Page 1

Soldering, Desoldering and Rework

OK

O K I N T E R N A T I O N A L

T M

Page 2

T o o l s f o r T e c h n o l o g y

International has been a leading manufacturer of tools for the electronics

OK

changing, our soldering, desoldering and rework systems have evolved from the old Metcal

brand to keep up with lead-free processes and the demand for fast, yet high performance.

Our new line of soldering, desoldering and rework systems features the OK International

brand logo.

These new systems are high-performance, yet competitively priced. Our Multi-function

Rework Systems (MFR) are versatile tools that not only expertly perform rework, they also

have tools for SMT and through-hole soldering. The PS-800 Soldering System is the perfect

compact system for repetitive manual soldering and touch-up. And, the new HCT-900 Hand

Held Convection Tool is ideal for removing components from 0201 up to 304 pin QFP, as well

as reworking through-hole devices such as sockets and connectors.

Our new soldering, desoldering and rework systems are part of our family of complimentary

products that also includes advance package rework, benchtop fume extraction and fluid

dispensing systems. Our systems are all developed to incorporate innovative designs,

professional performance and ease of use.

assembly work bench for almost 60 years. As the industry has been rapidly

Known. Trusted. Quality. That's OK In ternational. Wit h decades of exper ience we a re

committed more than ever to provide customer driven solutions and the reliable products

you demand.

Page 3

Page

SmartHeat Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

MFR Series Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MFR-SRC Soldering & Rework System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MFR-PST Production Soldering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

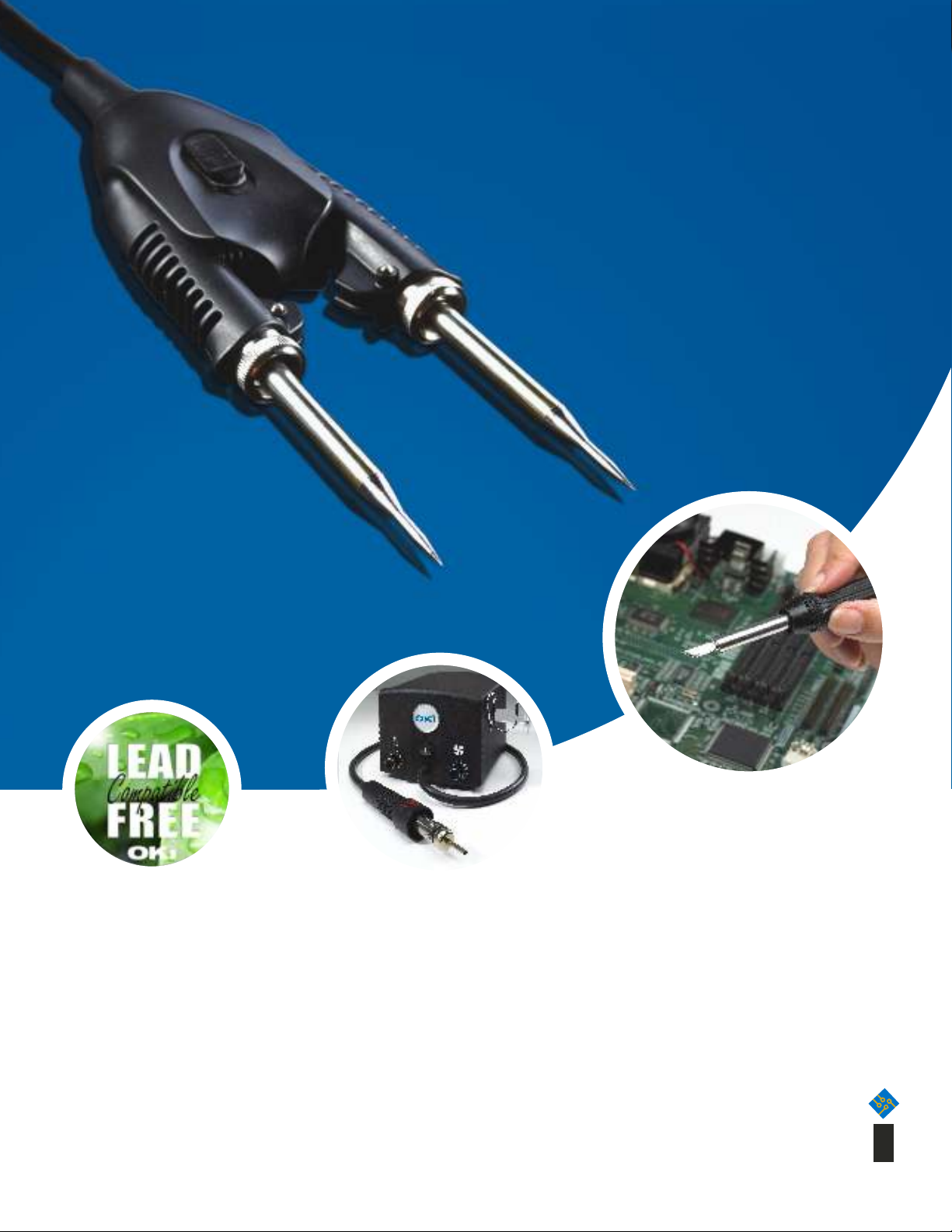

MFR-PTZ Precision Tweezer, Soldering & Rework System. . . . . . . . . . . . . . . . . . . . . . . . . 8

MFR-STZ Tweezer, Soldering & Rework System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hand-piece Upgrade Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MFR Desoldering Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Standard Tip Cartridges for Soldering & Rework System . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rework Cartridges for Soldering & Rework System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Desoldering Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Precision Tweezer Cartridges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Standard Tweezer Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

®

T a b l e o f C o n t e n t s

Power Tips for Production Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Accessories & Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PS-800 Soldering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

HCT-900 Hand Held Convection Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Product Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1

Page 4

S m a r t H e a t T e c h n o l o g y

SmartHeat Technology

®

®

Savvy electronic production engineers define

success by how they maximize their

productivity, yield, and product reliability. All

of these factors depend directly upon process

control. To achieve success, OK International

has developed SmartHeat conduction

soldering systems which uniquely sense the

exact thermal requirement for each solder

joint and respond by delivering the precise

amount of thermal energy at the rate required

to create a reliable connection. The result is a

high degree of control without resorting to

higher tip idle temperatures required by

conventional ceramic heater technologies.

Consequently the risk of component / board

damage is minimized, especially important

with the greater thermal demands required by

lead-free applications.

®

As you'll see below, SmartHeat provides

unique benefits in the delivery of high

reliability low risk conduction soldering

solutions, especially with lead-free alloys. All

of these add up to provide a highly consistent

level of process control.

®

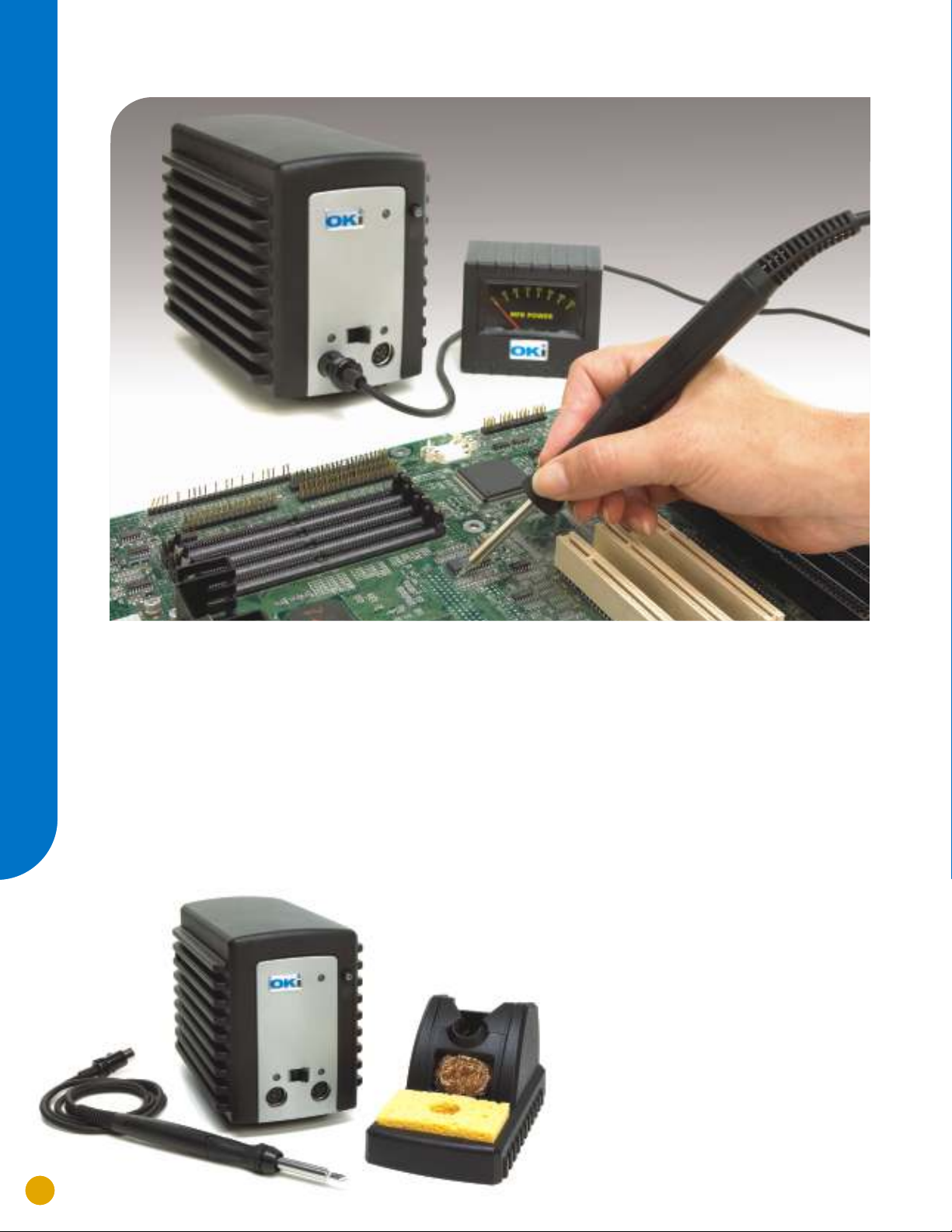

SmartHeat® Delivers Direct Power

First and foremost, the success of conduction soldering depends upon the

availability and controlled flow of thermal energy into the connection during

the two critical phases flux activation and intermetallic bond formation. Lead-

free alloys, with higher thermal demands, further heighten these

requirements. Conventional ceramic heaters attempt to control this process

by managing indirect parameters, such as the tip idle temperature. In contrast, SmartHeat technology senses the specific

thermal demand directly at the solder pad and delivers the precise quantity and flow of thermal energy during both phases to

ensure a reliable connection.

®

Powered by

SmartHeat

®

Precision Tip Selection – The Conductivity Factor

During the execution of a successful soldering

connection, the tip is the thermal energy “highway”

from the heater to the pad and, therefore, the choice

of tip geometry is critical to prevent power losses. In

addition to providing the most thermally efficient tip

designs, OK International has pioneered the tip

“Conductivity Factor” rating system providing

operators with quantifiable guidance in the selection

of the optimum tip geometry. Additionally, our

proprietary Power Meter can quantify exact pad

energy requirements, further refining the tip selection

process. Lead-free alloys, with tighter thermal

demands, make these tools mandatory.

> >

T h e r m a l P e r f o r m a n c e

637A 670A 642A

637A 670A 642A

CF=.89

CF=.50 CF=.25

Heavy

Light

2

Page 5

Temperature Stability – No Need for Calibration

Nearly all industry

standards associated with

CERAMIC HEATER

TECHNOLOGY

conduction soldering

performance cite

temperature stability as a

key requirement. To meet

C

D E G

5

+ / -

SMARTHEAT

TECHNOLOGY

the demands of

temperature stability,

conventional ceramic

heater systems depend on

the sensor, heater and

3 MOS 6 MOS 9 MOS 12 MOS

operator set point controls.

Each of these elements is

subject to drift and instability requiring frequent calibration and certification to ensure compliance. By contrast, the repeatability of

SmartHeat technology is inherently determined by the molecular properties of the heater material and does not shift over time,

®

ensuring long term stability without the need for calibration.

Reduced Risk of Overshoot

Conventional soldering stations strive to control the process with tip temperature using thermocouple sensors and ceramic

heaters. Inherent with this technology will be significant temperature variances throughout the tip body and consequently thermal

overshoot/undershoot. The risk is unreliable solder connections or damaged components. SmartHeat technology, on the other

hand, detects and controls the energy requirement of the pad, avoiding thermal delivery variances thereby eliminating the risk of

component damage.

®

®

S m a r t H e a t T e c h n o l o g y

Perfect for Lead-Free

The steps required for reliable lead-free

connections parallel those for traditional

alloys except that the thermal demands

are greater. The typical operator response

to the higher thermal demand is to

increase tip idle temperature,

unfortunately at higher temperatures the

contribution to thermal performance is

negligible. More importantly, the increase

in tip idle temperature comes dangerously

close to component and substrate

damage levels making process control

critical. Compared to conventional

technology, SmartHeat , combined with

®

°C

400

350

300

OPTIMUM REFLOW ZONE

250

LOW ENERGY FAIL ZONE

200

FLUX ACTIVATION ZONE

150

100

50

0

P S

Pb-Sn vs. SAC Process Window

FR-4 PAD DELAMINATION ZONE

EXCESSIVE ENERGY FAIL ZONE

OPTIMUM REFLOW ZONE

LOW ENERGY FAIL ZONE

FLUX ACTIVATION ZONE

n

b-

CA

S

Solder Melting Temperature

our Precision Tip Selection tools delivers precise process control assuring consistently reliable connections at low operating

temperatures which provide the thermal performance necessary for lead-free.

Increase Tip Life and Value

The useful life of a tip is dependent upon many factors including flux corrosion, oxidation and tin dissolution. With higher tip idle

temperatures, the contribution from these factors is dramatically increased. The resultant de-wetting from these chemical surface

interactions causes many operators to increase tip force, which significantly accelerates tip life deterioration. With the advantages

of SmartHeat technology operators can solder at lower temperatures and, combined with proper tip selection and care,

dramatically extend tip life and value.

®

3

Page 6

M F R S e r i e s M u l t i F u n c t i o n R e w o r k S y s t e m s

MFR Multi Function Rework Systems

The All in One Solution

Imagine performing all of your production soldering, rework and desoldering tasks with just one tool. The new Multi Function

Rework Systems (MFR) not only expertly perform rework, they also have tools for SMT and through-hole soldering. These flexible

systems feature two switchable outputs with a comprehensive choice of tools that support today's complex PCB and component

technologies.

Systems are configured with the following tools:

Soldering and Rework Production Soldering Adjustable Desoldering Hand-Piece

Standard Tweezer Precision Tweezer

Perfect for Lead-Free

The MFR Series uses SmartHeat Technology to

deliver the power required for lead-free

connections. SmartHeat Technology’s variable

power instantaneously senses and continuously

delivers the precise thermal energy to the pad,

yielding high quality solder joints while protecting

sensitive components from damage.

®

®

4

Page 7

Tip and Cartridge Options

With the MFR Series you can use heater tips or tip cartridges,

each filling a specific need. Heater tips are cost effective to meet

the demands of point to point, production soldering. While tip

cartridges are suited for high performance and rework

applications. Both options incorporate the popular quick change

design OK tips are well known for, which eliminates the

maintenance associated with traditional irons. The OK cartridge

tip has the slimmest diameter allowing access to the tightest

applications and its single piece design provides a secure

ground connection protecting sensitive components.

Versatility, Performance and Value

These high performance systems can be adapted to your exact

needs, whether it is cost effective production soldering, more

complicated rework with cartridges, handling small components

with the unique Precision Tweezer hand-piece or performing

through-hole desoldering.

All units include "Auto Standby" and "Auto Off" functions which

can be programmed to activate on different timing to help save

tip life, especially when working on a lead-free process.

Proprietary built-in motion detection then brings the unit back to

life when the operator lifts the hand-piece from the cradle. In

addition, a specially designed lead-free workstand provides

efficient tip cleaning and maintenance options.

And, when multiple units are used on the same bench or for the

same process, smart mechanical design allows for the units to

be interlocked, maximizing bench space.

Comfort and Simplicity

The short tip-to-grip distance of the MFR hand-piece improves

process precision for fine pitch applications. The cartridge

system provides the slimmest shaft for maximum access whilst

the precision tweezer design enables rework of the smallest

chips and resistors, such as 0201 chips. Ergonomic design

delivers superior performance with operator comfort and control.

M F R S e r i e s M u l t i F u n c t i o n R e w o r k S y s t e m s

5

Page 8

M F R S o l d e r i n g a n d R e w o r k S y s t e m

Soldering and Rework System

Cartridge heater technology provides soldering and rework performance to suit even the most demanding SMT removal and

placement applications. The cartridges provide fast thermal performance and respond quickly to the load demands. A small shaft

diameter provides access to tightly cramped rework areas and enables the most difficult operations to be performed effortlessly.

MFR-SRC Soldering & Rework System

Part No.

MFR-SRC

Includes

MFR-PS1K

MFR-HSR

MFR-WSSR

Description

Soldering and Rework System

Two Port Universal Voltage Power Supply

Soldering and Rework Hand-piece

Soldering Workstand

Contents of this brochure subject to change without notice

6

Page 9

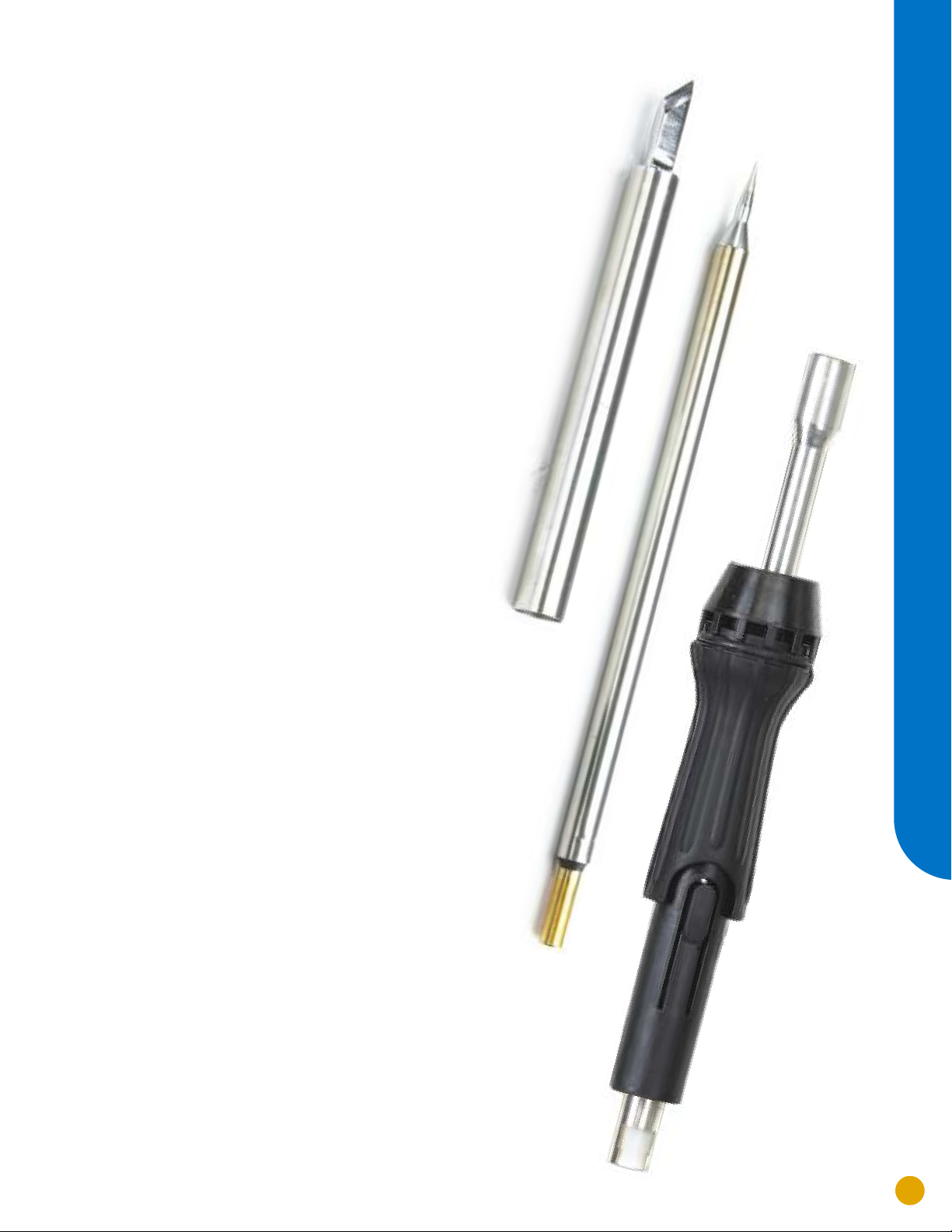

Production Soldering System

The Production Solder Tip System is designed for production soldering applications where superior SmartHeat Technology is

needed to provide the performance for lead-free, but with a lower cost of ownership due to the innovative tip design. The two-

piece, long life heater and cost effective tip design provide a viable production alternative for regular and lead-free soldering.

®

MFR-PST Production Soldering System

Part No.

MFR-PST

Includes

MFR-PS1K

MFR-HPS

MFR-WSSR

Description

Production Soldering System

Two Port Universal Voltage Power Supply

Production Soldering Hand-piece and Coil Assembly

Soldering Workstand

M F R P r o d u c t i o n S o l d e r i n g S y s t e m

7

Page 10

M F R P r e c i s i o n T w e e z e r S y s t e m

Precision Tweezer, Soldering and Rework System

The Precision Tweezer has been ergonomically designed to be lightweight and easy to use for removing even the smallest of

discrete components, such as 0201 packages. The Precision Tweezer has a double sided pivot for “true tweezer” action and a dual

position pitch adjustment to help the operator target the component to skillfully complete the application.

MFR-PTZ Precision Tweezer, Soldering &

Rework System

Part No.

MFR-PTZ

Includes

MFR-PS1K

MFR-HPT

MFR-WSPT

MFR-HSR

MFR-WSSR

Description

Precision Tweezer, Soldering and Rework System

Two Port Universal Voltage Power Supply

Precision Tweezer Hand-piece

Tweezer Workstand

Cartridge Solder / Rework Hand-piece

Soldering Workstand

Contents of this brochure subject to change without notice

8

Page 11

Tweezer, Soldering and Rework System

M F R T w e e z e r S y s t e m

This combination system offers flexibility with

the rework versatility of the Solder/Rework

Cartridge Hand-piece with a standard

tweezer system for discrete and SO

symmetrical components

Part No.

MFR-STZ

Includes

MFR-PS1K

MFR-HSR

MFR-WSSR

MFR-HST

MFR-WSPT

Tweezer, Soldering and Rework System

Two Port Universal Voltage Power Supply

Soldering & Rework Hand-piece

Soldering Workstand

Standard Tweezer Hand-piece

Tweezer Workstand

Upgrade Kits

Add versatility to your MFR System. Hand-piece Upgrade Kits can be ordered

to compliment any of the MFR Systems. Kits include both the hand-piece and

workstand.

Description

Part No.

MFR-STZ-AD

MFR-SRC-AD

MFR-PTZ-AD

MFR-PST-AD

Note: Tips and cartridges are not included and need to be ordered separately.

Description

Standard Tweezer Upgrade Kit, hand-piece and workstand

Solder / Rework Cartridge Upgrade Kit, hand-piece and workstand

Precision Tweezer Upgrade Kit, hand-piece and workstand

Production / Solder Tip Upgrade Kit, hand-piece and workstand

9

Page 12

M F R D e s o l d e r i n g S y s t e m s

Versatile Pencil and Pistol Grip

Combination Hand-piece System

The MFR Desoldering Systems provides superior thermal transfer

to the joint, effectively reflowing the solder and then quickly and

efficiently removing all solder. SmartHeat Technology makes

through-hole desoldering easy and safe from board damage. The

state-of-the-art hand-piece can be adjusted from a pencil to a gun

with a simple press of a button. Operators can find the most

comfortable and efficient position to tackle the rework challenge.

The paper solder collection chamber and filter system is quick and

easy to change, and provides low cost maintenance.

Two MFR Desoldering Systems are available. The MFR-DSX

system requires shop air for desoldering. If shop air is not

available, the MFR-DSI features an internal vacuum pump.

®

Part No.

MFR-DSX

MFR-DSI

System Includes

Complete MFR System for Soldering,

Desoldering and Rework

The MFR Solder / Desoldering Systems include both the

innovative desoldering hand-piece and the solder/rework

cartridge hand-piece to cover all your rework needs.

Two MFR Soldering / Desoldering Systems are available.

The MFR-SDX system requires shop air for desoldering. If

shop air is not available, the MFR-SDI features an internal

pump that provides suction.

MFR-PS2X

MFR-PS2K

MFR-HDS

MFR-WSDS

Description

Desolder System, External Air

Desolder System, Internal Air Pump

Two Port Universal Voltage Power Supply,

External Air (MFR-DSX only)

Two Port Universal Voltage Power Supply,

with Internal Air Pump (MFR-DSI only)

Desolder Hand-piece

Desolder Workstand

10

Part No.

MFR-SDX

MFR-SDI

Systems Include

MFR-PS2X

MFR-PS2K

MFR-HSR

MFR-WSSR

MFR-HDS

MFR-WSDS

Note: Tips and cartridges are not included and need to be ordered separately.

Description

Solder / Desolder System, External Air

Solder / Desolder System, Internal Air Pump

Two Port Universal Voltage Power Supply External Air (MFR-SDX only)

Two Port Universal Voltage Power Supply with

Internal Air Pump (MFR-DSI only)

Soldering and Rework Hand-piece

Soldering Workstand

Desoldering Hand-piece

Desoldering Workstand

Contents of this brochure subject to change without notice

Page 13

Soldering Tip Heater Options

With hand soldering, the task is to make a quality solder connection, without damaging the substrate and without negatively impacting

throughput. All of the standard MFR Series power tips & rework cartridges are designed for use with glass fiber (FR4) PCB substrates.

This is denoted by the second letter in the part number: “F”. For example: SFP-CH10, DFP-CN3, and SFV-CNL10.

However, some specialist applications require working with thermally demanding or temperature sensitive substrates, such as ceramic

hybrids or flexible circuits. OK International has developed specialty heaters that quickly deliver the necessary power, but operate at

temperatures that minimize the risk of substrate damage. These are denoted by replacing the "F" in the part number with a "T" for

temperature sensitive or a "C" for demanding loads. Please contact your local representative for information and availability of specialty tip

heaters. For example: STP-CH10 and DCP-CN3.

= Standard FR4 Substrate

F

= Temperature Sensitive

T

= Ceramic or Heavy Load

C

Standard Soldering Tip Cartridges

The Standard Soldering Tip Cartridges are used with the MFR-HSR Soldering & Rework Hand-piece and have been designed to deliver

outstanding performance for the majority of point-to-point soldering and basic rework applications. The geometries within the range have

been optimized to deliver maximum accessibility combined with optimal thermal efficiency within a narrow cartridge diameter

0.04"

1.0mm

0.04"

1mm

0.06"

1.5mm

0.08"

2.0mm

0.1"

2.5mm

0.06"

1.5mm

0.2"

5mm

0.56"

14.22mm

10.0mm

7.6mm

0.474"

12.04mm

0.36"

9.2mm

0.39"

10mm

0.4"

.394"

10mm

0.3"

0.6"

0.59"

0.6"

0.2"

4.95mm

F F

S P-BVL10 S P-CN05

Bevel Cartridge, Conical Cartridge,

60° 1.0mm (.04") 0.5mm (.02")

F F

S P-CH10 S P-CNB04

Chisel Cartridge, Conical Cartridge Bent,

30° 1.0mm (.04") 0.4mm (.016")

F F

S P-CH15 S P-CNB05

Chisel Cartridge, Conical Cartridge Bent,

30° 1.5mm (.06") 0.5mm (.02")

F F

S P-CH20 S P-CNL04

Chisel Cartridge, Conical Cartridge Long Reach,

30° 2.0mm (.08") 0.4mm (.016")

F F

S P-CH25 S P-DRH05

Chisel Cartridge, Drag Soldering Cartridge, Hoof

30° 2.5mm (.10") 0.5mm (.02")

F F

S P-CH50 S P-DRH15

Chisel Cartridge, Drag Soldering Cartridge, Hoof

1.5mm

0.06"

30° 5.0mm (.20") 1.5mm (.06")

F F

S P-CHB15 S P-DRH35

Chisel Cartridge, Drag Soldering Cartridge, Hoof

0.14"

3.5mm

30° Bent 1.5mm (.06") 3.5mm (.14")

0.016"

0.4mm

0.016"

0.4mm

0.5mm

0.02"

0.5mm

0.02"

30°

0.02"

0.5mm

15.21mm

.579"

14.7mm

14.9mm

15.21mm

16.5mm

0.65"

.70"

17.78mm

S o l d e r i n g T i p C a r t r i d g e s

0.2"

5.0mm

0.63"

16mm

F

0.08"

2.0mm

0.016"

0.4mm

.632"

16.04mm

0.34"

8.6mm

F F

S P-CHL20 S P-DRK50

Chisel Cartridge, Drag Soldering Cartridge, Knife

60° Long Reach 2.0mm (.08") 5.0mm (.20")

F

S P-CN04

Conical Cartridge,

0.4mm (.016")

To order specialty versions of the Soldering Tip Cartridges replace the " " in the part number with the appropriate letter designate for

your application when ordering: = Temperature Sensitive, = Ceramic or Heavy Load

T C

Dimensions and artwork listed are for indication/guidance only. Numbers have been rounded up.

Please contact your local technical support if you require specific technical information.

11

Page 14

S o l d e r i n g T i p s a n d C a r t r i d g e s

Rework Cartridges

The Rework Cartridges are used with the MFR-HSR Soldering & Rework Hand-piece for conduction rework of surface mount components.

The geometries are compatible with common SMT Chip and SOIC components.

.36"

.02"

0.5mm

.02"

0.5mm

.02"

0.5mm

9.14mm

9.14mm

9.14mm

.36"

.36"

.41"

10.4mm

.62"

15.6mm

.87"

22.1mm

.127"

3.22mm

.204"

5.18mm

.17"

4.32mm

To order specialty versions of the Rework Cartridges replace the " " in the part number with the appropriate letter designate for your

application when ordering: = Ceramic or Heavy Load

C

F F

R P-BL1 R P-DL2

Blade Cartridge, Tunnel Cartridge,

10mm (0.4") SOIC 8 Chip Package

F F

R P-BL2 R P-SL1

Blade Cartridge, Slot Cartridge,

16mm (0.63") 0805 Chip Package

F F

R P-BL3 R P-SL2

Blade Cartridge, Slot Cartridge,

22mm (0.87") 1206 Chip Package

F

R P-DL1

2.29mm

.204"

5.18mm

1.78mm

.092"

2.34mm

1.78mm

.137"

3.48mm

.09"

.07"

.07"

Tunnel Cartridge,

SOIC 14-16 Chip Package

F

.17"

4.32mm

.20"

5.07mm

.20"

5.07mm

Desoldering Tips

The Desoldering Tips are used with the MFR-HDS Desoldering Hand-piece, primarily for solder removal on through-hole components. The

tips are supplied in a range of diameters as well as in a long reach configuration to allow improved access on tightly packed PCBs.

Part Number Description Ø A mm (in) Ø B mm (in)

F

D P-CN2 Desolder Tip 0.67mm (.026”) 1.80mm (.070”)

Regular

F

D P-CN3 Desolder Tip 0.79mm (.031”) 2.05mm (.080”)

F

D P-CN4 Desolder Tip 1.05mm (.041”) 2.30mm (.090”)

Long Reach

Outer Tip Ø B

Internal Hole Ø A

F

D P-CN5 Desolder Tip 1.31mm (.052”) 2.65mm (.104”)

F

D P-CN6 Desolder Tip 1.55mm (.061”) 2.85mm (.112”)

F

D P-CN7 Desolder Tip 2.44mm (.096”) 3.65mm (.143”)

F

D P-CNL3 Desolder Tip Long Reach 0.79mm (.031”) 2.05mm (.080”)

F

D P-CNL4 Desolder Tip Long Reach 1.05mm (.041”) 2.30mm (.090”)

12

D P-CNL5 Desolder Tip Long Reach 1.31mm (.052”) 2.65mm (.104”)

F

To order specialty versions of the Desoldering Tips replace the " " in the part number with the appropriate letter designate for your application

when ordering: = Ceramic or Heavy Load

C

Dimensions and artwork listed are for indication/guidance only. Numbers have been rounded up.

Please contact your local technical support if you require specific technical information.

F

Page 15

Precision Tweezer Cartridges

The Precision Tweezer Cartridges are supplied in pairs to be used in the MFR-HPT

Precision Tweezer Hand-piece for conduction rework of very fine surface mount chip

components.

.55"

0.76mm

0.76mm

2.0mm

.015"

.38mm

.03"

.04"

1.0mm

.03"

.079"

14mm

.55"

14mm

.75"

19.1mm

F

T P-BLP1

Tweezer Cartridge,

Blade 1.0mm (0.04") Pair

F

T P-BLP2

Tweezer Cartridge,

Blade 2.0mm (0.08") Pair

F

T P-CNP1

Tweezer Cartridge,

Conical 0.4mm (.015") Pair

Standard Tweezer Cartridges

The Standard Tweezer Cartridges are supplied in pairs and are designed to work with the MFR-HST Standard Tweezer Hand-piece for

conduction removal of two sided surface mount components. The geometries are specifically designed for larger SMT Chip and Dual in-line

SOIC components. All tweezer cartridges are sold in pairs.

.55

"

14mm

Fine Point Tip

F

T P-BLH3 Tweezer Heavy Duty Cartridge, 2.0mm (0.08") Pair

F

T P-BLH4 Tweezer Heavy Duty Cartridge, A = 6.35mm (.25") Pair

F

T P-BLH5 Tweezer Heavy Duty Cartridge, A = 16mm (.62") Pair

F

T P-BLH6 Tweezer Heavy Duty Cartridge, A = 20.5mm (.81") Pair

A

0.028

0.57mm

"

0.055

1.4mm

0.03

0.76mm

0.08

2.0mm

"

"

"

T w e e z e r T i p C a r t r i d g e s

Blade Tip

To order specialty versions of the Precision Tweezer Cartridges replace the " " in the part number with the appropriate letter designate for your

application when ordering: = Temperature Sensitive = Ceramic or Heavy Load

T C

F

T P-BLH7 Tweezer Heavy Duty Cartridge, A = 28mm (1.1") Pair

F

Dimensions and artwork listed are for indication/guidance only. Numbers have been rounded up.

Please contact your local technical support if you require specific technical information.

13

Page 16

P o w e r S o l d e r i n g T i p s

Power Tips for Production Soldering

The Power Heater Tips offer a combination of performance and value. The replaceable tips are used on the MFR-HPS Production Soldering

Hand piece and deliver high power, economical soldering in high volume production applications. The tips come in a thermally optimized large

diameter tip that includes additional iron plating for longer life.

0.43

0.04

1.0mm

"

11.0mm

"

F F

S V-CH10 S V-CNB05

Chisel Solder Tip, Conical Bent Solder Tip,

30° 1.0mm (.04") 0.5mm (.02")

0.02

0.5mm

"

0.51

13.0mm

"

0.39

"

10.0mm

0.43

11.0mm

0.4

10.0mm

0.48

12.2mm

0.34

8.5mm

"

"

"

F F

S V-CH20 S V-CNL04

Chisel Solder Tip, Conical Long Solder Tip,

2.0mm (.08")

F F

S V-CH25 S V-CNL10

Chisel Solder Tip, Conical Long Solder Tip,

2.5mm (.10" ) 1.0mm (.04")

F F

S V-CH50 S V-CNL14

Extra Large Chisel Solder Tip, Conical Long Tip,

5.0mm (.20") 1.4mm (.056”)

F F

S V-CHB15 S V-DRH20

0.016

0.4mm

0.04

1.0mm

0.056

"

1.4mm

Chisel Bent 30° Solder Tip, Conical Bevel Solder Tip,

"

"

1.5mm (.06") 2.0mm (.08” )

2.4mm

F F

S V-CN05 S V-DRK50

Conical Solder Tip, Knife Solder Tip,

0.5mm (.02" ) 5.0mm (.20")

5.0m m

45º

.20"

0.8

"

2.0mm

0.1

"

2.5mm

0.2

"

5.0mm

0.06

"

1.5mm

0.02

0.5mm

"

"

.095"

14mm .55"

0.53

13.6mm

0.51

13.0mm

0.59

15.0mm

"

0.4mm (.016")

"

"

14

To order specialty versions of the Power Heater Tips replace the " " in the part number with the appropriate letter designate for your

application when ordering: = Temperature Sensitive = Ceramic or Heavy Load

T C

F

Dimensions and artwork listed are for indication/guidance only. Numbers have been rounded up.

Please contact your local technical support if you require specific technical information.

Page 17

MFR-PTZ, MFR-SRC, MFR-PST, MFR-STZ

System Specifications

Ambient Operating Temperature 10-40°C

Maximum Enclosure Temperature 55°C

Input Line Voltage 100- 240 VAC, grounded circuit

Input Line Frequency 50/60 Hz

Power Consumption 65 Watts max.

Output Power 50 Watts max. at 22°C ambient temperature

Output Frequency 450 KHz

Power Cord (3-wire) 183cm (72”)

Power Supply Dimensions w x d x h 122mm x 200mm x 152.5mm (4.8” x 8” x 6”)

Agency Tested Per IEC 61000-6-1,EC 61000-6-3 and UL499, FCC CFR Part 15

Tip-to-Ground Potential <2mV

Tip-to-Ground Resistance <2 ohms

Idle Tip Temperature Stability ± 1.1°C in still air

Hand-piece Cable Length L=71cm (48”), burn proof, ESD safe

Hand-piece Connector 8-pin power connector

Workstand Dimensions w x d x h 100mm x 200mm x 100mm (4” x 8” x 4”)

S p e c i f i c a t i o n s

MFR-DSI, MFR-SDI, MFR-DSX, MFR-SDX

System Specifications

Ambient Operating Temperature 10-40°C

Maximum Enclosure Temperature 55°C

Input Line Voltage 100- 240 VAC, grounded circuit

Input Line Frequency 50/60 Hz

Power Consumption 90 Watts max.

Output Power 50 Watts max. at 22°C ambient temperature

Output Frequency 450 KHz

Power Cord (3-wire) 183cm (72”)

Dimensions w x d x h 170mm x 200mm x 152.5mm (7” x 8” x 6”)

Agency Tested Per IEC 60335-2-45 and UL499, FCC CFR Part 15

Tip-to-Ground Potential <2mV

Tip-to-Ground Resistance <2 ohms

Idle Tip Temperature Stability ± 1.1°C in still air

Hand-piece Cable Length L=71cm (48”), burn proof, ESD safe

Hand-piece Connector 8-pin power connector

Workstand Dimensions w x d x h 100mm x 200mm x 100mm (4” x 8” x 4”)

Recommended Air Pressure Input 450kPa (65PSI) - shop air versions only

Noise Level Less than 70dBA

Vacuum Suction Force 22” Hg at vacuum pump (at sea level)

15

Page 18

A c c e s s o r i e s a n d S p a r e P a r t s

Hand-pieces and Cords

Part No.

MFR-HPT

MFR-HSR

MFR-HPS

MFR-HDS

MFR-HST

MFR-CA1

Description

Precision Tweezer Hand-piece W/Cord

Cartridge Solder / Rework Hand-piece W/Cord

Heater Tip Hand-piece W/Coil Assembly & Cord

Convertible Desolder Hand-piece

Standard Tweezer Hand-piece W/Cord

Coil Assembly for MFR-HPS Hand-piece

Replacement Workstands & Upgrades

In addition to the regular workstands, Auto

Sleep Workstands and Cradles are now

available. These new stands help extend

tip life by reducing the temperature

when the hand-piece is idle in the

workstand.

Part No.

MFR-WSPT

MFR-WSSR

MFR-WSDS

MFR-WSAS

MFR-WSC1

Description

Tweezer Workstand

Soldering Workstand

Desolder Workstand

Auto Sleeper Workstand

Solder Rework Cradle Auto Sleep (Black)

16

AC-Y10

AC-BP

Yellow Sponge (pack of 10)

Brass Pad (pack of 10)

Contents of this brochure subject to change without notice

Page 19

Lead-Free Process Identification

For factories that are transitioning to lead-free, it is important to identify which

processes are using lead-free to avoid accidental cross-contamination of solder

materials. To easily identify the lead-free processes, we have designed visual

indicators that fit on the system parts where cross-contamination can occur,

such as tips & workstand sponges.

Part No.

MFR-WSC2

AC-CK1

AC-CK4

Description

Green Solder Rework Cradle - Auto Sleep

Green cartridge identification ring for MFR & PHT

Consumables (Pack of 50)

Green cartridge identification ring for SFV Power Tips (Pack of 50)

Miscellaneous Accessories

Part No.

AC-BRUSH-P

AC-CP2

AC-FX1

AC-IK

AC-MFR-PM

A c c e s s o r i e s a n d S p a r e P a r t s

Description

Soft Brass Brush

Cartridge Removal Pad

Fume Extraction Kit

Inter Locking / Mounting Kit

Power Meter

MFR Desoldering Accessories & Maintenance Tools

Part No. Part No.

AC-TC-P

DP-SL3

AC-VL

AC-DFP

Description Description

Desoldering Tip Cleaner (Pack of 12)

Front Seal

ESD Air Hose

Chamber Liner, Filter & Fume

AC-PR1

AC-PM1

AC-CC

Pump Re-build Kit

Pump with Motor Replacement Kit

Solder Collection Chamber

17

Page 20

P S - 8 0 0 S o l d e r i n g S y s t e m

PS-800 Soldering System

Compact Production Soldering System

Designed to be the perfect, compact system for repetitive manual soldering and touch-up. The PS-800 Soldering System

features an innovative, compact power supply with a small footprint which is ideal for production environments. The

system combines the power and superior process control advantages of SmartHeat , with the system quality and

innovative design of OK International irons. In addition, the PS-800 Soldering System utilizing SmartHeat Technology

requires no calibration

®

®

Minimal Cost of Ownership

The PS-800 Soldering System uses replaceable heater tips rather than cartridges, with the cost being comparable to

that of conventional tips, making cost of ownership competitive. The unique two-piece design separates the induction coil

from the heater tip. The long-life induction coil remains in the handle, while replaceable heater tips are easily removed

and replaced.

OK International has developed a comprehensive line of soldering tip geometries for the PS-800 Soldering System.

Plus, enhancements to SmartHeat Technology have allowed for an increase to the plating thickness of the tips. The

result is extended tip life without reducing thermal performance.

®

18

Contents of this brochure subject to change without notice

Page 21

Perfect For Lead-Free Hand Soldering

The most important technical challenge of lead-

free hand soldering is being able to solder heat

sensitive components at 215-220°C, without

causing damage. This requires a soldering iron that

can respond to the thermal energy demands of the

application and deliver the correct amount of

energy to the joint without overshoot that can

cause damage.

OK International's PS-800 Soldering System is

perfect for lead-free hand soldering. SmartHeat

Technology allows the higher thermal performance

requirements of lead-free alloys to be met without

increasing the tip temperature. Thus, the risk of

thermal damage is eliminated.

The PS-800 Soldering System allows operators to produce high quality product quickly, easily and safely. It is a reliable, hassle-

free production tool that can be used to solder lead-free PCBs immediately without needing to be continually re-calibrated to meet

the higher temperature requirements like traditional technologies.

®

Shown with optional

PS-WSAS Workstand

PS-800 Soldering System

Part No.

PS-800

Includes

PS-PW1

PS-WSK1

PS-HC1

Description

PS-800 Soldering System

PS-800 Power Supply

PS-800 Workstand with Sponge

PS-800 Soldering Handle with Coil Assembly

Specifications

Power Supply

Ambient Operating Temperature 10 - 40°C

Maximum Enclosure Temperature 65°C

Input Line Voltage 90 - 240 VAC

Input Line Frequency 50/60 Hz

Power Consumption 50 Watts max.

Output Power 35 Watts max. at

22°C ambient temperature

Output Frequency 470 KHz

Power Cord (3-wire) 183cm (72”)

Dimensions (W x D x H) 70mm x 161mm x 100mm

(2.76" x 6.34" x 3.94")

P S - 8 0 0 S o l d e r i n g S y s t e m

19

Page 22

P S - 8 0 0 A c c e s s o r i e s

Lead-Free Process Identification

For factories that are transitioning to lead-free, it is important to identify which

processes are using lead-free to avoid accidental cross-contamination of solder

materials. To easily identify the lead-free processes, we have designed visual

indicators that fit on the system parts where cross-contamination can occur, such

as tips & workstand sponges.

Part No.

PS-WSAS-G

AC-CK1

Description

Auto Sleep Workstand with Green Cradle

Green cartridge identification ring for

PHT Consumables (Pack of 50)

Accessories & Spare Parts

Part No.

PS-PW1

PS-WSK1

PS-WSC1

PS-WSAS

AC-YS4

PS-HC1

PS-CA1

AC-CP2

AC-PM

Description

PS-800 Power Supply

PS-800 Workstand with Sponge

PS-800 Cradle

PS-800 Auto Sleep Workstand with Sponge

Sponge 3.12" ø x 1" (pack of 10)

PS-800 Soldering Handle with Coil Assembly

PS-800 Coil Assembly

Heater Tip Removal Pad

Power Meter – AC

PS-800 Heater Tips

.394"

10mm

.472"

12.0mm

3.0mm

.12"

2.5mm

.04"

1.78mm

.10"

.197"

5.0mm

1.0mm

.07"

.06"

1.5mm

10.0mm

10.0mm

.65"

16.5mm

.06"

1.5mm

.394"

10.0mm

.394"

.394"

.315"

8.0mm

PHT- 0315 PHT- 2017

Chisel Fine 30° 1.0mm (.04") Conical 60° 0.25mm (.01")

PHT- 0326 PHT- 2035

Chisel Fine/Bent 30° 1.5mm (.06") Conical Fine 0.5mm (.02")

PHT- 0335 PHT- 2057

Chisel Fine 30° 1.78mm (.07") Conical Fine 1.0mm (.04")

PHT- 1355 PHT- 2327

Chisel 30° 2.5mm (.10") Conical Fine/Bent 0.4mm (.016")

PHT- 0325 PHT- 2335

Chisel 60° 1.5mm (.06") Conical Fine 30° 0.5mm (.02")

PHT- 1367 PHT- 2337

Chisel 30° 3.0mm (.12") Conical Fine/Bent 30° 0.5mm (.02")

PHT- 1384 PHT- 3035

Chisel 30° 5.0mm (.197") Conical 30° 0.5mm (.02")

.59"

0.4mm

0.5mm

.04"

.02"

0.02"

.02"

0.5mm

1.0mm

.016"

0.5mm

15.0mm

10.0mm

.59"

15.0mm

.63"

16.0mm

0.5mm

10.0mm

.394"

15.0mm

.59"

15.0mm

0.59"

.39"

XY XY

.01"

0.25mm

XY XY

XY XY

XY XY

XY XY

XY XY

.02"

XY XY

20

650 Series = 65, 750 Series = 75

XY XY

Dimensions and artwork listed are for indication/guidance only. Numbers have been rounded up.

Please contact your local technical support if you require specific technical information.

Page 23

PS-800 Heater Tips

0.5mm

0.5mm

.02"

.02"

.04"

.04"

1.0mm

.04"

1.0mm

.04"

1.2mm

1.0mm

60°

45°

.59"

15.0mm

.59"

15.0mm

15.0mm

.590"

16.65mm

.656"

15.0mm

.59"

15.0mm

.59"

45°

XY XY

PHT- 3047 PHT- 4497

Conical 1.2mm (.05") Hoof 45° 4.0mm (.16")

XY XY

PHT- 3057 PHT- 4697

Power Conical 1.0mm (.04") Hoof 60° 4.0mm (.16”)

XY XY

PHT- 3067 PHT- 4627F

Conical Long 1.0mm (.04") Mini Hoof 60° Face Only 1.0mm (.04")

XY XY

PHT- 3077 PHT- 4637F

Power Conical 1.0mm (.04") Mini Hoof 60° Face Only 1.5mm (.06")

XY XY

PHT- 4607 PHT- 4467F

Mini Hoof 60° 0.5mm (.02") Hoof 45° Face Only 2.0mm (.08")

XY XY

PHT- 4617 PHT- 4487F

Mini Hoof 45° 0.5mm (.02") Hoof 45° Face Only 3.0mm (.12")

4.0mm

.16"

4.0mm

.16"

1.0mm

.04"

1.5mm

.06"

2.0mm

.08"

3.0mm

.12"

45°

45°

60°

60°

60°

17.0mm

.67"

17.0mm

.67"

15.0mm

.59"

15.0mm

.59"

17.0mm

.67"

17.0mm

.67"

P S - 8 0 0 H e a t e r T i p s

1.5mm

2.0mm

.08"

2.0mm

.08"

3.0mm

3.0mm

.12"

1.0mm

.04"

.06"

.12"

45°

60°

15.0mm

.59"

60°

15.0mm

.59"

45°

17.0mm

.67"

60°

17.0mm

.67"

45°

17.0mm

.67"

60°

17.0mm

.67"

XY XY

PHT- 4627 PHT- 4497F

Mini Hoof 60° 1.0mm (.04") Hoof 45°, 4.0mm (.16")

XY XY

PHT- 4637 PHT- 5437

Mini Hoof 60° 1.5mm (.06") Knife Sharp 45° 3.0mm (.12")

XY XY

PHT- 4467 PHT- 5457

Hoof 45° 2.0mm (.08") Knife Sharp 45° 4.5mm (.18")

XY XY

PHT- 4667 PHT- 5477

Hoof 60° 2.0mm (.08") Knife Bevel 45° 5.0mm (.20")

XY XY

PHT- 4487 PHT- 5487

Hoof 45° 3.0mm (.12") Knife Sharp 45° 5.0mm (.20")

XY

PHT- 4687

Hoof 60° 3.0mm (.12")

4.0mm

.16"

.12"

3.0mm

4.5mm

.18 "

5.0mm

5.0mm

0.5mm

.02"

.20"

0.43mm

.017"

.20"

45°

45°

45°

45°

17.0mm

.67"

15.0mm

.59 "

15.0mm

.5 9"

2.0mm

.08"

1.0mm

.04"

15.0mm .59"

16.38mm

.645"

4.32mm

.17"

650 Series = 65, 750 Series = 75

XY XY

Dimensions and artwork listed are for indication/guidance only. Numbers have been rounded up.

Please contact your local technical support if you require specific technical information.

21

Page 24

H C T - 9 0 0 H a n d H e l d C o n v e c t i o n T o o l

HCT-900 Hand Held Convection Tool

Versatile Hot Air Tool for Soldering and Desoldering Applications

The HCT-900 Hand Held Convection Tool offers a low cost, versatile rework solution for a wide variety of production and rework

application challenges. It has a simple, compact robust design comprising of analog controls for both airflow and heat. A closed

loop feedback circuit controls the temperature allowing the desired temperature to be achieved and maintained regardless of

changes in the volume of airflow.

The HCT-900 can be used for the removal and refitting of electronic components, including lead-free, from 0201 up to 304 pin

QFP. It is also effective at reworking pin in-hole devices such as sockets and connectors. And, using it with solder braid and flux is

a fast and efficient way to remove solder shorts and splashes. It can also be used in plastic applications such as applying shrink

wrap to components or the formation of plastic rivets.

The unique low noise air pump (less than 45 db) provides precise

airflow control for the most demanding applications. The “power off” cool

down function retains airflow through the hand piece while the unit

powers down, providing efficient heater cooling and reducing thermal

stress.

The HCT-900 is fully ESD compliant.

22

Part No.

HCT-900-11

HCT-900-21

HCT-900-10

Contents of this brochure subject to change without notice

Description

115 VAC, Hand Held Convection Tool

230 VAC, Hand Held Convection Tool

100 VAC, Hand Held Convection Tool

Page 25

Nozzle Selection

Part No.

Description

The HCT-900 is supplied with a standard

single jet H-D50 (0.2", 5.0 mm) nozzle. In

addition two rework nozzle kits, predefined for

specific applications, are available, as well as

a full selection of nozzles.

PLCC,BQFP,QFP

A

B

SOIC, TSOP

A

B

CHIP & SOT

A

Model Chip Type A mm (in) B mm (in)

H-P20

H-P28

H-P32

H-P44

H-P52

H-P68

H-P84

H-Q07

H-Q10

H-Q14

H-Q1420

H-Q28

H-BQ23

H-Q3232

H-BQ38

H-Q2626 QFP-208 29.8 29.8

H-S16

H-SL16

H-SL20

H-SL24

H-SL28

H-SL44

H-SOJ32

H-SOJ40

H-TS24

H-TS32

H-TS40

H-TS48

H-TSW24

H-TSW44 TSOP 24-28/40-44 12.7 19.8

Model Ø A (mm)

H-D25 2.5

H-D50 5.0

H-D120 12.0

NZKT-1

NZKT-2

PLCC-20

PLCC-28

PLCC-32

PLCC-44

PLCC-52

PLCC-68

PLCC-84

QFP-48

QFP-44

QFP-52,80

QFP-64,80,100

QFP-120,128,144,160

BQFP-100

QFP-240

BQFP-196

SOIC 14,16 6.8 10.2

SOL 14,16

SOL 20,20J

SOL 24,24J

SOL 28

SOL 44

SOJ 32

SOJ 40

TSOP 20-24

TSOP 28-32

TSOP 40

TSOP 48

TSOP 20-24

Nozzle Kit for Chip Resistors, SOIC

& TSOP Packages. Includes (one each):

• H-D25 • H-SL16 • H-SL28

• H-SOJ40 • H-TS48

Nozzle Kit for PLCC, QFP & BQFP

packages. Includes (one each):

• H-P20 • H-P44 • H-P84

• H-Q1420 • H-Q2626

(0.47")

11.9

(0.57")

14.5 14.5

(0.67")

(0.77")

(0.86")

22.0

(1.06")

27.0

(1.28")

(0.33")

8.4 8.4

(0.53")

(0.68")

17.3 17.3

(0.92")

23.4 18.1

(1.23")

31.2 31.2

(0.88")

22.4 22.4

(1.36")

34.5 34.5

(1.48") (1.48")

37.7 37.7

(1.17") (1.17")

(0.27")

(0.41")

10.6

(0.41")

10.6

(0.41")

10.6

(0.41")

10.6

(0.41")

16.0

(0.53")

13.5

(0.53")

13.5

(0.67")

17.0

(0.83")

21.0

(0.83")

21.0

(0.83")

21.0

(0.4")

10.2

(0.5")

(0.1”)

(0.2”)

(0.47”)

11.9

14.3 16.9

19.5 19.5

22.1

27.2

32.4 32.4

13.4 13.4

10.8

13.3

15.9

18.4

27.9

20.6

25.4

7.1

9.1

10.8

13.3

18.4

(0.47")

(0.57")

(0.56”)

(0.77")

(0.87")

(1.07")

(1.28")

(0.33")

(0.53")

(0.68")

(0.71")

(1.23")

(0.88")

(1.36")

(0.4")

(0.43”)

(0.52")

(0.63”)

(0.72")

(1.1")

(0.81")

(1.0")

(0.28")

(0.36")

(0.43")

(0.52")

(0.72")

(1.78")

H C T - 9 0 0 H a n d H e l d C o n v e c t i o n T o o l

Specifications

Input Line Voltage 115 VAC HCT-900-11

Power 320 W

Air Pump Type Diaphragm

Air Flow 6-25 l/min.

Control Temperature 100°C – 500°C (212°F – 932°F)

Dimensions w x l x h 6.7"x 8.7" x 5.5" inches, 170 x 210 x 140 mm

Noise Level Less than 46 dBA

Surface Resistivity Unit: 10 Ω - 10 Ω. Hand-piece & tube: 10 Ω - 10 Ω

Weight 10.4 lbs. (4.7 kg.)

Certification / Approvals cTUVus, CE

230 VAC HCT-900-21

100 VAC HCT-900-10

5 6 7 11

23

Page 26

P r o d u c t R a n g e

OK International has a full range of products for the electronics assembly work bench to meet

your application needs.

OK International’s full range of soldering, desoldering and rework systems is complemented by a

line of benchtop fume extraction systems that range from tip extraction to multi-user units. Our

rework and repair equipment offers best-in-class performance for BGA and array package rework.

OK International also has a comprehensive line of fluid dispensing products, including valves,

equipment and consumables. OK International products conform to global industry standards,

and meet today’s high standards of precision and performance.

For more information about the full scope of OK International products, please contact your local

OK International Representative.

24

Page 27

OK International provides solution based technologies to electronics manufacturing industries throughout the world.

Through our sales, service and distribution centers located in North America, Europe and Asia we are able to provide

seamless, proactive expertise and support to our customers worldwide.

Wherever industrial manufacturing facilities are located, OK International's global network of expertly trained

distributors is there, to supply essential technical support and advanced process solutions.

O K I n t e r n a t i o n a l

NORTH AMERICA UNITED KINGDOM FRANCE JAPAN

OK International OK International Ltd. OK International SAS OK International Japan Co.

12151 Monarch Street Eagle Close, Chandlers Ford Rue de la Saone 5-3-1 Heiwajima, Ota-ku

Garden Grove, Eastleigh, Hampshire SO53 4NF Zac de Folliouses-les Echets Tokyo 143-0006

California 92841 United Kingdom 01706 Miribel Cedex Japan

USA Tel: +44 (0) 2380 489100 France Tel: +81-3-5753-0085

Tel: +1-714-799-9910 Fax: +44 (0) 2380 489109 Tel: +33 (0)4 72 26 20 30 Fax: +81-3-3765-8855

Fax: +1-714-799-9533 Fax: +33 (0)4 72 26 20 35

GERMANY ITALY SINGAPORE CHINA

OK International GmbH OK International OK International OK Electronics (Beijing) Co.,Ltd.

Frankfurter Straße 74 Strada Statale 11 – No 28 10 Ang Mo Kio St. 65 No. 1 Building,

64521 Gross-Gerau 20010 Vittuone, Milano #05-13 Techpoint A -10 Long Qing Street

Germany Italy Singapore 569059 Beijing Economic &

Tel: +49 (0) 61 52-71 12-0 Tel: +39 02 902 5161 Tel: +65-62810991 Technical Developing Zone

Fax: +49 (0) 61 52-71 12-22 Fax: +39 02 901 11147 Fax: +65-62853473 Beijing, 100176

The People's Republic of China

Tel: +86-10-67878490

Fax: +86-10-67878491

Page 28

OK

O K I N T E R N A T I O N A L

North America

12151 Monarch Street • Garden Grove, California 92841 USA

Tel: +1-714-799-9910 • Fax: +1-714-799-9533

www.okinternational.com

© 2005 Delaware Capital Formation, Inc. All rights reserved

DOVER and the Dover logo are registered trademarks of Delaware Formation, Inc. a wholly-owned subsidiary of Dover Corporation

T M

BRO-SOL-US-05

Loading...

Loading...