Ohio Vacuum Regulator Service manual

6700-0078-000 Rev1 06/2009

Continuous Vacuum

Regulators

Service Manual

E

D

M

100

80

120

-mmHg

60

W

O

40

L

20

F

140

H

I

G

H

160

180

200

U

C

L

A

V

L

600

400

500

50

60

70

High Flow

High Vacuum

80

90

100

700

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

6700-0078-000 Rev1 06/2009

User Responsibility

This Product will perform in conformity with the description thereof contained in this manual and accompanying

labels and/or inserts, when assembled, operated, maintained and repaired in accordance with the instructions

provided. This Product must be checked periodically. A

malfunctioning Product should not be used. Parts that

are broken, missing, plainly worn, destroyed or contaminated, should be replaced immediately. Should such

repair or replacement become necessary, Ohio Medical

recommends that a telephonic or written request for service advice be made to the nearest Ohio Medical Service

Office. This Product or any of its parts should not be

repaired other than in accordance with written instructions provided by Ohio Medical, or altered without the

prior written approval of Ohio Medical’s Safety

Department. The user of this Product shall have the sole

responsibility for any malfunction which results from

improper use, faulty maintenance, improper repair, damage, or alterations by anyone other than Ohio Medical

Corporation.

Important: Federal law in the U.S.A. and Canada

restricts this device to sale by or on the order of a

licensed medical practitioner. This device is to be used

only by persons who have been adequately instructed in

its use.

Important: This document is not to be reproduced in any

manner, nor are the contents herein to be disclosed to

anyone without the express authorization of Ohio

Medical Corporation.

The procedures described in this service manual should

be performed by competent individuals who have a general knowledge of and experience with devices of this

nature. No repairs should ever be undertaken or attempted by anyone not having such qualifications.

Genuine replacement parts manufactured or sold by

Ohio Medical must be used for all repairs.

Read completely through each step in every procedure

before starting the procedure; any exceptions may result

in a failure to properly and safely complete the attempted procedure.

CCW Counterclockwise (Anti-clockwise)

MAX Full Line Vacuum

in Hg Inches of mercury

kPa Kilo pascals (kPa x 7.50 = mm Hg)

LPM Liters per minute

mm Hg Millimeters of mercury (mm Hg x .133 = kPa)

°C Degrees Celsius

°F Degrees Fahrenheit

N-m Newton-Meter (N-m x .737 = ft-lb)

ft-lb Foot-Pound Force (ft-lb x 1.356 = N-m)

oz Ounces

DISS Diameter Index Safety System

OES Oxequip Suction

NCG National Compressed Gases (Chemetron)

NPT National Pipe Thread (USA)

NPTF National Pipe Thread Female (USA)

MPTS Multi-Purpose Therapy Stand

gal Gallon

PTFE Teflon®

User Responsibility

User Responsibility

6700-0078-000 Rev1 06/2009

Table of Contents

1/Precautions

1.1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

2/Scope

2.1 North American Vacuum Regulators. . . . . . . .2-1

2.2 International Vacuum Regulators . . . . . . . . . .2-2

3/Description and Specifications

3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . .3-2

4/Operation

4.1 Equipment Set-up . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Attaching the Safety Trap . . . . . . . . . . . . . . .4-2

4.3 Mode Selection . . . . . . . . . . . . . . . . . . . . . . .4-3

4.4 Setting the Suction Level . . . . . . . . . . . . . . . .4-4

4.5 Pre-Use Checkout Procedure . . . . . . . . . . . .4-4

4.6 Patient Set-up . . . . . . . . . . . . . . . . . . . . . . . .4-7

5/Cleaning and Sterilization

5.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1.1 Routine Exterior Cleaning . . . . . . . . . . .5-1

5.1.2 Internal Component Cleaning . . . . . . . .5-1

5.2 Sterilization . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

6/Troubleshooting

7/Service - Disassembly and Assembly

7.1 Service Tools and Equipment . . . . . . . . . . . .7-1

7.2 Continuous Vacuum Regulators (All Models)7-1

7.2.1 Disassembly . . . . . . . . . . . . . . . . . . . . .7-1

7.2.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.3 Suction Level Limit Setting - Low

Models ONLY . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.3.1 Low Vacuum Limiting Screws . . . . . . . .7-3

7.3.2 Vacuum Relief Valve Adjustment . . . . .7-4

7.4 Regulator Module . . . . . . . . . . . . . . . . . . . . . .7-4

7.4.1 Disassembly . . . . . . . . . . . . . . . . . . . . .7-4

7.4.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . .7-5

8/Service Checkout Procedure

8.1 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.2 Flow Test . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.3 Gauge Test . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.3.1 High Vacuum Gauges ONLY . . . . . . . .8-2

8.3.2 Standard and Low Vacuum

Gauges ONLY . . . . . . . . . . . . . . . . . . .8-2

8.4 Regulation Test . . . . . . . . . . . . . . . . . . . . . . .8-2

8.5 Low Vacuum Regulators ONLY . . . . . . . . . . .8-2

8.6 Bleed Test . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.7 Leak Test - Supply Side . . . . . . . . . . . . . . . . .8-3

8.8 Leak Test - Patient Side . . . . . . . . . . . . . . . . . . .8-4

9/Maintenance

9.1 General Maintenance of Suction Equipment .9-1

9.2 Recommended Maintenance Schedule . . . . .9-1

9.2.1 Maintenance Schedule . . . . . . . . . . . . . . . . . .9-1

9.3 Repair Policy . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.4 Technical Assistance . . . . . . . . . . . . . . . . . . .9-2

9.5 Return Instructions . . . . . . . . . . . . . . . . . . . . .9-2

10/Ordering Information

10.1 Illustrated Parts . . . . . . . . . . . . . . . . . . . . . .10-1

10.2 Service Kits . . . . . . . . . . . . . . . . . . . . . . . . .10-2

10.3 Fittings and Adapters . . . . . . . . . . . . . . . . . .10-2

10.4 International . . . . . . . . . . . . . . . . . . . . . . . . .10-3

10.4.1 Regulator Options . . . . . . . . . . . . . . .10-3

10.4.2 Other Options . . . . . . . . . . . . . . . . . .10-4

Appendix

Installation procedure for Adapters/Probes and Fittings.

A-1

6700-0078-000 Rev1 06/2009

1/Precautions

1.1 Definitions

Note: A Note provides additional information to clarify a point in the text.

Important: An Important statement is similar to a note but of greater emphasis.

CAUTION: A CAUTION statement is used when the possibility of damage to the equipment exists.

WARNING: AWARNING statement is used when the possibility of injury to the patient or the operator

exists.

= Attention. Alerts you to a warning or caution in the text.

MAX = maximum

High Flow

High Vacuum = high flow, high vacuum

High Flow

Low Vacuum = high flow, low vacuum

I (On) = on

O (Off) = off

= European Union Representative

1.2 Warnings

The Pre-Use Checkout Procedure must be performed

before using this equipment on each patient. If the regulator fails any part of the Pre-Use Checkout Procedure, it

must be removed from service and repaired by qualified

service personnel.

Connect the Vacuum Regulator to the vacuum source

only. Connection to pressure sources even momentarily

could injure the patient or operator and damage the

equipment.

Always connect the regulator to the vacuum source and

check its operation before attaching the patient connection.

The fitting port of the regulator must be occluded when

setting the prescribed suction level. This prevents the

patient from receiving higher than required suction levels.

Do not use this device in the presence of flammable

anesthetics. Static charges may not dissipate and a possible explosion hazard exists in the presents of these

agents.

After patient use, regulators may be contaminated.

Handle in accordance with your hospital’s infection control policy.

Clean and sterilize all suction equipment before shipment or service to ensure transportation personnel

and/or service personnel are not exposed to any hazardous contamination.

Clean and sterilize all suction equipment if contaminated

before disassembly, to ensure service personnel are not

exposed to hazardous contamination.

Following sterilization with ethylene oxide, parts should

be quarantined in a well ventilated area to allow dissipation of residual ethylene oxide gas absorbed by the

material. Aerate parts for 8 hours at 130oF (54oC).

If the Vacuum Regulator is repaired or disassembled in

any manner, the Service Checkout Procedure must be

performed before using the equipment on the patient.

The Low Vacuum Limit Setting Procedure must be followed when repairing Low Vacuum Regulators. Failure

to do this may result in suction exceeding the prescribed

level.

1-1

6700-0078-000 Rev1 06/2009

Precautions/1

1.3 Cautions

Do not lubricate any internal components of the regulator

module.

Do not use any Loctite® products to seal the fitting and

adapter port threads (or products which contain

Methacrylate Ester as an active ingredient).

Only competent individuals trained in the repair of this

equipment should attempt to service it.

To help prevent aspirate from entering the regulator, as a

result of misuse, an Overflow Safety Trap and suction filter should be attached prior to its use. Aspirate in the regulator will impair the operation. The use of the Overflow

Safety Trap and suction filter will help prevent this and

extend the life of the suction equipment.

Use of lubricants other than recommended may degrade

plastic or rubber components.

Prior to placing the unit back into service after repair or

dissassembly , perform the Service Check-out Procedure.

Not for Field or Transport use**

®Loctite is a registered trademark of the Loctite Corp.

** The categories of Field and Transport Use are specifically defined in ISO

10079-3. "Field" means use at accidents or emergencies outside a hospital.

"Transport" means use in ambulances, cards and airplanes. These situations

may expose the equipment to uneven support, water, dirt mechanical shock and

temperature extremes. Ohio Medical suction equipment has not been tested to

comply with the specific requirements of these categories.

1-2

6700-0078-000 Rev1 06/2009

2/Scope

This service manual contains service, maintenance and parts information on all models of the Continuous Vacuum

Regulator.

North American

International

2.1 North American Vacuum Regulators.

Note: Part numbers given are for Vacuum Regulators without fittings or adapters.

2.2 International Vacuum Regulators

Important: International Vacuum regulators comply with the requirements of EN ISO 10079-3 and are CE marked.

Note: Part numbers given are for Vacuum Regulators without fittings or adapters.

Standard Three Mode

Continuous

0-200 mmHg-FULL VAC

Low Continuous

0-135 mmHg

High Three Mode

Continuous

0-760 mmHg

Standard Two Mode

Continuous

0-200 mmHg-FULL VAC

Two Mode High Continuous

CCW

0-760 mmHg/0-100 kPa

Two Mode Low Continuous

CCW

0-135 mmHg/0-18 kPa

Three Mode High Continuous

CCW

0-760 mmHg/0-100 kPa

2-1

D

E

E

D

M

100

80

120

-mmHg

60

W

O

40

L

20

140

H

I

G

H

160

180

200

F

U

C

L

A

V

L

M

100

H

mm Hg

I

G

120

H

140

160

80

Low Vacuum

60

W

O

40

L

20

400

60

70

High Vacuum

100

50

High Flow

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

600

80

90

700

400

60

70

High Vacuum

100

50

High Flow

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

600

80

90

700

100

80

120

16

140

18

20

Low Vacuum

14

High Flow

60

12

10

8

40

6

4

2

20

a

P

k

-

g

H

m

m

-

6700-0078-000 Rev1 06/2009

Description and Specification/3

3.1 Description

WARNING

Do not use this device in the presence of flammable anesthetics. Static

charges may not dissipate and a possible explosion hazard exists in the

presence of these agents.

The Continuous V acuum Regulator is a lightweight, compact unit used throughout the hospital primarily for pharyngeal/tracheal suctioning (airway management).

Various models provide regulated or full-line vacuum for

hospital suction procedures.

There are several models of the Continuous Vacuum

Regulators. All models contain a vacuum gauge which

indicates suction supplied by the regulator. Each has a

positive pressure safety relief valve to prevent pressurization by either failed injector vacuum (venturi) units or

inadvertent cross connection to pressurized gasses. In

addition, the Low Continuous models include a vacuum

relief valve to limit maximum suction.

Some models operate in a regulated or non-regulated

(MAX) mode. Others operate only in the regulated (limited) mode.

In the non-regulated (MAX) mode, the vacuum source is

connected directly to the fitting port. The regulator module is bypassed and full-line vacuum is provided.

In the regulated (limited) mode, the vacuum source is

connected through the regulator module which functions

as an automatic valve. Turning the suction control knob

adjusts the position of the regulator module and allows

selection of a predetermined level of suction when set

according to instructions.

During use, as the flow requirement increases, the valve

automatically opens to maintain suction at the preset

level. Conversely , when the flow requirement decreases,

the valve automatically closes to maintain suction at the

preset level. The same mechanism compensates for

changes in supply vacuum and automatically maintains

the pre-set suction level when set according to instructions.

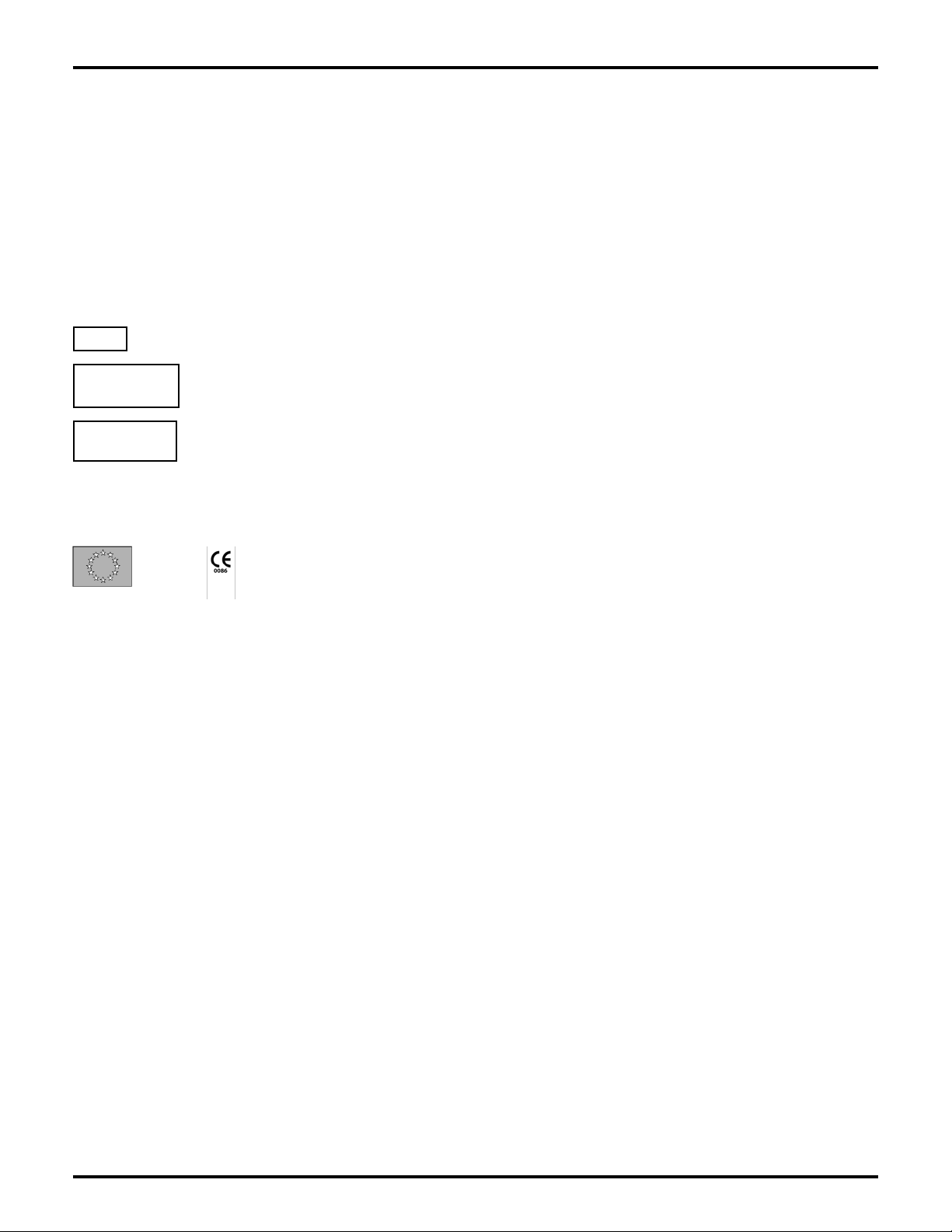

1. Suction Control Knob - Allows easy adjustment of

suction to the patient.

2. Mode Selector Switch - Allows quick and easy mode

changes.

a. | (On) - Suction can be adjusted with the suction

control knob.

b. O (Off) - No suction is supplied to the patient.

c. MAX - Maximum full-line vacuum is supplied to

the patient.

3. Vacuum Gauge - The suction level to the patient is

displayed during use.

Mode

Selector

Switch

Front and Side View

Fitting Port

Adapter

Port

Suction

Control

Knob

Vacuum

Gauge

3-1

400

50

60

High Flow

High Vacuum

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

70

600

80

90

100

700

6700-0078-000 Rev1 06/2009

3/Description and Specifications

3.2 Specifications

Gauge: Accuracy: ±5% of full scale deflection

Flow Rate: 0 to 80 LPM without fittings at full increase setting depending on supply vacuum and open

air flow

Positive Pressure Safety Located in the vacuum supply line to prevent pressurization of the patient connection by

Relief Valve: failed injector vacuum (venturi) units, or inadvertent cross connection to pressurized

gases

Ranges: Gauge Range Regulated Suction

Standard Models 0 to 200 mm Hg/0 to 26 kPa 0 to 760 mm Hg/0 to 100 kPa

High Models 0 to 760 mm Hg/0 to 100 kPa 0 to 760 mm Hg/0 to 100 kPa

Low Models 0 to 160 mm Hg/0 to 21 kPa 0 to 135 mm Hg/0 to 18 kPa*

* When measured with an independent measuring device.

Vacuum Relief Valve 140 mm Hg ± 5 mm Hg/18.7 kPa ± 0.7 kPa

(Low Vacuum models ONLY):

Weight: 11 oz/312 grams

(Less fittings)

Weight

Low Vacuum models: 12 oz/340 grams

(Less fittings)

Dimensions: Height: 5.7 inches/145 mm

(Less fittings) Width: 3.0 inches/76 mm

Depth: 3.8 inches/96 mm

Latex tubing, 0.25 in (6.4 mm) I.D. X 0 to full vacuum

12 in (30 cm) supplied: Flow dependent on source and setup

Disposable tubing (Available 0 to full vacuum

separate in some markets; Flow dependent on source and setup

6 mm I.D. X 450 mm, 750 mm

and 2M) to connect regulator

and collection bottle

Disposable Suction Filter: 0 to full vacuum

0 to 100 Lpm @ 650 mmHg (-87 kPa)

Environmental Specifications

Operating Temperature Range: 40oF (4oC) to 120oF (49oC)

Storage Temperature Range: 0oF (-18oC) to 150oF (71oC)

Operating and Storage Relative Humidity: 5 to 95%

3-2

6700-0078-000 Rev1 06/2009

Operation/4

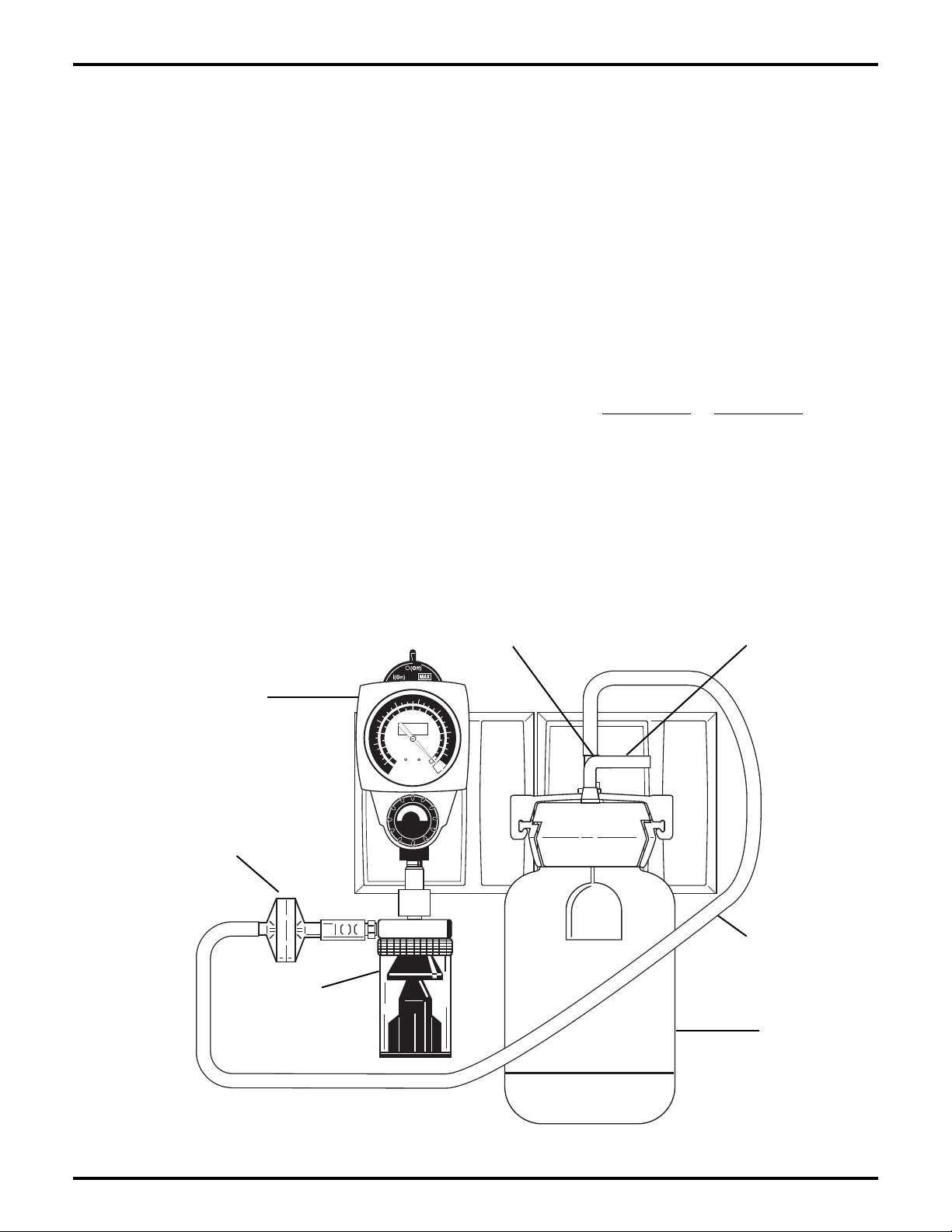

4.1 Equipment Set-up

Insert the probe into the vacuum wall outlet. If the regulator is mounted elsewhere, connect a vacuum supply

hose between the regulator’s probe adapter and the wall

outlet.

WARNING

Connect the vacuum regulator to the

vacuum source only and check its

operation before attaching the patient

connection. Connection to pressure

sources, even momentarily, could

injure the patient or operator and

damage the equipment.

Note: For proper installation of Adapters/Probes and

Fittings see Appendix.

Connect the collection bottle's vacuum port to the regu-

lator's fitting port or Overflow Safety Trap with the appropriate suction filter and vacuum tubing.

Use hospital-supplied suction tubing between the end

piece and the collection container, and between the

patient port and the patient (minimum inside diameter is

6 mm [0.25 in.]).

ISO 10079-3 (BS 7259: Part 2, section 5.1.2) states that

“the usable volume of the collection container shall not

be less than 500 ml.”

An Ohio Medical High Flow Suction Filter should be

used between the collection container and regulator to

prevent contamination of the regulator. Hospital-supplied suction tubing must be used between the catheter

and the collection bottle. Recommended minimum

inside diameter is 0.25 in (6 mm).

Suction Filters - Hydrophilic

Pkg of 20 6730-0350-800

Pkg of 200 6730-0351-800

Suction Filters - Hydrophobic

Tubing x 1/8 NPT x

tubing nipple

tubing nipple

Pkg of 3 6730-0570-800 6730-0580-800

Pkg of 10 6730-0571-800 6730-0581-800

Pkg of 100 6730-0572-900 6730-0582-800

Vacuum

Regulator

Overflow

Safety Trap

Equipment Set-Up

Collection

Bottle

Connective Tubing

Patient Port

Vacuum Port

Disposable

Suction Filter

4-1

400

80

90

70

100

50

60

High Flow

High Vacuum

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

600

700

Underwater Seal Line 2 cm H2O

Made in USA

6700-0078-000 Rev1 06/2009

4/Operation

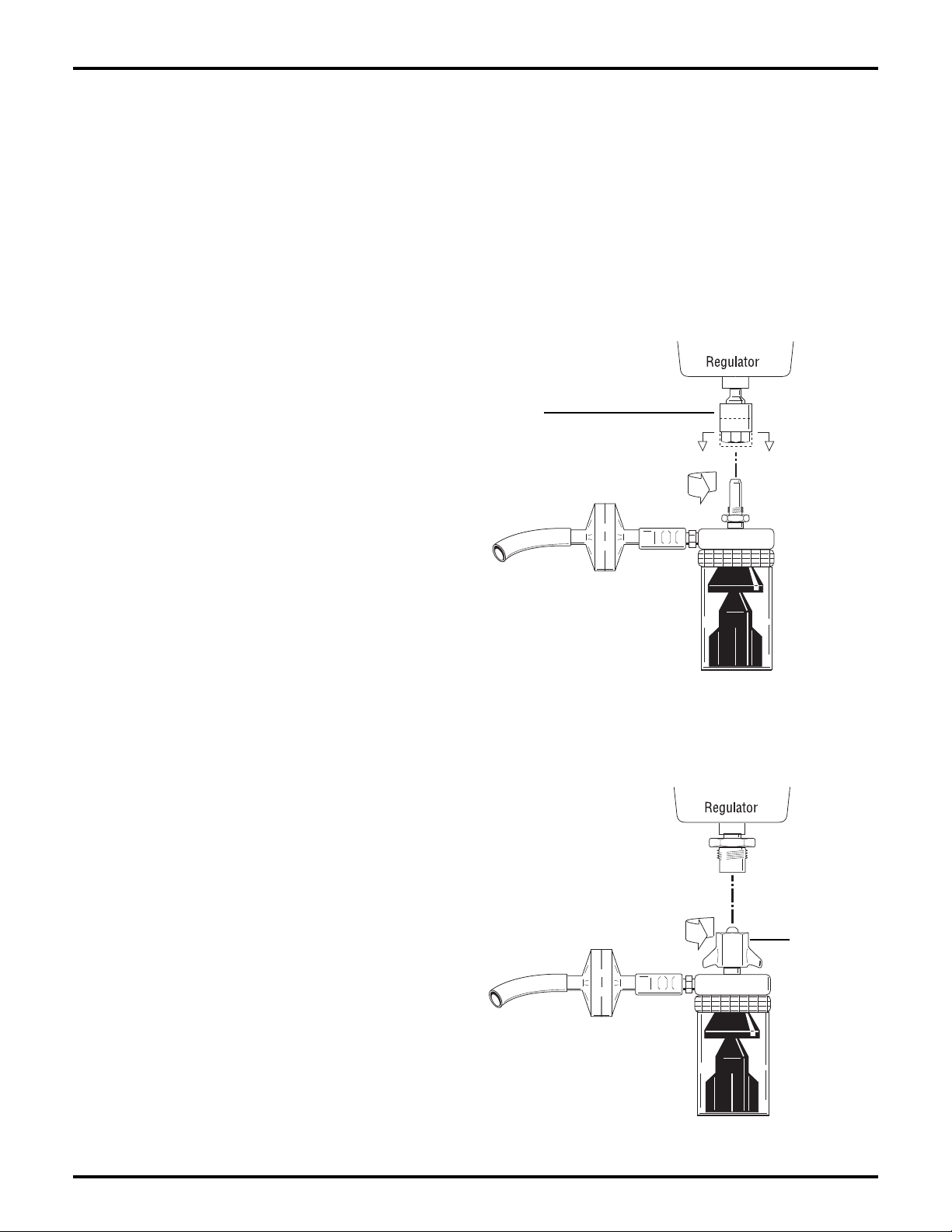

4.2 Attaching the Safety Trap

CAUTION

To help prevent aspirate from entering

the regulator, wall outlet and pipeline

system as a result of misuse, an

Overflow Safety Trap should be

attached prior to its use. Aspirate in the

regulator, wall outlet and pipeline system

may impair their operation. The use of

the Overflow Safety Trap and suction filter will help prevent this and extend the

life of suction equipment.

Standard fitting

1. Raise the sleeve and insert the trap into the regulator fitting.

2. Turn the trap clockwise about one and a half turns to

engage the threads. The trap does not need to be

screwed tight; an O-ring in the regulator fitting provides a vacuum seal. The trap should rotate freely to

allow the desired tubing positioning.

3. Lower sleeve to lock trap in position.

DISS fitting

1. Insert trap into the regulator fitting. Situate the tubing

in the desired position.

2. Turn the DISS wing nut clockwise to engage threads

and tighten (there is no O-ring, so the vacuum seal

depends on a tight connection).

Sleeve

Wing nut

4-2

6700-0078-000 Rev1 06/2009

Operation/4

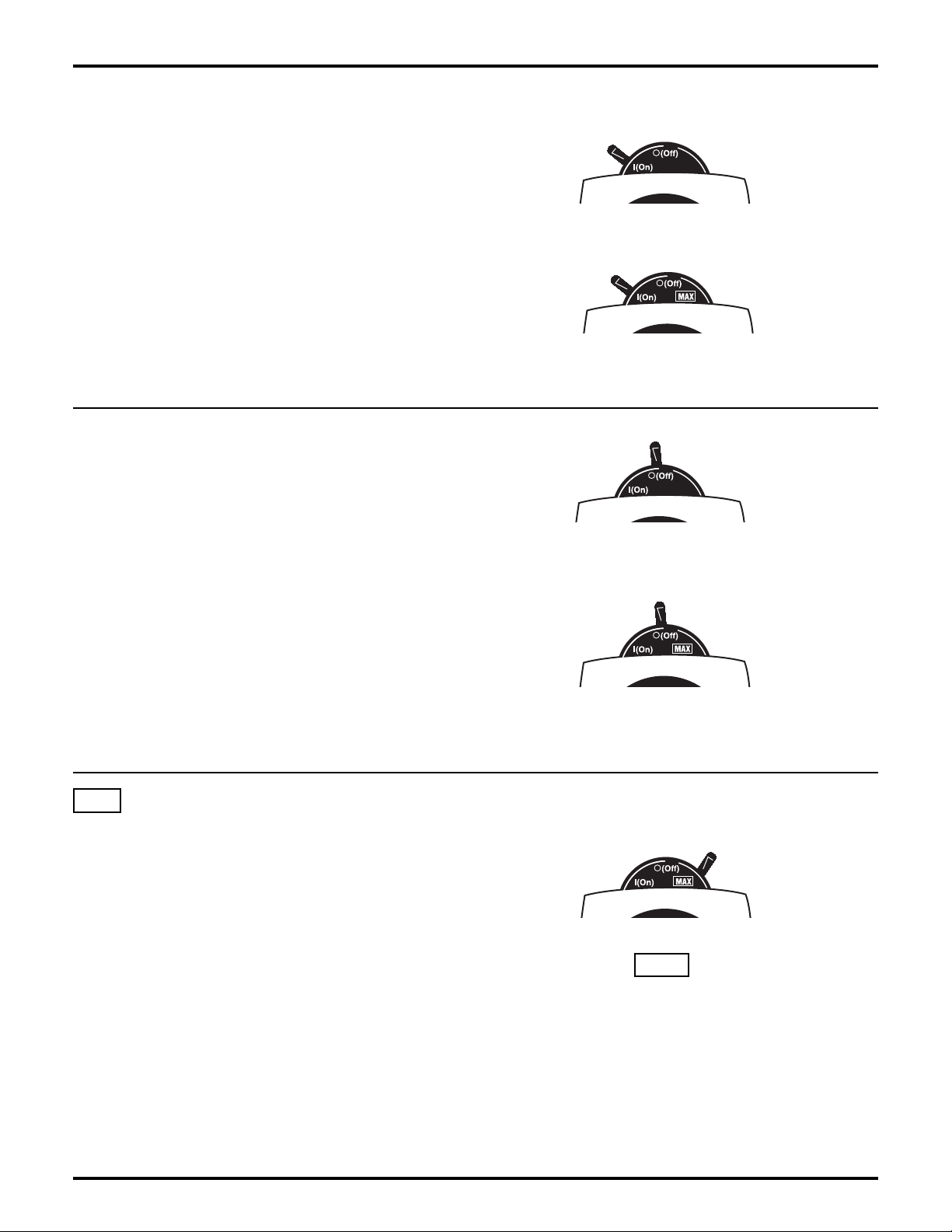

4.3 Mode Selection

| (On) - Suction can be adjusted with the suction control

knob.

O (Off) - No suction is supplied to the patient.

MAX - Maximum, full-line vacuum is supplied to the

patient.

Note: available on three mode vacuum regulators only.

2 - Mode Switch

3 - Mode Switch

I/(On)

2 - Mode Switch

3 - Mode Switch

O/(Off)

3 - Mode Switch

MAX

4-3

Loading...

Loading...