Page 1

¡

MICROLINE 3320/3321

PRINTER

Maintenance Manual

All specifications are subject to change without notice.

Page 2

PREFACE

This maintenance manual describes how to maintain the Microline 3320/3321 printer in the field.

This manual is for customer engineers.

For further information, refer to the Users Manual for handling or operating the equipment.

iii

Page 3

1. CONFIGURATION

1.1 Standard Printer Configuration

1.2 Options

2. THEORY OF OPERATION

2.1 Electrical Operation

2.1.1 Summary

2.1.2 Microprocessor and the Peripheral Circuit

2.1.3 Initialization

2.1.4 Parallel Interface Control

2.1.5 Print Control

2.1.6 SP/LF Motor Control

2.1.7 Operation Panel

2.1.8 Alarm Circuit

2.1.9 Power Supply Circuit

2.2 Mechanical Operation

TABLE OF CONTENTS

2.2.1 Printhead Mechanism and Operation

2.2.2 Spacing Operation

2.2.3 Head Gap Adjusting

2.2.4 Ribbon Drive

2.2.5 Paper Feed Operation

2.2.6 Paper Detection Mechanism

2.2.7 Automatic Sheet Feed

2.2.8 Paper Park Function

3. ASSEMBLY/DISASSEMBLY

3.1 Precautions for Parts Replacement

3.2 Service Tools

3.3 Disassembly/Reassembly Procedure

3.3.1 Printhead

3.3.2 Ribbon Protector

3.3.3 Pull-up Roller Assy

3.3.4 Upper Cover Assy, Access Cover Assy and Sheet Guide Assy

3.3.5 Gear Case Assy

3.3.6 PC Connector

3.3.7 Space Motor, Guide Roller Assy

3.3.8 Space Rack

i

Page 4

3.3.9 Carriage Cable

3.3.10 Backup Roller Holder Assy

3.3.11 Platen Assy

3.3.12 Driver Board (SDDV)

3.3.13 LF Motor

3.3.14 Operation Panel PCB (LEOP)

3.3.15 Control/Power Supply Board (SDCT)

3.3.16 Transformer Assy

3.3.17 Change Lever and Gears

3.3.18 Carriage Shaft

3.3.19 Paper Pan

3.3.20 Rear Tractor Assy

3.3.21 Rear Pressure Assy

3.3.22 Switch Lever

4. ADJUSTMENT

5. CLEANING AND LUBRICATION

5.1 Cleaning

5.2 Lubrication

6. TROUBLESHOOTING AND REPAIR

6.1 Items to Check Before Repair

6.2 Troubleshooting Table

6.3 Lamp Display

6.4 Connection Circuit Check for Printhead and SP/LF Motor

6.5 Troubleshooting Flow Chart

APPENDIX

A. PCB LAYOUT

B. SPARE PARTS LIST

C. RS-232C Serial Interface Board (OPTION)

ii

Page 5

1. CONFIGURATION

Page 6

1. CONFIGURATION

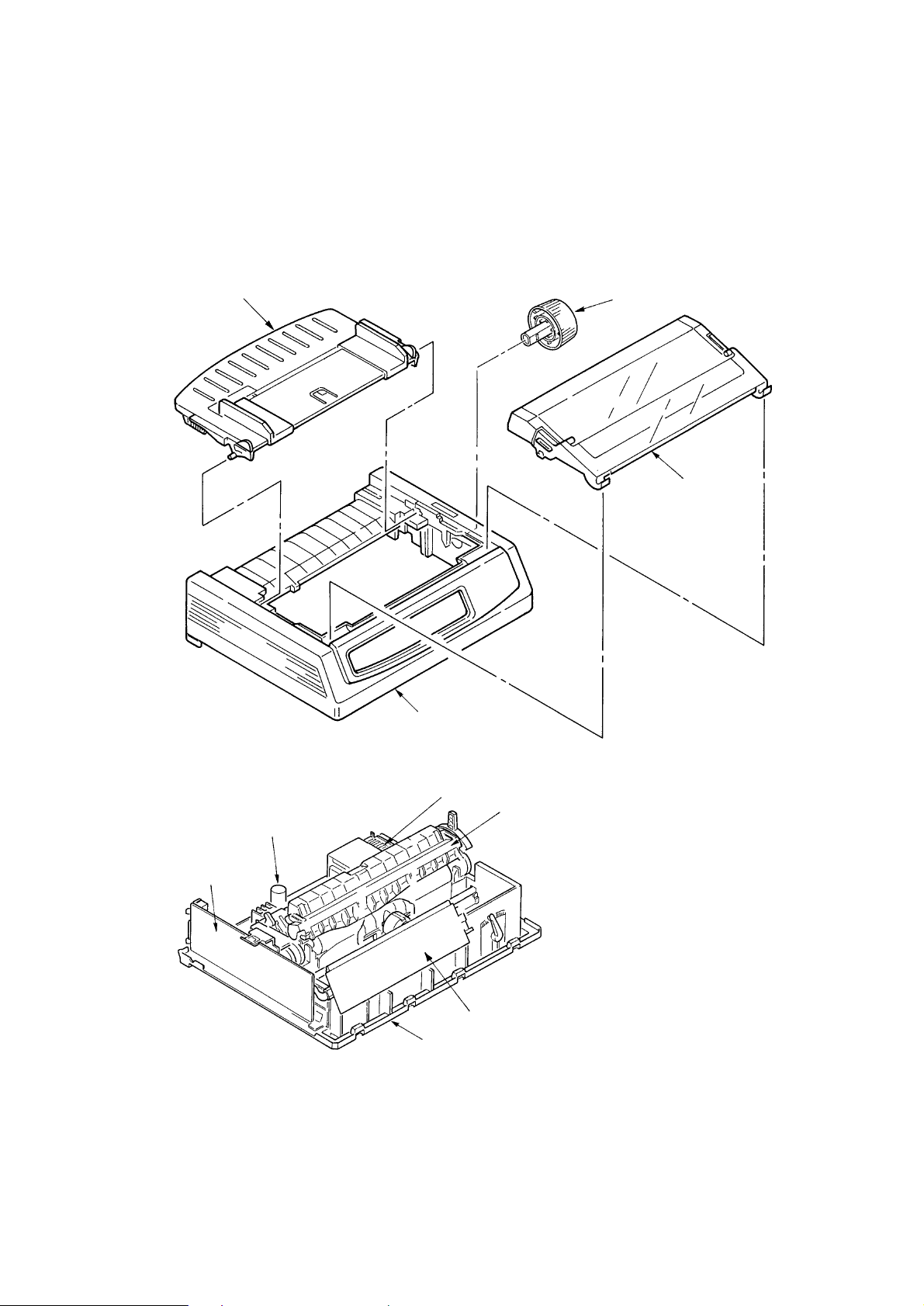

1.1. Standard Printer Configuration

This printer consists of the following assemblies:

Sheet guide assy

Platen knob

Access cover

assy

Upper cover

Control/Power supply assy

Driver board

Transformer assy

Pull-up roller assy

Operation panel assy

Main chassis assy

Figure 1-1 Configuration

1 – 1

Page 7

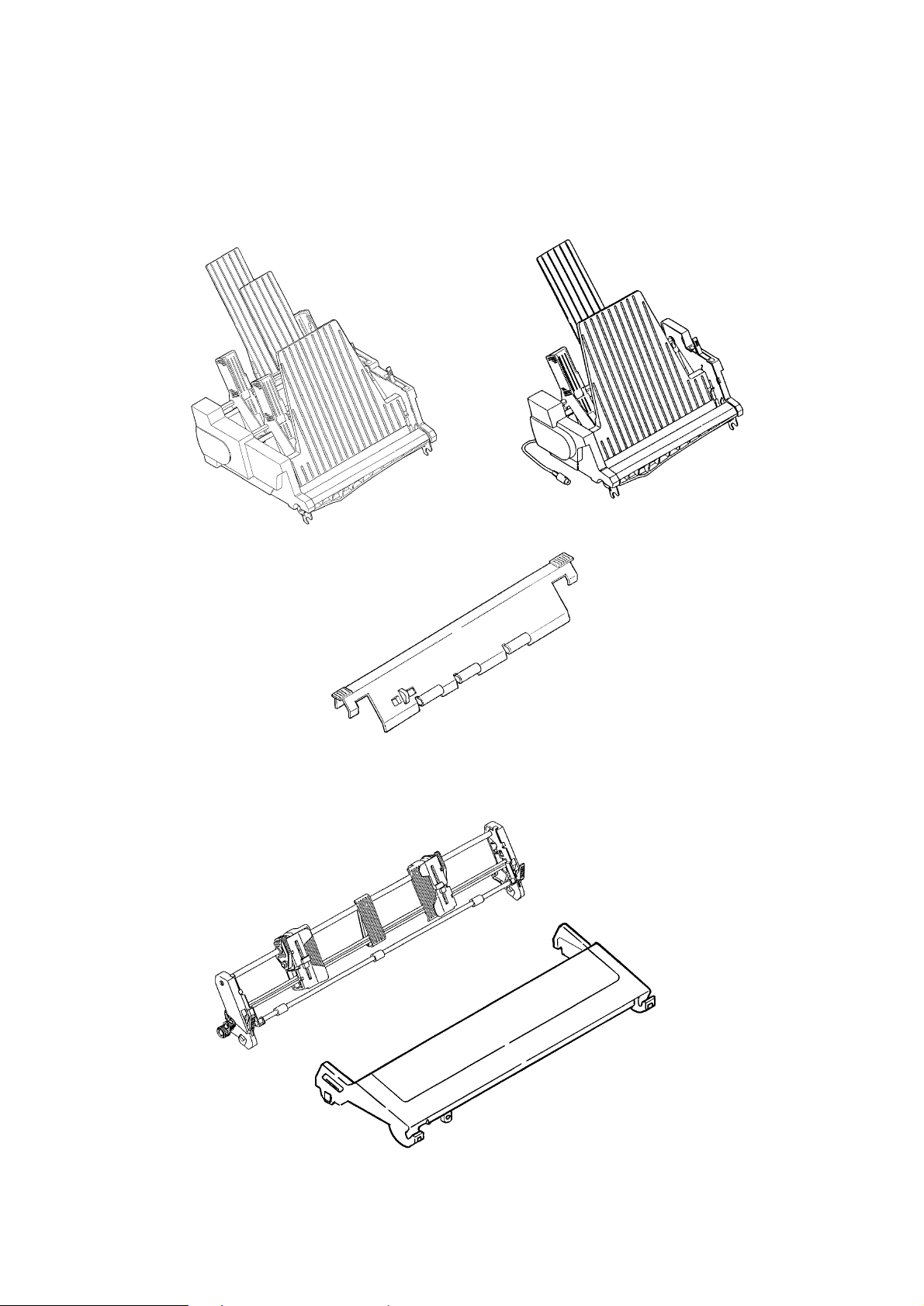

1.2 Options

(1) Cut sheet feeder unit (CSF)

(Narrow and wide versions available)

Dual-bin CSF Single-bin CSF

Attachment assy

(2) Pull-tractor assy

1 – 2

Page 8

(3) Bottom push tractor unit

(4) Roll paper stand (Narrow only)

(5) Serial I/F

• RS232C

• RS422A

• Current Loop

1 – 3

Page 9

2. THEORY OF OPERATION

Page 10

2. THEORY OF OPERATION

2.1 Electrical Operation

The electrical operation of the printer circuit is described in this section.

2.1.1 Summary

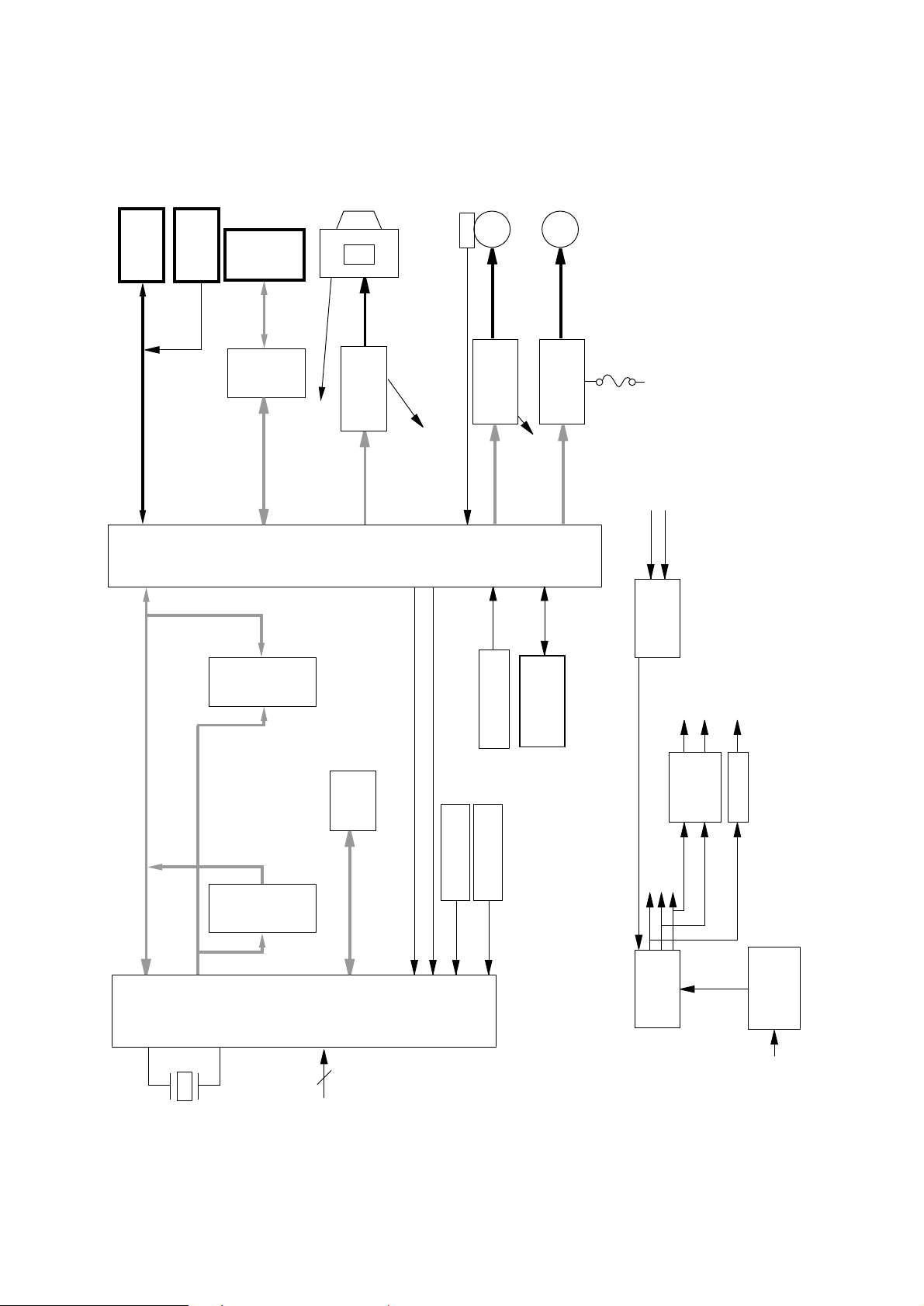

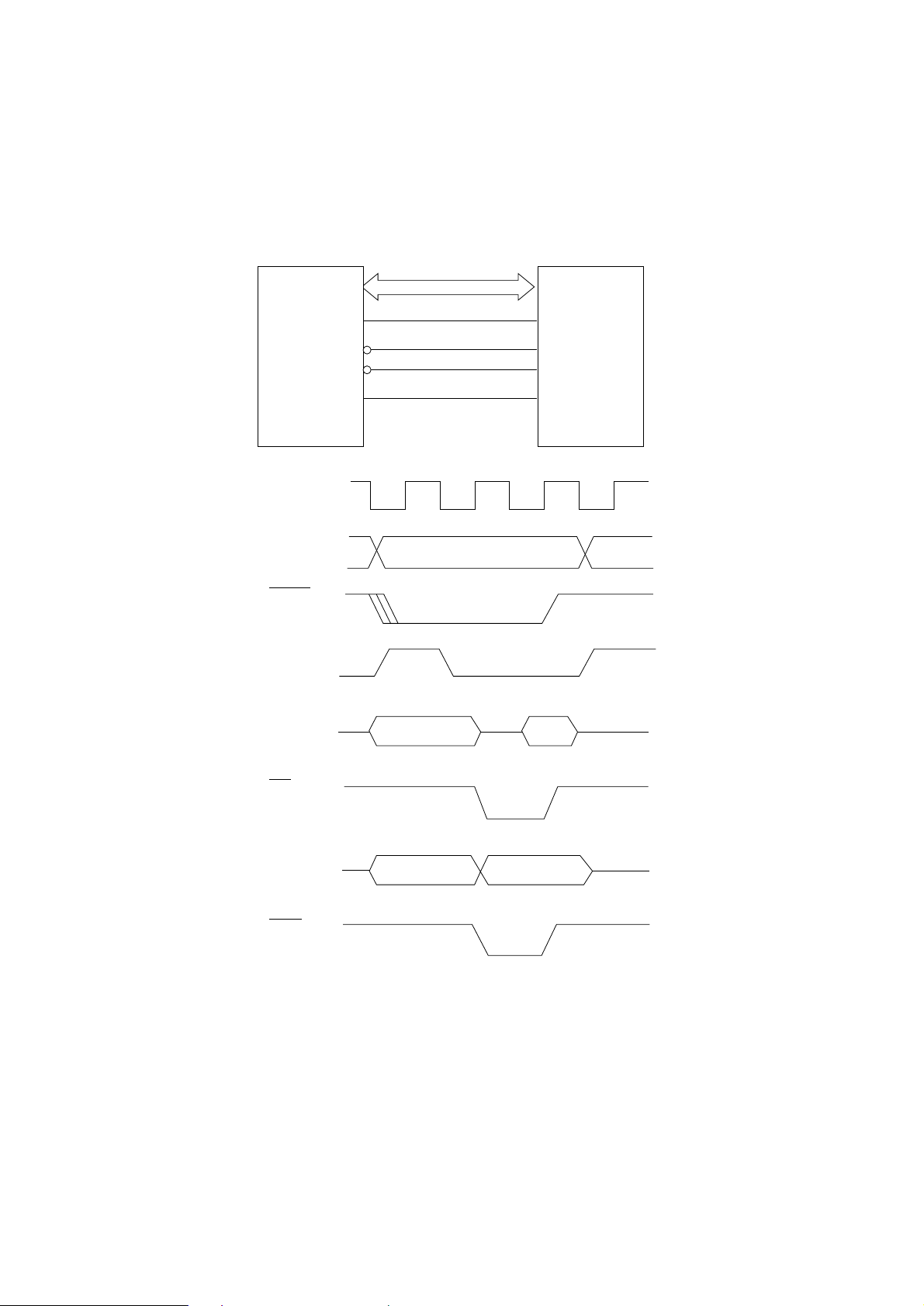

Fig. 2-1 shows the block diagram of the printer.

The control board is made up of the microprocessors, peripheral circuits, drive circuits, sensors

and interface connectors.

The power to the control board is supplied by the power board through the connector cord.

The power to other electrical parts is also distributed through the connectors within the control

board.

2.1.2 Microprocessor and the Peripheral Circuit

(1) Microprocessor (Q7: 67X640)

This processor is a CMOS single-chip computer with integrated peripheral device functions

and a 16 bit MPU core, all OKI original architecture.

The processor has a 20 bit address bus and a 16 bit data bus.

It is capable of accessing up to 1M word program memory and 1M bytes of data memory.

The following characteristics are also provided:

• Built-in type data memory of 512 bytes

• 8-bit 4-channel A/D converter × 1

• 16-bit automatic reload timer × 2

• 8-bit serial port × 2

• 8-bit parallel port × 3 (bitwise I/O specification available)

And others.

The function of this microprocessor is to provide a central mechanism for the entire printer

by executing the control program through the LSI and driver circuits.

2 – 1

Page 11

12.288

MHz

4

Vcc-Level

TSD

AUTO-LF

AI

INT

Release-SW

Bottom-Sensor

PE-SENSOR

OPERATION

PANEL

Serial

Rectifier

circuit

40 volt

8 volt

5 volt

Transformer

Reset

circuit

Print-IPT

I/F-IPT

EEPROM

1 Kbits

67 x 640

ADDRESS

ROM

AD-BUS

DRAM

4*64

Kbit*2

LSI

RESET

5VD

Vcc-Level

Fuse

40 V

LF

driver

SP

driver

SP alarm

HD-Alarm

Head

driver

2P Encoder

M

M

SP

LF

TSD

Para

-I/F

(opt.)

RS232C

-I/F

Roll paper

Stand

(opt.)

CSF

AC-input

1M

max

4M

16*256 Kbits

Alarm

circuit

Power-off

HD-Alarm

SP-Alarm

Divider

Figure 2-1

2 – 2

Page 12

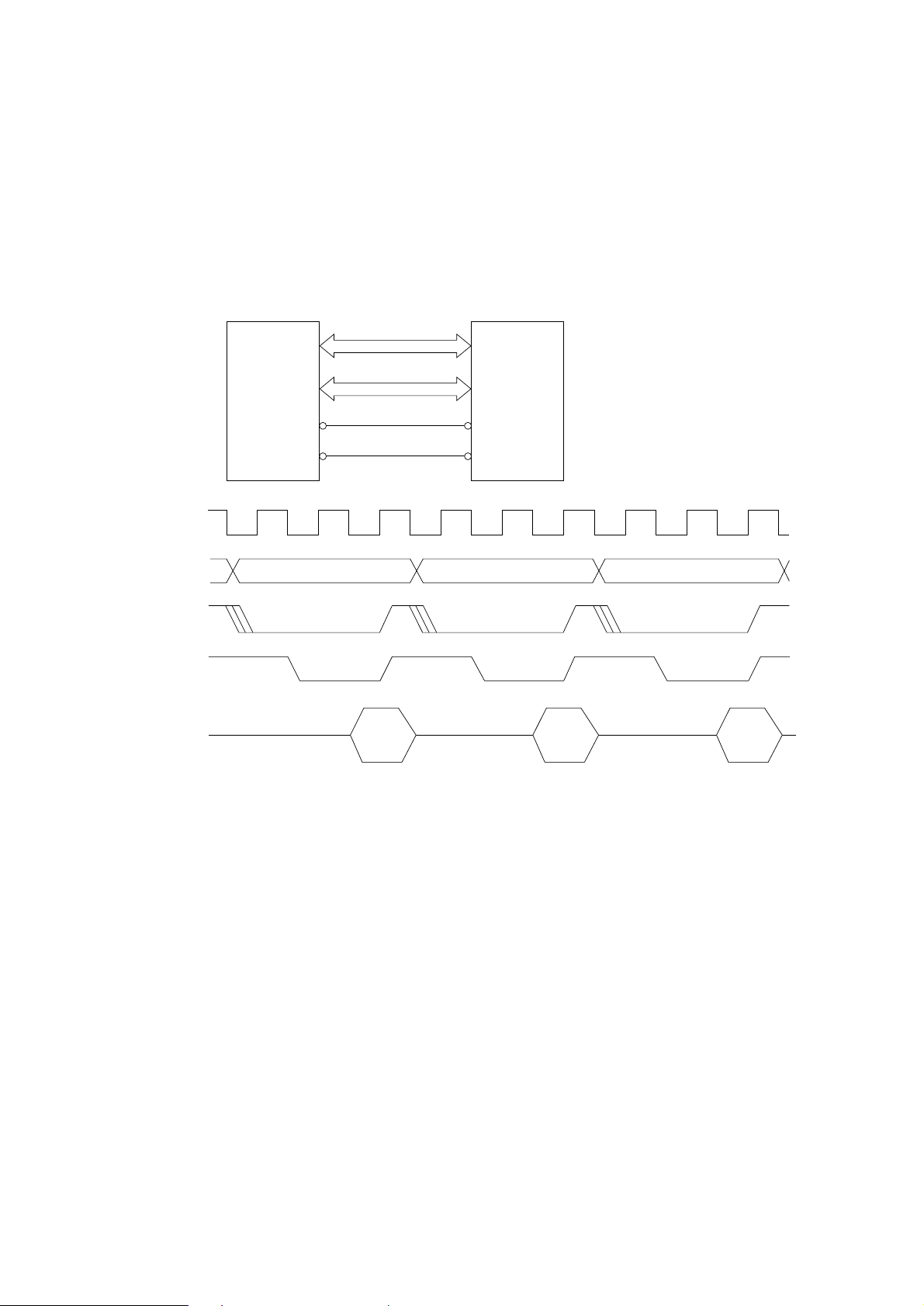

(2) Program ROM

This is a 256 × 16 bits (4M bit) [MAX] EPROM with the control program for the printer

stored. The MPU executes instructions under this program.

The program ROM is assigned to the program memory area of the MPU and is fetched

by the PSEN signal of the MPU.

The following shows the operation of the memory access.

MPU ROM

A0~A17

D0~D15

MPU CLOCK

A0~A17

PG-N

PSEN-N

D0~D15

CSO

PSEN

PG-N

Program Program Program

IN IN IN

CE

OE

2 – 3

Page 13

(3) RAM (MSM51C464A-80RS)

The RAM is CMOS dynamic RAM with (64K × 4-bit) × 2 configuration, and used as buffers

(such as receiving buffer, printing buffer, DLL buffer and working buffer).

The following shows the examples of the memory access operation.

RAM 1 (Q3)MPU

A0~A7

RAM 2 (Q4)

Clockout*

A0~A7

CS1~CS4

RD

D0~D7

(Read)

P03

CS1

RD

RAS

CAS

D0~D3

D4~D7

OE

T1 T2 T3

WRH

WRL

D0~D7

(Write)

8-bit bus, byte instruction

* Clockout is provided when the original excitation is selected.

2 – 4

Page 14

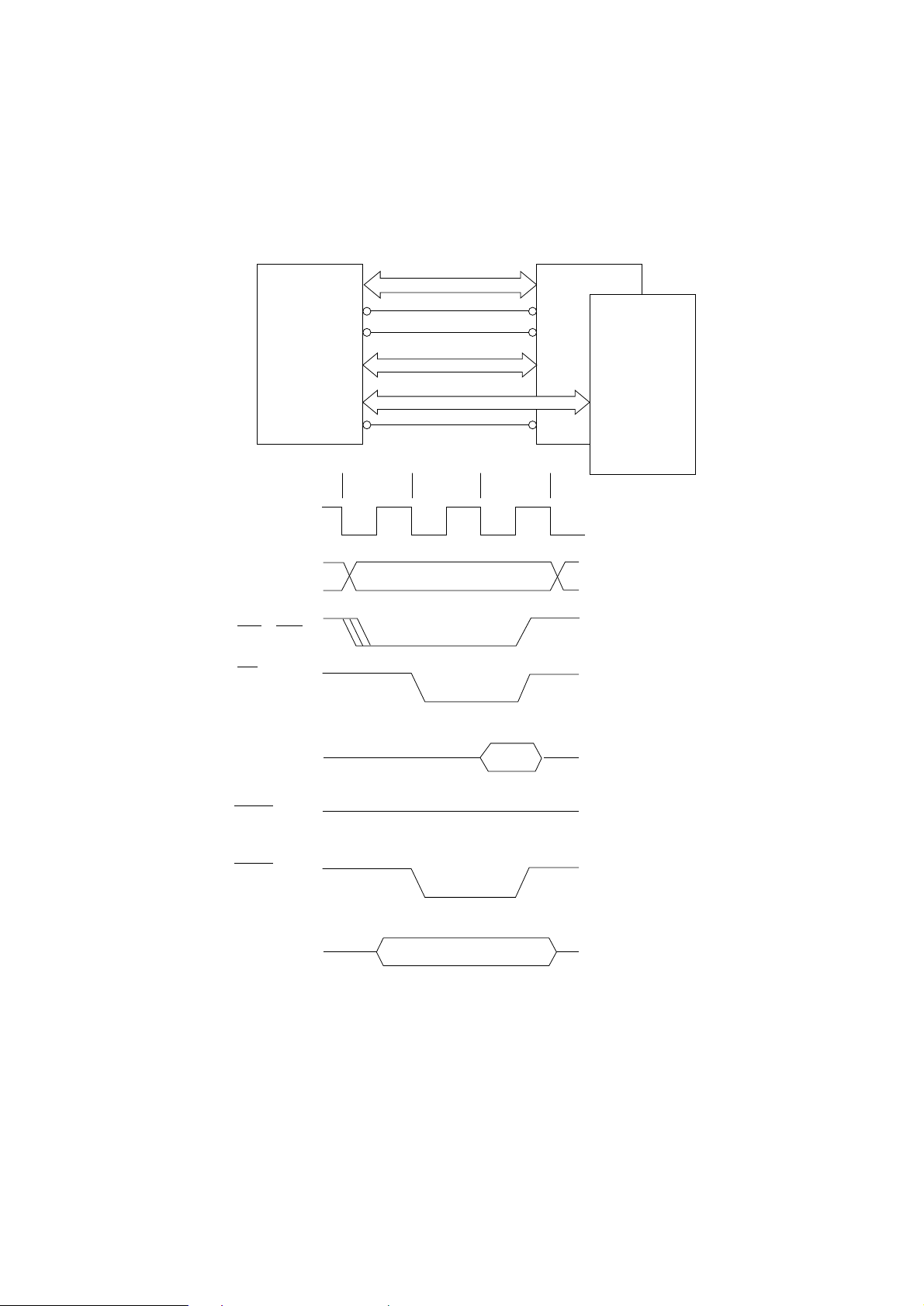

(4) EEPROM

The EEPROM is a CMOS serial I/O type memory which is capable of electrically erasing

and writing 1,024 bits.

The EEPROM contains menu data.

The following shows the memory access operation.

MPU EEPROM

EEDIN-P

P24

D1

EECS-P

P27

CS

EEDOUT-P

P25

DO

EECLK-P

P26

PRE = O

PE = X

SK

EECS-P

EECLK-P

EEDIN-P

EEDOUT-P

PRE = O

PE

EECS-P

EECLK-P

EEDIN-P

Start

code

Start

code

Operation

code

11

Operation

code

0

Address

0

A0A5

0

D15 D0 D15 D0 D15

Read cycle timing (READ)

Address Data

11

t

CS

t

CS

D0D15A0A5

EEDOUT-P

ReadyBus

twp

Write cycle timing (WRITE)

2 – 5

Page 15

(5) LSI

This LSI detects and controls the SP motor speeds by monitoring the two phase sensor

signals obtained from the DC motors and modifying the excitation phases as appropriate.

This LSI is connected in multiplex to the MPU.

MPU

P07

RD

WRL

P01

Clockout*

A0~A19

LSICS

ALE

A/D bus

LSI

ALE

RDN

WRL

LSIC

D0~D15

(Read)

RD

D0~D15

(Write)

WRL

Address

Address

Data

Data

* Clockout is provided when the original

excitation is selected.

2 – 6

Page 16

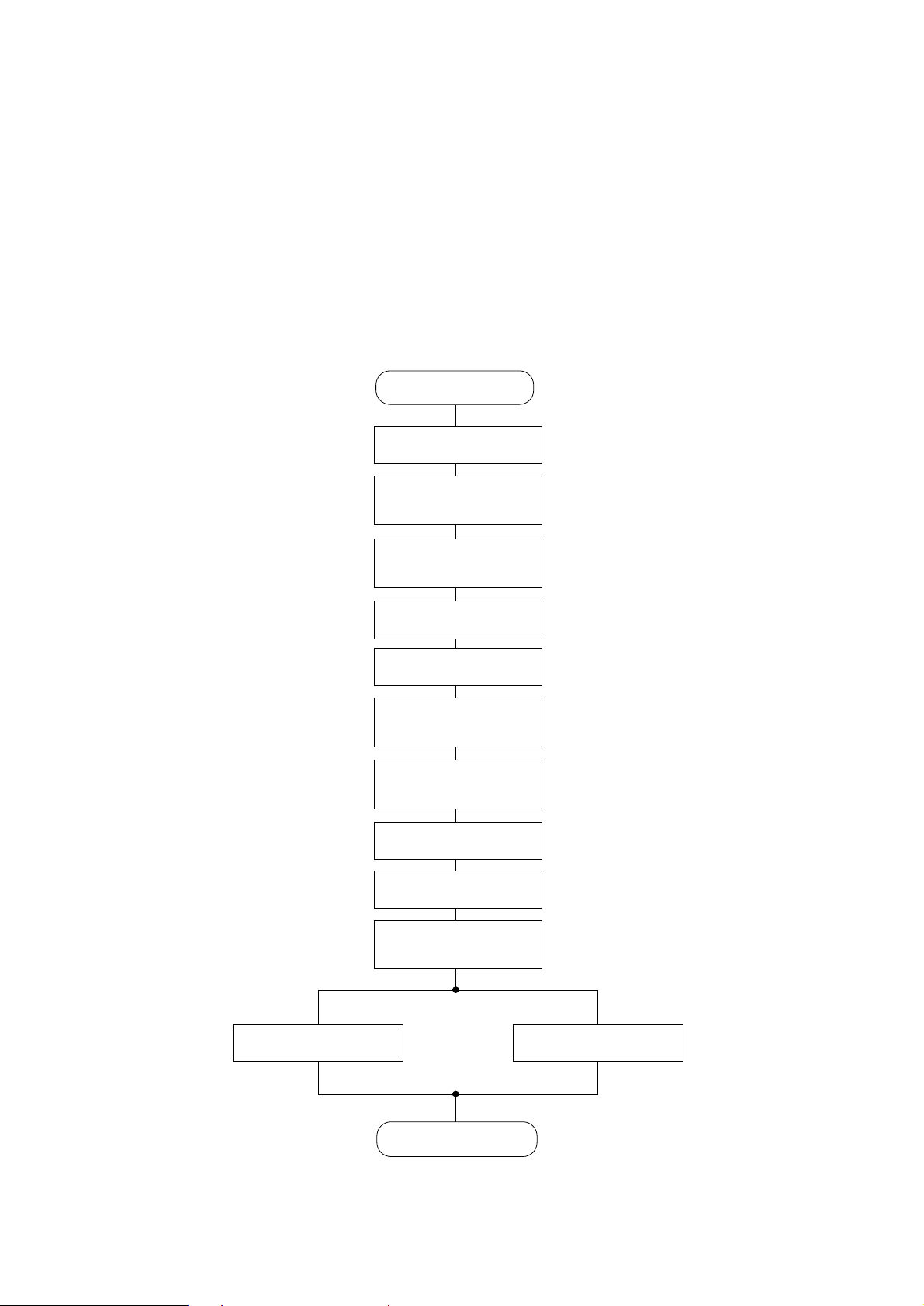

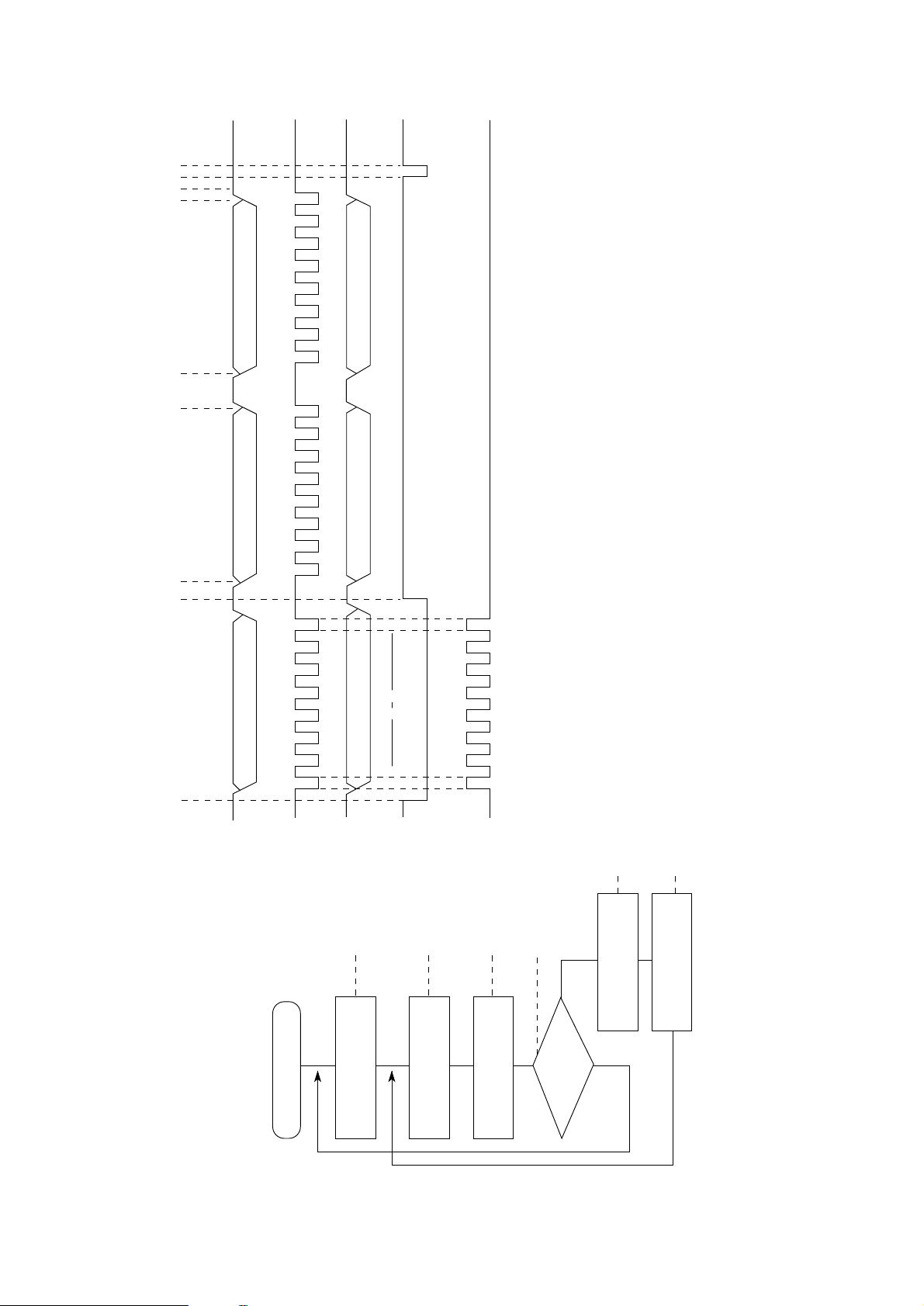

2.1.3 Initialization

This printer is initialized when the power is turned on or when the I-PRIME-N signal is input

from the host side via the parallel interface.

For the initialize operation, the RST-N signal is first output from the reset circuit to reset the

MPUs and LSIs. When resetting ends, the program starts and the LSIs are reset by MPU via

LSIRST-N. Reset operation by I-PRIME starts program to initialize, but does not reset the MPU.

The program here sets the mode of the LSI including the MPU, checks the memories (ROMs

and RAMs), then carries out carriage homing, and determines the LF motor phase.

Finally, the program establishes the interface signals (P-I/F: ACK-P signal sending, and S-I/F:

BUSY-N signal off) and lights the SELECT lamp to inform the ready state for receiving to the

host side and ends the initialize operation.

Start

MPU RESET

MPU

Initial Setting

Internal RAM

CHECK

Serial

I/F

I/F BUSY OFF

ROM CHECK

LSI RESET

External RAM

CHECK

LSI Initial Setting

and I/F Busy ON

RAM Clear

Carriage Homing

LF Motor Phase

Initialization

Parallel

I/F

I/F ACK Send

End

2 – 7

Page 17

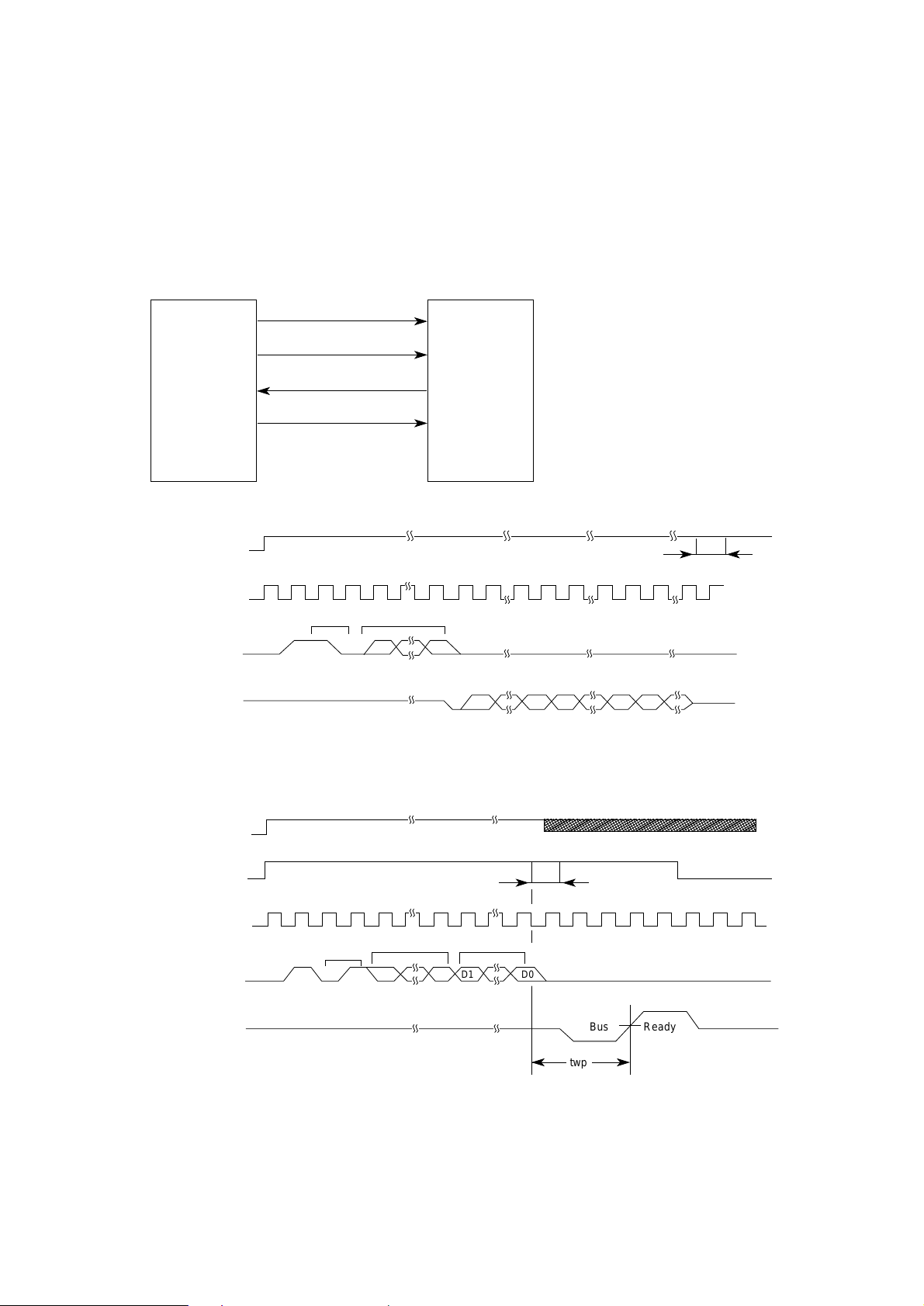

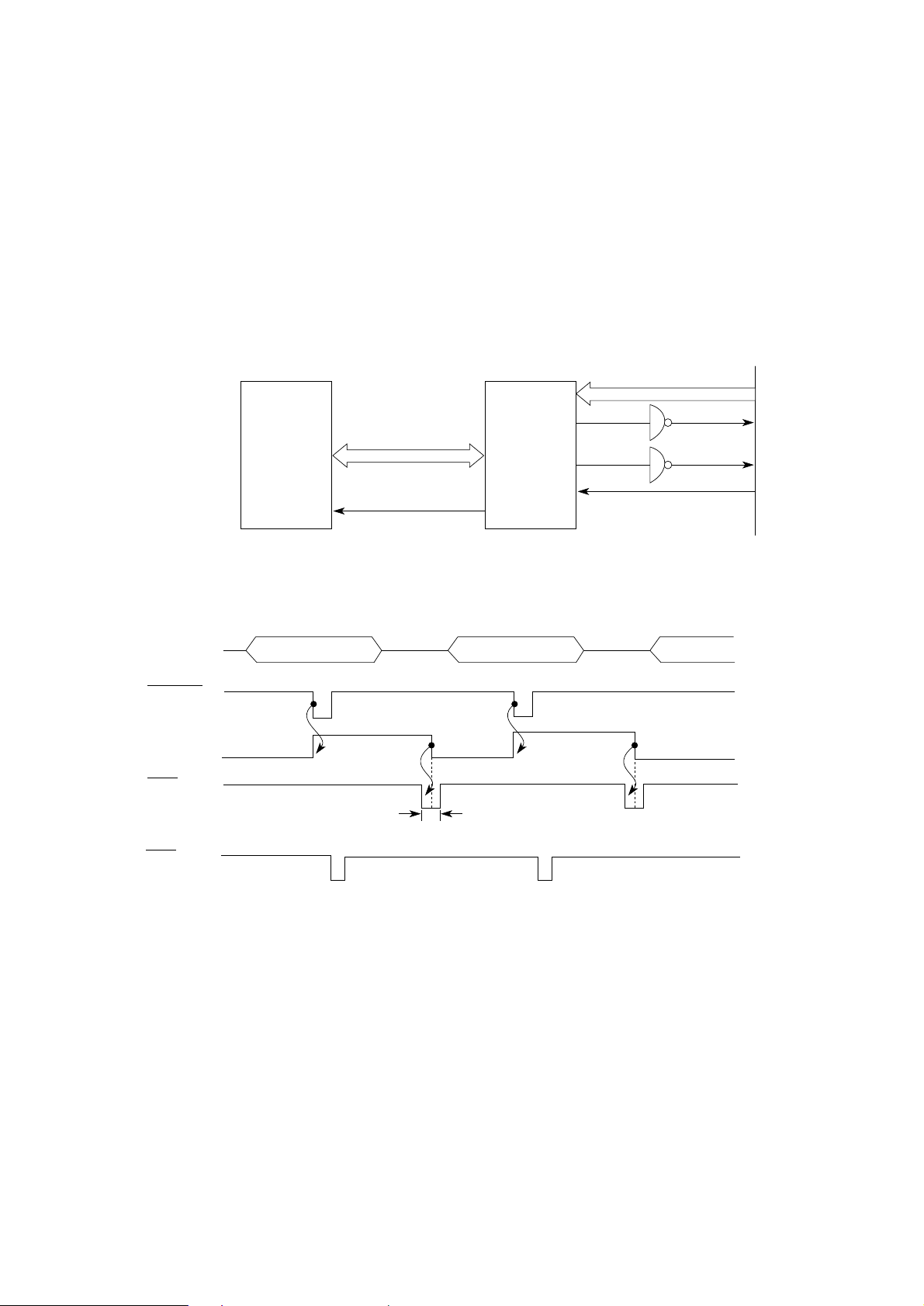

2.1.4 Parallel Interface Control

The parallel data input from the host to the interfaced LSI is latched to its internal register at

the falling edge of the STROBE-N signal.

At the same time, the LSI sets the BUSY signal to the high level to inform the host that the

data is being processed, and outputs the RXD signal to inform the MPU of data reception. The

data is read upon receiving the RD-N signal from the MPU.

When the data processing ends, the BUSY signal is set to off and the ACK-N signal in sent

to request the next data. When reception is impossible because the buffer is full, the BUSY signal

is sent to request stopping of data transmission.

MPU LSI

CN1

Receive Data

Data

1 to 8

STROBE

BUSY

ACK

RXD

A/D bus

RXD

P16 NRXD

500ns max.

2~8µs

NBSY

ACK

NSTB

BUSY

ACK-N

STB-N

2 – 8

Page 18

2.1.5 Print Control

Print data is transmitted as parallel data (HEAD1~HEAD9) from LSI to print head. LSI generates

print timing and drive time.

Control/Power Supply Board

MPU LSI

DT1

A/D bus

Driver Board

Print Data

HEAD1-N~

HEAD9-N

DRIVER

HEAD DRIVE TIMING CHART

Print Data

HEAD1~

HEAD9

Print Head

DT2

HEAD

DRIVE CURRENT

2 – 9

Page 19

Print Compensation Control

The print compensation can be made as shown below:

(a) Voltage compensation (See 2.1.8 “Alarm Circuit.”)

(b) Temperature compensation (See 2.1.8 “Alarm Circuit.”)

(c) Pin stroke compensation

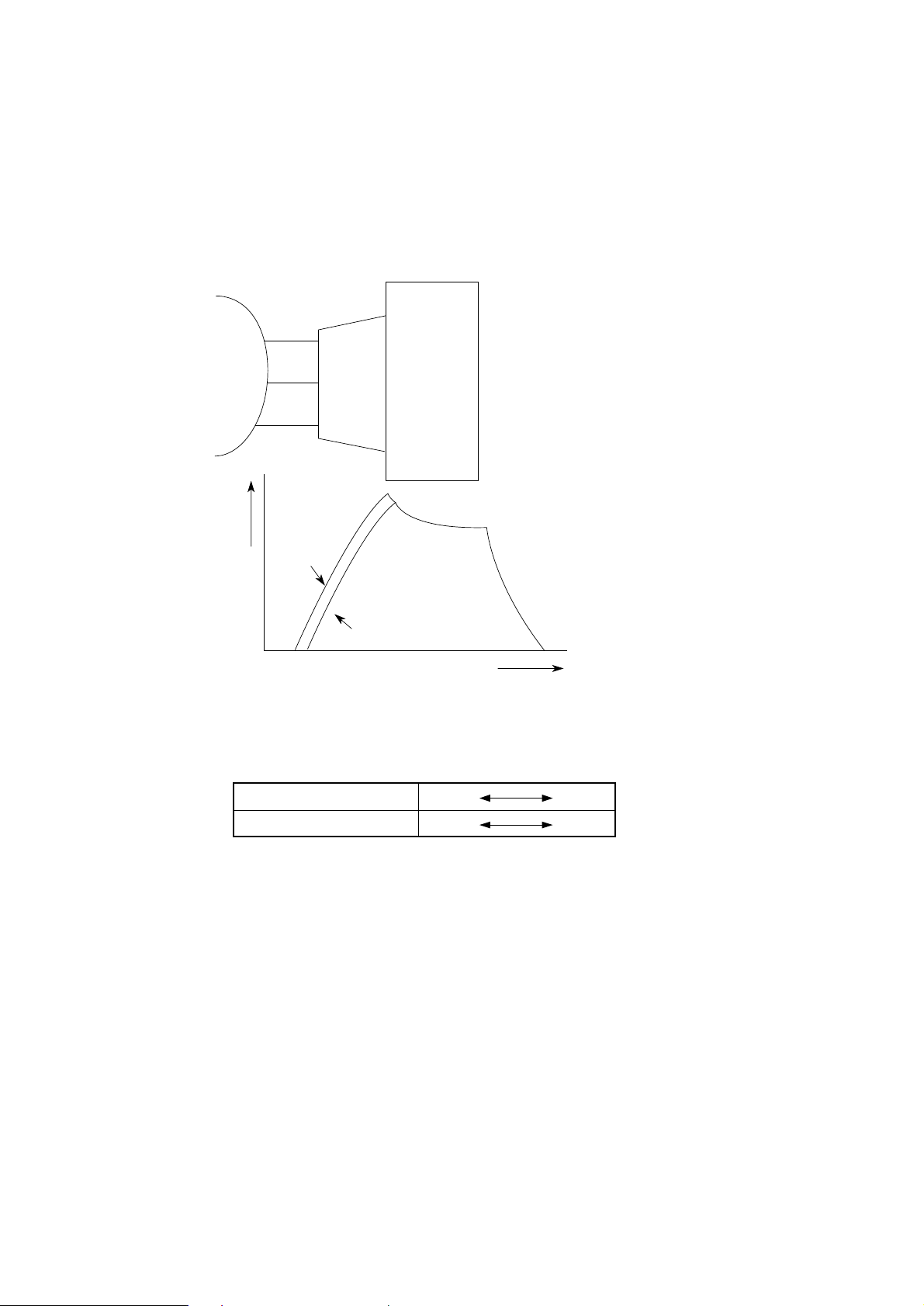

Platen

Print Head

Pin 1, 2

As shown in the drawing left, the stroke length

up to the platen is different for each pin.

3~6

8, 9

Pin coil

current

Pin 1, 2,

8, 9

Pin 3~6

Time

(d) Simultaneous Compensation of the number of impact pins

The MPU is provided with the compensation table for each pin to make necessary

compensation.

Number of impact pins Few Many

Drive time Short Long

2 – 10

Page 20

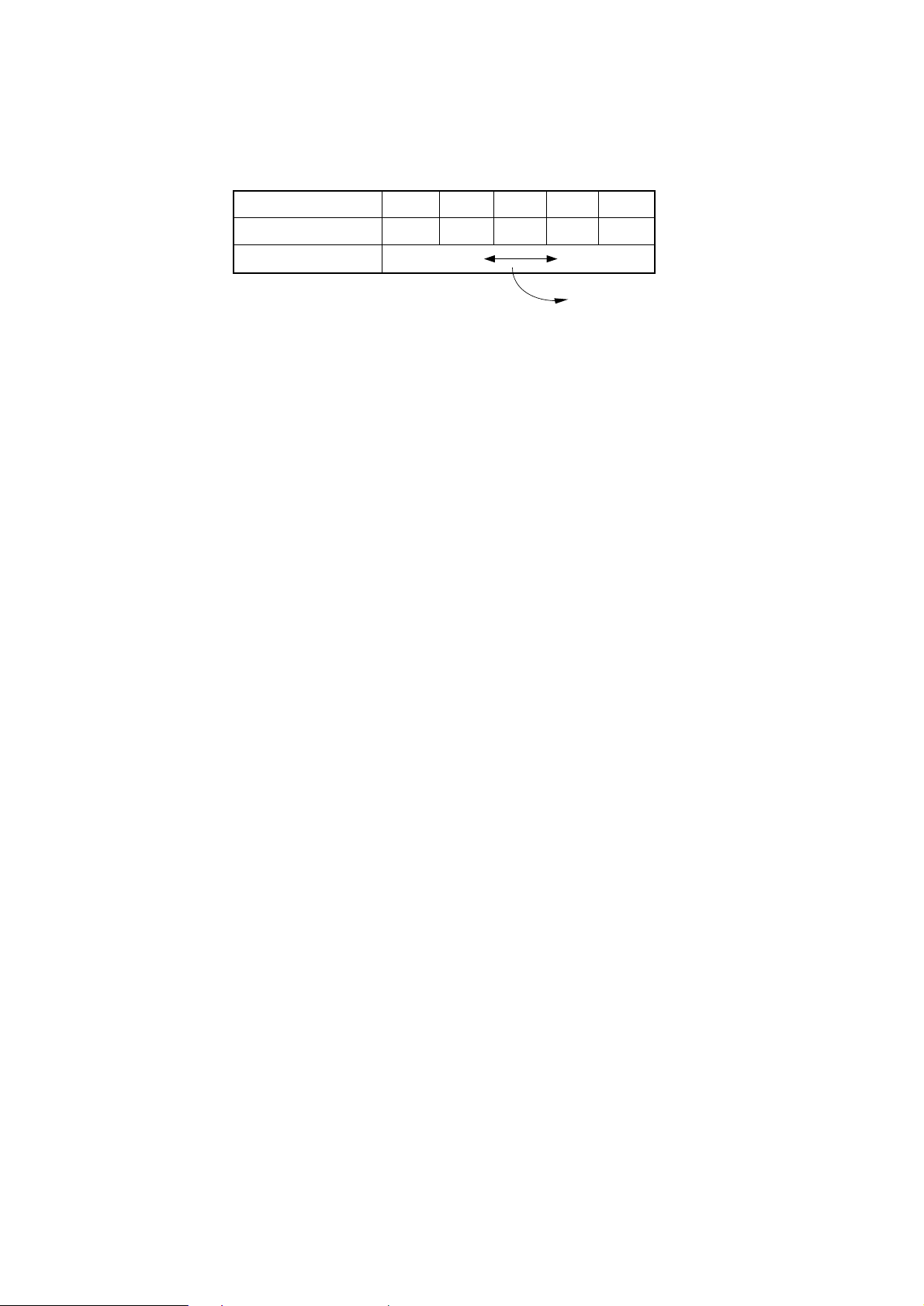

(e) Print mode compensation

According to the thickness of the printing medium, the print mode is compensated

as shown in the table below:

Head Gap Range 1 2 3 4 5

Print speed 100% 95% 85% 85% 80%

Drive time Short Long

(Drive time lengthens at each step.)

2 – 11

Page 21

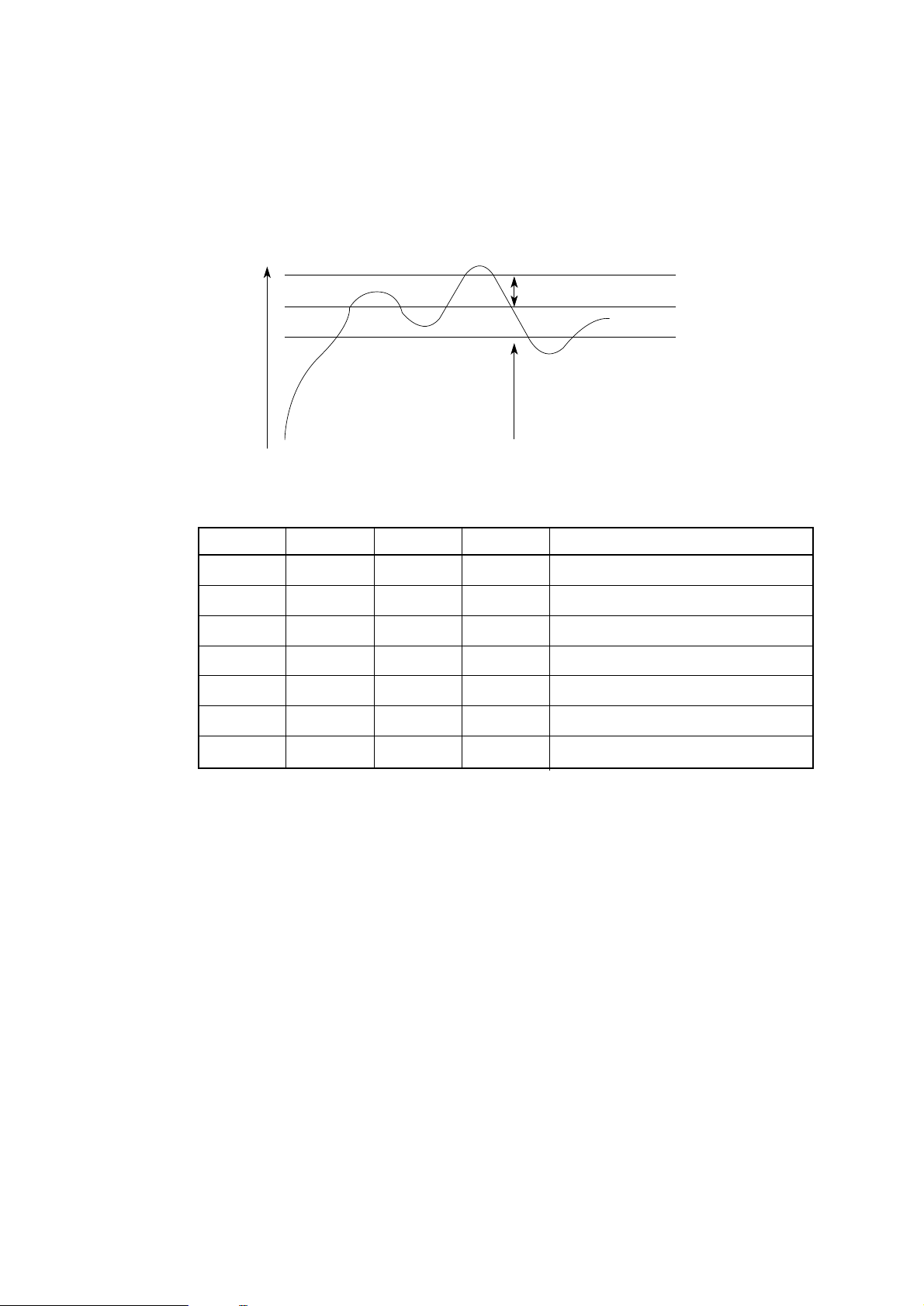

2.1.6 SP/LF Motor Control

(1) Space motor control

The SP motor driver (HA13412) drives the three-phase brushless motor based on the

phase signal (SPU, SPV and SPW) and the speed instruction data from the LSI. The MPU

can identify the current speed of the space motor by measuring through the LSI the pulse

length of the output (øA, øB) of the slit encoder included in the space motor.

By comparing the target speed for each print mode with the actual current speed to change

the speed instruction data, the motor speed is accelerated or decelerated to maintain the

specified speed for each print mode.

SPU

SPV

SPW

SP truth table

HALL AMP INPUT OUTPUT

SPU SPV SPW U V W

H H L OPEN L H

H L L L OPEN H

H L H L H OPEN

L L H OPEN H L

L H H H OPEN L

L H L H L OPEN

2 – 12

Page 22

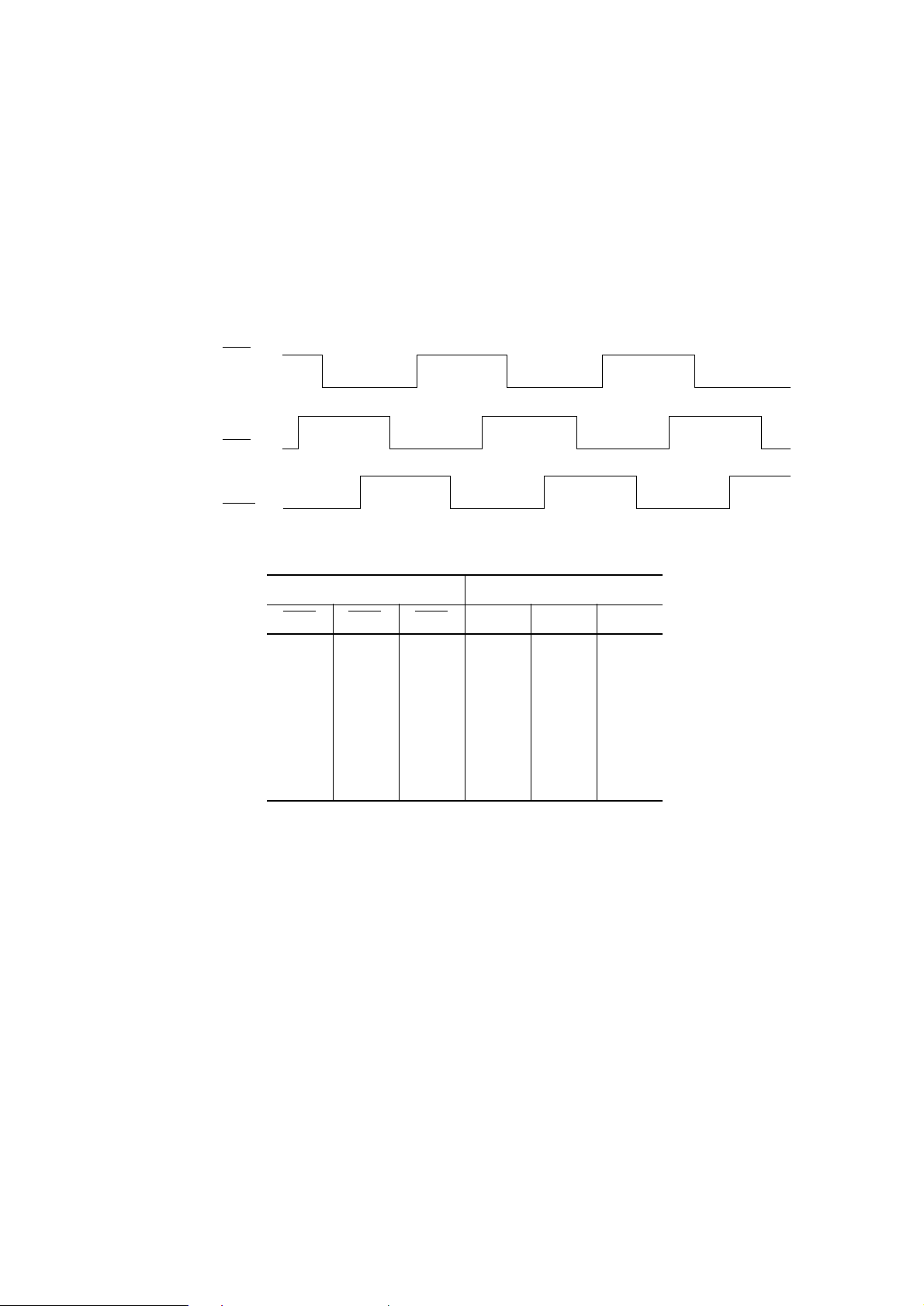

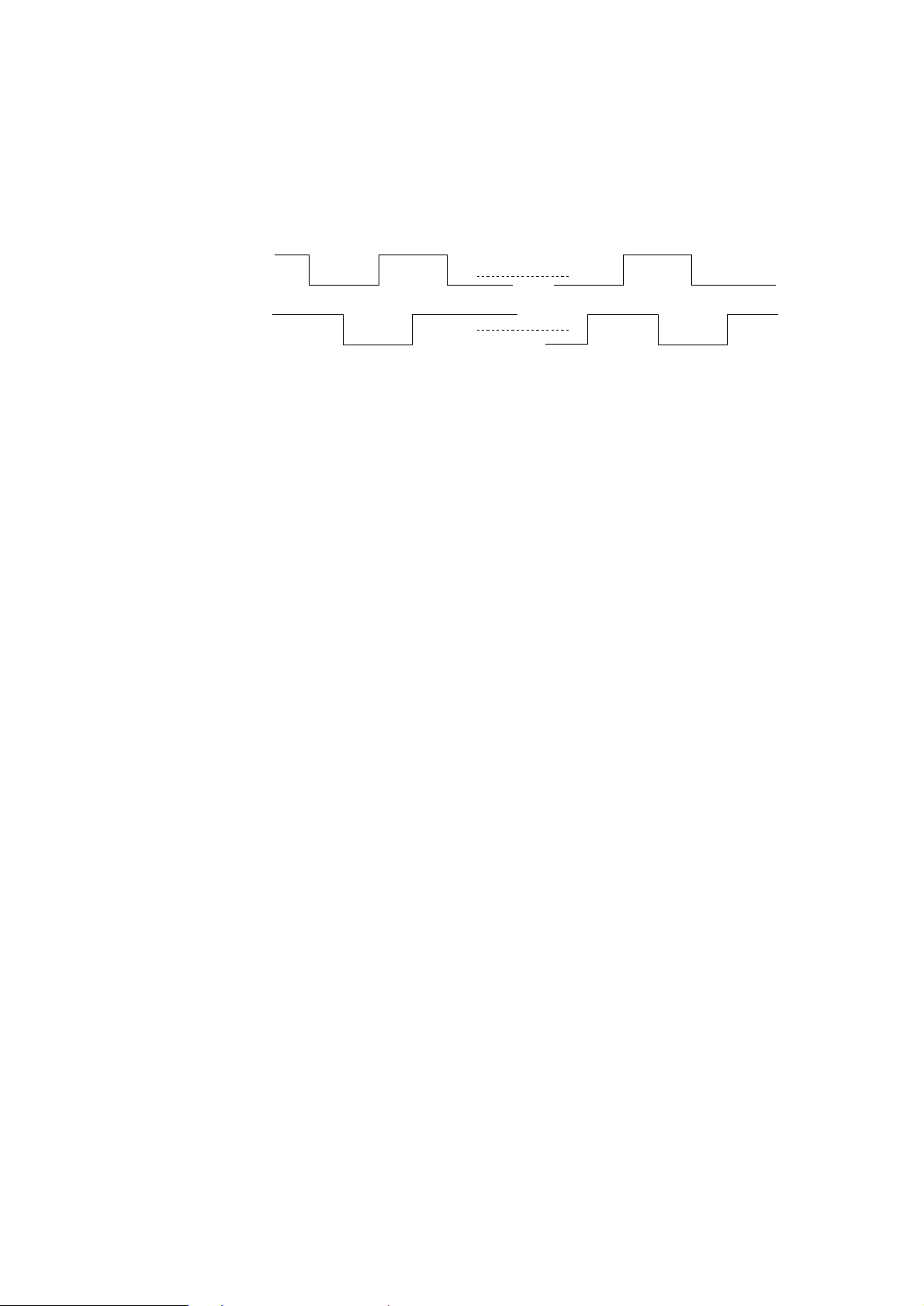

(2) Encoder disk

In the operation of the spacing motor, the PHASE-A and PHASE-B signals are generated

when the encoder disk interrupts the photo sensor.

The LSI divides these edge pulse signals in accordance with the print pitch, and sends

the IPT signal to provide dot-on timing and carriage position detection timing.

SPU

SPV

SPW

PHASE-A

PHASE-B

1/720"

IPT 10 CPI

IPT 12 CPI

IPT 15 CPI

IPT 17 CPI

IPT 20 CPI

• UTILITY MODE

1/120"

1/144"

1/180"

1/206"

1/240"

2 – 13

Page 23

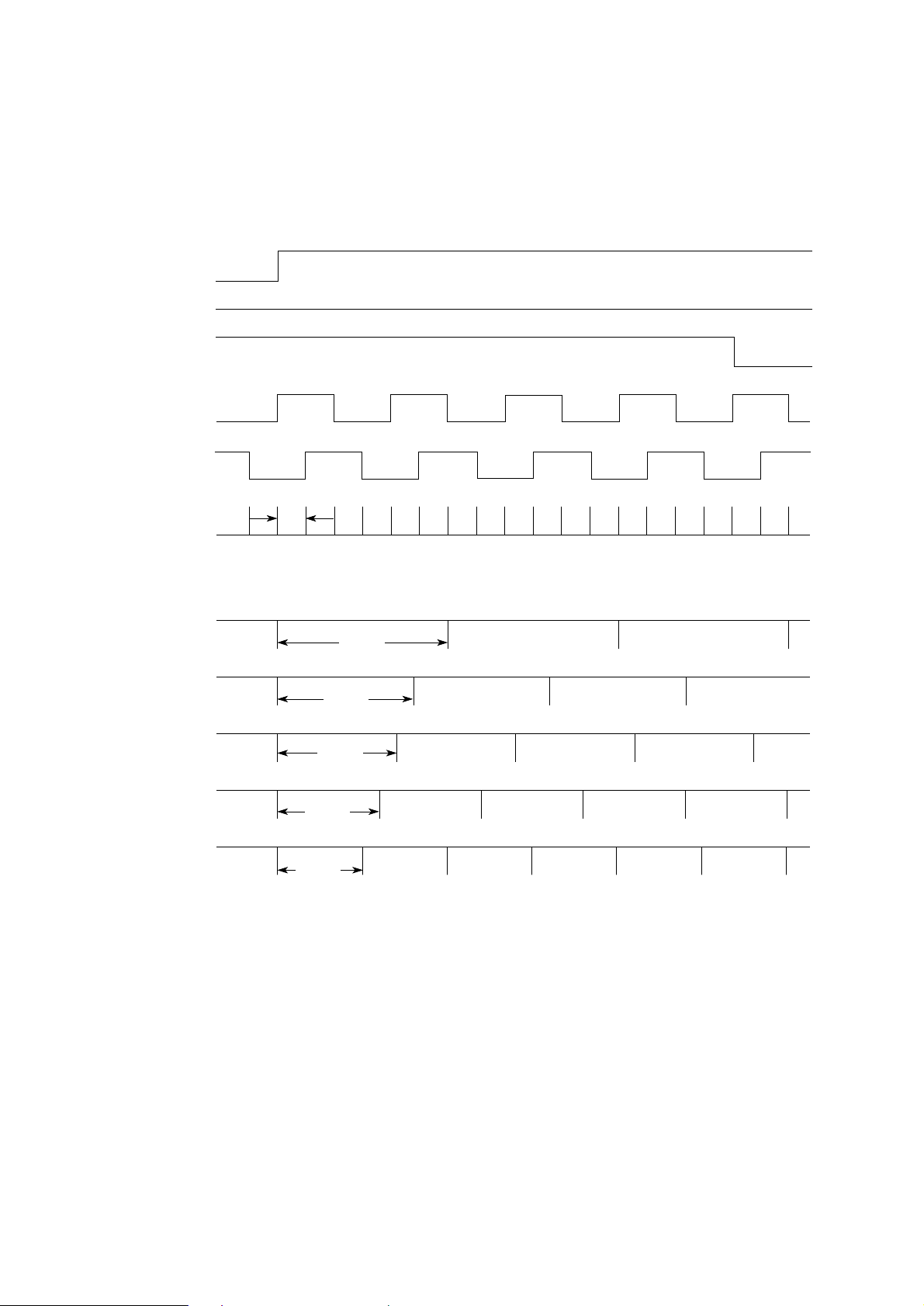

(3) LF motor control

The LF motor driver (MTD2005F) drives the LF motor in two-phase or 1-2 phase bipolar,

based on the phase changeover data and the output current data from the LSI.

The data from the LSI is processed by a specific register contained in the LF motor driver

to measure the overdrive time and to change the phase.

PHASE-A

PHASE-B

[FORWARD]

[REVERSE]

2 – 14

Page 24

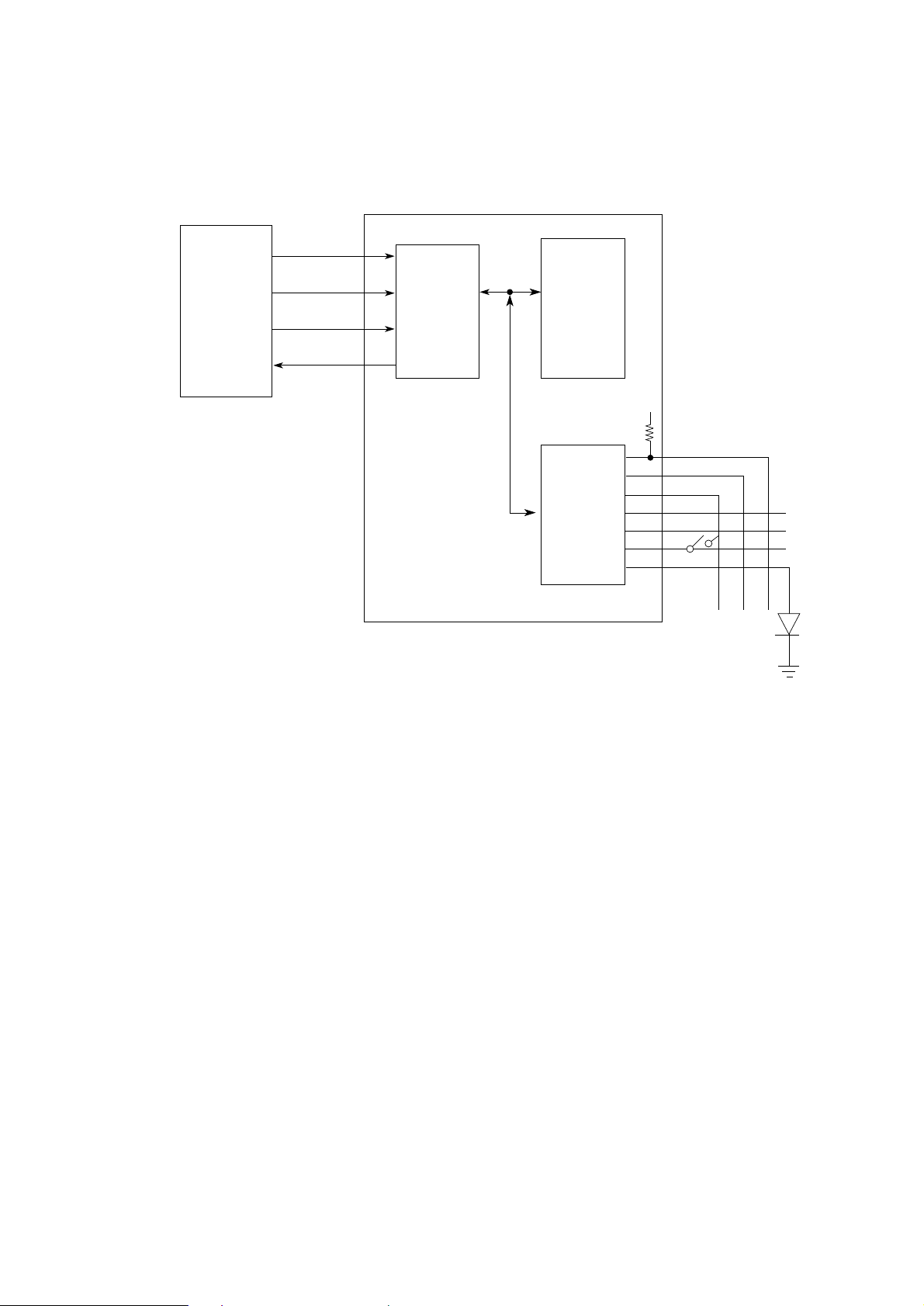

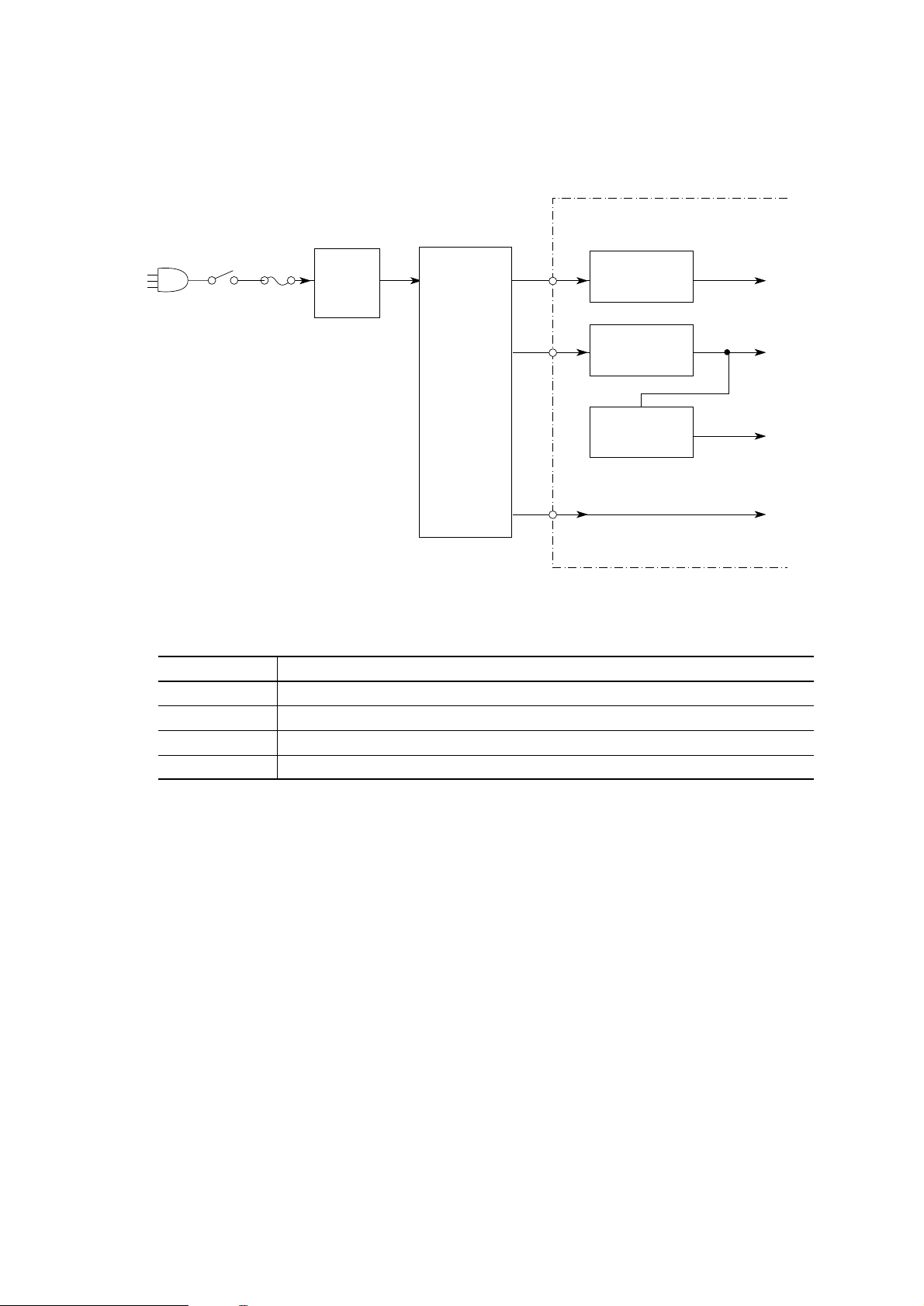

2.1.7 Operation Panel

The clock synchronization OPCLK of LSI is used to input the switch data and output the LED

data through the operation panel control LSI (IC1: BU5148S).

LSI

OPTD

OPCK

NPA2

OPRD

OPTXD

77

OPCLK

78

OPCLR-N

80

OPRXD

79

Command

and Data

latch

LED driver

+5V

Switch

controller

A 2-byte (15 bits + 1 even parity bit) command (OPTXD) is transmitted to the LSI (BU5148S)

in synchronization with the OPCLK signal. The LSI decodes this command and when it is found

to be legal, returns a 2-byte command response back to the LSI which includes data on Switch

information, LED status, receive command ACK/NAK and 1 odd parity bit.

Any transmission errors found cause the command to be reissued after the transmission of the

OPCLR-N signal.

2 – 15

Page 25

8

or

5

6

7

3 1

Command (second)

Command response (second)

Note

Command (first)

Command response (first)

bit0 bit7

bit0 bit7

1 2 3 2

OPTXD

OPCLK

OPRXD

1

OPCLR-N

2

Reset

within

3

BU5148S

4

NO

7

Error notification

8

Instruction for

retransmission

the bit 0 to bit 3 of OPRXD are fixed so that the response can be returned before decoding the command.

YES

for OK or NG

Response check

Note: From the illustration above, you can see that the command and the command response are output at the same time. This is because

5

6

Power ON

reset

Write instruction for LSI

etc.

LSI write for LED data,

data read

Read instruction for

2 – 16

Page 26

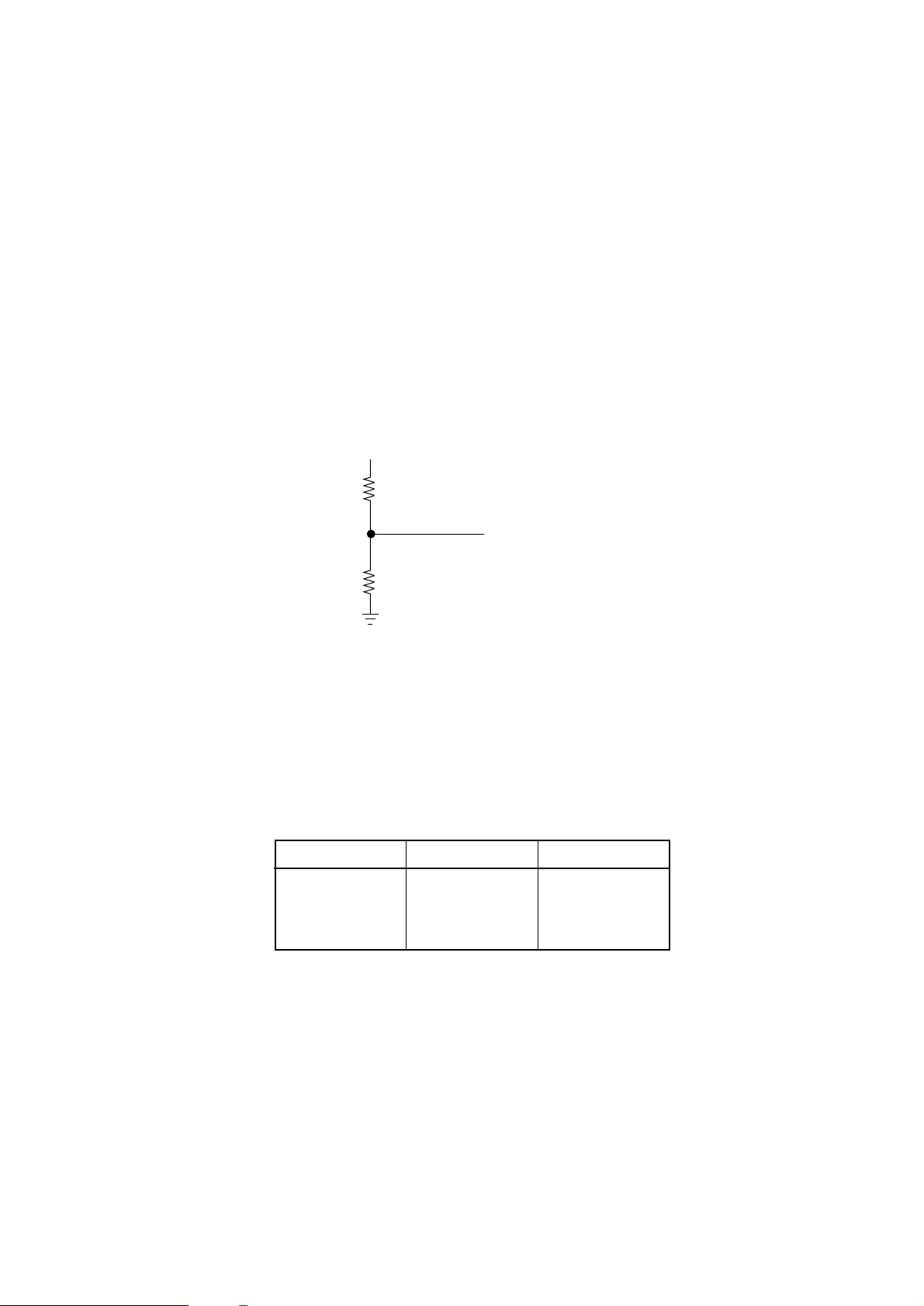

2.1.8 Alarm Circuit

(1) Head drive time alarm circuit

This circuit monitors the drive time using the HDALM signal interlocked with the overdrive

signal of each drive circuit.

If the drive time of any drive circuit exceeds the specified time, the drive fault alarm circuit

sends an ALARM-N signal to turn on the SCR (SO).

This cause the secondary coil (40V) of the transformer to be short-circuited, causing an

overcurrent to flow through the primary coil and making the AC fuse (transformer assy)

open.

(2) Alarm processing when DC power is low.

+ 40V is converted into the POWLEV signal (0V to +5V) by R28 and R29 and input into

the A/D port of the MPU to control the drive time and the print speed (pass number) of

the head.

+40V

R28

POWLEV

R29

(a) Head drive time

The head drive time is lengthened to compensate for the amount of voltage drop by

monitoring the POWLEV signal once every 500 µ sec. to control and maintain the

impact necessary for each printing pin at the fixed value.

(b) Print speed

Voltage, +40V Pass number Print speed

38V or more 1 Pass 100%

25V to 37V 1 Pass 100~30%

25V or less 1 Pass 30%

2 – 17

Page 27

(3) Head overheat alarm

The voltage of the output TSD signal of the thermistors, one of which is contained in the

print head and the other in the print head driver, is monitored by the CPU/AD port to control

the voltage

Temp

Mode and print control

Mode Speed Pass Direction

1 100% 1 Bi

2 85% 1 Bi

3 70% 1 Bi

4 55% 1 Bi

5 40% 1 Bi

Stop

119°C

Mode up

α°C

ß°C

Mode down

6 30% 1 Bi 1.5 Sec Stop

(7) Stop

• When the temperature is between α°C and 119°C, the mode switches sequentially to

higher level. When the temperature falls below ß°C, the mode switches to lower level.

• When the temperature exceeds 119°C, printing will stop.

• When temperature gradient is steep, higher mode shall be specified directly.

2 – 18

Page 28

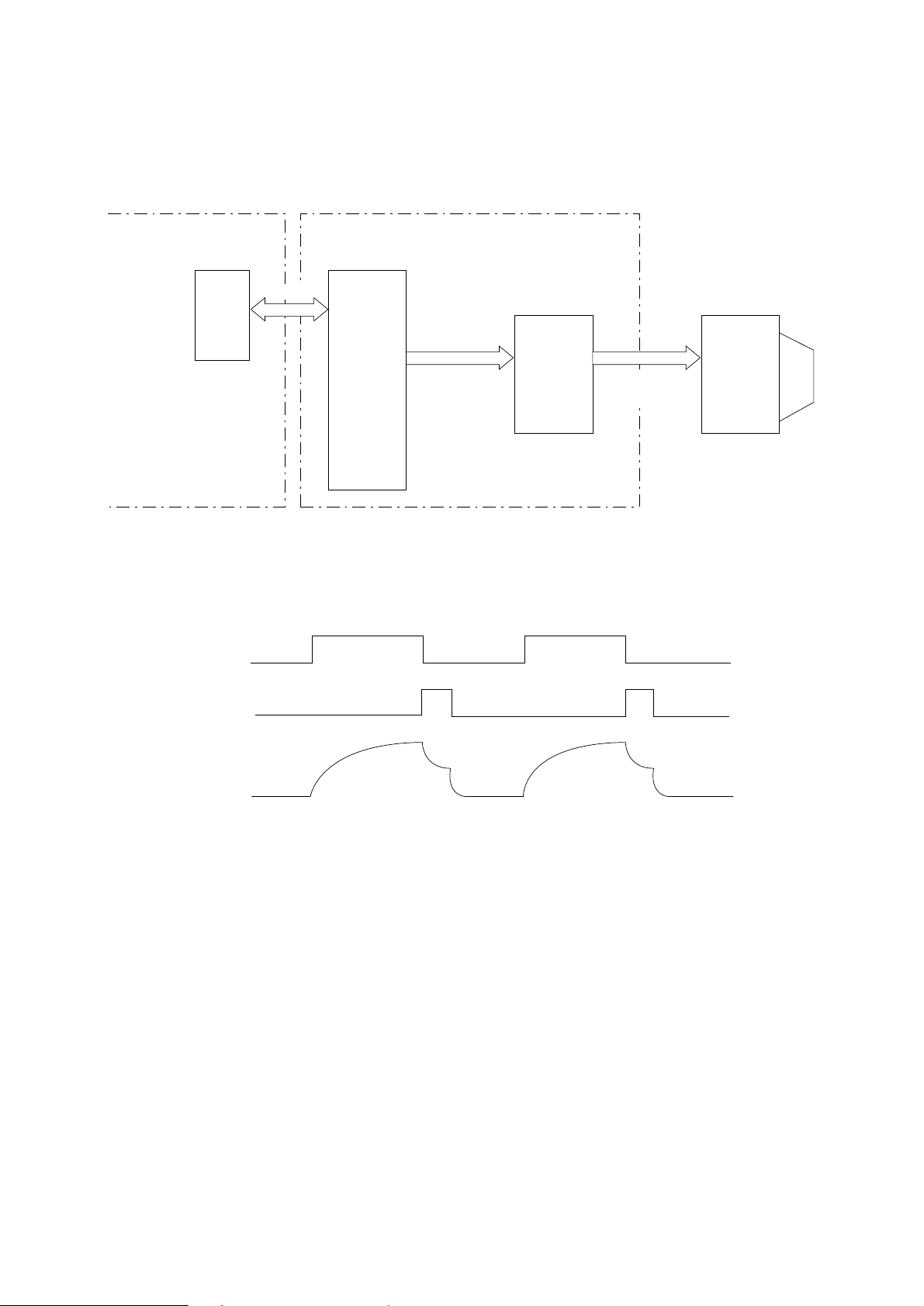

2.1.9 Power Supply Circuit

This power supply circuit supplies the +5VDC, +8VDC, +40VDC, 10VAC.

Control Board

SW

Fuse

Noise

filter

circuit

Transformer

The uses of output voltages and signals are described below.

Voltage/signal Use

+5V Logic IC/LED drive voltage

+8V Serial interface line voltage and SP motor driver

+ 40V Printhead, LF motor drive voltage, SP motor drive voltage

AC 10V Option board

Rectifier

Rectifier

Regulation

Circuit

+40V

+8V

+5V

AC10V

2 – 19

Page 29

2.2 Mechanical Operation

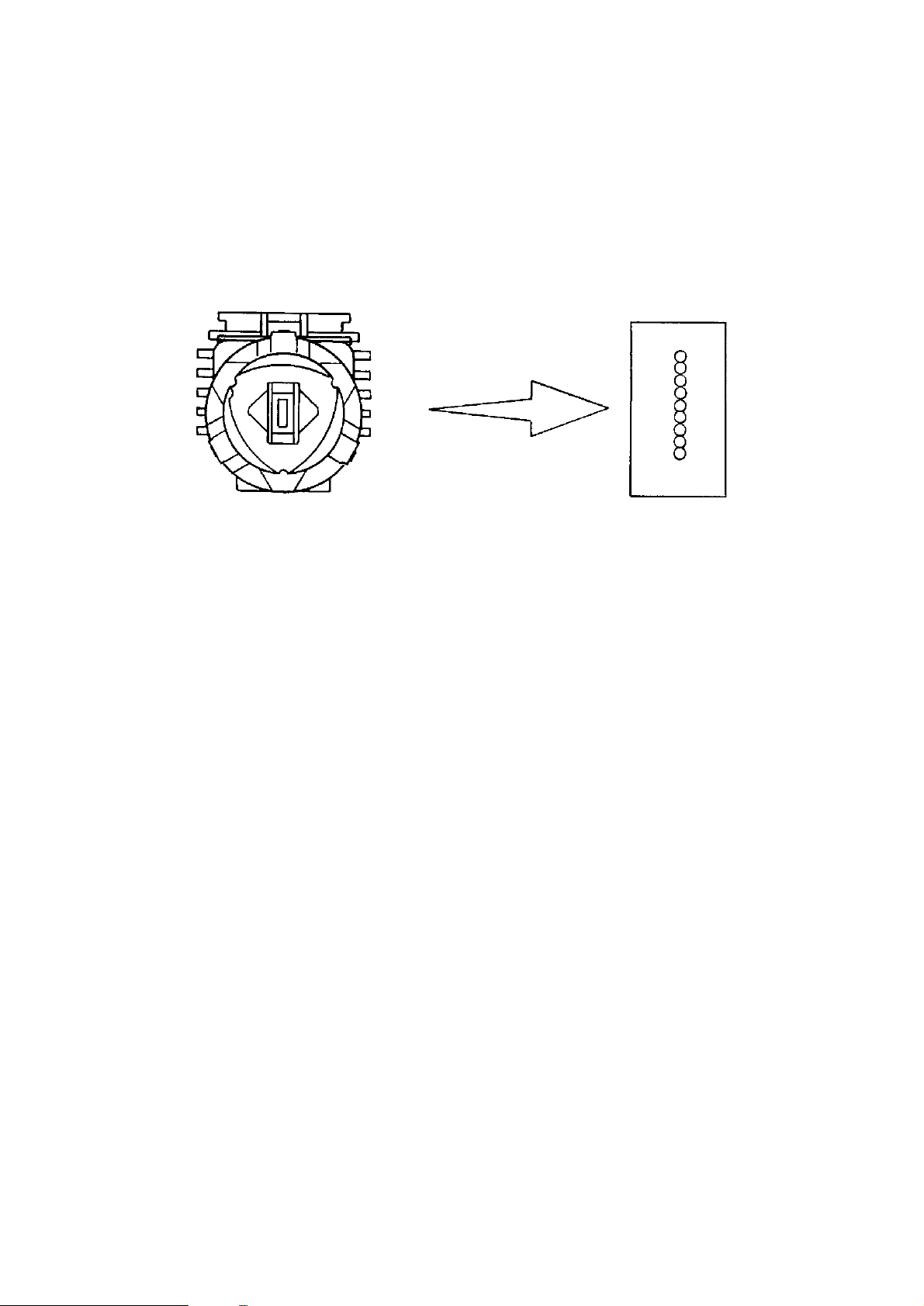

2.2.1 Printhead Mechanism and Operation (See Figure 2-2.)

The printhead is a spring charged 9-pin driving head using a permanent magnet. It is attached

to the carriage, which moves in parallel with the platen. Electrically, this unit is connected to

the control circuits through the control board.

Figure 2-2 Arrangement of the head pins

View from the tip of the printhead

(1) The printhead configuration:

The printhead is composed of the following parts:

(a) Wire guide

(b) Spring assembly (Wire, Armature, Spring, Yoke, Spacer)

(c) Magnet assembly (Magnet, core, coil, Yoke)

(d) Printed circuit board

(e) Fin

2 – 20

Page 30

(2) Operation of printhead (See Figure 2-3.)

(a) When the printhead is idle, the armature is attracted by a permanent magnet and

the spring fixing the armature is compressed. The print wires fixed to each armature

are thus concealed under the wire guide.

(b) When a signal for a character to be printed is detected, a current flows through the

coil. When the coil is activated, the magnetic flux (caused by the permanent magnet

between the armature and the core) is canceled to eliminate the attraction force. The

armature is driven in the direction of the platen by the force of the armature spring.

The print wire fixed to the armature protrudes from the tip of the wire guide, strikes

the paper through the ribbon and prints a dot on the paper.

(c) After the character has been printed, the armature is magnetically attracted again

and the print wires are again concealed under the wire guide.

A thermistor in the printhead prevents burning caused by over-heating of the coil

during extended continuous bi-directional printing. When the temperature of the coil

exceeds a pre-determined limit (about 119°C) the control circuit detects a thermistor

signal. Printing will then be intermittent or stop completely until the coil temperature

falls below the limit value.

2 – 21

Page 31

Paper

(1) When printing

Platen

Paper

Print wire

Printhead

Armature assembly

Thermistor

Print wire

(2) When not printing

Wire guide

Paper

Figure 2-3

Yoke

Spacer

Magnet assembly

2 – 22

Page 32

2.2.2 Spacing Operation (See Figure 2-4.)

The spacing mechanism consists of a carriage shaft mounted in parallel with the platen, and

a carriage frame that moves along the shaft. It is driven by a DC motor mounted on the bottom

of the carriage frame. Items included in the spacing mechanism are as follows:

(a) DC motor with motor gear

(b) Carriage frame (stationary yoke and motor driver board included)

(c) Carriage shaft

(d) Space rack

(e) Sensor

(f) Encoder disk

(1) Spacing operation

The carriage frame, on which the printhead and space motor are mounted, moves along

the carriage shaft in parallel with the platen. When the spacing motor rotates

counterclockwise, the driving force is transmitted to the motor gear. As the motor gear

rotates, the carriage moves from left to right.

Mechanically, it is designed in such a way that for every revolution of the DC motor, the

carriage frame moves 0.8 inch (20.32 mm).

At the same time the encoder disk rotates together with the motor and passes the sensor.

The position of the carriage frame can be determined by counting the interrupts detected

by the sensor.

In the same way, the rotation of the space motor can be recognized and controlled by

measuring the cycle of interrupts detected by the sensor.

2 – 23

Page 33

Carriage frame

Print Head

Carriage shaft

Space rack

Encoder disk

Encoder sensor

Motor gear

Slider

Figure 2-4

Guide rail

2 – 24

Page 34

2.2.3 Head Gap Adjusting (See Figure 2-5.)

The head gap adjusting lever moves back and forth to tilt the carriage frame, altering the gap

between the printhead and the platen.

The adjusting screw, which is connected to the adjusting gear rotates when the adjusting lever

is moved creating a fine gap adjustment. If the adjusting gear is pushed down, the adjusting

screw can be turned with a screw driver to change the coarse gap adjustment.

When the adjusting lever is set to range ➁ ~ ➄ the contact which is attached to the under side

of the carriage cover will connect with the contact of the space motor PC board. The printer

will reduce the printing speed automatically to ensure that adequate printing pressure is maintained

for multipart paper.

And, the adjusting cam adjusts the headgap toward left and right side in accordance with the

guide rail up and down as a position of the left end of it.

2 – 25

Page 35

Range

Platen

1

2

3

Adjusting lever

Range from 5 to 1

Adjusting screw

Adjusting cam

4

5

Idler gear

C.C.W.

Carriage shaft

Printhead

Adjusting screw

Adjusting gear

Narrows

Printhead

Platen

Range from 1 to 5

Guide rail

Widens

C.W.

Figure 2-5

2 – 26

Page 36

2.2.4 Ribbon Drive (See Figure 2-6.)

The ribbon driver mechanism moves the ribbon in synchronization with the space motor operation.

The ribbon drive mechanism consist of the following items:

(a) Ribbon drive gear assembly

(b) Ribbon gear (space motor)

(c) Ribbon cartridge

(1) Ribbon cartridge

An endless ribbon with a single direction feed is used. Ink is supplied from an ink tank,

which is built in to the ribbon cartridge.

(2) Ribbon feed operation

When the space motor is activated, the ribbon gear rotates. The rotation is transmitted

via the ribbon drive gear assembly to the drive gear in the ribbon cartridge, thus moving

the ribbon.

The feed direction of the ribbon is maintained by switching the rotational direction of the

gears in the ribbon drive gear assembly. This ensures ribbon movement when bidirectional

printing is used.

2 – 27

Page 37

Ribbon cartridge

Drive gear

Ink tank

Figure 2-6

2 – 28

Page 38

2.2.5 Paper Feed Operation

Feeding of the paper is performed by turning the platen and the pin tractor, which is driven by

the LF pulse motor.

Item of the paper feed mechanism are as follows:

(a) Pulse motor with gears

(b) Decelerating gear

(c) Platen

(d) Tractor feed unit

(e) Pressure roller

2 – 29

Page 39

(1) Cut sheet and continuous sheet switching mechanism (See Figure 2-8.)

Three different paper paths can be selected and set by the change lever.

(a) TOP (for cut sheet)

When the cut sheet is used in the manual mode or fed by the CSF (option), set the

change lever at the position marked TOP.

[Operation]

The driving force of the platen gear (R) is transmitted to the idle gear by setting the

change lever to the TOP position. However, this causes the idle gear to be disengaged

from the change gear, leaving it free.

At this time, the pressure rollers (at the rear and the front) are pressed securely to

the platen to feed the cut sheet. At the same time, the switch lever positions between

the rear switch and bottom switch, to confirm to the control board that you are in the

cut sheet mode.

In the cut sheet mode, the control board automatically feeds the sheet up to the print

start position after pausing for the wait time stored in the menu.

(b) REAR (Continuous sheet from push tractor)

When the change lever is set to REAR position, the change gear is engaged with

the idle gear and the tractor gear to transmit the rotation of the platen to the push

tractor shaft, and the continuous sheet is fed from the push tractor.

At the same time, the switch lever turns on the rear switch, to confirm to the control

board that you are in the continuous sheet mode.

2 – 30

Page 40

(c) BOTTOM (Continuous sheet from bottom feeder) (option)

When the change lever is set in the BOTTOM position, the rotation of the platen

is transmitted to the drive gear of the bottom tractor feed unit through the idle gear

to feed the sheet which has been set in the bottom tractor feed.

At the same time, the switch lever turns on the bottom switch, to confirm to the control

board that you are in the continuous sheet mode.

Correlation in Mechanism

Mechanism

Lever

Position

TOP

REAR

BOTTOM

Rear

Switch

OFF

ON

OFF

Bottom

Switch

OFF

OFF

ON

Idle

Gear

Rotate

Rotate

Rotate

Change

Gear

Stop

Rotate

Rotate

Tractor

Gear

Stop

Rotate

Stop

Sheet

Insertion

Manual/

automatic

CSF:

Operation SW

or instruction

•

Operation

SW

or

•

instruction

•

Operation

SW

or

•

instruction

2 – 31

Page 41

Control Power

supply Assy

Bottom switch

Switch lever

Change gear shaft

Rear switch

Change lever

Release shaft

Change arm

TOP

Platen gear (R)

Platen

BOTTOM

Change lever

REAR

Tractor gear

Change gear

Reset spring

Idle gear

(Bottom tractor unit)

Figure 2-8

2 – 32

Page 42

(2) Cut-sheet feeder operation (See Figure 2-9.)

The pulse motor used for the paper feed mechanism is mounted on the left of the frame,

and the rotation of the motor is transmitted through decelerating gears (LF idle gear, platen

gear) to the platen. When using cut-sheet paper, the change lever must be in the TOP

position to grab the paper, while disengaging the push tractor.

When the change lever is set to the TOP position, the cut sheet is automatically fed

in up to the print start position after pausing for the wait time stored in the menu.

Stepping motor

(LF motor)

Pressure roller

Platen

Platen gear

LF Idel gear

Figure 2-9

2 – 33

Page 43

(3) Continuous paper feed operation (Rear) (See Figure 2-10.)

The force transmitted to the platen, rotates the tractor gear through platen gear, the idler

gear and the change gear. The rotation of the tractor gear makes the pin tractor belt rotate

through a sheet feeder shaft, feeding the continuous paper.

Paper

Idle gear

Figure 2-10

Platen gear

Tractor gear

Change gear

2 – 34

Page 44

(4) Push and pull tractor mechanism (Option) (See Figure 2-11).

This mechanism consist of an optional pull tractor and a standard push tractor mechanism.

This mechanism can perform forward and reverse feed by setting continuous sheets to

the push tractor and pull tractor.

The rotation of the platen is transmitted to the push tractor and the pull tractor. Sheets

are fed by these two tractors at the same time.

To remove slack from the sheets, set the sheets according to the following procedure when

using the push and pull tractors.

1 Set the change lever to the REAR position (setting the sheets to the push tractor

to feed).

2 Set the paper, which is fed in front of the platen, to the pull tractor.

3 Set the change lever to the TOP position and feed paper using the platen knob.

4 If paper slack is removed, set the change lever to the REAR position.

Pull tractor

Drive gear

Platen gear

Idle gear

Push tractor

Platen

Figure 2-11

2 – 35

Page 45

(5) Pull tractor mechanism (option) (See Figure 2-12.)

Bottom feed of continuous sheets is possible only when an optional pull tractor unit is

installed.

The rotation of the platen is transmitted to the idle gear of the pull tractor unit through

the platen gear at the left end of the platen. The rotation of the idle gear is transmitted

to the drive gear, and continuous sheet forms are fed by the pull tractor being rotated

through the sheet feeder shaft.

Continuous sheet form

Pull

Tractor assembly

Sheet feeder shaft

Drive gear

Idle gear

LF motor

Platen

Platen gear

LF Idle gear

Figure 2-12

2 – 36

Page 46

(6) Bottom push feed operation (Option) (See Figure 2-13.)

The bottom push feed of the continuous sheet is possible only when the bottom tractor

feed unit is installed.

When the platen rotates, the rotational force of the platen is transmitted through the tractor

idle gear and the tractor change gear to the tractor drive gear of the bottom push tractor,

and the sheet of paper is fed in to the print start position.

Platen

Platen gear

Figure 2-13

Change gear

Idle gear

Tractor change gear

Tractor idle gear

Tractor drive gear

2 – 37

Page 47

(7) Paper clamp mechanism (See Figure 2-14.)

When setting the change lever to the BOTTOM , TOP or REAR position, the operation

of the front release gear arm changes according to the position of the release cam. And

at the same time, the position of the cam installed to the front release gear shaft changes,

and the open and close of the pressure roller.

Position of

change lever

BOTTOM OPEN OPEN

TOP CLOSE CLOSE

REAR OPEN OPEN

Open or close of

front pressure roller

Open or close of

rear pressure roller

2 – 38

Page 48

TOP

BOTTOM

Change lever

Release cam

Platen

Front release

gear arm

REAR

Figure 2-14

2 – 39

Page 49

2.2.6 Paper Detection Mechanism (See Figure 2-15.)

(1) Cut sheet detection

When the cut sheet is inserted, the point A is pushed backward and the paper near end

lever B rotates counter clockwise (CCW).

At this time, the rear sensor lever rotates counterclockwise (CCW), the rear sensor lever

and pulls out of the rear and top paper end sensor to detect that the sheet is provided.

The procedure for the paper end is made in the reverse order, that is, its detection is

performed when the paper end sensor is blocked.

(2) Rear feed detection

When the sheet is fed from the push tractor, the point B is pushed to the front side and

the paper near end lever A rotates clockwise (CW). At this time, the rear sensor lever

rotates counterclockwise (CCW), and pulls out of the rear and top paper end sensor to

detect that the sheet is provided.

The procedure for the paper end is made in the reverse order, that is, its detection is

performed when the rear sensor lever intercepts the sensor.

(3) Bottom feed detection

When the sheet is fed from the bottom, the point C rotates clockwise (CW). When the

bottom sensor lever rotates clockwise (CW), it pulls out of the bottom paper end sensor

to detect that the sheet is provided.

The procedure for the paper end is made in the reverse order, that is, its detection is

performed when the bottom sensor lever intercepts the sensor.

2 – 40

Page 50

Paper end sensor

Shaded portion

Sensor lever

A

Paper end lever

B

Bottom paper end lever

Figure 2-15

2 – 41

Page 51

(4) Top line print mechanism (See Figure 2-16.)

The front edge of the sheet is protected by the ribbon protector so that it can stop at a

position just near to the print head (0 tear off position) to start printing at the front end

of the sheet, without causing the sheet to crumple or curl up.

The printing starts at the front end of the sheet, and continues uni-directionally until the

front end of the sheet gets to the inside of the pull up roller cover.

After that, that printing continues bi-directionally.

2 – 42

Page 52

Ribbon protector

Platen

Printhead

Carriage frame assembly

Figure 2-16

2 – 43

Page 53

2.2.7 Automatic Sheet Feed

This function is used to feed in the sheet automatically up to the print start position when the

cut sheet or the continuous sheet is used.

[Operational procedure]

(1) When using the cut sheet

1) Set the change lever to the TOP position. (See Figure 2-17.)

2) Insert a sheet of paper between the platen and the paper shoot.

3) After the lapse of time selected by the “wait time” in the menu, the LF motor starts

its operation to feed the sheet of paper up to the print position.

4) When the default is selected, the sheet of paper is feed in up to the position 0.35

inches (first dot position) from the upper end of the sheet. However, the 0 tear off

mechanism allows the printing at the front end of the sheet by changing the TOF

position.

Sheet setting

REAR

PE

Detection timer

LF action

BOTTOMTOP

Time selected

on the menu

Time out

BOTTOM

SW2

TOP

SW1

REAR

Figure 2-17

2 – 44

Page 54

(2) When using the continouos paper

1) Set the change lever either to the rear side or the bottom side position. (See Figure

2-17.)

2) Set a sheet of paper either to the push tractor or the bottom tractor.

3) Press the “FF/LOAD” switch.

4) The LF motor starts its operation to feed the paper up to the print start position.

5) The paper is fed in up to the TOF position (Factory default: 0.35 inches from the top).

Push down the “FF/LOAD” switch.

Detection of the sheet supplied

PE

LF action

Line feed (about 3 inches) until the

detection of the sheet supplied

When the “”FF/LOAD” switch is pushed down, the LF motor feeds in the sheet about 3

inches. When the LF motor completes the operation and the sheet has not been fed in,

the feeding operating operation becomes, ineffective, thus resulting in the feeding jam.

2 – 45

Page 55

2.2.8 Paper Park Function (Continuous paper)

Continuous sheets which have been inserted can be reversed automatically by using the “PARK”

button on the operation panel.

1) Press the “PARK” button on the operation panel.

2) Reverse LF is started and paper is fed in reverse until paper end occurs or 19 inches

maximum have been fed.

3) The paper is fed in reverse, to leave the paper on the push-tractor or bottom-tractor.

PARK

PE

LF action

Reverse LF until paper end or 19 inches max.

Paper end detection

Reverse LF from P.E. Sensor to tractor feed assy.

Alarm LED lights up when P.E. is not detected after 19 inches reverse feeding.

Operator can press SEL key to turn off the ALARM LED then press PARK key to continue

park function.

This operation is required when the length of paper for parking is more than 19 inches.

2 – 46

Page 56

3. ASSEMBLY/DISASSEMBLY

Page 57

3. ASSEMBLY/DISASSEMBLY

This section explains the procedures for removing and installing various assemblies and units

in the field.

Description is mainly limited to the removal procedure; installation should basically be performed

in the reverse sequence of the removal procedure.

3.1 Precaution for Parts Replacement

(1) Remove the AC cable and the interface cable before disassembling or assembling.

(a) Turn off the AC power switch. Remove the AC input plug of the AC cable from the

receptacle. Remove the AC cable from the inlet on the printer (only 200V).

(b) To connect the AC cable again, connect it to the inlet on the printer (only 200V) first,

then insert the AC input plug into a receptacle.

AC input plug

AC receptacle

AC cable

Interface cable

(2) Do not disassemble the printer as long as it is operating normally.

(3) Do not remove unnecessary parts, and limit the disassembly area as much as possible.

(4) Use the designated service tools.

(5) Carry out disassembly in the prescribed sequence; otherwise, damage to the parts may

result.

(6) It is advisable to temporarily install screws, snap rings and other small parts in their original

positions to avoid losing them.

(7) Whenever handling the microprocessors, ROM, RAM IC chips and boards, do not use

gloves which may cause static electricity.

(8) Do not place the printed circuit board directly on the equipment or on the floor.

(9) If adjustment is specified in the middle of installation, follow the instructions.

3 – 1

Page 58

3.2 Service Tools

Table 3.1 lists the tools necessary for replacing printed circuit boards and parts of units in the

field.

No. Service Tool Q’ty Use Remarks

Table 3.1 Service tools

1

2

3

4 Spring hook 1

5 J-YX4025–83335-3 1

6 Volt/ohmmeter 1

7 Feeler gauge 1

8 Pliers 1

No. 1-100 Phillips

screwdriver 2.6 mm

No. 2-200 Phillips

screwdriver 3-5 mm

No. 3-100

screwdriver

1

1

1

Screws

Screws

Head gap

adjustment

Head gap

adjustment

9 No. 5 nippers 1

10

1.1 lbs (500 g)

bar pressure gauge

1

3 – 2

Page 59

3.3 Disassembly/Reassembly Procedure

This section explains the assembly replacement procedures according to the following disassembly

system.

[Parts Layout]

Upper cover assy

Control/Power

supply board

Driver board

Transformer assy

Printhead

Operation panel board

Printer unit

Figure 3-1 Printer unit

3 – 3

Page 60

[How to Change Parts]

This section explains how to change parts and assemblies appearing in the disassembly diagram

below.

Printer unit

3.3.1 Printhead

3.3.2 Ribbon protector

3.3.3 Pull-up roller assy

3.3.4 Upper cover, access cover and sheet guide

3.3.5 Gear case assy

3.3.6 PC connector

3.3.7 Space motor and guide roller assy

3.3.8 Space rack

3.3.9 Carriage cable

3.3.10 Back-up roller holder assy

3.3.11 Platen assy

3.3.19 Paper pan

3.3.12 Driver board (SDDV)

3.3.13 LF motor

3.3.18 Carriage shaft

3.3.14 Operation panel PCB (LEOP)

3.3.15 Control/Power supply board (SDCT)

3.3.16 Transformer assy

3.3.17 Change lever and gears

3.3.20 Rear tractor assy

3.3.21 Rear pressure assy

3.3.22 Switch lever

3 – 4

Page 61

3.3.1 Printhead

(1) Open the access over.

(2) Pull up and rotate the head clamp 1 to unclamp the printhead 2 as shown fig. 3.3.1.

(3) Disconnect the printhead 2 from PC connector 3.

(4) To install, follow the removal steps in the reverse order.

Notes on installation:

(1) Insert the printhead 2 into the PC connector 3 while pushing it against the carriage frame

4.

(2) The head clamp 1 must surely be sandwiched between printhead 2 and carriage frame

4 as shown fig. 3.3.2.

(3) Be sure to check the gap between platen and printhead (see 4).

(4) Be careful not to touch the print head while it is very hot.

1

4

2

1

2

Figure 3.3.1 Figure 3.3.2

2

4

1

3 – 5

3

Page 62

3.3.2 Ribbon Protector

(1) Remove the printhead (see 3.3.1).

(2) Open the pull-up roller cover 1.

(3) Raise and remove the ribbon protector 2.

(4) To install, follow the removal steps in the reverse order.

2

1

3 – 6

Page 63

3.3.3 Pull-up Roller Assy

(1) Open the access cover 1.

(2) Lift up the sheet guide Assy 4 to remove.

(3) Tilting the pull-up roller Assy 2 toward the front, remove from the shaft of platen Assy

3.

(4) To install, follow the removal steps in the reverse order.

Note: Remove the sheet guide Assy 4 before installing or removing the pull-up roller Assy

2.

2

4

3

1

3 – 7

Page 64

3.3.4 Upper Cover Assy, Access Cover Assy and Sheet Guide Assy

(1) Pull off the platen knob 1.

(2) Turn the change lever 2 toward the bottom position.

(3) Insert a flat-blade screwdriver into grooves (5 places) (4 places for narrow type) of frame

and twist to disengage claws of upper cover 3.

(4) Raise the front side of upper cover Assy 3 and shift toward the rear to disengage claws

(6 places) (5 places for narrow type) of frame.

(5) Raise the upper cover Assy 3 to remove.

(6) Open the access cover Assy 4 toward the front to remove.

(7) Lift up the sheet guide Assy 5 to remove.

(8) To install, follow the removal steps in the reverse order.

Remark on assembly:

Match the posts A at the both sides of the Sheet Guide 5 with the arrow marks on

the upper cover. Push the Guide into the Cover.

5

A

4

1

3

2

3 – 8

Page 65

3.3.5 Gear Case Assy

(1) Remove the printhead (see 3.31).

(2) Remove the upper cover (see 3.3.4 (1) – (5)).

(3) Move the carriage Assy to right hand side, remove two screws 1, then the space motor

2.

(4) Disconnect a carriage cable.

(5) Disengage claws (4 places).

Using a flat-blade screwdriver, push to widen the claw for easy disengagement.

(6) Remove the gear case Assy 3 in upper direction and release the carriage cable from the

cable clamp of the gear case Assy.

(7) To install, follow the removal steps in the reverse order.

Note on installation:

(1) To assemble, align the direction of the SP motor axis 4 with the Gear Hole of the Gear

Case assy.

(2) Be sure to check, and adjust if necessary, the gap between platen and printhead (see

4-1).

2

4

1

3

3 – 9

Page 66

3.3.6 PC Connector

(1) Remove the printhead (see 3.3.1).

(2) Remove the upper cover (see 3.3.4 (1) – (5)).

(3) Remove the gear case Assy (see 3.3.5).

(4) Remove the PC connector 1 from the space motor Assy 2.

(5) To install, follow the removal steps in the reverse order.

Note on installation:

(1) Do not touch the space motor 2 or terminals of PC connector 1. Also, take care to avoid

dust or foreign matters.

(2) After installation, check and adjust the gap between platen and printhead (see 4-1).

1

2

3 – 10

Page 67

3.3.7 Space Motor, Guide Roller Assy

(1) Remove the printhead (see 3.3.1).

(2) Remove the upper cover (see 3.3.4 (1) – (5)).

(3) Remove the gear case Assy (see 3.3.5).

(4) Remove the PC connector (see 3.3.6).

(5) Remove screw 2, then the guide roller Assy 3 from the space motor 1.

(6) To install, follow the removal steps in the reverse order.

Notes on installation:

(1) Do not touch the terminals of space motor 1. Also, take care to avoid dust or foreign

matters.

(2) When installing the guide roller Assy 3, push portions A and B against the space motor

1.

(3) When installing the space motor 1, align the face C with carriage frame 4 and push portion

D against the frame.

(4) After installation, check and adjust the gap between platen and printhead (see 4-1).

4

C

D

1

1

B

3

A

2

3

3 – 11

Page 68

3.3.8 Space Rack

(1) Remove the printhead (see 3.3.1).

(2) Remove the upper cover (see 3.3.4 (1) – (5)).

(3) Remove the gear case Assy (see 3.3.5).

(4) Remove the space motor (see 3.3.7).

(5) Remove the spring 1.

(6) Disengage the claw on left side of space rack 2 from the frame, and remove the space

rack 2 in upper direction.

(7) To install, follow the removal steps in the reverse order.

Note on installation:

(1) After installation, check and adjust the gap between platen and printhead (see 4-1).

1

2

1

2

2

3 – 12

Page 69

3.3.9 Carriage Cable

(1) Remove the printhead (see 3.3.1).

(2) Remove the upper cover (see 3.3.4 (1) – (5)).

(3) Remove the gear case Assy (see 3.3.5).

(4) Remove the space motor (see 3.3.7).

(5) Remove the space rack (3.3.8).

(6) Remove two screws 1, release the driver board 2 and PCB sheet 9 by lifting clamp 8,

and disconnect cable from connector 3, 4, 5, 6.

(7) Remove carriage cable 7 from fasteners on frame.

(8) To install, follow the removal steps in the reverse order.

Note on installation:

(1) Take care not to fold the carriage cable 7 during installation. Curve slightly the carriage

cable 7 when assembling into the fasteners.

(2) Make sure that the paper end lever A will not contact the Paper end Sensor 0 when

mounting the Driver Board.

9

2

6

0

8

A

7

1

2

5

1

3

4

3 – 13

Claw

7

Claw

Page 70

3.3.10 Backup Roller Holder Assy

(1) Remove the printhead (see 3.3.1),

(2) Remove the upper cover (see 3.3.4 (1) – (5)).

(3) Remove the gear case Assy (see 3.3.5).

(4) Remove the space motor (see 3.3.7).

(5) Remove the backup roller spring 2.

Disengage claws (2 places) of roller holder from the carriage frame 1, and remove the

backup roller holder assy 3.

(6) To install, follow the removal steps in the reverse order.

1

2

Note: Small round hole with metal tip on back up roller holder assy 3 should be facing

up when installing.

Claw (2 places)

3

3 – 14

Page 71

3.3.11 Platen Assy

(1) Remove the printhead (see 3.3.1).

(2) Remove the ribbon protector (see 3.3.2).

(3) Remove the pull-up roller Assy (see 3.3.3).

(4) Remove the upper cover (see 3.3.1 (1) – (5)).

(5) Turn the change lever 1 to the bottom position.

(6) Push in the lock levers 2 on both sides to unlock from the frame, then rotate them upward

by 90°.

(7) Remove the platen Assy 4 from base frame.

(8) To install, follow the removal steps in the reverse order.

2

2

2

2

4

1

3 – 15

Page 72

3.3.12 Driver Board (SDDV)

(1) Remove the upper cover (see 3.3.4 (1) – (5)).

(2) Remove two screws 1, and release the driver board 2 and PCB sheet 5 by lifting clamp

4.

(3) Disconnect all cables from driver board 2.

(4) To install, follow the removal steps in the reverse order.

Note on installation:

(1) Insert one sensor lever 3 between sensor when installing the driver board 2.

5

1

2

1

2

4

4

Sensor

2

3

3 – 16

3

Page 73

3.3.13 LF Motor

(1) Remove the printhead (see 3.3.1).

(2) Remove the ribbon protector (see 3.3.2).

(3) Remove the pull-up roller Assy (see 3.3.3).

(4) Remove the upper cover (see 3.3.4 (1) – (5)).

(5) Remove the platen Assy (see 3.3.11).

(6) Remove the driver board (see 3.3.12).

(7) Remove the left FG plate 1.

(8) Release the lock A to remove the LF motor 2.

(9) To install, follow the removal steps in the reverse order.

Remark on assembly:

(1) Press the LF Motor Cable with a portion A of the Motor Plate.

1

Lock A

2

A

3 – 17

Page 74

3.3.14 Operation Panel PCB (LEOP)

(1) Remove the upper cover (see 3.3.4 (1) – (5)).

(2) Disconnect the cable 1 from connector 3 of Driver board 2.

(3) Disengage claws on both sides from the frame, and remove the operation panel 4.

(4) Open claws (8 places) and remove the operation panel PCB 5 from the operation panel

4.

(5) To install, follow the removal steps in the reverse order.

5

2

3

4

1

3 – 18

Page 75

3.3.15 Control/Power Supply Board (SDCT)

(1) Remove the upper cover (see 3.3.4 (1) – (5)).

(2) Disconnect two flexible cable 3 from the connector 2 the Control/Power Supply Board

1.

(3) Remove the cable 5 from the connector 4 on the Control/Power Supply board 1.

(4) Remove two screws 6, and remove the Control/Power Supply Board 1.

(5) To install, follow the removal steps in the reverse order.

Remark on assembly:

(1) To mount the Control/Power Supply Board, set the change lever to the top position so

that the Switch Lever 7 will not hooked on the microswitches 8.

3

6

5

7

4

8

8

2

1

3 – 19

Page 76

3.3.16 Transformer Assy

(1) Remove the upper cover (see 3.3.4 (1) – (5)).

(2) Remove AC inlet 1 and AC switch 2 from the frame guide.

(3) Disconnect the cable 3 from the connector 4 on the Control/Power Supply Board 5.

(4) Remove a screw 6 and disconnect ground cable 7.

(5) Remove two screws 8 and shift the transformer Assy 9 to the left and remove it.

6

1

8

7

2

5

9

3

4

3 – 20

Page 77

3.3.17 Change Lever and Gears

(1) Remove the upper cover (see 3.3.4 (1) – (5)).

(2) Remove the reset spring 1, then remove the idle gear 2, the tractor gear 4 and the change

gear 5.

(3) Push back the protrusion of the Change Gear Shaft 6 with a flatblade screw driver to

remove the change lever 3.

(4) To perform mounting, follow the reverse procedure of removal.

Remark on assembly:

(1) To insert the change lever into the Change Gear Shaft 6, match the flat surface (D cut).

6

4

5

3

1

2

3

D cut

3 – 21

Page 78

3.3.18 Carriage Shaft

(1) Remove the printhead (see 3.3.1).

(2) Remove the upper cover (see 3.3.4 (1) – (5)).

(3) Remove the driver board (see 3.3.12).

Remove the FG plate (L) 2.

(4) Slide the carriage shaft 1 to the left side (in the direction of the arrow) to remove.

(5) To perform mounting, follow the reverse procedure of removal.

Note on installation:

(1) After installation, check and adjust the gap between platen and printhead (see 4-1).

1

2

3 – 22

Page 79

3.3.19 Paper Pan

(1) Remove the printhead (see 3.3.1).

(2) Remove the ribbon protector (see 3.3.2).

(3) Remove the pull-up roller assy (see 3.3.2).

(4) Remove the upper cover assy (see 3.3.4 (1) – (5)).

(5) Remove the platen assy (see 3.3.11).

(6) Release claws A .

(7) Lift up the paper chute assy 1 and remove.

(8) To perform mounting, follow the reverse procedure of removal.

1

A

3 – 23

Page 80

3.3.20 Rear Tractor Assy

(1) Remove the printhead (see 3.3.1).

(2) Remove the ribbon protector (see 3.3.2).

(3) Remove the pull-up roller assy (see 3.3.3)

(4) Remove the upper cover (see 3.3.4 (1) – (5)).

(5) Remove the reset spring (see 3.3.17 (3))

(6) Remove the tractor gear 1.

(7) Shift the drive shaft 2 to the right side to remove (in the direction of the arrow).

(8) To perform mounting, follow the reverse procedure of removal.

Remark on assembly:

(1) When the Tractor Assy (L) 3 (R) 4 have been detached from the Drive Shaft, align the

protrusions 5 of the Pin Tractor Wheels to the same direction before assembly.

5

3

4

2

1

3 – 24

Page 81

3.3.21 Rear Pressure Assy

(1) Remove the upper cover (see 3.3.4 (1) – (5)).

(2) Remove the change lever and gears (see 3.3.17).

(3) Remove the paper pan (see 3.3.19).

(4) Remove the rear pressure roller 1.

(5) Rotate the release shaft 2 and move it to the left to detach the release shaft 2.

Match the Main Frame Rib A with the protrusion B of the Release Shaft.

(6) Remove rear pressure SP assy 3.

(7) To install, follow the removal step in the reverse order.

Note: (1) At mounting release shaft 2, pay attention to the gear engagement of release

shaft 2, change arm lever 6, change gear shaft 7.

(2) There are 5 Rear pressure Spring Assemblies. Use two pieces which have

larger spring diameter on the right side. Use three remaining pieces on the

left side (for ML3321).

(3) Make sure that the Release Shaft 2 will be on top of the Support spring 4.

(4) To assemble the Release Shaft 2, make sure that the protrusion of the switch

lever 5 is in the U groove of the Release Shaft 2.

1

3

5

2

3

2

A

B

3

4

7

3 – 25

6

2

Page 82

3.3.22 Switch Lever

(1) Remove the upper cover (see 3.3.4 (1) – (5)).

(2) Remove the change lever and gears (see 3.3.17).

(3) Remove the paper pan (see 3.3.19).

(4) Remove the rear pressure assy (see 3.3.21).

(5) Pull the Switch Lever toward you and remove it upward.

(6) To install, follow the removal step in the reverse order.

Remark on assembly:

(1) At the time of the Switch Lever assembly, make sure that the Micro switch on the Main

Board works properly.

Switch lever

Switch lever

Micro switch

3 – 26

Page 83

4. ADJUSTMENT

Page 84

4. ADJUSTMENT

(1) Be sure to carry out this adjustment with the printer mechanism mounted on the lower

cover.

(2) Be sure to carry out this adjustment operation on a level and highly rigid work table

(flatness: less than 0.039 inch or 1 mm) so as to minimize adjustment error.

4 – 1

Page 85

ItemNo. Specification Drawing Adjustment method

4–1–1

Gap between the platen and the print head

1) Parallelism ad-

justment

Variation of

value at the

left, the center

and the right

shall be less

than 0.02 mm

Marking

After adjustment, mark the adjust

composition with a red pen.

Left

Right

Adjust cam

It shall be measured

at 3 points: the left

end, the center and

the right end of the

platen.

Adjustment method

(1) Gap between the

platen and the

print head at the

left end and the

right end shall be

adjusted by rotating the adjust

cam.

(2) Set the adjust

lever at the

Range: 1. Press

the adjust gear

downward (in

direction A) to

push the adjust

gear and the

adjust gear out of

mesh.

2) Initial adjustment

Carriage shaft

Range: 1

Range: 5

Adjust lever

Adjust screw

0.41±0.03 mm

Left

Center

Adjust gear

Platen

Right

Print head

Adjust cam

(3) Adjust the gap by

rotating the adjust

screw in direction

B or C while the

adjust lever and

the adjust gear

are disengaged.

(4) After adjustment,

mark the adjust

cam position with

a red pen.

4 – 2

Page 86

ItemNo. Specification Drawing Adjustment method

Note 1)

The head gap shall be

Adjust lever

Adjust gear

Adjust

spring

A

B

Adjust

screw

C

measured with the

change lever set to

rear position.

Note 2)

The head gap shall be

measured positioning

the platen gear (R)

craw on the top.

Note 3)

Move the adjust

screw in clockwise

direction (in direction

B) to measure.

Adjust lever

Adjust gear

Adjust cam

Measure variation of

4–1–2 Gap=0.71

gap when range is

changed.

±0.05 at the

range 5.

Print head

Click of platen gear R

Gap

Platen

4 – 3

Page 87

ItemNo. Specification Drawing Adjustment method

Gap between the contact and the monitor

0.3mm or more

Contact

Adjust lever

Confirm followings.

Make sure that the

gap between the contact and the motor

PCB is 0.3 mm or

more.

0.3mm or

more

Motor PCB

At the time of printing

test, make sure that

the contact touches

the motor PCB and it

becomes reduced

speed mode when the

adjust lever is set to

range 2 and 4.

Touching

4 – 4

Page 88

ItemNo. Specification Drawing Adjustment method

Gap between the

4–2 1±0.5 Confirm followings.

platen and the paper

pan

1±0.5

Rear

Platen

Change lever

(At friction)

1±0.5

Bottom

Paper pan

(1) When the change

lever is set at

Friction position,

the gap between

the platen and the

paper pan at the

rear side shall be

1±0.5mm.

(2) When the change

lever is set at

Rear or Bottom

position, the gap

between the platen and the paper

pan at the front

side shall be

1±0.5 mm.

(Rear,

Bottom

position)

Change lever

4–3 Confirm followings.

Gap between the

platen and the pressure

roller

Front pressure

roller

Rear

Platen

(Center friction)

Friction

position

Rear, Bottom

position

Bottom

Paper pan

Pressure roller

(1) When the change

lever is set at

Friction position,

all the pressure

rollers shall be

pressed to the

platen.

(2) When the change

lever is set at

Rear or Bottom

position, the gap

between the platen and the pressure roller at the

rear side shall be

3mm. The front

pressure rollers

shall be pressed

to the platen.

4 – 5

Page 89

ItemNo. Specification Drawing Adjustment method

Rotation of the push

4–4–1 To confirm:

tractor

Change lever (Center friction)

Push tractor

The tractor gear shall

rotate smoothly when

the change lever is

set at Friction position.

Slight backlash

Backlash between

4–4–2 Approx. 0.05 to

gears

0.11 mm

Tractor gear

To confirm:

There shall be slight

backlash between

gears to allow smooth

rotation of gears.

(Backlash 0.05 to

0.11 mm)

4 – 6

Page 90

ItemNo. Specification Drawing Adjustment method

Ribbon feed4–5–1 To confirm:

Ribbon shall be fed

smoothly when the

carriage is moved

from side to side.

Ribbon feeding

Running load to spac-

4–5–2 To confirm:

ing mechanism

250g or less

without a ribbon cartridge

Ribbon

Load

measurement

portion

Make sure that the

power is turned off at

the time of measurement.

Ribbon

cartridge

4 – 7

Page 91

ItemNo. Specification Drawing Adjustment method

4–6 To confirm:

Engagement of the

double gear and the LF

motor idle gear of the

Platen Assy.

LF Motor

idle gear

Bias gear

Platen gear (L)

The idle gear of the

LF motor and the

platen gear (L) and

the bias gear of the

platen shall be in

mesh in such way that

the platen gear (L)

and the bias gear

rotate against each

other to pinch the

teeth of idle gear.

The idle gear stays in

mesh with the platen

gear (L) and the bias

gear and not locked.

The bias gear and the

platen gear shall be

staggered by one

teeth as shown in the

drawing.

Tension

Good

Not good

(Locked)

4 – 8

Page 92

5. CLEANING AND LUBRICATION

Page 93

5. CLEANING AND LUBRICA TION

5.1 Cleaning

[Cautions]

1. Be sure to turn OFF the AC POWER switch before cleaning. Remove the AC power cord

from the printer.

2. Avoid dust inside the printer mechanism when cleaning.

3. If a lubricated part has been cleaned, be sure to apply lubricating oil to that portion after

cleaning.

(1) Cleaning time

When the equipment operating time has reached six months or 300 hours, whichever

comes first.

(2) Cleaning tools

Dry cloth (soft cloth such as gauze), vacuum cleaner

(3) Places to be cleaned

Table 5.1 lists the places to be cleaned:

Table 5.1

Place to be cleaned Cleaning procedure

Carriage shaft and the vicinity Remove paper waste and wipe off

Paper travel surface stain, dust, ribbon waste. etc.

5 – 1

Page 94

Carriage

shaft

5 – 2

Page 95

5.2 Lubrication

This printer is designed to be maintenance free and requires no lubrication during normal

operation. However it is necessary to apply lubricant in case the printer is disassembled,

reassembled, cleaned or parts have been changed.

(1) Cleaning time

Remarks:

1) Turn off the power before cleaning.

2) Make sure that paper dust will not fall inside of the machine.

• Cleaning period:

6 months of operation or 300 hours of operation, whichever the earlier.

• Cleaning points:

Carriage shaft and surroundings: Remove paper and ribbon dust.

Paper path: Clean stains and dusts.

Paper End Sensor Remove the dust on the Sensor.

(2) Lubricant

• Pan motor oil (or equivalent): PM

• Molicort (or equivalent): EM-30L

(3) Amount of lubricant

• Medium amount A : Apply three to four drops of oil, or 0.008 inch (0.2 mm) thick grease.

• Small amount B : Apply one drop of oil (0.006±0.002 g)

(4) Areas to Avoid

No. Do not lubricate Reason Remarks

1 Platen assembly To prevent stained paper

(rubber face) and illegal paper feed.

2 Pressure roller (rubber To prevent stained paper Pay attention not to put

face) the grease on the rubber

face of the pressure roller.

3 Carriage shaft To stabilize carriage

traveling load

4 Ink ribbon To prevent blurring of print

image

5 Pin tractor To prevent stained paper

6 Flexible cable To prevent loose connection

and crack

7 Motor PCB To prevent loose connection

8 Connector terminals To prevent loose connection

5 – 3

Page 96

(5) Lubrication point

1. Ribbon feed gear Assy.

Planetary gear shaft

(upper and lower)

EM-30L-A

Idle gear shaft (upper and lower)

PM-B (0.006±0.002g)

Drive gear shaft (upper and lower)

PM-B (0.006±0.002g)

2. Space rack

Space rack

Rack upper side

Approx. 35 (greasing range)

EM-30L-A

Approx. 30 (greasing range)

5 – 4

Page 97

3. Platen Assy.

Bias gear

Contact face of platen shaft

and platen FG spring

EM-30-L-B

Grease the contact face of

platen gear (L) and bias gear

PM-B

Platen gear (L)

5 – 5

Page 98

4. Tractor driving mechanism

5

5

5

Change arm

Idle gear teeth

EM-30L-A

Reset spring

Sliding surface of

change arm and

change lever

EM-30L-A

Change lever

Tractor gear bearing portion

EM-30L-A

Gear

bearing portion

EM-30L-A

Sliding surface of

reset spring and gear

EM-30L-A

5. Tractor drive shaft

Sliding surface of FG spring and drive shaft end

EM-30L-A

Sliding surface of change

lever and gear

EM-30L-A

Drive shaft bearing portion

234

234

234

EM-30L-A

A-A Arrow view

5 – 6

Page 99

6. Pressure roller

Change arm

Support spring

Contact portion of support

spring and shaft

EM-30L-A

Contact portion of rear

holder and shaft

EM-30L-A

Sliding portion of

release shaft and rear

roller holder

EM-30L-A

Sliding portion of release

shaft and change arm

EM-30L-A

Release shaft

Front pressure roller

Controller holder

Sliding portion of rear roller holder and

release shaft cam surface (release

shaft plane portion)

EM-30L-A

Release shaft protruding

portion - 2 portions

EM-30L-A

Shaft

Rear roller holder

Bearing portion of front roller

holder and pressure roller

EM-30L-B

5 – 7

Page 100

7. Pull up roller Assy.

Pull-up roller

frame

Pull-up roller

shaft

All bearing portions

of pull-up roller

shaft and pull-up

roller frame

EM-30L-B

Gear and post

EM-30L-A

5 – 8

Loading...

Loading...