Page 1

Page 2

Page 3

Foreword

This manual has be en designed for train e d ser vi ce personnel and describes how to maint ai n and repair.

This manual is not intended for general users.

This manual comprises the following chapters.

Chapter 1: Printer Illustration

P2-

Chapter 2: Decomposition

P6-

Chapter 3: Assembly

P19-

Chapter 4: Adjustments, Printing test

P37-

Chapter 5: Maintenance/Lubrication

P47-

Chapter 6: Troubleshooting

Chapter 7: Component List

Chapter 8: Parts Exchange

Chapter 9: Software

P50-

P53-

P60-

P68-

1/71

Page 4

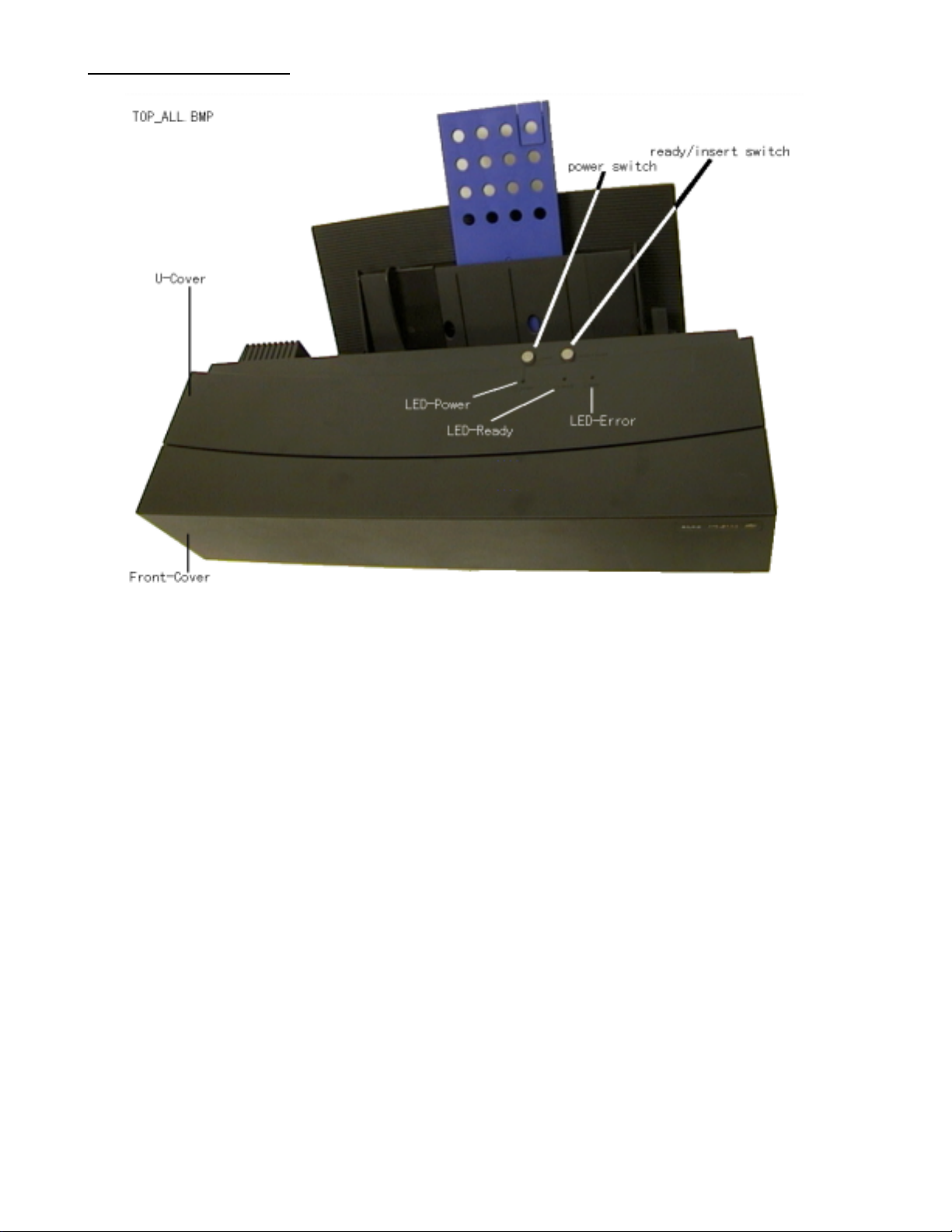

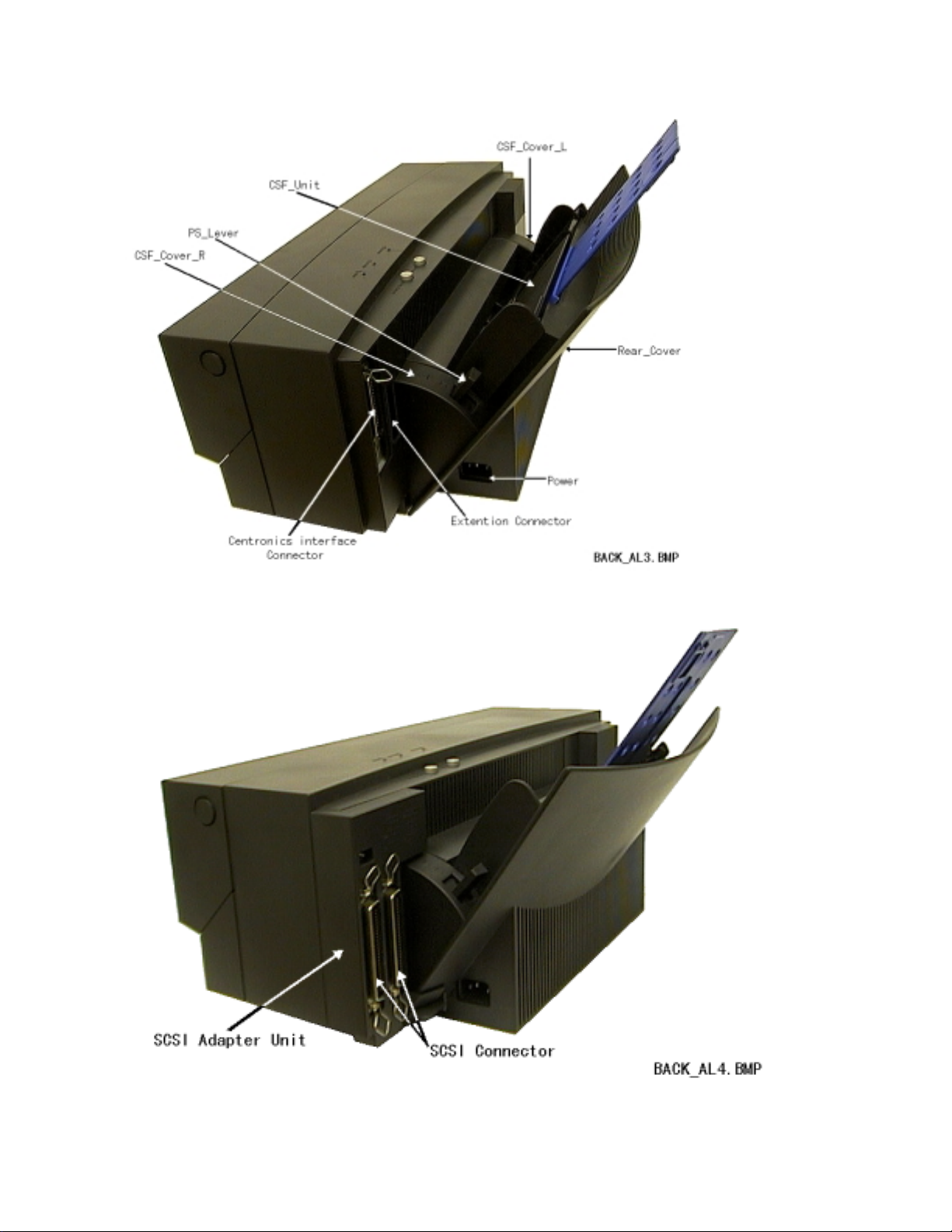

Chapter 1: Printer Illustration

2/71

Page 5

3/71

Page 6

4/71

Page 7

1.1 Operation Panel

1) power Switch

Printer power

2) ready/insert Switch

Self-printing ,Paper intake/eject

3) LED

Power : Indicates if power is turn ed on. This LED also blinks the HEX dump/self printing status.

Ready : This LED blinks when the print data is receiv ed. Moreover, when an error occ urs, LED is

turned off.

error : Indicates printer is in an error st at e.

Blinking: Alarm Off: Normal

5/71

Page 8

Chapter 2: Decomposition

R

t

L

t

)

L

d

P

t

C

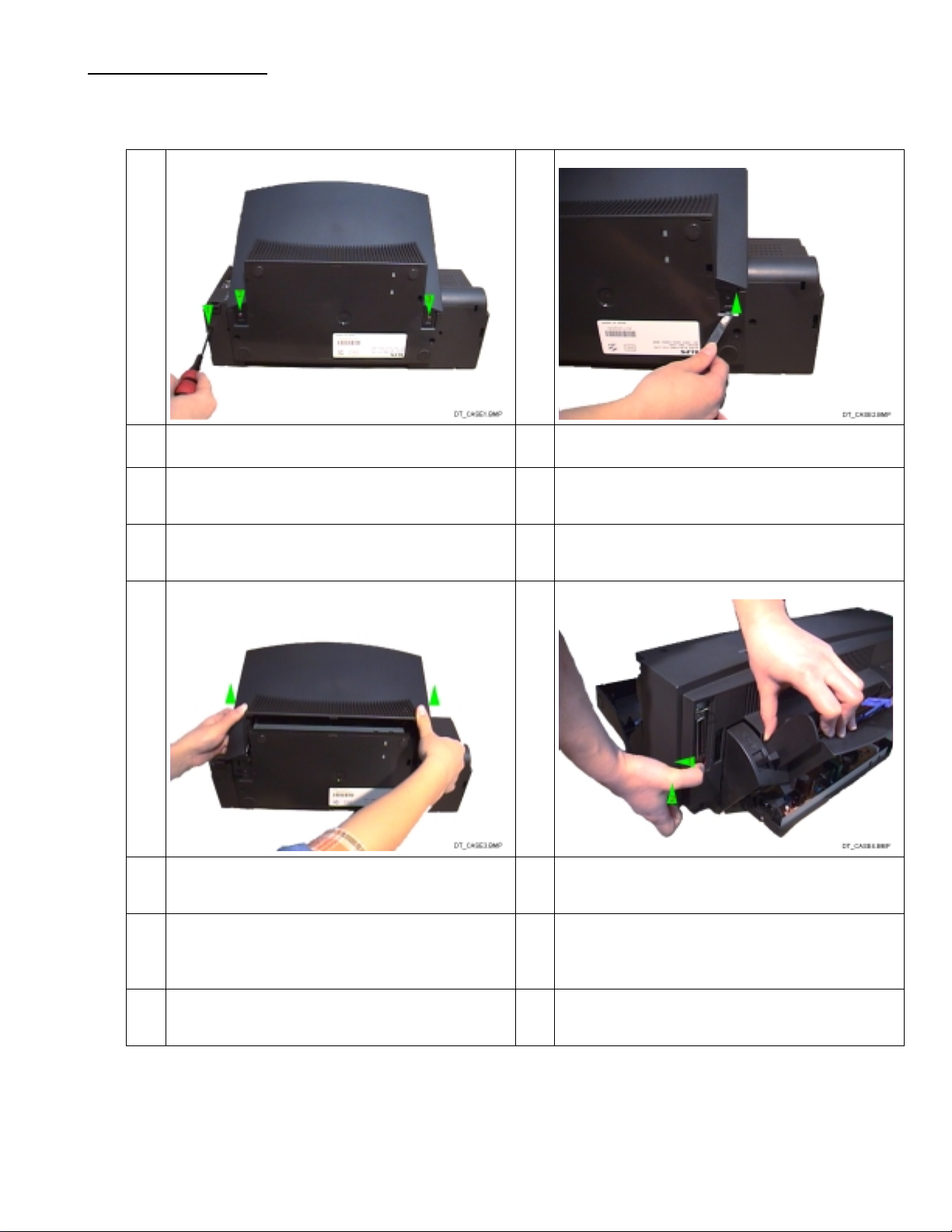

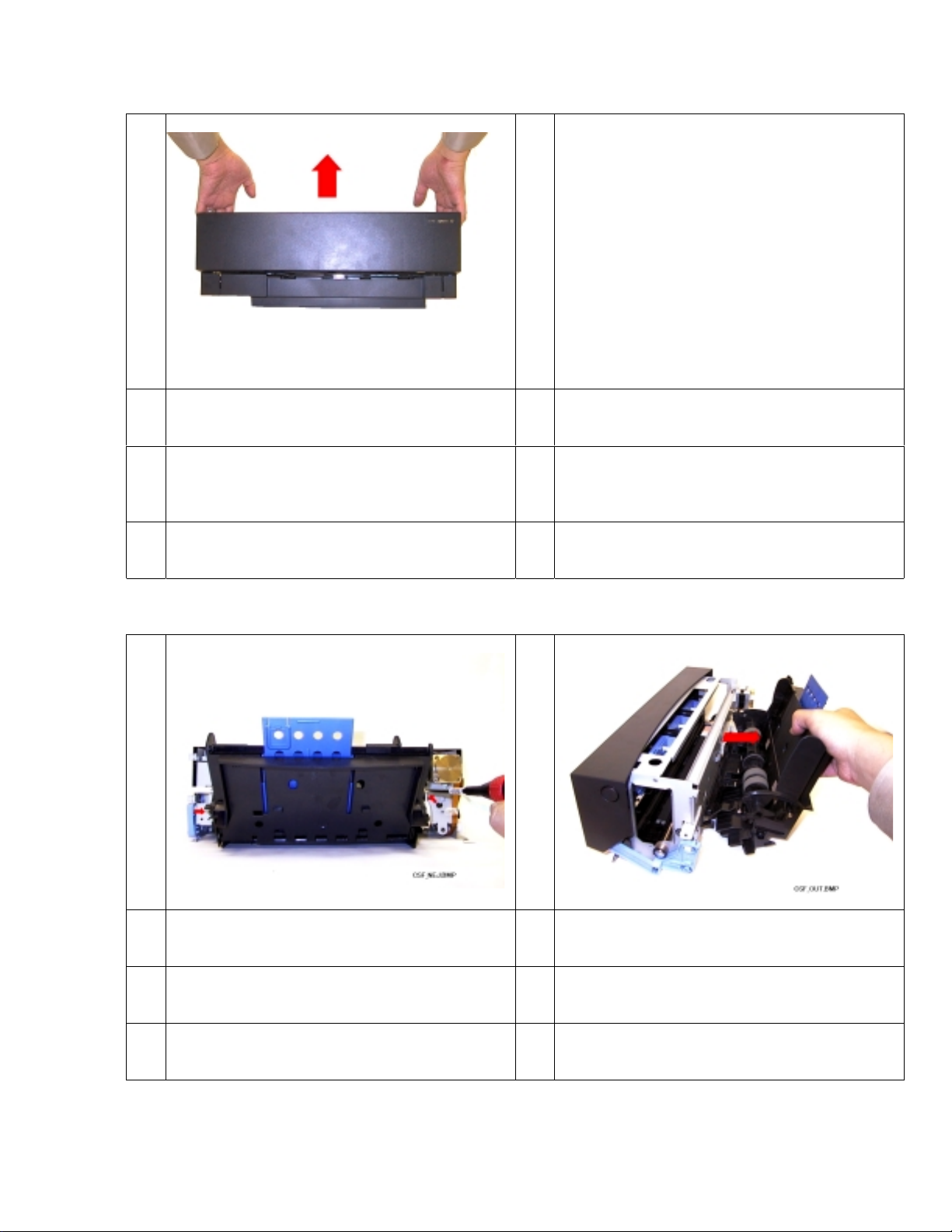

2.1 Detaching of Cases

1

emove the screw (M3*L10P) in the place of

he arrows 1, 2 and 3.

3 4

2

ift the point of Rear Cover with tweezer s in

he direction of the arrow .(2 places

ift up and remove the Rear Cover in the

irection of the arrow.

ull right side of U Cover Assy af t er

Front Cover is opened in the direction of

he arrow 1, and lift up the lower part of U

over Assy in the direction of th e ar r ow 2.

6/71

Page 9

5

I

U

t

f

I

l

m

u

R

t

i

R

t

6

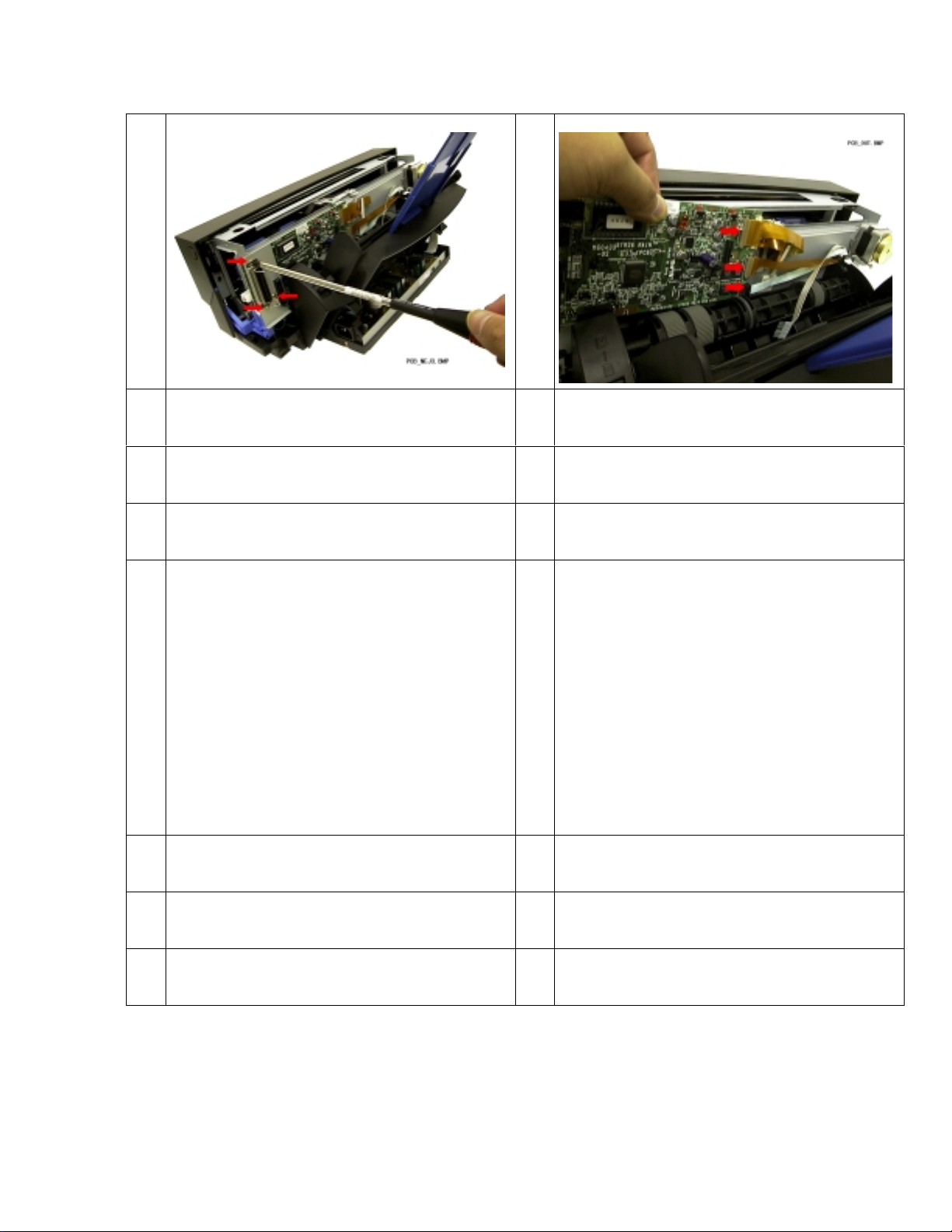

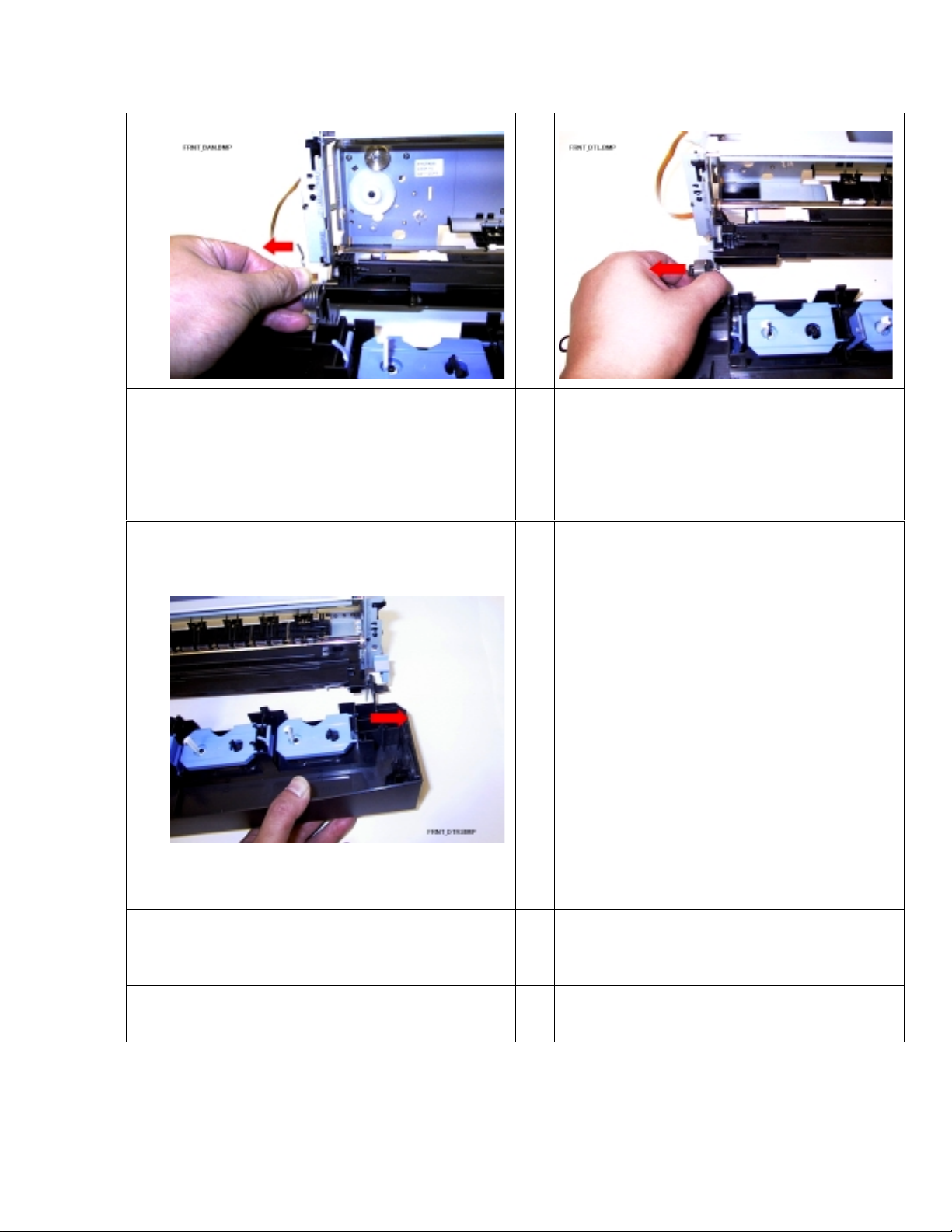

nsert the tweezers in the space between

_Cover Assy and CSF Cover_L, remove

he CSF Cover_L. Next, pull out FAN cable

rom the connector of pow er supply.

2.2 Detaching of Main_PCB

1

nsert the tweezers through the opening of

ower part of left side of U_Cover Assy and

ove tweezers in the direction of the arrow

ntil clicks. And remove U_Cover Assy.

2

emove the DC_Tape from the connect or on

he Main_PCB side and the screw-driver is

nserted from the hole shown in Figure.

emove the screw (M3*L6TP) in the place of

he arrow.

7/71

Page 10

3

R

3

2

T

f

4

emove the screws(1,2-M3*L12,

-M3*L6BIND) in the place of the arrows 1,

and 3.

ake off the one harness and the t hree FP C’s

rom connectors in the place of t he arrows.

8/71

Page 11

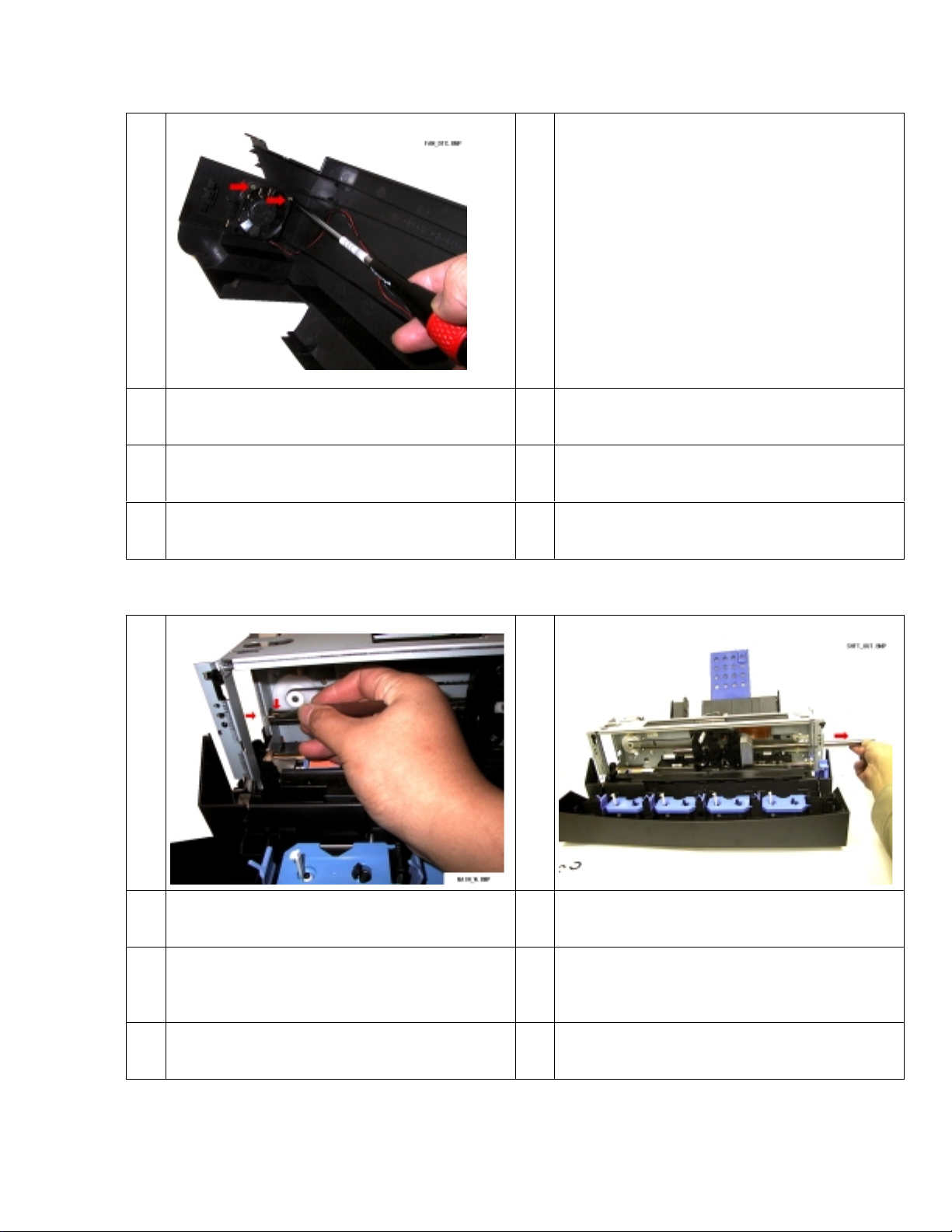

2.3 Detaching of FAN

R

R

t

3.P

t

1

emove the screws in the place of t h e arrows

1 and 2.

.

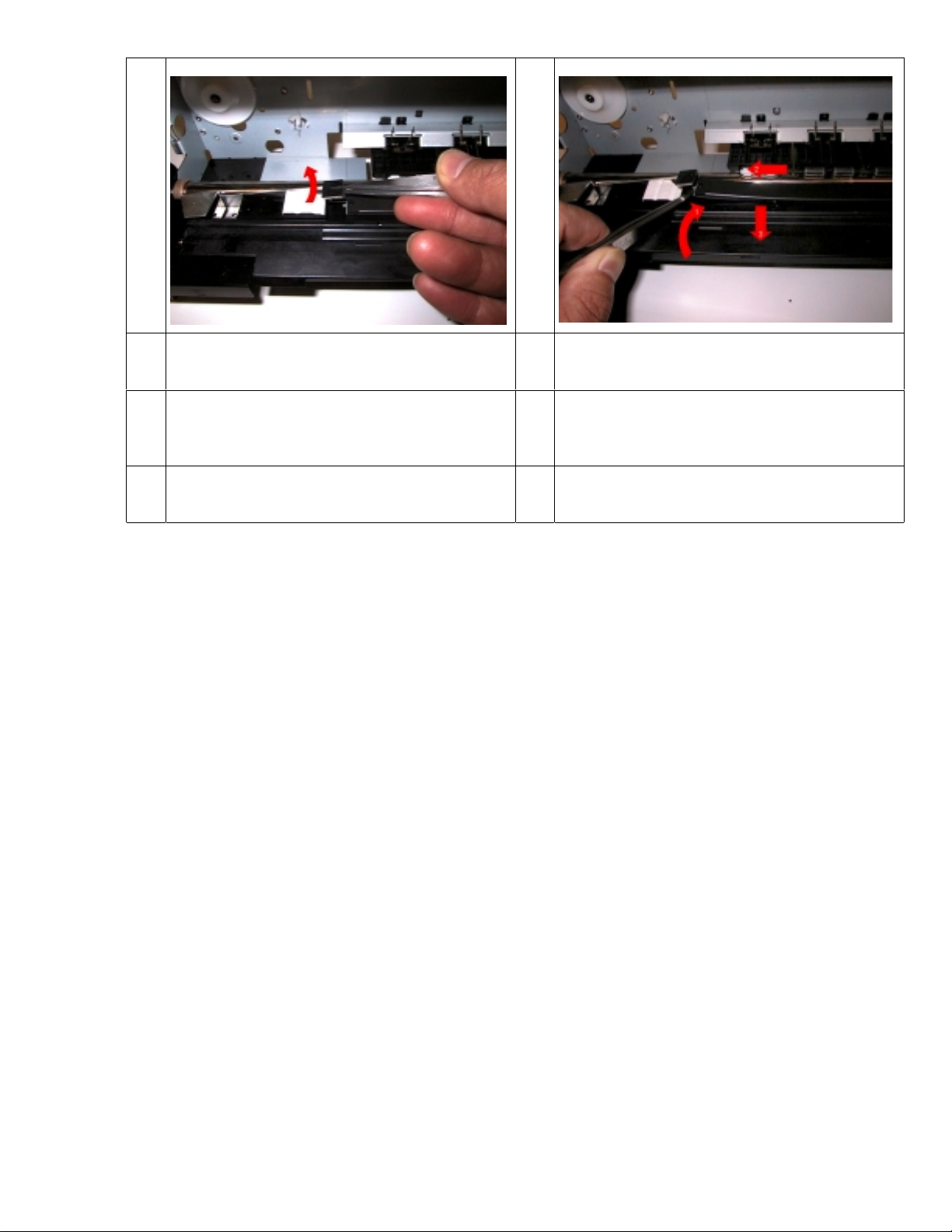

2.4 Detaching of Carriage_Unit

1

emove the Washer (for Main_Shaft) with

weezers in the place of the arr ows 1, 2 and

2

ull out the Main_Shaft in the direction of

he arrow.

9/71

Page 12

3

T

P

r

a

s

L

o

T

d

4

ake off the CR_Belt from Drive_Pulley.

5 6

ift up and pull out the Carriage from inside

f Frame_Unit.

ush the snap in the place of the arrow and

emove the FPC_Holder from Frame_Assy

nd then move the FPC to Carriage_Unit

ide.

ake off the CR_Belt from Carriage in the

irection of the arrow.

10/71

Page 13

2.5 Detaching of Sub_Pulley

R

o

t

S

d

S

r

R

a

R

F

1

emove the Pulley_Base_Shaft in the place

f the arrow with screwdriver. And remove

he Belt_Spring.

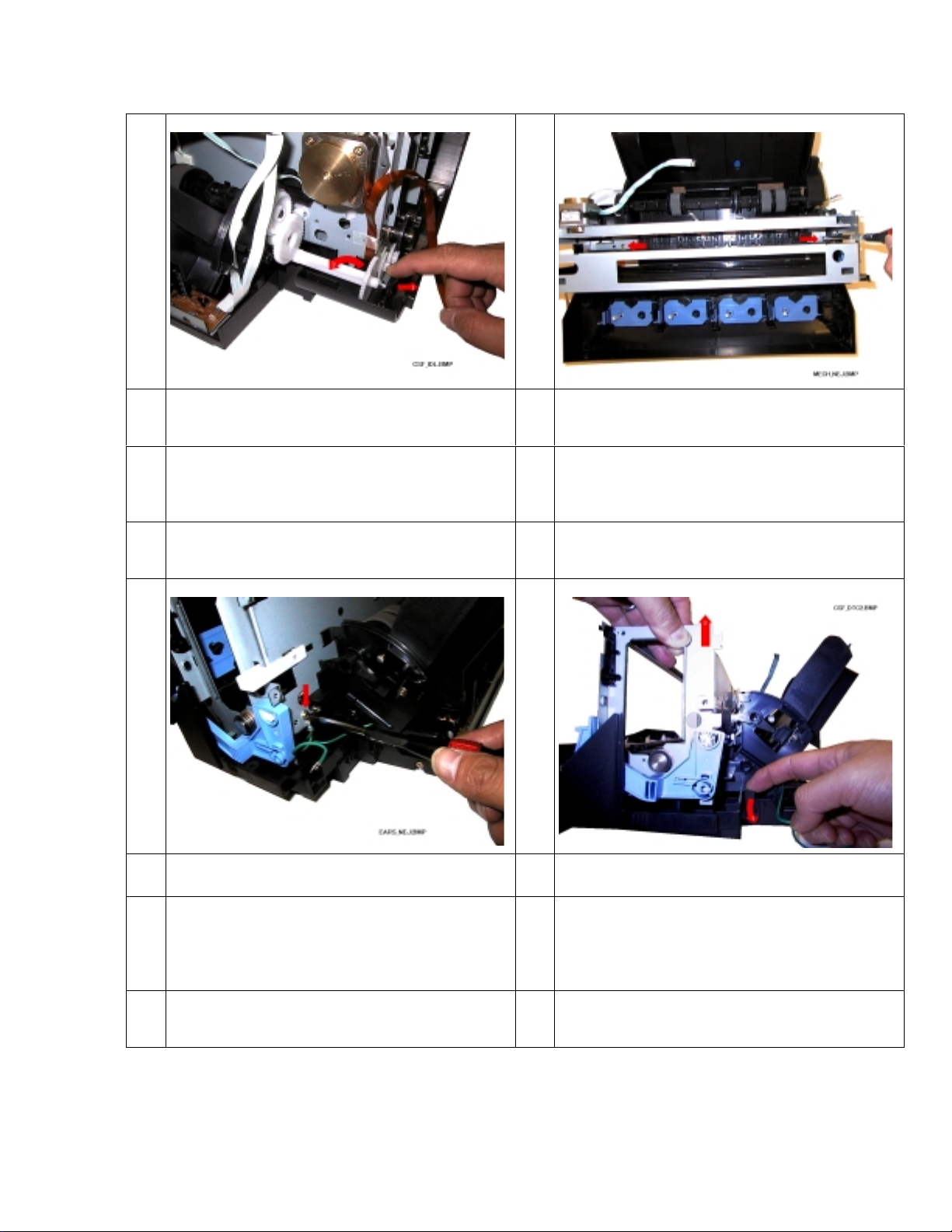

2.6 Detaching of Mechanism

2

pread the points of Pulley_Base in the

irection of arrow 1 and remove the

ub_Pulley to the direction of arrow 2. And

emove the CR_Belt.

1

emove the CSF_Cover_R in the direct ion of

rrow.

2

emove the Three FPC(DC Tape,frame

PC,and CR motor cable).

11/71

Page 14

3

P

d

C

2.R

t

R

o

P

d

M

a

D

4

ull the point of L_Cover_Assy in the

irection of the arrow 1 and remove the

SF_Idle_Gear in the direction of the arrow

5 6

emove the screw (M3*L6BIN D) in the place

f the arrow.

emove the screws (M3*L 10P) in the plac e of

he arrows 1 and 2.

ull the point of L_Cover_Assy in the

irection of the arrow 1 and lift up the

echanism a little in the direction of the

rrow 2.

o same procedur e on each side.

12/71

Page 15

7

L

r

R

t

R

a

ift up in the direction of the arrows and

emove the Mechanism.

2.7 Detaching of CSF_Unit

1

emove the screws (M3*L 6TP) in the plac e of

he arrows 1 and 2.

2

emove the CSF_Unit in the direction of the

rrow.

13/71

Page 16

2.8 Detaching of Front_Cover_Unit

R

F

R

f

a

R

f

a

1

emove the Damper_Spring from

rame_Unit in the direction of the arrow.

2

emove the left side of Front_Cover_Unit

rom Frame_Unit in the direction of the

rrow.

3

emove the right side of Front_Cover_Unit

rom Frame_Unit in the direction of the

rrow.

14/71

Page 17

2.9 Detaching of Veil_Unit

P

o

(

)

P

i

V

u

R

F

R

w

1

lace the leg of the Veil_Spring in the hooks

n the Veil_Unit.

To prevent the Spring being lost.

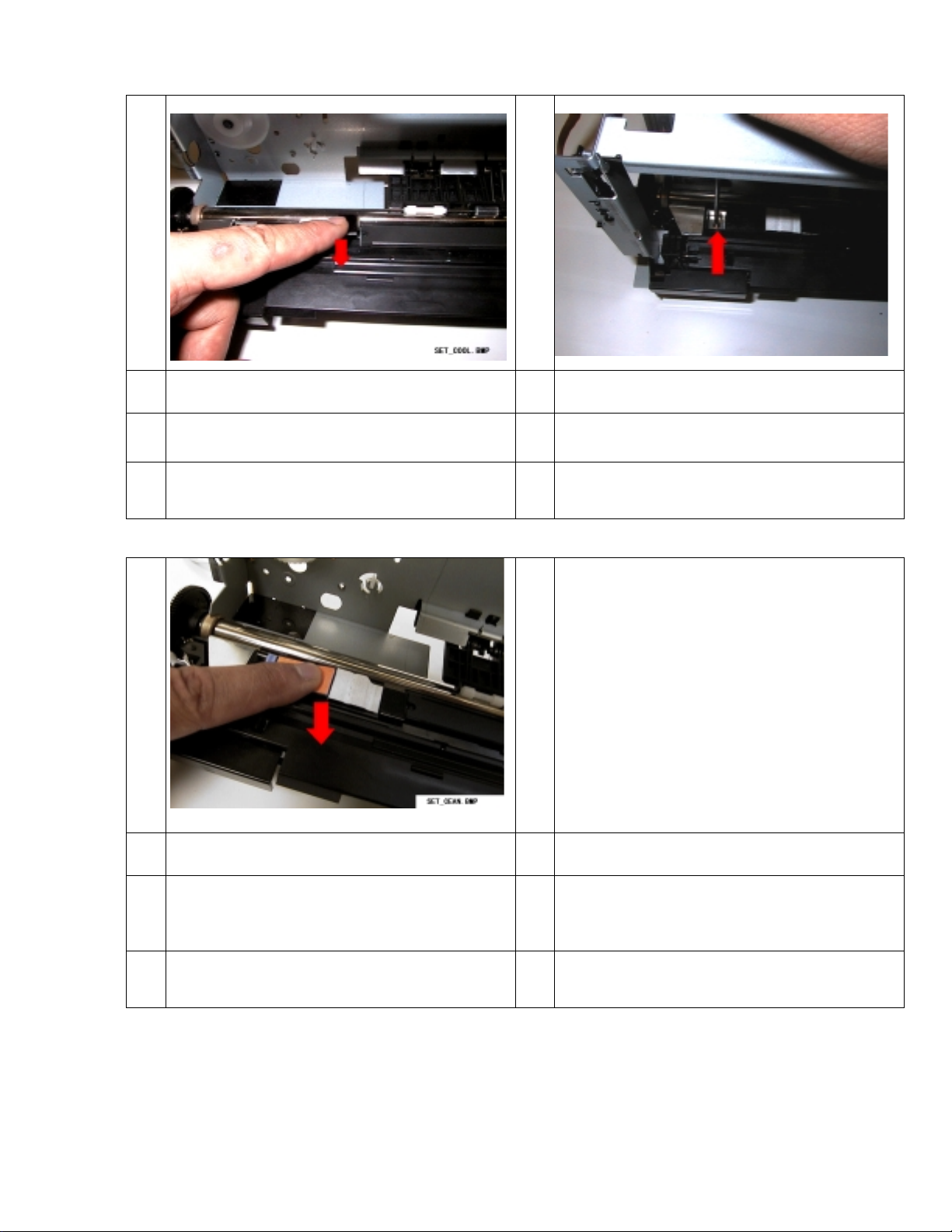

2.10 Detaching of Platen

2

ush the projection in the hole of Veil_Unit

n the direction of arrow 1 and shift

eil_Unit in the direction of arrow 2. And lift

p and remove it in the direct ion of arrow 3.

1

emove Cleaning-Pad_Dye-Sub from

rame_Unit in the direction of the arrow.

2

emove the screw in the place of the arrow

ith screwdriver.

15/71

Page 18

3

L

a

L

a

t

d

4

ift up the heat sink in the direction of the

rrow.

ift up the Platen in the direction of the

rrow 1 and shift Platen in the direction of

he arrow 2. And lift up and remove it in the

irection of the arrow 3.

16/71

Page 19

2.11 Detaching of Cleaning_Pad

L

S

T

d

R

p

D

L

d

t

1

ift up and remove the Cleaning_Pad_Dyeub in the direction of the arrow.

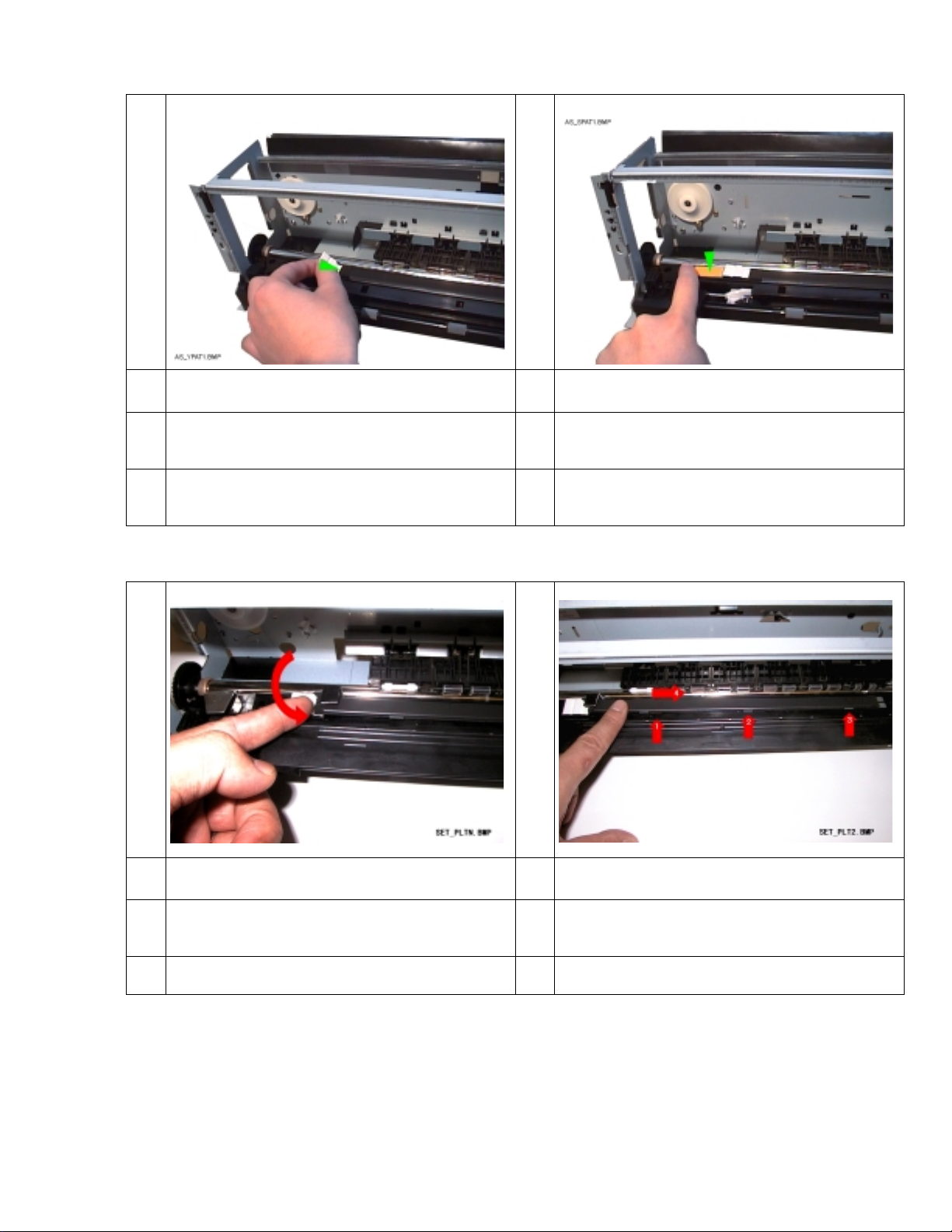

2.12 Detaching of Power_Supply

2

ake and remove the Cleaning_Pad in the

irection of the arrow.

1

emove the screws (1,2-M3*L6BIND) in the

lace of the arr ows 1 and 2. And take off t he

C_Cable in the place of t h e arrow 3.

2

ift up and shift the Power_Supply in the

irection of the arrows 1, 2 and remove it in

he direction of the arrow 3.

17/71

Page 20

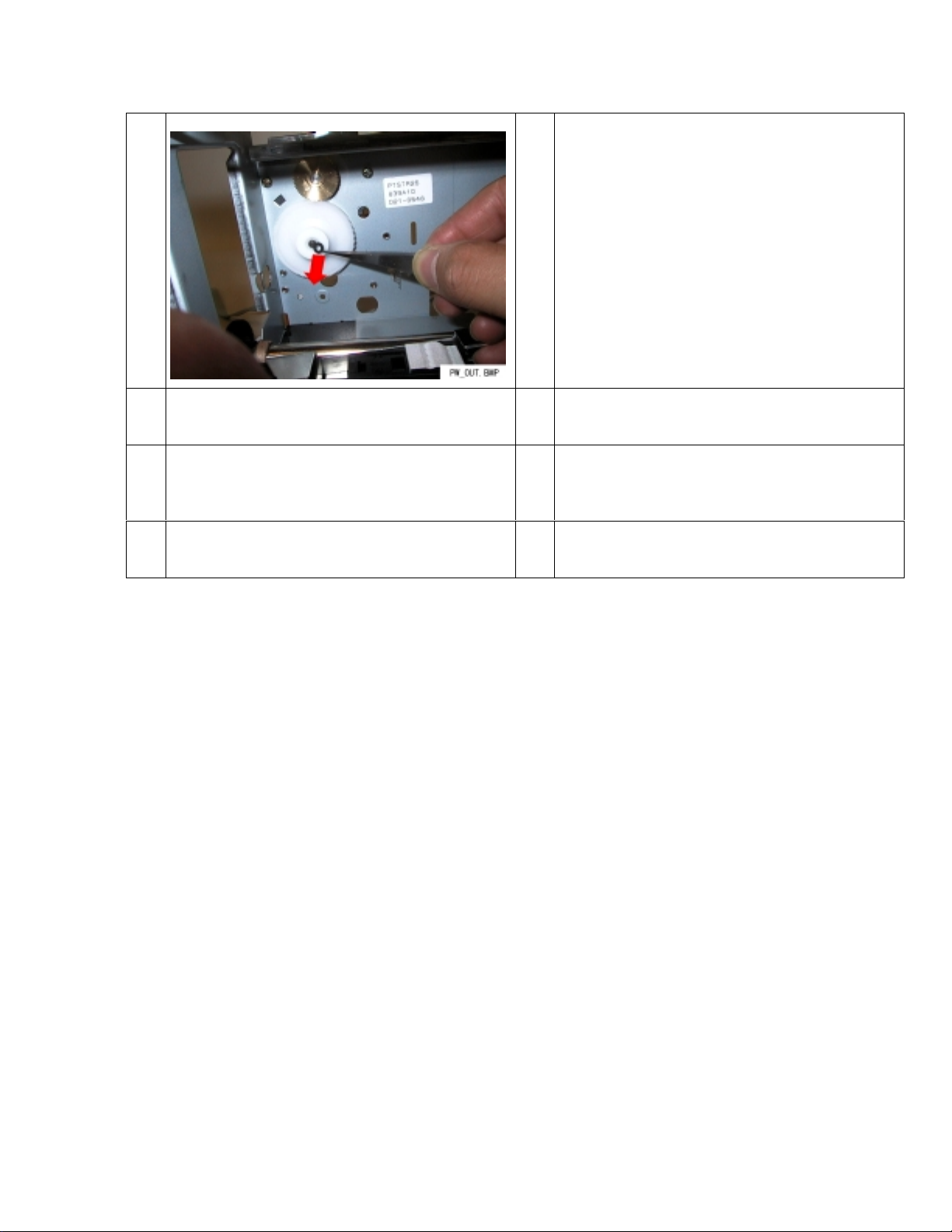

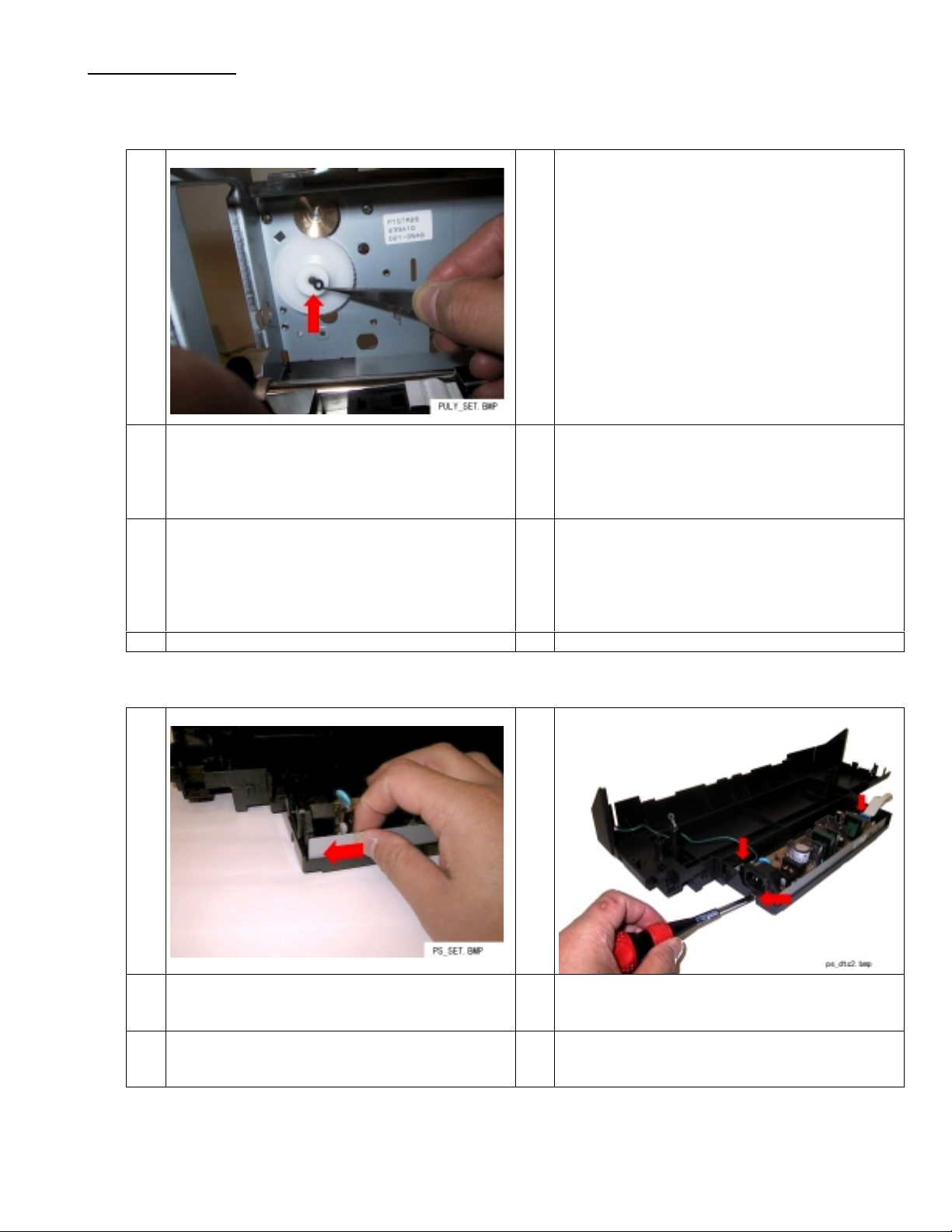

2.13 Detaching of CR_Drive_Pulley

R

P

P

1

emove the CR_Drive_Pulley and

ulley_Flange after removing the Washer (f or

ulley) as shown.

18/71

Page 21

Chapter 3: Assembly

I

t

s

P

d

I

p

D

3.1 Installing of CR_Drive_Pulley

1

nstall the Washer (for pulley) after installing

he CR_Drive_Pulley and Pulley_Flange as

hown.

The removed Washer(for pulley) cannot be

Reused once. Use the new art i cle.

3.2 Installing of Power_Supply

1

2

ut the Power_Supply in and shift it in the

irection of the arrow.

nstall the screws (1,2-M3*L6BIND) in the

lace of the arr ows 1 and 2. And insert t he

C_Cable in the place of t h e arrow 3.

19/71

Page 22

3.3 Installing of Cleaning_pad

S

t

P

t

P

P

N

a

1

tick the Cleaning_Pad in the area shown in

he direction of the arrow.

3.4 Installing of Platen

2

ut and push the Cleaning_Pad_Dye-Sub in

he direction of the arrow until clicks.

1

ut the Platen under the heat sink.

2

ut the Platen under the projection of No.1-

o.3 doing the slide in the direction of the

rrow (No.4).

20/71

Page 23

3

P

a

T

P

d

ush the cooling pad in the direction of the

rrow.

ighten the screw in the place of th e ar r ow.

ush the Cleaning_Pad_Dye-Sub in the

irection of the arrow.

21/71

Page 24

3.5 Installing of Veil_Unit

I

V

I

i

1

nstall the Veil_Spring on left side of the

eil_Unit as shown.

2

nsert the point of right side of the Veil_Unit

n the hole at the place of the arrow.

22/71

Page 25

3

I

i

proj

p

T

V

D

4

nstall the point of the left side of Veil_Unit

n the place of the arrow 1 and install the

ection in the hole of Veil_Unit by

ushing the place of the arr ow 2.

5

ake off this side leg of Veil_Spring from

eil_Unit.

etail after installing.

23/71

Page 26

3.6 Installing of Front_Cover_Unit

I

F

I

F

nstall right side of the Front_Cover_Unit to

rame_Unit.

nstall left side of the Front_Cover_Unit to

rame_Unit.

24/71

Page 27

H

b

I

a

I

a

a

ung the point of Dumper_Spring on the

ehind the Frame_Unit.

3.7 Installing of CSF_Unit

1

nstall the CSF_Unit in the direction of the

rrow.

2

nstall the screw(M3*L6TP) while push down

gainst the CSF_Unit in the place of the

rrow.

25/71

Page 28

3

I

a

a

C

F

C

F

4

nstall the screw(M3*L6TP) while push down

gainst the CSF_Unit in the place of the

rrow.

5

heck no opening between CSF_Unit and

rame_Unit in the direction of arrow.

heck no opening between CSF_Unit and

rame_Unit in the direction of arrow.

26/71

Page 29

3.8 Installing of Mechanism

P

Adj

proj

a

C

a

o

D

1

ut the Mechanism on the L_Cover _Assy.

3 4

2

ust two holes of Frame_Unit and

ections of L_cover_Assy in the place of

rrow.

heck installation point of L_Cover_Assy

nd CSF_Unit in the place of the arrow. Pull

ut the FG_Cable as show n.

o same procedur e on each side.

27/71

Page 30

5

I

t

C

m

t

P

a

t

L

I

s

6

nstall the screws(M3*L10P) in the place of

he arrows 1 and 2.

7 8

lamp the FPC (the upper part)and CR

otor-cable(the lower side) in the place of

he arrow.

ut the CSF_Idle_Gear in the place of the

rrow 1 and push down it in the direct ion of

he arrow 2 and install it into the point of

_Cover_Assy.

nstall the PS_Lever to CSF_Cover_R as

hown.

28/71

Page 31

9

I

P

t

C

a

t

10

nstall the CSF_Cover_R while pushing the

S_Lever in the direction of “A”. Next,hung

he FG_cable on the gate of CSF_Cover_R.

lose the CSF_Cover_R in the place of the

rrow and install the FG_Cable(arrow 1) with

he screws.(M3*L6BIND).

29/71

Page 32

3.9 Installing of Sub_Pulley

I

S

B

I

s

I

S

s

S

t

1

nstall the Pulley_Base to Frame_Unit with

ub_Pulley_Shaft after inserting the

elt_Spring in the place of the arr ow 1.

2

nstall the CR_Belt and Sub_Pulley as

hown.

3 4

nstall Sub_Pulley, Sub_Pulley_Flange and

ub_Pulley_Shaft in the disposition as

hown.

pread the points of Pulley_Base and insert

hese parts.

30/71

Page 33

3.10 Installing of Carriage_Unit

H

t

t

C

i

1

old the CR_Belt while kee ping the teeth to

his side. And into the place of the arrow on

he Carriage.

2

omplete installation of CR_Belt (pushed

nto the iterior)to Carriage as shown.

31/71

Page 34

3

I

I

o

t

I

C

I

p

4

nstall the CR_Belt on the CR_Drive_P ulley.

5 6

nsert the Main_Shaft into Frame_Unit and

arriage in the direction of the ar r ow.

nstall the Carriage on the Frame_ Unit after

pening each Cariage_Stopper in the place of

he arrows.

nstall the Washer(for Main_Shaft) in the

lace of the arrows 1, 2 and 3 with tweezers.

32/71

Page 35

7

M

t

H

a

i

a

P

a

i

I

s

8

ove the FPC behind of the Frame_Unit

hrough the hole of the place of t he arrow.

3.11 Installing of Main_PCB

1

ook the FPC_Holder in the place of the

rrows 1 and 2 on the Frame_Unit and

nstall the snap in the place of the arr ows 3

nd 4 by pushing.

2

ut the Main_PCB in the place as shown

nd install one harnesses and three FPC’s

nto these connectors.

nsert the screwdriver through a hole of

hown.

33/71

Page 36

3

I

a

s

I

M

a

a

I

I

4

nstall the screw(L3*L6TP) in t he place of t he

rrow. Next, two FP C is fixed by clampi ng as

hown in Figure.

nstall the screws(1,2-M3*L12,3-

3*L6BIND) in the place of the arr ows 1 ,2

nd 3 after putting the I/F_Plate in the place

s shown.

nstall the DC_Tape as shown in th e f i gur e.

nstall the DC_Tape as shown in th e f i gur e.

34/71

Page 37

3.13 Installing of Cases

P

F

I

P

u

P

I

s

B

a

1

ut the U_Cover_Assy on as shown with

ront_Cover_Unit opened. Then pull out the

nterface_Lock from U_Co ver_Assy.

2

ush down each side of the U_Cover_Assy

ntil clicks. At this time, put the edge of the

aper_Guide in U_cover_Assy.

3 4

nstall the FAN-Cable and DC_Tape as

hown in the figure.

uilt CSF_cover_L into the direction of the

rrow.

35/71

Page 38

5

I

a

b

I

t

2

3

4

nstall the Rear_Cover in the dir ection of the

rrow. Check that there are no openings

etween CSF_Unit and Rear_C over.

3.14 Lubrication

1

nstall the screw (M3*L10P) in the place of

he arrows 1, 2 and 3.

2

1-Frame(both side of rail):EM60L

-Main_Shaft:EM50L T-6

-Drive_Pulley_Shaft:T-6

-Sub_Pulley_Shaft:EM50L

1,2,3-LF_Idle_Gear’s:EM60L

36/71

Page 39

Chapter 4: Adjustments, Printing test

4.1 Upper an d l ower light and shade adjustments for 60 0 dpi print mode.

When something wrong is found in the print inspection, the following work is done.

1) Connect the printer cable to the printer and turn it on.

2) Start the program of \TOOL\W26_EDIT.EXE.

3) 10. Bank8 1/2 is sel ected with the cursor key.

4) The data of 30 bytes is manually adjusted respectively of Cyan (Fut ure C), Magenta (Future M),

Yellow (Future Y), and Black (Future B) about 600dpi print.

The first numerical value corresponds to one byte of the print head on. The last numerical Value

corresponds at a last one byte. The densit y can be adjusted by adding and subtracting (+10 shade

37/71

Page 40

10 light ) the numerical value every 30 blocks. Adjust the values of the references to the print

result.

5) Press F10 to return ba ck and pr ess F1 to wr ite to EEP_R OM. Press F1 0 and start “22.Q uit“

for finishing

the light and shade adjustments. The print inspection is repeated an d if something wr ong is

found in the

light and shade of the doing print, this work is repeated.

4.2 Upper and lower light and shade adjustments for “Vphoto Print with Vphoto Primer (Future

Primer)” mode.

This needs to use the color scanner EPS ON GT-9500 and some ph oto retouch soft wear(EPSON

SCAN Photo SHOP etc. ). The OS must be Win3.1.

Do following adjustments after f inishing Head voltage adjustments.

(1) Starting \SCANER\PT_100.BAT prints the adjustment pattern.

(2) The print result is read with full color scanner (300dpi).

Store the result of reading in the same directory as \SCANER\PT_100.BAT.

Assume the file name to be 101.BMP always when you store it.

About notes when EPSON SCAN is used

When the data is pr eserved with this software, the number of 01 is automatically added

behind the file

name. Therefore, it should be specified 1.BMP when specifyin g for 101.BMP.

3) \SCANER\CLC_100.BAT is started.

The calculation of the light and shade adjustment is aut omatically begun. The result is

written in EEP-•

ROM.

(4) (1) - (3) is repeated twice.

Refer to the attached paper for setting the scanner. Start \SCANER\W26BKD10.EXE to

return the content

of the light and shade adjustment to an initial value.

4.3 Upper and lower light and shade adjustments for “Vphoto Print with Vphoto Print Film”

mode.

38/71

Page 41

This needs to use the color scanner EPS ON GT-9500 and some ph oto retouch soft wear(EPSON

SCAN Photo SHOP etc. ). The OS must be Win3.1.

Do following adjustments after f inishing Head voltage adjustments.

(1) Starting \SCANER\PT_50.BAT prints the adjustment pattern.

(2) The print result is read with full color scanner (300dpi).

Store the result of reading in the same director y as \SCANER\PT_50.BAT.

Assume the file name to be 101.BMP always when you store it.

About notes when EPSON SCAN is used

When the data is preserved with this software, the number of 01 is automatically added

behind the file

name. Therefore, it should be specified 1.BMP when specifyin g for 101.BMP.

(3) \SCANER\CLC_50.BAT is started.

The calculation of the light and shade adjustment is automatically begun. The result is

written in EEP ROM.

(4) (1) - (3) is repeated twice.

Refer to the attached paper for setti ng t h e scanner .

Start \SCANER\W26BKD50.EXE to return the content of the light and shade adjustment to

an initial

value.

4.4 Upper and lower light and shade adjustments for “Dye-Sublimation Print (Future Dye-Sub

Print)” mode.

This needs to use the color scanner EPS ON GT-9500 and some ph oto retouch soft wear(EPSON

SCAN Photo SHOP etc. ). The OS must be Win3.1.

The OS must be Win3.1.Do following adjustments after finishing Head voltage adjustments.

(1) Starting \SCANER\PT_DSub.BAT prints the adjustment pattern.

(2) The print result is read with full color scanner (300dpi).

Store the result of reading in the same director y as \SCANER\PT_DSub.BAT.

Assume the file name to be 101.BMP always when you store it.

About notes when EPSON SCAN is used

When the data is preserved with this software, the number of 01 is automatically added

behind the file

name. Therefore, it should be specified 1.BMP when specifyin g for 101.BMP.

39/71

Page 42

(3) \SCANER\CLC_DSub.BAT is started.

The calculation of the light and shade adjustment is automatically begun. The result is

written in EEP ROM.

(4) (1) - (3) is repeated twice.

Refer to the attached paper for setti ng t h e scanner .

Start \SCANER\W26BKDSub.EXE to return the content of the light and shade adjustment to

an initial

value.

Attention

Use the undermentioned card ridg e in the up per and lower light and shade

adjustment According to each

mode.

Upper and lower light and shade adjustments for “Vphoto Print with Primer”

mode.

Use card ridge C M Y B VP Finish (Future F ) Primer

Upper and lower light and shade adjustments for “Vphoto Print with

Vphoto Print Film” mode.

Use card ridge C M Y B F

Upper and low er light and shad e adjustments for “Dye-Sublimation Col or

Print” mode.

Use card ridge Dye-S u blimation Cyan(Future Dye-sub C) Dye-

Sublimation Magenta

(Future Dye-su b M)• Dye-Sublimation Overcoat (Future Dye-sub OC)

( Dye-sub M) Dye-Sublimation Overcoat ( Dye-sub OC)

40/71

Page 43

4.5 Printing test

1) Connect the printer cable to the printer and turn it on.

2) Start the program of \STM32\W26.BAT.

3) Supply each cartridge and each paper to the printer and st ar t printing test.

41/71

Page 44

4) Main menu and Cartridge and Paper.

No. TEST Paper Cartridge

1 Test of OHP Film 600dpi OHP C,M,Y,B

2 Test of High Grade Paper 600dpi HGP C,M,Y,B

3 Test of Post Card 600dpi Card C,M,Y,B

4 Test of Dye-Sub Paper Dsub Dye-

SubC,M,Y,OC

5 Test of Foil print position Card B,Gold Foil

6 Test of Foil Card C,M,Y,B

Gold/Silver Foil

7 Test of Vphoto Color with Primer HGP C,M,Y,B,F,Primer

8 Test of Vphoto Color Vphoto C,M,Y,B,F

9 Test of Vphoto Mono Vphoto B,F

11 Test of High Grad e Paper 600dpi HGP C,M,Y,B

12 Adjust of print position --------- ---------------------

---

13 Test of Dye-Sub Color

Paper(Short)

14 Adjust of Dye-Sub Color Dsub Dye 15 Adjust of (only white line

and black line check)

16 Check Printer tenperature ---------- ------- ------------- 17 Adjust of Vphoto Color Vphoto C,M,Y,B,F

18 Adjust of Vphoto Mono Vphoto C,M,Y,B,F

19 Check ---------- ---------------------

20 Adjust of Vphoto Color LF Vphoto C,M,Y,B,F

21 Adjust of Dye-Sub Color LF -1 --------- ---------------------

22 Adjust of Dye-Sub Color LF +1 ---------- -------------------- 23 Test of Dye-Sub Color Paper(Full) Dsub Dye 27 Test of Vphoto Card Vcard C,M,Y,B,F

29 Check Vphoto C &M Vphoto C,M,Y,B,F

Dsub Dye-

SubC,M,Y,OC

SubC,M,Y,OC

OHP C,M,Y,B

---

---

---

---

SubC,M,Y,OC

Paper types

OHP:OHP Film Dsub: Dye-Sub Paper

HGP: High Grade Paper Vphoto: Vphoto Print Film

Card: Post Card Vcard: Vphoto Card

••

5) Check the working of FAN after taking off and inserting each harness once while printing by

printer driver .

42/71

Page 45

43/71

Page 46

4.6 Explanation of usage of each print mode

No.1-No.9 No.1-No.9 is a usual shipment inspection and an adjustment pattern.

However, No. ,5 is not usually used.

No.11 It is an insp ection pattern of the 600dpi Print of Hi gh Grade Paper.

This does not contain the cartridge change t est.

No.12 It is positioning of the print beginning. It is only input of the numerical value.

No.13 It is a shortening pattern of the Dye-Sub Color inspection. This is used to confirm

something wrong.

No.14 This is used to correct something wrong with the Dye-Sub Color print.

The repair of upper and lower light and shade and a black line and the white line can be

corrected.

No.15 In this item , a w hite line and a black line can be adjusted by t h e OHP print.

However, the numerical value can be only input in this it em.

Please confirm the result of the adjustment (clause of No.1).

No.16 Confirm a tion of temperature of printer

An environmental temperature and the t emperature of the head can be confirmed.

This item is not usually used.

No.17 It is a manual upper and lower light and shade adjustment of th e Vphoto Color.

Please confirm the state of the print r esult and select the best adjustment item.

No.18 It is a manual upper and lower light and shade adjustment of th e Vphoto Mono.

Please confirm the state of the print r esult and select the best adjustment item.

No.19 It is for the confirmat ion of fan operation. The fan works when this it em is selected.

The operation stops to come off this item.

44/71

Page 47

No.20 It is LF adjustment of the Vphoto Color. Please ch oose the best item seeing the print result.

No.21 It is LF adjustment of the Dye-Sub color print. The pa per feed ste p doe s aut omati cally w hen

this

item is Selected and –1( contract)is done. However, the numerical value is only input in this

item.

Please confirm the result of the adjustment (clause of No.4).

No.22 It is LF adjustment of the Dye-Sub color print. The pa per feed ste p doe s aut omati cally w hen

this

item is Selected and +1(extend) is done. However, the numerical value is only input in this

item.

Please confirm the result of th e adjustment (clause of No.4).

No.23 It is a A4 full pattern of the Dye-Sub Color inspection. This is not usually used.

No.27 It is a postcard inspection pattern of the Vphoto Color. This is not usually used.

No.29 Cyan and magenta of the Vphoto color are printed dividing. When light and shade is

adjusted,

each state can be confirmed. It is convenient to judge the adjustment method.

45/71

Page 48

4.7 Method of adjusting light and shade without using scanner.

Or, the method of adjusting the manual when light and shade cannot be adjusted with the

scanner.

(1) Connect the printer cable to the printer and turn it on.

(2) Start the program of \TOOL\W26_EDIT. EXE.

The light and shade adjustment data of each print mode is stored in an under mentioned item.

If you need the manual adjustment, the adju stment be comes po ssible by r ewrit ing these num er ical

values.

10.Bank8 ½ PPC C/PP C M/PPC Y/PPC K

The 600dpi light and shade adjustment data

8.Bank7[1/2] • SUBLIMATE C/ SUBLIMA TE M/ SUBLIMATE Y

Dye-Sub Color prints light and shade adjustment data

VARY 100co C/ VARY 100co M/ VARY 100co Y/ VARY 100co K

Vphoto Color prints with Vphoto Print Film light and shade adjustment data

VATY50mo

Vphoto Mono prints with Vphoto Print Film light and shade adjustment data

8.Bank7[2/2] UP+VARYco C/ UP+VARYco M/ UP+VARYco Y/ UP+VARYco K/

Vphoto Color prints with Primer light and shade adjustment data

46/71

Page 49

UP+VATYmo

Vphoto Mono prints with Primer light and shade adjustment data

47/71

Page 50

Chapter 5: Maintenance

5.1 Cleaning

5.1.1 Cleaning of exterior

Use a soft cloth moistened with alcohol or watered neutrality clean ser (if necessary) to clean the exterior .

Do not use any other chemicals (s uch as t h inner ) as these may damage the plastic.

5.1.2 Cleaning of inside

Use a vacuum cleaner (if necessary) t o r emov e dust.

5.1.3 Cleaning of Print_Head

1) Turn off the power. Remove the power cord from the power inlet.

2) Open the Front_Cover_Unit and wipe the Print_Head lightly with a cotton swab moistened with alcohol

(if necessary).

3) Do a print test and check the print quality.

Caution: Do not touch the sur f ace of Platen with the alcohol cotton swab.

47/71

Page 51

5.1.4 Cleaning of Platen

1) Turn off the power. Remove the power cord from the power inlet.

2) Open the Front_Cover_Unit.

3) Affix cellophane tapes to the Platen and rub it lightly.

4) Remove the tape.

5) Repeated the 3 and 4 until becomes the Platen is cl ean.

6) Do a print test and check the print quality.

Caution: Do not place tape on the Cleaning_Pad be cause the pad may peel off and cause the printer to

malfunction.

48/71

Page 52

5.1.5 Cleaning of CSF_Unit

1) Turn off the power. Remove the power cord from the power inlet.

2) Remove the U_Cover_Assy.

3) Wipe the rubber roller with a damp cotton swab.

4) Install the U_Cover_Assy.

5) Check the paper feeding operati on .

Caution: Do not use an exces sively wet cotton swab. The water may dr op on ot her components causing

damage to the printer.

49/71

Page 53

Chapter 6: Trouble shooting

1. Power

Problem Cause Action

Connector is not prop er ly inserted. Check CN1 (Main_PCB).

Check the connector of Power_Supply

DC_Cable is broken off . Replace the DC_Cable.

No Power

Power is turned on but

Carriage does not

function.

Blown Fuse. Replace the Power_Supply and adjust

head voltage.

No DC power. Replace the Power_Supply and adjust

head voltage.

Main_PCB is missing Replace the Main_PCB and return the

EEP_ROM.

Connector is not prop erly inserted. Check CN5, 6 (Main_PCB).

FPC is br oken off. Replace mechanical unit and set each

adjustment.

Main_PCB is missing Replace the Main_PCB and return the

EEP_ROM.

Curl_Motor does not move. Check moving or replace Frame_Unit

and set each adjustment.

UD_Motor does not move.

Bad RC_Sensor.

Replace the Carriage_Unit and set

each adjustment.

50/71

Page 54

2. Pri n ting

Problem Cause Action

Connector is not prop er ly inserted. Check CN4 (Main_PCB).

FPC is broken off. Replace the Carriage_Unit and set

Mechanism moves but

cannot print.

Incorrect head voltage. Check and adjust head volt age.

Main_PCB is missing Replace the Main_PCB and return the

Connector is not prop er ly inserted. Check CN4 (Main_PCB).

each adjustment.

EEP_ROM.

Upper and lower light

and shade.

Vertical constant

stripes.

Inconstant stripe.

Missing dot. Bad Head. Replace the Carriage_Unit and set

Broken ribbon

FPC is broken off. Replace the Carriage_Unit and set

each adjustment.

Miss adjustment. Adjustment of Light and shade.

No oil on the Main_Shaft.

No oil on the Frame_Unit.

CR_Drive_Pulley is missing. Replace the CR_Drive_Pulley.

Some alien substance on the Pl at en. Cleaning or replacing of Platen.

Some alien substance on the Frame

rail.

Connector is not prop er ly inserted. Check CN7, 8(Main_PCB).

FPC is br oken off. Replace mechanical unit and set each

Lubrication

Replace the Frame_Unit and set each

adjustment.

each adjustment.

adjustment.

51/71

Page 55

3. Paper f eed

Problem Cause Action

Veil_Unit is not properly installed. Check or replace the Veil_Unit.

Paper jam

Does not feed paper

4. Cartridge Change

Problem Cause Action

Cartridge change error.

CSF_Unit is not properly installed. Check or replace the CSF_Unit.

Frame_Unit is damaged. Replace Frame_Unit or CSF_Unit and

set each adjustment.

Connector is not prop er ly inserted. Check CN5 (Main_PCB).

Bad PE_Lever or LF_Sensor Replace the Frame_Unit and set each

adjustment.

Bad CSF_Sensor or PE_Sensor Replace the Main_ PCB and return the

EEP_ROM.

Bad Carriage_Uni t.

Detached Cassette_Lever

Cassette_Carrier position

Replace the Carriage_Unit and set

each adjustment.

5. Paper curl correction

Paper curl correction

does not work

properly.

5. Other

Front_Cover opens too

quickly.

Front_cover_Unit is not properly

installed.

Veil_Unit is not properly installed. Check or replace the Veil_Unit.

Dumper_Spring is not properly

installed.

Check or replace the

Front_Cover_Unit.

Adjust the spring.

52/71

Page 56

Chapter 7 Parts List

Illustration

Part’s Number Part’s Name

M03274 Platen 1 25 3

1 M40072 Cleaning_Pad_Dye-Sub 1 25 3

2 M40087 Cleaning_Pad 1 25 3

•••••

Qty

Min Lot LT

1 M10193 CR Drive_Pulley 1 25 3

2 M10177 Pulley_Flange 1 25 3

3 PW0250002 Washer(for Pulley) 1 1,000 3

DM01165 Carriage_Unit

Data File(Floppy Disk)

light and shade Data

middle press Data

head voltage Data

130 10

EM2652C.DOC 53/71

Page 57

Illustration

Part’s Number Part’s Name

1 M06701 Main_Shaft 1 25 3

2 PW1100002 Washer(for Main_Shaft) 3 1,000 3

DM01158 Veil Unit 1 25 10

M31608 Veil Spring 1 50 3

Qty

Min Lot LT

DM01170 Front_Cover_Unit

• (with Damper spring)

1 DM01146 CSF_Unit 1 25 6

125 6

EM2652C.DOC 54/71

Page 58

Illustration

Part’s Number Part’s Name

M05354A Paper_Holder_Assy 1 25 3

1 M05356 Holder_Base 1 25 3

2 M05355 Paper_Holder 1 25 3

3 M05354 Card_Stopper 1 25 3

TM26A03BX Main_PCB 1 25 10

M73051 Power_Supply 1 25 10

Qty

Min Lot LT

1 M66154 DC Tape 1 25 6

2 DQC10034A0 Ferite Core 1 25 3

3 M68003 Binder 1 25 3

4 PEB01025AA Cramp 1 25 3

EM2652C.DOC 55/71

Page 59

Illustration

Part’s Number Part’s Name

DM01154 Frame_Unit

Data File(Floppy Disk)

LF Adjustment Data

1 M06648 Sub_Pulley_Shaft 1 25 3

2 M10181 Sub_Pulley 1 25 3

3 M10180 Sub_Pulley_Frange 1 25 3

4 M31612 Belt_Spring 1 25 3

5 M07399 Pulley_Base 1 25 3

6 M06642 Pulley_Base_Shaft 1 25 3

Qty

110 10

Min Lot LT

M02412A L_Cover_Assy 1 10 3

EM2652C.DOC 56/71

Page 60

Illustration

Part’s Number Part’s Name

M02417 Rear_Cover 1 10 3

1 M02418 CSF_Cover_L 1 50 3

2 M02414 CSF_Cover_R 1 50 3

3 M13286 PS_Lever 1 15 3

M02453A U_Cover_Assy 1 10 6

Qty

Min Lot LT

M11499 CSF_Idle_Gear 1 25 3

M61004 FAN 1 25 3

EM2652C.DOC 57/71

Page 61

Illustration

Part’s Number Part’s Name

1 S01300100 M3*L12 S c rew 2 5,000 3

2 S03300002 M3*L6BIND Screw 4 4,000 3

3 S95300011 M3*L6TP Screw 3 4,000 3

4 S93300004 M3*L10P Screw 5 4,000 3

M66153 FG_Cable_2 1 25 8

M07388 I/F_Plate 1 25 3

1 M92717 CR_Stopper 1 25 3

Qty

Min Lot LT

2 M92676 CarriagePackingMaterial 1 50 3

M92668A Packing_Unit 1 25 3

M92726A Cushion Assy 1 25 3

EM2652C.DOC 58/71

Page 62

Illustration

Reference Material

Grease

Part’s Number Part’s Name

M92611 Packing Box 1 25 3

Manufacture Dow Corning

Product Name Moricoat EM60L

Manufacture Dow Corning

Product Name Moricoat EM50L

Qty

Min Lot LT

Oil

Manufacture Kanto Chemical Industry

Product Name Froil T-6

EM2652C.DOC 59/71

Page 63

Chapter 8 Exchang i n g parts

Refer to Chapter 2 and Ch apter 3 for t he exchange proc edures of parts. Inspect and adj ust un der menti oned

content after exchanging parts.

Exchange Parts Head voltage

adjustment

Platen - - X OOXOXOOOO

CR Drive Pulley - - - ---O----Carriage Unit O O O OOXOXOOOO

Veil Unit - - - OOXOXOOOO

Front Cover Unit - - - -O------CSF Unit - - - OOXOXOOOO

Main PCB(return EEP) O X X OOXOXOOOO

Power Supply Unit O - X OOXOXOOOO

Frame Unit - O X OOXOXOOOO

L Cover Assy - - - OOXOXOOOO

Paper feed(LF)

/middle press

Install

Light and

Shade

Adjustment

Print test menu No.

123456789

- : Don’t care

O : Do Test or Adjustment

X : Do if it is necessary.

60/71

Page 64

8.1 Various adjustment met h ods when parts are exchanged

8.1.1 Carriage_Unit

When the carriage unit is exchanged, the following adjustments are necessary.

Input of the light and shade adjustment data

Voltage adjustment of power supply unit

Voltage adjustment of MAIN-PCB

Please do the following procedures after exchanging the carriage unit.

(1) Please install a special connector at a MAIN-PCB and the voltag e t est er.

(2) Please connect the comput er and the printer.

Please start special software. [\TOOL\W26TOOL.BAT]

• (3) Wr ite the content of the floppy disk ap pended to a new carriage unit in the pr inter.

Please set the floppy disk in the computer and select menu number 3.

Please work according to the display. The number is described on the flop py disk.

61/71

Page 65

(4) Please select menus number 5 be cause the voltage is adjusted.

(5) Adjustment of normal voltage

Please adjust the voltage of the power supply to the voltage di splayed on the screen.

(6) Adjustment of Dye-Sub voltage

Please adjust the power supply with the voltage of main PCB within the range of the voltage that the

screen

was displayed.

!(6)

62/71

Page 66

(7) Please input the value which the volt age tester indicates because it is displayed on the screen as "In put

HD-Voltage [1]". This display exists to [1]-[5]. *Voltage tester is PCB-Voltage

(8) HD-Voltage[DSub]

HD-Voltage[DSubOP1]

HD-Voltage[DSubOP2]

HD-Voltage[VD50cps]

HD-Voltage[VDOP4]

Each above-mentioned voltage is displayed on the screen.

Please confirm be the same as the value, which t he voltage tester indicates.

(9) Please do necessary adjust and the pr int tests.

!(8)

63/71

Page 67

8.1.2 Power supply

(1) Please install a special connector at a MAIN-PCB and the voltag e t est er.

(2) Do clause (4) - (9) in clause 8.1.1 aft er exchanging the power supply.

8.1.3 MAIN-PCB

When the MAIN-PCB is exchanged, the f ollowing adjustments are necessary.

Replacement of various the data

Voltage adjustment of power supply unit

Voltage adjustment of MAIN-PCB

8.1.3.1 If the error lamp does not bli n k

(1) Please connect the comput er and the printer.

Please start special software. [\TOOL\W26TOOL.BAT]

(2) The data of EEP-ROM is read from old PCB to the computer.

Please set the floppy disk in the com p uter and select menu 1.

Please work according to the display. Please inp ut the arbitrary number.

(3) Please exchanging MAIN-PCB

(4) Please connect the comput er and the printer.

Please start special softwar e. [ W 26TOOL.BAT ]

64/71

Page 68

(5) The content of former data is written in new MAIN-PCB.

Please set the floppy disk in the computer and select menu number 2.

Please work according to the display. Please Input the same number used in (2).

(6) It is necessary to adjust the voltage. Please do the same w ork as the power supply exchange of cla use

8.1.2.

(9) Please do necessary adjust and the pr int tests.

8.1.3.2 When t he error always occur s

(1) The data cannot be r eplaced.

Please install at NEW-MAIN-PCB detaching EEP-ROM from former MAIN-PCB.

(2) It is necessary to adjust the voltage. Please do the same w ork as the power supply exchange of cla use

8.1.2.

(3) Please do necessary adjust and the pr int tests.

8.1.4 Frame_Unit

(1) Please connect the comput er and the printer.

Please start special softwar e. [\TO OL W 26LFADJ.BAT ]

65/71

Page 69

Explanation of usage of each menu

No.1 After wri ting LF parameter , test printing i n 600dpi mode.

No.5 Test printing in 600dpi mode.

No.6 Widen 1 step line feed, and test printing in 600dpi mode.

No.7 Shorten 1 step line feed, and test printing in 600dpi mode.

(2) Write the content of the f l oppy disk appended to a new Frame_U nit in the printer.

Please set the floppy disk in the computer and select menu number 1.

Please work according to the display. Th e n umber is describe d on the floppy disk.

And test printing at the last.

(3) Please confirm the state of t h e t est print result and select the best adjust ment item (menu No6, 7).

(4) Please do necessary adjust and t h e print tests.

66/71

Page 70

67/71

Page 71

Chapter 9: Software

9.1 Content of software

The following content is included in appended CD.

Empty capacity of the hard disk is a bo ut 500 MB necessary.

Please cancel Read_Only attribute, af t er copying these data (\STM32,\SCANR,\TOOL) to C drive.

(1) \STM32

Print inspection pattern for maintenance

Edit software of EEP-ROM [W26_edit.exe]

Please install this data at C drive.

(2) \SCANER

Software, which relates to scanner for upper and lower light and shade adjustment.

The operating system must use “Win3.1".

Please install this data at C drive.

(3) \TOOL

Software for maintenance• W26TOOL.BAT•

Software of EEP-ROM is Read and Write•

Software of HD-Voltage adjustment

Software for LF Parameter setup W26LFADJ.BAT

Please install this data at C drive.

(4) \MANU_BMP

It is the bit map data used when the maintenance manual is made.

(5) \PART_BMP

It is the bit map data used when the Part-List is made.

68/71

Page 72

(6) \PRN_DATA

It is the print data of this book. “LP1" It is possible to print with DP-5000 with a tool.

[Example] lp1 file-name. PRN

(7) \DOC

These sentences are described with Microsoft Word“Word97".

69/71

Page 73

9.2 About the range of reading of the data when upper and lower light and shade is adjusted

9.2.1 Upper and l ower light and shad e adjustments for “Vphoto Print with Primer” mode.

Upper and lower light and shade adjustments for “Vphoto Print with Vphoto Print Film” mode.

about

(2inch)

Range of reading

X=Read the width of about 2inches in the vicinity of t h e cent er w i t h in the r ange of t h e pr int.

Y=Read the entire pattern.

9.2.2 Upper and lower light and shad e adjustments for “Dye-Sub Print ” mode.

70/71

Page 74

Range of reading

X=600

Y=2049

71/71

Loading...

Loading...