Page 1

Chapter 0

Front Cover

Okifax 1000

Service Handbook

P/N 59261202

Page 2

Manual Copyright

This document may not be reproduced without written permission of the Okidata® Technical Training Group. Every effo

© 1994 by Okidata All rights reserved.

P/N 59261201 First Edition August, 1993

P/N 59261202 First Edition July, 1994

Written and produced by the Okidata Technical Training Group

Please address any comments on this publication to:

Okidata

Technical Training Group

532 Fellowship Road

Mount Laurel, NJ 08054-3499

Facsimile Number: (609) 235-2600, ext. 7034

Okilink Login Name: Technical Training

OKIDATA® is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de Oki Electric Industry

OKIFAX® is a registered trademark of Oki Electric Industry Company, Ltd.

Touch-Tone® is a registered trademark of American Telephone and Telegraph

Page 3

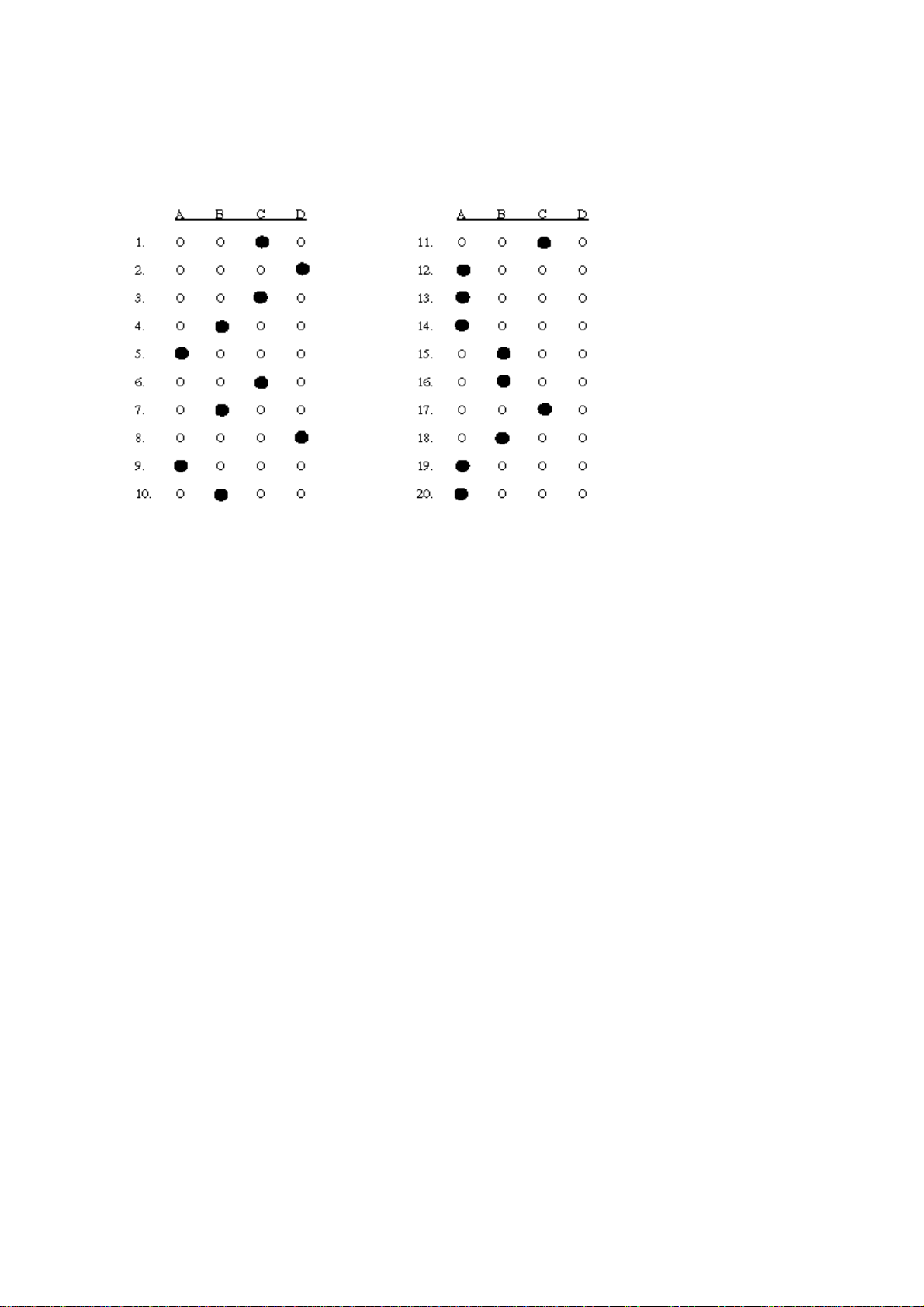

Blank Test & Question Sheet

Answer Sheet: Okifax 1000

Dealer Code: Todays Date:

Technicians Name:

Company:

Companys Address:

City:

State/Province:

Zip/Postal Code:

Country:

Phone #: Fax #:

If your Dealership uses Okilink II, please provide your Dealerships Login Name.

First: Last:

A B C D A B C D

1. O O O O 11. O O O O

2. O O O O 12. O O O O

3. O O O O 13. O O O O

4. O O O O 14. O O O O

5. O O O O 15. O O O O

6. O O O O 16. O O O O

7. O O O O 17. O O O O

8. O O O O 18. O O O O

9. O O O O 19. O O O O

10. O O O O 20. O O O O

Test: Okifax 1000

1. According to the Okifax 1000 Service Handbook, what is the sequence you should follow

when setting the LED Head Drive Time?

1. Remove the package shelf assembly.

2. Determine the dip switch settings associated with the head intensity rating.

3. Set the dip switches.

4. Look at the last three numbers of the label on the LED head.

5. Assemble the unit.

A. 1, 4, 3, 5, and 2

B. 2, 4, 1, 3, and 5

C. 4, 2, 1, 3, and 5

D. 4, 2, 3, 1, and 5

2. The voice answering IC is located on the__________ board.

Page 4

A. PCNT-150

B. NCU-U

C. PSUB-150

D. MCNT-150

3. Where do you check the +38 vdc on the power supply board?

A. CN1, Pins 2,3 and CN2 Pins 1,2

B. CN2, Pins 2,3 and CN4 Pins 1,2

C. CN3, Pins 2,3 and CN2 Pins 1,2

D. CN4, Pins 2,3 and CN2 Pins 1,2

4. Which of the following adjusts the monitor volume of the Okifax 1000?

A. The three position switch on the back of the Okifax 1000

B. User Function 5

C. User Function 11

D. User Function 16

5. Technical Function 27 is the Service Bit. This function must be ON for which of the following?

1. Printing the Protocol Dump Report

2. Printing the Activity Report

3. Resetting the Toner Counter

4. Resetting the Drum Counter

5. Running the Self-Diagnosis Test

6. Resetting the Fuser Counter

7. Modifying the date and time settings.

A. 1, 3, 4, and 6

B. 2, 5, 6, and 7

C. 3, 4, 6, and 7

D. 1, 2, 5, and 6

6. According to Appendix A in the Service Handbook, the __________ provides the

high-voltages needed for electrostatic printing.

A. power supply unit

B. network control unit

C. sub-power supply board

D. main control board

7. The registration stepper motor and the main stepper motor are interchangeable.

A. True

B. False

8. During automatic document feeding, the purpose of the PC2 sensor is to

1. detect the leading edge of the document.

2. detect the presence of a document placed on the ADF.

3. detect the trailing edge of the document.

4. hold back the top originals during multi-feed operations.

A. Both 1 and 2

B. Both 2 and 3

C. Both 3 and 4

D. Both 1 and 3

Page 5

9. Touching the transfer roller may cause incomplete toner transfer, resulting in output with

faded print.

A. True

B. False

10. The Okifax 1000 comes from the factory with AUTO START set to OFF.

A. True

B. False

11. According to the Okifax 1000 Service Handbook, what is the sequence of events during

Automatic Fall-back Mode?

1. The receiving station detects six consecutive error lines during reception of the SECOND

page.

2. First transmission occurs at 9600 bps.

3. Transmission speed drops to 7200 bps.

4. The total number of errors (detected by the receiving station) during the reception of the

FIRST page exceeds 10% of the data on the page. An RTN signal is sent to the

transmitting

station.

5. The transmitting station receives the second RTN signal and downgrades the transmission

speed another level.

A. 2, 1, 3, 4, and 5

B. 2, 5, 3, 4, and 1

C. 2, 1, 4, 3, and 5

D. 2, 4, 3, 1, and 5

12. Okidatas information updates are made available through the electronic bulletin board,

Okilink II.

A. True

B. False

13. Before performing ALL DATA CLEAR, Okidata strongly recommends printing the

Configuration Report, Service Default Report, and the Telephone Directory Report. By doing

this, you will have a record of the customized settings and programmed telephone/facsimile

numbers before the system resets.

A. True

B. False

14. The Okifax 1000 does not allow transmit and receive operations to take place at the same

time. However, documents can be prepared for transmission while the unit is engaged in

message reception.

A. True

B. False

15. The line interface impedance for the Okifax 1000 is __________ ohms.

A. 300

B. 600

C. 900

Page 6

D. 1200

16. In No Paper Receive Mode, with the optional 1 megabyte memory card installed, the

maximum number of non-ECM pages which can be stored in memory is__________ .

A. 108

B. 78

C. 48

D. 248

17. Which of the following statements are true?

1. A PAPER OUTLET JAM occurs when the paper has passed over the paper sensor, but

does not pass over the outlet sensor within a pre-determined period of time.

2. If the paper size of the loaded paper differs by + 45 mm or more from the paper size set by

the menu, a PAPER SIZE ERROR occurs.

3. A PAPER INLET JAM occurs when the printer is powered ON and paper is at inlet sensor 1

or when the leading edge of the paper fails to reach inlet sensor 1 after hopping is attempted

three times.

4. When paper does not pass over the paper sensor within a pre-determined period of time or

when the leading edge of the paper does not reach the outlet sensor within a pre-determined

period of time after the paper has passed over the paper sensor, a PAPER FEED JAM

occurs.

A. 1 and 2

B. 1, 2, and 3

C. 1, 2, 3, and 4

D. None of the above

18. According to the Service Handbook, the Ring Signal Detection Sensitivity can be adjusted

through User Function 24 with the optional second tray installed and User Function 23 if the

second tray is not installed.

A. True

B. False

19. The Okifax 1000 you are troubleshooting displays the message

PRINTER ALARM 4 [TEL]

CONFIRM AND "STOP"

Which of the following are true?

1. This message indicates a fuser unit thermal error.

2. The fuser counter needs to be reset.

3. You should refer to RAP 21E to troubleshoot this message.

4. This message indicates a fan motor rotation error.

A. 1 and 3

B. 2 and 4

C. 2 and 3

D. 3 and 4

20. Documents should be placed face-down on the automatic document feeder (ADF).

A. True

B. False

Page 7

Answer Key // Test Questions with Answers (internal only)

Answer Key // Test Questions with Answers (internal only)

Test: Okifax 1000

1. According to the Okifax 1000 Service Handbook, what is the sequence you should follow when

setting the LED Head Drive Time?

1. Remove the package shelf assembly.

2. Determine the dip switch settings associated with the head intensity rating.

3. Set the dip switches.

4. Look at the last three numbers of the label on the LED head.

5. Assemble the unit.

A. 1, 4, 3, 5, and 2

B. 2, 4, 1, 3, and 5

C. 4, 2, 1, 3, and 5

D. 4, 2, 3, 1, and 5

Correct Answer: C Page 3-116, Service Handbook

2. The voice answering IC is located on the__________ board.

A. PCNT-150

B. NCU-U

C. PSUB-150

D. MCNT-150

Correct Answer: D Page A-4, Service Handbook

3. Where do you check the +38 vdc on the power supply board?

A. CN1, Pins 2,3 and CN2 Pins 1,2

B. CN2, Pins 2,3 and CN4 Pins 1,2

C. CN3, Pins 2,3 and CN2 Pins 1,2

D. CN4, Pins 2,3 and CN2 Pins 1,2

Correct Answer: C Page A - 8, Service Handbook

4. Which of the following adjusts the monitor volume of the Okifax 1000?

A. The three position switch on the back of the Okifax 1000

B. User Function 5

C. User Function 11

D. User Function 16

Page 8

Correct Answer: B Page 4-7, Service Handbook

5. Technical Function 27 is the Service Bit. This function must be ON for which of the following?

1. Printing the Protocol Dump Report

2. Printing the Activity Report

3. Resetting the Toner Counter

4. Resetting the Drum Counter

5. Running the Self-Diagnosis Test

6. Resetting the Fuser Counter

7. Modifying the date and time settings.

A. 1, 3, 4, and 6

B. 2, 5, 6, and 7

C. 3, 4, 6, and 7

D. 1, 2, 5, and 6

Correct Answer: A Page 4-54, 4-56, 4-67, 4-70, and 4-74 Service Handbook

6. According to Appendix A in the Service Handbook, the __________ provides the high-voltages

needed for electrostatic printing.

A. power supply unit

B. network control unit

C. sub-power supply board

D. main control board

Correct Answer: C Page A-18, Service Handbook

7. The registration stepper motor and the main stepper motor are interchangeable.

A. True

B. False

Correct Answer: B Page 3-20, 3-82, 3-94, B-12, and B-38, Service Handbook

8. During automatic document feeding, the purpose of the PC2 sensor is to

1. detect the leading edge of the document.

2. detect the presence of a document placed on the ADF.

3. detect the trailing edge of the document.

4. hold back the top originals during multi-feed operations.

A. Both 1 and 2

B. Both 2 and 3

C. Both 3 and 4

D. Both 1 and 3

Correct Answer: D Pages 2-10 and 2-18, Service Handbook

9. Touching the transfer roller may cause incomplete toner transfer, resulting in output with faded

print.

A. True

B. False

Correct Answer: A Pages 3-98, 3-1118, and 3-119 Service Handbook

10. The Okifax 1000 comes from the factory with AUTO START set to OFF.

A. True

B. False

Correct Answer: B Page 28, Operators Guide

11. According to the Okifax 1000 Service Handbook, what is the sequence of events during

Automatic Fall-back Mode?

1. The receiving station detects six consecutive error lines during reception of the

2. First transmission occurs at 9600 bps.

3. Transmission speed drops to 7200 bps.

4. The total number of errors (detected by the receiving station) during the reception of the

page exceeds 10% of the data on the page. An RTN signal is sent to the transmitting station.

SECOND

page.

FIRST

Page 9

5. The transmitting station receives the second RTN signal and downgrades the transmission speed

another level.

A. 2, 1, 3, 4, and 5

B. 2, 5, 3, 4, and 1

C. 2, 1, 4, 3, and 5

D. 2, 4, 3, 1, and 5

Correct Answer: D Page 2-1, Service Handbook

12. Okidatas information updates are made available through the electronic bulletin board, Okilink II.

A. True

B. False

Correct Answer: A Page i - 5, Service Handbook.

13. Before performing ALL DATA CLEAR, Okidata strongly recommends printing the Configuration

Report, Service Default Report, and the Telephone Directory Report. By doing this, you will have a

record of the customized settings and programmed telephone/facsimile numbers before the

system resets.

A. True

B. False

Correct Answer: A Page 4-78, Service Handbook

14. The Okifax 1000 does not allow transmit and receive operations to take place at the same time.

However, documents can be prepared for transmission while the unit is engaged in message

reception.

A. True

B. False

Correct Answer: A Page 2-1, Service Handbook

15. The line interface impedance for the Okifax 1000 is __________ ohms.

A. 300

B. 600

C. 900

D. 1200

Correct Answer: B Page 1-5, Service Handbook

16. In No Paper Receive Mode, with the optional 1 megabyte memory card installed, the maximum

number of non-ECM pages which can be stored in memory is__________ .

A. 108

B. 78

C. 48

D. 248

Correct Answer: B Page 16, Operators Guide, Users Documentation

17. Which of the following statements are true?

1. A PAPER OUTLET JAM occurs when the paper has passed over the paper sensor, but does not

pass over the outlet sensor within a pre-determined period of time.

2. If the paper size of the loaded paper differs by + 45 mm or more from the paper size set by the

menu, a PAPER SIZE ERROR occurs.

or

or

when

3. A PAPER INLET JAM occurs when the printer is powered ON and paper is at inlet sensor 1

when the leading edge of the paper fails to reach inlet sensor 1 after hopping is attempted three

times.

4. When paper does not pass over the paper sensor within a pre-determined period of time

the leading edge of the paper does not reach the outlet sensor within a pre-determined period of

time after the paper has passed over the paper sensor, a PAPER FEED JAM occurs.

A. 1 and 2

B. 1, 2, and 3

C. 1, 2, 3, and 4

D. None of the above

Page 10

Correct Answer: C Pages 2-36, 2-38, 2-39, and 2-40, Service Handbook

18. According to the Service Handbook, the Ring Signal Detection Sensitivity can be adjusted

through User Function 24 with the optional second tray installed and User Function 23 if the

second tray is not installed.

A. True

B. False

Correct Answer: A Page 1-6, Service Handbook Not in Users Doc

19. The Okifax 1000 you are troubleshooting displays the message

PRINTER ALARM 4 [TEL]

CONFIRM AND "STOP"

Which of the following are true?

1. This message indicates a fuser unit thermal error.

2. The fuser counter needs to be reset.

3. You should refer to RAP 21E to troubleshoot this message.

4. This message indicates a fan motor rotation error.

A. 1 and 3

B. 2 and 4

C. 2 and 3

D. 3 and 4

Correct Answer: A Pages 4-34, Service Handbook

20. Documents should be placed face-down on the automatic document feeder (ADF).

A. True

B. False

Correct Answer: A Page 2-10, Service Handbook

Page 11

Chapter 1

1.1.01 General Information

1.1.01 General Information

The Okifax 1000 is a Group 3 facsimile unit which utilizes an LED page printer engine to produce a plain

paper, permanent copy of received data. The unit can store 85 auto dial locations and has 15 one touch

programmable keys. Scanning is accomplished by the direct contact image sensor method. The image

sensor consists of 1,728 elements. The Okifax 1000 has a scanning width of up to 8.5 inches.

Page 12

1.2 General Facsimile Specifications

1.2 GENERAL FACSIMILE SPECIFICATIONS

1.2.01 Style

· Desktop

1.2.02 Compatibility

· CCITT Group 3

1.2.03 Physical Dimensions

· Width

16.1 inches ( Approximately 410 mm)

· Depth

16.4 inches (Approximately 417 mm )

· Height

8.38 inches (Approximately 212.8 mm)

· Weight

26.5 pounds (Approximately 12 kg)

1.2.04 Ambient Temperature and Relative Humidity (RH)

· Operation

50° to 90° F

10° to 30° C

20 to 80% RH

ONLY

· Storage

-20° to 43° C

-4° to 109° F

Temperature Conversion Formulas

F° to C°:

C°= (F°-32) * .5556

C° to F°:

F°= (C°* 1.8) +32

1.2.05 Power Requirement

· 115 vac

1.2.06 Power Consumption

Mode

Transmit 40W

Receive 120W

Local Copy (All black) 118W (580W**)

Local Copy 125W

Standby 35W

**

Peak Power when the input voltage is 120V.

1.2.07 LCD Display

· 2-line by 20 digit display

Typical Power

1.2.08 Memory

· Standard Memory

256 Kbytes (up to 14 pages of CCITT No.1 Sample Document)

Page 13

· Optional Expansion Memory

1 Mbyte (up to 64 pages of CCITT No.1 Sample Document)

1.2.09 Copy Mode Resolution

· Fixed at 200 lines per inch

1.2.10 Warm-up Time

· From power On until printer is ready

Maximum of 120 seconds

1.2.11 Receive Options

· Auto Receive

· Manual Receive

· Tel/Fax Receive

· Telephone Answering Device (TAD) Mode

· No Paper Receive

· No Toner Receive

1.2.12 Transmit Document Specifications

· Document Width

Minimum 5.8 inches

Maximum 8.5 inches

· Document Length

Minimum 5 inches (single page), 5.8 inches (multi-page document)

Maximum 14 inches, or unlimited length for 1 hour

· Document Weight Range

16 pounds to 24 pounds

· Desired opacity

Less than 40 % of the scanner source light should be able to pass

through the paper.

1.2.13 Automatic Document Feeder (ADF) Capacity

· 30 sheets (20 pound bond)

Page 14

1.3 Communications

1.3 COMMUNICATIONS

1.3.01 Telephone Line Compatibility

· PSTN (public switched telephone network)

· PBX (private branch exchange)

1.3.02 Communication Mode

· Half Duplex

1.3.03 Protocol

· CCITT Recommendation T.30

· Oki Special Protocol

In multi-document reception, the local unit can start transmitting

the modem training bits immediately after transmitting end of

message (EOM) and upon reception of message confirmation (MCF)

from the remote unit, instead of repeating all procedures (which takes

about six seconds).

· Oki Special High Speed

The T.30 handshake is conducted at message transmission speed

(instead of 300 bps) during multi-page transmission.

1.3.04 Line Interface

· Impedance

600 ohms balanced

· Send Power Level

0 dbm to -15 dbm (can be adjusted in 1 dbm steps by modifying TF #21)

1.3.05 Ring Signal Detection Sensitivity

· Voltage Range

25 to 150 r.m.s.

· Frequency Range

15 to 68 Hz (with 44 to 56 volts superimposed)

· Ring Signal Detection Time

One Ring Signal

or

Adjustable between 5 and 30 seconds, in 5 second increments

Refer to User Function 24 (optional second tray installed)

Refer to User Function 23 (optional second tray NOT installed)

· Ring Signal Voltage Duration

Longer than 180 milliseconds (inoperative if duration is

90 milliseconds or less)

1.3.06 Coding Schemes

· Modified Huffman (MH)

· Modified-Modified Read (MMR)

· Modified Huffman (MH)

1.3.07 Error Correction Methods

· CCITT Error Correction Mode (ECM)

· Page Re-transmission (Memory Mode / ECM Off)

1.3.08 High Speed Modem

· CCITT Recommendation V.29 (9600/7200 bps)

· CCITT Recommendation V.27 Ter. (4800/2400 bps)

Only

Page 15

1.3.09 Low Speed Modem

· CCITT Recommendation V.21 Channel 2 (300 bps)

1.3.10 Transmission Time

· 10 seconds

CCITT No. 1 sample document at 9600 bps

1.3.11 Transmit Resolution

· Horizontal

8 PELs per mm

(PEL = Picture ELement)

· Vertical

STD

3.85 lines per mm or 98 lines per inch

FINE

7.7 lines per mm or 196 lines per inch

Ex.FINE

15.4 lines per mm or 392 lines per inch

1.3.12 Photo/Half Tone Transmit Resolution

· 32 Levels (using error diffusion)

1.3.13 Ringer Equivalent Number

· 0.68

1.3.14 Transmit Dialing Methods

· Auto Dialing

70 two-digit auto dial codes

· One Touch Dialing

15 one-touch keys)

· Off Hook Dialing

· On Hook Dialing

· Broadcasting

Group Dial

1.3.15 Receive Mode

· Auto Receive

Dedicated fax machine

· Manual Receive

Telephone manual switch to fax mode

· Tel\Fax Auto Switching

Telephone will auto switch to fax mode

· TAD Interface

1.3.16 Broadcast Transmit Capabilities

· Maximum: 85 locations in one session

1.3.17 TSI/CSI

· Maximum: 20 characters are displayed. If the function is enabled, the

received TSI is marked at the top of the first reproduced copy.

NOTE:

FEDERAL COMMUNICATIONS COMMISSION

TELEPHONE CONSUMER PROTECTION ACT

Part 68 Implementation of the Telephone Consumer Protection Act states:

Page 16

" The Telephone Consumer Protection Act of 1991 makes it unlawful for any person to use a

computer or other electronic device to send any message via a telephone fax machine unless

such message clearly contains in a margin at the top or the bottom of each transmitted page, or

on the first page of the transmission, the date and time it is sent and an identification of the

business, other entity, or individual sending the message and the telephone number of the

sending machine of such business, other entity or individual."

To comply with this law, the End-User must:

1. Enter the DATE and TIME into the Okifax 1000

2. Enter the NAME and TELEPHONE NUMBER to identify the source

of their facsimile transmission.

Page 17

1.4 Printer Specifications

1.4 PRINTER SPECIFICATIONS

1.4.01 Print Method

· Development

Dry electro-photography

· Exposure

Stationary LED head

1.4.02 Print Speed

· Continuous Print

4 sheets per minute (letter size)

· Warm-up Time

Power-ON (Cold): approximately 120 seconds

Idle: approximately 15 seconds

1.4.03 Receive Paper Sizes

· Letter

8.5 inches x 11.0 inches

· Legal (Option)

8.5 inches x 14.0 inches

1.4.04 Receive Paper Types

· 20 pound Bond Paper

1.4.05 Copy Stacking

· The Okifax 1000 stacks the printed output printed side down.

Face-down Stacker Capacity: 100 sheets

1.4.06 Paper Cassette Capacity

· First Cassette

100 sheets

· Second Cassette (Option)

250 sheets

1.4.07 One-Line Minimum Print Time

· Standard Resolution

10 milliseconds per line

· Fine Resolution

5 milliseconds per line

1.4.08 Contrast Selection

· Normal

· Light

· Dark

Page 18

1.5 User Functions

1.5 USER FUNCTIONS

1.5.0l Transmit Mode

· Auto transmit mode

The Okifax 1000 begins sending messages after detecting

the remote stations answer.

· Manual transmit mode

The operator presses the Start Key after an answer tone has been heard.

1.5.02 Receive Mode

· Auto Receive Mode

· Manual Receive Mode

· Telephone / Fax Automatic Switch

· TAD Interface

1.5.03 Absent Mode Auto Timer

· This feature enables switching to the auto receive mode at a specified time.

1.5.04 Group Dial

· One group of up to 85 locations

1.5.05 Telephone Directory and Location ID

· In addition to telephone numbers, an alphanumeric name can be assigned to

each of the numbers. This alphanumeric name is called the Location ID and can

contain up to 15 characters.

1.5.06 Voice Request

· A voice request from the transmitter is available only upon completion of the

total message transmission.

Page 19

1.6 Scanner Specifications

1.6 SCANNER SPECIFICATIONS

1.6.01 Scanning Method

· 1728 bit contact image sensor

1.6.02 Effective Reading Width

· Maximum: 8.5 inches

1.6.03 Scanning Resolution

· Horizontal

8 PELs per mm (PEL= Picture ELement) - approximately 200 PELs

per inch

· Vertical

3.85 lines per mm or 98 lines per inch (STD)

7.7 lines per mm or 196 lines per inch (FINE)

15.4 lines per mm or 392 lines per inch (Ex.FINE)

1.6.04 Automatic Document Feeder

· Maximum 30 sheets of 8.5 x 11 inch, 20 pounds bond paper

NOTE:

Documents must be placed face down on the ADF document guide.

Page 20

1.7 Consumable Items

1.7 CONSUMABLE ITEMS

1.7.01 Toner Cartridge Kit

· Toner Cartridge

· LED Lens Cleaner Pad

1.7.02 Image Drum Cartridge Kit

· Image drum

Page 21

1.8 Options

1.8 OPTIONS

1.8.01 Letter / Legal / Universal Paper Tray

· 100 sheet capacity

· Adjustable sizing capability (letter, legal, universal)

1.8.02 Second Tray Unit (ST-250)

· 250 sheet capacity

1.8.03 Memory Expansion Kit

· 1 MByte Memory Card

Page 22

1.9 Agency Approvals

1.9 AGENCY APPROVALS

· FCC Class A

· UL 478 Ver. 5

· CSA 22.2 220

Page 23

1.10 Reliability Data

1.10 RELIABILITY DATA

1.10.01 Automatic Document Feeder Jam Rate

· Approximately one for every 500 operations

1.10.02 Separation Rubber Life

· Approximately 10,000 document feeds

1.10.03 Lithium Battery Life

· Approximately 5 years

1.10.04 Image Drum Life

· One page print jobs

Up to 11,000 pages

· Continuous print

Up to 20,000 pages

1.10.05 Toner Cartridge Life

· First toner cartridge in image drum

Up to 1,250 pages

· Subsequent toner cartridges

Up to 2,500 pages

1.10.06 Estimated Fuser Life

· Approximately 180,000 pages

1.10.07 Facsimile Mean Time Between Failure (MTBF)

· Approximately 3,000 hours

1.10.08 Printer Duty Cycle

· Approximately 6,000 pages per month

1.10.09 Estimated Printer Life

· Approximately 180,000 pages

1.10.10 Mean Time To Repair (MTTR)

· Approximately 30 minutes

Page 24

Chapter 2

2.1 Principles Of Operation

2.1 PRINCIPLES OF OPERATION

The Okifax 1000 Principles of Operation section is comprised of three sub-sections.

· Transmitter Theory of Operation

· Receiver Theory of Operation

· LED Printer Theory of Operation

Page 25

2.1.01 Compatibility

2.1.01 Compatibility

The Okifax 1000 facsimile machine operates as a Group 3 (G3) facsimile device.

Page 26

2.1.02 Communications Mode

2.1.02 Communications Mode

The Okifax 1000 operates as a half-duplex facsimile transceiver. Transmit and receive operations

cannot take place at the same time. However, documents can be prepared for transmission while

the Okifax 1000 is engaged in message reception. These documents will be automatically

transmitted upon completion of the receiving operation.

Page 27

2.1.03 Modem Operation

2.1.03 Modem Operation

The high-speed modem conforms to CCITT Standard V.29 for 9600/7200 bps (bits per second)

operation and to CCITT Standard V.27 ter. for 4800/2400 bps operation.

The low-speed (300 bps) modem, which is used for handshaking, conforms to CCITT standard

V.21 channel 2 or equivalent.

Page 28

2.1.04 Automatic Fall-Back Mode

2.1.04 Automatic Fall-back Mode

The Okifax 1000 will change the message transmitting speed according to the following fall-back

plan. The Okifax 1000 will first transmit a page of the message at 9600 bps. The receiving station

will continuously monitor the received data. If the receiving station detects six or more consecutive

error lines during reception of a single page, or if the total number of errors detected during the

reception of a single page exceeds 10% of the data on the transmitted page, it will return an RTN

(Retrain Negative) signal to the transmitting station upon termination of the page reception. With

an RTN signal received, the transmitting station will downgrade its speed by one level (to 7200

bps in this case) and continue transmission of the next page. Similarly, should the transmitting

station again receive an RTN signal from the receiving station, it will downgrade speed another

level.

Page 29

2.1.05 Telephone Line Connection

2.1.05 Telephone Line Connection

The Okifax 1000 is connected to the telephone line via the LINE-JU Board. Two RJ-11 connectors

are provided; one for connection to the phone line, and the other for an external telephone. A

separate modular jack is provided for connection of the Okifax 1000s handset.

The Okifax 1000 will control the switching between the handset (or the external telephone) and

the telephone line to permit use of the handset or telephone for voice communication.

Page 30

2.1.06 Error Correction Mode (ECM)

2.1.06 Error Correction Mode (ECM)

The Okifax 1000 features Error Correction Mode (ECM). When communicating with a remote unit

that also has ECM, this feature provides error-free transmission.

What follows is an explanation of how ECM works.

· The transmit machine groups image data into blocks and transmits one block

of data at a time to the receive machine. At the end of each block, a PPS (Partial Page

Signal) is transmitted.

· The receive machine stores the data block in memory and checks each frame within that block

for errors.

- Modified Huffman assigns a binary code to consecutive recurring bits of white or black.

The codes must add up to a total of 1728 bits, which is the Main Scan Rate established

by CCITT.

- Modified Read uses a comparison technique. The line being coded is compared to

the previous line and differences are noted. Codes are then assigned to reflect the

differences between the two lines.

· If no errors are detected, the receiver sends MCF (Message Confirmation) which requests the

transmit machine to transmit the next data block.

· If an error is detected by the receive machine, it transmits the frame number of the defective

frame back to the transmit machine in a signal called PPR (Partial Page Request).

· The transmit machine will then re-transmit the frame to the receive machine as a Partial Page.

· The receive machine rechecks the Partial Page, and (if all frames are correct) the receive

machine transmits MCF (Message Confirmation).

· The next data block is then transmitted.

Page 31

2.1.07 Major Assemblies

2.1.07 Major Assemblies

The following major assemblies make up the Okifax 1000 facsimile machine.

· Main Control Board MCNT-150

· Printer Interface Board PCNT-150

· Network Control Unit Board NCU-U

· Operation Panel Assembly OPE-150

· Power Supply Board (FXLA) PWU-150

· Sub-Power Supply Board (FXHA) PSUB-150

· Line Board LINE-JU

· Hook Switch Board HOOK SW

· Printer Unit

· Scan Unit

Page 32

Okifax 1000 Cross-Sectional View

Okifax 1000 Cross-Sectional View

Page 33

Copy Function Block Diagram

Copy Function Block Diagram

Page 34

Report Print Function Block Diagram

Report Print Function Block Diagram

Page 35

*2.2 Transmitter Theory Of Operation - Typical Transmission

2.2 TRANSMITTER THEORY OF OPERATION

2.2.01 Typical Transmission

When a telephone number is dialed through the Okifax 1000 (either manually or through auto-dial), a

connection will be established with the receiving station through the Public Switched Telephone Network

(PSTN). When the call is answered, the operator will hear the Called Equipment Device (CED) tone from

the receiving station. With CED received, the transmit machine acknowledges that the connection is

established and proceeds to the CCITT T.30 300 bps handshake procedure.

NOTE:

Refer to the Receive and Transmit Handshake Procedure Block Diagrams for functional overviews of 300

bps handshaking.()

Refer to the Transmit Block Diagram for an overview of G3 Transmit Operations()

When the DIS (Digital Identification Signal) is received, G3 mode transmission is possible and the Okifax

1000 starts scanning the document, page by page. The image data is temporarily stored in FIFO (First In

First Out) memory until it becomes valid for transmission. In about 3 seconds, the machine will receive

CSI (Called Subscriber Identification) from the distant station. After reading the document pages and

storing the image data in memory, the machine begins the handshake with the distant station. If the 9600

bps training is successfully completed, the machine will start transmitting the image data in digital, coded

form. Training is a high speed data pattern transmitted to the receive modem. This training data pattern

causes the receive modem to synchronize with the transmit modem. If the training fails due to the line

condition, an automatic fallback to a lower rate will occur. The result will be indicated on the LCD display.

As the machine transmits each page of image data, the page count on the LCD display will increment.

Training is used :

· To test the line condition for valid transmissions at a particular data rate.

The TCF consists of 100 binary 0s transmitted in a burst. At least 98% accuracy

must be achieved before transmission can take place at that data rate.

· By the receiving station in setting preliminary equalization for the current line conditions.

Page 36

300 bps Transmit Handshake Operation Diagram

300 bps Transmit Handshake Operation Diagram

Page 37

300 bps Receive Handshake Procedure Diagram

300 bps Receive Handshake Procedure Diagram

Page 38

G3 Transmit Functional Block Diagram

G3 Transmit Functional Block Diagram

Page 39

2.2.02 Operator Panel

2.2.02 Operator Panel

Through the operator panel (OPE-150), the end user initiates transmit and receive operations,

sets desired options, programs telephone numbers and other data, and interfaces in all facets of

the operation of the machine. The panel consists of an LCD display (two rows of 20 characters), a

numeric key pad, 8 LED indicators, and function keys. The functions of the keys and indicators

are described in the Okifax 1000 Users Documentation.

Page 40

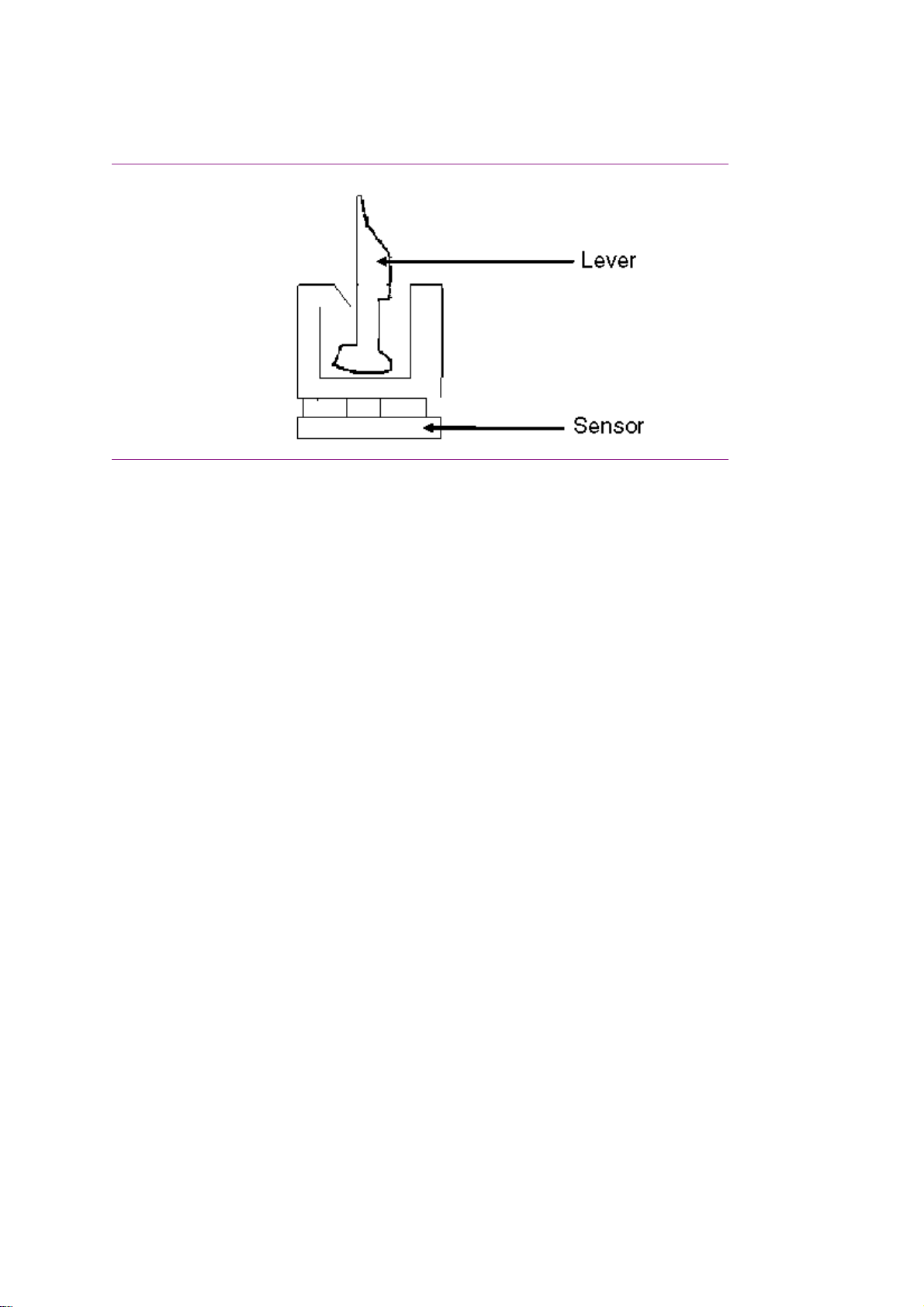

2.2.03 Automatic Document Feeder (ADF)

2.2.03 Automatic Document Feeder (ADF)

The automatic document feeder transfers document sheets to the scan unit automatically, one at

a time. The following diagram shows the mechanism used for detecting the leading and trailing

edges of a document.

When a document is placed on the feeder, it is sensed by PC1. This causes the feed rollers to

activate, feeding the document. The document is fed to the PC2 lever, where the leading edge of

the document is detected. When transmit (or copy) begins, the document is fed by the transmit

stepper motor to the start scan position where reading start. The documents trailing edge is

detected when the PC2 lever is released. If another document is on the feeder, the process is

repeated.

The separation rubber holds back the top originals and allows only one document to be fed into

the scanner area. The separation rubber and ADF rollers should be cleaned or replaced according

to the cleaning schedule (in Section 3 of this manual) to assure proper operation.

The ADF capacity is 30 pages of 20 lb. bond. Documents are placed on the feeder image face

side down. When feeding multiple pages, the bottom page is fed first, working toward the top.

Document Leading/Trailing Edge Detection Diagram

Page 41

*2.2.04 Scanner Assembly

2.2.04 Scanner Assembly

The Okifax 1000 uses a 1728-element direct contact type image scanning sensor. LEDs are

located at the bottom of the scan glass and image sensors are located at the top of the glass.

When the document reaches the scanning unit, it passes directly in front of the image sensor. The

LEDs illuminate the document and the light reflects back to the image sensors. This image data is

sent to the printer control board (PCNT-150). The transmitted document length is limited to 14

inches; however, the machine can be modified for longer transmissions. (See

Documents

Transmission will stop and a line disconnect will occur if the end of the document is not detected

within 14 inches after scanning begins (unless the unit is set for unlimited transmission.) The

message

will be displayed if the document does not reach the scanning position within 5 seconds after the

start of a document feed.

NOTE:

When a jam condition is displayed on the operator panel during message transmission, the

machine will stop

in the Users Documentation).()

RE-LOAD DOCUMENT

CONFIRM AND "STOP"

, but its receiving capability will remain active.

Transmitting Long

Page 42

2.2.05 Encoder

2.2.05 Encoder

Scanned image data received by the PCNT is sent to the encoder/decoder (ENC/DEC) on the

MCNT-150 board. The image data is compressed by the ENC/DEC according to the Modified

Huffman (MH) and Modified Read (MR) encoding scheme, or MH only. The use of MH only or

both MH and MR is determined by a function setting. Data is then stored in the FIFO area in one

byte units. Fill bits are inserted if the length of one encoded line is less than the minimum scan

time of the remote unit. Data is transferred to the NCU board, then sent to the line board for

transmission over the phone line.

Page 43

2.2.06 Modem

2.2.06 Modem

The modem, located on the MCNT-150 board, modulates the data in the correct G3 (9.6, 7.2, 4.8,

or 2.4K bps) data rate that was determined during handshaking between the local machine and

the remote receiver. Modulation is the process of converting the digital output of the scanner into

an analog signal that can be transmitted over the telephone system.

Page 44

2.2.07 Network Control Board (NCU)

2.2.07 Network Control Board (NCU)

The NCU-U board receives the modulated data from the MCNT-150 board and transfers the data

to the line board.

The NCU board performs the following functions during the transmit operation.

· Unit connection / disconnection to the telephone line via the CML Relay

· Dial pulse generation

· The PIS Tone detection

· Off-Hook Detection (Line Current Detector)

· Tx Output Signal Attenuation (normally 9 db output)

· Separation of the TX and RX signals (performed by the Hybrid Transformer)

· Impedance matching (the 600 ohm impedance of the telephone line)

Page 45

2.2.08 Line Board

2.2.08 Line Board

The line board provides the RJ-11 connection used to transmit data to the PSTN or PBX.

Page 46

*2.3 Receiver Theory Of Operation

2.3 RECEIVER THEORY OF OPERATION

NOTE:

Refer to the G3 Receive Operation Block Diagram.()

2.3.01 Operator Panel

Through the operator panel, the user initiates manual receive operations and sets auto-answer

options.

2.3.02 Line Board

The line board provides the RJ-11 connection used to receive data from the PSTN or PBX.

2.3.03 Network Control Board (NCU)

The NCU receives the modulated data from the line board and sends it to the modem (located on

the MCNT board). The operation of the NCU in the receive mode is very similar to the transmit

mode. However, during receive operations, the NCU also functions as an amplifier for the

received signal.

2.3.04 Modem

The modem demodulates the data from the G3 (9.6, 7.2, 4.8, or 2.4K bps) scheme that was

determined during handshaking. The data is then sent to the read-only memory for temporary

storage. The storage time is dependent on whether the machine is printing real-time or from

memory.

2.3.05 Decoder

The decoder decodes the MH, MR, or MMR data from the RAM into lines of picture data that are

1,728 bits in length. After the data has been received, demodulated, and decoded, it is transferred

to the PCNT board.

2.3.06 Document Size

Since the available printing area of the printer is smaller than the paper size, document contents

may be missed on both sides of the paper, or a document image having the same length as the

printing paper may be split into separate pages during printing. To prevent this, the Okifax 1000

automatically sets the proper reduction ratio within the range of 90 to 100% if the RX

REDUCTION function has been set ON. If a received document image is longer than the available

printing length, the excess part of the image is eliminated. If the SPLIT PRINT function has been

set ON, the excess image will be printed on the next page.

Page 47

G3 Receive Operation Block Diagram

G3 Receive Operation Block Diagram

Page 48

2.4 LED Printer - Principal Components

2.4 LED PRINTER

2.4.01 Principal Components

The principal hardware components of the printer unit are listed below.

· Printer Control Board (PCNT-150)

· Power Supply Board (PWU-150)

· Sub-Power Board (PSUB-150)

· Fuser Unit

· Main Motor

· LED Head

· Registration Motor

· DC Fan

· Second Paper Tray Mechanism (option)

Page 49

2.4.02 Printer Control Board (PCNT-150)

2.4.02 Printer Control Board (PCNT-150)

The printer control board (PCNT-150) contains a microprocessor, an EPROM which stores the

printer control program, and 640 Kbytes of dynamic RAM.

This board controls the paper feed and paper transport functions. This board also activates the

LED array diodes, which leave a latent electrostatic image on the photosensitive drum. This latent

image is printed by fusing toner to the paper.

Page 50

2.4.03 Power Supply Board (PWU-150)

2.4.03 Power Supply Board (PWU-150)

The power supply is a switching-type unit, which generates the following voltages from the AC

input voltage.

· + 5 vdc : Printer Logic

· + / - 12 vdc: Interface Signal Levels

· + 38 vdc: Transmit Stepper Motor, Registration / Drum Motor Drive,

Fan Drive, high-voltage source.

When the PCNT-150 board enables the HEATON signal, the power supply provides the AC

voltage to the fuser lamp via the PSUB-150 board.

Page 51

Power Supply Block Diagram

Power Supply Block Diagram

Page 52

2.4.04 Sub-Power Supply Board (PSUB-150)

2.4.04 Sub-Power Supply Board (PSUB-150)

The PSUB-150 consists of IC1 (a one-chip CPU), a cover-open switch, the high voltage generation circuit

and the photo-sensors.

Photosensors

· PS1 - Outlet Sensor

- Detects paper jams at the paper exit path.

· PS2 - Paper Sensor

- Along with the outlet sensor, is used to monitor paper feed and paper length.

· PS3 - Inlet Sensor 1

- Detects the leading edge of the paper. Used in the determination of when to

switch from the hopping to feeding operation.

· PS4 - Paper-end Sensor

- Detects the presence of paper in the cassette. (ON: Paper is present)

· PS5 - Inlet Sensor 2

- Detects the width of the receive paper (ON: A4 or larger)

· PS6 - Toner-low Sensor

- Detects a lack of toner

Cover Open Switch

Whenever the stacker cover is opened, the cover open switch is turned OFF. This removes the + 38 vdc

source voltage from the high-voltage generation circuit. As a result, all high-voltage outputs are disabled.

The CVOPN signal is sent to the MCNT-150 and the cover open routine is performed. The message

COVER OPEN will be displayed on the operator panel.

High-Voltage Circuits

The following voltages are generated for use in the electro-static printing process.

Page 53

Sub-Power Supply Board Block Diagram

Sub-Power Supply Board Block Diagram

Page 54

2.4.05 Fuser Unit

2.4.05 Fuser Unit

The fuser unit is controlled by a thermistor, the printer interface gate array, an LSI and the CPU to

keep the heat roller surface temperature within a predetermined range (about 150 degrees

Celsius). A thermal fuse within the fuser unit prevents abnormal temperature rises in case the

thermistor fails.

NOTE:

The CPU checks for an open circuit in the thermistor at power -on, setting a fuser alarm if this

error is detected.

The CPU also sets a fuser alarm if the proper temperature is not attained within a specified period

of time after power-on.

Upon detecting a fuser alarm, the CPU will halt (after printing the current page).

Page 55

2.4.06 Main Motor (Drum Motor)

2.4.06 Main Motor (Drum Motor)

The main motor is controlled by the motor control LSI, on the PCNT-150 board. The motor used is

a four-phase motor, driven by the two phase excited signal generated by the LSI.

Page 56

2.4.07 LED Array

2.4.07 LED Array

Data for the 1,728 LEDs in the LED array is placed in the shift register by the HD CLK signal. The

data is loaded in the latch circuit by the HD LD signal.

Page 57

2.4.08 DC Fan

2.4.08 DC Fan

The fan is controlled by the FAN ON-P signal from the PCNT-150 board. In order for the

facsimiles printer to operate, the signal FAN SENSE-N must be active.

NOTE:

The fuser and the fan are not enabled when the cover is open. If the fan fails to run, the fuser will

turn off and the message

PRINTER ALARM 4

will be displayed. Printing is disabled.

Page 58

2.4.09 Registration Motor

2.4.09 Registration Motor

The registration motor is driven clockwise for initial receive paper loading, then counterclockwise

for paper feeding. The motor is controlled by the motor drive IC on the PCNT-150 board.

Page 59

2.5 Printing Process - General Information

2.5 PRINTING PROCESS

2.5.01 General Information

Hopping and feeding are controlled by a single registration motor.

Turning the registration motor in the "A" direction drives the hopping roller.

Turning the registration motor in the "B" direction drives the registration roller.

The registration gear and hopping gear contain one-way bearings. Turning each of these gears in

the reverse direction will

turn the corresponding roller.

NOT

Page 60

Printing Process Diagram

Printing Process Diagram

Page 61

2.5.02 Hopping

2.5.02 Hopping

Hopping loads paper from the paper cassette.

During the hopping operation, the registration motor turns in a clockwise direction. This motor

drives the hopping roller, which in turn advances the paper until the inlet sensor 1 switches ON.

The registration gear turns, but the one-way bearing does not allow the registration roller to turn.

After inlet sensor 1 switches ON, the paper is advanced a predetermined length (until the paper

reaches the registration roller).

Page 62

2.5.03 Feeding

2.5.03 Feeding

Feeding transports paper through the printer.

After the completion of hopping, the registration motor turns in a counter-clockwise direction. This

counter-clockwise motion drives the registration roller and advances the paper. The hopping gear

turns, but the one-way bearing does not allow the hopping roller to turn.

Page 63

2.5.04 Charging

2.5.04 Charging

Charging applies -1.3 Kvdc to the charge roller. The charge roller contacts the image drum

surface.

The charge roller has two layers: a conductive layer and a surface protective layer. The surface

layer is flexible, which assures proper contact with the photosensitive drum.

The drum surface charges to approximately -750 vdc.

Page 64

2.5.05 Exposing

2.5.05 Exposing

The image drum has four layers.

· Carrier Transfer Layer (CTL)

· Carrier Generation Layer (CGL)

· Underlayer (UL)

· Aluminum Base

The CTL and CGL make up the organic photo conductor layer (OPC), which is about 20 micrometers (m

m) thick.

When light from the LED head irradiates the image drum surface, the light energy generates positive and

negative carriers in the CGL. The positive carriers are moved to the CTL by an electrical field acting on the

image drum. The negative carriers flow into the aluminum layer (ground).

The positive carriers moved to the CTL combine with the negative charges on the image surface

(accumulated by the contact charge of the charge roller), lowering the potential on the image drum

surface. The resultant drop in the potential of the irradiated part of the image drum surface forms an

electrostatic latent image on it. The surface potential on this irradiated part of the image drum is

approximately -100 vdc.

Page 65

Page 66

2.5.06 Developing

2.5.06 Developing

The electrostatic latent image formed on the image drum surface is developed into a visible image.

Developing takes place when contact is made between the image drum and the developing roller.

As the toner supply roller rotates, toner is absorbed into the sponge type roller material.

A charged particle will be attracted to a particle having a MORE POSITIVE charge than its own.

The developing roller surface is charged to -300 vdc and the toner supply roller is charged to -450 vdc.

Since the development roller is charged more positive than the toner supply roller, the toner on the toner

supply roller is attracted to the developing roller. The toner on the developing roller contacts the doctor

blade, forming a thin coat of toner on the developing roller surface.

The exposed portion of the image drum contains a more positive charge than the development roller (-100

vdc vs -300 vdc). Therefore, toner is attracted to the exposed areas of the image drum, making the

electrostatic latent image visible.

Page 67

NOTE:

The toner supply roller and the developing roller are supplied with the bias voltages required

during the developing process. The toner supply roller is charged to -450 vdc. The developing

roller is charged to -300 vdc.

Page 68

2.5.07 Transfer

2.5.07 Transfer

The transfer roller is made of a conductive sponge material. The roller keeps the paper in constant

contact with the image drum. Paper is placed over the image drum surface. A positive charge

(opposite in polarity to the toner) is applied to the paper from the reverse side.

A charged particle will be attracted to a particle having a MORE POSITIVE charge than its own.

A high positive charge is applied to the transfer roller by the power supply board. This induced

charge (on the surface of the transfer roller) is transferred to the paper when contact is made

between the transfer roller and the paper. The lower side of the paper is positively charged. The

negatively charged toner (on the photosensitive drum) is transferred to the upper side of the paper

because of the positive charge on the lower side of the paper.

Page 69

2.5.08 Fusing

2.5.08 Fusing

After transfer, the toner image is fused to the paper by heat and pressure. The paper passes

between the fusing roller and the pressure roller. The fusing roller has a teflon coating and

contains a 400 watt halogen lamp. A thermistor (which contacts the fusing roller) maintains the

fusing roller temperature at approximately 150 degrees Celsius. A thermostat cuts off the voltage

supply to the lamp if there is an abnormal temperature rise.

The pressure roller provides 2.5 Kg of pressure. This is generated by the pressure springs at each

side of the roller.

Page 70

2.5.09 Cleaning

2.5.09 Cleaning

The image drum is cleaned at the end of transfer. The residual toner on the image drum is

attracted to the cleaning roller, which has a + 400 vdc static charge.

Page 71

*2.5.10 Printing

2.5.10 Printing

Refer to the Printing Process Diagram()

Printing is accomplished as follows.

· Approximately - 1.3 Kvdc is supplied to the charge roller. This causes the drum to charge to

approximately - 750 vdc.

· The LED head is turned ON in accordance with signals from the printer control board. This

causes a latent electrostatic image to be formed on the surface of the drum.

· Through the development process, a toner image replaces the electrostatic image.

· A + 1 Kvdc charge is applied to the transfer roller. This causes the toner image to be transferred

to the receive paper.

· Heat and pressure cause the toner image to become fused to the receive paper. The 150 degree

Centigrade fusing temperature is attained by turning a 400 watt halogen lamp ON. The fusing

temperature is controlled by a thermistor. In the event of a thermistor failure, a temperature fuse

will OPEN, turning off the quartz lamp, and preventing equipment damage.

· The residual toner is removed from the drum.

Page 72

2.6 Sensors And Switches

2.6 SENSORS AND SWITCHES

2.6.01 Paper Jam Detection

Paper jam detection monitors the location of paper when the printer is powered ON and during printing. If

any of the following jams are present, the printing process is interrupted and the message PAPER JAM

will be displayed on the LCD.

To return to the printing process, the paper jam condition MUST be cleared. This is accomplished by

opening the upper cover, clearing the jam, and closing the cover.

Paper Outlet Jam

This jam occurs if,

· The paper does

period of time, however, the paper has already passed over the paper sensor.

Paper Size Error

The time interval between when the paper contacts the paper sensor and the outlet sensor determines

which size (length) paper is being used.

This error occurs if,

· The paper size of the loaded paper differs by + 45 mm or more from the paper

size set by the menu.

pass over the outlet sensor within a pre-determined

NOT

Cover Open Switch

When the stacker cover is opened, the cover open microswitch on the sub-power supply board

(PSUB-150) is deactivated. This disables the + 38 vdc and the high voltage power supply circuit. As a

result, all high voltage outputs are interrupted. At the same time, the CVOPN signal is sent to the main

control board (MCNT-150) to notify it of the OFF state of the microswitch. The MCNT-150 executes the

cover open routine. The operation panel displays the message COVER OPEN.

Page 73

Sensor Location Diagram (Top View)

Sensor Location Diagram (Top View)

Page 74

Detail of Sensor / Lever

Detail of Sensor / Lever

`

Page 75

Paper Inlet Jam

Paper Inlet Jam

This jam occurs when either of the following conditions occur.

· When the printer is powered ON, paper is at inlet sensor 1.

· After the hopping operation is attempted three times, the leading edge of the paper does

reach inlet sensor 1.

NOT

Page 76

Paper Feed Jam

Paper Feed Jam

This jam occurs when either of the following conditions occur.

· The paper does not pass over the paper sensor within a pre-determined period of time.

· The leading part of the paper does not reach the outlet sensor within a pre-determined period of

time after the paper has passed over the paper sensor.

Page 77

2.6.02 Toner Low Sensor

2.6.02 Toner Low Sensor

The toner well of the image drum cartridge contains a toner agitator. Whenever the image drum

rotates, the toner agitator attempts to turn. A spring clip in the bottom of the toner well (along with

the proper amount of toner) holds the agitator at the bottom of the well. However, when toner is

distributed unevenly or an insufficient amount of toner is in the well, the toner agitator will rotate.

Therefore, as long as the toner well contains an adequate supply of evenly distributed toner, the

toner agitator will not rotate.

The toner sensor lever has a magnet embedded in it. Whenever the toner agitator is positioned at

the bottom of the toner well, the toner sensor lever is magnetically attracted to the toner agitator.

This causes the toner sensor lever to be lifted from the path of the toner sensor.

During a low toner condition (less than 20 grams of toner remaining), the toner agitator will rotate

continuously

operator panel will then display the TONER LOW message.

. This causes the toner sensor to turn ON / OFF as the image drum rotates. The

During an unevenly distributed toner condition, the toner agitator will rotate

distributed sufficiently

drum rotations. The operator panel will not display an error message since this is normal printer

operation.

If the toner sensor remains in an ON condition, the operator panel will display the TONER SNS

message.

. This causes the toner sensor to turn ON / OFF for only a few image

until the toner is

Page 78

Chapter 3

3.1 Maintenance - General Information

3.1 MAINTENANCE

3.1.01 General Information

This section lists the parts replacement, adjustment, cleaning, and lubrication procedures.

Disassembly should not be performed unless absolutely necessary.

malfunctioning unit until you have followed the failure analysis procedures in Section Four of this Service

Handbook.

NEVER

perform disassembly on a

Follow the procedures listed in

adjustments may be required when either consumables or parts are replaced. Failure to perform these

procedures could result in unnecessary service calls.

The Okifax 1000 is a xerographic device. Cleaning procedures must be performed correctly if high print

quality is to be achieved.

3.1.02 Maintenance Tools

The following tools are required to service the unit.

· #2 Phillips screwdriver (with magnetic tip)

· Straight-slot screwdriver

· Needle nose pliers (4 inch)

· 5.5 mm wrench

· Digital multimeter

· Shop vacuum with toner filter

· Soft, lint-free cloth

· All-purpose cleaner

· Dow Corning Molycoat BR-2 or Molycoat EM-30L or equivalent

3.1.03 Maintenance Precautions

· Do not disassemble the unit if it is operating normally.

· Before starting disassembly and assembly, always power OFF

the unit and detach the AC power cord.

Adjustments and Service Settings

.

Counters may have to be reset and

· Detach the interface cable, if installed.

· Do not remove parts unnecessarily: try to keep disassembly to a minimum.

· Use the recommended maintenance tools.

· When disassembling, follow the listed sequence.

Failure to follow the correct sequence may result in damaged parts.

· Since screws, collars and other small parts are easily lost, they

should be temporarily attached to the original positions.

· When handling circuit boards use extreme care.

Integrated circuits (microprocessors, ROM, and RAM) can be destroyed

by static electricity.

· Do not place printed circuit boards directly on conductive surfaces.

Page 79

· Follow the recommended procedures when replacing assemblies and units.

Page 80

3.2 Disassembly/Assembly Procedures

3.2 DISASSEMBLY/ASSEMBLY PROCEDURES

General Information

This section contains the disassembly procedures. Only the removal procedures are explained

here. Reverse the procedure for the installation.

At the bottom of each procedure is a listing of Okidata part numbers, item descriptions, and

cross-references to Appendix B. Items included in the Recommended Spare Parts List are

designated by the acronym RSPL. N/A will appear where a part number is not available.

This Service Handbook lists the disassembly procedures for major components of the unit. If you

decide to perform disassembly during this training, Okidata recommends that you perform

the disassembly procedures for RSPL items. All other procedures are provided to assist you in

identifying parts. It is not likely that you will perform these procedures while servicing the unit.

Be sure to read all notes, cautions, and warnings, as they contain important information regarding

disassembly / assembly.

only

Page 81

*3.2.01 Preliminary Items

3.2.01 Preliminary Items

NOTES:

Refer to Section 3.4 of this Service Handbook for cleaning details.()

Refer to Section 4.8 of this Service Handbook for Toner and Drum Counter Information.()

1. Press the AC switch and power OFF the unit.

2. Detach the AC power cord.

3. Detach the modular telephone cord.

4. Remove the document support tray (1).

5. Remove the handset cord (2) and handset (3).

6. Remove the document stacker tray (4).

7. Remove the paper cassette assembly (5).

8. Raise the document table (6).

9. Press the buttons and raise the copy stacker (7).

10. Remove the image drum with toner cartridge.

P/N 56618901 Cord: AC Power RSPL B.2.16()

P/N 56621001 Cord: Modular Telephone RSPL B.2.16()

P/N 50103401 Tray: Document Support RSPL B.2.01()

P/N 56628101 Cord: Handset RSPL B.2.01, 16()

P/N 53549709 Handset RSPL B.2.01()

P/N 50102001 Tray: Document Stacker RSPL B.2.01()

P/N 50101901 Cassette: Paper Assembly RSPL B.2.01()

P/N 70026101 Tray: Legal/Universal Paper Option (100 Sheet Capacity) B.2.18()

P/N 56116901 Kit: Image Drum Consumable B.2.04, 20()

P/N 52106701 Kit: Toner Cartridge Consumable B.2.04, 20()

P/N 53571901 Cassette Separator Assembly RSPL B.2.07()

P/N 50925801 Spring: Cassette Separator RSPL B.2.07()

Page 82

*3.2.02 LED Head

3.2.02 LED Head

CAUTION

Do NOT touch the LEDs.

1. Perform this procedure:

3.2.01().

2. Raise the document table (1).

3. Press the buttons (2) and raise the copy stacker (3).

4. Detach the cable (4).

5. Press the copy stacker out at positions (A) and release the tabs of the LED head (5).

6. Remove the LED head, being careful not to lose the ground clip (6).

NOTES:

The Cable: LED-PCNT runs from the LED Head to connector CN4 of the PCNT board. This is a

flat white cable.

INSTALLATION

The blue strip of the cable faces the top of the unit.

When installing a new LED head, set the LED Head Drive Time. Refer to Section 3.3 of this

Service Handbook for details().

Clean the LED head using the LED lens cleaner provided in the toner cartridge kit or use a lens

cleaning tissue and ethyl alcohol. Refer to Section 3.4 of this Service Handbook for cleaning

details().

P/N 56110801 LED Head RSPL B.2.04()

Page 83

*3.2.03 Terminal Cover Cap, Rear Cover, and Fan

3.2.03 Terminal Cover Cap, Rear Cover, and Fan

1. Perform this procedure:

3.2.01()

2. Remove the screw (1).

3. Remove the terminal cap cover (2).

NOTE:

You do not have to remove the terminal cover cap to remove the rear cover and fan.

4. Remove the two screws (3).

5. Detach the rear cover (4) and tilt it out to access the fan cable (5).

6. Detach the fan cable from connector CN11 (6) from the board (PCNT) (7).

7. Release the latches (8) and remove the fan (9).

8. Remove the rear cover.

NOTES:

The fan connector cable goes to CN11 of the PCNT board. This is a 3 pin connector.

When installing the rear cover, be careful not to damage the ring volume switch cover.

When installing the fan, be careful not to leave the cable in front of the fan. Be sure to place the

cable on the side of the fan. If you do not, it may cause excessive vibration noise or prevent the

fan from operating. If fan motion is stopped completely, a PRINT ALARM 3 will be displayed on

the operator panel.

P/N N/A Screw B.2.01()

P/N 53070206 Cover: Terminal Cap RSPL B.2.01()

P/N 53070002 Cover: Rear RSPL B.2.01()

P/N 56510902 Fan RSPL B.2.01, 16()

Page 84

Page 85

*3.2.04 Line Board (LINE-JU)

3.2.04 Line Board (LINE-JU)

1. Perform these procedures:

3.2.01()

3.2.03()

2. Detach the cable to connector CN2 of the line board (LINE-JU) (1).

3. Detach the cable to connector CN5 of the board.

4. Remove the two screws (2).

5. Remove the board.

P/N 55073401 PCB: Line-JU RSPL B.2.07()

P/N 53070901 Cover: Ring Volume Switch RSPL B.2.07()

P/N 56628510 Cable: NCU-Line (8 pin) B.2.16()

P/N 56628901 Cable: NCU-Line (2 Pin) B.2.16()

Page 86

*3.2.05 Package Shelf Assembly

3.2.05 Package Shelf Assembly

1. Perform these procedures:

3.2.01()

3.2.03()

3.2.04()

2. Remove the four screws (1).

3. Pull the package shelf (2) out slightly.

4. Remove the three screws (3) holding the tie wraps down.

5. Detach the cables from the thirteen connectors (Not identified).

6. Remove the package shelf assembly, with boards.

P/N N/A Package Shelf Assembly B.2.07 08()

P/N N/A Bracket: Line B.2.07 08()

P/N N/A Guide: Package B.2.07 08()

P/N N/A Insulator (2) B.2.07 08()

P/N N/A Plate: Shield (L) B.2.07 08()

P/N N/A Screw B.2.07 08()

Page 87

*3.2.06 Network Control Unit (NCU-U)

3.2.06 Network Control Unit (NCU-U)

1. Perform these procedures:

3.2.01()

3.2.03()

3.2.04()

3.2.05()

2. Disconnect the cables from the connectors (see below).

3. Remove the three screws (1).

4. Remove the network control unit (NCU) (2).

P/N 55073501 PCB: NCU-U RSPL B.2.07()

P/N 56628510 Cable: NCU-Line B.2.16()

P/N 56629209 Cable: NCU-Hook B.2.16()

P/N 56628901 Cable: NCU-Line (2 Pin) B.2.16()

P/N 56628501 Cable: MCNT-NCU (15 Pin) B.2.16()

P/N 56628604 Cable: NCU-Hand Set B.2.07, 16()

P/N N/A Screw B.2.07()

P/N 56628801 Cable: MCNT-PCNT B.2.16()

Page 88

*3.2.07 Main Control Board (MCNT-150)

3.2.07 Main Control Board (MCNT-150)

1. Perform these procedures:

3.2.01()

3.2.03()

3.2.04()

3.2.05()

2. Detach the cables from connectors (see below).

3. Remove the two screws (1).

4. Remove the main control board (2).

P/N 56628501 Cable: MCNT-NCU (15 Pin) B.2.16()

P/N 56628801 Cable: MCNT-PCNT B.2.16()

P/N 57001302 Speaker B.2.02, 16()

P/N 56628508 Cable: MCNT-PWU (12 Pin) B.2.16()

P/N 56628505 Cable: MCNT-Hook (2 Pin) B.2.16()

P/N 56628701 Cable: OPE-MCNT B.2.16()

P/N N/A Screw B.2.07()

P/N 55073701 PCB: MCNT-150 RSPL B.2.07()

Page 89

*3.2.08 Printer Control Board (PCNT-150)

3.2.08 Printer Control Board (PCNT-150)

1. Perform these procedures:

3.2.01()

3.2.03()

3.2.04()

3.2.05()

2. Detach the cables from the connectors (see below).

3. Remove the two screws (1).

4. Remove the printer control board (2).

P/N N/A Screw B.2.07()

P/N 55073601 PCB: PCNT-150 RSPL B.2.07()

P/N 56628801 Cable: MCNT-PCNT B.2.16()

P/N N/A Cable: PCNT-PSUB B.2.17()

P/N 56628302 Cable: PCNT-Image Sensor RSPL B.2.17()

P/N 56629101 Cable: LED-PCNT B.2.17()

P/N 56628603 Cable: PC1+PC2-PCNT B.2.17()

P/N 56628605 Cable: PCNT-PWU B.2.17()

P/N 56628507 Cable: PCNT-2nd Tray PCB B.2.17()

P/N 56510702 Motor: Registration Stepper B.2.05, 17()

P/N 56510703 Motor: Main Stepper B.2.05, 17()

P/N 57001301 Cable: PCNT-S Motor B.2.17()

P/N 56510902 Fan B.2.16()

Page 90

*3.2.09 Left Side Cover

3.2.09 Left Side Cover

1. Perform this procedure:

3.2.01()

2. Open the control panel unit (1).

3. Remove the two screws (2).

4. Open the document guide assembly (3).

5. Open the copy stacker (4).

6. Remove the screw (5).

7. Remove the left side cover (6).

P/N 50317201 Cover: Cradle RSPL B.2.01()

P/N 53069901 Cover: Side (Left) RSPL B.2.01()

Page 91

*3.2.10 Hook Switch Board (Hook-SW)

3.2.10 Hook Switch Board (Hook-SW)

1. Perform these procedures:

3.2.01()

3.2.09()

2. Remove the two screws (1).

3. Detach the two cables (2).

4. Remove the hook switch board (3).

P/N N/A Screw B.2.01()

P/N 56629209 Cable: NCU-Hook B.2.16()

P/N 56628505 Cable: MCNT-Hook (2 Pin) B.2.16()

P/N 55074002 PCB: Hook Switch RSPL B.2.01()

P/N 51709801 Insulator: Hook Switch B.2.01()

Page 92

*3.2.11 Power Supply Unit (PWU)

3.2.11 Power Supply Unit (PWU)

1. Perform these procedures:

3.2.01()

3.2.09()

2. Remove the two screws (1).

3. Disconnect the four connectors (see below).

4. Remove the power supply unit (2).

P/N N/A Screw B.2.07()

P/N 56628512 Cable: PSUB-PWU (7 Pin) B.2.16()

P/N N/A Cable: PSUB-PWU B.2.17()

P/N 56628605 Cable: PCNT-PWU B.2.17()

P/N 56628508 Cable: MCNT-PWU (12 Pin) B.2.16()

P/N 56413101 Power Supply (120V) RSPL B.2.07()

Page 93

*3.2.12 Gear Frame Assembly

3.2.12 Gear Frame Assembly

1. Perform these procedures:

3.2.01()

3.2.09()

3.2.11()

2. Disconnect the cable from the transmit stepper motor. (Not shown)

3. Remove the five screws (1).

4. Remove the gear frame assembly (2).

NOTE:

The gear frame assembly includes the gear frame, the Z43 gear, the Z31/19 gear, the Z81/15

gear, the heat sink, the ADF earth plate, the F2 earth plate, the screws, and the spring washer. To

replace any of these parts, order the assembly.

Lubrication

Lightly lubricate the gears in the gear frame assembly. Refer to Section 3.5 of this Service

Handbook for lubrication details().

P/N 53343401 Frame: Gear Assembly RSPL B.2.09()

Page 94

*3.2.13 Transmit Stepper Motor

3.2.13 Transmit Stepper Motor

1. Perform these procedures:

3.2.01()

3.2.09()

3.2.11()

3.2.12()

2. Remove the two screws (1).

3. Disconnect the connector (2).

4. Remove the transmit stepper motor (3).

NOTE:

The PCNT-S Motor Cable connects the transmit stepper motor to connector CN 10 of the PCNT

board.

Lubrication

Lightly lubricate the gearing of the transmit stepper motor. Refer to Section 3.5 of this Service

Handbook for lubrication details.

P/N 56511101 Motor: Transmit Stepper RSPL B.2.09()

P/N 57001301 Cable: PCNT-S Motor B.2.17()

Page 95

*3.2.14 Gear Frame and Gears

3.2.14 Gear Frame and Gears

1. Perform these procedures:

3.2.01()

3.2.09()

3.2.11()

3.2.12()

3.2.13().

2. Remove the four screws (1).

3. Remove the heat sink (2).

4. Remove the four gears.

Gear Z81 / 15 (3)

Gear Z31 / 19 (4)

Gear Z43 (5)

NOTE:

Lubrication

Lightly lubricate the gears. Refer to Section 3.5 of this Service Handbook for lubrication details().

P/N N/A Screw B.2.09()

P/N N/A Heat Sink B.2.09()

P/N N/A Gear: Z81/15 B.2.09()

P/N N/A Gear: Z31/19 B.2.09()

P/N N/A Gear: Z43 B.2.09()

P/N N/A Frame: Gear B.2.09()

P/N N/A Plate: Earth (ADF) B.2.09()

P/N N/A Plate: Earth (F2) B.2.09()

P/N N/A Spring Washer B.2.09()

P/N N/A Screw B.2.09()

P/N N/A Screw B.2.09()

Page 96

Page 97

*3.2.15 Memory Card (Option)

3.2.15 Memory Card (Option)

1. Power OFF the unit and detach the AC power cord.

2. Remove the memory card cover (1).

3. Remove the memory card (2).

P/N 53070101 Cover: IC Card Cap RSPL B.2.01()

P/N 70025301 1 MB Memory Expansion Kit Option B.2.18()

Page 98

*3.2.16 Right Side Cover

3.2.16 Right Side Cover

CAUTION

Do NOT attempt to remove the right side cover until the memory card has been removed.

To completely remove the right side cover, you must also remove the speaker.

1. Perform these procedures:

3.2.01()

3.2.15()

2. Raise the control panel unit (1).

3. Remove the two screws (2).

4. Raise the document guide table (3) and copy stacker (4).

5. Remove the screw (5).

6. Remove the right side cover (6).

P/N N/A Screw B.2.01()

P/N 53069801 Cover: Side (Right) RSPL B.2.01()

P/N 56628507 Cable: PCNT-2nd Tray PCB B.2.17()

Page 99

*3.2.17 Document Guide Assembly

3.2.17 Document Guide Assembly

1. Perform these procedures:

3.2.01()

3.2.15()

3.2.16()

2. Close the copy stacker (1).

3. Remove the document guide assembly (2).

NOTE:

The document guide assembly includes the left and right document guides, the document hopper,

and the document guide cover. To replace any of these parts, order the assembly.

Lubrication

Lightly lubricate the damper gear. Refer to Section 3.5 of this Service Handbook for lubrication

details.()

P/N 51012201 Guide: Document Assembly RSPL B.2.02()

P/N N/A Cover: Document Guide B.2.02()

P/N N/A Guide: Document (R) B.2.02()

P/N N/A Guide: Document (L) B.2.02()

P/N N/A Hopper: Document B.2.02()

P/N N/A Screw B.2.02()

P/N N/A Gear: Damper B.2.02()

Page 100

*3.2.18 Speaker

3.2.18 Speaker

1. Perform these procedures:

3.2.01()

3.2.03()

3.2.04()

3.2.05()

3.2.15()

3.2.16()

2. Remove the screw (1).

3. Remove the speaker bracket (2) and speaker (3).

NOTE:

The speaker harness goes to connector CN5 of the MCNT board.

P/N N/A Screw B.2.02()

P/N N/A Bracket: Speaker B.2.02()

P/N 57001302 Speaker B.2.02, 17()

Loading...

Loading...