Page 1

MICROLINE

390/391 TURBO

Printer Handbook

Page 2

Every effort has been made to ensure that the information in this document is complete, accurate and up-to-date. OKI assumes no responsibility for the results of errors

beyond its control. OKI also cannot guarantee that changes in software and equipment made by other manufacturers, and referred to in this handbook, will not affect

the applicability of the information in this manual. Mention of software products manufactured by other companies does not necessarily constitute endorsement by OKI.

OKI and MICROLINE are registered trademarks of OKI Electric Industry Company,

Ltd..

IBM and PC are registered trademarks of International Business Machines Corporation.

Epson is a registered trademark of Seiko Epson Corp. Lotus and 1-2-3 are registered

trademarks of Lotus Development Corporation. Microsoft and MS-DOS are registered trademarks and Windows is a trademark of Microsoft Corporation.

WordPerfect is a registered trademark of WordPerfect Corporation.

Page 3

Important Safety Instructions

Your OKI printer has been carefully designed to give you years of safe, reliable performance. As with all electrical equipment, however, there are a few basic precautions you should take to avoid hurting yourself or damaging the unit:

• Read the setup and operation instructions in this manual carefully. Be sure to

save it for future reference.

• Read and follow all warning and instruction labels on the printer itself.

• Unplug the printer before you clean it. Use only a damp cloth; do not use liquid

or aerosol cleaners.

• Place your printer on a firm, solid surface. If you put it on something unsteady,

it might fall and be damaged; if you place it on a soft surface, such as a rug, sofa,

or bed, the vents may be blocked, causing it to overheat.

• To protect your printer from overheating, make sure no openings on the printer

are blocked. Don’t put the printer on or near a heat source, such as a radiator or

heat register. If you put the printer in any kind of enclosure, make sure it is well

ventilated.

• Do not put anything into the ventilation slots on the sides of printer, you could

get a shock or cause a fire.

• The printhead can get quite hot when it has been printing for a length of time.

Do not touch the printhead untill it has had a chance to cool off.

• Do not use your printer near water, or spill liquid of any kind into it.

• Be certain that your power source matches the rating listed on the back of the

printer. If you’re not sure, check with your dealer or with your local power company.

• Your printer has a grounded plug as a safety feature, and it will only fit into a

grounded outlet. If you can’t plug it in, chances are you have a non-grounded

ontlet; contact an electrician to have it replaced with a grounded outlet. Do not

use an adapter to defeat the grounding.

• To avoid damaging the power cord, don’t put anything on it or place it where it

will be walked on. If the cord becomes damaged or frayed, replace it immediately.

Page 4

• If you’re using an extension cord or power strip with the printer, make sure that

the total of the amperes required by all the equipment on the extension is less

than the extension’s rating. Generally, the total ratings of all equipment plugged

into any one power line should not exceed 15 amperes. Don’t exceed this unless

you know that the power line your equipment is plugged into has a rating above

15 amperes.

• Aside from the routine maintenance described in this handbook, don’t try to

service the printer yourself; opening the cover may expose you to shocks or

other hazards. Don’t make any adjustments other than those outlined in the

manual – you might cause damage requiring extensive repair work.

• If anything happens that indicates that your printer is not working properly or

has been damaged, unplug it immediately and follow the procedures in Chapter 5. These are some of the things to look for:

The power cord or plug is frayed or damaged.

Liquid has been spilled into the housing, or the printer has been exposed to

water.

The printer has been dropped or its cabinet has been damaged.

The printer doesn’t function normally when you’re following the operating

instructions.

Page 5

ontents

C

Introduction ............................................................................................................. 1

Chapter 1: Installation ........................................................................................... 3

Unpacking ................................................................................................................... 3

Removing Shipping Retainers........................................................................4

Installing Ribbon Cartridge ......................................................................................5

Making Connections ..................................................................................................6

Connection with Computer ............................................................................6

Connection with Power................................................................................... 8

Chapter 2: Loading Paper ...................................................................................... 9

Loading Single-Sheet Paper ....................................................................................11

Loading Rear-Feed Paper ........................................................................................14

Paper Handling......................................................................................................... 19

Tear Feature.....................................................................................................19

Forms Tear-off Feature ..................................................................................20

Paper Park Feature......................................................................................... 20

Switching Paper Paths ...................................................................................21

Chapter 3: Operation ............................................................................................ 23

Control Panel.............................................................................................................23

Print Mode .................................................................................................................25

Indicator Lights .............................................................................................. 25

Buttons ............................................................................................................. 26

Menu Mode ...............................................................................................................30

Sample Menu ..................................................................................................31

Summary of Menu Settings ..........................................................................32

Menu Mode Indicator Lights .......................................................................34

Menu Mode Buttons ......................................................................................34

Resetting Menu to Factory Defaults ............................................................35

Page 6

Performing Basic Tasks ............................................................................................36

Selecting Print Quality ..................................................................................36

Selecting Character Pitch ..............................................................................37

Testing Your printer ....................................................................................... 39

Resetting Top of Form ...................................................................................42

Using Bar codes ..............................................................................................42

Chapter 4: Working with Software ................................................................... 47

Basic Terminology ....................................................................................................47

Printer Commands ......................................................................................... 47

Emulations ...................................................................................................... 48

Printer Drivers ................................................................................................48

Compatible Printer Drivers .......................................................................... 49

Chapter 5: Ploblem Solving, Maintenance, & Service................................... 51

Problem Solving .......................................................................................................51

Maintenance ..............................................................................................................54

Replacing the Ribbon Cartridge...................................................................54

Clearing Paper Jams ......................................................................................57

Cleaning the Housing ....................................................................................61

Accessories ................................................................................................................62

Replacement Parts .......................................................................................... 64

Appendix A: Specifications ................................................................................ 65

Appendix B: Menu Selections ............................................................................ 69

Explanation of Menu Items .....................................................................................72

Appendix C: Commands–Epson Emulation .................................................... 79

Appendix D: Commands–IBM Emulation ...................................................... 97

Page 7

Appendix E: ASCII Character Codes .............................................................. 113

ASCII Character Sets .............................................................................................. 113

Superscript/ Subscript Characters ...................................................................... 117

Appendix F: Interfacing .................................................................................... 119

Pin Assignments for Parallel Interface Signals .................................................. 119

Installing the Serial Interface ................................................................................120

Pin Assignments for Serial Interface Signals ......................................................122

Page 8

ntroduction

I

This Guide is arranged to help you get your new MICROLINE 390 T urbo or 391 Turbo

printer set up and running quickly as well as providing you with more detailed information for future reference. Here’s how it’s organised:

• Chapter 1 (Installation) shows you how to get your printer ready to run and

how to connect it to your computer.

• Chapter 2 (Loading Paper) explains how to load paper for any of the two methods of paper feed.

• Chapter 3 (Operation) describes how to control your printer from the front panel.

It also explains how to change the defaults, how to test your printer and how to

use bar codes.

• Chapter 4 (Working with Software) gives you information on selecting a driver

and installing your printer on popular software packages.

• Chapter 5 (Problem Solving/Maintenance/Service) gives helpful hints on how

to solve common printer problems and how to maintain your printer in tip-top

shape.

• Appendices A through E contain a variety of reference material, including specifications, menu listings, lists of printer programming commands and ASCII

characters.

ML390/391 Turbo Printer Handbook 1

Page 9

2 Introduction

Page 10

hapter 1: Installation

C

This chapter explains how to unpack and install your new printer.

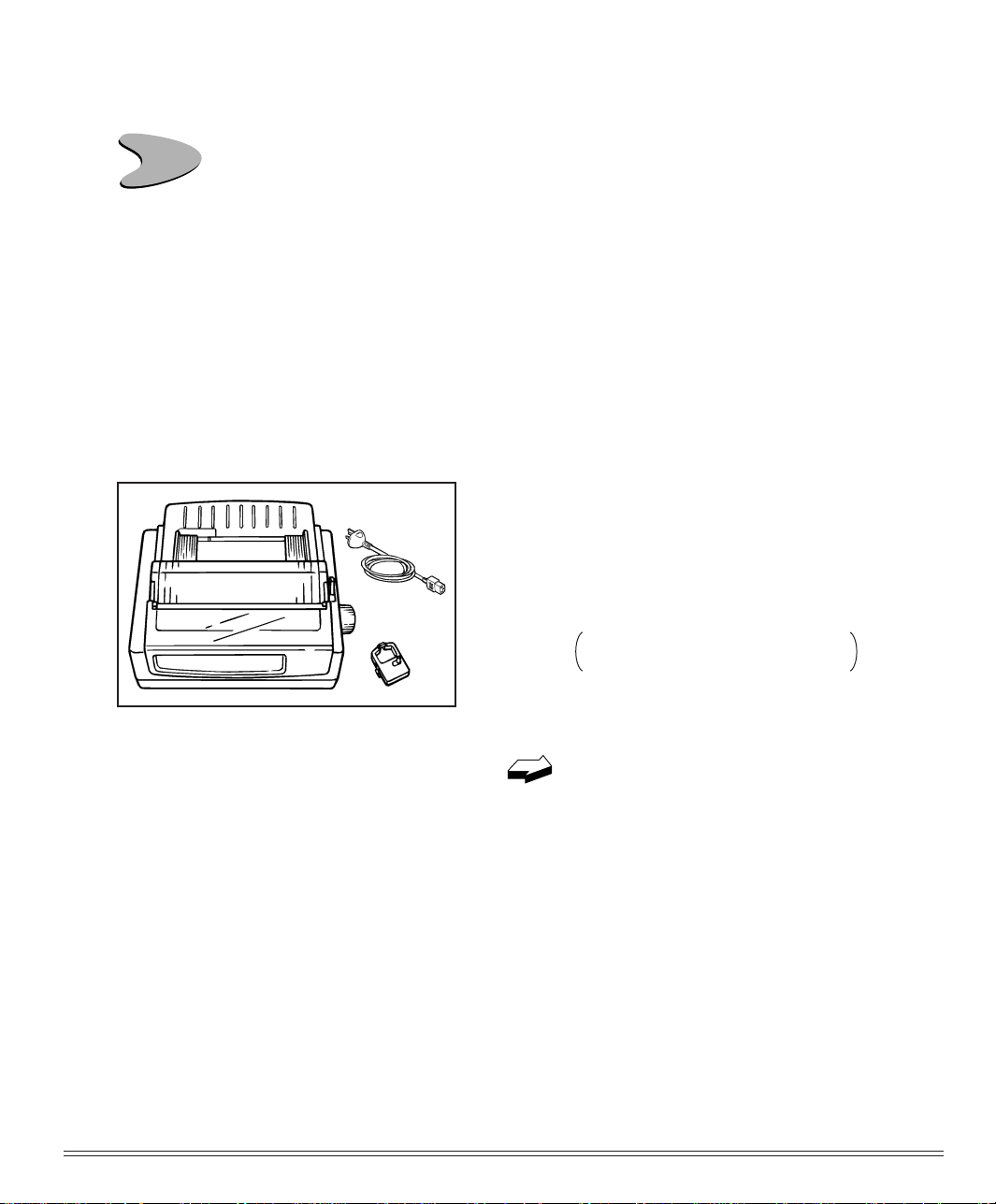

Unpacking

Unpack your printer and make sure you have the following items. If you are missing

any of these items, contact your dealer immediately for a replacement.

• Printer

• Ribbon cartridge

• AC cord

It is not included in case of

some models.

• Printer handbook.

Interface cable and paper are sold

separately.

ML390/391 Turbo Printer Handbook 3

Page 11

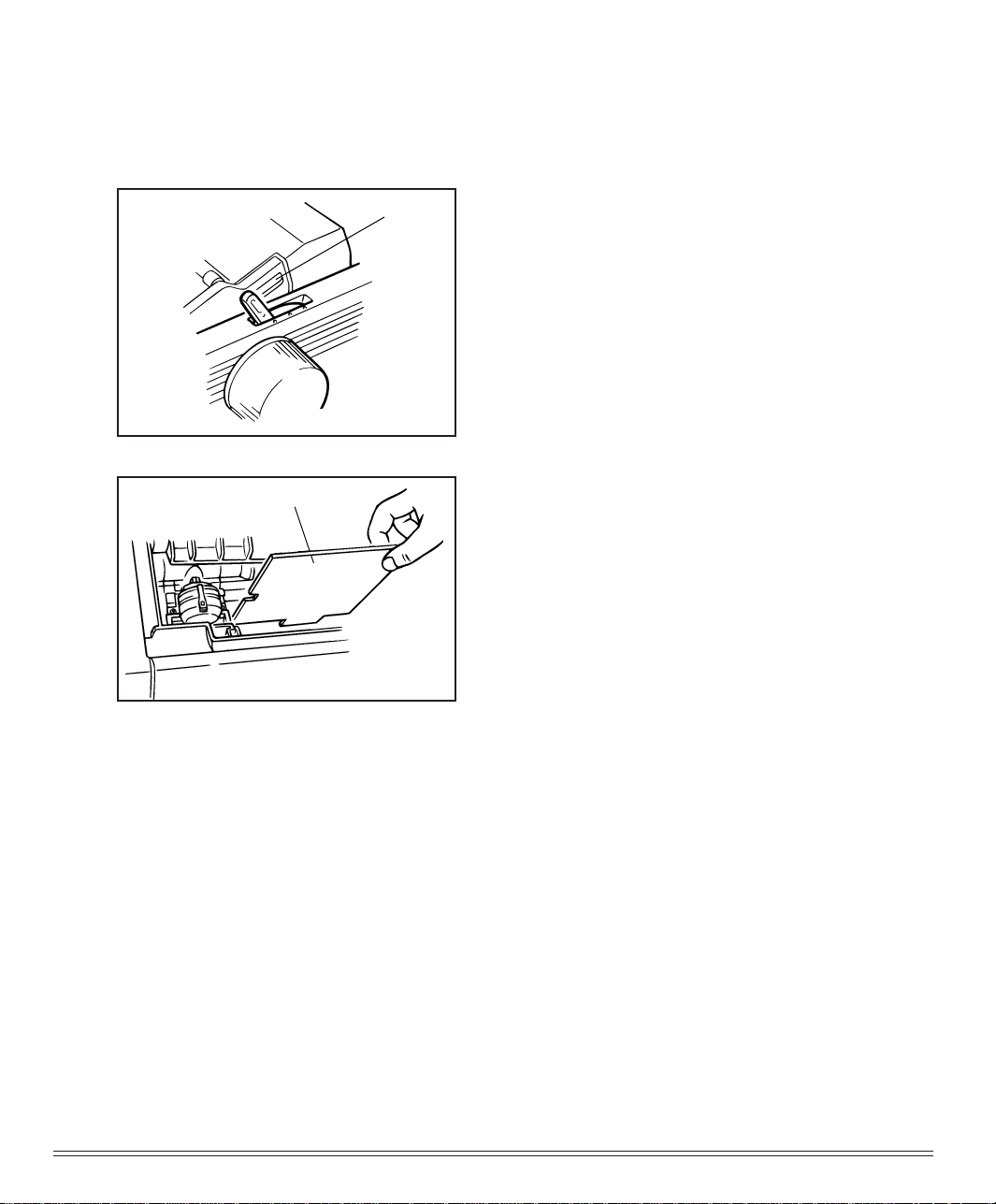

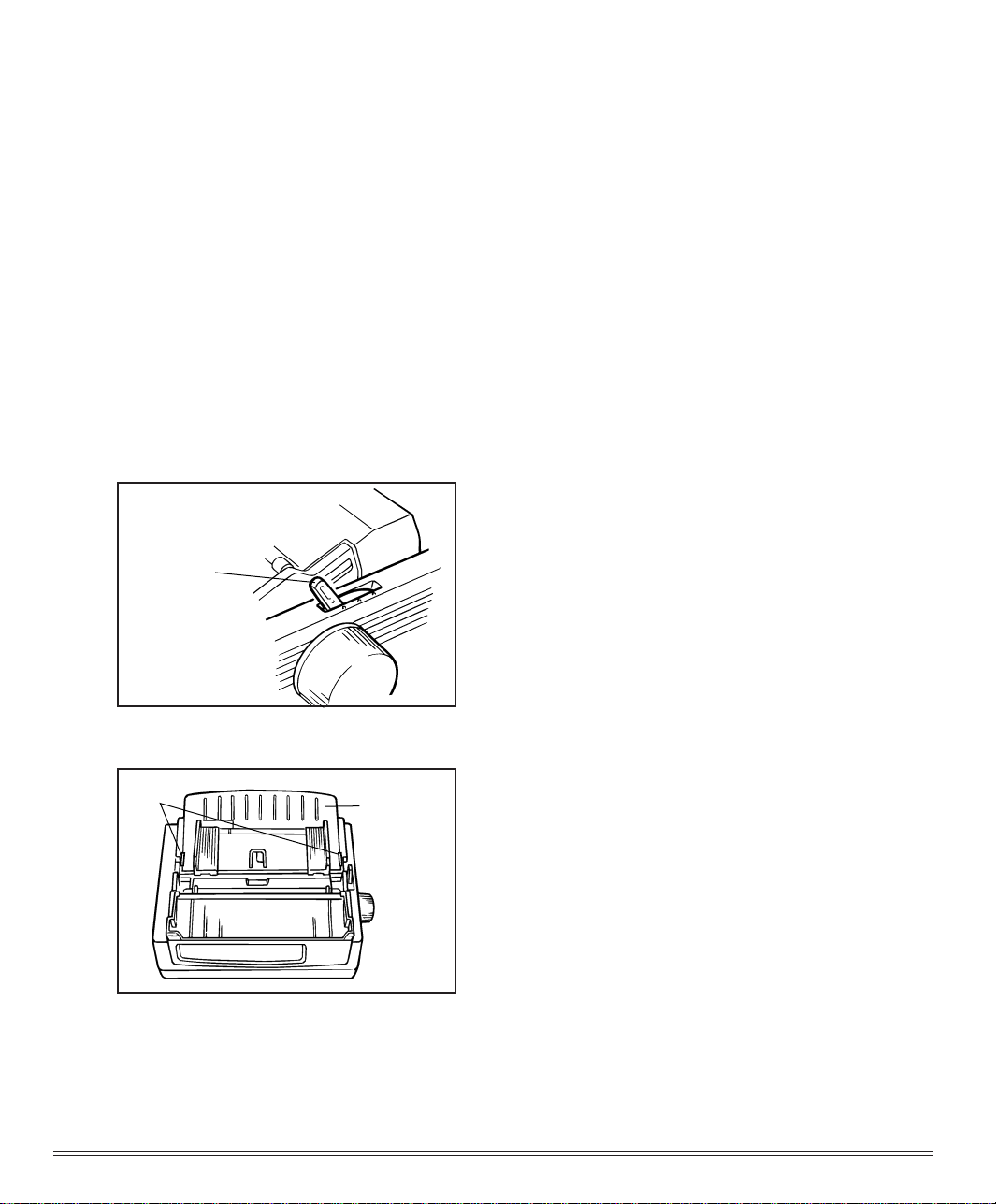

Removing Shipping Retainers

Shipping retainer

Tab

1. Open access cover by grasping tabs at

either end and lifting.

2. Remove printhead shipping retainer

(leave cover open for installation of ribbon).

4 Installation

Page 12

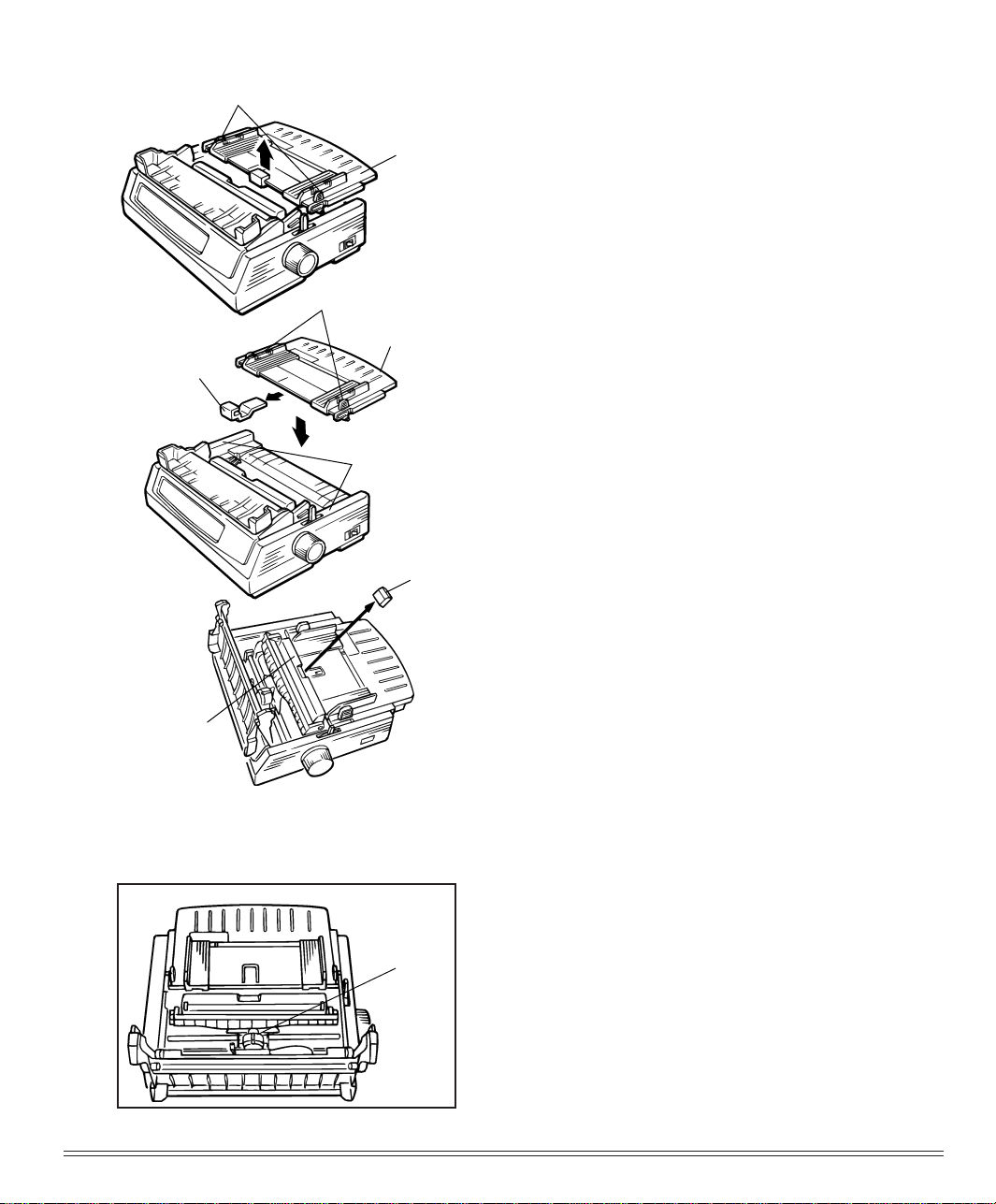

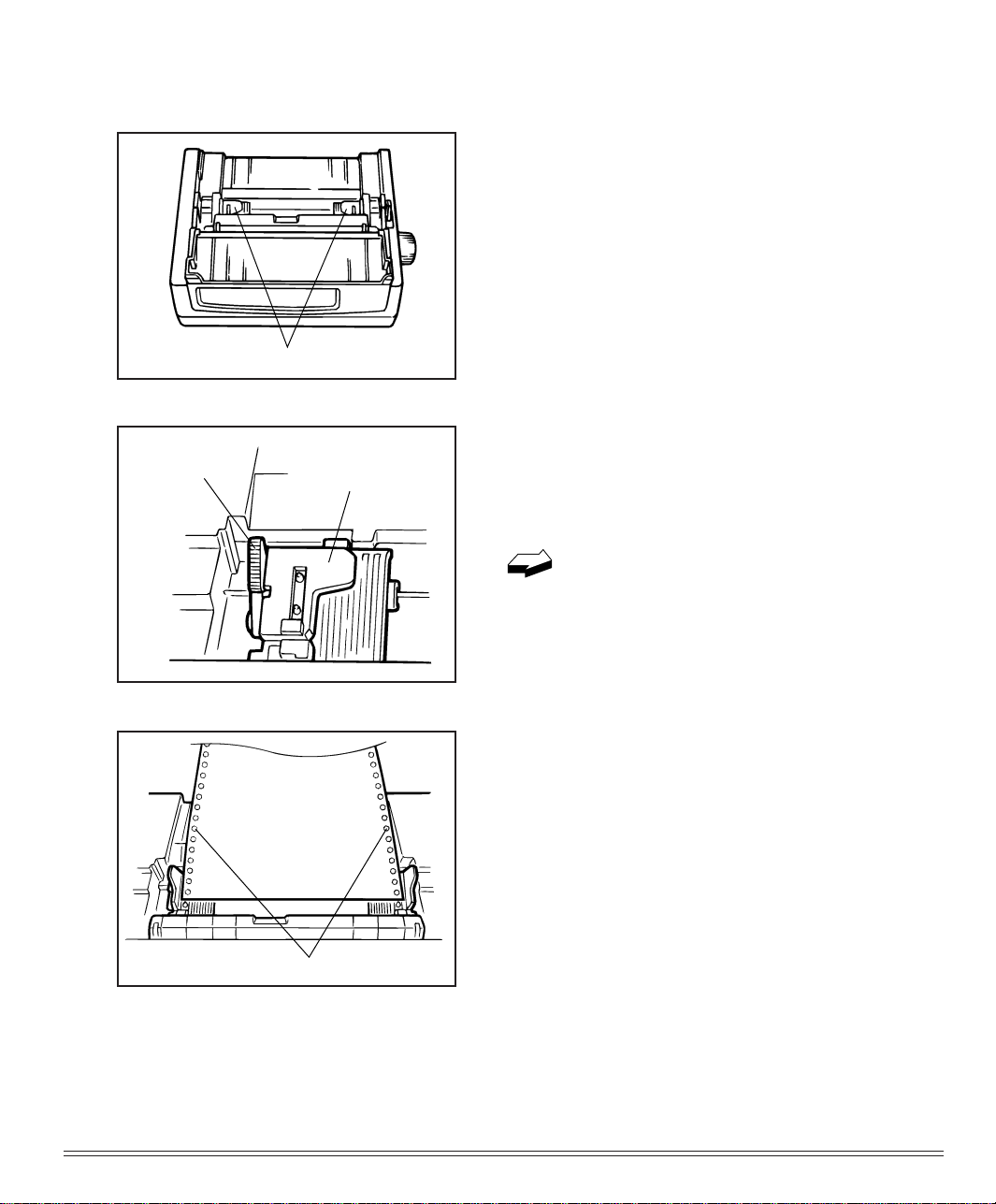

knob

Protictive

material

Paper separator

”∆”mark

separator

”∆”mark

Paper

3. Hold the knob and remove the paper

separator.

4. Remove the protective material.

5. Set and attach the post to the“∆”mark

of the upper cover and the paper separator .

Protictive

material

6. Remove the protective material from

the pull-up roller assembly.

Pull-up roller

assembly

Installing Ribbon Cartridge

Center

printhead

on platen

ML390/391 Turbo Printer Handbook 5

1. With access cover open, grasp print-

head and slide it until it is centered on

platen.

2. Remove ribbon cartridge from its pack-

aging.

Important!

Leave the clear plastic rib-

bon shield on the cartridge!

Page 13

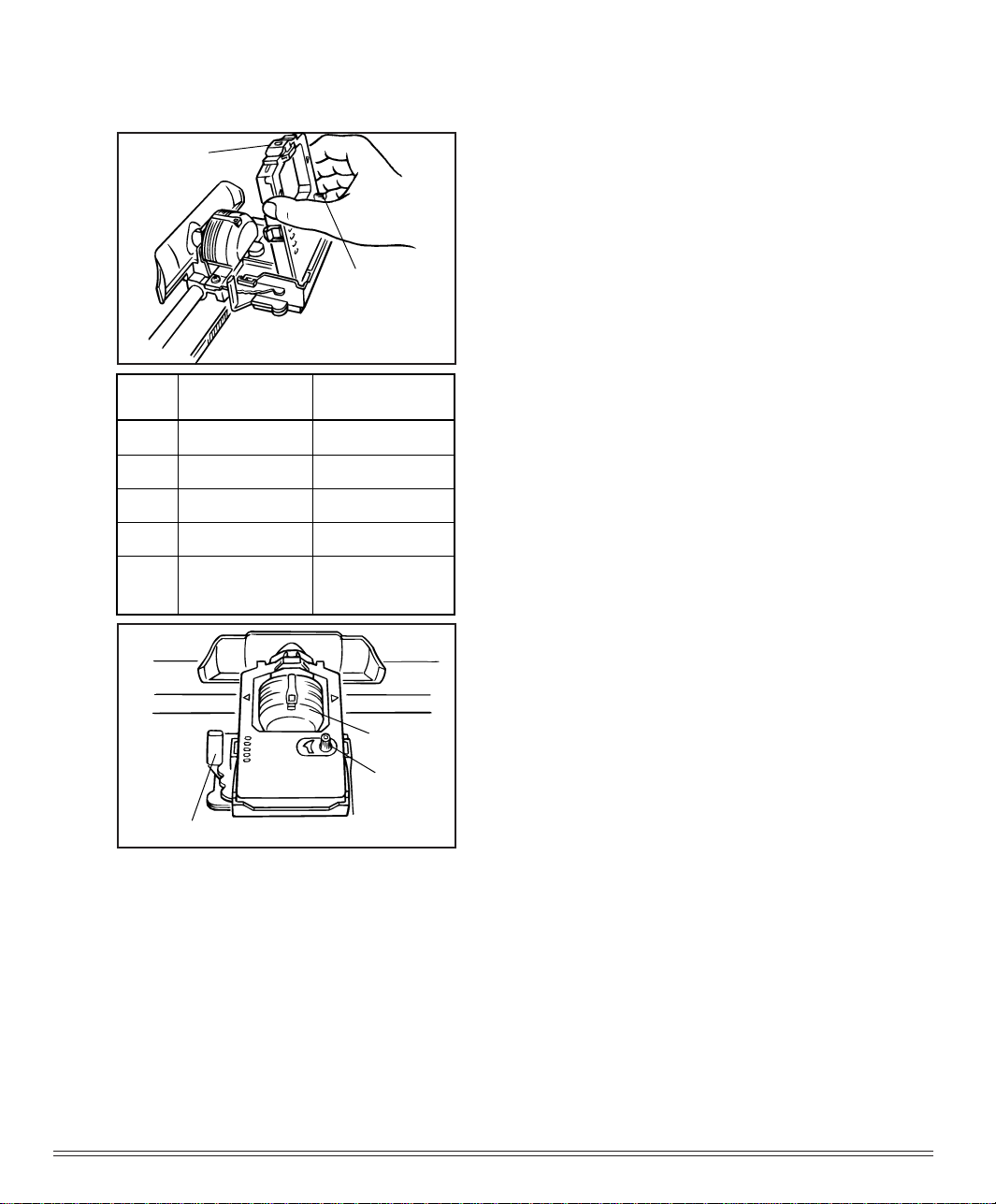

Ribbon

shield

Setting

Headgap lever

position

1

2

3

4

5

Headgap lever

3. Holding ribbon cartridge with knob facing up and ribbon sheild facing platen,

fit grooves on either side at back end of

cartridge over pins on ribbon plate.

Knob

4. Lower front of cartridge over printhead

Number of

sheets

1

2

3

4

5

extra-thick paper

1

2

3

4

envelopes or

until it snaps into place, then turn knob

in direction of arrow (clockwise) to take

up ribbon slack.

5. The headgap lever by the side of cartridge

adjusts for different paper thicknesses.

Set it for the number of sheets in the

forms you’re using from 1 to 4; use setting 5 for envelopes or extra-thick paper. Adjust the setting up or down for

the best print quality.

Note: When the setting is set at 2~5, the

printer automatically slows down for better

print quality with thicker multipart forms.

1

2

3

4

5

Printhead

Knob

Important!

Be sure to use only ribbons

specifically for use with MICROLINE 390

series.

For best results, use genuine OKI ribbons.

Making Connections

Connection with Computer

There instructions are for the standard parallel interface. Instructions for installation/connection of a serial interface are included with the serial interface accessory.

For more information on the serial interface accessory, see Chapter 5.

6 Installation

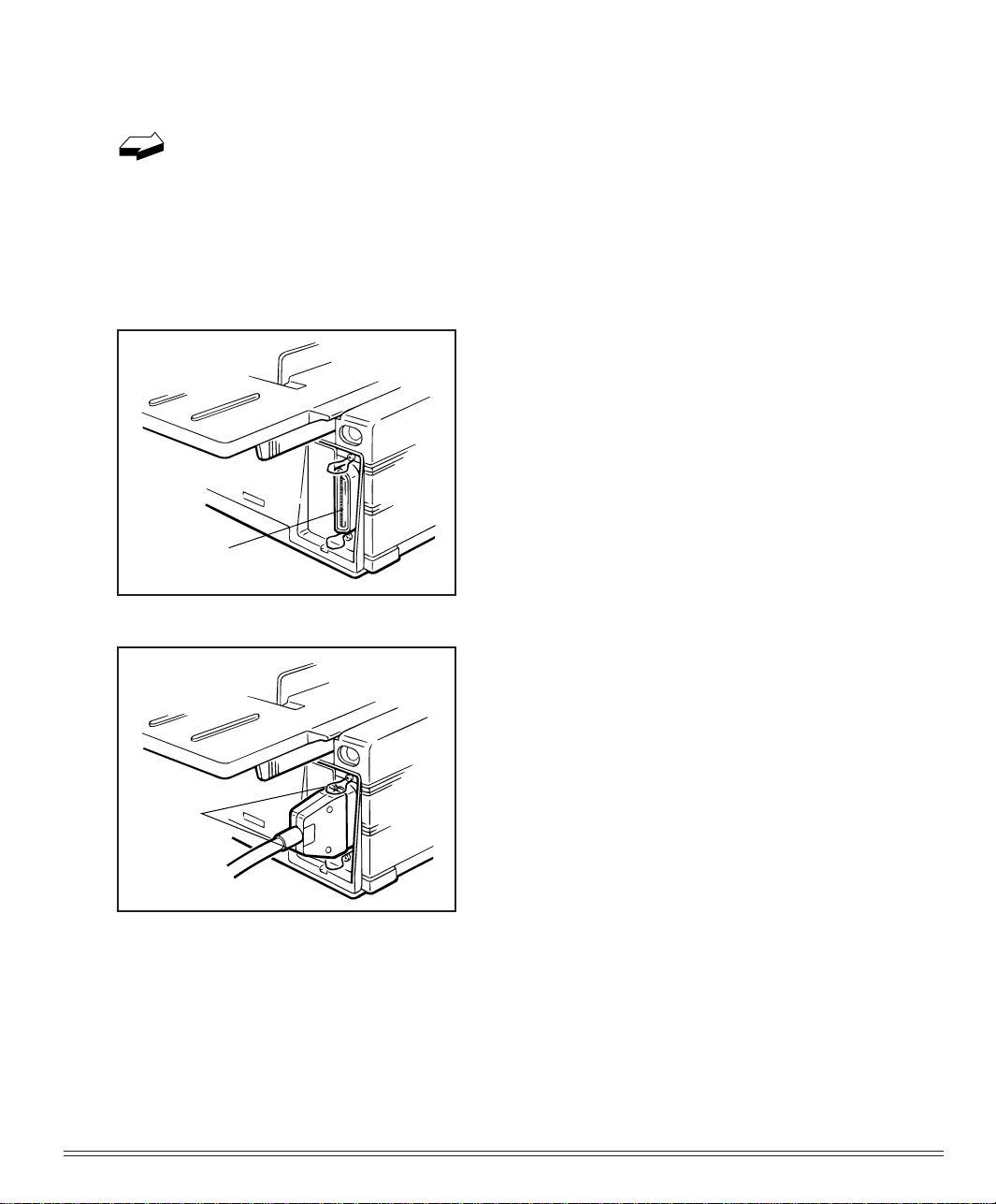

Page 14

Pin assignments for both the parallel and the serial interfaces are listed in

appendix E.

You must supply the cable for connecting your printer to your computer.

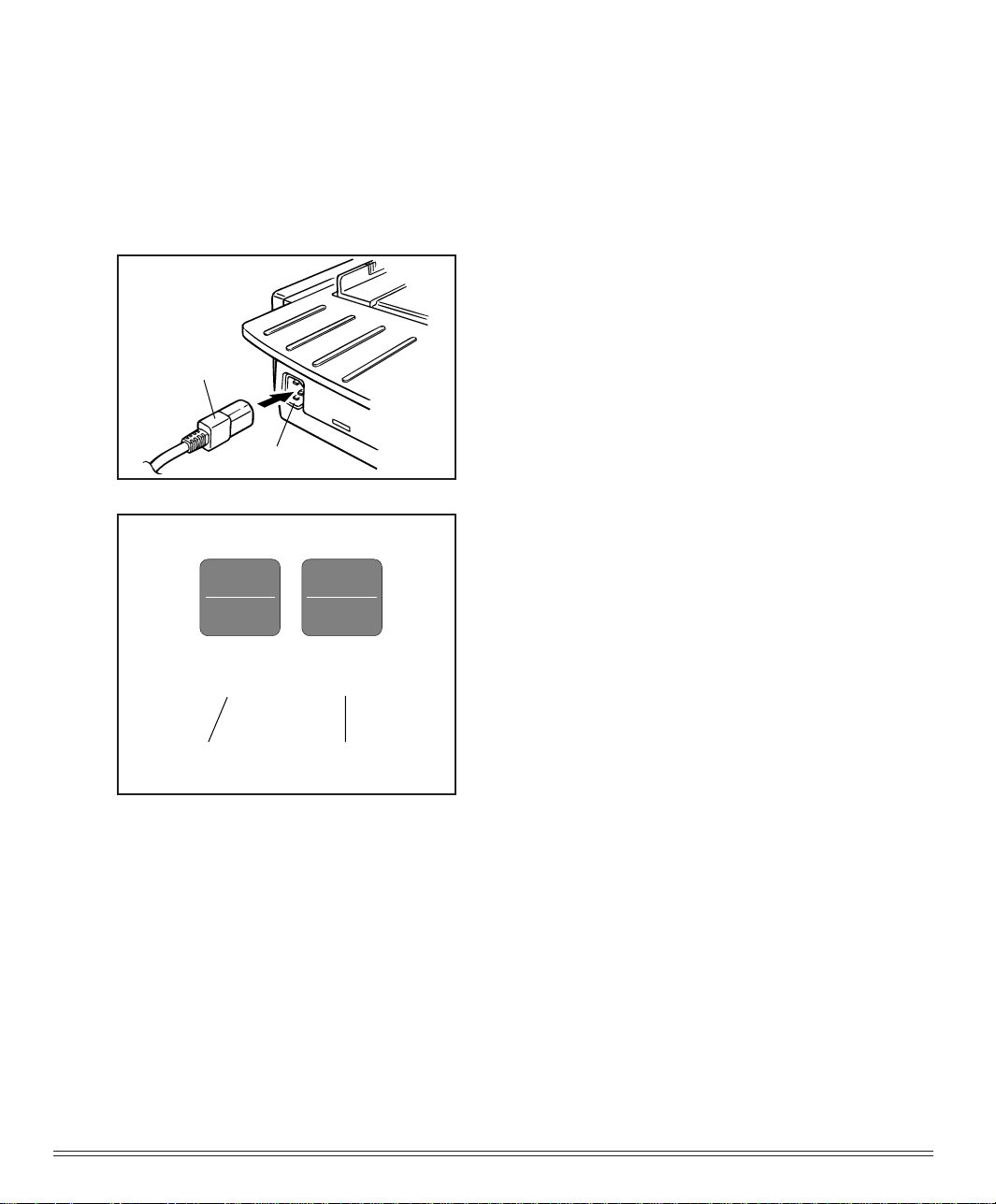

1. Make sure both printer and computer

are OFF.

2. Locate interface port on back of printer.

Interface port

3. Plug parallel interface cable into port

and secure it in place with wire loops.

Wire

loops

ML390/391 Turbo Printer Handbook 7

Page 15

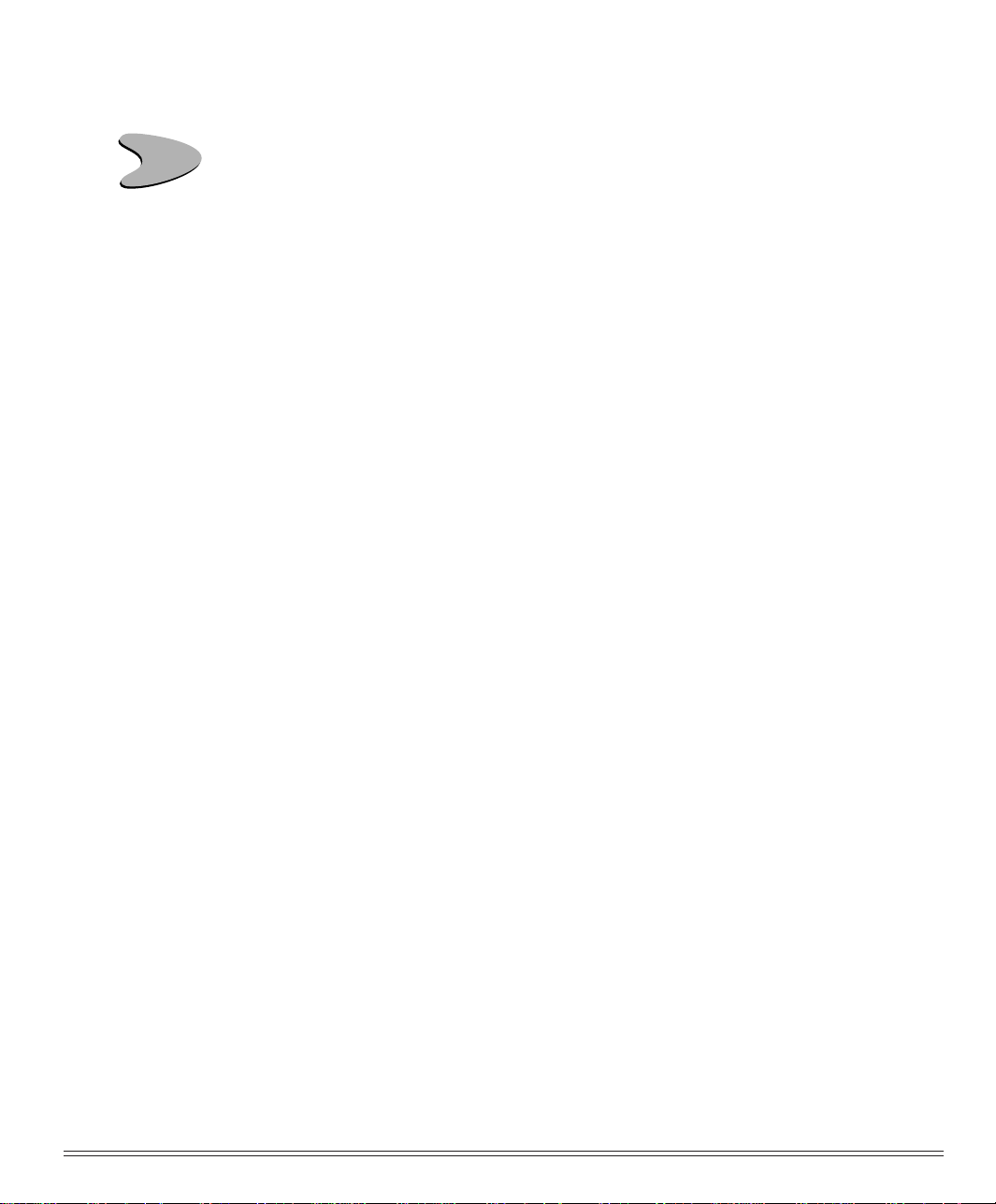

Connection with Power

Power cord

Socket

1. Make sure both printer and computer

are OFF.

2. Plug power cord into back of printer.

Plug other end into grounded outlet.

SEL

SEL

MENU

EXIT

POWER

Power light Alarm light

SHIFT

ALARM

3. Turn printer on. Printhead will cross

back and forth along platen, and

POWER light will come on. ALARM

light will also come on, but don’t be

concerned: it’s just telling you that there

is no paper loaded.

You’re now ready to load paper—proceed

to Chaper2.

8 Installation

Page 16

hapter 2: Loading Paper

C

Your printer has provision for single-sheet paper feed from the top and for continuous-form paper feed from the rear. Y ou can also install options: the Cut Sheet Feeder,

which holds a stack of 100 sheets for feeding from the top and the Push and/or Pull

Tractors for feeding continuous-form labels, heavy card stock or multi-part forms

from the bottom. See Chapter 5 for more information on these options.

Top Feed

• Single sheets (basis weight 14 to 24 lbs)

• Single envelopes

– 24-lb maximum

– 6.5” to 9.5” wide

• Transparencies (8.5 x 11”)

Rear feed (continuous forms only, thickness to 0.014” [0.36 mm])

• Single-part continuous forms

– 12 to 24 lb.

– Minimum 3” wide

• Carbonless, multi-part forms

– Original, plus 3 copies

– 9 to 11 lb

– Minimum 3” wide

• Interleaf, multi-part forms (with carbon paper)

– Original, plus 3 copies

– 10 to 12 lb paper, with 9 lb carbon

– Minimum 3” wide

ML390/391 Turbo Printer Handbook 9

Page 17

Bottom feed (continuous forms only, thickness to 0.017” [0.44mm])

• Single-part continuous forms

– 12 to 24 lb

– Minimum 3” wide

• Carbonless, multi-part forms

– Original, plus 4 copies

– 9 to 11 lb

– Minimum 3” wide

• Interleaf, multi-part forms (with carbon paper)

– Original, plus 4 copies

– 10 to 12 lb paper, with 9 lb carbon

– Minimum 3” wide

• Continuous-feed envelopes

– 24 lb maximum

– 6.5” to 9.5” wide (envelope itself)

• Labels

– minimum 3” wide

– maximum 10”(ML390 Turbo) or 16” (ML391 Turbo) wide

• Card stock: papers up to 120 lb maximum

10 Loading Paper

Page 18

Loading Single-Sheet Paper

The single-sheet paper path is best for letterhead stationery, memos, and envelopes.

We also recommend it for printing graphs and charts because it provides the most

accurate control of the paper.

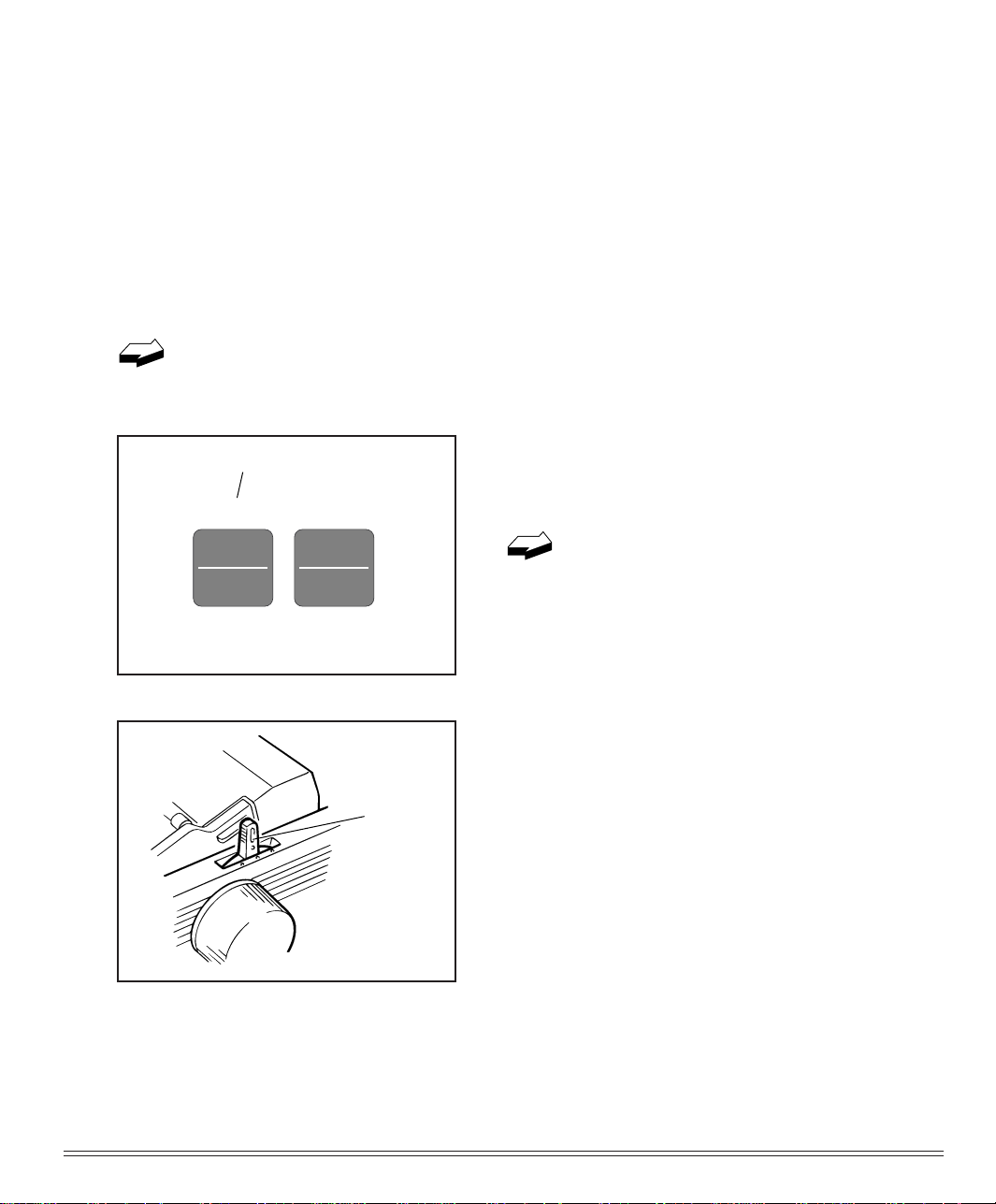

To load in single sheets of paper:

If you have any continuous-form paper in the paper path, you must press the

P ARK button on the front panel to remove it fr om the path befor e lading single

sheets.

SEL light

SEL

SEL

MENU

EXIT

POWER

1. Make sure printer is turned ON and

deselected (SEL light off – press SEL

button to deselect it necessary).

The ALARM light will remain on

until paper is loaded.

SHIFT

ALARM

2. Move paper lever to position marked

“TOP”.

Move

to "TOP"

ML390/391 Turbo Printer Handbook 11

Page 19

Wire feed

guide

Paper

separator

3. Grasp back of paper separator and un-

snap it from housing, then swing it up

into single-sheet feed position, making

sure that wire feed guide is nestled in

separator.

SHIFT

ALARM

CHARA

RESET

Press

Paper feed

guides

Flashes

15

PROP

4. Adjust paper feed guides for width of

paper and drop sheet of paper into

separator. Paper will automatically

feed into printer.

If the sheet of paper doesn’t feed in

properly , the “15” light in the Character Pitch section at the bottom

right of the control panel will begin flashing. To correct this, press

the SHIFT and RESET buttons simultaneously, then reload the

sheet.

12 Loading Paper

Page 20

Baseline

5. Baseline for Top of Form (TOF) on paper is indicated by red line on clear plastic paper shield.

1

2

3

4

5

Hold

SEL

SEL

MENU

EXIT

POWER

Press to feed

paper down in

micro increments

SHIFT

ALARM

Micro Feed

GROUP ITEM

Press to feed

paper up in micro

increments

SEL

SEL

MENU

EXIT

POWER

LF

Down

FF/LOAD

Micro Feed

Up

6. If desired, change TOF setting using

control panel:

☛ to set TOF further down on page,

hold SHIFT button while pressing FF/

LOAD button: this will advance paper

up in micro increments

☛ to move TOF further up on page,

hold SHIFT button while pressing LF

button: this will advance paper down

in micro increments

7. Press SEL button (SEL light will come

on).

ML390/391 Turbo Printer Handbook 13

Page 21

Loading Rear-Feed Paper

The rear-feed paper path is recommended for single-thickness, continuous fan-fold

paper when printing spreadsheets, long reports, etc. For graphics or charts, it’s best to

use the single-sheet paper path.

To load continuous-form paper from the rear:

1. If you have paper in paper path, be sure

to remove it before installing rear-feed

paper . T o remove single sheet, press FF/

LOAD button. To remove bottom-feed

paper, press PARK button.

2. Move paper lever to position marked

“REAR”.

Position

"Rear"

Knob

14 Loading Paper

Remove

paper

separator

3. Open the access cover , hold up the knob

of the paper separator, and remove the

paper separator.

(Remove the paper separator.)

Page 22

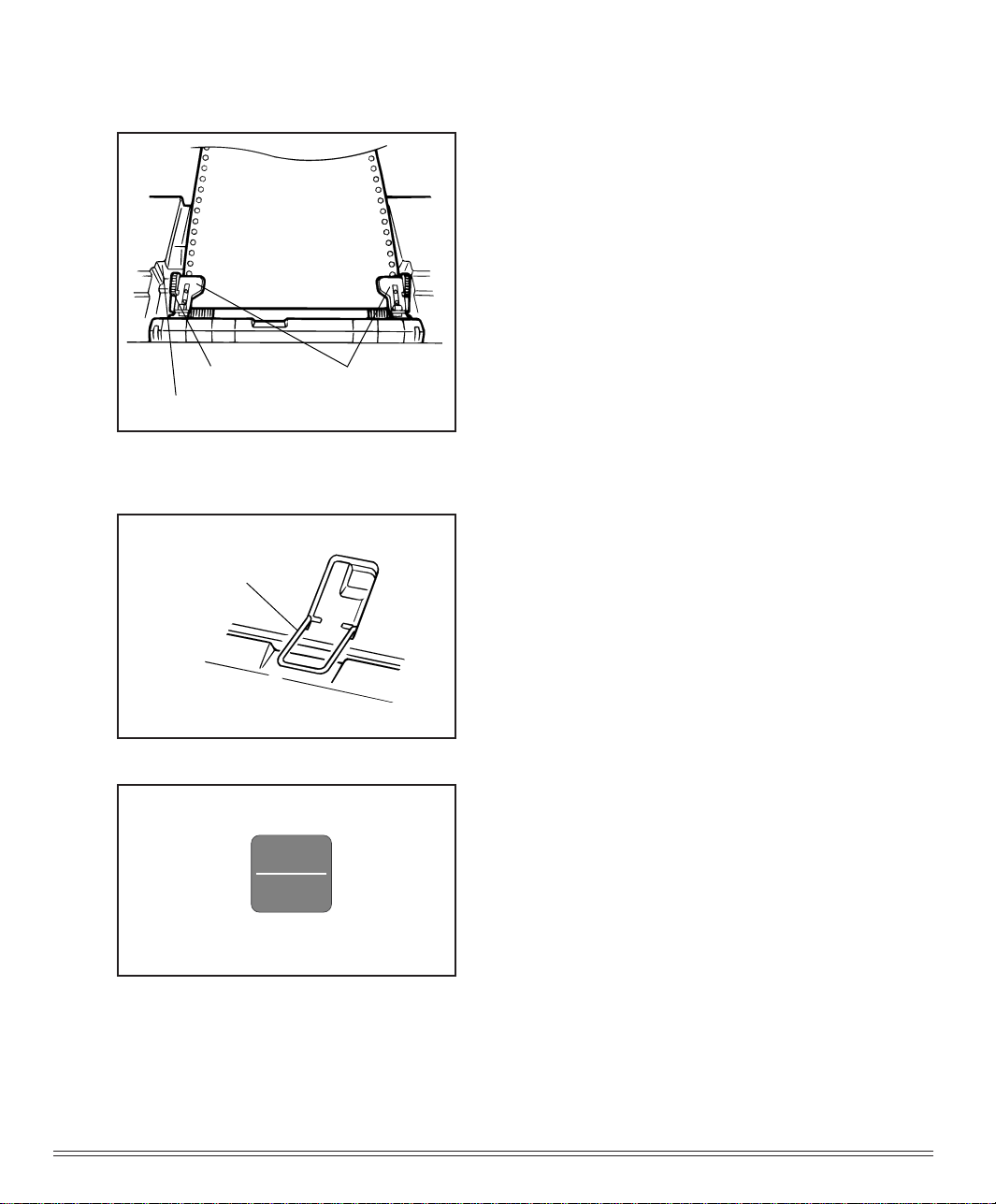

Lock lever

Tractors

Tractor cover

4. Locate tractors.

5. Pull up on lock levers to release tractors and swing open tractor covers. Position right-hand tractor for width of

paper you’re loading.

The movement of the left tractor is

limited to ensure that the paper

will always contact the paper sensor when loaded.

6. Pull paper, and place first two holes on

each side over tractor pins.

Please note that an equal number of paper holes must be engaged on either

tractor in order to ensur e proper paper

feed.

Paper holes on pins

ML390/391 Turbo Printer Handbook 15

Page 23

Lock lever

Reference marks

Wire feed guide

Tractor covers

7. Close tractor covers and adjust left trac-

tor to position edge of paper: reference

marks on printer indicate left edge position for the two most common paper

sizes. When paper is properly aligned,

lock left tractor in place by pushing back

on lock lever.

8. Adjust right tractor so that paper holes

are centered on pins(careful – if paper

is stretched too tight or left too loose, it

can jam and cause problems), then lock

right tractor in place by pushing back

on lock lever.

9. Set Paper separator and swing wire feed

guide over to rest on pull-up roller assembly to prevent from curling back

into printer.

10.Push FF/LOAD button. Paper will au-

tomatically feed into printer and

FF/LOAD

Micro Feed

Up

ITEM

16 Loading Paper

ALARM light will go out.

Page 24

Baseline

11. Baseline for top of Form(TOF) on paper is indicated by red line on clear plastic paper shield.

1

2

3

4

5

Press to hold the

paper before

releasing the TEAR

button.

LF

SHIFT

ALARM

Micro Feed

Down

GROUP ITEM

Press to feed

Hold

SEL

SEL

MENU

EXIT

POWER

paper down in

micro increments

SHIFT

ALARM

Press to bring

the paper down

to the print

position.

FF/LOAD

Micro Feed

Up

LF

Micro Feed

Down

GROUP ITEM

MENU

TEAR

SET

FF/LOAD

Micro Feed

Up

Press to feed

paper up in micro

increments

12.If desired, change TOF setting using

control panel:

If form tear off is being selected in the

printer menu, press the TEAR button

to bring the paper down to the print

position. Hold down the SHIFT button

and release the TEAR button.

☛ to set TOF further down on page,

hold SHIFT button while pressing FF/

LOAD button: this will advance paper

up in micro increments

☛ to move TOF further up on page,

hold SHIFT button while pressing LF

button: this will advance paper down

in micro increments

ML390/391 Turbo Printer Handbook 17

Page 25

SEL

SEL

MENU

EXIT

POWER

LF

Micro Feed

Down

GROUP

13.Press SEL button (SEL light will come

on).

To temporarily change the Top of

Form setting for a particular print

job, deselect the printer and press

the LF button until you reach the

TOF position you want to use. The

printer will retain this setting until you turn it off.

18 Loading Paper

Page 26

Paper Handling

Your printer has several handy paper handling features:

• Tear

• Form Tear-off

• Paper Park

Tear Feature

When you’re using continuous forms with either the built-in rear-feed tractor or the

optional bottom-feed push tractor , you can use this feature to advance the forms up to

the tear position so you can easily tear off a printed sheet without wasting paper or

readjusting the printer. To do this, simply press the TEAR button on the front panel.

Press

SEL

SEL

MENU

EXIT

POWER

LF

SHIFT TOF

ALARM

Micro Feed

Down

GROUP PRINT

FF/LOAD

Micro Feed

Up

ITEM

TEAR

SET

MENU

PARK

QUIET

The tear feature can not be used when the optional pull tractor is installed.

ML390/391 Turbo Printer Handbook 19

Page 27

Forms T ear-off Feature

Caution!

Do not engage Forms Tear-off when printing on labels!

The Forms Tear-off feature can be engaged to automatically move the paper up to the

tear position after the selected interval (500 milliseconds, one second, or two seconds).

The page will stay in the tear-off position until the printer receives data. It will then

move down to the initial printing position.

This feature is normally turned off. To activate it, enter the printer menu (see Menu

Mode in Chapter3) and choose one of the intervals.

Some programs, such as high resolution graphics packages, pause occasionally while sending data to the printer. If the pause lasts mor e than the selected

interval, the paper will advance to the rear-off position until more data is

received. No data will be lost, but this extra paper movement can cause uneven print registration in graphics. If you have this problem, use the menu to

deactivate Forms Tear-off.

Paper Park Feature

If you have continuous-form paper loaded and you wish to switch to another paper

path, first tear off the printed pages, then simply press the PARK button. The continuous-form paper will immediately retract from the paper path.

Press

SEL

SEL

MENU

EXIT

POWER

20 Loading Paper

SHIFT TOF

ALARM

LF

Micro Feed

Down

GROUP PRINT

FF/LOAD

Micro Feed

Up

ITEM

TEAR

SET

MENU

PARK

QUIET

Page 28

Switching Paper Paths

To switch from continuous-form feed from the rear or bottom (optional push or pull

tractor installed) of the printer to single-sheet feed from the top:

1. Tear off printed pages.

2. Press PARK button.

3. Swing wire guide up into paper separator, then pivot separator to upright position.

4. Move paper lever to position marked “TOP”.

5. Load single sheet paper into paper separator.

To switch from top feed to continuous-form tear or bottom (optional push or pull

tractor installed) feed:

1. Make sure no sheet is in paper path (press FF/LOAD to r emove single sheet from

path).

2. Lower paper separator to continuous forms position and swing wire guide over

onto pull-up roller assembly.

3. Move paper lever to position marked “REAR” or “BOT”, as appropriate.

4. Press FF/LOAD button. Continuous-form paper will advance into print position.

ML390/391 Turbo Printer Handbook 21

Page 29

22 Loading Paper

Page 30

hapter 3: Operation

C

This chapter explains how to operate your printer. It also provides instructions on

how to change the default settings and how to perform basic tasks, including selecting typeface/print quality, selecting character pitch, testing your printer, and resetting Top of Form to the factory default.

Control Panel

SEL

SEL

MENU

EXIT

POWER

FF/LOAD

LF

Micro Feed

SHIFT TOF

ALARM

GROUP PRINT

Down

Micro Feed

ITEM

TEAR

Up

SET

MENU

PARK

PRINT QUALITY

QUIET

CHARACTER PITCH

RESET

LQ COURIER GOTHIC

UTILITY PRESTIGE ORATOR

10 12 15

17 20 PROP

–ROMAN–

–SWISS–

Your printer ’s front panel lets you control paper feeding, customize your printer ’s

defaults to your particular needs, and select print quality and character pitch.

Here’s a breakdown of the controls on the front panel:

ML390/391 Turbo Printer Handbook 23

Page 31

SEL

SEL

MENU

EXIT

POWER

LF

SHIFT TOF

Micro Feed

Down

GROUP PRINT

ALARM

FF/LOAD

Micro Feed

Up

ITEM

TEAR

SET

MENU

PARK

QUIET

The seven buttons to the left on your control panel are multi-function buttons. In

routine printer operation, they are used to manipulate the paper , but you can also use

them to enter and make changes in the printer’s program menu.

PRINT QUALITY

CHARACTER PITCH

RESET

LQ COURIER GOTHIC

UTILITY PRESTIGE ORAT OR

10 12 15

17 20 PROP

–ROMAN–

–SWISS–

The PRINT QUALITY and CHARACTER PITCH sections at the right on the front

panel are used to select the quality and size of the printing. See “Performing Basic

Tasks” later in this chapter for information on how to use these buttons.

Important!

The print quality and character pitch set by means of the front panel can

be overridden by commands sent by the commercial software package from which

you’re printing a document. If you run into this problem, see Chapter 5 for information on how to correct it.

24 Operation

Page 32

Print Mode

In its normal operating state, your printer’s front panel is in the Print Mode.

Indicator Lights

In the Print Mode, your printer has the following lights to indicate its status:

24

SEL

SEL

MENU

EXIT

POWER

FF/LOAD

LF

Micro Feed

SHIFT TOF

ALARM

GROUP PRINT

Down

Micro Feed

ITEM

TEAR

Up

SET

MENU

PARK

QUIET

13

1. POWER light: Glows whenever printer is on.

PRINT QUALITY

CHARACTER PITCH

RESET

LQ COURIER GOTHIC

UTILITY PRESTIGE ORATOR

10 12 15

17 20 PROP

–ROMAN–

–SWISS–

2. SEL light: Glows when printer is selected, ready to receive data. Flashes when

printer is in print suppress mode. Goes out when printer is deselected (can’t receive data).

3. ALARM light: Glows when error condition exists, such as out of paper or paper

jam. Also glows when paper lever is set to wrong position.

Important!

If the ALARM light is blinking, an unrecoverable err or condition exists.

Try turning the printer off, then on again; if the light is still flashing, contact your

service dealer (see Chapter 5 for more information on obtaining service).

4. QUIET light: Glows when printer is in QUIET state (printer selected or deselected).

ML390/391 Turbo Printer Handbook 25

Page 33

Buttons

SEL

SEL

MENU

EXIT

POWER

LF

SHIFT TOF

ALARM

Micro Feed

Down

GROUP PRINT

FF/LOAD

Micro Feed

Up

ITEM

TEAR

SET

MENU

PARK

QUIET

When the printer is selected (SEL light on), only the functions marked at the top of the

bank of buttons (LF , FF/LOAD, TEAR, PARK, QUIET) are in effect. When the printer

is deselected (SEL light of f), the functions marked at the bottom of the buttons (Micro

Feed Down, Micro Feed Up, TOF) can be accessed by means of the SHIFT button.

Each button can have several functions, depending on the mode in use (Print Mode

or Menu Mode), on whether or not the printer is selected and on whether or not the

optional Cut Sheet Feeder (CSF) is installed. Most buttons also have a different function if they are pressed while the printer is being turned on. In addition, different

combinations of two buttons can be used to access functions.

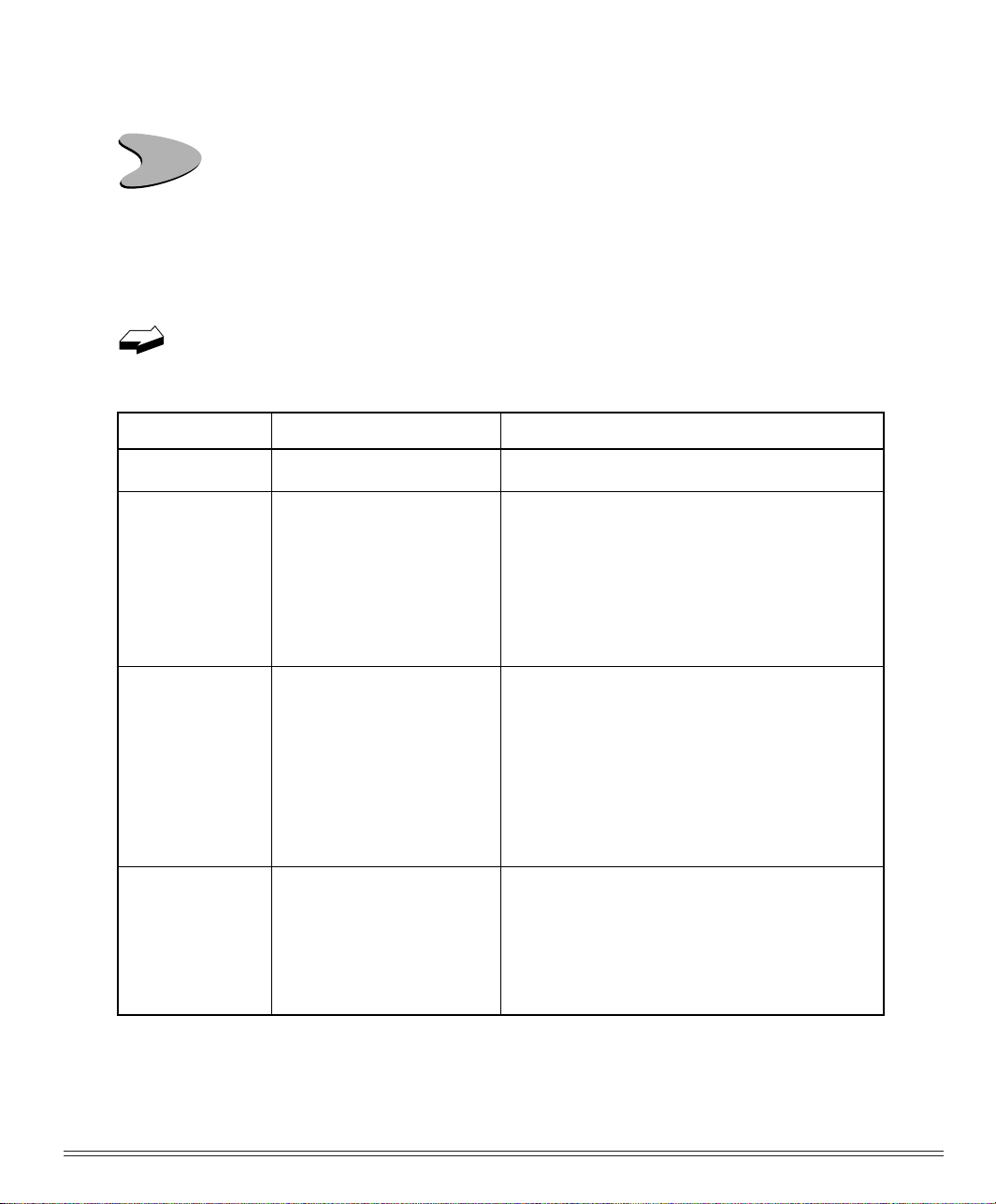

The various function available for each button are summarized in the table below.

The PRINT QUALITY and CHARACTER PITCH buttons are discussed under

“Performing Basic Tasks,” later in this chapter.

26 Operation

Page 34

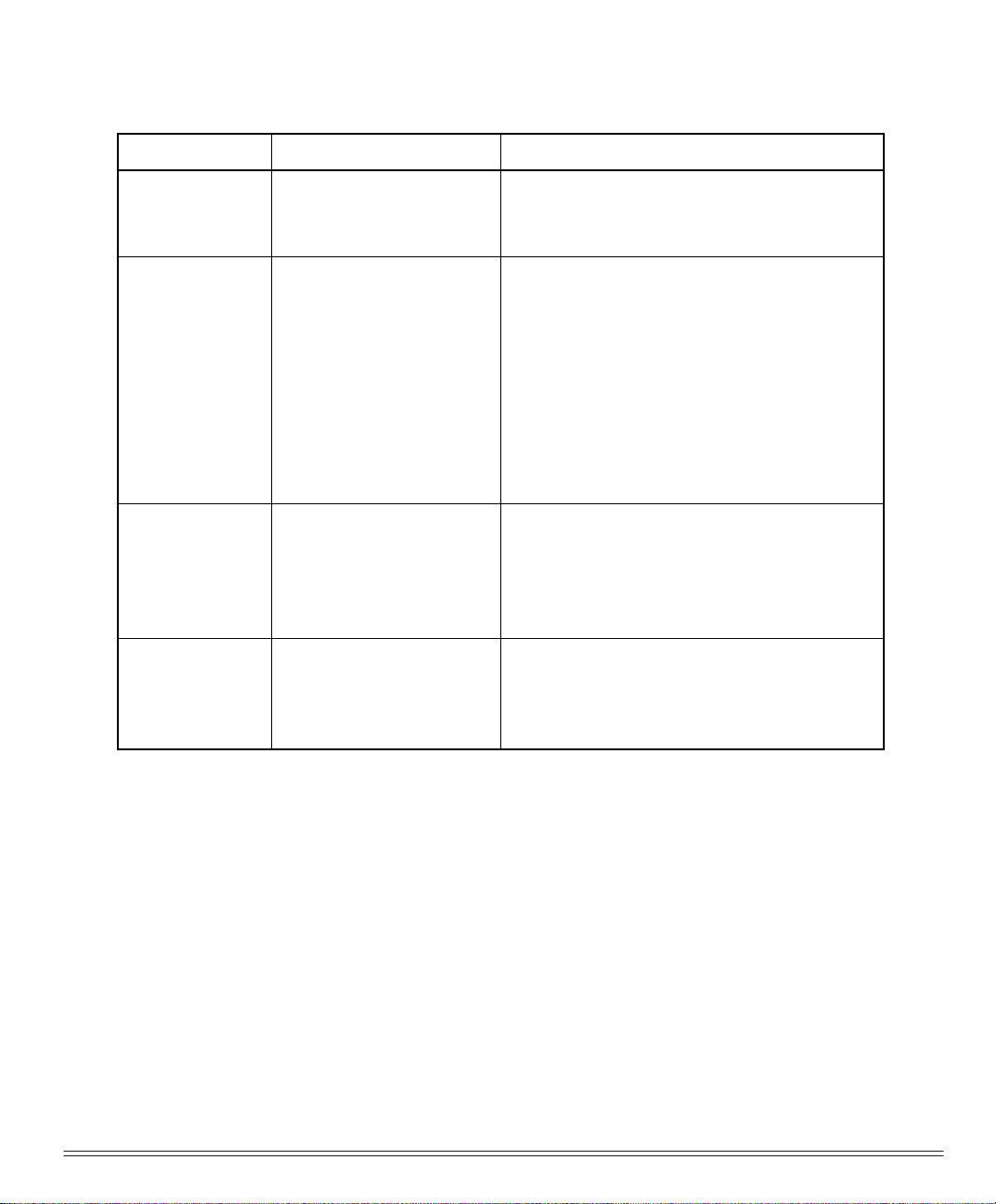

Summary of Front Panel Button Functions

Button Print Mode Help on Power Up

SEL

SEL +

SHIFT

SHIFT

LF

LF+

SHIFT

Selects/deselects printer.

Resets Paper Out of Paper

Jam Alarm. Also ends Font

Test or Rolling ASCII test .

Activates Menu Mode.

With printer deselected:

used with other keys to set

and store Top of Form.

Advances paper Up one

line. Press and hold to advance by repetitive line

feeds.

With printer deselected,

moves Top of Form setting up (paper moves

down) on page in micro

increments.

Activates Menu

Mode.

Activates Menu

Mode.

N/A

Activates Font

Test.

Activates Font

Test.

With CSF Installed

Same as Print

Mode

Same as Print

Mode

Same as Print

Mode

Same as Print

Mode

Same as Print

Mode

Menu Mode

Resets Paper

Out Alarm.

Exits Menu

Mode.

N/A

Advances to

next Group in

Menu.

Goes back to

previous

Group in

Menu.

FF/LOAD

FF/LOAD

+SHIFT

TEAR

ML390/391 Turbo Printer Handbook 27

Feeds in sheet of paper or

advances continuousform paper to print position.

With printer deselected,

moves Top of Form setting down (paper moves

up) on page in micro increments.

Moves continuous-feed

paper up for tear-off or

back down for printing

(select/deselect states).

N/A

N/A

N/A

Inserts or Ejects

Page.

With printer deselected, moves

Top of Form setting down on

page in micro increments.

N/A

N/A : Not applicable.

Advances to

next Item in

Menu.

Goes back to

previous Item

in Menu.

Advances to

next Value in

Menu.

Page 35

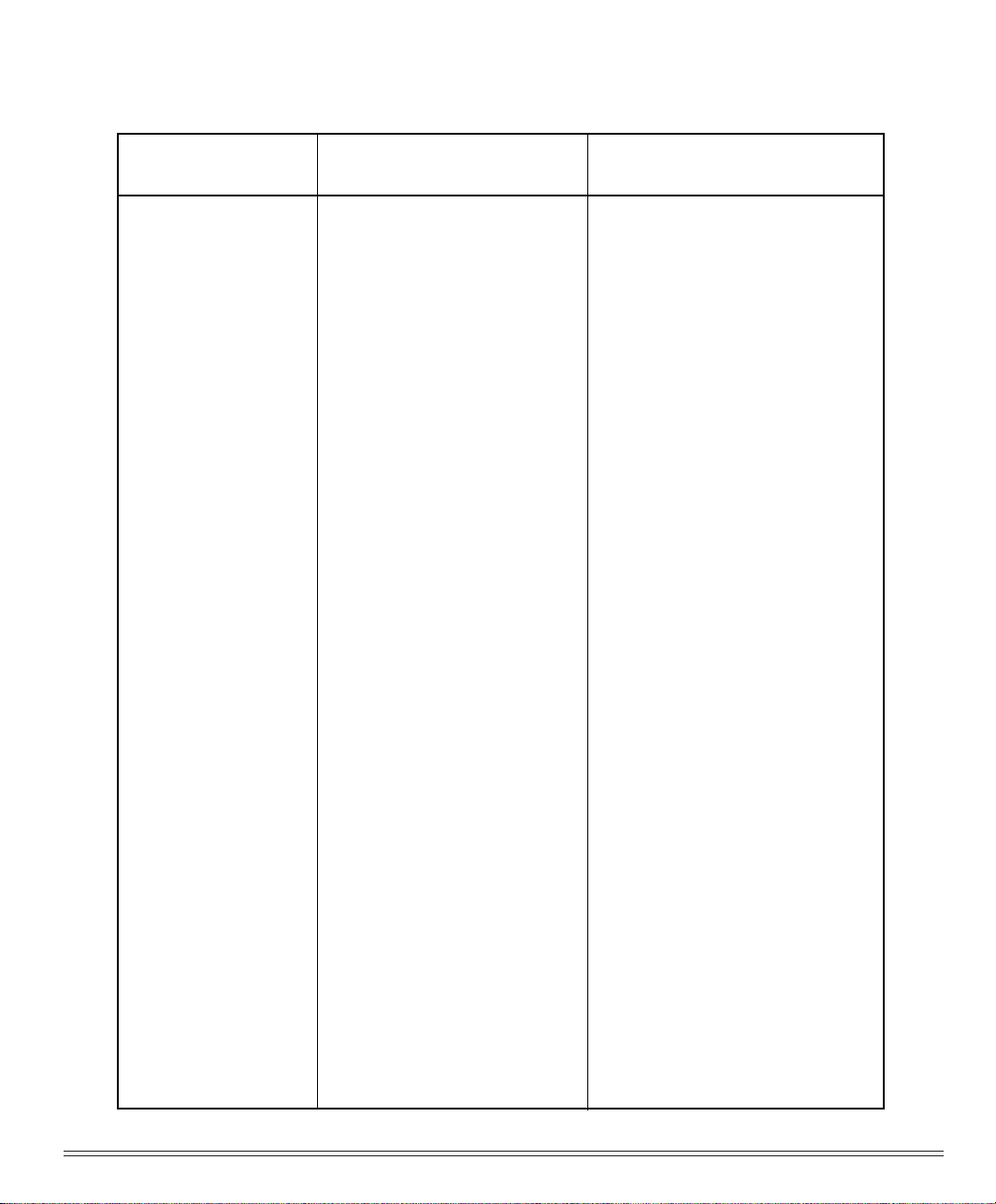

Button Print Mode

Help on Power Up

With CSF Installed

Menu Mode

TEAR+

SHIFT

PARK

PARK+

SHIFT

QUIET

QUIET+

SHIFT

PRINT

QUALITY

PRINT

QUALITY

+SHIFT

Move the print head to Reverse.

Parks continuous-form paper.

Move the print head to

Forward.

Activates/deactivates

QUIET mode.

Sets Top of Form.

Selects next Print Quality

mode.

Sets/Resets Incremental

Print mode.

N/A

N/A

N/A

Activates Rolling ASCII Test.

Activates Rolling ASCII Test.

N/A

N/A

Move the print

head to Reverse.

Ejects paper.

Move the print

head to Forward.

Activates/deactivates QUIET mode.

Sets Top of Form.

Selects next Print

Quality mode.

Sets/Resets Incremental Print

mode.

Goes back to

previous Value

in Menu.

Prints list of all

Menu settings

for current emulation.

Prints current

Group Menu

Setting.

N/A

N/A

N/A

Prints all Menu

settings, regardless of emulation/options

engaged.

CHARAC-

TER

Selects next pitch setting.

N/A

Selects next pitch

setting.

N/A

PITCH

CHARAC-

TER

PITCH+

With printer deselected,

resets printer.

N/A

With printer deselected, resets

printer.

N/A

SHIFT

FF/LOAD

+TEAR

N/A

Resets Menu

and Top of

N/A

N/A

Form to factory

default.

N/A : Not applicable.

28 Operation

Page 36

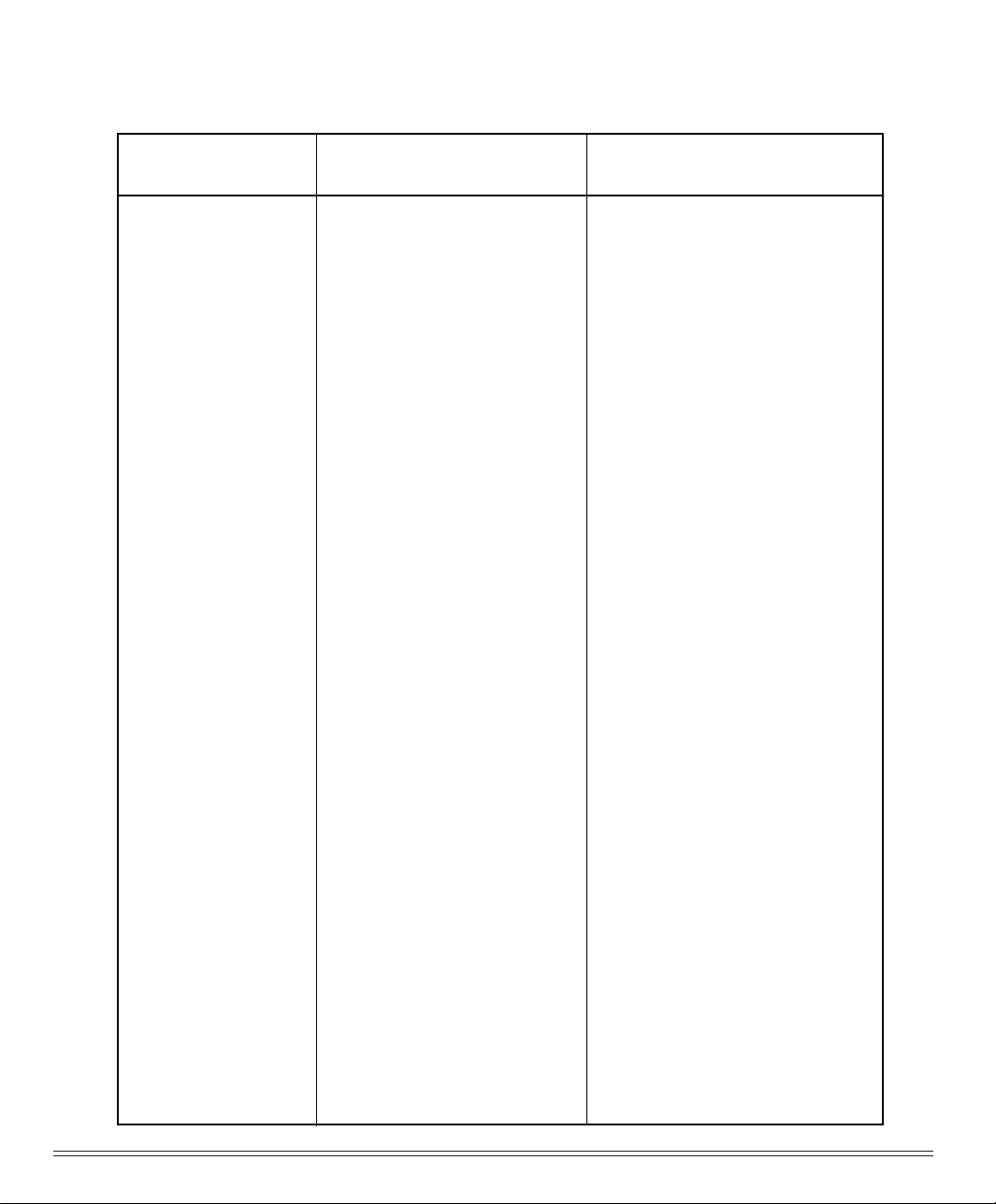

Button Print Mode

Help on Power Up

With CSF Installed

Menu Mode

SEL+LF

QUIET+

PARK

SEL+

FF/LOAD

N/A

N/A

N/A

Resets Menu to

factory default.

Resets Top of

Form to factory

default.

Activates hex

dump mode.

N/A

N/A

N/A

N/A

N/A

N/A

N/A : Not applicable.

ML390/391 Turbo Printer Handbook 29

Page 37

Menu Mode

When your printer is in the Menu Mode, you can use the front panel controls to change

the defaults for the printer parameters, including emulation, page length, line spacing, typeface, pitch, etc. For example, you might want to change the page length to 14

inches if you’re printing on legal-size documents, or to 3 inches if you’re printing on

labels or small cards.

To place your printer in the Menu Mode, hold the SHIFT button while pressing the

SEL button (printer either selected or deselected). The MENU light will come on and,

if the printer was selected, the SEL light will go out.

To exit the Menu Mode, hold the SHIFT button and press the SEL button. The MENU

light will go out and the SEL light will come on.

30 Operation

Page 38

Sample Menu

The menu is made up of groups of parameters. Within each group is a list of items

and each of those items has several possible settings. Here’s a sample Menu printout.

The first column lists the groups; the second, items; the third, settings:

ML390/391 Turbo Printer Handbook 31

Page 39

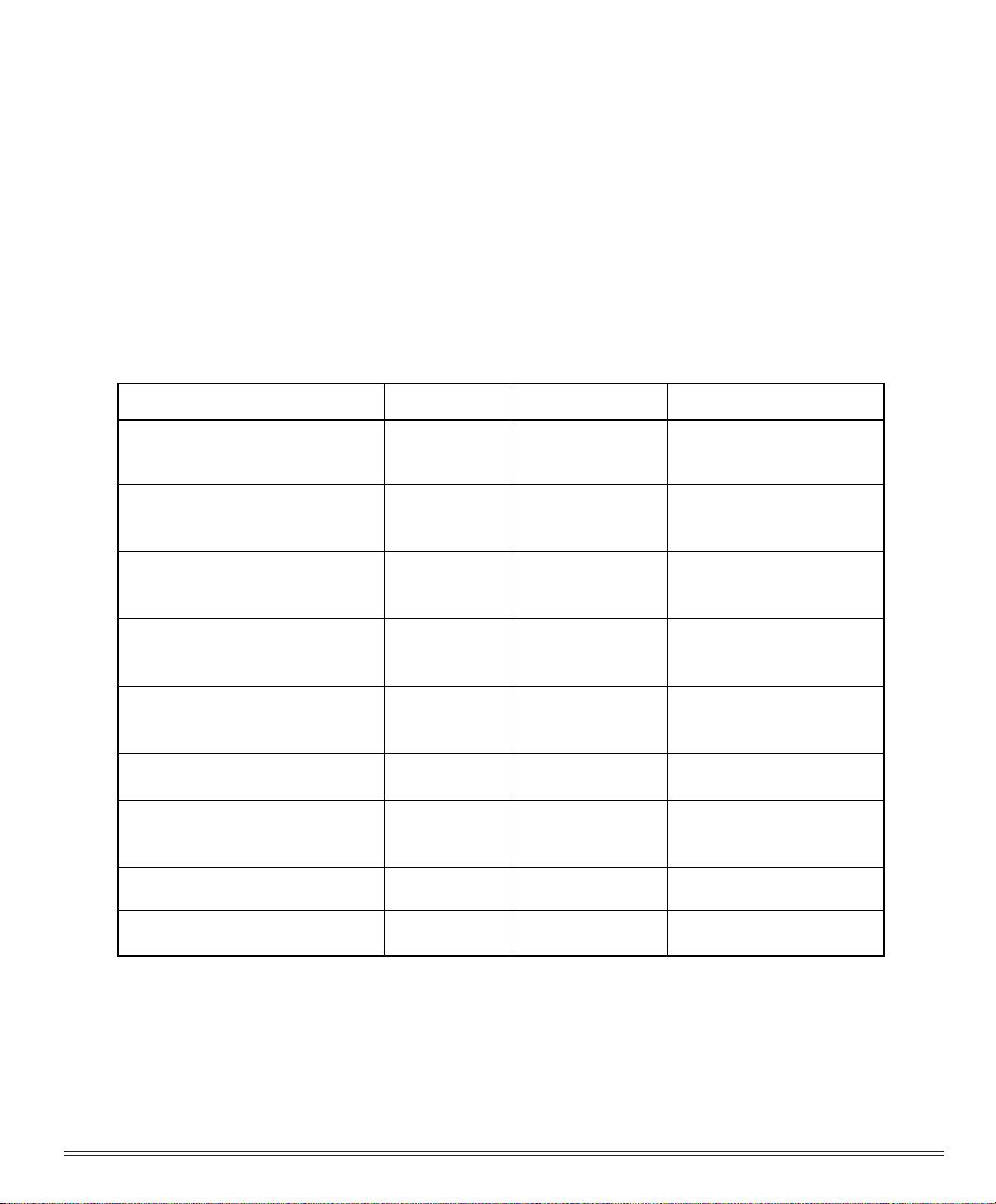

Summary of Menu Settings

The table below details the entries in the printer Menu as it comes from the factory.

The defaults are in bold face italic type.

Other entries will appear in the Menu depending on what options you have installed

and what emulation is engaged.

For a complete listing of all the available Menu selections, along with explanations for each

setting, see appendix B.

Group Item Setting

Printer Control

Font

Symbol Sets

Rear Feed

Emulation Mode

Print Mode

Pitch

Proportional Spacing

Style

Size

Character Set

Language Set

Zero Character

Code Page

Line Spacing

Form Tear-Off

Skip Over Perforation

Page Width*

Page Length

Epson LQ, IBM PPR, IBM AGM

LQ Courier, LQ Roman, LQ Swiss, LQ

Swiss Bold, LQ Orator, LQ Gothic, LQ

Prestige, Utility

10 cpi, 12 cpi, 15 cpi, 17.1 cpi, 20 cpi

No, Yes

Normal, Italics

Single, Double

Set I, Set II

American, French, German, Britishi, Dan-

ish I, Swedish, Italian, Spanish I, Japanese,

Norwegian, Danish II, Spanish II, Latin

American, French Canadian, Dutch, Publisher

Slashed, Unslashed

USA, Canada French, Multilingual, Portu-

gal, Norway, BRASCII, Abicomp

6 LPI, 8 LPI

Off, 500 ms, 1 sec, 2 sec

No, Yes

13.6", 8"

11", 11 2/3", 12", 14", 17", 3", 3.5", 4", 5.5",

6", 7", 8", 8.5"

* ML391 Turbo only

32 Operation

Page 40

Group Item Setting

Bottom Feed

Top Feed

Set-Up

Line Spacing

Form Tear-Off

Skip Over Perforation

Page Width *

Page Length

Line Spacing

Bottom Margin

Page Width *

Page Length

Wait Time

Page Length Control

Graphics

Receive Buffer Size

Paper Out Override

Print Registration

Operator Panel Function

Reset Inhibit

Print Suppress Effective

Auto LF

Auto CR *

1

SI Select Pitch (10 CPI) *

SI Select Pitch (12 CPI) *

Time Out Print

Auto Select

Graphics Speed

Centering Position

CSF Type *

6 LPI, 8 LPI

Off, 500 ms, 1 sec, 2 sec

No, Yes

13.6", 8"

11", 11

2

/3", 12", 14", 17", 3", 3.5", 4", 5.5",

6", 7", 8", 8.5"

6 LPI, 8 LPI

Valid, Invalid

13.6", 8"

11", 11 2/3", 12", 14", 17", 3", 3.5", 4", 5.5", 6",

7", 8", 8.5"

1 sec, 2 sec, 500ms

by Menu Setting, by Actual Page Length

Uni-directional, bi-directional

8K, 1 Line, 23K

No, Yes

0, 0.05 mm Left, 0.10 mm Left, 0.15 mm Left,

0.20 mm Left, 0.25 mm Left, 0.25 mm Right,

0.25 mm Right, 0.15 mm Right, 0.10 mm Right,

0.05 mm Right

Full Operation, Limited Operation

No, Yes

Yes, No

No, Yes

No, Yes

1

17.1 CPI, 15 CPI

1

20 CPI, 12 CPI

Valid, Invalid

No, Yes

Low, High

DEFAULT, MODE 1, MODE 2

Wide, Narrow

Parallel I/F

I-Prime

Pin 18

Auto Feed XT *

2

Buffer Print, Buffer Clear, Invalid

+5V, Open

Invalid, Valid

* ML391 Turbo only

*1 IBM mode Only

*2 EPSON mode Only

ML390/391 Turbo Printer Handbook 33

Page 41

Menu Mode Indicator Lights

In the Menu Mode, the following lights indicate your printer’s status:

SEL

SEL

MENU

EXIT

POWER

FF/LOAD

LF

Micro Feed

SHIFT TOF

ALARM

GROUP PRINT

Down

Micro Feed

Up

ITEM

TEAR

SET

MENU

PARK

QUIET

12

1. POWER light: Glows when printer is on.

2. MENU light: Glows when printer is in Menu Mode.

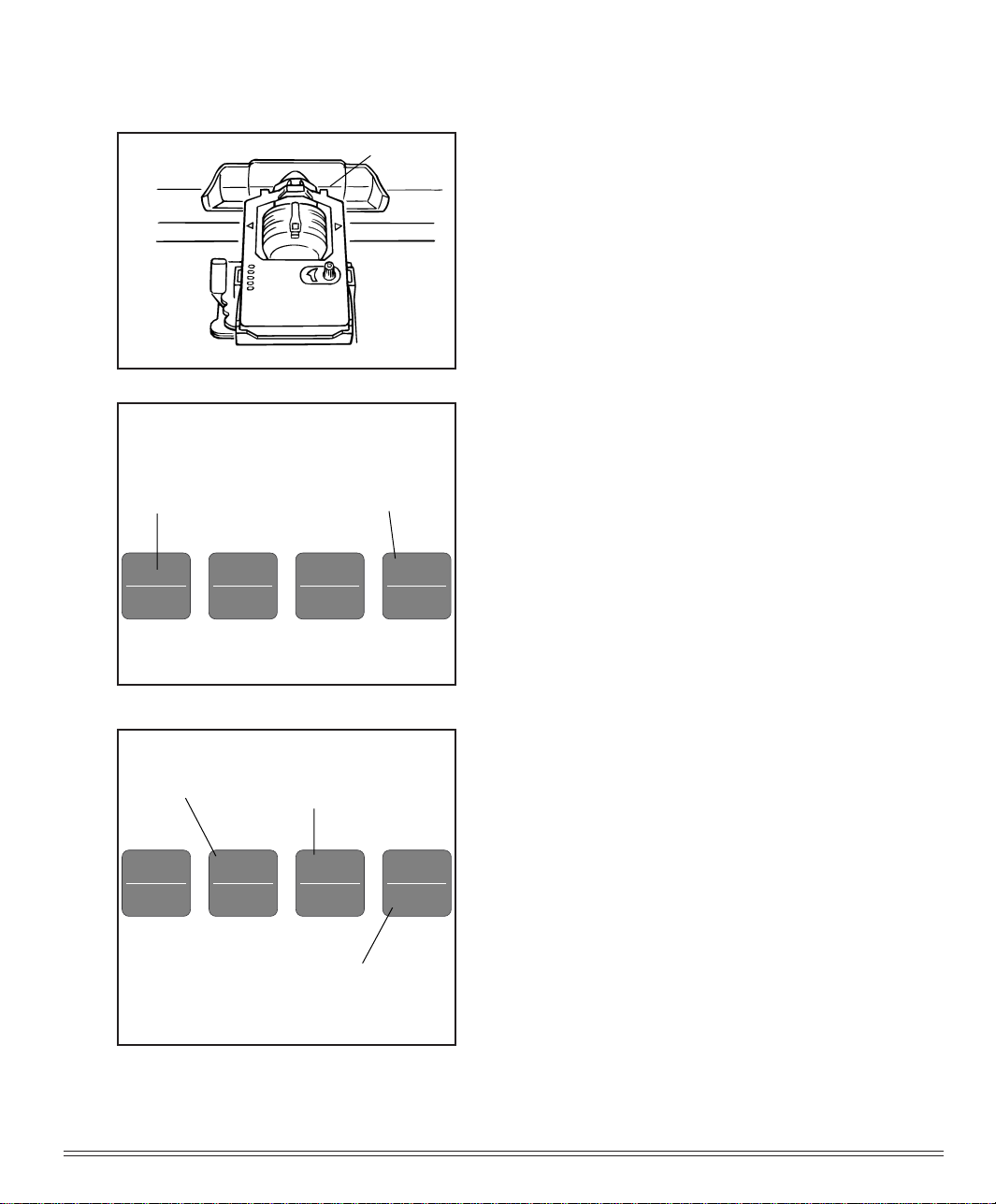

Menu Mode Buttons

SEL

SEL

MENU

EXIT

POWER

LF

SHIFT TOF

Micro Feed

Down

GROUP PRINT

ALARM

FF/LOAD

Micro Feed

Up

ITEM

TEAR

SET

MENU

PRINT QUALITY

CHARACTER PITCH

RESET

LQ COURIER GOTHIC

UTILITY PRESTIGE ORATOR

10 12 15

17 20 PROP

PARK

–ROMAN–

–SWISS–

QUIET

1 2 3 4

34 Operation

Page 42

Here is a summary of the buttons active in the Menu Mode:

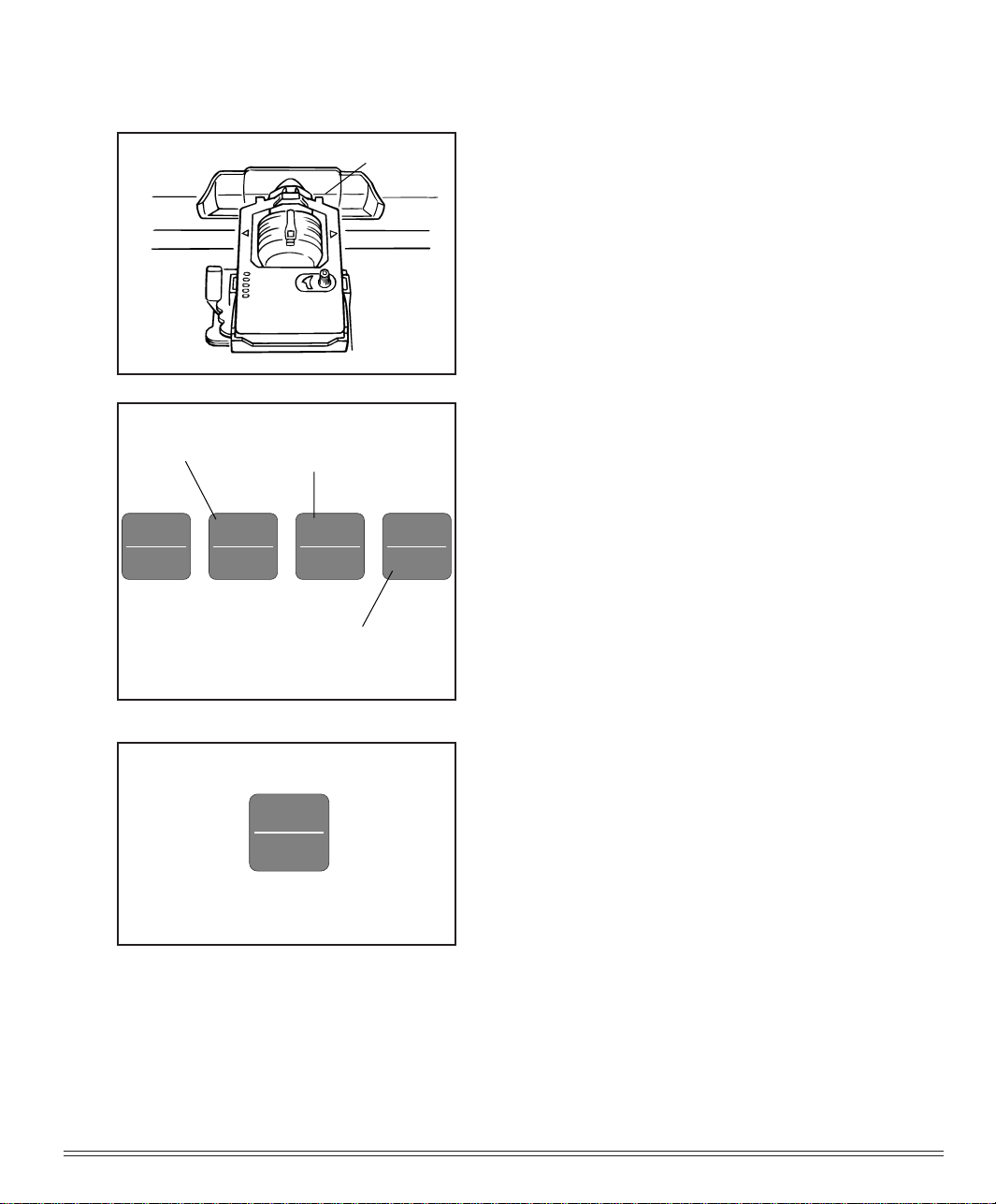

1. GROUP button: Press to scan through gr oups of listings. Each time you pr ess the

GROUP button, a line will print, showing the next group in the Menu. To go back

one group, hold the SHIFT button while pressing the GROUP button.

2. ITEM button: Press to scan through items for a particular group. Each time you

press the ITEM button a line will print, showing the next item within the group. To

go back one item, hold the SHIFT button while pressing the ITEM button.

3. SET button: Press to change setting for the items. Each time you press the SET

button, a line will print across the page showing the next setting for that item.

Keep pressing the button until the setting you wish to engage appears. To go back

one setting, hold the SHIFT button while pressing the SET button.

4. PRINT button: Press to print out listing of current settings for each items, group

by group.

Resetting Menu to Factory Defaults

To reset your printer Menu to the factory settings, turn the printer off, then hold the

SEL and LF buttons while turning it back on again.

Hold while turning printer on

SEL

SEL

MENU

EXIT

POWER

LF

SHIFT TOF

ALARM

Micro Feed

Down

GROUP PRINT

FF/LOAD

Micro Feed

Up

ITEM

TEAR

SET

MENU

PARK

QUIET

ML390/391 Turbo Printer Handbook 35

Page 43

Performing Basic T asks

Selecting Print Quality

PRINT QUALITY

Print quality button

LQ COURIER GOTHIC

UTILITY PRESTIGE ORAT OR

–ROMAN–

–SWISS–

Your printer allows you to select from two print qualities: utility and letter quality

(LQ), Utility printing is in the Gothic typeface. The LQ printing is of noticeably higher

quality and offers you a choice of six typefaces: Courier, Gothic, Pr estige, Orator, Roman and Swiss. To select the print quality/ typeface you want, keep pressing the

PRINT QUALITY button until the lights are lit beside the combination you want. The

LQ Roman and LQ Swiss typefaces are selected when the lights on either side are

both lit.

For example, to select the LQ Roman typeface, press the PRINT QUALITY button

until the following lights appear:

Your printer also prints any of eight different bar codes accessible through

printer commands. For more information on bar codes, see the end of this chapter.

36 Operation

Page 44

Selecting Character Pitch

CHARACTER PITCH

RESET

Character Pitch button

10 12 15

17 20 PROP

The character pitch determines the width of the individual characters and is measured in characters per inch (cpi). To select the character pitch, press the CHARACTER PITCH button successively until the light underneath the pitch you wish to engage is lit (10 cpi, 12cpi, 15cpi, 17cpi, 20cpi, or Proportional).

To reset the pitch to the user default (Menu Setting):

1. Be sure printer is deselected (SEL light out). If not, press SEL button.

2. Hold SHIFT button while pressing CHARACTER PITCH button.

If the SI command is received from your software, the character pitch selected

on the control panel will be overridden by the SI command.

ML390/391 Turbo Printer Handbook 37

Page 45

The table below summarizes the fonts available from your printer:

Typeface Spacing Style

LQ Courier

LQ Letter Gothic

LQ Prestige

LQ Orator

LQ Roman

LQ Swiss

10 cpi

12 cpi

Proportional

8 point

10 cpi

12 cpi

Proportional

10 cpi

12 cpi

Proportional

10 cpi

12 cpi

Proportional

10 cpi

12 cpi

Proportional

8 point

10 cpi

12 cpi

Proportional

8 point

Normal, superscript, subscript

Normal, superscript, subscript

Normal, superscript, subscript

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal, superscript, subscript

Normal, superscript, subscript

Normal

Normal

Normal, superscript, subscript

Normal, superscript, subscript

Normal

Normal

LQ Swiss Bold

Utility Gothic

Barcode

Scalable fonts'

(LQ Courier, LQ

Roman< LQ Swiss)

10 cpi

12 cpi

Proportional

10 cpi

12 cpi

Code 39

UPC A, UPC E, EAN 8,

EAN 13, Interleaved 2 of

5, Code 128, Postnet

11 point~ 64 point

Normal

Normal

Normal

Normal, superscript, subscript

Normal, superscript, subscript

N/A

Normal

38 Operation

Page 46

T esting Your printer

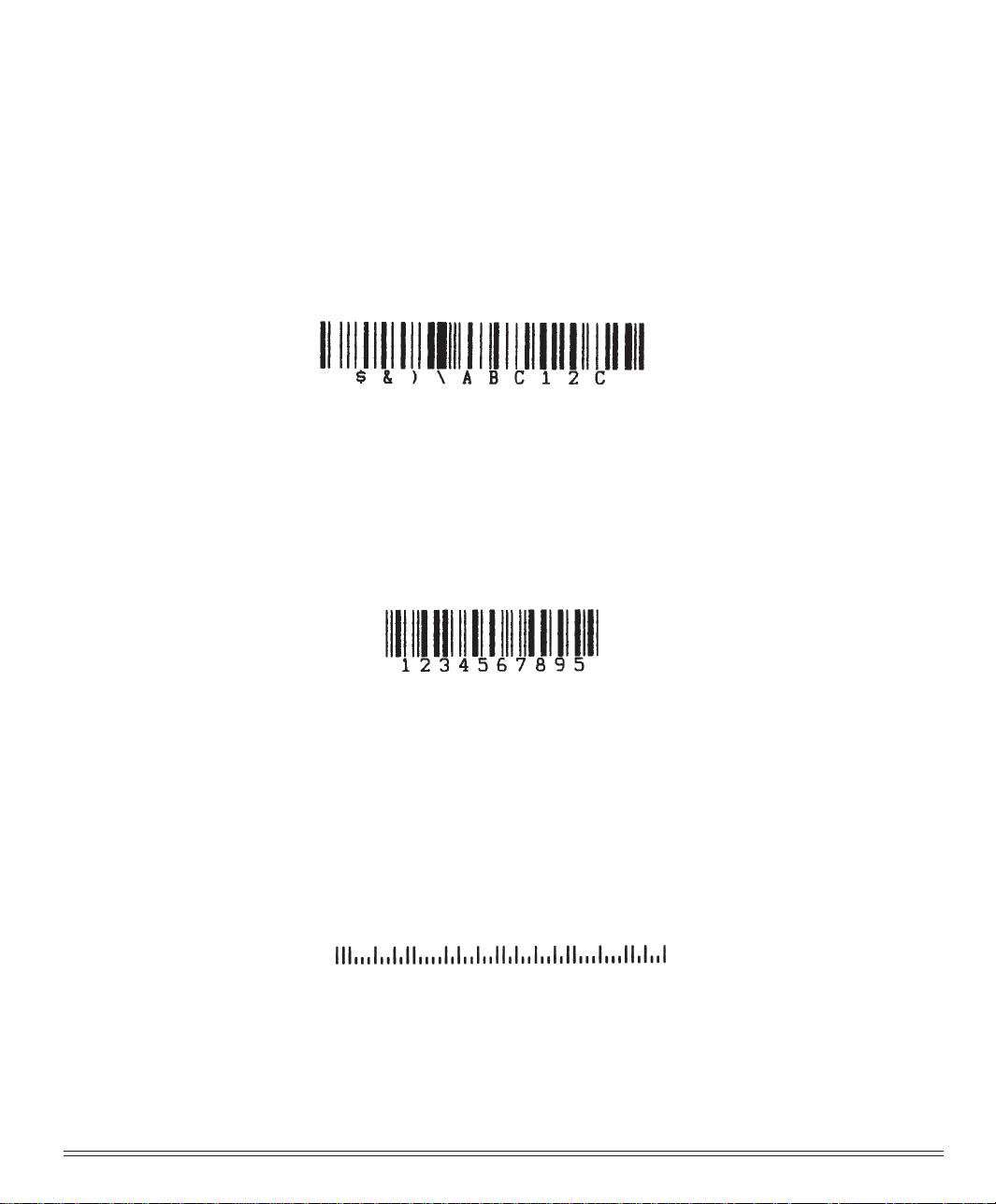

Your printer has three your can run: the Font Test, the Rolling ASCII Test, and the

Hexadecimal Dump Test.

Font Test

The Font Test provides a printout containing samples of available typefaces. Here’s a

portion of a Font Test printout:

ML390/391 Turbo Printer Handbook 39

Page 47

To run the Font Test:

1. Be sure paper is loaded.

2. Turn off printer.

3. Hold LF button for several seconds while turning printer on. (IF printer simply

turns on without starting to print, you didn’t hold down LF button long enough.)

Rolling ASCII Test

The Rolling ASCII Test produces a continuous printout of all ASCII characters. The

printing will continue until you stop it manually by pressing the SEL button. Here’s a

sample portion of a Rolling ASCII Test:

40 Operation

Page 48

To activate the Rolling ASCII Test:

1. Be sure paper is loaded.

Caution!

2. Turn off printer.

3. Hold QUIET button for several seconds while turning printer on. (If printer sim-

ply turns on without starting to print, you didn’t hold down QUIET button long

enough.)

Hexadecimal Dump Test

If you want to test the data your computer is sending to the printer , you can place the

printer in the Hexadecimal Dump Mode. When the printer is in the Hex Dump Mode,

all data received, including text and printer commands, will be printed in both hexadecimal and ASCII format.

For example, this line of BASIC code:

LPRINT CHR$ (27);“0”;CHR$ (30);“This is an example of a hexadecimal

dump.”

For wide carriage Model 391 Turbo, be sure you have wide paper loaded!

In the ASCII format, all non-printable characters will be represented by a period.

would print like this:

ML390/391 Turbo Printer Handbook 41

Page 49

To engage the Hexadecimal Dump Mode:

1. Be sure paper is loaded.

2. Turn off printer.

3. Hold SEL and FF/LOAD buttons for several seconds while turning on printer.

The printer will print the line “Hex Data Dump” and be ready to receive data in the

Hexadecimal Dump Mode. To run the test, simply send data to the printer while it is

in the Hexadecimal Dump Mode.

When you’re done, you can exit the Hexadecimal Dump Mode by either pressing the

SEL button or by turning the printer off, then on again.

Resetting T op of Form

To reset the Top of Form to the factory default:

1. Turn off printer.

2. Hold down QUIET and PARK buttons while turning printer back on.

Using Bar codes

Your MICROLINE 390/391 Turbo printer incorporates eight different bar codes:

• UPC A

• UPC E

• EAN 8

• EAN 13

• Code 39

• Code 128

• Interleaved 2 of 5

• Postnet

42 Operation

Page 50

You will find a list of the bar code printer commands for each emulation in appendix

C.

Here is a brief explanation of each of the available bar codes, along with a sample

printout for each one.

UPC A Bar Code

UPC (Universal Product Code) bar coding is used in the supermarket industry. UPC

A coding contains ten digits: the first five digits represent the manufacturer, the second five digits identify the product.

UPC E

UPC E bar coding is a six-digit variation of UPC A, used for labeling small items.

ML390/391 Turbo Printer Handbook 43

Page 51

EAN 8

EAN (European Article Numbering) bar coding is a variation of UPC coding. EAN 8

encodes eight digits.

EAN 13

EAN 13 encodes 13 digits and contains the same number of bars as UPC A. The thirteenth digit combined with the twelfth digit provides a code representing a country.

Code 39

Also known as 3 of 9 Code, code 39 is used in non-retail applications. Each character

has five bars and four spaces. Code patterns have been developed for 44 different

alphabetic, numeric and graphic characters.

44 Operation

Page 52

Code 128

Code 128 has 106 different characters, each of which can have any one of three dif fer ent meanings depending on which code set (A, B, or C) is engaged. A special code at

the beginning indicates which set is engaged: three shift codes are also available for

use within the bar code to indicate a change in the code set engaged, as required.

Interleaved2 of 5

Inerleaved2 of 5 bar coding is used mainly in the distribution industry. Two digits are

encoded: one in the bars and one in the spaces.

Postnet

Postnet bar coding is used by the U.S. Post Office for sorting mail by automated equipment. It incorporates a coding system using five bars and four spaces for each digit.

ML390/391 Turbo Printer Handbook 45

Page 53

46 Operation

Page 54

hapter 4: W orking with Software

C

This chapter covers the fundamentals of setting up commercial software packages for

use with your printer . Be sure to read your software documentation car efully for more

details.

Basic T erminology

Before we start, let’s examine a few terms with which you may not be familiar.

Printer Commands

If you’re using commercial software with an appropriate printer driver (see

“Printer Drivers” below), the printer commands will normally be sent to the

printer by your software and you won’t even need to think about them.

Printer commands are signals sent by your PC to the printer which guide and control

its operation. Printer commands tell the printer what character pitch to use, what font

to use, what margins to use, whether to use single or double spacing, when to engage/disengage double width or double height printing, etc.

Printer commands can be sent in decimal, ASCII, or hexadecimal form. The values

(decimal/ASCII/hexadecimal) for each type of command depend on which emulation is active (see Appendix C for a listing of printer commands for each emulation).

With only a few exceptions, printer commands begin with the ESC character, decimal

27 (hexadecimal 1B), which serves as signal to the printer that what follows is to be

interpreted as a command rather than just a string of characters. Some printer commands expect you supply a numerical value, representing tab stops, line spacing, etc.

ML390/391 Turbo Printer Handbook 47

Page 55

Emulations

In order to eliminate hundreds of different sets of printer commands, most printers

emulate, or imitate, one of several general printers; i.e., they accept all of that printer’s

commands and behave as though they were the emulated printer.

Your printer has three emulations:

• IBM Proprinter

• IBM AGM

• Epson LQ (factory default)

Printer Drivers

Most of the time, your printer will be controlled by standard commercial software

packages such as Lotus

Commercial software packages use printer drivers to control the appearance of printed

documents. A driver is simply a list of printer commands tailor-made to cause the

printer to perform various functions at the request of the software, producing documents with the correct format. The availability of different drivers makes it possible

for a program to function roughly the same way no matter which printer is being

used, so long as you select the correct driver for the printer you’re using. If you don’t

select the correct driver , you’ll get strange symbols, incorr ect fonts, etc., being printed

instead of a great-looking document!

®

1-2-3®, WordPerfect®, and Microsoft® Windows.

When you use your printer with a software package, you need to select a driver compatible with your printer in order to have the software send the people printer commands to instruct your printer as to how to format and print the document.

A Printer Driver Diskette is not included in your package. If you have any questions

or need further information about Printer Driver , please contact the dealer where you

purchased your printer.

48 Working with Software

Page 56

Compatible Printer Drivers

Many of the software packages you use will contain drivers 100% compatible with

your printer. For older software, however, it may be necessary to select a driver that

functions nearly the same as a driver specifically designed for your printer. This generally means that you will be selecting a driver that provides commands to access

most, but not all of the available functions; however , the commands that are available

will perform properly with your printer.

The table below summarizes the various drivers that will work with your printer.

They are listed in order by decreasing compatibility as you go down the list: select

one from as high up on the list as possible, based on what is available from among the

drivers supplied with your software. If you don’t see one from near the top of the list,

give the software manufacturer a call to see if they have added any drivers to those

supplied when you purchased your software. Softwar e manufacturers ar e constantly

updating their lists of drivers to keep up with the printer market and they may very

well have one which will give maximum compatibility with your printer.

IBM Proprinter Emulation IBM X24e AGM/XL24e AGM

Emulation

Oki ML 590/1 IBM

IBM Proprinter

X24e/ XL24e

IBM Proprinter

X24/ XL24

IBM Proprinter

IBM Graphics Printer

Use this emulation only when

you've selected an IBM Proprinter X24e/ XL24e driver

and you need to use Epson

LQ high density graphics.

Oki ML 590/1 Epson

Epson LQ 870/ 1170

Epson LQ 850/ 1050

Epson LQ 860/ 2550

Epson LQ 2500

Epson LQ 1500

Epson LQ

Epson FX

Epson JX

Epson LX

Epson RX

Epson MX

Epson LQ

Emulation

Because there are some differences in characteristics such as speed or access to various features, you may wish to experiment with several differ ent drivers. If you must

select a driver that is not listed in the table, be sure to check it thoroughly for print

features such as boldface, underline and changes in pitch. Don’t be surprised if boldfaced items are printed twice, underlines are misplaced, wide spaces are left between

lines or the printer behaves chaotically (turn off the printer if the latter occurs). These

are all characteristics of an incompatible driver selection.

ML390/391 Turbo Printer Handbook 49

Page 57

50 Working with Software

Page 58

hapter 5: Ploblem Solving,

C

Maintenance, & Service

This chapter provides solutions to some common printer problems and explains the

routine maintenance procedur es that will help keep your printer in tip-top operating

condition. It also tells you how to order parts, consumables and accessories, and provides information on obtaining service for your printer. You will find your printer’s

warranty at the back of this Printer Handbook.

Problem Solving

What if …

…nothing happens when I turn on the printer?

The printer may not be plugged in. Check the power cord connection to the outlet

and to your printer. If you’re using a power strip, make sure it’s turned on. Check to

be sure that the fuse hasn’t blown or that the circuit breaker hasn’t tripped.

…the printer doesn’t print when the computer sends data?

The printer may be deselected. If the SEL light is out, press the SEL button to select the

printer .

The printer cable may not be securely connected. Check the cable to be sure that it is

properly connected to both the PC and the printer.

If you have installed the serial I/F board, check to be sure that the board is firmly

seated in the printer.

ML390/391 Turbo Printer Handbook 51

Page 59

…I’m getting strange symbols, incorrect fonts, etc., when I try to print a document?

The printer driver you have engaged does not agree with the emulation selected for

your printer.

To check the emulation selected, first make sure paper is loaded, then press the SEL

and SHIFT buttons simultaneously to enter the MENU on your printer. Next, press

the GROUP button: this will print the emulation selected.

If the emulation is not the one you want to use, press the SET button to change it to

the one you want before exiting the MENU (to exit, press SEL and SHIFT buttons).

If the emulation is correct, check your software documentation on how to select a

printer driver , then check to be sure that you have selected one of the drivers listed for

that emulation on page 49). The closer the driver is to the top of the list, the more

compatible it will be with your printer. If your software doesn’t have any of the indicated drivers available, check with the software manufacturer to see if they have added

any additional drivers since you purchased your software.

If you have embedded any printer commands in your software, check to be sur e that

you entered them correctly.

…I’ve installed a brand new ribbon and the printing is smeared and streaked?

The plastic shield on the ribbon is either loose or missing. The shield must be left on

the ribbon when you are installing the cartridge. To remedy this situation, move the

printhead to the center of the platen (careful – printhead may be HOT!) and lift off the

ribbon cartridge. Check the ribbon shield. If it’s loose, secure it in place properly. If it’s

missing, locate it and reinstall it.

…there are dots missing in my printouts?

The head gap may not be set correctly. Try moving the head gap lever to a lower

setting. If that doesn’t help, the printhead may be damaged; call for service.

52 Ploblem Solving, Maintenance, & Service

Page 60

… the Alarm light is on and the Character Pitch 15 light is flashing?

This indicates a paper loading error. To stop the flashing light, press the SEL button.

Before trying to load paper in again, check to be sur e that you have the paper lever in

the correct position (BOT, TOP, REAR) for the path you’re using.

Caution!

If the paper lever is in the correct position and you’re using rear feed, lift up the paper

separator and check to be sure that paper is properly on the tractors and has not

jammed up somehow.

If the paper lever is in the correct position and you’re using the optional bottom-feed

push tractor, check the bottom tractor unit to be sure that paper is properly on the

tractors and has not jammed up before entering the printer.

Once the paper is correctly loaded, press and release the SEL button, then hold the

SHIFT button and press the RESET (Character Pitch) button.

…I need to load paper, but the Alarm light is not on?

If the Alarm light is of f, the printer thinks it has paper loaded. T o correct this pr oblem,

press and release the SEL button, then hold the SHIFT button and press the RESET

(Character Pitch) button. The Alarm light will come on and you’ll be able to load

paper.

…my word processor files don’t print the way I have the MENU and front panel set?

Always turn the printer off before you turn the platen knob!

Before sending a file to the printer, many word processors send either an “initialization string” or an I-Prime signal to the printer.

The initialization storing contains codes that reset the printer to a default set of features: otherwise the printer might accidentally print using features set for a pr evious

job. These codes will override panel or MENU settings. To set your printer to ignore

the reset code, enter the printer MENU (hold SHIFT button while pressing SEL/MENU

button) and change the Reset Inhibit item (in the Set-Up group) to Yes. Please note

that while this will stop the reset code from resetting your printer, other codes in the

initialization string may still override the printer MENU and/ or front panel settings.

ML390/391 Turbo Printer Handbook 53

Page 61

The I-Prime signal is sent over the parallel interface (pin 31) and will automatically

override any settings you have made using the front panel buttons. To eliminate this

problem, enter the program MENU (hold SHIFT button while pressing SEL/MENU

button) and change the I-Prime item (in the Parallel I/F group) to Invalid.

…the Print Quality and Character Pitch buttons on the front panel won’t work?

The Operator Panel Function item on the printer MENU can be used to disable these

buttons. If the printer is part of a customized system or if it is used by a number of

people, the system manager may have used this option to make sure the printer is

always set properly.

…static electricity causes the paper to stick?

In cold, dry weather, static charges can build up on continuous-form paper. This can

make the paper cling to the paper separator. If you have this problem during highvolume printing jobs, try moving the single sheet paper guides on the separator together so that the paper rests on the guides rather than on the separator itself.

Maintenance

This section explains how to change ribbons, clear paper jams and clean your printer .

Replacing the Ribbon Cartridge

When replacing the ribbon, be sure to use only ribbons specifically for use with

MICROLINE 390 /391 Turbo printers. For best results,use genuine OKI ribbons.

1. Turn printer off.

2. Disengage and swing open access cover.

Caution!

printhead: it may be hot!

54 Ploblem Solving, Maintenance, & Service

Be careful not to touch the

Page 62

Center

printhead

Swing front end

up to remove

3. Slide ribbon cartridge along until it is

centered on platen, being careful not to

touch printhead.

4. Swing front-end of cartridge up off

printhead, then lift cartridge out and

discard it.

5. Remove new ribbon cartridge from its

packaging — do NOT remove clear

plastic ribbon shield!

6. Hold ribbon cartridge with knob facing up and exposed portion of ribbon

facing platen. Place flat end on ribbon

plate, fitting grooves over pins on plate.

Plastic shield

facing platen

ML390/391 Turbo Printer Handbook 55

Page 63

7. Lower front end of cartridge over

printhead until it snaps into place. T urn

knob in direction of arrow (clock-wise)

to take up any slack in ribbon.

1

2

3

4

5

Knob

56 Ploblem Solving, Maintenance, & Service

Page 64

Clearing Paper Jams

Caution!

Always turn the printer off before you turn the platen knob!

Rear Feed Jams

To clear a rear-feed paper jam:

1. Turn off printer

2. T urn platen knob to back paper out of printer. Remove any ripped pieces of paper.

3. Reload paper, turn printer back on and press FF/LOAD button.

If your paper keeps jamming, the chances are excellent that you have bits of paper

stuck in the paper path. To eliminate this problem:

1. Turn off printer.

2. Use platen knob to back paper out of

printer.

3. Remove the paper separator.

Remove

paper

separator

ML390/391 Turbo Printer Handbook 57

Page 65

Tractor covers

4. Open tractor covers and remove paper

from printer.

Remove pull-up

roller assembly

Quadruple-thick paper

5. Open access cover and lift off pull-up

roller assembly.

Note: Never attach or remove the pull-up roller

assembly when the paper separator is in the

standing state.

6. Fold some single-sheet, continuous-

feed paper over three times to produce

page four sheets thick.

7. Load this quadruple-thick sheet onto

tractor pins and close tractor covers.

8. Turn platen knob to draw quadruple-

thick paper around platen. This will

bring jammed pieces of paper up and

out so you can dispose of them.

9. Back quadruple-thick sheet out of

printer using platen knob.

58 Ploblem Solving, Maintenance, & Service

Page 66

Replace pull-up

roller assembly

10.Replace pull-up roller assembly.

Note: When installing a pull-up roller assem-

bly, Shift the paper lever in agreement with the

“Rear” mark before the installation.

11.Reload regular paper (open tractor covers, place paper on pins, close tractor

covers).

Replace

paper

separator

12. Swing access cover and paper separator back into place.

13.Turn printer on and press FF/LOAD

button.

ML390/391 Turbo Printer Handbook 59

Page 67

Single Sheet Feed Jams

To remove jammed single sheets of paper (top feed):

1. Turn printer OFF.

2. Rotate platen knob to back paper out

of carriage.

Lift off pull-up roller

Button Feed Jams

If bottom-feed paper jams:

Lift off pull-up roller

assembly

assembly

3. If necessary, open access cover and lift

off pull-up roller assembly to provide

access to remove any ripped pieces

from around carriage.

1. T urn of f printer and use platen knob to

back paper out carefully.

2. Be sure to remove any shreds of paper

from printer before reloading paper.

(Open access cover and lift off pull-up

roller assembly to provide access to carriage area.)

60 Ploblem Solving, Maintenance, & Service

Page 68

Cleaning the Housing

You should clean the printer every six months (or after about 300 hours of operation).

To do this:

1. Turn printer OFF and remove paper

from path.

Remove pull-up roller

assembly

2. Open access cover and remove pull-up

roller assembly.

3. Use clean, dry cloth to dust area around

carriage shaft and platen. Be sure to r emove any loose particles of paper.

Note: The built-up of dust or paper powder in

the printer, which may be occurred by some

environmental settings or media used, may

cause a mulfunction, so execute cleaning according to how the printer is dirty.

4. Reinstall pull-up roller assembly and

close access cover.

Note: When installing a pull-up roller assem-

bly, Shift the paper lever in agreement with

the “Rear” mark before the installation.

Never use solvents or strong detergents on the cabinet–they could

damage the housing.

ML390/391 Turbo Printer Handbook 61

Page 69

Accessories

You can add even more flexibility to your printer by means of the following optional

accessories.

Cut Sheet Feeder, Single-Bin and Dual-Bin

Mounts on the platen to provide continuous single-sheet paper feed. The bin will

hold up to 100 sheets of standard, 20-lb

paper . W ith cable for connection to printer .

Push Tractor, Bottom-Feed

Converts printer for feeding continuousform paper from the bottom. Use of bottom feed eliminates the curling which

takes place as rear-feed paper moves

around the platen. Bottom feed is ideal for

card stock, thick multi-part forms, labels

which could peel off and jam the unit if

fed in from the rear, etc.

Includes tractor, support legs for printer,

and metal tear bar.

62 Ploblem Solving, Maintenance, & Service

Page 70

Pull Tractor, Top-Mount

Used for bottom-feed of labels or heavy

card stock, or in conjunction with the rearfeed tractor to provide more precise paper control when you’re using multi-part

forms. Includes cover for installation in

place of access cover.

Roll Paper Stand

Adapts ML 390 Turbo printer for use with

roll-type paper (not supplied). Not usable

on ML 391 Turbo.

Includes stand and support. With cable for

connection to printer.

Serial Interface

Includes serial interface board and locking piece for installation in printer next to

standard parallel interface. Without interface cable.

Note: The use of the locking piece to 390/391

TURBO should be impermissible due to the

exclusiveness for other models.

ML390/391 Turbo Printer Handbook 63

Page 71

Replacement Parts

Replacement Part

Access Cover, ML 390 Turbo

Access Cover, ML 391 Turbo

AC Cord

Poll-up Roller Assembly, ML 390 Turbo

Poll-up Roller Assembly, ML 391 Turbo

Platen Knob

Printhead

Ribbon, Black

64 Ploblem Solving, Maintenance, & Service

Page 72

ppendix A: Specifications

A

Print Method Impact dot matrix

Printhead 24 pins, 0.20 mm diameter with thermal protec-

tion

Print Speed

Mode Characters Characters

Per Inch (CPI) Per Second (CPS)

Utility 10 260

12 312

15 390

17.1 223

20 260

Letter Quality (LQ)

10 87

12 104

15 131

17.1 149

20 174

Characters per Line (CPL)

Setting ML390 Turbo ML391 Turbo

10 cpi 80 cpl 136 cpl

12 cpi 96 cpl 163 cpl

15 cpi 120 cpl 204 cpl

17.1 cpi 137 cpl 233 cpl

20 cpi 160 cpl 272 cpl

Emulations Epson LQ, IBM Proprinter, IBM AGM

Interface Standard: Centronics parallel

Optional: RS-232C serial

ML390/391 Turbo Printer Handbook 65

Page 73

Graphics Resolution: 360 x 360 dots per inch

Resident Font

Letter Quality Courier, Gothic, Prestige, Orator, Roman, Swiss,

Swiss Bold

Utility Gothic

Bar Code: Code 39, UPC A, UPC E, EAN 8, EAN 13, Inter-

leaved 2 of 5, Code 128, Postnet

Receive Buffer Size MAX 23K

Reliability

Mean Time Between 10000 hours at 25% duty cycle and 35%

Failures (MTBR) Page density

Mean T ime to Repair (MTTR) 15 minutes

Printhead life 200 million characters average in 10 cpi utility

mode at 25% duty and 35% page density

Ribbon Life 2 million characters

(on average, 10 cpi utility)

66 Appendix A: Specifications

Page 74

Paper Specifications

Width

Minimum 3”

Maximum ML 390 Turbo: 10”

ML 391 Turbo: 16”

Weight 12 to 24 lb.

Thickness

Rear feed 0.014”(0.36 mm)

Bottom feed 0.017”(0.44 mm)

Paper type Feed Width range

Cut sheets

Single-part continuous forms

Carbonless, multipart continuous form (orig. + 4 copies)

Interleaf, multipart continuous form (orig. + 4 copies)

Labels

Envelopes, single feed

Envelopes, continuous feed,

non-overlap type

Card stock

Transparencies

Top only

Rear, Bottom

Rear, Bottom

Rear, Bottom

Bottom only

Top

Bottom only

Bottom only

Top only

Weight

14 to 24 lb.

12 to 24 lb.

9 to 11 lb.

10 to 12 lb paper,

9 lb carbon

N.A.

24 lb. max.

24 lb. max.

120 lb. max

—

ML390Turbo: 7.2" to 8.5"

ML391Turbo: 7.2" to 14.3"

ML390Turbo: 3" to 10"

ML391Turbo: 3" to 16"

ML390Turbo: 3" to 10"

ML391Turbo: 3" to 16"

ML390Turbo: 3" to 10"

ML391Turbo: 3" to 16"

ML390Turbo: 3" to 10"

ML391Turbo: 3" to 16"

6.5" to 9.5"

6.5" to 9.5"

N.A.

8.5" x 11"

ML390/391 Turbo Printer Handbook 67

Page 75

Dimensions (W x D x H)

ML 390 Turbo: 15.7 x 13.6 x 4.6 inch (398 x 345 x 116 mm)

ML 391 Turbo: 21.7 x 13.6 x 4.6 inch (552 x 345 x 116 mm)

Weight

ML 390 Turbo: 16 lb (7.4Kg)

ML 391 Turbo: 20 lb (9.2Kg)

Environmental Requirements

Operating Temperature: 41 to 95˚F (5 to 35˚C)

Storage Temperature: 14 to 122˚F (-10 to +50˚C)

Operating Humidity: 20 to 80% RH

Storage Humidity: 5 to 95% RH

Electrical requirements 230/240 volts ac (+10%, -14%)

50/60 Hz (±2%)

Specifications subject to change without notice.

68 Appendix A: Specifications

Page 76

ppendix B: Menu Selections

A

The menu selections for your printer are summarized below. Factory defaults are

indicated in bold face italic. Explanations for each item follow the table.

The table below summarizes all possible menu settings available with your

printer. Which of these you will actually see when you are working in the

Menu depends on the active emulation and on the options installed.

Group Item Setting

Printer Control

Font

Symbol Sets

Rear Feed

Emulation Mode

Print Mode

Pitch

Proportional Spacing

Style

Size

Character Set

Language Set