Page 1

OKIP AGE 10i

LED Page Printer

T roubleshooting Manual

with Component Parts List

ODA/OEL/INT

All specifications are subject to change without notice.

Page 2

CONTENTS

1. OUTLINE.........................................................................................................1

2. TOOLS............................................................................................................1

3. CIRCUIT DESCRIPTION................................................................................2

4. TROUBLESHOOTING..................................................................................36

5. CIRCUIT DIAGRAM........................................................................................6

6. COMPONENT PARTS LIST

Page 3

1. OUTLINE

This manual has been written to provide guidance for troubleshooting of the OKIPAGE 10i Printer

(primarily for its printed circuit boards), based on the assumption that the reader has a thorough

knowledge concerning the printer. Read the maintenance manual for this printer, if necessary.

Notes:

1. The power supply board containing a high voltage power supply is dangerous. From the

viewpoint of the safety standards, the local repairing of a defective board is not allowed. Thus,

the objects to be locally repaired as a result of troubleshooting are switches and fuses.

2. Replacement of CPU (MHM2029) is not recommended. If CPU is found to be defective,

board replacement is suggested.

2. TOOLS

For troubleshooting the printer, the tools listed below may be needed in addition to general

maintenance tools.

Tool Remarks

Extension cord kit

Oscilloscope

Soldering iron

P/N: 40581901

Frequency response 100 MHz or higher

A slender tip type, 15-20 watts

- 1 -

Page 4

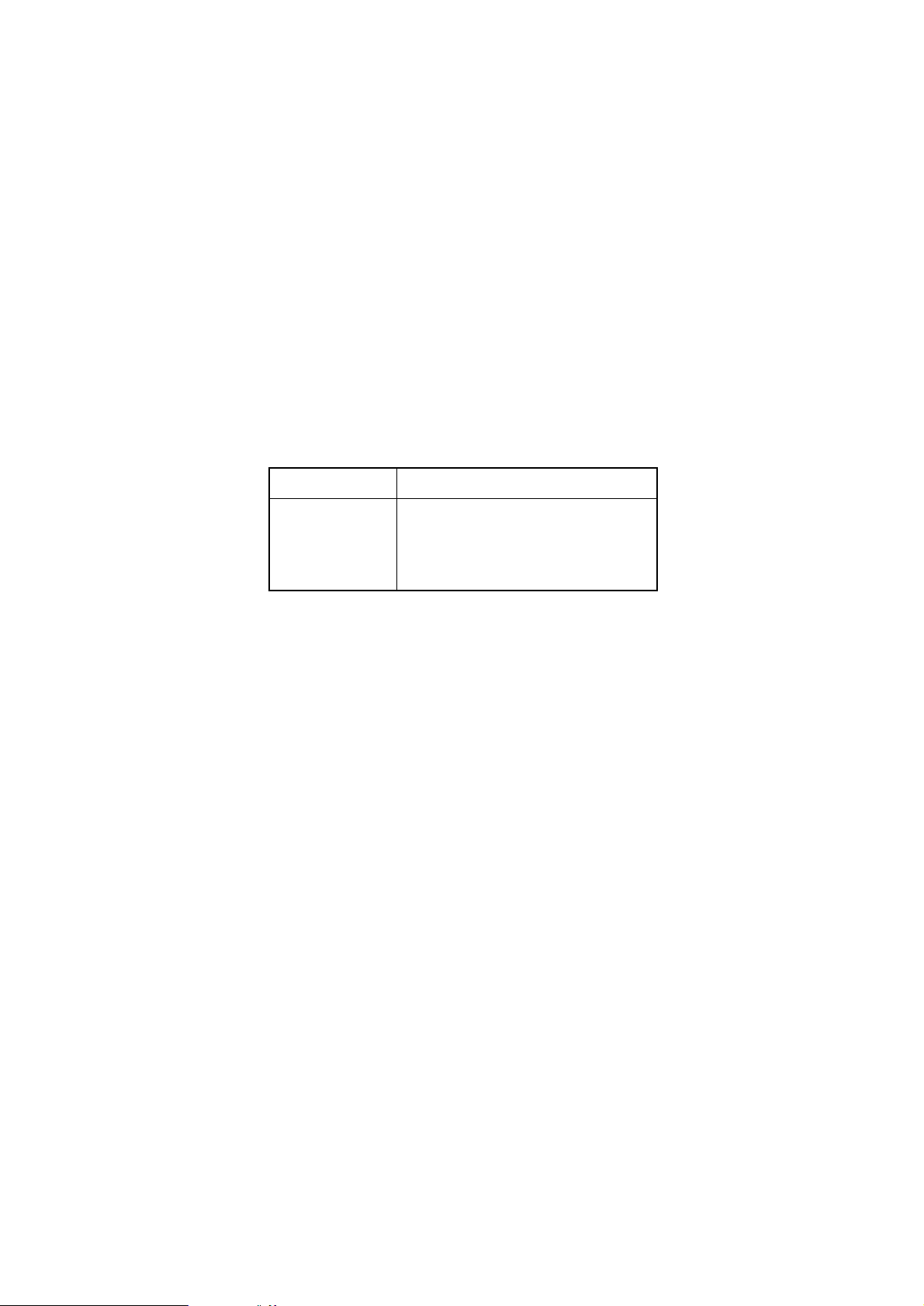

3. CIRCUIT DESCRIPTION

3.1 Outline

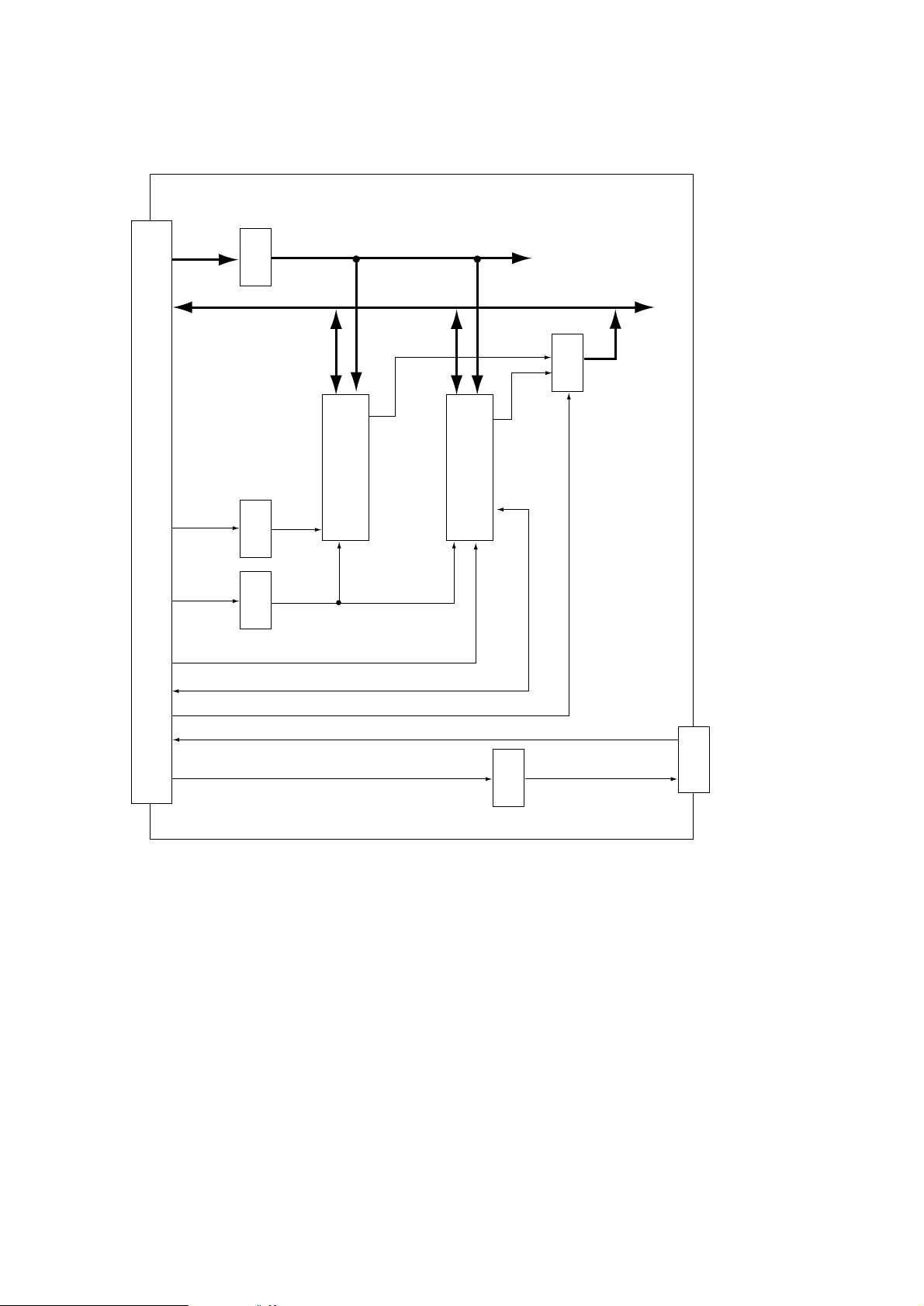

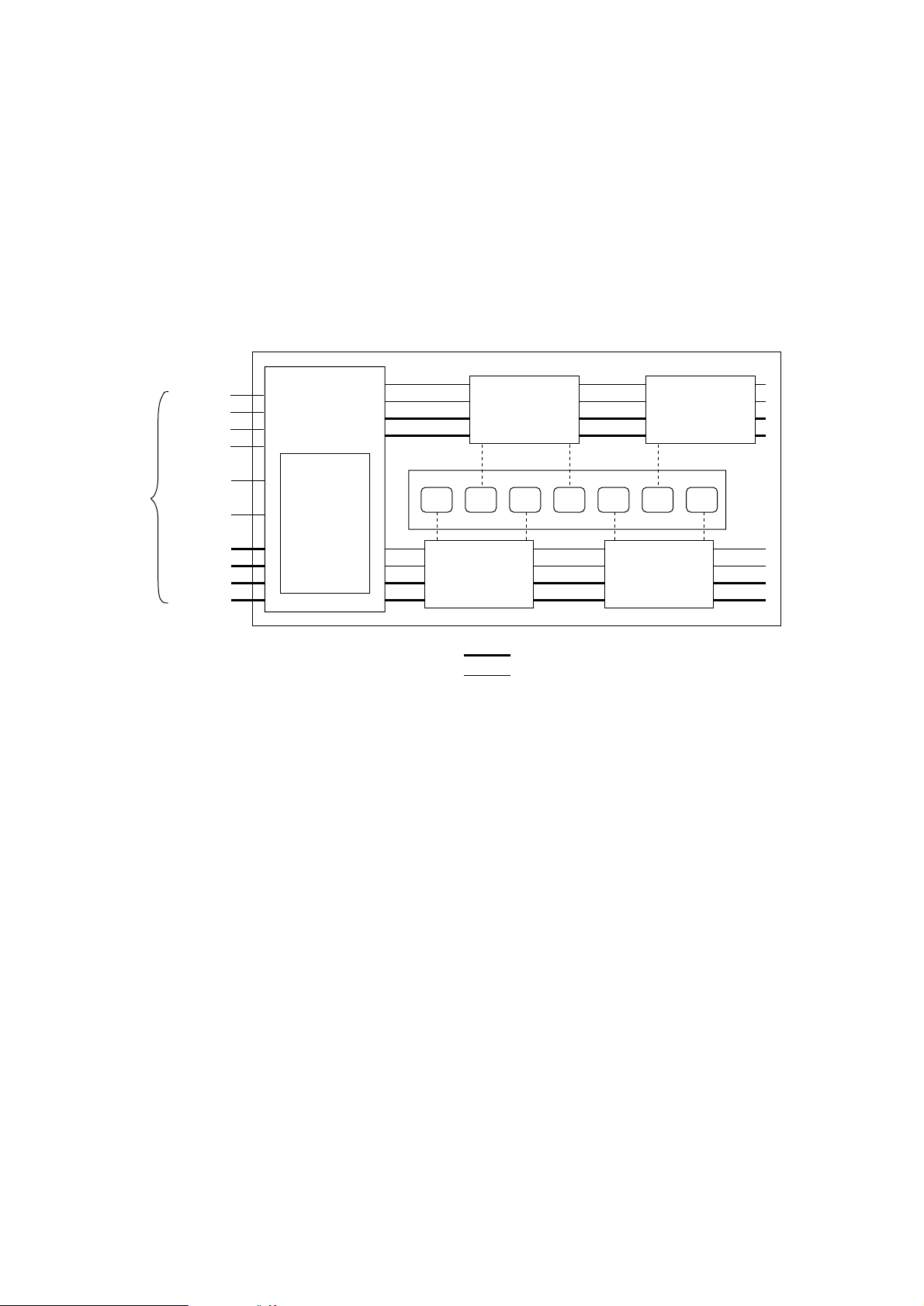

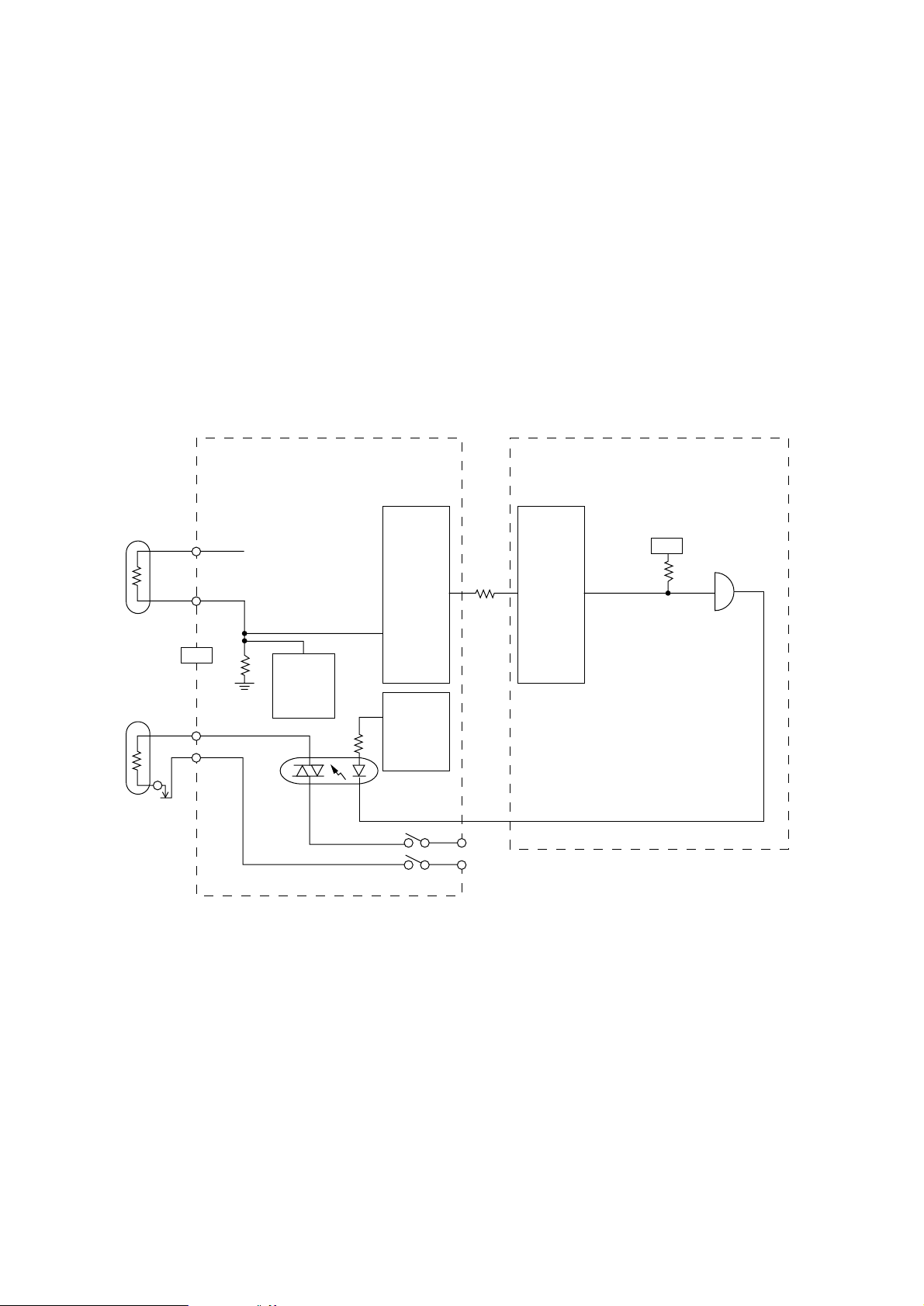

The main control board controls the reception of data transferred through a host I/F and processes

command analysis, bit image development, raster buffer read. It also controls the engine and the

operator panel. Its block diagram is shown in Fig. 3-1 and 3-2.

(1) Reception control

OKIPAGE 10i Printer can be equipped with two I/F ports by adding an RS232C I/F or network

I/F option board in addition to the Centronics I/F on the main control board.

Either of the two I/F ports which receives data first can be used automatically.

The other I/F port outputs a busy state signal.

The parallel I/F port can specify the following item when set by the control panel:

I-PRIME: Enabled/Disabled

The serial I/F port can specify the following item when set by the control panel:

Flow control : DTRHI/DTR LO/XONXOFF/RBSTXON

Baud rate : 300/600/1200/2400/4800/9600/19200 (Baud)

Data bit : 7/8 (bits)

Minimum busy time : 200/1000 (ms)

Parity : NONE/ODD/EVEN

An interface task stores all data received from the host into a receive buffer first.

(2) Command analysis processing

The OKIPAGE 10i printers support PCL6 (Hewlett Packard LJ6P compatible).

An edit task fetches data from the receive buffer, analizes commands, and reconstructs the

data in such a way that print data are aligned from up to down and from right to left; then it

writes the resultant data into a page buffer with such control data as print position coordinate,

font type, etc. added.

(3) Font Processing

When one page editing is finished, a developing task makes an engine start and fetches data

from the page buffer synchronizing with a printing operation; then it developes the fetched

data to a bit map as referring to data from a character generator, and writes the resultant data

into the raster buffer (of band buffer structure).

(4) Raster buffer read.

As controlling the engine operation, an engine task sends data from the raster buffer to the

LED head.

- 2 -

Page 5

1MB Memory Board

(Option)

RS232C Interface Board

or

(Option)

Network Interface Board

or

(Option)

Main Control Board

Program & Font ROM

6MB Mask ROM

EEPROM

Centronics

parallel I/F

7407

+8V -8V 0V +5V+30V

Reset

circuit

For optional board

DATA

BUS

(32bit)

1 Chip CPU

Resident RAM

512K x 8 DRAM

(2MB)

Drum motor &

Registration motor

HEAT ON

drive circuit

FAN Driver

Multi-Purpose

Feeder (Option)

High Capacity

Second Paper

Feeder (Option)

Operation Panel

Drum Motor

MMRegistration Motor

FAN

FAN ALM

LED Head

Power Supply

Board

Inlet sensor 1

Inlet sensor 2

Paper sensor

Outlet sensor

Paper out sensor

Toner low sensor

Cover

open

switch

Low voltage

generation circuit

LSI

AC

transformer

Charge roller

Transfer roller

High voltage

generation

circuit

Fusing temperature

control circuit

Heater drive

circuit

Filter circuit AC IN

Developping

roller

Toner supply

roller

Cleaning

roller

Thermistor

Heater

Figure 3-1 Block Diagram

- 3 -

Page 6

A2 to A23

D0 to D31

CAS0 to

CAS3

ALS244ALS244ALS244

DRAM

1M Byte

SIMM1

DRAM SIMM

PD2, 3

ALS244

BSY

SIMM2

PS SIMM or Flash SIMM

OPTION CONNECTOR

RAS2 to

RAS4

ORE, RD,

WR

CS3, EEPCS, EECLK

EEPDAT

IOS1

Figure 3-2 Memory Expansion Board Block Diagram (Option)

RAS2

ORE

WR

RAS3, 4

WR

RD

WR

- 4 -

Page 7

A2 to A23

D0 to D31

CAS0 to

CAS3

ALS244ALS244

SIMM1

DRAM SIMM

PD2, 3

ALS244

BSY

SIMM2

PS SIMM or Flash SIMM

OPTION CONNECTOR

RAS2 to

RAS4

ORE, RD,

WR

CS3, EEPCS, EEPCLK

EEPDAT

IOS1

TXD, RST, DTR

ALS244

Figure 3-3 RS-232C Serial Interface Board Block Diagram (Option)

RAS3, 4

WR

RD

WR

RXD

RS-232C

CONNECTOR

75188

- 5 -

Page 8

A2 to A23

D0 to D31

ALS244ALS244ALS244

PD2, 3

ALS244

CAS0 to

CAS3

OPTION CONNECTOR

RAS2 to

RAS4

ORE, RD,

WR

CS3, EEPCS, EEPCLK

EEPDAT

IOS1

CS2

IOS0

INT2, DMARQ

Figure 3-4 Network Interface Board Block Diagram (Option)

SIMM1

DRAM SIMM

RAS3, 4

WR

BSY1

SIMM2

PS SIMM or Flash SIMM

RD

WR

RD

WR

BSY2

CS2

Flash ROM

0.5M Byte

LZ9FF22

CS 8900

Puls

Traus

10 base T

CONNECTOR

- 6 -

Page 9

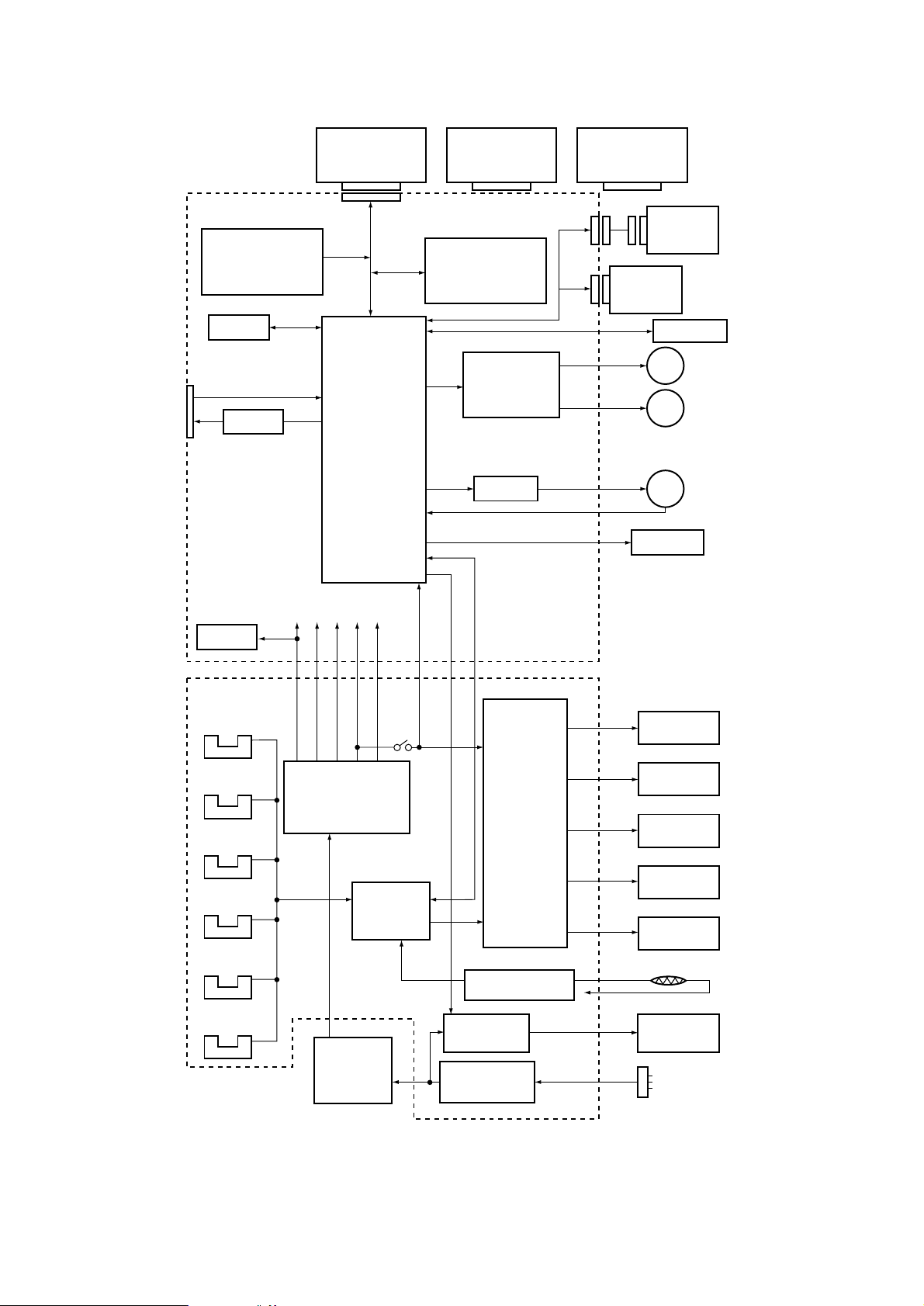

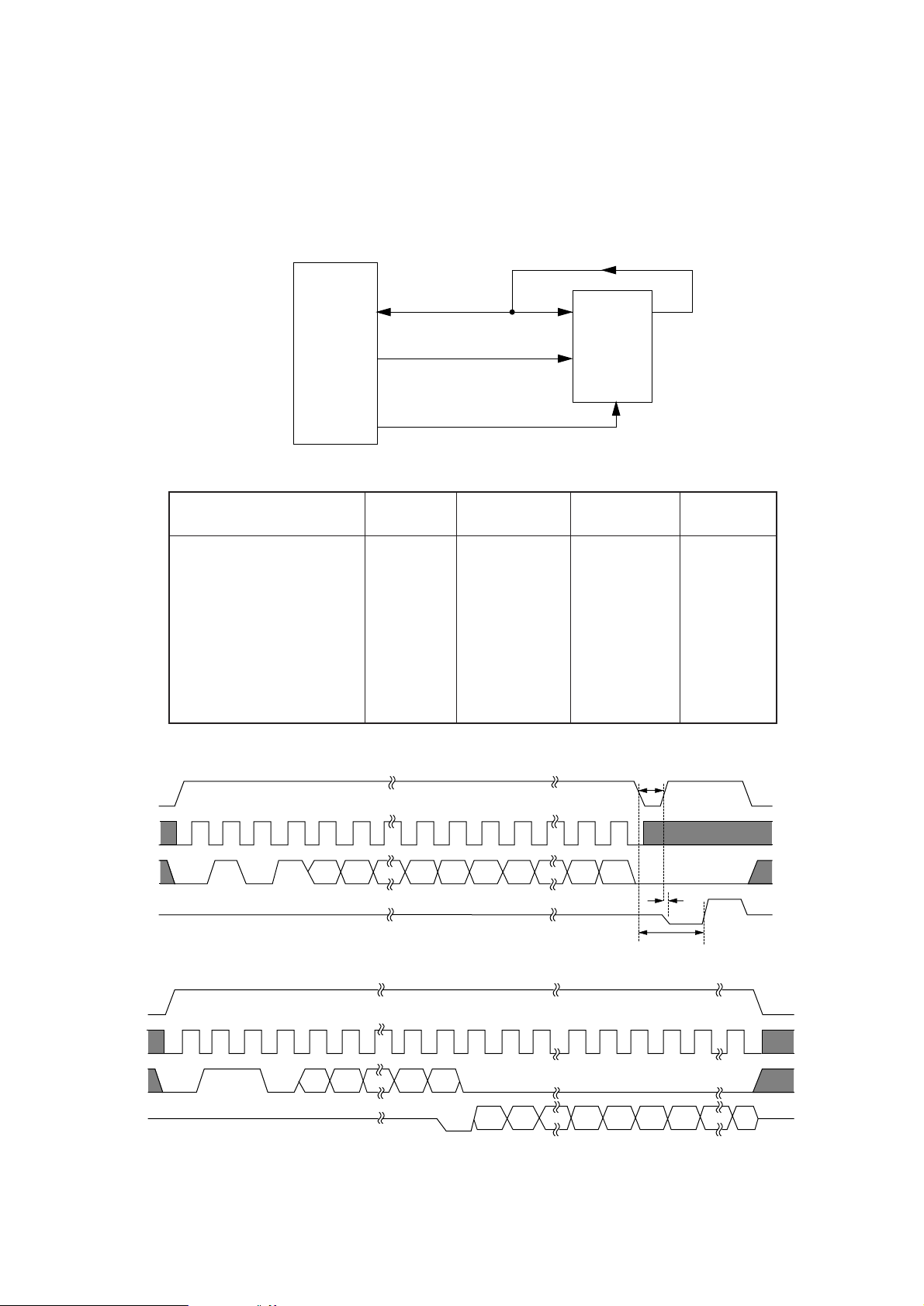

3.2 CPU and Memory

(1) CPU (MHM2029-004K)

CPU core RISC CPU (MIPS R3000 compatible)

CPU clock 7.067 MHz

Internal CPU CLK 28.268 MHz

(2) Program and Font ROMs

ROM capacity 6M bytes (24M bit mask ROM two pieces)

ROM type 24M bits (1.5M x 16 bits)

Access time 100 ns

(3) Resident RAM

RAM capacity 2M bytes (4-Mbit D-RAM four pieces)

RAM type 4M bits (512k x 8 bits)

Access time 80 ns

(4) Option Board

RAM capacity (chip) 1M byte

RAM type (chip) 4M bits D-RAM two pieces Memory Expansion Board only

Access time (chip) 80 ns

SIMM 1 socket 2, 4, 8, 16 or 32M bytes, 72 pin DRAM SIMM, 60 to 100 ns

SIMM 2 socket PS-SIMM or Flash SIMM (72 pin)

}

Flash ROM capacity (chip) 0.5 M byte

Flash ROM type (chip) 4M bits Flash ROM one pieces

Access time (chip) 100 ns

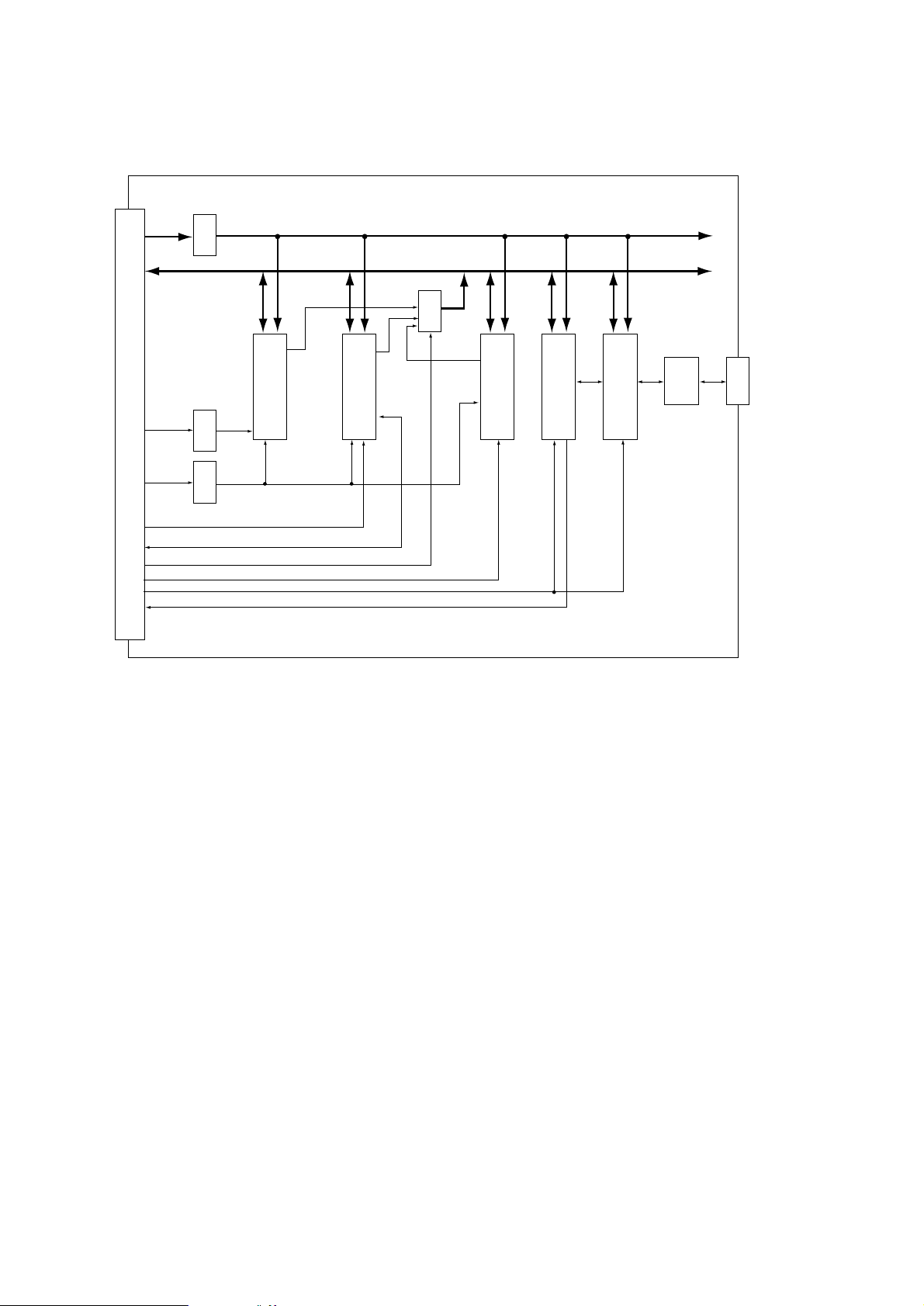

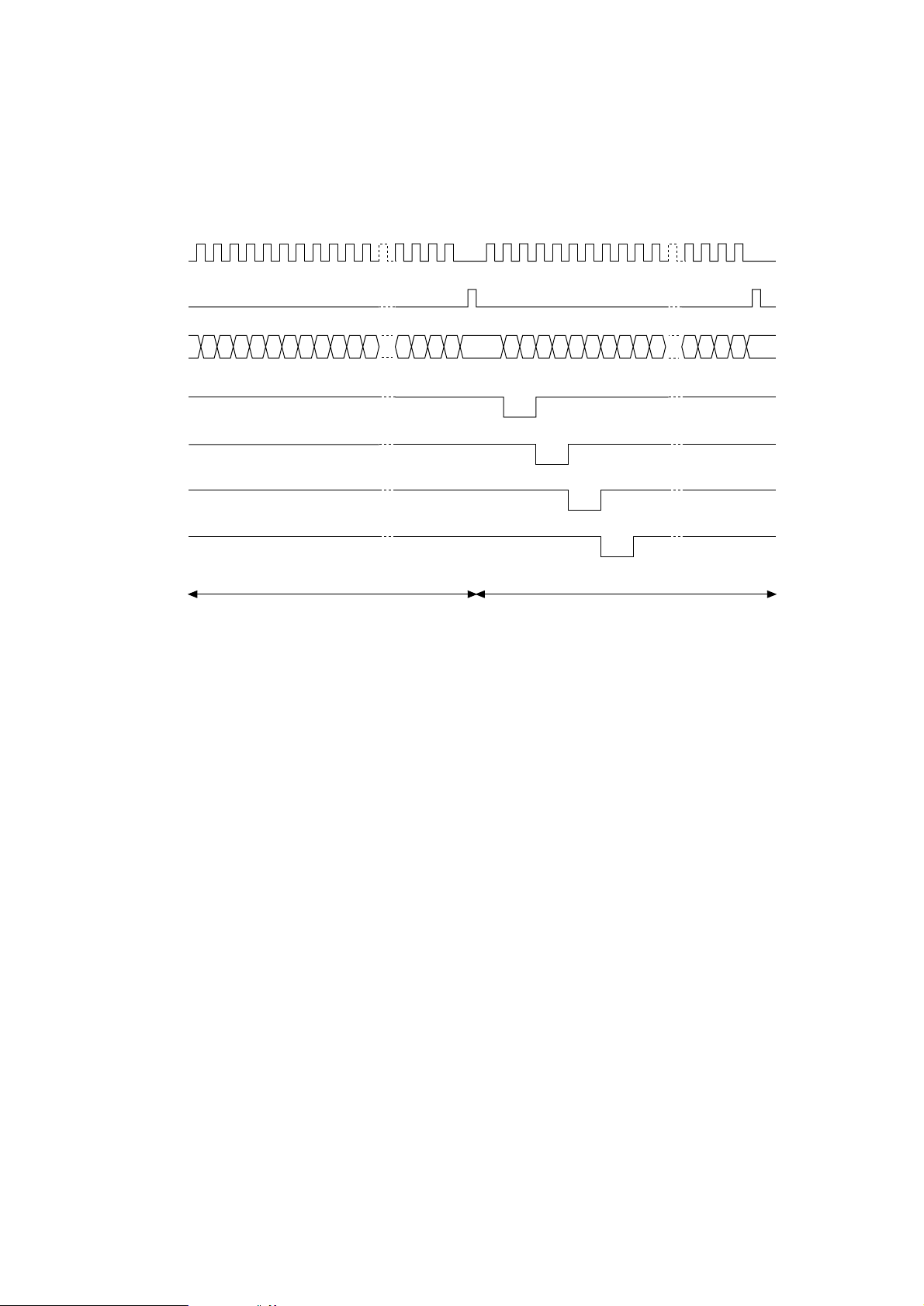

The block diagram of CPU and memory circuit is shown in Fig. 3-3.

The timing chart of CPU and memory ciucuit is shown in Fig. 3-4.

- 7 -

Page 10

CPU

CS0

CS2

CS3

CS4

RAS0

RAS1

RAS2

RAS3

RAS4

RAS5

Option board

A00 to A25

D00 to D32

CS0

RD

IC2, IC3

Mask ROM

(1.5M x 16 bits)

2 pieces

<Program>

CAS0

CAS1

CAS2

CAS3

RAS0

RD/WR

CAS0, 1, 2, 3

RAS2, 3, 4, 5CAS0, 1, 2, 3 RD/WR

RAS2 WR

CAS0,1,2,3

RAS3, 4 WR

CAS0,1,2,3

CS3, RD/WR

IC4, IC5, IC6, IC7

DRAM

(512 k x 8 bits)

4 pieces

Main

control

board

Option

board

DRAM

1M Byte

(Memory Expansion Board only)

SIMM 1

DRAM SIMM

SIMM 2

PS SIMM or

Flash SIMM

Flash ROM

CS2, RD/WR

0.5M byte

(Network Board only)

Figure 3-8 Block Diagram of CPU & Memory Circuit

- 8 -

Page 11

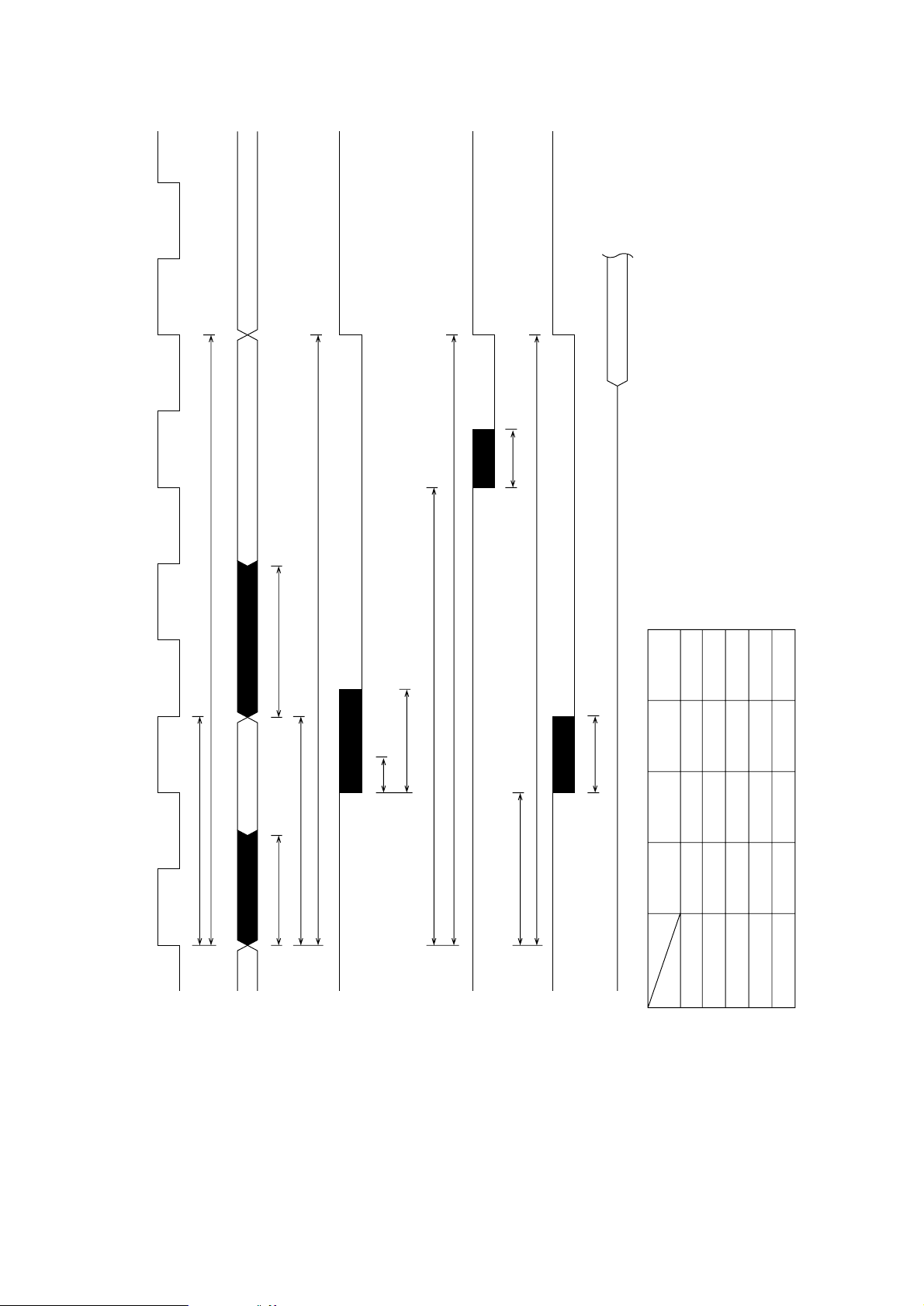

DATA

T1

T2

VARIDVARID

39.13

29.32

T3

T2

(DRAS1~5-N)

(DRAS0-N)

27.3

12.25

T4

T2

14.6

T3

T2

17.91

CPU detects the type of SIMM memory installed on the memory

expansion board, and sets the suitable timing as shown in the left

handside table.

Due to this, T1~T4 values shown above vary depending on the type

of SIMM memory being used.

122.1 ns

142.4 ns

142.4 ns

142.4 ns

142.4 ns

40.7 ns

61.0 ns

61.0 ns

61.0 ns

61.0 ns

162.8 ns

183.1 ns

223.8 ns

223.8 ns

223.8 ns

T1 T2 T3 T4

61.0 ns

101.7 ns

101.7 ns

101.7 ns

101.7 ns

0 17.7 35.4 53.1 70.8 88.4 106.1 123.8 141.5 159.2 176.9 (ns)

(28.268 MHz)

SYSCLK

A00-A25-P

DRAS0~5-N

DCAS0~3-N

RD-N

Figure 3-9 Timing Chart of CPU & Memory Circuit

- 9 -

TIME

SIMM speed

D00~D31-P

60 ns

No SIMM

70 ns

80 ns

100 ns

Page 12

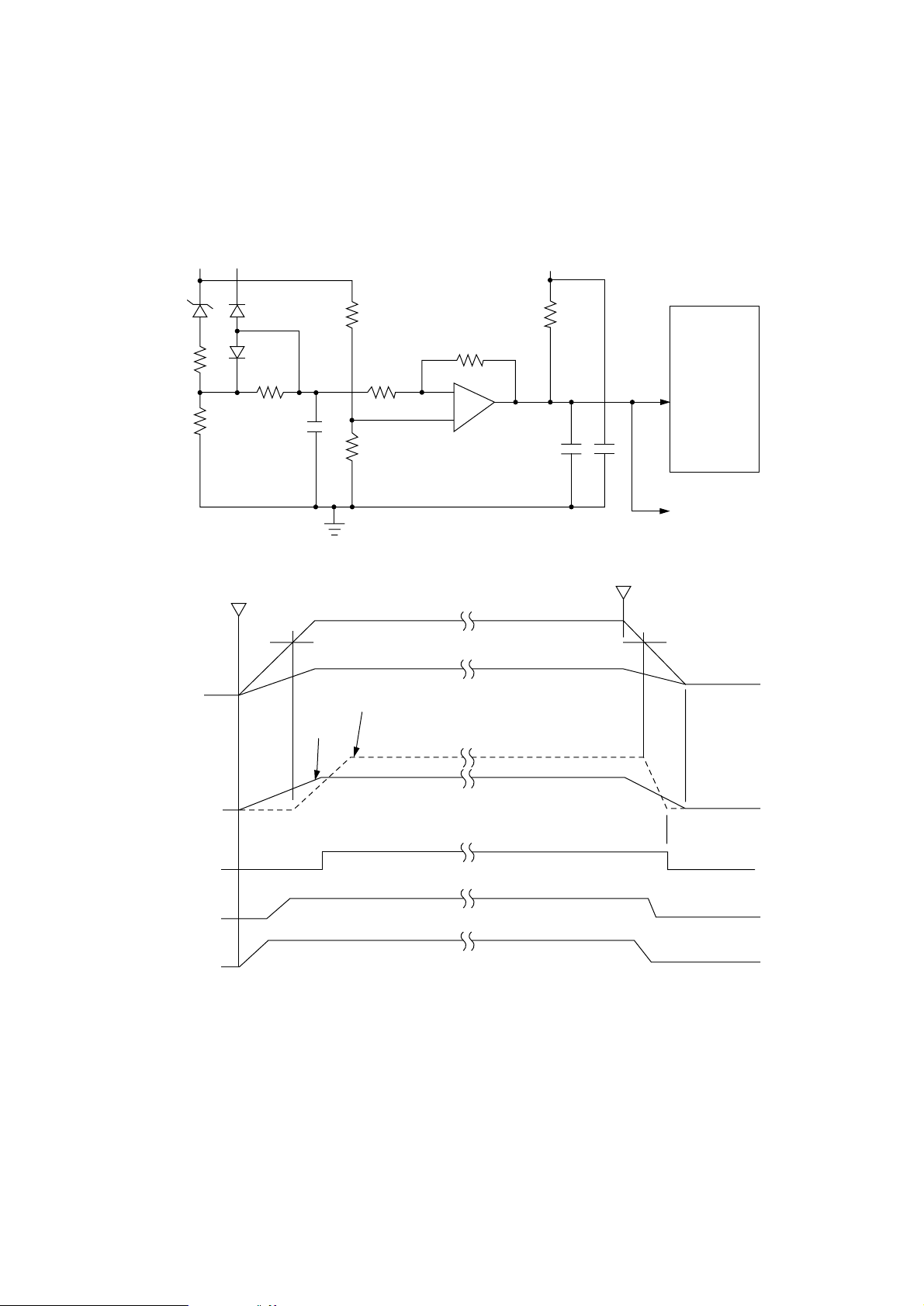

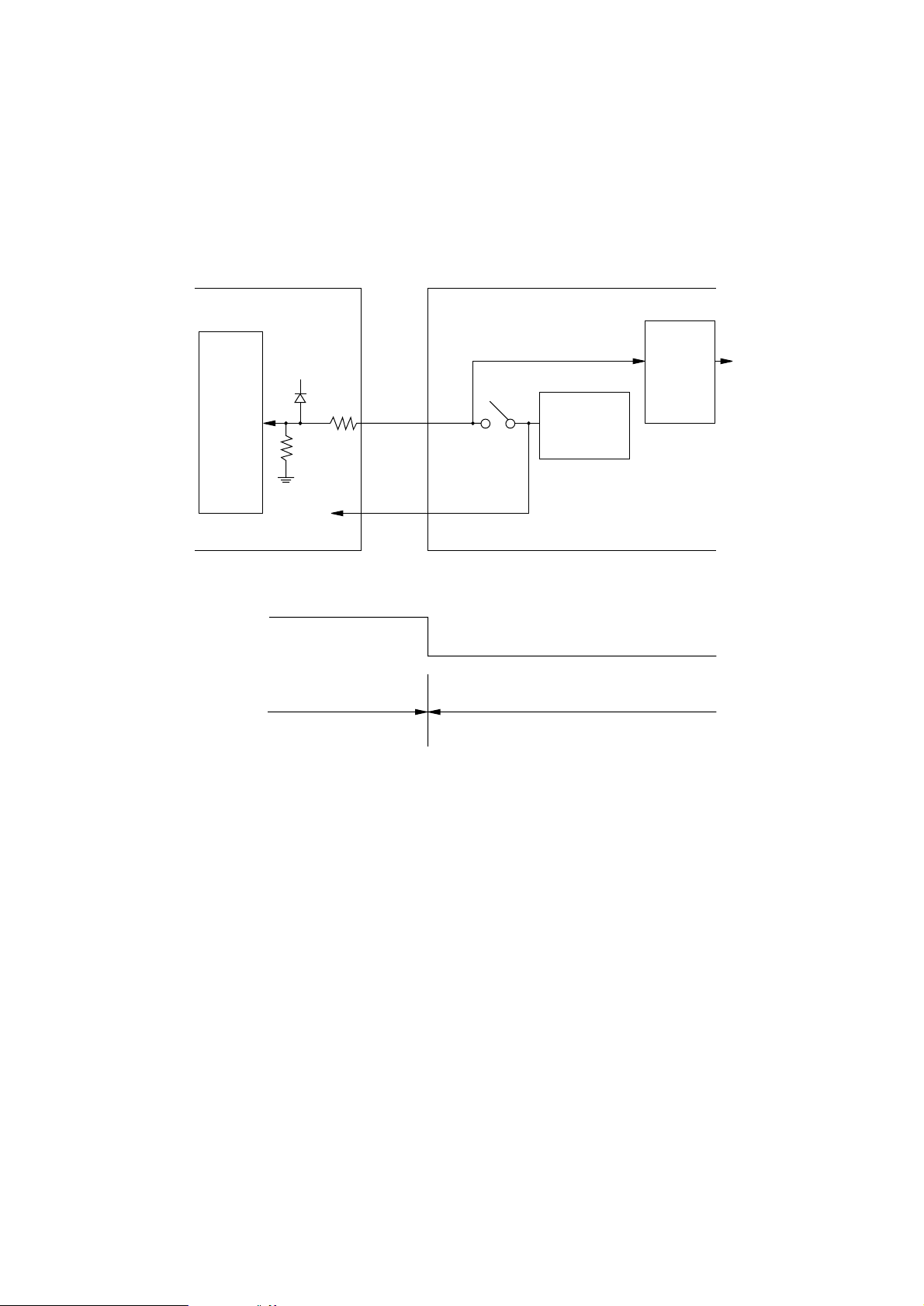

3.3 Reset Control

When power is turned on, a CLRST-N signal is generated by the rising sequence of +30V and

+8V power supply.

D2

(15V)

+30V

+30V +8V

Power ON

+30V

IC10-10

IC10-11

11

10

+8V

+

–

IC10

13

+5V

172

Power OFF

CPU

To Option Board

Q10 Input

CLRST-N

+5V

+8V

- 10 -

Page 13

3.4 EEPROM Control

The 93LC46A is an electrical erasable/programmable ROM of 64-bit x 16-bit configuration. Data

input to and output from the ROM are bidirectionally transferred in units of 16 bits through a serial

I/O port (SSTXD-P) in serial transmission synchronized with a clock signal from the CPU.

The EEPROM operates in the following instruction modes

3

DI DO

4

1

CS

CPU

SSTXD-P

154

EEPRMCS0-P

150

SK

EEPRMCLK-P

2

151

The EEPROM operates in the following instruction modes

Instruction Start bit Operation Address Data

code

Read (READ) 1 10 A5 to A0

Write Enabled (WEN) 1 00 11XXXX

Write (WRITE) 1 01 A5 to A0 D15 to D0

Write All Address (WRAL) 1 00 01XXXX D15 to D0

Write Disabled (WDS) 1 00 00XXXX

Erase 1 11 A5 to A0

Chip Erasable (ERAL) 1 00 10XXXX

CS

SK

DI

DO

Write cycle timing (WRITE)

CS

SK

DI

DO

1 2 4 9 10 25

10 1

HIGH-Z

Read cycle timing (READ)

12

110

HIGH-Z

A5 A4 A1 A0 D15 D14 D1 D0

4

A5 A4 A1 A0

910

D15 D14 D1 D00 D15 D14

Min. 450 ns

STATUS

Max. 500 ns

BUSY READY

Max. 10 ms

25 26

- 11 -

Page 14

3.5 Centronics Parallel Interface

The CPU sets a BUSY-P signal to ON at the same time when it reads the parallel data (PDATA1P to PDATA 8-P) from the parallel port at the fall of PSTB-N signal. Furthermore, it makes the store

processing of received data into a receive buffer terminate within a certain fixed time and outputs

an ACK-N signal, setting the BUSY-P signal to OFF.

87, 88, 91 to 96

97

85

86

CPU

83

81

79

80

82

84

PDATA1-P to PDATA8-P

PSTB-N

PBUSY-P

PACK-N

PRE-P

PSEL-P

PERROR-P

PINIT-N

PSELIN-N

PALITOFD-N

IC11

+5V

2 to 9

1

11

10

12

13

32

31

36

14

CENT

DATA8-P

to

DATA1-P

STB-N

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

IPRIME-N

SELIN-N

AUTOFEED-N

PARALLEL DATA

(DATA BITs 1 to 8)

DATA STOROBE

BUSY

ACKNOWLEDGE

0.5 µs min.

0.5 µs min.

0.5 µs max.

5V

0 min.

0.5 µs to 10 µs

3.9k

A

B

Ω

0.5 µs min.

0.5 µs min.

0 min.

+5V

18

0 min.

0 min.

- 12 -

Page 15

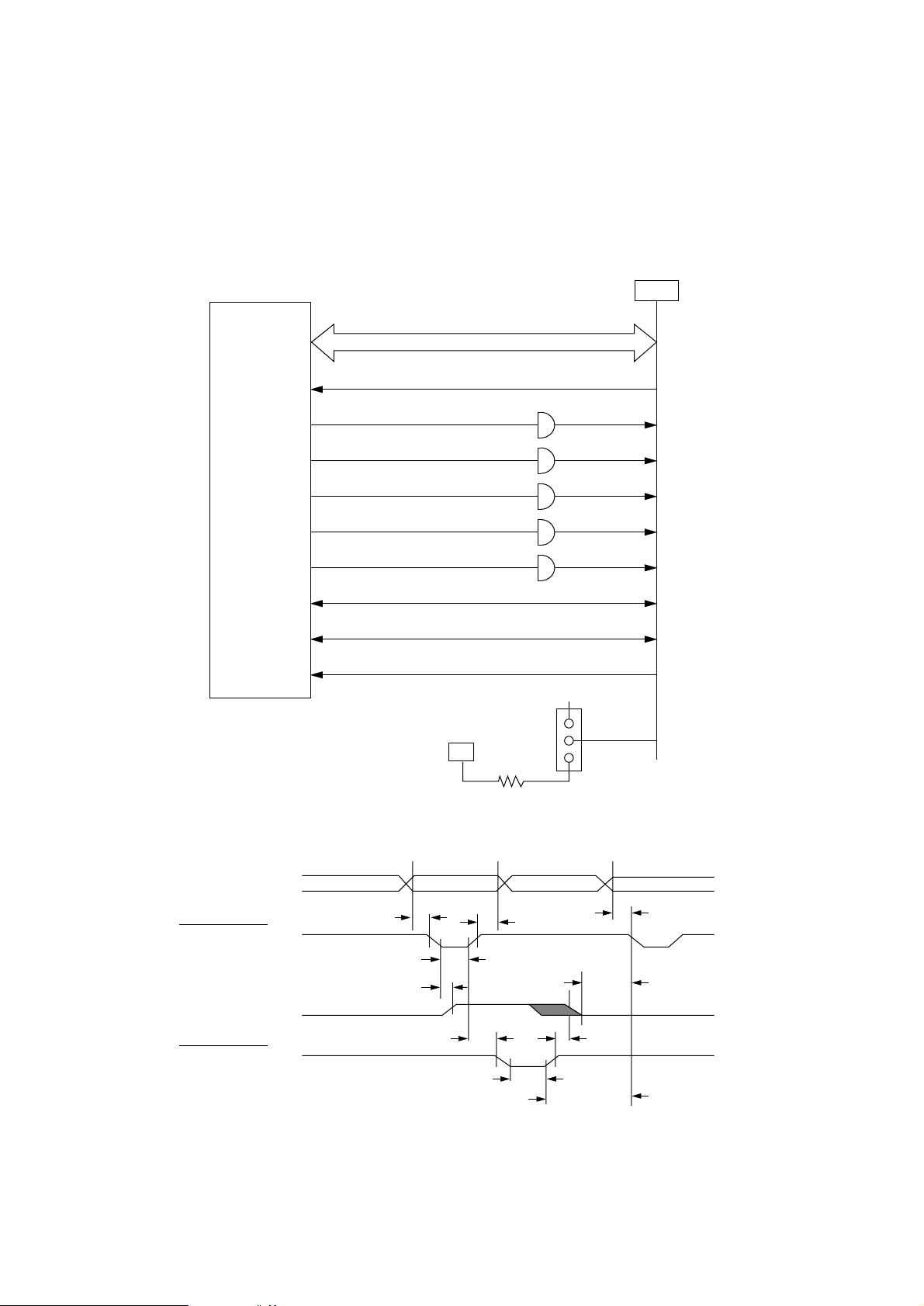

3.6 Operator Panel Control

The operator panel consists of the following circuits.

OLCC-2

Main control board

SSTXD-P

154

SSRXD-P

158

CPU

SSCLK-N

153

SSLD-N

152

PANEL

3

4

6

1

Flexible

Cable

CN1

BU6152S

4

3

1

6

LSI

DB4~DB7

RS

R/W

E

44780

LCD

Control

Driver

Zebra Rubber

LCD

(1) BU6152S (LSI)

This LSI is connected to a clock synchronous serial port of the CPU. It controls switch data

input, LED data output and LCD data input/output according to the commands given by the

CPU. The CPU sends the 2-byte (16-bit) command (SSTXD-P) together with the shift clock

signal (SSCLK-N) to the LSI and then makes a predetermined input/output control if the

command decoded by the LSI is found to be a normal command.

LED

On receiving a command sent from the CPU, the LSI, synchronizing with the serial clock of

the command, returns a 2-byte command response to the CPU.

SSTXD-P

SSCLK-N

SSRXD-P

SSLD-N

bit 0 bit 7

Command (first)

bit 0

Command response (first) Command response (second)

bit 7

Command (second)

- 13 -

Page 16

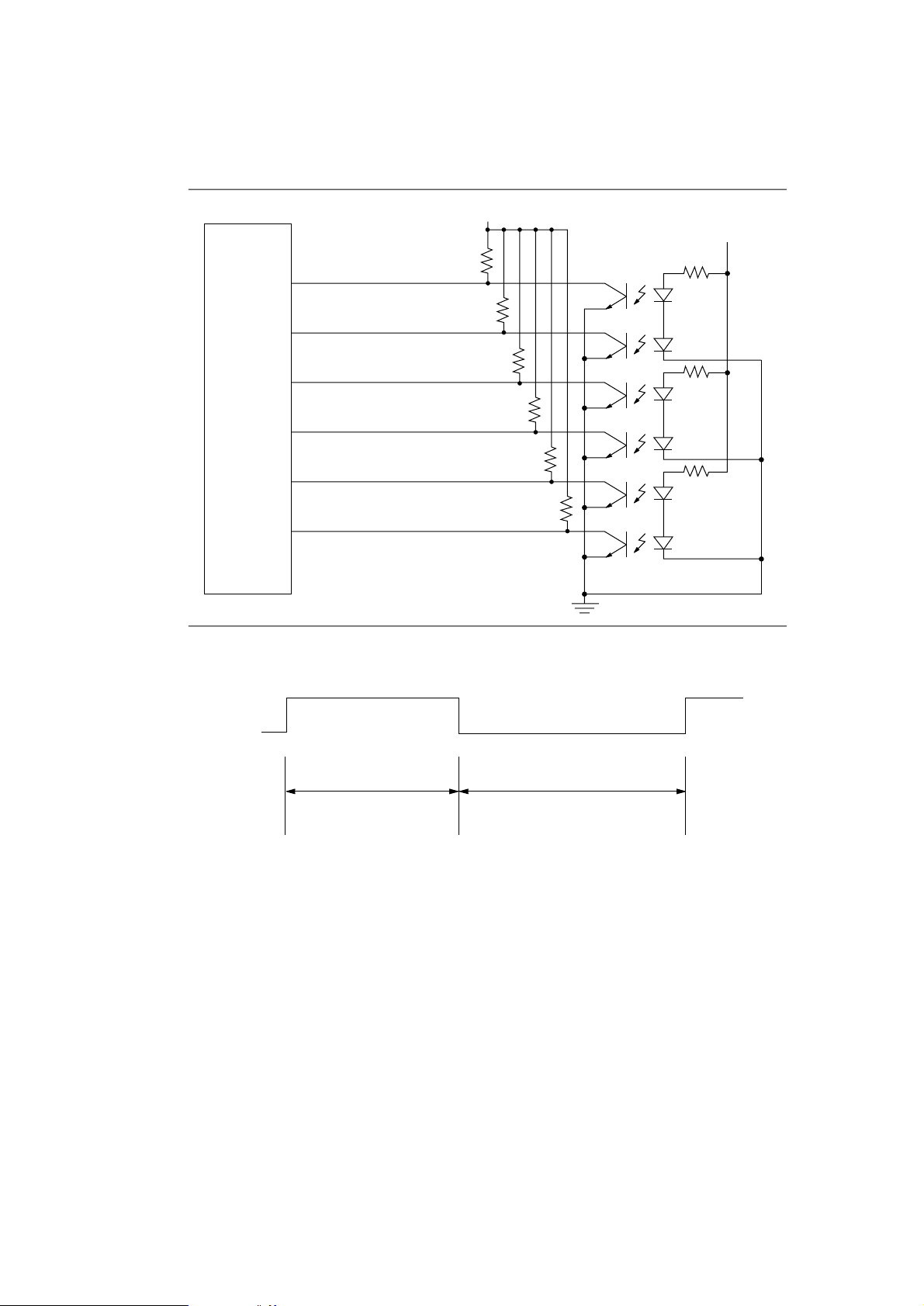

3.7 LED Head Control

An LED correcting head, which is capable of correcting the illumination of the LED for each dot,

is being used in this printer. LED illumination correction function of 16 steps is carried out by using

an EEPROM which is installed in the LSI that maintains the LED illumination correction values,

and an LED correction drivers (MSM6731BWAF or MSM6732BWAF) together as a pair.

The LED correcting head consists of the correction control LSI (MSM6730WAF), LED drivers

(MSM6731BWAF or MSM6732BWAF), and an LED array.

From

CPU

STRB1-N

STRB2-N

STRB3-N

STRB4-N

LOADI

CLOCKI

DATAI0

DATAI1

DATAI2

DATAI3

MSM6730

WAF

EEPROM

Correction

Values

LED Driver

MSM6732BWAF

LED Array

LED LED LED LED LED LED LED

LED Driver

MSM6731BWAF

Printing and correction data combined signal line

Correction data signal line

LED Driver

MSM6731BWAF

LED Driver

MSM6732BWAF

- 14 -

Page 17

CLOCKI

LOADI

DATAI3~0

STRB1I-N

STRB2I-N

STRB3I-N

STRB4I-N

Normal Mode Printing Timing Chart

First line printing data sent Second line printing data sent

First line printing

The printing operation is carried out in the following sequence. First, the printing data DATAI3

through DATAI0 are stored, sequentially shifted, in the shift registers of the LED drivers, by the

printing data synchronous clock, CLOCKI. Then the printing data stored in shift registers are

latched by the high level pulse of LOADI. The latched printing data turns the LEDs on by STRB1IN through STRB4I-N and actuates printing.

- 15 -

Page 18

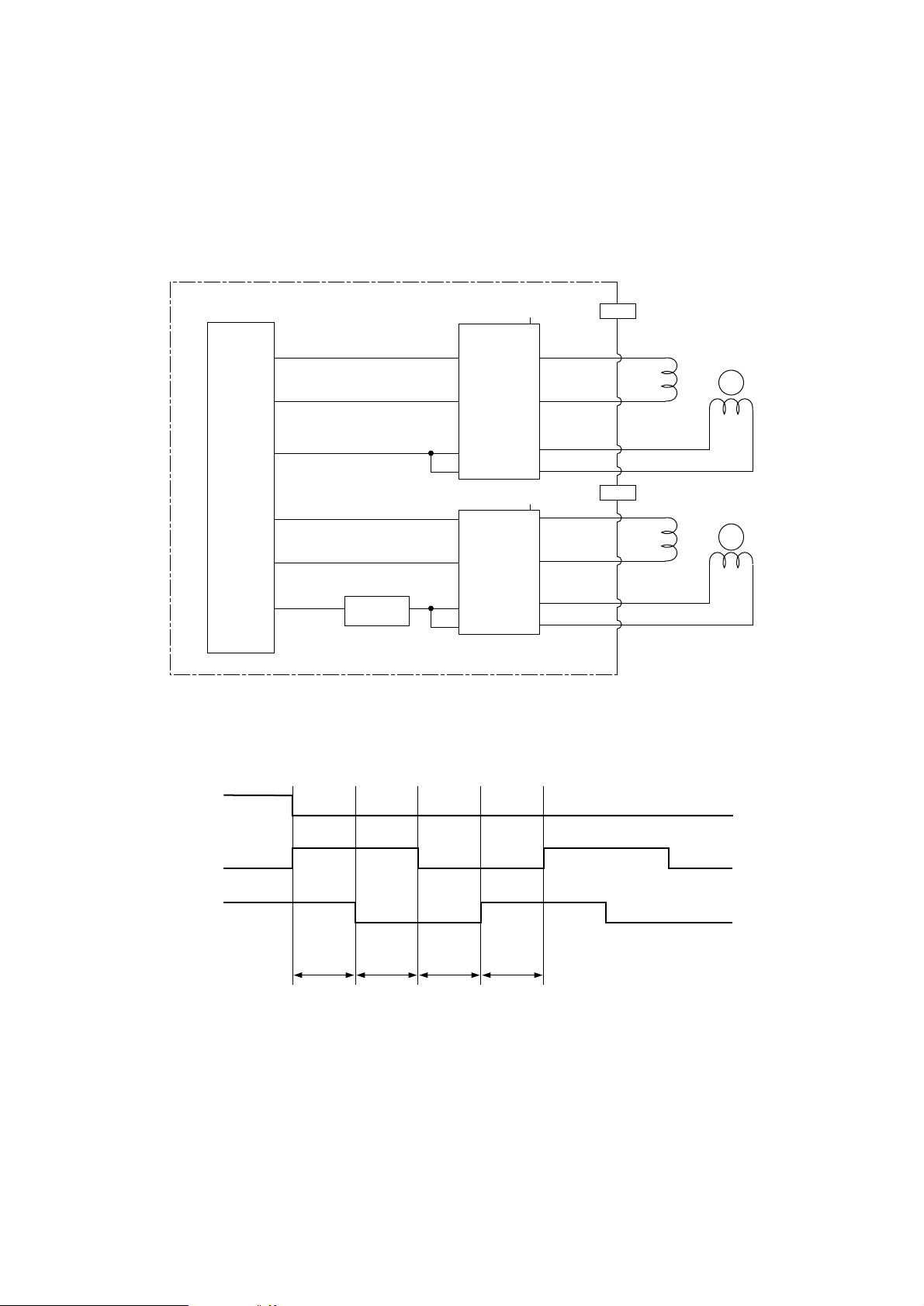

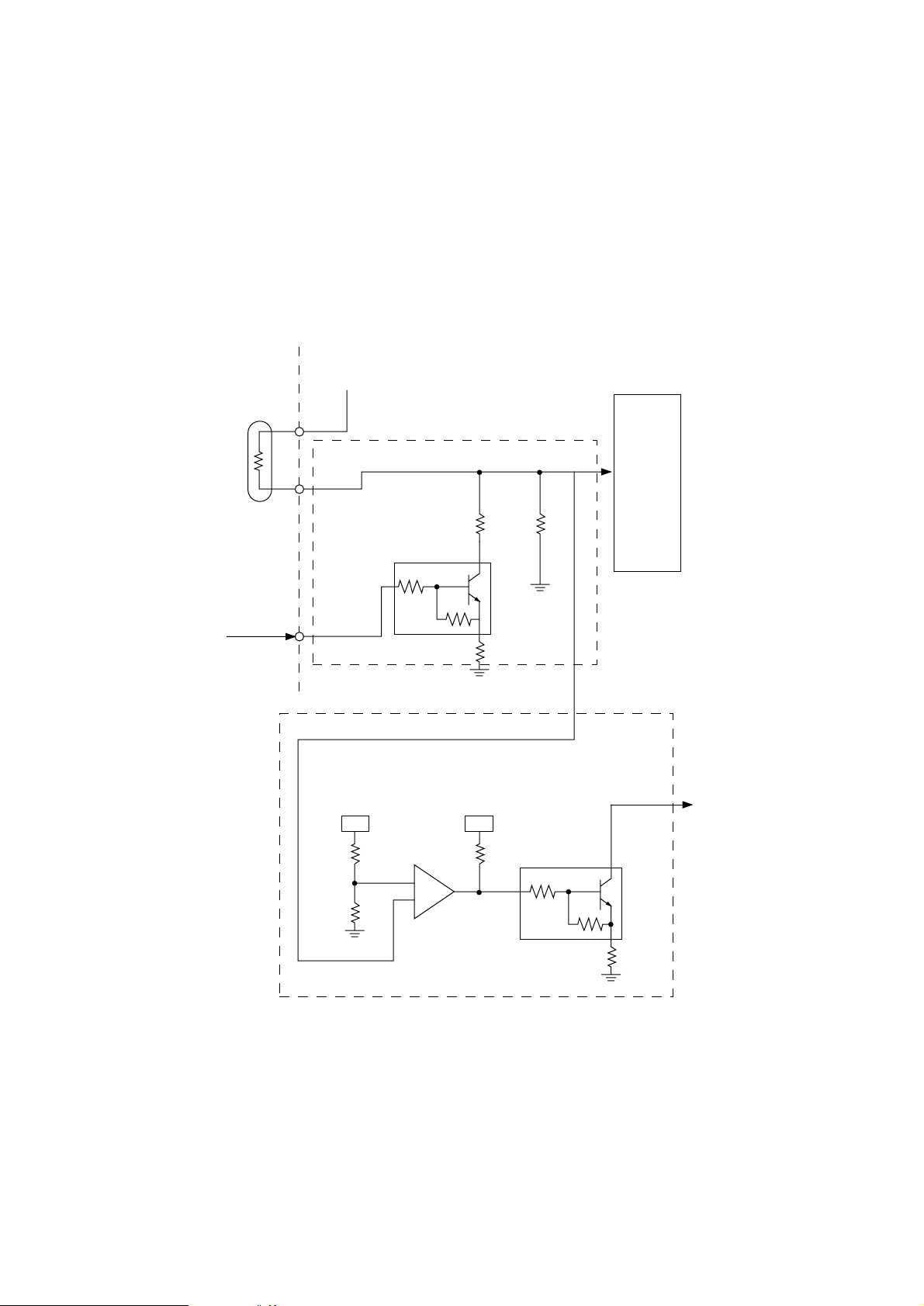

3.8 Motor Control

(1) Registration and main (drum) motors

A registration motor and a drum motor are driven by means of control signals from the CPU

and a driver IC.

Main Control Board

CPU A2918SW

132

131

127

134

133

RMON-N

3

(2) Drum motor

DMPH1-P

DMPH2-P

DMON1-N

RMPH1-P

RMPH2-P

Current

control (IC10)

13

8

7

14

26

MTD2005F

17

20

23

06F

06E

+30V

+30V

DMPH1-N 1

1

DMPH1-P 2

17

DMPH2-N 3

2

DMPH2-P 4

4

RMPH1-P 1

3

RMPH1-P 2

7

RMPH2-N 3

8

RMPH2-P 4

12

DM

Main (Drum) Motor

M

RM

Registration Motor

M

DMON1-N

DMPH1-P

DMPH2-P

T0

T1 T2 T3

Operation at normal speed: T0 to T3 =1.016 ms

- 16 -

Page 19

(3) Registration motor

RMON-N

RMPH1-P

RMPH2-P

T0 T1 T2 T3

Rotation

Stop

Forward rotation

Hopping drive

Operation at normal speed: T0 to T3 = 1.016 ms

Reverse rotation

Registration roller drive

(4) Drive control

Time T0 to T3 determines the motor speed, while the difference of phase direction between

phase signals DMPH1-P and DMPH2-P (RMPH1-P and RMHPH2-P) determines the

rotation direction. DMON1-N and RMON-N signals control a motor coil current. According to

the polarity of the phase signal, the coil current flow as follows:

1) +30V → SW → motor coil → SW → resistor → earth, or,

2) +30V → SW → motor coil → SW → resistor → earth

The voltage drop across the resistor is input to comparator, where it is compared with a

reference voltage. If an overcurrent flow occurs, a limiter operates to maintain it within a

certain fixed amount of current.

- 17 -

Page 20

3.9 Fuser Temperature Control

For the temperature control by heater control, the variation in the resistance of the thermistor is

A/D converted in IC2 and the resultant digital value is read and transferred to the CPU. The CPU

turns on or off the HEATON-N signal according to the value of the signal received from IC2 to keep

the temperature at a constant level.

Immediately after the power is turned on, the thermistor is checked for shortcircuit and

breakdown. If the thermistor is shorted, the A/D converted value shows an abnormally high

temperature, so that the shortcircuit can be detected. If the breakdown of the thermistor occurs,

the A/D converted value shows the normal temperature. In this case, the thermistor breakdown

can be detected by the sequence shown at the end of this section. If the heater is overheated,

5V supply is turned off when the resistance of the thermistor is detected to be exceeding the

predetermined value.

Main Control BoardPower Supply Board

Thermistor

Heater

TH1

TH2

CN2

1

2

5V

Thermistor

Breakdown

Detector

Circuit

PC1

IC2 CPU

Power

40

Abnormally

High

Temperature

Detection

Circuit

Supply

Interface

ACIN

20

HEATON-N

116

5V

IC11

1

0C

2

- 18 -

Page 21

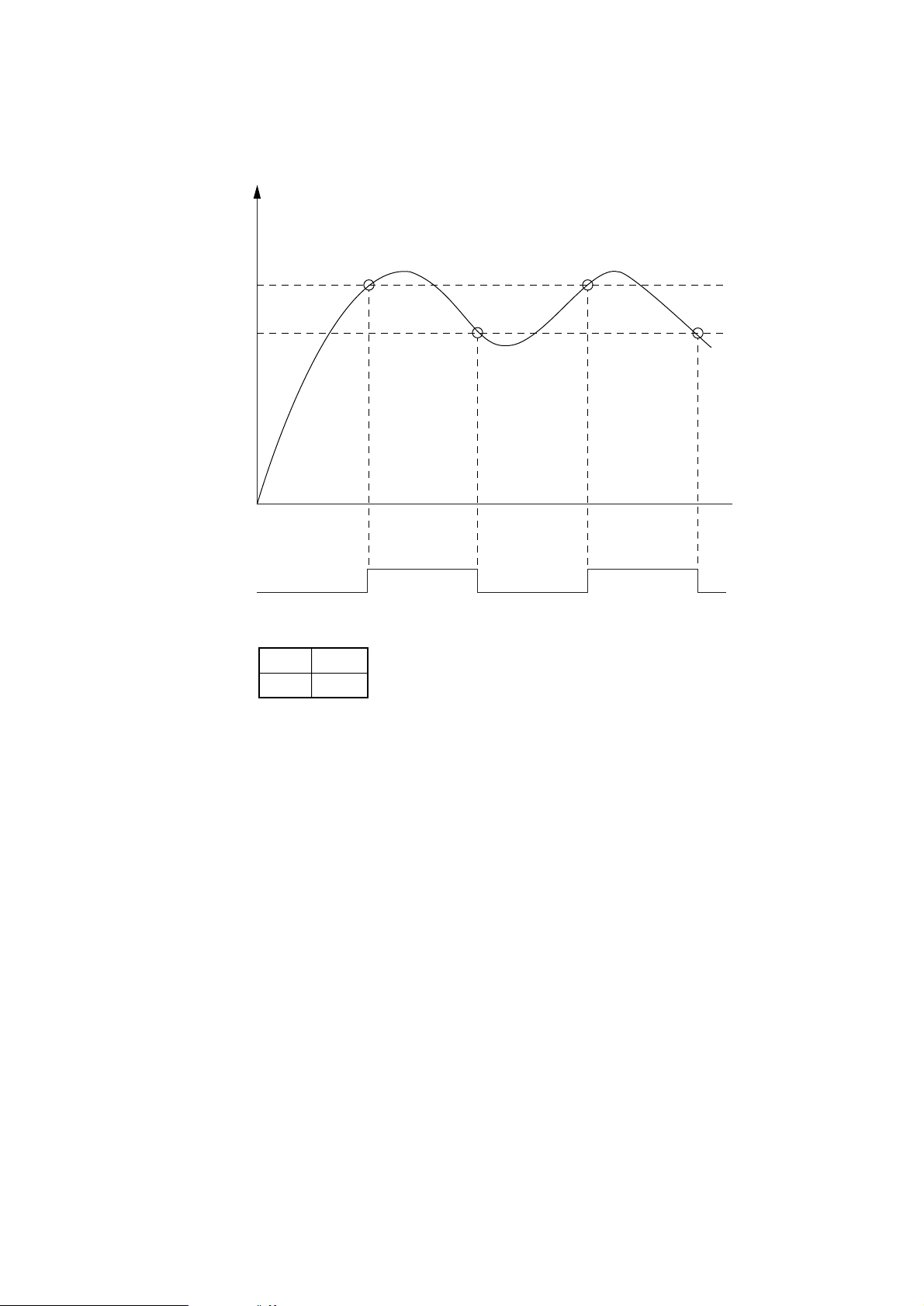

The temperature control is described below.

Vt

Temperature

˚C

V2

V1

ON OFF ON OFF ONHEATON-N

V2 176˚C

V1 175˚C

* The values V1 and V2 vary according to setting mode.

(Standard temperature)

When Vt rises to V2 or more, the heater is turned of (by setting HEATON-N signal to LOW).

When Vt drops to V1 or less, the heater is turned on (by setting HEATON-N signal to HIGH). In

this way, the temperature can be kept within the predetermined range.

- 19 -

Page 22

For heater breakdown detection, the heater must first be turned on. When a temperature rise

which corresponds to the switching on of the heater does not occur, then a heater breakdown is

detected. To shorten the breakdown detection time, the following circuit is used. Immediately

after the power is turned on, the thermistor is checked and THERM-CMP signal is turned on to

turn the resistor Q44 on. The reading resolution is increased through the variation of the

thermistor resistance value.

If, for whatever reason, temperature control fails and the temperature rises abnormally, the

abnormal high temperature detection circuit shown below forcibly cuts the power supply to the

fuser.

5V

Thermistor

From CPU

Thermistor Breakdown Detection Circuit

R306

1.5kW

THERM-CMP

Abnormal High Temperature Detection Circuit

+5V +5V

R303

1kW

R302

1kW

R305

100kW

Q43

+

324

R304

1.8kW

–

IC2

A/D

Converter

HEAT-N0

To PC1

- 20 -

Page 23

3.10 Fan Motor Control

The stop/rotation of the fan motor is controlled by FANON1-P and FANON2-N signals. When the

fan motor rotates normally, FANALM-P signal generated in the hole element built in the fan motor

is input to the CPU.

FANON1-P

109

5V

CPU

FANON2-N

126

FANALM-N

110

R545

38V

R549

0V

R4

IC10

TR503

8VR

339/2901

0V

5V

R540

38V

R554

3

0V

TR501

TR504

FAN

1

TR502

3

D1

1

D503

1

2

3

0V

Fan Motor

M

FANON1-P

H

H

L

FANON2-N

L

H

X

Fan motor rotation

Normal speed

Half speed

STOP

FANON1-P

FANALM-P

0.7 sec max

FAN MOVE

Lock

Fan motor start: Initial request, heater on, print start request

Fan motor stop: • The motor immediately stops when an engine error or a fan error occurs.

• The motor stops 0 second or 20 minutes after the occurrence of a paper jam, size

error, or fuse error.

• The motor stops in the power save mode as below.

Main (drum) motor

ON

Heater control

OFF

OFFON

Fan motor

Heater

hold time

8 min. or

0 sec.

Rotation state

- 21 -

30 sec.

Stop state

Page 24

3.11 Cover Open

When the cover is opened, a cover open microswitch is opened. This makes a CVOPN-N signal

low, thereby the CPU detects the open state. Furthermore, opening the cover stops applying a

+5V power to the high voltage power supply unit, resulting in stopping all high voltage outputs.

Main Control Board

CPU

+5V

CVOPN-N

0V

Power Supply Board

+5V

125

Cover close Cover open

CVOPN-N

Cover

Open

Microswitch

+5V

+5V

Low Voltage

Power

Supply Unit

High

Voltage

Power

Supply

Unit

High

voltage

output

- 22 -

Page 25

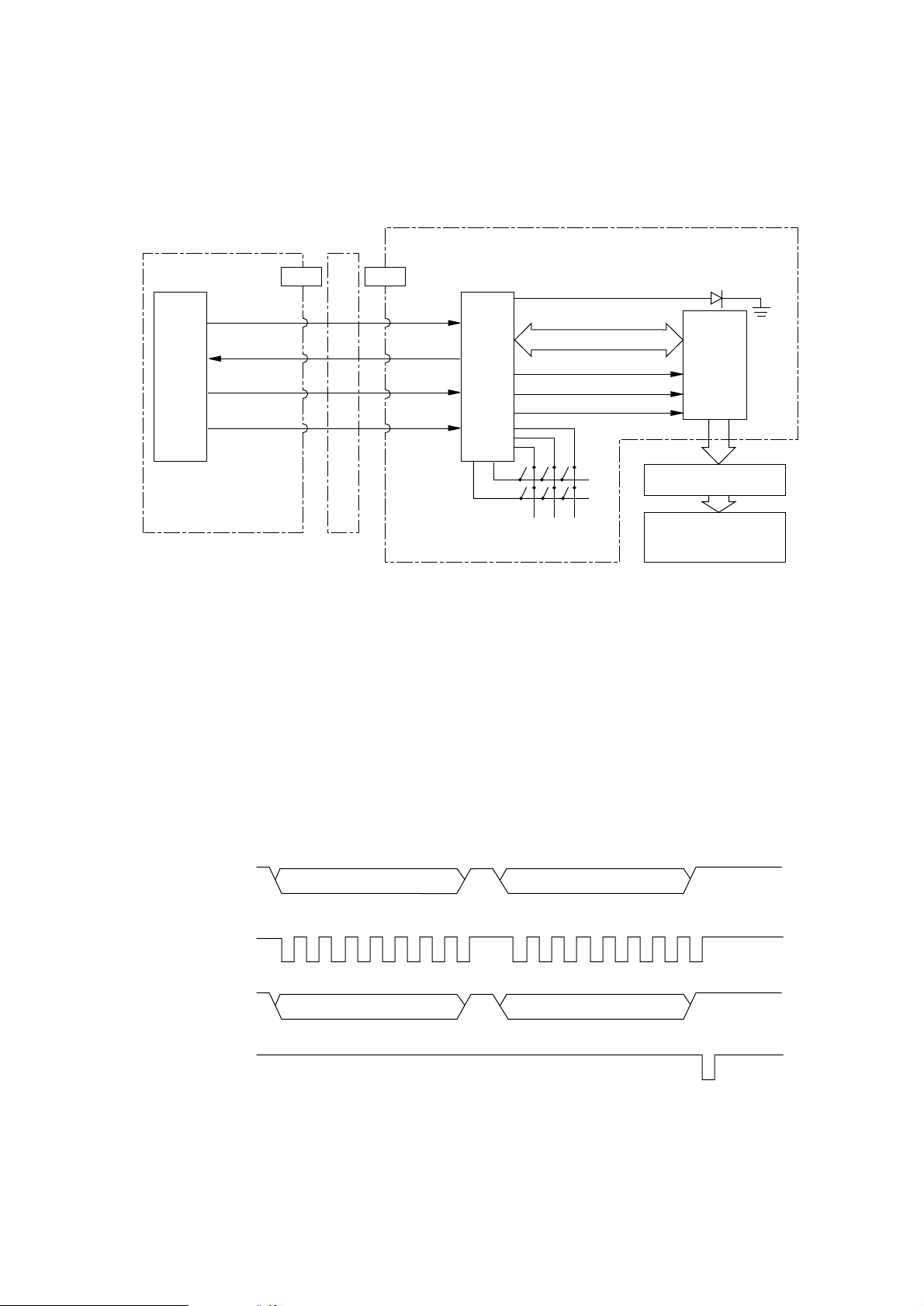

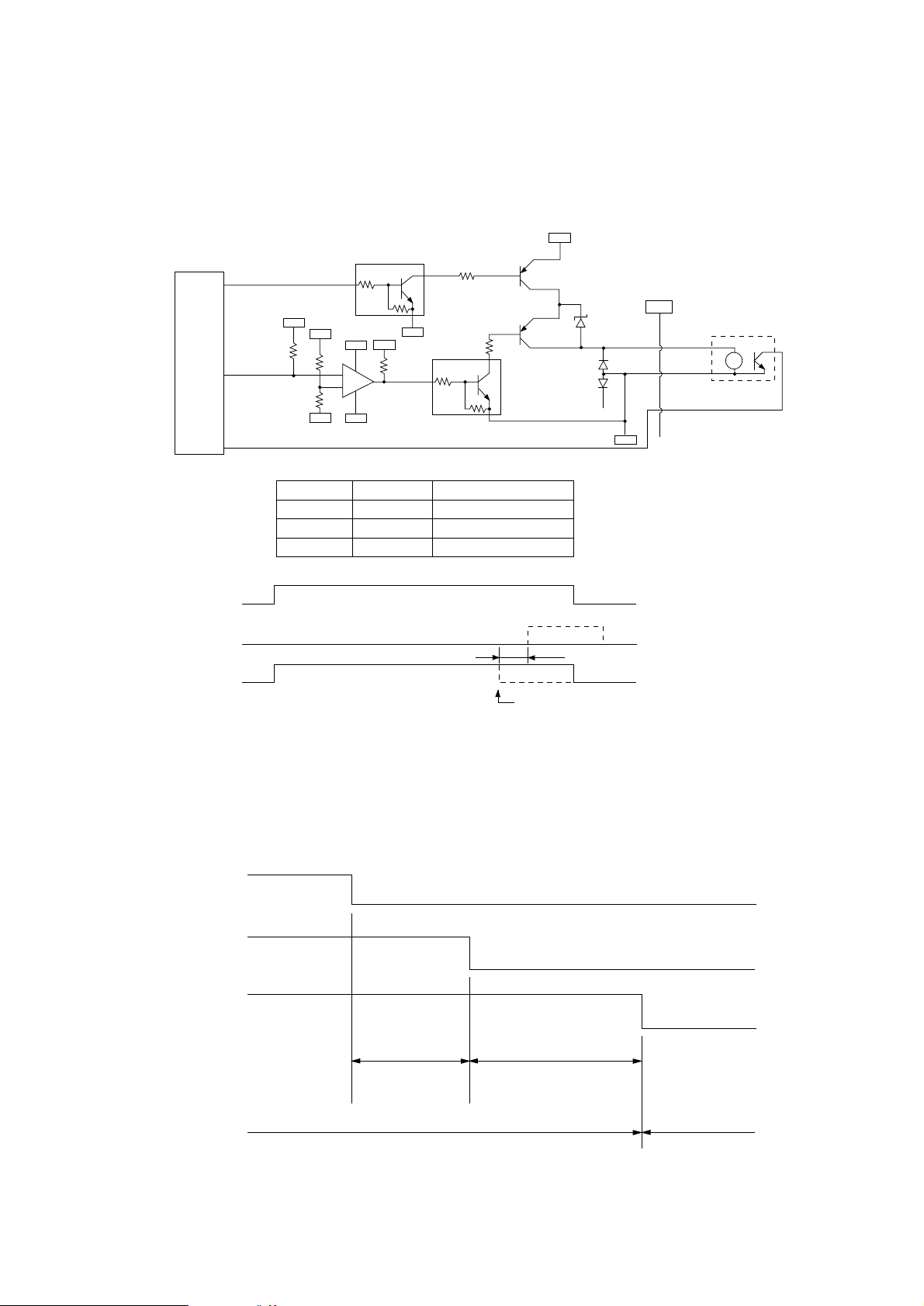

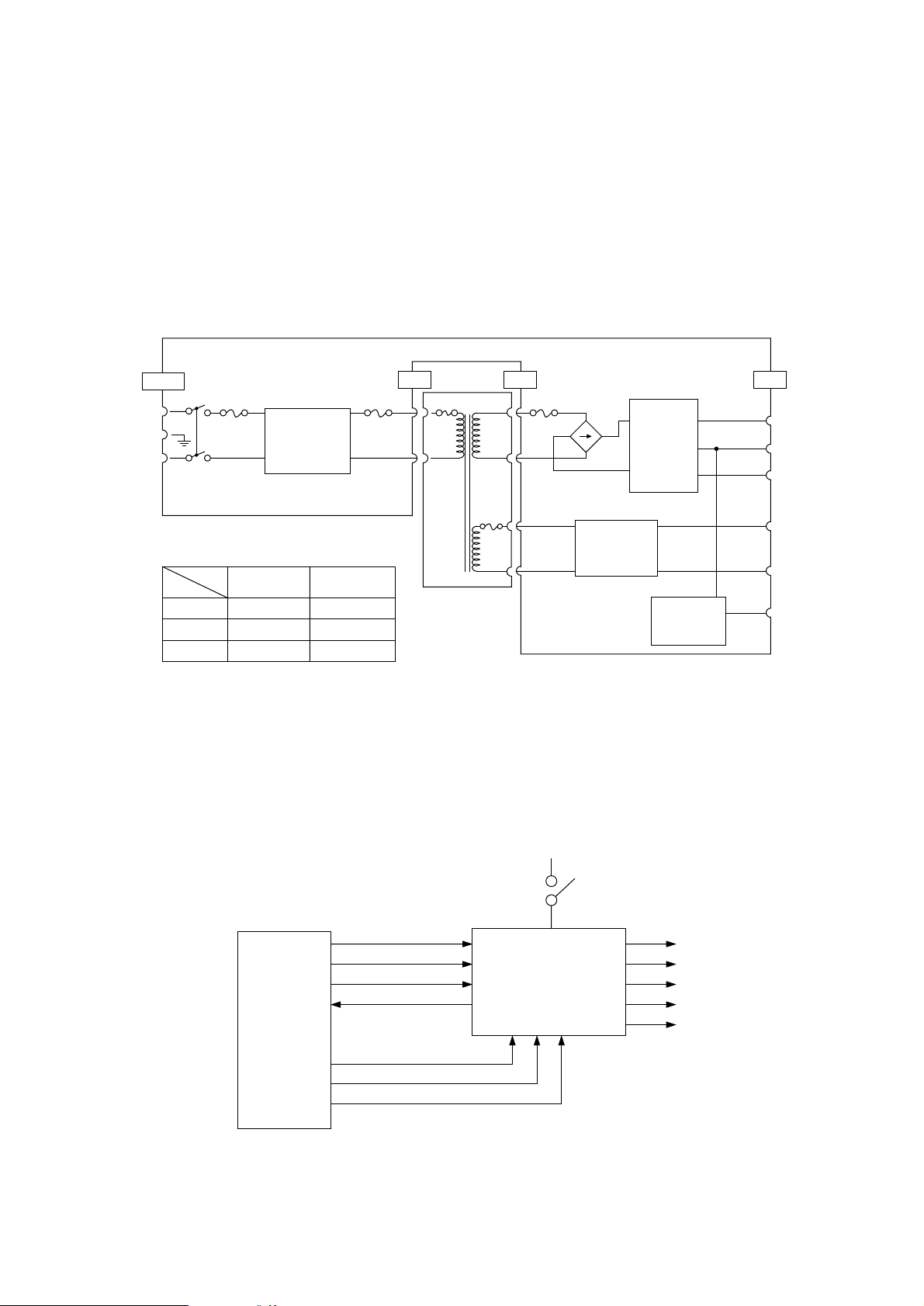

3.12 Power Supply Board

(1) Low voltage power supply

An AC power from an inlet is input to a transformer via fuses, AC switch and noise filter and

then lowered to a 32 VAC power and a 10 VAC power. The 32 VAC power is converted to

a +30 VDC output through a rectifying/smoothing circuit. A +5 VDC output is derived from the

resultant +30 VDC power through a regulation circuit. The 10 VAC power is converted to a

+8 VDC output and a -8 VDC output through a rectifying/smoothing circuit.

Power supply board

ACIN

FG

N

Filter

Circuit

Fuse Ratings

AC Input

Fuse

F1

F2

F3

120 V 230 V

125 V 6.3 A

125 V 1.6 A

125 V 3.15 A

250 V 5 A

–

250 V 2.5 A

(2) High voltage power supply

The +5 VDC power supplied to the high voltage power supply unit via the cover open

microswitch as source voltage. The high voltage power supply unit supplies necessary

voltage for electro-photography print to output terminals CH, DB, SB, TR, and CB according

to a control signal from the CPU. The table on the next page shows the relationship between

control signals and high voltage outputs.

CN1 CN2

Thermal Fuse

1

2

AC Transformer

1, 2

3, 4

6

5

F3F2F1L

+5V

Smoothing

Stabilizing

±

8V

Rectifying/

Smoothing

Circuit

+30V

Circuit

+5V

Circuit

+8 V 24

-8 V 22

+3.3 V

Generating

Circuit

CN3

+30 V 17, 18

+5 V 11, 12

0 V 9, 15, 16

13, 14

+3.3 V

CPU

SCLK

SQCR

DATA IN

DATA OUT

TRSEL 3

TRSEL 4

TRSEL 5

- 23 -

Cover Open Switch

High Voltage

Power Supply

Unit

CH

DB

SB

TR

CB

Page 26

(3) Sensor control

Main Control Board

9

8

6

IC2

10

7

4

PSOUT-N

WRSNS-N

PSIN1-N

PAPER-N

PSIN2-N

TNRSNS-N

Power Supply Board

+5V

+5V

PS1

PS2

PS3

PS4

PS5

PS6

Sensor

signal

OFF

ON

TransparentShield

- 24 -

Page 27

(4) High-voltage power supply circuit

This high-voltage power supply circuit receives the high-voltage generation timing control

command that is transmitted in serial through the power supply interface from the control

section. It decodes this command by LSI (IC2) and outputs high-frequency pulses to the

corresponding high-voltage generating circuits through pins 12, 13, 14, 15 and 16 of LSI

(IC2). It supplies +5V to each high-voltage generating circuit as the source voltage. When

the cover is open, the supply of +5V is interrupted to interrupt all the high-voltage outputs.

The relationship between the high-frequency pulse output pins and the high-voltage outputs

is shown in the following table.

Power Supply CircuitMain Control Board

CPU

Power supply interface

IC2

LSI

13

15

11

14

+5V

DB

CB

TR

SB

SB

DB

CB

TR

High-voltage

outputs

High

-frequency

pulse output pins

11

12

13

14

15

SB

0V

DB

+300V

-500V -265V

CB

+400V

-1.35kV

TR

+1.2kV

-1.1kV

12

CH

-1.3kV

CH

Remarks

TRSEL 3: Hi-Z

TRSEL 5: L

TRSEL 3: L

TRSEL 5: Hi-Z

Part with slant line: no output

CH

- 25 -

Page 28

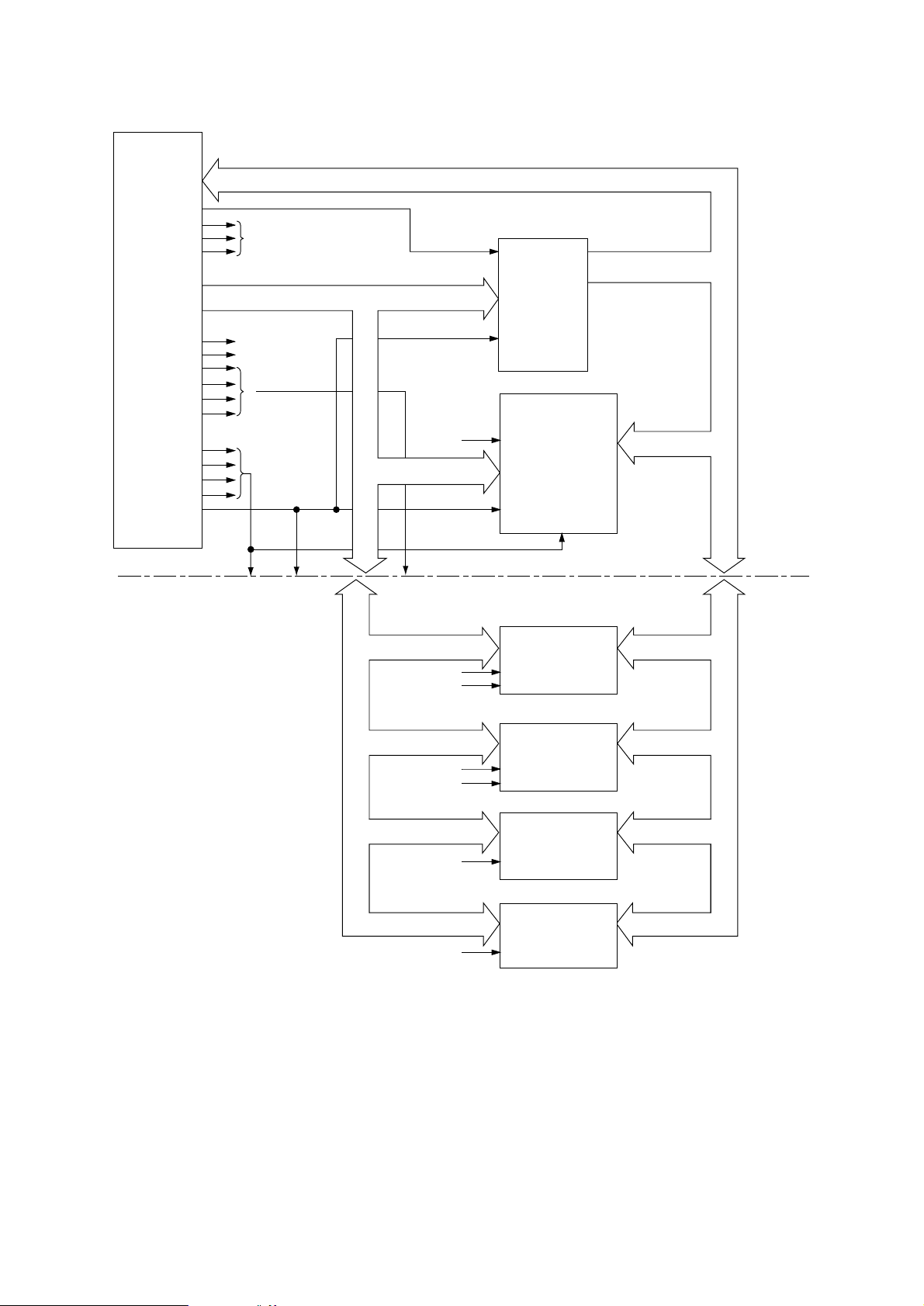

3.13 Option Tray Control

The kinds of option trays, High capacity Second Paper Feeder and Multi purpose Feeder can be

connected to the printer. The trays are distinguished by two digit ID numbers.

The option trays and the printer communicate with each other through bi-directional clock

synchoronized serial interface. The printer always sends a command first, then each option tray

interpret it. Because the command contains an ID, the selectes option tray takes approriate

actions, then sends back a reply. The command and reply are transmitted back and forth on

OPTSD-P signal line by synchronizing OPTSCLK-N clock signal which is sent by the printer. The

printer knows the timing when it outputs the clock for the reply by sensing OPTSDR-N signal which

is turned to zero by the option tray when it is ready for the reply.

The option tray’s paper feeding action is triggered by a command sent by the printer. When the

tray delects a signal on OPTPSIN-N signal line, which indicates the paper reaches a input sensor

in the printer, the tray stops the paper feeding after carrying out the paper feeding according to

the predetermined steps which have been downloaded from the printer at power-up time.

Status of the option trays such as no paper cassette, paper out and cover open, are infoemed to

the printer though a reply in response to a status inquiry command.

- 26 -

Page 29

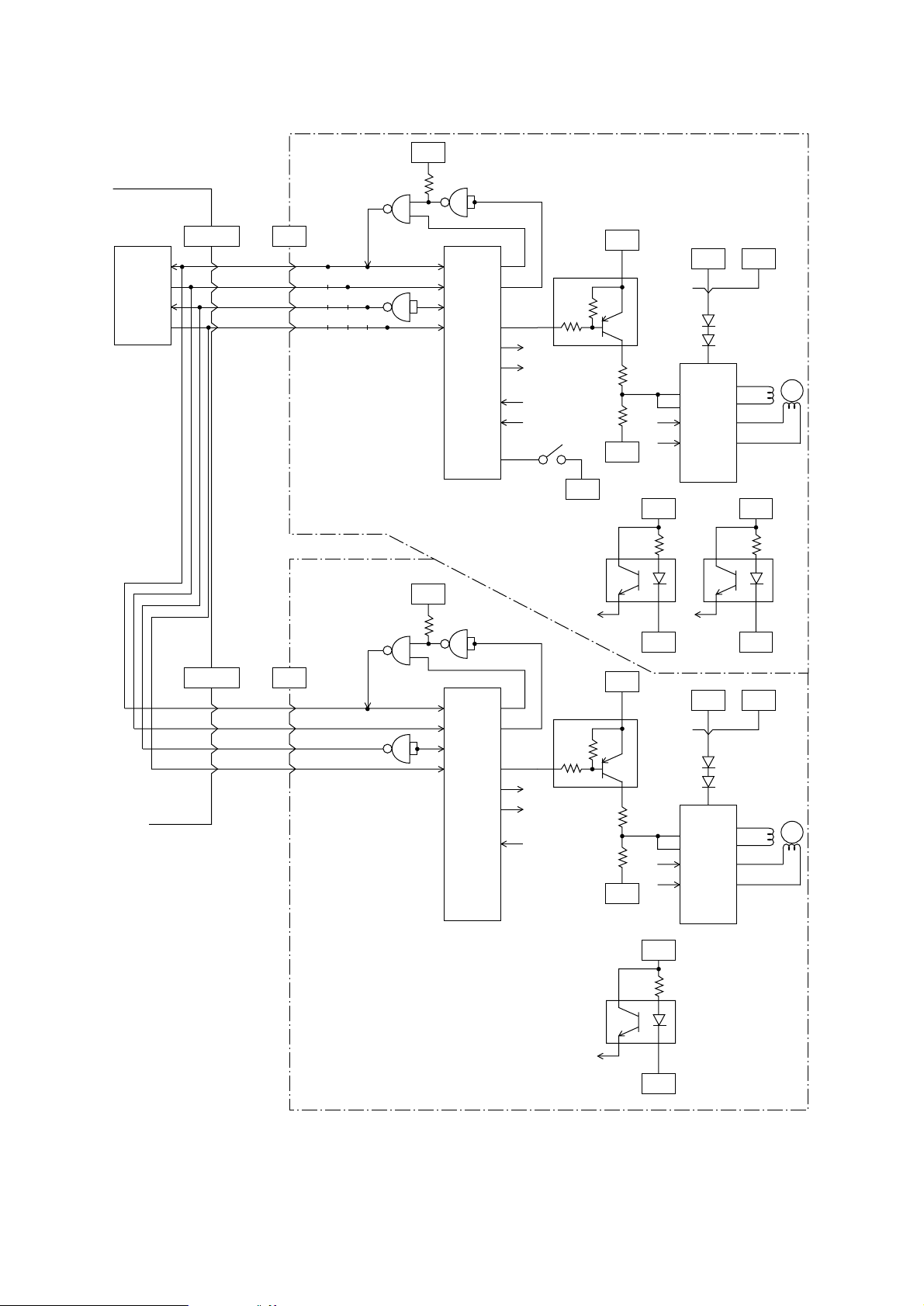

Main Control board

2ND TRAY

CPU

3

2

4

1

PU

OPTSD-P

OPTSCLK-N

OPTSDR-N

OPTSIN-N

TQSB-2

(Option)

6

3

2

8

4

1

High capacity Second

Paper Feeder

0C

0C

4

5

10

9

5V

3

3

5

9

28

IC1

1

0C

2

IC2

65-43

F0

G0

F2

F1

G2

E0 C2

C1

C0

D0

E1

A0

7

4

3

22

A

21

B

20

C

24

D

29

1, 2 3, 4

11

SW1

(Cassette)

TR2

270

560

0V

5V

1

30V

CN2

6

D1

D2

2

Ω

Ω

0V

IC3

MS4646

MA1

2

VR1

27

24

A

15

B

VR2

PH1

PH2

MA2

MB1

MB2

5V

25

10

19

M

4

5V

ENVELOPE

OPTSD-P

3

OPTSCLK-N

2

OPTSDR-N

4

OPTSIN-N

1

OLEV-(Option)

CN2

3

2

4

1

SEN1

3

SEN2

1

3

1

(Paper)

5V

42

IC1

12

0C

11

0C

9

13

8

C

0V

D

(Cover Open)

2

4

0V

10

IC2

65-43

3

F0

G0

5

F2

1

3

0C

2

9

G2

28

E0 C2

F1

C1

C0

D0

22

21

20

24

7

4

3

A

B

C

TR1

5V

1

30V

CN2

D1

D2

2

IC3

MS4646

MA1

0V

2

VR1

27

24

A

15

B

VR2

PH1

PH2

MA2

MB1

MB2

25

10

19

4

M

5V

SEN2

3

1

(Paper)

42

Multi purpose Feeder

C

Option Tray Connection and Block Diagram

- 27 -

0V

Page 30

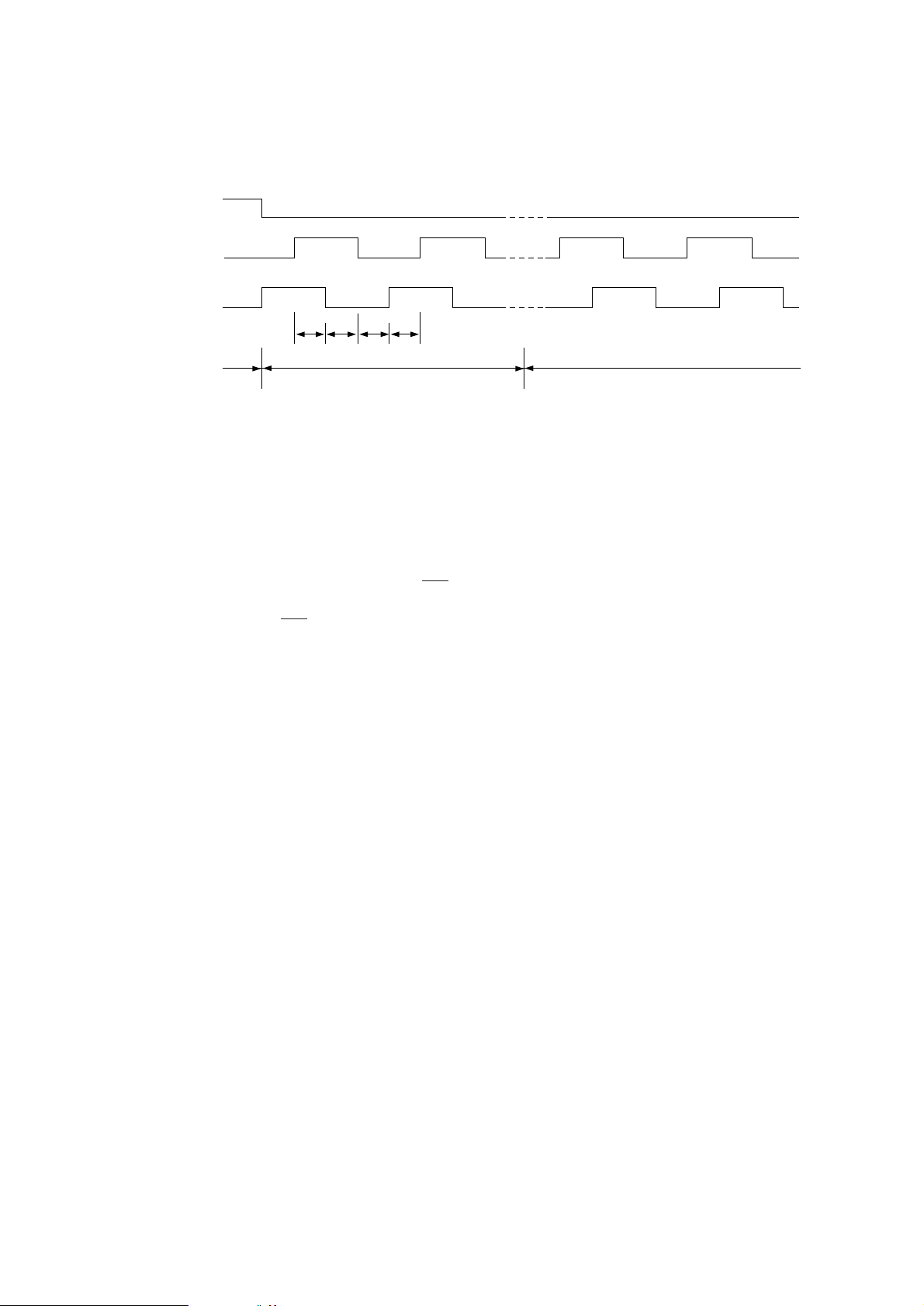

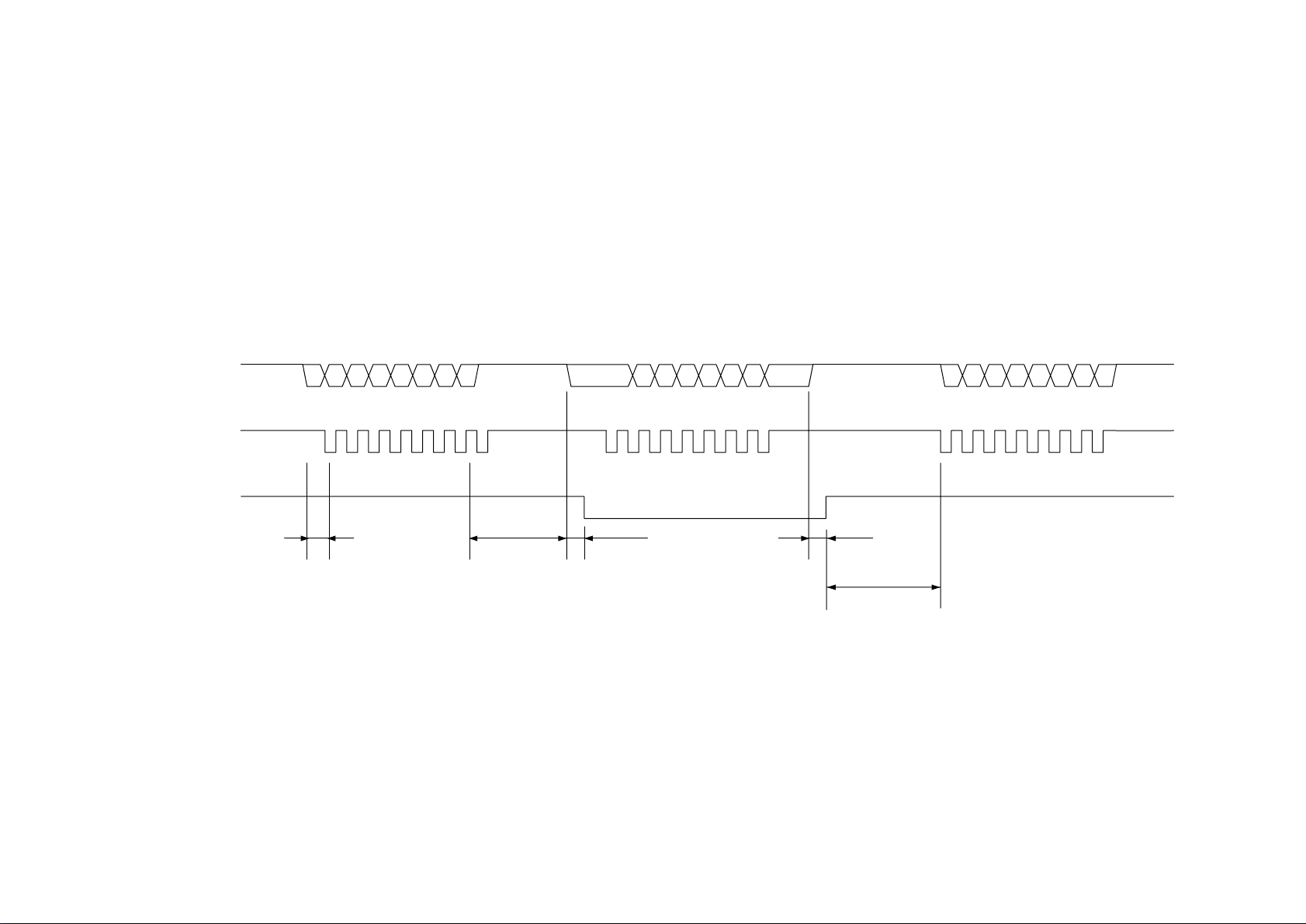

O

PTSD-P

O

O

Option Tray Control Serial Interface Time Chart

b7 b6 b5 b4 b3 b2 b1 b0 b7 b6 b5 b4 b3 b2 b1 b0 b7 b6 b5 b4 b3 b2 b1 b0

Next Command (CPU

→

Tray)Reply (Tray→CPU)Command (CPU→Tray)

- 28 -

PTSCLK-N

PTSDR-N

µ

1.5µS40

Min. 1300

Max. 3000

S

µ

S

µ

S21

µ

S

Min. 3000

Option Tray Serial Interface Time Chart

µ

S

Page 31

- 29 -

Motor Control Time Chart

Motor on

(C2)

Phase change

(C1, C0)

Paper sensor

(OPTPSIN-N)

# of Phase changes after

paper sensor detection is

downloaded by CPU

Triggered by CPU

Option Tray Motor Control Time Chart

Automatically stops

Page 32

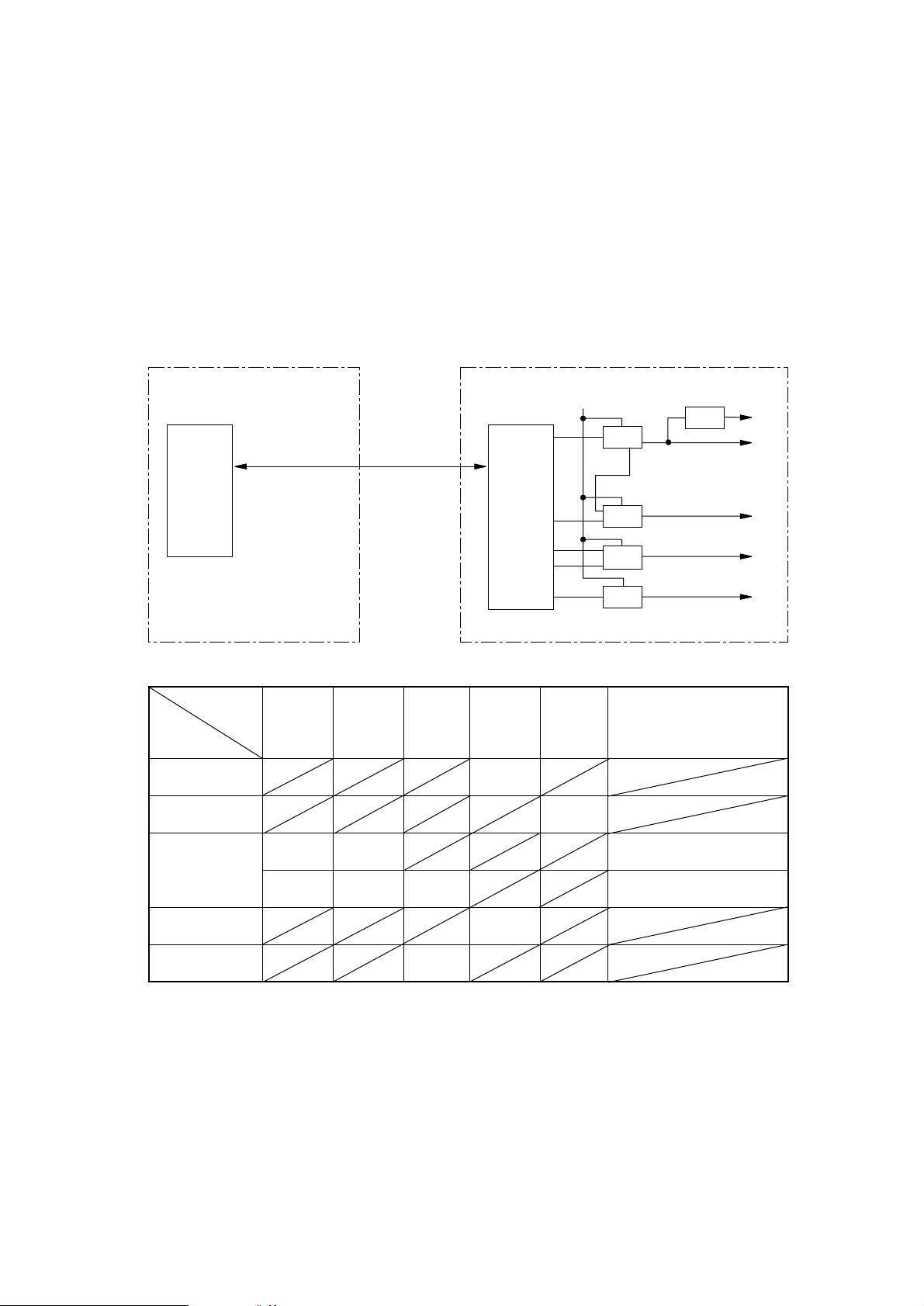

3.14 Memory Expansion Option Board

A2 to A23

ALS244ALS244ALS244

D0 to D31

DRAM

CAS0 to

CAS3

OPTION CONNECTOR

RAS2 to

RAS4

ORE, RD,

WR

CS3, EEPCS, EEPCLK

EEPDAT

IOS1

1M Byte

RAS2

ORE

WR

SIMM1

DRAM SIMM

RAS3, 4

WR

PD2, 3

BSY

SIMM2

PS SIMM or Flash SIMM

RD

WR

ALS244

Memory Expansion Board Block Diagram (Option)

The Memory Expansion Option Board is provided with two DRAM chips and two SIMM slots.

The SIMM1 slot is used for installation of a DRAM SIMM.

The SIMM2 slot is used for installation of a PS SIMM or Flash SIMM.

With the Board, a printer will have 3M bytes of Memory even without any additional DRAM SIMM

memory on the SIMM1 slot because 1M DRAM is mounted on the board.

(1) DRAM

Two 4M bits DRAMs are installed. Memory capacity totals 1M byte.

(2) SIMM Memory Module

The board is provided with two Slots for a 72-pin DRAM SIMM Memory Module and PS SIMM

or Flash SIMM.

The SIMM1 slot is used for installation of a 72-pin DRAM SIMM Memory Module. Up to 6

types of SIMM Memory Module can be installed.

1M byte, 2M bytes, 4M bytes, 8M bytes, 16M bytes and 32M bytes. 4 types of access speed

can be used. 60, 70, 80 and 100n sec.

The SIMM2 slot is used for installation of a PS SIMM or Flash SIMM.

THe PS SIMM is a PostScript Program ROM Memory Module.

The Flash SIMM is a Flash ROM Memory Module.

- 30 -

Page 33

3.15 RS-232C Serial Interface Option Board

A2 to A23

ALS244ALS244

D0 to D31

PD2, 3

SIMM1

CAS0 to

CAS3

OPTION CONNECTOR

RAS2 to

RAS4

ORE, RD,

WR

CS3, EEPCS, EEPCLK

EEPDAT

IOS1

TXD, RST, DTR

ALS244

DRAM SIMM

RAS3, 4

WR

RD

WR

SIMM2

PS SIMM or Flash SIMM

ALS244

BSY

RXD

RS-232C

CONNECTOR

75188

RS-232C Serial Interface Board Block Diagram (Option)

The RS-232C Serial Interface Option Board is provided with a RS-232C I/F and two SIMM slots.

The SIMM1 slot is used for installation of a DRAM SIMM.

The SIMM2 slot is used for installation of a PS SIMM or Flash SIMM.

- 31 -

Page 34

(1) RS-232C Interface

The serial data RXD from the host system, whose line voltage is clamped at the TTL level

by D4/D512, are received by the CPU built-in serial controller.

DSR and CTS signals are terminated through 5.6kΩ resistors. Send signals TXD, RTS and

DTR are put out from the CPU and are sent to lines through a line driver IC (75188).

CPU

RSRXDO-N

101

RSTXDO-P

108

RSRTDO-N

102

RSDTDO-N

103

Option

connector

D512

+5V

75188

+8V -8V

D4

680pF

3.3K

3.3K

5.6K

5.6K

Idle

Idle

SERIAL

RXD

2

DSR

6

CTS

8

CD

1

TXD

3

RTS

7

DTR

4

SSD

9

Input 0V

Output 0V

(a) Send signal level (b)Receive signal level

TTL level

Input 0V

+8V

-8V

Output 0V

- 32 -

+8V

-8V

TTL level

Page 35

(2) SIMM Memory Module

The board is provided with two Slots for a 72-pin DRAM SIMM Memory Module and PS SIMM

or Flash SIMM.

The SIMM1 slot is used for installation of a 72-pin DRAM SIMM Memory Module. Up to 6

types of SIMM Memory Module can be installed.

1M byte, 2M bytes, 4M bytes, 8M bytes, 16M bytes and 32M bytes. 4 types of access speed

can be used; 60, 70, 80 and 100n sec.

The SIMM2 slot is used for installation of a PS SIMM or Flash SIMM.

THe PS SIMM is a PostScript Program ROM Memory Module.

The Flash SIMM is a Flash ROM Memory Module.

- 33 -

Page 36

3.16 Network Interface Option Board

A2 to A23

ALS244ALS244ALS244

D0 to D31

PD2, 3

ALS244

RD

WR

BSY2

CS2

Flash ROM

0.5M Byte

LZ9FF22

CS 8900

Puls

Traus

10BASE-T

CONNECTOR

CAS0 to

CAS3

OPTION CONNECTOR

RAS2 to

RAS4

ORE, RD,

WR

CS3, EEPCS, EEPCLK

EEPDAT

IOS1

CS2

IOS0

INT2, DMARQ

SIMM1

DRAM SIMM

RAS3, 4

WR

BSY1

SIMM2

PS SIMM or Flash SIMM

RD

WR

Network Interface Board Block Diagram (Option)

The Network Interface Option Board is provided with a Network I/F, one Flash ROM chip and two

SIMM slots.

The SIMM1 slot is used for installation of a DRAM SIMM.

The SIMM2 slot is used for installation of a PS SIMM or Flash SIMM.

(1) Network Interface

It is an interface to communicate with 10BASE-T cable.

The physical specification is according to IEEE802.3.

(2) Flash ROM

One 4M bits Flash ROM are installed. Program totals 0.5M bytes.

(3) SIMM Memory Module

The board is provided with two Slot for a 72-pin DRAM SIMM Memory Module and PS SIMM

or Flash SIMM.

The SIMM1 slot is used for installation of a 72-pin DRAM SIMM Memory Module. Up to 6

types of SIMM Memory Module can be installed.

1M byte, 2M bytes, 4M bytes, 8M bytes, 16M bytes and 32M bytes. 4 tyoes of access speed

can be used; 60, 70, 80 and 100n sec.

The SIMM2 slot is used for installation of a PS SIMM or Flash SIMM.

The PS SIMM is a PostScript Program ROM Memory Module.

The Flash SIMM is a Flash ROM Memory Module.

- 34 -

Page 37

3.17 PS-SIMM Option (PostScript Program SIMM Option)

A2 to A23

D0 to D31

RD, CS3

BSY1

Mask ROM

EEPDAT

EEPCS

EEPCLK

EEPROM

PS · SIMM Block Diagram (Option)

The PS-SIMM Option (PostScript Program SIMM Option is provided with two program and font

ROMs and one EEPROM.)

The PS-SIMM is installed to SIMM slot on the Memory Extension Option Board, RS-232C Serial

Interface Option Borad or Network Interface Option Board.

(1) Program and Font ROMs

Two 16M bits Mask ROMs are Installed. Program totals 4M bytes.

(2) EEPROM

Electrical Erassable PROM of 4096 bits. It stores information necessary of PostScript

program.

- 35 -

Page 38

4. TROUBLESHOOTING

4.1 Troubleshooting Table

(A) Power Supply Board (OL1- or OL2-PCB)

Note:

treated here is that of sensors only.

Paper input jam occurs frequently.

#: TRAY1, TRAY2, FEEDER, MANUAL

The malfunction of the power supply is not repaired by an agency. The abnormality to be

Failure LCD Message

#

INPUTJAM

Flowchart

No.

A - 1

Paper feed jam occurs frequently.

#: TRAY1, TRAY2, FEEDER

Paper-exit jam occurs frequently.

#: TRAY1, TRAY2, FEEDER, MANUAL

Paper size error occurs frequently.

#: TRAY1, TRAY2, FEEDER, MANUAL

The message "TRAY PAPEROUT" remains

displayed on the LCD.

#: TRAY1, TRAY2, FEEDER

The message "COVER OPEN" remains

displayed on the LCD.

The message "TONERLOW" remains

displayed on the LCD.

#

FEED JAM

#

EXIT JAM

#

SIZE ERR

#

PAPEROUT

COVER

OPEN

TONERLOW

ERROR 77

A - 2

A - 3

A - 4

A - 5

A - 6

A - 7

or

The message "TONERSNS" remains

displayed on the LCD.

The printer does not function at all, and the

LCD does not display any messages.

Thermistor open error.

Thermistor short error.

Serial interface does not connect to the host

device.

TONERSNS

ERROR 72

ERROR 73

- 36 -

A - 8

A - 9

A - 10

A - 10

A - 11

Page 39

(B) Main Control Board (1/2)

Failure LCD Message

Abnormal message display on the LCD

(no display, unclear display, display with

some dot not lit).

Program ROM error.

Font ROM error.

Resident RAM error. B - 4

EEPROM error. B - 5

Option RAM error.

ERROR 10

ERROR 20

ERROR 30

ERROR 40

ERROR 60

Flowchart

No.

B - 1

B - 2

B - 3

B - 6

Cooling fan error. B - 7

SSIO error. B - 8

Operator panel I/F error.

Option tray I/F timeout error

Watchdog timer timeout occurs frequently, or illegal

CPU version.

Program error.

ERROR 70

ERROR 74

ERROR 80

ERROR 81

ERROR 9*

ERROR F*

B - 9

B - 10

B - 11

B - 12

- 37 -

Page 40

(B) Main Control Board (2/2)

Failure LCD Message

Processor error.

Print overrun occurs frequently.

Error host I/F occurs frequently.

Error receive buffer overflow occurs

frequently.

Paper input jan occurs frequently.

#: TRAY1, TRAY2, FEEDER, MANUAL

Paper input jam occurs frequently.

#: TRAY1, TRAY2, FEEDER, MANUAL

ERROR 0*

PRINT

OVERRUN

HOST I/F

ERROR

REC BUF

OVERRUN

#

INPUTJAM

#

FEED JAM

Flowchart

No.

B - 13

B - 14

B - 15

B - 16

B - 17

B - 18

The key switch operation on the operator

panel is disabled frequently.

Data sent through the Centronics I/F cannot

be received.

Cover open occurs frequently.

COVER

OPEN

B - 19

B - 21

B - 22

- 38 -

Page 41

(C) Operator Panel Board (OLCC-2-PCB)

Failure LCD Message

Abnormal message display on the LCD

(no display, unclear display, display with

some dot not lit, etc.)

The key switch operation on the operator

panel is disabled.

The LCD does not display any message. C - 3

Display on the LCD with some dot not lit. C - 4

Unclear display on the LCD. C - 5

Flowchart

No.

C - 1

C - 2

- 39 -

Page 42

(D) High capacity second paper feeder board (TQSB-2)

Failure LCD Message

Paper input jams occur frequently.

TRAY 2

INPUTJAM

Paper out occurs even if the papersare in

cassette or a tray.

TRAY 2

PAPEROUT

Second tray cover open errors occur even if

the cover is closed.

COVER T2

OPEN

The printer does not recognize an option tray. D - 4

(E) Multi purpose feeder (OLEV)

Failure LCD Message

Paper input jams occur frequently.

FEEDER

Flowchart

No.

D - 1

D - 2

D - 3

Flowchart

No.

E - 1

Paper out occurs even if the papers are in

cassette or a tray.

INPUTJAM

FEEDER

PAPEROUT

E - 2

E - 3The printer does not recognize an option tray.

- 40 -

Page 43

(F) Memory Expansion Option Board (MM6)

Option RAM error.

Failure

LCD Message

ERROR 60

Flowchart

No.

F - 1

- 41 -

Page 44

(G) Network Interface option board (MN5)

Failure

Option ROM error.

Error Host I/F occurs frequently. G - 2

ERROR 50

HOST I/F

LCD Message

Flowchart

No.

G - 1

ERROR

- 42 -

Page 45

(H) RS-232C interface option board (SMIF)

Failure

LCD Message

HOST I/F

ERROR

Loop test error occurs during loop test. H - 2

(I) PS-SIMM (PostScript Program SIMM option)

LCD Message

Option ROM error.

Failure

ERROR 5*

Flowchart

No.

H - 1Error host I/F occurs frequently.

Flowchart

No.

I - 1

The menu settings always go back to the default

setting at Power-up time.

I - 2

- 43 -

Page 46

4.2 Troubleshooting Flowchart

A-1 Paper input jam occurs frequently.

• Is PS3 (Inlet Sensor 1) operating normally?

• No Replace PS3.

▼

• Yes Is PS5 (Inlet Sensor 2) operating normally?

• No Replace PS5.

▼

• Yes Replace IC2 (LC26023A).

A-2 Paper feed jam occurs frequently.

• Is PS3 (Inlet Sensor 1) operating normally?

• No Replace PS3.

▼

• Yes Is PS5 (Inlet Sensor 2) operating normally?

• No Replace PS5.

▼

• Yes Is PS2 (Paper Sensor) operating normally?

• No Replace PS2.

▼

• Yes Is PS1 (Outlet Sensor) operating normally?

• No Replace PS1.

▼

• Yes Replace IC2 (LC26023A).

A-3 Paper exit jam occurs frequently.

• Is PS1 (Outlet Sensor) operating normally?

• No Replace PS1.

▼

• Yes Replace IC2 (LC26023A).

- 44 -

Page 47

A-4 Paper size error occurs frequently.

• Is PS3 (Inlet Sensor 1) operating normally?

• No Replace PS3.

▼

• Yes Is PS5 (Inlet Sensor 2) operating normally?

• No Replace PS5.

▼

• Yes Replace IC2 (LC26023A).

A-5 The message “TRAY PAPEROUT” remains displayed on the LCD

• Is PS4 (Paper End Sensor) operating normally?

• No Replace PS4.

▼

• Yes Replace IC2 (LC26023A).

A-6 The message “COVER OPEN” remains displayed on the LCD.

• Is SW2 (Cover Open Switch) operating normally?

• No Replace SW2.

▼

• Yes Is the CVOPN-N signal low at SW2?

• No Replace SW2.

▼

• Yes Is CVOPN-N signal low at Pin-2 of R600?

• No Replace the power supply board.

▼

• Yes Replace R564.

A-7 The message “TONERLOW” remains displayed on the LCD, or ERROR 77.

• Is PS6 (Toner Sensor) operating normally?

• No Replace PS6.

▼

• Yes Replace IC2 (LC26023A).

A-8 The message “TONERSNS” remains displayed on the LCD.

• Is PS6 (Toner Sensor) operating normally?

• No Replace PS6.

▼

• Yes Replace IC2 (LC26023A).

- 45 -

Page 48

A-9 The printer does not function at all, and the LCD does not display any messages.

• Is fuse F1 open?

• Yes Replace F1.

▼

• No Is the voltage waveform between Pins 1 and 3 of the connector (CN2) same

as the waveform shown below?

T

CH1 + CH1

CH1: DC 20V/div. Normal 5ms/div.

• No Replace the transformer T1.

▼

• Has the problem been solved?

• Yes End.

▼

• No Is the voltage output between Pins 2 and 3 of the filter L101 100 VAC?

• No Replace the filter L101.

▼

• Yes Replace the filter L1.

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace the capacitors C1, C2 and C3.

▼

• Yes Is the fuse F3 open?

• Yes Replace F3.

▼

• No Is the voltage output of Pin 17 of the connector (CN3) about 30 VDC?

• No Replace the diode bridge DS1.

▼

• Yes Is the voltage output of Pin 11 of the connector (CN3) about 5 VDC?

- 46 -

Page 49

• No Replace the transistor Q1.

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace the transistor Q2.

▼

• Has the problem been solved?

▼

• No Replace IC1 (FA7617P-1).

▼

• Yes Check the connection between the power supply board and M5B-PCB.

A-10 Thermistor open error (ERROR 72), Thermistor short error (ERROR 73).

• Is the voltage output between (L) and (N) of the connector ACOUT correct (240V or

120V)?

• Yes Replace IC2 (LC26023A).

▼

• Has the problem been solved?

• Yes End.

▼

• No Thermistor of fuser failure.

▼

• No Is Pin 2 (HEAT-N signal) of PC1 (S21ME4) low?

• No Check the connection between the power supply board and M5BPCB.

• Yes Is Pin 1 (HEAT-NO signal) of PC1 (S21ME4) low?

• No Replace the photo coupler PC1 (S21ME4).

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace the thyristor D1 (TM1241/TM1261).

▼

• Yes Is Pin 10 of IC4 (324P) low?

• No Replace Q7 (2SC3400).

▼

• Yes Replace IC4 (324P).

- 47 -

Page 50

A-11 Serial interface does not connect to the host device.

• Is the voltage waveform between Pins 5 and 6 of the connector (CN2) same as the

waveform shown below?

T

CH1 + CH1

CH1: DC 5V/div. Normal 5ms/div.

• No Replace the transformer T1.

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace the diode D10.

▼

• Yes Is the voltage output at Pin 24 of the connector CN3 +8 VDC?

• Yes Check the connector to the power supply board and M5B-PCB.

▼

• No Replace the diode D9.

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace the capacitors C17 and C18.

- 48 -

Page 51

B-1 Abnormal message display on the LCD.

• Replace IC2, IC3.

▼

• Has the problem been solbed?

• Yes End.

▼

• No Is the 7.067-MHz clock signal being sent to Pin 3 of OSC1?

• No Replace OSC1 (CST 7.067MTW).

▼

• Yes Is the output at Pin 13 (CLRST-N) of IC10 (NJM2901 or µPC339G2) normal

(see Section 3.3 Reset Control on page 7)?

• No Replace IC10 (NJM2901 or µPC339G2).

▼

• Yes Failure of IC1 (MHM2029-004K).

B-2 Program ROM error (ERROR 10).

• Replace IC2 and IC3.

B-3 Font ROM error (ERROR 20).

• Replace IC2 and IC3.

B-4 Resident RAM error (ERROR 30).

• Are negative pulses being put out to Pin 8 (DRASO-N) of IC4, IC5, IC6, IC7,

(M514807A-80J)?

• No Failure of 03E (MHM2029-004K).

▼

• Yes Are negative pulses being sent to Pin 23 (DCAS0-N, DCAS1-N, DCAS2-N,

DCS3-N) of IC4, IC5, IC6, IC7 (M514807A-80J)?

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Replace IC4, IC5, IC6, IC7 (M514807A-80J).

B-5 EEPROM error (ERROR 40).

• Replace IC12 (93LC46A).

▼

• Has the problem been solved?

• Yes End.

▼

• No Failure of IC1 (MNM2029-004K).

- 49 -

Page 52

B-6 Option RAM error (ERROR 60).

• The MENU PRINT memory capacity does not increase even when an expansion

memory board is installed.

• Are negative pulses being sent to Pin 83 (DRAS2-N), Pin 84 (DRAS3-N), Pin 85

(DRAS4-N), Pin 86 (DRAS5-N) of the connector (OPTION)?

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Failure of Option PCB. Go to flowchart F-1 , G-1 or H-1 .

B-7 Cooling fan error (ERROR 70).

• Is the fan rotating?

• No Is +38V power being supplied to Pin 1 (FAN POW) of the connector

(FAN)?

• No Is the output at Pin 109 (FANON-P) of IC1 (MHM2029K-

004K) at high level?

• No Failure of IC1 (MHM2029K-004K).

▼

• Yes Is +38V power being supplied to Pin 3 of TR501?

• No Replace TR502, TR503 and TR504.

▼

• Yes Replace TR501 and IC10 (NJM 2901 or PC339G2)

▼

• Yes Are negative pulses being sent to Pin 3 (FANALM-N) of the connector

(FAN)?

• No Replace the fan.

▼

• Failure of IC1 (MHM2029K-004K).

B-8 SSIO error (ERROR 74).

• Is the connection at the connector (POWER) properly engaged?

• No Replace the connector (POWER).

▼

• Yes Failure of IC1 (MHM2029-004K).

B-9 Operator panel I/F timeout error (ERROR 80).

• Is the connection at the connector (PANEL) properly engaged?

• No Replace the connector (PANEL).

▼

• Yes Failure of IC1 (MHM2029-004K).

- 50 -

Page 53

B-10 Option tray I/F timeout error (ERROR 81).

• Is the connection at the connector (2NDTRAY) properly engaged?

• No Replace the connector (2NDTRAY).

▼

• Yes Is the connection at the connector (ENVELOPE) properly engaged?

• No Replace the connector (ENVELOPE).

B-11 Watchdod timer timeout error occurs frequently (ERROR 90), or illegal CPU version

(ERROR 91).

• Failure at IC1 (MHM2029-004K).

B-12 Program error (ERROR F*).

• Replace IC2 and IC3.

▼

• Has the problem been solved?

• Yes End.

▼

• No Failure of IC1 (MHM2029-004K).

B-13 Processor error (ERROR 0*).

• Replace IC4, IC5, IC6 and IC7.

▼

• Has the problem been solved?

• Yes End.

▼

• No Failure of IC1 (MHM2029K-004K).

- 51 -

Page 54

B-14 Print overrun occurs frequently.

• Is an option board mounted?

• Yes Go to the flowchart B-6.

▼

• No Set DRAM SIMM Memory Module on an option board, then mount it to the

printer.

• Has the problem been solved?

• Yes Print Data is too complex to print out, so it is necessary to

mount an option board with DRAM (SIMM Memory Module)

to the printer.

▼

• No Go to the flowchart B-6.

B-15 Error host I/F occurs frequently.

• Remove the option PCB (RS-232C or Network). Has the Problem been solved?

• Yes Failure of option PCB. Go to flowchart of each option PCB

▼

• No Failure of IC1 (MHM2029-004K)

B-16 Error receive buffer overflow occurs frequently.

[Centronics I/F]

• Is the BUSY signal being sent to Pin 11 (BUSY-P) of the connector (CENT)?

• No Is the BUSY signal being sent to Pin 3 (BUSY-P) of IC11 (7407)?

• Yes Replace IC11 (7407).

▼

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Verify the host settings.

[Serial I/F]

• Is the DTR signal being sent to Pin 4 (DTR) of the connector (CN2 on the RS-232C

option PCB)?

• No Is the DTR signal being set to Pin 9 (DTR-N) of Q111 (75188 on the

RS-232C option PCB)?

• Yes Replace Q11 (75188 on the RS-232C option PCB).

▼

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Verify the operation of the host.

- 52 -

Page 55

B-17 Paper input jam.

• Is the hopping motor rotating normally?

• No Are the waveforms of RMPH1-P and RMPH2-P signals as shown in

▼

• Yes When the motor is rotating, does the output to Pin 20 and Pin 23 of

▼

• Yes Is the voltage at Pin 1 of IC9 (MTD2005F) +38V?

Section 3.9 (2) being sent to Pins 26 and 17 of IC9 (MTD2005F)

respectively?

• No Failure of IC1 (MHM2029-004K).

IC9 (MTD2005F) go high?

• No Is the waveform of RMON-N as shown in Section 3.9 (2)

being sent to Pin 6 of IC10 and TR4 (NJM2901 or

µPC339G2)?

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Replace IC10 (NJM2901 or µPC339G2).

• No Is the voltage at Pin 2 of FU1 +38V?

• No Replace FU1 (fuse).

▼

• Yes Replace IC9 (MTD2005F).

▼

• No Failure of the power supply board or mechanical parts.

- 53 -

Page 56

B-18 Paper feed jam occurs frequently.

• Is the main (drum) motor rotaing normally?

• No Are the waveforms of DMPH1-P and DMPH2-P as shown in Section

3.9 (1) being sent to Pins 13 and 8 of IC8 (A2918SW) respectively?

• No Failure of IC1 (MHM2029-004K).

▼

• Yes When the main (drum) motor is rotating, is DMON1-N at Pin 7 and 14

of IC8 (A2918SW) low?

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Is the voltage at Pin 5 of IC8 (A2918SW) +38V?

• No Replace FU1 (FUSE).

▼

• Yes Replace IC8 (A2918SW).

▼

• No Failure of the power supply board or mechanical parts.

B-19 The key switch operation on the operator panel is disabled frequently.

• Is the clock signal (285kHz) being sent to Pin 6 of PANEL during key operations?

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Is the data signal being sent to Pin 3 (PDATAOUT-P) of PANEL during key

operations?

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Verify the connection of PANEL.

- 54 -

Page 57

B-21 Data sent through the centronics I/F cannot be received.

• Is the signal at Pin 11 (BUSY-P) of the connector (CENT) low?

• No Is the signal at Pin 3 (PBUSY-P) of IC11 (7407) change at data

reception as shown below?

ON-LINE OFF-LINE

PBUSY-P Low High

• No Failure of IC1 (MHM2029-004K).

▼

• Yes Replace IC11 (7407).

▼

• Yes Is the level of the signal at Pin 1 (STB-N) of the connector (CENT) change at

data reception?

• No Verify the connection of I/F cable or the operation of the host

computer.

▼

• Yes Are the signals at Pin 5 (PACK-N), Pin 13 (PERROR-N) of IC11 (7407)

respectively low and high in on-line mode?

• No Replace IC11 (7407).

▼

• Has the problem been solved?

• Yes End.

▼

▼

• Yes Failure of IC1 (MHM2029-004K).

▼

• No

B-22 Cover open occurs frequently.

• Are Pins 2 and 3 of the diode D501 open?

• Yes Replace D501.

▼

• No Is the connection of the connector (POWER), correct?

• No Replace the connector (POWER).

▼

• Yes Failure of IC1 (MHM2029-004K).

- 55 -

Page 58

C-1 Abnormal message display on the LCD (no display, unclear display, display with some

dot not lit, etc.)

• Is +5V power being supplied to Pin 8 of IC1 (BU6152S)?

• No Replace CN1.

▼

• Yes Is the CLOCK signal being sent to Pin 26 (OP-CLOCK-N) of IC1 (BU6152S)?

• No Replace CN1.

▼

• Yes Is the DATA signal being sent to Pin 2 (OP-DATA-IN) of IC1 (BU6152S)?

• No Replace CN1.

▼

• Yes Is the LOAD signal being sent to Pin 11 (OP-LOAD-N) of IC1 (BU6152S)?

• No Replace Replace CN1.

▼

• Yes Is the DATA signal being sent to Pin 24 (OP-DATA-OUT) of IC1 (BU6152S)?

• No Replace IC1 (BU6152S).

▼

• Yes Is +5V power being supplied to Pin 2 of CN1? (OLCC-PCB)

• No Replace CN1. (OLCC-PCB)

▼

• Yes Is the DB signal being sent to Pins, 19, 20, 29, 30 (DB4 to DB7) of IC1

(BU6152S)?

• No Replace IC1 (BU6152S).

▼

• Yes Is the RS signal being sent to Pin 22 of IC1 (BU6152S)?

• No Replace IC1 (BU6152S).

▼

• Yes Is the R/W signal being sent to Pin 27 of IC1 (BU6152S)?

• No Replace IC1 (BU6152S).

▼

• Yes Is the E signal being sent to Pin 9 of IC1 (BU6152S)?

• No Replace IC1 (BU6152S).

▼

• Yes Replace CN2.

- 56 -

Page 59

C-2 The key switch operation on the operator panel is disabled.

• Do the signals at Pins, 3, 7, 10, 18, 23, 31 of IC1 (BU6152S) change from high to low

level by key switch pushing?

• No Replace SW1 to SW8.

▼

• Yes Is the connection of CN1 correct? (OLCC-PCB)

• No Connect the connector correctly.

▼

• Yes Replace IC1 (BU6152S).

C-3 The LCD does not display any message.

• Is +5V power being supplied to Pin 33 of IC2 (HD44780)?

• No Replace CN1. (OLCC-PCB)

▼

• Yes Are 4.15V, 3.3V, 2.46V, 1.61V, and 0.77V powers being supplied respectively

to Pins 26,27, 28, 29 and 30 of IC2 (HD44780)?

• No Are the resistance values of R5 through R10 correct? (OLCC-PCB)

• No Replace R5 through R10. (OLCC-PCB)

▼

▼

• Yes Replace IC2 (HD44780).

▼

• Has the problem been solved?

▼

• Yes

• Yes End.

▼

• No Replace CN1. (OLCC-PCB)

▼

• Has the problem been solved?

• Yes End.

▼

• No Is the contact surface of the zebra rubber dirty?

• No Clean the dirt.

▼

• Yes Replace the zebra rubber.

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace the LCD.

- 57 -

Page 60

C-4 Display on the LCD with some dot not lit.

• Are 4.15V, 3.3V, 2.46V, 1.61V, and 0.77V powers being supplied respectively to Pins

26, 27, 28, 29 and 30 of IC2 (HD44780)?

• No Replace R5 through R10. (OLCC-PCB)

▼

• Yes Is the COM signal being sent to Pins 47 through 62 (COM01 to COM16) of IC2

(HD44780)?

• No Replace IC2 (HD44780).

▼

• Yes Is the SEG signal being sent to Pins 1 through 22 (SEG 19 to SEG40), Pins,

63 through 80 (SEG01 to SEG18) of IC2 (HD44780)?

• No Replace IC2 (HD44780).

▼

• Yes Is the contact surface of the zebra rubber dirty?

• No Clear the dirt.

▼

• Yes Replace the zebra rubber.

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace the LCD.

C-5 Unclear display on the LCD.

• Is +5V power being supplied to Pin 33 of IC2 (HD44780)?

• No Replace CN1. (OLCC-PCB)

▼

• Yes Are 4.15V, 3.3V, 2.46V, 1.61V, and 0.77V power being supplied respectively

to Pins 26, 27, 28, 29 and 30 of IC2 (HD44780)?

• No Replace R5 through R10. (OLCC-PCB)

▼

• Yes Is the contact surface of a zebra rubbber dirty?

• No Clear the dirt.

▼

• Yes Replace the zebra rubber.

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace the LCD.

- 58 -

Page 61

D-1 Paper input jams occur frequently.

• Has the fuse F1 opened?

• No Is the high voltage (around 30V being sent to Pin 2 of D1 and Pin 2

of D2?

• No Replace D1 or D2.

▼

• Yes Is the signal level at Pin 22 of IC2 at low level?

• No Replace IC2.

▼

• Yes Are the signals at Pins 20 and 21 of IC2 being altered?

• No Replace IC2.

▼

• Yes Is the signal level at Pin 2 of TR2 around 5V?

• No Replace TR2.

▼

• Yes Are the signal levels at Pin 20 and 27 of IC3 around 3.4V?

• No Replace R6 and R17.

▼

• Yes Are the signals at Pins 1 to 4 of connector (MOTOR) being altered?

• No Replace IC3.

▼

• Yes Replace motor.

▼

• Yes Replace the Fuse F1.

D-2 Paper out occurs even if the papers are in a cassette.

• Is paper sensor (SEN1) operating normally?

• No Replace the paper sensor.

▼

• Yes Replace IC2.

D-3 High capacity Second Paper Feeder cover open errors occur even if the cover is closed.

• Is cover open sensor (SEN2) operatingnormally?

• No Replace SEN2.

▼

• Yes Replace IC2.

- 59 -

Page 62

D-4 The printer does not recognize High capacity Second Paper Feeder.

• Do signal levels at Pin 2 (OPTSCLK-N) and 3 (OPTSD-P) PU alter at power-up time?

• No Replace Cable.

• No Replace D1 or D2.

▼

• Yes Do signal levels at Pin 4, 7, and 9 of IC2 alter at power-up time?

• No Is signal level at Pin 2 of D5 at 3.9V?

• No Replace D5.

▼

• Yes Is signal level at Pin 2 of TR1 around 5V?

• No Replace TR1.

▼

• Yes Is signal level at Pin 2 of C3 high?

• No Replace C3.

▼

• OK?

▼

• No Is OSC1 being oscillated at 4MHz?

• No Replace OSC1.

▼

• Yes Replace IC2.

▼

• Yes Do signal levels at Pin 3 and 8 of IC1 alter at power-up time?

• No Replace IC1.

▼

• Yes Does signal level at Pin 6 of IC1 alter at power-up time when Pin 8 of IC1 is

at low level?

• No Replace IC1.

- 60 -

Page 63

E-1 Paper input jams occur frequently.

• Is the motor rotating?

• No Has the fuse F1 opened?

• No Is the high voltage (around 30V) being sent to Pin 2 of D1

and Pin 2 of D2?

• No Replace D1 or D2.

▼

• Yes Is the signal level at Pin 22 of IC2 at low level?

• No Replace IC2.

▼

• Yes Are the signals at Pins 20 and 21 of IC2 being altered?

• No Replace IC2.

▼

• Yes Is the signal level at Pin 2 of TR1 around 5V?

• No Replace TR1.

▼

• Yes Is the signal level at Pin 2 and 27 of IC3 around 1.8V?

• No Replace R6 and R17.

▼

• Yes Are the signals at Pins 1 to 4 of CN3 being altered?

• No Replace IC3.

▼

• Yes Replace motor.

▼

• Yes Replace the Fuse F1.

E-2 Paper out occurs even if the papers are in a cassette or a tray.

• Is paper sensor (SEN1 in Second Tray and SEN2 in Multi-purpose Feeder) operating

normally?

• No Replace the paper sensor.

▼

• Yes Replace IC2.

- 61 -

Page 64

E-3 The printer does not recognize Multi Purpose Feeder.

• Do signal levels at Pin 2 (OPTSCLK-N) and 3 (OPTSD-P) CN1 alter at power-up time?

• No Replace Option Tray Cable.

▼

• Yes Do signal levels at Pin 4, 7, and 9 of IC2 alter at power-up time?

• No Is signal level at Pin 2 of D4 at 3.9V?

• No Replace D5.

▼

• Yes Is signal level at Pin 2 of TR4 around 5V?

• No Replace TR4.

▼

• Yes Is signal level at Pin 2 of C2 high?

• No Replace C2.

▼

• OK?

▼

• No Is OSC1 being oscillated at 4MHz?

• No Replace OSC1.

▼

• Yes Replace IC2.

▼

• Yes Do signal levels at Pin 3 and 11 of IC1 alter at power-up time?

• No Replace IC1.

▼

• Yes Does signal level at Pin 8 of IC1 alter at power-up time when Pin 3 of IC1 is

at low level?

• No Replace IC1.

- 62 -

Page 65

F-1 Option RAM error (ERROR 60)

• The MENU PRINT memory capacity does not increase even when an expansion

memory board is installed.

▼

• No Remove the DRAM SIMM. Has the problem been solved?

• Yes Failure of DRAM SIMM.

▼

• Are negative pulses being sent to Pin 83 (DRAS2-N), Pin 84 (DRAS3-N), Pin 85

(DRAS4-N), PIn 86 (DRAS5-N) of the connector (CN1)?

• No Failure of IC1 (MHM2029-004K) or Main Control PCB (M5B).

▼

• Yes Replace D1, D2 (514260).

- 63 -

Page 66

G-1 Option ROM error (ERROR 50)

• Is the connector at the connector (CN1) properly engaged?

• No Replace the connector (CN1).

▼

• Yes Replace the IC3 (29F400TA)

G-2 Error host I/F occurs frequently.

• Is the connection at the connector (CN2) properly engaged?

• No Replace the connector (CN2).

▼

• Yes Replace the T1 (TD43-2006k)

▼

• Is the 20.000 MHz clock signal being sent to Pin 3 of OSC1?

• No Replace OSC1 (CX0-049 20.000 MHz)

▼

• Replace the IC1 (CS8900)

▼

• Replace the IC2 (LZ9FF22).

▼

• Replace the IC3 (29F400TA).

- 64 -

Page 67

H-1 Error host I/F occurs frequently.

• Is the connection at the connector (CN2) properly engaged?

• No Replace the connector (CN2).

▼

• Yes Is the voltage at Pin 14 of Q11 (75188) about +8V and the voltage at Pin 1 of

Q11 (75188) about -8V?

• No Check the connection of the connector (CN1).

▼

• Yes Replace Q11 (75188).

▼

• Has the problem been solved?

• Yes End.

▼

• No Replace BF1 (ZBF253D-01).

▼

• Has the problem been solved?

• Yes End.

▼

• No Failure of IC1 (MHM2029-001K) on the Main Control PCB (M5B).

H-2 Loop test error occurs during loop test.

• Does the state of RXD-N signal vary?

• No Does the state of TXD signal at Pin 3 of Q11 (75188) vary?

• No Check the loop connector.

▼

• Yes Does the state of TXD signal at Pin 2 of Q11 (75188) vary?

• No Failure of IC1 (MHM2029-004K) on the Main Control PCB

(M5B).

▼

• Yes Replace Q11 (75188).

▼

• Yes Failure of IC1 (MHM2029-004K) on the Main Control PCB (M5B).

- 65 -

Page 68

I-1 Option ROM error (ERROR 5*)

• Is the connection of SIMM2 slot correct?

▼

• Replaces PostScript ROMs ROM1 and ROM2.

▼

• No Failure of PS-SIMM.

I-2 The menu settings always go back to the default settings at power-up time.

• Is the signal at Pin 16 of 08G (74ACT244) altered when PostScript menu setting is

changed?

• No Replace 08G (74ACT244).

▼

• Replace 01H (93C66).

- 66 -

Page 69

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

5. CIRCUIT DIAGRAM

- 67 -

Page 70

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

5. CIRCUIT DIAGRAM

Figure 5-1(1/11~11/11)Main Control Board (M5B-PCB, Rev.5) (40217002)

Figure 5-2(1/1) Operator Panel Board (OLCC-2-PCB, Rev.4) (4YA4130-1001G2)

Figure 5-3(1/4~4/4) Power Supply Board (OL1-PCB, Rev.4) (40217701)

Figure 5-4(1/4~4/4) Power Supply Board (OL2-PCB, Rev.4) (40217702)

Figure 5-5(1/1) High Capacity Second (TQSB-2-PCB, Rev.1) (4YA4046-1651G2)

Paper Feeder Board

Figure 5-6(1/2~2/2) Multi Purpose Feeder (OLEV-PCB, Rev.4) (4YA4121-1014G11)

Board

Figure 5-7(1/5~5/5) Memory Expansion (MM6-PCB, Rev.4) (40369105)

Board

Figure 5-8(1/6~6/6) Network interface (MN5-PCB, Rev.5) (40369205)

Board

Figure 5-9(1/5~5/5) RS-232C interface (SMIF-PCB, Rev.4) (00025304)

Board

Figure 5-10(1/1) PS SIMM (MSM-1-PCB, Rev.1) (40368704)

- 68 -

Page 71

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.5W

0.5W

0.1W0.1W

0.01u

6.3

0.1W

0.1W

0.1W

0.1W4.7K

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (1/11)

- 69 -

Page 72

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.1W

0.1W

0.1W

0.1W

3.3K

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W4.7K

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1u

2.7K

4.7K

4.7K

1.2K

4.7K

4.7K

2.4K

2.7K

2.7K

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (2/11)

- 70 -

Page 73

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (3/11)

- 71 -

Page 74

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.1W4.7K0.1W

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (4/11)

- 72 -

Page 75

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.1W

0.1W

0.1W

0.1W

0.50.510.50.51

4.7K

5.6K 0.1

0.1

0.5

0.5

0.1W

0.1W0.1W2.7K

0.1u

5.1K

0.1u

0.1u

0.14.3K

0.1 0.13.9K

0.1

0.1W

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (5/11)

- 73 -

Page 76

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.1W

0.1W

0.1W

0.1W

0.1W

0.1u

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (6/11)

- 74 -

Page 77

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.1W

0.1u

1.2K

1.2K

0.1W

0.1W

0.1W

0.1W

6.3

0.1W

0.1W1.1K

0.1W

1.1K

0.1W

0.1W

0.1W

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (7/11)

- 75 -

Page 78

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.1W

0.1W

0.1W

0.1W

2.2K 0.1W

0.1W

3.3K

0.1u

1.2M

0.1W

0.1W 0.1W

0.1W

0.1u

0.1W

0.01u

0.1W

2.4K

0.1u

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (8/11)

- 76 -

Page 79

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.1W

0.1W

0.1W

0.1W

0.01u

0.01u

0.1W 0.1W

6.3

1.5K

0.1W

0.1W

4.7K

0.1W

620 620

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (9/11)

- 77 -

Page 80

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

0.1W

0.1W

0.1W

0.1W

0.1W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1W

0.1u

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.3K 0.063W

3.9K 0.1W

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (10/11)

- 78 -

Page 81

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

6.3

0.1u

0.1W

Figure 5-1 Main Control Board (M5B-PCB, Rev.5) (11/11)

- 79 -

Page 82

123456789XY

1

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

234 5 678 9X Y

CN1

ZC-106

2

1

C2

100pF 50V

2

1

C4

100pF 50V

2

1

C3

100pF 50V

2

1

C5

100pF 50V

C1

2+

1

100

µ

F 10V

2

1

C5

0.1µF 25V

2

1

C7

0.1µF 25V

R1

1

180

Ω

J 1/10W

200

Ω

J 1/10W

200

Ω

J 1/10W

2

R2

1

2

R4

1

2

R11

1

2

10K

Ω

J 1/10W

7.5K

Ω

J 1/10W

R12

1

2

10K

Ω

J 1/10W

R13

1

2

10K

Ω

J 1/10W

R14

1

2

10K

Ω

J 1/10W

R15

1

2

10K

Ω

J 1/10W

R16

1

2

10K

Ω

J 1/10W

R17

1

2

10K

Ω

J 1/10W

R18

1

91K

Ω

F 1/10W

2

R10

1

2

7.5K

Ω

J 1/10W

R9

1

2

7.5KΩJ 1/10W

R8

1

2

7.5K

Ω

J 1/10W

R7

1

2

7.5KΩJ 1/10W

R6

1

2

6.8K

Ω

J 1/10W

R5

1

2

1

2NL

SW1

1

2NL

SW5

1

2NL

SW2

1

2NL

SW6

1

2NL

SW3

1

2NL

SW7

1

2NL

SW4

1

2NL

SW8

D1

1

2

SEL3410G-YG

+5V

0V

0V

+5V

0V

0V

0V

+5V

0V

OP-DATA-IN

OP-LDAD-N

OP-DATA-OUT

OP-CLOCK-N

+5V

0V

463

1

2

5

IC1

5148

IC2

44780

2

112426

12

8

172532

16

142128

13

561

4

2030291922

279317151823

10

3

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

DT04

DT15

DT26

DT37

DRIR

RWSG

ESOP

SWC1

SWC2

SWC3

SWI1

SWI2

SWI3

SWI4

PSIN

SGCR-N

SOUT

SCLK-N

P60S

VDD1

VDD2

VDD3

VDD4

GND

3637383940414243444546

4748495051525354555657585960616222212019181716151413121110

987654321

807978777675747372717069686866656463353231

34

COM1

COM2

COM3

COM4

COM5

COM6

COM7

COM8

COM9

COM10

COM11

COM12

COM13

COM14

COM15

COM16

SEG1

SEG2