Page 1

Solvent Ink Color Inkjet Printer

IP-6620

日本語

クイックリファレンスガイド

ENGLISH

Quick Reference Guide

FRANÇAIS

Guide de référence rapide

ITALIANO

Guida di riferimento rapido

DEUTSCH

Schnellreferenz

ESPAÑOL

Guía de consulta rápida

PORTUGUÊS

Manual de Consulta Rápida

РУССКИЙ

Краткое справочное руководство

Page 2

IP-6620

目次

◆ 本 機 前 面( 排 紙 側 )............................................2

◆本機背面(給紙側)............................................3

◆本機内部............................................................4

◆ヒーター .............................................................4

◆操 作パネル........................................................ 5

◆ 給 紙 装 置 へ のメデ ィ アの セット ........................6

◆ 巻 き 取り 装 置 へ のメディア の セ ット ..................8

◆巻き取り装置からのメディア取り外し............10

◆ 給 紙 装 置 からのメディア取り外し ..................11

◆送り調整をする...............................................12

◆往 復調整をする...............................................13

◆ ワ イパ ーブレ ード の 汚 れ チェック、

キャッピングユニットの清掃、

クリーニング(開 始前 のメン テ ナンス )...........14

◆ ノズ ルプ リント ................................................16

◆ワイパークリーニング液のチェックと交 換 .....17

◆ ワ イパ ーブレ ード の 汚 れ チェックと 交 換 .........18

◆廃インクボトルのチェックと交換.................. 20

◆その他のメンテナンス.................................... 21

◆そ の日使い 終 わったら ................................... 23

◆インクカートリッジの交換............................. 24

Copyright© 2013 株式会社沖データ

無 断 転載 を 禁じま す。

本書の 内容は 、断りなく変更することがあります。

Copyright© 2013 OKI Data Corporation.

All rights reserved.

The contents of this manual may be changed without prior notice.

1

Page 3

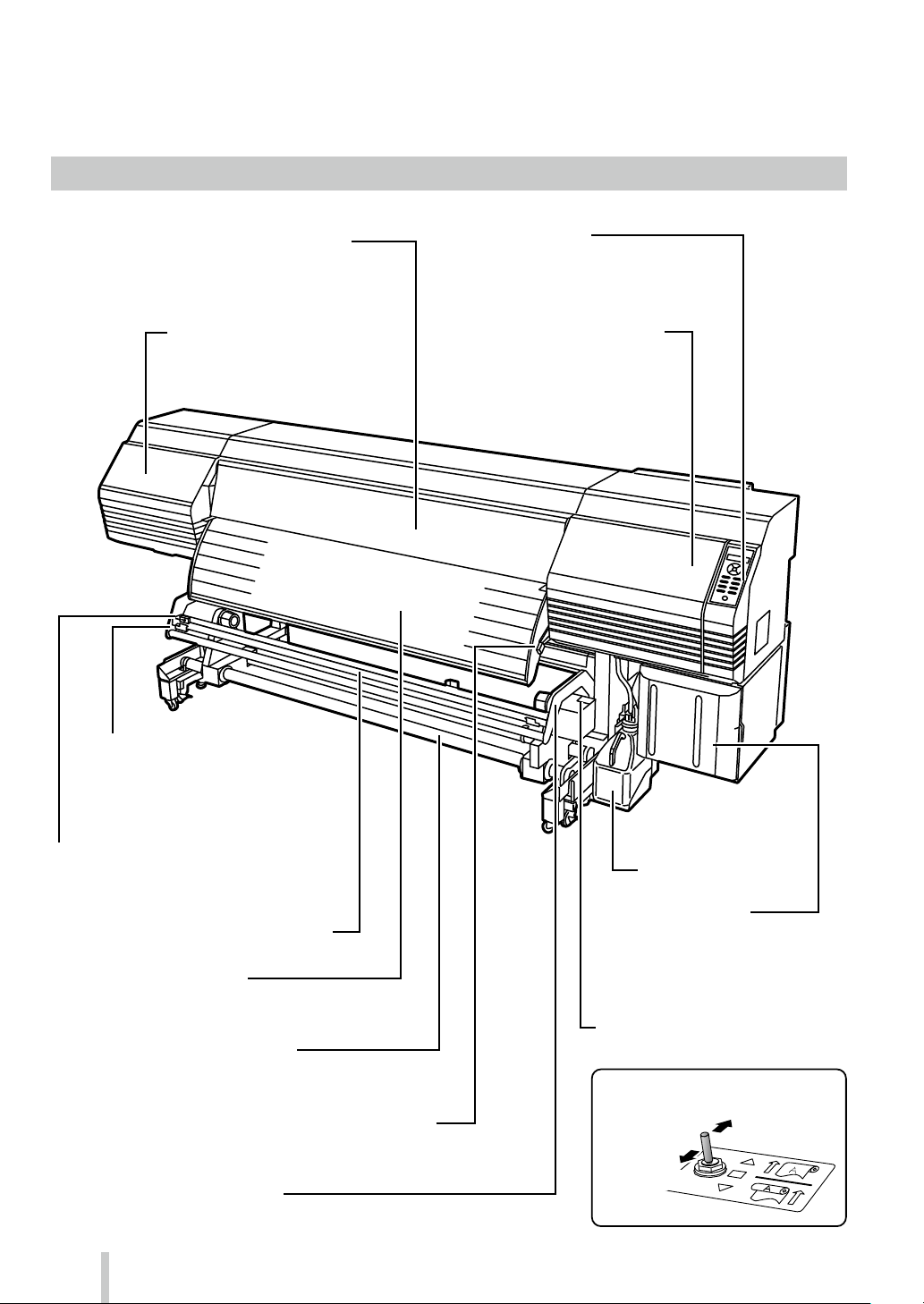

装置外観・各 部の名称と働き

◆ 本機前面(排紙側)

印刷 するときは 必ず閉じて

お き ま す。

プ リント ヘッド のメ ン テ ナ ン ス を 行

う際に開けます。

メディアをカットした後、 メディア

が 落 下しな いように 止 め ま す。

プリンターの状態を表示するランプや

LCD、各 種機能を設定するキーが割り

付 け ら れて いま す。

キャッピングユニットの清 掃やワイ

パーブレードの交換をする時などに

開けます。

メディ ア をカ ットしま す。

インクを乾 燥させるアフターヒーターが内蔵されています。

印刷したメディアを巻き取ります。

メディアを固定また は 解 除するレバ ーです。

たる み 巻 き の と き にメデ ィ ア をガ イド し ま す。

2

カバーを開けてインクカートリッジを

セットしま す。

メディアを巻き取る方向を設定します。

巻き取りオフ

外巻き

外巻き

内巻き

Page 4

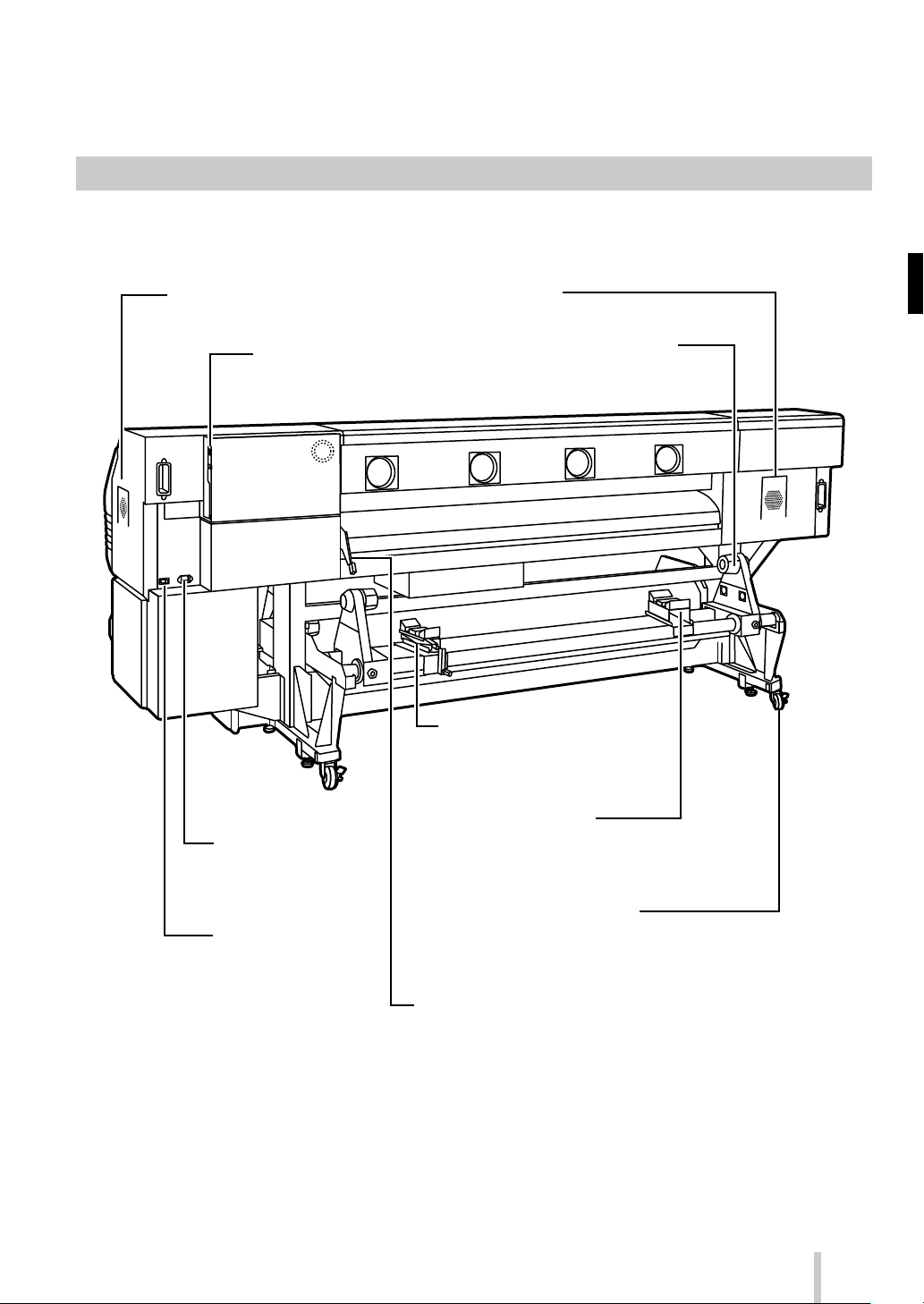

◆ 本機背面(給紙側)

コンピューターと接続します。

電 源コ ード を 接 続しま す。

ロールメディ アの両 端に 取り

付けます。

メディアの 脱 着 作 業 を 補 助 し ま す。

巻 き 取 り 装 置 側に 移 動して使 うこ

ともで きま す。

脱 着 時 に メディア を 一 時 的に 支 え ます。

巻 き 取り装 置 側に 移 動して使 う こ と もで き ま す。

プリンターを移 動 するときは ロックを OFF に

し、 固 定 す る と き は ロ ック を O N に し ま す。

メディアを固定また は 解 除するレバ ーです。

プ リン タ ー 前 面 の 加 圧 ロ ー ラ ーア ッ プ ダ ウ ンレ

バ ー と 同 期 して 動き ま す。

3

Page 5

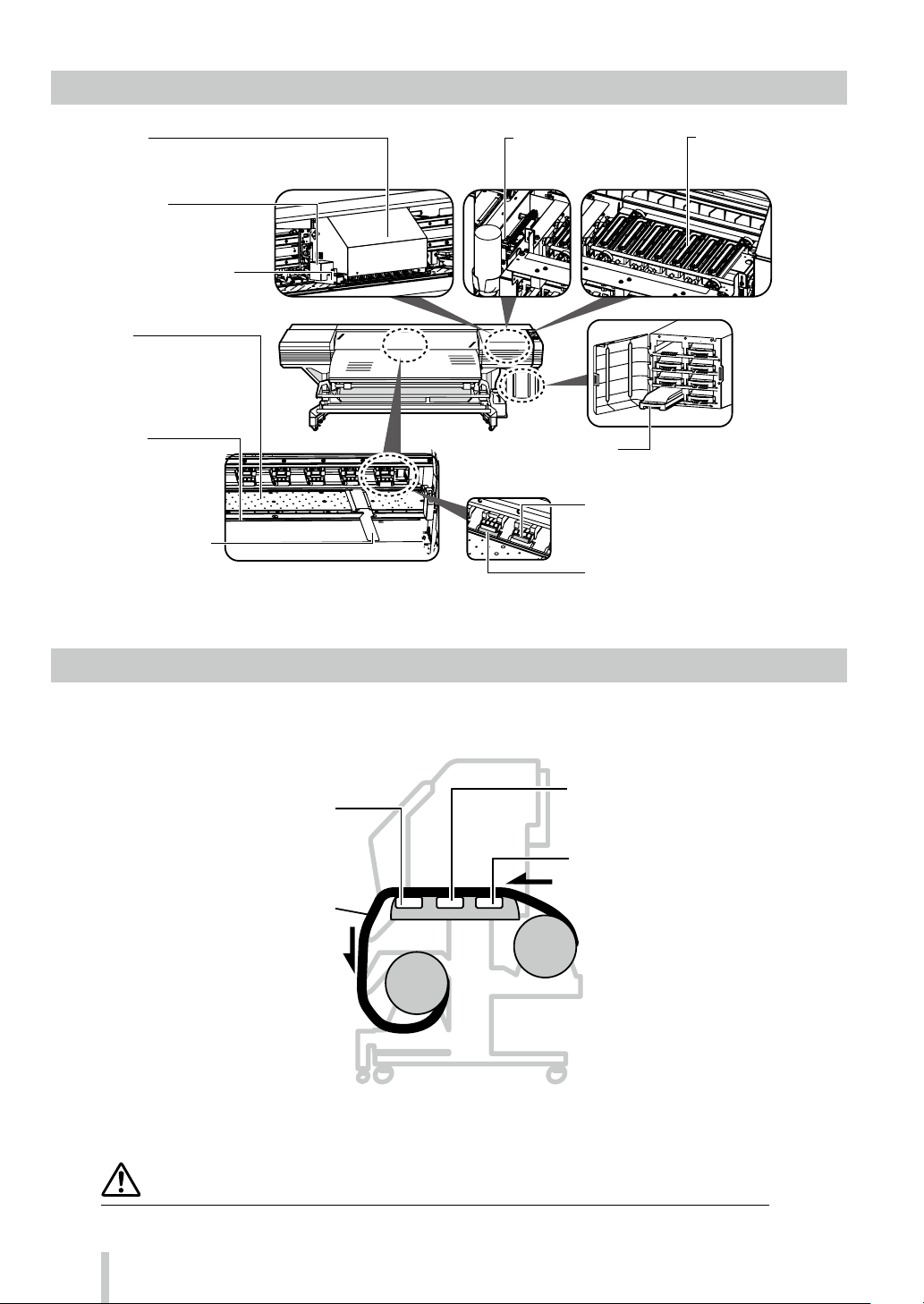

◆ 本機内部

プリントヒーター(前面)

メディア に インクを 浸 透 さ せ 、

アフターヒーター(仕 上げ)

インクを乾燥し、画質を安定させます。

■キャリッジ

プリ

印刷時

■

メデ

ス

■

自

です

■

メデ

やケバか

護し

■

この

挿入

ガイ

とが

■

メデ

かな

を定

さ

■ワイピングユニット

■キャッピングユニット

ントヘッドが 格納されているユニットで、

メディア を走査し て印刷します 。

イオナイザー

ィアの静電気を中和し、イン クミ

トによる印刷汚れを軽減します。

自動印刷調整用センサー

動印刷調整に使用する光学センサー

。

プラテン

ィアの通り道です。メディア が浮

いようにする吸着ファンとインク

着させるプリントヒ ーターが内蔵

れています。

カッター溝

溝にカッターナイフの刃を

してメディア を切ると 刃が

ドされてまっすぐに切るこ

できます。

メディア エッジガード

ィア 両端(エッジ )のカール

らプリントヘッドを保

ます。

◆ ヒーター

プリントヘッドのノズ ル面の

異物を取り除きます。

プリントヘッドのノズ ルが乾く

のを防ぎます。

■インクトレイ

インクカートリッジをセットするためのトレ イです。

■グリットロ ーラー

メディア を送り出したり、戻したり

するローラーです。

■加圧ローラー

加圧ローラーアップダウンレバーを下げると

メディア を挟み込みます。

本機には、印刷メディアへのインクの定着・画質の安定化のために3つのヒーターを搭載しています。

* 3 つのヒーターは各 々 独立にコントロールされます。

ヒーター温度は操作パネル、ソフト RIP および CP_Mana ger からコントロールできます。

警告

◆◆ 各ヒーター面は熱くなりますので、決して触らないでください。火傷をするおそれがあります。

4

メディア

インクを 定 着させ ま す 。

プリヒーター(背面)

メディア を 予 熱し ま す 。

Page 6

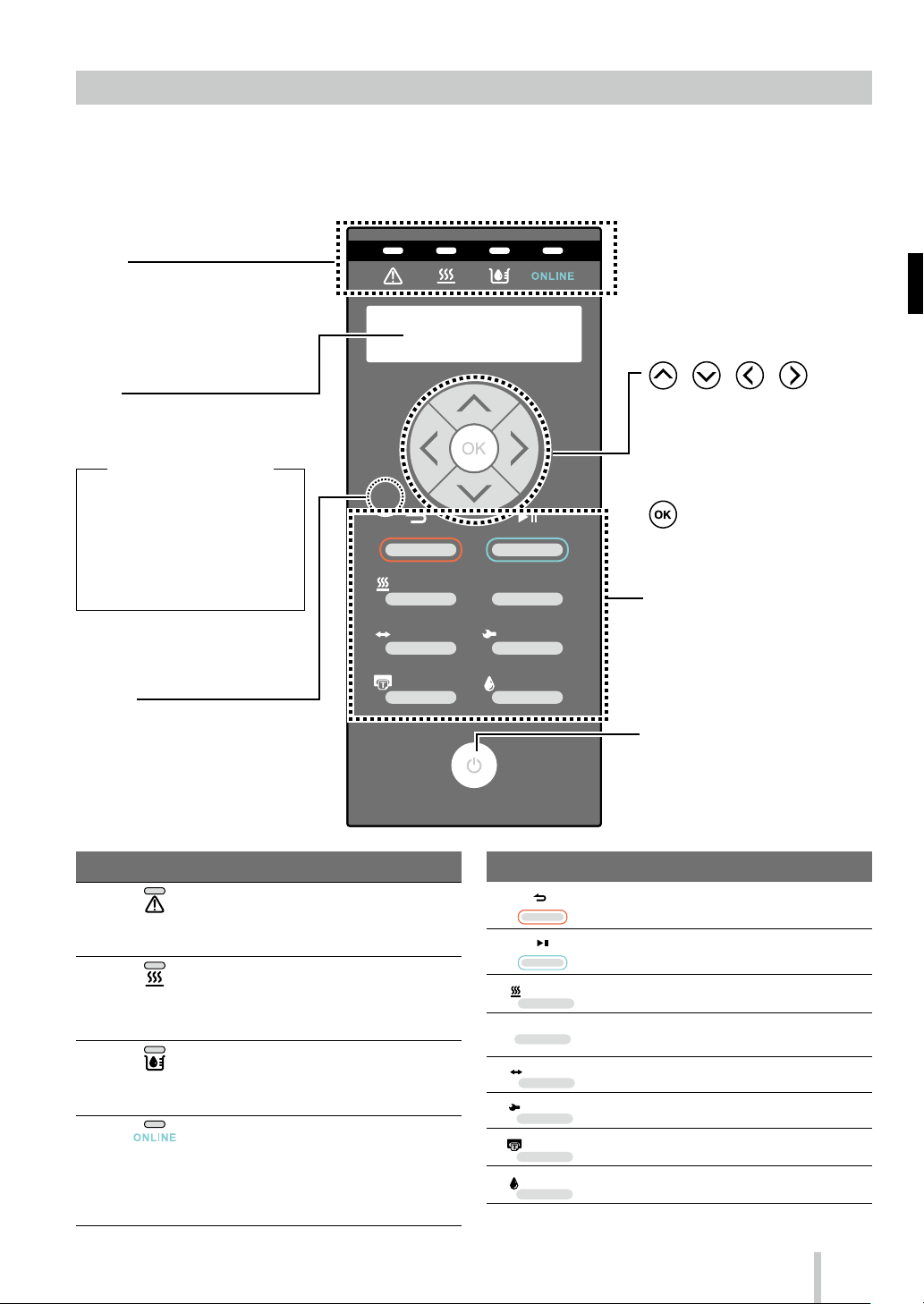

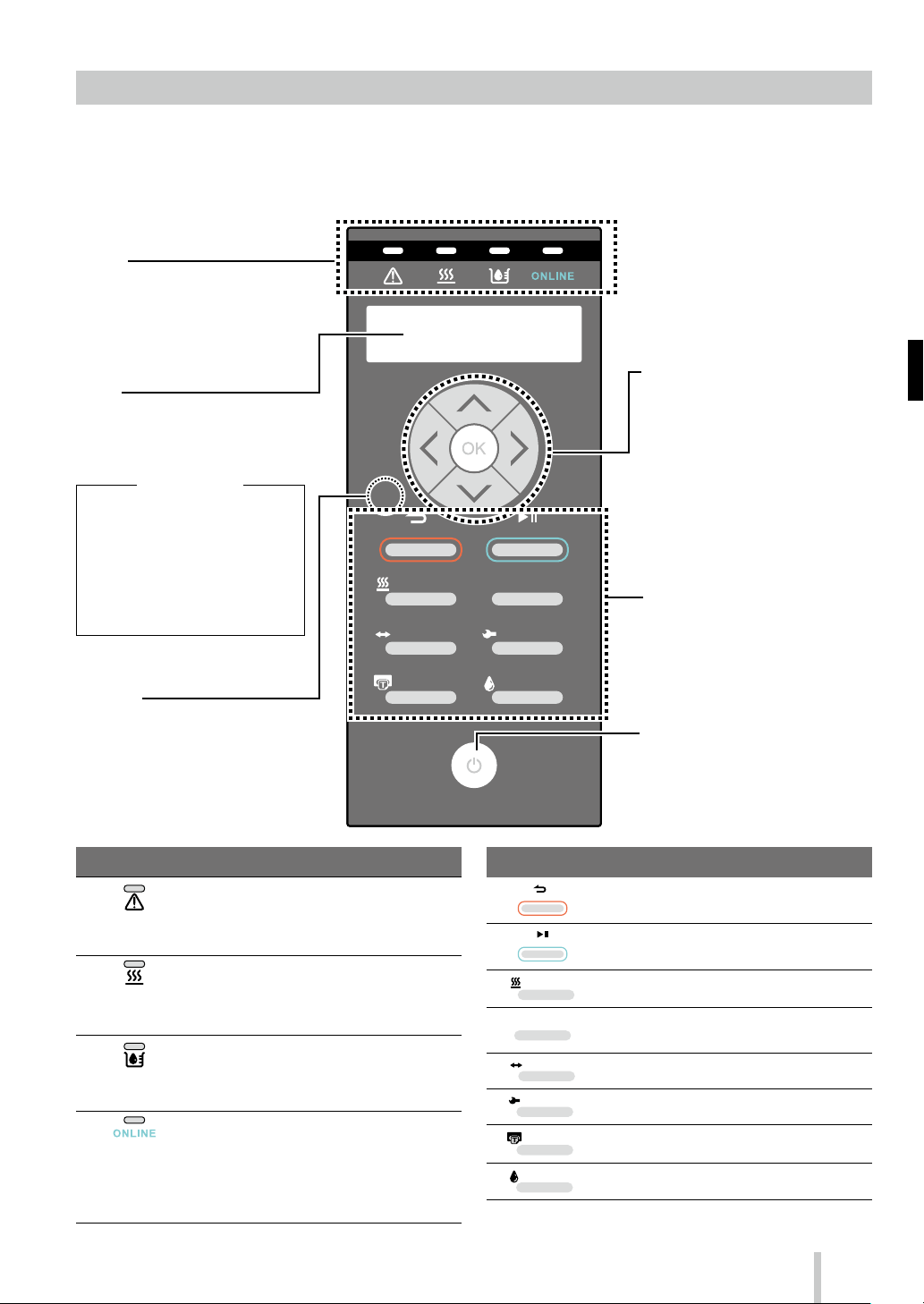

◆ 操作パネル

MENU

ADJUST

MAINTENANCE

NOZZLE PRINT

PH.RECOVERY

本機の操作パネルには、キー,LED,LCD が下図のようにレイアウトされています。なお、エラー時や無効キー

入力時には、ブザーで通知する機能もついています。

また、一定時間装置を使用しない場 合、ウェイティングモードに遷移します。

点灯、点滅、消灯によって本機の状

態 を 表 示しま す。

下 表 を 参 照してく だ さ い 。

プリンターの 状 態やメニュー 画 面な

ど を 表 示 し ま す 。( 2 0 文 字 2 行 )

( ウェイティングモ ード の状 態 )

LCD:表示および、バックライト O FF

オンライン LED:ゆっくり点滅

オンライン LED 以外:消灯

( ウェイティングモ ード の 解 除 )

いずれかのキーを操作した場合。

印刷データを受信した場 合。

エラー発生時、無効キー入力の警告、

およ び日常メンテナンスなどプリン

ト ヘッド が キャ ッ プ され て い な い 状

態 の 警 告 時 に 鳴 動しま す。

エラ ー の 有/無 を 表 示し ま す。

・ 点 灯 : エ ラ ー あ り

・ 点 滅 : ワ ー ニ ン グ あ り

・ 消 灯 : 正 常( エ ラ ー な し )

メディ ア ヒー ター の 状 態 を 表 示 し ま す。

・点灯: メディアヒーター設定温度に到達

・ 点 滅 : メ デ ィ ア ヒ ー タ ー 昇 温 中

・ 消 灯: メ デ ィ ア ヒ ー タ ー O F F

イン ク の 有 / 無 を 表 示 しま す。

・点灯: すべてのインクあり

・ 点 滅 : イ ン ク の 残 量 が 少 な い

・ 消 灯: イ ン ク な し

プリンターのオンライン / オフライン/データ

受 信 / プ リ ント ポ ーズ 状 態 を 表 示しま す。

・ 点 灯 : オ ン ラ イ ン

・点滅(ゆっくり):プリントポーズ

・点滅(はやい):データ受 信

・消灯: オフライン

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

NOZZLE PRINT PH.RECOVERY

ONLINE

MAINTENANCE

POWER

CANCEL

ONLINE

HEATER

メニューグル ープの 選 択、メ

ニ ュ ー の 切 り 換 え( 選 択 、 数

値のアップ/ダウン)など に

使 用し ま す。

メニューの確定,パラメータの確定

に使 用しま す。

プリンターのメニュー 操作 などに使

用しま す。

下 表 を 参 照してく だ さ い 。

プリンターの電源をオン / オフする

電 源 スイッ チ と して 使 用し ま す。

手動でウェイティングモ ードに遷移さ

せる 場 合 やウェイティング モ ード を

解 除 す る 場 合 に使 用しま す。

入力した パラメーターをキャンセル、メニュー階層 を戻る

ときに使 用します。

プリンターのオンライン / オフラインの切り 替え、プリン

トポーズ/プリント再開 するとき に使 用します。

ヒーターコントロールメニューに入るときに使 用します。

プリンターの各 種 情 報表 示、各 種 設 定変 更 するとき に使

用し ま す。

調整 メニューに入るときに使 用します。

メンテナンスメニューに入るときに使 用します。

ノズルプリントを 印刷 するとき に使 用します。

クリーニングメニュー に入るときに使 用します。

5

Page 7

メディア の セット と 取 り 外 し

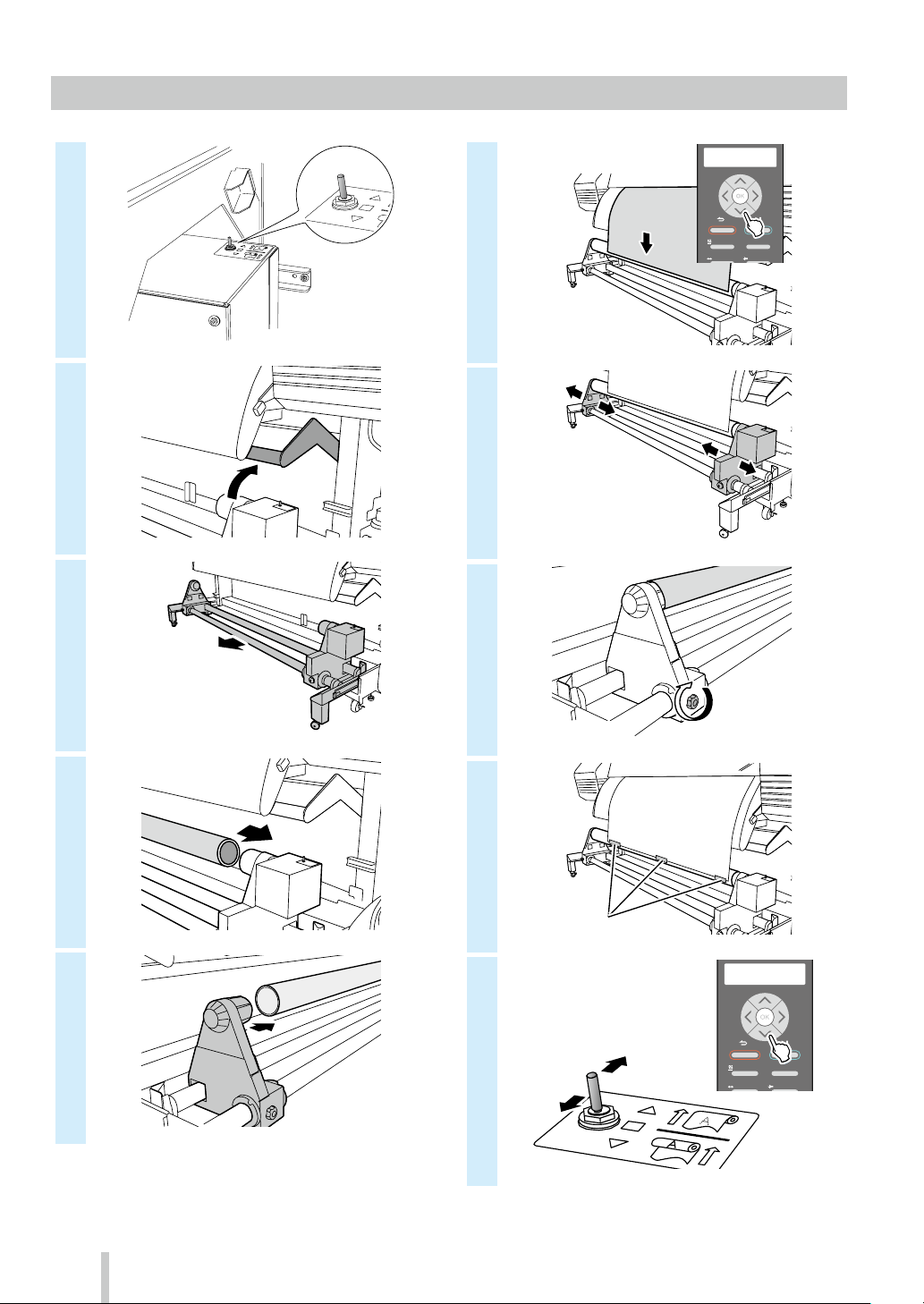

◆ 給 紙 装 置 へ のメデ ィア の セ ット

1

2

4

5

6

3

6

Page 8

7

11

8

9

10

12

13

14

15

SET

ORIGIN

CANCEL

HEATER MENU

ONLINE

7

Page 9

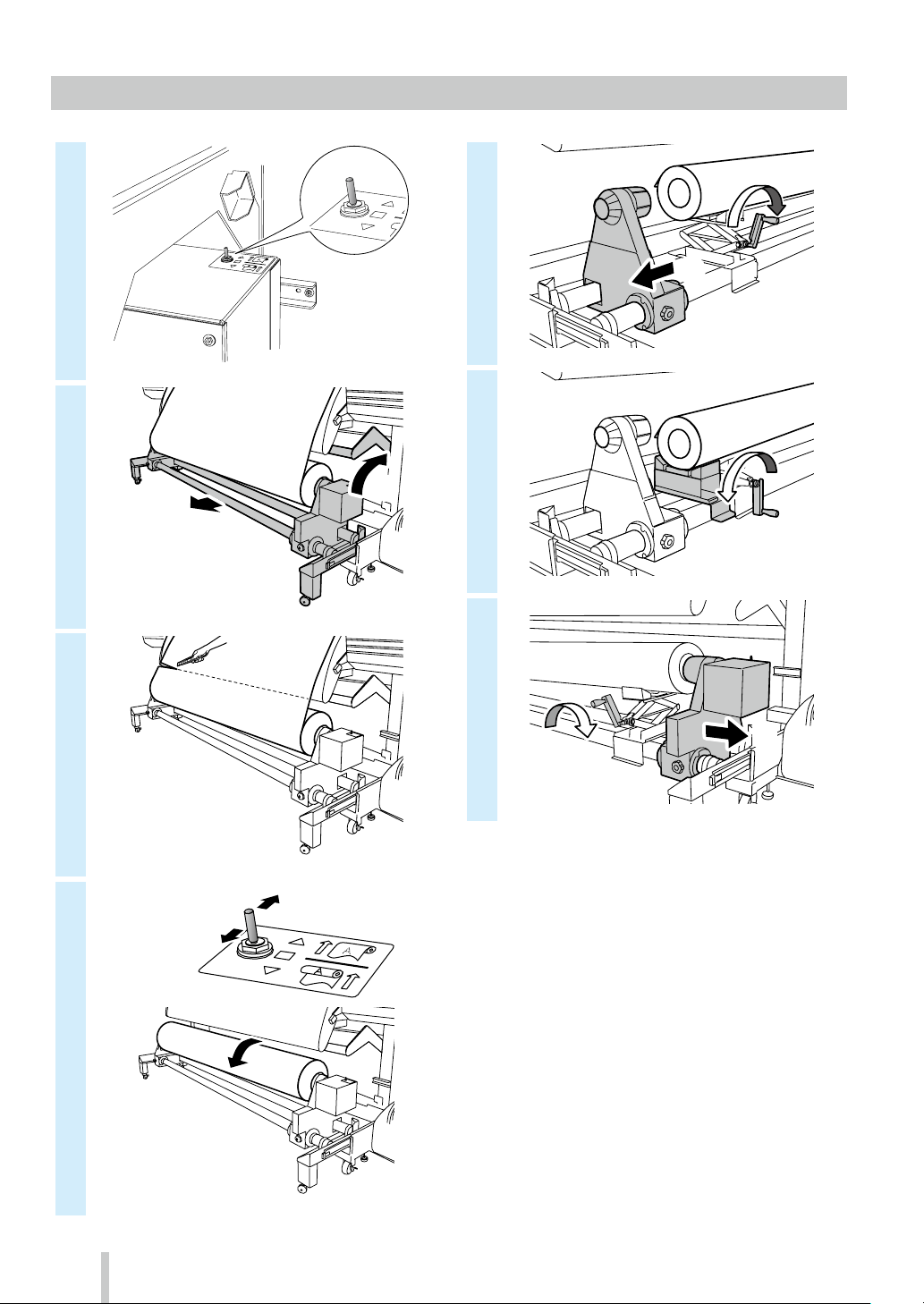

◆ 巻 き 取り 装 置 へ のメデ ィア の セット

ON

1

2

3

OFF

6

7

8

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

ONLINE

MAINTENANCE

8

4

5

9

10

テープ

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

ONLINE

MAINTENANCE

Page 10

11

OFF

(

12

15

13

14

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

ONLINE

MAINTENANCE

16

メディア送り

モード

対象メディア)

内巻き

ON

たるみ巻き巻き取り方式 テンション巻き テンション巻き

チュウ(推奨)吸着ファン ジャク(推奨) ジャク(必須)

ツウジョウ

ジャク

キョウ

シワケイゲン

(塩ビ、コート紙)

使用できません 使用できません

ツウジョウ

シワケイゲン

(ターポリン) (薄手ターポリン)

サイキョウ

外巻き

9

Page 11

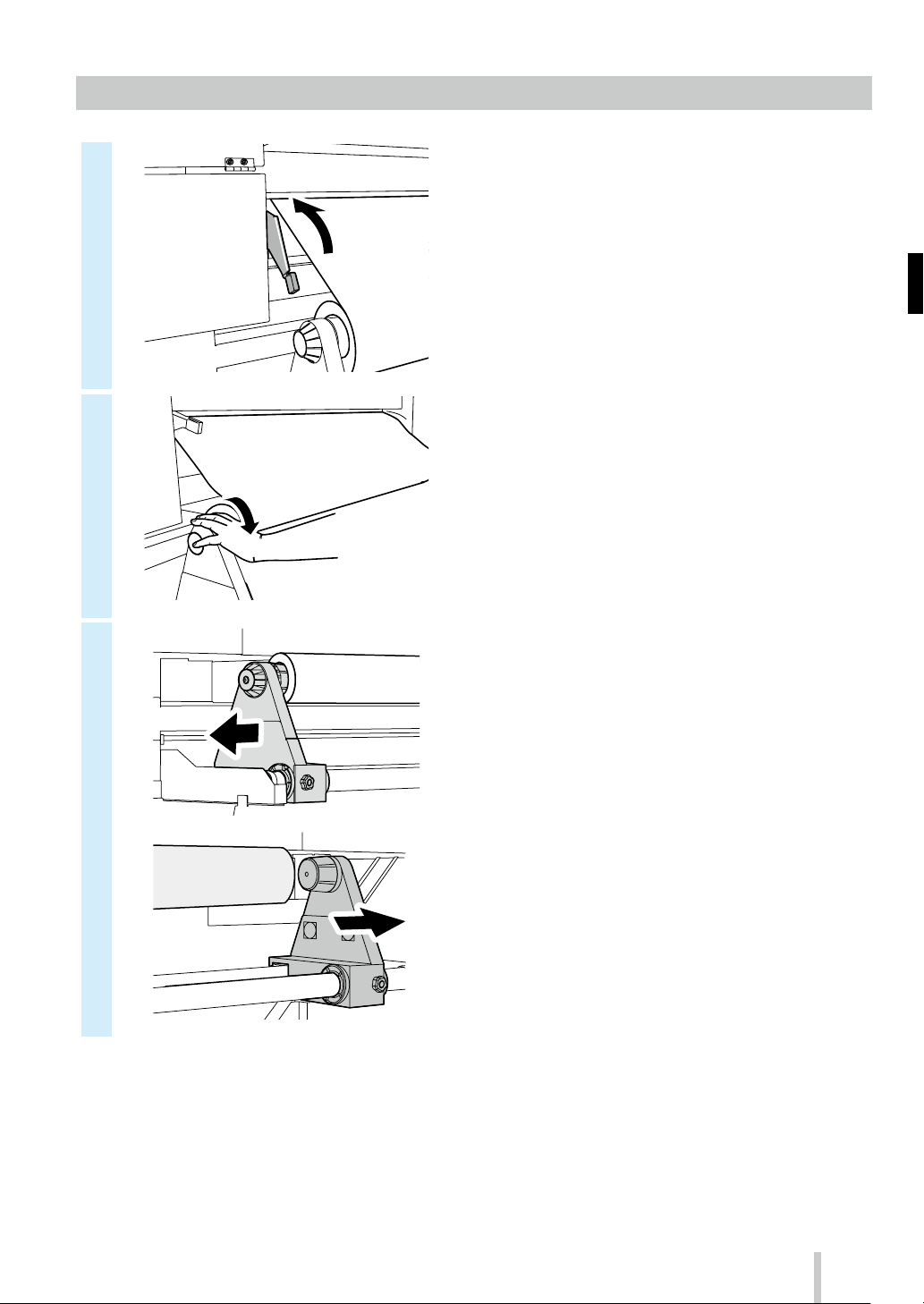

◆ 巻き取り装 置からのメディア取り外し

ON

1

2

3

②

OFF

①

5

6

7

①

②

4

①

②

10

Page 12

◆ 給 紙 装 置 からのメディア 取り外し

1

2

3

11

Page 13

調整をする

◆ 送り調整をする

1

2

3

4

フ°リントテ゛キマス

01:PAPER/1626mm

ADJUST

↕オクリチョウセイ ◎

>オクリチョウセイ

↕シ゛ト゛ウチョウセイ ◎

6

7

>> シ゛ト゛ウチョウセイ

インサツシ゛ッコウ OK?

12

5

>> シ゛ト゛ウチョウセイ

↕サイコウソク ◎

サイコウソク

コウソク

ソクド ユウ セン

ヒョウジュン

ガシ ツユウ セン

コウガシツ

サイコウ ガ シ ツ

さらに 細 かい調 整 を 行 う場 合は、「マニュアル 調整 」

を 行 ってく だ さ い 。

「マニュアル調整」の方法は、取扱説明書を参照し

てくだ さい 。

Page 14

◆ 往復調整をする

1

2

3

4

フ°リントテ゛キマス

01:PAPER/1626mm

ADJUST

↕オウフクチョウセイ ◎

>オウフクチョウセイ

↕シ゛ト゛ウチョウセイ ◎

6

>> シ゛ト゛ウチョウセイ

インサツシ゛ッコウ OK?

7

さらに 細 かい調 整 を 行 う場 合は、「マニュアル 調整 」

を 行 ってく だ さ い 。

「マニュアル調整」の方法は、取扱説明書を参照し

てくだ さい 。

5

>> シ゛ト゛ウチョウセイ

↕1:サイソク,コウソク,ソクト゛ユウ◎

スベテノ インサツモード

1: サイソク , コウソク ,

ソクド ユウ

2:ヒョウジュン ,

ガシツユウ

3:コウガシツ 高画質

4: サイコウガシツ 最高画質

全ての 印刷 モード

を調整します

最高速、高速、

速度優先

標準、画質優先

13

Page 15

メンテナンスをする

◆ ワイパーブレードの汚れチェック、キャッピングユニットの清掃、クリーニング(開 始前のメンテナンス)

1

2

3

4

フ°リントテ゛キマス

01:PAPER/1626mm

MAINTENANCE

↕カイシマエノメンテナンス ◎

>カイシマエノメンテナンス

OK?◎

7

OK NG

ワイパ ーブ レ ード に 汚 れ や き ず が 見 ら れ た 場

合は、「カイシマエノメンテナンス」終了後に、

「ワイパーブレードコウカン」を実施して、ワ

イパーブレードを交換してください。

8

14

IP7-2 64 クリーニング 棒(大)

※IP6-271 日常メンテナンスキット A にも

含 ま れ ま す。

5

6

マエショリチュウ

シハ゛ラクオマチクタ゛サイ 1:00

カハ゛ーヲアケテ キャッフ゜セイソウ

ワイフ゜カクニンヲ シテクタ゛サイ

IP6-272キャップクリーニング液 A

※IP6-271 日常メンテナンスキット A にも

含 ま れ ま す。

※一度キャップを清掃したクリーニング棒

(大 )をキャップクリーニング 液 ボトル の 中

に入れないでください。キャップクリーニ

ング 液 が 汚 れてしま い ま す。

※1 本のクリーニング 棒(大 )をキャップクリー

ニング液に1 回浸ければ、すべてのキャッ

ピ ングユ ニット を 清 掃 する こ とが で き ま す。

Page 16

9

13

クリーニンク゛ヲシ゛ッシシマスカ?

OK/CANCEL ◎

10

1. は じ め に 、各 キ ャップ上 面 の 外 周 部 分 を、

クリーニング棒( 大 )で 1 周させます。

これにより、各キャップ表面の汚れに

キャップクリーニング液を浸 透させます。

作業は、左のキャップから右方向に向

か って 行 い ま す。

2.次に、各キャップ上面の外周部分を、ク

リーニング棒(大)で 5 周させて、汚れ

を拭き取ります。

作業は、左のキャップから右方向に向

か って 行 い ま す。

キャッフ゜セイソウ ワイフ゜カクニンシテ

カハ゛ーヲシメテクタ゛サイ

14

15

16

クリーニンク゛スタート

ホ゛トルカクニンOK?

クリーニンク゛チュウ 1234567

ノコリシ゛カン Y:YY

NOZZLE PRINTヲ

シ゛ッシシテクタ゛サイ

MAINTENANCE

↕カイシマエノメンテナンス ◎

11

12

>キャッフ゜セイソウカンリョウ

OK? ◎

アトショリチュウ

シハ゛ラクオマチクタ゛サイ 1:00

15

Page 17

◆ ノズルプリント

例

が161番ノズル側に寄っている。

1

フ°リントテ゛キマス

01:PAPER/1626mm

2

NOZZLE PRINT

↕インサツシ゛ッコウOK?◎

3

4

5

NOZZLE PRINT

シ゛ッコウチュウ

ノズ ルプリント の印 刷 サン プ ル

線の抜けが発生している

NG

24番ノズルと133番ノズルが抜けている例 159番ノズルにインク吐出方向の曲がりがある

インク吐出方向の曲がり

が発生している

NG

6

7

8

9

フ゜リントテ゛キマス

01:PAPER/1626mm

ADJUST

↕ノス゛ルマッフ゜セッテイ ◎

>ノス゛ルマッフ゜セッテイ

◎

↕Lc

ノス゛ルマッフ゜セッテイ

>>

↕#1:***/カヘン ◎

Lc

159番ノズルで印刷した線(←の線)

※ノズルプリントで線の抜けや線の曲がりがある場

合には、「通常クリーニング」 を 実 施して、再度 1

の 手 順 か ら 繰 り 返 してく だ さ い 。

通常クリーニングは 、

と で 実 施 で き ま す。

それでも線の抜けや線の曲がりが直らない場合

は、6 以降の手順でそのノズル番号に対して「ノ

ズルマップ」 を設 定してください 。

※「ノズルマップ」の設定には、「マニュアル設定」

と「自動 設定 」 があります。

(自動設定の詳細は、取扱説明書( を

参 照 し て く だ さ い 。)

キーを押すこ

10

11

>>>Lc:#1

↕***/カヘン→133/カヘン ◎

>>>Lc:#1

↕133/カヘン→133/カヘン

※線の抜け、線の曲がりが複数ある場合はこ

の手 順を繰り返しすべ てのノズ ル番 号を 設

定してく ださ い 。

16

Page 18

◆ ワイパークリーニング 液のチェックと交換

終了 2以降の手順を実施

②

1

2

3

OK NG

フ°リントテ゛キマス

01:PAPER/1626mm

MAINTENANCE

↕ワイハ゜ーメンテナンス ◎

8

使 用済 み ワ イパー クリーニング 液

※ 手 袋 を 着 用して 作 業 を 行 ってく だ さ い 。

9

IP6-251ワイパークリーニング液セット A

※IP6-271 日常メンテナンスキット A にも

含 ま れ ま す。

プ リ ン タ ー セ ット 用 キ ャッ プ

新しいワイパークリーニング液

10

4

5

6

7

ワイハ゜ーメンテナンス

↕ワイハ゜ークリーニンク゛エキコウカン◎

11

> ワイハ゜ークリーニンク゛エキコウカン

OK?◎

ワイハ゜ークリーニンク゛エキヲ

コウカンコ゛カハ゛ーヲシメテクタ゛サイ

12

カハ゛ーヲアケテワイハ゜ークリーニンク゛

エキヲコウカンシテクタ゛サイ

①

②

13

コウカン シマシタカ?

↕YES ◎

※毎日のチェックのほか、プリンターの交換

メッセージが 表 示 されたときにもワイパー

クリーニング液を交 換してください。

①

17

Page 19

◆ ワイパーブレ ードの 汚れチェックと交 換

終了 2以降の手順を実施

1

OK NG

2

3

フ°リントテ゛キマス

01:PAPER/1626mm

MAINTENANCE

↕ワイハ゜ーメンテナンス ◎

8

①

②

9

10

4

5

6

7

> ワイハ゜ーメンテナンス

↕ワイハ゜ーフ゛レート゛コウカン ◎

>> ワイハ゜ーフ゛レート゛コウカン

OK?◎

キャリッシ゛イト゛ウチュウ

シハ゛ラクオマチクタ゛サイ

カハ゛ーヲアケテワイハ゜ーフ゛レート゛ヲ

コウカンシテクタ゛サイ

18

Page 20

11

③ スポンジ

平行になっていること

②

①

②

② ゴム

左右の隙間が均等であること

① ゴム

14

コウカン シマシタカ?

↕YES ◎

※毎日のチェックのほか、プリンターの交換

メッセージが 表 示 されたときにもワイパー

ブレードを交換してください。

12

13

ツメが中心にあること

ツメ

左右ともここに当たっていること

IP6-259ワイパーブレード

※取りつける順番を間違えないでください。

※IP6-271 日常メンテナンスキット A にも

含 ま れ ま す。

ワイハ゜ーフ゛レート゛ヲコウカンコ゛

カハ゛ーヲシメテクタ゛サイ

①

19

Page 21

◆ 廃 インクボトルの チェックと交 換

実施

1

OK NG

FULL

終了 2以降の手順を

2

4

5

FULL

IP6-109廃インクボトル

3

6

7

ハイインクカウンターリセット

↕YES ◎

※毎日のチェックのほか、プリンターの交換

メッセージが 表 示 されたときにも廃インク

ボトルを交換してください。

20

Page 22

◆ そ の他 のメンテナンス

ド

加圧ローラー

ペーパー

フロントカバー

そのほか、プリンターの交換メッセージが表示された

ときに「ワイパースポンジ」を交換してください。

プリンターの汚れが目立つ場合には、以下の箇所を清

掃してく ださ い 。

<ヘッド ガード の 清 掃 >

キャリッジ

キャッピングユニットの汚れが目立つ場合は、「シート

マウントクリーニング」 を実 施してください。

<加 圧ローラー、プラテンの清掃>

ヘッドガー

プラテン

<外装(フロントカバー)、ペーパーガイドの清掃>

<メディアエッジ ガ ードの 清 掃>

ガイド

これらの詳細な方法については取扱説明書を参照して

ください。

21

Page 23

各種メンテナンスを行 う周 期は 以下の通りで す。

・・・パネル操作

メディ アセ ット

ワイパ ーブレ ード

の汚 れチェック

開始前のメ

ンテ ナンス

キャッピ ング

ユ ニ ット の 清 掃

クリーニング

ノズ ルプ リント

廃 インクボトル の チェックと

交換

ワイパー クリーニング液の

チェックと交 換

ワイパ ーブレ ードの 汚 れ チェッ ク

と交換

ワ イパース ポン ジ 交 換

IP6-272

キャップクリーニング 液 A

IP 7- 264

クリーニング 棒(大)

※1

※1

IP6-109廃インクボトル

IP6 -251

ワイパー クリーニング液 セット A

IP6-259ワイパーブレード

IP6-258ワイパースポンジ

※1

※1

シートマウントクリーニング

( 実 施 の目 安 は 1 ヶ月に 1 度 で す )

メディアエッジ

ガード清 掃

ヘッド ガード

清掃

プリンター

の清掃

(実 施の目安

は 1 週間に 1

度です)

プラ テン 清 掃

ペーパーガイド

清掃

加圧ローラー

清掃

外 装( フ ロ ン ト カ

バー) 清 掃

自動印刷 調整用のセンサーと

イオナイザー 周りの 清掃

(実 施の目安 は 1 年に 1 度で す)

※ 1 これらは、IP6-271日常メンテナンスキット A にも含まれます。

・・・確認

・・・交換

IP6-261

シートマウントクリーニングキット A

IP6 -147 クリーニング棒

IP6-272

キャップクリーニング 液 A

IP6 -147

クリーニング 棒

※1

※1

※1

・・・外す

22

・・・セット

・・・清掃

Page 24

◆ そ の日使い終わったら

1

2

ON

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

NOZZLE PRINT PH.RECOVERY

ONLINE

MAINTENANCE

POWER

3

23

Page 25

◆ インクカ ートリッジ の 交 換

爪2ヶ所を押す

②

新しいインクカートリッジ

1

2

※インク色と装着位置を間違えないでくださ

い。

5

I P 6 - 2 21 イエロ ー

IP6-222 マゼンタ

I P 6 - 2 2 5 ラ イトシ アン

IP 6 -223 シアン

IP 6 -224 ブラック

I P 6 - 2 2 6 ラ イトマゼ ンタ

IP 6 -227 グレー

6

②

①

3

4

使用済みインクカートリッジ

①

7

8

24

Page 26

IP-6620

Table of Contents

Appearance and main components

Cartridge ink system (CIS) ............................. 26

Printer front (take-up side) ............................................. 26

Printer rear (supply side) ................................................. 27

Printer interior ....................................................................28

Printer heater unit ............................................................. 28

Operation panel ................................................................. 29

Appearance and main components

Large capacity ink system (LCIS) ..................30

Printer front (take-up side) ............................................. 30

Printer rear (supply side) ................................................. 31

Printer interior ....................................................................32

Printer heater unit ............................................................. 32

Operation panel ................................................................. 33

Media installation and removal ................... 34

Loading the media on the feeding unit .................... 34

Installing the media on the TUR unit ......................... 36

Removing the media from the TUR unit ................... 38

Removing the media from the feeding unit ........... 39

Quick Reference Guide

ENGLISH

Adjustment ...................................................... 40

Adjusting the media advance ......................................40

Adjusting the bidirectional position .......................... 41

Maintenance .................................................... 42

Start maintenance (wiper blades check,

capping unit cleaning, cleaning) .................................. 42

Nozzle print ......................................................................... 44

Wiper cleaning liquid check and supply ................... 45

Wiper blade cleanliness check and replacement .. 46

Waste ink bottle check and replacement ................. 48

Other maintenance operations .................................... 49

After the operation of the day ...................................... 51

Ink cartridge replacement (CIS)..................................... 52

Ink bottle replacement (LCIS) ........................................ 53

Reading the ink amount extension chip (LCIS) ....... 55

25

Page 27

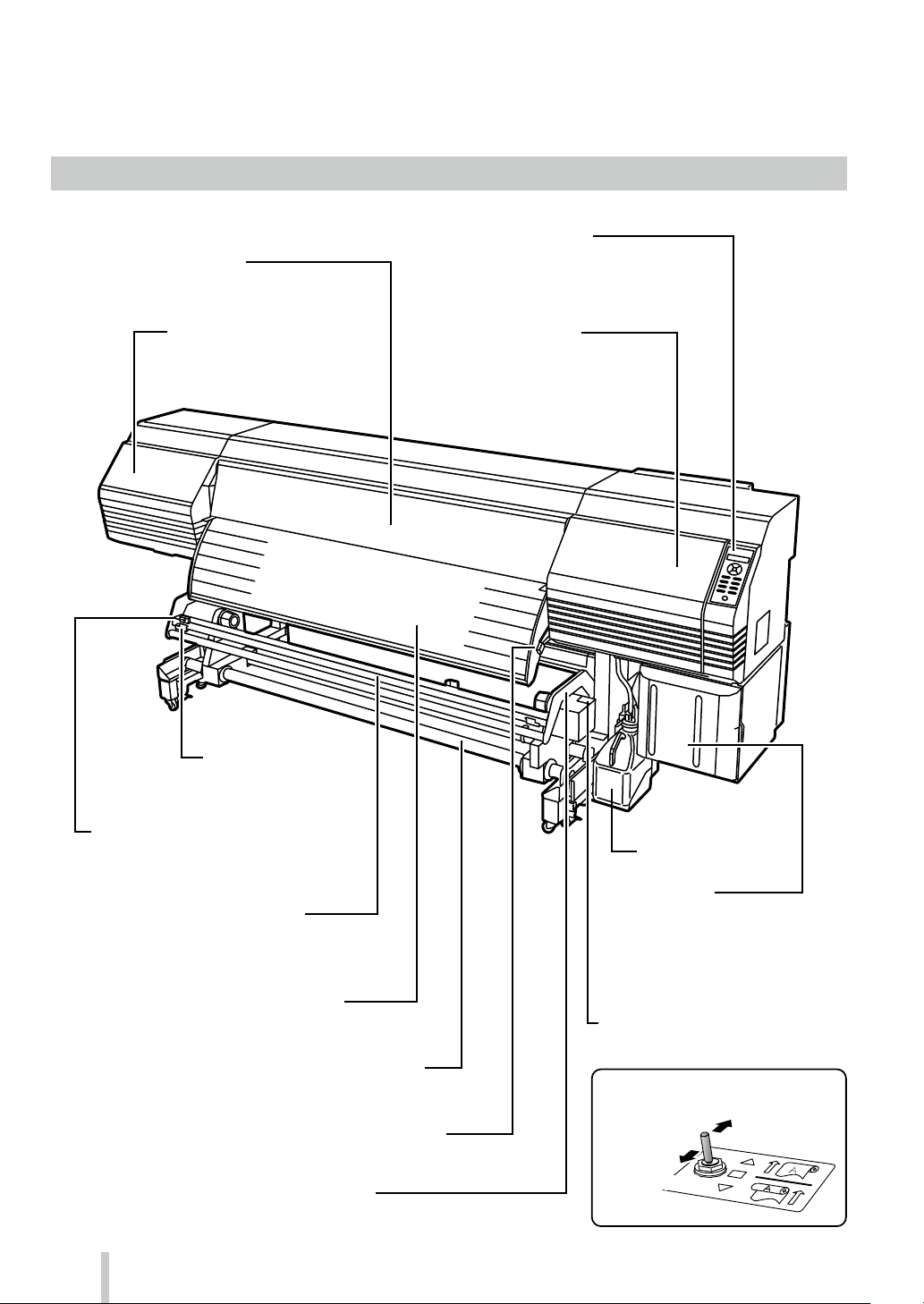

Appearance and main components

Printer front (take-up side)

•

Operation panel

•

Front cover

Must be closed during printing.

Equipped with LEDs and LCD to display

the printer status, and buttons to set

functions.

Cartridge ink system (CIS)

•

Maintenance area cover

Open to perform print head

maintenance.

•

Media clip (option)

After cutting the media,

clip it to not let it fall.

•

Media cutter blade (option)

It cuts the media.

•

Capping unit cover

Opened when cleaning the capping

unit or the carriage.

•

Waste ink bottle

26

•

Cutter unit (64) (option)

•

Output paper guide

Contains the afterheater that dries ink.

•

Take-up reel unit

Winds the printed media.

•

Pressure roller lever

This lever fixes or releases the media.

•

Guide bar

Guides the media in loose mode.

•

Ink box

Open the cover to install

the ink cartridges.

•

Take-up direction switch

Sets the media take-up direction.

Winding o

Outer take-up

Inner take-up

Page 28

Printer rear (supply side)

•

Position to install optional exhaust attachment

•

USB connector

Used to connect the printer to a

computer.

•

Media holder

To be installed at both ends of

the roll media.

•

Power inlet

Connect the power cable to

the power inlet.

•

Printer power switch

•

Media jack

Lifts or lowers the media during

loading and removal procedures.

Can be used also when moved to the

TUR unit side.

•

Media support

Temporarily supports the media during

loading and removal procedures.

Can be used also when moved to the

TUR unit side.

•

Caster

Set the lock to OFF when moving the printer and set the

lock to ON when locking the printer.

•

Pressure roller lever

A lever used to fixe or release the media.

Moves together with the pressure roller lever at the

printer front side.

27

Page 29

Printer interior

Penetrates ink into media to fuse the ink.

• Afterheater (nishing)

Dries ink to stabilize print quality.

• Ionizer

R

and reduces print def

•

Optical sensors used f

adjustment.

• Carriage

Houses the print heads inside

image with scanning media.

• Media edge guar

Pr

being damaged by the curling

or

• C

T

into this groove when cutting

the media so that it is cut

straight.

• Platen

T

T

and print heater to cure the ink

• Wiping unit

• Capping unit

, and prints

emoves static electricity from the media

ects caused by ink mist.

Sensors for automatic print adjustment

or automatic print

ransports media.

he platen incorporates suction fans

.

utter groove

he cutter blade is inserted

d

otects print heads from

feathering media edge.

Printer heater unit

Removes foreign substances on

the print head’s nozzle surface.

• Ink tray

Supports ink cartridge setting.

• Grit roller

The grit roller advances or rewinds

the media.

• Pressure roller

When lowering the pressure roller

up/down lever, it pinches the media.

Prevents the print head’s

nozzles from drying.

The printer is equipped with three heaters for ink fusing and image quality stabilization.

• Print heater (front)

28

* These three heaters are controlled independently.

The temperature of the heaters can be controlled from the operation panel, the RIP software and CP_

Manager.

WARNING

Do not touch these heaters to avoid burn as they become hot.

Media

• Preheater (rear)

Preheats media.

Page 30

Operation panel

MENU

ADJUST

MAINTENANCE

NOZZLE PRINT

PH.RECOVERY

The buttons, LEDs and LCD are placed on the printer's operation panel as shown below. In addition, the operation

panel is also equipped with a buzzer to draw attention in case an error occurs or an invalid button is pressed.

The printer enters waiting mode if it is not used for a given length of time.

•

LED

ON, blinking and OFF indicate the

status of the printer.

Refer to the table below.

•

Up, Down, Left, Right buttons

•

LCD

It shows the status of the printer and

displays the menu window (2 rows, 20

characters).

Waiting mode

(During waiting mode)

LCD: Display and backlight turned o

Online LED: Flashes slowly

Other LEDs: O

(Exiting waiting mode)

The printer exits waiting mode when

- any button is pressed,

- the printer receives print data.

•

Buzzer

Sounds when an error occurs or an

invalid button is pressed, and warns of

daily maintenance and when the print

heads are uncapped.

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

NOZZLE PRINT PH.RECOVERY

ONLINE

MAINTENANCE

POWER

Used to select menu options, switch

between menus (selection, increasing/

decreasing values), etc.

•

OK button

Used to confirm the menu and

parameters.

•

Buttons

Use these buttons to operate the menu

of the printer.

Refer to the table below.

•

Power switch

Used to turn on or off the power of the

printer.

Used to manually enter and exit waiting

mode.

Error LED

(Orange)

Media heater LED

(Green)

Ink LED (Green)

ONLINE LED

(Green)

LED

Indicates whether an error has occurred.

ON: An error has occurred.

Blink: Warning state.

OFF: Normal (no error)

Indicates the status of the media heater.

- ON: The set temperature has been reached

- Blink: Currently heating

- OFF: Media heater is o

Indicates whether ink is remaining.

ON: Ink of all colors is present.

Blink: Ink near-end ( The level of any color is low.)

OFF: No ink .

Indicates the online, oine, data reception, and

pause status.

- ON: Online

- Blink (slowly): In pause

- Blink (fast): Data reception

- OFF: Oine

CANCEL

ONLINE

HEATER

Buttons

Cancels entered parameters or returns back to the

upper menu.

Switches between online and oine states, and

puts the printer in pause or resumes printing.

Enters heater control menu.

Used to display information about the printer and

change printer settings.

Used to enter the adjustment menu.

Used to enter the maintenance menu.

Used to per form a nozzle print.

Used to enter the cleaning menu.

29

Page 31

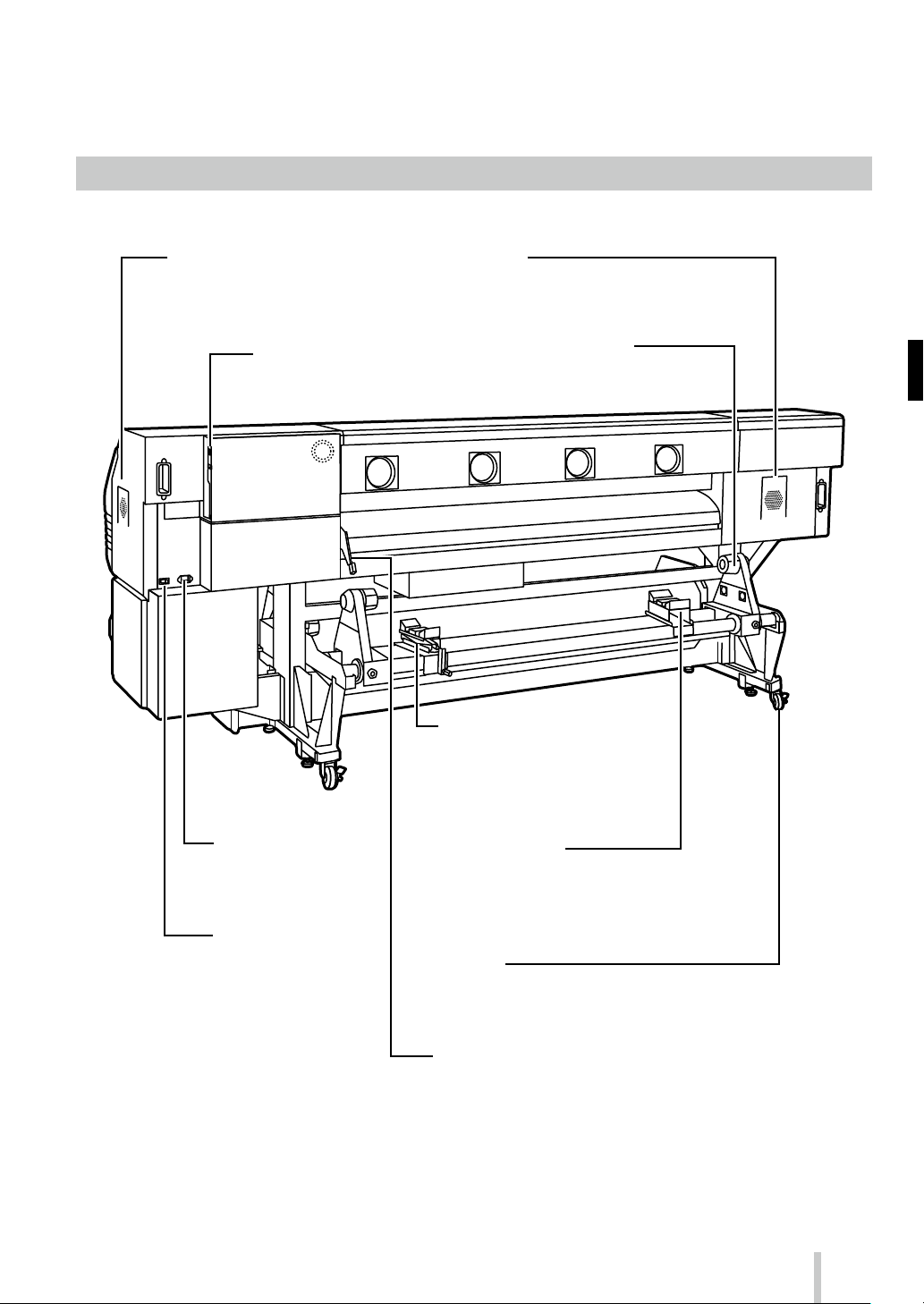

Appearance and main components

Printer front (take-up side)

•

Operation panel

•

Front cover

Must be closed during printing.

Equipped with LEDs and LCD to display

the printer status, and buttons to set

functions.

Large capacity ink system (LCIS)

•

Maintenance area cover

Open to perform print head

maintenance.

•

Media clip (option)

After cutting the media,

clip it to not let it fall.

•

Media cutter blade (option)

It cuts the media.

•

Capping unit cover

Opened when cleaning the capping

unit or the carriage.

•

Waste ink bottle

30

•

Cutter unit (64) (option)

•

Output paper guide

Contains the afterheater that dries ink.

•

Take-up reel unit

Winds the printed media.

•

Pressure roller lever

This lever fixes or releases the media.

•

Guide bar

Guides the media in loose mode.

•

LCIS unit

Open the drawer to install the ink

bottles.

•

Chip reader

To be used with the ink amount extension chip.

•

Take-up direction switch

Sets the media take-up direction.

Winding o

Outer take-up

Inner take-up

Page 32

Printer rear (supply side)

•

Position to install optional exhaust attachment

•

USB connector

Used to connect the printer to a

computer.

•

Lifts or lowers the media during

loading and removal procedures.

Can be used also when moved to

the TUR unit side.

Media jack

To be installed at both ends of

the roll media.

•

Media holder

•

Power inlet

Connect the power cable to

the power inlet.

•

Printer power switch

•

Media support

Temporarily supports the media during

loading and removal procedures.

Can be used also when moved to the

TUR unit side.

•

Caster

Set the lock to OFF when moving the printer and set the

lock to ON when locking the printer.

•

Pressure roller lever

A lever used to fixe or release the media.

Moves together with the pressure roller lever at the

printer front side.

31

Page 33

Printer interior

Penetrates ink into media to fuse the ink.

• Afterheater (nishing)

Dries ink to stabilize print quality.

• Carriage

Houses the print heads inside

prints image with scanning media.

• Media edge guar

Pr

being damaged by the curling

or

• C

T

into this groove when cutting

the media so that it is cut

straight.

• Platen

T

T

and print heater to cure the ink

• Wiping unit

• Capping unit

• Ionizer

R

and reduces print def

•

Optical sensors used f

adjustment.

, and

emoves static electricity from the media

ects caused by ink mist.

Sensors for automatic print adjustment

or automatic print

ransports media.

he platen incorporates suction fans

.

utter groove

he cutter blade is inserted

d

otects print heads from

feathering media edge.

Printer heater unit

Removes foreign substances on

the print head’s nozzle surface.

• Ink bottle

Used to supply ink.

• Grit roller

The grit roller advances or rewinds

the media.

• Pressure roller

When lowering the pressure roller

up/down lever, it pinches the media.

Prevents the print head’s

nozzles from drying.

The printer is equipped with three heaters for ink fusing and image quality stabilization.

• Print heater (front)

32

* These three heaters are controlled independently.

The temperature of the heaters can be controlled from the operation panel, the RIP software and CP_

Manager.

WARNING

Do not touch these heaters to avoid burn as they become hot.

Media

• Preheater (rear)

Preheats media.

Page 34

Operation panel

MENU

ADJUST

MAINTENANCE

NOZZLE PRINT

PH.RECOVERY

The buttons, LEDs and LCD are placed on the printer's operation panel as shown below. In addition, the operation

panel is also equipped with a buzzer to draw attention in case an error occurs or an invalid button is pressed.

The printer enters waiting mode if it is not used for a given length of time.

•

LED

ON, blinking and OFF indicate the

status of the printer.

Refer to the table below.

•

Up, Down, Left, Right buttons

•

LCD

It shows the status of the printer and

displays the menu window (2 rows, 20

characters).

Waiting mode

(During waiting mode)

LCD: Display and backlight turned o

Online LED: Flashes slowly

Other LEDs: O

(Exiting waiting mode)

The printer exits waiting mode when

- any button is pressed,

- the printer receives print data.

•

Buzzer

Sounds when an error occurs or an

invalid button is pressed, and warns of

daily maintenance and when the print

heads are uncapped.

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

NOZZLE PRINT PH.RECOVERY

ONLINE

MAINTENANCE

POWER

Used to select menu options, switch

between menus (selection, increasing/

decreasing values), etc.

•

OK button

Used to confirm the menu and

parameters.

•

Buttons

Use these buttons to operate the menu

of the printer.

Refer to the table below.

•

Power switch

Used to turn on or off the power of the

printer.

Used to manually enter and exit waiting

mode.

Error LED

(Orange)

Media heater LED

(Green)

Ink LED (Green)

ONLINE LED

(Green)

LED

Indicates whether an error has occurred.

ON: An error has occurred.

Blink: Warning state.

OFF: Normal (no error)

Indicates the status of the media heater.

- ON: The set temperature has been reached

- Blink: Currently heating

- OFF: Media heater is o

Indicates whether ink is remaining.

ON: Ink of all colors is present.

Blink: Ink near-end ( The level of any color is low.)

OFF: No ink .

Indicates the online, oine, data reception, and

pause status.

- ON: Online

- Blink (slowly): In pause

- Blink (fast): Data reception

- OFF: Oine

CANCEL

ONLINE

HEATER

Buttons

Cancels entered parameters or returns back to the

upper menu.

Switches between online and oine states, and

puts the printer in pause or resumes printing.

Enters heater control menu.

Used to display information about the printer and

change printer settings.

Used to enter the adjustment menu.

Used to enter the maintenance menu.

Used to per form a nozzle print.

Used to enter the cleaning menu.

33

Page 35

Media installation and removal

Loading the media on the feeding unit

1

2

4

5

34

3

6

Page 36

7

11

8

9

10

12

13

14

15

SET

ORIGIN

CANCEL

HEATER MENU

ONLINE

35

Page 37

Installing the media on the TUR unit

ON

1

2

3

OFF

6

7

8

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

ONLINE

MAINTENANCE

36

4

5

9

10

Adhesive tape

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

ONLINE

MAINTENANCE

Page 38

11

OFF

12

15

<In loose mode>

13

14

SET

ORIGIN

CANCEL

ONLINE

HEATER MENU

MAINTENANCE

ADJUST

<Inner take-up direction>

LOW

ON

LOW (required)

BACK & FWD MAX

16

LOOSETUR MODE TENSION TENSION

SUCTION FAN

POWER

MEDIA ADVANCE

MODE

Target media Banner Thin banner

Inner take-up

HIGH

(recommended)

FORWARD ONLY

BACK & FWD LOW

BACK & FWD HIGH

FWD LESS WRINKLES

Vinyl and coated paper

Cannot be used Cannot be used

(recommended)

FORWARD ONLY

FWD LESS WRINKLES

<Outer take-up direction>

Outer take-up

37

Page 39

Removing the media from the TUR unit

ON

1

2

3

②

OFF

①

5

6

7

①

②

4

①

②

38

Page 40

Removing the media from the feeding unit

1

2

3

39

Page 41

Adjustment

Adjusting the media advance

1

2

3

4

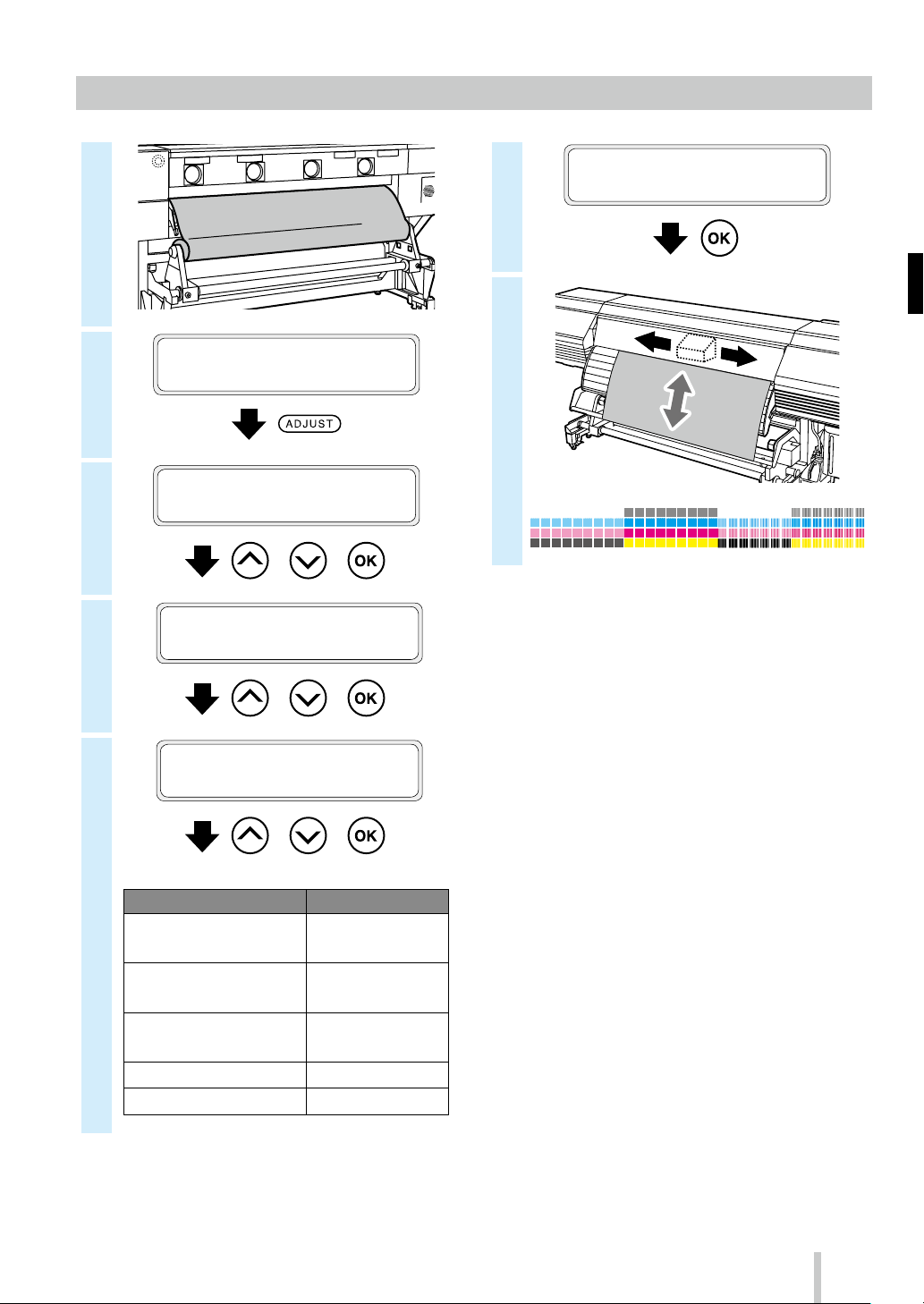

PRINTER READY

01: PAPER / 1626mm

ADJUST

MEDIA ADVANCE

2

, ,

>MEDIA ADVANCE

MEDIA ADVANCE AUTO

2

(LCIS)

Print mode

FAST PRODUCTION

PRODUCTION

STANDARD

QUALIT Y

HIGH QUALITY

MAX QUALITY

6

>>MEDIA ADVANCE AUTO

EXECUTE OK?

7

40

5

(CIS)

DRAFT

FAST PRODUCTION

PRODUCTION

STANDARD

QUALIT Y

HIGH QUALITY

MAX QUALITY

, ,

>>MEDIA ADVANCE AUTO

DRAFT

2

, ,

Print mode

To make finer adjustment, perform manual adjustment.

Refer to the User’s Guide for the manual adjustment

procedure.

Page 42

Adjusting the bidirectional position

1

2

3

4

PRINTER READY

01: PAPER / 1626mm

ADJUST

BIDIR POSITION

2

, ,

>BIDIR POSITION

MEDIA ADVANCE AUTO

2

(LCIS)

Bidirectional

adjustment pattern

ALL PRINT MODES All print modes

1: FAST PRO, PRO Fast production and

2: STD & QUALITY Standard and quality

3: HIGH QUALITY High quality

4: MAX QUALITY Max quality

6

>>MEDIA ADVANCE AUTO

EXECUTE OK?

Print mode

production

7

, ,

5

>>MEDIA ADVANCE AUTO

1: DRA,FAST PR,PRO

2

, ,

(CIS)

Bidirectional

adjustment pattern

ALL PRINT MODES All print modes

1: DRA,FAST PR,PRO Draft, fast production,

2: STD & QUALITY Standard and quality

3: HIGH QUALITY High quality

4: MAX QUALITY Max quality

Print mode

and production

To make finer adjustment, perform manual adjustment.

Refer to the User’s Guide for the manual adjustment

procedure.

41

Page 43

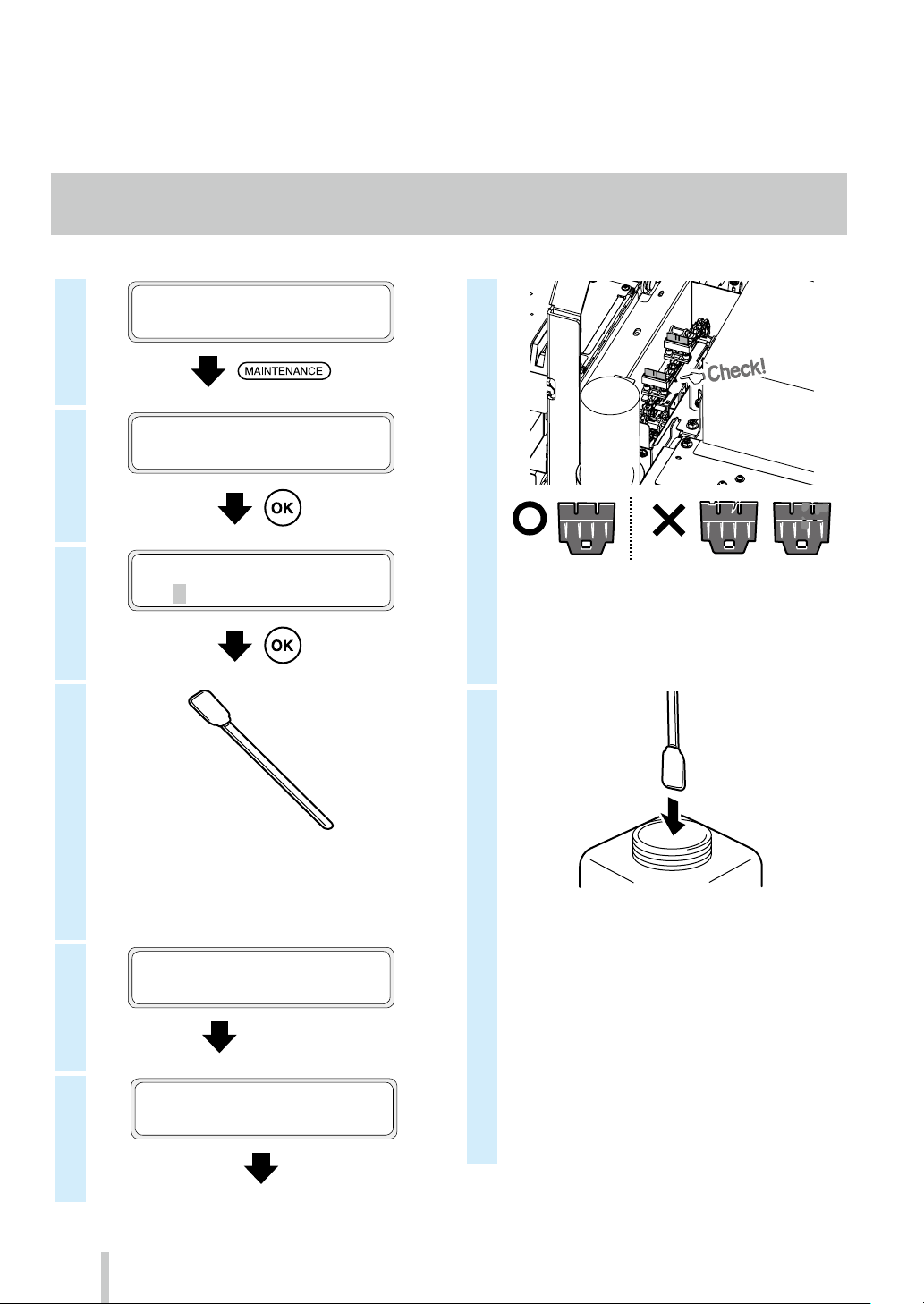

Maintenance

GOOD

Start maintenance (wiper blades check, capping unit cleaning, cleaning)

1

2

3

PRINTER READY

01: PAPER / 1626mm

MAINTENANCE

START MAINTENANCE

2

>START MAINTENANCE

OK?

7

BAD

If you find that the wiper blades are damaged or

dirty, execute REPLACE WIPER BLADE to replace

the wiper blades after START MAINTENANCE has

finished.

4

IP7-264 Cleaning swab (Thick)

* IP6-264 is also included in the IP6-271 daily

maintenance kit A.

5

6

1ST WIPING OPERATION

PLEASE WAIT 1:00

Carriage stops moving.

OPEN COVERS, CLEAN

CAPS AND CHECK WIPER

8

IP6-272 Cap cleaning liquid A

* IP6-272 is also included in the IP6-271 daily

maintenance kit A.

* To keep the cap cleaning liquid clean, do

not soak the cleaning swab (thick) in the cap

cleaning liquid bottle again after you have

cleaned the caps with it.

* You can clean the entire capping unit with

one cleaning swab (thick) soaked once in cap

cleaning liquid.

42

Page 44

9

13

14

START PH RECOVERY?

OK/CANCEL

PH RECOVERING

BOTTLE IS EMPTY?

(1) First, pass the cleaning swab (thick) over the

entire circumference of each cap top surface

to impregnate the dirt on the surface with cap

cleaning liquid.

Pass the cleaning swab (thick) starting from the

leftmost cap and continue to the rightmost cap

in order.

(2) Next, clean all the dirt by passing the cleaning

swab (thick) 5 times over the circumference of

each cap top surface.

Start from the leftmost cap and continue to the

rightmost cap in order.

10

CLEAN CAPS, CHECK

WIPER & CLOSE COVERS

15

16

PH RECOVERING 1234567

REQUIRED TIME Y:YY

The cleaning is complete.

PERFORM NOZZLE PRINT

MAINTENANCE

START MAINTENANCE

2

11

12

CAP CLEAN COMPLETE?

OK?

2ND WIPING OPERATION

PLEASE WAIT 1:00

43

Page 45

Nozzle print

toward the line of nozzle 161.

1

2

3

4

5

PRINTER READY

01: PAPER / 1626mm

NOZZLE PRINT

PRINT?

2

NOZZLE PRINT

EXECUTING

Example of nozzle print pattern

Missing lines are found

BAD BAD

Example when lines for nozzles 24 and

133 are missing in the printout.

6

7

8

Ink is not ejected

straight

Example when the nozzle 159

does not eject ink straight.

9

PRINTER READY

01: PAPER / 1626mm

ADJUST

SET NOZZLE MAP

2

, ,

>SET NOZZLE MAP

Lc

2

, ,

>>SET NOZZLE MAP Lc

#01:***/VAL

2

, ,

The line printed by the nozzle 159

(shown with the arrow) is bent

* If lines are missing or bent lines are found on the the

nozzle print pattern, perform normal cleaning and

repeat the procedure starting from step 1.

Press the PH.RECOVERY button to perform normal

cleaning.

If the same problems occur even after normal

cleaning, set nozzle map for the defective nozzle

numbers following the procedure from step 6.

* Nozzle map can be set to manual configuration or

automatic configuration.

(Refer to the User’s Guide page 104 for details on

automatic configuration.)

10

11

>>>Lc:#1

VAL

2

***/

>>>Lc:#1

133/ VALg133/ VAL

2

* If several lines are missing or several bent lines

are found, repeat the procedure to set nozzle

map for all defective nozzles.

VAL

g

133/

, , , ,

44

Page 46

Wiper cleaning liquid check and supply

is nished.

procedure from step 2.

GOOD

New wiper cleaning liquid

(2)

1

2

3

BAD

The procedure

PRINTER READY

01: PAPER / 1626mm

MAINTENANCE

WIPER MAINTENANCE

2

, ,

Continue the

8

Used wiper cleaning liquid

* Wear gloves to perform this procedure.

9

IP6-251 Wiper cleaning liquid set A

* IP6-251 is also included in the IP6-271 daily

maintenance kit A.

Printer set cap

10

4

5

6

7

WIPER MAINTENANCE

REPLACE LIQUID

2

, ,

>REPLACE LIQUID

OK?

OPEN COVERS, REPLACE

WIPER CLEANG LIQUID

(1)

(2)

11

12

13

AFTER REPLACING WCL

CLOSE COVERS

REPLACED WCL?

YES

2

* In addition to daily checks, supply wiper

cleaning liquid also when the printer displays

a message that prompts you to do so.

GOODBAD

(1)

, ,

45

Page 47

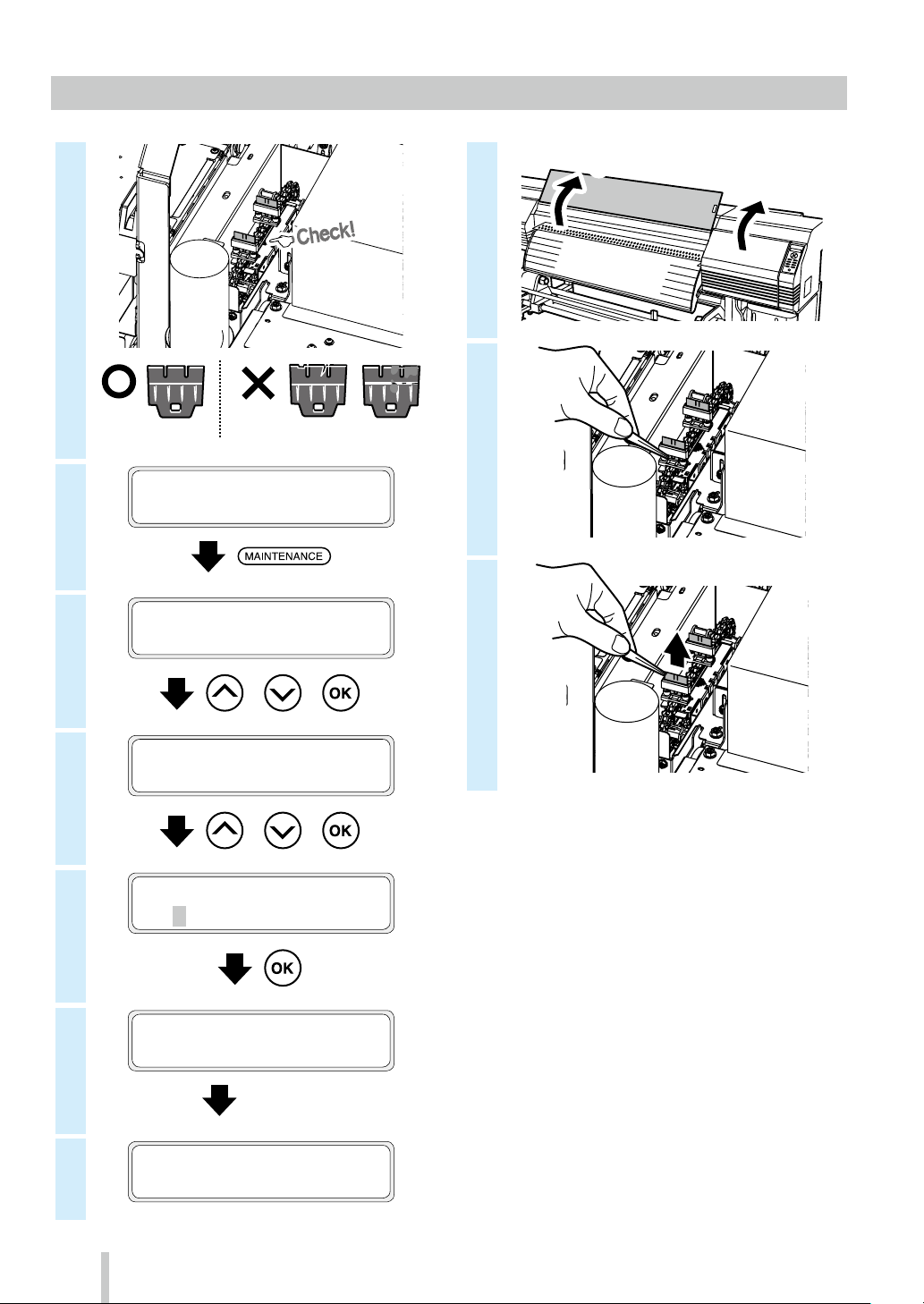

Wiper blade cleanliness check and replacement

GOOD

1

7

OPEN COVERS AND

REPLACE WIPER BLADE

2

3

4

BAD

The procedure

is nished.

PRINTER READY

01: PAPER / 1626mm

MAINTENANCE

WIPER MAINTENANCE

2

>WIPER MAINTENANCE

REPLACE BLADE

2

Continue the procedure

from step 2.

, ,

8

(1)

(2)

9

10

46

5

6

, ,

>>REPLACE BLADE

OK?

CARRIAGE IS MOVING

PLEASE WAIT

Carriage stops moving.

Page 48

11

(3) Sponge

(1) Rubber

s

They are parallel

(2)

(1)

(2)

(2) Rubber

The spaces on the right and left are equal

14

REPLACED WIPE BLADE?

YES

2

, ,

* In addition to daily checks, replace the wiper

blades also when the printer displays a

message that prompts you to do so.

IP6-259 Wiper blade

* Be sure to install the blades in the right order.

* IP6-259 is also included in the IP6-271 daily

maintenance kit A.

12

13

The protrusion is in the center

Parts are in contact at both the right and left side

AFTER REPLACING WB

CLOSE COVERS

Protrusion

(1)

47

Page 49

Waste ink bottle check and replacement

ntinue the procedure

GOOD

1

2

FULL

The procedure

is nished.

Co

BAD

from step 2.

4

5

FULL

IP6-109 Waste ink bottle

3

6

7

RESET WST INK COUNT?

YES

2

, ,

* In addition to daily checks, replace the waste

ink bottle also when the printer displays a

message that prompts you to do so.

48

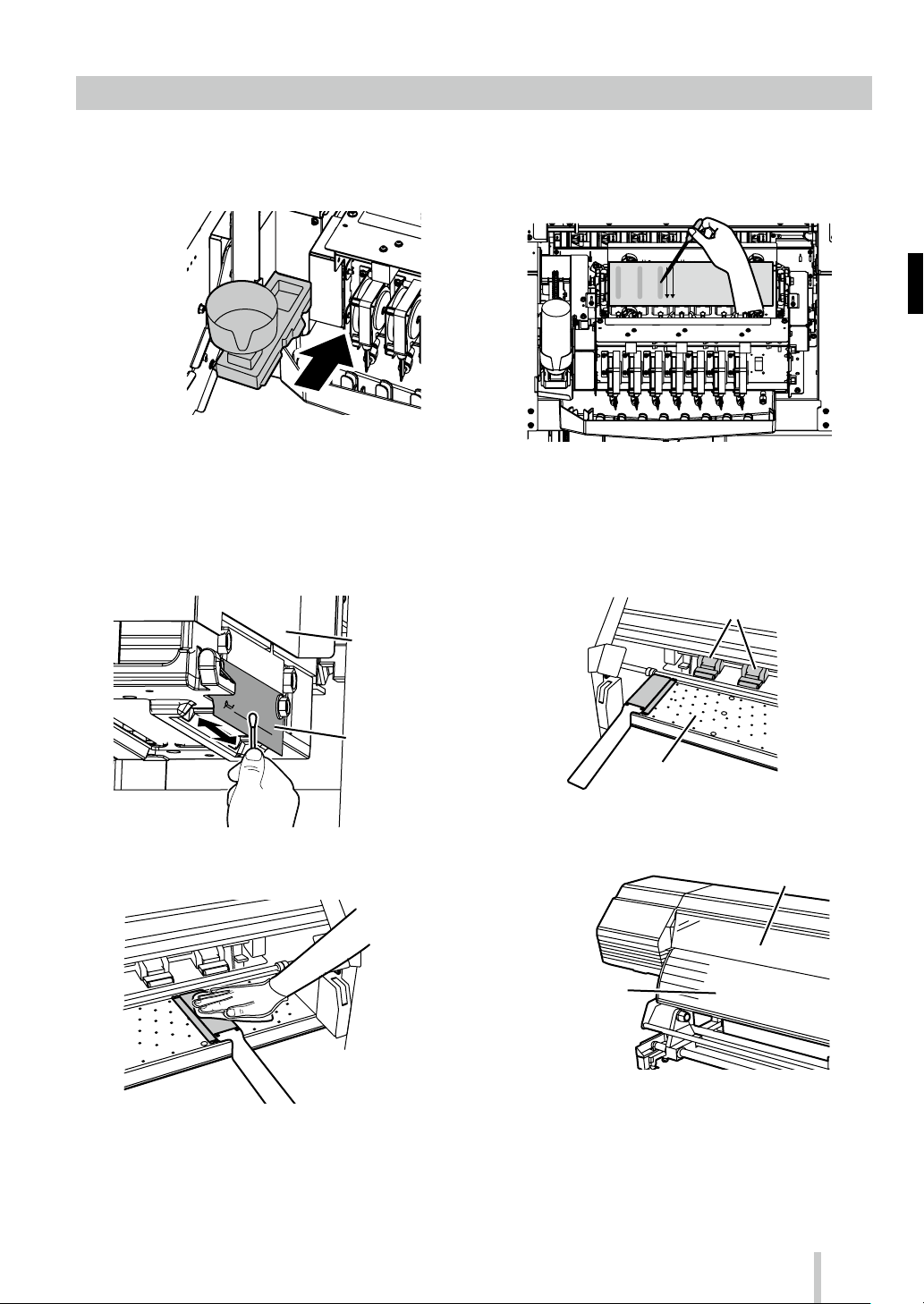

Page 50

Other maintenance operations

Pressure roller

Replace also the wiper sponge when the printer displays

a message that prompts you to do so.

Clean the following parts when when you notice any dirt.

<Head guard cleaning>

Carriage

Perform sheet mount cleaning if you notice that the

capping unit is not clean.

<Pressure roller and platen cleaning>

<Media edge guards cleaning>

Head guard

Platen

<Front cover and paper guide cleaning>

Front cover

Output paper guide

See the User’s Guide for the cleaning procedures.

49

Page 51

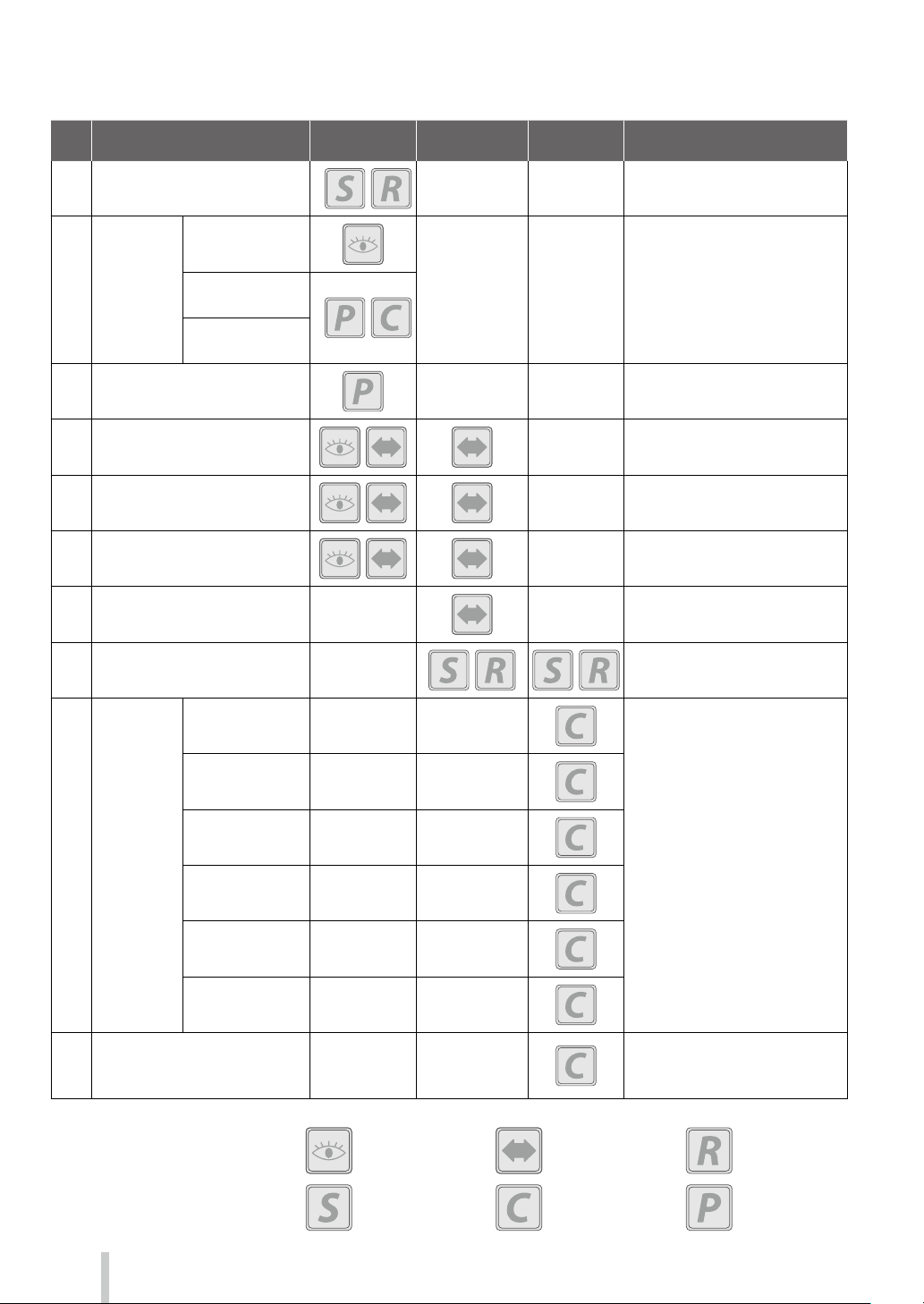

The timing to perform each maintenance item is shown in the table below.

Panel operation

No. Item Daily

When a mess age is

displaye d

noticeably dirty

When it is

Consumables

A Media installation

Wiper blades

check

B Start maintenance

Capping unit

cleaning

Cleaning

C Nozzle print

Waste ink bottle check and

D

replacement

Wiper cleaning liquid check and

E

supply

Wiper blade cleanliness check and

F

replacement

G Wiper sponge replacement

Sheet mount cleaning

(This operation must be performed

H

approximately every month)

Media edge

guard cleaning

IP6-272 Cap cleaning liquid A *

IP7-264 Cleaning swab (Thick) *

1

1

IP6-109 Waste ink bottle

IP6-251 Wiper cleaning liquid set A *1

IP6-259 Wiper blade *1

IP6-258 Wiper sponge

IP6-261 Sheet mount cleaning kit A

Head guard

cleaning

Printer cleaning

(This operation

must be per formed

I

approximately once

per week)

Platen cleaning

Paper guide

cleaning

Pressure roller

cleaning

Front cover

cleaning

Cleaning around the ionizers and the

sensors for automatic print adjustment

J

(This operation must be performed

approximately once per year)

*1 Also included in the IP6-271 daily maintenance kit A.

• • •

• • •

Check

Set

• • •

• • •

Replace

Clean

IP6-147 Cleaning swab *1

IP6-272 Cap cleaning liquid A *

IP6-147 Cleaning swab *1

• • •

Remove

• • •

1

50

Page 52

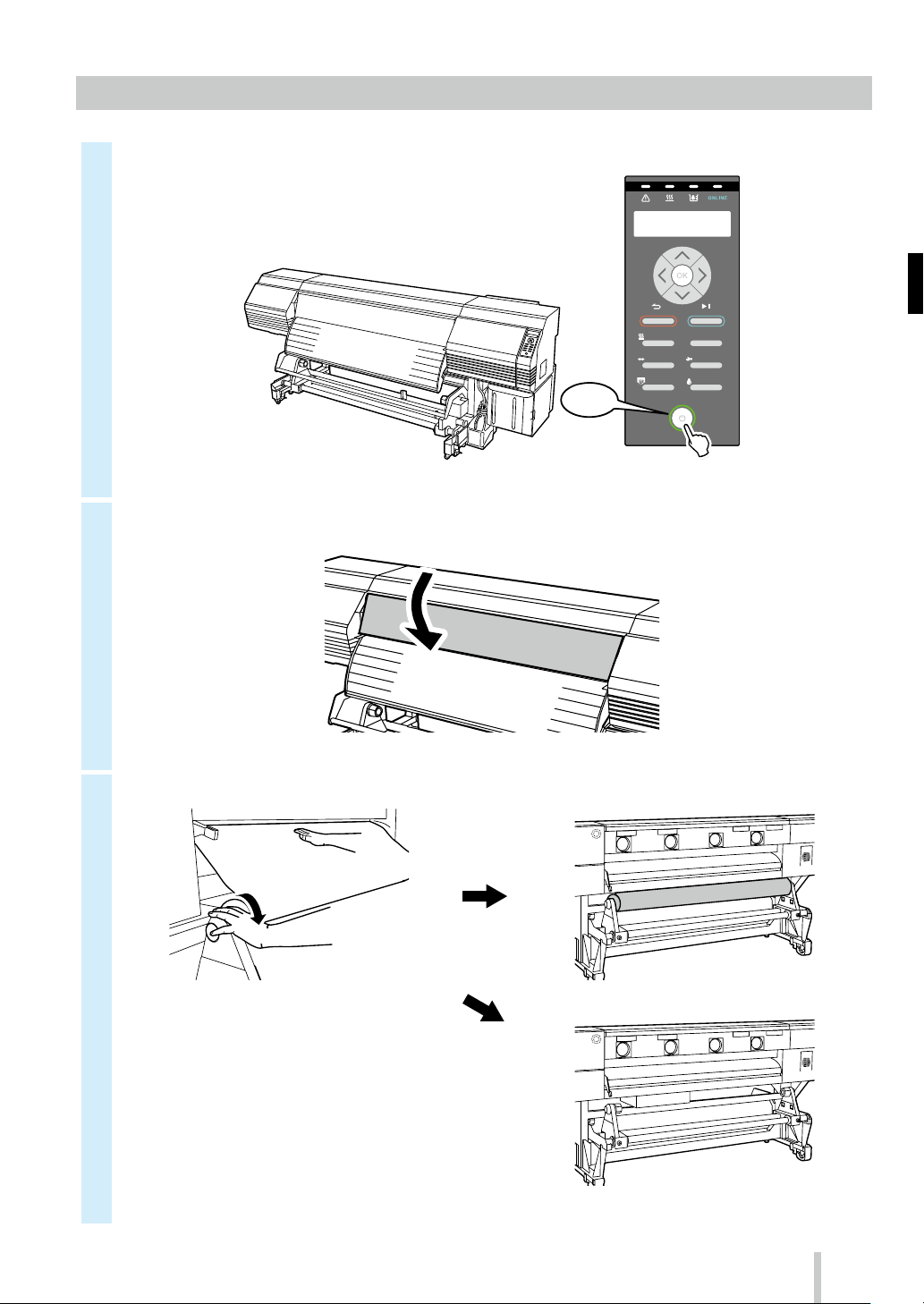

After the operation of the day

Keep the printer turned on.

1

Keep the front cover closed.

2

ON

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

NOZZLE PRINT PH.RECOVERY

ONLINE

MAINTENANCE

POWER

Take up the media on the TUR unit, or remove the media from the printer.

3

51

Page 53

Ink cartridge replacement (CIS)

(2)

New ink cartridge

1

2

* Be sure to install the correct ink color in the

corresponding slot.

5

IP6-221 Y (yellow)

IP6-222 M (magenta)

IP6-223 C (cyan)

IP6-224 K (black)

IP6-225 Lc (light cyan)

IP6-226 Lm (light magenta)

IP6-227 Gy (gray)

6

(2)

(1)

3

4

Push two claws

7

8

Old ink cartridge

(1)

52

Page 54

Ink bottle replacement (LCIS)

1

2

PRINTER READY

01: PAPER / 1626mm

MENU

INFORMATION

2

7

3

4

5

6

>INFORMATION

WARNING INFO

2

,

>INFORMATION

INK INFORMATION

2

>>INK INFORMATION

BOTTLES TO SUPPLY

2

>>>BOTTLES TO SUPPLY

Lc*: Lm*: C*: Y*: K*: M*

* Number of ink bottles that can be supplied to

the reservoir

A hyphen “-” is displayed when the reservoir

drawer is open.

8

Lc

Lm

C

9

Turn slowly the B part in the counter-clockwise

direction while holding the A part with your hand

to prevent it from turning.

(2)

FULL

B

(1)

A

FULL

FULL

Y

K

M

53

Page 55

10

IP6-241 Y (yellow)

IP6-242 M (magenta)

IP6-243 C (cyan)

IP6-244 K (black)

IP6-245 Lc (light cyan)

IP6-246 Lm (light magenta)

11

12

13

(2)

(1)

FULL

FULL

FULL

54

Page 56

Reading the ink amount extension chip (LCIS)

1

2

3

4

PRINTER READY

01: PAPER / 1626mm

MENU

INFORMATION

2

MENU

INK AMT EXTENSION

2

>INK AMT EXTENSION

AVAILABLE INK

2

,

8

9

Open

Push

5

6

7

,

>INK AMT EXTENSION

READ EXT. CHIP

2

>>READ EXT. CHIP

OK?

INSERT EXT. CHIP

PRESS CANCEL TO QUIT

10

11

READING...

PLEASE WAIT

Close

Push

55

Page 57

12

OPERATION COMPLETED

X.XXL

X.XXL: Amount of ink that can be used

13

14

15

16

REMOVE THE

EXTENSION CHIP

Open

Close

Push

56

17

Push

INSERT EXT. CHIP

PRESS CANCEL TO QUIT

>INK AMT EXTENSION

READ EXT. CHIP

2

Page 58

IP-6620

Table des matières

Aspect et principaux composants

Système d’encre de la cartouche (CIS) ........58

Avant de l'imprimante (côté sortie papier) ................ 58

Arrière de l'imprimante (côté entrée papier) ............ 59

Intérieur de l'imprimante ................................................. 60

Unité de chauage de l'imprimante ............................ 60

Panneau de commande ................................................... 61

Aspect et principaux composants

Système d’encre à grande capacité (LCIS) ..62

Avant de l'imprimante (côté sortie papier) ................ 62

Arrière de l'imprimante (côté entrée papier) ............ 63

Intérieur de l'imprimante ................................................. 64

Unité de chauage de l'imprimante ............................ 64

Panneau de commande ................................................... 65

Installation et enlèvement de support ....... 66

Chargement du support dans l'unité d'alimentation

Chargement du support dans la bobine réceptrice

Retrait du support de la bobine réceptrice ............... 70

Retrait du support de l'unité d'alimentation ............ 71

.. 66

.. 68

Guide de référence rapide

FRANÇAIS

Réglage ............................................................. 72

Réglage de l'avance du support ................................... 72

Réglage de la position bidirectionnelle ..................... 73

Maintenance ....................................................74

Maintenance au démarrage (contrôle de la

lame de l’essuyeur, nettoyage de l’unité de

protection, nettoyage) .................................. 74

Impression avec les buses ................................................ 76

Alimentation et vérication du liquide de nettoyage

Vérication de la propreté et remplacement de

l'essuyeur ................................................................................ 78

Vérication et remplacement de la bouteille

de résidus d'encre ............................................................... 80

Autres opérations de maintenance .............................. 81

Après le fonctionnement quotidien ............................ 83

Remplacement de cartouche d'encre (CIS) ................ 84

Remplacement de la bouteille d'encre (LCIS) ............ 85

Lecture de la puce d’extension du niveau

d’encre (LCIS) ......................................................................... 87

.. 77

57

Page 59

Aspect et principaux composants

Avant de l'imprimante (côté sortie papier)

•

Panneau de commande

Équipé de voyants DEL et d'un écran LCD

•

Capot avant

Doit être fermé durant l'impression.

•

Capot de la zone de maintenance

Ouvrez-le pour procéder à la maintenance

de la tête d'impression

permettant d'acher l'état de l'imprimante

ainsi que des boutons permettant de

dénir les fonctions.

•

Capot de l’unité de protection

Ouvert lors du nettoyage de l'unité de

protection ou du chariot.

Système d’encre de la cartouche (CIS)

58

•

Clip de support (option)

Après avoir coupé le support, fixez-le

de façon à ce qu’il ne tombe pas.

•

Lame de massicot du support (option)

Elle sert à couper le support.

•

Unité de massicot (64) (option)

•

Guide-papier avant

Comprend le post-chauage permettant

de sécher l'encre.

•

Bobine réceptrice

Enroule le support imprimé.

•

Levier du rouleau presseur

Ce levier sert à xer ou à libérer le support.

•

Barre de guidage

Guide le support en mode feuillet par feuillet.

•

Boîte d'encre

Ouvrez le capot pour installer

les cartouches d'encre.

•

Bouteille de résidus d'encre

•

Commutateur de sens de sortie

Dénit le sens de sortie du support.

Enroulement

désactivé

Chargement vers

l’extérieur

Chargement vers

l’intérieur

Page 60

Arrière de l'imprimante (côté entrée papier)

•

Positions d’installation de l’accessoire d’échappement

•

Connecteur USB

Utilisé pour raccorder l'imprimante à un

ordinateur.

•

Porte-support

Il doit être installé aux deux

bouts du support en rouleau.

•

Prise d'entrée

d'alimentation

Raccordez le câble

d'alimentation à la prise

d'entrée d'alimentation.

•

Commutateur

d'alimentation de

l'imprimante

•

Guide de support

Soulève ou abaisse le support durant

les procédures de chargement et

d’enlèvement.

Peut également être utilisé lorsqu’il

est déplacé sur le côté de la bobine

réceptrice.

•

Soutien du support

Maintient temporairement le support durant les

procédures de chargement et d’enlèvement.

Peut également être utilisé lorsqu’il est déplacé sur le

côté de la bobine réceptrice.

•

Roulette

Placez le verrou sur OFF pour déplacer l'imprimante et sur

ON pour la bloquer en place.

•

Levier du rouleau presseur

Un levier utilisé pour xer ou libérer le support.

Se déplace avec le levier du rouleau presseur sur

l'avant de l'imprimante.

59

Page 61

Intérieur de l'imprimante

• Unité de chauffage de l'imprimante (avant)

• Unité de post-chauffage (nition)

Sèche l'encre de manière à stabiliser

la qualité d'impression.

• Ionisateur

Élimine l’

défauts d’

•

Capteurs optiques utilisés pour

l’

• Chariot

Abrite les têtes d’

l’

• Rainure du massicot

La lame du massicot est

insérée dans cette rainure lors

du découpage du suppor

d’

• Plateau

Déplace le suppor

des ventilateurs aspirants et une unité

de chauage de l’

sécher l’

• Unité d’essuyage

• Unité de protection

•

Pr

dommages causés par les cornes et

les bavures sur les bords du suppor

image avec le support de scannage.

impression, et imprime

électricité statique du support et réduit les

impression causés par le brouillard d’encre.

Capteurs pour l’ajustement

d’impression automatique

ajustement d’impression automatique.

t. Le plateau intègre

imprimante pour

encre.

t, an

assurer un découpage droit.

Protection des bords du support

otège les têtes d’impression des

t.

Unité de chauage de l'imprimante

Retire les corps étrangers de la surface

de la buse de la tête d’impression.

Empêche les buses de la

tête d’impression de sécher.

• Conteneur d’encre

Est destiné à l’installation de la

cartouche d’encre.

• Rouleau d’entraînement

Le rouleau d’entraînement sert à faire

avancer ou reculer le support.

• Rouleau presseur

Lorsque vous abaissez le levier montée/descente

du rouleau presseur, le support est pincé.

L'imprimante est équipée de trois unités de chauage pour la fusion de l'encre et la stabilisation de la qualité d'image.

Fait pénétrer l'encre dans le support en vue

60

* Ces trois unités de chauage sont contrôlées indépendamment les unes des autres.

La température des unités de chauage peut être contrôlée depuis le panneau de commande, le logiciel RIP

et CP_Manager.

AVERTISSEMENT

Ne touchez pas ces unités de chauage. Leur température devient très élevée et vous risquez de vous brûler.

Support

de la fusion de l'encre.

• Unité de post-chauffage (arrière)

Eectue un pré-chauage du support.

Page 62

Panneau de commande

MENU

ADJUST

MAINTENANCE

NOZZLE PRINT

PH.RECOVERY

Les boutons, les voyants DEL et l'écran LCD sont situés sur le panneau de commande de l'imprimante tel que guré cidessous. De plus, le panneau de commande est muni d'une alerte sonore signalant une erreur ou le fait d'appuyer sur

un mauvais bouton.

L’imprimante se met en mode attente si elle n’est pas utilisée pendant un certain temps.

•

Voyants DEL

Ils indiquent l'état de l'imprimante en étant

allumés ou éteints, ou en clignotant.

Voir le tableau ci-dessous.

•

Boutons directionnels

•

Écran LCD

Il montre l'état de l'imprimante et ache la

fenêtre de menu (2 lignes, 20 caractères).

Mode attente

(Pendant le mode attente)

LCD: écran et rétroéclairage désactivés

Voyant LED en ligne: clignote lentement

Autres voyants LED: désactivés

(Quitter le mode attente)

L’imprimante quitte le mode attente quand

- vous appuyez sur un bouton,

- l’imprimante reçoit des données à imprimer.

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

NOZZLE PRINT PH.RECOVERY

MAINTENANCE

ONLINE

Utilisés pour sélectionner des options de

menu, passer d'un menu à l'autre (sélection,

valeurs croissantes/décroissantes), etc.

•

Bouton OK

Utilisé pour conrmer le menu et les

paramètres.

•

Boutons

Utilisez ces boutons pour naviguer dans le

menu de l'imprimante.

Voir le tableau ci-dessous.

•

Alerte sonore

Résonne lorsqu'une erreur se produit ou

qu'un mauvais bouton est pressé. Elle

avertit également de la maintenance

journalière et de l'ouverture des capots des

têtes d'impression.

Voyants DEL

Indique si une erreur s'est produite.

ALLUMÉ: une erreur s'est produite.

Voyant DEL d'erreur

(orange)

Voyant DEL de l'un ité

de chau age de

Clignote: aver tissement.

ÉTEINT: normal (pas d'erreur).

Indique l'état de l'unité de chauage du support.

- ALLUMÉ: la température dénie a été atteinte

- Clignote: en cours de chauage

- ÉTEINT: l'unité de chauage du support est éteinte

support (vert)

Indique s'il reste de l'encre.

ALLUMÉ: il reste des encres de toutes les couleurs.

Voyant DEL d'enc re

(ver t)

Voyant DEL d'éta t

(ver t)

Clignote: encre en voie d'épuisement (le niveau d'une

des couleurs est bas.)

ÉTEINT: pas d'encre.

Indique l'état de l'imprimante (en ligne, hors ligne,

réception de données, pause).

- ALLUMÉ: en ligne

- Clignote (lentement): en pause

- Clignote (rapidement): réception de données

- ÉTEINT: hors ligne

POWER

CANCEL

ONLINE

HEATER

•

Commutateur d'alimentation

Utilisé pour mettre l'imprimante sous ou

hors tension.

Utilisé pour entrer en mode attente et le

quitter manuellement.

Boutons

Annule les paramètres saisis et retourne au menu

supérieur.

Permet de basculer entre mode en ligne et hors

ligne, de mettre l'imprimante en pause ou de

reprendre l'impression.

Ouvre le menu de commande de l'unité de chauffage.

Utilisé pour acher les informations relatives à

l'imprimante et modier ses paramètres.

Utilisé pour entrer dans le menu de réglage.

Utilisé pour entrer dans le menu de maintenance.

Utilisé pour eectuer une impression avec les

buses.

Utilisé pour entrer dans le menu de net toyage.

61

Page 63

Aspect et principaux composants

Avant de l'imprimante (côté sortie papier)

•

Panneau de commande

Équipé de voyants DEL et d'un écran LCD

•

Capot avant

Doit être fermé durant l'impression.

•

Capot de la zone de maintenance

Ouvrez-le pour procéder à la maintenance

de la tête d'impression

permettant d'acher l'état de l'imprimante

ainsi que des boutons permettant de

dénir les fonctions.

•

Capot de l’unité de protection

Ouvert lors du nettoyage de l'unité de

protection ou du chariot.

Système d’encre à grande capacité (LCIS)

•

Clip de support (option)

Après avoir coupé le support, fixez-le

de façon à ce qu’il ne tombe pas.

•

Lame de massicot du support (option)

Elle sert à couper le support.

•

Unité de massicot (64) (option)

•

Guide-papier avant

Comprend le post-chauage permettant

de sécher l'encre.

•

Bobine réceptrice

Enroule le support imprimé.

•

Levier du rouleau presseur

Ce levier sert à xer ou à libérer le support.

•

Barre de guidage

Guide le support en mode feuillet par feuillet.

•

Bouteille de résidus d'encre

•

Unité LCIS

Ouvrez le tiroir pour installer les bouteilles

d’encre.

•

Lecteur de puce

À utiliser avec la puce d’extension du niveau

d’encre.

•

Commutateur de sens de sortie

Dénit le sens de sortie du support.

Enroulement

désactivé

Chargement vers

l’extérieur

Chargement vers

l’intérieur

62

Page 64

Arrière de l'imprimante (côté entrée papier)

•

Positions d’installation de l’accessoire d’échappement

•

Connecteur USB

Utilisé pour raccorder

l'imprimante à un ordinateur.

•

Prise d'entrée

d'alimentation

Raccordez le câble

d'alimentation à la prise

d'entrée d'alimentation.

•

Guide de support

Soulève ou abaisse le support durant

les procédures de chargement et

d’enlèvement.

Peut également être utilisé lorsqu’il

est déplacé sur le côté de la bobine

réceptrice.

•

Soutien du support

Maintient temporairement le support durant les

procédures de chargement et d’enlèvement.

Peut également être utilisé lorsqu’il est déplacé sur le

côté de la bobine réceptrice.

•

Porte-support

Il doit être installé aux deux

bouts du support en rouleau.

•

Commutateur

d'alimentation de

l'imprimante

•

Roulette

Placez le verrou sur OFF pour déplacer l'imprimante et sur

ON pour la bloquer en place.

•

Levier du rouleau presseur

Un levier utilisé pour xer ou libérer le support.

Se déplace avec le levier du rouleau presseur sur

l'avant de l'imprimante.

63

Page 65

Intérieur de l'imprimante

• Unité de chauffage de l'imprimante (avant)

• Unité de post-chauffage (nition)

Sèche l'encre de manière à stabiliser

la qualité d'impression.

• Ionisateur

Élimine l’

défauts d’

•

Capteurs optiques utilisés pour

l’

• Chariot

Abrite les têtes d’

l’

• Rainure du massicot

La lame du massicot est

insérée dans cette rainure lors

du découpage du suppor

d’

• Plateau

Déplace le suppor

des ventilateurs aspirants et une unité

de chauage de l’

sécher l’

• Unité d’essuyage

• Unité de protection

•

Pr

dommages causés par les cornes et

les bavures sur les bords du suppor

image avec le support de scannage.

impression, et imprime

électricité statique du support et réduit les

impression causés par le brouillard d’encre.

Capteurs pour l’ajustement

d’impression automatique

ajustement d’impression automatique.

t. Le plateau intègre

imprimante pour

encre.

t, an

assurer un découpage droit.

Protection des bords du support

otège les têtes d’impression des

t.

Unité de chauage de l'imprimante

Retire les corps étrangers de la surface

de la buse de la tête d’impression.

• Bouteille d’encre

Utilisée pour l’alimentation en encre.

• Rouleau d’entraînement

Le rouleau d’entraînement sert à faire

avancer ou reculer le support.

• Rouleau presseur

Lorsque vous abaissez le levier montée/descente

du rouleau presseur, le support est pincé.

Empêche les buses de la

tête d’impression de sécher.

L'imprimante est équipée de trois unités de chauage pour la fusion de l'encre et la stabilisation de la qualité d'image.

Fait pénétrer l'encre dans le support en vue

64

* Ces trois unités de chauage sont contrôlées indépendamment les unes des autres.

La température des unités de chauage peut être contrôlée depuis le panneau de commande, le logiciel RIP

et CP_Manager.

AVERTISSEMENT

Ne touchez pas ces unités de chauage. Leur température devient très élevée et vous risquez de vous brûler.

Support

de la fusion de l'encre.

• Unité de post-chauffage (arrière)

Eectue un pré-chauage du support.

Page 66

MENU

ADJUST

MAINTENANCE

NOZZLE PRINT

PH.RECOVERY

Panneau de commande

Les boutons, les voyants DEL et l'écran LCD sont situés sur le panneau de commande de l'imprimante tel que guré cidessous. De plus, le panneau de commande est muni d'une alerte sonore signalant une erreur ou le fait d'appuyer sur

un mauvais bouton.

L’imprimante se met en mode attente si elle n’est pas utilisée pendant un certain temps.

•

Voyants DEL

Ils indiquent l'état de l'imprimante en étant

allumés ou éteints, ou en clignotant.

Voir le tableau ci-dessous.

•

Boutons directionnels

•

Écran LCD

Il montre l'état de l'imprimante et ache la

fenêtre de menu (2 lignes, 20 caractères).

Mode attente

(Pendant le mode attente)

LCD: écran et rétroéclairage désactivés

Voyant LED en ligne: clignote lentement

Autres voyants LED: désactivés

(Quitter le mode attente)

L’imprimante quitte le mode attente quand

- vous appuyez sur un bouton,

- l’imprimante reçoit des données à imprimer.

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

NOZZLE PRINT PH.RECOVERY

MAINTENANCE

ONLINE

Utilisés pour sélectionner des options de

menu, passer d'un menu à l'autre (sélection,

valeurs croissantes/décroissantes), etc.

•

Bouton OK

Utilisé pour conrmer le menu et les

paramètres.

•

Boutons

Utilisez ces boutons pour naviguer dans le

menu de l'imprimante.

Voir le tableau ci-dessous.

•

Alerte sonore

Résonne lorsqu'une erreur se produit ou

qu'un mauvais bouton est pressé. Elle

avertit également de la maintenance

journalière et de l'ouverture des capots des

têtes d'impression.

Voyants DEL

Indique si une erreur s'est produite.

ALLUMÉ: une erreur s'est produite.

Voyant DEL d'erreur

(orange)

Voyant DEL de l'un ité

de chau age de

Clignote: aver tissement.

ÉTEINT: normal (pas d'erreur).

Indique l'état de l'unité de chauage du support.

- ALLUMÉ: la température dénie a été atteinte

- Clignote: en cours de chauage

- ÉTEINT: l'unité de chauage du support est éteinte

support (vert)

Indique s'il reste de l'encre.

ALLUMÉ: il reste des encres de toutes les couleurs.

Voyant DEL d'enc re

(ver t)

Voyant DEL d'éta t

(ver t)

Clignote: encre en voie d'épuisement (le niveau d'une

des couleurs est bas.)

ÉTEINT: pas d'encre.

Indique l'état de l'imprimante (en ligne, hors ligne,

réception de données, pause).

- ALLUMÉ: en ligne

- Clignote (lentement): en pause

- Clignote (rapidement): réception de données

- ÉTEINT: hors ligne

POWER

CANCEL

ONLINE

HEATER

•

Commutateur d'alimentation

Utilisé pour mettre l'imprimante sous ou

hors tension.

Utilisé pour entrer en mode attente et le

quitter manuellement.

Boutons

Annule les paramètres saisis et retourne au menu

supérieur.

Permet de basculer entre mode en ligne et hors

ligne, de mettre l'imprimante en pause ou de

reprendre l'impression.

Ouvre le menu de commande de l'unité de chauffage.

Utilisé pour acher les informations relatives à

l'imprimante et modier ses paramètres.

Utilisé pour entrer dans le menu de réglage.

Utilisé pour entrer dans le menu de maintenance.

Utilisé pour eectuer une impression avec les

buses.

Utilisé pour entrer dans le menu de net toyage.

65

Page 67

Installation et enlèvement de support

Chargement du support dans l'unité d'alimentation

1

2

4

5

66

3

6

Page 68

7

11

8

9

10

12

13

14

15

SET

ORIGIN

CANCEL

HEATER MENU

ONLINE

67

Page 69

Chargement du support dans la bobine réceptrice

ON

1

2

3

OFF

6

7

8

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

ONLINE

MAINTENANCE

68

4

5

9

10

Ruban adhésif

SET

ORIGIN

CANCEL

HEATER MENU

ADJUST

ONLINE

MAINTENANCE

Page 70

11

OFF

12

15

<En mode feuillet par feuillet>

13

SET

ORIGIN

CANCEL

HEATER MENU

MAINTENANCE

ADJUST

<Direction du chargement vers l’intérieur>

14

FAIBLE

ON

TENSIONTENSION

FAIBLE (requis)

MAX ARR. & AVANT

16

ONLINE

MODE TUR

PUISSANCE

VENTILATEUR

ASPIRANT

MODE D’ AVANCE

SUPPORT

Support cible Bannière Bannière étroite

Réception

interne

FEUILLET PAR FEUILLET

ÉLEVÉE

(recommandé)

AVANT UNIQUEMENT

BAS ARR. & AVANT

HAUT ARR. & AVANT

AVANT SANS GONDOLEMENT

Vinyle et papier enduit

(recommandé)

AVANT UNIQUEMENT

AVANT SANS GONDOLEMENT

<Direction du chargement vers l’extérieur>

Réception

externe

Ne peut être utilisée Ne peut être utilisée

69

Page 71

Retrait du support de la bobine réceptrice

ON

1

2

3

②

OFF

①

5

6

7

①

②

4

①

②

70

Page 72

Retrait du support de l'unité d'alimentation

1

2

3

71

Page 73

Réglage

Réglage de l'avance du support

1

2

3

4

IMPRIMANTE PRETE

01 : PAPIER / 1.626 mm

ADJUST

AVANCE SUPPORT

2

, ,

>AVANCE SUPPORT

AUTO AVANCE SUPT

2

(LCIS)

Mode d'impression

PRODUCTION RAPIDE

PRODUCTION

NORMAL

QUALITE

HAUTE QUALITE

QUALITE MAX

6

>>AUTO AVANCE SUPT

EXECUTER ?

7

72

5

>>AUTO AVANCE SUPT

IMP. BROUILLON

2

(CIS)

IMP. BROUILLON

PRODUCTION RAPIDE

PRODUCTION

NORMAL

QUALITE

HAUTE QUALITE

QUALITE MAX

, ,

, ,

Mode d'impression

Pour eectuer un réglage plus n, procéder à un réglage

manuel.

Voir le manuel d'utilisation au sujet de la procédure de

réglage manuel.

Page 74

Réglage de la position bidirectionnelle

1

2

3

4

IMPRIMANTE PRETE

01 : PAPIER / 1.626 mm

ADJUST

POSITION BIDIR.

2

, ,

>POSITION BIDIR.

AUTO AVANCE SUPT

2

(LCIS)

Motif d'ajustement

bidirectionnel

TOUS MODES IMP. Tous les modes d’impres-

1: RAPID, PROD Production rapide et

2: NORMAL, QUALITE Standard et qualité

3: HAUTE QUALITE Haute qualité

4: QUALITE MAX Qualité maximale

6

>>AUTO AVANCE SUPT

EXECUTER ?

Mode d'impression

sion

production

7

, ,

5

>>AUTO AVANCE SUPT

1 : BROU,RAPID,PROD

2

, ,

(CIS)

Motif d'ajustement

bidirectionnel

TOUS MODES IMP. Tous les modes d’impres-

1: BROU,RAPID,PROD Brouillon, production

2: NORMAL, QUALITE Standard et qualité

3: HAUTE QUALITE Haute qualité

4: QUALITE MAX Qualité maximale

Mode d'impression

sion

rapide et production

Pour eectuer un réglage plus n, procéder à un réglage

manuel.

Voir le manuel d'utilisation au sujet de la procédure de

réglage manuel.

73

Page 75

Maintenance

Maintenance au démarrage (contrôle de la lame de l’essuyeur, nettoyage de l’unité de protection, nettoyage)

1

2

IMPRIMANTE PRETE

01 : PAPIER / 1.626 mm

MAINTENANCE

MAINTENANCE DEMARR

2

7

3

>MAINTENANCE DEMARR

OK ?

4

IP7-264 Chion de nettoyage (épais)

* IP6-264 est également inclus dans le kit A de

maintenance quotidienne IP6-271.

5

6

1ÈRE OPÉRATION ESSUYAGE

VEUILLEZ PATIENTER 1:00

Le chariot cesse de se déplacer.

OUVRIR CAPOT, NETTOY

PROTEC & VÉRIF ESSUY

Incorrect Correct

Si vous trouvez que la lame de l’essuyeur est

sale ou endommagée, exécutez REMPLACER

ESSUYEUR pour remplacer la lame de l’essuyeur

après la fin de MAINTENANCE DEMARR.

8

IP6-272 Liquide de nettoyage de la protection A

* IP6-272 est également inclus dans le kit A de

maintenance quotidienne IP6-271.

* Pour maintenir la propreté du liquide de

nettoyage de la protection, ne trempez pas le

chion de nettoyage (épais) dans la bouteille

de liquide de nettoyage de la protection après

avoir utilisé celui-ci pour nettoyer les protections.

* Vous pouvez nettoyer l’unité de protection

entière avec un chion de nettoyage (épais)

trempé une seule fois dans le liquide de nettoyage de la protection.

74

Page 76

9

13

14

DEMARR RECUP TI ?

OK/ANNULER

REC TI

BOUTEILLE VIDE ?

(1) Passez d’abord le chiffon de nettoyage

(épais) sur toute la circonférence de la surface

supérieure de chaque protection pour

imprégner la salissure présente sur la surface de

liquide de nettoyage de la protection.

Passez le chiffon de nettoyage (épais) en

commençant par la protection la plus à gauche,

puis continuez dans l’ordre jusqu’à la protection

la plus à droite.

(2) Ensuite, nettoyez toute la salissure en passant

le chiffon de nettoyage (épais) 5 fois sur la

circonférence de la surface supérieure de

chaque protection.

Commencez par la protection la plus à gauche

puis continuez dans l’ordre jusqu’à la protection

la plus à droite.

10

NETTOY PROTEC, VÉRIF

ESSUY & FERM. CAPOTS

15

16

REC TI 1234567

EXECUTI ON Y:Y Y

Le nettoyage est terminé.

IMP. BUSE

MAINTENANCE

MAINTENANCE DEMARR

2

11

12

NETT. PROT TERMINE?

OK?

2ÈME OPÉRATION ESSUYAGE

VEUILLEZ PATIENTER 1:00

75

Page 77

Impression avec les buses

(indiquée par la èche) est recourbée

vers la ligne de la buse 161.

Incorrect

1

IMPRIMANTE PRETE

01 : PAPIER / 1.626 mm

2

IMP BUSE

IMPRESSION ?

2

3

4

5

IMP BUSE

EXECUTION

Exemple de motif d’impression de buse

Des lignes manquantes

sont trouvées

Exemple de lignes manquantes pour les

buses 24 et 133 dans l’impression.

L’encre ne sort pas

droite

Incorrect

Exemple lorsque l’encre ne sort

pas droite de la buse 159.

6

IMPRIMANTE PRETE

01 : PAPIER / 1.626 mm

7

8

9

ADJUST

RÉGL. CORR BUSES

2

, ,

>RÉGL. CORR BUSES

Lc

2

, ,

>>RÉGL. CORR BUSES Lc

#01:***/VAR

2

, ,

La ligne imprimée par la buse 159

* Si des lignes sont manquantes ou que des lignes

courbées apparaissent dans le motif d'impression de

buse, eectuez un nettoyage normal ou répétez la

procédure à partir de l'étape 1.

Appuyez sur le bouton PH.RECOVERY pour eectuer

un nettoyage normal.

Si les mêmes problèmes se reproduisent après un

nettoyage normal, dénir un plan buse pour les

numéros de buses défectueuses en reprenant la

procédure à partir de l'étape 6.

* Le plan de buse peut être réglé en configuration

automatique ou manuelle.

(Voir le Manuel d’utilisation à la page 104 pour plus

de détails sur la configuration automatique.)

10

11

>>>Lc:#1

2

***/VARg133/ VAR

, , , ,

>>>Lc:#1

133/ VARg133/ VAR

2

* Si plusieurs lignes sont manquantes ou que