Page 1

Wide Format Solvent Inkjet Printer

IP-7900-22/23

Read this User’s Guide carefully before use of this printer and

handle it properly.

After reading, keep it for later use.

U00133704002

IP-7900-22

Page 2

IP-7900-22/23 Wide Format Solvent Inkjet Printer Advanced Operation Guide

Documents Number U00133704002, Third edition, December 2015

Copyright© 2015 OKI Data Infotech Corporation.

All rights reserved

OKI Data Infotech Corporation. reserves the right to make changes without notice to the specications and materials contained herein and

shall not be responsible for any damages (including consequential) caused by reliance on the materials presented, including but not limited

to typographical, arithmetic, or listing errors.

Please address any questions, comments, and suggestions to the regional oce on :

See http://www.okidata-infotech.com/

This guide acknowledges the following trademarks :

All other trademarks are the properties of their respective companies.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

The CE mark, that shows that the products sold in the EU are conformed to the requirements of EC directive, is statutorily obliged to be

axed to the products.

In each directive, the scope of directive to be applied to equipment is explicitly dened. Our company’s product IP-7900 conforms to the

EMC directive, low voltage directive and RoHS Directive.

Inquiry of CE mark:

OKI Europe Ltd.

Wide Format Division

Siemensstrasse 9 , D-63263 Neu-Isenburg

Germany

Tel.: +49 (0)6102 297 400

Fax: +49 (0)6102 297 50 400

OKI Data Infotech Corporation

8 Nakase 1-chome, Mihama-ku, Chiba-shi, Chiba 261-8507, Japan

Phone : +81 43 211 1363

Fax : +81 43 211 8709

Page 3

Introduction

IP-7900-22/23 Wide Format Solvent Inkjet Printer (hereafter simply called the Printer below.) is equipped with

built-in USB interface that adopts solvent ink and supports media of up to 104-inch width.

The IP-7900-22-23 Wide Format Solvent Inkjet Printer Advanced Operation Guide describes:

- Function setting operation

- Adjustment procedures

For the information below required to start operating the Printer, refer to the Basic Operation Guide.

- Basic information required for the operation

- Basic operations to turn the Printer on and off and to handle the media and ink system

To operate the Printer safely and properly, before starting the operation be sure to read the following of the Basic

Operation Guide.

• Safety precautions

• Components delivered with the Printer

• Manual legend (notation rules)

Keep these Guides near the Printer so that you can quickly access it at any time.

3

Page 4

How do the two Guides work?

Basic Operation Guide

Read the Basic Operation Guide before your rst Printer operation.

This guide describes the basic handling and daily operation of

media, printing, and maintenance.

To perform your rst printing

To print on other media

To perform double-sided printing

To perform the Printer’s maintenance

To replace the Printer’s ink cartridge

page 24

page 50

page 56

page 60

page 129

To replace the Printer’s waste ink bottle

To recover error messages

To clear media jams

IP-7900 Advanced Operation Guide

4

page 127

page 116

page 115

Page 5

Advanced Operation Guide

Read the Advanced Operation Guide so that you can operate

the Printer eectively.

This Guide describes the Printer’s ne setting and adjustment to

maximize the Printer’s performance.

To operate the Printer with ne settings

To create a new media preset

To clear banding, white lines, and bleeding

To turn the Printer o for a long time

page 77

page 26

page 55

page 8

To print on cut-sheet media

To change heater temperature while printing

page 42

page 69

5

Page 6

TABLE OF CONTENTS

Manage the media advance compensation

Change media advance compensation

51

51

Introduction

Manual legend (Notational rules)

To assist your Printer in operating

effectively

When you do not use the Printer for

2 weeks or longer

Service cleaning

Head wash

Charging the ink system after head wash

Check the Printer status

Check the remaining ink level

Check remaining media length

Print reports on the Printer status.

Check the USB connection status

Check the firmware version on your Printer

Check the total print distance

Handle the media

Create a new media preset

Select a preset media

Minimize the right and left margins

Prevent the media from sticking and wrinkling

Solve media lifting up problem

Print on a thick media

Suspend printing when media wrinkles are detected

Change the automatic cleaning timing

Copy a preset media type to create a new one

Change the type of the preset media without

reloading the media

Feed or rewind media

Move a print start position (nest function)

Use the media until the very end

Print on a cut-sheet media

Adjust the head margin before printing

Reinstall the edge guards during printing

Remove some media wrinkles during printing

Solve skew in LOOSE winding mode

8

14

19

22

22

23

23

24

25

25

26

26

28

28

30

31

32

33

34

35

37

37

39

40

42

44

45

46

46

Print conditions

3

Set PRINT MODE

7

Set SMART PASS

Set DENSITY

Troubleshoot print quality issues

The print is light.

Missing dots are found at the beginning of printing.

The media is curled or wrinkled.

8

White stripes appear on the print.

9

Edges of objects are blurred.

A vertical barding appears at the print's edge.

Different bandings appear on the print’s right and left.

Clear missing dots (nozzle clogging)

Strong cleaning

Fill the cap with ink

Adjust the heaters’ temperature

Procedure to set the heater temperature

Display the heater control menu.

Button operation in the heater control menu

Finish displaying the heater control menu

Set the heater preset temperature

Select the standby time

Smart pass technology

Adjust and calibrate the Printer

Before adjustment and calibration

Cautions regarding automatic print adjustment

Automatic print adjustment cannot be performed

Procedures

Adjusting media feeding: Media advance adjustment

Correcting ink output position: Bidirectional

print position adjustment

Adjust the print linkage before or after automatic

cleaning

Adjust the print head position and the nozzle

positions at the print head's right and left

Asjust the edge sensor position

52

52

53

53

55

55

55

56

57

63

64

65

66

66

67

69

69

70

70

70

71

72

73

74

74

75

75

77

77

82

87

89

92

To change the Printer’s basic settings

Turn the audio warning beep off

Update the system firmware

Cleaning options

Perform cleaning only for the specified print head

IP-7900 Advanced Operation Guide

6

48

48

48

49

49

Menu tree

Index

94

100

Page 7

Manual legend (Notational rules)

The notational rules such as marks, buttons, LCD, and LEDs used for explanation in this guide are as follows:

Marks

WARNING

- Boxes marked with a WARNING describe points of caution for avoiding serious personal

injury.

CAUTION

- Boxes marked with a CAUTION describe points of caution for avoiding injury to yourself or

damage to the Printer.

TIP:

- This mark offers you the information to

facilitate the Printer operation.

Reference mark

This mark is followed by a reference section or page number.

7

Page 8

To assist your Printer in operating effectively

When you do not use the Printer for 2 weeks or longer

Always set the Printer power to on to perform the fill cap operation.

Fillcap is...?

- To remove nozzle clogging from nozzle surface, use fillcap option. This option fills the cap with ink to

soak the print head (nozzle surface) in the ink for a minimum of 1 to 2 hours. If possible, leave the Printer

overnight.

Use this option also when nozzles cannot be fixed by cleaning repeatedly.

The Printer has an internal clock which allows it to automatically wash the print heads, flushing some ink through

the print heads, which keeps the print heads in good condition. The Printer automatically washes the print heads

72 hours after the last printing, and then regularly washes every 3 days.

If the Printer has been left turned on and has not been used for 2 weeks or longer, it is necessary to wash the

print heads, charge the ink system, and perform daily maintenance using the procedure below.

If you have to keep the Printer turned off for a long without using it, first perform a service cleaning using the

procedure below, and then turn the Printer off.

Power-off

For a short period

Power-on

For a several days For two weeks or more

(

(

page 14

Service cleaning

Clean the print head and the ink flow path with the

storage liquid, and leave the printer with storage

liquid filled.

Prepare the storage liquid set (IP7-137).

Head wash

Clean the print head and the ink flow path with the

cleaning liquid.

Prepare the cleaning liquid set (IP7-136).

Charging ink after head wash

After the head wash, Insert ink trays and charge the

ink system.

Daily maintenance

(

Basic Operation Guide page 60

Perform the daily maintenance.

page 9

)

)

(

)

page 19

For one month or more

When leaving the Printer for

more than one month,

contact your service

representative beforehand.

A service call error is

displayed when the Printer is

turned on. Contact your

dealer or a service

representative.

)

CAUTION

- To protect the print head, do not leave your Printer for more than one month with no ink charged.

- During the service cleaning or head wash, do not open or close the front cover or the lever. Otherwise, the Printer may

restart its initial operation from the beginning, while wasting the ink and cleaning liquid.

IP-7900 Advanced Operation Guide

8

Page 9

Turn the Printer o / Check the Printer status / Handle the media / To change the Printer’s basic settings /

MENU

Cleaning options / Manage the media advance compensation / Manage print modes / Troubleshoot print quality issues /

Clear missing dots (nozzle clogging) / Adjust the heaters’ temperature / Smart pass technology

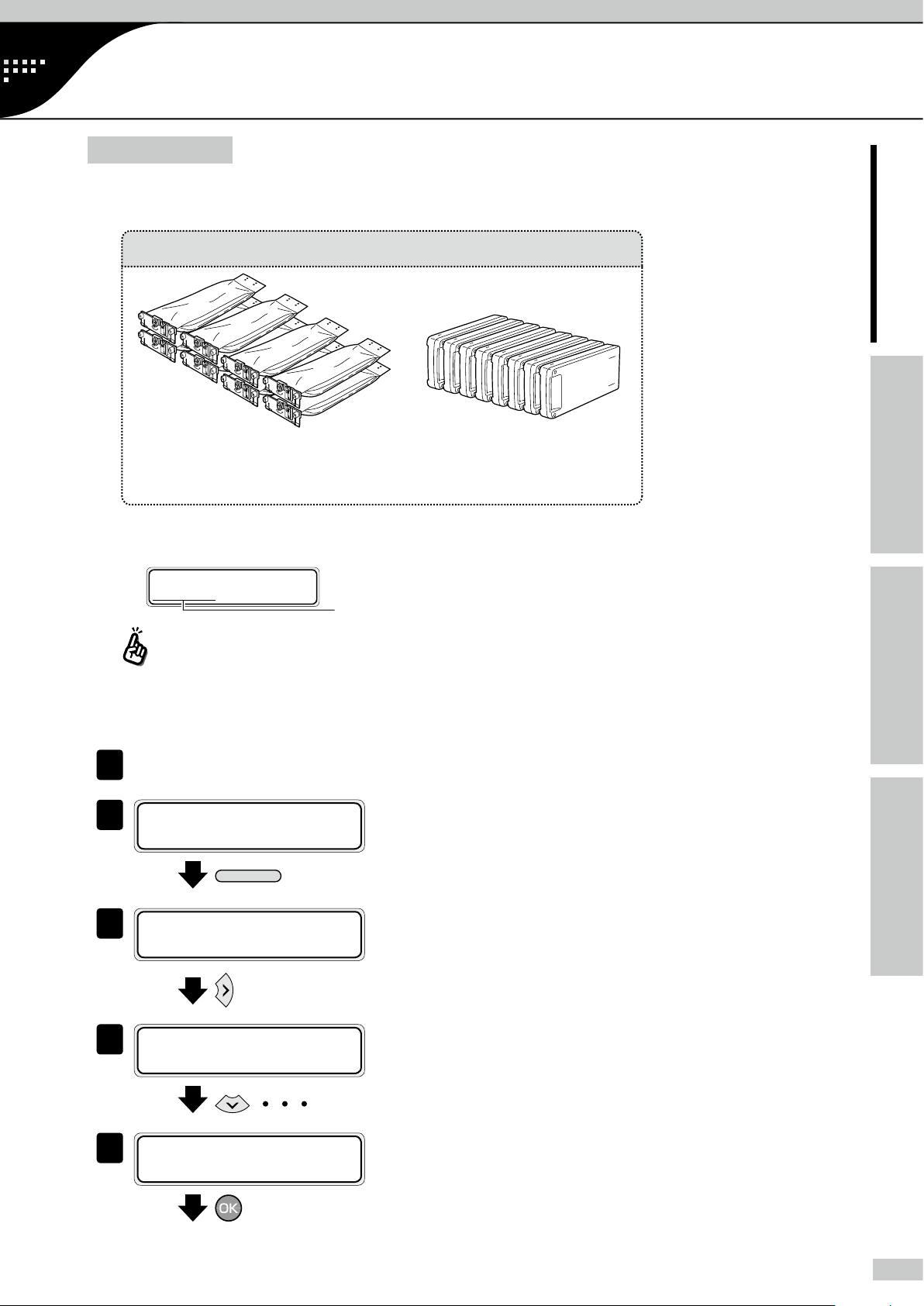

Service cleaning

Required items

Use the eight storage liquid cartridges completely in a single service cleaning.

NOTE

On the LCD, ink box cover is indicated as INK COVER.

OPEN

INK COVER

Before the operation check that the items below are prepared.

Storage liquid set A (IP7-237)

Storage liquid cartridge

INK COVER is displayed to indicate an ink box cover.

Dummy subcartridge

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

To facilitate this work, set the storage liquid cartridges to the optional ink trays in advance.

Install an empty waste ink bottle.

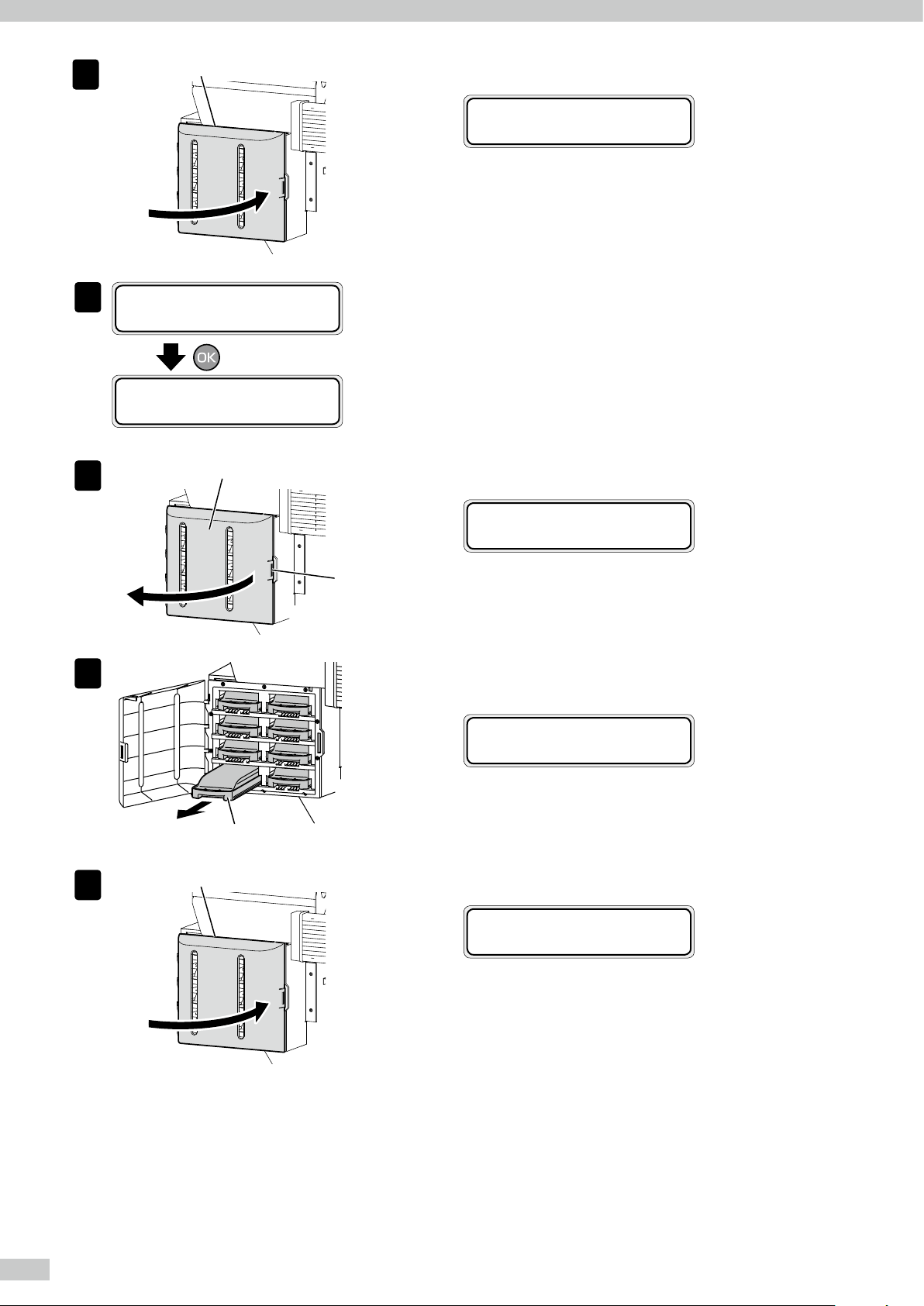

1

2

INK MEDIA REGâ

á

MEDIA M.ADV

ß

3

REWIND FORM FEED

á

PH.REC PH.MAIN

ß

#CAP CLEANING

4

>

à

â

à

Set the Printer to oine state and press the

MENU button.

IndexMenu tree

Press the Right button.

With the Down button scroll to #INK SYSTEM

OPT.

#INK SYSTEM OPT

5

>STORE INK SYS

Press the OK button.

9

Page 10

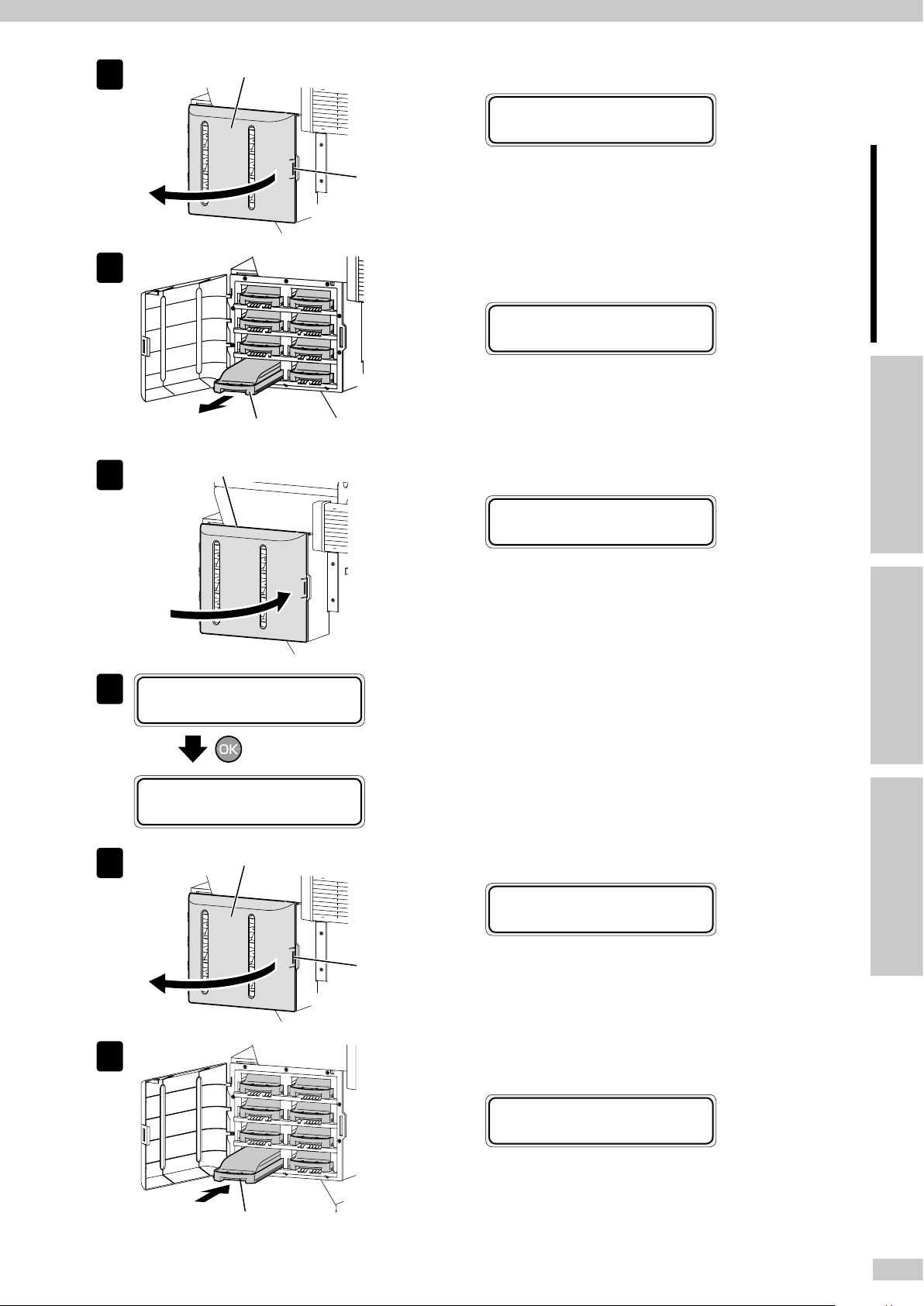

#INK SYSTEM OPT

6

*STORE INK SYS

Press the OK button.

7

8

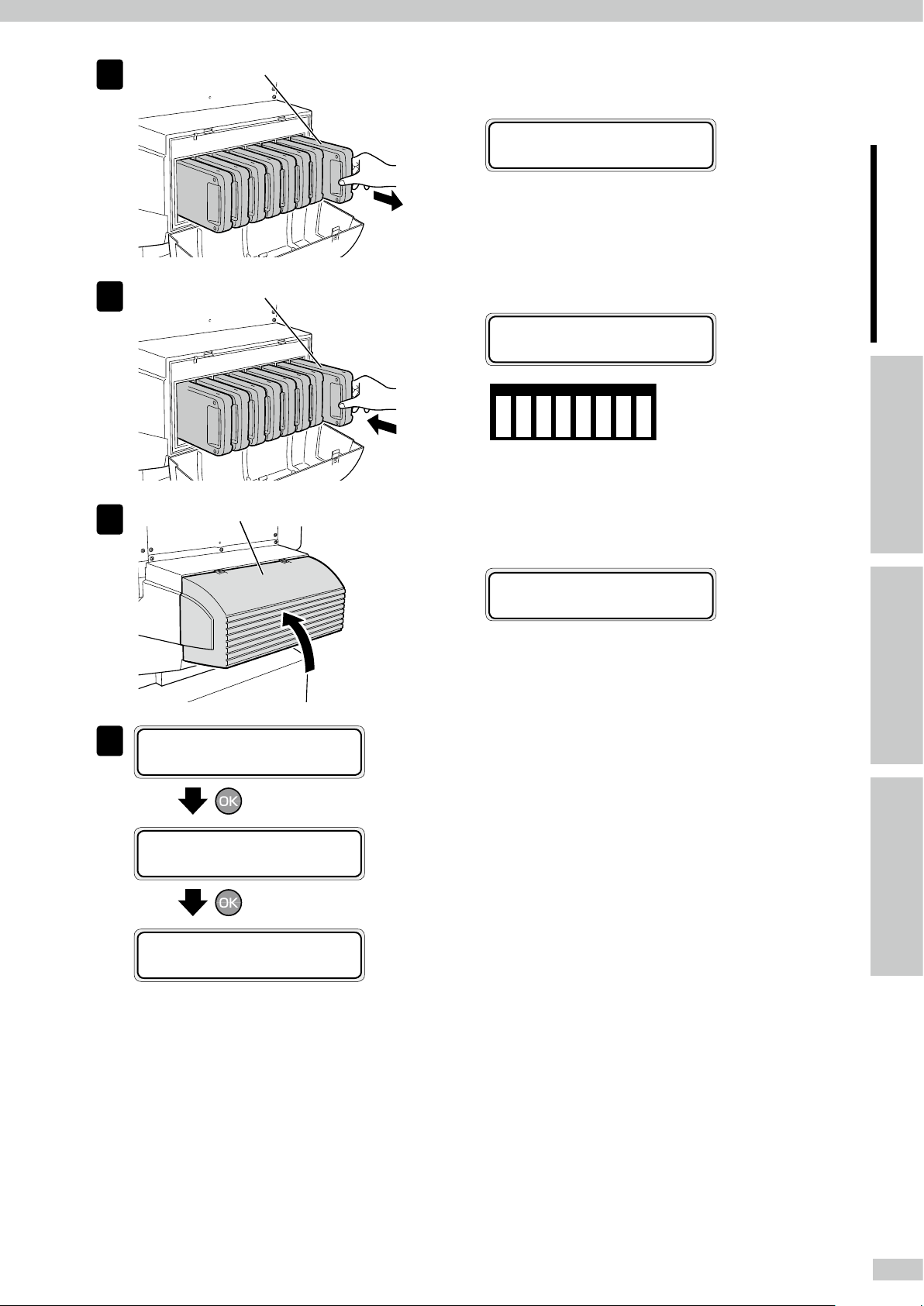

Knob screws

Subcartridge cover

Subcartridges to be removed

Open the subcartridge cover.

Loosen the two knob screws on the subcartridge cover

and open the subcartridge cover.

OPEN

SUBCARTRIDGE COVER

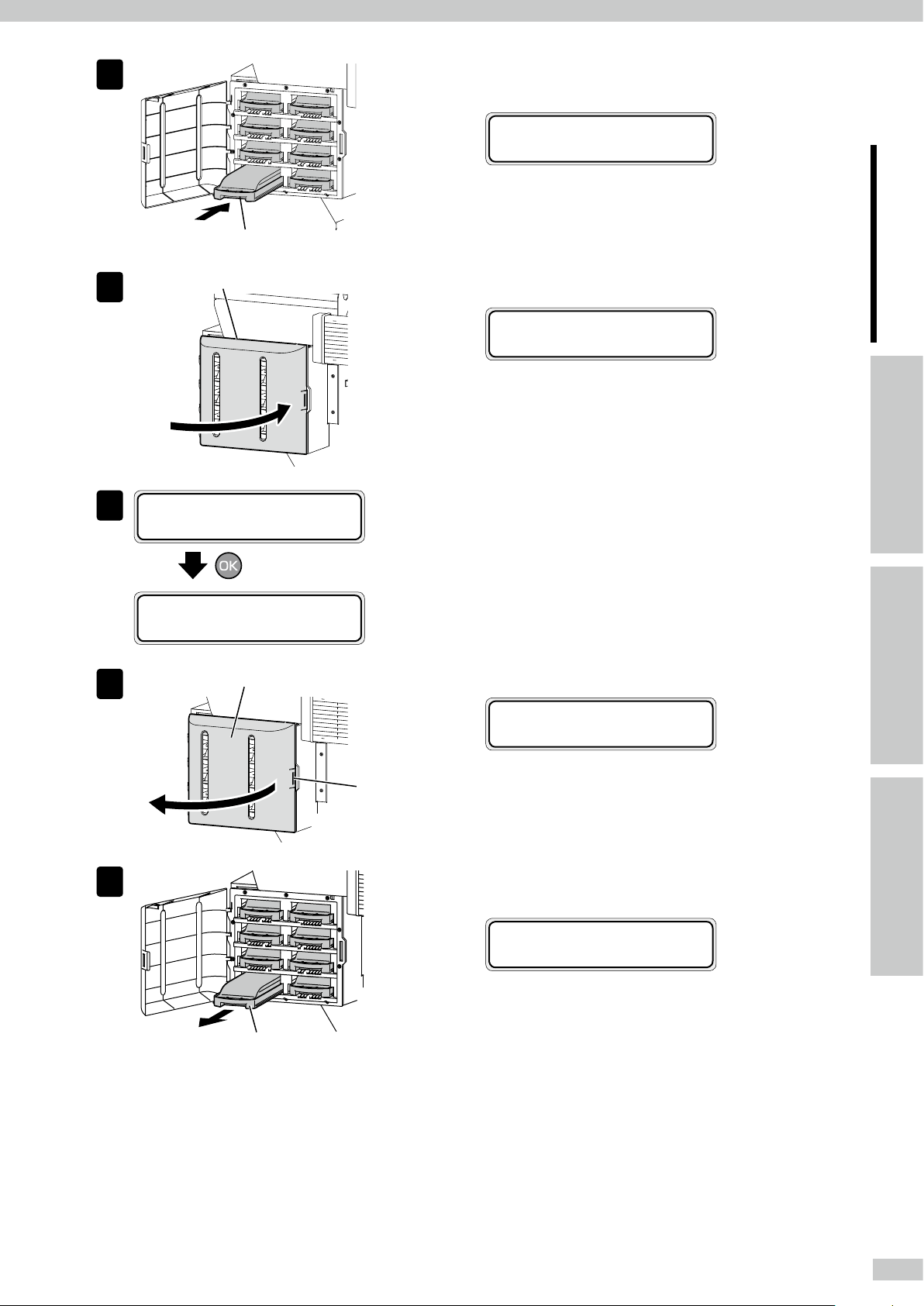

Remove the eight subcartridges.

REMOVE

Y1 SUBCARTRIDGE

9

10

Dummy subcartridges

Subcartridge cover

Set the dummy subcartridges of the storage

liquid set A.

LOAD

Y1 DUMMY SUBCART

Close the subcartridge cover and tighten the

two knob screws.

CLOSE

SUBCARTRIDGE COVER

10

IP-7900 Advanced Operation Guide

Page 11

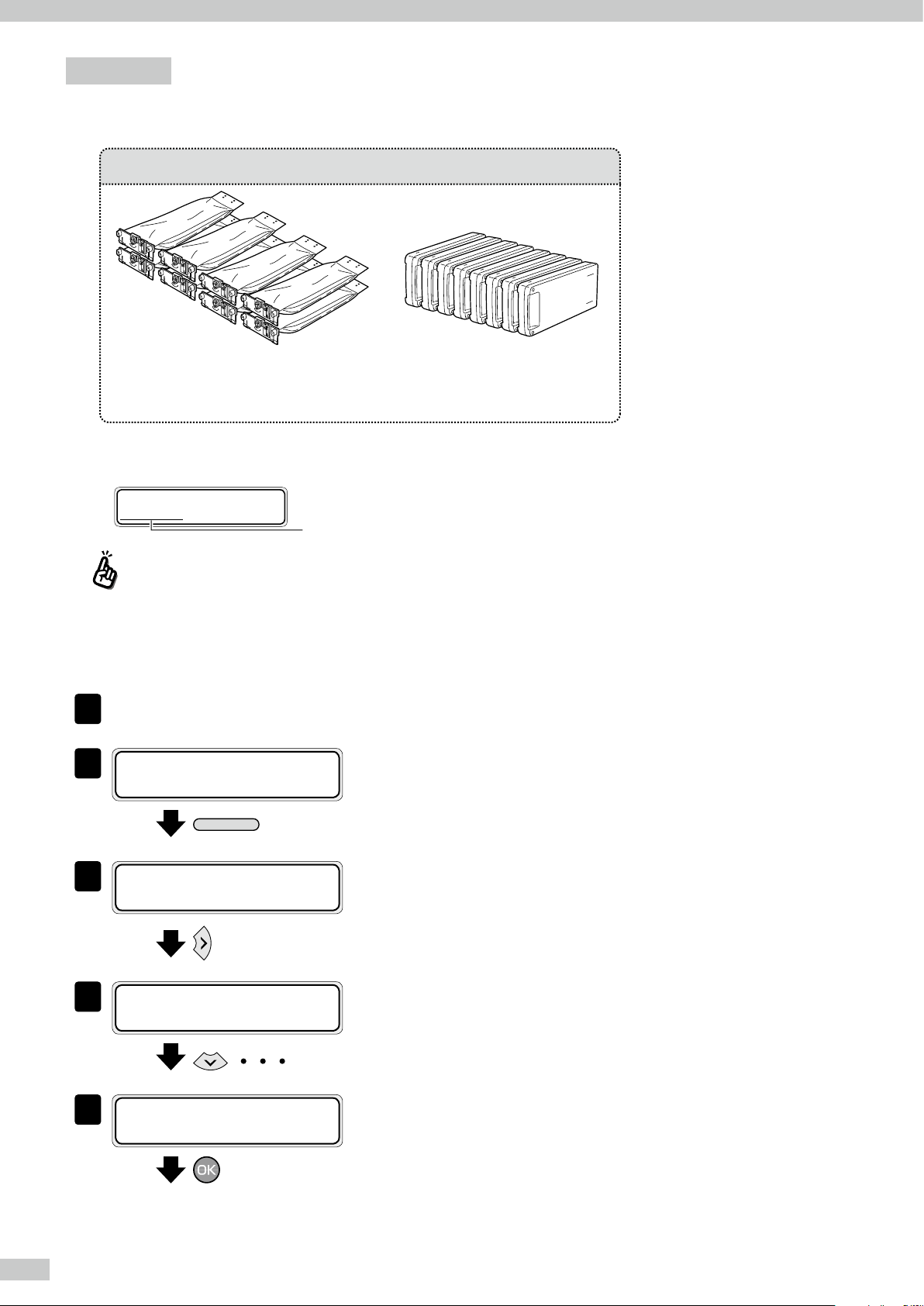

11

Ink box cover

Knob

Open the ink box cover.

OPEN

INK COVER

To assist your Printer

in operating eectively

12

13

START PURGING

14

*BOTTLE OK?

Ink trays to be removed

Ink box cover

Remove the eight ink trays.

REMOVE

Y1 INK PACK

Adjust and calibrate

the Printer

Close the ink box cover.

CLOSE

INK COVER

Press the OK button.

Ink is purged from the ink system.

PURGING

PLEASE WAIT 12

15

Ink box cover

16

Knob

Open the ink box cover.

OPEN

INK COVER

Insert the ink trays with storage liquid cartridges

into the slots of the ink box.

LOAD

Y1 SL PACK

IndexMenu tree

Ink trays to be set

11

Page 12

17

Ink box cover

Close the ink box cover.

CLOSE

INK COVER

START SL CHARGING

18

*BOTTLE OK?

CHARGING SL

PLEASE WAIT 12

19

Ink box cover

20

Press the OK button.

Open the ink box cover.

OPEN

INK COVER

Knob

Remove the ink trays with cleaning liquid

cartridges.

REMOVE

Y1 SL PACK

21

12

Ink trays to be removed

Ink box cover

IP-7900 Advanced Operation Guide

Close the ink box cover.

CLOSE

INK COVER

Page 13

START PURGING

22

*BOTTLE OK?

Press the OK button.

Ink is purged from the ink system.

PURGING

PLEASE WAIT 12

23

Ink box cover

24

Knob

Open the ink box cover.

OPEN

INK COVER

Insert the ink trays with storage liquid cartridges

into the slots of the ink box.

LOAD

Y1 SL PACK

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

Ink trays to be set

25

START SL CHARGING

26

*BOTTLE OK?

Ink box cover

CHARGING SL

PLEASE WAIT 12

Close the ink box cover.

CLOSE

INK COVER

IndexMenu tree

Press the OK button.

#INK SYSTEM OPT

>STORE INK SYS

13

Page 14

Head wash

MENU

Required items

Use the eight cleaning liquid cartridges completely in a single head wash.

Before the operation check that the items below are prepared.

Cleaning liquid set A (IP7-236)

Cleaning liquid cartridge

Dummy subcartridge

NOTE

On the LCD, ink box cover is indicated as INK COVER.

OPEN

INK COVER

INK COVER is displayed to indicate an ink box cover.

To facilitate this work, set the cleaning liquid cartridges to the optional ink trays in advance.

Install an empty waste ink bottle.

1

2

INK MEDIA REGâ

á

MEDIA M.ADV

ß

à

Set the Printer to oine state and press the

MENU button.

3

REWIND FORM FEED

á

PH.REC PH.MAIN

ß

â

à

Press the Right button.

#CAP CLEANING

4

>

With the Down button scroll to #INK SYSTEM

OPT.

5

14

#INK SYSTEM OPT

>STORE INK SYS

IP-7900 Advanced Operation Guide

Press the OK button.

Page 15

#INK SYSTEM OPT

6

*STORE INK SYS

With the Down button scroll to *CLEAN INK

SYS.

#INK SYSTEM OPT

7

*CLEAN INK SYS

8

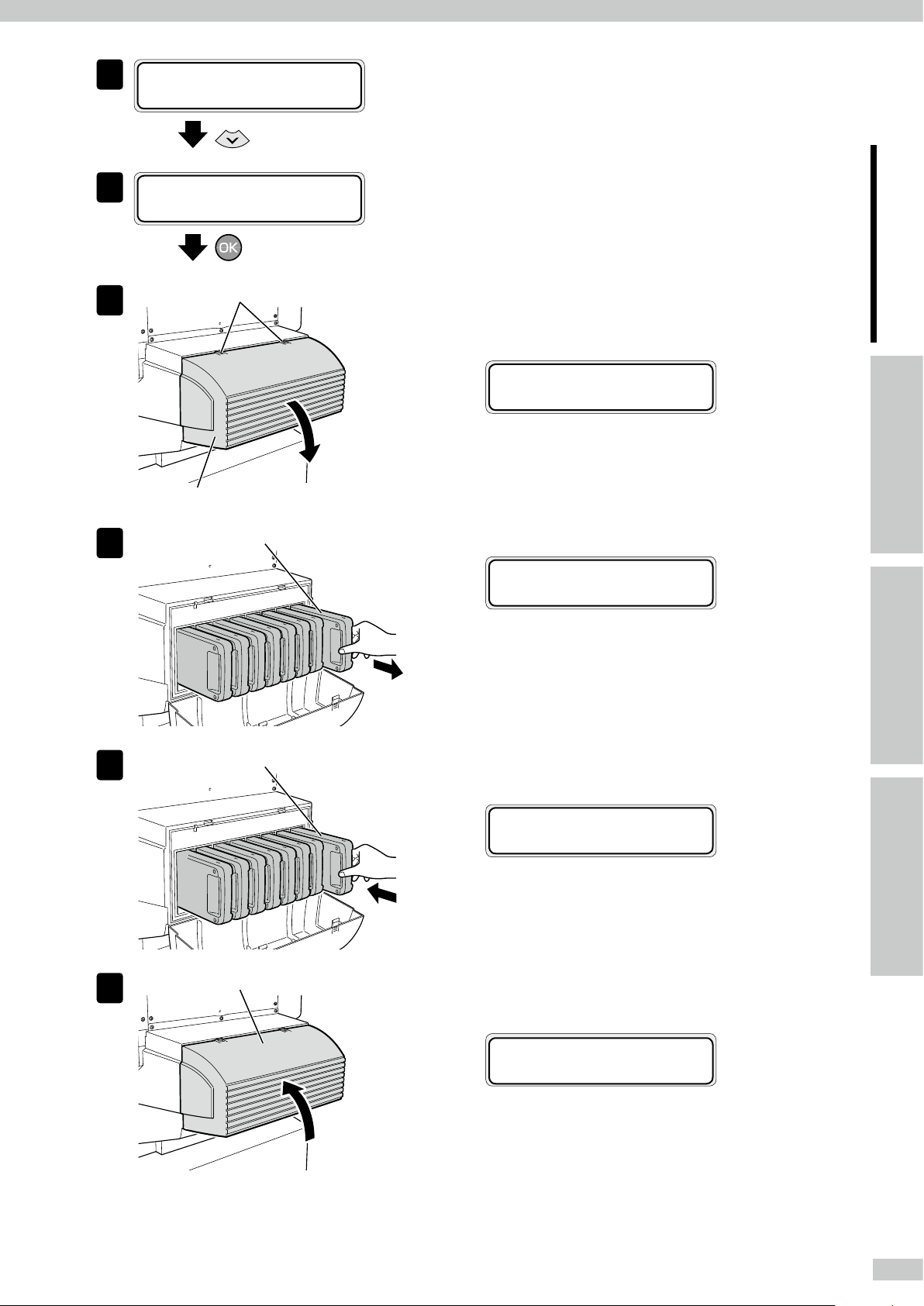

Subcartridge cover

9

Subcartridges to be removed

Knob screws

Press the OK button.

Open the subcartridge cover.

Loosen the two knob screws on the subcartridge cover

and open the subcartridge cover.

OPEN

SUBCARTRIDGE COVER

Remove the eight subcartridges.

REMOVE

Y1 SUBCARTRIDGE

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

10

11

Dummy subcartridges

Subcartridge cover

Set the dummy subcartridges of the cleaning

liquid set.

LOAD

Y1 DUMMY SUBCART

Close the subcartridge cover and tighten the

two knob screws.

CLOSE

SUBCARTRIDGE COVER

IndexMenu tree

15

Page 16

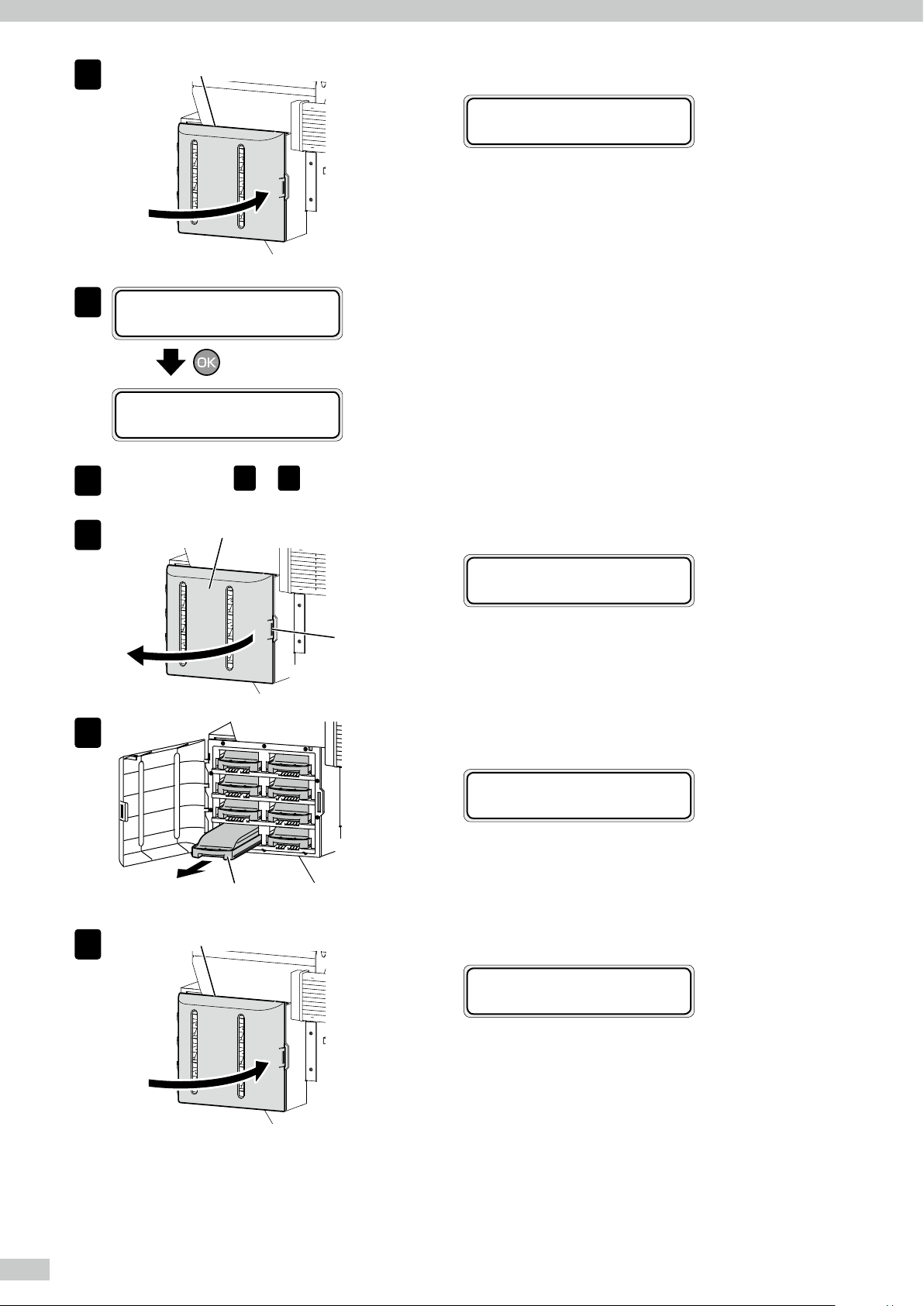

12

Ink box cover

Open the ink box cover.

OPEN

INK COVER

Knob

13

14

START PURGING

15

*BOTTLE OK?

Ink trays to be removed

Ink box cover

Remove the eight ink trays.

REMOVE

Y1 SL PACK

Close the ink box cover.

CLOSE

INK COVER

Press the OK button.

Ink is purged from the ink system.

PURGING

PLEASE WAIT 12

16

Ink box cover

Open the ink box cover.

OPEN

INK COVER

Knob

16

IP-7900 Advanced Operation Guide

Page 17

17

Ink trays to be set

Insert the ink trays with cleaning liquid

cartridges into the slots of the ink box.

LOAD

Y1 CL PACK

To assist your Printer

in operating eectively

18

START CL CHARGING

19

*BOTTLE OK?

Ink box cover

CHARGING CL

PLEASE WAIT 12

20

Ink box cover

Close the ink box cover.

CLOSE

INK COVER

Adjust and calibrate

the Printer

Press the OK button.

Close the ink box cover.

OPEN

INK COVER

21

Knob

IndexMenu tree

Remove the ink trays with cleaning liquid

cartridges.

REMOVE

Y1 CL PACK

Ink trays to be removed

17

Page 18

22

Ink box cover

Close the ink box cover.

CLOSE

INK COVER

START PURGING

23

*BOTTLE OK?

PURGING

PLEASE WAIT 12

Repeat the steps 16 to 19 to perform the cleaning again.

24

25

Ink box cover

Knob

26

Press the OK button.

Ink is purged from the ink system.

Open the ink box cover.

OPEN

INK COVER

Remove the ink trays with cleaning liquid

cartridges.

27

Ink trays to be removed

Ink box cover

REMOVE

Y1 CL PACK

Close the ink box cover.

CLOSE

INK COVER

18

IP-7900 Advanced Operation Guide

Page 19

START PURGING

MENU

28

*BOTTLE OK?

Press the OK button.

PURGING

PLEASE WAIT 12

OPEN INK COVER

Y1 LOAD INK PACK

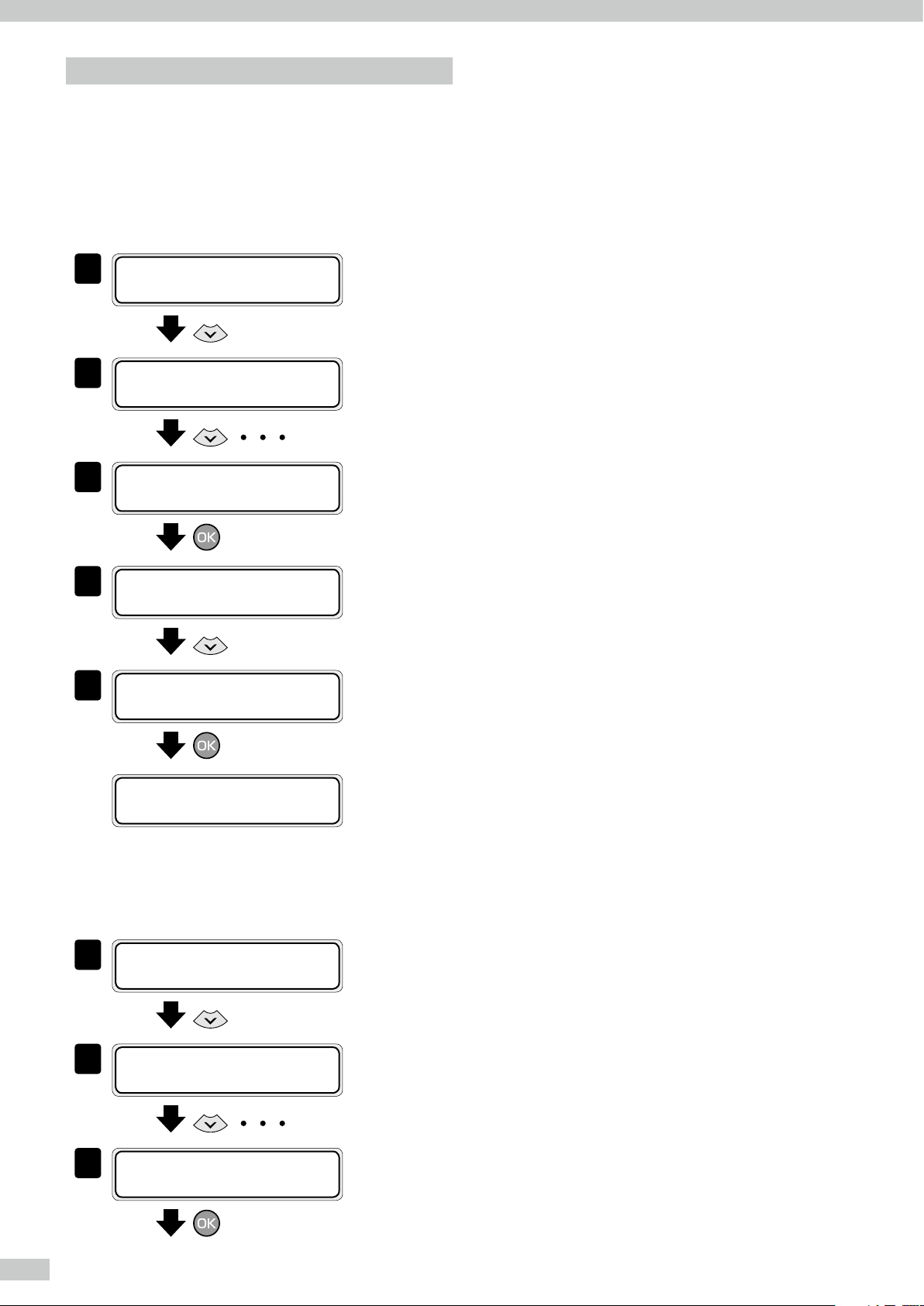

Charging the ink system after head wash

Clear out the waste ink bottle.

1

2

3

INK MEDIA REGâ

á

MEDIA M.ADV

ß

REWIND FORM FEED

á

PH.REC PH.MAIN

ß

à

â

à

Set the Printer to oine state and press the

MENU button.

Press the Right button.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

#CAP CLEANING

4

>

#INK SYSTEM OPT

5

>STORE INK SYS

#INK SYSTEM OPT

6

*STORE INK SYS

#INK SYSTEM OPT

7

*CHARGE(INKPACK)

With the Down button scroll to #INK SYSTEM

OPT.

Press the OK button.

IndexMenu tree

With the Down button scroll to

*CHARGE(INKPACK).

Press the OK button.

19

Page 20

#INK SYSTEM OPT

8

*BOTTLE OK?

Check that the waste ink bottle is empty, and

press the OK button.

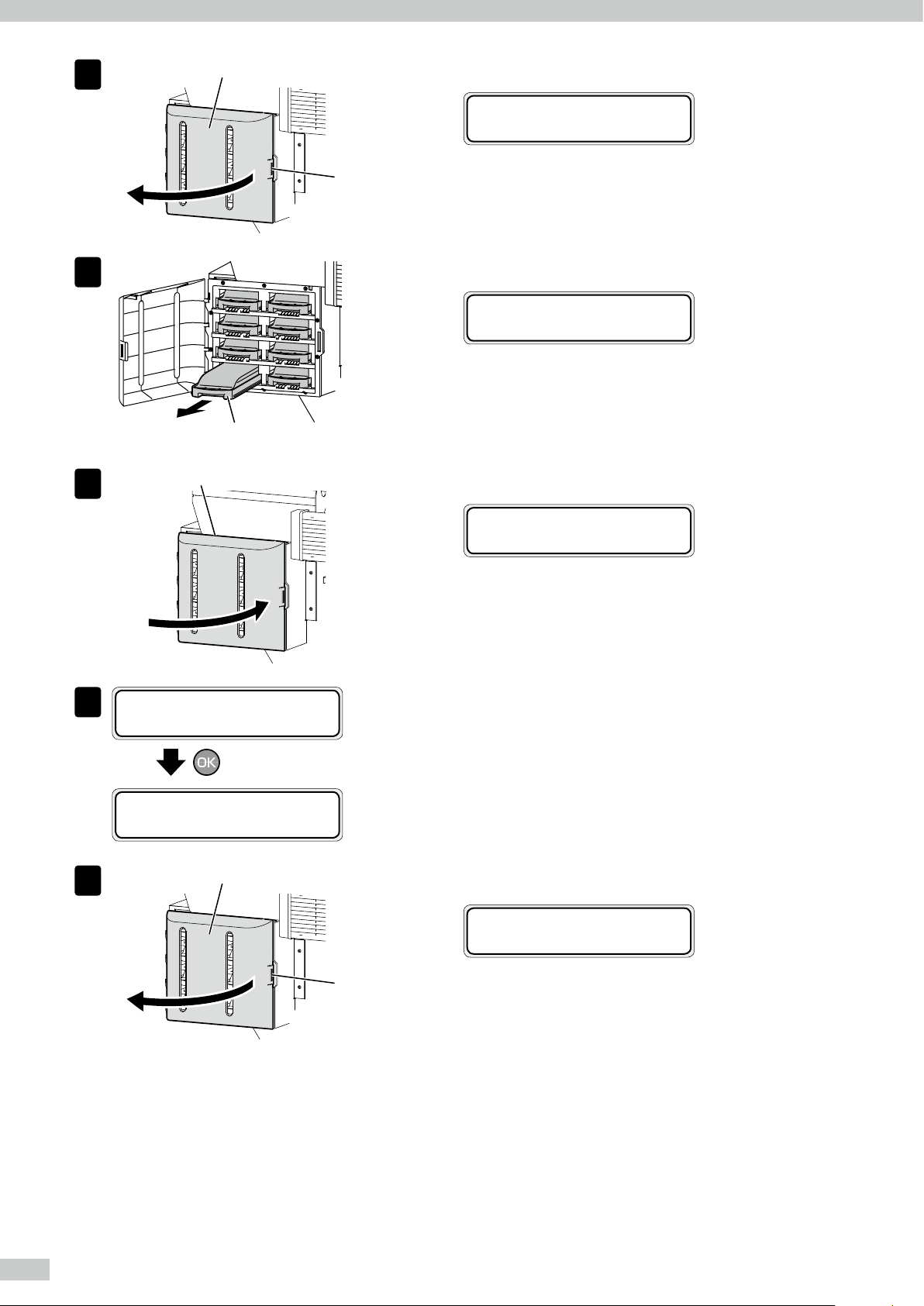

9

10

11

Ink box cover

Ink tray

Ink box cover

Knob

Open the ink box cover.

OPEN

INK COVER

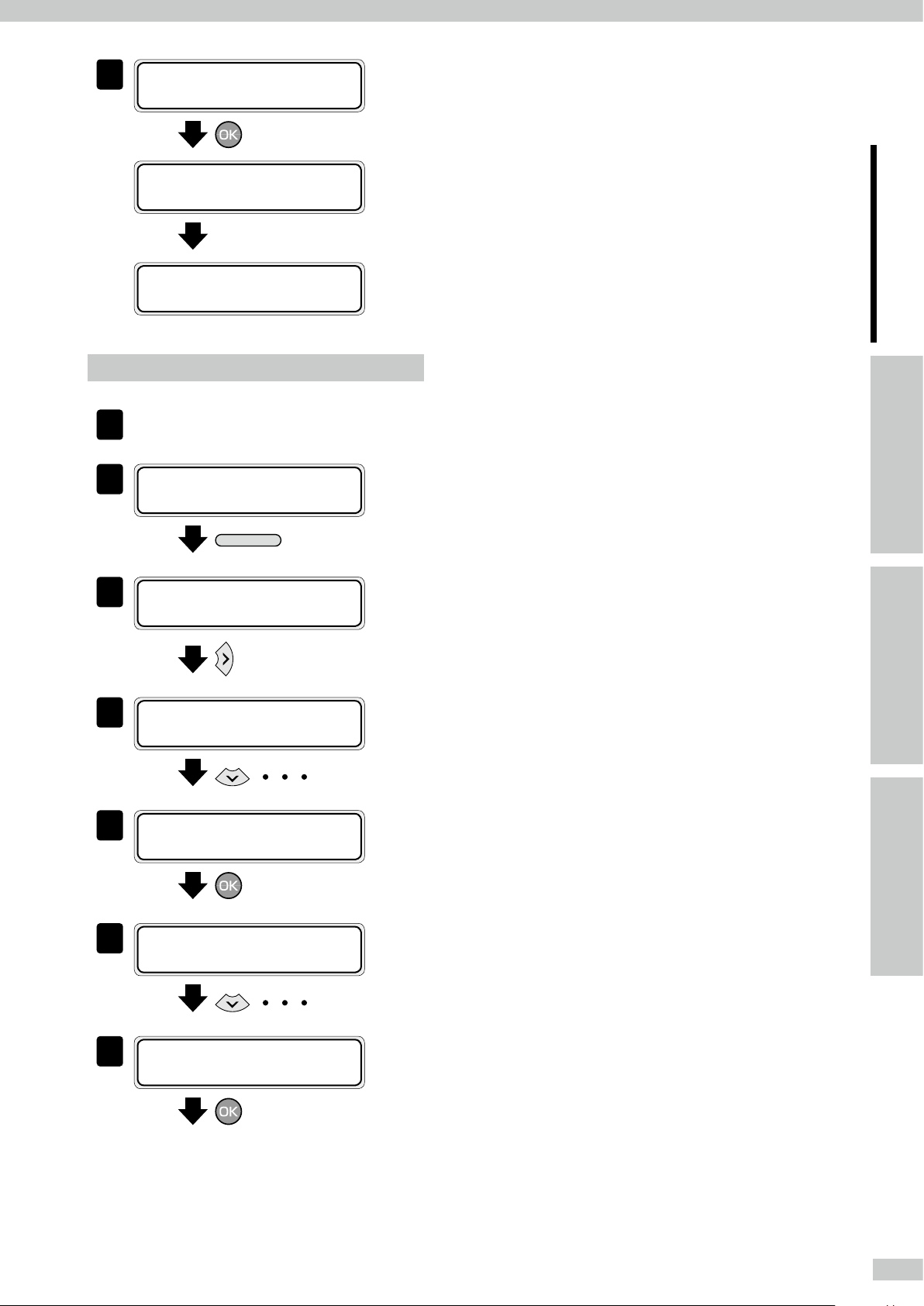

Insert the eight ink trays.

LOAD

Y1 INK PACK

Inktray

Lg8

M7

Lc6

K5

Y1

Lm2

C3

Gy4

Close the ink box cover.

START INK CHARGING

12

*BOTTLE OK?

CHARGING INK

PLEASE WAIT 12

13

Knob screws

CLOSE

INK COVER

Press the OK button.

Open the subcartridge cover.

Loosen the two knob screws on the subcartridge cover

and open the subcartridge cover.

OPEN

SUBCARTRIDGE COVER

20

Subcartridge cover

IP-7900 Advanced Operation Guide

Page 21

14

Subcartridge

Dummy subcartridges

Remove the eight dummy subcartridges of the

cleaning liquid set A.

REMOVE

Y1 DUMMY SUBCART

To assist your Printer

in operating eectively

15

16

CLEANING

17

*BOTTLE OK?

Subcartridges

Subcartridge cover

CLEANING

PLEASE WAIT 12

Set the eight subcartridges.

LOAD

SUBCARTRIDGE

Y1Lm

2C3Gy4K5Lc6M7Lg8

Close the subcartridge cover and tighten the

two knob screws.

CLOSE

SUBCARTRIDGE COVER

Press the OK button.

A normal cleaning is performed.

When the normal cleaning is completed, the LCD

displays message at the step 7.

Adjust and calibrate

the Printer

IndexMenu tree

#INK SYSTEM OPT

*CHARGE(INKPACK)

21

Page 22

Check the Printer status

MENU

MENU

MENU

MENU

MENU

MENU

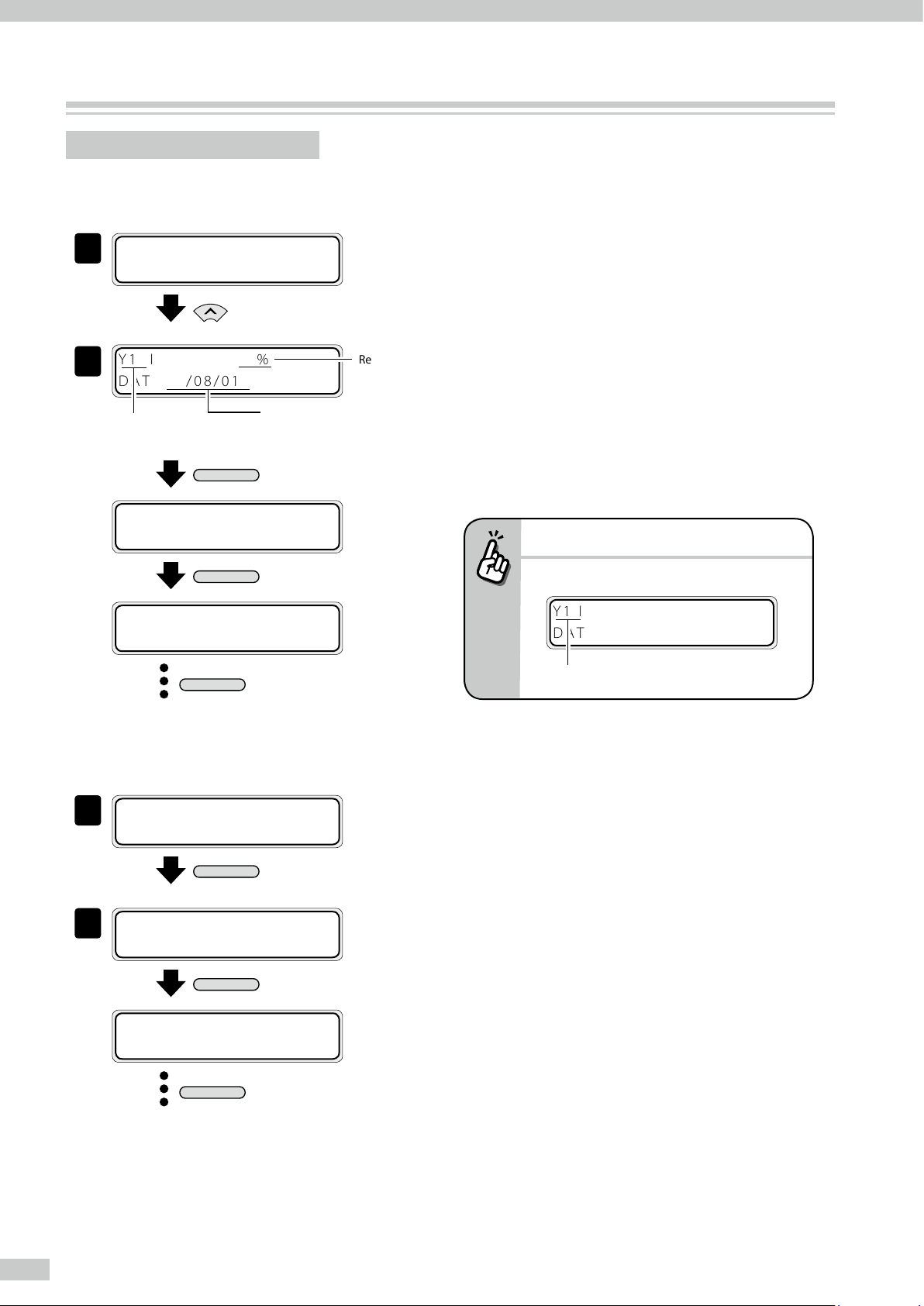

Check the remaining ink level

■ Check in oine

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

Y1 INK LEVEL 95%

2

DATE:09/08/01

Ink color/location

Lm2 INK LEVEL 85%

DATE:09/08/01

C3 INK LEVEL 90%

DATE:09/08/01

à

Remaining ink

Manufactured date of

ink cartridge

or 3 seconds later

or 3 seconds later

or 3 seconds later

Set the Printer to oine state and press the Up

button.

Press the MENU button to switch from one ink

data to the other ink data.

Displayed at intervals of 3 seconds.

When the CANCEL or Left button is pressed, the

display returns to offline state (menu mode) display.

To move to online state (idle mode) display, press the

ONLINE button.

When ink is running out...

- The message below is displayed.

Y1 INK LEVEL LOW

DATE:09/08/01

Ink color/location

■ Check at printing in online

PRINTING

1

NORMAL M ND BI

Y1 INK LEVEL 95%

2

Lm2 INK LEVEL 85%

C3 INK LEVEL 90%

Gy4 INK LEVEL 87%

x2

Press the MENU button twice.

Press the MENU button to switch from one ink

data to the other ink data.

22

IP-7900 Advanced Operation Guide

Page 23

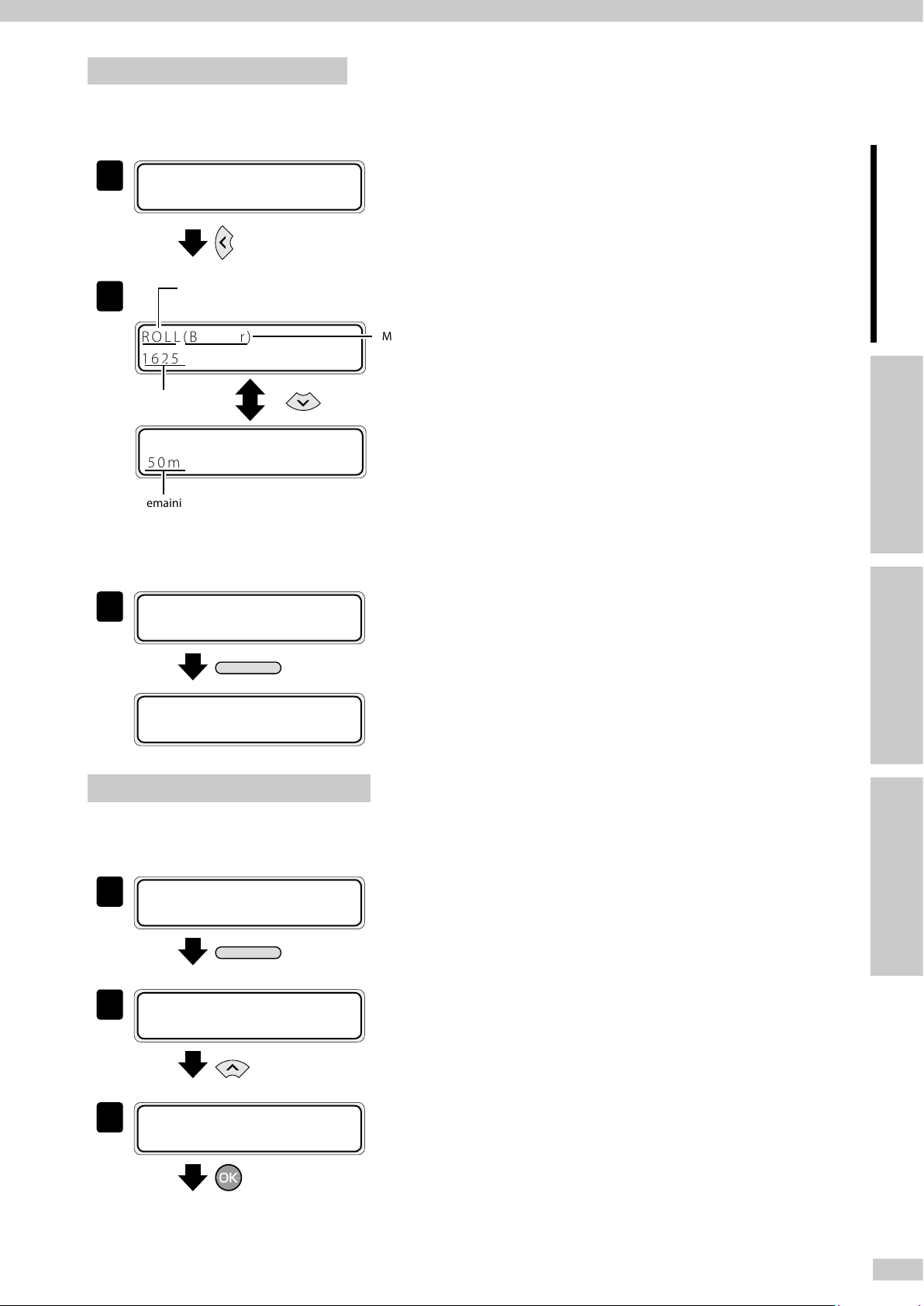

Check remaining media length

MENU

MENU

■ Check in oine

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

à

Set the Printer to oine state and press the

Left button.

To assist your Printer

in operating eectively

2

Media status

ROLL/SHEET/FACE/BACK/NEST

ROLL(Banner)

1625mm

Media width

REMAINING MEDIA

50m

Remaining media

■ Check at printing in online

PRINTING

1

NORMAL M ND BI

REMAINING MEDIA

50m

x6

Media type

Adjust and calibrate

the Printer

Press the MENU button six times.

Print reports on the Printer status.

Perform the operation below to print reports on the Printer status and panel settings.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

2

PRINTER SETUP

á

ADJUST HEATER

ß

#CONFIG PRINT

3

>

à

x2

â

à

Set the Printer to oine state and press the

MENU button twice.

Press the Up button.

Press the OK button.

IndexMenu tree

23

Page 24

#CONFIG PRINT

MENU

*OK?

#CONFIG PRINT

*EXECUTING

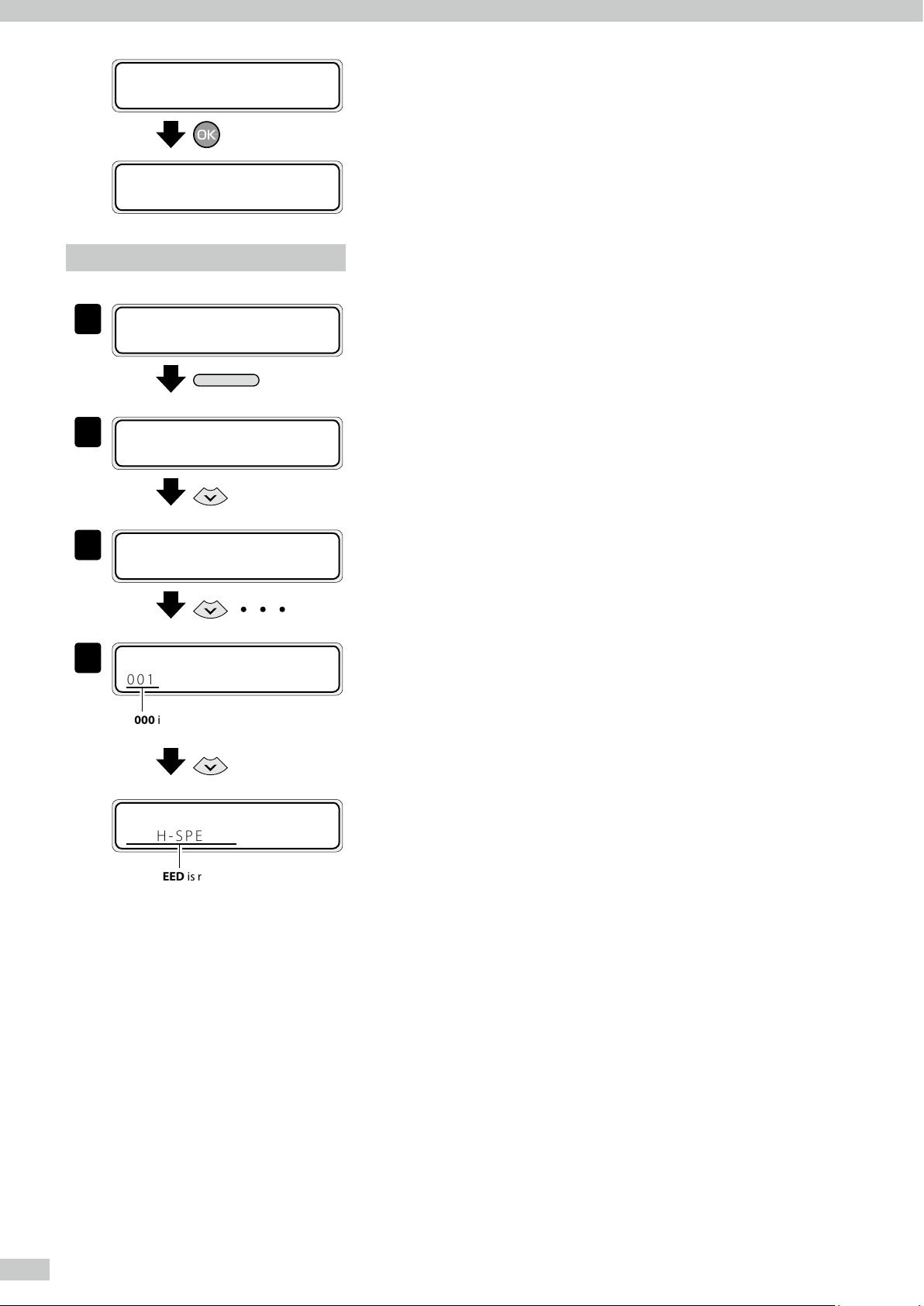

Check the USB connection status

Press the OK button.

The Printer prints the reports on the Printer status.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

2

PRINTER SETUP

á

ADJUST HEATER

ß

#LANGUAGE

3

>ENGLISH

#USB ADDRESS

4

*001

000 is NG.

x2

à

â

à

Set the Printer to oine state and press the

MENU button twice.

Press the Down button.

With the Down button scroll to #USB

ADDRESS.

The LCD displays the USB address,

If the LCD displays the USB address as 000, start the

USB cable connection over again.

Press the Down button.

#USB SPEED

*HIGH-SPEED

HIGH-SPEED is recommended.

The LCD displays the USB speed.

If the LCD displays FULL-SPEED, print speed is

reduced.

24

IP-7900 Advanced Operation Guide

Page 25

Check the rmware version on your Printer

1

MENU

MENU

INK MEDIA REGâ

á

MEDIA M.ADV

ß

2

INK MEDIA REGâ

á

MEDIA M.ADV

ß

#LANGUAGE

3

>ENGLISH

#PRINTER FW VER

*X.XX_YY

x2

à

à

Set the Printer to oine state and press the

MENU button twice.

Press the Down button.

With the Down button scroll to #PRITER FW

VER.

The LCD displays your Printer’s rmware version.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

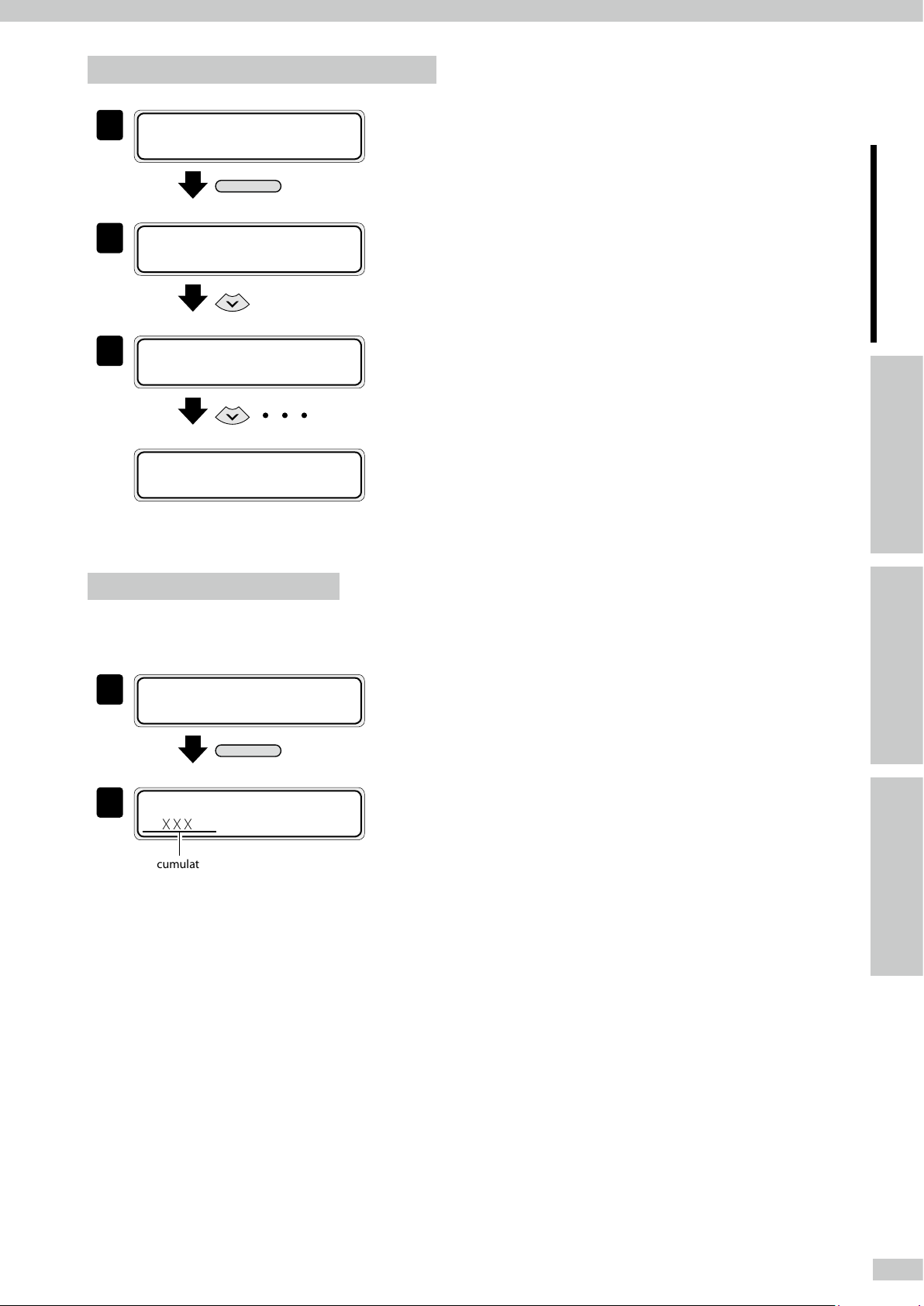

Check the total print distance

The Printer’s accumulated print distance is checked with the operation below.

PRINTING

1

NORMAL M ND BI

MEDIA USED:

2

XXXXXXXm

Accumulated print distance

Press the MENU button in online state.

IndexMenu tree

25

Page 26

Handle the media

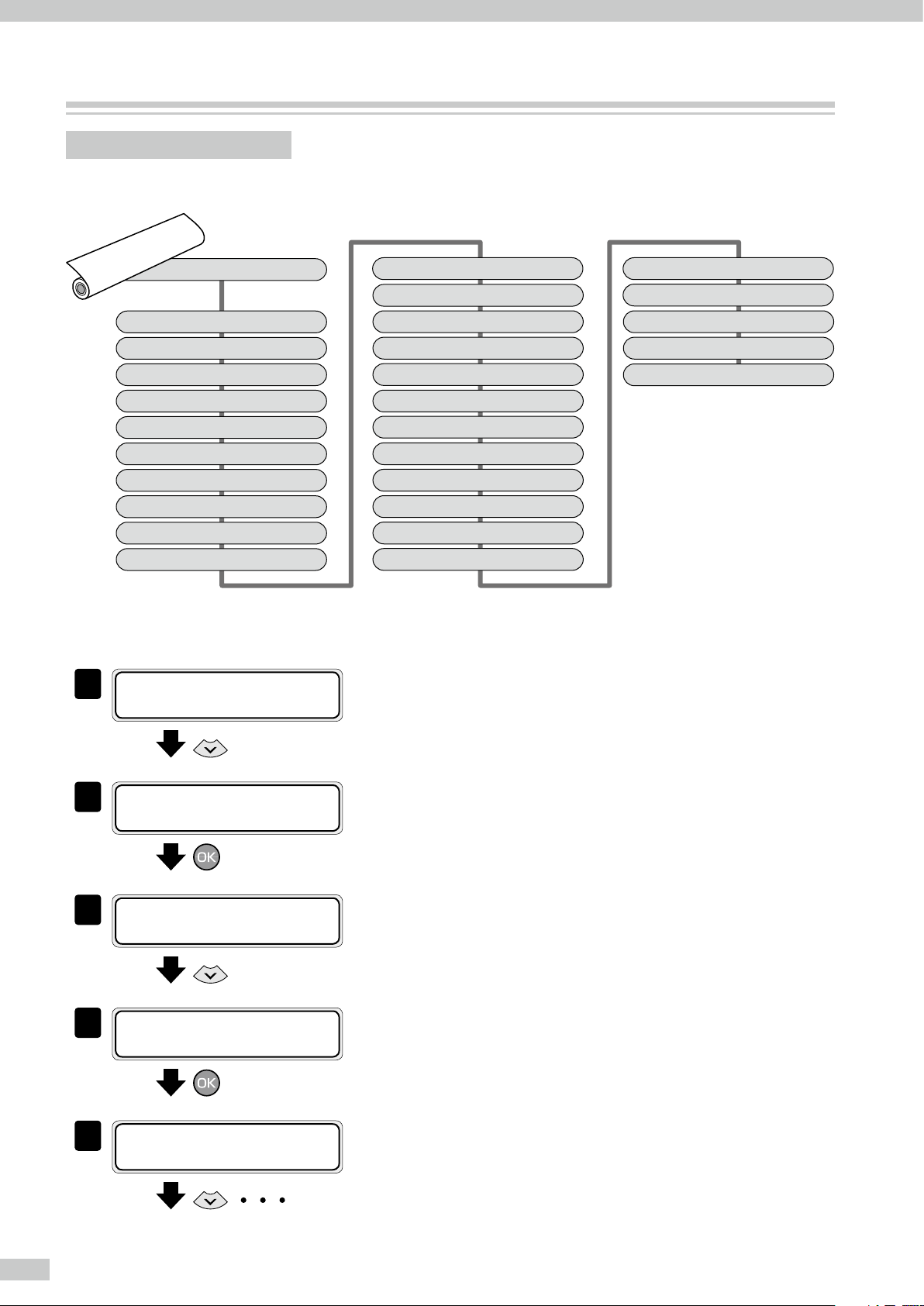

Create a new media preset

As preset media, up to 20 types of media with the information below are registered.

(1) SELECT MEDIA

(2) RENAME MEDIA

(3) USE EDGE GUARD

(4) SKEW CHECK

(5) MEDIA ADV MODE

(6) MEDIA BACK MODE

(7) SUCTION FAN LEVEL

(8) AFTERHEATER INIT

(9) PRINTHEATER INIT

(10) PREHEATER INIT

(11) COLOR STRIPE

(12) PH HEIGHT ADJ

(13) PH CLEANING

(14) ROLL END DETECTION

(15) ADVANCE PREF

(16) HEATER PREF

(17) PH REST PERIOD

(18) PH REST TIME

(19) CARRIAGE SPEED

(20) SAFE SCANNING

(21) MEDIA ADV VALUE

(22) BACK ADJUST VAL

(23) BIDIR VALUE1

(24) BIDIR VALUE2

(25) BIDIR VALUE3

(26) BIDIR VALUE4

(27) SET REMAINING MEDIA

(28) DELETE MEDIA

The parameter setting procedure is described below using an example of setting the media advance adjustment

value in media number 02.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

à

Set the Printer to oine state and press the

Down button.

#SELECT MEDIA

2

>01:PAPER *

#SELECT MEDIA

3

*01:PAPER *

#SELECT MEDIA

4

*02:Glossy *

#SELECT MEDIA

5

>02:Glossy *

Press the OK button.

Press the Down button.

Press the OK button.

With the Down button scroll to #MEDIA ADV

VALUE.

26

IP-7900 Advanced Operation Guide

Page 27

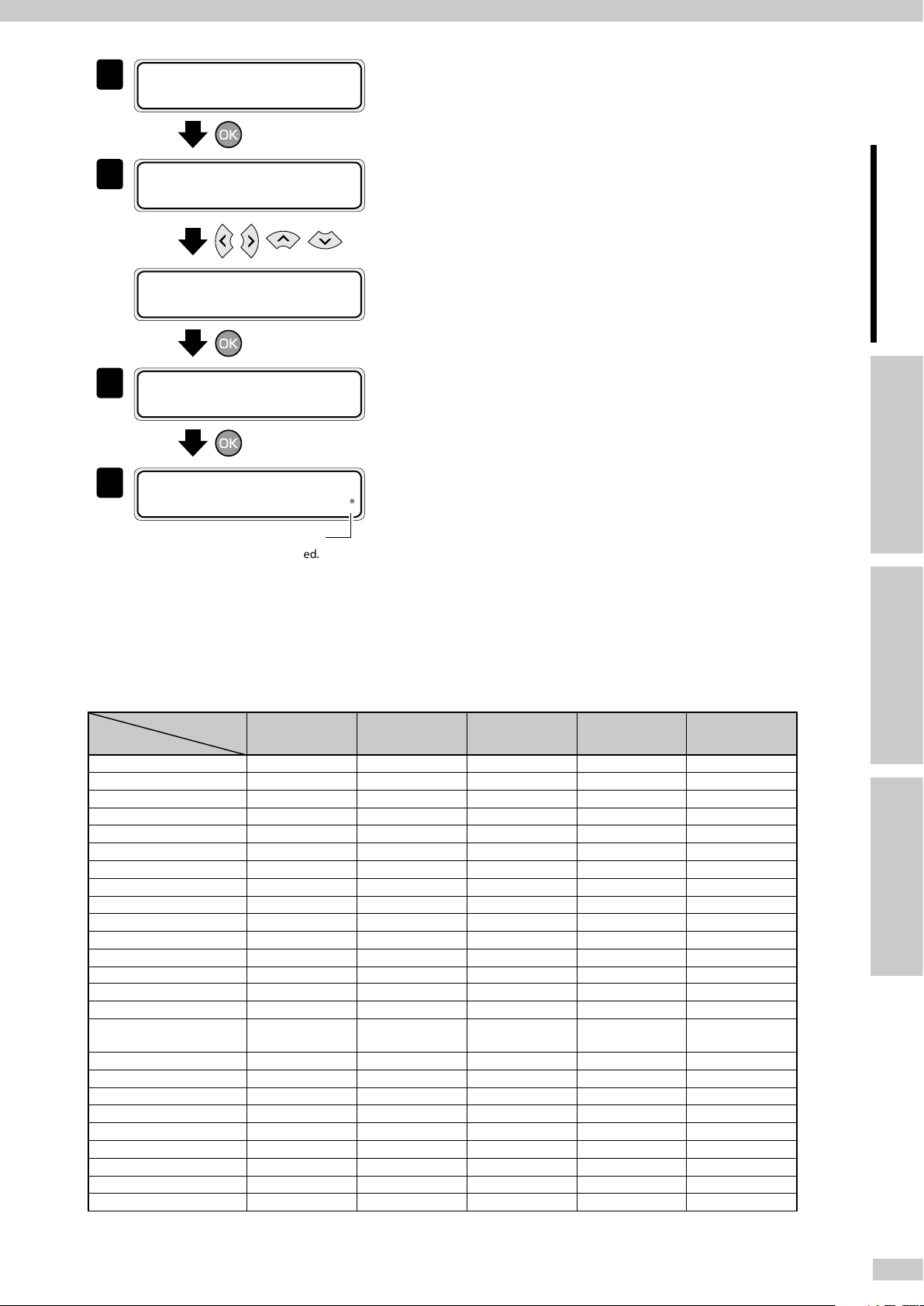

#MEDIA ADV VALUE

6

>02:100. 00%

Press the OK button.

#MEDIA ADV VALUE

7

*02:100. 00%

, , ,

#MEDIA ADV VALUE

*02:099. 80%

#MEDIA ADV VALUE

8

*02:OK?

#MEDIA ADV VALUE

9

*02:099. 80% *

When the media is already

registered, a * mark is displayed.

Enter the media advance adjsutment value and

press the OK button.

Align the digit with the Right or Left button and set

the value with the Up or Down button.

Press the OK button.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

■ Preset media defult values

Up to 20 types (media No. 01 to 20) of media can be registered. Registered media can also be deleted or

changed. However, the information of the preset media No. 01 to No. 05 below initially set in the Printer cannot

be deleted.

For the preset media 01-05, the initial values are listed below.

Media No

Setting

RENAME MEDIA PAPER Glossy Matte Banner BLT_B

USE EDGE GUARD YES YES YES YES YES

SKEW CHECK ON ON ON ON ON

MEDIA ADV MODE FWD ONLY FWD ONLY FWD ONLY BACK & FWD1 BACK & FWD1

MEDIA BACK MODE BACK & FWD BACK & FWD BACK & FWD BACK & FWD BACK & FWD

SUCTION FAN LEVEL NORMAL NORMAL NORMAL LOW LOW

AFTERHEATER INIT **˚C 50˚C 50˚C 50˚C 50˚C

PRINTHEATER INIT **˚C 40˚C 40˚C 40˚C 40˚C

PREHEATER INIT **˚C 45˚C 45˚C 45˚C 45˚C

COLOR STRIPE OFF OFF OFF OFF OFF

PH HEIGHT ADJ +0.00mm +0.00mm +0.00mm +0.00mm +0.00mm

PH CLEANING START & END START & END START & END START & END START & END

ROLL END DETECTION DETECT ONLY DETECT ONLY DETECT ONLY DETECT ONLY DETECT ONLY

ADVANCE PREF SOFTWARE SOFTWARE SOFTWARE SOFTWARE SOFT WARE

HEATER PREF SOFT WARE SOFTWARE SOFTWARE SOFTWARE SOFTWARE

PH REST PERIOD 0000 CYCLES

PH REST TIME 1 second 1 second 1 second 1 second 1 second

CARRIAGE SPEED NORMAL NORMAL NORMAL NORMAL NORMAL

SAFE SCANNING STOP PRINTING STOP PRINTING STOP PRINTING STOP PRINTING STOP PRINTING

MEDIA ADV VALUE 100.00% * 100.00% 100.00% 100.00%

BACK ADJUST VAL +0000PULSE +0000PULSE +0000PULSE +0000PULSE +0000PULSE

BIDIR VALUE1 +00 +00 +00 +00 +00

BIDIR VALUE2 +00 +00 +00 +00 +00

BIDIR VALUE3 +00 +00 +00 +00 +00

BIDIR VALUE4 +00 +00 +00 +00 +00

* The default values are adjusted at the factory shipment.

01 02 03 04 05

(not provided)

0000 CYCLES

(not provided)

0000 CYCLES

(not provided)

0000 CYCLES

(not provided)

0000 CYCLES

(not provided)

IndexMenu tree

27

Page 28

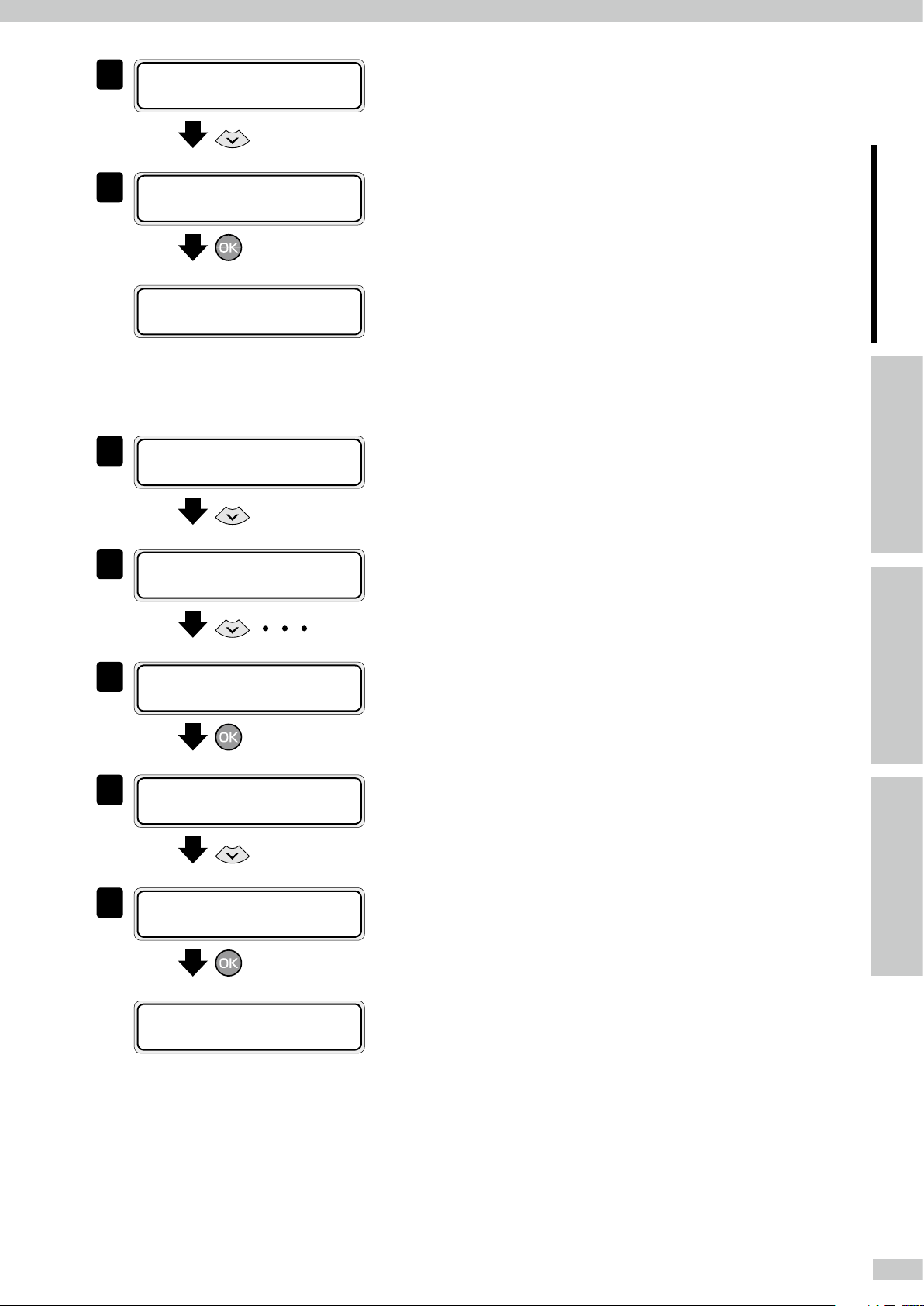

Select a preset media

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

2

#SELECT MEDIA

>01:PAPER *

When the media is already

registered, a * mark is displayed.

#SELECT MEDIA

3

*01:PAPER *

#SELECT MEDIA

4

*02:Glossy *

à

Set the Printer to oine state and press the

Down button.

Press the OK button.

Press the Down button.

Select your preferred preset media.

Press the OK button.

#SELECT MEDIA

>02:Glossy *

Minimize the right and left margins

■ Deactivate the media edge guards

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

à

#SELECT MEDIA

2

>01:PAPER *

Set the Printer to oine state and press the

Down button.

With the Down button scroll to #USE EDGE

GUARD.

3

28

#USE EDGE GUARD

>01:YES

IP-7900 Advanced Operation Guide

Press the OK button.

Page 29

#USE EDGE GUARD

4

*01:YES

Press the Down button.

#USE EDGE GUARD

5

*01:NO

#USE EDGE GUARD

>01:NO

■ Activate the color stripe bar

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

#SELECT MEDIA

2

>01:PAPER *

à

Press the OK button.

Set the Printer to oine state and press the

Down button.

With the Down button scroll to #COLOR

STRIPE.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

#COLOR STRIPE

3

>01:OFF

#COLOR STRIPE

4

*01:OFF

#COLOR STRIPE

5

*01:ON

#COLOR STRIPE

>01:ON

Press the OK button.

Press the Down button.

IndexMenu tree

Press the OK button.

29

Page 30

Prevent the media from sticking and wrinkling

■ Decrease the platen suction fan level

The vacuum pressure applied to the media in the printing zone helps to hold the media down on the platen,

which keeps the distance from media to print heads constant.

When the media sticks to the platen, set the vacuum pressure to LOW. The LOW vacuum pressure is also effective

when your media is so flexible and easily wrinkled.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

#SELECT MEDIA

2

>01:PAPER *

#SUCTION FAN LEVEL

3

>01:HIGH

#SUCTION FAN LEVEL

4

*01:HIGH

x2

#SUCTION FAN LEVEL

5

*01:LOW

à

Set the Printer to oine state and press the

Down button.

With the Down button scroll to #SUCTION FAN

LEVEL

Press the OK button.

Press the Down button twice.

Press the OK button.

#SUCTION FAN LEVEL

>01:LOW

■ Change the media advance mode

Select the media advance mode according to the media used.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

à

Set the Printer to oine state and press the

Down button.

#SELECT MEDIA

2

>01:PAPER *

With the Down button scroll to #MEDIA ADV

MODE

#MEDIA ADV MODE

3

>01:FWD ONLY

Press the OK button.

30

IP-7900 Advanced Operation Guide

Page 31

#MEDIA ADV MODE

4

*01:FWD ONLY

Press the Down button.

#MEDIA ADV MODE

5

*01:BACK & FWD1

#MEDIA ADV MODE

>01:BACK & FWD1

FWD ONLY

BACK&FWD1

BACK&FWD2

FWD WRINKLEFREE

Press the OK button.

Media is fed in the normal advance sequence.

Media is fed in the media adhesion prevention sequence. At the beginning of printing,

media peeling is performed during feeding when the pause mode is cancelled.

Media is fed in the media adhesion prevention sequence. Media peeling is performed

during feeding at each scan.

Advance sequence to prevent wrinkles on solvent printing coated paper.

If five minutes have elapsed after the end of the last printing, the Printer feeds 30 cm of

media before starting to print.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

Solve media lifting up problem

The vacuum pressure applied to the media in the printing zone helps to hold the media down on the platen,

which keeps the distance from media to print heads constant.

When the media lifts up off the platen, set the vacuum pressure to HIGH.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

#SELECT MEDIA

2

>01:PAPER *

#SUCTION FAN LEVEL

3

>01:LOW

à

Set the Printer to oine state and press the

Down button.

With the Down button scroll to #SUCTION FAN

LEVEL

Press the OK button.

IndexMenu tree

#SUCTION FAN LEVEL

4

*01:LOW

x2

Press the Down button twice.

31

Page 32

#SUCTION FAN LEVEL

5

*01:HIGH

Press the OK button.

#SUCTION FAN LEVEL

>01:HIGH

Print on a thick media

■ Change the print head height

The Printer automatically adjusts the print head height to the best position when the Printer is turned on or when

a media is loaded on the Printer. However, you may need to adjust the position finely as the media rigidity and

temperature response are relevant.

To adjust the print head height depending on the loaded media, select MEDIA REG MENU on the operation panel

and adjust the print head height.

CAUTION

- Adjust the print head height carefully to avoid the print head touching the media. The print head scratched by media

causes the poor ink ejection and degrades the print quality.

On the other hand, a too high print head position also degrades the print quality.

You are recommended to operate the Printer with the print head height automatically set by the Printer.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

à

Set the Printer to oine state and press the

Down button.

#SELECT MEDIA

2

>01:PAPER *

With the Down button, scroll to #PH HEIGHT

VAL.

#PH HEIGHT VAL

3

>01:+0.0mm

Press the OK button.

#PH HEIGHT VAL

4

*01:+0.0mm

, , ,

#PH HEIGHT VAL

*01:+0.1mm

Enter the print head height adjustment value,

and press the OK button.

Align the digit with the Right or Left button and set

the value with the Up or Down button.

The adjustment value range is: +0.0 to +1.0 mm.

32

#PH HEIGHT VAL

>01:+0.1mm

IP-7900 Advanced Operation Guide

Page 33

Suspend printing when media wrinkles are detected

To prevent the printouts to be soiled due to the print heads touching the media, this function can suspend

printing when contact between the print heads and the media is detected. Select the mode according to the

characteristics of the media used.

To assist your Printer

in operating eectively

STOP PRINTING

(default setting)

SUSPEND PRINTING

SUSPEND&WARNING

WARNING ONLY

Printing is stopped immediately if a contact between the print heads and the media is detected.

The printing interruption is notified by a warning sound and a message displayed on the panel.

Printing cannot be resumed after it has been stopped, so it is required to perform printing again after

reloading the media.

Printing is suspended temporarily and the print heads are capped if a contact between the print heads

and the media is detected.

The printing temporary suspension is notified by a warning sound and a message displayed on the

panel.

Printing can be resumed after checking the media conditions and removing the wrinkles, if any.

Printing is suspended temporarily and the print heads are capped if five contacts between the media

and the print heads are detected consecutively.

Any contact detected between the media and the print heads is notified by a warning sound and a

message displayed on the panel.

Printing suspension is also notified by a warning sound and a message displayed on the panel.

Printing can be resumed after checking the media conditions and removing the wrinkles, if any.

Printing continues even when contacts between the media and the print heads are detected.

However, any contact detected between the media and the print heads is notified by a warning sound

and a message displayed on the panel.

The warning sound stops and the panel message disappears when contact is not detected anymore.

Printing can be suspended manually and resumed after all wrinkles have been removed.

Adjust and calibrate

the Printer

CAUTION

Pay attention to the following when Safe Scanning is set to STOP PRINTING.

- When the printing has been stopped, load the media again without delay to prevent the print heads from drying.

Pay attention to the following when Safe Scanning is set to WARNING ONLY.

- The print heads may be damaged if printing is performed during a long time while the warning indicating that the

print heads contact the media is emitted.

Pay attention to the following when Safe Scanning is set to SUSPEND PRINTING or SUSPEND&WARNING.

- Make sure that all the wrinkles have been removed when resuming the printing after it has been suspended.

- If missing dots appear on the printout after resuming the printing, pause printing and perform PH Recovery.

The procedure to change the Safe Scanning setting is explained below, taking the procedure to change STOP

PRINTING to SUSPEND&WARNING for the preset media 1 as an example.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

#SELECT MEDIA

2

>01:PAPER *

à

Set the Printer to oine state and press the

Down button.

With the Down button, scroll to #SAFE

SCANNING.

IndexMenu tree

#SAFE SCANNING

3

>01:STOP PRINTING

Press the OK button.

33

Page 34

#SAFE SCANNING

This mode shows less misalignment at the linkage than the DURING PRINT1. However, the hue after

4

*01:STOP PRINTING

Press the Down button.

#SAFE SCANNING

5

Press the OK button.

*01:SUSPEND&WARNING

#SAFE SCANNING

>01:SUSPEND&WARNING

Change the automatic cleaning timing

To ensure that the print heads are in the best condition, the Printer performs automatic cleaning. The cleaning

mode can be specified for each preset media. Select the cleaning mode depending on the media characteristics.

START & END

DURING PRINT1

Based on the past print operation history, the Printer performs the automatic cleaning on starting

and completing the print operation.

Based on the past print operation history, the cleaning is performed when printing starts or during

printing. In this mode, the Printer completes the print band in process before the cleaning starts.

This mode is recommended when printing on the media subject to the heater temperature, for

example, on Vinyl.

After the cleaning, the Printer starts the rest of the interrupted print job.

Some media shows misalignment at the linkage of the prints before and after the cleaning. In such

a case, START & END or DURING PRINT2 is recommended.

DURING PRINT2

OFF

Cleaning

Correct with

the BACK

ADJUST VAL.

Based on the past print operation history, the cleaning is performed when printing starts or during

printing. In this mode, the Printer completes the print band in process before the cleaning starts.

This mode is recommended when printing on the media less subjected to the heater temperature,

for example, on Banner.

After the cleaning, the Printer starts the rest of the interrupted print job.

the cleaning may be dierent from the one before the cleaning.

Cleaning

Current print band

Automatic cleaning is not performed. Set this mode in the following case.

- When printing continuously several data les on media with which dierences between

printouts will be noticeable if automatic cleaning is performed between two les.

If automatic cleaning is set to OFF, determine suitable timing to execute cleaning manually.

INK SAVE

34

Based on the past print operation history, the Printer performs the automatic cleaning when the

printing starts or nishes.

* With INK SAVE, the interval between automatic cleaning operations is longer than with START &

END.

IP-7900 Advanced Operation Guide

Page 35

CAUTION

- Pay attention to the following points when automatic cleaning is set to OFF or INK SAVE.

- Missing dots may appear if the cleaning operation has not been performed for a long time.

- Manually perform cleaning when the PERFORM PH RECOVERY NOW message is displayed on the panel to prevent

the missing dots problem.

The procedure to change the automatic cleaning timing is explained as follows, taking the procedure to select

the automatic cleaning DURING PRINT1 for the preset media 1 as example.

To assist your Printer

in operating eectively

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

#SELECT MEDIA

2

>01:PAPER *

#PH CLEANING

3

>01:START & END

#PH CLEANING

4

*01:START & END

à

Set the Printer to oine state and press the

Down button.

With the Down button, scroll to #PH

CLEANING.

Press the OK button.

Press the Down button.

Adjust and calibrate

the Printer

#PH CLEANING

5

*01:DURING PRINT1

Press the OK button.

#PH CLEANING

>01:DURING PRINT1

Copy a preset media type to create a new one

The following describes the procedure to copy the parameter registered in media No. 13 to media No. 20.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

#SELECT MEDIA

2

>01:PAPER *

à

Set the Printer to oine state and press the

Down button.

With the Down button scroll to #COPY MEDIA.

IndexMenu tree

35

Page 36

#COPY MEDIA

3

3

>01

Press the OK button.

#COPY MEDIA

4

*01

#COPY MEDIA

5

*13

#COPY MEDIA

6

>13

#PASTE MEDIA

7

>13à01*

Select a copy source with the Up or Down

button.

,

Only numbers for media types that already exist are

displayed.

By pressing the CANCEL button the operation returns

to the step

.

3

Press the OK button.

By pressing the CANCEL button the operation returns

to the step

.

Press the Down button.

Press the OK button.

#PASTE MEDIA

8

*13à01*

#PASTE MEDIA

9

*13à20

#PASTE MEDIA

10

*13à20OK?

#PASTE MEDIA

11

*13à20*

Select a copy destination with the the Up or

Down button.

,

Copy destination numbers 01 to 20 are displayed.

If the number on the right is followed by an asterisk

(*), the number displayed already contains media type

information.

Press the OK button.

Press the OK button.

The operation was completed.

36

IP-7900 Advanced Operation Guide

Page 37

Change the type of the preset media without reloading the media

The settings of the preset media are also changed.

To assist your Printer

in operating eectively

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

ROLL(XXXXXX)

2

YYYYmm

#SELECT MEDIA

3

>01:TYPE01

#SELECT MEDIA

4

*01:TYPE01

à

Set the Printer to oine state and press the Left

button.

With the Down button scroll to #SELECT

MEDIA.

Press the OK button.

Press the Down button several times to select

the desired media.

Adjust and calibrate

the Printer

#SELECT MEDIA

5

*04:Banner

#SELECT MEDIA

6

>04:Banner

Feed or rewind media

■ Feed or rewind media in online state (idle mode)

PRINT READY

1

ROLL:1625/PAPER

Press and hold the or button.

Press the OK button.

IndexMenu tree

Press and hold the Up or Down button.

To feed media, press the Down button.

To rewind media, press the Up button.

(A cut-sheet media, if installed into the Printer, is

discharged from the Printer.)

37

Page 38

The button is pressed.

MENU

2

FEEDING MEDIA

The button is pressed.

REWINDING MEDIA

Release the or button.

PRINT READY

ROLL:1625/PAPER

■ Feed or rewind media in oine state

Release the Up or Down button.

The Printer stops feeding or rewinding media, and the

display returns to online state (idle mode).

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

à

2

REWIND FORM FEED

á

PH.REC PH.MAIN

ß

â

à

Press and hold the or button.

The button is pressed.

3

FEEDING MEDIA

The button is pressed.

REWINDING MEDIA

Set the Printer to oine state and press the

MENU button.

Press and hold the Up or Down button.

To feed media, press the Down button.

To rewind media, press the Up button.

(A cut-sheet media, if installed into the Printer, is

discharged from the Printer.)

Release the Up or Down button.

The Printer stops feeding or rewinding media, and the

display returns to offline state (menu mode).

Release the or button.

REWIND FORM FEED

á

PH.REC PH.MAIN

ß

â

à

CAUTION

- Apply the roll feed unit to backfeed media only for a short distance. For a long distance, carefully apply it and lower the

slack position gradually so that the media slack would not reach the oor.

Besides note that the take-up reel unit does not perform the backfeed operation.

Do not backfeed media with the take-up reel unit applied.

38

IP-7900 Advanced Operation Guide

Page 39

Move a print start position (nest function)

2

By moving a print start position, the image is printed on your preferred position.

After printing, rewind the roll, and with this function you can print an image in the blank area.

(First print)

(Media rewound)

(Second print)

To assist your Printer

in operating eectively

Blank

Second image with the print start

position moved

CAUTION

- Complete this operation as immediately as possible. Otherwise the print heads dry, which may cause ink ejection

failure. In such a case perform a cleaning.

REWINDING MEDIA

1

PRINT READY

ROLL:1625/PAPER

Press and hold the button for 1.5 seconds.

Rewind the media.

See Feed or rewind media on the

page 37

CAUTION

- Rewind the media after the printed image completely

dries. If the media is rewound while the image is not

suciently dry, the image may be damaged.

Press and hold the Left button for 1.5 seconds.

The carriage moves and the nest function is activated.

Align the

cover’s front panel with the origin of the next print

image.

mark at the lower left of the carriage

Adjust and calibrate

the Printer

.

IndexMenu tree

Origin

NEST ORIGIN SETTING

3

CARRIAGE MOVING

Move the carriage with the Right or Left button

to the position to be set as an origin.

,

39

Page 40

NEST ORIGIN SETTING

4

*OK?

Press the OK button to x the origin setting.

The carriage returns, and the Printer enters online state

(idle mode) and becomes ready to print.

NEST ORIGIN SETTING

PLEASE WAIT

To cancel the origin above, press and hold the Right

button for 1.5 seconds in the idle mode or raise the

pressure control knob. When the origin is cancelled,

the display returns from NEST to ROLL.

PRINT READY

NEST:1625/PAPER

<Display when the origin is cancelled>

PRINT READY

ROLL:1625/PAPER

Use the media until the very end

Even when the media end is detected during printing (online mode), a margin remains at the media bottom end.

This remaining margin can also be used for printing.

Print quality may be affected when printing near the media bottom end. Use this function only if you can afford this loss

in print quality.The tension bar on the supply side must be removed to print near the media bottom end. The media

advance adjustment value may not be adequate anymore after the tension bar has been removed, which may affect the

print quality.

Set roll end detection to Action Selection beforehand.

Detect Only Printing stops when media end is detected.

Action Selection Printing stops temporarily when media end error is detected.

Select Print or Cancel with the operation panel.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

à

Set the Printer to oine state and press the

Down button.

#SELECT MEDIA

2

>01:TYPE01 *

With the Down button scroll to #SELECT

MEDIA.

#ROLL END DETECTION

3

>01:DETECT ONLY *

Press the OK button.

40

IP-7900 Advanced Operation Guide

Page 41

#ROLL END DETECTION

4

*01:DETECT ONLY *

Press the Down button.

#ROLL END DETECTION

5

*02:ACTION SELECT. *

Press the OK button.

#ROLL END DETECTION

6

>02:ACTION SELECT. *

When roll end is detected during printing (online mode), printing stops temporarily and the following screen is

displayed.

ROLL END DETECTED

PRINT/CANCEL

<Procedure to continue printing>

Tension bar

1. Remove the tension bar.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

ROLL END DETECTED

PRINT/CANCEL

Peel roller

Peel roller

2. Detach the media end from the paper tube

using the cutter.

Press the OK button.

IndexMenu tree

41

Page 42

PREHEATING

CANCEL

ROLL:1626/PAPER

<Procedure to suspend or stop printing>

The printing resumes.

The loss in print quality can be

compensated by pulling the media

by hand to keep it stretched during

printing.

ROLL END DETECTED

PRINT/CANCEL

NO MEDIA LOADED

LOAD MEDIA

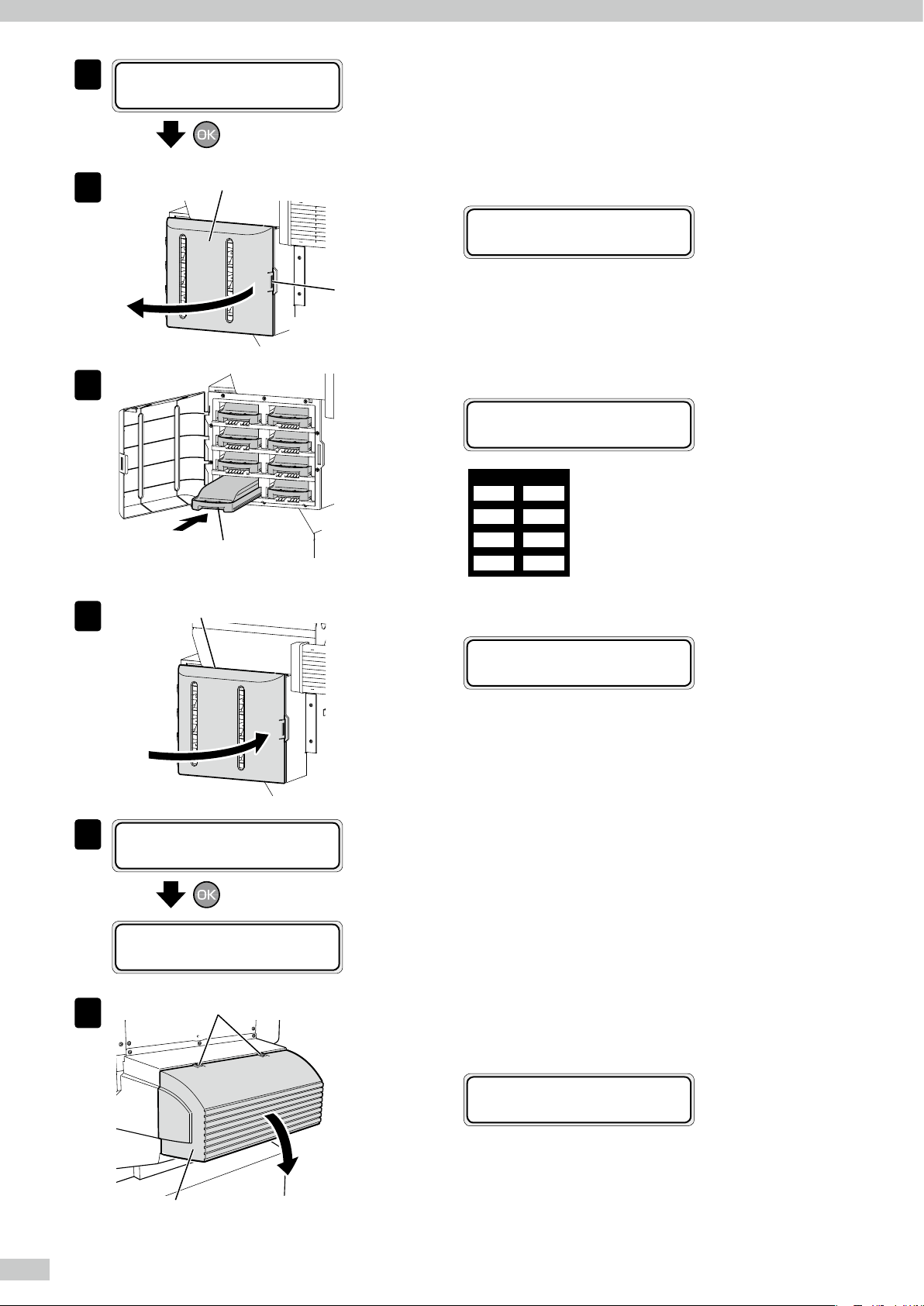

Print on a cut-sheet media

1

Front cover

Protection bar

Press the CANCEL button.

The printing is suspended and the following

message is displayed. Load the new media.

Remove the protection bar, and open the front

cover.

42

2

Wiping unit side

With pressing the media

edge guard’s your side

part, move each media

edge guard.

IP-7900 Advanced Operation Guide

Capping unit side

Move the media edge guards to each side.

Move the media edge guards to each side so that they

are not under the media.

With pressing the media edge guard’s your side part,

move each media edge guard.

CAUTION

- Be sure to press the media edge guard on your side

when moving the media edge guards. You may get

injured if your nger slips while strongly pressing the

plate’s edge.

Page 43

3

Media output side

Set the pressure to Open by rotating the

pressure control knob.

To assist your Printer

in operating eectively

Pressure control knob

4

Insert a cut-sheet media into the paper feeder

slot.

Insert the cut-sheet media so that the media feed

sensor is covered with the media.

Adjust and calibrate

the Printer

5

Suppy side

6

Set the pressure to Normal by rotating the

pressure control knob.

Point to be checked again

- Check that the media on the platen is not lifted

up or wrinkled.

Set the media edge guards.

(1) With pressing the media edge guard’s your side part,

move each media edge guard to the media edge.

(2) Align each media edge guard’s notch with the

media edge.

Check that:

- The media edge guards are not under the media.

- The thick media, being inserted forcibly, is not jammed

under the media edge guards.

IndexMenu tree

(1) (2)

With pressing the media

edge guard’s your side part,

move each media edge

guard.

Align each media edge

guard’s notch with the

media edge.

Notch

CAUTION

- To prevent a media jam, be sure to apply the media

edge guards to prevent a media jam.

- Be sure to press the media edge guard on your side

when moving the media edge guards. You may get

injured if your nger slips while strongly pressing the

plate’s edge.

43

Page 44

7

ONLINE

Close the front cover, and then install the

protection bar.

8

CHECK EDGE GUARD

*OK?

SELECT MEDIA

9

ROLL/SHEET:ROLL

ROLL/SHEET:SHEET

SELECT MEDIA

10

MEDIA:PAPER

SELECT MEDIA

MEDIA:Banner

SET MEDIA

11

*OK?

Press the OK button.

Select SHEET and press the OK button.

(To return to the media selection, press the CANCEL

button.)

Select the type of media, and then press the OK

button.

Select a preset media with the Up or Down button.

Here explains the procedure taking banner for

example.

Press the OK button.

PREPARING MEDIA

PLEASE WAIT

Adjust the head margin before printing

Advance or rewind the media during the preheating time before printing to adjust the margin to the previous

printout.

This function cannot be used for the current job once printing

(or scan) has started.

PREHEATING

1

MAX-QUA M ND UNI

Press the ONLINE button during the preheating

time before printing.

44

IP-7900 Advanced Operation Guide

Page 45

PRINTER PAUSED

ONLINE

ONLINE

ONLINE

2

ROLL:1626/PAPER

The Printer enters pause mode. Keep the Down

button pressed.

FEEDING MEDIA

3

PRINTER PAUSED

4

ROLL:1626/PAPER

PREHEATING

5

MAX-QUA M ND UNI

Reinstall the edge guards during printing

Release the Down button to stop feeding the

media.

Press the ONLINE button to resume printing.

Press the Up button to rewind the

media.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

If the edge guards are accidentally removed or particles adhere to the media advance path during printing, put

the Printer into pause mode to be able to open and close the front cover.

PRINTING

1

MAX-QUA M ND UNI

Press the ONLINE button during printing.

PRINTER PAUSED

2

ROLL:1626/PAPER

CLOSE

3

COVER

PRINTER PAUSED

4

ROLL:1626/PAPER

Open the front cover

Close the front cover

The Printer enters pause mode. Open the front

cover.

Close the cover to return to the Printer pause

display.

Press the ONLINE button to resume printing.

IndexMenu tree

PRINTING

5

MAX-QUA M ND UNI

45

Page 46

Remove some media wrinkles during printing

ONLINE

ONLINE

If the media wrinkles during printing (online mode), put the Printer into pause mode to be able to release the

grip.

Media wrinkles can be partially removed by releasing the grip.

However, in that case the media may skew and the print quality

may decrease.

PRINTING

1

MAX-QUA M ND UNI

PRINTER PAUSED

2

ROLL:1626/PAPER

HOLD MEDIA

3

PRINTER PAUSED

4

ROLL:1626/PAPER

Release the grip

Set the grip

Press the ONLINE button during the preheating

time before printing.

The Printer enters pause mode. Release the

grip.

CAUTION

- When the grip is released, hold the media in your

hands to prevent it from skewing.

Set the grip back to return to the Printer pause

display.

Press the ONLINE button to resume printing.

PRINTING

5

MAX-QUA M ND UNI

Solve skew in LOOSE winding mode

1

Tension bar hook

Tension bar

Hook the tension bar to the tension bar hook

beforehand.

46

IP-7900 Advanced Operation Guide

Page 47

2

Load the media on the Printer.

3

For the procedure, see the Basic Operation Guide, To take up media in LOOSE winding mode .

Close the tension bar guide’s cover.

Close the cover, and x the cover by fastening the knob

screw.

To assist your Printer

in operating eectively

4

Input the data in the software RIP.

5

Place the tension bar with gear on the closed

tension bar guide.

Place the tension bar carefully to prevent the tension

bar with gear from being dropped.

Media

Tension bar with gear

LOOSE winding mode

Supply-side tension bar

Adjust and calibrate

the Printer

47

IndexMenu tree

Page 48

To change the Printer’s basic settings

MENU

Turn the audio warning beep o

The default beep is set to on. So the Printer issues the audio warning beep when:

- The print heads are not capped during the daily maintenance or print head height adjustment.

- The print heads cannot be capped because of a media jam during the print operation.

With the procedure below the audio warning beep is turned off.

1

INK MEDIA REGâ

á

MEDIA M.ADV

ß

2

PRINTER SETUP

á

ADJUST HEATER

ß

#LANGUAGE

3

>JAPANESE

#BEEP(UNCAP CARRI)

4

>ON

x2

à

â

à

Set the Printer to oine state and press the

MENU button twice.

Press the Down button.

With the Down button scroll to #BEEP(UNCAP

CARRI).

Press the OK button.

#BEEP(UNCAP CARRI)

5

*ON

Press the Down button.

#BEEP(UNCAP CARRI)

6

*OFF

Press the OK button.

#BEEP(UNCAP CARRI)

>OFF

Update the system rmware

To improve the Printer’s performance, you are recommended to update the system firmware.

For the procedure, refer to the documents attached to the system firmware.

48

IP-7900 Advanced Operation Guide

Page 49

Cleaning options

MENU

Perform cleaning only for the specied print head

When a specific length of media has been printed since the last

cleaning operation, print heads cannot be selected and cleaned

individually.

1

2

3

INK MEDIA REGâ

á

MEDIA M.ADV

ß

REWIND FORM FEED

á

PH.REC PH.MAIN

ß

#PH RECOVERY

>NORMAL

à

â

à

Set the Printer to oine state and press the

MENU button.

Press the Left button.

Press the OK button.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

#PH RECOVERY

4

*NORMAL

*STRONG

#PH RECOVERY

5

*NORMAL

#PH RECOVERY

6

*NORMAL:8 7654321

, , ,

With the Up or Down button scroll to

*STRONG.

,

Press the OK button.

IndexMenu tree

Select your preferred print head for cleaning.

With the Right or Left button, select the print head

number. Then with the Up or Down button, display or

delete the number. Display it to clean the print head,

or delete it not to clean the print head.

The ink colors and print head numbers

correspondence is shown in the table below.

Lg M Lc K Gy C Lm Y

8 7 6 5 7 3 2 1

49

Page 50

#PH RECOVERY

7

*NORMAL:8 5

Press the OK button.

The left LCD display shows that the Printer performs

the cleaning only for the print heads 5 and 8.

#PH REC 8 5

8

*BOTTLE OK?

#PH REC 8 5

*EXECUTING 12

This value is counted down every 10 seconds.

#PH RECOVERY

9

>NORMAL

REWIND FORM FEED

á

PH.REC PH.MAIN

ß

Press the OK button.

Check visually that the waste ink bottle is not full.

Cleaning is started.

Print head cleaning takes several minutes.

When the cleaning starts, the required time is

displayed and the time is counted down every 10

seconds.

Press the Left button.

The Printer returns to offline state, that is, menu mode.

â

à

50

IP-7900 Advanced Operation Guide

Page 51

Manage the media advance compensation

Change media advance compensation

PRINTING

1

NORMAL M ND BI

MEDIA ADV:099.80%

2

*099. 80%

The value is incremented or decremented by 0.01%

with the

(Settable range: 97.00% to 106.00%)

MEDIA ADV:099.80%

3

*099. 96%

,

The value at

the start of

printing

or button.

,

Press the Up or Down button while PRINTING

is displayed.

With the Up or Down button, change the

media advance compensation.

When the value is changed, it is reflected in printing

immediately.

The value displayed at the start of printing does not

changeuntil the printing is completed. However, when

the cleaning mode is set to DURING PRINT, the value

displayed changes after the cleaning is completed.

The changed value is registered and retained.

When no button is operated for three seconds, the

display returns to the original one.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

PRINTING

NORMAL M ND BI

IndexMenu tree

51

Page 52

Print conditions

On the Printer, print conditions can be configured with the following interrelated settings

- 5 print mode settings

- 2 smart pass settings

in addition to

- 2 density settings.

- 2 carriage speeds

Configure the print conditions according to the media type, productivity and print quality.

Generally, we recommend printing with NORMAL print mode, NORMAL density, and NORMAL carriage speed

settings.

Use other modes and settings to emphasize productivity or print quality.

After changing the print mode

Adjust the media advance compensation again (

Settings for the print mode, smart pass, and density can be configured only from the RIP software.

page 77

).

Set PRINT MODE

Set the print resolution.

Reduce the resolution to maximize productivity.

Increase the resolution for high definition printout with no visible grains.

Print mode Resolution Explanation

MAX SPEED 360dpi x 360dpi x DDP This is the fastest print mode. Use it to emphasize productivity.

The smart pass setting can be configured.

HIGH SPEED 360dpi x 540dpi x DDP This print mode is balanced between print speed and quality.

NORMAL 540dpi x 540dpi x DDP This is the normal print mode. Usually, use this print mode.

HIGH QUALITY 720dpi x 720dpi The quality is emphasized rather than print speed.

MAX QUALITY 900dpi x 900dpi This print mode has the highest resolution.

CAUTION

- The NORMAL print mode is recommended. Use the other modes according to your needs regarding productivity and quality.

52

IP-7900 Advanced Operation Guide

Page 53

Set SMART PASS

Set the auto correction level to enhance image quality by correcting unevenness or other print defects. Adjust

the enhancing effect by setting the correction level to low or to medium for further effect.

Smart pass Explanation

LOW The productivity is emphasized rather than the quality. Since the enhancing effect is low,

unevenness, banding, spots, or other print defects may appear. Smart pass can be set to

LOW only in MAX SPEED print mode.

MEDIUM The enhancing effect is fully used. Smart pass setting is fixed to MEDIUM in print modes

other than MAX SPEED.

To assist your Printer

in operating eectively

CAUTION

- Print speed with LOW setting is approximately 50% faster than with MEDIUM setting.

Set DENSITY

The print density can be set to NORMAL and HIGH DENSITY.

The following shows the relationship between the density level for HIGH DENSITY and each print mode, when

the density for NORMAL is assumed to be 1.0.

Density

Print mode

NORMAL HIGH DENSITY

MAX SPEED 1.0 1.0 (*1)

HIGH SPEED 1.0 2.0

NORMAL 1.0 1.9

HIGH QUALITY 1.0 2.0

Adjust and calibrate

the Printer

MAX QUALITY 1.0 1.9

*1 With MAX SPEED print mode, the density does not change even when HIGH DENSITY is set.

CAUTION

- The print speed does not change between NORMAL and HIGH DENSITY printing.

- Since a large quantity of ink is used with HIGH DENSITY, printing with this setting may generate ink bleeding or drying

unevenness. In this case, select a slower print speed.

IndexMenu tree

53

Page 54

- The print speed depends on the combination of the three following settings.

- Print mode

- Smart pass

- Carriage speed

Approximate speed values are shown in the tables below.

- The indicated print speeds can be reduced by print conditions such as the media width.

Print speed (*1)

CARRIAGE SPEED

NORMAL SLOW

Print mode

Smart pass Smart pass

LOW MEDIUM LOW MEDIUM

MAX SPEED 56.6 m2/h 37.7 m2/h 35.4 m2/h 23.6 m2/h

2

HIGH SPEED Cannot be set 25.1 m

NORMAL Cannot be set 17.6 m

HIGH QUALITY Cannot be set 9.8 m

MAX QUALITY Cannot be set 6.0 m

/h Cannot be set 15.7 m2/h

2

/h Cannot be set 10.5 m2/h

2

/h Cannot be set 5.9 m2/h

2

/h Cannot be set 3.8 m2/h

*1 Print speed values are for full width print on a media of 2642 mm width (104 inches). The values in the upper rows are for 8-color

mode, and the values for the lower rows are for the 4-color mode.

54

IP-7900 Advanced Operation Guide

Page 55

Troubleshoot print quality issues

This section describes the hint for you for one symptom, to get good image quality with the Printer.

Take appropriate actions according to the printout's symptom.

When several actions are described, they are arranged in the order of effectiveness. Therefore, you are

recommended to take actions from the top and confirm the effect on the improvement. (Note that all the

described actions are not always necessary to solve the problem.)

The print is light.

Cause Solution

The density setting does not

l

match.

The operating environment is

l

outside the specication of the

Printer.

Media is not selected properly.

l

Set density to HIGH DENSITY if high density printing is required, such as when

using backlit banner media. (

Raise the ambient temperature to 15°C or more (20 to 25°C recommended) to

warm the Printer adequately

Check the media selection. (

page 53

Basic Operation Guide page 50

)

)

Missing dots are found at the beginning of printing.

To assist your Printer

in operating eectively

Adjust and calibrate

the Printer

Cause Solution

Outside the operating

l

temperature/humidity range

Obstructions in the nozzle

l

surface path

Use the Printer within the operating temperature/humidity range.

(

Basic Operation Guide page 17

Check the obstructions in the nozzle surface path, with the order of on: platen,

media edge guards, spittoon case, capping unit, and wiper blade, and remove the

obstruction and stains.

Lint or paper fibers caused by a ragged media may touch the print head, which

may cause missing dots. Replace the media with a media with no lint or paper fiber.

Check that the exhaust fan filter is not encrusted with dust. If it is, replace the filter.

(

Basic Operation Guide page 74

)

)

IndexMenu tree

55

Page 56

The media is curled or wrinkled.

Cause Solution

Outside the operating

l

temperature/humidity range

(1) Use the Printer within the operating temperature/humidity range.

* Note that some media may be wrinkled even within the operating temperature and

humidity range.

(2) Use the proven media.

The media storage conditions

l

are not the same as the printer

operation conditions.

The difference between the media storage conditions and the printer operation

conditions may cause the media curled or wrinkled. To prevent it, when carrying

the media in storage to the operation area, before printing leave the media for a

proper time.

*The time depends on the media type and the storage conditions.

The media was poorly installed. Check that the media was installed properly with the conditions below.

l

- The installed media is properly parallel to the Printer and the ange.

- The operation panel shows the media type correctly.

- The supply-side tension bar length is proper and it is placed on the center of the

media.

- The media winding mode is optimal to the installed media.

The heater temperature wrinkled

l

the media.

(1) If the media is wrinkled while the Printer is warmed by the heaters, install the

media only after the Printer is warmed up by the heaters.

(2) Change the heater temperature. Increase or decrease the all three heaters by

*1

5°C.

(3) Use the proven media.

The media is curled. (1) Do not use the media curled in the x direction, that is, the vertical direction of

l

the media.

(2) Do not use the media curled in the y direction, that is, on the right and left

edges of the media. The curl is so excessive that the media edge guards and the

suction fan cannot flat the media

(3) Use the proven media.

*1

When the heaters temperature is changed, again adjust the media advance compensation.

56

IP-7900 Advanced Operation Guide

Page 57

White stripes appear on the print.

Basic image Symptom A Symptom B Symptom C

To assist your Printer

in operating eectively

[Cause]

Media advance compensation is

not proper.

[Check]

White stripes appear in all

colors when a color stripe

bar is printed.

Cause Solution

[Symptom A]

Media feed is not adjusted

l

properly.

[Symptom A]

The media advance accuracy is

l

poor, or is not stable.

[Cause]

The print head nozzles are

clogged.

[Check]

White stripes appear in some

colors when a color stripe bar

is printed.

[Cause]

The ink does not match well with

the media.

Adjust the media advance compensation.

* The media advance compensation diers depending on the winding mode, LOOSE or

TENSION.

(1) Check that the media was installed properly with the conditions below.

- The installed media is properly parallel to the Printer and the ange.

- The operation panel shows the media type correctly.

- The supply-side tension bar length is proper and it is placed on the center of the

media.

- The media winding mode is optimal to the installed media.

- If the media is curled or wrinkled, see the description on the problem, The media is

curled or wrinkled.

(2) Adjust the pressure on the media with the pressure control knob.

(3) Set smart pass to a higher setting.

(4) Change the print mode to be slower.

*1*2*3

*1*2

*1

Adjust and calibrate

the Printer

[Symptom B]

Print head nozzles are clogged.

l

(1) Perform a nozzle print, and set nozzle map for the clogged nozzles.

(

Basic Operation Guide page 101

)

(2) Check the obstructions such as media lint or ink clot in the nozzle surface path

including the platen surface, and remove them.

(3) If the ink is accumulated or the net tears on the spittoon case surface, replace

them.

(4) If the media is curled or wrinkled, solve the problem by referring to the

description on the problem, The media is curled or wrinkled.

(5)

Perform the daily maintenance.

* Do not forget to clean the head guard and edge guards.

* Be sure to perform the print head cleaning.

(6) With the print sheet mount cleaning (