Ohio Push-To-SetTM Intermittent User manual

Push-To-Set

Suction Unit (PTS-ISU)

TM

Intermittent

Service Manual

400

60

70

High Vacuum

100

50

High Flow

300

40

200

30

20

100

10

a

P

k

-

g

H

m

m

-

500

600

80

90

700

ANSI

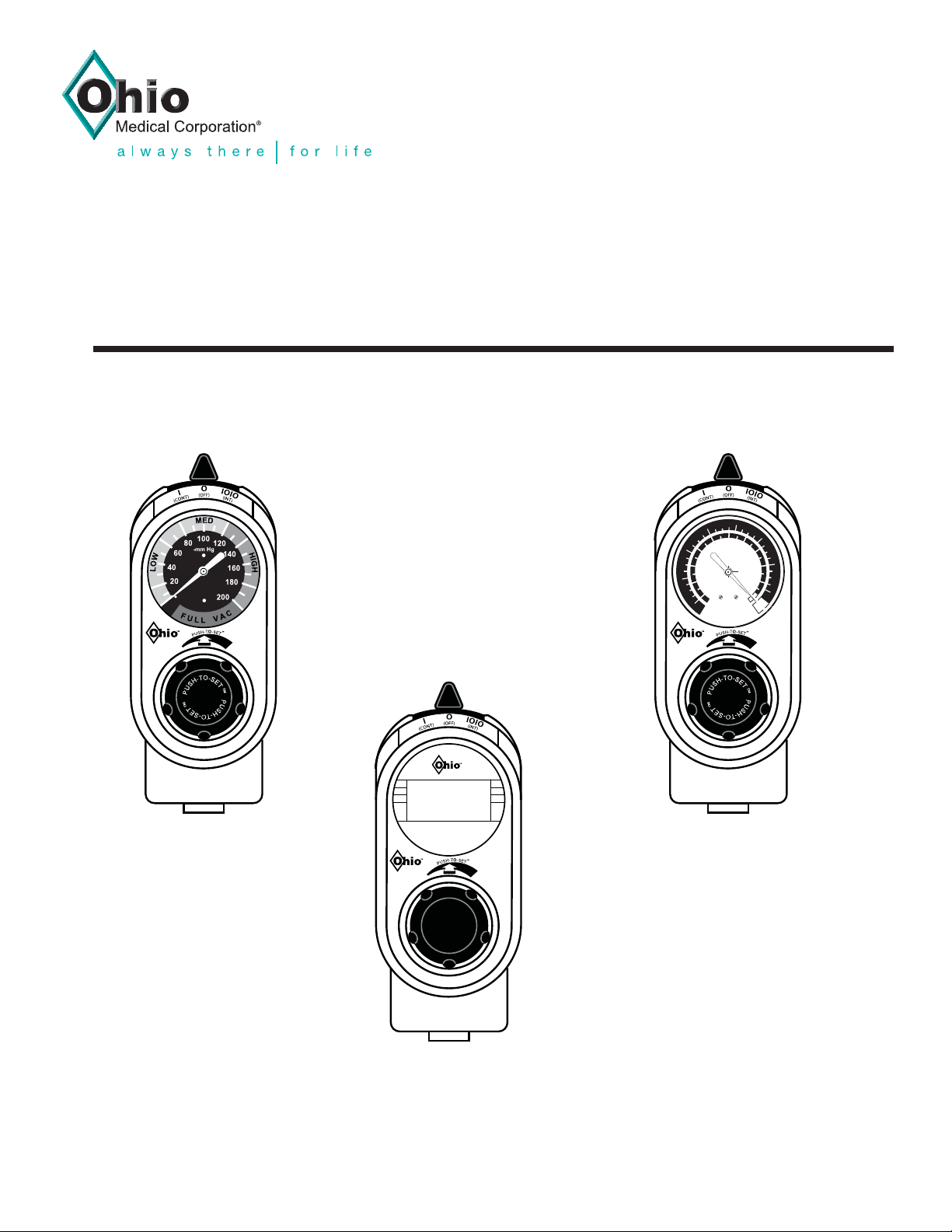

PTS-ISU - Analog

F

H

M

L

MEDICAL VACUUM

F

H

M

L

ANSI/ISO

PTS-ISU - Analog

ISO

PTS-ISU - Analog

8700-0001-000, Rev4 (11/2010)

User Responsibility

IMPORTANT: Federal law in the U.S.A. and Canada

restricts this device for sale by or on the order of a

license medical practitioner.

WARNING: This device is to be used only by

persons who have been adequately instructed

in its use.

WARNING: Do not use this device in the

presence of fl ammable anesthetics. Static

charges may not dissipate and a possible

explosion hazard exists in the presence of

these agents.

This Product will perform in conformity with the

description thereof contained in this operating

manual and accompanying labels and/or inserts,

when assembled, operated, maintained and repaired

Product Date Coding:

in accordance with the instructions provided. This

Product must be checked periodically. A defective

product should not be used. Parts that are broken,

missing, plainly worn, distorted or contaminated

should be replaced immediately. Should such

repair or replacement become necessary, see the

Ohio Medical service manual for service or repairs

to this product. For service advice, Ohio Medical

recommends that a telephone request be made to

the nearest Ohio Medical Regional Service Center.

This product or any of its parts should not be repaired

other than in accordance with written instructions

provided by Ohio Medical or by Ohio Medical trained

personnel. The Product must not be altered without

the prior written approval of Ohio Medical’s Quality

Assurance Department. The user of this Product

shall have the sole responsibility for any malfunction

which results from improper use, faulty maintenance,

improper repair, damage, or alteration by anyone

AAA A 12345

This alpha character indicates the year of product manufacture

and when the serial number was assigned; “L” = 2007, “M” =

2008, “N” = 2009, etc. “I” and “O” are not used.

Technical Competence

other than Ohio Medical.

The procedures described in this service manual

should be performed by trained and authorized

personnel only. Maintenance should only be

undertaken by competent individuals who have a

general knowledge of and experience with devices of

this nature. No repairs should ever be undertaken or

attempted by anyone not having such qualifi cations.

Genuine replacement parts manufactured or sold by

Ohio Medical must be used for all repairs.

Read completely through each step in every

procedure before starting the procedure; any

exceptions may result in a failure to properly and

safely complete the attempted procedure.

8700-0001-000 Rev4

Table of Contents

1/ Defi nitions and Abbreviations

1.1 Defi nitions ............................................................1

1.2 Abbreviations .......................................................1

2/ Scope

2.1 ANSI Vacuum Regulator ......................................2

2.2 ISO Vacuum Regulator ........................................2

3/ Description and Specifi cations

3.1 Description...........................................................2

3.2 Specifi cations ......................................................3

4/ Operation

4.1 Equipment Setup .................................................4

4.1.1 Attaching the OST ......................................4

4.2 Mode Selection ....................................................5

4.3 Setting the Suction Level .....................................5

4.4 Pre-Use Checkout Procedure..............................5

4.5 Patient Setup .......................................................6

5/ Cleaning and Sterilization

5.1 Cleaning ..............................................................6

5.1.1 Routine Exterior Cleaning...........................6

5.1.1.1 Approved Cleaning Solutions .........6

5.1.2 Internal Component Cleaning .....................7

5.1.2.1 Approved Flush Solutions ...............7

5.1.3 Cold Flush Procedure .................................7

5.2 Disinfection ..........................................................7

7.5 Digital Gauge .....................................................13

7.5.1 Removal of Batteries ................................13

7.5.2 Inserting Batteries

8/ Service Checkout Procedure

8.1 Setup .................................................................14

8.2 Push-To-Set™ Test ............................................14

8.3 Leak Test – Supply Side ....................................14

8.4 Flow Test ...........................................................14

8.4.1 Continuous Mode Flow Test .....................14

8.4.2 Intermittent Mode Flow Test .....................14

8.5 Timing Cycle Adjustment ...................................15

8.6 Gauge Test ........................................................15

8.7 Regulation Test ..................................................16

8.8 Vacuum Buildup/Bleed-down Test – Intermittent

Mode........................................................................16

8.9 Bleed Test ..........................................................16

8.10 Leak Test – Patient Side ..................................16

9/ Maintenance

9.1 General Maintenance of Suction

Equipment ...............................................................17

9.2 Recommended Maintenance Schedule.............17

9.2.1 Maintenance Schedule ............................17

9.3 Repair Policy .....................................................18

9.4 Technical Assistance .........................................18

9.5 Return Instructions ............................................18

9.6 Installation Procedure for Adapters/Probes

and Fittings ..............................................................18

6/ Troubleshooting ............................................8

7/ Service – Disassembly and Assembly

7.1 Service Tools and Equipment ............................11

7.2 PTS-ISU Disassembly/Assembly ......................11

7.2.1 Disassembly ............................................. 11

7.2.2 Assembly ..................................................12

7.3 Regulator Module ..............................................13

7.3.1 Disassembly .............................................13

7.3.2 Assembly ..................................................13

7.4 Timing and Flow Control Valves ........................13

7.4.1 Disassembly .............................................13

7.4.2 Assembly ..................................................13

8700-0001-000 Rev4

10/Ordering Information

10.1 Illustrated Parts...........................................19-20

TOC

1/Defi nitions and Abbreviations

1.1 Defi nitions

Note: A note provides additional information to clarify

a point in the text.

Important: An important statement is similar to a note

but of greater emphasis.

CAUTION: A CAUTION statement is used

when the possibility of damage to the equipment exists.

WARNING: A WARNING statement is used

when the possibility of injury to the patient or

the operator exists.

1.2 Defi nitions

in Hg

in

ISU

kPa

LPM

mm Hg

mm

oz

| (CONT)

|O|O (INT)

O (Off)

°C

°F

N-m

ft-lb

in-lb

DISS

OES

NCG

BOC

NPT

MPTS

I.D.

gal.

PTS

PTFE

NG

RH

Inches of mercury

Inch

Intermittent Suction Unit

Kilo pascals (kPa x 7.50 = mm Hg)

Liters per minute

Millimeters of mercury (mm Hg x .133 = kPa)

Millimeters

Ounces

Continuous (On)

Intermittent (On/Off)

Off

Degrees Celsius

Degrees Fahrenheit

Newton-Meter (N-m x .737 = ft-lb)

Foot-Pound Force (ft-lb x 1.356 = N-m)

Inch-Pound Force (ft-lb x 12 = in-lb)

Diameter Index Safety System

Oxequip Suction®

National Compressed Gases (Chemetron)

British Oxygen Corporation

National Pipe Thread (USA)

Multi-Purpose Therapy Stand

Inner Diameter

gallon

Push-To-SetTM

Tefl on®

Naso - Gastric

Relative Humidity

1

8700-0001-000 Rev4

2/Scope 3/Description/Specifi cations

This service manual contains service, maintenance

and parts information for the Push-To-SetTM

Intermittent Suction Unit (PTS-ISU)

2.1 ANSI Vacuum Regulator

Analog/Digital

Note: Part numbers given are for Vacuum Regulators

without fi ttings or adapters/probes.

MEDICAL VACUUM

F

H

M

L

PTS-ISU

8700-1251-900

(1271,7251, 7271)

F

H

M

L

PTS-ISU Digital

8700-1351-900

(1371, 1372, 7351,

7371, 7372)

3.1 Description

WARNING: Do not use this device in the

presence of fl ammable anesthetics. Static

charges may not dissipate and possible

explosion hazard exists in the presence of

these agents.

The PTS-ISU is a dual purpose vacuum regulator

which provides either intermittent or continuous

suction. It can be used for NG drainage (intermittent)

or pharyngeal/tracheal (continuous) suctioning

throughout the hospital.

A patented safety feature Push-To-Set™ (PTS)

automatically occludes the patient circuit as the

desired vacuum level is selected. It prevents higher

than desired vacuum levels from being accidentally

delivered when patient suctioning begins. The suction

control knob must fi rst be pushed and then turned to

set vacuum levels.

Each unit contains a dual spring regulator module

to regulate and adjust suction which is precise in

the critical care range (0-200 mmHg/26.7 kPa) and

quickly moves to full wall vacuum for resuscitation. It

requires only two turns from zero to full wall vacuum.

Each unit contains a vacuum gauge, an ON/OFF

switching module and adjustable timing valves.

2.1 ISO Vacuum Regulator

Analog/Digital

Note: Part numbers given are for Vacuum Regulators

without fi ttings or adapters/probes.

400

300

500

50

60

40

200

30

70

High Flow

High Vacuum

600

700

20

80

90

100

10

100

a

P

k

-

g

H

m

m

-

PTS-ISU

8700-1253-900

(1273)

PTS-ISU Digital

8700-6353-900

Figures 1

F

H

M

L

(6373, 6372)

MEDICAL VACUUM

F

H

M

L

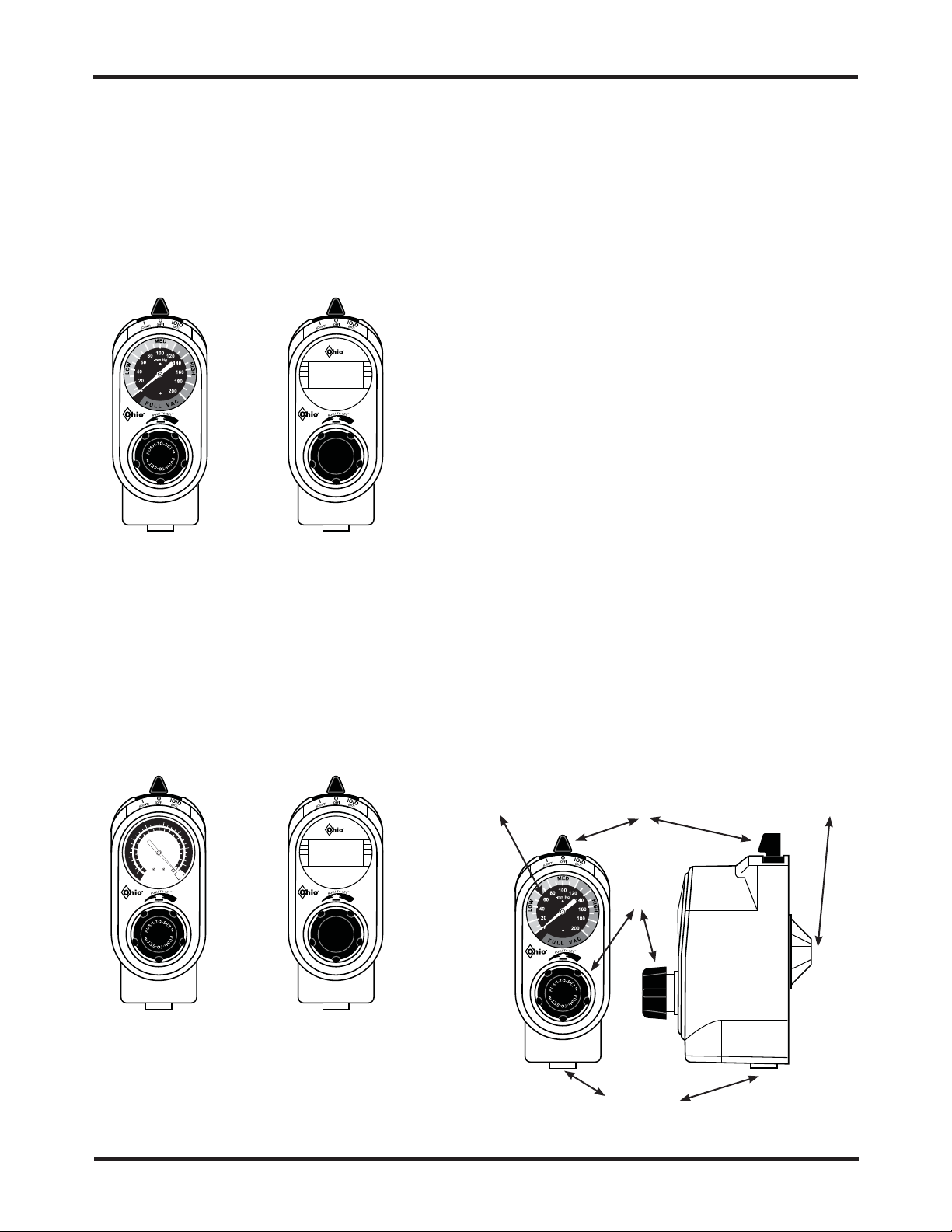

In use, the vacuum source is connected through the

regulator module which functions as an automatic

valve. Rotating the suction control knob adjusts

the position of the regulator module and selects a

predetermined level of suction.

Vacuum

Gauge

Mode Selector

Switch

Suction

Control

Knob

Fitting Port

Figure 2: Front and Side View

Adapter/Probe

Port

8700-0001-000 Rev4

2

3/Descriptions/Specifi cations

(3.1 Description Continued)

During use, as the fl ow requirement increases, the

valve automatically opens to maintain suction at the

preset level. Conversely, when the fl ow requirement

decreases, the valve automatically closes to maintain

suction at the preset level. The same mechanism

compensates for changes in supply vacuum to

automatically maintain the pre-set suction level.

3.2 Specifi cations

Gauge: Accuracy (Analog): ±5% of full scale defl ection

Accuracy (Digital): ±1% of full range @ 22oC

Flow Rates | Continuous (CONT) Mode - 0 - 80 LPM without

fi ttings at full increase setting depending on supply

vacuum and open air fl ow

|O|O Intermittent (INT) Mode - 8 LPM with the suction

control knob set to 120 mm Hg/16 kPa

Regulated Suction Range: 0 to 200 mm Hg/0 to 26 kPa and up to full wall

vacuum

Pre-Set Timing Cycles: On time cycle-15 seconds ± 3 seconds

Off time cycle-8 seconds ± 3 seconds

Weight: (Less Fittings) 20 oz/567 grams

Dimensions: (Less Fittings) Height: 6.5 inches/16.5 cm

Width: 2.8 inches/7.1 cm

Depth: 4.8 inches/12.2 cm

Environmental Specifi cations

Operating Temperature Range: 50oF (10oC) to 104oF (40oC)

Storage Temperature Range: -13oF (-25oC) to 158oF (70oC)

Operating and Storage Relative Humidity: 5 to 95% RH (Non-condensing)

3

8700-0001-000 Rev4

4/Operation

4.1 Equipment Setup

Insert the adapter/probe into the vacuum wall outlet.

If the regulator is mounted elsewhere, connect a

vacuum supply hose between the regulator’s adapter/

probe and the wall outlet.

WARNING: Connection to pressure sources,

even momentarily, could injure the patient or

operator and damage the equipment.

Use hospital-supplied suction tubing between the

vacuum regulator and the collection container, and

between the patient port of the collection container

and the patient (minimum inside diameter is 6

mm[0.25 in]).

An Ohio Medical Hydrophobic Filter or Hydrophilic

Filter and Overfl ow Safety Trap (OST) should be used

between the collection container and regulator to

prevent contamination of the regulator, wall outlet and

pipeline system.

ISO 10079-3 (BS 7259: Part 2, section 5.1.2) states

that “the usable volume of the collection container

shall not be less than 500 ml.”

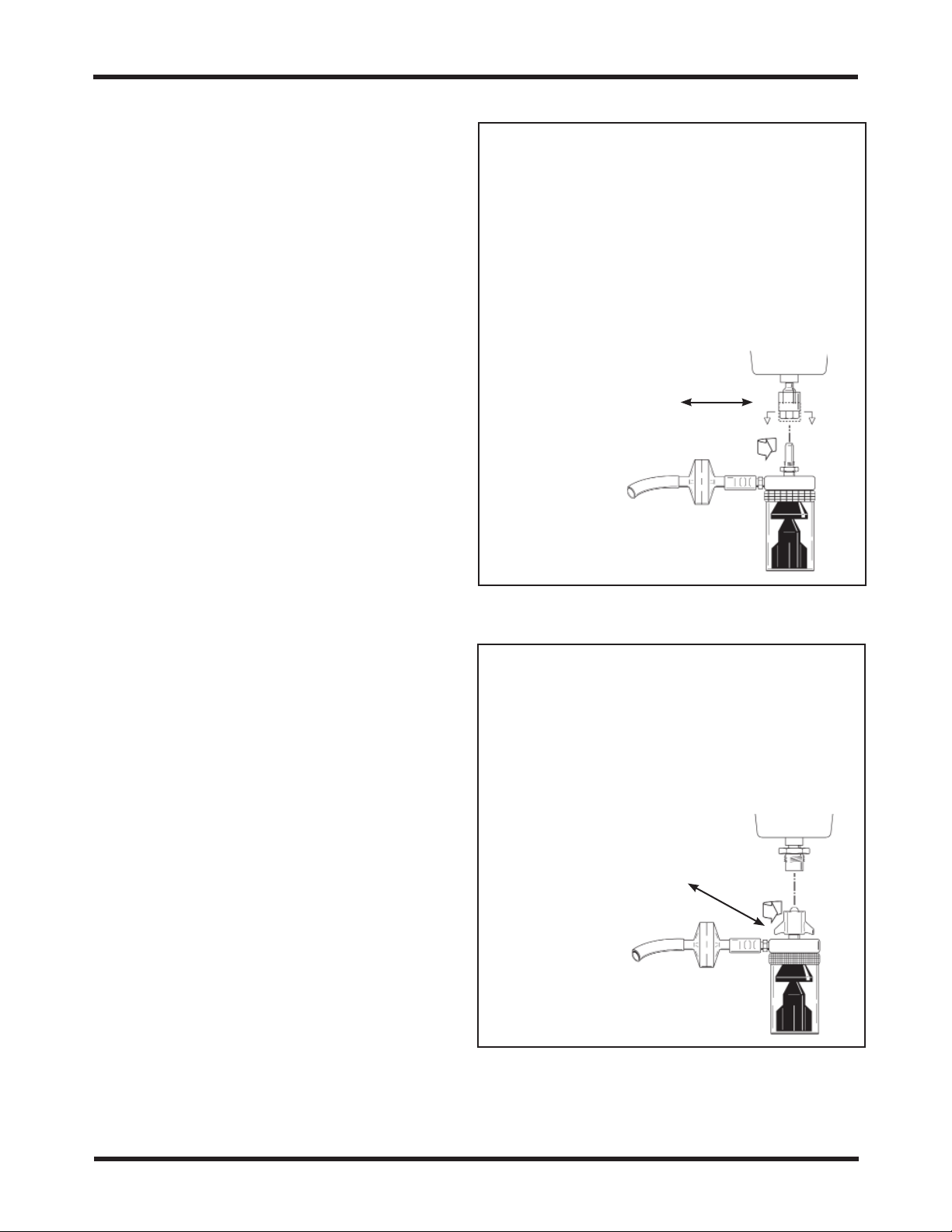

Locking Gland Fitting

Figure 3

1. Raise the sleeve and insert the OST into the

regulator fi tting.

2. Turn the trap clockwise about one and a half turns

to engage the threads. The trap does not need to

be screwed tight; an O-ring in the regulator fi tting

provides a vacuum seal. The trap should rotate

freely to allow the desired nipple positioning.

3. Lower sleeve to lock trap in position.

1 Regulator

2 Sleeve

2

1

3 OST

3

Suction Filters

Hydrophilic:

Nipple

20 Pack 6730-0350-800

200 Pack 6730-0351-8000

Hydrophobic:

Nipple Threaded

3 Pack 6700-0570-800 6700-0580-800

10 Pack 6700-0571-800 6700-0581-800

50 Pack 6700-0572-800 6700-0582-800

Note: For proper installation of adapters/probe and

fi ttings, see section 9.

4.1.1 Attaching the Overfl ow Safety Trap

(OST))

CAUTION: To help prevent aspirate from

entering the regulator as a result of misuse, an

OST should be attached prior to its use. Aspirate

in the regulator may impair its operation. The use

of the OST and suction fi lter will help prevent this

and extend the life of suction equipment.

DISS fi tting

Figure 4

1. Insert the OST into the regulator fi tting. Situate

the nipple in the desired position.

2. Turn the DISS wing nut clockwise to engage

threads and tighten (there is no O-ring, so the

vacuum seal depends on a tight connection).

1Regulator

2Wing nut

3OST

2

1

3

8700-0001-000 Rev4

4

4/Operation

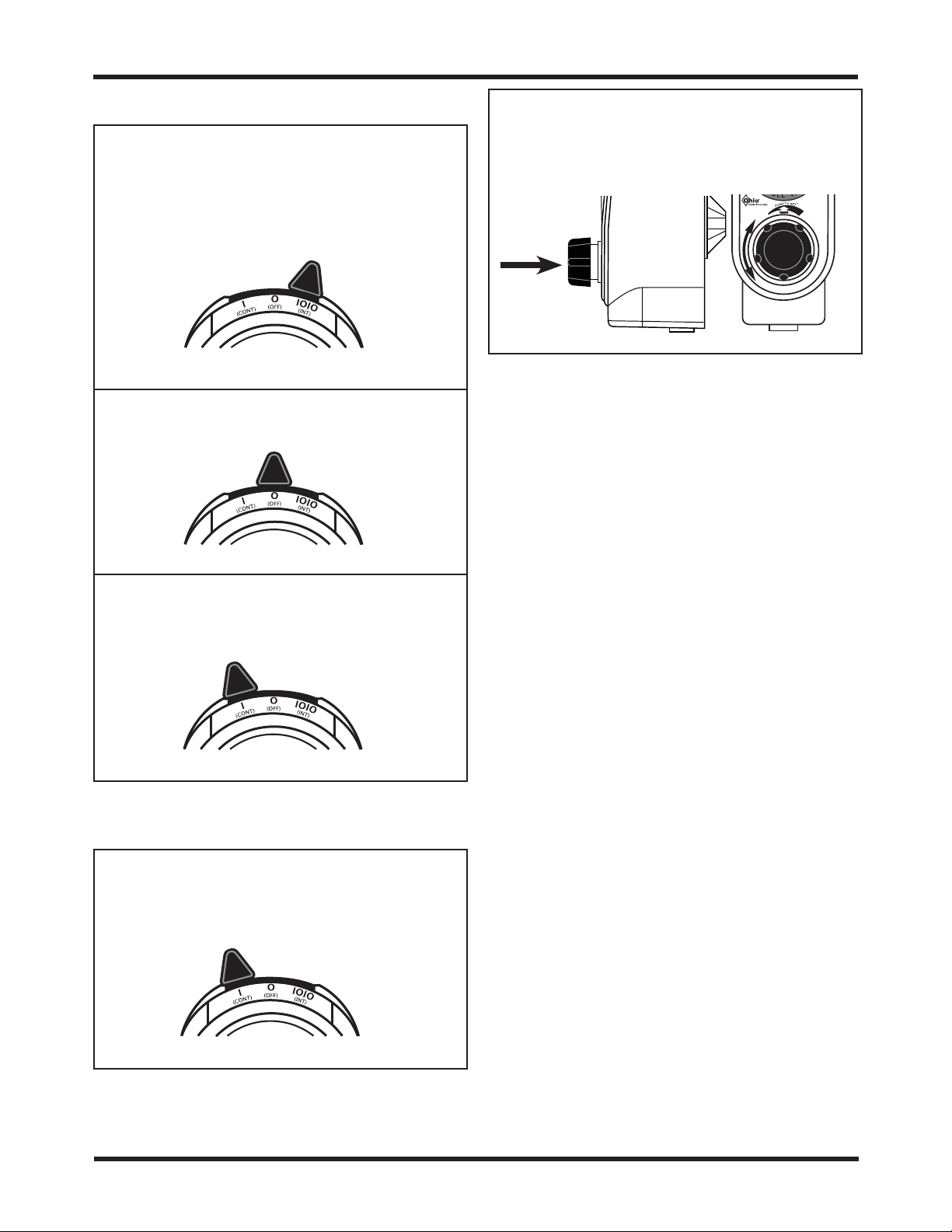

4.2 Mode Selection

Figure 5

IOIO (INT)- suction is intermittent (cycled “on” and

“off”) and the suction level can be adjusted with the

suction control knob when cycled “ON”.

O (OFF)- No suction is supplied to the patient.

I (CONT) - Suction is continuous and can be

adjusted with the suction control knob.

Figure 7

2. Push and rotate the suction control knob until the

vacuum gauge indicates the required setting.

CAUTION: The suction control knob must be

completely depressed in order to adjust the

vacuum level. Failure to do so may damage the

vacuum regulator.

4.4 Pre-Use Checkout Procedure

WARNING: The Pre-Use Checkout Procedure

must be performed before using the

equipment on each patient. If the regulator

fails any part of the Pre-Use Checkout

Procedure, it must be removed from service

and repaired by qualifi ed service personnel.

4.3 Setting the Suction Level

Figure 6

1. Turn the mode selector switch to I (CONT).

All tests must be performed with supply vacuum of

500 mmHg (67 kPa) minimum.

1. Turn the mode selector switch to O (OFF).

Push and rotate the suction control knob one full

turn clockwise (increase). Release. The gauge

needle should not move.

2. Move the mode selector switch to I (CONT). The

gauge should indicate vacuum. Push and rotate

the suction control knob fully counter-clockwise

(decrease) until it stops and release. The gauge

needle should move to zero and remain there.

3. Push the suction control knob and set the

following:

REGULATOR (Type) SETTING

PTS-ISU Increase the suction to

90 mmHg (12 kPa)

4. Slowly release and push the suction control knob

to create various fl ow rates through the regulator.

Check that the suction level is maintained when

the knob is fully pushed in.

5

8700-0001-000 Rev4

Loading...

Loading...