be dangerous both for the environment and public

health. Offenders will be subject to the penalties and measures laid down by Law.

TO CORRECTLY DISPOSE OF OUR EQUIPMENT:

a) Contact your Local Authorities who will be able to provide you with instructions and practical advice

on correct waste management, for example: location and opening times of waste disposal centres,

etc.

b) When purchasing a piece of new equipment from us, you can consign your used equipment, of the

same type purchased, to our Reseller

The crossed out wheelie bin symbol that appears on equipment signifies that:

- When the equipment has reached its end of life, it must be taken to a specially equipped

disposal station where it will be processed separately from urban waste;

- Olivetti - a company registered in the Producers of Electrical and Electronic Equipment

register - declares that it has activated the procedures for the collection, treatment,

recycling and disposal of the equipment in conformity with the provisions of Directive

2012/19/UE.

2. OTHER (NON EU) COUNTRIES

The treatment, collection, recycling and disposal of electrical and electronic equipment must be carried

out in compliance with the laws in force in each Country.

DIRECTIVE 2006/66/EC ON BATTERIES AND ACCUMULATORS AND ON WAIST BATTERIES

AND ACCUMULATORS

Applicable in European Union countries and in other countries with recycling collection systems.

The symbol shown on batteries, on their packaging or on their documentation means that

the batteries supplied with the product must not be disposed of as solid urban waste, but

must be collected separately. Take used batteries to the authorised recycling centres.

Improper disposal could have dangerous effects on the environment and on health.

When any of the chemical symbols Hg (mercury), Cd (cadmium) or Pb (lead) are present, they indicate

that the battery contains a higher quantity of the related substance than stipulated in the directive.

Loading...

Loading...