Page 1

Oki Data CONFIDENTIAL

ES1624n/ES1624MFP

Printer Maintenance Manual

050901A

Page 2

Oki Data CONFIDENTIAL

42615101TH Rev.5 2 /

Page 3

Oki Data CONFIDENTIAL

PREFACE

This manual describes the procedures of the maintenance of the ES1624n printers.

The document is produced for maintenance personnel use. For details on the procedures for handling

the ES1624n of printers, see its user documentation.

Note!

• The descriptions in this manual are subject to change without prior notice.

• In preparing the document, efforts have been made to ensure that the information in it is accurate.

However, errors may be crept into the document. Oki Data assumes no responsibility for any

damage resulting from, or claimed to be the results of, those repairs, adjustments or modifications to the printers which are made by users using the manual.

• The parts used for the printers are sensitive and, if handled improperly, may be damaged. It is

strongly recommended that the products are maintained by maintenance men registered with

Oki Data.

• Remove static electricity before working.

42615101TH Rev.5 3 /

Page 4

Oki Data CONFIDENTIAL

CONTENTS

1. SPECIFICATIONS ............................................................................................... 7

1.1 System Configuration ........................................................................................................... 7

1.2 Printer Configuration .......................................................................................................... 10

1.3 Option Configuration .......................................................................................................... 13

1.4 Specifications ..................................................................................................................... 14

1.5 INTERFACE SPECIFICATIONS ........................................................................................ 18

1.5.1 Parallel Interface Specifications (ES1624n) ........................................................ 18

1.5.1.1 Parallel Interface ................................................................................... 18

1.5.1.2 Parallel Interface Connector and Cable ................................................ 18

1.5.1.3 Parallel Interface Level .......................................................................... 18

1.5.1.4 Timing Charts ........................................................................................ 19

1.5.1.5 Parallel I/F Signals ................................................................................ 20

1.5.2 Universal Serial Bus (USB) Interface Specifications(ES1624n)............................... 21

1.5.2.1 USB Interface ........................................................................................ 21

1.5.2.2 USB Interface Connector and Cable ..................................................... 21

1.5.2.3 USB Interface Signals ........................................................................... 21

1.5.3 Network Interface Specifications(ES1624n) ..........................................................22

1.5.3.1 Network Interface .................................................................................. 22

1.5.3.2 Network Interface Connector and Cable ............................................... 22

1.5.3.3 Network Interface Signals ..................................................................... 22

2. OPERATION DESCRIPTION ............................................................................ 23

2.1 Electrophotographic Process Mechanism .......................................................................... 23

2.2 Printing Processes ................................................................................................................ 28

3. PRINTER INSTALLATION ................................................................................. 38

3.1 Precautions and Prohibition .................................................................................................. 38

3.2 Printer Unpacking Procedure ................................................................................................40

3.3 Printer Installation Instructions .............................................................................................. 41

3.4 Packed Units and Attachments ............................................................................................. 42

3.5 Assembly Procedure ............................................................................................................. 43

3.5.1 Printer Main Body .................................................................................................... 43

3.5.2 Power Cable Connection ......................................................................................... 48

3.5.3 Installation of Optional Components ........................................................................ 51

3.5.4 Checking of Optional-Component Recognition........................................................ 60

3.6 MenuMap Printing ................................................................................................................. 61

3.7 Connection Procedures ........................................................................................................ 64

3.8 Checking of User Paper ........................................................................................................ 66

4. PARTS REPLACEMENT ................................................................................... 67

4.1 Precautions in Replacing Parts .......................................................................................... 67

4.2 Part Replacement Procedures ........................................................................................... 69

4.2.1 Left Side Cover ..................................................................................................... 69

4.2.2 Right Side Cover .................................................................................................. 70

4.2.3 Face-Up Tray........................................................................................................ 71

4.2.4 Rear Cover ........................................................................................................... 72

4.2.5 LED Assy / LED Assy-Springs.............................................................................. 73

4.2.6 Controller PCB...................................................................................................... 74

4.2.7 Print Engine Controller PCB ................................................................................. 76

4.2.8 Top Cover Assy .................................................................................................... 79

4.2.9 Top Cover ............................................................................................................. 80

4.2.10 Controller Panel Assy ........................................................................................... 81

4.2.11 Board-PRP / Top Cover Handle ........................................................................... 82

4.2.12 Low-Voltage Power Unit / ID-FAN / Low-Voltage Power Unit FAN /

Hopping Motor / Fuser Motor................................................................................ 83

42615101TH Rev.5 4 /

Page 5

Oki Data CONFIDENTIAL

4.2.13 Board-PRT............................................................................................................ 84

4.2.14 Guide-Eject Assy / Color Registration Assy / Board-PRM.................................... 85

4.2.15 FAN (Fuser) / Belt Motor / High Voltage Power Supply Board / Cover Open Switch 87

4.2.16 MPT-Assy ............................................................................................................. 88

4.2.17 Feeder Unit / Board-RSF / MPT Hopping Roller / Frame Assy Separator /

Cover-Front .......................................................................................................... 89

4.2.18 Main Motors / Solenoid / Paper-End Sensor ........................................................ 90

4.2.19 Feed Roller ........................................................................................................... 92

4.2.20 Shaft Assy-Eject (FU) / Shaft Assy-Eject (FD) / Eject Sensor .............................. 93

4.2.21 Fuser Unit ............................................................................................................. 94

4.2.22 Belt Unit ................................................................................................................ 95

4.3 Parts to lubricate ................................................................................................................ 96

5. MAINTENANCE MENU ................................................................................... 111

5.1 System Maintenance Menu(For Maintenance Staff) ........................................................ 111

5.2 Maintenance Utility ........................................................................................................... 114

5.3 Changing the display language ........................................................................................ 118

5.4 Maintenance Menu Function of the User Menu ............................................................... 119

5.4.1 Maintenance Menu(For End-Users) ................................................................... 119

5.4.2 Self-diagnostic Mode .......................................................................................... 120

5.4.2.1 Operator panel .................................................................................... 120

5.4.2.2 Normal self-diagnostic mode (level 1) ................................................. 124

5.4.2.2.1 Entering self-diagnostic mode (level 1) ............................... 126

5.4.2.2.2 Exiting self-diagnostic mode ............................................... 126

5.4.2.3 Switch scan test .................................................................................. 127

5.4.2.4 Motor and clutch test ........................................................................... 130

5.4.2.5 Test printing ........................................................................................ 132

5.4.2.6 Color registration adjustment test ....................................................... 137

5.4.2.7 Print density adjustment test ............................................................... 137

5.4.2.8 Consumable counter display ............................................................... 138

5.4.2.9 Counter display of numbers of prints and images ............................... 138

5.4.2.10 Switching between Factory and Shipping modes ............................... 139

5.4.2.11 Self-diagnosis function setting ............................................................ 140

5.4.2.12 Waste toner counter display................................................................ 141

5.4.2.13 LED head serial number display ......................................................... 141

5.4.2.14 Operator panel display ........................................................................ 142

5.4.3 Printing on Controller-Equipped Printer on a Standalone Basis ......................... 147

5.4.4 Switch Press Functions at Printer Power-On ..................................................... 148

5.5 Settings after Parts Replacement .................................................................................... 149

5.5.1 Instructions to exchange the engine control board ............................................. 149

5.5.2 EEPROM Setting after ARC Board/SPY Board/SPA Board Replacement ........ 152

5.5.3 Destination Setting [Check Method: Printing demo page (ES1624n),

Printing Menu Map (ES1624n)] .......................................................................... 153

5.6 Settings by Hand for Print Density Adjustment ................................................................ 155

6. REGULAR MAINTENANCE ............................................................................ 156

6.1 Parts Replaced Regularly ................................................................................................ 156

6.2 Cleaning ........................................................................................................................... 156

6.3 Cleaning the LED Lens Array .......................................................................................... 156

6.4 Cleaning the Pick-up Roller and the Pad ......................................................................... 158

6.5 Cleaning the Printer Inside ............................................................................................... 159

7. TROUBLESHOOTING PROCEDURES .......................................................... 161

7.1 Precautions before troubleshooting ................................................................................. 161

7.2 Precautions before handling an abnormal image ............................................................ 161

7.3 Precautions upon handling an abnormal image............................................................... 161

7.4 Preparing for Troubleshooting ......................................................................................... 161

42615101TH Rev.5 5 /

Page 6

Oki Data CONFIDENTIAL

7.5 Troubleshooting Procedure .............................................................................................. 161

7.5.1 LCD message list ............................................................................................... 162

7.5.2 Preparing for troubleshooting ............................................................................. 174

7.5.2.(1)LCD Display Malfunction ................................................................................. 176

7.5.2.(2)Irregular Operation of the device after turning on the power ........................... 179

7.5.2.(3)Paper Feed Jam(Error 391:1st Tray)............................................................... 189

7.5.2.(4)Paper Feed Jam (Error 390:Multi-purpose Tray)............................................. 191

7.5.2.(5)Paper Path Jam(Error 381) ............................................................................. 193

7.5.2.(6)Paper Exit Jam(Error 382)............................................................................... 198

7.5.2.(7)Duplex Print Jam(Error 370,371,372,373,383) ............................................... 201

7.5.2.(8)Paper Size Error (Error 400) ........................................................................... 203

7.5.2.(9)ID Unit Up-Down Error(Service Call 140-143)................................................. 204

7.5.2.(10)Fuser Unit Error(Error 170-177) .................................................................... 205

7.5.2.(11)Motor Fan Error(Error 120,127,051) .............................................................. 206

7.5.2.(12)Print Speed is Slow (Low Performance)........................................................ 207

7.5.2.(13)Option unit is not recognized ......................................................................... 207

7.5.2.(14)LED head is not recognized(Error 131,132,133,134) .................................... 208

7.5.2.(15)Toner cartridge is not recognized(Error 540,541,542,543) ............................ 209

7.5.2.(16)Fuse Cutout Error (Error 150-155) ................................................................ 213

7.5.2.(17)Dew Condensation Errors (Error 123) ........................................................... 213

7.5.3 Image Problem Troubleshooting ........................................................................ 214

7.5.3.(1)Color is totally pale (Fig.7.2 A )........................................................................ 215

7.5.3.(2)Background is dirty (Fig.7.2 B ) ....................................................................... 216

7.5.3.(3)Blank Print (Fig.7.2 C ) .................................................................................... 217

7.5.3.(4)Vertical lines are printed .................................................................................. 218

7.5.3.(5)Cyclic Print Trouble (Refer to Fig.7.2 E )......................................................... 219

7.5.3.(6)Color drift is wide. ............................................................................................ 220

7.5.3.(7)Solid Black Print .............................................................................................. 221

7.5.4 Actions Taken after Forced HDD/Flash Initialization .......................................... 222

7.5.5 Network Troubleshooting.................................................................................... 223

7.5.6 Displaying Details of Service Call Error Codes (ES1624n) ................................ 224

7.6 Fuse Checking ................................................................................................................. 225

8. CONNECTION DIAGRAM ............................................................................... 226

8.1 Resistance Checks .......................................................................................................... 226

8.2 Program/Font ROM Layouts ............................................................................................ 230

42615101TH Rev.5 6 /

Page 7

1. SPECIFICATIONS

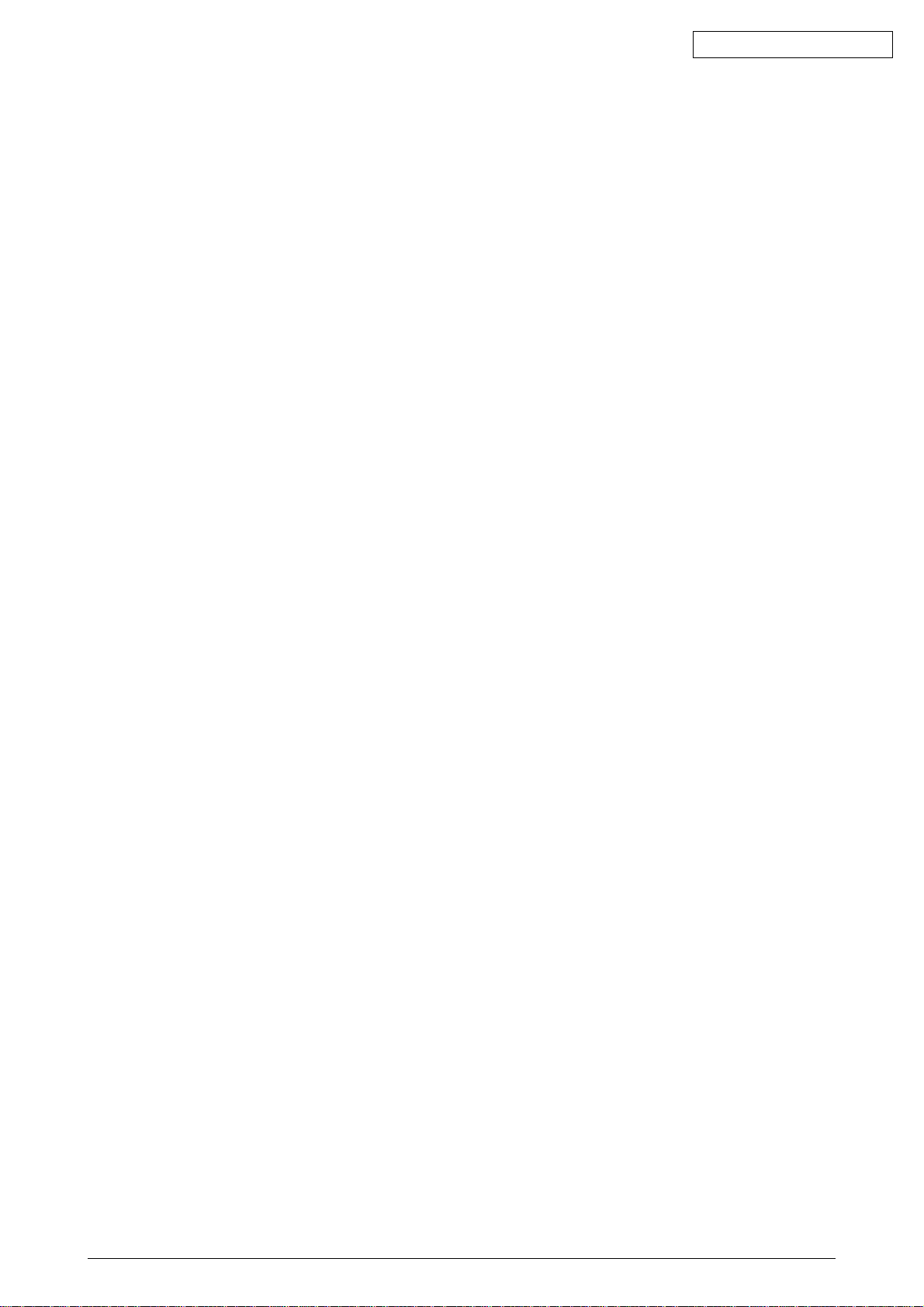

1.1 System Configuration

ES1624n

Figure 1-1-1 shows the system configuration of ES1624n

IN1 IN2 WR

Oki Data CONFIDENTIAL

M

HEAT

Color

Color

M

BELT

M

HOP

M

CID

M

MID

M

YID

Belt Unit

Registration

Belt Unit Fuse

Board-Right

Registration

Cut-Out

Board-Left

Driver Relay Board

Sensor

Density

Up & Low/

Fuser Fuse Cut-Out/

EXIT

Sensor

Thermistor

Inlet

Fuser

Duplex Board 2nd Tray Board

HDD

LAN, USB, Centro I/F

LVDS

CU Board

Front Sensor Board

CU-FAN

Video

Interface

fsync × 4,

Isync, wclk)

(data8bit × 4,

Driver

M

KID

Solenoid

Paperfeed

1st

P. E

Sensor

DCON

Command

CU Area

50MHz

DCON I/F, LSYNC

Interface

PU-Board

Humidity Signals

Environment Temperature

8M bit

FLASH

SRAM

MCON CPU

256Kbit

Color Registration,

Fuse Cut-Out,

28MHz

Signals

Density, Thermistor

Exit,

Motor Control

EEPROM

ID

0VL, 0VP

3.3V, 5V, 24V,

Control, etc

Fan, Heater

High Voltage Interface,

Fan Control, Cover-Open

FAN

Thermistor

Heater Frame

AC-SW

FAN

Low-Voltage

Y LED HEAD

K LED HEAD

C LED HEAD

M LED HEAD

Board

Operator Panel

Toner Sensor Board

Sensor

Environment

cut-out

Image drum fuse

sensor

C toner

sensor

M toner

sensor

Y toner

sensor

K toner

Open

Cover-

Belt

Thermistor

Fusing

Sensor

FAN

High Voltage Board Low Voltage Board

Down

ID UP/

K-ID Y-ID M-ID C-ID

Figure 1-1-1

42615101TH Rev.5 7 /

Page 8

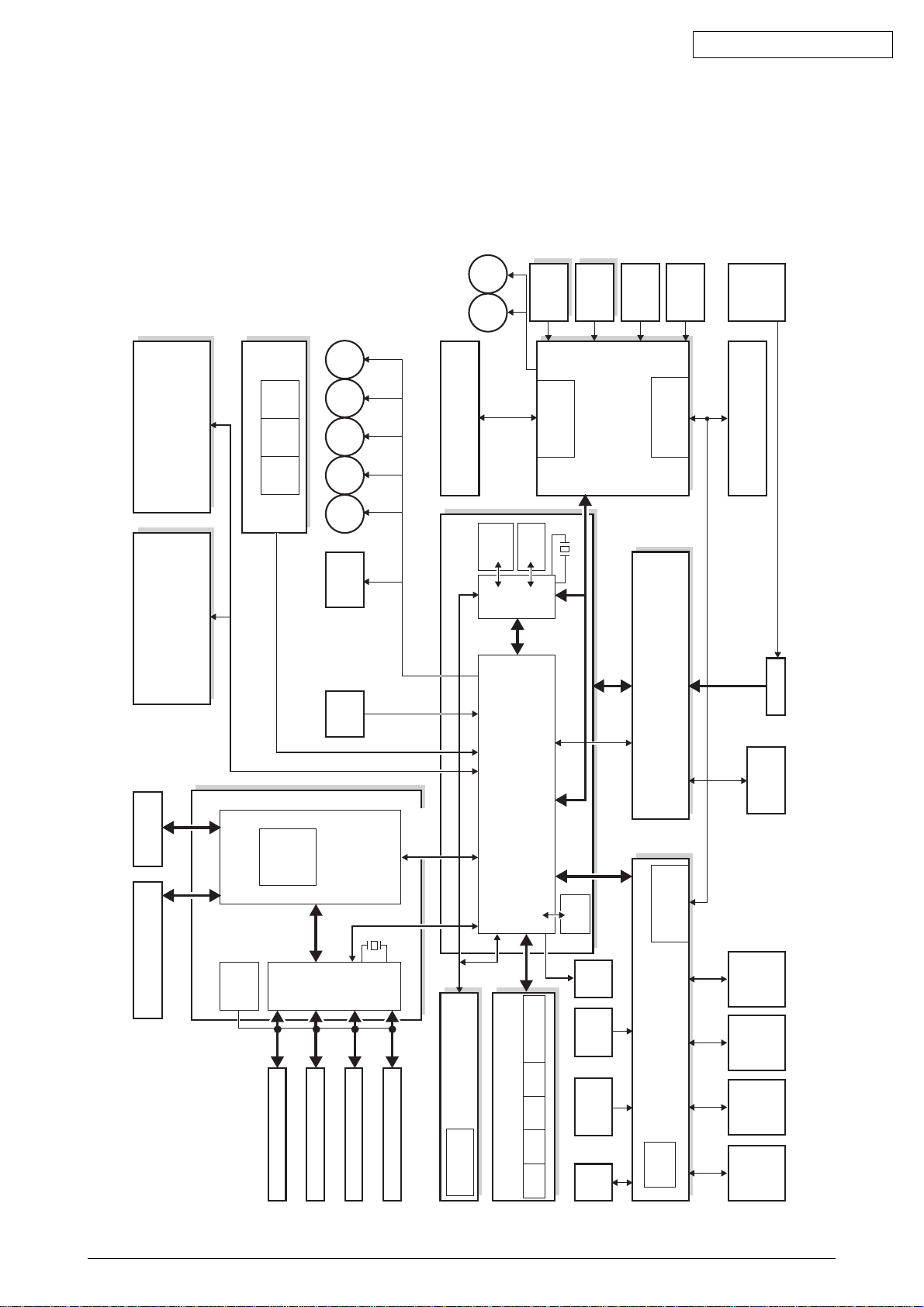

1.2 Printer Configuration

The inside of ES1624n printers is composed of the following:

• Electrophotographic Processor

• Paper Paths

• Controller Block (CU and PU)

• Operator Panel

• Power Units (High Voltage Unit and Low Voltage Unit)

Figure 1-2-1 shows the configuration of each printer.

Oki Data CONFIDENTIAL

Figure 1-2-1

42615101TH Rev.5 10 /

Page 9

1.3 Option Configuration

The following options are available for ES1624n.

(1) 2nd Tray

(2) Duplex Unit

Oki Data CONFIDENTIAL

(3) Expansion Memory 64 MB

Recommend to add an optional memory for duplex print, banner print.

(4) Expansion Memory 64/256 MB

Recommend to add an optional memory for duplex print, banner print.

(5) Hard Disk

(6) Upgrade DIMM

42615101TH Rev.5 13 /

Page 10

1.5 INTERFACE SPECIFICATIONS

1.5.1 Parallel Interface Specifications (ES1624n)

1.5.1.1 Parallel Interface

Item Description

Mode Compatibility mode, Nibble mode, ECP mode

Data bit length 8 bits: Compatibility mode, 4bits: Nibble mode,9 bits: ECP mode

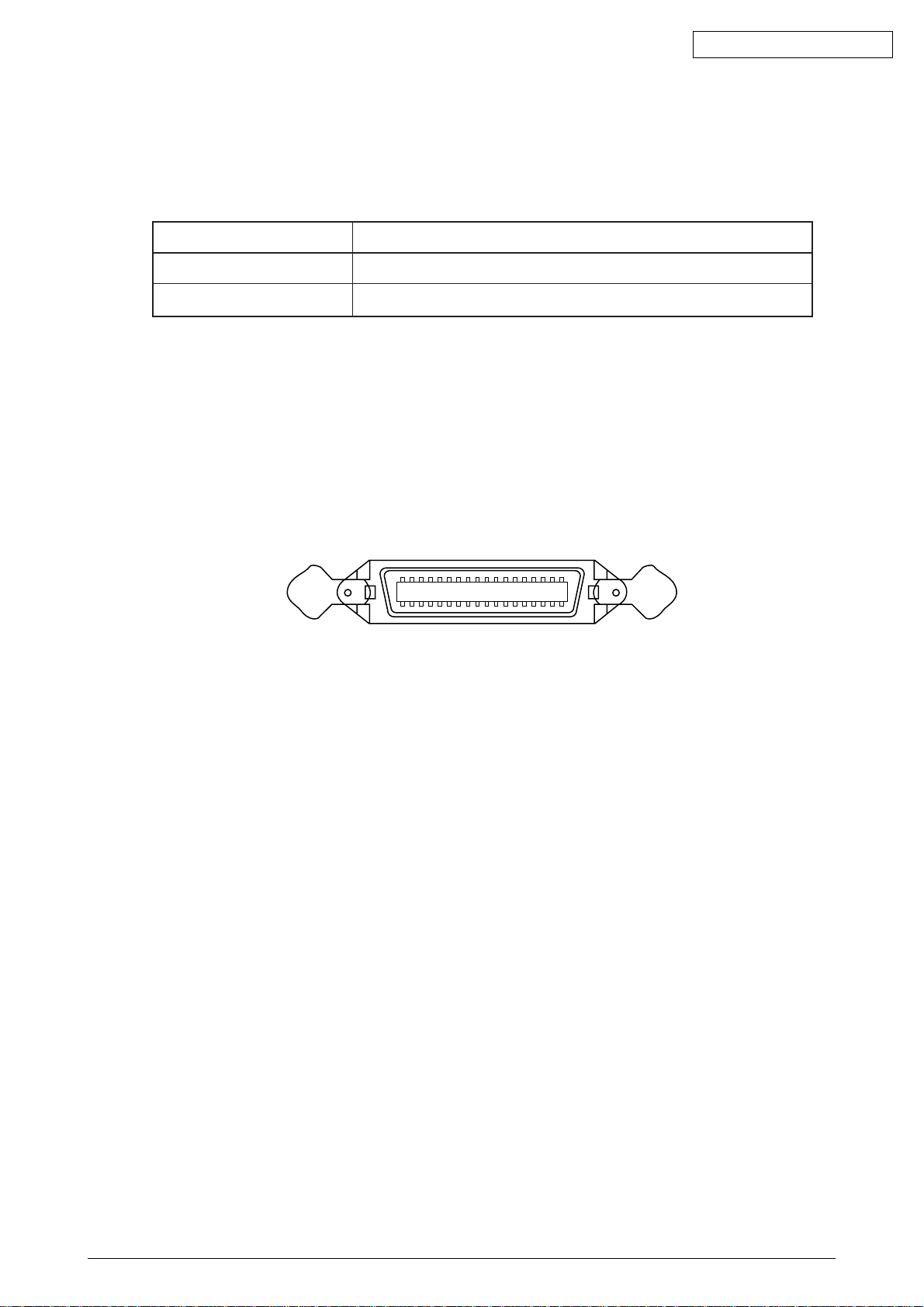

1.5.1.2 Parallel Interface Connector and Cable

1) Connector

Printer side: 36-pin receptacle

Type 57LE-40360-12 (D56) (made by Daiichi Denshi) or equivalent

Cable side: 36-pin plug

Type 57FE-30360-20N (D8) (made by Daiichi Denshi) or equivalent

Oki Data CONFIDENTIAL

Connector Pin Arrangement Viewed from Cable Side

2) Cable

Cable length: 1.8 m max.

(A shielded cable composed of twisted pair wires is recommended for noise prevention.)

1.5.1.3 Parallel Interface Level

LOW: 0 V to +0.8 V

HIGH: +2.4 V to 5.0 V

118

1936

42615101TH Rev.5 18 /

Page 11

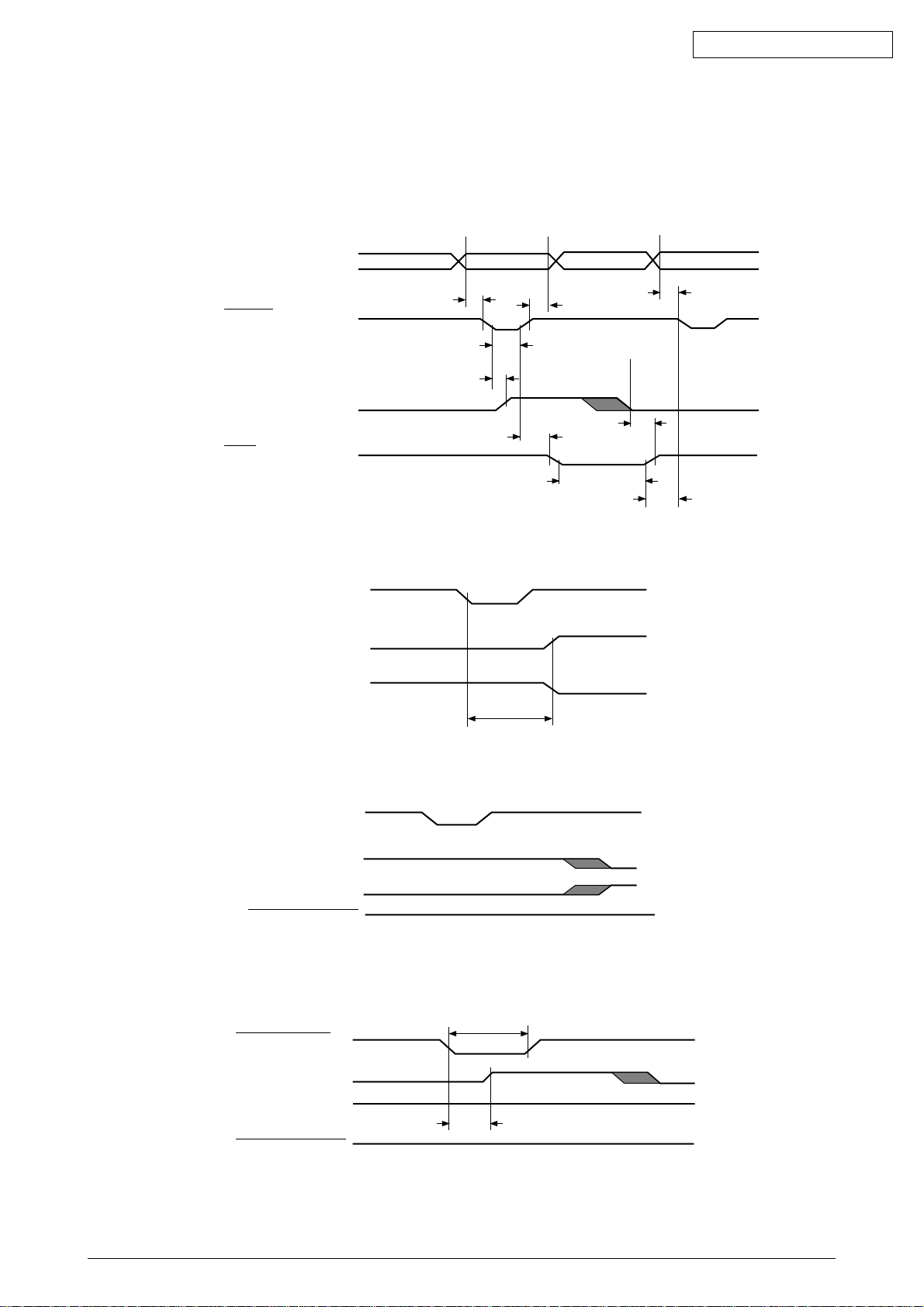

1.5.1.4 Timing Charts

Compatible mode

a) Data receiving timing

PARALLEL DATA

(DATA BITs 1 to 8)

nStrobe

0.5 µs min.

0.5 µs min.

0.5 µs max.

0.5

0.5

µ

s min.

µ

s min.

Oki Data CONFIDENTIAL

BUSY

0 min.

nAck

0.5 µs to 3 µs

b) On-line (off-line switching timing by ON-LINE SW)

ON-LINE SW

BUSY

SELECT

100 ms max.

c) Off-line (on-line switching timing by ON-LINE SW)

ON-LINE SW

BUSY

0 min.

0 min.

SELECT

ACKNOWLEDGE

d) nlnit timing (invalid by default)

* Menu-set

50 µs min.

INPUT. PRIME

BUSY

SELECT

ACKNOWLEDGE

42615101TH Rev.5 19 /

5µs max.

Page 12

Oki Data CONFIDENTIAL

1.5.1.5 Parallel I/F Signals

Table 1-1 shows interface signal names and pin numbers.

Table 1-1 Signals

Pin No. Signal Name Signal Direction Functions

1 Nstrobe (HostClk) →PR Pulse for reading data in at trailing edge.

2 DATA 1

3 DATA 2

4 DATA 3 8-bit parallel data.

5 DATA 4 →PR Each signal is HIGH when data is logical 1 and

6 DATA 5 LOW when it is logical 0.

7 DATA 6

8 DATA 7

9 DATA 8

10 nAck (PtrClk) ←PR Indicates the completion of data reception.

11 Busy (PtrBusy) ←PR Indicates whether the printer is ready for receiving

data. Data cannot be received while the signal is

HIGH.

12 PError (AckDataReq) ←PR Indicates paper error when held HIGH.

13 Select (Xflag) ←PR HIGH without exception when the parallel

interface is enabled.

14 NAutoFd (HostBusy) →PR Used in bidirectional communication.

15 - - Unassigned.

16 GND - Signal ground.

17 FG - Chassis ground.

18 +5V ←PR Used for supplying +5V. Power cannot be

supplied to the outside of the printer.

19

~ GND - Signal ground.

30

31 Nlnit (nlnit) →PR Initializes the printer when held LOW.

32 NFault (nDataAvail) ←PR LOW during alarm.

33 GND - Signal ground.

34 - - Unassigned.

35 HILEVEL ←PR Pulled up to +5V at 3.3KΩ inside the printer.

36 Nselectin →PR Used in bidirectional communication. Low without

(IEEE 1284 active) exception in compatible mode.

Note:

42615101TH Rev.5 20 /

Parenthesized signal names are used in nibble mode.

Only functions in compatible mode are listed.

This printer supports the IEEE std 1284-1994 nibble mode. Note that, when used with

personal computers or cables that do not comply with the standards, the printers may

exhibit unpredictable behavior.

Page 13

1.5.2 Universal Serial Bus (USB) Interface Specifications(ES1624n)

1.5.2.1 USB Interface

(1) Basic specifications

Conforms to USB specification, revision 1.1.

(2) Transmission mode

Full speed (max. 12 Mbps + 0.25%)

(3) Power Control

Self-power device

1.5.2.2 USB Interface Connector and Cable

(1) Connector

Printer side: Type B receptacle

Upstrem port

UBB-4R-D14T-1 (made by JST) or equivalent

Oki Data CONFIDENTIAL

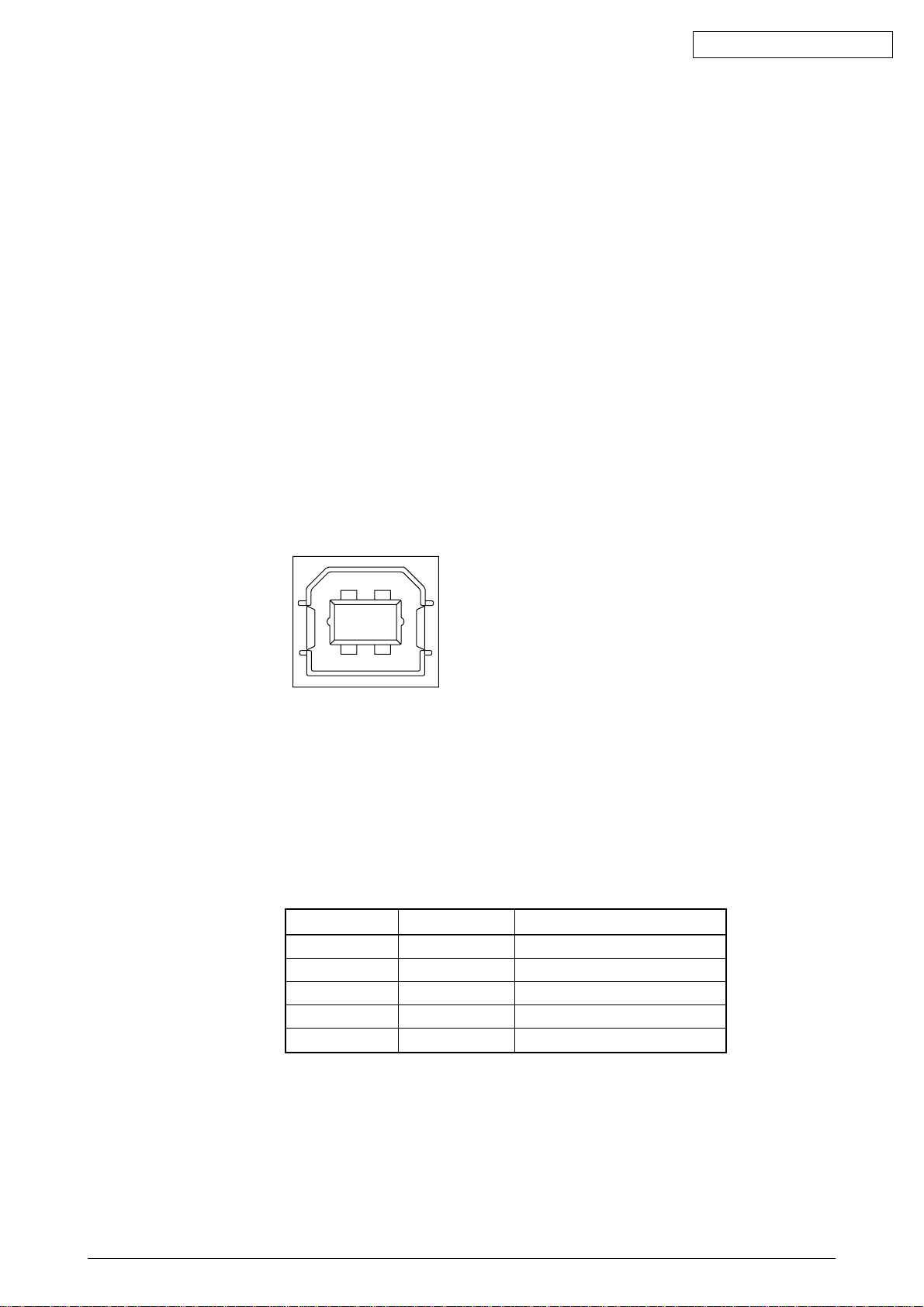

Connector pin layout

2

34

Cable side: Type B plug

(2) Cable

Cable length: 5 m max. (cable compliant with USB specification, revision 1.1)

(A shielded cable must be used.)

1.5.2.3 USB Interface Signals

1 Vbus Power Supply (+5V) (red)

2 D - Data transmission (white)

3 D + Data transmission (green)

4 GND Signal ground (black)

Shell Shield

1

R1 Function

42615101TH Rev.5 21 /

Page 14

1.5.3 Network Interface Specifications(ES1624n)

1.5.3.1 Network Interface

(1) Basic specifications

Network protocol

TCP/IPSpecification Network layer

ARP, RARP, IP, ICMP

Transport layer

TCP, UDP

Application layer

LPR, FTP, TELNET, HTTP, BOOTP, SMTP

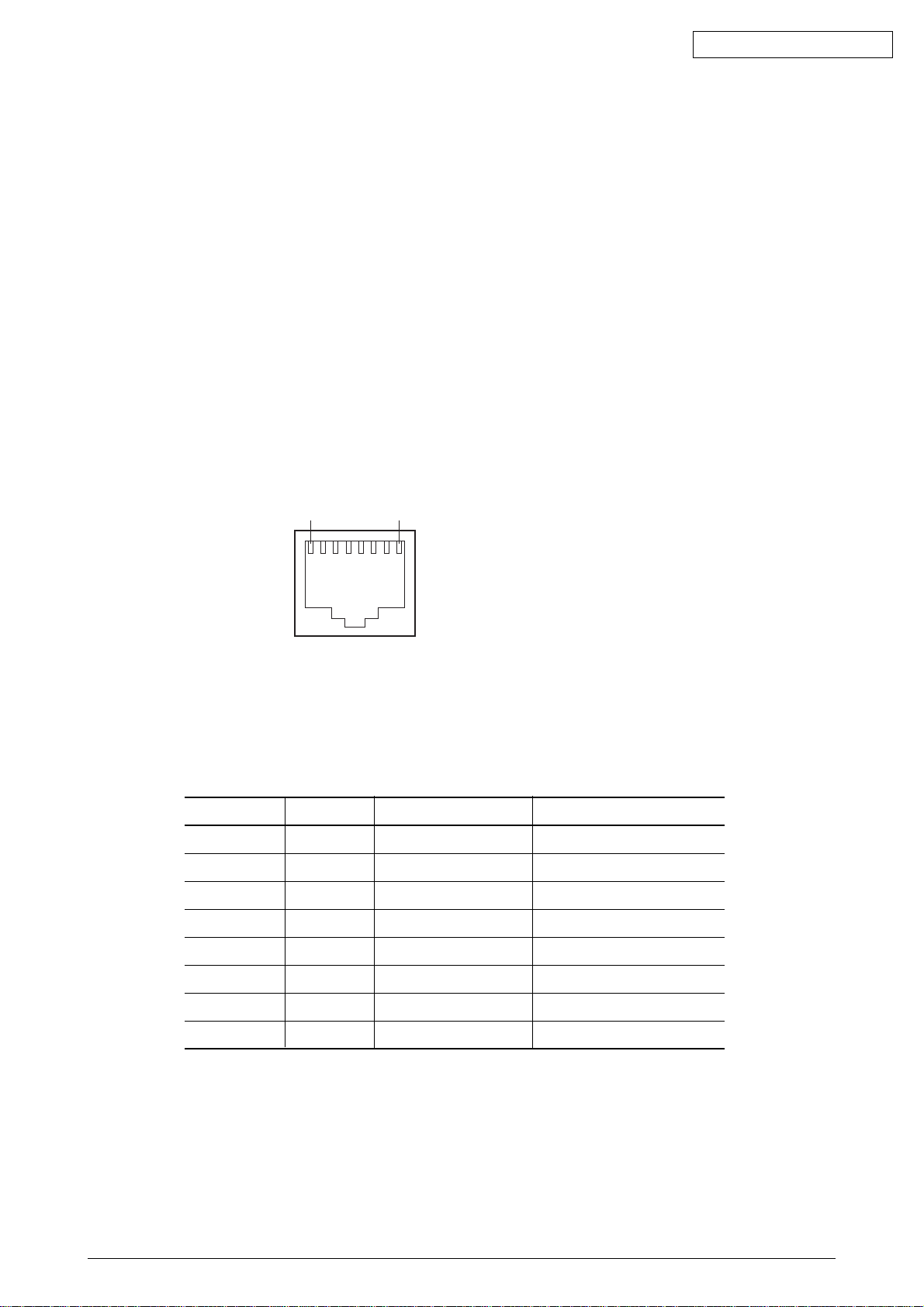

1.5.3.2 Network Interface Connector and Cable

(1) Connector

100 BASE-TX / 10 BASE-T

Connector pin layout

Oki Data CONFIDENTIAL

18

(2) Cable

RJ-45 anti-Shield twist pair cable with connector (Category 5 recommended)

1.5.3.3 Network Interface Signals

Pin No. Signals Signal Direction Functions

1 TXD+ FROM PRINTER Send Data +

2 TXD- FROM PRINTER Send Data -

3 RXD+ TO PRINTER Received Data +

4 - - Unassigned

5 - - Unassigned

6 RXD- TO PRINTER Received Data -

7 - - Unassigned

8 - - Unassigned

42615101TH Rev.5 22 /

Page 15

2. Operation Description

2.1 Electrophotographic Process Mechanism

(1) Electrophotographic Process

Following describes the outline of an electrophotographic process incorporated into printers.

1. Charging

Applying a voltage to a charging (CH) roller charges the surface of an optical

photoconductive (OPC) drum.

2. Exposure

The surface of the drum having a charge is exposed to light an LED head emits under

each image signal. Segments of the surface have a reduced charge according to the

intensities of the light they receive, a static latent image being created on the surface

based on electrical potentials on the surface

3. Development

Charged toner is attracted to the latent image of the drum by static electricity and

makes the image visible on the surface of the drum.

Oki Data CONFIDENTIAL

4. Transfer

Paper is brought into contact with the drum, and applied with a charge by a transfer

roller from the back, the toner image being transferred to the paper.

5. OPC Drum Cleaning

A drum cleaning blade removes residual toner from the drum after the transfer.

6. Transfer Belt Cleaning

A belt cleaning blade removes residual toner from a transfer belt.

7. Fusing

Heat and pressure fuses the toner image to the paper.

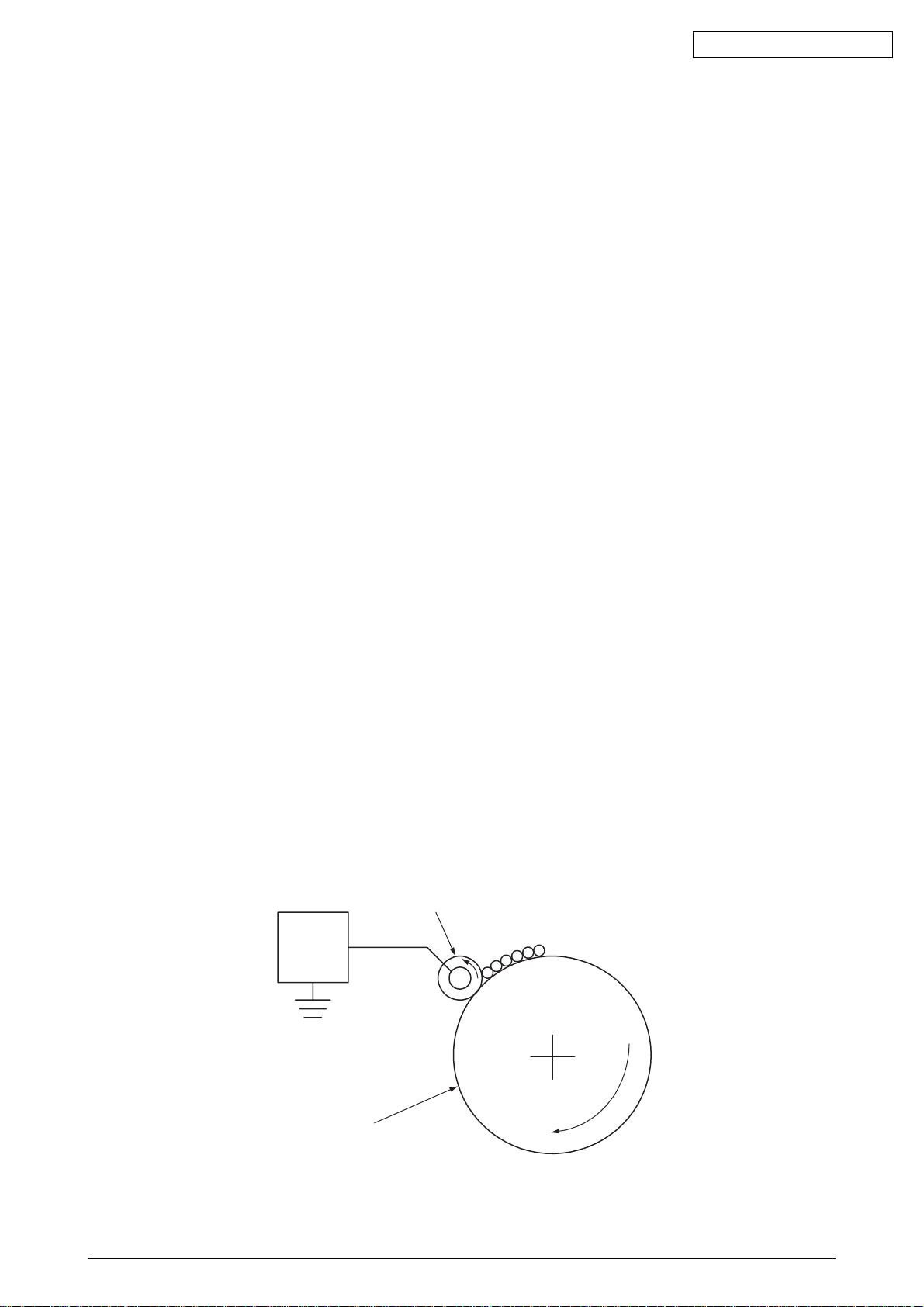

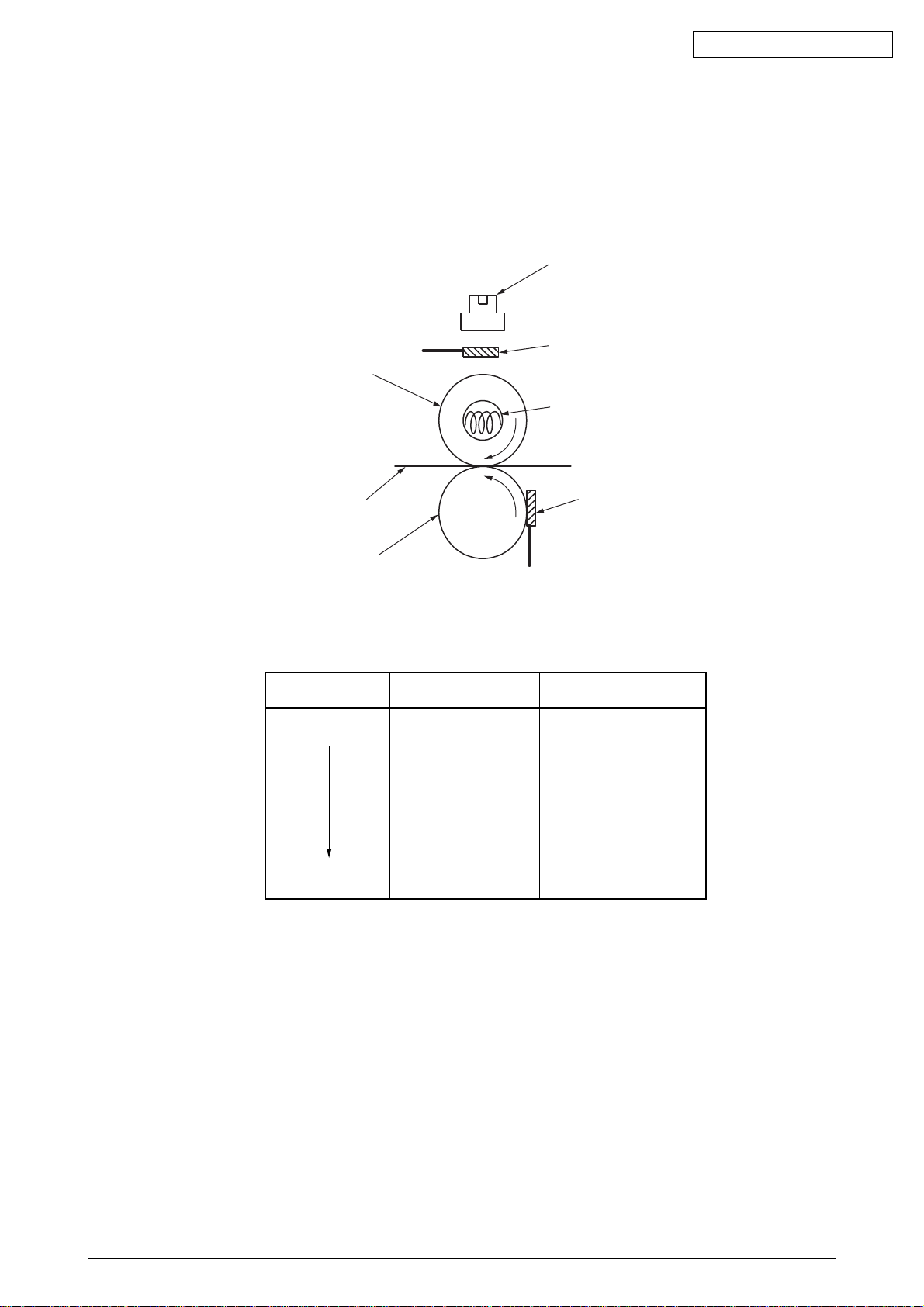

(2) Charging

Voltage is applied to a CH roller contacting the surface of an OPC drum, depositing a charge

over the surface.

CH Roller

Power

Supply

Unit

-

-

-

-

-

-

OPC Drum

42615101TH Rev.5 23 /

Page 16

Oki Data CONFIDENTIAL

(3) Exposure

The surface of the charged drum is exposed to light emitted from an LED head. Charges of

segments of the surface are reduced according to the intensities of the light the segments

receive, a static latent image being created on the surface.

LED Head

CH Roller

Power

Supply

Unit

OPC Drum

(4) Development

Toner is attracted to the latent image on the surface of the drum, making the image a toner

image.

-

-

-

-

-

-

-

-

-

Paper

1. The sponge roller supplies toner onto the developing roller.

Developing Blade

LED Head

OPC Drum

CH Roller

-

-

-

-

-

-

-

-

-

-

-

-

OPC Drum

Developing Roller

2. The latent image on the surface of the drum is made visible by the toner.

Sponge Roller

42615101TH Rev.5 24 /

Page 17

Oki Data CONFIDENTIAL

(5) Transfer

The paper made contact with the surface is applied with a charge by the roller from the back.

Applying high voltage provided by a power supply to the roller transfers the roller-induced

charge to the surface of the paper at the contact between the roller and the paper, attracting

the charged toner from the surface of the drum to the surface of the paper.

-

-

-

OPC Drum

-

-

-

-

-

-

-

-

-

-+-

+

Transfer Roller

+

+

-+-+-+-+-+-

-+-

-+-

-

-

-

+

+

-

+

-

+

-

+

-

+

Paper

Transfer Belt

Power

Supply

Unit

42615101TH Rev.5 25 /

Page 18

Oki Data CONFIDENTIAL

(6) Fusing

When passing between a heat roller and a backup roller, the toner image transferred to the

paper is fused into place with heat and pressure.

A safety thermostat is provided and, when the temperature of the heat roller rises to or exceeds

a predetermined temperature, it opens, cutting off voltage supply to the heater.

Thermostat

Thermistor

Heat Roller

Halogen Lamp

Paper

Backup Roller

Fusing Temperature Settings

Media Weight

Paper Type Settings

Light

Heavy

Light

Medium

Heavy

U.Heavy

OHP

Thermistor

Temperature Settings

Warm

High

Warm

Low

Low

42615101TH Rev.5 26 /

Page 19

Oki Data CONFIDENTIAL

(7) OPC Drum Cleaning

Unfused, residual toner on the drum is scraped off with a drum cleaning blade, and collected

in the waste toner area of a toner cartridge.

Waste Toner Area

Toner Cartridge

Image Drum (ID) Unit

-

Drum Cleaning Blade

-+-

-+-+-+-

-+-

-+-

+

+

+

+

-

-

-

+

-

+

(8) Transfer Belt Cleaning

Residual toner on a transfer belt is scraped off with a belt cleaning blade, and collected in the

waste toner box of a transfer belt unit.

Transfer Belt

Waste Toner Box

Belt Cleaning Blade

42615101TH Rev.5 27 /

Page 20

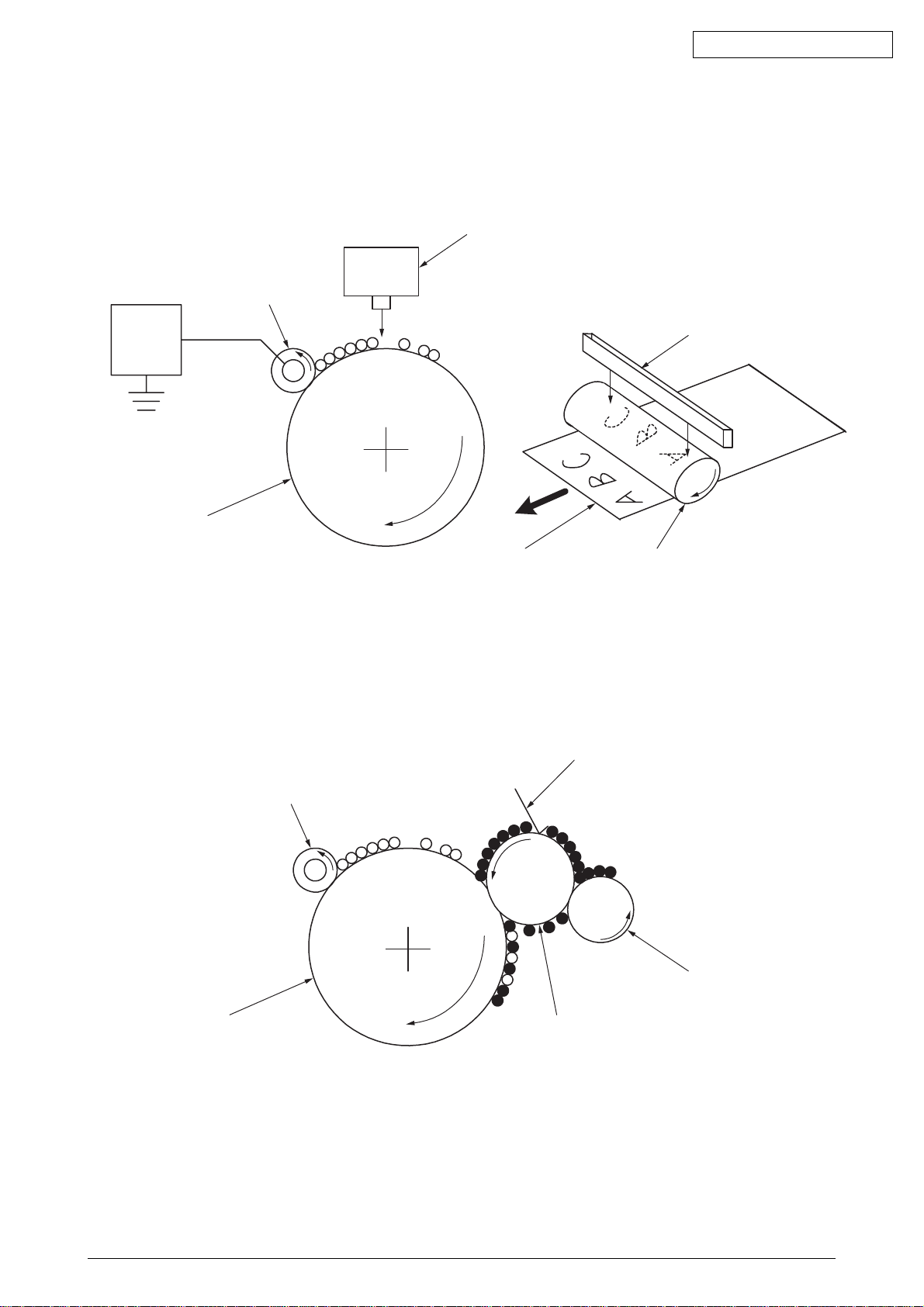

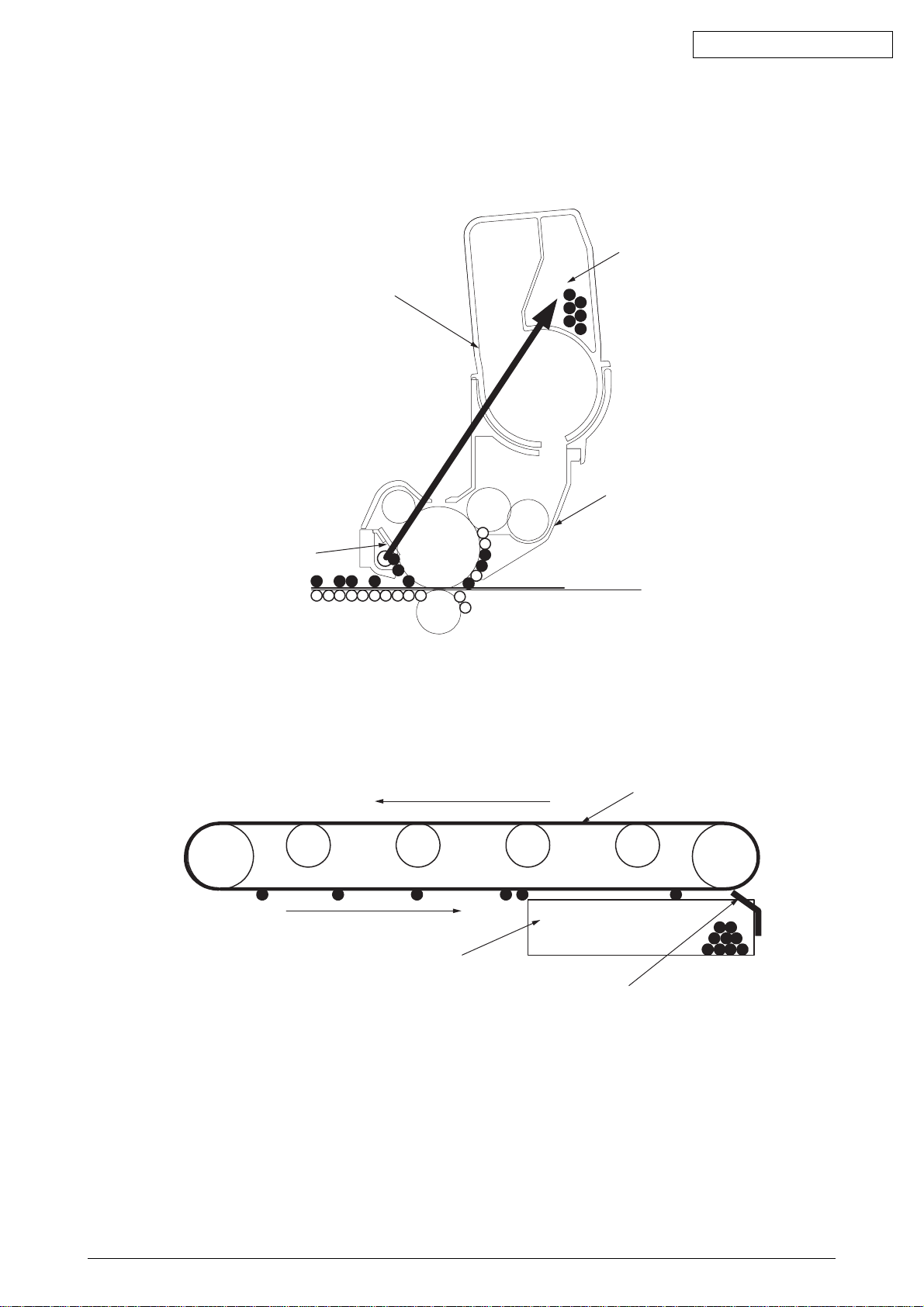

2.2 Printing Processes

Paper fed from a tray 1 or 2 is forwarded by Hopping roller, Registration Roller L and Feed roller.

When feeding paper from a multiple tray, it is forwarded by a MPT Hopping roller and Registration

Roller U. Then, the paper is moved onto a transfer belt and, through K, Y, M and C electrophotographic

processes performed taking their turns, a yet-to-be-fused toner image is produced on the paper.

While the paper passes through a fuser unit, heat and pressure fuses the toner to the paper. After

the fusing process, the paper is ejected to a face-up or face-down stacker, whichever is selected

according to whether the face-up stacker is opened.

These operations are performed in single-side printing. Following are operations in two-side

(duplex) printing.

In duplex printing, paper passed through a fuser unit after it is first printed on the back is fed into

a duplex unit via a dup-in separator. Reversing roller’s reversing operation sends the paper via a

paper reversing path into the duplex unit. After Feed rollers on a paper path in the duplex unit pass

the paper through the unit, the paper is fed via a paper feeding path routed from the unit. Then,

the paper is forwarded to the same route from the tray. After that, the same operation as that

performed after the paper moving by the first registration roller L in single-side printing using tray

feeding is performed.

Oki Data CONFIDENTIAL

Face-up Stacker

Dup-In Separator

Reversing Roller

Face-down Stacker

Heat Roller

Halogen Lamp

Backup Roller

Paper Reversing Path

MPT Hopping Roller

Transfer Belt

MPT

Registration Roller U

Feed Rollers

Registration Roller L

Hopping Roller

Sub Roller

Sub Roller

Feed Roller

Hopping Roller

42615101TH Rev.5 28 /

Page 21

Oki Data CONFIDENTIAL

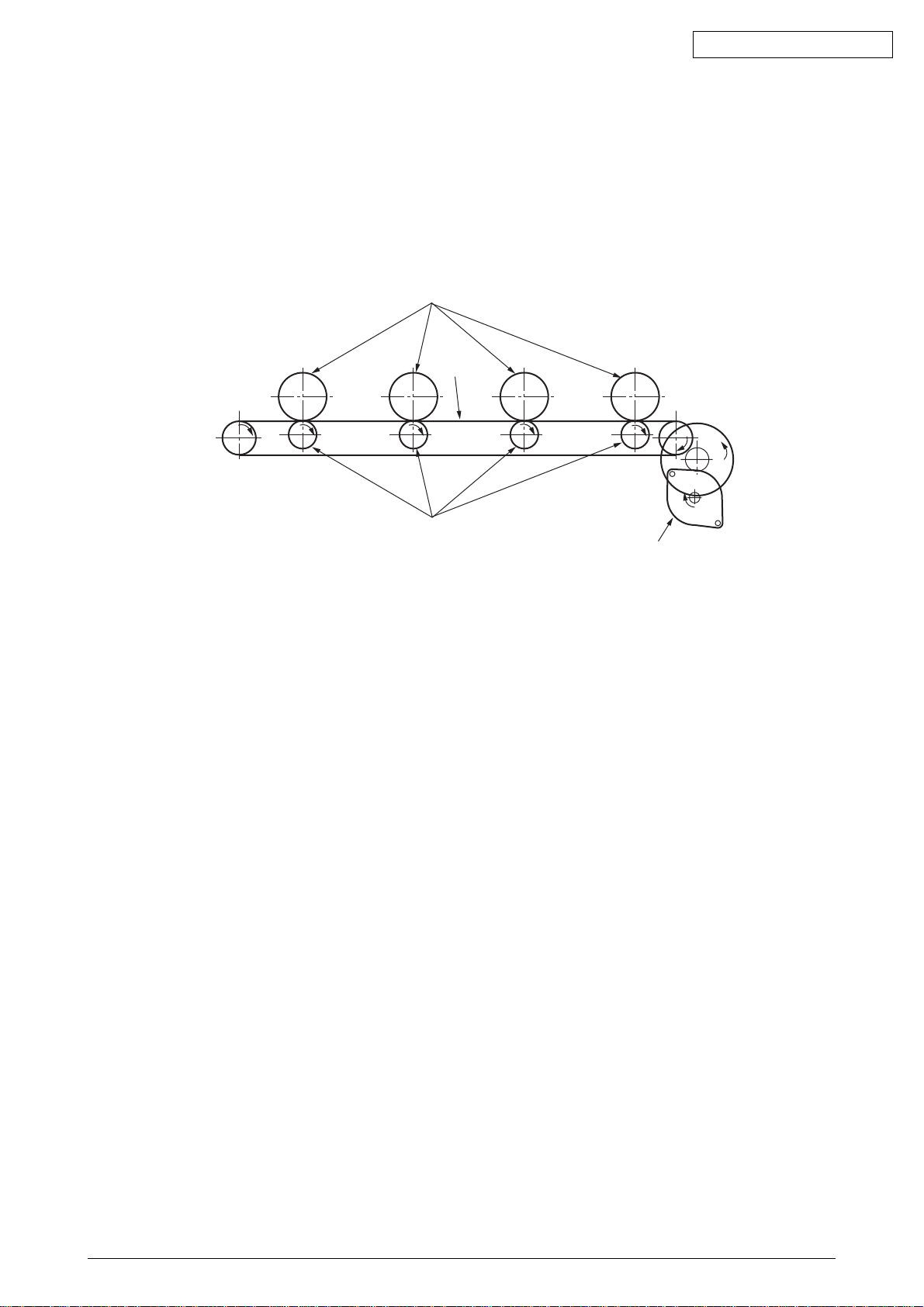

(1) Paper Feed from 1st Tray

1. As indicated in Figure 2-1, when the solenoid is ON, the registration motor rotates (CCW),

and transports the paper until IN1 sensor turns ON. (The hopping roller rotates when the

solenoid is ON.)

2. When IN1 sensor is ON, a constant number of sheets are transported against registration

roller L. (This corrects paper skewing.)

3. As indicated in Figure 2-2, the solenoid is turned OFF and paper is fed with registration roller

L. (The registration roller L feeds the paper when the solenoid is OFF.)

Registration Roller U

(Drive)

WR Sensor

Hopping Gear Assy

Solenoid Lever

(Solenoid ON)

Sub Roller

(Drive)

Hopping Roller

(Drive)

Paper

Figure 2-1 Figure 2-2

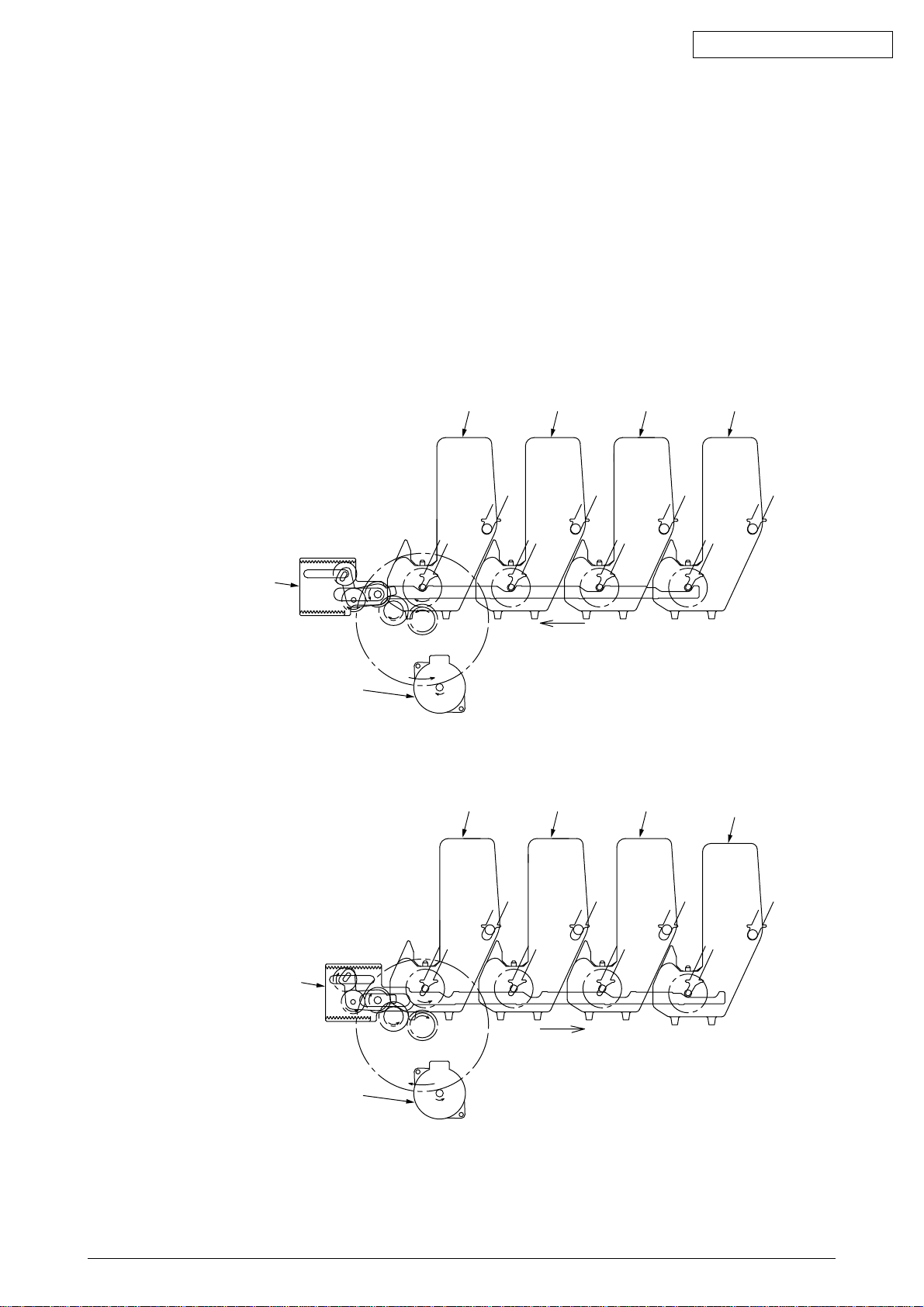

(2) Paper Feed from MPT

1. As indicated in Figure 2-3, when the solenoid is OFF, the registration motor rotates (CW)

and continues to transport paper until IN2 sensor turns ON. (The MPT hopping roller drives

the paper until the registration motor rotates in the CW direction.)

2. When IN2 sensor is turned ON, a constant number of sheets are transported against

registration roller U. (This corrects paper skewing.)

IN2 Sensor

Registration Roller L

(Stop)

IN1 Sensor

Registration Motor

(CCW)

Registration Roller U

(Drive)

WR Sensor

Solenoid Lever

(Solenoid OFF)

Sub Roller

(Stop)

Hopping Roller

(Stop)

IN2 Sensor

Registration Roller L

(Drive)

IN1 Sensor

Registration Motor

(CCW)

3. As indicated in Figure 2-4, the registration motor rotates (CCW), and transports the paper

with registration roller U. (The registration roller U feeds the paper when the registration

motor rotates in the CCW direction.)

IN2 Sensor

Registration Roller U

(Stop)

WR Sensor WR Sensor

Hopping Gear Assy

Solenoid Lever

(Solenoid OFF)

MPT Hopping Roller

Paper Paper

Hopping Gear Assy

Solenoid Lever

(Solenoid OFF)

Registration Motor

(CW)

Registration Roller U

(Drive)

IN2 Sensor

Registration Motor

(CCW)

Figure 2-3 Figure 2-4

42615101TH Rev.5 29 /

Page 22

Oki Data CONFIDENTIAL

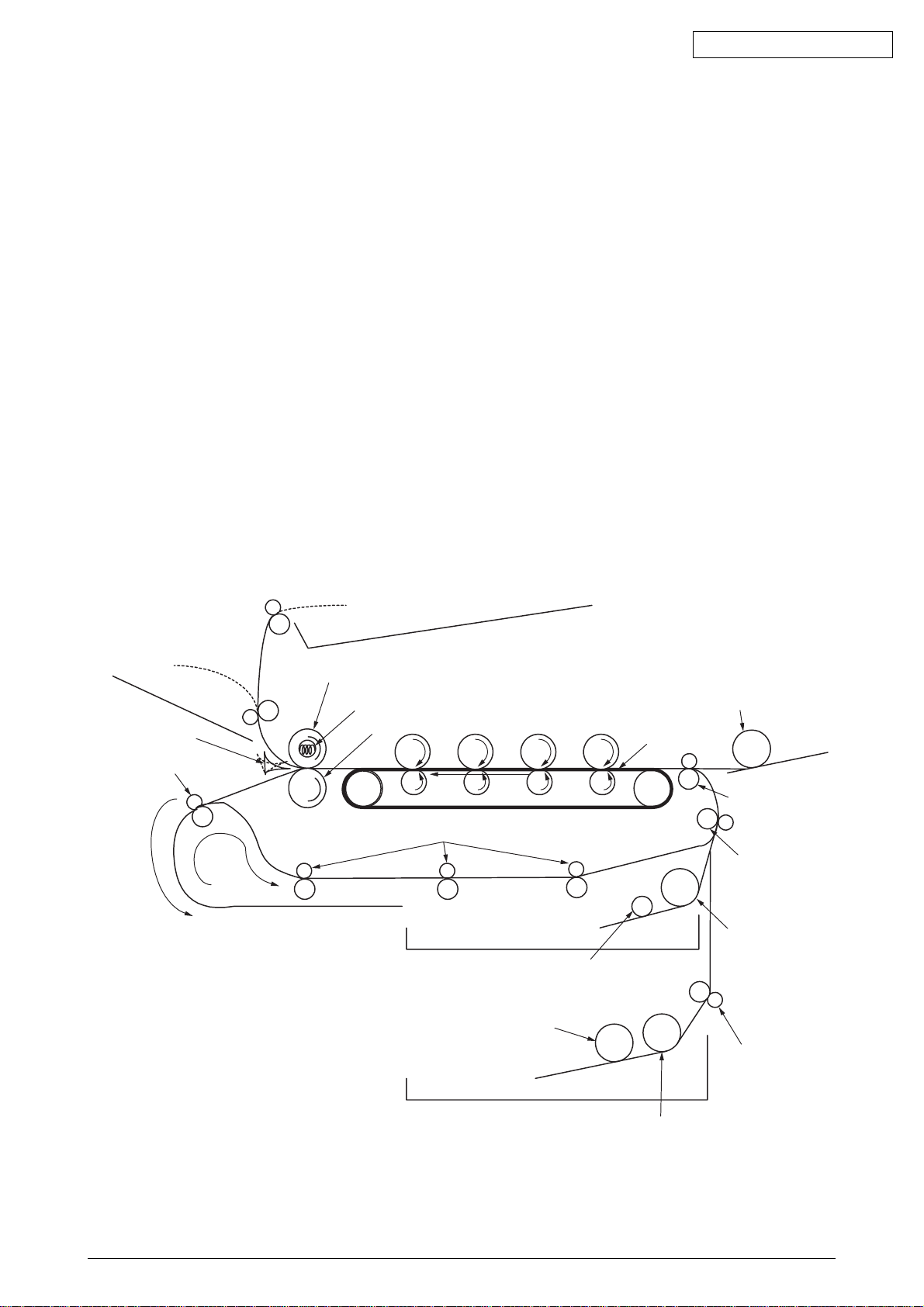

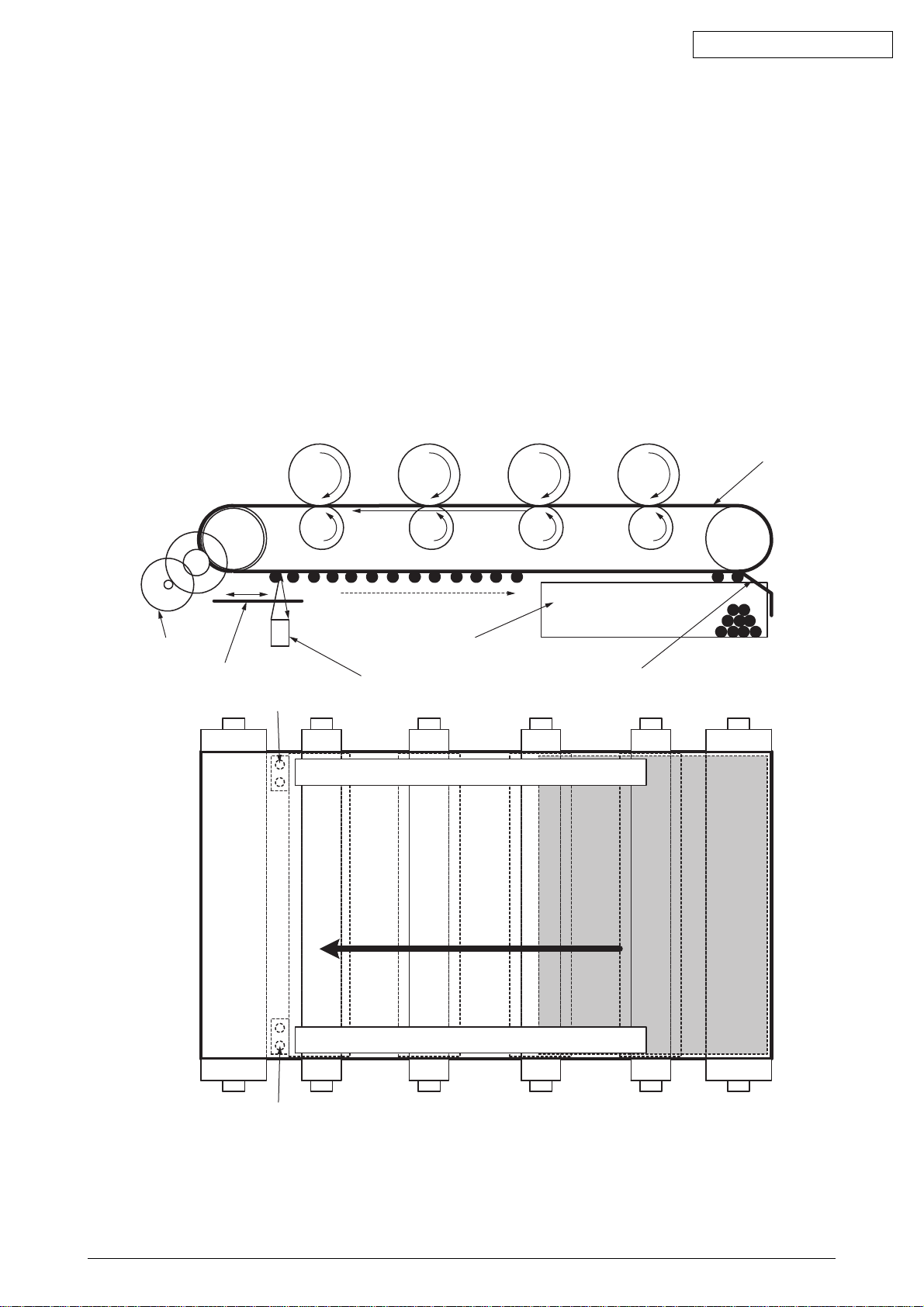

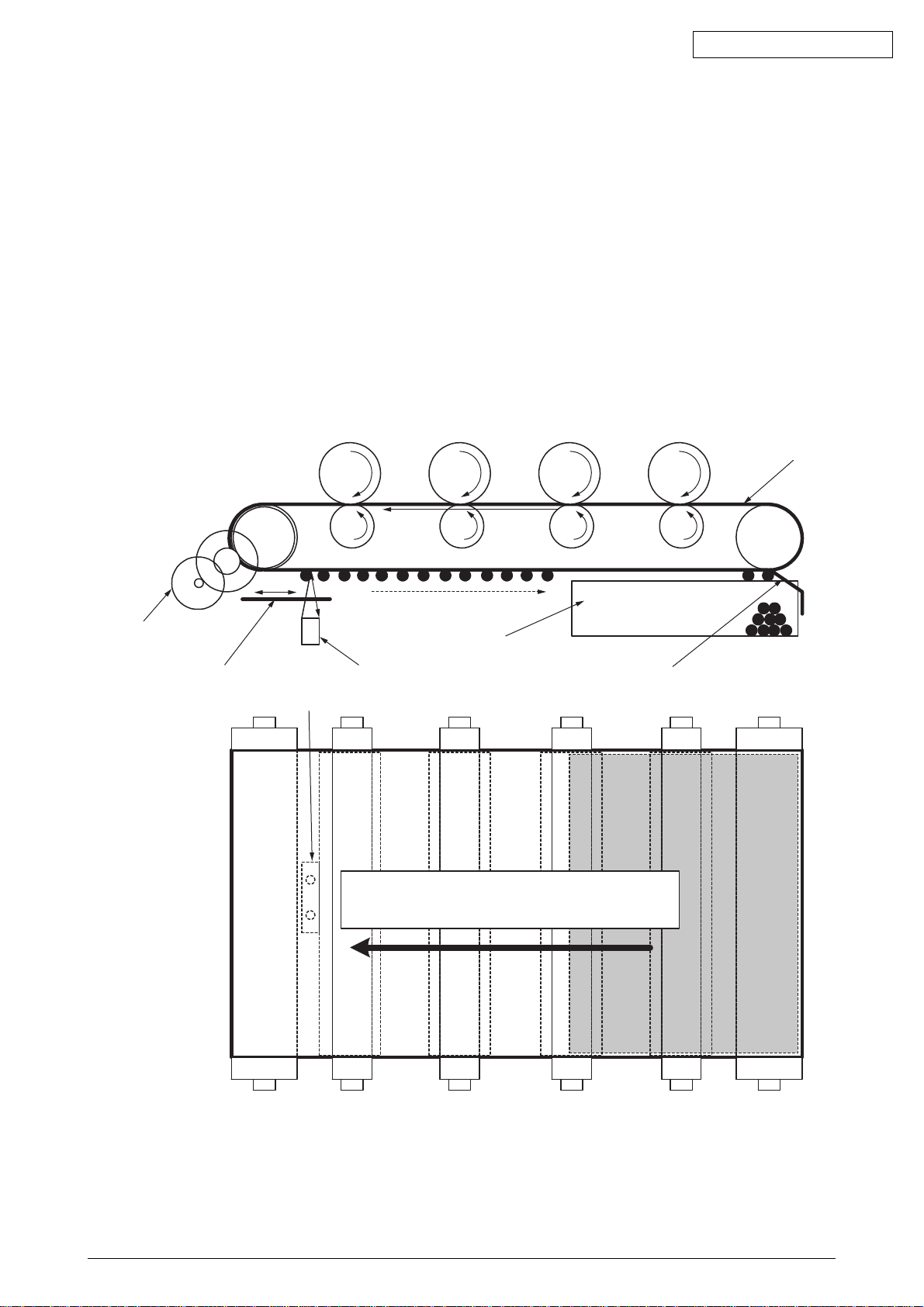

(3) Carrier Belt

1. The running of the carrier belt motor in the direction of the arrow drives the carrier belt. The

belt unit sits with one carrier roller immediately below each color’s drum, and the carrier belt

between them. By the application of a fixed voltage, the carrier belt and carrier roller feed

paper on the carrier belt into the fuser unit, transferring a toner image on each color’s drum.

Drum

Carrier belt

KYMC

Carrier (transfer) roller

Figure 2-5

Carrier (transfer) belt motor

42615101TH Rev.5 30 /

Page 23

Oki Data CONFIDENTIAL

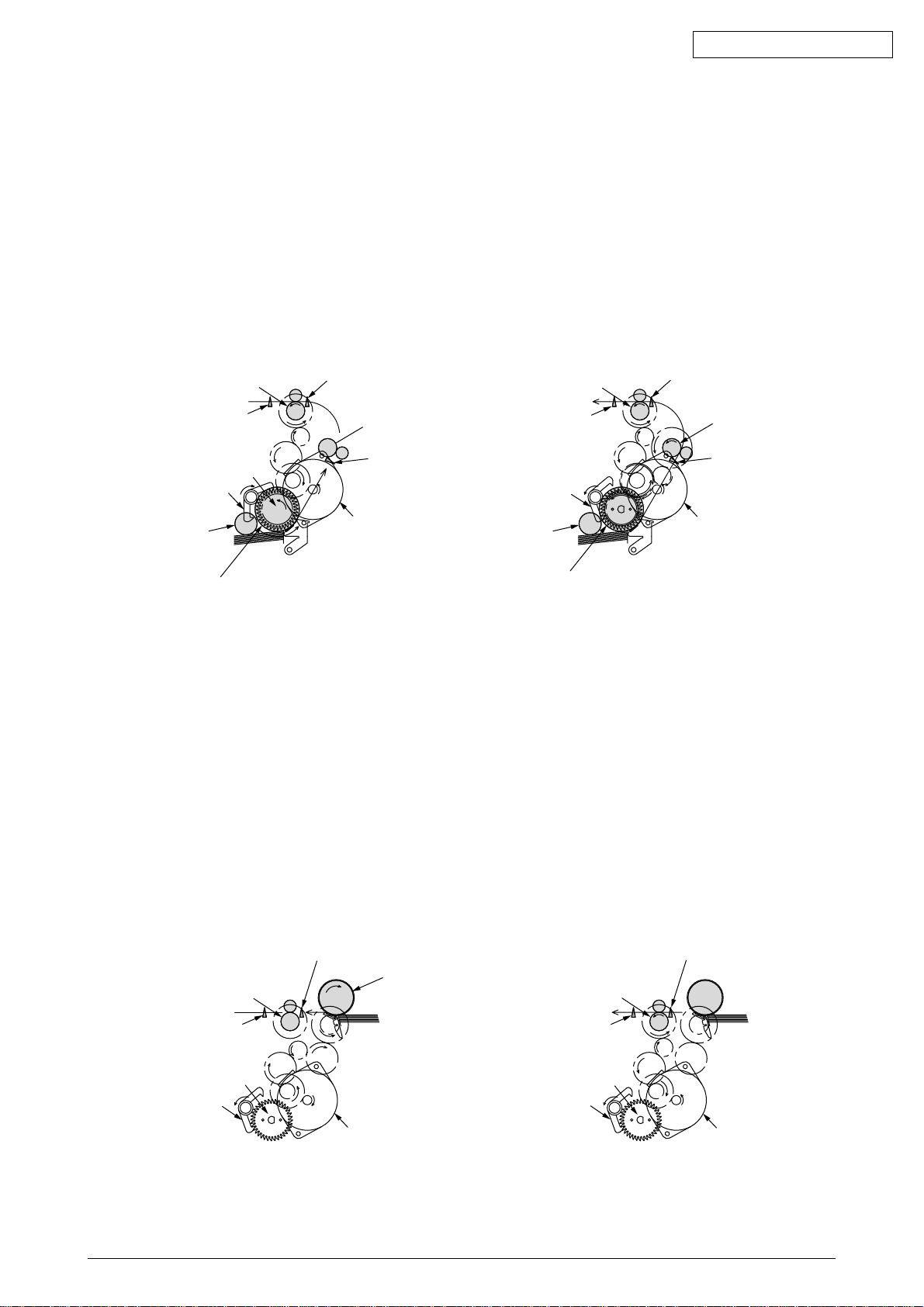

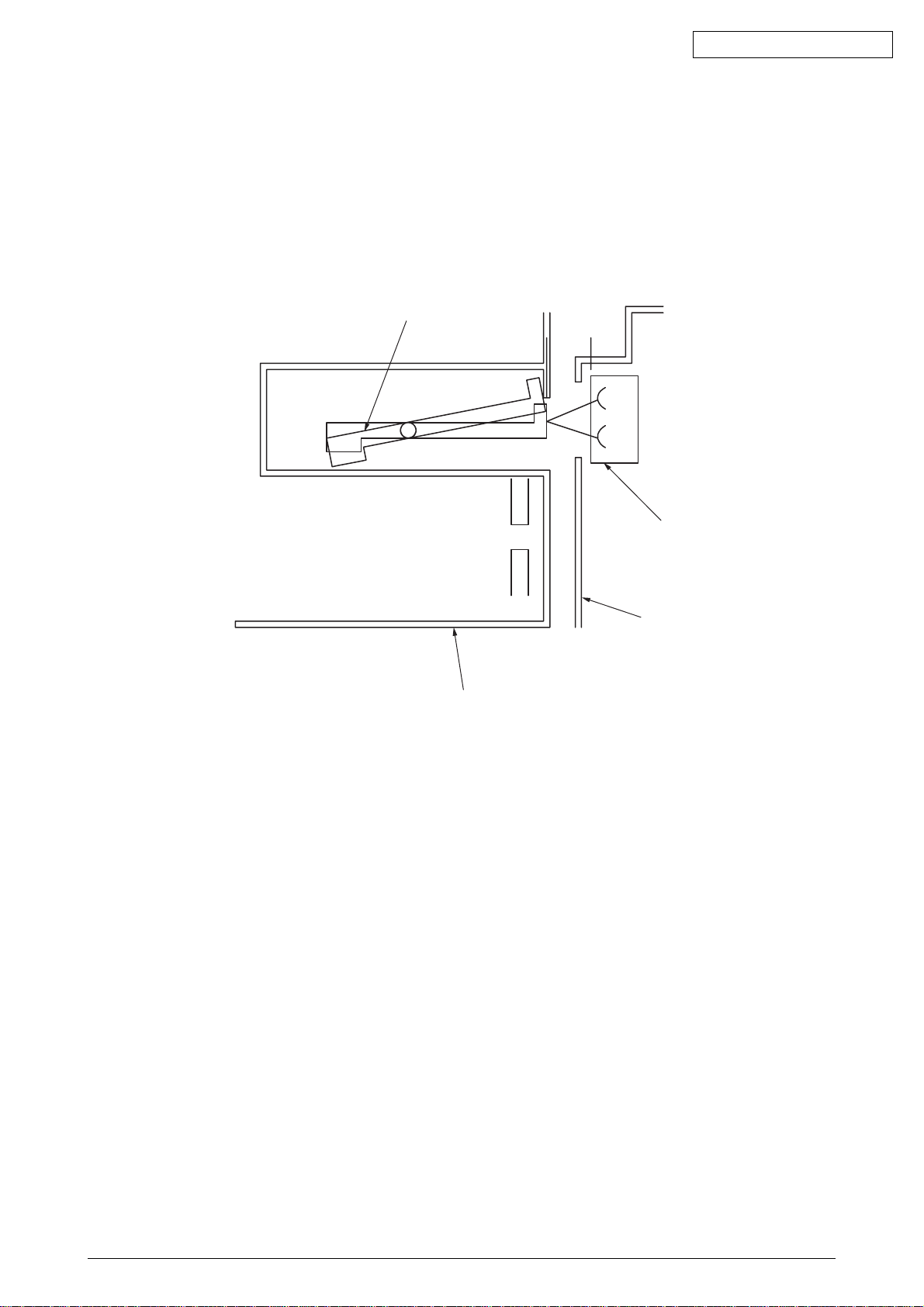

(4) ID Unit Up/Down Operations

1. The C-ID motor drives the ID unit up and down.

2. Figure 2-6 indicates ID unit operations during color printing. When the C-ID motor rotates

(CCW), the lift uplink slides to the left, and as indicated in Figure 2-6, each ID unit moves

DOWN. The printer is now ready for color printing.

3. Figure 2-7 indicates the ID unit operations during monochrome printing. When the C-ID

motor rotates (CW), the lift uplink slides to the right, and as indicated in Figure 2-7, all units

other than the K-ID moves UP. The printer is now ready for black-and-white printing.

ID Unit Operations During Color Printing

C-ID Unit down

C-ID Unit

M-ID Unit down

Y-ID Unit down

K-ID Unit down

Lift uplink

C-ID Motor

(CCW)

Figure 2-6

ID Unit Operations During Monochrome Printing

C-ID Unit

C-ID Unit lift up

M-ID Unit lift up

Y-ID Unit lift up

K-ID Unit down

M-ID Unit Y-ID Unit K-ID Unit

M-ID Unit Y-ID Unit

K-ID Unit

Lift uplink

C-ID Motor

(CW)

Figure 2-7

42615101TH Rev.5 31 /

Page 24

Oki Data CONFIDENTIAL

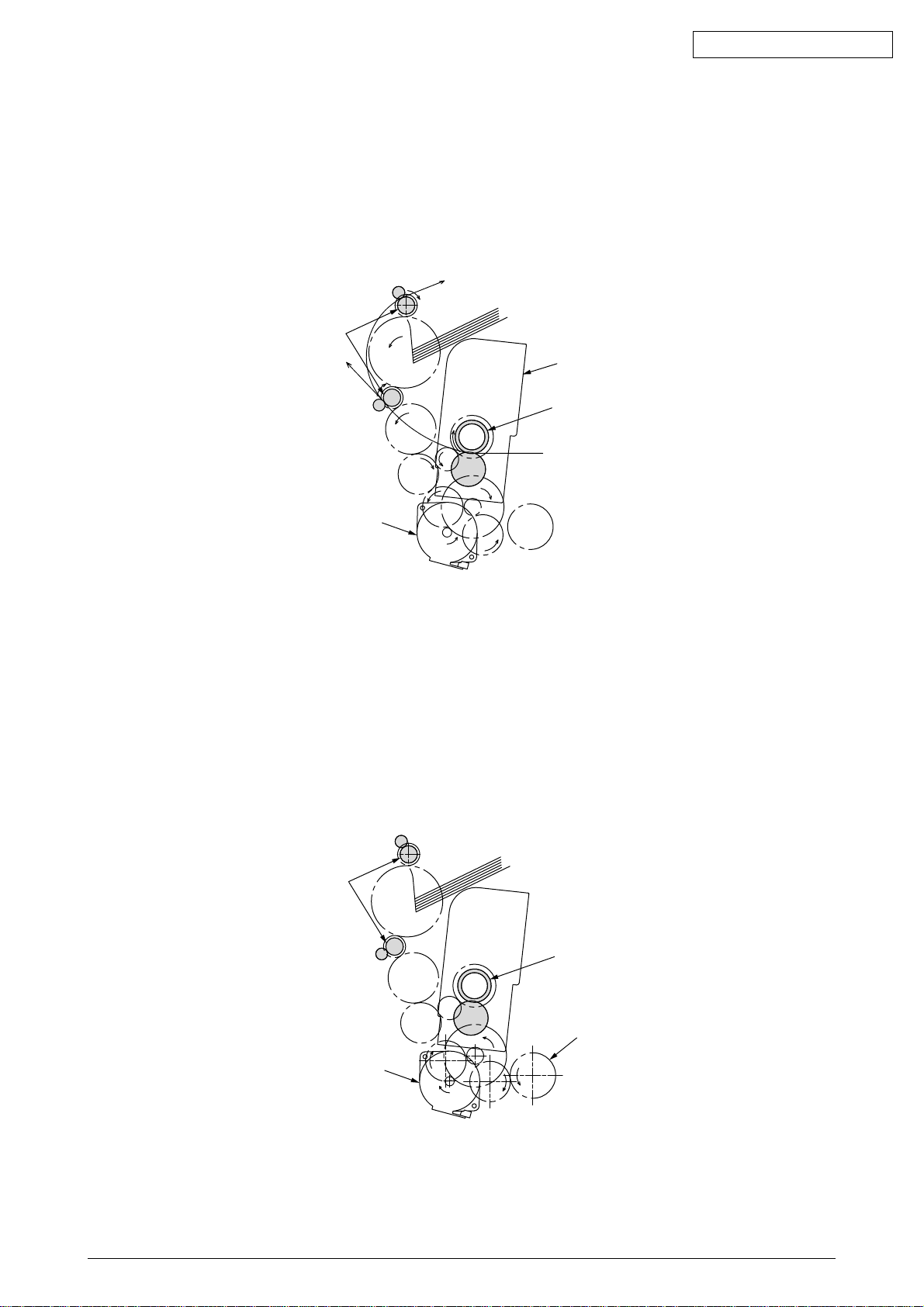

(5) Fuser Unit and Paper Expeller

1. As indicated in Figure 2-8, a single pulse motor drives the fuser unit and expeller roller. The

heat drum turns when the fuser motor turns (CCW). This drum transfers the toner image

on the paper by high temperature and pressure.

2. At the same time, the expeller roller expels the paper.

Eject Roller

(Drive)

Fuser Unit

Heat Roller

(Drive)

Fuser Motor

(CCW)

Figure 2-8

(6) Operations when the Color Drift Sensor and Density Sensor Cover is Opened

1. As indicated in Figure 2-9, when the fuser motor rotates (CW), the cover open gear rotates

and then opens the cover of the color drift sensor and density sensor.

2. When the fuser motor turns in the reverse direction (CCW), the cover open gear bite no

longer meshes, and then the color drift sensor and the density sensor cover closes.

Eject Roller

(Stop)

Heat Roller

(Stop)

Cover Open Gear

Fuser Motor

(CW)

Figure 2-9

42615101TH Rev.5 32 /

Page 25

Outline of Color Misalignment Adjustment Method

Adjustment patterns printed on a transfer belt are read using sensors that are installed inside a

sensor shutter placed under a transfer belt unit, for adjusting color misalignments. The sensor

detects the patterns for adjusting color misalignments.

Auto-Start timing for Color registration

• In power-on

• When a cover is closed after the cover is open in a short time

• When printing 400 pages or more after the previous implementation

Toner amounts on the produced patterns, contamination of the sensor with toner, problems with

opening or closing of the sensor shutter, or other reasons, a color misalignment adjustment error

may occur. No control panel display of the error is provided. In such cases, adjustments on any

color misalignments (Section 5.4.2.6) are forced to be executed by the Self-diagnostic Mode and

displayed errors must be checked.

Oki Data CONFIDENTIAL

Transfer Belt

Belt Motor

Sensor Shutter

Color Registration Sensor

Belt Waste Toner Box

Color Registration Sensor

Right Color Misalignment Adjustment Pattern

Left Color Misalignment Adjustment Pattern

Belt Cleaning Blade

Color Registration Sensor

42615101TH Rev.5 33 /

Page 26

Oki Data CONFIDENTIAL

How to check errors and Handling of the errors

Confirm with the color registration adjustment test of the self-diagnostic mode (Section 5.4.2.6)

Handling for each error

• CALIBRATION(L or R), DYNAMICRANGE(L or R)

Check 1 Check a connection state of a sensor cable (FFC) if the above description

appears.

Correct to a normal state if the connection state is wrong.

Check 2 Check that the surface of the sensor is clean without paper dust and toner.

Wipe it off if it is dirty.

Check 3 Check whether an opening-closing motion of the sensor shutter is normal with

MOTOR&CLUTCH TEST of the self-diagnostic mode.

Exchange the shutter unit when the opening-closing motion is not complete.

• BELT REFLX ERR

Check 4 Check a cleaning state of the toner left on a belt surface besides the above

Check 1, 2, and 3 if this message appears.

Take the belt unit out of the device and check that the belt surface is clearly

cleaned by rotating a drive gear in the back at the left side.

Exchange a belt unit when a toner of the belt surface is left and it is not clean even

if the drive gear rotates.

• (Y or M or C) LEFT, (Y or M or C) RIGHT, (Y or M or C) HORIZONTAL

Check 5 Check that a toner is not deficient due to NG color when the above message

appears.

Exchange a toner cartridge if needed.

42615101TH Rev.5 34 /

Page 27

Outline of Print Density Adjustment Method

Adjustment patterns printed on a transfer belt are read using sensors that are installed inside a

sensor shutter placed under a transfer belt unit, for adjusting print density.

Auto-Start timing of Print Density Adjustment

• When environment is different considerably compared to the previous implementation in power-on

• At least 1 or more from 4 ID count values is almost new in power-on

• When ID count value is over 500 from the previous implementation

Toner amounts on produced patterns, contamination of optical sensors with toner, problems with

opening or closing of the sensor shutter, or other reasons, a print density adjustment error may

occur. No control panel display of the error is provided. In such cases, print density adjustments

(Section 5.4.2.7) on defective colors are forced to be executed by the Self-diagnostic Mode and

displayed errors must be checked.

Oki Data CONFIDENTIAL

Transfer Belt

Belt Motor

Sensor Shutter

Density Sensor

Density Sensor

Belt Waste Toner Box

Belt Cleaning Blade

Print Density Adjustment Pattern

42615101TH Rev.5 35 /

Page 28

Oki Data CONFIDENTIAL

How to check errors and Handling of the errors

Confirm with the color registration adjustment test of the self-diagnostic mode (Section 5.4.2.7)

Handling for each error

• CALIBRATION ERR, DENS SENSOR ERR

Check 1 Check a connection state of the sensor cable when the above message

appears.

Correct to a normal state if the connection state is wrong.

Check 2 Check that the surface of the sensor is clean without paper dust and toner.

Wipe it off if it is dirty.

• EDENS SHUTTER ERR

Check 3 Check whether an opening-closing motion of the sensor shutter is normal with

MOTOR&CLUTCH TEST of the self-diagnostic mode.

• DENS ID ERR

Check 4 Check that there is no abnormal blushing on a drum surface by taking an ID unit

out.

Exchange a LED head (Defocusing) or exchange an ID unit.

Apply FUSE KEEP MODE of the maintenance menu when a new ID unit is used

as a test.

42615101TH Rev.5 36 /

Page 29

Principle of Detection by Toner Sensors

Movements of that sensor lever of a toner cartridge which is powered by an image drum (ID) motor

are read by a toner sensor for detecting that the cartridge is low on toner. The lever moves

concurrently with movement of a mixing bar placed in the cartridge. With the lever, or the sensor,

contaminated with toner etc., or the cartridge not facing the sensor properly due to improper ID unit

or toner cartridge installation, the sensor may not properly detect the cartridge being low on toner,

causing a toner sensor error.

Sensor Lever

Oki Data CONFIDENTIAL

Principle of the toner counter

After image data is developed to binary data which is printable, Dot counter counts the data as print

dots in LSI. Calculate the amount of the used toner with this count value to display a remaining

amount. Meanwhile, the toner LOW detection by the toner sensor has a function that Toner LOW

is detected when toner quantity in side of the toner cartridge is under a certain amount physically.

Principle of ID, Belt andFuser counter

ID counter : One third of the amount of drum rotation when three sheets of A4 paper is

printed continuously is regarded as one count.

Belt counter : One third of the amount of belt rotation when three sheets of A4 paper is printed

continuously is regarded as one count.

Fuser counter: On the basis of paper length of Leagal 13 inch, if it is 13 inch or less, it is

regarded as 1 count. If it is over 13 inch , the number of counters is determined

by multiples of Leagal 13 inch.(Round off to an integer value)

Toner Sensor

Side Plate

Toner Cartridge

42615101TH Rev.5 37 /

Page 30

Oki Data CONFIDENTIAL

3. Printer Installation

3.1 Precautions and Prohibition

• Keep away from high temperatures and open flames.

• Please do not install in a place from which a chemical reaction is started (laboratory etc.).

• Do not install near inflammable solutions such as alcohol or thinner.

• Keep out of reach of children.

• Do not install on an unstable surface (the shaky stand, leaning place, etc.).

• Keep away from dust, humidity and direct sunlight.

• Keep away from the sea breeze and corrosive gases.

• Keep away from sources of vibration.

• Pull the power plug out of the socket and contact with a customer's service centre when the printer

is dropped or the cover is damaged.

There is a risk of getting an electric shock and/or causing fire leading to personal injury.

• Do not use a power code, a printer cable, or a ground wire other than those that are indicated in

User's Manual.

Doing so may case fire.

• Do not insert materials in a vent hole.

Doing so may cause an electric shock and/or fire leading to personal injury.

• Do not put a cup with liquids such as water on the printer.

Doing so may cause an electric shock and/or fire leading to personal injury.

• Do not touch the fuser and other parts when opened the cover.

Doing so may result in getting burns.

• Do not throw toner cartridges and image drum cartridges into fire. Doing so may cause dust

explosion leading to get burns.

• Do not use an inflammable spray near the printer. Failure to follow may cause fire since there is

an area heating up within the printer.

• Pull the power plug out of the socket and contact with a customer's service centre when the cover

is unusually hot, smoking, giving off questionable odour, or making a strange noise.

There is a risk of fire.

• Pull the power plug out of the socket and contact with a customer's service centre when a liquid

such as water enters in the internal parts of the printer.

There is a risk of fire.

• Pull the power plug out of the socket and remove foreign materials such as clips when they fall

inside the printer.

There is a risk of getting an electric shock and/or causing fire leading to personal injury.

• Do not operate and/or disassemble the printer other than that which is directed in User's Manual.

Doing so may cause an electric shock and/or fire leading to personal injury.

42615101TH Rev.5 38 /

Page 31

Oki Data CONFIDENTIAL

• Do not block the vents on the printer.

• Do not place printer directly onto a carpet.

• Ensure printer has adequate ventilation.

• Keep printer way from sources of noise and magnetic fields.

• Do not install near a monitor or television.

• Please lift both sides when moving the printer.

Since this printer has about 25kg of weight, please raise by two or more persons

•

•

Do not come closer to the paper's exit area when the power is turned on, and while in printing.

.

Doing so may result in personal injury.

Explain instructions for use and settings to customers, showing instructions of the user’s manual.

Especially, explain the power cord and earth cable carefully.

42615101TH Rev.5 39 /

Page 32

3.2 Printer Unpacking Procedure

Personal injuries may occur.

Each printer weighs about 25 kg. Lift it by more than one person.

• Punch four handle holes each on the side, or the end, of the carton box as shown below,

to lift it.

Oki Data CONFIDENTIAL

Handle Holes

(each on side or on end)

42615101TH Rev.5 40 /

Page 33

3.3 Printer Installation Instructions

• Printers must be installed in a place that meets the following temperature and humidity

conditions:

Ambient Temperature : 10 to 32°C

Ambient Humidity : 20 to 80% relative humidity

Maximum Wet-Bulb Temperature: 25°C

• Take care not to allow dew condensation on printers.

• When installing printers in an area of which ambient humidity is 30% or less, use a humidifier or

antistatic mat.

Installation Space

• Place printers on a flat table having the size that allows their legs to fit on the table.

• Leave sufficient space around each printer.

Top View

Oki Data CONFIDENTIAL

Side View

60cm

20cm

100cm

20cm

70cm

42615101TH Rev.5 41 /

Page 34

3.4 Packed Units and Attachments

• Check the packed units are free of flaws and dirt.

• Check there are no missed attachments, or damage to the packed attachments.

• Should any defective or unusual conditions are found, contact the section in charge.

Personal injuries may occur.

Each printer weighs about 25 kg. Lift it by more than one person.

■■Printer (main body)

Oki Data CONFIDENTIAL

■■Image Drum Cartridges with Starter Toner Cartridges (four sets) (contained in printer)

Explain that a toner cartridge and image drum cartridge is separable to customers.

■■Printer Software CD-ROM

■■LED Lens Cleaner

■■Power Cord

■■Warranty and Registration Card

■■Users Manual (Setup Guide)

■■Users Manual on CD-ROM

■■Quick Guide

■■Quick Guide Bag

Note!

No printer cables are included in printer packages.

42615101TH Rev.5 42 /

Page 35

3.5 Assembly Procedure

3.5.1 Printer Main Body

Remove Protective Equipment

(1) Remove protection tapes (5) of the front of the printer and protection tapes (2) of the back.

(2) Remove the paper cassette.

(3) Pull out the retainer frontward.

Oki Data CONFIDENTIAL

Paper

Protective Tape

Protective Tape

OPEN button

(4) Press the OPEN button to open the top cover.

(5) Pulling down the lever (blue) of the fuser unit in the direction of the arrow 1, remove the

stopper release (orange color).

Note!

Instruct the user of the printer to be sure to keep the stopper release, which is used for

transporting the printer, at hand.

Lever (blue) of Fuser Unit

Retainer

1

2

Stopper Release (orange color)

42615101TH Rev.5 43 /

Page 36

Install Image Drum Cartridges

(1) Take image cartridges (Four cartridges) with toner cartridges softly.

Oki Data CONFIDENTIAL

Note!

• Take sufficient care in handling the image drums (green cylindrical parts), which are

very sensitive.

• Do not expose the image drum cartridges to direct sunlight, strong light (of about 1500

lux. or more) or, for five minutes or more, room light.

• Make sure that a blue lever of the toner cartridge should not be moved here.

Toner Cartridge

Image Drum Cartridge

(2) Put an image cartridge on a flat desk and remove tape holding a protection sheet. Then,

pull it in the direction of an arrow.

Note!

Make sure to work with an image drum putting on a desk.

Protective sheet 1

Tape

Protective sheet 1

Protective sheet 2

(3) Pull protective sheet 2 in the arrow direction from image drum cartridge.

Protective sheet 2

42615101TH Rev.5 44 /

Page 37

Oki Data CONFIDENTIAL

(4) Make sure the labels of the image drum cartridges have the same colors as the labels

beside the places of the cartridges, respectively.

(5) Reinstall the four image drum cartridges carefully.

Image Drum Cartridge

Label

Label

(6) Turn the blue lever of the toner cartridge in the arrow direction until it stops completely.

Note!

• 1500 pages are printable with Starter toner (a toner cartridge which is attached at the

time of purchase) under the condition of A4 and 5% print density.

• Make sure that a lever of the toner cartridge turn in the arrow direction until it stops

completely when [REPLACE THE TONER] remains displayed.

• It is invalid to use Starter toner once a regular toner cartridge is used. Use Starter

toner up first, and then a regular toner should be used.

• The starter toner should be replaced after displaying [ORDER TONER].

If it is replaced before the display, the correct remaining amount of the toner is not

displayed.

Blue

Lever

42615101TH Rev.5 45 /

Page 38

Load Paper in Paper Cassette

(1) Slide out the paper cassette.

Note!

Do not remove the rubber from the plate.

(2) Place the paper stopper in the position of the size of print paper.

Paper Stopper

Oki Data CONFIDENTIAL

Paper Guide

Plate

(3) Sufficiently loosen the paper, and jog the paper so as that its edges line up.

(4) Load the paper face down in the paper cassette.

Note!

• Print paper must be placed in the paper cassette so as to touch sides of the paper

cassette.

• Loaded print paper must not exceed the position pointed by the inverted triangles

▼▼)(300 sheets for 70-kg paper).

(

(5) Secure the paper with the paper guide.

(6) Slide the paper cassette back in.

Place Print side down.

Paper guide

42615101TH Rev.5 46 /

Paper life display

Page 39

Load Paper in MP (Multipurpose) Tray

(1) Open the MP tray and then the paper supporter.

(2) Align the manual feeding paper guide with the size of print paper.

(3) Jog the paper so as that its edges line up.

Oki Data CONFIDENTIAL

MP Tray

Manual Feeding Paper Guide

MP Tray

Paper Supporter

Manual Feeding Paper Guide

(4) Insert the paper face up, straight along the paper guides for manual feeding, as far as it

will go.

(5) Press the setup button.

Setup Button

42615101TH Rev.5 47 /

Page 40

Oki Data CONFIDENTIAL

3.5.2 Power Cable Connection

Conditions for Power Supplies

• The following conditions apply to the power supplies of printers:

Alternate Current (AC) : 100 V ±10%

Power Supply Frequency : 50, or 60 ±2 Hz

• For unstable power supplies, use voltage regulators etc.

• The maximum power consumptions of printers are 950 W. Be sure power supplies have power

supply capacities adequate for the printers.

It may expose you to electric shocks or cause a fire.

• Make sure to turn off printers before attaching and detaching power supply cords and grounding

wires to the printers.

• Grounding wires must be connected to dedicated grounding terminals. Never connect them to

water or gas pipes, or telephone grounds, lighting conductors or other lines.

• Be sure to insert or remove power supply cords by pushing or pulling on the plugs.

• Insert power supply plugs into receptacle outlets as far as they will go.

• Do not insert or pull out power supply plugs with wet hands.

• Install power supply cords in a location where they will not be trodden, and do not place things on

them.

• Do not tie, in bundles, or knot power supply cords in use for printers.

• Do not use damaged power supply cords for printers.

• Do not use star-burst connections for printers.

• Do not connect a printer to the same receptacle outlet being used for electrical equipment other

than the printer. Connecting a printer such a receptacle outlet, particularly being used for air

conditioning, copying or shredding equipment, may cause a malfunction in the printer due to

electrical noises. If a printer is connected to such a receptacle outlet by necessity, use a

commercially available noise filter or noise-cut transformer.

• For power supply cords of printers, use only those packed with the printers.

• Do not use extension cords for printers. If they are used by necessity, select cords with a rating

of 15 A or more.

• Printers may not function correctly when used with extension cords.

• Do not turn off printers or pull out their power supply plugs while the printers are printing.

• Please disconnect printers from the mains supply if they will not be used for an extended period

of time.

Explain connections of the power cord and earth cable to customers carefully, showing the user’s

manual.

42615101TH Rev.5 48 /

Page 41

Connect Power Supply Cord

Oki Data CONFIDENTIAL

Note!

Be certain the power switch is placed in the OFF (O) position.

(1) Plug the power supply cord in the printer.

(2) After the grounding wire is connected to the grounding terminal. Insert the power supply

cord into the receptacle socket.

OI

Press ON (I) of Power Switch

Grounding Terminal

Grounding Wire

OI

The control panel provides messages as shown below and, after the printer is activated

completely, it displays [ONLINE].

R A M C H E C K

I N T I A L I Z I N G

[ONLINE] and [CHECK] lamps,

and the backlight blink.

O N L I N E

T R A Y 1

42615101TH Rev.5 49 /

Page 42

Turning off the Printer

Turn off the printer without an internal hard disk (option) and in ES1624n.

Oki Data CONFIDENTIAL

OI

Note!

Do not turn OFF the printer while printing.

In case that an internal hard disk (option) is installed, follow the procedure as shown below

without turning off the printer immediately.

Note!

• The internal hard disk may be damaged and unusable if the printer is switched off

immediately.

• [SHUTDOWN MENU] is displayed only when an optional internal hard disk is installed.

(1) Press the "MENU +" switch a couple times to show [SHUTDOWN MENU].

(2) Press the "ENTER" switch to show [SHUT DOWN START/EXECUTE].

(3) Press the "ENTER" switch.

[SHUTDOWN] is displayed and shutdown process is executed.

(4) Press the power switch OFF(O) after [TURN OFF POWER/ SHUTDOWN IS COMPLETED]

is displayed.

OI

42615101TH Rev.5 50 /

Page 43

3.5.3 Installation of Optional Components

(1) Extension Memory Installation

ES1624n Expansion Memory

Model name

Memory Size (total memory size)

Oki Data CONFIDENTIAL

None (standard)

MLMEM64C

Note!

• Be sure to use Oki Data genuine memory. Printers do not operate using memory

64MB (64MB)

+64MB (128MB)

other than Oki Data genuine memory.

•Installing 64-MB extension memory in printers is recommended for the printers to print

both sides of paper.

• Installing 64-MB extension memory in printers is recommended for the printers to print

banner-sheet paper.

• One memory slot is provided.

•

Power Off Printer and Remove Power Supply Cord

Note!

nstalling options to printers while the printers are powered on may cause a problem with

the printers.

OI

Open Top Cover and Front Cover

Top Cover

Front Cover

OPEN Button

Handle

42615101TH Rev.5 51 /

Front Cover

Page 44

Remove Side Cover

(1) Loosen the screw (at one place).

(2) Remove the side cover. It can become detached by moving it upward and outward.

Front Cover

Screw

1

Oki Data CONFIDENTIAL

Top Cover

2

Side Cover

Install Memory

ES1624n

(1) Remove static electricity by bringing a bag into contact with a metal part before the memory

is taken out of the bag.

(2) Insert the memory into an empty slot.

(3) Make sure that the memory is completely held by the right and left lock lever.

Note!

• Do not touch electronic components and connector terminals.

• Be careful of the memory direction. There is a cutting part to adapt to the connector of

the slot.

Lock Levers

42615101TH Rev.5 52 /

Page 45

Oki Data CONFIDENTIAL

(1) Remove static electricity by bringing a bag into contact with a metal part before the memory

is taken out of the bag.

(2) Insert the memory into an empty slot.

(3) Make sure that the memory is held completely by the top and bottom lock lever.

Note!

• Do not touch electronic components and connector terminals.

• Be careful of the memory direction. There is a cutting part to adapt to the connector of

the slot.

Lock Levers

Reinstall Side Cover

(1) Reinstall the side cover.

(2) Fasten the cover with the one screw.

(3) Close the top cover and the front cover.

Front Cover

2

Screw

Top Cover

3

3

1

Side Cover

42615101TH Rev.5 53 /

Page 46

(2) Second Tray Installation

A second tray expands the printer’s paper holding capacity, and can hold 530 sheets of 70-kg

paper in it. A printer equipped with the tray can continuously print those 930 sheets of the

paper, using the paper cassette and MP tray that are standard on the printer.

Type: MLTRY-C4C1

Power Off Printer to Remove Power Supply Cord

Oki Data CONFIDENTIAL

Note!

Installing the second tray with the printer powered on may cause a problem with the

printer.

Place Printer on Second Tray Unit

Note!

Each printer weighs about 25 kg. Lift it by more than one person.

(1) Align the cuts on the bottom surface of the printer with the protrusions of the second tray

unit.

(2) Put the printer on the second tray unit carefully.

For removing the second tray, reverse the installation procedure.

OI

Cut on Bottom Surface of Printer

Protrusion

42615101TH Rev.5 54 /

Page 47

(3) Duplex-Unit Installation

A duplex unit is used for a printer to print both sides of paper.

Note!

Installing extension memory in printers is recommended for the printers to print both

sides of paper.

Type: MLDXU-C4C

Power Printer Off to Remove Power Supply Cord

Oki Data CONFIDENTIAL

Note!

nstalling the duplex unit with the printer powered on may cause a problem with the

printer.

OI

Remove Protective Tape from Duplex Unit

Install Duplex Unit

(1) Slide the duplex unit into the rear of the printer as far as the unit will go.

(2) Be sure the lock piece of the unit is completely engaged in the cut on the rear on each side.

Protective Tape (at two places)

Holes

Lock Pieces

Duplex Unit

42615101TH Rev.5 55 /

Page 48

(4) Internal Hard Disk (ES1624n)

It is an internal hard disk which is added to the printer. It is used when printing for validation,

authentication, saving of the print job or buffer printing are implemented or [COLLATE FAIL]

is shown in collation copy printing.

It is not available to download a font.

Note!

Turn off the power after Shut down menu is executed when an internal hard disk is

installed. The hard disk may be damaged and unusable if the printer is switched off

immediately.

Oki Data CONFIDENTIAL

Memo

The hard disk is divided into three partitions such as "PCL", "SHARING" and "PSE", and

each partition size is allocated as below.

PCL

SHARING

PSE

20%

50%

30%

Power Printer Off to Remove Power Supply Cord, the printer cable

Note!

nstalling the duplex unit with the printer powered on may cause a problem with the

printer.

OI

42615101TH Rev.5 56 /

Page 49

Open the top cover and the front cover

(1) Press OPEN button to open the top cover.

OPEN button

Handle

Oki Data CONFIDENTIAL

Top cover

Front cover

(2) Lift up the handle in the center of the front cover, and then, pull the front cover.

Front cover

Note!

It differs from how to open multi-purpose tray (See the following figure.)

Multi-purpose tray

42615101TH Rev.5 57 /

Page 50

Detach the side cover

(1) Slacken a screw.

(2) Detach the side cover.

Slide out lifting the top part of the side cover.

Front cover

1

Screw

Oki Data CONFIDENTIAL

Top cover

2

Side cover

Memo

Make sure the front cover is open when the side cover is not detached.

[The condition where the front cover is open] [The condition where Multi-purpose tray is open]

Install an internal hard disk

(1) Pull a lock lever of the internal hard disk.

(2) Insert the cable of the internal hard disk into the connector on the control base.

(3) Sets the internal hard disk to fit the line displayed in "HDD".

(4) Fold the lock lever until you hear it click.

Front cover

Multi-purpose tray

Displayed "HDD"

Lock lever

Click

3

1

4

2

42615101TH Rev.5 58 /

Page 51

Attach the side cover

(1) Attach the side cover.

(2) IFix it with a screw.

(3) Close the top cover and the front cover.

Oki Data CONFIDENTIAL

Top cover

Front cover

3

3

2

Screw

1

Side cover

Connect the power code and printer cable to the printer and turn ON the printer

Print MenuMap and confirm that an internal hard disk is appropriately installed

(1) Print MenuMap.

Refer to “ Chapter 3.6 Menu Map Printing” to print MenuMap.

(2) Check the capacity of the internal hard disk is displayed in HDD.

Memo

Note!

In addition, a setting to recognize the internal hard disk in the printer driver is required.

Please refer to Chapter 3-9 if the printer driver is not set up, proceed after the printer driver is

installed.

42615101TH Rev.5 59 /

The capacity of the hard disk may differ from the example of the left figure.

Reinstall the internal hard disk when the capacity of HDD is not displayed.

Page 52

3.5.4 Checking of Optional-Component Recognition

Please refer to “3.6 Menu Map Printing” to print MenuMap to confirm that options are correctly

installed.

(1) Checking for Proper Extension Memory Recognition

Check Information Contained in MenuMap

Check the total memory size appearing at Total Memory Size on the header of MenuMap.

Oki Data CONFIDENTIAL

(2) Checking for Proper Second Tray Recognition

<Checking for Proper Second Tray Recognition>

Check Information Contained in MenuMap

Check Tray 2 is in the header part.

(3) Checking for Proper Duplex Unit Recognition

<Checking for Proper Duplex Unit Recognition>

Check Information Contained in MenuMap

Check [Duplex printing : installed] is in the header of MenuMap.

42615101TH Rev.5 60 /

Page 53

3.6 MenuMap Printing

Make sure that the printer operates normally.

For ES1624n

(1) Set A4 papers in a tray.

(2) Press the "MENU +" switch a couple times to show [Information menu].

(3) Press the "ENTER" switch to show [Menu map Printing/ EXECUTE].

(4) Press the "ENTER" switch.

Menu map printing is started (2pages for ES1624n,

Following it, Network Information is printed (4 pages.)

Oki Data CONFIDENTIAL

(Sample) In case of ES1624n

42615101TH Rev.5 61 /

Page 54

3.7 Connection Procedures

<USB Connection>

Prepare a USB Cable.

Oki Data CONFIDENTIAL

Note!

• No cables are included with the product. Prepare a cable.

• A cable to be prepared must be a USB cable.

• For connecting the printer in USB 2.0 Hi-Speed mode, use a Hi-Speed USB cable.

Power off Printer and Personal Computer

Memo

The USB cable can be plugged in and off with the printer powered on. For the purpose

of printer driver and USB driver installation to be performed later, power off the printer.

Connect Personal Computer and Printer

(1) Plug a prepared USB cable in the USB interface connector of the printer.

(2) Plug the cable in the USB interface connector of the personal computer.

Note!

Be careful not to plug the USB cable in the network interface connectors; a problem with

the printer may result.

USB Interface Connector

42615101TH Rev.5 64 /

Page 55

<LAN Cable Connection>

Prepare a LAN Cable and Power Off Printer and Personal Computer

Connect Personal Computer and Printer

(1) Remove the misplugging prevention cover fitted into the network interface connector of the

printer.

Misplugging Prevention Cover

Oki Data CONFIDENTIAL

(2) Plug the prepared Ethernet cable in the network interface connector of the printer.

(3) Plug the cable in the hub.

Network Interface Connector

<Parallel Connection>

Prepare a Parallel Port Cable and Power Off Printer and Personal Computer

Connect Personal Computer and Printer

(1) Plug the prepared parallel port cable in the parallel interface connector of the printer, and

secure the cable with the metal fitting.

(2) Plug the cable in the parallel interface connector of the computer, and secure the cable with

the screw.

Screw

Screw

Metal Fitting

42615101TH Rev.5 65 /

Page 56

3.8 Checking of User Paper

Load the paper in printers used by users, select the settings at MEIDA TYPE and MEDIA WEIGHT

and print MenuMap and Demo Page to check no occurrence of peeled off toner.

Oki Data CONFIDENTIAL

Setting values of the operation

WeightTypes

Media weight

2

Regular

3

paper*

Postcard*

4

Envelope*

Label paper

55-64kg (64-74g/m

65-89kg (75-104g/m

90-103kg (105-120g/m

104-172kg (121-200g/m

4

Less than 0.1-0.17mm

)

2

)

2

)

2

)

-

-

0.17-0.2mm

Transparency

5

film

*

*1

: [Light] is set as factory-default of media type.

*2

: Media weight and type can be set by the operation panel and the printer driver. The printer

-

Light

Medium

Heavy

Ultra heavy

Thicker paper

Thickest paper

panel

Media type *

1

Light

-

-

-

-

Label paper

-

Transparency

film

Setting *

[Media weight] of the

printer driver

Ultra heavy

Label paper 1

Label paper 2

Transparency

2

Light

Medium

Heavy

-

-

film

for

driver takes priority if it is set in the printer driver. Images are printed out by the setting of

the operation panel when [Auto selection] is set in [Feed tray] or [Printer setting] is set in

[Media weight].

*3

: The ream weight of the paper for duplex print is 55-90kg (64-105g/m2).

42615101TH Rev.5 66 /

Page 57

4. PARTS REPLACEMENT

This section describes the procedure for replacing the parts, assemblies and units in the field. The

replacing procedure is given for detachment. To attach, use the reverse procedure.

The Parts No. (1, 2, etc.) appearing in this manual vary from the numbers appearing in the

diagram numbering of the Disassembly for Maintenance Configuration (********TL) and RSPL

(********TR).

4.1 Precautions in Replacing Parts

(1) Before replacing the parts, be sure to remove the AC cord and the interface cable.

(a) To remove the AC cord, always use the following procedure.

i) Flip the power switch of the printer off (to “O”).

ii) Pull the AC inlet plug of the AC cord out of the AC plug.

iii) Remove the AC cord and the interface cable from the printer.

(b) To connect the printer again, always use the following procedure.

Oki Data CONFIDENTIAL

Disconnect

(2) Do not disassemble the printer so long as it operates properly.

(3) Minimize the disassembly. Do not detach parts other than those shown in the replacing procedure.

(4) For maintenance, use designated tools.

i) Connect the AC cord and the interface cable to the printer.

ii) Insert the AC inlet plug into the AC plug.

iii) Flip the power switch of the printer on (to “I”).

Connect

(5) Follow the order instructed to disassemble the printer. Incorrect order may damage the parts.

(6) Small parts such as screws and collars tend to get lost, so temporarily place and fix them in

their original positions.

(7) When handling ICs and circuit boards such as microprocessors, ROMs and RAMs, do not use

gloves that likely to have static.

(8) Do not place the printed circuit boards directly on the printer or the floor.

42615101TH Rev.5 67 /

Page 58

Oki Data CONFIDENTIAL

[Maintenance Tools]

Table 4-1-1 lists tools necessary to replace the printed circuit boards and the units.

Table 4-1-1 Maintenance Tools

No. Q' ty Place of use RemarksService Tools

1

2

3

4

5

6

7

8

No. 2-200 Philips

screwdriver, Magnetized

No. 3-100 screwdriver

No. 5-200 screwdriver

Digital multimeter

Pliers

Handy cleaner

LED Head cleaner

P/N 4PB4083-2248P001

E-ring pliers

1

3~5 mm screws

1

1

1

1

1

1

Cleans LED head

1

Required tools for the maintenance utility are shown in Table 4-1-2.

Table 4-1-2 Maintenance Tools

No. Q' ty Place of use RemarksService Tools

1 Laptop computer 1

2 USB cable 1

42615101TH Rev.5 68 /

Page 59

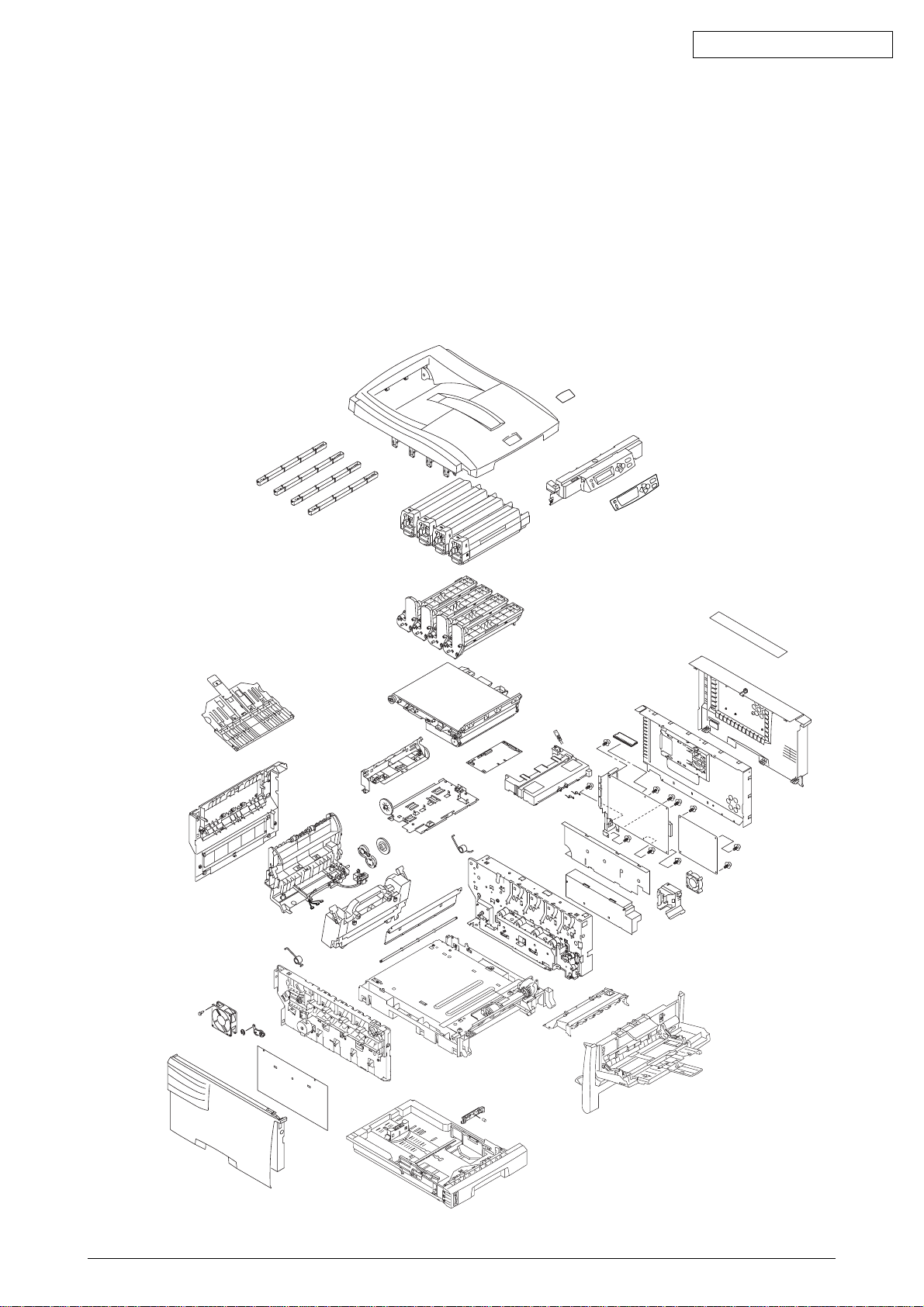

4.2 Part Replacement Procedures

This section describes the procedures for replacing the parts and assemblies shown in the

following disassembly chart:

4.2.1 Left Side Cover

(1) Open the top cover 1.

(2) Open the feeder unit 2.

(3) Remove the screw (golden) 3 to detach the left side cover 4.(Tool No.1)

Oki Data CONFIDENTIAL

1

3

2

4

Figure 4-2-1 Left Side Cover

42615101TH Rev.5 69 /

Page 60

2

4.2.2 Right Side Cover

(1) Open the top cover 1.

(2) Open the feeder unit 2.

(3) Loosen the screw 3 to detach the right side cover 4.(Tool No.1)

1

3

Oki Data CONFIDENTIAL

(loosen)

4

Figure 4-2-2 Right Side Cover

42615101TH Rev.5 70 /

Page 61

4.2.3 Face-Up Tray

(1) Open the face-up tray 1 in the direction of the arrow, and disengage it at its two places to

detach it with bowing down.

Oki Data CONFIDENTIAL

Figure 4-2-3 Face-Up Tray

1

42615101TH Rev.5 71 /

Page 62

4.2.4 Rear Cover

(1) Slide out the face-up tray.

(2) Remove the two screws (golden) 1.(Tool No.1)

(3) As shown in Fig.2, insert a flat- blade driver (Tool No.3) into the hole A to disengage the claw A,

at each of the two places.

(4) Disengage the two claws B and pull in an arc the rear cover 2 in the direction of the allow A.

(5) As shown in Fig.3, push the lower part of the rear cover 2 in the direction of the allow B to

disengage the three claws C, then detach the rear-cover.

Oki Data CONFIDENTIAL

Fig.1

Claw B

Claw A

1

A

Claws A

2

1

A

Hole A

Fig.2

Claws B

Claws C

Claw A

2

Hole A

B

Claws C

42615101TH Rev.5 72 /

Fig.3

Figure 4-2-4 Rear Cover

Page 63

4.2.5 LED Assy / LED Assy-Springs

(1) Open the top cover 1.

(2) As shown in Fig.2, push in the direction of the allow after removing a cable. Then, disengage

the hook A first and the hook B to detach LED Assy 2 (the two springs 3 become detached

together with the LED Assy 2).

Oki Data CONFIDENTIAL

Hook A

1

3

Fig.1

Hook A

2

Fig.2

Hook B

Figure 4-2-5 LED Assy / LED Assy-Springs

42615101TH Rev.5 73 /

Page 64

4.2.6 Controller PCB

ES1624n