3000 Series Indicators

Instruction Manual

T32XW Indicator

i

ii

3000 Series Indicators

TABLE OF CONTENTS

1. INTRODUCTION ..........................................................................................................................................EN-4

1.1 Safety Precautions .....................................................................................................................................EN-4

1.2 Overview of Parts and Controls ...................................................................................................................EN-5

1.3 Control Functions .......................................................................................................................................EN-8

2. INSTALLATION ...........................................................................................................................................EN-9

2.1 Unpacking ................................................................................................................................................EN-9

2.2 External Connections ..................................................................................................................................EN-9

2.2.1 RS232 Interface Cable to the indicator ................................................................................................ EN-9

2.2.2 AC Power ....................................................................................................................................... EN-9

2.2.3 Battery power ............................................................................................................................... EN-10

2.2.4 Mounting Bracket to the indicator ..................................................................................................... EN-10

2.3 Internal Connections ................................................................................................................................. EN-10

2.3.1 Opening the Housing .......................................................................................................................EN-10

2.3.2 Scale Base to the indicator ............................................................................................................. EN-11

2.3.3 RS232 Interface Cable to the indicator ............................................................................................... EN-11

2.4 Mounting Bracket ....................................................................................................................................EN-12

EN-1

3. SETTINGS ................................................................................................................................................EN-13

3.1 Menu Structure ........................................................................................................................................EN-13

3.2 Menu Navigation .....................................................................................................................................EN-14

3.3 Calibration Menu .....................................................................................................................................EN-14

3.3.1 Span Calibration ...........................................................................................................................EN-15

3.3.2 Linearity Calibration ......................................................................................................................EN-15

3.3.3 Geographical Adjustment Factor .....................................................................................................EN-16

3.3.4 End Calibration ............................................................................................................................. EN-16

3.4 Setup Menu .............................................................................................................................................EN-18

3.4.1 Reset ........................................................................................................................................... EN-18

3.4.2 Legal for trade .............................................................................................................................. EN-18

3.4.3 Calibration Unit ............................................................................................................................. EN-18

3.4.4 Capacity ......................................................................................................................................EN-18

3.4.5 Graduation ................................................................................................................................... EN-20

3.4.6 Power On Unit ..............................................................................................................................EN-20

3.4.7 Zero Range ..................................................................................................................................EN-20

3.4.8 End Setup ....................................................................................................................................EN-20

EN-2

3000 Series Indicators

TABLE OF CONTENTS (Cont.)

3.5 Readout Menu .........................................................................................................................................EN-20

3.5.1 Reset ........................................................................................................................................... EN-22

3.5.2 Filter ............................................................................................................................................ EN-21

3.5.3 Auto-Zero Tracking ........................................................................................................................EN-21

3.5.4 Backlight .....................................................................................................................................EN-21

3.5.5 Auto Off Timer ..............................................................................................................................EN-21

3.5.6 End Readout .................................................................................................................................EN-21

3.6 Mode Menu .............................................................................................................................................EN-22

3.6.1 Reset ........................................................................................................................................... EN-22

3.6.2 Parts Counting Mode ..................................................................................................................... EN-22

3.6.3 End Mode ....................................................................................................................................EN-22

3.7 Unit Menu ...............................................................................................................................................EN-23

3.7.1 Reset ........................................................................................................................................... EN-23

3.7.2 Kilogram Unit ...............................................................................................................................EN-23

3.7.3 Pound Unit ................................................................................................................................... EN-23

3.7.4 Gram Unit ....................................................................................................................................EN-23

3.7.5 Ounce Unit ...................................................................................................................................EN-23

3.7.6 Pound Ounce Unit ......................................................................................................................... EN-23

3.7.7 End Unit ......................................................................................................................................EN-24

3.8 Print Menu ..........................................................................................................................................EN-24

3.8.1 Reset ........................................................................................................................................... EN-24

3.8.2 Baud ...........................................................................................................................................EN-24

3.8.3 Parity ..........................................................................................................................................EN-24

3.8.4 Stop Bit .......................................................................................................................................EN-25

3.8.5 Handshake ..................................................................................................................................EN-25

3.8.6 Print Stable Data Only ...................................................................................................................EN-25

3.8.7 Auto Print ..................................................................................................................................... EN-25

3.8.8 Content ........................................................................................................................................ EN-25

3.8.9 End Print .....................................................................................................................................EN-25

3.9 Menu Lock Menu .....................................................................................................................................EN-26

3.9.1 Reset ........................................................................................................................................... EN-26

3.9.2 Lock Calibration ...........................................................................................................................EN-26

3.9.3 Lock Setup ...................................................................................................................................EN-26

3.9.4 Lock Readout ............................................................................................................................... EN-26

3.9.5 Lock Mode ...................................................................................................................................EN-26

3.9.6 Lock Unit .....................................................................................................................................EN-26

3.9.7 Lock Print ...................................................................................................................................EN-27

3.9.8 End Lock .....................................................................................................................................EN-27

3000 Series Indicators

TABLE OF CONTENTS (Cont.)

3.10 Security Switch .......................................................................................................................................EN-27

4. OPERATION ............................................................................................................................................. EN-27

4.1 Turning Indicator On/Off ............................................................................................................................EN-27

4.2 Zero Operation .........................................................................................................................................EN-27

4.3 Manual Tare ............................................................................................................................................EN-27

4.4 Changing Units of Measure .......................................................................................................................EN-28

4.5 Printing Data ...........................................................................................................................................EN-28

4.6 Application Modes ...................................................................................................................................EN-28

4.6.1 Weighing .....................................................................................................................................EN-28

4.6.2 Parts Counting .............................................................................................................................EN-28

5. SERIAL COMMUNICATION ..........................................................................................................................EN-30

5.1 Interface Commands ................................................................................................................................EN-30

5.2 Output Format .........................................................................................................................................EN-31

6. LEGAL FOR TRADE ................................................................................................................................... EN-32

6.1 Settings ..................................................................................................................................................EN-32

6.2 Verification ..............................................................................................................................................EN-32

6.3 Sealing ...................................................................................................................................................EN-32

6.3.1 Physical Seals .............................................................................................................................. EN-32

6.3.2 Audit Trail Seal .............................................................................................................................EN-33

EN-3

7. MAINTENANCE .........................................................................................................................................EN-35

7.1 Cleaning .................................................................................................................................................EN-35

7.2 Troubleshooting .......................................................................................................................................EN-35

7.3 Service Information ..................................................................................................................................EN-36

8. TECHNICAL DATA .....................................................................................................................................EN-37

8.1 Specifications .......................................................................................................................................... EN-37

8.2 Accessories and Options ........................................................................................................................... EN-38

8.3 Drawings and Dimensions ........................................................................................................................EN-39

8.4 Compliance ............................................................................................................................................. EN-40

EN-4

3000 Series Indicators

1. INTRODUCTION

This manual contains installation, operation and maintenance instructions for the T32XW Indicator. Please read this manual

completely before installation and operation.

1.1 Safety Precautions

For safe and dependable operation of this equipment, please comply with the following safety precautions:

• Verify that the input voltage range printed on the data label matches the local AC power to be used.

• Make sure that the power cord does not pose a potential obstacle or tripping hazard.

• Use only approved accessories and peripherals.

• Operate the equipment only under ambient conditions specified in these instructions.

• Disconnect the equipment from the power supply before cleaning.

• Do not operate the equipment in hazardous or unstable environments.

• Do not immerse the equipment in water or other liquids.

• Service should only be performed by authorized personnel.

• The Indicator is supplied with a grounded power cable. Use only with a compatible grounded power outlet.

3000 Series Indicators

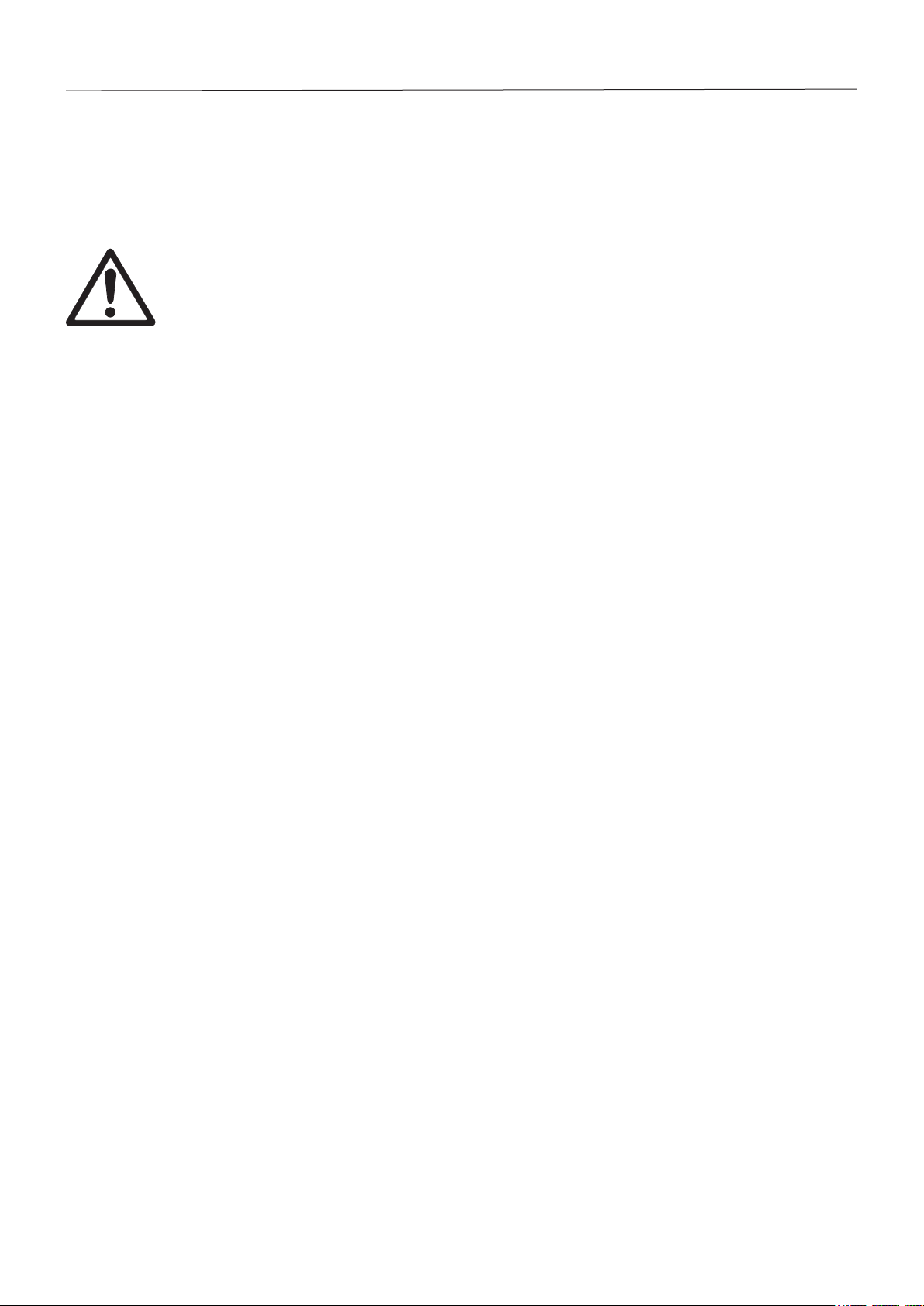

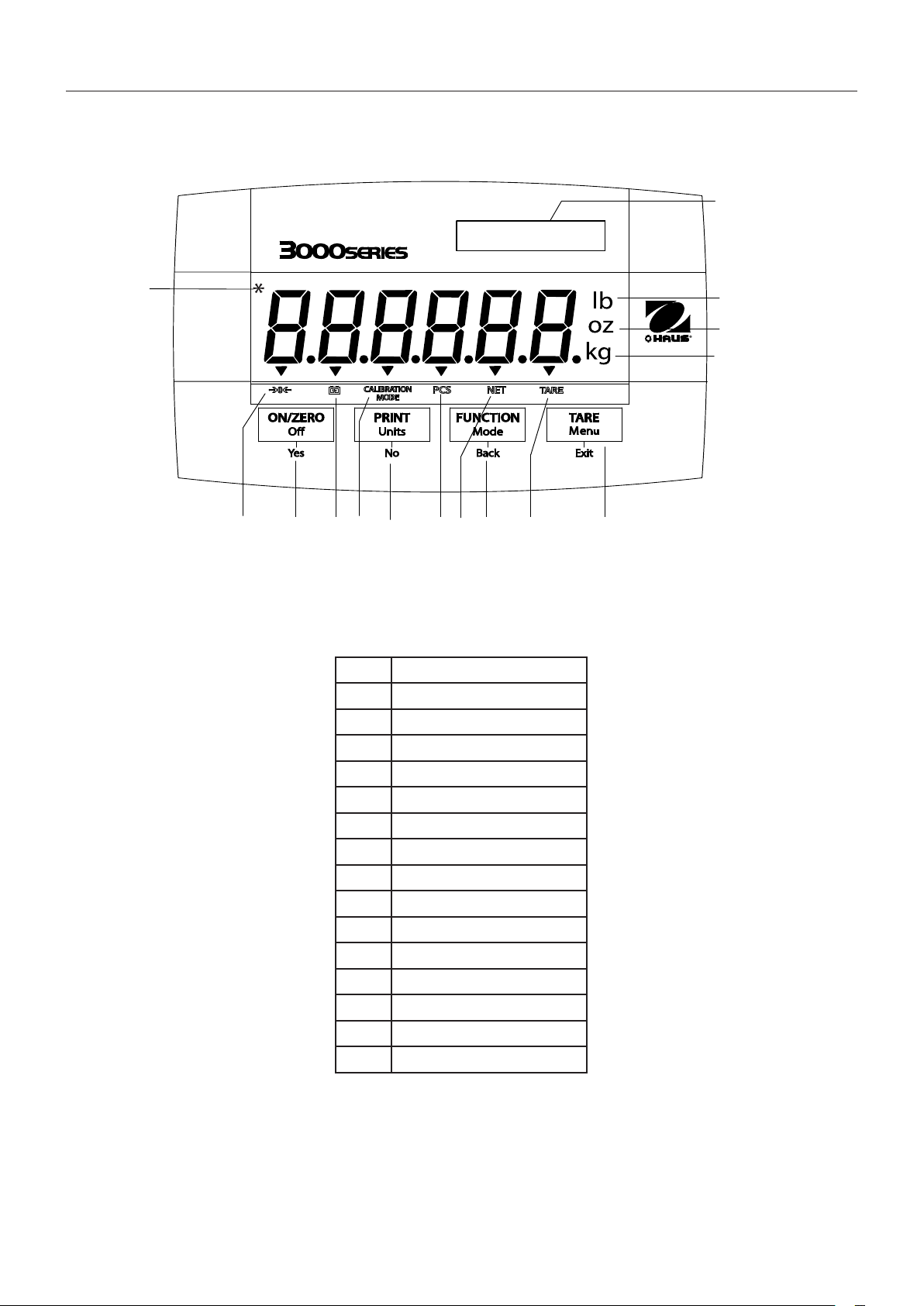

1.2 Overview of Parts and Controls

EN-5

1

2

3

4

5

6

TABLE 1-1. T32XW PARTS.

Item Description

1 Data Label

2 Front Housing

3 Adjusting Knob (2)

4 Control Panel

5 Mounting Bracket

6 Screw (4)

7 Rear Housing

8 Safety Data Label

9 Strain Relief for RS232

10 Strain Relief for Load Cell

Cable

11 Power cord

7

8

9 10

Figure 1-1. Indicator.

11

EN-6

1

2

3

4

7

5

6

8

J8

J1

J5

J7

W1

W2

J2

GND

LFT OFF

RXD

-EXE

-SEN

-SIG

CGND

+SIG

LFT ON

+SEN

TXD

+EXE

TXD GND

RXD

+EXC +SIG -SIG -EXC

+SENS GND -SENS

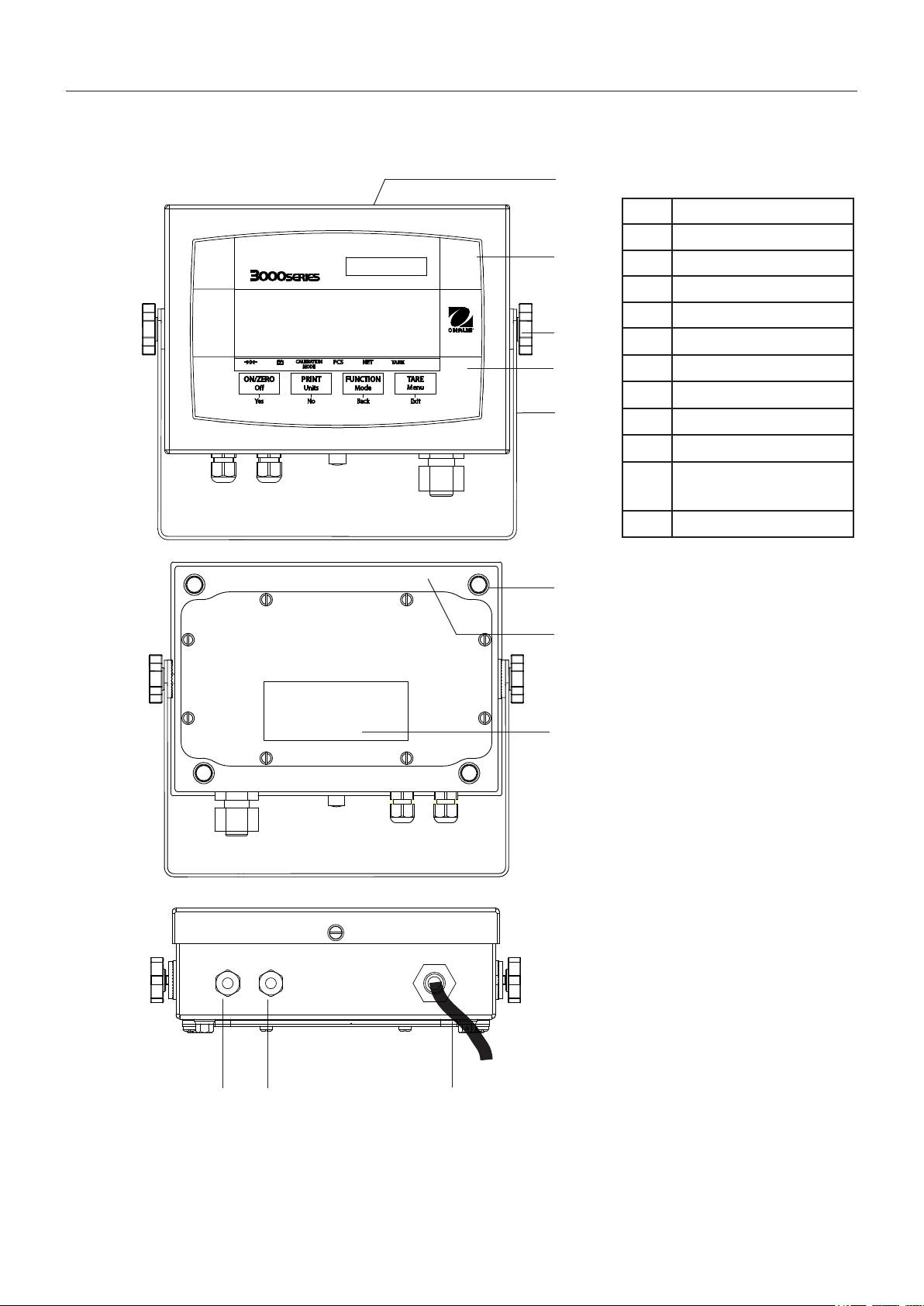

1.2 Overview of Parts and Controls (Cont.)

3000 Series Indicators

LOAD CELL WIRING

RS232 WIRING

Figure 1-2. Main PC Board.

TABLE 1-2. MAIN PC BOARD.

Item Description

1 Keypad Connector J8

2 Battery Connector

3 Line Power Input

4 Sense Jumper W2

5 Load Cell Terminal Block J5

6 Sense Jumper W1

7 RS232 Terminal Block J7

8 LFT On / Off Switch

3000 Series Indicators

1

2

3

4

56

78

910

11

12

1314

15

1.2 Overview of Parts and Controls (Cont.)

EN-7

Figure 1-3. Controls and Indicators.

TABLE 1-3. CONTROL PANEL.

No. Designation

1 Capacity Label Window

2 Pound symbol

3 Ounce symbol

4 Kilogram, gram symbols

5 TARE

6 TARE symbol

7 FUNCTION

8 NET symbol

9 PCS symbol

10 PRINT

11 Calibration Mode symbol

12 Battery symbol

13 ON/ZERO

14 Center of Zero symbol

15 Stable weight indicator

Menu

Units

Off

button

Mode

button

button

button

EN-8

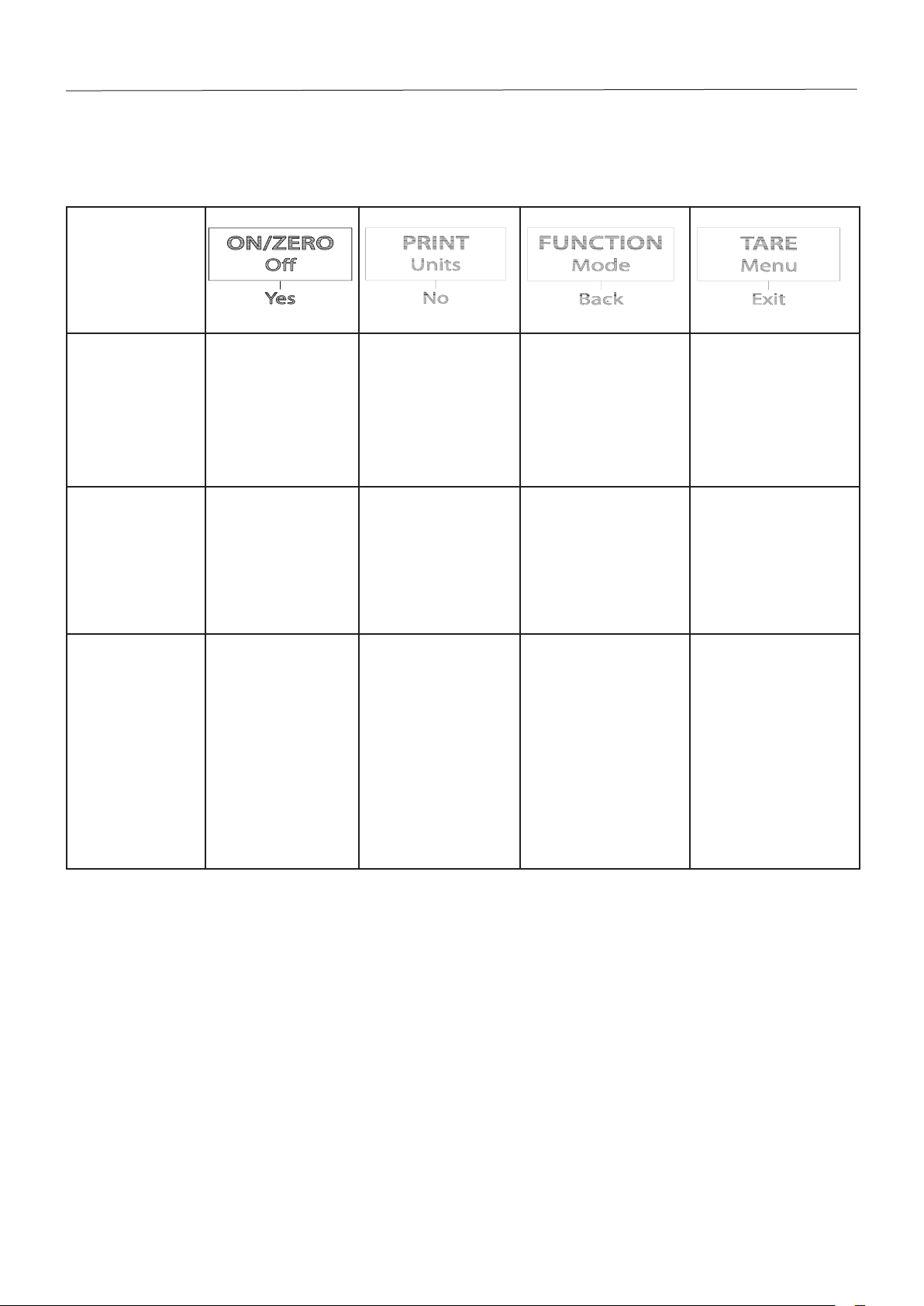

1.3 Control Functions

Button

3000 Series Indicators

TABLE 1-4. CONTROL FUNCTIONS.

Primary Function

(Short Press)

Secondary Function

(Long Press)

Menu Function

(Short Press)

ON/ZERO

If Indicator is On, sets

zero.

Off

Turns the Indicator on

or off.

Yes

Accepts the current

setting on the display.

PRINT

Sends the current value

to the COM port if

AUTOPRINT is set to Off.

Units

Changes the weighing

Unit.

No

Advances to the next

menu or menu item.

Rejects the current

setting on the display

and advances to the

next available setting.

Increments the value.

FUNCTION

Initiates an application

mode.

Mode

Allows changing the

application mode.

Press and hold allows

scrolling through modes.

Back

Moves Back to previous

menu item.

Decrements the value.

TARE

Performs a tare

operation.

Menu

Enter the User menu.

View the Audit Trail event

counters (extended

press)

Exit

Exits the User menu.

Aborts the calibration in

progress.

3000 Series Indicators

1

2

3

4

5

6

78

9

2. INSTALLATION

2.1 Unpacking

Unpack the following items:

• Indicator

• Mounting Bracket

• Knobs (2)

• Capacity Label Sheet

• Instruction Manual CD

• Warranty Card

• LFT sealing Kit

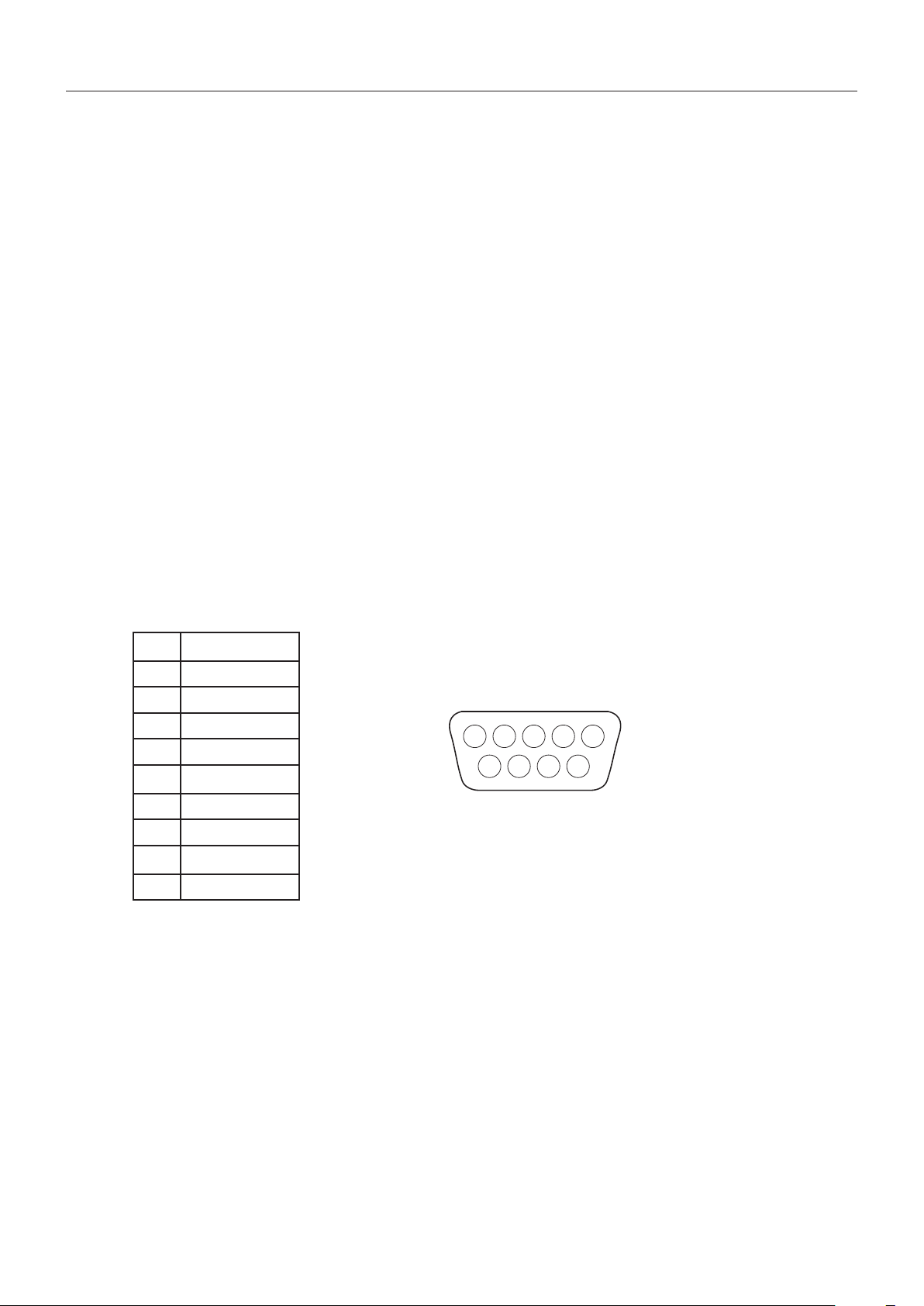

2.2 External Connections

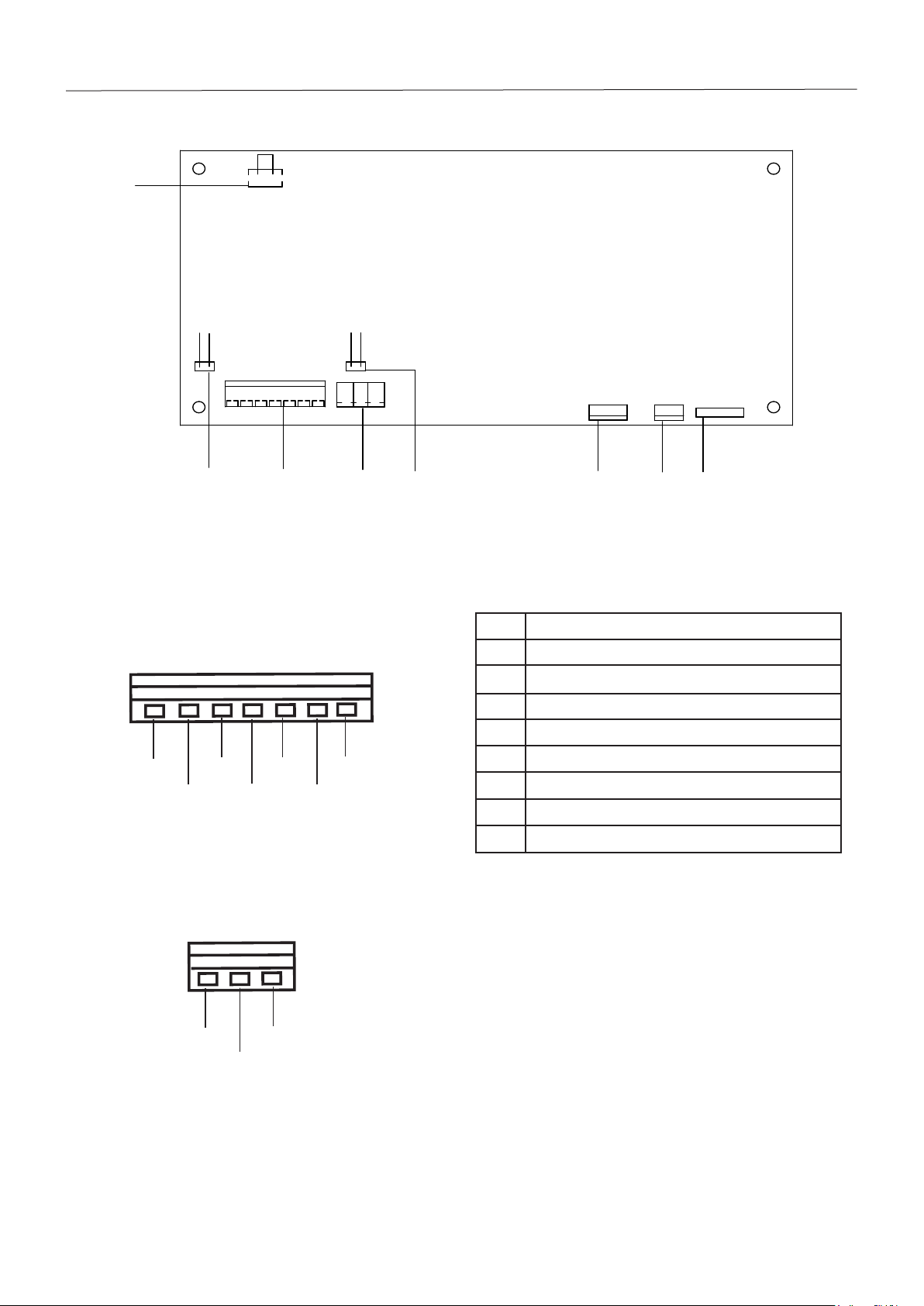

2.2.1 RS232 interface Cable to the indicator

Connect the optional RS232 cable to the RS232 connector Figure 1-1, item 9).

EN-9

Pin Connection

1 N/C

2 TXD

3 RXD

4 N/C

5 GND

6 N/C

7 N/C

8 N/C

9 N/C

2.2.2 AC Power

Connect the AC plug to a properly grounded electrical outlet.

Figure 2-1. RS232 Pins.

EN-10

3000 Series Indicators

2.2.3 Battery Power

The indicator can be operated on the internal rechargeable battery when AC power is not available. The indicator will

automatically switch to battery operation if there is a power failure or the power cord is removed.

Note:

Before using the indicator for the first time, the internal rechargeable battery should be fully charged for up to

12 hours. The indicator can be operated during the charging process. The battery is protected against over

charging and the indicator can remain connected to the AC power line.

Connect AC power to the indicator and allow it to charge. While the battery is charging, the triangle above the battery function

symbol will light. When the battery is fully charged, this triangle will disappear.

The indicator can operate for up to 100 hours on a fully charged battery.

During battery operation, a flashing triangle above the battery function symbol indicates the battery is low and requires

recharging. Approximately 60 minutes of operation will remain when the battery symbol starts to blink. The indicator will

display Lo.BAT and automatically turn off when the battery is fully discharged.

CAUTION

BATTERY IS TO BE REPLACED ONLY BY AN AUTHORIZED OHAUS

SERVICE DEALER.

RISK OF EXPLOSION CAN OCCUR IF REPLACED WITH THE

WRONG TYPE OR CONNECTED IMPROPERLY.

Dispose of the lead acid battery according to local laws and regulations.

2.2.4 Mounting Bracket to the Indicator

Align the mounting bracket over the threaded holes in the side of the indicator and install the knobs. Adjust the indicator to the

desired angle and tighten the knobs.

2.3 Internal Connections

Some connections require the housing to be opened.

2.3.1 Opening the Housing

CAUTION: ELECTRICAL SHOCK HAZARD. REMOVE ALL POWER CONNECTIONS TO THE INDICATOR

BEFORE SERVICING OR MAKING INTERNAL CONNECTIONS. THE HOUSING SHOULD ONLY BE OPENED

BY AUTHORIZED AND qUALIFIED PERSONNEL, SUCH AS AN ELECTRICAL TECHNICIAN.

3000 Series Indicators

Remove the four hex head screws from the rear housing.

Open the housing by carefully pulling the top of the front housing forward.

Once all connections are made, reattach the front housing.

The screws should be tightened fully to maintain a watertight seal.

2.3.2 Scale Base to the Indicator

Pass the load cell cable through the strain relief (Figure 1-1,

item 10) and attach it to terminal block J5 (Figure 1-2, item 5).

Re-tighten the strain relief to ensure a watertight seal.

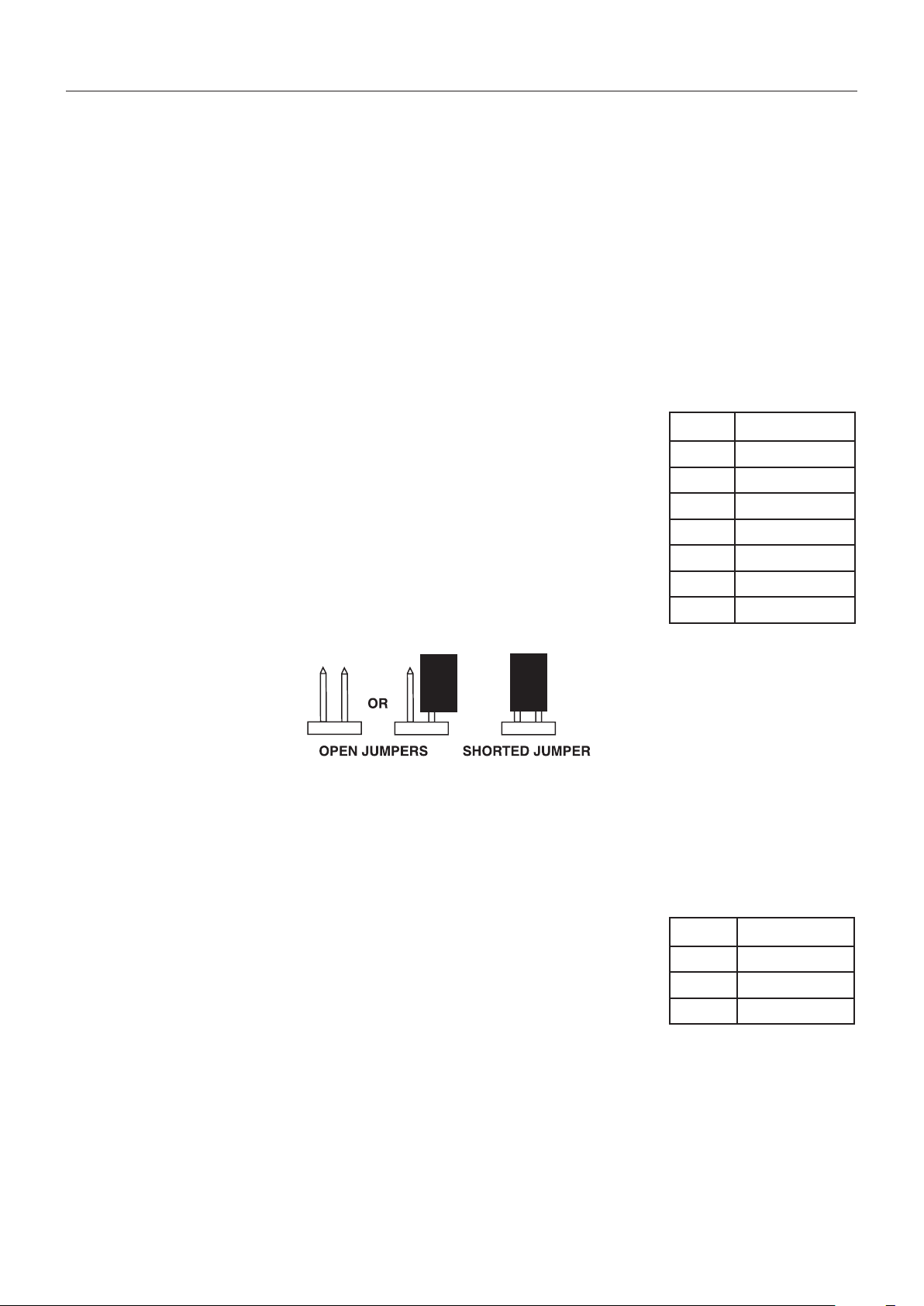

Jumper Connections

For a 4-wire load cell with no sense wires: Jumpers W1 and W2 must be shorted.

For a 6-wire load cell that includes sense wires, see Figure 2-2. Jumpers W1 and W2 must

be opened.

For load cells with an extra ground shield wire: Connect the shield to the center position (GND)

of J5.

EN-11

Pin Connection

J5-1 +EXCITATION

J5-2 +SENSE

J5-3 +SIGNAL

J5-4 GND

J5-5 -SIGNAL

J5-6 -SENSE

J5-7 -EXCITATION

Figure 2-2. Jumper Connections.

After wiring is completed and jumpers are in place, replace the indicator housing screws. Make sure the strain relief is properly

tightened.

2.3.3 RS232 Interface Cable to the indicator

Pass the optional RS232 cable through the strain relief (Figure 1-1, item 9) and attach it to

terminal block J7 (Figure 1-2, item 7). Re-tighten the strain relief to ensure a water tight seal.

Pin Connection

J7-1 TXD

J7-2 RXD

J7-3 GND

EN-12

3000 Series Indicators

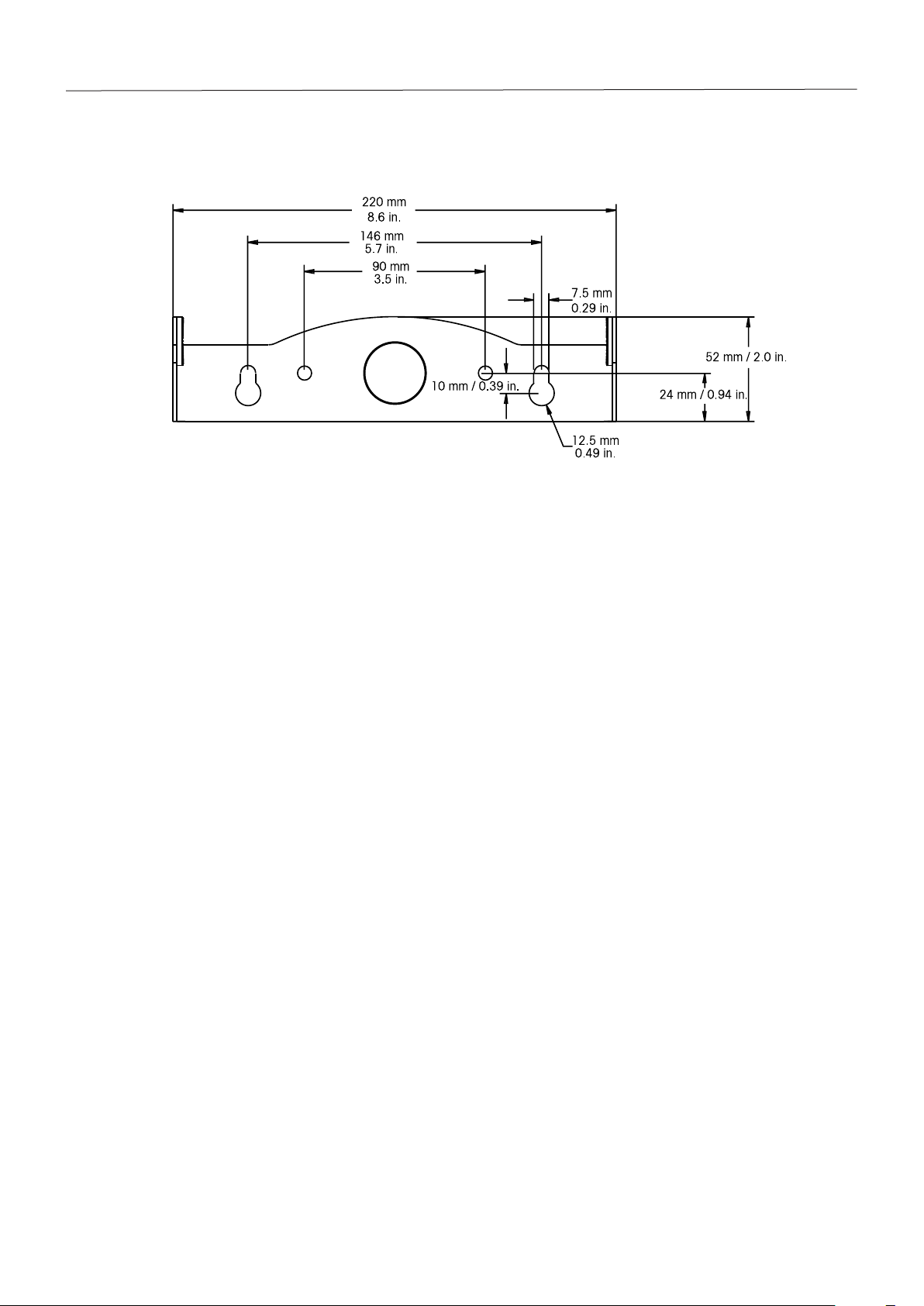

2.4 Mounting Bracket

Attach the bracket to a wall or table using fasteners (not supplied) that are appropriate for the type of mounting surface. The

bracket will accommodate up to 6 mm (1/4”) diameter screws. Locate the mounting holes as shown in Figure 2-3.

Figure 2-3. Mounting Bracket Dimensions.

3000 Series Indicators

3 SETTINGS

3.1 Menu Structure

TABLE 3-1. MENU STRUCTURE.

CALIBRATIONSETUP

SPAN RESET RESET RESET RESET

LINEARITY NO NO NO NO

GEO YES YES YES YES

0…31 LEGAL FOR TRADE AVERAGING COUNT KILOGRAM

END CAL OFF LOW OFF OFF

ON MEDIUM ON ON

CALIBRATION UNIT HI END MODE POUND

KILOGRAM AUTO ZERO OFF

POUND OFF ON

CAPACITY 0.5d GRAM

5…20000 1d OFF

GRADUATION 3d ON

0.001…20 EXPAND MODE OUNCE

POWER ON UNIT OFF OFF

AUTO ON ON

GRAM BACKLIGHT POUND OUNCE

KILOGRAM AUTO OFF

POUND ON ON

OUNCE OFF END UNIT

POUND OUNCE AUTO OFF

ZERO RANGE OFF

0% SET 1

2% SET 2

100% SET 5

END SETUP END READOUT

READOUT

MODE

UNIT

PRINT

RESET RESET

NO NO

YES YES

BAUD LOCK CAL

300, …19200 OFF

PARITY ON

7 EVEN LOCK SETUP

7 ODD OFF

7 NONE ON

8 NONE LOCK READOUT

STOP OFF

1 ON

2 LOCK MODE

HANDSHAKE OFF

OFF ON

XON-XOFF LOCK UNIT

STABLE ONLY OFF

OFF ON

ON LOCK PRINT

AUTO PRINT OFF

OFF ON

WHEN STABLE END MENU LOCK

LOAD

LOAD AND ZERO

INTERVAL

1…3600

CONTINUOUS

CONTENT

GROSS

NET

TARE

UNIT

END PRINT

MENU LOCK

EN-13

END

EN-14 3000 Series Indicators

3.2 Menu Navigation

TO ENTER THE MENU MODE

Press and hold the Menu button until MENU appears on the display. The first upper level menu appears on the display.

Summary of button navigation functions in menu mode:

--Yes Allows entry into the displayed menu.

- Accepts the displayed setting and advances to the next menu item.

--No Skips by the displayed menu.

- Rejects the displayed setting or menu item and advances to the next available item.

--Back Moves backwards through the upper and middle level menus.

- Backs out of a list of selectable items to the previous middle level menu.

--Exit Exits from menu directly to the active weighing mode.

3.3 Calibration Menu

Two calibration processes are available: Span Calibration and Linearity

Calibration.

NOTES:

1. Make sure that appropriate calibration masses are available before

beginning calibration.

2. Make sure that the scale base is level and stable during the entire

calibration process.

3. Calibration is unavailable with LFT set to On.

4. Allow the Indicator to warm up for approximately 5 minutes after

stabilizing to room temperature.

5. To abort calibration, press the Exit button anytime during the calibration

process.

Span Perform

Linearity Perform

Geographic

Adjustment Set 00…Set 19… Set 31

End Calibration Exit CALIBRATE menu

3.3.1 Span Calibration

Span Calibration uses two points to adjust the scale. The first point is the zero value where there is no weight

on the scale. The second point is the Span value where a calibration mass is placed on the scale.

When SPAN is displayed, press the Yes button to access the Span Calibration menu item.

The display flashes 0.

With no weight on the scale, press the Yes button to establish the zero point.

The display shows --C-- while the zero point is established.

The display flashes the span calibration point. Place the specified weight on the scale and press the Yes

button.

To choose a different span point, repeatedly press the No button to increment the selections or press the Back

button to decrement the selections. Refer to Table 3-3 for available span points. When the desired value is

displayed, place the specified weight on the scale and press the Yes button.

EN-153000 Series Indicators

The display shows --C-- while the span point is established.

If span calibration was successful, the scale exits to the active weighing mode and displays the actual weight

value.

3.3.2 Linearity Calibration

Linearity calibration uses 3 calibration points. The first calibration point is established with no weight on the

scale. The second calibration point is established at approximately half capacity. The third calibration point

is established at capacity. The Linearity calibration points are fixed and cannot be altered by the user during

the calibration procedure. Refer to Table 3-3 for the linearity points.

When LINEAr is displayed, press the Yes button to access the Linearity Calibration menu item.

The display flashes 0. With no weight on the scale, press the Yes button to establish the zero point.

The display shows --C-- while the zero point is established.

The display flashes the mid calibration point.

Place the specified weight on the scale and press the Yes button.

The display shows --C-- while the mid point is established.

The display flashes the full calibration point.

Place the specified weight on the scale and press the Yes button.

The display shows --C-- while the full point is established.

If linearity calibration was successful, the scale exits to the active weighing mode and displays the actual

weight value.

EN-16 3000 Series Indicators

3.3.3 Geographical Adjustment Factor

The Geographcial Adjustment Factor (GEO) is used to compensate for variations in gravity.

Note: Changing the GEO Factor alters the calibration. The GEO value was set at the factory and should only

be changed by an authorized manufacturer’s representative or certified verirication personnel.

Refer to table 3-2 to determine the GEO factor that corresponds to your location.

3.3.4 End Calibration

Advance to the next menu.

EN-173000 Series Indicators

TABLE 3-2. GEOGRAPHICAL ADJUSTMENT VALUES

Elevation in meters

0 325 650 975 1300 1625 1950 2275 2600 2925 3250

325 650 975 1300 1625 1950 2275 2600 2925 3250 3575

Elevation in feet

0 1060 2130 3200 4260 5330 6400 7460 8530 9600 10660

1060 2130 3200 4260 5330 6400 7460 8530 9600 10660 11730

Latitude GEO value

0°00’ 5°46’ 5 4 4 3 3 2 2 1 1 0 0

5°46’ 9°52’ 5 5 4 4 3 3 2 2 1 1 0

9°52’ 12°44’ 6 5 5 4 4 3 3 2 2 1 1

12°44’ 15°06’ 6 6 5 5 4 4 3 3 2 2 1

15°06’ 17°10’ 7 6 6 5 5 4 4 3 3 2 2

17°10’ 19°02’ 7 7 6 6 5 5 4 4 3 3 2

19°02’ 20°45’ 8 7 7 6 6 5 5 4 4 3 3

20°45’ 22°22’ 8 8 7 7 6 6 5 5 4 4 3

22°22’ 23°54’ 9 8 8 7 7 6 6 5 5 4 4

23°54’ 25°21’ 9 9 8 8 7 7 6 6 5 5 4

25°21’ 26°45’ 10 9 9 8 8 7 7 6 6 5 5

26°45’ 28°06’ 10 10 9 9 8 8 7 7 6 6 5

28°06’ 29°25’ 11 10 10 9 9 8 8 7 7 6 6

29°25’ 30°41’ 11 11 10 10 9 9 8 8 7 7 7

30°41’ 31°56’ 12 11 11 10 10 9 9 8 8 7 7

31°56’ 33°09’ 12 12 11 11 10 10 9 9 8 8 7

33°09’ 34°21’ 13 12 12 11 11 10 10 9 9 8 8

34°21’ 35°31’ 13 13 12 12 11 11 10 10 9 9 8

35°31’ 36°41’ 14 13 13 12 12 11 11 10 10 9 9

36°41’ 37°50’ 14 14 13 13 12 12 11 11 10 10 9

37°50’ 38°58’ 15 14 14 13 13 12 12 11 11 10 10

38°58’ 40°05’ 15 15 14 14 13 13 12 12 11 11 10

40°05’ 41°12’ 16 15 15 14 14 13 13 12 12 11 11

41°12’ 42°19’ 16 16 15 15 14 14 13 13 12 12 11

42°19’ 43°26’ 17 16 16 15 15 14 14 13 13 12 12

43°26’ 44°32’ 17 17 16 16 15 15 14 14 13 13 12

44°32’ 45°38’ 18 17 17 16 16 15 15 14 14 13 13

45°38’ 46°45’ 18 18 17 17 16 16 15 15 14 14 13

46°45’ 47°51’ 19 18 18 17 17 16 16 15 15 14 14

47°51’ 48°58’ 19 19 18 18 17 17 16 16 15 15 14

48°58’ 50°06’ 20 19 19 18 18 17 17 16 16 15 15

50°06’ 51°13’ 20 20 19 19 18 18 17 17 16 16 15

51°13’ 52°22’ 21 20 20 19 19 18 18 17 17 16 16

52°22’ 53°31’ 21 21 20 20 19 19 18 18 17 17 16

53°31’ 54°41’ 22 21 21 20 20 19 19 18 18 17 17

54°41’ 55°52’ 22 22 21 21 20 20 19 19 18 18 17

55°52’ 57°04’ 23 22 22 21 21 20 20 19 19 18 18

57°04’ 58°17’ 23 23 22 22 21 21 20 20 19 19 18

58°17’ 59°32’ 24 23 23 22 22 21 21 20 20 19 19

59°32’ 60°49’ 24 24 23 23 22 22 21 21 20 20 19

60°49’ 62°90’ 25 24 24 23 23 22 22 21 21 20 20

62°90’ 63°30’ 25 25 24 24 23 23 22 22 21 21 20

63°30’ 64°55’ 26 25 25 24 24 23 23 22 22 21 21

64°55’ 66°24’ 26 26 25 25 24 24 23 23 22 22 21

66°24’ 67°57’ 27 26 26 25 25 24 24 23 23 22 22

67°57’ 69°35’ 27 27 26 26 25 25 24 24 23 23 22

69°35’ 71°21’ 28 27 27 26 26 25 25 24 24 23 23

71°21’ 73°16’ 28 28 27 27 26 26 25 25 24 24 23

73°16’ 75°24’ 29 28 28 27 27 26 26 25 25 24 24

75°24’ 77°52’ 29 29 28 28 27 27 26 26 25 25 24

77°52’ 80°56’ 30 29 29 28 28 27 27 26 26 25 25

80°56’ 85°45’ 30 30 29 29 28 28 27 27 26 26 25

85°45’ 90°00’ 31 30 30 29 29 28 28 27 27 26 26

EN-18 3000 Series Indicators

3.4 Setup Menu

When the Indicator is used for the first time, enter this

menu to set the Capacity and Graduation.

Reset No, Yes

Legal for Trade Off, On

Cal Unit kg, lb

Capacity 5…20000

Graduation 0.001…20

Power On Unit g, kg, lb, oz, lb:oz, Auto

Zero Range 0%, 2%, 100%

End Setup Exit SETUP menu

3.4.1 Reset

Reset the Setup menu to the factory defaults.

No = not reset.

Yes = reset.

NOTE: If the Legal for Trade menu item is set to ON, the Capacity, Graduation, Zero Range and Legal For

Trade settings are not reset.

3.4.2 Legal for Trade

Set the legal for trade status.

OFF = off

ON = on

Turning on the “LFT” menu setting has the following effects:

• Zero-range is set and locked on “2”.

• Auto Zero Tracking is set and locked on 0.5d

• The lb:oz unit is not available as a power-on setting.

3.4.3 Calibration Unit

Set the unit during calibration.

CAL UN kg = Calibrate using kg weights

CAL UN lb = Calibrate using pound weights

3.4.4 Capacity

Set the scale capacity from 5 to 20000. Refer to the Setup Table 3.3 for available settings.

TABLE 3-3. SETUP AND CALIBRATION VALUES

EN-193000 Series Indicators

Capacity Graduation size

with LFT OFF

5 0.0005, 0.001, 0.002,

0.005

10 0.0005, 0.001, 0.002,

0.005, 0.01

15 0.001, 0.002, 0.005, 0.01 0.005, 0.01 5, 10, 15 5, 15

20 0.001, 0.002, 0.005, 0.01,

0.02

25 0.002, 0.005, 0.01, 0.02 0.005, 0.01, 0.02 5, 10, 15, 20, 25 10, 25

30 0.002, 0.005, 0.01, 0.02 0.005, 0.01, 0.02 5, 10, 15, 20, 25, 30 15, 30

40 0.002, 0.005, 0.01, 0.02 0.01, 0.02 5, 10, 15, 20, 25, 30, 40 20, 40

50 0.005, 0.01, 0.02, 0.05 0.01, 0.02, 0.05 5, 10, 15, 20, 25, 30, 40, 50 25, 50

60 0.005, 0.01, 0.02, 0.05 0.01, 0.02, 0.05 5, 10, 15, 20, 25, 30, 40, 50, 60 30, 60

75 0.005, 0.01, 0.02, 0.05 0.02, 0.05 5, 10, 15, 20, 25, 30, 40, 50, 60, 75 30, 75

100 0.005, 0.01, 0.02, 0.05,

0.1

120 0.01, 0.02, 0.05, 0.1 0.02, 0.05, 0.1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120 60, 120

150 0.01, 0.02, 0.05, 0.1 0.05, 0.1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150 75, 150

200 0.02, 0.01, 0.02, 0.05,

0.1, 0.2

250 0.05, 0.1, 0.2 0.05, 0.1, 0.2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

300 0.02, 0.05, 0.1, 0.2 0.05, 0.1, 0.2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

400 0.02, 0.05, 0.1, 0.2 0.1, 0.2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

500 0.05, 0.1, 0.2, 0.5 0.1, 0.2, 0.5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

600 0.05, 0.1, 0.2, 0.5 0.1, 0.2, 0.5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

750 0.05, 0.1, 0.2, 0.5 0.2, 0.5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

1000 0.05, 0.1, 0.2, 0.5, 1 0.2, 0.5, 1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

1200 0.1, 0.2, 0.5, 1 0.2, 0.5, 1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

1500 0.1, 0.2, 0.5, 1 0.5, 1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

2000 0.1, 0.2, 0.5, 1, 2 0.5, 1, 2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

2500 0.2, 0.5, 1, 2 0.5 ,1, 2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

3000 0.2, 0.5, 1, 2 0.5 ,1 ,2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

5000 0.5, 1, 2, 5 1, 2, 5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

6000 0.5, 1, 2, 5 1, 2, 5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

7500 0.5, 1, 2, 5 2, 5 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

10000 0.5, 1, 2, 5, 10 2, 5, 10 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

12000 1, 2, 5, 10, 20 2, 5, 10 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

15000 1, 2, 5, 10 5, 10 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

20000 1, 2, 5, 10, 20 5, 10, 20 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200,

Graduation size with LFT ON Span calibration points Linearity

calibration

points

0.001, 0.002, 0.005 5 2, 5

0.002, 0.005, 0.01 5, 10 5, 10

0.005, 0.01, 0.02 5, 10, 15, 20 10, 20

0.02, 0.05, 0.1 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100 50, 100

0.05, 0.1, 0.2 5, 10, 15, 20, 25, 30, 40, 50, 60, 75, 100, 120, 150, 200 100, 200

120, 250

250

150, 300

250, 300

200, 400

250, 300, 400

250, 500

250, 300, 400, 500

300, 600

250, 300, 400, 500, 600

300, 750

250, 300, 400, 500, 600, 750

500, 1000

250, 300, 400, 500, 600, 750, 1000

600, 1200

250, 300, 400, 500, 600, 750, 1000, 1200

750, 1500

250, 300, 400, 500, 600, 750, 1000, 1200, 1500

1000, 2000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000

1200, 2500

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500

1500, 3000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000

2500,5000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000

2500,5000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 6000

3000,7500

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 6000, 7500

5000,10000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 6000, 7500, 10000

6000,12000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 6000, 7500, 10000, 12000

7500,15000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 6000, 7500, 10000, 12000, 15000

10000,20000

250, 300, 400, 500, 600, 750, 1000, 1200, 1500, 2000,

2500, 3000, 5000, 6000, 7500, 10000, 20000

EN-20 3000 Series Indicators

3.4.5 Graduation

Set the scale readability.

0.001, 0.002, 0.005, 0.01, 0.02, 0.05, 0.1, 0.2, 0.5, 1, 2, 5, 10, 20.

NOTE: Not all settings are available for each capacity. Refer to the Setup Table 3.3 for available settings.

•

•

•

3.4.6 Power On Unit

Set the unit that will be active at power on.

oz, lb, g, kg, lb:oz or

Auto (last unit in use when power was turned off.)

3.4.7 Zero Range

Set the percentage of scale capacity that may be zeroed.

0% = zeroing disabled

2% = zero up to 2 percent of capacity

100% = zero up to full capacity

3.4.8 End Setup

Advance to the next menu.

3.5 Readout Menu

Enter this menu to customize display functionality.

Reset: No, Yes

Filter Level Lo, Med, Hi

Auto Zero Tracking Off, 0.5d, 1d, 3d

Backlight Off, On, Auto

Auto Shut Off Off

End Readout Exit READOUT menu

3.5.1 Reset

Set the Readout menu to factory default settings.

No = not reset

Yes = reset

If the Legal for Trade menu item is set to ON, the Stable Range, Averaging Level, Auto Zero Tracking and Auto

Off settings are not reset.

3.5.2 Filter

Set the amount of signal filtering.

LO = less stability, faster stabilization time (<1 sec.)

MEd = normal stability, stabilization time (<2 sec.)

HI = greater stability, slower stabilization time (<3 sec.)

3.5.3 Auto-Zero Tracking

Set the automatic zero tracking functionality.

OFF = disabled.

0.5 d = the display will maintain zero until a drift of 0.5 divisions per second has been

exceeded.

1 d = the display will maintain zero until a drift of 1 division per second has been

exceeded.

3 d = the display will maintain zero until a drift of 3 divisions per second has been

exceeded.

NOTE: When the LFT menu item is set to ON, the selections are limited to 0.5d and 3d. The setting is

locked when the hardware lock switch is set to the ON position.

EN-213000 Series Indicators

3.5.4 Backlight

Set the display backlight functionality.

OFF = always off.

ON = always on.

AUtO = turns on when a button is pressed or the displayed weight changes.

turns off after 5 seconds of no activity.

3.5.5 Auto Off Timer

Set the automatic shut off functionality.

OFF = disabled

SEt 1 = powers off after 1 minute of no activity.

SEt 2 = powers off after 2 minutes of no activity.

SEt 5 = powers off after 5 minutes of no activity.

3.5.6 End Readout

Advance to the next menu.

EN-22 3000 Series Indicators

3.6 Mode Menu

Enter this menu to activate the desired application

modes.

3.6.1 Reset

Set the Mode menu to the factory defaults.

No = not reset.

Yes = reset.

NOTE: If the Legal for trade menu item is set ON, the settings are not reset.

3.6.2 Parts Counting Mode

Set the status.

OFF = Disabled

ON = Enabled

Reset: No, Yes

Count: Off, On

End Mode Exit MODE menu

3.6.3 End Mode

Advance to the next menu.

3.7 Unit Menu

kg

Enter this menu to activate the desired units.

Default settings are bold.

3.7.1 Reset

Set the Unit menu to the factory defaults.

Settings:

NO = not reset.

YES = reset

If the Legal for Trade menu item is set ON, the settings are not reset.

EN-233000 Series Indicators

Reset: No, Yes

Kilograms: Off, On

Pounds: Off, On

Grams: Off, On

Ounces: Off, On

Pounds:Ounces Off, On

End Unit Exit UNIT menu

3.7.2 Kilogram Unit

Set the status.

OFF = Disabled

ON = Enabled

3.7.3 Pound Unit

Set the status.

OFF = Disabled

ON = Enabled

3.7.4 Gram Unit

Set the status.

OFF = Disabled

ON = Enabled

3.7.5 Ounce Unit

Set the status.

OFF = Disabled

ON = Enabled

3.7.6 Pound Ounce Unit

Set the status.

OFF = Disabled

ON = Enabled

EN-24

3.7.7 End Unit

Advance to the next menu.

3.8 Print Menu

3000 Series Indicators

Enter this menu to define printing parameters. Default settings are bold.

3.8.1 Reset

Set the Print menu to factory defaults.

NO = not reset.

YES = reset.

NOTE: If the Legal for Trade menu item is set to ON, the following

settings are not reset: Stable, Auto Print

Reset No, Yes

Baud Rate: 300, 600, 1200, 2400, 4800,

9600, 19200

Parity: 7 Even, 7 Odd, 7 None, 8 None

Stop Bit 1 or 2

Handshake: Off, XON/XOFF

Stable Only Off, On

Auto Print Off,

On Stable (-> Load, Load and Zero),

Interval (-> 1…3600), Continuous

Content Gross (->Off, On)

Net (->Off, On)

Tare (->Off, On)

Unit (->Off, On)

End Print

Exit PRINT menu

3.8.2 Baud

Set the Baud rate.

300 = 300 bps

600 = 600 bps

1200 =1200 bps

2400 = 2400 bps

4800 = 4800 bps

9600 = 9600 bps

19200 = 19200 bps

3.8.3 Parity

Set the data bits and parity.

7 EVEN = 7 data bits, even parity.

7 Odd = 7 data bits, odd parity.

7 NONE = 7 data bits, no parity.

8 NONE = 8 data bits, no parity.

3000 Series Indicators

3.8.4 Stop Bit

Set the number of stop bits.

1 = 1 stop bit.

2 = 2 stop bits.

3.8.5 Handshake

Set the flow control method.

NONE = no handshaking.

ON-OFF = XON/XOFF software handshaking.

3.8.6 Print Stable Data Only

Set the print critera.

OFF = values are printed immediately.

ON = values are only printed when the stability criteria are met.

EN-25

3.8.7 Auto Print

Set the automatic printing functionality.

OFF = disabled.

ON.StAb = printing occurs each time the stability criteria are met.

INtEr = printing occurs at the defined interval.

CONt = printing occurs continuosly.

When INtEr is selected, set the Print Interval.

1 to 3600 (seconds)

3.8.8 Content

Select the additional content of the printout.

GROSS OFF = Gross weight is not printed.

ON = Gross weight is printed.

NET OFF = Net weight is not printed.

ON = Net weight is printed.

TARE OFF = Tare weight is not printed.

ON = Tare weight is printed.

UNIT OFF = Unit is not printed.

ON = Unit weight is printed.

3.8.9 End Print

Advance to the next menu.

EN-26

3.9 Menu Lock Menu

3000 Series Indicators

Enter this menu. Default settings are bold.

3.9.1 Reset

Set the menu Lock menu to factory defaults.

NO = not reset.

YES = reset.

NOTE: Settings for LFT controlled menu items are not reset.

3.9.2 Lock Calibration

Set the status.

OFF = Calibration menu is not locked.

ON = Calibration menu is locked and hidden.

Reset: No, Yes

Lock Calibration Menu Off, On

Lock Setup Menu Off, On

Lock Readout Menu Off, On

Lock Mode Menu Off, On

Lock Unit Menu Off, On

Lock Print Menu Off, On

End Lock Menu

3.9.3 Lock Setup

Set the status.

OFF = Setup menu is not locked.

ON = Setup menu is locked and hidden.

3.9.4 Lock Readout

Set the status.

OFF = Readout menu is not locked.

ON = Readout menu is locked and hidden.

3.9.5 Lock Mode

Set the status.

OFF = Mode menu is not locked.

ON = Mode menu is locked and hidden.

3.9.6 Lock Unit

Set the status.

OFF = Unit menu is not locked.

ON = Unit menu is locked and hidden.

3000 Series Indicators

EN-27

3.9.7 Lock Print

Set the status.

OFF = Print menu is not locked.

ON = Print menu is locked.

3.9.8 End Lock

Advance to the next menu.

3.10 Security Switch

A security switch is located on the Main PCB board. When the switch is set to the on position, user menu settings that were

locked in the Menu Lock can not be changed.

Open the housing as explained in Section 2.3.1. Set the position of security switch to ON as shown in Figure 1-3.

4 OPERATION

4.1 Turning Indicator On/Off

To turn the Indicator on, press the and hold the ON/ZERO

performs a display test, momentarily displays the software version, and then enters the active

weighing mode.

Off

button for 2 seconds. The Indicator

To turn the Indicator off, press and hold the ON/ZERO

Off

button until OFF is displayed.

4.2 Zero Operation

Zero can be set under the following conditions:

• Automatically at Power On (initial zero).

• Semi-automatically (manually) by pressing the ON/ZERO

• Semi-automatically by sending the Zero command (Z or alternate zero command).

Press the ON/ZERO

operation.

Off

button to zero the weight display. The scale must be stable to accept zero

Off

button.

4.3 Manual Tare

When weighing an item that must be held in a container, taring stores the container weight in

memory. Place the empty container on the scale (example 0.5 kg) and press the TARE button.

The display will show the net weight.

To clear the Tare value, empty the scale and press the TARE button. The display will show the

gross weight.

EN-28

3000 Series Indicators

4.4 Changing Units of Measure

Press and hold the PRINT

will be displayed (refer to Section 3.7).

Units

button until the desired measuring unit appears. Only measuring units enabled in the Unit Menu

4.5 Printing Data

Printing the displayed data to a printer or sending the data to a computer requires that the communication parameters in the Print

Menu are set (refer to Section 3.8).

Press the PRINT

must be Off).

Units

button to send the displayed data to the communication port (the Auto-Print Mode in Section 3.8 function

4.6 Application Modes

Only modes enabled in the mode menu will be displayed (refer to Section 3-6).

4.6.1 Weighing

Place the item to be weighed on the scale. The illustration indicates a sample of 1.5 kg, Gross

weight.

Note: To return to the Weighing mode from the Parts Counting mode, press and hold the

button until WEIGH is displayed.

Mode

4.6.2 Parts Counting

Use this mode to count parts of uniform weight. The Indicator determines the quantity based on the

average weight of a single part. All parts must be uniform in weight for accurate measurements.

To enter the Parts Counting mode, press and hold the

Mode

button until Count is displayed.

Average Piece Weight (APW)

When the

NOTE: If no APW has been previously stored, the CLr.PW display is skipped and the display shows

PUt10Pcs.

Clearing a Stored APW

Press the Yes button to clear the stored APW.

Mode

button is released, CLr.PW Pcs is displayed.

3000 Series Indicators

Recalling a Stored APW

Press the No button to recall the existing APW.

EN-29

Press the FUNCTION

Mode

button to temporarily display the APW value.

Establishing the Average Piece Weight (APW)

The display shows Put10 Pcs.

Establishing a New APW

Press the No button to increment the sample size. Choices are 5, 10, 20, 50, 100 and 200.

To establish the APW, place the specified quantity of samples on the scale and press the Yes

button to capture the weight.

Begin Counting

Place the parts on the scale and read the count. If a container is used, be sure to tare the empty

container first.

EN-30 3000 Series Indicators

5 SERIAL COMMUNICATION

The Indicator include an RS232 serial communication interface.

The setup of RS232 operating parameters are more fully explained in Section 3.8. The physical hardware connection is

explained in in Section 2.2.

The interface enables display data to be sent to a computer or printer. A computer can be used to control some functions of

the indicator using the commands listed in Table 5-1.

5.1 Interface Commands

Communicate to the indicator using the command characters listed in Table 5-1.

TABLE 5-1. SERIAL INTERFACE COMMAND TABLE.

Command

Character

IP Immediate Print of displayed weight (stable or unstable).

P Print stable displayed weight (according to stability setting).

CP Continuous Print.

SP Print when stable.

xP Interval Print x = Print Interval (1-3600 sec)

Z Same as pressing Zero button

T Same as pressing Tare button

xT Download Tare value in grams (positive values only). Sending 0T clears tare (if allowed)

PU Print current unit: g, kg, lb, oz, lb:oz

xU Set scale to unit x: 1=g, 2=kg, 3=lb, 4=oz, 5=lb:oz

PV Version: print name, software revision and LFT ON (if LFT is set ON).

Esc R Global reset to reset all menu settings to the original factory defaults

NOTES:

• Commands sent to the Indicator must be terminated with a carriage return (CR) or carriage return-line feed (CRLF).

• Data output by the Indicator is always terminated with a carriage return-line feed (CRLF).

• The xT (preset tare) command is not available when LFT is set to ON.

Function

5.2 Output Format

The default serial output format is shown below.

Field: Polarity Space Weight Space Unit Stability Legend CR LF

Length: 1 1 7 1 5 1 3 1 1

Definitions: Polarity, “-” sign if negative, blank if positive.

Weight, up to 6 numbers and 1 decimal, right justified, leading zero blanking.

Units, up to 5 characters.

Stability, “?” character is printed if not stable, blank if stable.

Legend, up to 3 characters: G = gross weight, NET = net weight, T = tare

EN-313000 Series Indicators

EN-32 3000 Series Indicators

6. LEGAL FOR TRADE

When the indicator is used in trade or a legally controlled application it must be set up, verified and sealed in accordance with

local weights and measures regulations. It is the responsibility of the purchaser to ensure that all pertinent legal requirements are

met.

6.1 Settings

Before verification and sealing, perform the following steps:

1. Verify that the menu settings meet the local weights and measures regulations.

2. Perform a calibration.

3. Set Legal for Trade to ON in the Setup menu.

4. Exit the menu.

5. Disconnect power from the indicator and open the housing as explained in Section 2.3.1.

6. Set the position of the security switch to ON as shown in Section 1.2, Figure 1-2, Item 8.

7. Close the housing.

8. Reconnect power and turn the indicator on.

NOTE: For installations that employ the audit trail sealing method, steps 5 to 8 are not required. However, the security switch

may be set to ON to safeguard against unintentional changes to configuration and calibration settings.

NOTE: When Legal for Trade is set to ON and the security switch is set to ON, the following menu settings cannot be changed:

Span Calibration, Linearity Calibration, GEO, LFT, Calibration Unit, Capacity, Graduation, Power On Unit, Zero Range, Auto Zero

Tracking, Expanded Mode, Count Mode, Kilogram Unit, Pound Unit, Gram Unit, Ounce Unit, Pound Ounce Unit, Stable Only. To

enable editing of these menu settings, return the security switch to the off position and set LFT menu item to off.

6.2 Verification

The local weights and measures official or authorized service agent must perform the verification procedure. Please contact your

local weights and measures office for further details.

6.3 Sealing

6.3.1 Physical Seals

For jurisdictions that use the physical sealing method, the local weights and measures official or authorized service agent must

apply a security seal to prevent tampering with the settings. Refer to the illustrations below for sealing methods.

EN-333000 Series Indicators

SEAL

Seal

CALIBRATION

MODE

CALIBRATION

MODE

Figure 6-1. Wire Seal Figure 6-2. Paper Seal

6.3.2 Audit Trail Seal

For jurisdictions that use the audit trail sealing method, the local weights and measures official or authorized service agent must

record the current configuration and calibration event counter values at the time of sealing. These values will be compared to

values found during a future inspection.

NOTE: A change to an event counter value is equivalent to breaking a physical seal.

The audit trail uses two event counters to record changes to configuration and calibration settings.

The configuration event counter (CFG) will index by 1 when exiting the menu if one or more of the following settings

•

are changed Legal for Trade, Calibration Unit, Capacity, Graduation, Power On Unit, Zero Range, Auto Zero Tracking,

Expanded Mode, Count Mode, Kilogram Unit, Pound Unit, Gram Unit, Ounce Unit, Pound Ounce Unit, Stable Only. Note

that the counter only indexes once, even if several settings are changed. The configuration event counter values range

from CFG000 to CFG999. When the value reaches CFG999, the count starts over at CFG000.

The calibration event counter (CAL) will index by 1 when exiting the menu if a Span Calibration, Linearity Calibration

•

or GEO setting change is made. Note that the counter only indexes once, even if several settings are changed. The

calibration event counter values range from CAL000 to CAL999. When the value reaches CAL999, the count starts over

at CAL000.

The event counters can be viewed by pressing and holding the MENU button.

While the button is held, the display will show MENU followed by Audit.

Release the button when Audit is displayed to view the audit trail information.

EN-34 3000 Series Indicators

CALIBRATION

MODE

CALIBRATION

MODE

CALIBRATION

MODE

The audit trail information is displayed in the format CFGxxx and CALxxx.

Then the indicator returns to normal operation.

7 MAINTENANCE

CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE CLEANING.

7.1 Indicator Cleaning

• Use approved cleaning solutions for the stainless-steel Indicator housing and rinse with water. Dry thoroughly.

• Do not use solvents, chemicals, alcohol, ammonia or abrasives to clean the control panel.

7.2 Troubleshooting

TABLE 7-1. TROUBLESHOOTING.

SYMPTOM PROBABLE CAUSE(s) REMEDY

Unit will not turn on. Power cord not plugged in or properly

connected.

Check power cord connections. Make sure

power cord is plugged in properly into the

power outlet.

EN-353000 Series Indicators

Power outlet not supplying electricity.

Battery power used up.

Other failure.

Cannot zero the Scale, or will not zero when

turned on.

Unable to calibrate. Lock Calibration Menu set to On.

Cannot display weight in desired weighing

unit.

Cannot change menu settings. Menu has been locked.

Battery indicator is flashing. Battery discharged. Connect indicator to power and charge

Battery fails to charge fully. Battery is defective. Have the battery replaced by an authorized

Error 7.0 Unstable weight reading when defining

Load on Scale exceeds allowable limits.

Load on Scale is not stable.

Load Cell damage.

Lock switch is “on”.

LFT menu set to On.

Incorrect value for calibration mass.

Unit not set to On. Enable unit in the Units Menu.

Lock switch set on.

reference weight.

Check power source.

Reconnect AC power to charge the battery.

Service required.

Remove load on Scale.

Wait for load to become stable.

Service required.

Set Lock Calibration Menu to Off.

Refer to Section 3.9 Menu Lock.

Set the Lock switch to Off.

Set LFT menu to Off.

Use correct calibration mass.

Refer to Section 3.7 in the Unit Menu.

Set selected menu to Off in the Lock Menu.

Lock Switch on the circuit board may

need to be set to the Off position.

Set the Lock switch to off.

battery.

Ohaus service dealer.

Unstable Error, check platform location.

EN-36 3000 Series Indicators

TABLE 7-1. TROUBLESHOOTING (Cont.).

SYMPTOM PROBABLE CAUSE(s) REMEDY

Error 8.1 Weight reading exceeds Power On Zero limit. Remove load from scale. Recalibrate scale.

Error 8.2 Weight reading below Power On Zero limit. Add load to scale. Recalibrate scale.

Error 8.3 Weight reading exceeds Overload limit. Reduce load on scale.

Error 8.4 Weight reading below Underload limit. Add load to scale. Recalibrate scale.

Err 9.0 Internal fault Service required.

Err 9.5 Calibration data not present. Calibrate scale.

Err 53 EEPROM data incorrect. Service required.

CAL E Calibration Error. Calibration value outside

allowable limits.

LOW.rEF The average piece weight of the parts is small

(warning).

REF.WT Err The average piece weight of the parts is too

small.

Repeat calibration using correct calibration

weights.

Use parts with average piece weight greater

than or equal to 1 division.

Use parts with a average piece weight

greater than or equal to 0.1 division.

7.3 Service Information

If the troubleshooting section does not resolve your problem, contact an authorized Ohaus Service Agent. For Service assistance

in the United States, call toll-free 1-800-526-0659 between 8:00 AM and 5:00 PM Eastern Standard Time. An Ohaus Product

Service Specialist will be available to assist you. Outside the USA, please visit our website www.ohaus.com to locate the Ohaus

office nearest you.

8. TECHNICAL DATA

8.1 Specifications

Materials

Housing: stainless steel

Keypad: polyester

Display Window: polycarbonate

Ambient conditions

The technical data is valid under the following ambient conditions:

Ambient temperature: -10°C to 40°C / 14°F to104°F

Relative humidity: Maximum relative humidity 80% for temperatures up to 31°C decreasing linearly to 50%

relative humidity at 40°C.

Altitude: up to 2000m

Operability is assured at ambient temperatures between -10°C. and 40°C.

TABLE 8-1. SPECIFICATIONS

Capacity Range 5 to 20000 kg or lb

Maximum Displayed Resolution 1:20,000

Type Approved Resolution 1:6,000

Minimum Average Piece Weight

(APW)

Weighing Units kg, lb, g, oz, lb:oz

Functions Weighing, Parts Counting

Display 1 in./2.5 cm digit height, 6-digit, 7-segment

1.5 in./3.8 cm high x 4.9 in./12.5 cm wide backlit LCD

Backlight White LED

Keypad 4-button mechanical switches

Ingress Protection IP65 for PCBA Chamber

Load Cell Excitation Voltage 5V DC

Load Cell Drive Up to 4 x 350 ohm Load Cells

Load Cell Input Sensitivity Up to 3 mV/V

Stabilization Time Within 2 Seconds

Auto-zero Tracking Off, 0.5, 1 or 3 Divisions

Zeroing Range 0%, 2% or 100% of Capacity

Span Calibration 5 kg or 5 lb to 100% Capacity

Interface RS232

Overall Dimensions (W x D x H)

(in/mm)

Net Weight (lb/kg) 7.1 / 3.2

Shipping Weight (lb/kg) 9.7 / 4.4

Operating Temperature Range -10°C to 40°C/14°F to 104°F

Power Internal rechargeable, Sealed Lead-Acid Battery (58-hour typical life)

100-240 VAC~0.5A MAX / 50-60 Hz, Internal Power Supply

8.3 x 2.8 x 5.8 / 212 x 71 x 149

1d

EN-373000 Series Indicators

EN-38 3000 Series Indicators

8.2 Accessories

TABLE 8-2. ACCESSORIES.

DESCRIPTION PART NUMBER

Column Mount Kit, 35 cm painted steel 80251743

Column Mount Kit, 70 cm painted steel 80251744

Column Mount Kit, 35 cm stainless steel 80251745

Column Mount Kit, 70 cm stainless steel 80251746

Interface Cable/PC 9-pin 80500552

Interface Cable/PC 25-pin 80500553

8.3 Drawings and Dimensions

239 mm

212 mm

9 in

.

8.3 in

.

149mm

5.8 in

.

71 mm

2.8 in

.

201 mm

8.1 in

.

EN-393000 Series Indicators

Figure 8-1. Indicator Overall Dimensions with Mounting Bracket.

EN-40 3000 Series Indicators

8.4 Compliance

Compliance

Compliance to the following standards is indicated by the corresponding mark on the product.

Marking Standard

This product conforms to the EMC directive 2004/108/EC, the Low Voltage Directive 2006/95/EC and the

Non-automatic Weighing Instruments Directive 90/384/EEC. The complete Declaration of Conformity is

available from Ohaus Corporation.

AS/NZS4251.1 Emission, AS/NZS4252.1 Immunity

UL60950-1: 2003

EC Emissions Note

This device complies with EN55011/CISPR 11 Class B Group 1.

Important notice for verified weighing instruments

Weighing Instruments verified at the place of manufacture bear one of the preceding mark on the packing

label and the green ‘M’ (metrology) sticker on the descriptive plate. They may be put into service immediately.

Weighing Instruments to be verified in two stages have no green ‘M’ (metrology) on the descriptive plate and

bear one of the preceding identification mark on the packing label. The second stage of the initial verification

must be carried out by the approved service organization of the authorized representative within the EC or by

the national weight & measures (W+M) authorities.

The first stage of the initial verification has been carried out at the manufacturers work. It comprises all tests

according to the adopted European standard EN 45501:1992, paragraph 8.2.2.

If national regulations limit the validity period of the verification, the user of the weighing instrument must

strictly observe the re-verification period and inform the respective W+M authorities.

EN-413000 Series Indicators

Disposal

In conformance with the European Directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE) this device may not be disposed of in domestic waste. This also applies to countries outside the EU,

per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point specified for

electrical and electronic equipment.

If you have any questions, please contact the responsible authority or the distributor from which you

purchased this device.

Should this device be passed on to other parties (for private or professional use), the content of this regulation

must also be related.

Thank you for your contribution to environmental protection.

For disposal instructions in Europe, refer to www.ohaus.com/weee.

FCC Note

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Industry Canada Note

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

ISO 9001 Registration

In 1994, Ohaus Corporation, USA, was awarded a certificate of registration to ISO 9001 by Bureau Veritus Quality International

(BVQI), confirming that the Ohaus quality management system is compliant with the ISO 9001 standard’s requirements. On May

15, 2003, Ohaus Corporation, USA, was re-registered to the ISO 9001:2000 standard.

LIMITED WARRANTY

Ohaus products are warranted against defects in materials and workmanship from the date of delivery through the duration of

the warranty period. During the warranty period Ohaus will repair, or, at its option, replace any component(s) that proves to be

defective at no charge, provided that the product is returned, freight prepaid, to Ohaus.

This warranty does not apply if the product has been damaged by accident or misuse, exposed to radioactive or corrosive

materials, has foreign material penetrating to the inside of the product, or as a result of service or modification by other than

Ohaus. In lieu of a properly returned warranty registration card, the warranty period shall begin on the date of shipment to the

authorized dealer. No other express or implied warranty is given by Ohaus Corporation. Ohaus Corporation shall not be liable

for any consequential damages.

As warranty legislation differs from state to state and country to country, please contact Ohaus or your local Ohaus dealer for

further details.

Ohaus Corporation

19A Chapin Road

P.O. Box 2033

Pine Brook, NJ 07058, USA

Tel: (973) 377-9000

Fax: (973) 593-0359

www.ohaus.com

*80252869*

P/N 80252869 © 2009 Ohaus Corporation, all rights reserved.

Printed in China

Loading...

Loading...