4048P

REPAIR PARTS LIST

2

8

12

16

14

15

17

7

7

404

1

12.5 CUB

EAPED DUMP CART

H

ASSEMBLY MA

8P

IC FOOT

NUAL

4

9

19

10

8

3

5

18

9

11

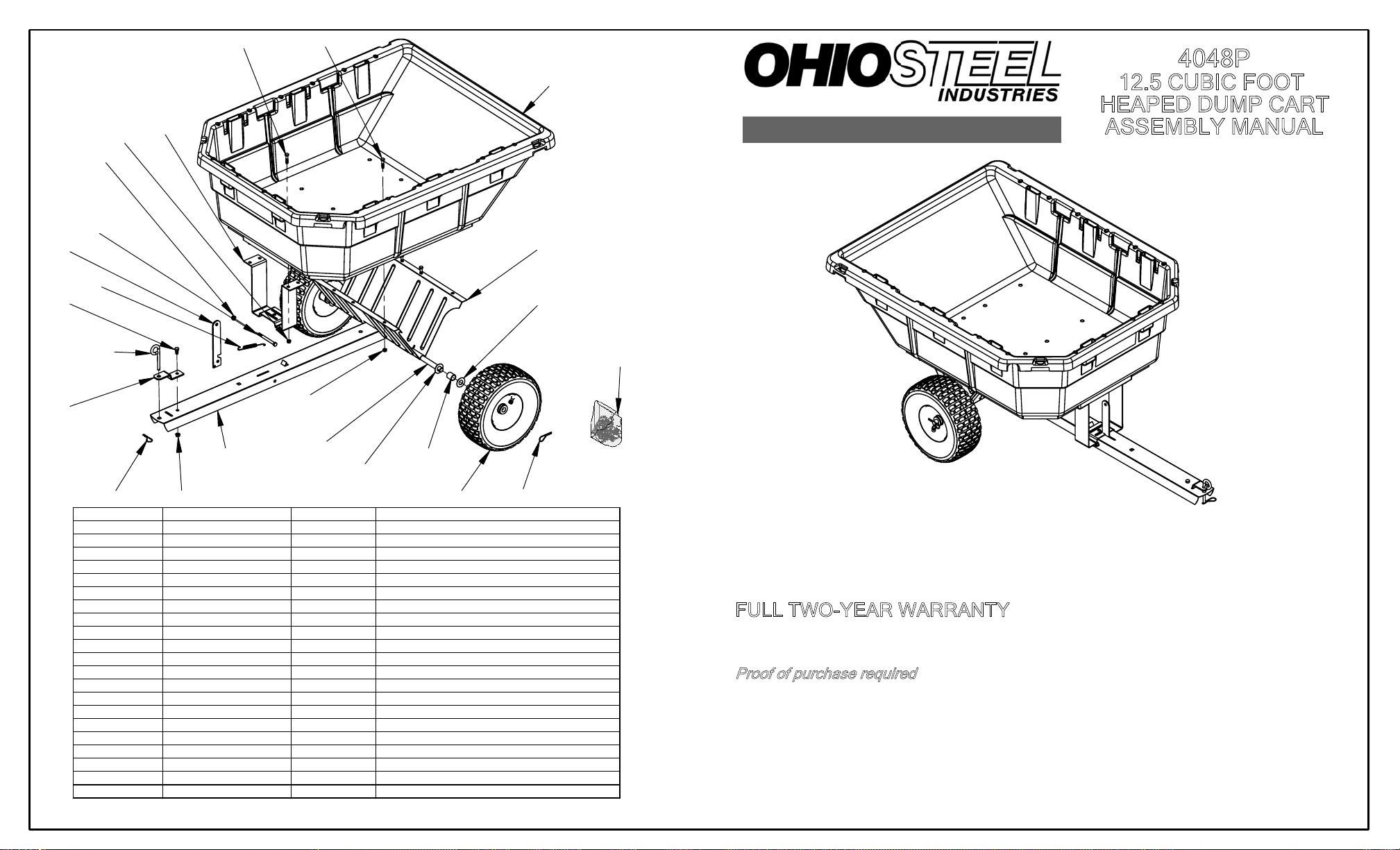

REF. NO . PART NO. AMT. DESC RIPTIO N

1 4048P-01 1 Body

2 55-9A 1 Front Support

3 55-12A 1 Hitch Assembly

4 4048P-04 1 Axle Holder

5 55-17 1 Axle #1

6 4048P-06 2 Wheel 15 X 6.00 - 6

7 STDBH3131500 12 5/16"-18 x 1-1/2" Hex Head Bolt

8 STDNK313 12 5/16"-18 Keps Nut

9 STDWA750T 4 3/4" Axle Washer

10 STDHP375 1 Hitch Pin

11 STDPH7 3 Hairpin Cott er

12 STDNC375 2 3/8"-16 Lock Nut

14 55-13A 1 Latch Bar

15 55-15A 1 Latch Spring

16 STDBH3754000 1 Bolt 3/8"-16 x 4" Hex Head

17 STDBH3750375 1 Bolt 3/8"-16 X 3/4" Hex Head

18 4048P-18 2 HDPE Axle Spacer

19 55-16A 1 Hitch Bracket

20 4048P-35 1 Decal

21 4048P-21 1 User Guide

22 4048P-22 1 Hardware Bag

12

6 11

Hardware

Bag

REV-NC

22

CAUTION:

READ AND FOLLOW ALL SAFETY

RULES AND INSTRUCTIONS

Ohio Steel Industries

Columbus, OH 43224 U.S.A.

Visit our website: www.ohiosteel.com

BEFORE USING THIS EQUIPMENT

For missing parts or questions

Call 1-800-652-2321

FULL TWO-YEAR WARRANTY

If this product fails due to a defect in material or workmanship within two years from the date

of purchase, Ohio Steel will at its option repair or replace it free of charge. This warranty

excludes Tires and Wheels which are expendable and become worn during normal use.

Proof of purchase required

This warranty does not cover:

· Repairs necessary because of operator abuse or negligence.

· Equipment use for commercial or rental purposes.

Contact Ohio Steel (800-652-2321) to arrange for product repair, or return this product to

place of purchase for replacement.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state. This Warranty applies only while this product is in use in the United States.

.

TOOLS REQUIRED

Large blade screwdriver.•

1/2" wrench and/or socket.•

Electric / cordless drill.•

SAFETY INSTRUCTION

Do not carry passengers in cart.•

Do not tow cart on public roads.•

Never exceed LOAD CAPACITY of 750lbs.•

Avoid sudden turns or maneuvers.•

When operating on slopes, use lowest •

ground speed and limit load to 200lbs.

Operate up and down slopes, never •

across the face.

MAINTENANCE

Check tire pressure regularly, 30psi.•

Periodically check all nuts & bolts for tightness.•

Grease wheel at axle for longer life.•

Keep cart clean and dry to prevent rust.•

When not using, store inside a clean dry area.•

REF. NO . AMT. DESC RIPTION

11Body

2 1 Fr ont S uppor t

3 1 Hitch Assem bly

41Axle Holder

51Axle #1

6 2 Wheel 15 X 6.00 - 6

7 12 5/16"-18 x 1-1/2" Hex Head Bolt

8 12 5/16"-18 Keps Nut

9 4 3/4" Axle Washer

10 1 Hitch Pin

11 3 Hairpin Cotter

12 2 3/8"-16 Lock Nut

14 1 Latch Bar

15 1 Latch Spring

16 1 Bolt 3/8"-16 x 4" Hex Head

17 1 Bolt 3/8"-16 X 3/4" Hex Head

18 2 HDPE Axle Spacer

19 1 Hitch Br acket

20 1 Decal

21 1 User Guide

22 1 Har dw a re B ag

Step 1. Secure front support (2) and axle holder (4) to body (1) as shown.

1

4

8

7

2

11

11

3

6

18

9

9

5

18

Step 2. Slide axle (5) through axle

holder (4) and hitch assembly (3).

Cart configurations you can make with standard lumber.

Step 3. Place axle washer (9), HDPE

4

9

9

spacer (18), axle washer (9)and wheel

(6) onto axle.

Repeat for other side.

6

Step 4. Insert hairpin cotter (11) in

each end of axle (5).

Step 5. Set cart upright on wheels and

insert hitch pin (10) into hitch (3)and

Increase capacity. Divide / segregate loads.

secure with hairpin (11).

Step 6. To install supplied tool holders.

We recommend you measure the

spacing by attaching holders to the tool

you intend to use with cart. Mark

1110

locations on cart body, and drill 3/16"

hole. Secure with hardware provided.

Create flat work space.

Create your own.

Loading...

Loading...