Page 1

Chapter 0

Manual Front Cover

Okifax 2200/2400/2600

Service Handbook

P/N 59264202

Part of service training kit #: 58234202

Page 2

Copyright

This document may not be reproduced without the written permission of the Okidata® Sales and

Product Training Group. Every effort has been made to ensure the accuracy of the information

contained in this training course. Okidata is not responsible for errors beyond its control.

© 1994 by Okidata All rights reserved.

First Edition January, 1994

Second Edition July, 1994

Written and produced by the Okidata Sales and Product Training

Please send any comments on this publication to the address listed below.

Okidata

Sales and Product Training

532 Fellowship Road

Mount Laurel, NJ 08054-3499

Facsimile Number: (609) 235-2600, ext. 7034.

Okilink Login Name: Technical Training

OKI is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de Oki

Electric Industry Company, Ltd.; marca registrada, Oki Electric Industry Company, Ltd.

OKIDATA is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de

Oki Electric Industry Company, Ltd.; marca registrada, Oki Electric Industry Company, Ltd.

OKIFAX is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de

Oki Electric Industry Company, Ltd.; marca registrada, Oki Electric Industry Company, Ltd.

Touch Tone is a registered trademark of American Telephone and Telegraph

Page 3

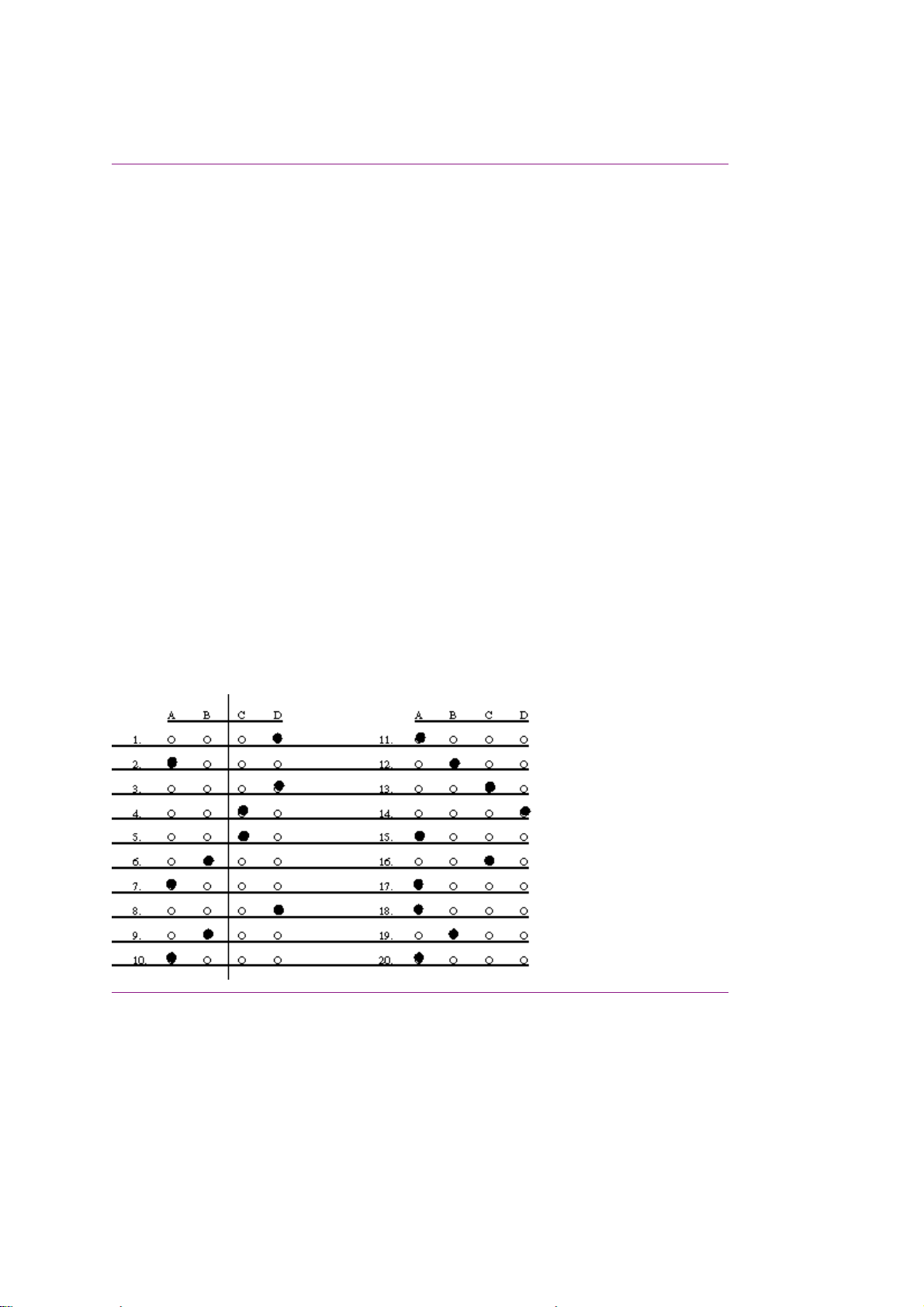

Blank Answer Sheet: Okifax 2200/2400/2600

Answer Sheet: Okifax 2200/2400/2600

Dealer Code: Todays Date:

Technicians Name:

Company:

Companys Address:

City:

State/Province:

Zip/Postal Code:

Country:

Phone #: Fax #:

If your Dealership uses Okilink II, please provide your Dealerships Login Name.

First: Last:

A B C D A B C D

1. O O O O 11. O O O O

2. O O O O 12. O O O O

3. O O O O 13. O O O O

4. O O O O 14. O O O O

5. O O O O 15. O O O O

6. O O O O 16. O O O O

7. O O O O 17. O O O O

8. O O O O 18. O O O O

9. O O O O 19. O O O O

10. O O O O 20. O O O O

Page 4

Blank Test: Okifax 2200/2400/2600

Blank Test: Okifax 2200/2400/2600

1. When should the LED head be cleaned?

1. When paper is installed.

2. When a new toner cartridge is installed.

3. When the main board is replaced.

4. When vertical white lines or stripes appear on output.

A. 1 and 2

B. 3 and 4

C. 1 and 3

D. 2 and 4

2. When troubleshooting any image problems of received faxes, always make a local

copy before assuming a defect in the receiving unit. The transmitting facsimile unit may be

defective.

A. True

B. False

3. According to the Service Handbook, lubrication should be

1. performed once a year.

2. performed as necessary.

3. done with Dow Corning Molycoat BR-2, Molycoat EM-30L, or equivalent.

4. done lightly, being careful not to over-lubricate.

A. 1

B. 1 and 2

C. 1, 2, and 3

D. 1, 2, 3, and 4

4. The image sensor for an Okifax 2200 or Okifax 2400 has __________ less elements

than the image sensor for the Okifax 2600.

A. 184

B. 284

C. 384

D. 484

Page 5

5. Which of the following are true?

1. The LED Head Drive Time is adjusted by setting positions 1 through 4 of Switch 1 on the main

controller board (for the Okifax 2200) and the printer control board (for the Okifax 2400/2600).

2. The LED Head Drive Time is always changed when a new LED head is installed.

3. The LED intensity rating is shown by the last three numbers of the label on the LED head.

4. The LED Head Drive Time can be modified through the operator panel.

A. 1 and 2

B. 3 and 4

C. 1 and 3

D. 2 and 4

6. The Okifax 2200, Okifax 2400 and the Okifax 2600 contain the same number of PC-1

sensors.

A. True

B. False

7. Both the Okifax 2400 and the Okifax 2600 accept additional memory cards.The

Okifax 2400 will accept one card at a time.The Okifax 2600 will accept two cards at a time.

A. True

B. False

8. According to the FCC Telephone Consumer Protection Act, which of the following

must the facsimile operator do?

1. Program the date into the facsimile unit.

2. Program the time into the facsimile unit.

3. Program a name (to identify the source facsimile) into the facsimile unit.

4. Program the telephone number of the source facsimile into the facsimile unit.

A. 1

B. 1 and 2

C. 1, 2, and 3

D. 1, 2, 3, and 4

9. The separation rubber should be cleaned with ethyl alcohol and replaced when the

toner is replaced.

A. True

B. False

10. You are working on an Okifax 2400. Technical Function 18 is ON. After the

successful reception of a transmission, a verification stamp mark will be placed on the

bottom of the original document.

Page 6

A. True

B. False

11. Documents should be placed face DOWN on the automatic document feeder guide.

A. True

B. False

12. When checking the PC1 sensors on an Okifax 2600, the positive lead of the digital

multimeter goes to pins __________ of CN12 on the main control board.

A. 2, 7, 11

B. 2, 8, 11

C. 3, 8, 11

D. 3, 9, 12

13. Which Technical Function enables sensor calibration during the Sensor Calibration

/ Scanning Check on an Okifax 2400/2600?

A. 64

B. 74

C. 84

D. 94

14. The Self-Diagnosis Test

1. prints the ROM version.

2. confirms the presence of RAM.

3. verifies printer unit operation.

4. confirms the presence of ROM.

A. 1

B. 1 and 2

C. 1, 2, and 3

D. 1, 2, 3, and 4

15. Performing a System Reset will erase all programmed user and service data.

Before resetting the system, you should print a copy of the Configuration Report, the Auto

Dial List, and the One Touch List.

A. True

B. False

16. You are working with an Okifax 2400. Technical Function 47 is Department ID.

When ALL settings for this function are ON, which of the following are true?

Page 7

1. Use of the facsimile unit is restricted to authorized operators. Users must enter a

pre-registered (access) code to operate the unit.

2. Twenty-four, four digit codes may be programmed into the unit.

3. Technicians can enter **** to access unit functions.

4. Thirty-five, five digit registered access codes may be programmed into the unit.

A. 1 only

B. 1 and 2 only

C. 1, 2, and 3 only

D. 1, 3, and 4 only

17. You are using RAP 04. The document reaches PC1. It then feeds three inches and

stops. SELECT LOCATION is displayed on the LCD. Place the items listed below in the

correct order.

1. The Scan Adjustment does NOT correct the problem.

2. Copy quality is NOT acceptable.

3. Perform a local copy.

4. Replace the main control board.

5. The copied document is NOT all black.

A. 3, 5, 2, 1, 4

B. 5, 1, 3, 2, 4

C. 3, 5, 2, 4, 1

D. 3, 2, 5, 1, 4

18. Touching the transfer roller may cause incomplete toner transfer, resulting in faded

output.

A. True

B. False

19. You are troubleshooting an Auto Reception Problem on an Okifax 2600. Using RAP

07, place these actions in the correct order.

1. The main control board has been replaced.

2. Manual reception is okay.

3. The LINE board has been replaced.

4. User Function 21 is set to OFF.

5. The AUTO REC key has been pressed and the unit is in auto receive mode.

A. 2, 5, 1, 4, 3

B. 2, 5, 4, 1, 3

C. 2, 5, 4, 3, 1

D. 2, 5, 3, 1, 4

20. When installing the control panel assembly, make sure that the longer scanner

hinge goes on the right.

A. True

B. False

Page 8

Page 9

Okifax 2200/2400/2600 Certification Test Answer Key

Okifax 2200/2400/2600 Certification Test Answer Key

Dealer Code: Todays Date:

Technicians Name:

Company:

Companys Address:

City:

State/Province:

Zip/Postal Code:

Country:

Phone #: Fax #:

If your Dealership uses Okilink II, please provide your Dealerships Login Name.

First: Last:

Page 10

Chapter 1

1.1 Principles Of Operation

1.1 PRINCIPLES OF OPERATION

This module contains three sections.

· Transmitter Theory of Operation

· Receiver Theory of Operation

· LED Printer Theory of Operation

Page 11

1.1.01 Compatibility

1.1.01 Compatibility

The facsimile machine operates as a Group 3 (G3) facsimile device.

Page 12

1.1.02 Communications Mode

1.1.02 Communications Mode

The unit operates as a half-duplex facsimile transceiver. Transmit and receive operations cannot

take place at the same time. However, documents can be prepared for transmission while the

machine is engaged in message reception. These documents will be automatically transmitted

upon completion of the receiving operation.

Page 13

1.1.03 Modem Operation

1.1.03 Modem Operation

The high-speed modem conforms to the following standards.

· CCITT Standard V.29 for 9600/7200 bps (bits per second) operation

· CCITT Standard V.27 ter. for 4800/2400 bps operation

· CCITT Standard for V.17 14400/12000 bps (Okifax 2400, 2600 only)

· CCITT Standard for V.33 14400/12000 bps (Okifax 2400, 2600 only)

The low-speed (300 bps) modem, which is used for handshaking, conforms to CCITT standard V.21

Channel 2 or equivalent.

Page 14

1.1.04 Automatic Fall-Back Mode

1.1.04 Automatic Fall-back Mode

The unit will change the message transmitting speed according to the following fall-back plan. The first

page of the message is transmitted at 14.4 kbps (Okifax 2200 communicates at 9600 bps maximum).

The receiving station will continuously monitor the received data. If the receiving station detects six or

more consecutive error lines during reception of a single page, or if the total number of errors detected

during the reception of a single page exceeds 10% of the data on the transmitted page, it will return a

Retrain Negative (RTN) signal to the transmitting station upon termination of the page reception. With

an RTN signal received, the transmitting station will downgrade its speed by one level (to 12 kbps in

this case) and continue transmission of the next page. Similarly, should the transmitting station again

receive an RTN signal from the receiving station, it will downgrade the speed another level.

Page 15

1.1.05 Telephone Line Connection

1.1.05 Telephone Line Connection

The facsimile machine is connected to the telephone line via the line interface board. Two RJ-11

connectors are provided. One connects to the telephone line. The other connects to an external

telephone. A separate modular jack is provided for connection of the handset.

The unit will control the switching between the handset (or the external telephone) and the telephone line

to permit use of the handset or telephone for voice communication.

Page 16

1.1.06 Error Correction Mode (ECM)

1.1.06 Error Correction Mode (ECM)

Error Correction Mode (ECM) provides error-free transmission when communicating with a remote unit

that also has ECM.

Here is an explanation of the ECM process.

· The transmit machine groups image data into blocks and transmits one block of data at a time to

the receive machine. At the end of each block, a Partial Page Signal (PPS) is transmitted.

· The receive machine stores the data block in memory and checks each frame within that block for

errors.

Modified Huffman assigns a binary code to consecutive recurring bits of white or black. The codes

must add up to a total of 1728 bits, which is the Main Scan Rate established by CCITT.

Modified Read uses a comparison technique. The line being coded is compared to the previous line

and differences are noted. Codes are then assigned to reflect the differences between the two

lines.

· If no errors are detected, the receiver sends Message Confirmation (MCF). MCF requests the

transmit machine to transmit the next data block.

· If an error is detected by the receive machine, the receive machine will transmit the frame number

of the defective frame back to the transmit machine in a signal called Partial Page Request (PPR).

· The transmit machine will then re-transmit the frame to the receive machine as a Partial Page.

· The receive machine rechecks the Partial Page, and (if all frames are correct) the receive machine

transmits MCF.

· The next data block is transmitted.

Page 17

1.1.07 Quick Scan Mode

1.1.07 Quick Scan Mode

Both the Okifax 2400 and Okifax 2600 have quick scan capability. With MEM Transmission enabled, the

units will scan documents placed on the ADF tray into memory. During a quick scan operation, each letter

size page is scanned in approximately three seconds. Once the documents are stored in memory, the

transmission is initiated, without requiring additional user action.

· Okifax 2200 Quick Scan = 7.6 seconds per page (@ Standard Resolution)

· Okifax 2400 Quick Scan = 6.0 seconds per page (@ Standard Resolution)

· Okifax 2600 Quick Scan = 3.0 seconds per page (@ Standard Resolution)

Page 18

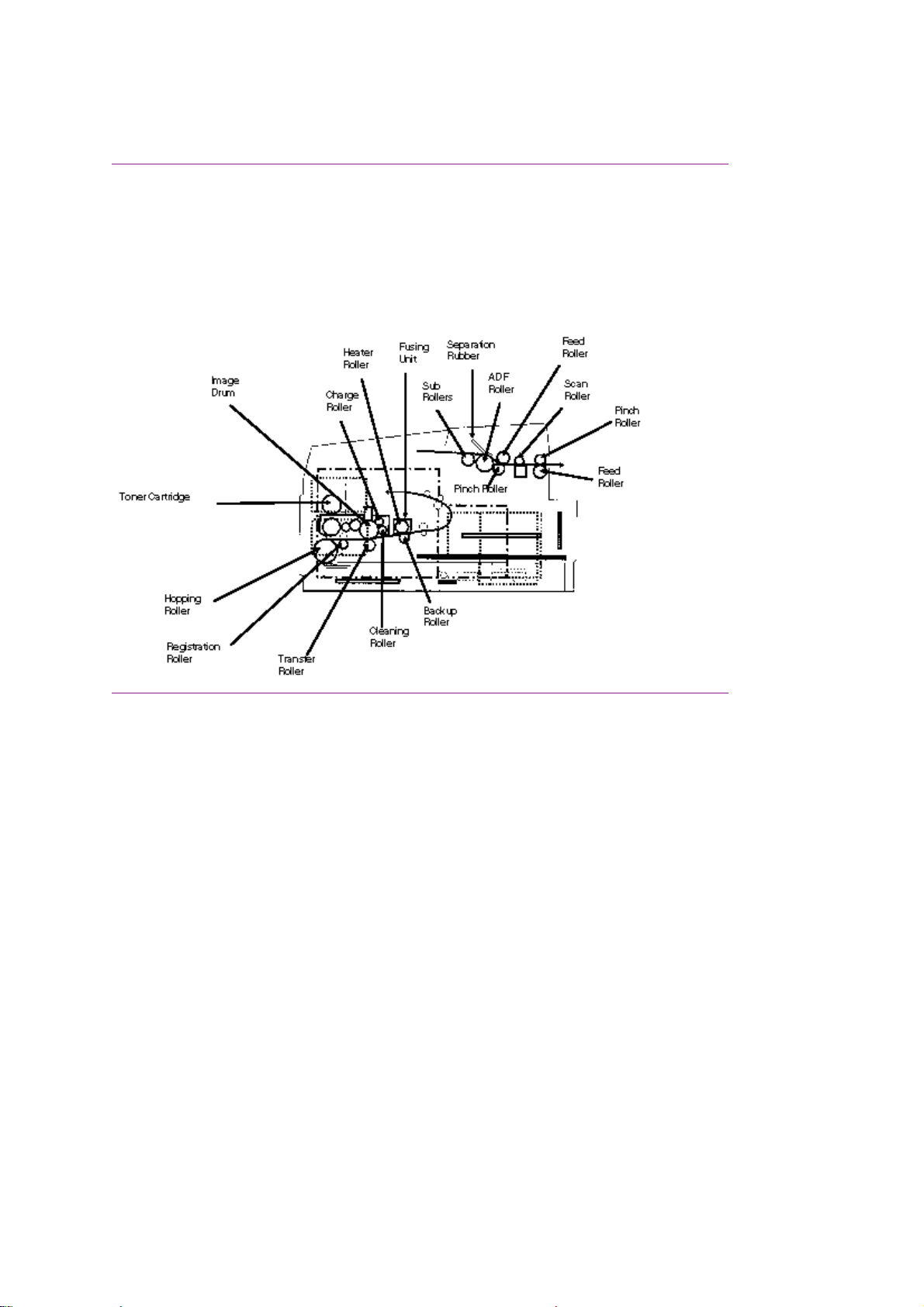

1.1.08 Major Assemblies (Mechanical) - Cross-Section Diagram

1.1.08 Major Assemblies (Mechanical)

The following major mechanical assemblies make up the facsimile machine.

· Automatic Document Feeder (ADF) Unit / Scan Unit

· Printer Unit

Page 19

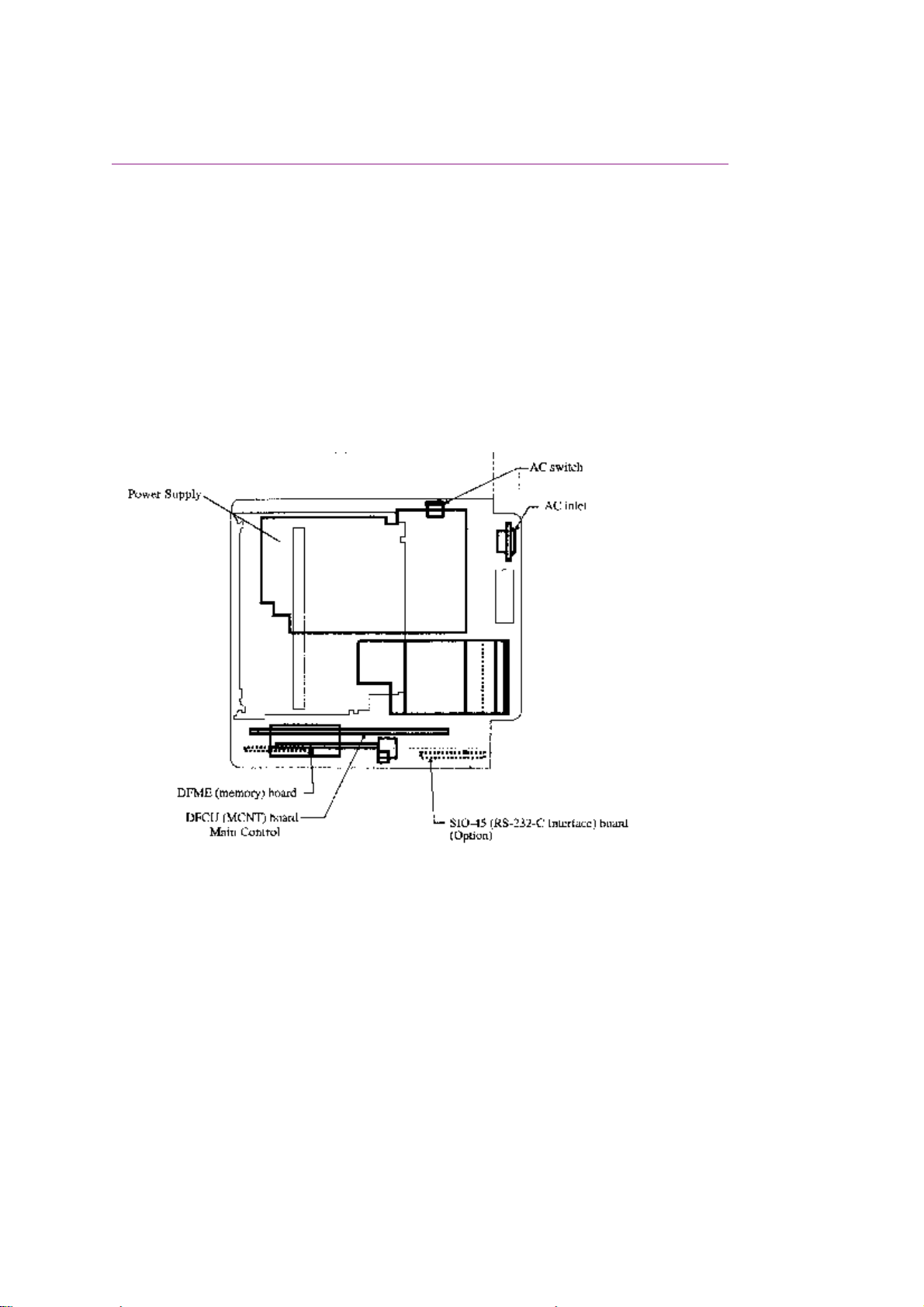

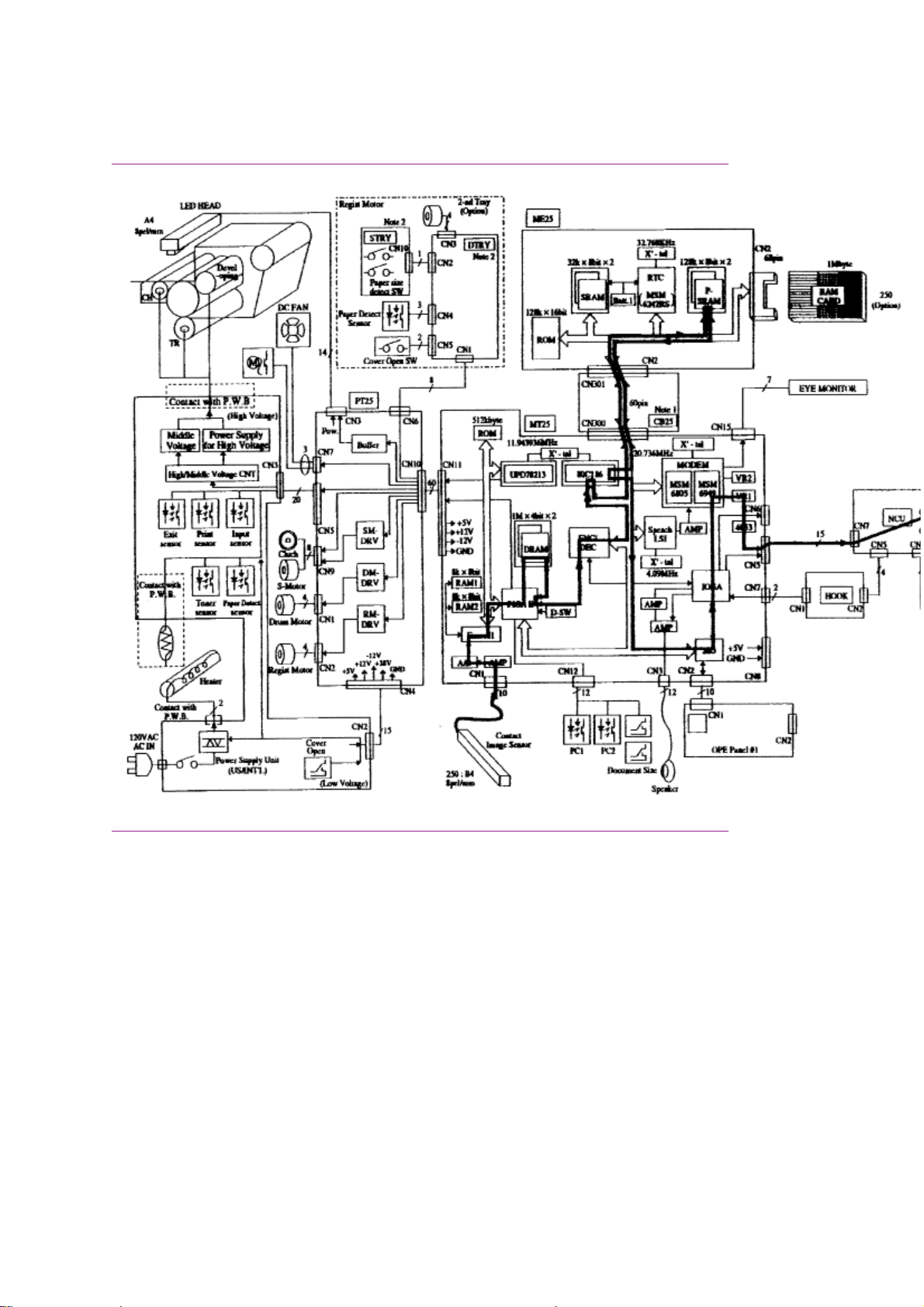

1.1.09 Major Assemblies (Electrical)

1.1.09 Major Assemblies (Electrical)

The following major electrical assemblies make up the facsimile machine.

· Main Control Board (DFCU / MCNT)

· Printer Control Board (DFPU / PCNT)

· Network Control Board (NCU)

· Operator Panel Assembly Not Shown

· Power Supply Unit Not Shown

· Memory Board Not Shown

· Line Interface Board Not Shown

· Hook Switch Board Not Shown

· Connecting Board

· Second Paper Tray Mechanism Board

Page 20

Page 21

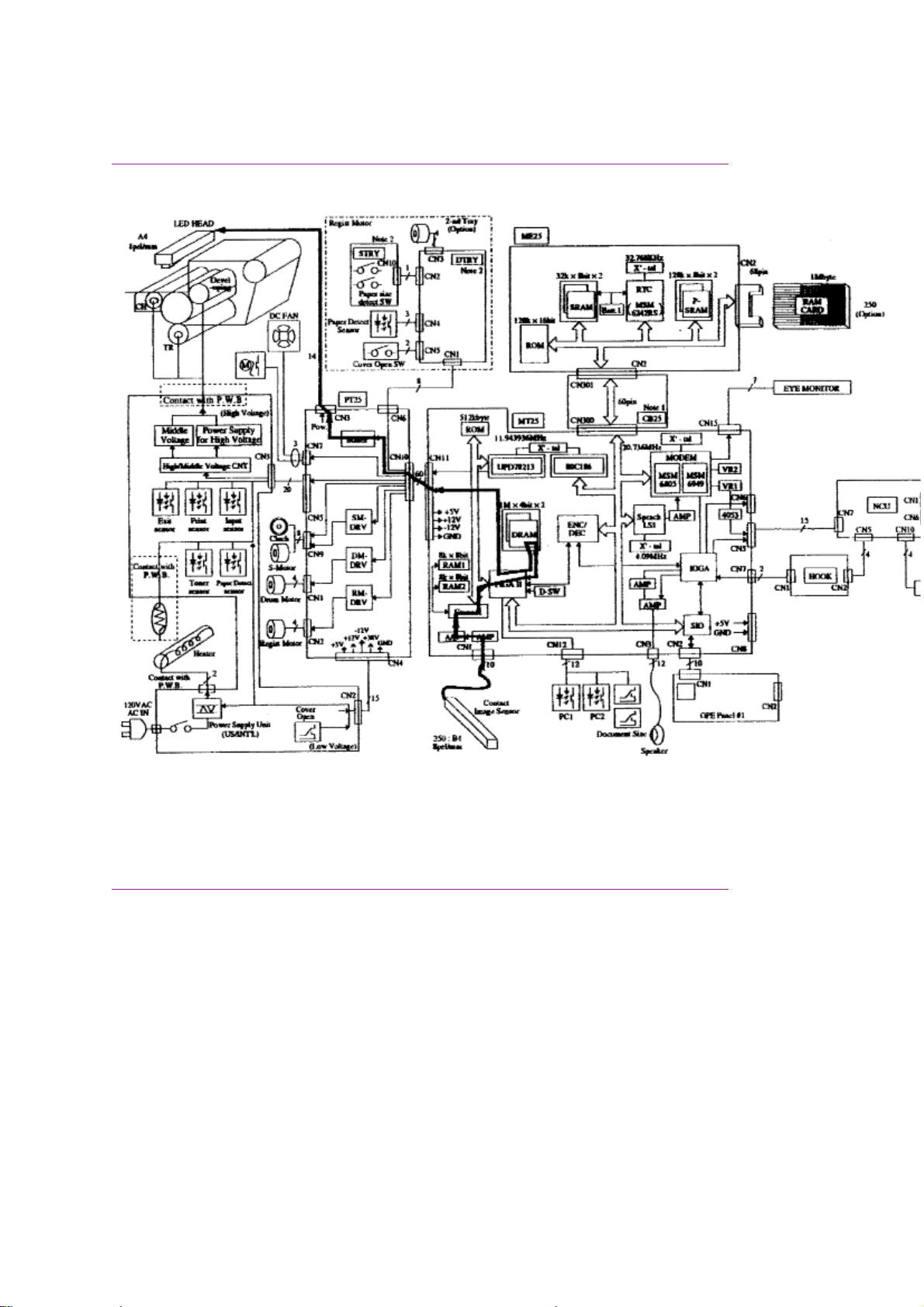

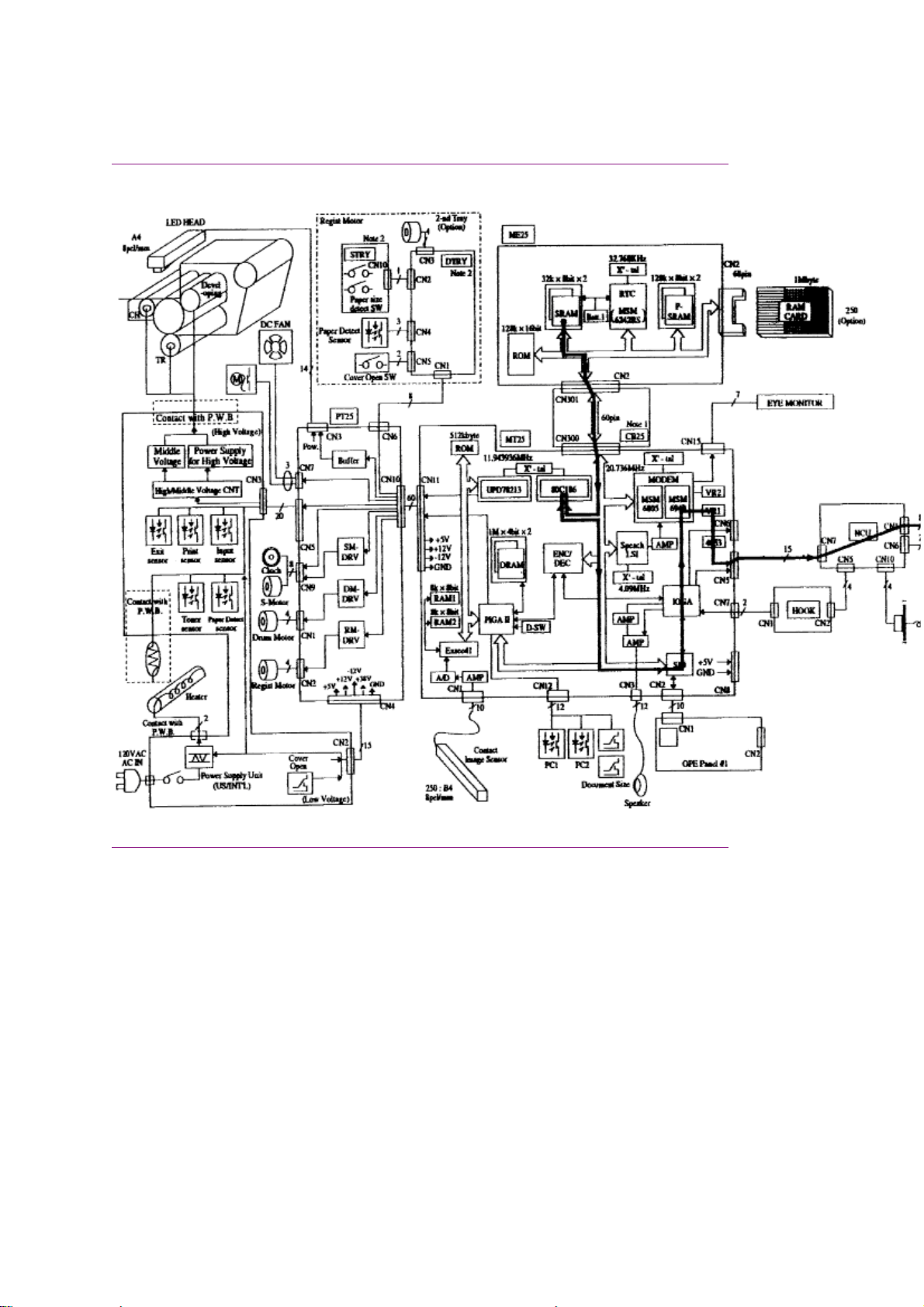

Okifax 2200 - Copy Function Block Diagram

Okifax 2200 - Copy Function Block Diagram

Page 22

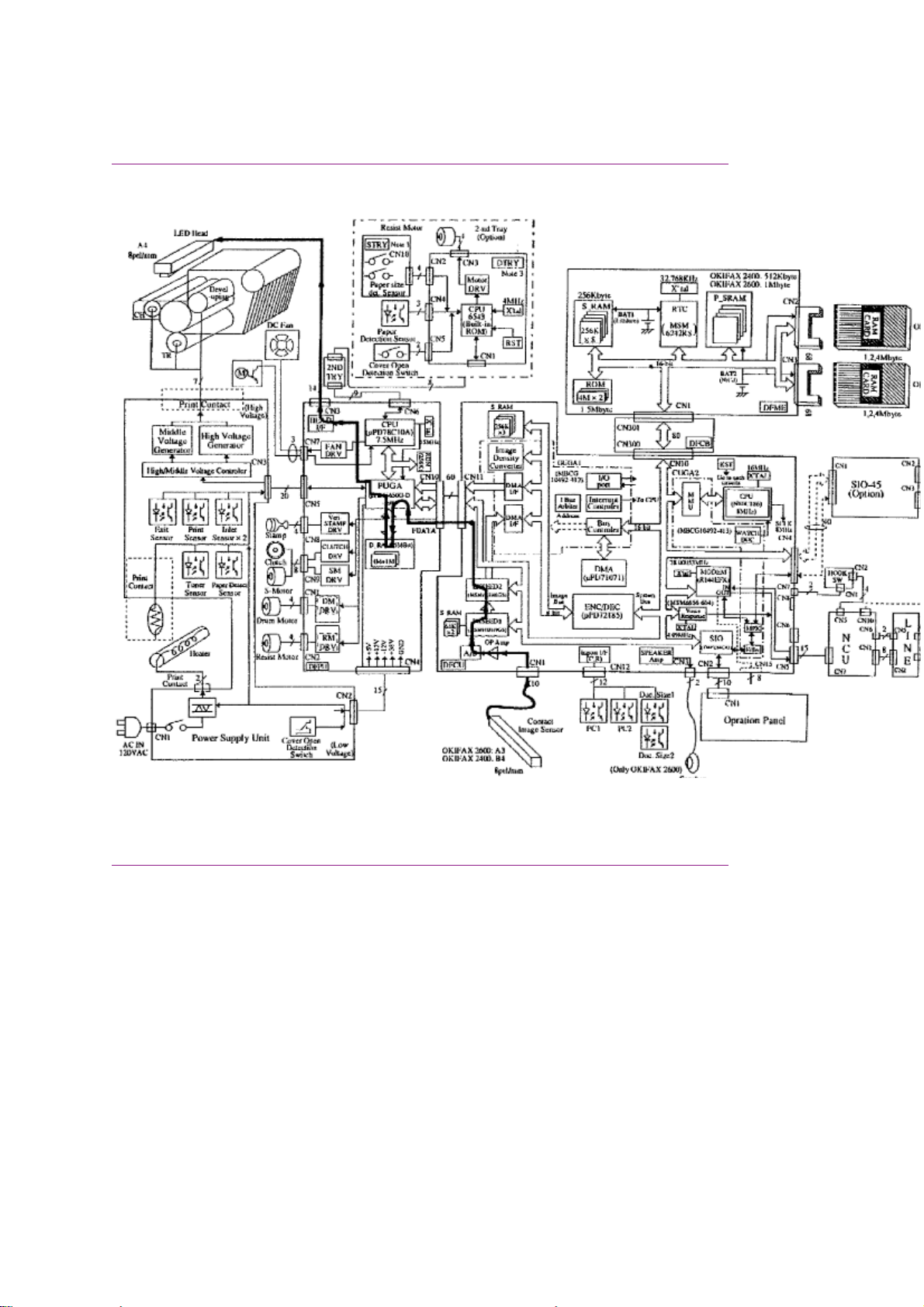

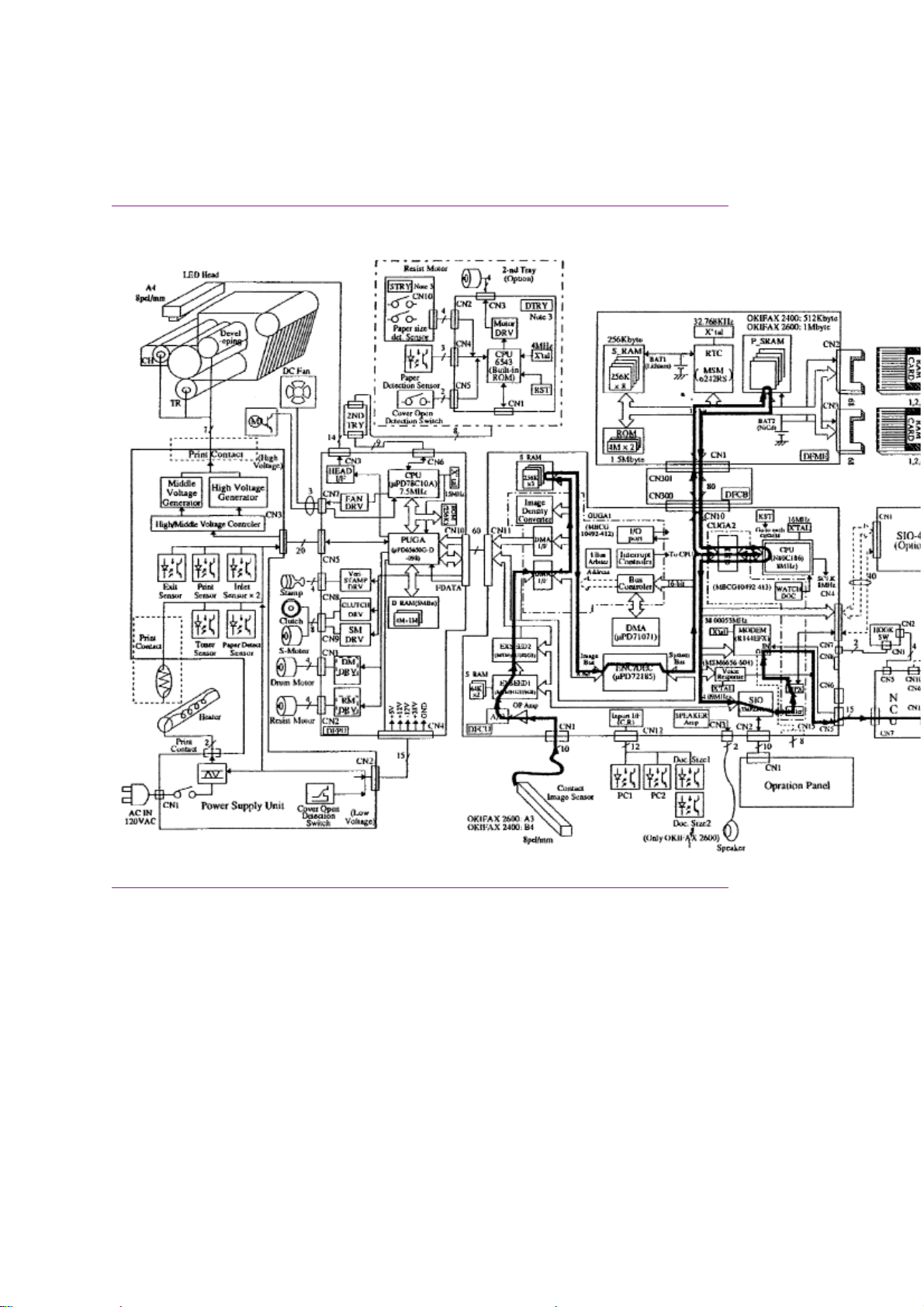

Okifax 2400/2600 - Copy Function Block Diagram

Okifax 2400/2600 - Copy Function Block Diagram

Page 23

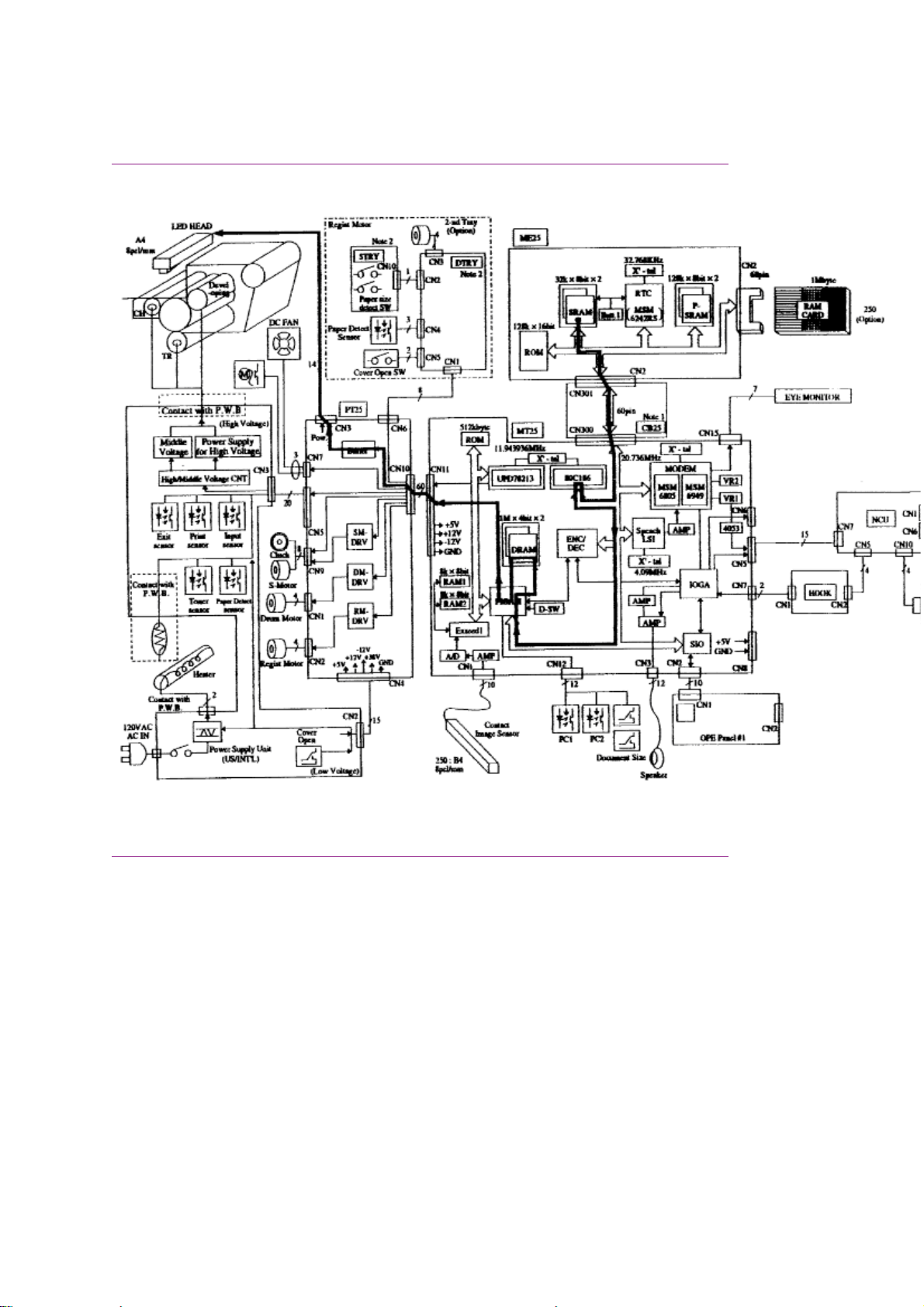

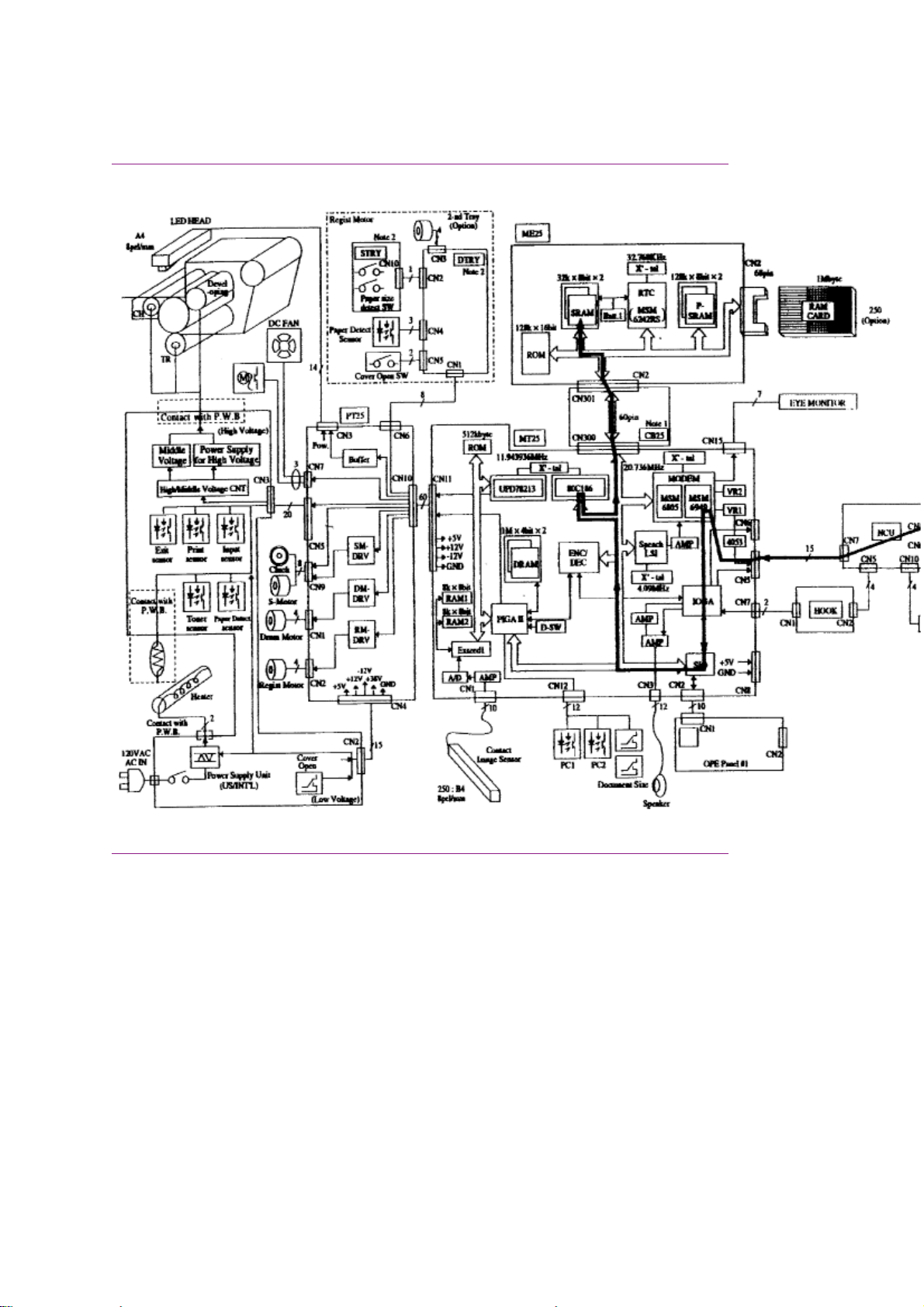

Okifax 2200 - Report Print Function Block Diagram

Okifax 2200 - Report Print Function Block Diagram

Page 24

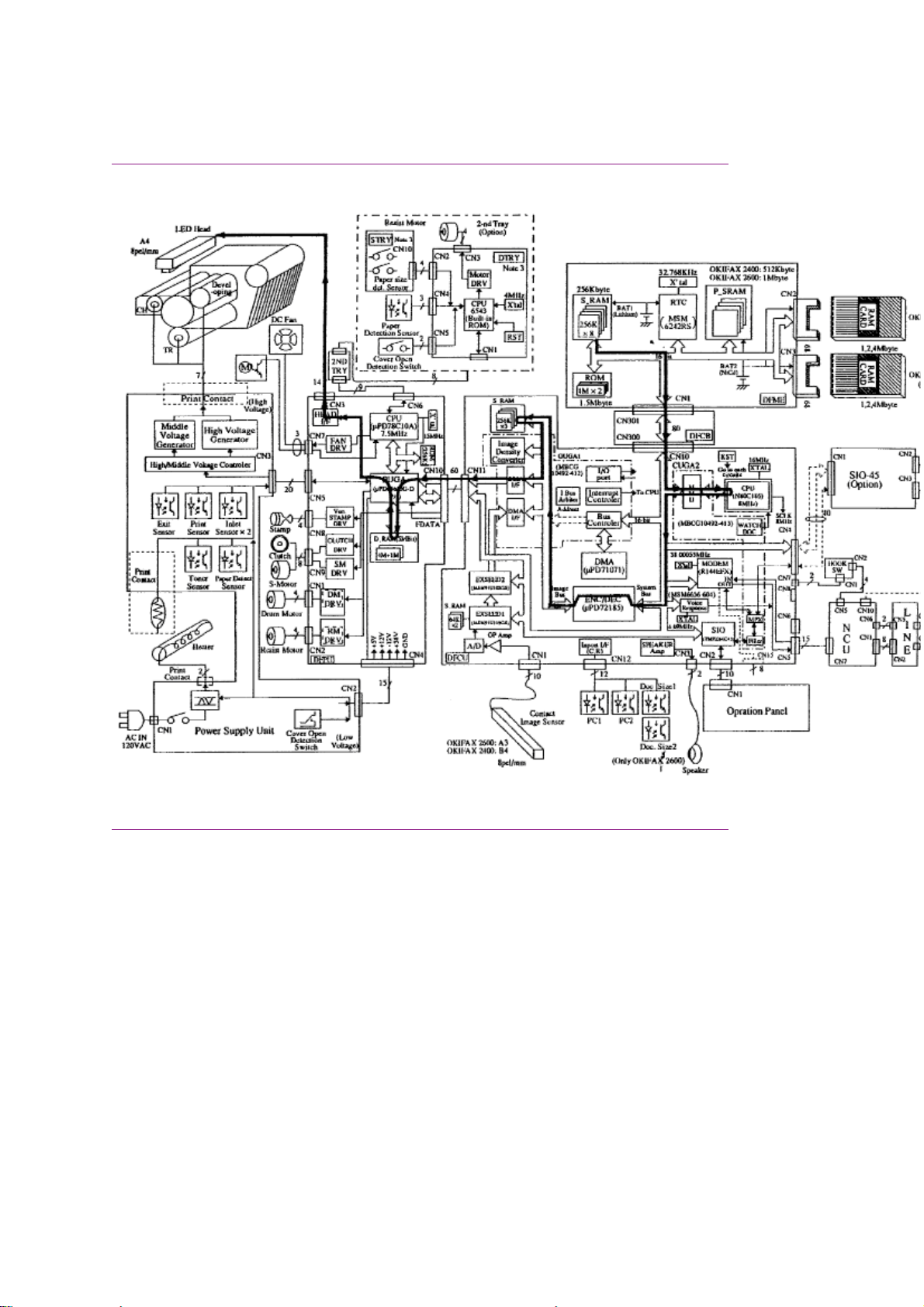

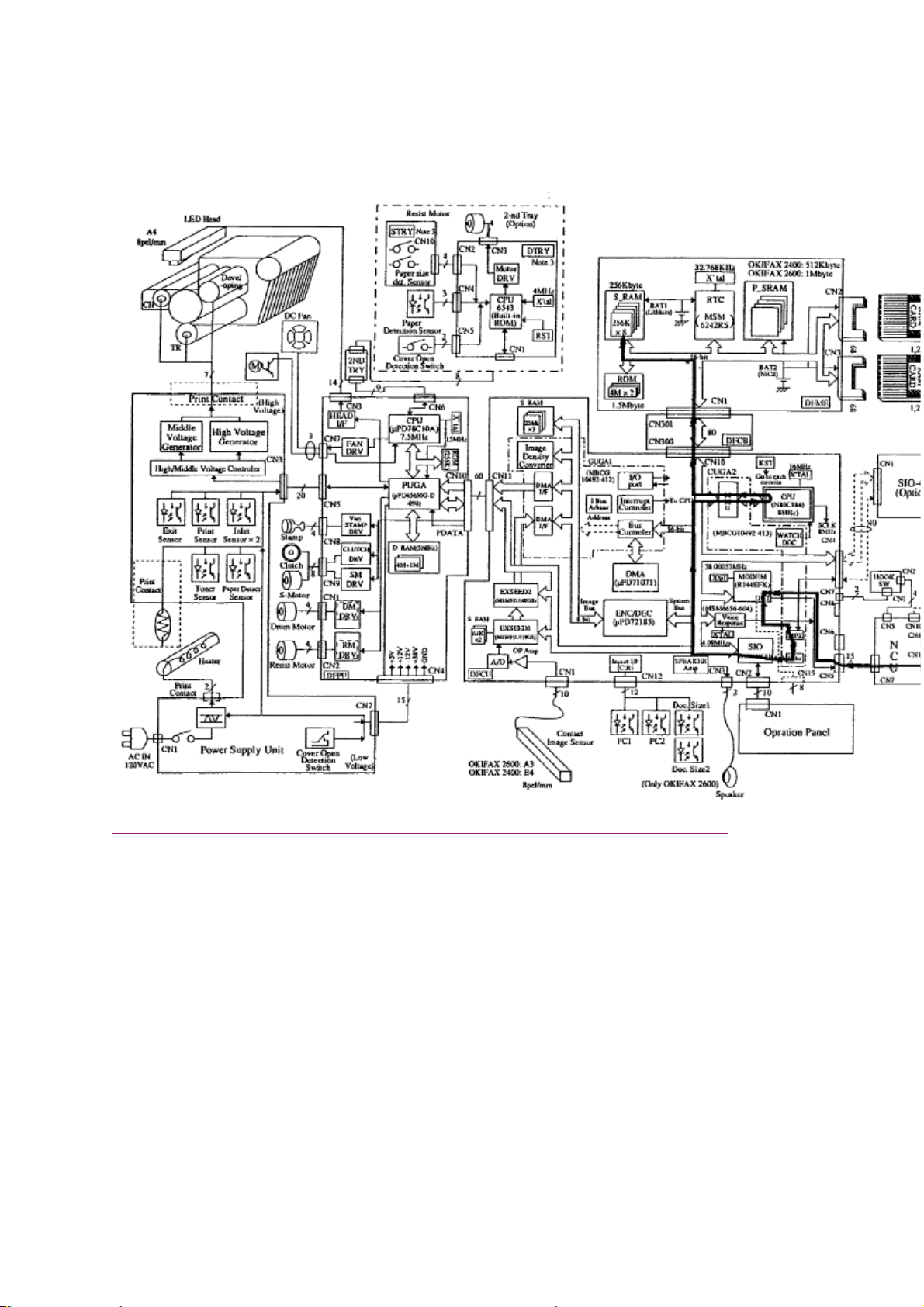

Okifax 2400/2600 - Report Print Function Block Diagram

Okifax 2400/2600 - Report Print Function Block Diagram

Page 25

1.2 Transmitter Theory Of Operation

1.2 TRANSMITTER THEORY OF OPERATION

1.2.01 Typical Transmission

When a telephone number is dialed through the machine (either manually or through auto-dial), a

connection will be established with the receiving station through the Public Switched Telephone Network

(PSTN). When the call is answered, the operator will hear the Called Equipment Device (CED) tone from

the receiving station. With CED received, the transmit machine acknowledges that the connection is

established and proceeds to the CCITT T.30 300 bps handshake procedure.

NOTE:

Refer to the Receive and Transmit Handshake Procedure Block Diagrams for functional overviews of 300

bps handshaking.

Refer to the Transmit Block Diagram for an overview of G3 Transmit Operations

When the Digital Identification Signal (DIS) is received, G3 mode transmission is possible and the

document is scanned, page by page. The image data is temporarily stored in First In First Out (FIFO)

memory until it becomes valid for transmission. In approximately three seconds, the machine will receive

Called Subscriber Identification (CSI) from the distant station. After reading the document pages and

storing the image data in memory, the machine begins the handshake with the distant station. If the

14.4/9.6 kbps training is successfully completed, the machine will start transmitting the image data in

digital, coded form. Training is a high speed data pattern transmitted to the receive modem. This training

data pattern causes the receive modem to synchronize with the transmit modem. If the training fails due to

bad phone line conditions, an automatic fallback to a lower rate will occur. The result will be indicated on

the LCD display. As the machine transmits each page of image data, the page count on the LCD display

will increment.

Training performs the functions listed below.

· Training tests the line condition for valid transmissions at a particular data rate. The TCF consists of

100 binary zeroes transmitted in a burst. At least 98% accuracy must be achieved before

transmission can take place at that data rate.

· The receiving station uses training to set the preliminary equalization for the current line conditions.

Page 26

Okifax 2200 - 300 Bps Transmit Handshake Operation Diagram

Okifax 2200 - 300 bps Transmit Handshake Operation Diagram

Page 27

Okifax 2400/2600 - 300 Bps Transmit Handshake Operation

Diagram

Okifax 2400/2600 - 300 bps Transmit Handshake Operation Diagram

Page 28

Okifax 2200 - 300 Bps Receive Handshake Operation Diagram

Okifax 2200 - 300 bps Receive Handshake Operation Diagram

Page 29

Okifax 2400/2600 - 300 Bps Receive Handshake Operation Diagram

Okifax 2400/2600 - 300 bps Receive Handshake Operation Diagram

Page 30

Okifax 2200 - G3 Transmit Functional Block Diagram

Okifax 2200 - G3 Transmit Functional Block Diagram

Page 31

Okifax 2400/2600 - G3 Transmit Functional Block Diagram

Okifax 2400/2600 - G3 Transmit Functional Block Diagram

Page 32

1.2.02 Operator Panel Assembly (OPE)

1.2.02 Operator Panel Assembly (OPE)

Through the operator panel assembly, the end user initiates transmit and receive operations, sets desired

options, programs telephone numbers and other data, and interfaces in all areas of the operation of the

machine. The panel consists of an LCD display (two rows of 20 characters), a numeric key pad, nine LED

indicators, and function keys. The functions of the keys and indicators are described in the Users

Documentation.

Page 33

1.2.03 Automatic Document Feeder (ADF)

1.2.03 Automatic Document Feeder (ADF)

The automatic document feeder transfers document sheets to the scan unit automatically, one at a time.

The following diagram shows the mechanism used for detecting the leading and trailing edges of a

document.

When a document is placed on the feeder, it is sensed by the document detect sensor (PC1). This causes

the feed rollers to activate, feeding the document. The document is fed to the PC2 lever, where the

leading edge of the document is detected. When transmit (or copy) begins, the document is fed by the

transmit stepper motor to the start scan position. The documents trailing edge is detected when the PC2

lever is released. If another document is on the feeder, the process is repeated.

The Okifax 2200/2400/2600 also contain a B4 paper width sensor (PC1). The Okifax 2600 has an

additional photosensor (PC1) to detect A3 paper width.

The separation rubber holds back the top originals and allows only one document to be fed into the

scanner area. The separation rubber and automatic document feed rollers should be cleaned or replaced

according to the cleaning schedule (in Module 3 of this manual) to assure proper operation.

The automatic document feed capacity is 50 pages of 20 pound paper. Place documents (on the feeder)

image side DOWN. When feeding multiple pages, the bottom page is fed first, working toward the top.

Page 34

*1.2.04 Scanner Assembly

1.2.04 Scanner Assembly

The Okifax 2200 and 2400 use a 2048-bit element direct contact type image scanning sensor. The Okifax

2600 uses a 2432-bit element direct contact image scanning sensor. LEDs are located at the bottom of

the scan glass and image sensors are located at the top of the glass. When the document reaches the

scanning unit, it passes directly in front of the image sensor. The LEDs illuminate the document and the

light reflects back to the image sensors. This image data is sent to the printer control board via the main

control board. The transmitted document length is limited to 14 inches; however, the machine can be

modified for longer transmissions. (See

Transmission will stop and a line disconnect will occur if the end of the document is not detected within 14

inches after scanning begins (unless the unit is set for unlimited transmission.) This message will be

displayed if the document does not reach the scanning position within five seconds after the start of a

document feed.

Okifax 2200 RELOAD DOCUMENT

CONFIRM AND "STOP"

Okifax 2400/2600 (DATE/TIME, RX MODE)

REMOVE DOCUMENT AND "STOP"

Transmitting Long Documents in the Users Documentation)()

NOTE:

When a jam condition is displayed on the operator panel during message transmission, the machine will

stop, but its receiving capability will remain active.

Page 35

1.2.05 Encoder

1.2.05 Encoder

Scanned image data received by the board is sent to the encoder/decoder (ENC/DEC) integrated chip of

the main control board. The image data is compressed by the ENC/DEC according to the Modified

Huffman (MH) and Modified Read (MR) encoding scheme, or MH only. The use of MH only or both MH

and MR is determined by a function setting. Data is then stored in the FIFO area in one byte units. Fill bits

are inserted if the length of one encoded line is less than the minimum scan time of the remote unit. Data

is transferred to the network control unit, then sent to the line interface board for transmission over the

phone line.

Page 36

1.2.06 Modem

1.2.06 Modem

The modem, located on the main control board, modulates the data in the correct G3 (14.4, 12, 9.6, 7.2,

4.8, or 2.4K bps) data rate that was determined during handshaking between the local machine and the

remote receiver. Modulation is the process of converting the digital output of the scanner into an analog

signal that can be transmitted over the telephone system.

Page 37

1.2.07 Network Control Unit (Ncu)

1.2.07 Network Control Unit (NCU)

The network control unit receives the modulated data from the main control board and transfers the data

to the line interface board.

The network control unit performs the following functions during the transmit operation.

· Unit connection / disconnection to the telephone line via the CML Relay

· Dial pulse generation

· PIS tone detection

· OFF-HOOK detection (Line Current Detector)

· TX output signal attenuation (normally 9 decibel output)

· Separation of the TX and RX signals (performed by the Hybrid Transformer)

· Impedance matching (the 600 ohm impedance of the telephone line)

Page 38

1.2.08 Line Interface Board

1.2.08 Line Interface Board

The line interface board provides the RJ-11 connection used to transmit data to the PSTN, PBX, or

Leased Line.

Page 39

1.3 Receiver Theory Of Operation

1.3 RECEIVER THEORY OF OPERATION

1.3.01 Operator Panel

Through the operator panel, the user initiates manual receive operations and sets auto-answer options.

1.3.02 Line Interface Board

The line interface board provides the RJ-11 connection used to receive data from the PSTN, PBX, or

Leased Line.

1.3.03 Network Control Board (NCU)

The network control unit receives the modulated data from the line interface board and sends it to the

modem (located on the main control board). The operation of the network control unit in the receive mode

is very similar to the transmit mode. However, during receive operations, the network control unit also

functions as an amplifier for the received signal.

1.3.04 Modem

The modem demodulates the data from the G3 (14.4, 12, 9.6, 7.2, 4.8, or 2.4K bps) scheme that was

determined during handshaking. The data is then sent to the RAM memory for temporary storage. The

storage time is dependent on whether the machine is printing real-time or from memory.

1.3.05 Decoder

The decoder decodes the MH, MR, or MMR data from the RAM into lines of picture data that are 1,728

bits in length. After the data has been received, demodulated, and decoded, it is transferred to the printer

control board.

1.3.06 Document Size

Since the available printing area of the printer is smaller than the paper size, document contents may be

missed on both sides of the paper, or a document image having the same length as the printing paper

may be split into separate pages during printing. To prevent this, the unit automatically sets the proper

reduction ratio within the range of 76 to 100% if the RX REDUCTION function has been set ON. If a

received document image is longer than the available printing length, the excess part of the image is

eliminated. If the SPLIT PRINT function has been set ON, the excess image will be printed on the next

page.

Page 40

Okifax 2200 - G3 Receive Operation Block Diagram

Okifax 2200 - G3 Receive Operation Block Diagram

Page 41

Okifax 2400/2600 - G3 Receive Operation Block Diagram

Okifax 2400/2600 - G3 Receive Operation Block Diagram

Page 42

1.4 Led Printer - Principal Components

1.4 LED PRINTER

1.4.01 Principal Components

The principal hardware components of the printer unit are listed below.

· Printer Control Board

· Power Supply Unit

· Fuser Unit

· Main Motor

· LED Head

· Registration Motor

· DC Fan

· Second Paper Tray Mechanism (option)

1.4.02 Printer Control Board

The printer control board contains a printer unit gate array, 7.5 megahertz microprocessor, send motor

driver (transistor array), registration motor driver integrated circuit, drum motor driver integrated circuit,

and fan motor driver transistors.

This board controls the paper feed and paper transport functions. It also activates the LED array diodes,

which leave a latent electrostatic image on the photosensitive drum. This latent image is printed by fusing

toner to the paper.

1.4.03 Power Supply Unit

The power supply is a switching-type unit, which generates the following voltages from the AC input

voltage.

· + 5 vdc : Printer Logic

· + / - 12 vdc: Interface Signal Levels

· + 38 vdc: Transmit Stepper Motor, Registration / Drum Motor Drive,

Fan Drive, High-Voltage Source.

When the board enables the HEATON signal, the power supply provides the AC voltage to the fuser lamp.

1.4.04 Power Supply Board Components and Functions

The power supply consists of integrated circuit 1 (a one-chip CPU), a cover-open switch, the high,

medium, and low voltage generation circuits and photosensors.

Photosensors

· Outlet Sensor (PS1) ON: Paper is present

Detects paper jams at the paper exit path.

· Paper Sensor (PS2) ON: Paper is present

Along with the outlet sensor, is used to monitor paper feed and paper length.

· Inlet Sensor 1 (PS3) ON: Paper is present

Detects the leading edge of the paper.

Used to determine when to switch from the hopping to the feeding operation.

· Paper End Sensor (PS4) ON: Paper is present

Detects the presence of paper in the cassette.

· Inlet Sensor 2 (PS5) ON: A4 or larger

Detects the width of the receive paper.

· Toner Low Sensor (PS6)

Detects a low toner condition

Cover Open Switch

Whenever the stacker cover is opened, the cover open switch is turned OFF. This removes the + 38 vdc

Page 43

source voltage from the high-voltage generation circuit. As a result, all high-voltage outputs are disabled.

The CVOPN signal is sent to the main control board and the cover open routine is performed. The

message COVER OPEN will be displayed on the operator panel.

High-Voltage Circuits

The following voltages are generated for use in the electrostatic printing process.

OUTPUT

SB1/SB2 - 450 vdc Toner Supply Roller

DB1/DB2 +/- 300 vdc Toner Development Roller

TR1/TR2 + 1 Kvdc/-750 vdc Transfer Roller

CH - 1.3 Kvdc Charging Roller

CB + 400 vdc Toner Cleaning Roller

1.4.05 Fuser Unit

The fuser unit is controlled by a thermistor, the printer interface gate array (PIGA), an LSI, and the CPU to

keep the heat roller surface temperature within a predetermined range (about 150 degrees Celsius). A

thermal fuse within the fuser unit prevents abnormal temperature rises in case the thermistor fails.

NOTE:

The CPU checks for an open circuit in the thermistor at power-on. A fuser alarm is set if this error is

detected.

The CPU also sets a fuser alarm if the proper temperature is not attained within a specified period of time

after power-on.

VOLTAGE USE

Upon detecting a fuser alarm, the CPU will stop printing (after printing the current page).

1.4.06 Main Motor (Drum Motor)

The main motor is controlled by the motor control LSI, on the main control board via the printer control

board. The motor used is a four-phase motor, driven by the motor driver integrated circuit located on the

printer control board.

1.4.07 LED Array

The printer control board provides serial transfer of print data (HDDT0) to the LED array. The signal

HDCLK provides data transfer timing. 1728 bits of data are shifted into the LED array registers. Then, the

signal HDLD loads this data into the latch circuits. This enables the individual LEDs.

1.4.08 DC Fan

The fan is controlled by the FAN ON-P signal from the main control board via the printer control board. In

order for the facsimiles printer to operate, the signal FAN SENSE-N must be active.

NOTE:

The fuser and the fan are not enabled when the cover is open. If the fan fails to run, the fuser will turn off

and the message PRINTER ALARM 3 will be displayed. Printing is disabled.

1.4.09 Registration Motor

The registration motor is driven clockwise for initial receive paper loading. It is driven counter-clockwise for

paper feeding. The motor is controlled by the motor control LSI on the main control board and is driven by

the motor driver integrated circuit on the printer control board.

Page 44

1.5 Printing Process - General Information

1.5 PRINTING PROCESS - General Information

1.5.01 General Information

Hopping and feeding are controlled by a single registration motor.

Turning the registration motor in the "A" direction drives the hopping roller.

Turning the registration motor in the "B" direction drives the registration roller.

The registration gear and hopping gear contain one-way bearings. Turning each of these gears in the

reverse direction will

turn the corresponding roller.

NOT

Printing Process Diagram

Page 45

### Printing Process Overview ####

Page 46

1.5.02 The Full Printing Process

1.5.02 Hopping

Hopping loads paper from the paper cassette.

During the hopping operation, the registration motor turns in a clockwise direction. This motor drives the

hopping roller, which in turn advances the paper until the inlet sensor 1 switches ON. The registration gear

turns, but the one-way bearing does not allow the registration roller to turn.

After inlet sensor 1 switches ON, the paper is advanced a predetermined length (until the paper reaches

the registration roller).

1.5.03 Feeding

Feeding transports paper through the printer.

After the completion of hopping, the registration motor turns in a counter-clockwise direction. This

counter-clockwise motion drives the registration roller and advances the paper. The hopping gear turns,

but the one-way bearing does not allow the hopping roller to turn.

1.5.04 Charging

Charging applies -1.3 Kvdc to the charge roller. The charge roller contacts the image drum surface.

The charge roller has two layers: a conductive layer and a surface protective layer. The surface layer is

flexible, which assures proper contact with the photosensitive drum.

Page 47

1.5.05 Exposing

The image drum has four layers.

· Carrier Transfer Layer (CTL)

· Carrier Generation Layer (CGL)

· Underlayer (UL)

· Aluminum Base

The CTL and CGL make up the organic photo conductor layer (OPC), which is about 20 micrometers (m

m) thick.

When light from the LED head irradiates the image drum surface, the light energy generates positive and

negative carriers in the CGL. The positive carriers are moved to the CTL by an electrical field acting on the

image drum. The negative carriers flow into the aluminum layer (ground).

The positive carriers moved to the CTL combine with the negative charges on the image surface

(accumulated by the contact charge of the charge roller), lowering the potential on the image drum

surface. The resultant drop in the potential of the irradiated part of the image drum surface forms an

electrostatic latent image on it. The surface potential on this irradiated part of the image drum is

approximately -100 vdc.

Page 48

1.5.06 Developing

The electrostatic latent image formed on the image drum surface is developed into a visible image.

Developing takes place when contact is made between the image drum and the developing roller.

As the toner supply roller rotates, toner is absorbed into the sponge type roller material.

A charged particle will be attracted to a particle having a MORE POSITIVE charge than its own.

The developing roller surface is charged to -300 vdc and the toner supply roller is charged to -450 vdc.

Since the development roller is charged more positive than the toner supply roller, the toner on the toner

supply roller is attracted to the developing roller. The toner on the developing roller contacts the doctor

blade, forming a thin coat of toner on the developing roller surface.

1.5.07 Transfer

The transfer roller is made of a conductive sponge material. The roller keeps the paper in constant contact

with the image drum. Paper is placed over the image drum surface. A positive charge (opposite in polarity

to the toner) is applied to the paper from the reverse side.

A charged particle will be attracted to a particle having a MORE POSITIVE charge than its own.

A high positive charge is applied to the transfer roller by the power supply board. This induced charge (on

the surface of the transfer roller) is transferred to the paper when contact is made between the transfer

roller and the paper. The lower side of the paper is positively charged. The negatively charged toner (on

the photosensitive drum) is transferred to the upper side of the paper because of the positive charge on

the lower side of the paper.

Page 49

The exposed portion of the image drum contains a more positive charge than the development roller (-100

vdc vs -300 vdc). Therefore, toner is attracted to the exposed areas of the image drum, making the

electrostatic latent image visible.

NOTE:

The toner supply roller and the developing roller are supplied with the bias voltages required during the

developing process. The toner supply roller is charged to -450 vdc. The developing roller is charged to

-300 vdc.

1.5.10 Printing

Refer to the Printing Process Diagram.

Printing is accomplished as follows.

· Approximately - 1.3 Kvdc is supplied to the charge roller. This causes the drum to charge to

approximately - 750 vdc.

· The LED head is turned ON by the printer control board in accordance with signals from the main control

board. This causes a latent electrostatic image to be formed on the surface of the drum.

· Through the development process, a toner image replaces the electrostatic image.

· A + 1 Kvdc charge is applied to the transfer roller. This causes the toner image to be transferred to the

receive paper.

· Heat and pressure cause the toner image to become fused to the receive paper. The 150 degree

Page 50

Centigrade fusing temperature is attained by turning a 400 watt halogen lamp ON. The fusing temperature

is controlled by a thermistor. In the event of a thermistor failure, a temperature fuse will OPEN, turning off

the quartz lamp, and preventing equipment damage.

· The residual toner is removed from the drum.

Printing Process Diagram

Page 51

1.6 Sensors And Switches

1.6 SENSORS AND SWITCHES

1.6.01 Paper Jam Detection

Paper jam detection monitors the location of paper when the printer is powered ON and during printing. If

any of the following jams are present, the printing process is interrupted and the message PAPER JAM

will be displayed on the LCD.

To return to the printing process, the paper jam condition MUST be cleared. This is accomplished by

opening the upper cover, clearing the jam, and closing the cover.

Paper Outlet Jam

NOT

This jam occurs if the paper does

However, the paper has already passed over the paper sensor.

Paper Size Error

The time interval between when the paper contacts the paper sensor and the outlet sensor determines

which size (length) paper is being used.

This error occurs if the paper size of the loaded paper differs by + 45 mm or more from the paper size set

by the menu.

Cover Open Switch

When the stacker cover is opened, the cover open microswitch on the power supply unit is deactivated.

This disables the + 38 vdc and the high voltage power supply circuit. As a result, all high voltage outputs

are interrupted. At the same time, the CVOPN signal is sent to the main control board main control board

to notify it of the OFF state of the microswitch. The main control board executes the cover open routine.

The operation panel displays the message COVER OPEN.

pass over the outlet sensor within a pre-determined period of time.

Page 52

Page 53

Paper Inlet Jam

Paper Inlet Jam

This jam occurs when either of the following situations occur.

· When the printer is powered ON, paper is at inlet sensor 1.

· After the hopping operation is attempted three times, the leading edge of the paper does

reach inlet sensor 1.

NOT

Page 54

Paper Feed Jam

Paper Feed Jam

This jam occurs when either of the following conditions occur.

· The paper does not pass over the paper sensor within a pre-determined period of time.

· The leading part of the paper does not reach the outlet sensor within a pre-determined period of

time after the paper has passed over the paper sensor.

Paper Feed Jam Timing Diagram

Page 55

1.6.02 Toner Low Sensor

1.6.02 Toner Low Sensor

The toner well of the image drum cartridge contains a toner agitator. Whenever the image drum

rotates, the toner agitator attempts to turn. A spring clip in the bottom of the toner well (along with the

proper amount of toner) holds the agitator at the bottom of the well. However, when toner is distributed

unevenly or an insufficient amount of toner is in the well, the toner agitator will rotate. Therefore, as

long as the toner well contains an adequate supply of evenly distributed toner, the toner agitator will

not rotate.

The toner sensor lever has a magnet embedded in it. Whenever the toner agitator is positioned at the

bottom of the toner well, the toner sensor lever is magnetically attracted to the toner agitator. This causes

the toner sensor lever to be lifted from the path of the toner sensor.

During a low toner condition (less than 20 grams of toner remaining), the toner agitator will rotate

continuously

panel will then display the TONER LOW message.

. This causes the toner sensor to turn ON / OFF as the image drum rotates. The operator

During an unevenly distributed toner condition, the toner agitator will rotate

sufficiently

operator panel will not display an error message since this is normal printer operation.

. This causes the toner sensor to turn ON / OFF for only a few image drum rotations. The

until the toner is distributed

Page 56

Chapter 2

*2.1 Overview

2.1 OVERVIEW

2.1.01 Introduction

This section is used to isolate problems to the assembly level. Application problems and detection of faulty

components on the printed circuit boards are not addressed.

When troubleshooting a defective unit, refer first to Module 2.4 of this Service Handbook(). This section

contains tips on preventing problems as well as a list of common problems.

Next, refer to Module 2.5. Repair Analysis Procedures (RAPs()) will ask you questions or require you to

make observations. The answers to these questions and the results of your observations determine your

next course of action. Use the RAP Index to identify which RAP should be used to resolve the problem

with the machine.

If you encounter a situation that is not addressed by the documentation in this kit, please report the

problem to Okidata. Send your report to the Okidata Technical Training Group. Refer to the Service

Center Reference Guide for information on contacting Okidata.

The following information is provided to detect and analyze failures.

1. Okilink II, Faxable Facts, Technical Service Bulletins

2. Troubleshooting Tips / Common Problems

3. Repair Analysis Procedures

4. Tests

5. Reports

6. Resets

7. Technical Functions

8. TEL / FAX Automatic Switching

9. Touch Tone Mode

10. User Functions

11. Dialing Parameters

Page 57

2.2 Troubleshooting Updates

2.2 TROUBLESHOOTING UPDATES

2.2.01 General Information

Okidata distributes updated troubleshooting information in three ways.

1. Okilink II

2. Faxable Facts

3. Technical Service Bulletins

2.2.02 Okilink II

Okilink II is Okidatas Bulletin Board Service. This service is available to all Okidata Certified Service

Technicians. Okilink II provides additional troubleshooting and service information. Technicians can

download files, ask questions of Okidatas technical support personnel, and participate in round table

discussions about Okidata products and services. Technical Service Bulletins, Recommended Spare

Parts Lists, Printer Drivers, Product Specifications, and Service Training Information are also available.

Refer to the Service Center Reference Guide for information on accessing Okilink II.

2.2.03 Faxable Facts

Okidatas Faxable Facts is an automated fax document retrieval system. It is maintained by Okidatas

Customer Information Center. Answers to common questions about Okidata products are available

through faxable facts.

Refer to the Service Center Reference Guide for information on accessing Faxable Facts.

2.2.04 Technical Service Bulletins

Okidatas Technical Service Bulletins (TSBs) contain technical information obtained after product release.

Firmware updates, part number changes, and procedural changes are some of the subjects covered by

these bulletins. The TSBs are distributed through Okilink II.

Refer to the Service Center Reference Guide for information on accessing Okilink II.

Page 58

2.3 Reporting Problems

2.3 REPORTING PROBLEMS

2.3.01 General Information

Okidata strives to provide accurate and detailed service information through its training materials. The

Technical Training Group realizes that service technicians have valuable experience, knowledge, and

opinions. Okidata strongly encourages you to report any problems you may encounter when using the

materials of this training kit. Please be as specific and detailed as possible. Your comments, suggestions,

and criticisms are used to update and revise training kits.

You should reference the training materials when servicing Okidata products. Most problems can be

solved by using the information provided in the training materials. If you encounter a situation that cannot

be solved, please let Okidata know.

Refer to the Service Center Reference Guide for information on contacting Okidata.

2.3.02 Problem Lists

Technicians frequently request a list of common problems specific to a product. Technical Training Kits

are written before a product is shipped to customers. Therefore, such information is not available when a

product is first released.

However, Okidata wants to respond to these requests. Okilink II provides round-table discussions on

technical problems. Errors and corrections in the training materials are listed in the Training Section of

Okilink II. The Technical Service Bulletins (also known as Okidatas Monthly Mail) are available via Okilink

II. Situations that are not addressed in the reference documentation, Technical Service Bulletins, or round

tables may be reported to the Dealer Service and Support Engineers (DSSEs) or the Technical Training

Group. You will receive a response to your message within one business day.

The information on Okilink II is the most accurate and up-to-date technical information available from

Okidata. This is only possible with your assistance. By reporting your suggestions, concerns, and

problems, Okidata can provide the best possible information.

Your cooperation is greatly appreciated. Thank you for your help!

2.3.03 Reporting Methods

Okilink II

You may use Okilink II to report your findings. Refer to the Service Center Reference Guide for

information on using Okilink II.

Course Critique

Use the Course Critique to report any problems you find as you are completing the self-paced training.

Fax Number

If you wish to fax your response, please use the numbers listed in the Service Center Reference Guide.

Mailing Address

If you respond by mail, please use the appropriate address listed in the Service Center Reference Guide.

Information Provided

Please provide the following information when reporting problems.

1. Okidata Dealer Number

2. Technicians Name

3. Company Name

4. Companys Address (Street, City, State/Province, ZIP / Postal Code, Country)

5. Telephone and Fax Numbers (with area / country access codes)

Page 59

6. Product Name

7. Units Serial Number

8. Description of Problem

9. Document Name (with page number or procedure) with error or problem.

Page 60

2.4 Troubleshooting Tips

2.4 TROUBLESHOOTING TIPS

2.4.01 Preliminary Checks

1. Is the unit operated under the proper ambient conditions?

2. Is the paper being used made specifically for xerographic printing?

3. Have the toner cartridge and image drum been replaced as recommended?

4. Has the image drum cartridge been installed properly?

5. Is Okidata toner being used?

2.4.02 Tips for Preventing Image Problems

1. Do not let anything touch the surface of the image drum.

2.

NEVER

3. Do not touch the fusing unit. Oil from your skin can cause fusing temperature variation.

4. Do not expose the image drum to light for more than five minutes.

5. Do not touch the transfer roller. Touching the transfer roller may cause incomplete toner transfer,

resulting in faded output.

2.4.03 Common Problems

1. The display is blank.

expose the image drum to direct sunlight.

- Check that the power switch is ON.

- Check that the power cord is firmly plugged into the unit and the wall

outlet, and make sure that power is supplied to the wall outlet.

- Make sure the memory board is properly connected.

2. Nothing happens when you press the operator panel keys.

- Power OFF the unit, wait 10 seconds, then power ON the unit.

- Check that the power cord is firmly plugged into the unit and the wall outlet.

- Verify that the ROMs on the memory board are installed properly.

3. The display tells you to replace paper even though there is paper in the cassette.

- Remove the paper cassette and make sure that the paper is firmly stacked

in the cassette. Push the paper under the tabs on the sides of the paper cassette.

4. Your original document jams.

- Make sure the document is not wider than the width of the document feeder.

- Check the document for wrinkles, tears, or other damage.

- Make sure there are no staples or paper clips attached to the paper,

and that the paper is clean and dry.

- Check for contaminants on the contact image sensor.

- Make sure the feed rollers and separator pad are clean and free of contaminants.

- If the problem persists, copy the document on a photocopier and fax the copy.

5. Your unit will not dial.

- Make sure the telephone line is connected to the line jack at the rear of the unit.

- Lift the handset and check for a dial tone. If you do not hear one,

there may be a problem with your telephone line.

- If you hear a dial tone, you may be using the wrong dial method

(pulse or tone) for your area.

- Make sure the telephone jack is an RJ-11C.

6. The display shows a communication error.

- You may be trying to communicate with a non-group 3 facsimile machine.

- The remote machine may not be able to perform the function that you

want (such as polling or confidential reception).

Page 61

- The remote machine may be out of paper or experiencing a paper jam.

- Bad telephone lines can cause communication errors. Try sending the fax again.

- The receiving facsimile machine may have a service problem. Send a

fax to a different location to test your unit.

7. You sent a fax, but it was received completely blank.

- Make sure that you have loaded your document face-down.

8. You keep getting reports that you do not want.

- Check the User Function settings and disable all unwanted reports.

9. When you receive long faxes or make copies of long documents, the bottom is always cut off.

- Try enabling the RX SPLIT PRINT or COPY SPLIT PRINT User

Functions. These functions will split long documents across two pages.

10. You sent a fax, but the image the remote fax received was very poor quality.

- If your document has small type, complex illustrations, photographs or was

extremely light or dark, try changing the TRANSMIT RESOLUTION and

TYPE OF ORIGINAL settings.

- Copy the document on the unit to see how well it copies. If the copy looks

good, the problem may be telephone line interference or a defective

facsimile machine at the receiving side.

11. Your unit does not receive faxes.

- Check which reception mode is set on your unit. The mode will be displayed

in the upper right-hand corner of the LCD when the unit is in idle mode.

12. The image received on your unit is very poor.

- If your document has small type, complex illustrations, photographs or was

extremely light or dark, ask the person sending the fax to change the

TRANSMIT RESOLUTION and TYPE OF ORIGINAL Settings.

- Copy a similar document to test your unit. If the copy looks good, the problem

may be telephone line interference or a defective facsimile machine at the

transmitting side.

13. You tried dialing with a one touch key or an auto dial code but nothing happened.

- Check that the One Touch or Auto Dial key being used has a programmed number.

- Check the telephone number to make sure it was entered correctly.

- When you are dialing with an Auto Dial Code, be sure to press the Auto Dial Key

before you enter the code.

- If your unit has the AUTO START feature disabled, you must press START

to begin dialing (refer to Dialing Parameters in the Users Documentation for

AUTO START information).

- Confirm that the correct dial method is set (pulse or tone).

14. You set your unit for delayed transmission but nothing happened.

- Verify that the DATE and TIME are correctly set.

15. Your received documents are light or have vertical white streaks on them and you are not out of toner.

- You may need to replace the image drum unit.

16. Your unit disconnected before you could answer a voice request.

- You have only 15 seconds to answer a voice request. Once you hear the warbling

tone, pick up the handset, then press the VOICE REQUEST.

17. Your unit will not poll the remote fax machine.

- Call the person at the remote fax machine and make sure they have loaded

documents and placed their machine in the Polling Transmission Mode.

Page 62

- Make sure that the remote machines polling number matches the password

that you entered.

18. Someone tried to send you a confidential fax but nothing happened.

- You must set up a confidential mailbox and enter a 4-digit password before

anyone can send you a confidential fax.

- If your message is left in the unit for more than the specified amount of days,

your fax machine will erase it.

Okifax 2200: Ten days

Okifax 2400/2600: Twenty days

19. Your received faxes sometimes look distorted.

- If the received document is wider/longer than the paper loaded in the paper

cassette, the unit will automatically reduce the width/length of the document to fit.

- This could also be caused by communication problems.

20. Your unit is connected to a PBX and cannot dial out.

- You must enter your access digit(s) before the telephone number for each

number that you dial or program into your machine.

- Use the "Pause" Character after the access digits. This allows time for the

PBX to switch to an outside line.

- You should enable the PBX Function.

Okifax 2200: Dialing Parameter Settings

Okifax 2400/2600: Technical Function 61.

21. You want to answer the phone but your unit always answers first.

- If you are using an external telephone, change the units RING RESPONSE setting.

Okifax 2200: User Function 24

Okifax 2400/2600: Technical Function 65

- If you are using the Telephone/Fax Reception Mode, and require more time

to answer the telephone before the unit switches back to fax mode, modify the

TEL/FAX TIMER PRG.

Okifax 2200: User Function 10

Okifax 2400/2600: Technical Function 64

22. The unit is too loud.

- Adjust the Monitor Volume

Okifax 2200: User Function 05

Okifax 2400/2600: Technical Function 10

- Adjust the Incoming Ring Volume. The volume switch is at the rear of the unit.

- Adjust the Buzzer Volume.

Okifax 2200: User Function 16

Okifax 2400/2600: Technical Function 11

- Change the Key Touch Response.

Okifax 2200: User Function 16 (Buzzer Volume)

Okifax 2400/2600: Technical Function 12

- Change the No Paper Call Feature. (The unit warbles when it is out of paper).

Okifax 2200: User Function 11.

Okifax 2400/2600: Not applicable. Saves to memory.

Page 63

23. The machine wont program. (Okifax 2200)

- During multiple location polling reception or multiple location memory

transmission, the program menus cannot be accessed. Try again after

the operation is completed.

24. Transmission of a fax has been stopped. The ALARM is on and the document

cannot be removed. (Okifax 2200)

- Press STOP. This deactivates the ALARM.

- Press STOP.

- Remove the document.

25. The fax machine will not allow user operation. (Okifax 2200)

- A department id has been programmed. Enter the four digit department ID, then proceed.

- If a department ID is not in use, power OFF the unit. Wait ten seconds. Power ON the unit.

26. The unit is connected to an answering machine and it doesnt work.

- Enable the Telephone Answering Device (TAD) Mode.

Okifax 2200: Technical Function 45

Okifax 2400/2600: TAD Mode is not used

Page 64

2.5 Repair Analysis Procedures

2.5 REPAIR ANALYSIS PROCEDURES

2.5.01 General Information

When using the Repair Analysis Procedures (RAPs), follow these steps.

1. Work through the Start Here Flowchart. If the problem is not resolved, proceed to the next step.

2. Use the RAP Index to find the RAP which is associated with the units problem.

3. Go to the appropriate RAP.

4. All of the RAPs will begin with a START Statement, followed by either questions or another type of

statement.

Page 65

*2.5.02 RAP Index

2.5.02 RAP Index

RAP & Description()

01 No LCD Display

02 Alarm LED is lit

03 Printing Test Failure

04 Local Copy Problem

05 Auto Dial Problem

06 Data Transmission Problem

07 Auto Reception Problem

08 Reception Problem

09 Scan Operation Test Failure

10 LED Test Failure

11 Tone Send Test Failure

12 High-Speed Modem Test Failure

13 Multi-frequency Send Test Failure

14 Voice Message Test Failure

15 No Acoustic Line Monitor

16 Document Does Not Feed

17 Multiple Document Feeds

18 Document Skews

19 Document Jams

20 Problems Shown on LCD Display

20A Cover Open

20B Printer Alarm 1

20C Printer Alarm 2

20D Printer Alarm 3

20E Printer Alarm 4

20F Paper Jam

20G No Paper

21 Image Problems

21A Poor Print Quality

21B Dark Background Density

21C Printed Output is Blank

21D Vertical Black Stripes

21E Repetitive Spaced Marks

21F Vertical White Stripes

21G Areas Missing

21H Poor Fusing

Page 66

Start Here Flowchart

Start Here Flowchart

START

Does the LCD operate?

NO Refer to RAP 01().

YES Does the ALARM LED light?

YES Refer to RAP 02.()

NO Press SELECT FUNCTION. Does the appropriate message appear on the LCD?

Okifax 2200: POLLING RX

Okifax 2400/2600: SELECT FUNCTION (OT)

NO Replace the operation panel

Has the problem been resolved?

YES End of procedure.

NO Replace the main control board.

YES Perform Self Diagnosis

Go to A

A

Perform the Print Test. Are the results satisfactory?

NO Refer to RAP 03().

YES Go to the next step listed below.

Is the ROM check OK?

NO Replace the ROM on the printer control board. Then, replace the ROM(s) on the memory

board.

YES Go to the next step listed below.

Is the RAM check OK?

NO Replace the following in the listed order

1. Memory Board

2. Main Control Board

3. Printer Control Board

YES Is the Local Copy OK?

NO Refer to RAP 04 (No Local Copy)().

YES Go to the next step listed below.

Is the Auto Dial OK?

NO Refer to RAP 05 (Auto Dial Failure).()

YES Is there a data transmission problem?

YES Refer to RAP 06 (Data Transmission Problem).()

NO Go to the next step listed below.

Is Auto Reception OK?

NO Refer to RAP 07 (Auto Reception Failure)().

YES Is there a reception problem?

YES Refer to RAP 08 (Reception Problem)().

NO Verify symptom and refer to the appropriate RAP.

Page 67

RAP 01 No LCD Display

RAP01 No LCD Display

START

Is the LCD lit?

NO Is the unit powered ON?

NO Power ON the unit. Verify that the memory board is properly installed.

YES Go to CHECK 1.

YES Press SELECT FUNCTION. Does the appropriate message appear on the LCD?

Okifax 2200: POLLING RX

Okifax 2400/2600: SELECT FUNCTION (OT)

YES End of procedure.

NO Go to CHECK 1.

CHECK 1

Is +5 vdc present at pins 7, 8, 14, 15 of CN4 on the printer control board?

NO Go to CHECK 2

YES Is +5 vdc present at pin 2 of CN1 on the operator panel board?

YES Replace the operation panel.

NO Go to CHECK 2.

CHECK 2

Make sure the main control board and the operator panel board, and their connecting cables are

properly installed. Then, replace the power supply board.

Has the problem been resolved?

YES End of procedure.

NO Replace the main control board.

Has the problem been resolved?

YES End of procedure.

NO Check that the memory board is properly connected.

If the problem remains, replace the memory board.

Page 68

*RAP 02 Alarm Led Is Lit

RAP 02 Alarm LED Is Lit

START

Is the problem a communication error?

NO Go to CHECK 1.

YES Press the STOP key.

Does the ALARM LED go OFF?

YES End of procedure.

NO Go to CHECK 1.

CHECK 1

Is "COVER OPEN" displayed on the LCD?

YES Refer to RAP 20A().

NO Is "PRINTER ALARM (1-4)" displayed on the LCD?

YES Refer to the appropriate RAP. (20B, C, D, or E)

NO Is "PAPER JAM" displayed on the LCD?

YES Refer to RAP 20F().

NO Go to the next step listed below.

Is "NO TONER" displayed on the LCD?

YES Perform each of the following until the problem is resolved.

Replace the toner cartridge.

Try a known "good" drum cartridge.

Replace the printer control board.

NO Is "DOCUMENT JAM" displayed on the LCD?

YES Refer to RAP 20F.

NO End of procedure.

Page 69

RAP 03 Print Test Failure

RAP 03 Print Test Failure

START

Perform the Self Diagnosis Test.

Is the Self Diagnosis Test OK?

YES End of procedure.

NO Perform the Print Test.

Is the Print Test OK?

NO Refer to the RAP 21.

YES Replace the printer control board.

Has the problem been resolved?

YES End of procedure.

NO Replace the main control board.

Page 70

RAP 04 Local Copy Problem

RAP 04 Local Copy Problem

START

Perform the Self Diagnosis Test. Are the results satisfactory?

NO Refer to RAP 03.

YES Load a document.

Does the document reach PC1 photocoupler?

NO Perform each of the following until the problem is resolved.

Check PC1.

Replace the main control board.

Verify that the scan motor assembly is operating properly.

YES Is the document fed about three inches and stops with

"SELECT LOCATION" displayed on the LCD?

NO Perform each of the following until the problem is resolved.

Check PC2.

Replace the main control board.

YES Go to the next step listed below.

Press the COPY key. Is the copied document all black?

YES Verify that -12 vdc is present at Pin 9 of CN2 of the power supply board.

If the voltage is not present, replace the power supply board.

NO Is the quality of the copy acceptable?

YES End of procedure.

NO Perform a Scan Adjustment.

Has the problem been resolved?

YES End of procedure.

NO Perform each of the following until the problem is resolved.

Replace the main control board.

Replace the contact image sensor assembly.

Page 71

Checking PC1 And PC2

Checking PC1 and PC2

Okifax 2200 / Okifax 2400

This unit has two PC1 sensors and one PC2 sensor.

To check the sensors, follow this procedure.

1. Place the positive lead from a digital multimeter at the points listed below.

PC1 (Document Detect Sensor): Main Control Board CN 12, Pin 2

PC1 (B4 Width Sensor): Main Control Board CN 12, Pin 8

PC2 (Paper Leading Edge Sensor): Main Control Board CN 12, Pin 5

2. Place the negative lead of the digital multimeter on frame ground.

3. While making contact with the pin , press the appropriate lever. The voltage should go from +5 vdc to 0

vdc.

4. Release the lever. The voltage should return to +5 vdc.

5. If necessary, replace the sensor.

Okifax 2600

This unit has three PC1 sensors and one PC2 sensor.

To check the sensors, follow this procedure.

1. Place the positive lead from a digital multimeter at the points listed below.

PC1 (Document Detect Sensor): Main Control Board CN 12, Pin 2

PC1 (B4 Width Sensor): Main Control Board CN 12, Pin 8

PC1 (A3 Width Sensor): Main Control Board CN 12, Pin 11

PC2 (Paper Leading Edge Sensor): Main Control Board CN 12, Pin 5

2. Place the negative lead of the digital multimeter on frame ground.

3. While making contact with the pin , press the appropriate lever. The voltage should go from +5 vdc to 0

vdc.

4. Release the lever. The voltage should return to +5 vdc.

5. If necessary, replace the sensor.

Page 72

RAP 05 Auto Dial Problem

RAP 05 Auto Dial Problem

Make sure that the selected dialing method (tone/pulse) is appropriate for the TELCO / PBX needs. Refer

to the Dialing Parameters in the Users Documentation.

START

Does the manual dial function properly?

NO Can a dial tone be heard when the handset is picked up?

NO Check the line cable and the exchange.

YES Check for closed network, method of dialing, dial rate.

YES Replace the problem unit with a known " good" unit. Does the "good" unit dial?

NO Go to LOCATION PROBLEM.

YES Does "DIALING" appear on the LCD display?

YES End of procedure.

NO Does "TELEPHONE BUSY" appear on the LCD display?

NO End of procedure.

YES Hang up the external telephone set.

Has the problem been resolved?

YES End of procedure.

NO Replace the following.

Network control board

Main control board

LOCATION PROBLEM

Check the following.

One Touch and Auto Dial parameters

OFF-Hook Bypass

Has the problem been resolved?

YES End of procedure.

NO Contact Technical Support.

Page 73

RAP 06 Data Transmission Problem

RAP 06 Data Transmission Problem

This section explains how to localize the cause of problems occurring after completion of connection with

a remote station.

START

Adjust send signal power level.

Okifax 2200: Technical Function 21

Okifax 2400/2600: Technical Function 57

Has the problem been resolved?

YES End of procedure.

NO Set SHORTEN PROTOCOL to OFF.

Okifax 2200: Technical Function 08

Okifax 2400/2600: Technical Function 76

Has the problem been resolved?

YES End of procedure.

NO Set CCITT ECM to OFF.

Okifax 2200: Technical Function 30

Okifax 2400/2600: Technical Function 77

Has the problem been resolved?

YES End of procedure.

NO Set IGNORE 1ST DIS to ON.

Okifax 2200: Technical Function 14

Okifax 2400/2600: Technical Function 78

Has the problem been resolved?

YES End of procedure.

NO Set PROTECTIVE TONE to ON (for international calling)

Okifax 2200: Technical Function 16

Okifax 2400/2600: Technical Function 80

Has the problem been resolved?

Page 74

YES End of procedure.

NO Set MH ONLY to ON.

Okifax 2200: Technical Function 07

Okifax 2400/2600: Technical Function 75

Has the problem been resolved?

YES End of procedure.

NO Change the HIGH-SPEED MODEM RATE as follows.

Okifax 2200: 4800 bps - Technical Function 13

Okifax 2400/2600: 9600 bps - Technical Function 86

Has the problem been resolved?

YES End of procedure.

NO Replace the problem unit with a known "good" unit. Follow the preceding steps.

Does the replaced fax unit transmit normally?

NO Check the line and the network of the problem fax.

YES Replace the main control board of the problem fax.

Has the problem been resolved?

YES End of procedure.

NO Replace the NCU board.

Page 75

RAP 07 Auto Reception Problem

RAP 07 Auto Reception Problem

START

Is the manual reception OK?

NO Does the handset /telephone ring when a call arrives?

NO Perform the following

Check the handset/telephone set, the line, and the exchange.

YES Answer the call. Then, check the following items.

Is the unit placed in the manual receive mode?

Was the START key pressed to answer the call?

Is the closed network ON? Is the remote phone number registered

in one touch keys or three-digit auto dial codes?

YES Is machine in the auto receive mode? If not, place the unit in auto receive

mode by pressing AUTO REC key.

Has the problem been resolved?

YES End of procedure.

NO Set CLOSED NETWORK to OFF.

Okifax 2200: User Function 08

Okifax 2400/2600: User Function 21

Has the problem been resolved?

YES End of procedure.

NO Is the ringing signal detected at Pin 9 of CN7 of the network control unit board?

YES Replace the main control board.

NO Replace network control unit board.

Has the problem been resolved?

YES End of procedure.

NO Replace the line board.

Has the problem been resolved?

YES End of procedure.

Page 76

NO Contact Technical Support.

Page 77

RAP 08 Reception Problem

RAP 08 Reception Problem

This section explains how to localize the cause of problems occurring after completion of connection with

a remote station.

START

Adjust the equalizing level.

Okifax 2200: Technical Function 22

Okifax 2400/2600: Technical Function 60

Has the problem been resolved?

YES End of procedure.

NO Set CED-DIS INTERVAL to 1.5 seconds.

Okifax 2200: Technical Function 15

Okifax 2400/2600: Technical Function 79

Has the problem been resolved?

YES End of procedure.

NO Set SHORTEN PROTOCOL to OFF.

Okifax 2200: Technical Function 08

Okifax 2400/2600: Technical Function 76

Has the problem been resolved?

YES End of procedure.

NO Set CCITT ECM to OFF.

Okifax 2200: Technical Function 30

Okifax 2400/2600: Technical Function 77

Has the problem been resolved?

YES End of procedure.

NO Set MH ONLY to ON.

Okifax 2200: Technical Function 07

Okifax 2400/2600: Technical Function 75

Has the problem been resolved?

Page 78

YES End of procedure.

NO Change the HIGH-SPEED MODEM RATE as follows.

Okifax 2200: 4800 bps - Technical Function 13

Okifax 2400/2600: 9600 bps - Technical Function 86

Replace the problem unit with a known "good" unit. Then repeat the preceding procedures.

Does the replaced unit receive normally?

NO Check the line and the network of the problem unit.

YES Replace the main control board of the problem unit.

Page 79

RAP 09 Scan Operation Test Failure

RAP 09 Scan Operation Test Failure

NOTE:

Set SENSOR CALIBRATION to ON.

Okifax 2200: Technical Function 25

Okifax 2400/2600: Technical Function 84

START

Perform the Sensor Calibration Adjustment.

Does "SCANNING ERROR" appear on LCD while adjusting?

YES Check that white plain bond paper of correct size is loaded on the feeder.

Okifax 2200: B4 size

Okifax 2400: B4 size

Okifax 2600: A3 size

Disconnect the cable from connector CN4 on the printer control board and leave the other end connected

to CN2 on the power supply board. Voltage measurements should be taken from this cable. Check -12

vdc at Pin 9. If -12 vdc is not present, replace the power supply board.

Has the problem been resolved?

YES End of procedure.

NO Replace the following in the order listed.

1. Printer Control Board

2. Contact Image Sensor Assembly

3. Main Control Board

NO Are there document feeding problems during the scanning check?

YES Refer to the appropriate RAP, depending on the type of abnormal feed.

NO End of procedure.

Page 80

RAP 10 LED Test Failure

RAP 10 LED Test Failure

START

Perform the LED TEST.

Do all of the listed LEDs light?

Okifax 2200

ALARM > PHOTO >DARK > NORMAL> LIGHT> AUTO REC

Okifax 2400/2600

ALARM > PHOTO > EX.FINE > FINE > STD> LIGHT> NORMAL> DARK >AUTO REC

YES End of procedure.

NO Replace the operator panel board.

Has the problem been resolved?

YES End of procedure.

NO Check the connection cable between the main control board and the

operator panel unit.

Has the problem been resolved?

YES End of procedure.

NO Replace the main control board.

End of procedure.

Page 81

RAP 11 Tone Send Test Failure

RAP 11 Tone Send Test Failure

START

Is the Line Monitor Volume adjusted so the tone will be audible?

Okifax 2200: Technical Function 05

Okifax 2400/2600: Technical Function 10

NO Modify the appropriate Technical Function.

YES Is CN3 (Speaker Harness) connected to CN3 of the main control board?

YES Replace the main control board.

NO Connect the cable.

End of procedure.

Page 82

RAP 12 High Speed Modem Test Failure

RAP 12 High Speed Modem Test Failure

START

Perform the High Speed Modem Send Test for the transmitter.

Perform the High Speed Modem Receive Test for the receiver.

If you are in RX mode, go to A. If you are in the TX mode, continue here.

Does the modem signal (.14 vac) appear at Pin 1 and 4 of CN7 (network control board)?

YES Replace network control board.

Has the problem been resolved?

YES End of procedure.

NO Replace the main control board.

NO Check for +12 vdc and -12 vdc on the main control board.

+ 12 vdc present at CN5 Pin 14. - 12 vdc present at CN5 Pin 15

Do +12 vdc and -12 vdc appear at these points?

NO Disconnect the cable from CN4 of the printer control board and

measure the voltage at pin 14 and 15 of the disconnected cable.

If +/-12 vdc are not present, replace the power supply board.

YES Replace the main control board.

A

Does the receive signal (.9 vac) appear between L1 and L2 on the line-JU board?

NO Check the line.

YES Does the receive signal (.12 vac) appear between CN7-2 (R) and CN7-1 (GND) of network control

board?

YES Replace the main control board.

NO Is +12 vdc present at CN7- Pin 14 and -12 vdc present at CN7- Pin 15 of the

network control board?

YES Replace the network control board.

Has the problem been resolved?

YES End of procedure.

NO Replace the line board.

Has the problem been resolved?

Page 83

YES End of procedure.

NO Checking CN5 on the main control board, is -12 vdc present at

Pin 14 and +12 vdc present at Pin 15?

YES Check the route of these voltages (cable between the network

control board and the main control board).

NO Disconnect the cable from CN4 of the printer control board and

measure the voltage at pin 14 and 15 of the connecting cable. If +/-12 vdc

are not present, replace the power supply board.

Check the cables and the route of these voltages (main control, network

control, and printer control boards).

Has the problem been resolved?

YES End of procedure.

NO Replace the main control board.

End of procedure.

Page 84

RAP 13 Multi-Frequency Send Test Failure

RAP 13 Multi-frequency Send Test Failure

START

Detach the phone line from the unit.

Remove the right side and rear covers.

Set up an oscilloscope as listed below.

Set the time / div to .5 ms / division. Set Channel 1 volts / div to .1 volt / division.

Perform MF Send Test.

Place the oscilloscope probe on pin 1 of CN3 on the main control board.

Is a .15 v analog signal present?

YES Replace the speaker.

NO Replace the main control board.

Is the problem resolved?

YES End of procedure.

NO Replace the operator panel assembly.

Is the problem resolved?

YES End of procedure.

NO Contact Okidata Technical Support.

Page 85

RAP 14 Voice Message Test Failure

RAP 14 Voice Message Test Failure

START

Perform the Voice Message Test.

Has the Monitor Volume been set to LOW or HIGH?

Okifax 2200: User Function 05

Okifax 2400/2600: Technical Function 10

NO Set Monitor Volume to LOW or HIGH.

YES Replace the main control board.

Has the problem been resolved?

YES End of procedure.

NO Replace the speaker.

Page 86

RAP 15 No Acoustic Line Monitor

RAP 15 No Acoustic Line Monitor

There are two source routes of the acoustic line monitor.

General communication signal

DP pulse signal

START

Has the Monitor Volume been set to LOW or HIGH?