Ohaus VN User Manual [en, es, fr]

VN Series Floor Scale

Instruction Manual

Báscula para piso serie VN

Manual de instrucciones

Balance au sol Série VN

Manuel d’instructions

VN Series Floor Scale EN-1

INTRODUCTION

This manual contains installation, operation and maintenance instructions for the VN Series Floor Scale.

SAFETY PRECAUTIONS

Please follow these safety precautions:

• Never operate in hazardous areas.

• The VN Series may be used in dry environments only.

• The foundation at the installation site must be capable of safely supporting the weight of the floor scale

plus the weight of the maximum load.

• Ensure that vibrations due to machines near the installation site are kept to a minimum. This applies also

when the floor scale is integrated into conveying systems.

INSTALLATION

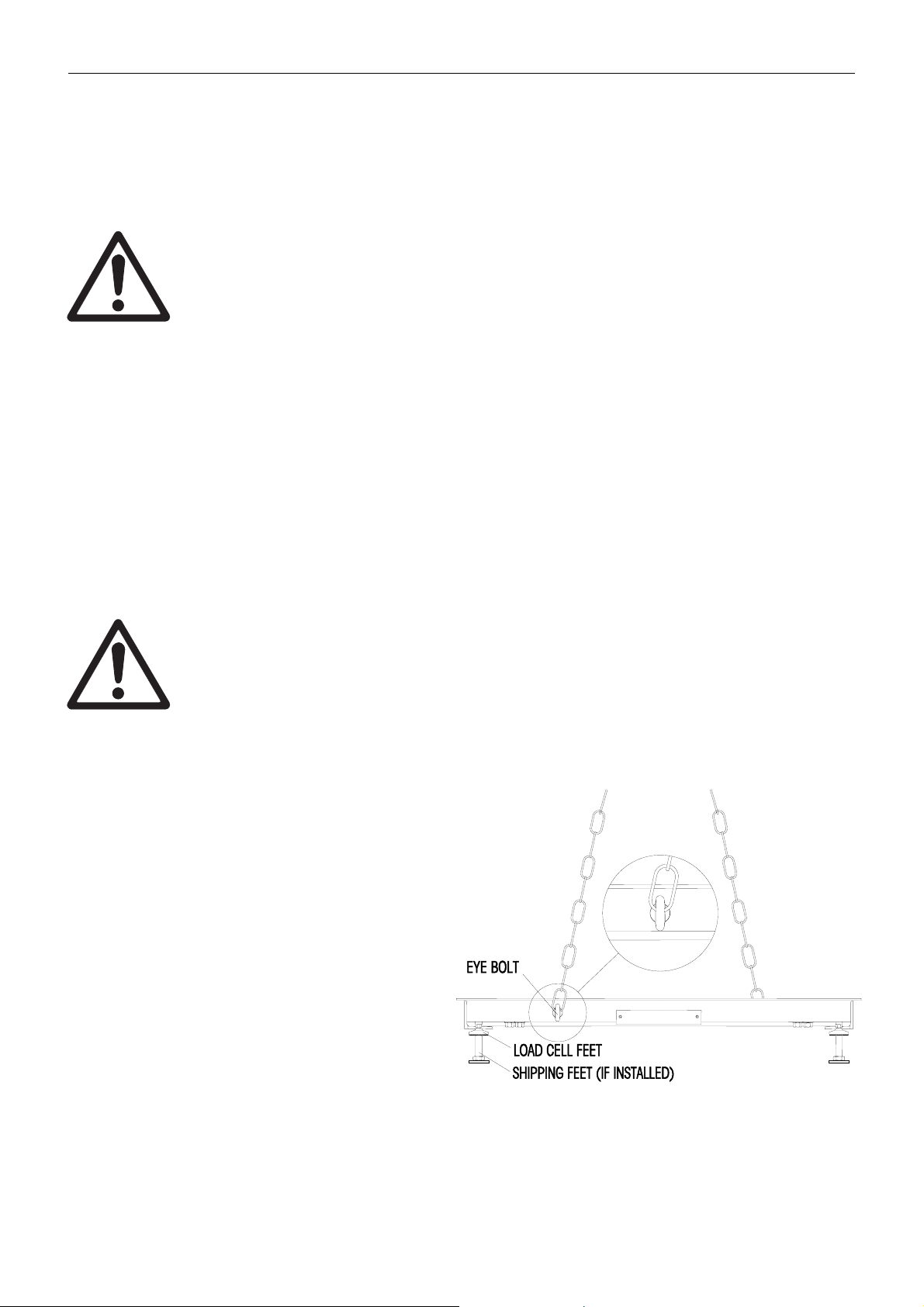

CAUTION: THE FLOOR SCALE IS VERY HEAVY. ALWAYS USE AN APPROPRIATE HOIST TO LIFT IT

FROM THE PACKAGING OR TO MOVE IT INTO THE REQUIRED POSITION.

Unpacking

1. Remove the outer packaging materials from the

top and sides of the floor scale.

2. Install the two included eye bolts into opposing

sides of the floor scale, see Figure 1.

3. Lift the floor scale from the packaging material,

see caution notice.

Figure 1. Hoisting Method.

EN-2 VN Series Floor Scale

Positioning

Ensure the surface is flat in the area where the scale will be positioned, especially in the region of the load cell feet. Small

differences in height can be compensated by adjusting the load cell feet.

1. If an Indicator is included with the floor scale ensure that it is kept with the floor scale during positioning as there may

be an attached connecting cable.

2. With the floor scale positioned over the final work area, remove the 4 shipping feet (if installed).

3. Install the 4 load cell feet (if not already installed).

4. Lower the scale on to the final work area.

5. Check that the floor scale is level; check that the 4 feet are in contact with the floor; make adjustments by rotating the

nuts on the load cell feet. Use an external level.

6. Ensure that the floor scale’s output cable does not become trapped or crushed during lifting or positioning.

Foot Plates

Foot Plates (available separately) mount around the feet of the Floor Scale and prevent movement of the scale. Installation of

Floor Plates must be done before final placement of the Floor Scale. Refer to the section on Accessories for Foot Plate

installation.

Connecting an Indicator

Certain Floor Scale systems will have an Indicator already attached to the cable end. If the Indicator is not attached or if the

Indicator is purchased separately follow the steps listed below to make the proper connections.

1. Route the Floor Scale cable to the position where the

Indicator will be mounted.

2. Consult the installation instructions of the Indicator to

properly attach the cable connections inside the Indicator,

3. The Signal names of the Floor Scale wires are shown in

Table 1, Floor Scale Wiring Color Code.

CAUTION: Ensure that the cable is protected against possible

damage when routed to the Indicator.

TABLE 1. FLOOR SCALE WIRING COLOR CODE

Indicator Signal Name Floor Scale Wire Color

EXC+ (IN+) Green

SEN+ Yellow

SIG+ (OUT+) White

SIG- (OUT-) Red

SEN- Blue

EXC- (IN-) Black

Shield (GND) Yellow/Green

VN Series Floor Scale EN-3

OPERATION

For setup, calibration and proper operation, refer to the instruction manual supplied with the indicator. Refer to the specifications

section of the floor scale for capacity, and readability information.

For continued best operating performance:

• Avoid falling loads, shocks and hard lateral impacts

• When weighing, all items should be centrally located on the floor scale and not over

hanging the sides or the ramps.

• Verify the calibration of the floor scale system at regular intervals.

Operating Limits

Although the floor scales have extremely rugged construction, certain load limits must not be exceeded. Depending on the type of

loading, the maximum safe static load, i.e. the maximum admissible loading, is shown in Table 2.

TABLE 2. MAXIMUM ADMISSIBLE LOADING.

Model

1

Maximum Central load

(80% Surface Area)

Maximum Side load

(30% Surface Area)

2

One Side Corner Load

3

(10% Surface Area)

VN5000L 8000 lb 5000 lb 2600 lb

VN5000X 8000 lb 5000 lb 2600 lb

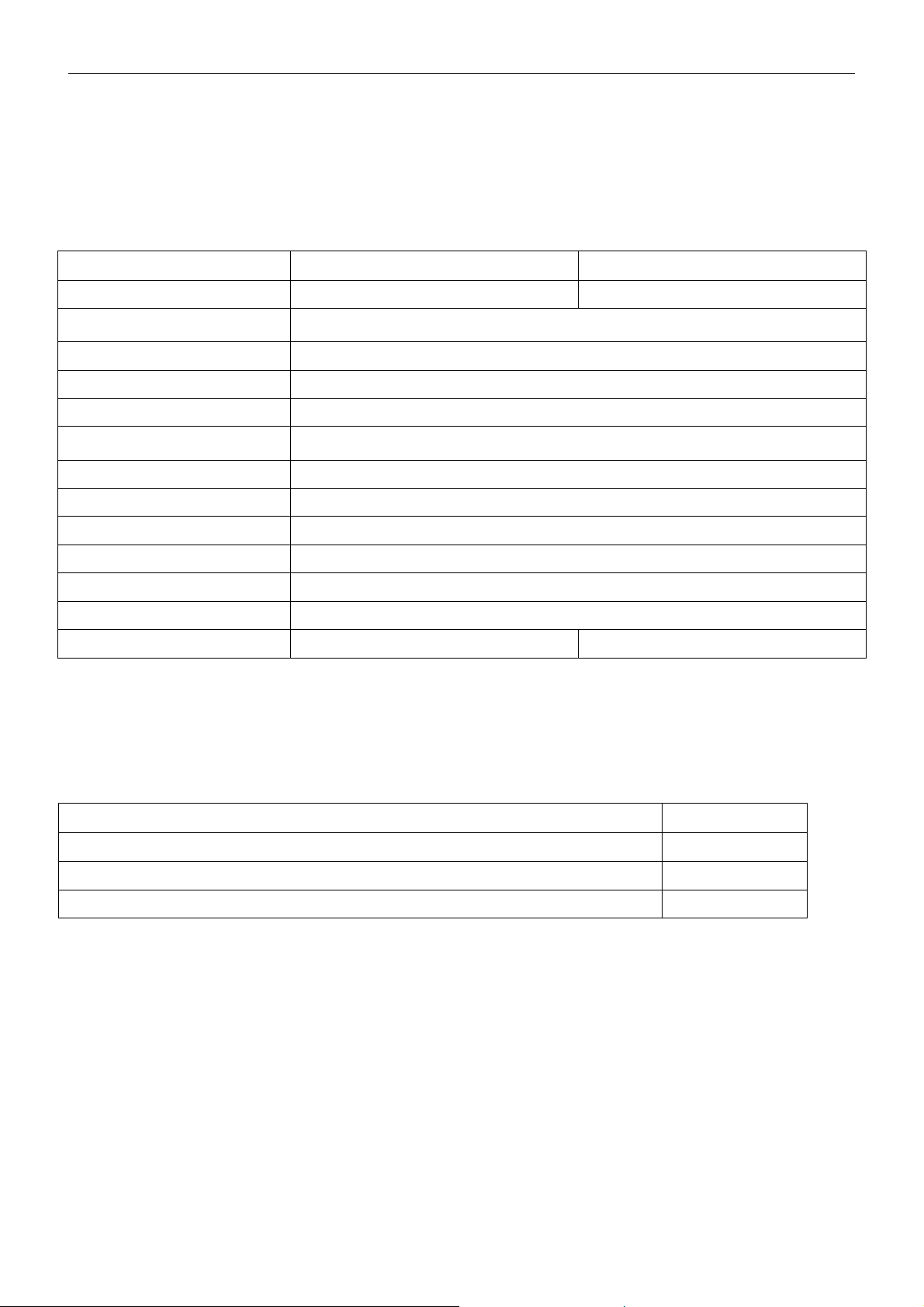

SEALING METHODS

Figure 2. Sealing Method 1 Figure 3. Sealing Method 2

EN-4 VN Series Floor Scale

MAINTENANCE

Daily Checks

• Check that the feet are properly seated in the holes of each load cell.

• Check that the 4 feet are in contact with the floor.

• Check that the scale is free from debris, especially under the edges of the scale.

• Check that there is no damage to the connecting cable.

Cleaning

Risk of Electrical Shock

Disconnect the power source before cleaning the scale with any liquids.

Maintenance of the floor scale is limited to regular cleaning.

- Wipe surfaces with a damp cloth.

- Use only common household cleaning agents.

- Never use water spray or high pressure cleaners.

- Keep the air gap at the edge of the Floor Scale free of debris.

VN Series Floor Scale EN-5

TECHNICAL DATA

Specifications

TABLE 3. FLOOR SCALE SPECIFICATIONS

Floor Scale Models VN5000L VN5000X

Dimensions 4’ x 4’ x 3.5” / 1220 x 1220 x 90mm 5’ x 5’ x 3.5” / 1524 x 1524 x 90 mm

Capacity x emin

Material Painted Carbon Steel, treaded surface, fixed top plate

Feet 4 x swivel design, rubber bottom, adjustable height

Load Cell 4 x Shear Beam, Alloy Steel, NTEP

Load Cell Capacity Emax 2500 lb

Load Cell Safe Overload Limit 120% of Emax

Load Cell Output Impedance 350 Ω

Load Cell Excitation Voltage 5V ~15V, DC/AC

Junction Box Side panel access, IP65, Stainless Steel, with 16’ / 5m Cable

Operating Temperature 14°F to 104°F / -10 °C to 40 °C

Humidity 0% to 95% Relative Humidity, Non-Condensing

Net Weight 271 lb / 123 kg 408 lb / 185 kg

5000 lb x 1 lb / 2200 kg x 0.5 kg

Accessories TABLE 4. LIST OF ACCESSORIES

Item Part Number

Foot Plate Kit, Painted Steel 72198344

Ramp Kit, 48”, Painted Steel, for VN5000L 80252565

Ramp Kit 60”, Painted Steel, for VN5000X 80252566

Notes: 1. Foot Plate Kits include 2 Foot Plates, Mounting Hardware

2. Ramp Kits include 1 Ramp, 2 Foot Plates, Mounting Hardware

EN-6 VN Series Floor Scale

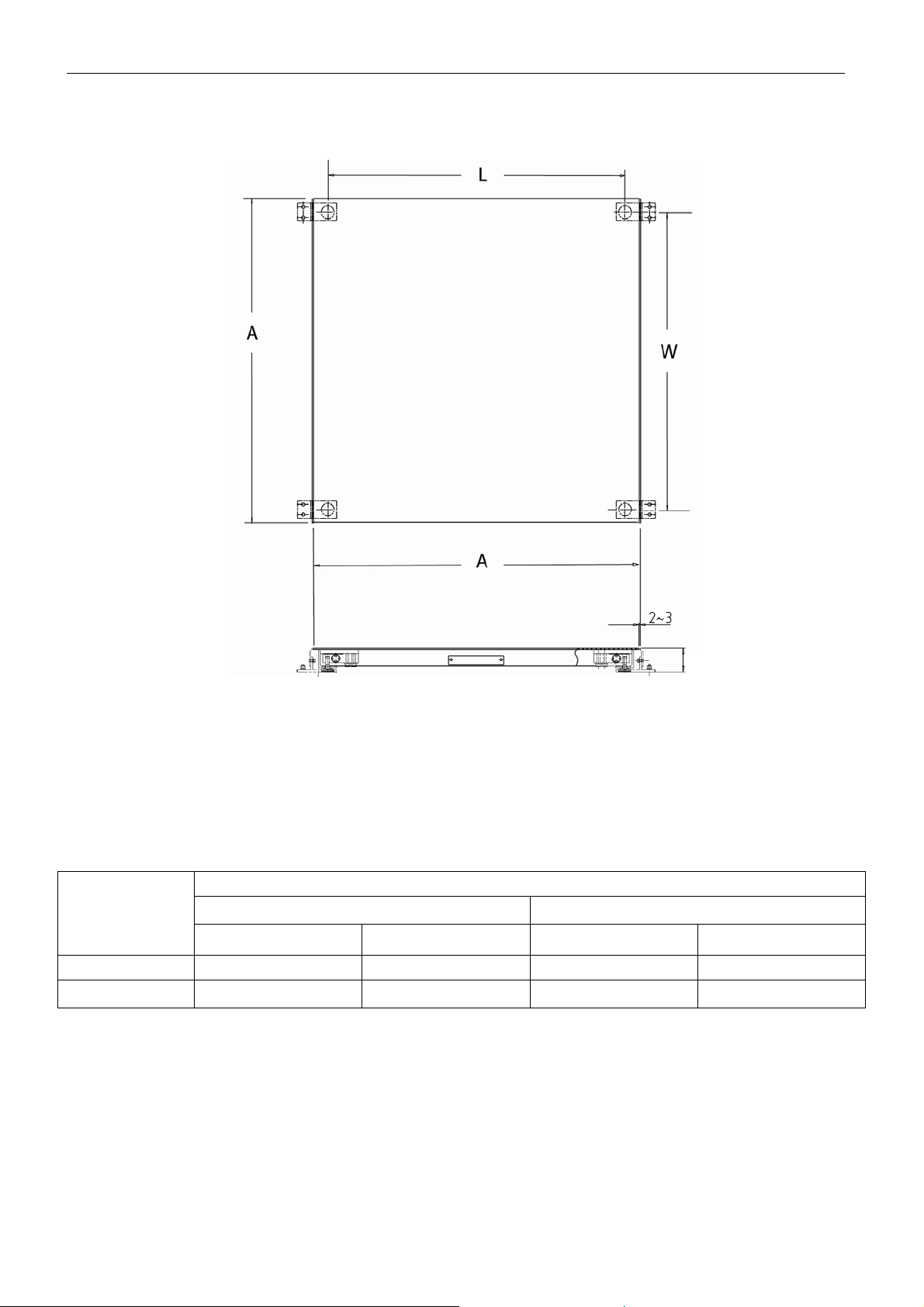

Dimensions

H

Figure 4. Floor Scale Dimensions, (Shown with optional Foot Plates)

TABLE 5. FLOOR SCALE DIMENSIONS

DIMENSIONS

MODELS

FLOOR SCALE PLATFORM FOOT CENTERS

A H (min) W L

VN5000L 4’ / 1220 mm 3.5” / 90 mm 43.7” / 1110 mm 43.7” / 1110 mm

VN5000X 5’ / 1524 mm 3.5” / 90 mm 55.7” / 1414 mm 55.7” / 1414 mm

VN Series Floor Scale EN-7

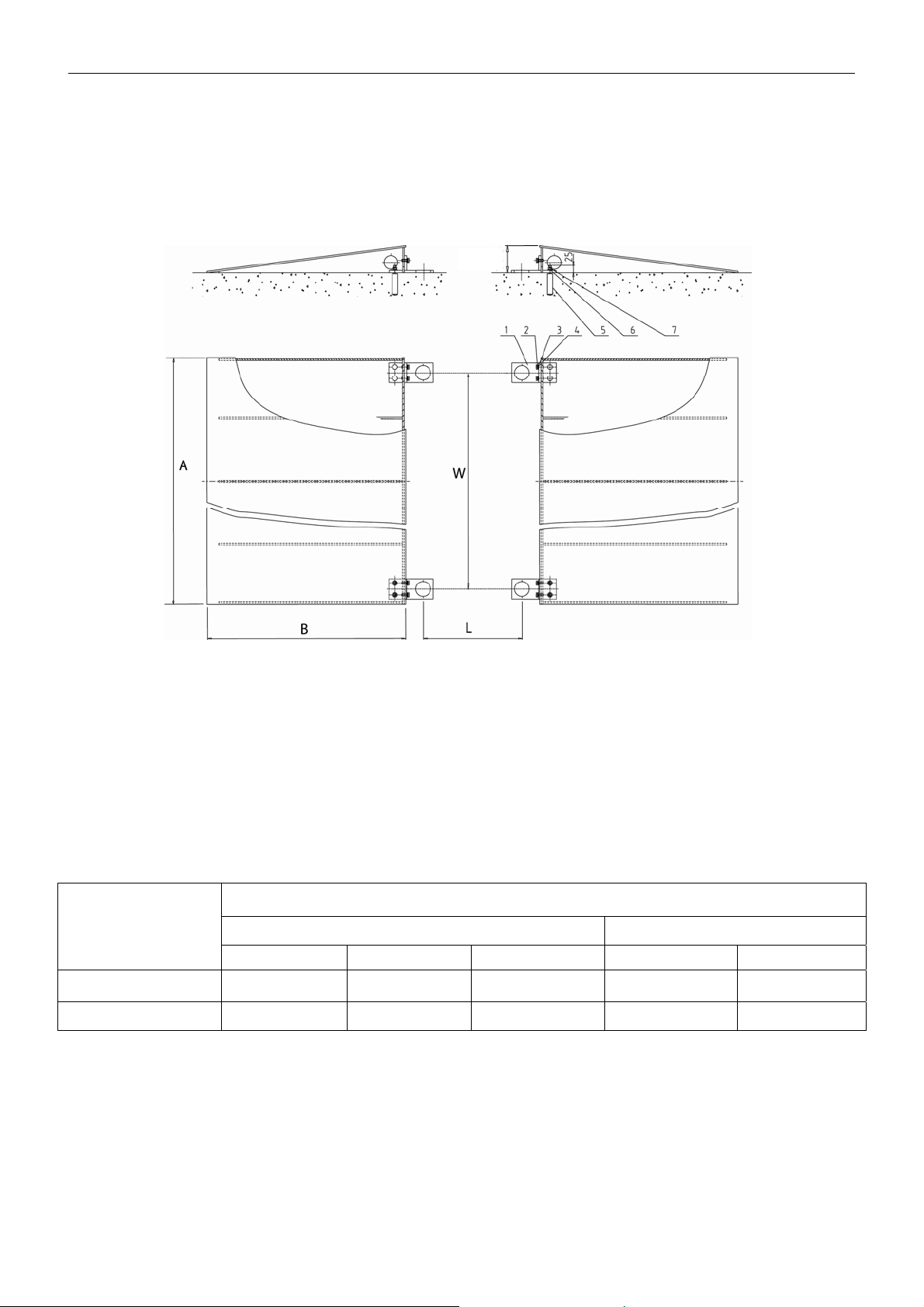

INSTALLATION OF OPTIONAL FOOT PLATES AND RAMPS

Installation of each Ramp also requires the installation of one set of Foot Plates. Foot Plates are available separately and are

included with the Ramp accessory kit. Refer to Figure 5 for mounting of the Foot Plates and Ramps. Installation of Floor Plates

and Ramps must be done before final placement of the Floor Scale.

H

Figure 5. Optional Foot Plate and Ramp Installation

LEGEND: 1.Foot Plate, 2. Bolt, 3. Spring Washer, 4. Washer, 5. Expanding Bolt, 6. washer, 7. Nut

Notes: 1. Expanding bolts require 12.5mm (0.5”) diameter holes drilled 60mm (2.4”) deep into the floor surface.

2. Foot Plate center to center dimensions W and L are shown in Table 6.

3. The Floor Scale must be positioned so that the load cell feet rest within the large holes of the Foot Plates.

4. Ensure that a free air gap exists between the sides of the Floor Scale and the edges of the Ramps.

TABLE 6. DIMENSIONS FOR FLOOR PLATE AND RAMP INSTALLATION

DIMENSIONS

MODELS

A B H W L

Ramp for VN5000L 4’ / 1220 mm 26.4” / 670 mm 3.56” / 90.5mm

Ramp for VN5000X 5’ / 1524 mm 26.4” / 670 mm 3.56” / 90.5mm

RAMP FOOT PLATE CENTERS

43.7” / 1110 mm 43.7” / 1110 mm

55.7” / 1414 mm 55.7” / 1414 mm

EN-8 VN Series Floor Scale

Conformance

This product conforms to the EMC directive 89/336/EEC and the Low Voltage Directive 73/23/EEC. The complete

declaration of Conformity is available from Ohaus Corporation.

Disposal

I

n conformance with the European Directive 2002/96 EC on Waste Electrical and Electronic Equipment

(WEEE) this device may not be disposed of in domestic waste. This also applies to countries outside the

EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point specified for

electrical and electronic equipment.

ISO 9001 Registration

In 1994, Ohaus Corporation, USA, was awarded a certificate of registration to ISO 9001 by Bureau Veritus Quality International

(BVQI), confirming that the Ohaus quality management system is compliant with the ISO 9001 standard’s requirements. On

May 15, 2003, Ohaus Corporation, USA, was re-registered to the ISO 9001:2000 standard.

If you have any questions, please contact the responsible authority or the distributor from which you

purchased this device.

Should this device be passed on to other parties (for private or professional use), the content of this

regulation must also be related.

Thank you for your contribution to environmental protection.

For disposal instructions in Europe, refer to www.ohaus.com/weee.

Loading...

Loading...