Page 1

OKIP AGE 20

LED Page Printer

T roubleshooting Manual

with Component Parts List

ODA/OEL/INT

All specifications are subject to change without notice.

40692901TH

Page 2

CONTENTS

1. OUTLINE ............................................................................................................ 1

2. TOOLS................................................................................................................ 1

3. CIRCUIT DESCRIPTION.................................................................................... 2

3.1 Outline ...................................................................................................... 2

3.2 CPU and Memory..................................................................................... 4

3.3 Reset Control ........................................................................................... 6

3.4 EEPROM Control ..................................................................................... 7

3.5 Centronics Parallel Interface .................................................................... 9

3.6 RS232C Interface................................................................................... 10

3.7 Operator Panel Control........................................................................... 11

3.8 LED Head Control .................................................................................. 12

3.9 Motor Control.......................................................................................... 14

3.10 Fuser Temperature Control .................................................................... 16

3.11 Fan Motor Control................................................................................... 19

3.12 Sensor Supervision ................................................................................ 21

3.13 Cover Open ............................................................................................ 22

3.14 Power Supply Interface .......................................................................... 23

3.15 Option (2nd/3rd paper feeder and Multi feeder) Interface ...................... 24

3.16 DUPLEX Interface .................................................................................. 25

3.17 Power Supply Board............................................................................... 26

4. TROUBLESHOOTING...................................................................................... 28

4.1 Troubleshooting Table............................................................................ 28

4.2 Troubleshooting Flowchart ..................................................................... 32

5. CIRCUIT DIAGRAM ......................................................................................... 48

6. COMPONENT PARTS LIST............................................................................. 70

APPENDIX A DUPLEX UNIT (OPTION) ..........................................................A-1

1. CIRCUIT DESCRIPTION ......................................................................A-1

2. TROUBLESHOOTING ..........................................................................A-3

3. CIRCUIT DIAGRAM ..............................................................................A-8

4. COMPONENT PARTS LIST................................................................A-12

APPENDIX B

1. CIRCUIT DESCRIPTION ......................................................................B-1

2. TROUBLESHOOTING ..........................................................................B-3

3. CIRCUIT DIAGRAM ..............................................................................B-7

4. COMPONENT PARTS LIST................................................................B-10

HIGH CAPACITY SECOND/THIRD PAPER FEEDER (OPTION).........B-1

Page 3

APPENDIX C MULTI PURPOSE FEEDER (OPTION) .................................... C-1

1. CIRCUIT DESCRIPTION ..................................................................... C-1

2. TROUBLESHOOTING ......................................................................... C-3

3. CIRCUIT DIAGRAM ............................................................................. C-6

4. COMPONENT PARTS LIST................................................................. C-8

Page 4

1. OUTLINE

This manual has been written to provide guidance for troubleshooting of the OKIPAGE 20 Printer

(primarily for its printed circuit boards), on an assumption that the reader is knowledgeable of the

printer. Read the maintenance manual for this printer P/N 40300001TH if necessary.

Notes:

1. The power supply board containing a high voltage power supply is dangerous. From the

viewpoint of the safety standards, the local repairing of a defective board is not allowed. Thus,

the objects to be locally repaired as a result of troubleshooting are switches and fuses.

2. Replacement of CPU (MHM2029K) is not recommended. If CPU is founded to be defective,

board replacement is suggested.

2. TOOLS

For troubleshooting the printer, the tools listed below may be needed in addition to general

maintenance tools.

Tool Remarks

Oscilloscope

Soldering iron

Frequency response 100 MHz or higher

A slender tip type, 15-20 Watt

- 1 -

Page 5

3. CIRCUIT DESCRIPTION

3.1 Outline

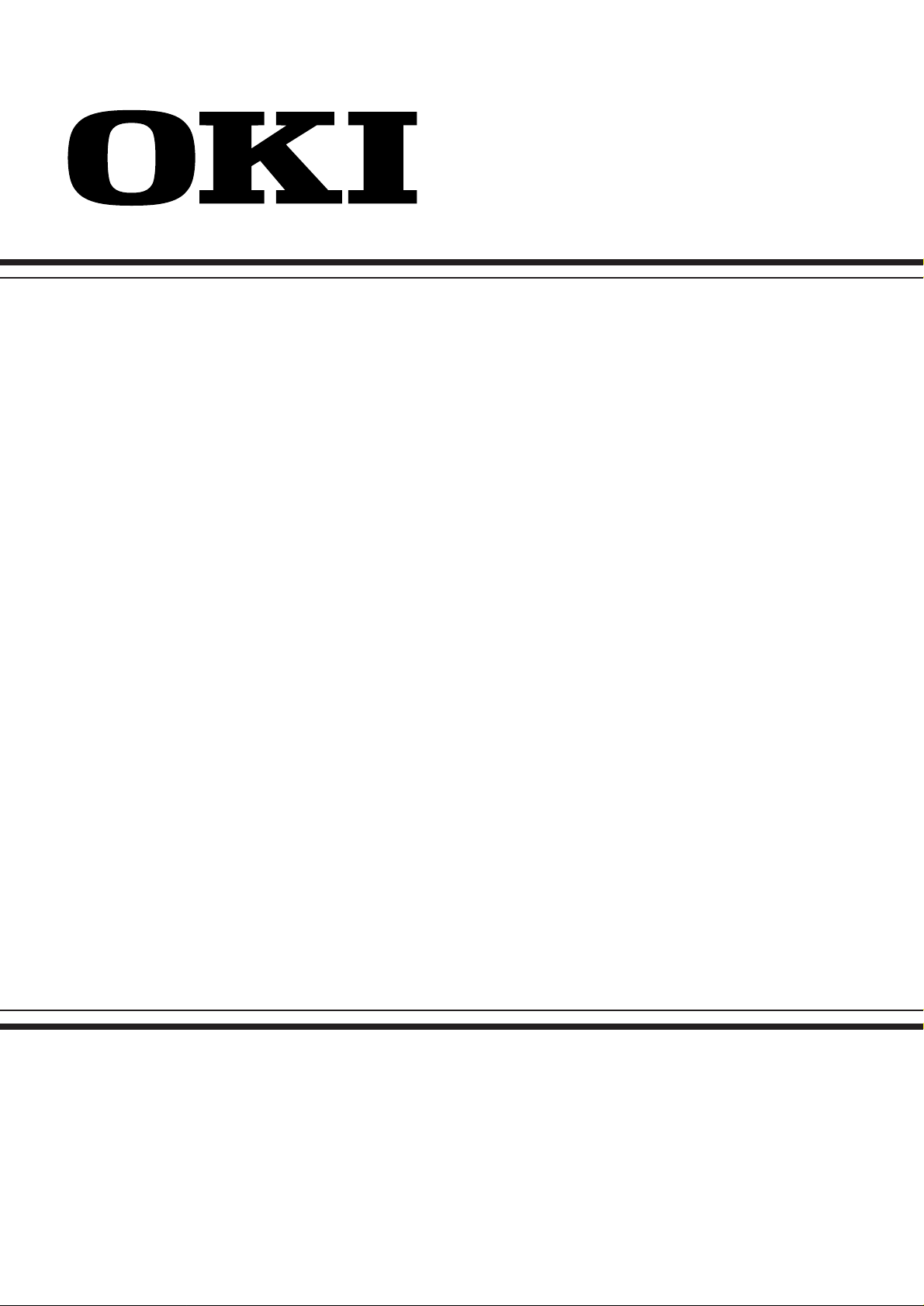

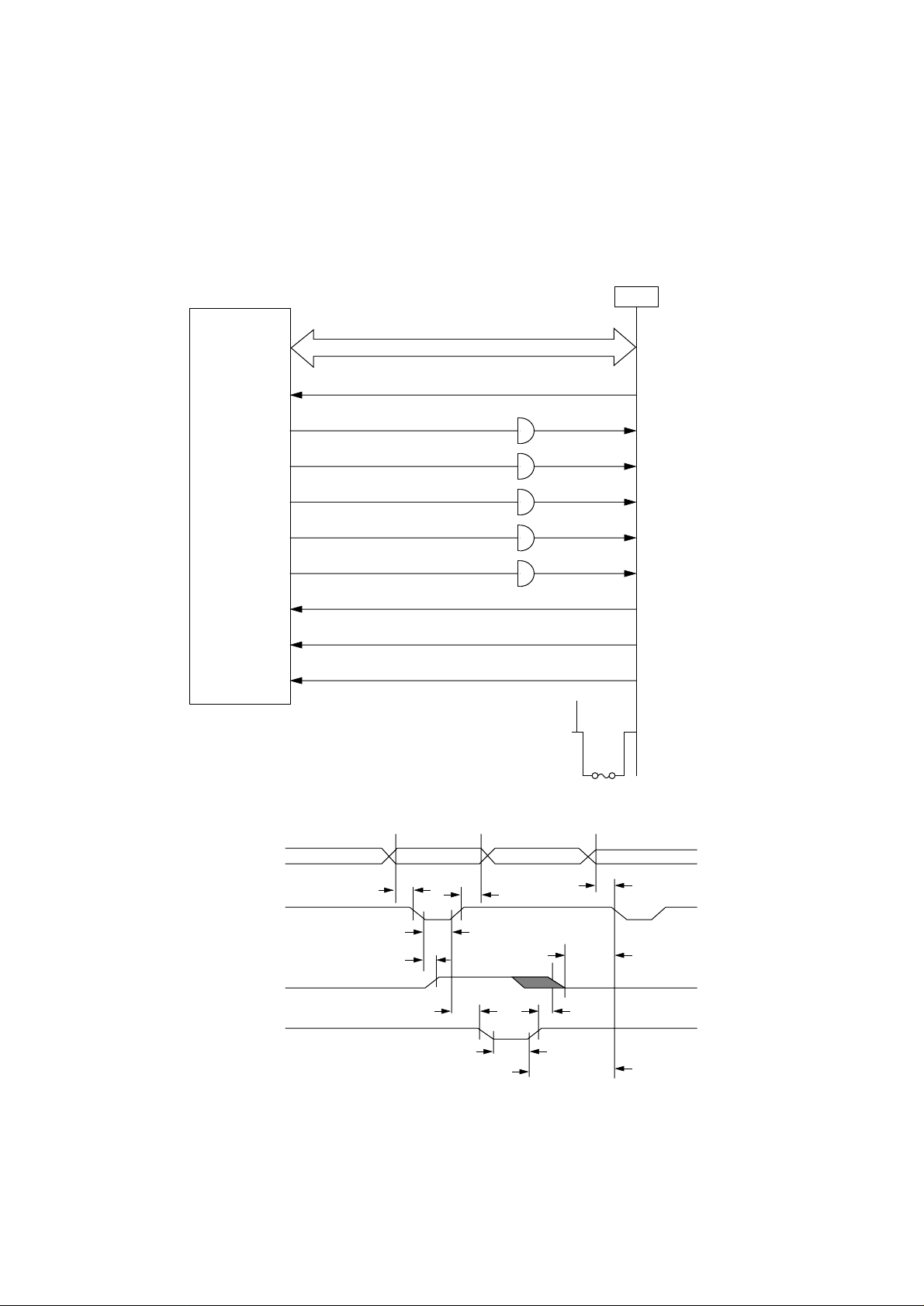

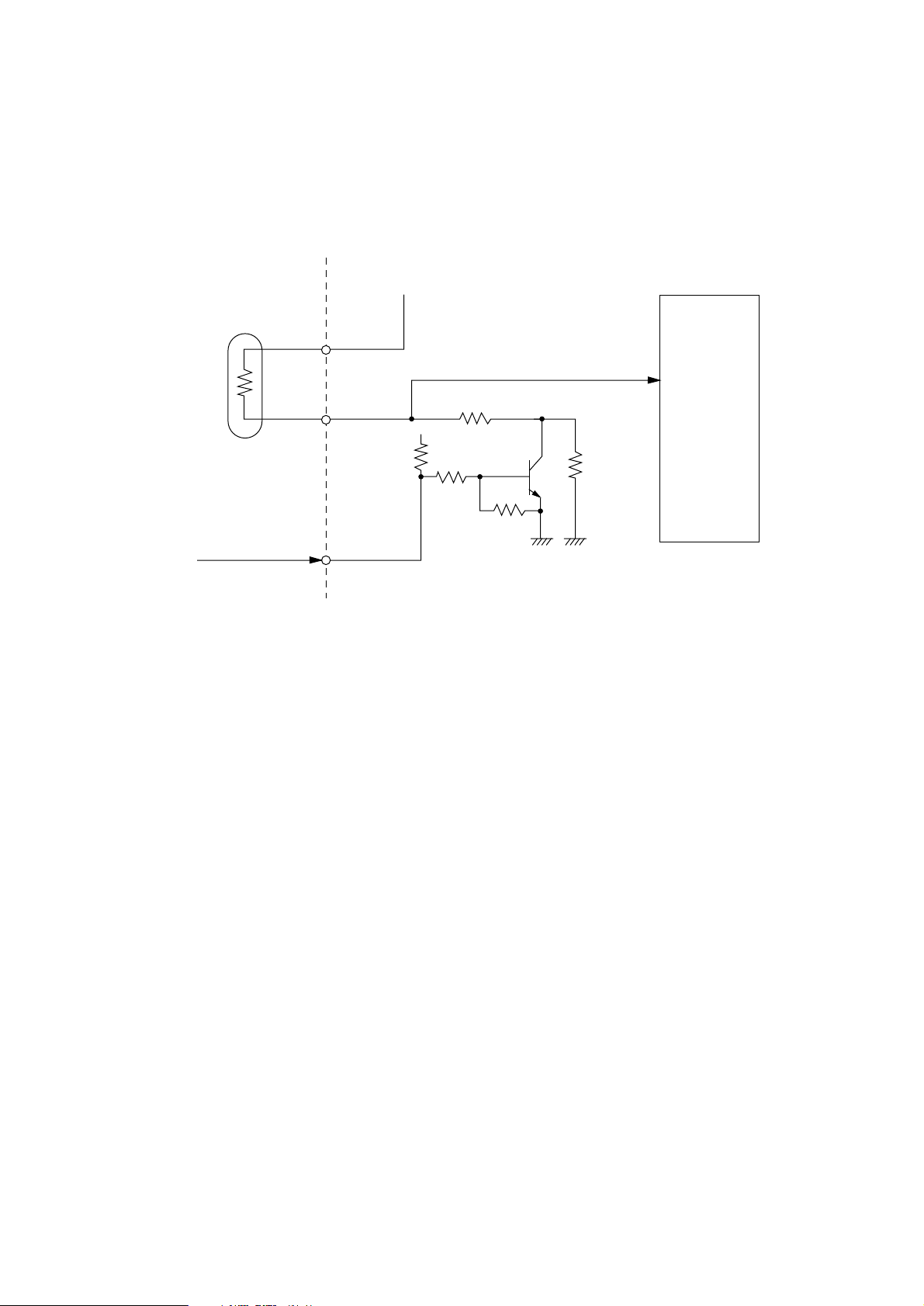

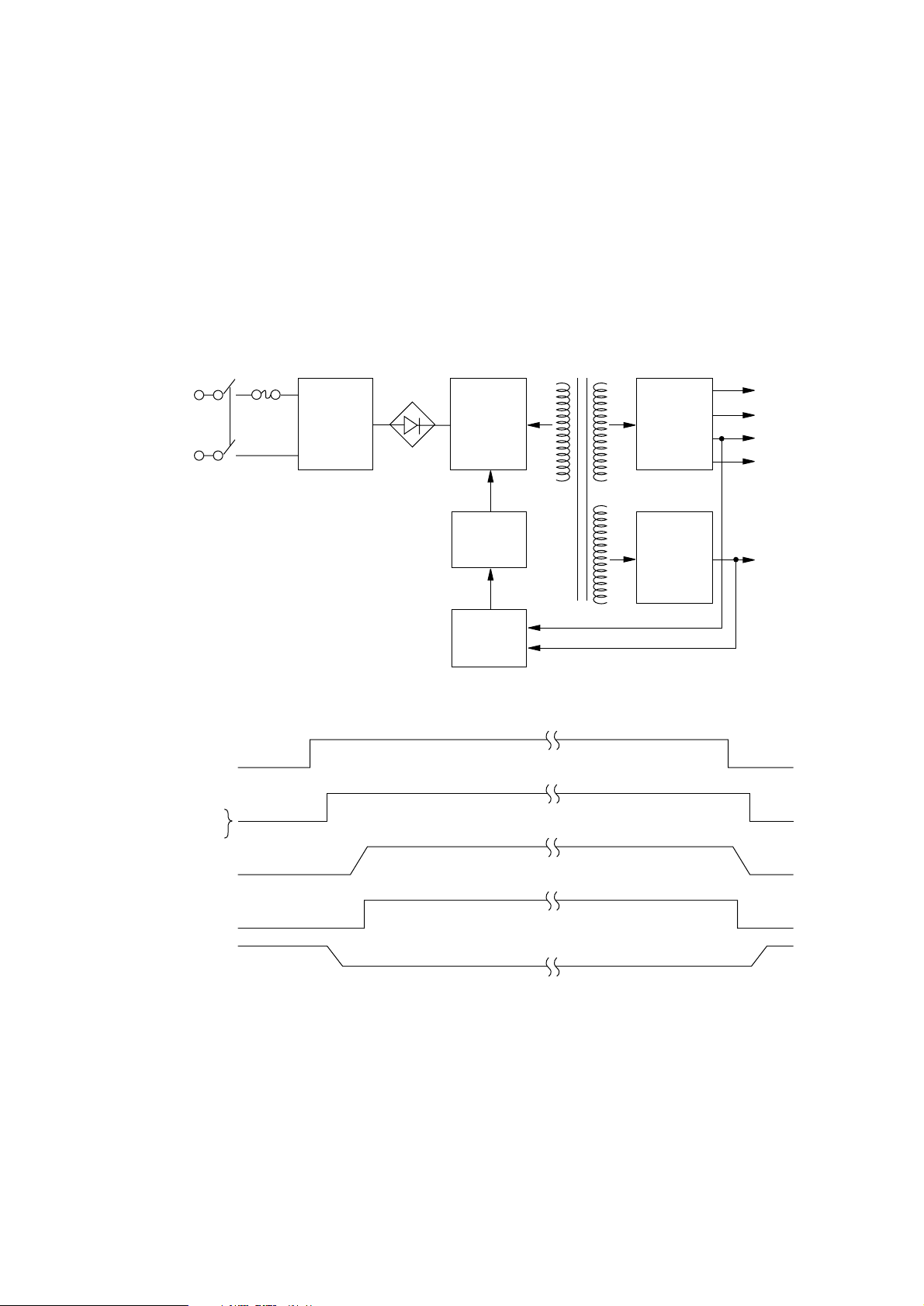

The control board controls the reception of data transferred through a host I/F and processes

command analysis, bit image development, raster buffer read. It also controls the engine and the

operator panel. Its block diagram is shown in Fig. 3-1.

(1) Reception control

The OKIPAGE 20 has one centronics parallel I/F port and one RS-232C serial I/F port.

Two I/F ports which receives data first can be used automatically.

The other I/F port outputs a busy state.

The centronics parallel I/F port can specify the following item when set by the control panel:

PARALLEL SPEED: HIGH/MEDIUM

BI-DIRECTION : ENABLE/DISABLE

I-PRIME : OFF/ON

The RS-232C serial I/F port can specify the following item when set by the control panel.

Flow control : DTRHI/DTRLO/XONXOFF/RBSTXON

Baud rate : 300/600/1200/2400/4800/9600/19200 (Baud)

Data bit : 7/8 (bit)

Minimum busy time: 200/1000 (ms)

Parity : NONE/ODD/EVEN

An interface task stores all data received from the host into a receive buffer first.

(2) Command analysis processing

The OKIPAGE 20 has the following emulation mode.

Laser Jet Series V : Hewlett Packard

Proprinter III XL : IBM

FX : EPSON

PostScript Level 2 : Adobe (Only when the PostScript SIMM is installed additionally.)

An edit task fetches data from the receive buffer, analizes commands, and reconstructs the

data in such a way that print data are aligned from up to down and from right to left; then it writes

the resultant data into a page buffer with such control data as print position coordinate, font

type, etc. added.

(3) Font Processing

When one page editing is finished, a developing task makes an engine start and fetches data

from the page buffer synchronizing with a printing operation; then it developes the fetched data

to a bit map as referring to data from a character generator, and writes the resultant data into

the raster buffer (of band buffer structure).

(4) Raster buffer read.

As controlling the engine operation, an engine task sends data from the raster buffer to the

LED head.

- 2 -

Page 6

FLASH ROM

Module

or

PS ROM

Module

ROM

DRAM

Module

DRAM

MAIN BOARD(BOARD - AAA)

LSI

DUPLET unit

MULTI feeder

2nd tray

Paper end

sensor

Paper near end

sensor

BOARD PXC

3rd tray

Tray size

sensor boad

Parllel

I/F

RS232C

I/F

LAN etc.

(option)

POWER

SUPLY

UNIT

(AC120/230V)

Outlet sensor

7407

75188

OKI

HSP

Boad

(option)

3V 5V +8V -8V 38V

CPU

EEPROM

LSI

TRANSISTOR

TRANSISTOR

DRIVER

DRIVER

CL

CL

M

M

Operator panel

Inlet sensor 1

paper sensor

Inlet sensor 2

Toner sensor

Clutch for

Regist Roller

Clutch for

Hopping Roller

Hopping Motor

Main Motor

LED HEAD

THERMISTOR

LOW VOLTAGE

GENERATINO

CIRCUIT

FILTER CIRCUIT

AC120V/230V

COVER

OPEN

SW

DRIVER

DRIVER

POWER

SUPLY

UNIT

(high voltage)

Figure 3-1 Block Diagram

- 3 -

0V

HIGH

VOLTAGE

CIRCUIT

Sub-CH

CH

TR

DB

SB

CB

SUB CHARGE ROLLER

CHARG ROLLER

TRANSFER ROLLER

DEVELOPPING ROLLER

TONER SUPLY ROLLER

CLEANING ROLLER

FAN

HEATOR

Page 7

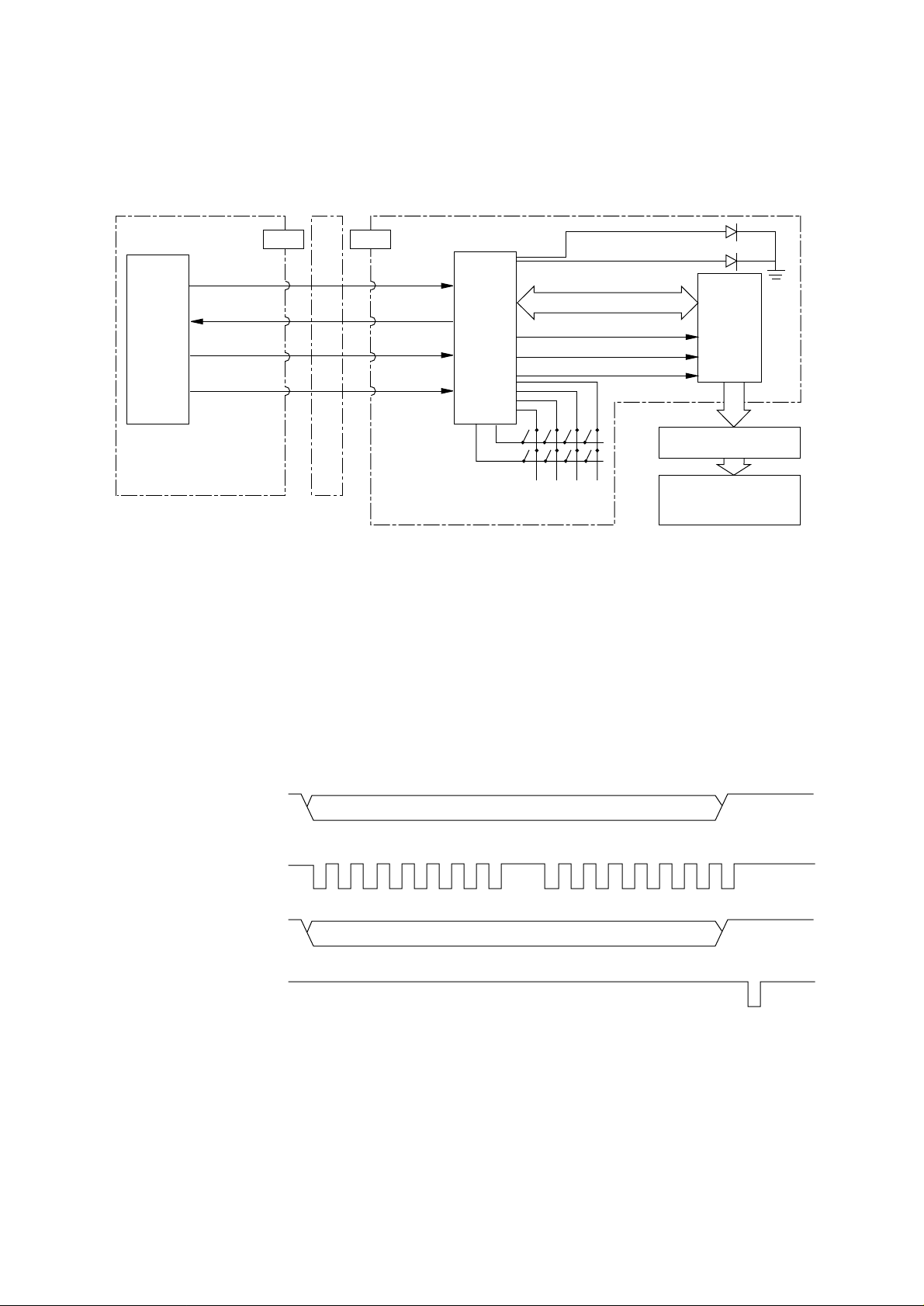

3.2 CPU and Memory

(1) CPU (MHM2029-003K-41)

CPU core : RISC CPU (MIPS R3000 compatible)

CPU clock : 40.5504 MHz

Data bus width: Exterior 32 bits, Interior 32 bits

(2) ROM (HP LaserJet V emulation)

ROM capacity : 6 Mbytes (24-Mbit mask ROM two pieces)

ROM type : 24 Mbits (1.5M x 16 bits)

Access time : 100 ns

(3) Option ROM (SIMM: one slot)

PostScript SIMM or FLASH SIMM

• PostScript SIMM (Adobe PostScript emulation)

ROM capacity : 4 Mbytes (16 Mbit mask ROM two pieces)

ROM type : 16 Mbits (2M x 16 bits)

Access time : 100 ns

• FLASH SIMM

ROM capacity : 4 Mbytes (8 Mbit FLASH ROM four pieces)

ROM type : 8 Mbits (1M x 8 bits) or 16 Mbits (2M x 8 bits)

Access time : 90 ns

or 8 Mbytes (16 Mbit FLASH ROM four pieces)

(4) Resident RAM

RAM capacity : 4 Mbytes (16 Mbit D-RAM two pieces)

RAM type : 16 Mbits (1 M x 16 bits)

Access time : 60 ns

(5) Option RAM (SIMM: two slots)

RAM capacity : Max. 32 Mbytes (4 Mbytes, 8 Mbytes, 16 Mbytes, 32 Mbytes)

Access time : 60 ns, 70 ns, 80 ns, 100 ns

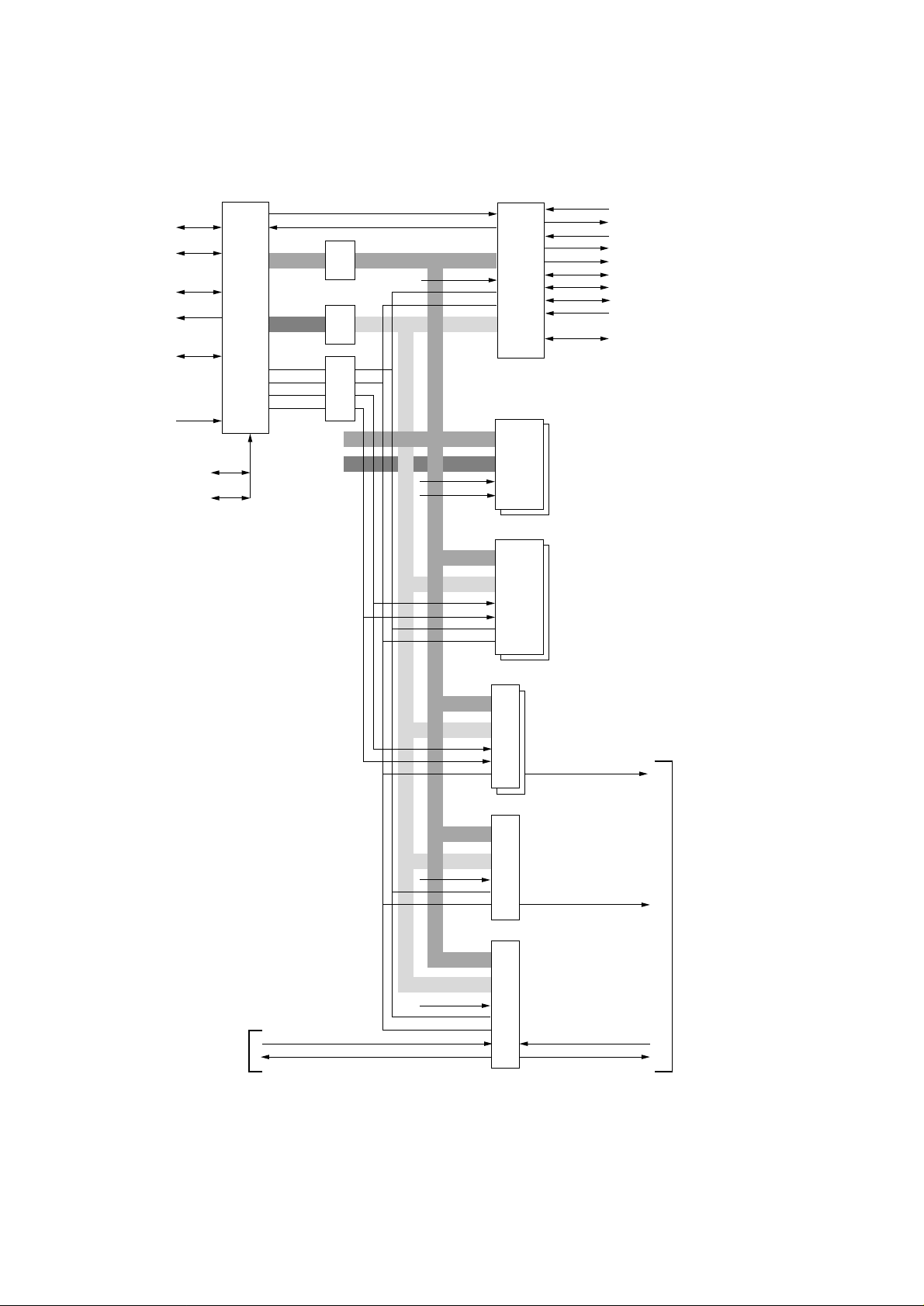

The block diagram of CPU and memory circuits is shown in Fig. 3-2.

- 4 -

Page 8

RS232C I/F

Centronics

I/F

LED Head

Dram Motor

Driver

Power supply

(SSIO)

Sensor

Ope-Pane

EEPROM

(MHM2029-003K-41)

CPU

HIOCLK

SUBINT,SUBRDY

CADR

[1-24]

CDATA

[0-31]

CRD

CWR

CRAS[0-5]

CCAS[0-3]

(SSIO)

IOS1

CADR

[2-22]

CDATA

[0-31]

CS0

CRD

RAS0

CAS[0-3]

(LZ9FF22)

Sub Chip

Sensor

Power supply :THERMCMP,PSOUT

1st tray paper size detection

Hopping motor driver

Clutch driver

Duplex(SSIO)

Option(Multi/2nd/3nd)(SSIO)

DRAM SIMM :PD

FLASH SIMM :BSY0

OKI HSP NIC :CURST,OPDCT[0-3]

ROM(6MB:24Mbit MASK *2)

RAM(4MB:16Mbit DRAM *2)

Connected

to theCPU

CUREQ

MUPISINT

MUPISRDY

RAS[2-5]

CAS[0-3]

CS3

CS6

SIMM(For DRAM*2)

PD

SIMM(For PSMASKROM

or FLASHROM)

BSY0

OKI HSP NIC

Connected

to the LSI

CURST

OPDCT[0-3]

Figure 3-2 Block Diagram of CPU & Memory

- 5 -

Page 9

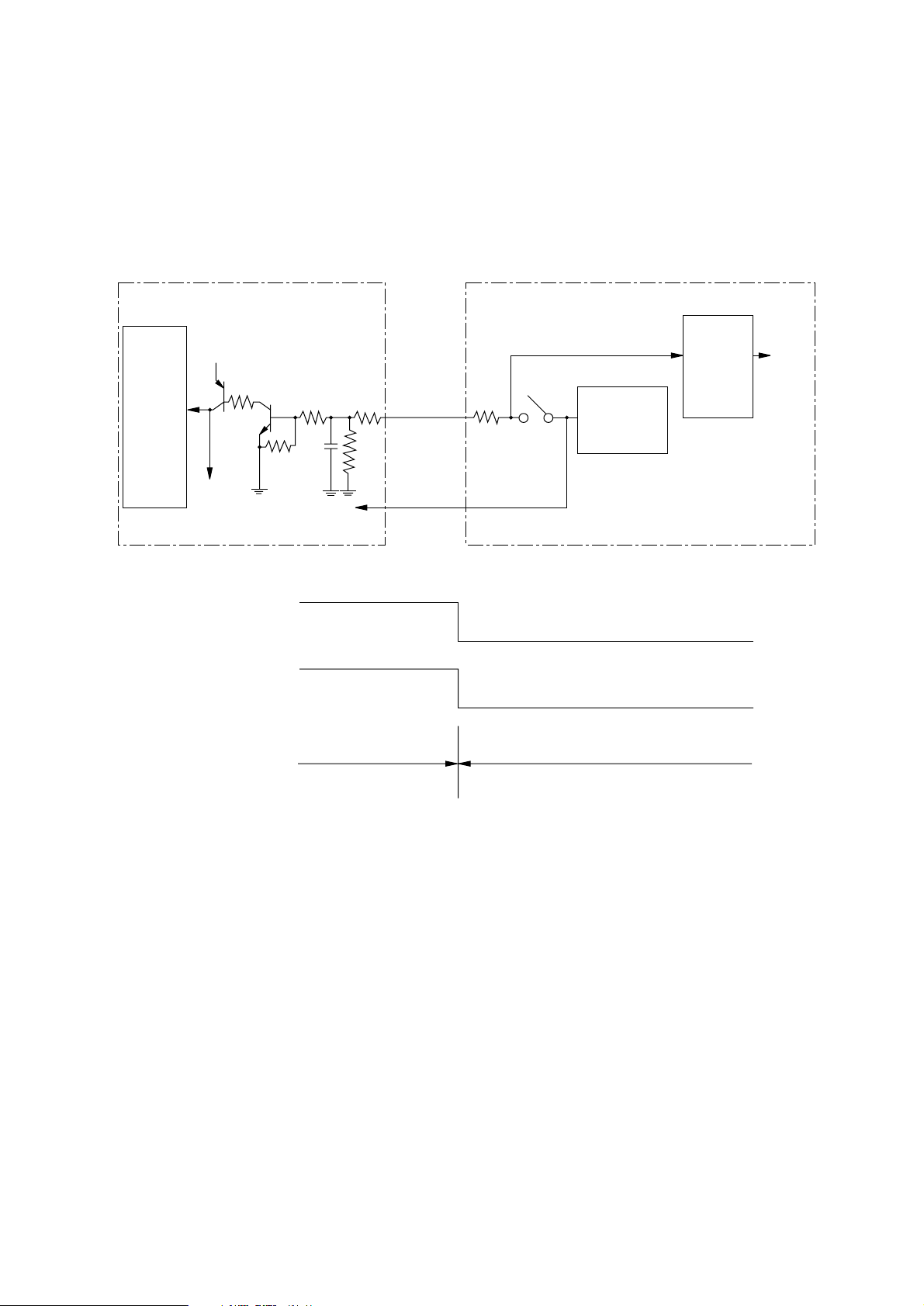

3.3 Reset Control

When power is turned on, a RESET-N signal is generated by the rising sequence of +8V power

supply.

+8V

D1

(4.3V)

R33

4.3K

Ω

R26

2.2K

Ω

R32

430K

D501

R28

240K

Ω

+5V

R89

68K

IC20

3

+

2

–

UPC393

Ω

C35

0.22

µ

F

+5V

Ω

R508

3.3K

Ω

TR504

3

1

1

2

R509

3.3K

Ω

RESET-N 72

IC1

(MHM2029K)

ETC

+8V

IC20 UPC393

INPUT

IC20 UPC393

1 pin

RESET-N

+5V

Power ON

Power OFF

2 pin

3 pin

- 6 -

Page 10

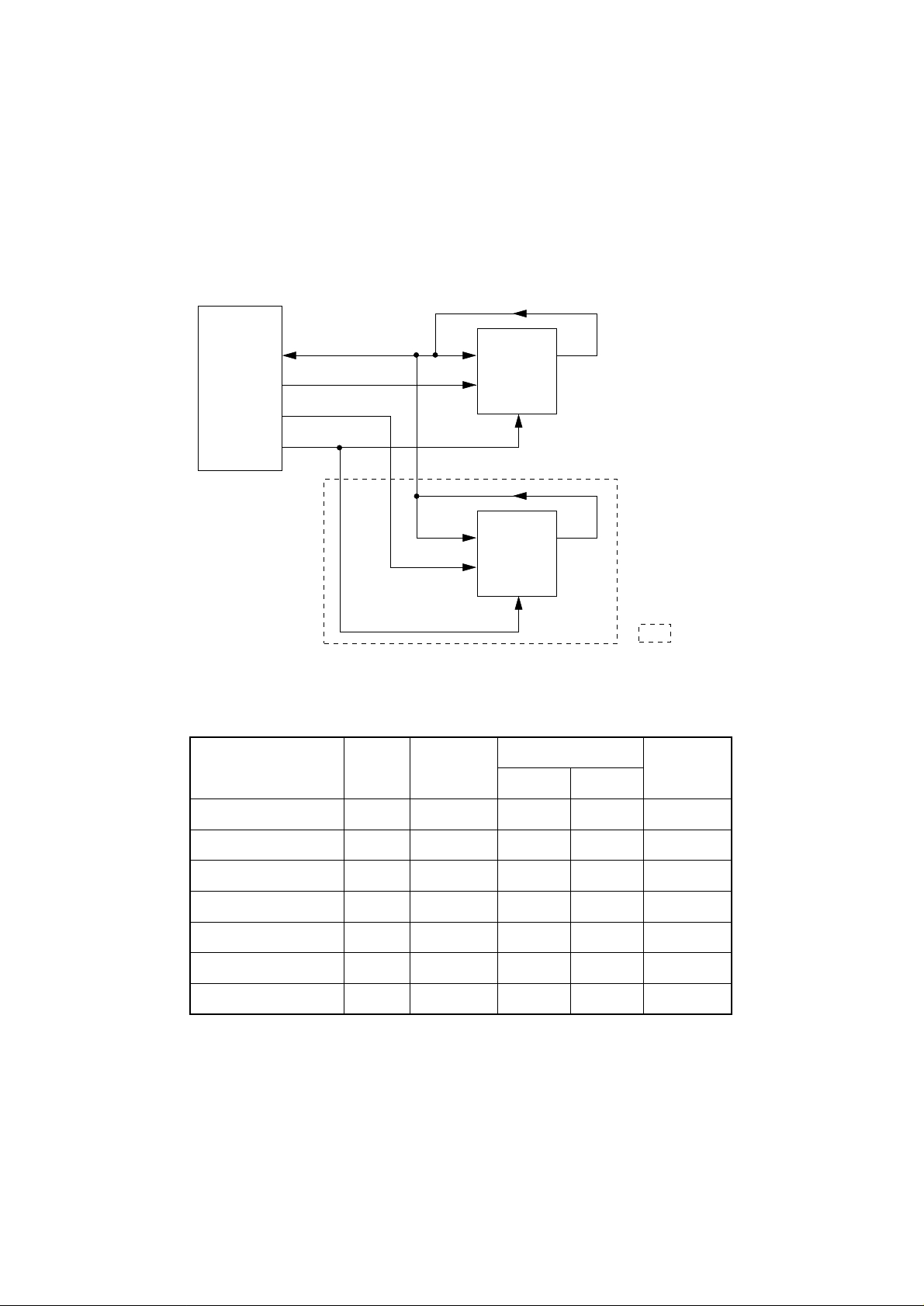

3.4 EEPROM Control

The NM93C46LN is an electrical erasable/programmable ROM of 64-bit x 16-bit configuration and

the NM93C66N is an electrical erasable/programmable ROM of 256-bit x 16-bit configuration.

Data input to and output from the ROM are bidirectionally transferred in units of 16 bits through

a serial I/O port (SERIALDATA-P) in serial transmission synchronized with a clock signal from the

CPU (IC1).

IC1

(MHM2029K)

SERIALDATA-P

154

EEPRMCS0-P

150

EEPRMCS1-P

165

EEPRMCLK-P

151

NM93C46LN

3

DI DO

1

CS

2

NM93C66N

3

DI DO

1

CS

2

SK

SK

(PS SIMM)

4

IC19

(AAA-PCB)

4

The EEPROM operates in the following instruction modes

Instruction Start Bit

Operation

Code

NM93C46LN

Address

NM93C66N

: Option

Data

Read (READ)

Write Enabled (WEN)

Write (WRITE)

Write All Address (WRAL)

Write Disabled (WDS)

Erase

Chip Erasable (ERAL)

1

1

1

1

1

1

1

10

00

01

00

00

11

00

A5 to A0

11XXXX 11XXXXXX

A5 to A0 A7 to A0

01XXXX 01XXXXXX

00XXXX 00XXXXXX

A5 to A0 A7 to A0

10XXXX 10XXXXXX

A7 to A0

D15 to D0

D15 to D0

- 7 -

Page 11

CS

SK

CS

SK

DI

DO

Write cycle timing (WRITE)

101

HIGH-Z

A5/A7

Read cycle timing (READ)

A4/A6

A1 A0 D15

D14

Min. 450 ns

STATUS

D1 D0

Max. 500 ns

BUSY READY

Max. 10 ms

DI

DO

HIGH-Z

11 0

A5/A7 A4/A6

A1 A0

A5/A7

A4/A6

D1 D00

- 8 -

Page 12

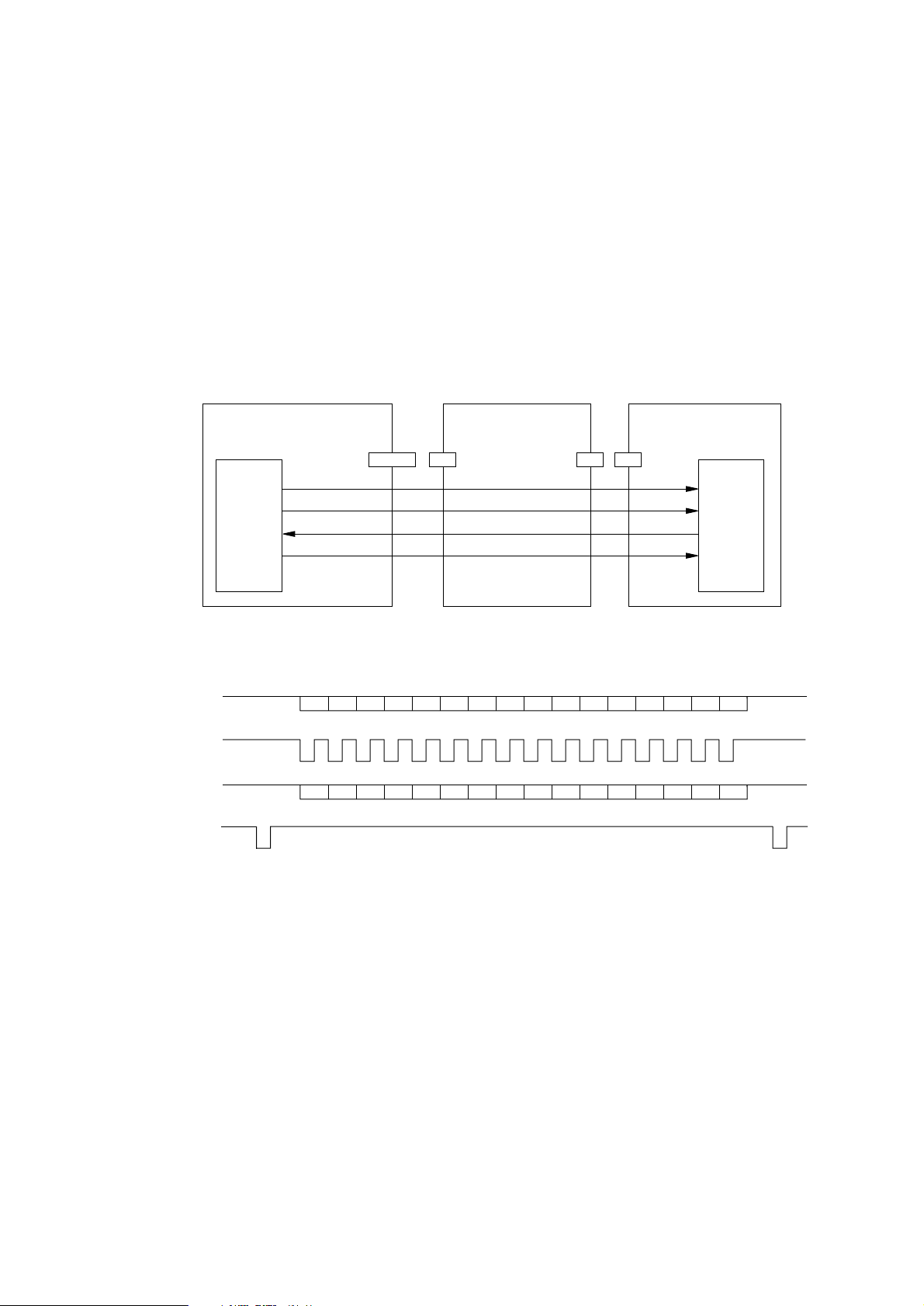

3.5 Centronics Parallel Interface

The CPU (IC1) sets a BUSY-P signal to ON at the same time when it reads the parallel data

(CENTDATA1-P to CENTDATA8-P) from the parallel port at the fall of STB-N signal. Furthermore,

it makes the store processing of received data into a receive buffer terminate within a certain fixed

time and outputs an ACK-N signal, setting the BUSY-P signal to OFF.

87, 88, 91 to 96

IC1

(MHM2029K)

97

85

86

83

81

79

80

82

84

CENTDATA1-P to CENTDATA8-P

STB-N

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

IPRIME-N

SELIN-N

AUTOFEED-N

IC17

2 to 9

11

10

12

13

32

31

36

+5V 14

CENT

DATA8-P

DATA1-P

STB-N

1

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

IPRIME-N

SELIN-N

AUTOFEED-N

to

CENTDATA

1~8-P

STB-N

BUSY-P

ACK-N

0.5 µs min.

0.5 µs min.

0.5 µs max.

0 min.

10 µs max.

+5V

18

FU1

1A

0.5 µs min.

0.5 µs min.

0 min.

0 min.

0 min.

- 9 -

Page 13

3.6 RS232C Interface

The serial data RXD from the host system, whose line voltage is clamped at the TTL level by D502/

D503, are received by the CPU built-in serial controller.

DSR, CTS and CD are not connected. Send signals TXD, RTS and DTR are put out from the CPU

and are sent to lines through a line driver IC (75188).

CPU

RXD-N

101

108

102

103

TXD-P

RTS-N

DTR-N

D502

+5V

RS232C

D503

3.3K

3.3K

2

75188

4

IC18

9

3

6

8

Idle

Idle

Idle

Idle

20

RXD

3

DSR

6

CTS

5

CD

1

TXD

2

RST

4

DTR

SSD

9

14 1

+8V -8V

(1) Send signal level (2) Receive signal level

Input 0V

Output 0V

TTL level

Input 0V

+8V

- 8V

Output 0V

+8V

- 8V

TTL level

- 10 -

Page 14

3.7 Operator Panel Control

The operator panel consists of the following circuits.

AAA- PCO-

IC1

(MHM2029K)

SERIALDATA-P

154

PDATAIN-P

158

PSCLK-N

153

PLD-N

152

3

4

6

1

Flexible

Cable

CN1PANEL

4

3

1

6

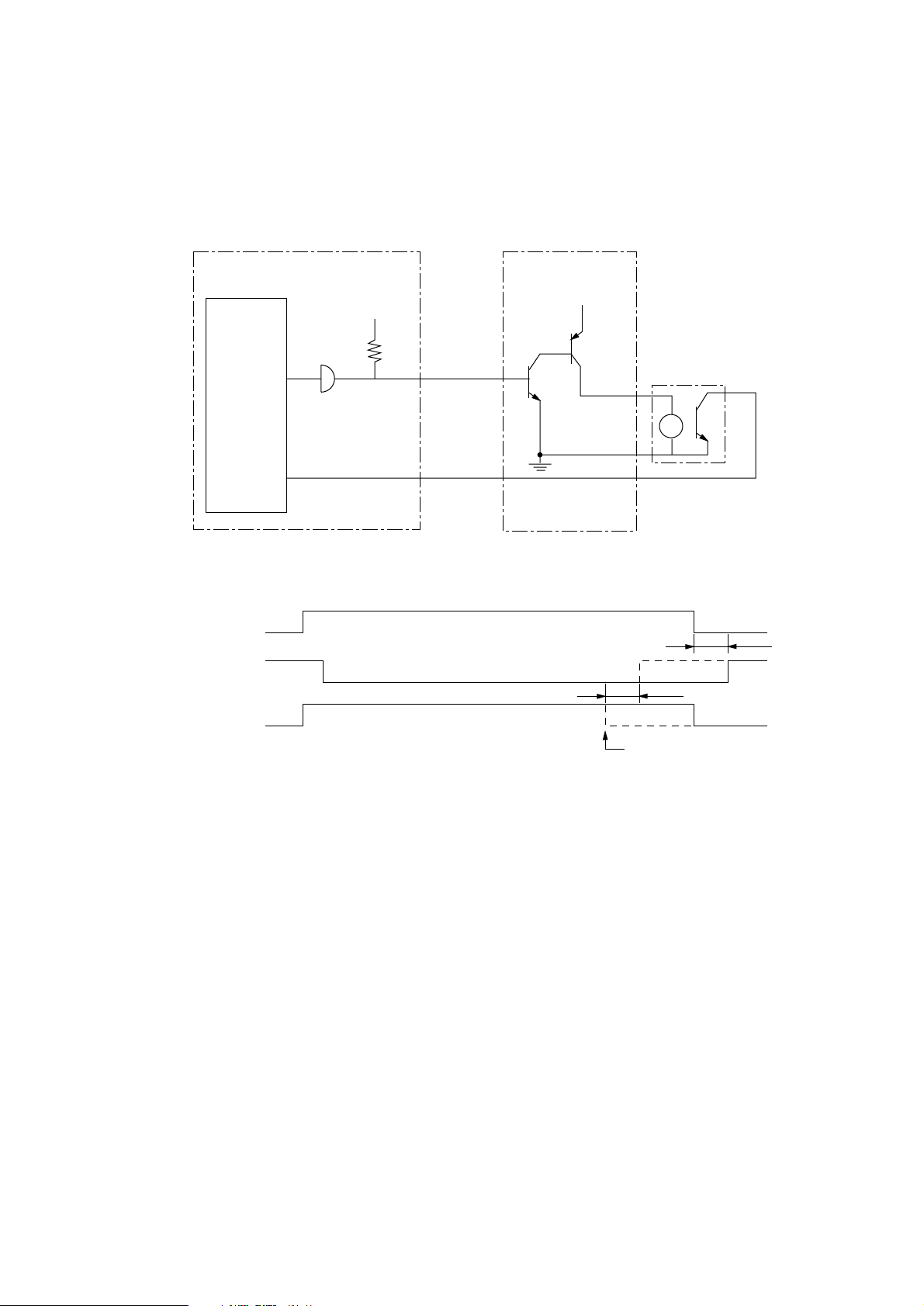

(1) BU6152S (LSI)

This LSI is connected to a clock synchronous serial port of the CPU (IC1). It controls switch

data input, LED data output and LCD data input/output according to the commands given by

the CPU. The CPU sends the 2-byte (16-bit) command (SERIALDATA-P) together with the

shift clock signal (PCLK-N) to the LSI and then makes a predetermined input/output control

if the command decoded by the LSI is found to be a normal command.

BU6152S

LSI

DB4~DB7

RS

R/W

E

LED

44780

LCD

Control

Driver

Zebra Rubber

LCD

On receiving a command sent from the CPU, the LSI, synchronizing with the serial clock of

the command, returns a 2-byte command response to the CPU.

SERIALDATA-P

PSCLK-N

PDATAIN-P

PLD-N

bit 0 bit 15

Command

bit 0

Command response

bit 15

- 11 -

Page 15

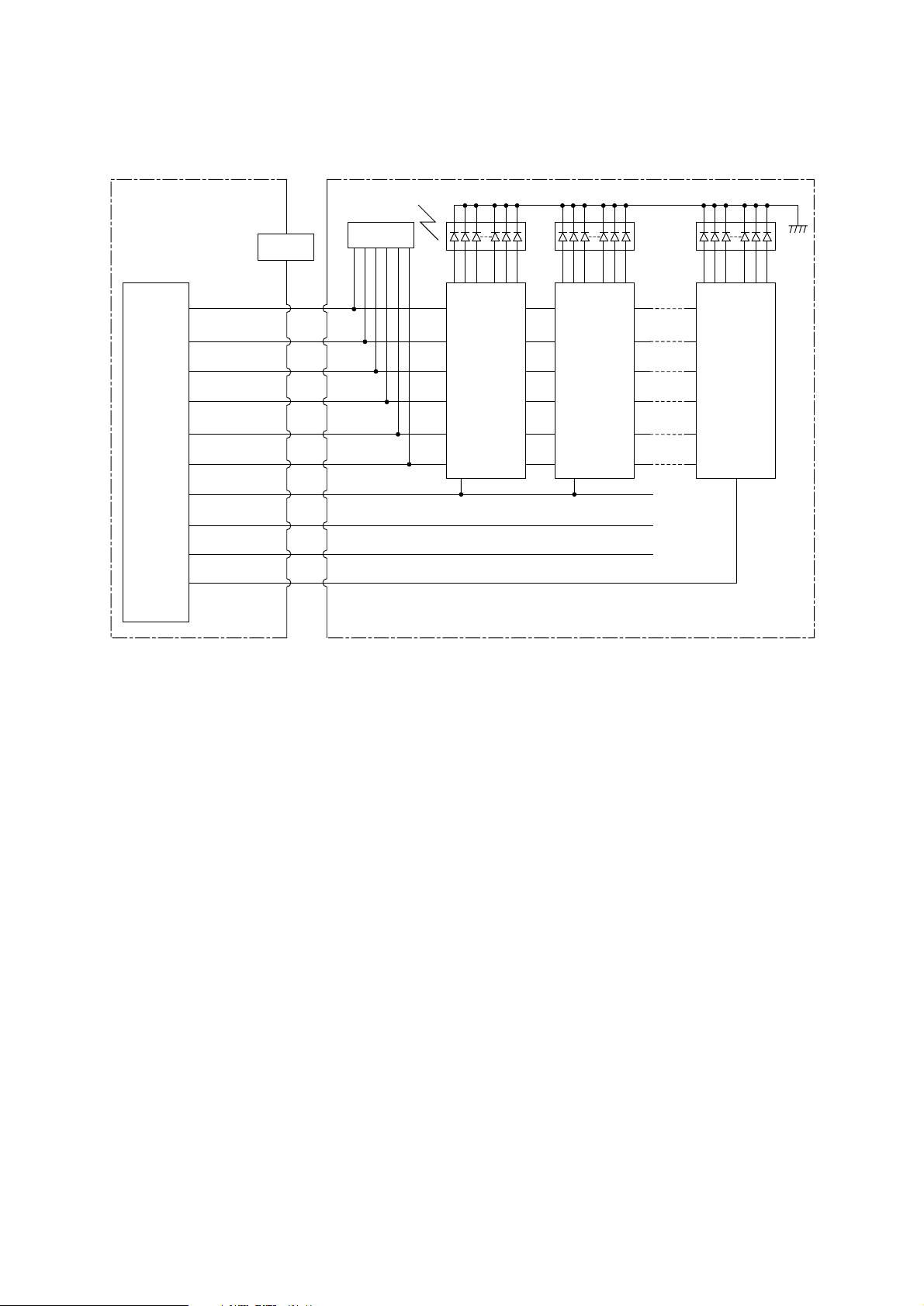

3.8 LED Head Control

AAA-

IC1

(MHM2029K)

181

180

144

143

HDCLK-P

142

HDDLD-P

139

HDSTB4-N

135

HDSTB3-N

136

HDSTB2-N

137

HDSTB1-N

138

HDD3-P

HDD2-P

HDD1-P

HDD0-P

HEAD 1

10

11

7

8

13

5

1

2

3

4

LED Head

EEPROM

5

4

8

7

2

10

14

13

12

11

Driver IC Driver IC

Driver IC Driver IC

38

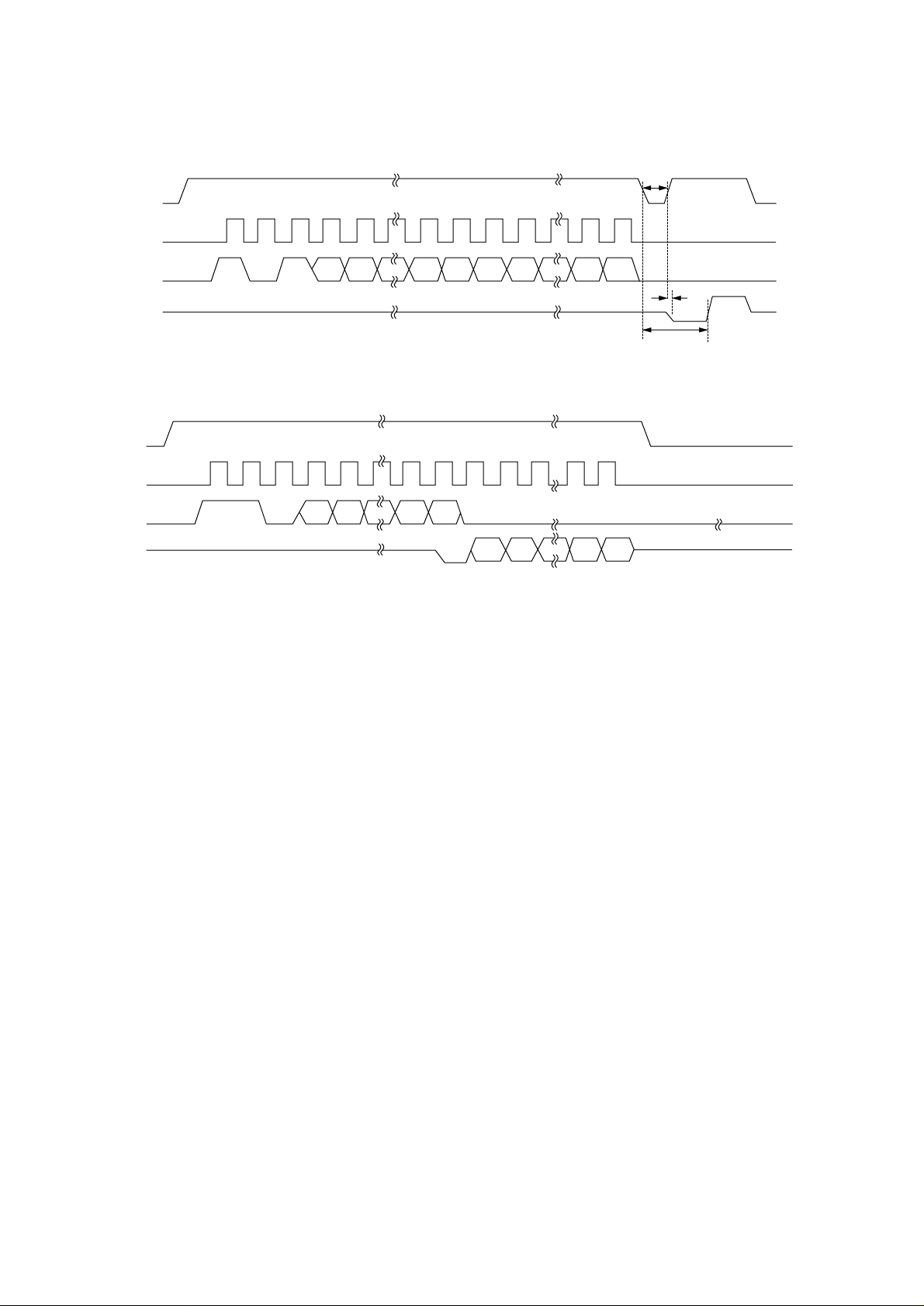

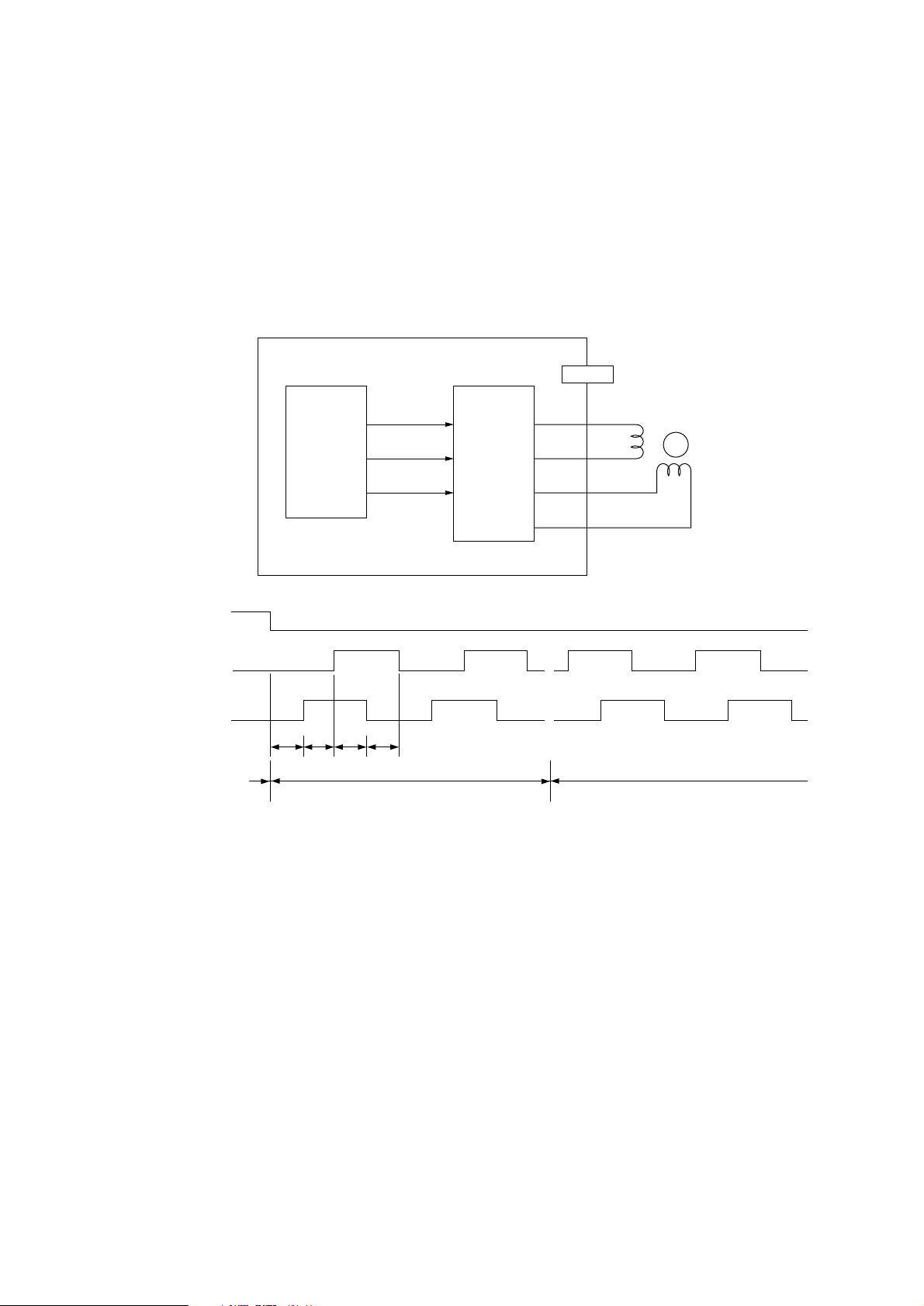

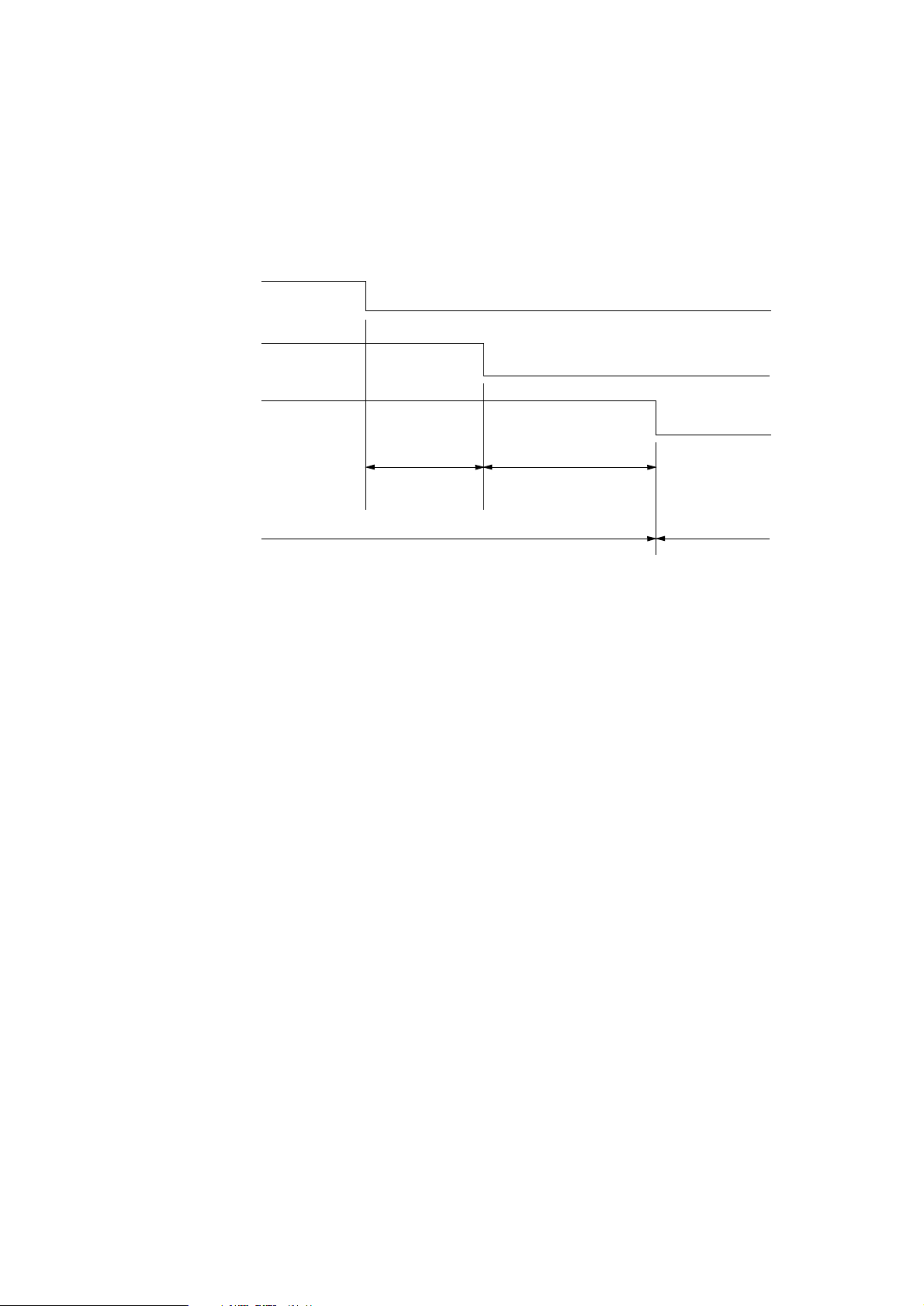

Data is transferred to the head unit starting with the data at the left end of the paper in the

synchronous serial transfer mode using the HDCLK-P signal as the sync signal.

The total number of LEDs in the head unit is 4992. The data for the driver latches causes the

corresponding LEDs to light only during the time when the HDSTBn-N signal is output. There are

four HDSTBn-N signals (HDSTB1-N, HDSTB2-N, HDSTB3-N, and HDSTB4-N), each of which

controls the corresponding driver for 1248 LEDs (4992/4).

The four HDSTBn-N signals must be output within the time when the LEDs for one line continue

to emit light. After the data is moved to the latches by the HDSTBn-N signal, the transfer of the

data of the next line can be started.

- 12 -

Page 16

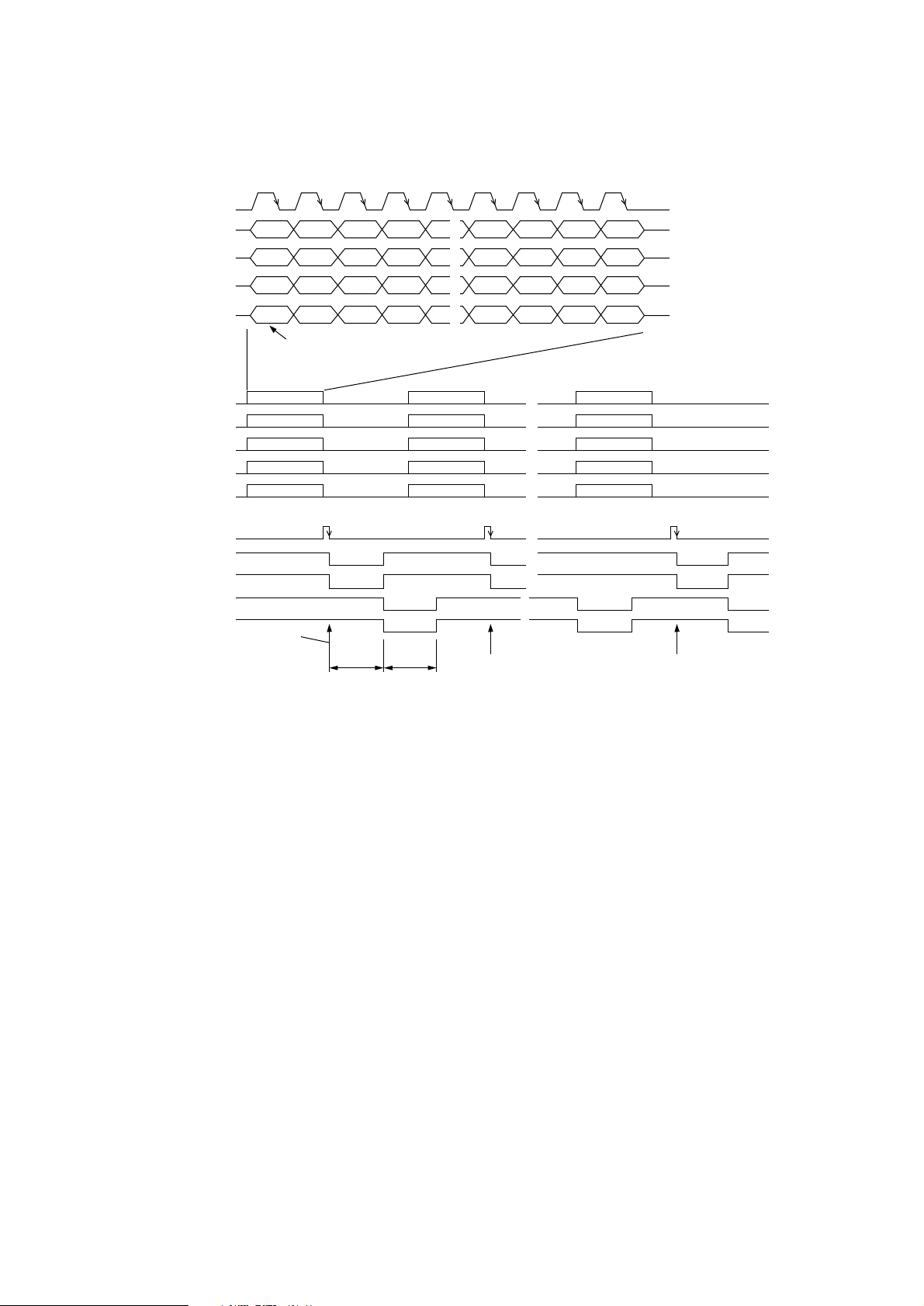

The timing chart for the outline of this operation is shown below.

HDCLK-P

HDD0-P

HDD1-P

HDD2-P

1

59

2 6 10 4986 4990

3

11 4987 4991

7

4985

4989

✰

The LED lights

when the head

data is HIGH.

HDD3-P

HDCLK-P

HDD0-P

HDD1-P

HDD2-P

HDD3-P

HDDLD-P

HDSTB1-N

HDSTB2-N

HDSTB3-N

HDSTB4-N

4 8 12 4988 4992

Each figure denotes the dot

position taking the left end bit

position as "1".

Print activation

timing for the

1st line

LEDs

1-2496

lit

LEDs

2497-4992

lit

Print activation timing

for the 2nd line

Print activation timing

for the final line

- 13 -

Page 17

3.9 Motor Control

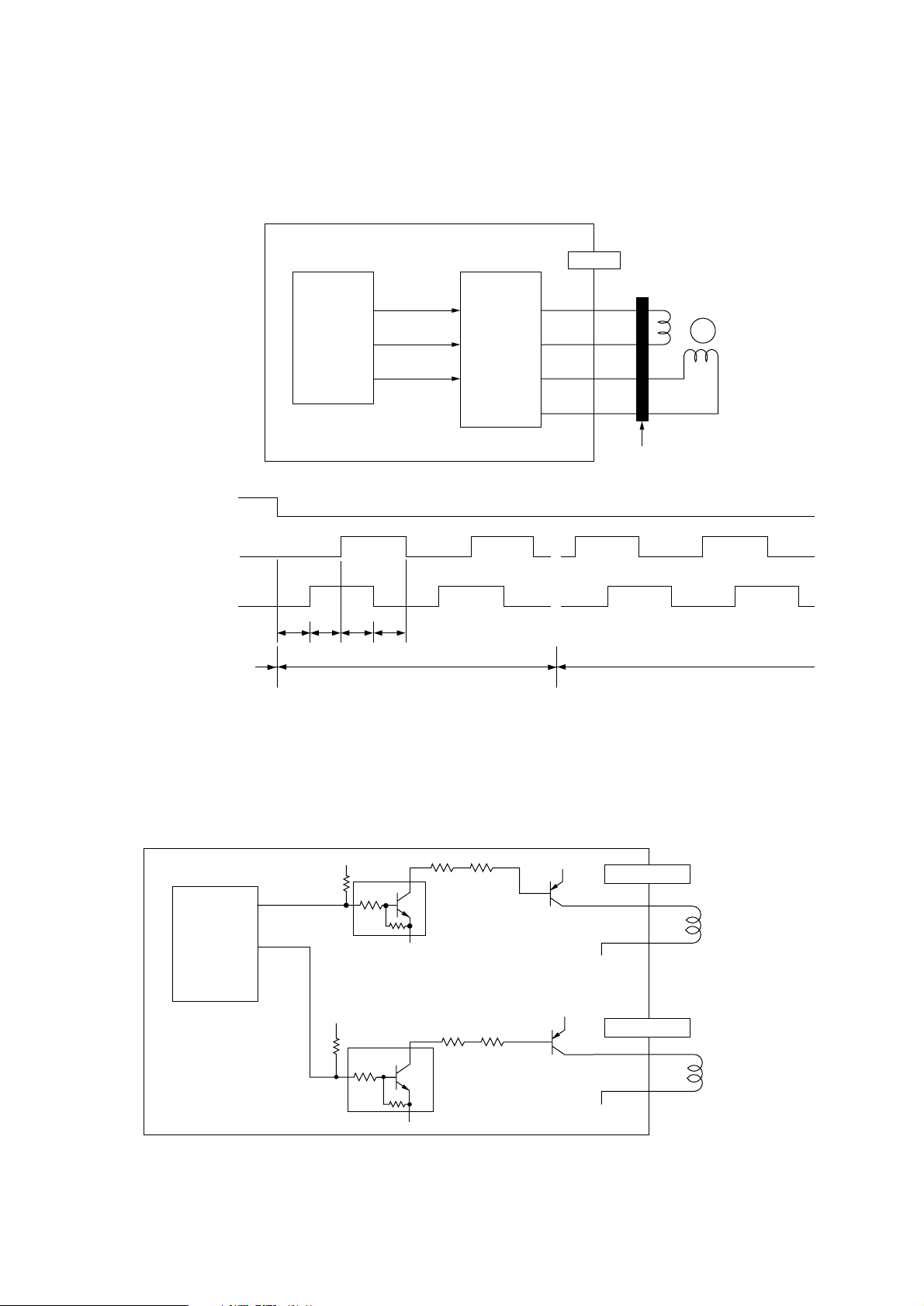

OKIPAGE20 controls the paper flow by two motors (main motor & hopping motor) and two clutches

(clutch for feeding roller and clutch for regist roller).

(1) Main motor

The main motor is driven by the driver IC according to the control signal from the CPU (IC1:

MHM2029K).

DMON-N

DMPH1-P

DMPH2-P

Rotation

AAA-PCB

IC1

(MHM2029K)

T0 T1 T2 T3

DMPH1-P

132

DMPH2-P

131

DMON-N

127

13

8

7, 14

Forward rotation

MAIN

(A2918)

1

17

2

4

MOTOR

1

2

3

4

Main

Motor

M

Reverse rotationStop

Operation at normal speed: T0 to T3 = 703

µ

s

- 14 -

Page 18

(2) Hopping motor

The hopping motor is driven by the driver IC according to the control signal from the LSI (IC2:

LZ9FF22).

HMON-N

HMPH1-P

HMPH2-P

Rotation

AAA-PCB

IC2

(LZ9FF11)

T0 T1 T2 T3

HMPH1-P

57

HMPH2-P

58

HMON-N

75

13

8

7, 14

Forward rotation

HOPPING

(A2918)

FRONT

1

1

2

17

3

2

4

4

Hopping

Motor

M

JackIn

connector (22P)

Reverse rotationStop

Operation at normal speed: T0 to T3 = 918

µ

s

(3) Clutch for feeding roller and clutch for regist roller

Clutch for feeding roller and clutch for regist roller are driven by the driver IC according to the

control signal from the LSI (IC2: LZ9FF22).

AAA-

IC2

(LZ9FF22)

PWM1-P

74

PWM2-P

59

+5VD

+5VD

0V

0V

TR505

TR506

TR1

TR2

+38V

+38V

0VP

0VP

CLH

1

2

3

CLR

1

2

Clutch for feeding roller

Clutch for regist roller

- 15 -

Page 19

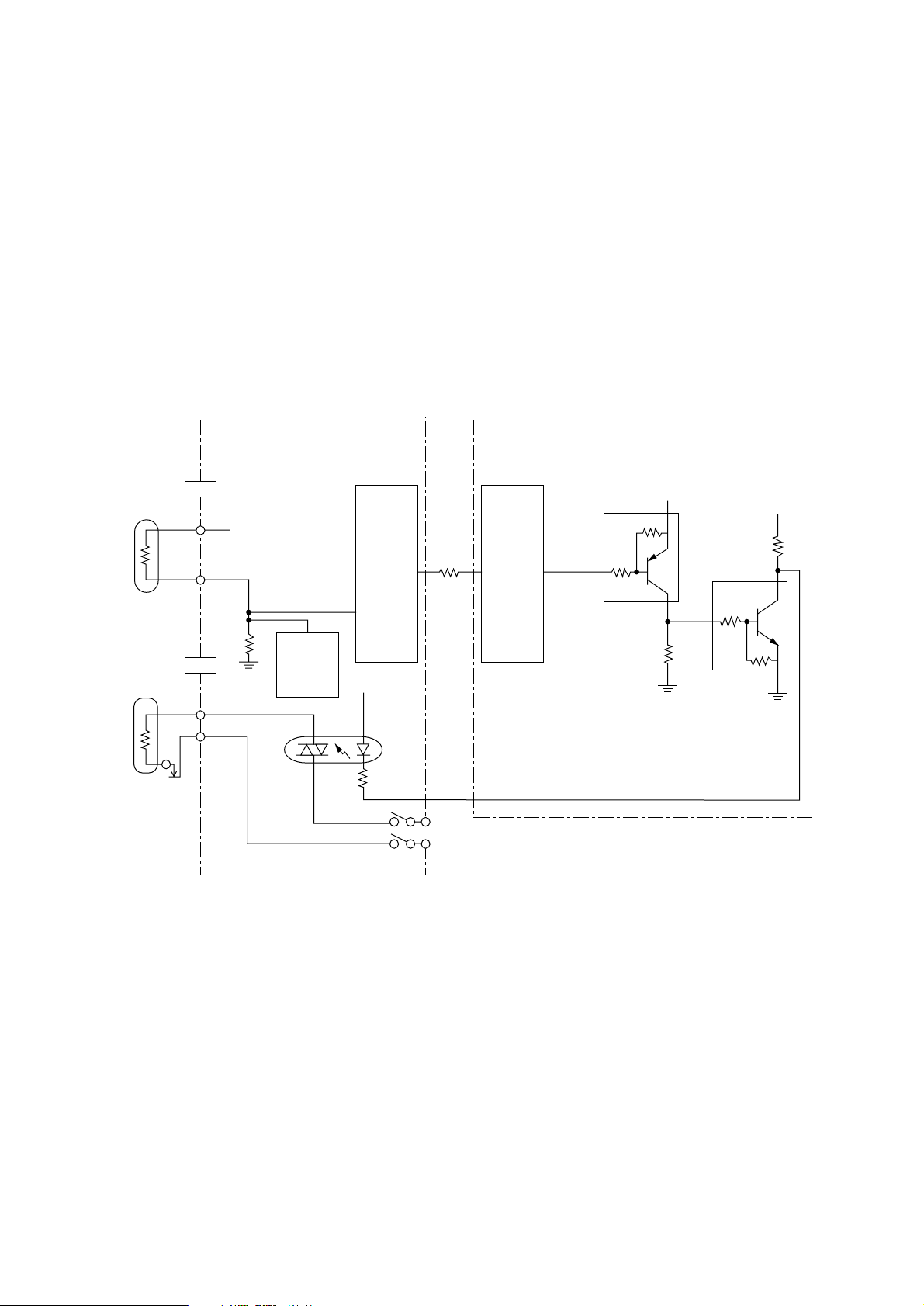

3.10 Fuser Temperature Control

For the temperature control by heater control, the variation in the resistance of the thermistor is A/

D converted in and the resultant digital value is read and transferred to the CPU. The CPU turns

on or off the HEATON-N signal according the value of the signal received from to keep the

temperature constant.

Immediately after the power is turned on, the thermistor is checked for shortcircuit and breakdown.

If the thermistor is shorted, the A/D converted value shows an extremely high temperature, so that

the shortcircuit can be detected. If the breakdown of the thermistor occurs, the A/D converted value

shows the normal temperature. In this case, the thermistor breakdown can be detected by the

sequence shown at the end of this section. If the heater is overheated, 5V supply is turned off by

detecting that the resistance of the thermistor exceeds the predetermined value.

Thermistor

Heater

Thermostat

CN8

1

2

CN2

1

2

Power Supply Board

5V

36

Thermistor

breakdown

detector

circuit

5V

PC1

AAA-

IC1 IC1

(MHM2029K)

Power

supply

interface

ACIN

HEATON-N

116

TR5

+5VD

+5V

TR4

- 16 -

Page 20

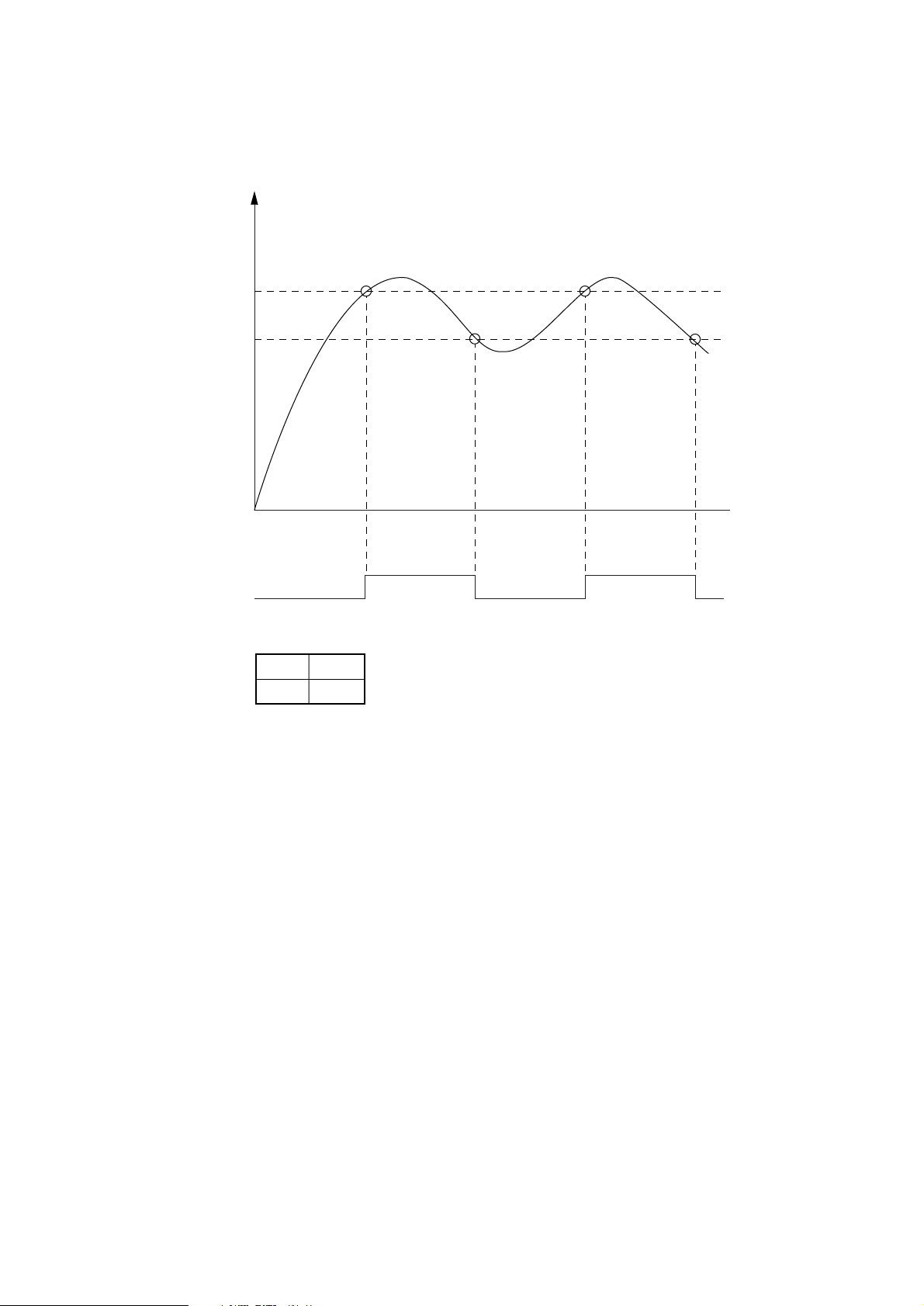

The temperature control is described below.

Vt

Temperature

˚C

V2

V1

ON OFF ON OFF ONHEATON-N

V2 192˚C

V1

169˚C

* The values V1 and V2 vary according to setting mode.

(Standard paper : MEDIA TYPE = MEDIUM)

When Vt rises to V2 or more, the heater is turned off (by setting HEATON-N signal to HIGH). When

Vt drops to V1 or less, the heater is turned on (by setting HEATON-N signal to LOW). In this way,

the temperature can be kept within the predetermined range.

- 17 -

Page 21

To detect the breakdown of the heater, the heater is turned on. If the corresponding temperature

rise is not detected, it is judged that heater breakdown occurs. To shorten the breakdown detecting

time, the following circuit is used. When the thermistor is checked for breakdown immediately after

the power is turned on, the THERMCHK-N signal is turned on to turn transistor Q5 off. As a result,

the thermistor serial resistance is varied to increase the reading resolution.

5V

Thermistor

A/D

converter

5V

THERMCHK-NFROM IC2 (LZ9FF22)

- 18 -

Page 22

3.11 Fan Motor Control

The stop/rotation of the fan motor is controlled by a FANON-P signal. When the fan motor rotates

normally, a FANALM-N signal generated in the hole element built in the fan motor is input to the

CPU.

AAA-

IC1

(MHM2029K)

FANON-P

FANALARM-N

IC17

QC

109

FANALARM-N

110

+5VD

FANON-P

Power Supply Board

+38V

FAN Motor

M

1 sec max

0.7 sec max

FAN MOVE

Lock

- 19 -

Page 23

Fan motor start:Initial request, heater on, print start request

Fan motor stop: • The motor immediately stops when an engine error or a fan error occurs.

• The motor stops 30 seconds after the occurrence of a paper jam, size error, or

fuse error.

• The motor stops in the power save mode as below.

Main motor

Heater control

Fan motor

ON

Heater

hold time

8 min.

or 0 min.

Rotation state

OFF

OFFON

30 sec.

Stop state

- 20 -

Page 24

3.12 Sensor Supervision

OKIPAGE20 unit is provided with 11 sensors.

The signals of Toner sensor and Inlet sensor 2 among these sensors are read through the Power

supply interface.

Other sensor signals are read directly from the input ports of CPU (IC1: MHM2029K) and LSI (IC2:

LZ9FF22).

Also, regarding Inlet sensor 1 signal, Paper sensor signal and Outlet sensor signal, their changed

status can be notified as a CPU interruption.

In addition, these three signals can be read through the Power supply interface.

to Duplex unit

to Duplex unit

to

2nd/3rd paper feeder

and Multi feeder

AAA-PCB

81

IC20

164 120

IC2

(LZ9FF22)

IC1

(MHM2029K)

15to18

21

80

73

123

1st tray

PXCPCB

Power supply board

Paper size sensor board

Paper end sensor

Paper low sensor

LSI

Outlet sensor

Paper sensor

Inlet sensorl

Power supply

interface

121

160

159

- 21 -

Inlet sensor2

Toner sensor

Front feeder

Paper end sensor

Home position sensor

Stacker cover

Stacker full sensor

Page 25

3.13 Cover Open

When the cover is opened, a cover open microswitch is opened. This makes a XCOVEROPENN signal low, then off the +5VD, thereby the CPU detects the open state. Furthermore, opening

the cover stops applying a +38V power to the high voltage power supply unit, resulting in stopping

all high voltage outputs.

AAA-

CPU

+5V

125

+5VD

COVEROPEN-N

+5VD

0V

Power Supply Board

+38V

COVEROPEN-N

Cover Open

Microswitch

+38V

Cover close Cover open

Low Voltage

Supply Unit

Power

High

Voltage

Power

Supply

Unit

High

voltage

output

- 22 -

Page 26

3.14 Power Supply Interface

The power supply interface is a 16 bit clock synchronous serial interface between the synchronous

serial I/O ports of CPU (IC1: MHM2029K) and the power control LSI in the power supply board

(High voltage) under the control of the CPU (IC1: MHM2029K).

When the control section transmits a command on POWTXD-P signal in synchronization with the

clock (POWSCLK-N) to the power supply board, this power supply board transmits a response on

POWRXD-P signal in synchronization with the same clock to the control section.

The commands include the control data of the high-voltage power supply, etc.

The responses include sensor information, fuser unit temperature information, etc.

AAA-PCB Power Supply Board

POWTXD-P

POWSCLK-N

POWRXD-P

POWLD-N

IC1

(MHM2029K)

Power Supply Board

(120V or 230V)

POWER CN3 CN6 CN7

POWTXD-P

112

POWSCLK-N

111

POWRXD-P

119

POWLD-N

115

LSB

b0 b1 b2 b3 b4 b5 b6 b7 b8 b9 b10 b11 b12 b13 b14 b15

b0 b1 b2 b3 b4 b5 b6 b7 b8 b9 b10 b11 b12 b13 b14 b15

3

3

2

2

4

4

1

1

11

12

10

13

Command

Response

(High voltage)

22

11

2

12

25

10

1

13

LSI

MSB

- 23 -

Page 27

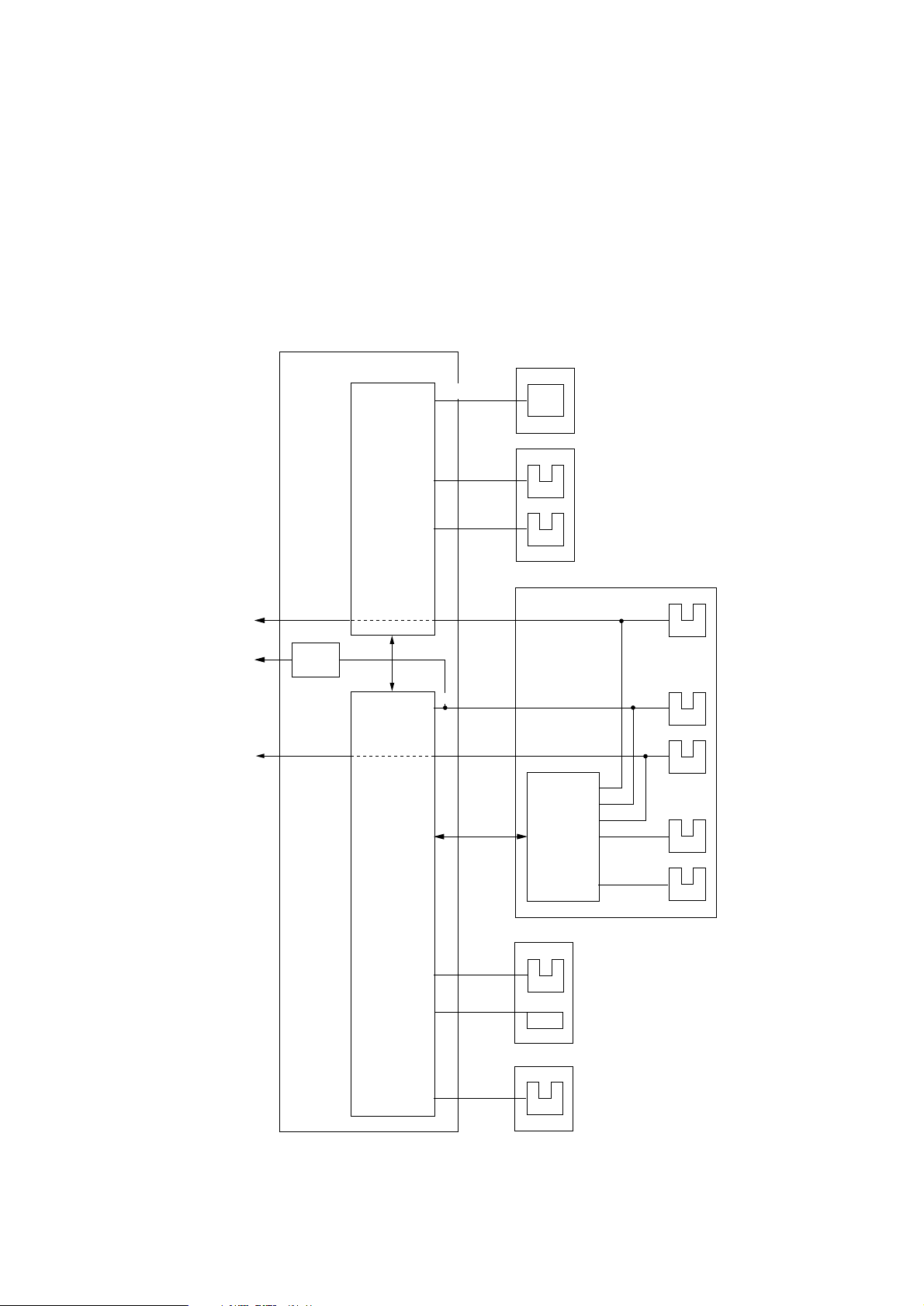

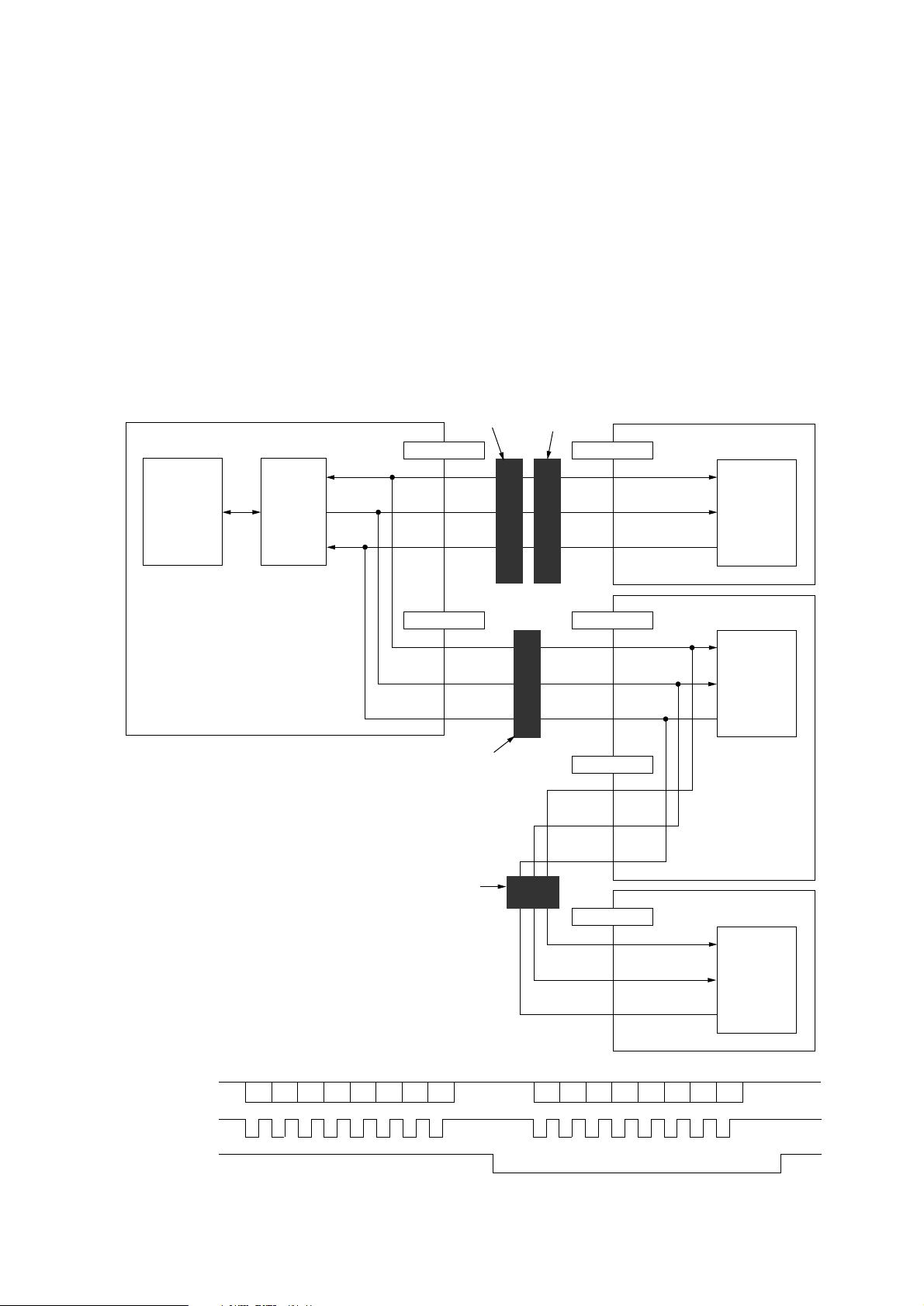

3.15 Option (2nd/3rd paper feeder and Multi feeder) Interface

The option interface is a 8 bit clock synchronous serial interface between the synchronous serial

I/O ports of LSI (IC2: LZ9FF22) and 4 bit micro-controllers in the option control boards under the

control of the CPU (IC1: MHM2029K).

First the control section transmits a command on OPDATA-P signal in synchronization with the

clock (OPSCLK-N) to the option.

The option which receives the command will analyze it and assert OPSDR-N signal after becoming

a ready state for returning a response. When the control section recognizes the OPSDR signal

asserted, it will output a clock signal only at this time.

The option will output a response on the OPDATA-P signal line in synchronization with this clock

signal (OPSCK-N).

The commands include the control data, etc.

The responses include sensor information, etc.

Jackln connector

(14P)

CN1

5

6

4

AOLE-PCB (Multi feeder)

AAA-PCB

IC1

(MHM2029K)

IC2

(LZ9FF22)

82

OPDATA-P

84

OPSCLK-N

83

OPSDR-N

Jackln connector

(22P)

ENVELOPE

3

2

4

Control

circuit

2NDTRAY

3

2

4

Jackln connector

(14P)

Jackln connector

(14P)

BBB-PCB (2nd paper feeder)

MAIN1

3

2

4

MAIN2

3

2

4

BBB-PCB (3rd paper feeder)

MAIN1

3

2

4

Control

circuit

Control

circuit

OPDATA-P

OPSCLK-N

OPSDR-N

COMMAND RESPONSE

b0 b1 b2 b3 b4 b5 b6 b7 b0 b1 b2 b3 b4 b5 b6 b7

- 24 -

Page 28

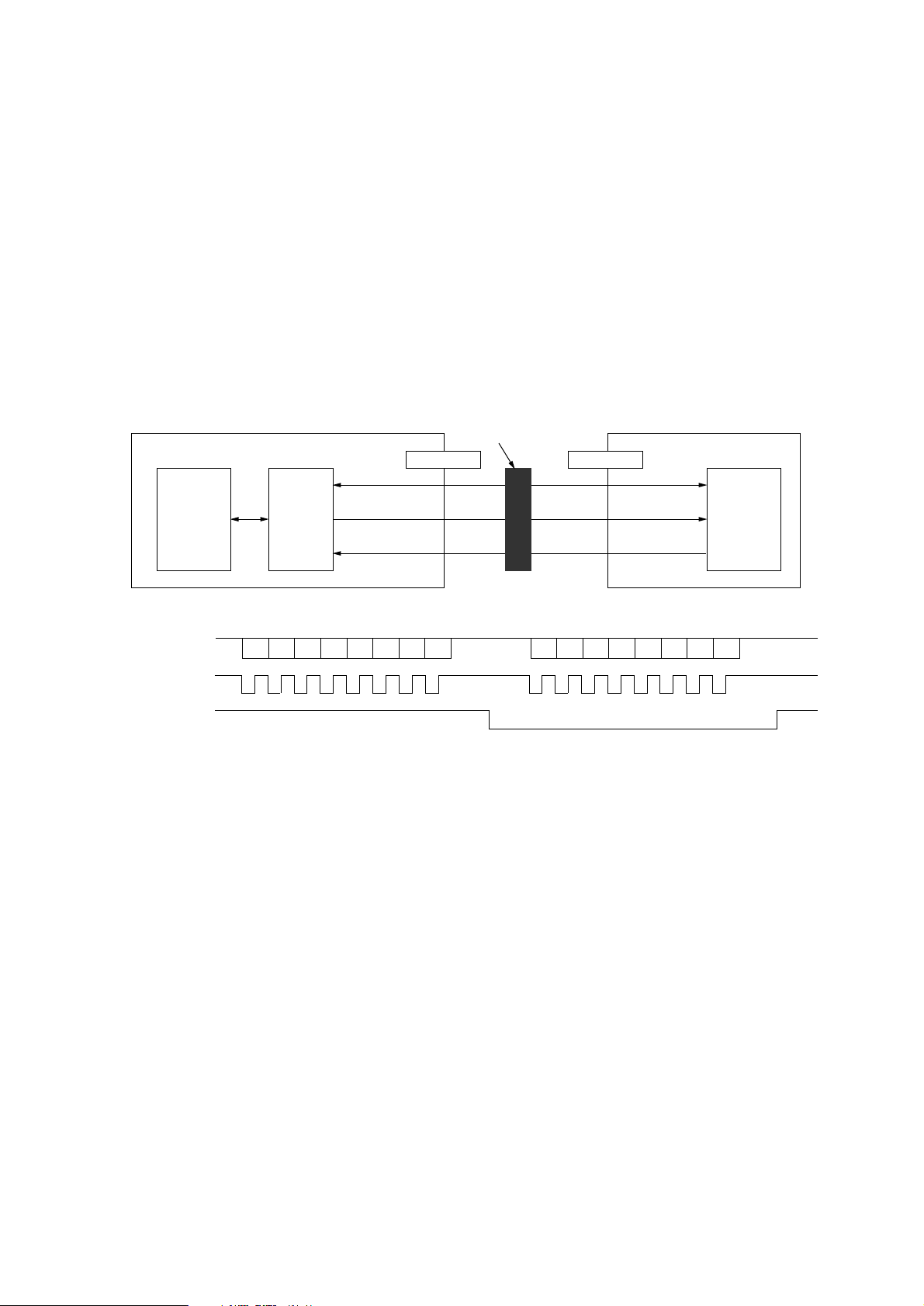

3.16 DUPLEX Interface

The Duplex interface is a 8 bit clock synchronous serial interface between the synchronous serial

I/O ports of LSI (IC2: LZ9FF22) and 8 bit micro-controllers in the option control boards under the

control of the CPU (IC1: MHM2029K).

First the control section transmits a command on DUPDATA-P signal in synchronization with the

clock (DUPSCLK-N) to the Duplex unit.

The Duplex unit which receives the command will analyze it and assert OPSDR-N signal after

becoming a ready state for returning a response. When the control section recognizes the OPSDR

signal asserted, it will output a clock signal only at this time.

The Duplex unit will output a response on the OPDATA-P signal line in synchronization with this

clock signal (OPSCK-N).

The commands include the control data, etc.

The responses include sensor information, etc.

AAA-PCB

IC1

(MHM2029K)

IC2

(LZ9FF22)

86

DUPDATA-P

88

DUPSCLK-N

87

DUPSDR-N

DUP

9

8

11

Jackln connerctor

(14P)

LEX-PCB (Duplex unit)

MAIN

9

8

11

Control

circuit

DUPDATA-P

DUPSCLK-N

DUPSDR-N

COMMAND RESPONSE

b0 b1 b2 b3 b4 b5 b6 b7 b0 b1 b2 b3 b4 b5 b6 b7

- 25 -

Page 29

3.17 Power Supply Board

The power supply circuit consists of the low-voltage power supply circuit and the high-voltage

power supply circuit. The low-voltage power supply circuit adopts a switching power supply system

and provides DC voltages required for the control of the equipment. The high-voltage power supply

circuit receives +38V power from the low-voltage power supply circuit and provides various high

voltages required for the electrophotographic process according to the control signals from the

control section.

(1) Low-voltage power supply circuit

SW

F2

Noise

filter

ACIN

circuit

Switching

circuit

Rectifying/

smoothing/

regulating

circuit

+8V

–8V

+5V

+3.3V

POW ON

+ 5V

+ 3.3V

+ 38V

+ 8V

– 8V

Switching

control

circuit

Overvoltage/

overcurrent

detector

circuit

Rectifying/

smoothing/

regulating

circuit

+38V

- 26 -

Page 30

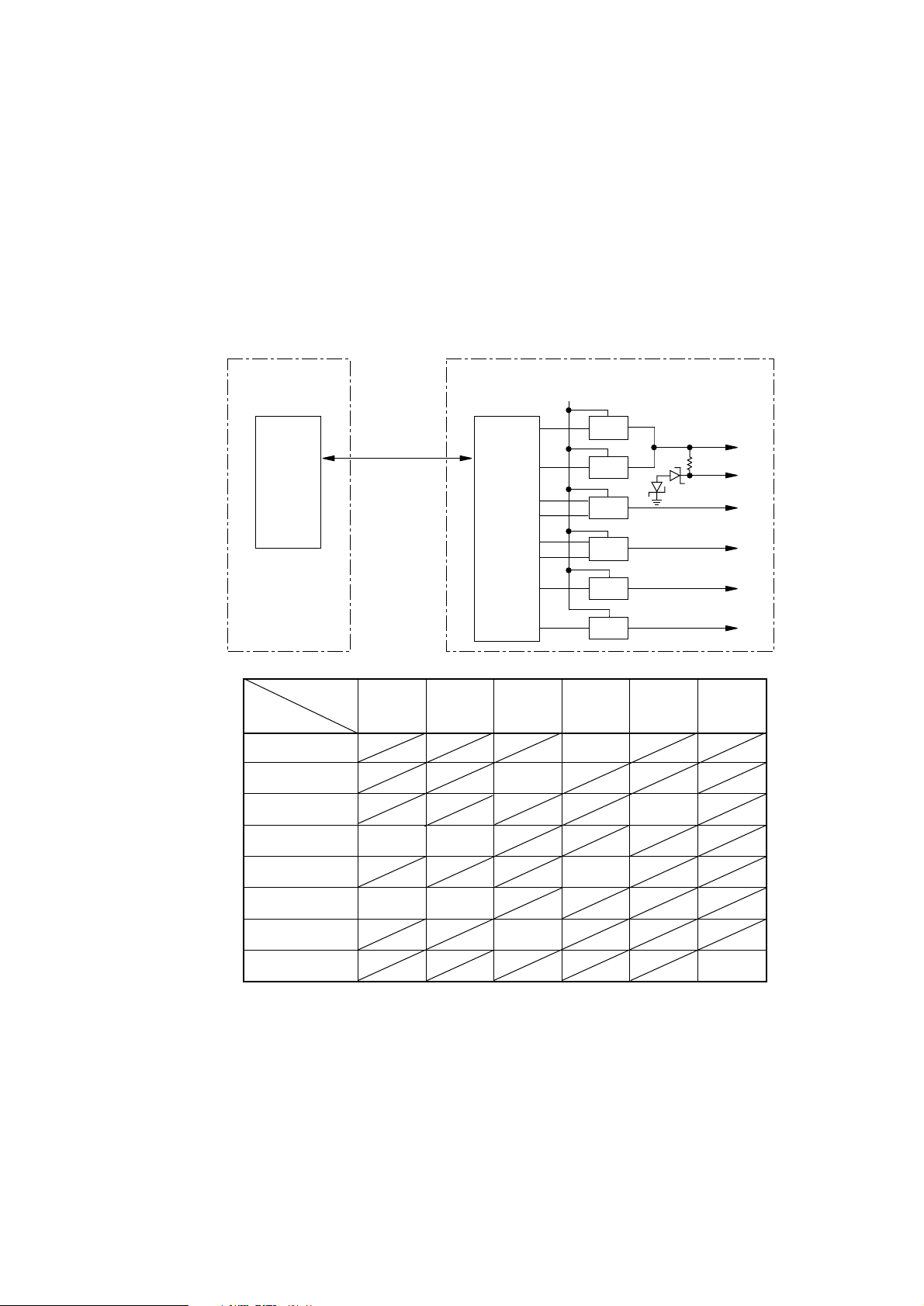

(2) High-voltage power supply circuit

This high-voltage power supply circuit receives the high-voltage generation timing control

command that is transmitted in serial through the power supply interface from the control

section. It decodes this command by LSI (IC1) and outputs high-frequency pulses to the

corresponding high-voltage generating circuits through pins 12, 13, 14, 15, 16, 17 and 18 of

LSI (IC1). It supplies +38V to each high-voltage generating circuit as the source voltage.

When the cover is open, the supply of +38V is interrupted to interrupt all the high-voltage

outputs. The relationship between the high-frequency pulse output pins and the high-voltage

outputs is shown in the following table.

Power Supply Board (High voltage)

+38V

CPU

Power supply

interface

LSI

14

16

12

17

11

15

DB+

DB–

CB

TR

SB

DB

CB

TR

High-voltage

High

-frequency

pulse output pins

outputs

11

12

13

14

15

16

-450V

17

18

CC : Constant Current

CV : Constant Voltage

13

18

SB DB TR CH CL

CB

CH

CL

CC : 0~20µA

CV : 0~5KV

+450V

-1.3KV

0V

+300V

-1.3KV

-220V

-1.35KV

CC : -15

Part with slant line: no output

CH

CL

µ

A

- 27 -

Page 31

4. TROUBLESHOOTING

4.1 Troubleshooting Table

(A) Power/sensor board

Note:

The malfunction of the power supply is not repaired by an agency. The abnormality

to be treated here is taht of sensors only.

Failure LCD Message

A paper input jam occurs frequently.

A paper feed jam occurs frequently.

A paper-exit jam occurs frequently.

A paper size error occurs frequently.

The message "COVER OPEN" remains

displayed on the LCD.

The message "TONER LOW" remains

displayed on the LCD.

PAPER INPUT JAM

CHECK ******

PAPER FEED JAM

CHECK ******

PAPER EXIT JAM

REMOVE THE PAPER

ERROR PAPER SIZE

CHECK ******

COVER OPEN

TONER LOW

Flowchart

No.

A - 1

A - 2

A - 3

A - 4

A - 5

A - 6

The message "TONER SENSOR" remains

displayed on the LCD.

A toner sensor error occurs frequently.

A thermistor open error occurs frequently.

A thermistor short error occurs frequently.

TONER SENSOR

ERROR

77

ERROR

72

ERROR

73

- 28 -

A - 7

A - 7

A - 8

A - 9

Page 32

(B) Main control board (AAA-) (1/3)

Failure LCD Message

Abnormal message display on the LCD

(no display, unclear display, display with

some dot not lit).

Program ROM error

Resident RAM error

EEPROM error

Option ROM error

ERROR

10

ERROR

30

ERROR

40

ERROR

50

ERROR

51

Flowchart

No.

B - 1

B - 2

B - 3

B - 4

B - 5

B - 6Flash SIMM error

Option RAM error

Cooling fan error

Thermistor open error

SSIO error

Opepanel I/F time out error

Option tray I/F timeout error

Duplex I/F timeout error

ERROR

60

ERROR

70

ERROR

72

ERROR

74

ERROR

80

ERROR

81

ERROR

B - 7

B - 8

B - 9

B - 10

B - 11

B - 12

B - 13

83

- 29 -

Page 33

(B) Main control board (AAA-) (2/3)

Failure LCD Message

Watchdog timer timeout

Program error

Processor error

Cover open occurs frequently

Paper input JAM occurs

ERROR

90

ERROR

F*

ERROR CONTROLLER

0*

COVER OPEN

PAPER INUT JAM

CHECK ******

PAPER FEED JAM

CHECK ******

Flowchart

No.

B - 14

B - 15

B - 16

B - 17

B -18

B - 19Paper feed JAM occurs

DUPLEX input JAM occurs

DUPLEX feed JAM1 occurs

Paper size error occurs

The message "STACKER FULL REMOVE

THE PAPER" remains displayed on the LCD

The message "PAPER OUT

******** TRAY1" remains displayed on the LCD

The message "PAPER NEAREND T1" remains

displayed on the LCD

The message "TONER SENSOR" remains

displayed on the LCD

DUPLEX INPUT JAM

REMOVE THE PAPER

DUPLEX FEED JAM1

REMOVE THE PAPER

ERROR PAPER SIZE

CHECK ******

STACKER FULL

REMOVE THE PAPER

PAPER OUT

******** TRAY1

PAPER NEAREND T1

TONER SENSOR

B - 20

B - 21

B - 22

B - 23

B - 24

B - 25

B - 26

- 30 -

Page 34

(B) Main control board (AAA-) (3/3)

Failure LCD Message

Data sent through the centronics I/F cannot be

received

Data sent through the RS232C I/F cannot be

received

(C) Operator panel board (PCO-)

Failure LCD Message

Abnormal message display on the LCD

(no display, display with some dot not lt, etc.)

The key switch operation on the operator

panel is disabled.

Flowchart

No.

B - 27

B - 28

Flowchart

No.

C - 1

C - 2

(D) Cassette switch board (PXC-)

Failure LCD Message

Paper size error occurs

ERROR PAPER SIZE

CHECK TRAY1

Flowchart

No.

D - 1

- 31 -

Page 35

4.2 Troubleshooting Flowchart

A-1 A paper input jam occurs frequently.

• Is PC3 (Inlet Sensor 1) operating normally?

• No Replace PC3.

▼

• Yes Is PC5 (Inlet Sensor 2) operating normally?

• No Replace PC5.

▼

• Yes Failure of IC1.

A-2 A paper feed jam occurs frequently.

• Is PC3 (Inlet Sensor 1) operating normally?

• No Replace PC3.

▼

• Yes Is PC5 (Inlet Sensor 2) operating normally?

• No Replace PC5.

▼

• Yes Is PC2 (Paper Sensor) operating normally?

• No Replace PC2.

▼

• Yes Is PC501 (Outlet Sensor) operating normally?

• No Replace PC501.

▼

• Yes Failure of IC1.

A-3 A Paper exit jam occurs frequently.

• Is PC501 (Outlet Sensor) operating normally?

• No Replace PC501.

▼

• Yes Failure of IC1.

A-4 A paper size error occurs frequently.

• Is PC3 (Inlet Sensor 1) operating normally?

• No Replace PC3.

▼

• Yes Is PC5 (Inlet Sensor 2) operating normally?

• No Replace PC5.

▼

• Yes Failure of IC1.

- 32 -

Page 36

A-5 The message "COVER OPEN" remains displayed on the LCD.

• Replace Cover Open Switch.

A-6 The message "TONER LOW" remains displayed on the LCD.

• Is PC6 (Toner Sensor) operating normally?

• No Replace PC6.

▼

• Yes Failure of IC1.

A-7 The message "TONER SENSOR" remains displayed on the LCD.

A toner sensor error occurs frequently.

• Is PC6 (Toner Sensor) operating normally?

• No Replace PC6.

▼

• Yes Failure of IC1.

A-8 A thermistor OPEN error occurs frequently.

• Is the heater lamp lit?

• No Failure of PC1 (photocoupler)

▼

• Yes Failure of IC1

A-9 A thermistor short error occurs frequently.

• Failure of IC1

- 33 -

Page 37

B-1 Abnormal message display on the LCD.

• Replace IC5–IC8.

▼

• OK?

▼

• No Is the 10.1376 MHz clock signal being put out to pin 1 of OSC1?

• No Replace OSC1.

▼

• Yes Is the output at pin 3 (RESET-N) of TR504

(DTC114EK) normal? (Refer to [3.3 Reset Control] page 7.)

• No Replace TR504 (DTC114EK).

▼

• OK?

▼

• No Replace IC20 (UPC393G2).

▼

• Yes Failure of IC1 (MHM2029K)

B-2 Program ROM error (ERROR10)

• Replace IC5–IC8.

B-3 Resident RAM error (ERROR 30)

• Are negative pulses being put out to Pin 14 (RAS0-N) of IC3, IC4?

• No Are negative pulses being put out to Pin 33 (CRAS0-N) of IC2

(LZ9FF22)?

• No Failure of IC1 (MHM2029K)

▼

• Yes Failure of IC2 (LZ9FF22)

▼

• Yes Are negative pulses being put out to Pins 30, 31 (CAS0-N, CAS2-N, CAS1-N,

CAS3-N) of IC3, IC4?

• No Are negative pulses being put out to Pins 71, 70, 69, 68 (CCAS0-N,

CCAS1-N, CCAS2-N, CCAS3-N) of Q13 (MHM2029K)?

• No Failure of IC1 (MHM2029K)

▼

• YES Replace IC16 (74ALS244).

▼

• Yes Replace IC3, IC4.

B-4 EEPROM error (ERROR 40)

• Replace IC19 (93LC46A).

▼

• OK?

▼

• No Failure of IC1 (MHM2029K)

- 34 -

Page 38

B-5 Option ROM error (ERROR 50)

• Replace PostScript SIMM.

▼

• OK?

▼

• No Failure of IC1 (MHM2029K)

B-6 Flash SIMM error (ERROR 51)

• Replace Flash SIMM.

▼

• OK?

▼

• No Failure of IC1 (MHM2029K)

B-7 Option RAM error (ERROR 60)

• Are negative pulses being pin out to Pins 33, 34, 44, 45 (RAS2-N, RAS3-N, RAS4-N,

RAS5-N) of SIMM1, SIMM2?

• No Are negative pulses being put out to Pin 34, 35, 36, 37 (CRAS2-N,

CRAS3-N, CRAS4-N, CRAS5-N) of IC2 (LZ9FF22)?

▼

• Yes Failure of IC2 (LZ9FF22)

▼

• No Failure of IC1 (MHM2029K)

▼

• Yes Replace SIMM.

B-8 Cooling fan error (ERROR 70)

• Is the fan rotating?

• No Is +38V power being supplied to Pin 1 (FAN POW) of Connector (CN5)

in Power supply board (120V or 230V)?

• No Is the output at Pin 22 (FANON) of Connector (Power) being

▼

▼

• Yes Replace Power supply board (120V or 230V).

▼

• Yes Replace the fan.

at high level?

• No Is the output at Pin 109 (FANON-P) of IC1

(MHM2029K) being at high level?

• No Failure of IC1 (MHM2029K)

• Yes Replace IC17 (74LS07).

▼

• Yes Is the output at Pin 21 (FANALARM) of Connector (Power) being at high level?

• No Failure of IC1 (MHM2029K)

▼

• Yes Replace the fan.

- 35 -

Page 39

B-9 Thermistor OPEN error (ERROR 72)

• Is the heater lamp lit?

• No Is pin 6 of the connector (power) in the OFF state (High level)?

• No Failure of the heater or the Power supply board

▼

• Yes Is pin 3 of TR4 (transistor) in the OFF state (High level)?

• No Replace TR4 (transistor).

▼

• Yes Is pin 3 of TR5 (transistor) in the OFF state (Low level)?

• No Replace TR5 (transistor).

▼

• Yes Failure of IC1 (MHM2029K)

▼

• Yes Failure of the Power supply board (120V or 230V)

B-10 SSIO error (ERROR 74)

• Are POWTXD-P (Power connector-3), POWSCLK-N (Power connector-2) and POWLDN (Power connector-1) operating normally?

• No Replace IC1 (MHM2029K).

▼

• Yes Failure of the Power supply board (High voltage)

B-11 Opepanel I/F Timeout error (ERROR 80)

• Is the connection of connector (PANEL) properly?

• No Replace connector (PANEL).

▼

• Yes Failure of IC1 (MHM2029K)

B-12 Option tray I/F Timeout error (ERROR 81)

• Is the connection of connector (2nd tray) properly?

• No Replace connector (2nd tray).

▼

• Yes Is the connection of connector (envelope) properly?

• No Replace connector (envelope).

▼

• Yes Failure of IC2 (LZ9FF22)

- 36 -

Page 40

B-13 Duplex I/F timeout error (ERROR 83)

• Is the connection of connector (DUP) properly?

• No Replace connector (DUP).

▼

• Yes Failure of IC2 (LZ9FF22)

B-14 Watchdog timer timeout (ERROR 90)

• Replace IC5–IC8.

▼

• OK?

▼

• No Failure of IC1 (MHM2029K)

B-15 Program error (ERROR F*)

• Replace IC5–IC8.

▼

• OK?

▼

• No Failure of IC1 (MHM2029K)

B-16 Processor error (ERROR 0*)

• Replace IC5–IC8.

▼

• OK?

▼

• No Failure of IC1 (MHM2029K)

B-17 Cover OPEN occurs frequently.

• Is the signal at Pin 125 (+5VD) of IC1 (MHM2029K) being at low level?

• Yes Is the signal at Pin 7 of Connector (Power) being at high level (30V)?

• No Failure of an element other than AAA-PCB

▼

• Yes Is the signal at Pin 3 of TR503 being at low level?

• No Replace TR503.

▼

• Yes Is the signal at Pin 3 of TR501 being at high level?

• No Replace TR501.

▼

• Yes Failure of IC1 (MHM2029K)

▼

• No Failure of IC1 (MHM2029K)

- 37 -

Page 41

B-18 PAPER INPUT JAM occurs.

• Is the hopping motor rotating normally?

• No Are the normal waveforms of the HMPH1-P, HMPH2-P and HMON-N

signals as shown in section 3.9 (2) output to pins 13, 8 and 7, 14 of

HOPPING (A2918) respectively?

• No Failure of IC2 (LZ9FF22)

▼

• Yes Is the voltage at Pin 5 of HOPPING (A2918) +38V?

• No Is there the continuity in Fuse FU4?

▼

• Yes Failure of Power supply board (120V or 230V)

▼

• Yes Is the voltage at pin 1, 2, 4 and 17 of HOPPING (A2918) +38V?

• No Replace HOPPING (A2918).

▼

• Yes Failure of Hopping motor

▼

• Yes Is the feeding roller rotating normally?

• No Replace FU4.

• No Does the 2 pin of TR505 is change to High level during the hopping

roller is rotating?

• No Failure of IC2 (LZ9FF22)

▼

• Yes Does the 3 pin of TR1 change to Low level during the hopping motor

is rotating?

• No Replace TR 505.

▼

• Yes Does the 2 pin of TR1 change to High level (+38V) during the hopping

roller is rotating?

• No Replace TR1.

▼

• Yes Failure of clutch

▼

• Yes Can a paper reach the Inlet sensor?

• No Failure of mechanical parts

▼

• Yes Failure of Power supply board (High voltage)

- 38 -

Page 42

B-19 Paper feed JAM occurs

• Is the registration roller normally rotating for paper feed?

• No Does the 2 pin of TR 506 change to High level for paper feed?

• No Failure of IC2(LZ9FF22)

▼

• Yes Does the 3 pin of TR2 change to Low level for paper feed?

• No Replace TR506.

▼

• Yes Does the 2 pin of TR2 change to High level (+38V) for paper feed?

• No Replace TR2.

▼

• Yes Does the connector (CLR) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (CLR).

▼

• Yes Failure of clutch

▼

• Yes Can a paper reach the Paper sensor?

• No Failure of mechanical parts

▼

• Yes Is Paper sensor signal normally input to the 123 pin of the IC1(MHM2029K)?

• No Does the connector (POWER) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (POWER).

▼

• Yes Failure of Power supply board (High voltage)

▼

• Yes Failure of IC1 (MHM2029K)

- 39 -

Page 43

B-20 Duplex input JAM occurs

• Are papers fed to the Duplex unit normally?

• No Are paper sensor signals normally output to the 12 pin of the connector

(DUP)?

• No Replace IC20.

▼

• Yes Does the connector (DUP) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (DUP).

▼

• Yes Failure of Duplex unit or Connection Code-Wire

▼

• Yes Failure of Duplex unit

B-21 Duplex feed JAM 1 occurs

• Is the Duplex unit motor rotating after a paper is fed into the Duplex unit.

• No Are Outlet sensor signals normally input to the 7 pin of the connector

(DUP)?

• No Are Outlet sensor signals normally input to the 8 pin of the

▼

• No Does the connector (POWER) have any trouble?

▼

• Yes Failure of Power supply board (High voltage) or Connection

▼

• Yes Does the connector (DUP) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time)

• No Replace the connector (DUP)

▼

• Yes Failure of Duplex unit or Connection Code-Wire

▼

• Yes Failure of Duplex unit

connector (POWER)?

• Yes Failure of IC2 (LZ9FF22)

(Carry out a connection check towards the connection cord

and connector at the same time)

• No Replace connector(POWER)

Code-Wire.

- 40 -

Page 44

B-22 PAPER SIZE ERROR occurs.

• Do the output signals (PAPER SIZE 0 to 3 -N) at pins 15, 16, 17 and 18 of IC2 (LZ9FF22)

comply with the following table?

Paper size Pin 15

Letter

Executive

A4

Legal 14

Legal 13

B5

A5

L

L

L

H

H

H

H

Pin 16

H

H

L

H

L

H

H

Pin 17

H

L

H

H

H

L

L

Pin 18

H

H

H

L

H

H

L

• No Check to see if the paper size SW of the paper tray is set properly.

▼

• Yes Failure of IC2 (LZ9FF22)

B-23 The message "STACKER FULL REMOVE THE PAPER" remains displayed on the LCD.

• Is the output signal (STKFULL-P signal) at pin 159 of IC1 (MHM2029K) being at low level?

• No Check the stacker full sensor.

▼

• Yes Failure of IC1 (MHM2029K)

- 41 -

Page 45

B-24 The message "PAPER OUT ******** TRAY1" remains displayed on the LCD

• Is there any change in signal (PAPEREND-N) at the pin 21 of the IC2 (LZ9FF22) when

moving the Paper end sensor lever?

• No Does the connector (END) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (END)

▼

• Yes Failure of Paper end sensor or Connection Cord-Wire

▼

• Yes Do the output signals (PAPERSIZE0 to 3 -N) at pins 15, 16, 17 and 18 of IC2

(LZ9FF22) comply with the following table?

Paper size Pin 15

Letter

Executive

A4

Legal 14

Legal 13

B5

A5

L

L

L

H

H

H

H

Pin 16

H

H

L

H

L

H

H

Pin 17

H

L

H

H

H

L

L

• No Does the connector (SIZE) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (SIZE).

▼

• Yes Failure of Paper size sensor board (PXC-PCB) or paper size SW of the

paper tray

▼

• Yes Failure of IC2 (LZ9FF22)

B-25 The message "PAPER NEAREND T1" remains displayed on the LCD

Pin 18

H

H

H

L

H

H

L

• Is there any change in signal (PAPERLOW-N) at the 80 pin of the IC2 (LZ9FF22)?

• No Does the connector (LOW) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (LOW)

▼

• Yes Failure of Paper nearend sensor or Connection Cord-Wire

▼

• Yes Failure of IC2 (LZ9FF22)

- 42 -

Page 46

B-26 The message "TONER SENSOR" remains displayed on the LCD

• Is the main motor rotating normally?

• No Are the normal waveforms of the DMPH1-P, DMPH2-P and DMON-N

signals as shown in section 3.9(1) output to pins 7, 8, 13 and 14 of MAIN

(A2918) respectively?

• No Failure of IC1 (MHM2029K)

▼

• Yes Is the voltage at pin 5 of MAIN (A2918) +38V?

• No Is there the continuity in Fuse FU3?

• No Replace FU3.

▼

• Yes Failure of Power supply board (120V or 230V)

▼

• Yes Is the voltage at pin 1, 2, 4 and 17 of MAIN (A2918) +38V?

• No Replace MAIN (A2918).

▼

• Yes Does the connector (MOTOR) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (MOTOR).

▼

• Yes Failure of Main motor

▼

• Yes Does the connector (POWER) have any trouble?

(Carry out a connection check towards the connection cord and connector at the

same time.)

• No Replace the connector (POWER).

▼

• Yes Failure of IC1 (MHM2029K)

- 43 -

Page 47

B-27 Data sent through the centronics I/F cannot be received.

• Is the signal at Pin 11 (BUSY-P) of connector (CENT) being at low level?

• No Is the signal at Pin 1 (BUSY-P) of IC17 (74LS07) changed as shown

below, at data reception?

ON-LINE

BUSY-P Low

OFF-LINE

High

• No Failure of IC1 (MHM2029K)

▼

• Yes Replace IC17 (74LS07).

▼

• Yes Is the level of the signal at Pin 1 (STB-N) of connector (CENT) changed at data

reception?

• No Make sure of the connection of I/F cable or the operation of the host

computer.

▼

• Yes Is the signal at Pin 3 (ACK-N), IC17 (74LS07) being respectively at low level at

data reception?

• Yes Replace IC17 (74LS07).

• OK?

▼

▼

• No Failure of IC1 (MHM2029K)

• No

- 44 -

Page 48

B-28 Data sent through the RS232C I/F cannot be received

• Is the voltage -8V at the 1 pin of the IC18 (75188)?

• No Does the connector (POWER) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (POWER).

▼

• Yes Failure of Power supply board (120V or 230V) or Connection Code-

Wire

▼

• Yes Is there any change in signal (DEBUGRXD-N) at the 101 pin of the IC1

(MHM2029K) when receiving data from the host computer?

• No Does the connector (RS232C) have any trouble?

(Carry out a connection check towards the connection cord and

connector at the same time.)

• No Replace the connector (RS232C).

▼

• Yes Make sure of setting of a host computer.

▼

• Yes Is there any change in signal (DEBUGTXD-P) at the 2 pin of the IC18 (75188)

when receiving data from the host computer?

• No Failure of IC1 (MHM2029K)

▼

• Yes Is there any change in signal (TXD) at the 2 pin of the connector (RS232C) when

receiving data from the computer?

• No Replace IC 18(75188)

▼

• Yes Does the connector (RS232C) have any trouble?

(Carry out a connection check towards the connection cord and connector at the

same time.)

• No Replace the connector (RS232C)

▼

• Yes Make sure of setting of a host computer.

- 45 -

Page 49

C-1 Abnormal message display on the LCD (no display, display some dot lit, etc.).

• Replace IC2 (HD44780).

▼

• OK?

▼

• No Replace IC3 (MSM5259).

▼

• OK?

▼

• Replace IC1 (BU6152S).

C-2 The key switch operation on the operator panel is disabled.

• Are the level of the signal at Pins, 3, 7, 10, 18, 23, 31 of IC1 (BU6152S) changed from

the high level to the low one by the key switch pushing?

• No Replace SW1 to SW8.

▼

• Yes Is the connection of CN1 correct?

• No Connect it correctly.

▼

• Yes Replace IC1 (BU6152S).

- 46 -

Page 50

D-1 PAPER SIZE ERROR occurs.

• Does the PAPER SIZE 0 signal at pin 4 of CN11 go LOW when SW1 is depressed and

does the same signal go HIGH when SW1 is not depressed?

• No Replace SW1.

▼

• Yes Does the PAPER SIZE 1 signal at pin 3 of CN11 go LOW when SW2 is depressed

and does the same signal go HIGH when SW2 is not depressed?

• No Replace SW2.

▼

• Yes Does the PAPER SIZE 2 signal at pin 2 of CN11 go LOW when SW3 is depressed

and does the same signal go HIGH when SW3 is not depressed?

• No Replace SW3.

▼

• Yes Does the PAPER SIZE 3 signal at pin 1 of CN11 go LOW when SW4 is depressed

and does the same signal go HIGH when SW4 is not depressed?

• No Replace SW4.

▼

• Yes Replace Core Assy. -FFC.

- 47 -

Page 51

5. CIRCUIT DIAGRAM

Figure 5-1(1/17~17/17) Main Controller PCB (AAA-PCB, Rev.4)

Figure 5-2(1/3~3/3) Operation Panel PCB (PCO-PCB, Rev.2)

Figure 5-3(1/1) Cassette Switch PCB (PXC-PCB, Rev.3)

- 48 -

Page 52

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

1000p 50

1000p 50

1000p 50

1000p 50

0.01u 50

1u 16

1u 16

1u 16

10u 16

300

300

300

300

330910

0.1u 25

0.1u 25

0.1u 25

0.1u 25

0.1u 25

0.1u 25

0.1u 25

0.1u 25

0.1u 25

5.1K 1/10W

NOMOUNT NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

220

100

(AAA-1/17) Rev. 4

Figure 5-1 Main Control PCB

- 49 -

Page 53

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

5.1K

5.1K

51

2.7K 1/10W

5.1K 1/10W

2.7K 1/10W

5.1K 1/10W

5.1K

51 1/10W

2.7K 1/10W

2.7K 1/10W

2K 1/10W

2K 1/10W

2K

51

5.1K 1/10W

5.1K 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

0 1/10W

51 1/10W

5.1K

51 1/10W

51 1/10W

51 1/10W

51 1/10W

51

51 1/10W

51 1/10W5151

5.1K 1/10W

5.1K

5.1K 1/10W

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K 1/10W

5.1K 1/10W

0 1/10W

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

(AAA-2/17) Rev. 4

Figure 5-1 Main Control PCB

- 50 -

Page 54

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

5.1K

5.1K

5.1K

5.1K

51

5151515151

51

0.1u 50

0.1u 50

0.1u 50

0.1u 50

5.1K

51

51

51

51

51

51

51

5.1K

5.1K

(AAA-3/17) Rev. 4

Figure 5-1 Main Control PCB

- 51 -

Page 55

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

Ω

Ω

1.5K

2.7K

0.1u 50

3.9K 3.9K

3.9K 3.9K

D504

1K

0.51 0.5W

0.51 0.5W

1.5K

200

10K

330

0.51 0.5W

0.51 0.5W

912mA (5VD=5.0V)

894mA (5VD=4.9V)

Im=0.9A

Im=0.6A

610mA (5VD=5.0V)

598mA (5VD=4.9V)

(AAA-4/17) Rev. 4

Figure 5-1 Main Control PCB

- 52 -

Page 56

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

3.3V

5.1K 5.1K

5.1K 1/10W

5.1K 1/10W

5.1K 1/10W

0.1u 25

0.1u 25

0.1u 25

100

100

100

100

0.1u 25

1K 1/10W

1K 1/10W

1K 1/10W

1K 1/10W

0.1u 25

560p 50

560p 50

560p 50

560p 50

0.1u 25

1K 0.1

15K 1/10W

1K 1/10W

33p 50

33p 50

33p 50

33p 50

33p 50

5.1K

100

100

100

100

0.1u 25

(AAA-5/17) Rev. 4

Figure 5-1 Main Control PCB

- 53 -

Page 57

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

4.3K 1/10W2.2K 1/10W

3.3K 1/10W

3.3K 1/10W

430 1/10W

0.22u 50

0.1u 25

0.1u 50

0.1u 25

1u 16

2.7K

0.1u 50

1.8K

15K

(AAA-6/17) Rev. 4

Figure 5-1 Main Control PCB

- 54 -

Page 58

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

3.3V

3.3V

1.5u 25

56

56

56

56

56

56

56

56

56

56

(AAA-7/17) Rev. 4

Figure 5-1 Main Control PCB

- 55 -

Page 59

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

1.2K

1.2K

200

240 1/10W

240 1/10W

240 1/10W

2.7K 1/10W

10K 1/10W

1K 1/10W 1K 1/10W

470 1/10W

0.1u 25

10u 50

2.7K

0.1u 25

10u 50

(AAA-8/17) Rev. 4

Figure 5-1 Main Control PCB

- 56 -

Page 60

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

1/10W 3.3K

1/10W 3.3K

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

22 0.063W

22 0.063W

22 0.063W

22 0.063W

22 0.063W

22 0.063W

22 0.063W

22 0.063W

10K 1/10W

10K 1/10W

1K 1/10W

100 1/10W 1K

0

3.3K

1A

0.1u 25

(AAA-9/17) Rev. 4

Figure 5-1 Main Control PCB

- 57 -

Page 61

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

5.1K 1/10W

5.1K 1/10W

0.1u 25

0.1u 25

5.1K 1/10W

5.1K 1/10W

0.1u 25

19323128181716151413123334454442414340

47112946486671

103059

13972

103059

13972

646260585654525038

19323128181716151413123334454442414340

47112946486671

646260585654525038

10 100u

(AAA-10/17) Rev. 4

Figure 5-1 Main Control PCB

- 58 -

Page 62

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

5.1K

0.1u 25

5.1K

5.1K

5.1K

1K

0.1u 25

0.1u 25

10u 16

SOCKET

NOMOUNT

FSIMM1

HDD

100

(AAA-11/17) Rev. 4

Figure 5-1 Main Control PCB

- 59 -

Page 63

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 50

0.1u 50

0.1u 25

0.1u 25

220u 16

5.1K 1/10W

5.1K 1/10W

5.1K 1/10W

5.1K 1/10W

5.1K

5.1K

5.1K

NOMOUNT

100p 50

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

MUPIS

(AAA-12/17) Rev. 4

Figure 5-1 Main Control PCB

- 60 -

Page 64

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

0.1u 250.1u 250.1u 25

100u 10

200

100

(AAA-13/17) Rev. 4

Figure 5-1 Main Control PCB

- 61 -

Page 65

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

0.1u 25

0.1u 25

0.1u 25

123

4

876

5

123

4

876

5

123

4

876

5

123

4

876

5

123

4

876

5

123

4

876

5

123

4

876

5

123

4

876

5

(AAA-14/17) Rev. 4

Figure 5-1 Main Control PCB

- 62 -

Page 66

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

0.1u 25

0.1u 25

0.1u 25

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

100 1/10W

NOMOUNT

IC6 SOCKET

NOMOUNT

IC8 SOCKET

NOMOUNT

IC5 SOCKET

NOMOUNT

IC7 SOCKET

(AAA-15/17) Rev. 4

Figure 5-1 Main Control PCB

- 63 -

Page 67

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

0.1u 25

0.1u 25

0.1u 25

0.1u 25

0.1u 25

(AAA-16/17) Rev. 4

Figure 5-1 Main Control PCB

- 64 -

Page 68

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

3.3K

3.3K

0.1u 50

0.1u 50

0.1u 50

(AAA-17/17) Rev. 4

Figure 5-1 Main Control PCB

- 65 -

Page 69

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

200 1/10W

200 1/10W

200 1/10W

200 1/10W

200 1/10W

200 1/10W

200 1/10W

200 1/10W

200 1/10W

(PCO-1/3) Rev. 2

Figure 5-2 Operation Panel PCB

- 66 -

Page 70

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

7.5K 7.5K 7.5K 7.5K 7.5K 7.5K

91K

10K

10K

10K

10K

10K

10K

10K

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

(PCO-2/3) Rev. 2

Figure 5-2 Operation Panel PCB

- 67 -

Page 71

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

0.1u 25

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

1234567891011121314151617181920222324252627282930313233343536373839404142

44

(PCO-3/3) Rev.2

Figure 5-2 Operation Panel PCB

- 68 -

Page 72

123 45678 9XY

123 45678 9XY

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

(PXC-1/1) Rev. 3

Figure 5-3 Cassette Switch PCB

- 69 -

Page 73

6. COMPONENT PARTS LIST

Main Controller PCB (AAA-PCB, Rev.4) 40285702

Operation Panel PCB (PCO-PCB, Rev.2)

Cassette Switch PCB (PXC-PCB, Rev.3) 40368602

- 70 -

Page 74

FRONT

HOPPING

MAIN

917171413111213 4

1

2

5

6

ENVELOPE

MOTOR

ENDLOW2NDTRAY

CLRCLH

PANEL

IC19

MUPIS

A1

C1

A32

C32

1

2

71

72

1

2

71

72

1

2

71

72

CENT

RS232C

1

14

13

25

18

36

1

19

HDD

FSIMM1 SIMM1 SIMM2

STKFULL

NW

HEAD2

HEAD1

IC17

DUP

POWER

SIZE

1

2

1

2

25

26

5

6

112

12

11

2

1

13

14

1

157

104

53

208

156

1

105

52

2

1

13

12

3

1

44

43

81

80 51

130

100

50

31

2

1

BF1

BF6

BF9D1BF10

BF11

FU2

BF12

BF7

C3

C39

PS4

C12

C33

R61

R17

R13

R62

R63

C34

C22

R27

R24

R32

R28

R33

R26

R59

R60

R89

C44

C43

C27

C26

C25

C24

R5

R15

R55

C19

C18

C17

C20

C21

R37

R6

R7

R54

R70

R23

C32

R9

R12

R11

R10

R16

R14

R58

R20

R19

R18

R21

RM4RM3RM7

C1

RM8

RM6RM5

C13

TR2TR1

FU4

FU3

R2R1

R4R3

C14

C15

C6

C11

C7

C9

IC20

R94

C5

C41

IC2

BF5

BF4

BF3

OSC1 C28

RM20RM19

RM22RM21

RM18RM17

IC5IC6

FU1

FU5

BF2

IC7IC8

IC16

EM6

R87

R86

TR3

IC21

R84

R85

R29

R88

R51

R46

R49

R50

R77

R53

R45

R47

R52

R73

R68

R48

R22

R25

R91

R56

IC3

IC4

IC15

IC16

R95

IC14

IC13

IC12

IC11

RM1RM2

RM9RM10 RM11 RM12

IC10

IC9

IC22

RM13 RM14 RM15 RM16

BF8

C40

TR4 TR5

R72

R30

R69

C16

R42

R71

R40

R41

R64

R75

R74

R67

R43

R38

R39

R44

C42

C8

IC1

C4

TA1

R90

R93

125

3

Reflow surface

2

1

124

123

121

122

120

124

122

119

126

Main Controller PCB (AAA-PCB) Rev. 4

(40285702 - 1/10)

- 71 -

Page 75

R593

R564

C533

C524

C517

C502

C513

C512

C519

TR504

TR503 TR501

TR502

R506

D501

D504

D505

TR505

TR506

R608

R532

C530

C592

C515

C593

C538

C520

C527

C532

C537

C539

C552

R525

C528

R700

C590

C591

C525

R517

R514

R513

R512

R526

R681

C554

R553

C562

C558

C555

C561

C557

R576

D503D502

C553

C568

C567

C566

C565

R628

R592

R591

R590

R589

R588

R587

R542

R541

R540

R539

R538

R716

R708

R715

R707

R714

R706

R713

R705

C560

R563

R562

R561

R560

R559

R558

C578

C577

C536

C535

C534

C523

C522

C521

C516

C595 C594

R701

R709

R702

R710

R703

R711

R704

R712

R509

R505

R504

C508

R503

C507

R502

C506

C505

R501

R516

C518

R515

R523

C526

R522

C564

R570

R615

C585

R613

R627

C588

R625

R612

C584

R610

R624

C587

R622

R621

R620

C586

R609

C583

C563

R569

R568

R567

R566

R565

R533

R531

R507

R506

C509

R536

R535

R534

C549

C548

C547

C546

R545

R577

C572

C571

C570

C569

C576

C575

R580

C574

C573

R578

R692

R699

R691

R698

R690

R697

R689

R685

R693

R686

R694

R687

R695

R688

R696

C514