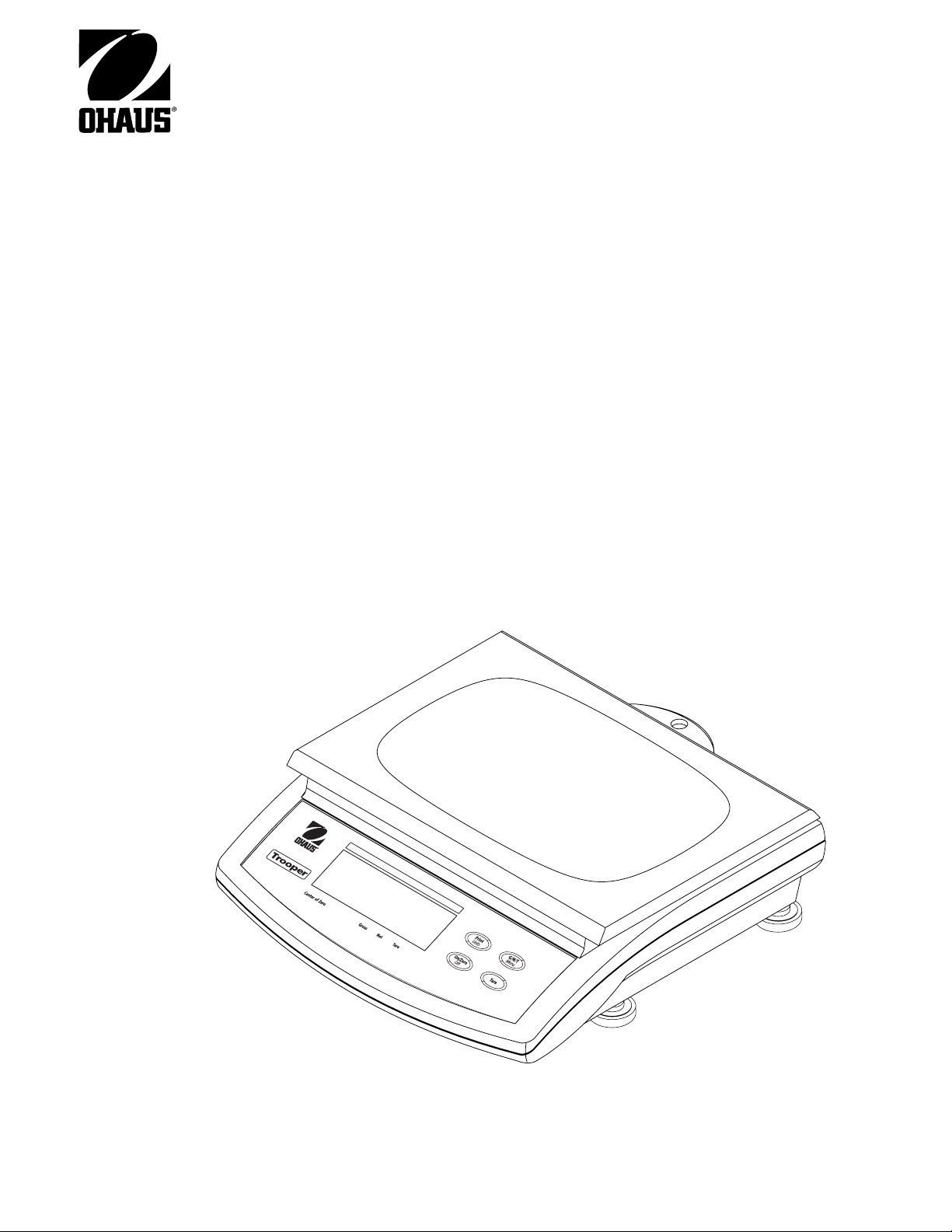

Ohaus TROOPER COMPACT SCALES User Manual [en, es, fr]

Trooper Scale

Instruction Manual

Báscula Trooper

Manual de Instrucciones

Balance Trooper

Manuel D'instructions

3

Ohaus Corporation, 19A Chapin Road, P.O. Box 2033 Pine Brook, New Jersey, 07058, USA

Declaration of Conformity We, Ohaus Corporation, declare under our sole responsibility that the balance models listed below marked with

“CE” - are in conformity with the directives and standards mentioned.

Declaración de Conformidad

indicados a continuación - con el distintivo ,CE’ - están conformes con las directivas y normas citadas.

Déclaration de conformité Nous, Ohaus Corporation, déclarons sous notre seule responsabilité, que les types de balance ci-dessous cité

- munis de la mention «CE» - sont conformes aux directives et aux normes mentionnées ci-après.

Models/Type Trooper Series

Modelo/Tipo Trooper Series

Modèle/Type Trooper Series

EC Marking: EC Directive Applicable Standards

Marcado EC Directive EC Normas aplicables

Marquage CE Directive CE Normes applicable

Nosotros, Ohaus Corporation, declaramos bajo responsabilidad exclusiva que los modelos de balanzas

73/23/EEC EN60950-1:2001

Low Voltage

Baja tensión

Basse tension

89/336/EEC EN61326:1997+A1:1998+A2:2001+A3:2003

Electromagnetic compatibility

Compatibilidad electromagnética

Compatibilité électromagnétique

For non-automatic weighing instruments used in an Article 1, 2.(a) application, additional metrological marking according to Annex

IV of Council directive 90/384/EEC must be attached to the instrument

Para instrumentos de pesaje no automático usados en una aplicación descrita en el Artículo 1, 2.(a), se debe colocar sobre el

instrumento una marcación metrológica adicional de acuerdo con el Anexo IV de la Directriz del Consejo 90/384/EEC.

Pour les instruments de pesage non-automatiques utilisés dans une application Article 1, 2.(a), un repérage métrologique

additionnel conforme à l’Annexe IV de la Directive 90/384/EEC du Conseil doit être présent sur l’instrument.

90/384/EEC EN45501:1992

year

Non Automatic Weighing Instruments

Para balanzas no automátäcas

Balances à fonctionnement non automatique

010

1)

M

1) Applies only to certified non-automatic weighing instruments

Aplicable solamente a instrumentos de pesaje aprobados de funcionamiento no automático

S’applique uniquement aux instruments de pesage à fonctionnement non automatique approuvés

Date CE mark first applied: March 2002

Ted Xia

President

Ohaus Corporation

Pine Brook, NJ USA

Jean-Yves Chever

General Manager

Ohaus Europe

Greifensee, Switzerland

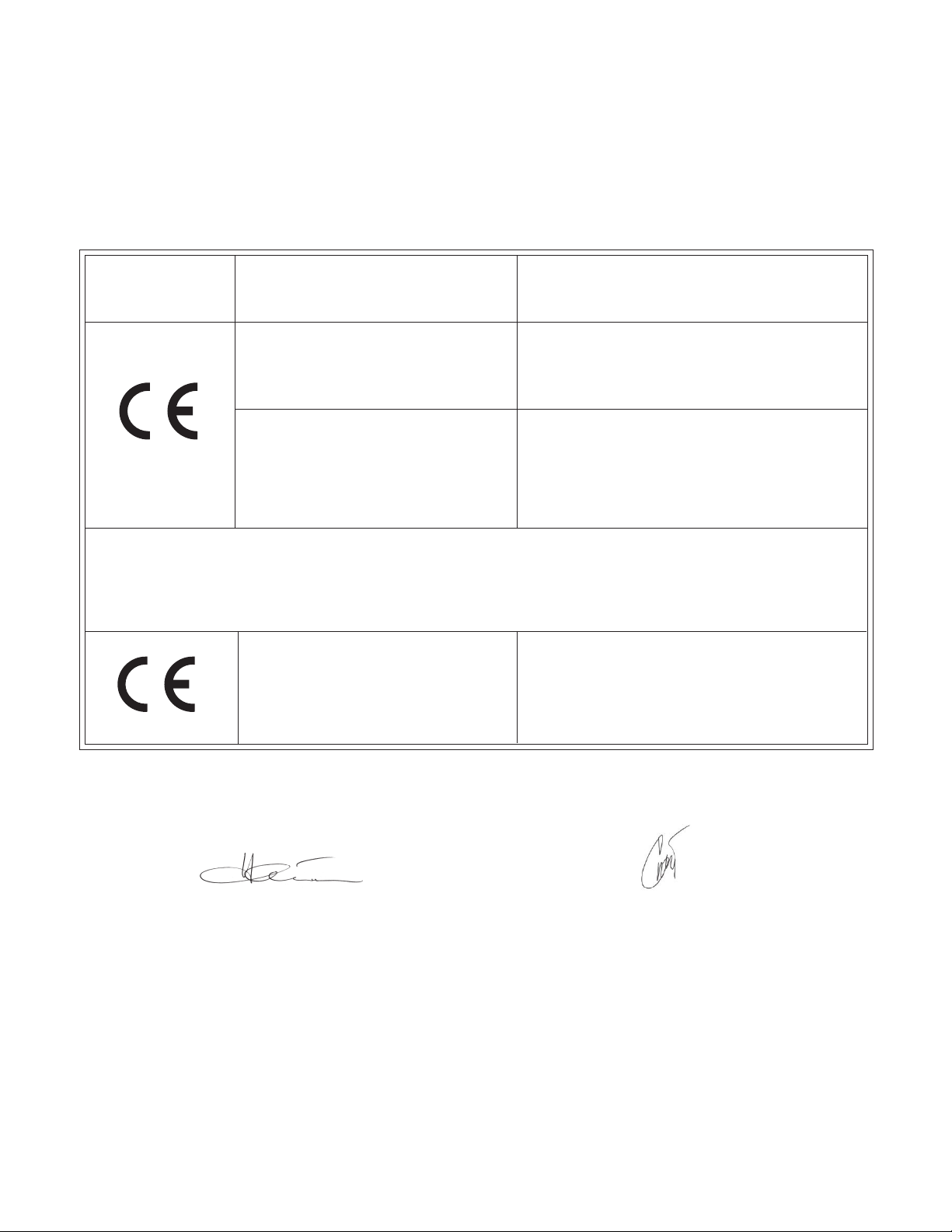

Important notice for verified weighing instruments

Weighing Instruments verified at the place of manufacture bear one of the preceding mark on the packing label and

the green ‘M’ (metrology) sticker on the descriptive plate. They may be put into service immediately.

Weighing Instruments to be verified in two stages have no green ‘M’ (metrology) on the descriptive plate and bear one

of the preceding identification mark on the packing label. The second stage of the initial verification must be carried

out by the approved service organization of the authorized representative within the EC or by the national weight &

measures (W+M) authorities.

The first stage of the initial verification has been carried out at the manufacturers work. It comprises all tests according to the adopted

European standard EN 45501:1992, paragraph 8.2.2.

If national regulations limit the validity period of the verification, the user of the weighing instrument must strictly observe the re-verification

period and inform

the respective W+M authorities.

Notificación importante para instrumentos de pesaje verificados

Los instrumentos de pesaje verificados en el sitio de fabricación llevan una de las marcas precedentes en el rótulo del

empaque y la etiqueta de la ‘M’ verde (metrología) en la placa descriptiva. Estos instrumentos se pueden poner en

funcionamiento inmediatamente.

Los instrumentos de pesaje a ser verificados en dos etapas no tienen ninguna ‘M’ verde (metrología) en la placa

descriptiva, y presentan una de las marcas de identificación precedentes sobre el rótulo del empaque. La segunda

etapa de la verificación inicial debe ser llevada a cabo por la organización de servicio aprobada del representante

autorizado dentro de la CE o por las autoridades nacionales de pesos y medidas.

La primera etapa de la verificación inicial ha sido llevada a cabo en el sitio de fabricación. Ésta comprende todas las pruebas

estipuladas por el estándar europeo adoptado: EN 45501:1992, párrafo 8.2.2.

Si las normas nacionales limitan el periodo de validez de la verificación, el usuario del instrumento de pesaje debe seguir estrictamente

el periodo de re-verificación e informar a las correspondientes autoridades de pesos y medidas.

Avis important pour les instruments de pesage vérifiés

Les instruments de pesage vérifiés sur le site de fabrication portent l’une des marques précédentes sur l’étiquette de

l’emballage avec un autocollant M (pour Métrologie) en vert sur la plaque descriptive. Ces instruments peuvent être

immédiatement mis en service.

Les instruments de pesage à vérifier en deux étapes ne portent pas d’autocollant M (pour Métrologie) en vert sur la

plaque descriptive et portent l’une des marques d’identification précédentes sur l’étiquette de l’emballage. La deuxième

étape de la vérification initiale doit être exécutée par l’organisation de service homologuée du représentant agréé au

sein de la CE ou par les autorités nationales de poids et mesures.

La première étape de la vérification initiale a été exécutée sur le site du fabricant. Elle se compose des tests requis par la norme

européenne EN45501:1992, paragraphe 8.2.2.

Si des règlements nationaux limitent la durée de validité de la vérification, il incombe à l’utilisateur dudit instrument de pesage de

respecter strictement la période de re-vérification et d’informer les autorités de poids et mesures respectives.

Disposal

In conformance with the European Directive 2002/96 EC on Waste Electrical and Electronic Equipment (WEEE) this

device may not be disposed of in domestic waste. This also applies to countries outside the EU, per their specific

requirements.

Please dispose of this product in accordance with local regulations at the collecting point specified for electrical and

electronic equipment.

If you have any questions, please contact the responsible authority or the distributor from which you purchased this

device.

Should this device be passed on to other parties (for private or professional use), the content of this regulation

must also be related.

Thank you for your contribution to environmental protection.

Eliminación de residuos

De conformidad con las exigencias de la directiva europea 2002/96 CE sobre residuos de aparatos eléctricos y

electrónicos (RAEE), este equipo no puede eliminarse como basura doméstica. Esta prohibición es asimismo

válida para los países que no pertenecen a la UE cuyas normativas nacionales en vigor así lo reflejan.

Elimine este producto, según las disposiciones locales, mediante el sistema de recogida selectiva de aparatos

eléctricos y electrónicos.

Si tiene alguna pregunta al respecto, diríjase a las autoridades responsables o al distribuidor que le proporcionó el

equipo.

Si transfiere este equipo (por ejemplo, para la continuación de su uso con fines privados, comerciales o

industriales), deberá transferir con él esta disposición.

Muchas gracias por su contribución a la conservación medioambiental.

Elimination

En conformité avec les exigences de la directive européenne 2002/96 CE relative aux déchets d'équipements

électriques et électroniques (DEEE), cet appareil ne doit pas être éliminé avec les déchets ménagers. Logiquement,

ceci est aussi valable pour les pays en dehors de l'UE conformément aux règlementations nationales en vigueur.

Veuillez éliminer cet appareil conformément aux prescriptions locales dans un conteneur séparé pour appareils

électriques et électroniques.

Pour toute question, adressez-vous aux autorités compétentes ou au revendeur chez qui vous avez acheté cet

appareil.

En cas de remise de cet appareil (p. ex. pour une utilisation privée ou artisanale/industrielle), cette prescription doit

être transmise en substance.

Merci pour votre contribution à la protection de l'environnement.

FCC Note

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Industry Canada Note

This Class B digital apparatus complies with the Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

ISO 9001 Registration

In 1994, Ohaus Corporation, USA, was awarded a certificate of registration to ISO 9001 by Bureau Veritus Quality International (BVQI),

confirming that the Ohaus quality management system is compliant with the ISO 9001 standard’s requirements. On May 15, 2003, Ohaus

Corporation, USA, was re-registered to the ISO 9001:2000 standard.

Registro ISO 9001

En 1994, Bureau Veritus Quality International (BVQI) le otorgó a Ohaus Corporation, EE.UU., un certificado de registro ISO 9001 el cual

confirma que el sistema administrativo de calidad de Ohaus cumple con los requerimientos del estándar ISO 9001. En mayo 15 del 2003,

Ohaus Corporation, EE.UU., fue registrada nuevamente al estándar ISO 9001:2000.

Enregistrement ISO 9001

En 1994, le Bureau Veritus Quality International (BVQI) a octroyé la certification d’enregistrement ISO 9001 à Ohaus Corporation, États-Unis

d’Amérique, confirmant que le système de gestion de la qualité Ohaus était conforme aux conditions normalisées de l’ISO 9001. Le 15 mai

2003, Ohaus Corporation, États-Unis d’Amérique, a été ré-enregistrée à la norme ISO 9001:2000.

Trooper ScaleTrooper Scale

Trooper Scale

Trooper ScaleTrooper Scale

EN-1

TABLE OF CONTENTS

OVERVIEW OF CONTROLS AND DISPLAY FUNCTIONS ............................................................................ EN-3

1. GETTING TO KNOW YOUR TROOPER SCALE .......................................................................................... EN-4

1.1 Introduction ....................................................................................................................................... EN-4

1.1.1 Features .................................................................................................................................. EN-4

2. INSTALLATION ................................................................................................................................... EN-5

2.1 Unpacking and Checking ..................................................................................................................... EN-5

2.2 Selecting the Location ......................................................................................................................... EN-5

2.3 Connecting Power .............................................................................................................................. EN-5

2.3.1 Battery Installation ..................................................................................................................... EN-5

2.3.2 AC Power ................................................................................................................................. EN-5

2.3.3 Leveling the Scale...................................................................................................................... EN-6

2.3.4 Stabilization.............................................................................................................................. EN-6

3. OPERATION ....................................................................................................................................... EN-6

3.1Turning On Scale ................................................................................................................................ EN-7

3.2Turning Off Scale ................................................................................................................................ EN-7

3.3 Zero Operation ................................................................................................................................... EN-7

3.4 Tare Operation ................................................................................................................................... EN-7

3.5 Gross/Net/Tare Recall Operation ........................................................................................................... EN-8

3.6 Unit Switch Operation .......................................................................................................................... EN-8

3.7 RS232 Commands ............................................................................................................................ EN-9

3.7.1 Output Formats ........................................................................................................................ EN-9

3.8 Printing Data ..................................................................................................................................... EN-9

3.8.1 RS-232 Pin Out........................................................................................................................ EN-9

4. SETUP ............................................................................................................................................. EN-10

4.1 Setup Protection ............................................................................................................

4.4.1 Control Functions ................................................................................................................... EN-10

4.4.2 Menu Structure ....................................................................................................................... EN-11

................... EN-10

4.4.3 Setup Menu ........................................................................................................................... EN-12

4.4.4 Readout Menu........................................................................................................................ EN-14

4.4.5 Print Menu............................................................................................................................. EN-18

4.4.6 Lockout Switch Menu .............................................................................................................. EN-20

EN-2

Trooper ScaleTrooper Scale

Trooper Scale

Trooper ScaleTrooper Scale

TABLE OF CONTENTS (Cont.)

5. CALIBRATION AND SEALING ............................................................................................................. EN-22

5.1Legal for Trade (LFT) Operation and LFT Sealing................................................................................... EN-29

6. CARE AND MAINTENANCE ................................................................................................................ EN-30

6.1 Troubleshooting ............................................................................................................................... EN-30

6.2Error Codes List................................................................................................................................ EN-32

6.3 Service Information ........................................................................................................................... EN-32

6.4 Accessories ..................................................................................................................................... EN-32

6.5Technical Data ................................................................................................................................. EN-32

Trooper Scale

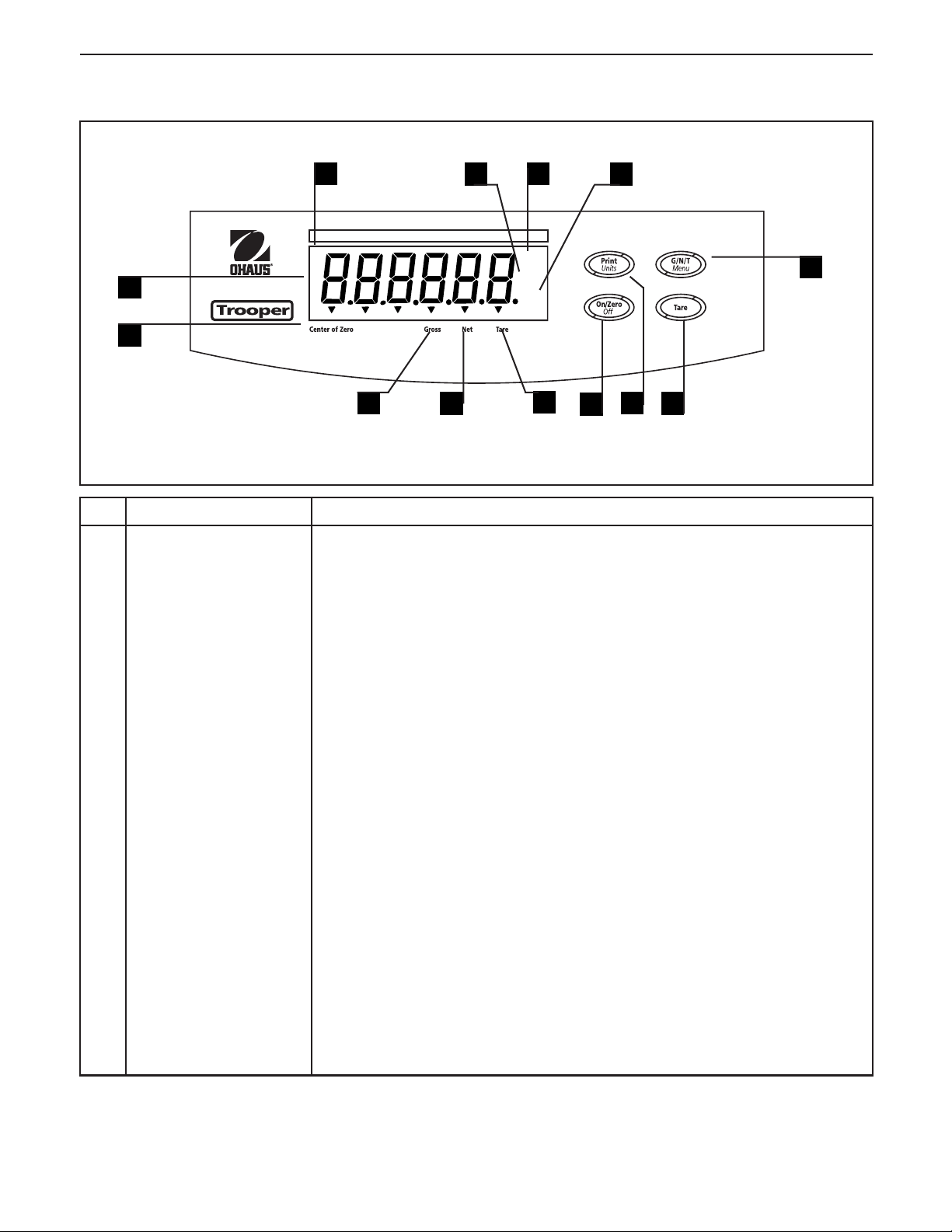

OVERVIEW OF CONTROLS AND DISPLAY FUNCTIONS

EN-3

13

12

11

10

*

1

2

3

No. Designation No. Designation

No. Designation

No. Designation No. Designation

1 Display LCD display, indicates weight, modes and setup information.

2 Center of Zero LCD indicator prompt, indicates center of zero when within +/- 0.25d.

3 Gross LCD indicator prompt, indicates gross weight.

FunctionFunction

Function

FunctionFunction

4

OE

R]

NJ

BAT

5

6

7

8

9

4 Net LCD indicator prompt indicates net weight.

5 Tare LCD indicator prompt indicates tare weight.

6 ON/ZERO/OFF button Turns Scale on or off. Secondary use, provides zero function.

7 Print/Units button Short press, prints data which is displayed on the Scale.

Long press, changes unit of measure.

When in menus, each press advances horizontally through the menus.

Finalizes a menu selection.

8 Tare button When pressed, enters tare value into memory.

9 G/N/T/Menu button Recalls Gross/Net/Tare. Long press allows entry into menus. When in

menus, advances through individual menu items.

10 kg LCD indicator, when lit, indicates weight in kilograms.

g LCD indicator, when lit, indicates weight in grams.

11 lb LCD indicator, when lit, indicates weight in pounds.

12 oz LCD indicator, when lit, indicates weight in ounces.

13 * Stability indicator, when lit, indicates stable weight.

EN-4

Trooper Scale

1. GETTING TO KNOW YOUR TROOPER SCALE

1.1 Introduction

Thank you for deciding to purchase a Trooper Scale from Ohaus. The Ohaus Trooper Scale is a rugged, reliable,

electronic scale designed for easy operation.

The Trooper Scale operates from AC power and can also be powered by six Alkaline “C” batteries internally. A six digit

LCD display is 1.0 inches/2.5 centimeters in height provides easy visibility when working at distances from the Scale.

Four buttons mounted on the front panel enable simple set up procedures. A menu lockout switch can be set to lock out

various functions of the Scale to prevent settings from being changed. An RS232 Interface is built in.

Behind your instrument stands OHAUS, a leading manufacturer of precision Indicators, Scales and Balances. An Aftermarket Department with trained instrument technicians is dedicated to providing you with the fastest service possible in

the event your instrument requires servicing. OHAUS also has a Customer Service Department to answer any inquiries

regarding applications and accessories.

To ensure you make full use of the possibilities offered by your Trooper Scale, please read the manual completely before

installation and operation.

1.1.1 Features

Major features include:

• 6 digits, 7-segments, 25 mm Numeric LCD display

• Durable ABS housing

• 4 membrane switches

• Push-button Tare/Clear

• Flexible unit switching-lb/kg/oz/g

• Enhanced digital filtering

• Overload/Underzero display indication

• RS232 Serial Communication in Ohaus RS-Interface

• Up to 100 hours continuous battery operation

• AC & DC power supply

• Low - BAT warning comes on 20 minutes prior to low power point

• Auto shut off for power saving

Trooper Scale

EN-5

2. INSTALLATION

2.1 Unpacking and Checking

Open the package and remove the instrument and the accessories. Check the completeness of the delivery. The following accessories are part of the standard equipment of your new Scale.

Remove packing material from the instrument.

Check the instrument for transport damage. Immediately inform your Ohaus dealer if you have complaints or parts are

missing. Your Trooper Scale package should contain:

• Trooper Scale

• Warranty card

• AC power adapter

• Instruction Manual

• Lead seal for weights and measures sealing

Store all parts of the packaging. This packaging guarantees the best possible protection for the transport of your

instrument.

NOTE: Remove the two shipping screws if present on top of the unit.

2.2 Selecting the Location

The Scale should be used in an environment which is free from corrosives, vibration or temperature extremes. These

factors will affect displayed weight readings. The Scale should be located on a stable level surface and kept away from

vibrating sources such as large machinery. Maximum accuracy will be achieved when the area is clean and vibration

free.

2.3 Connecting Power

2.3.1 Battery Installation

Remove battery cover and insert 6 Alkaline C-type batteries into the battery holder making sure that the batteries are

properly orientated (correct polarity).

NOTE: It is recommended that when the Trooper Scale is operated from batteries, the Auto-Off Timer feature be turned

on to extend battery life. When setting up the Scale, refer to Intial Setup, Readout menu, paragraph 4.4.4.

2.3.2 AC Power

Connect the AC power cord from the Scale and plug into a convenient power outlet.

NOTICE:

The socket/outlet must be installed near

the equipment and shall be easily accessible.

EN-6

Trooper Scale

2. INSTALLATION (Cont.)

2.3.3 Leveling the Scale

Exact horizontal positioning and stable installation are prerequisites for repeatable results. To compensate small

irregularities or inclinations at the location, the instrument can be leveled.

For exact horizontal positioning, the Scale is equipped with a level indicator located at the rear.

Adjust the leveling feet until the air bubble in the indicator is centered.

NOTE: The instrument should be leveled each time its location is changed.

2.3.4 Stabilization

Before initially using the Scale, allow time for it to adjust to its new environment. Recommended warm up period is

five (5) minutes.

3. OPERATION

The Trooper Scale has been factory calibrated and is ready for operation. You can operate the scale at this point using

the factory default settings. You can check the default menu settings on page 11. All bolded items on the menu are the

factory default settings. The scale will operate in the default mode. If you want to change the settings, continue with

Section 4, Setup.

When the Scale is positioned for operation, follow the operational procedure outlined next.

Trooper Scale

3. OPERATION (Cont.)

*

Center

of Zero

*

Center

of Zero

Gross

Gross

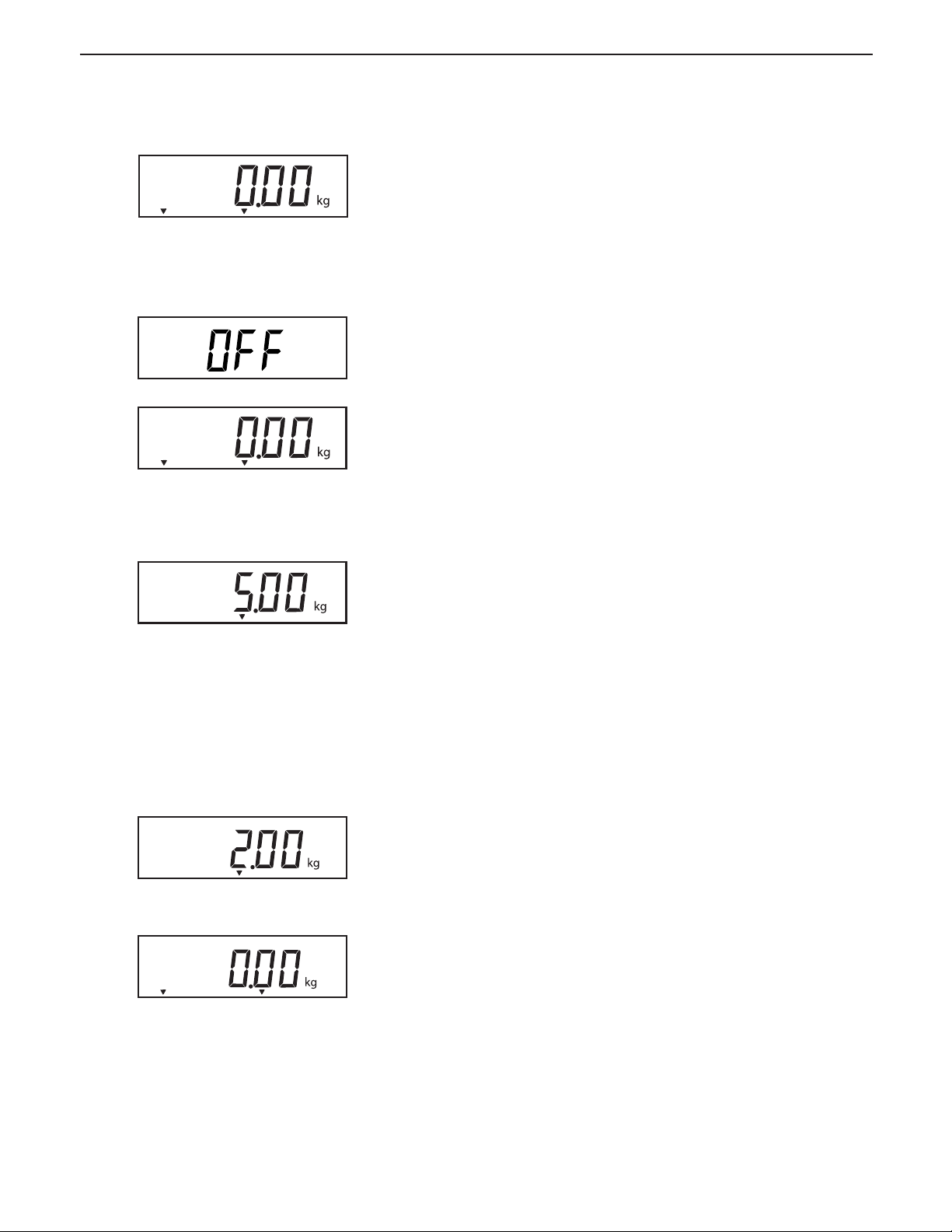

3.1 Turning On Scale

Press and hold ON/ZERO/

play appears, then release ON/ZERO/

display momentarily displays segment check, the software revision of the Scale and then goes into a weighing

mode.

OFF

button until the LCD dis-

OFF

button. The

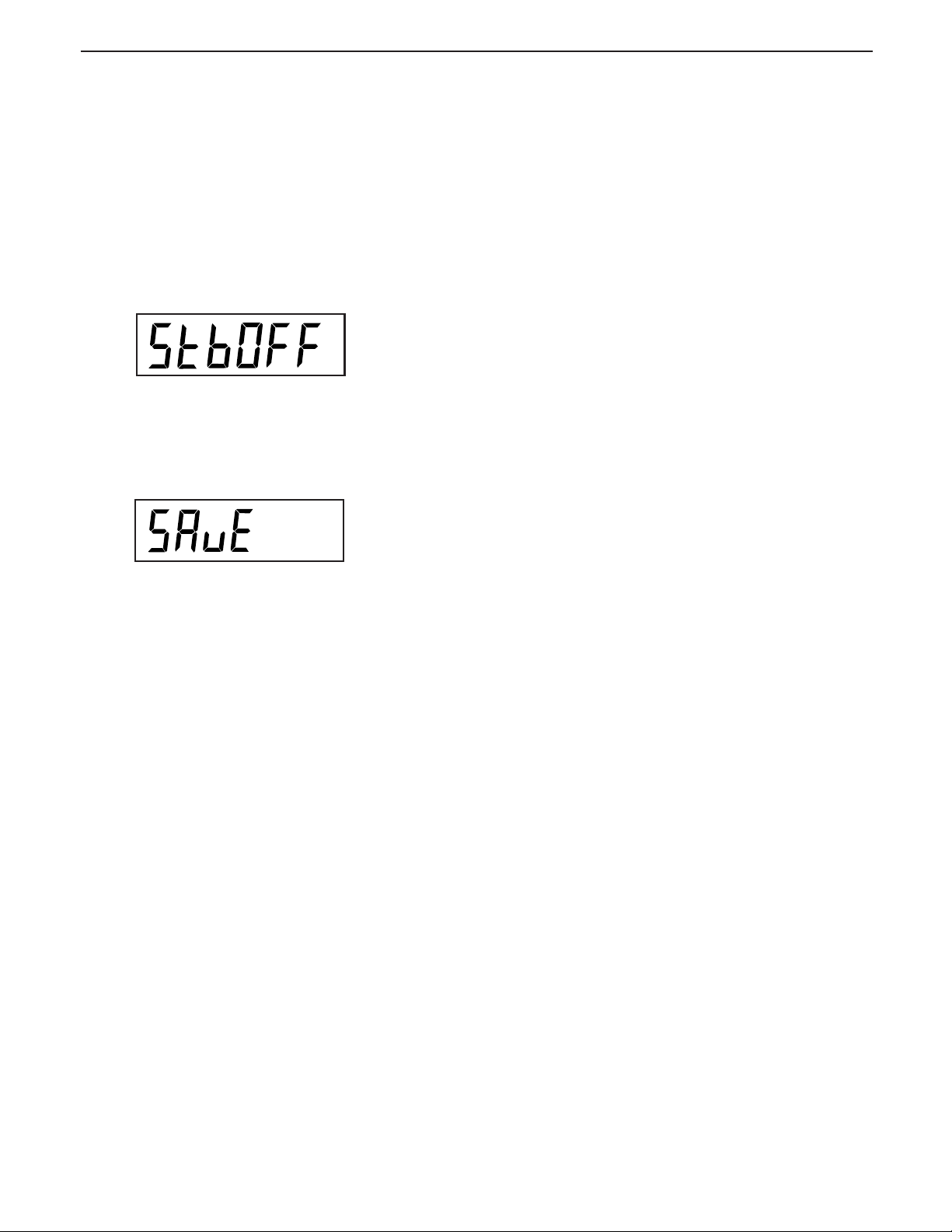

3.2 Turning Off Scale

To turn the Scale off, press the ON/ZERO/

OFF is displayed.

OFF

button until

3.3 Zero Operation

Using a

ton to zero the Scale. The display acknowledges by indicating the selected measuring unit followed by a zeroed

display.

shortshort

short

duration press, press ON/ZERO/

shortshort

OFF

EN-7

but-

NOTE: Stable cursor must be lit to accept zero operation.

*

Place item to be weighed on the scale platform. The display indicates a sample of 5kg, gross weight.

Gross

3.4 Tare Operation

When weighing material or objects that must be held in a

container, taring stores the container weight in the Indicator’s

memory. To store the container weight, proceed as follows:

*

Gross

*

Place the container on the scale. Sample shown is 2kg.

Press TARE button. Scale is tared andshows Net

weight.

Center

of Zero

Net

EN-8

3. OPERATION (Cont.)

Trooper Scale

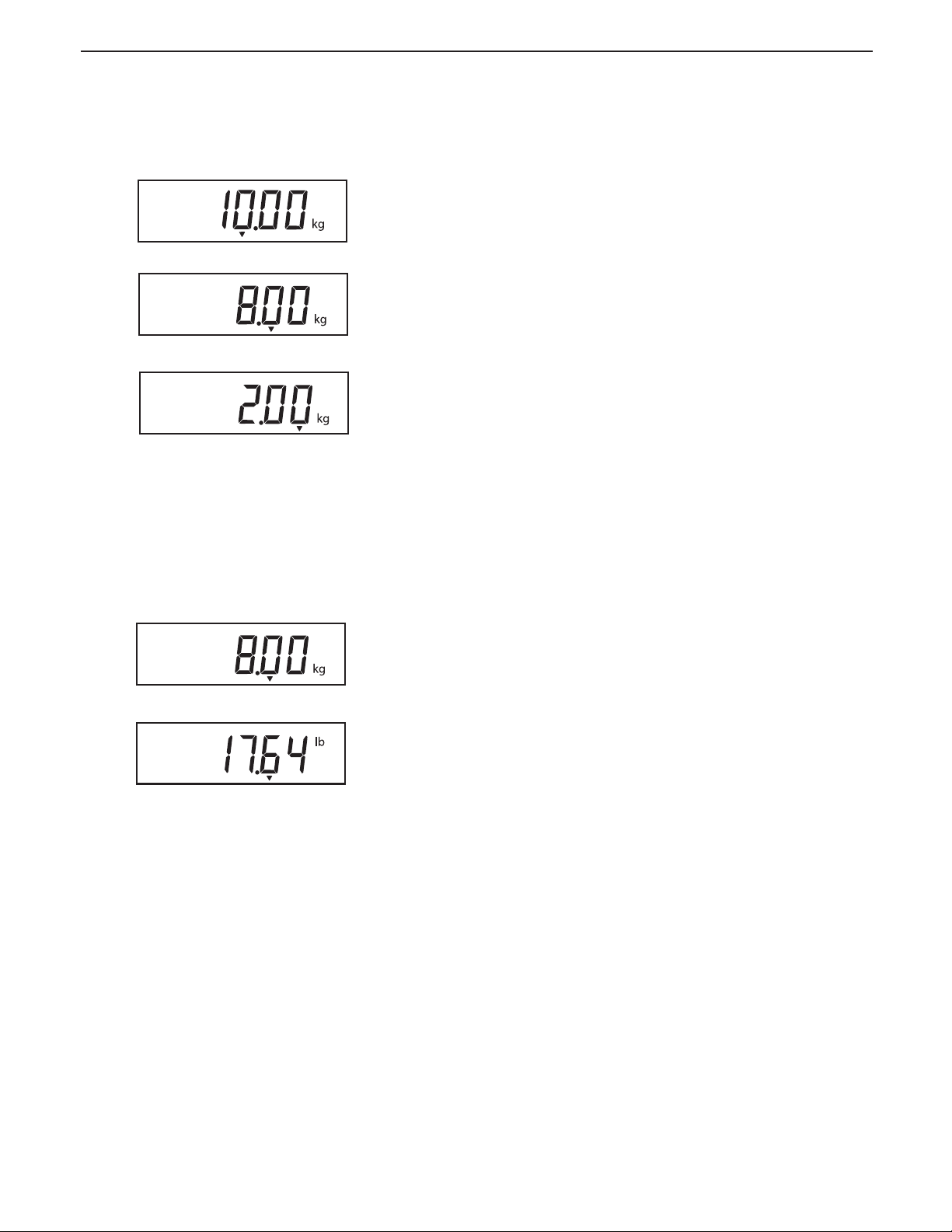

3.5 Gross/Net/Tare Recall Operation

*

When a container has been placed on the platform and

tared, it's weight is stored in memory. Adding material to

the container is shown as NET weight. The gross weight is

Gross

*

Net

a combination of the tared weight and the material. The G/

N/T/

MENU

button allows switching between GROSS, NET

and TARE weights.

Repeatedly press (short presses) the G/N/T/

MENU

but-

ton to cycle through Gross, Tare and Net readings. The

*

sample illustrations indicate a tare weight of 2kg simulating a container, a net weight of 8kg which would be

Tare

the material in a container and a gross weight of 10kg

which is the total weight of the container and material.

After 3 seconds, display returns to Net weight.

3.6 Unit Switch Operation

To switch measuring units, proceed as follows:

UNITS

*

Press and hold PRINT/

changes to selected measuring unit. Depending on which

units are enabled in the menu, you have a choice of g,

Net

lb, kg or oz. The display sample indicates 8kg load

changed to lbs shown as a net weight because a tared

*

weight of 2kg was used and stored in memory.

button until display

Net

Trooper Scale

EN-9

3. OPERATION (Cont.)

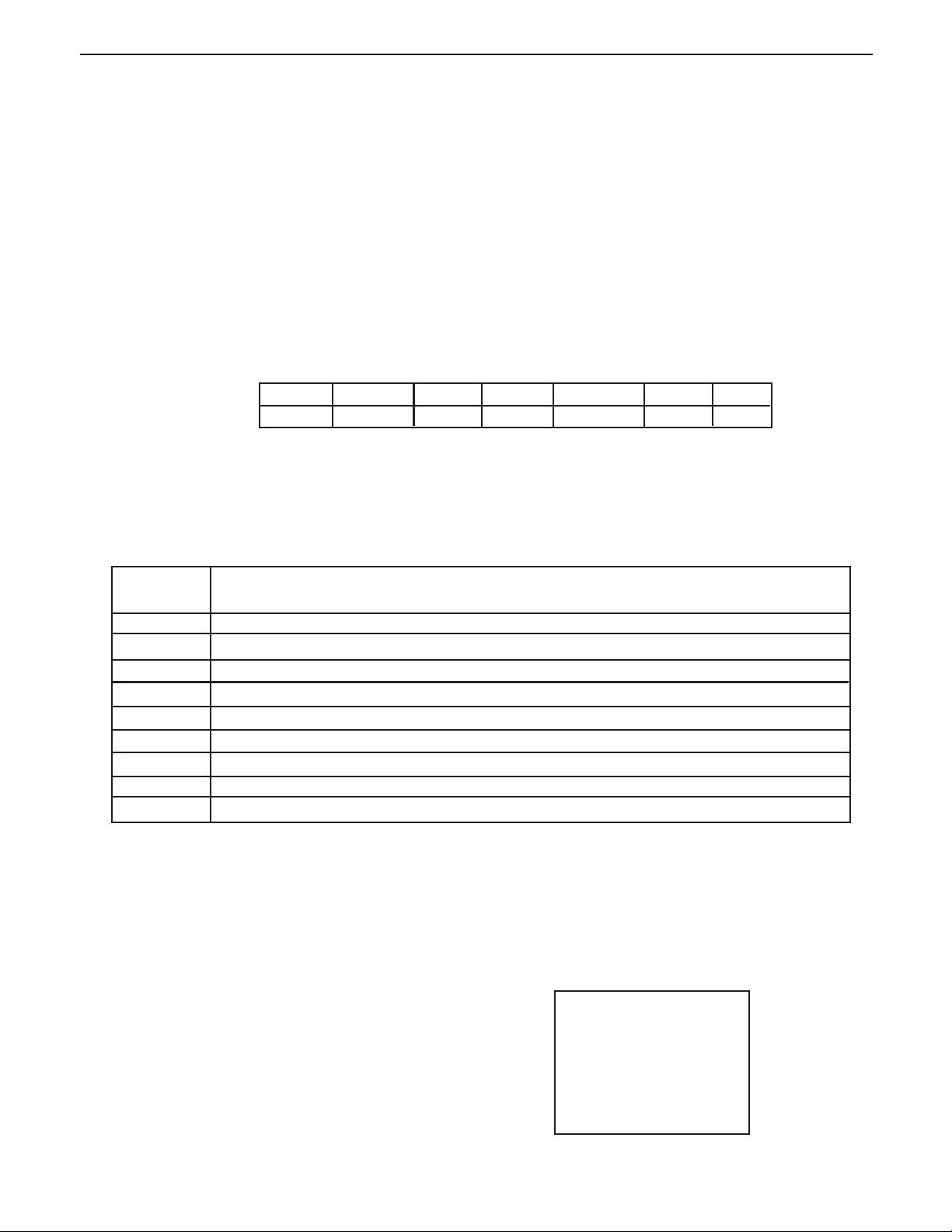

3.7 RS232 Commands

All communication is accomplished using standard ASCII format. Characters shown in the following table are acknowledged by the Scale. Invalid command response "ES" error indicates the Scale has not recognized the command.

Commands sent to the Scale must be terminated with a carriage return (CR) or carriage return-line feed (CRLF). Data

output by the Scale is always terminated with a carriage return-line feed (CRLF).

3.7.1 Output Formats

Data output can be initiated in one of two ways:

Units

1. By pressing the PRINT/

Output Formats

The output format is as follows:

Length: 9 1 3 1 1 1 1

button, or 2. Sending a print command (“P”) from a computer.

Weight* Spaces Unit Stable Legend CR LF

blank=stable G,N,T

"?"= not stable

* Displayed weight sent right justified with lead zero blanking. Nine characters (fixed) include:

decimal point (1), weight (7 max), polarity (1) : blank if positive, floating negative (1)

RS232 USER COMMAND TABLE

Command

Character Description

? Print current mode: kg, g, lb., oz.

P Same as pressing PRINT button.

T Same as pressing TARE button.

Z Same as pressing ZERO button.

xS Print Stable only. Where x=0 Off, and x=1 On

AS Automatically send data when stable after motion.

xxxxS Send at interval. Where xxxx=1 to 3600 seconds.

CS Send as fast as possible (continuous print)

M Increment to next enabled unit

To turn auto printing, interval printing or continuous printing off, send P to reset normal printing mode.

3.8 Printing Data

Printing data to an external computer or printer requires that the communications parameters in the Print menu, be set

first. Refer to paragraph 4.4.5 Print Menu for proper set up.

To print data, press PRINT/

NOTE: If you hold this button down too long, the display

will advance to another measuring unit.

UNITS

button with a short press. The display acknowledges by momentarily blinking off.

3.8.1 RS-232 Pin Out.

The table illustrates the pin-out connections on the RS232 connector.

1 N/C

2 Data In (RXD)

3 Data Out (TXD)

4 N/C

5 Ground

6, 7, 8, 9 N/C

EN-10

Trooper Scale

4. SETUP

For first time setup, step through all menus and set the parameters as desired.

4.1 Setup Protection

The Trooper Scale is equipped with menus which permit certain functions to be locked out (not changed) during

operation. If you intend to lock out changes to the setup selections you make, you will need to access the Lock Switch

located on the main PC circuit board following the setup procedure.

The Scale has five menus; CAL, SETUP, READ, PRINT and LOCSW which are entered by pressing and holding the G/N/

T/

MENU

button until MENU is displayed, then releasing it. The display then switches to SETUP. To access the rest of the

menus, the PRINT/

4.4.1 Control Functions

During setup, only the PRINT/

UNITS

button is repeatedly pressed until the desired menu is reached.

and

G/N/T/

MENU

buttons are used.

UNITS

PRINT/

Change between menus horizontally or change sub-menu parameters.

MENU

G/N/T/

Press and hold to enter menu. Enters menu and steps through sub-menus vertically.

UNITS

Button

Button

Trooper Scale

1234567890123456789012345

1

5

1

5

1

5

1234567890123456789012345

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

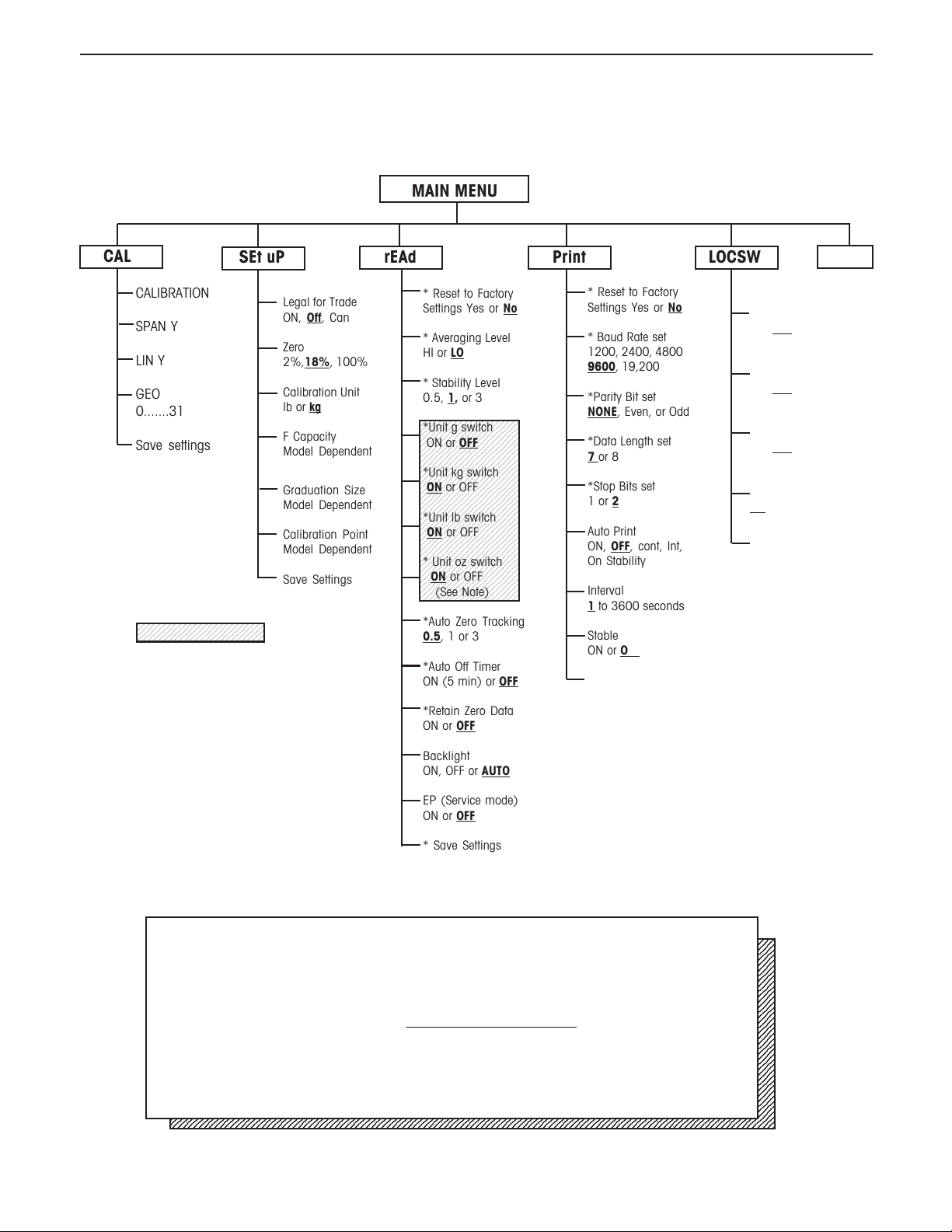

4.4.2 Menu Structure

The following table illustrates the menu structure in the Trooper Scale.

MAIN MENU

EN-11

CAL

CALIBRATION

SPAN Y

SEt uP rEAd Print LOCSW

Legal for Trade

ON,

Off, Can

Zero

LIN Y

GEO

0.......31

Save settings

2%,18%, 100%

Calibration Unit

lb or kg

F Capacity

Model Dependent

Graduation Size

Model Dependent

Calibration Point

Model Dependent

Save Settings

23456789012345678901234

23456789012345678901234

NOTE:

23456789012345678901234

FOR SHADED AREA

Whichever unit is used for calibration is automatically set to "ON" and does not appear

in the READ menu.

* Reset to Factory

Settings Yes or No

* Averaging Level

HI or LO

* Stability Level

0.5, 1, or 3

234567890123456789

234567890123456789

234567890123456789

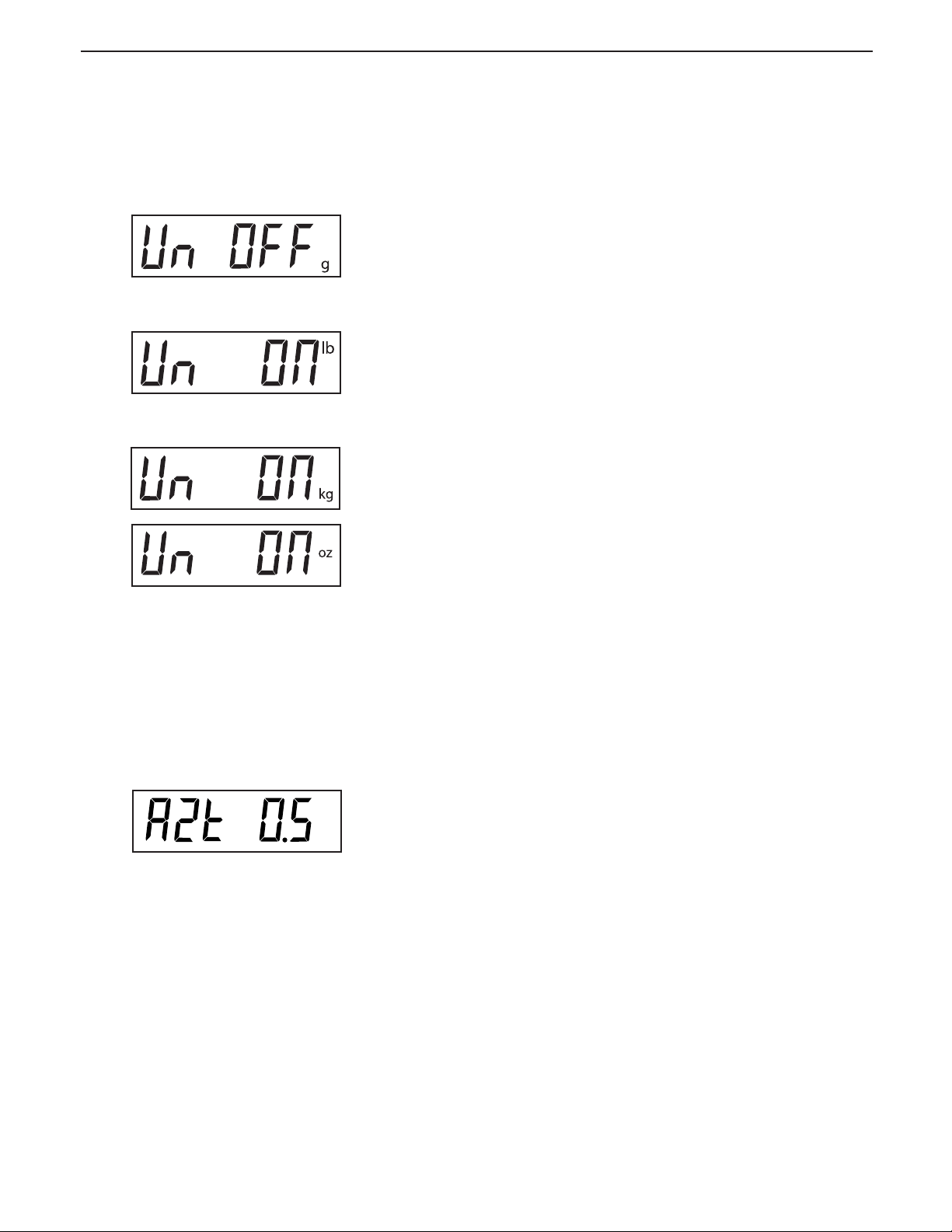

*Unit g switch

234567890123456789

234567890123456789

ON or OFF

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

*Unit kg switch

234567890123456789

234567890123456789

234567890123456789

ON or OFF

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

*Unit lb switch

234567890123456789

234567890123456789

234567890123456789

ON or OFF

234567890123456789

234567890123456789

234567890123456789

234567890123456789

234567890123456789

* Unit oz switch

234567890123456789

234567890123456789

234567890123456789

ON or OFF

234567890123456789

234567890123456789

234567890123456789

(See Note)

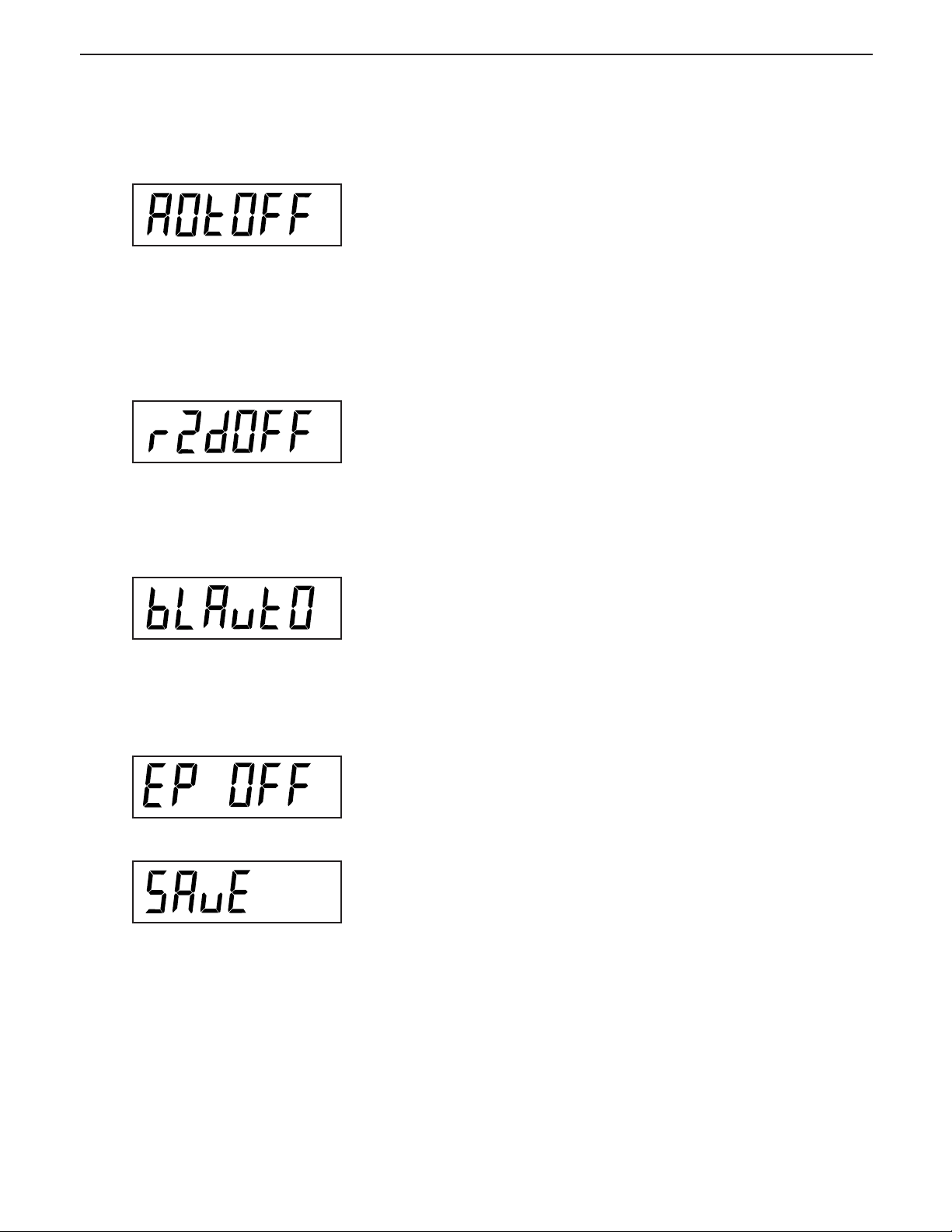

*Auto Zero Tracking

0.5, 1 or 3

*Auto Off Timer

ON (5 min) or OFF

*Retain Zero Data

ON or OFF

* Reset to Factory

Settings Yes or No

* Baud Rate set

1200, 2400, 4800

9600, 19,200

*Parity Bit set

NONE, Even, or Odd

*Data Length set

7 or 8

*Stop Bits set

1 or 2

Auto Print

ON, OFF, cont, Int,

On Stability

Interval

1 to 3600 seconds

Stable

ON or OFF

* Save Settings

Quit

SETUP Lock

Switch set

ON, OFF

* READOUT

Lockout Switch set

ON, OFF

* PRINT Lockout

Switch set

ON, OFF

CALIBRATION

Lockout Switch set

ON, OFF

* Save Settings

Backlight

ON, OFF or AUTO

EP (Service mode)

ON or OFF

* Save Settings

Press (G/N/T/

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

Press (PRINT/

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

Factory default settings are shown in

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

When CAL switch on the circuit board is in the LFT position, all of the menus can be

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

reached except CALIBRATION Menu, but only the submenus which are marked ' ' can be

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

setup, see menu structure.

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890

MENU

) to enter the display submenu or select a displayed setting.

UNITS

) to change the displayed submenu or setting.

underlined and boldface type.

*

EN-12

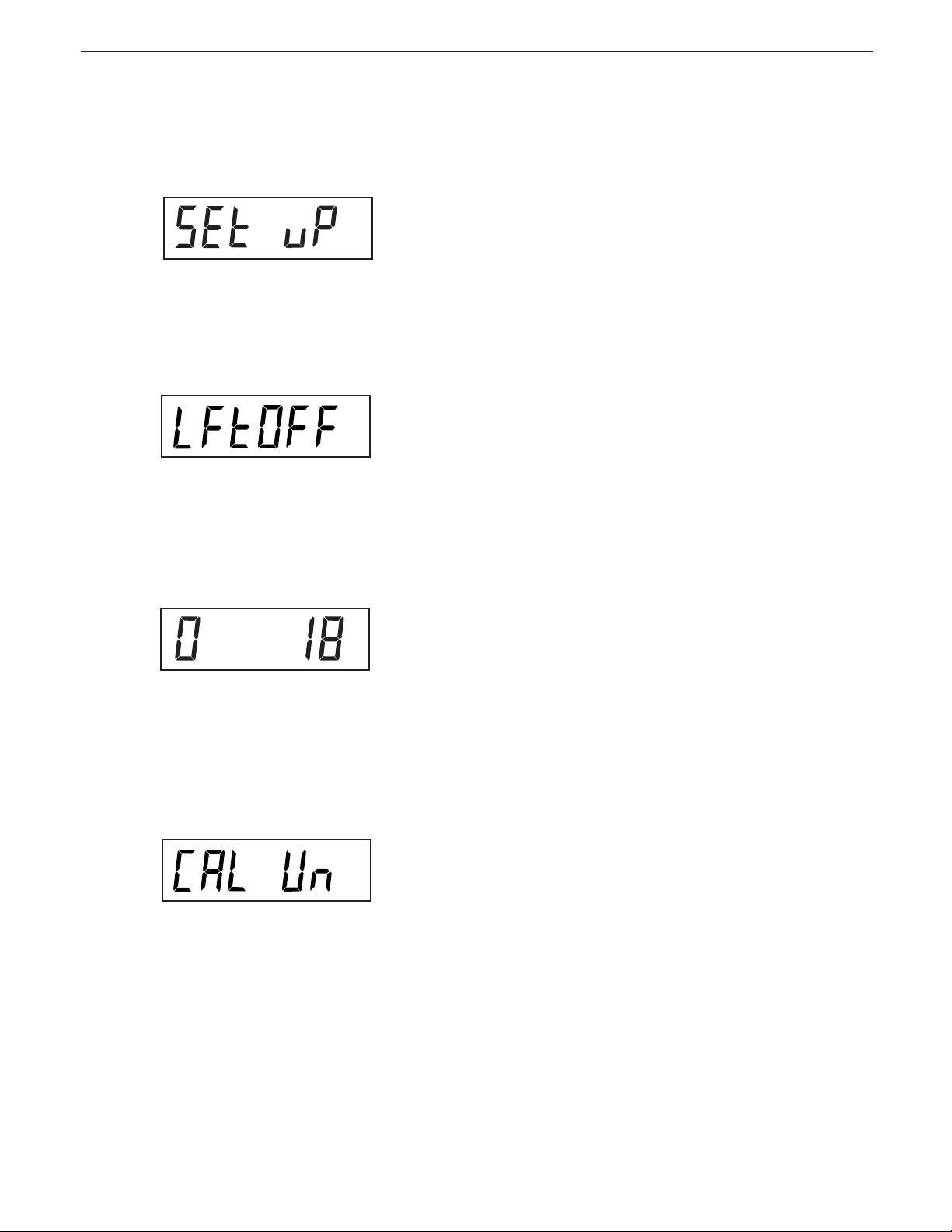

4.4.3 Setup Menu

The Setup Menu is used to set up the Scale for the first time.

Trooper Scale

Procedure

With the Scale ON, press and hold the

button until MENU is displayed. When you release G/N/

T/

MENU

button, SETUP is displayed when the CALIBRA-

TION Lock Switch (software) is in the locked position.

When the CALIBRATION Lock Switch is locked, the Scale

will not permit calibration.

Press

PRINT/

Press G/N/T/

for trade selections are:

UNITS

button, SETuP is displayed.

MENU

button, LFTOFF is displayed. Legal

'LFT ON' - LFT is ON

'LFTOFF' - LFT is OFF

'LFTCAn' - LFT is set for Canada

G/N/T/

MENU

kg

Press PRINT/

Canada.

Press G/N/T/

Zero 2%, 18% or 100% setting. 2% - zero operation

range is - 2% to + 2%. 18% - zero operating range is 2% to +18%, 100% - zero operation range is -2% to

+100%.

: :

NOTE

: If LFT is ON, only 2% and 18% are available.

: :

Press PRINT/

or 100%.

Press G/N/T/

This is the calibration unit setting. Selections are:

Press PRINT/

UNITS

MENU

UNITS

MENU

UNITS

button and select either ON, OFF or

button, 0 18 is displayed. This isthe

button, and select either 2%, 18%

button, CAL Un kg is displayed.

'lb' - calibration unit is lb

'kg' - calibration unit is kg.

button, and select either kg or lb.

NOTE: The Scale is factory calibrated. After changing

the calibration unit, the Scale must be recalibrated

befoe using!

Trooper Scale

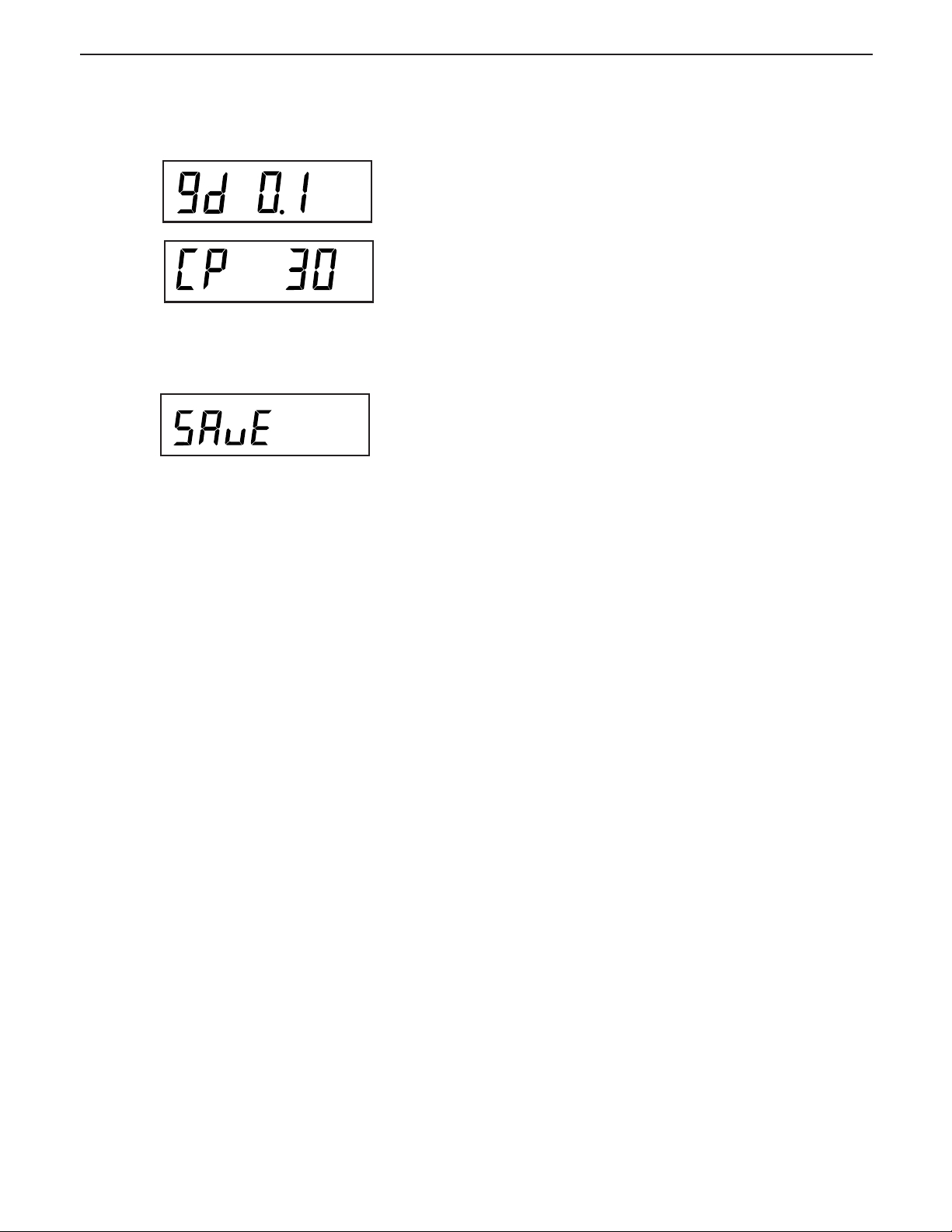

4.4.3 Setup Menu (Cont.)

EN-13

kg

kg

Press

G/N/T/

the graduation size. For available selections, press PRINT/

UNITS

button until desired graduation value is reached.

Press G/N/T/

is the full scale calibration point setting. Default is approximately 2/3 full scale capacity and can be selected

depending upon the model.

Press PRINT/

is reached.

Press G/N/T/

displayed.

Press G/N/T/

the next menu or press PRINT/

Setup menu.

MENU

MENU

MENU

button, Gd 0.1 is displayed. This is

button, CP 30 kg is displayed. This

UNITS

button until desired calibration value

button to end this block, SAVE is

MENU

button, rEAD is displayed which is

UNITS

button to return to

EN-14

Trooper Scale

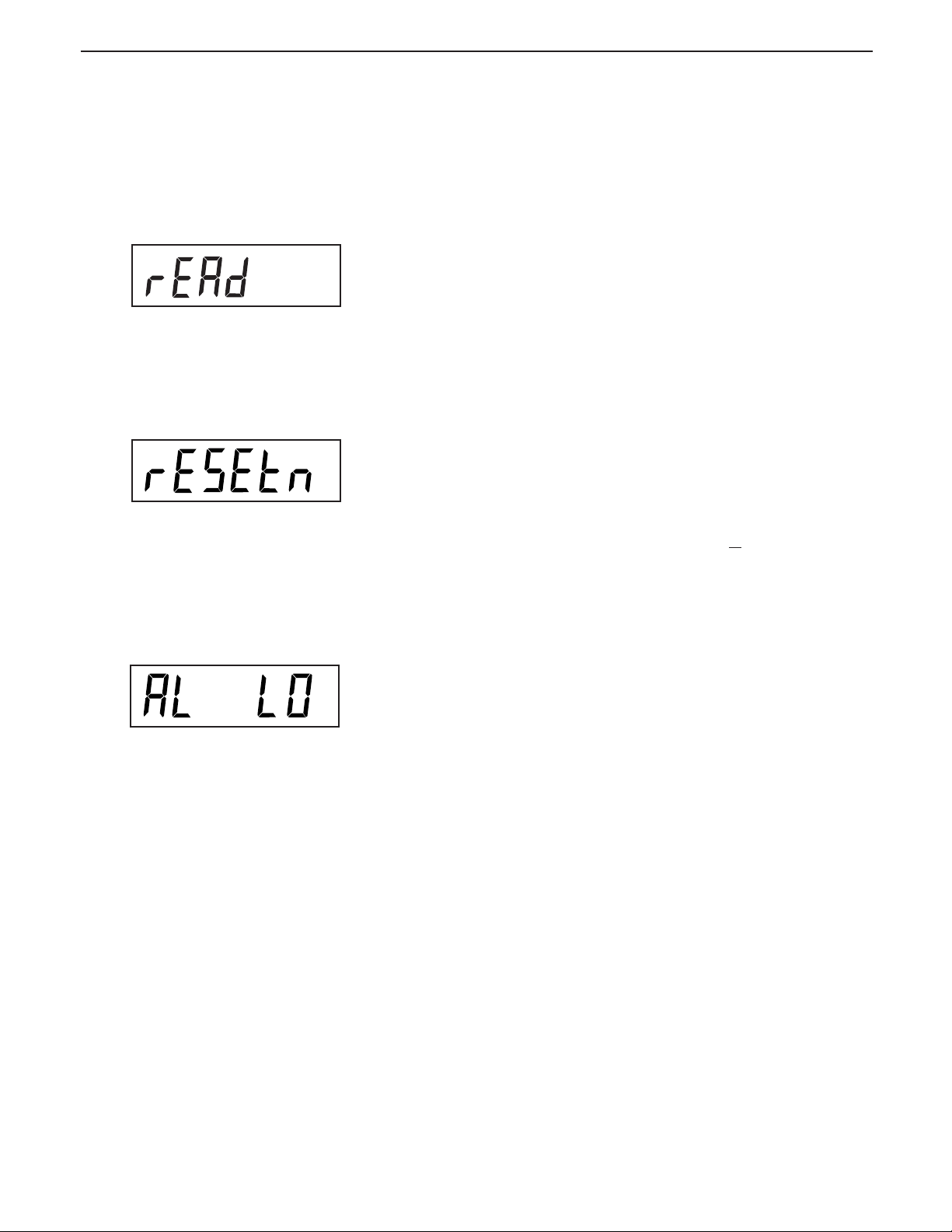

4.4.4 Readout Menu

The Readout menu is used to adapt the Scale to environmental conditions, set measuring units on/off, auto zero

tracking, timer on/off, retain zero data and backlighting. Review all of the settings available before proceeding.

Procedure

To select any of the items in the Readout menu, proceed

as follows: NOTE: If you have entered from the preceeding

menu, disregard the first step.

With the Scale ON, press and hold the

ton until MENU is displayed. When you releasethe G/N/

T/

MENU

UNITS

Press G/N/T/

lows resetting the readout menu to factory defaults.

rESETn = no and does not reset settings. rESETy= yes

and will reset the entire readout menu as follows: AL Lo,

StAb 1, Un Off g, Un On kg, Un On

Aot Off, rZd Off and Backlight Off.

Press PRINT/

AVERAGING LEVEL

Averaging level compensates for vibration or excessive air

currents on the scale platform. During operation, the Scale

continually takes weight readings from the load cell. Successive readings are then digitally processed to achieve a

stabilized display. Using this feature, you specify how much

processing you need.

button, CAL is displayed, then press

button, until rEAd is displayed.

MENU

button, rESETn is displayed. This al-

UNITS

button,and select N or Y.

G/N/T/

MENU

lb, Un Off oz, AZt 0.5,

but-

PRINT/

HI and LO settings are available.

HI setting:

More processing, greater stability and

slower stabilization time.

LO setting:

Less processing, less stability and faster

stabilization time.

Trooper Scale

4.4.4 Readout Menu (Cont.)

Procedure

AVERAGING LEVEL (Cont.)

MENU

Press G/N/T/

averaging level settings. Selections are:

button, AL LO is displayed. This is

'Lo' - Averaging level is low

'Hi' - Averaging level is high.

EN-15

Press PRINT/

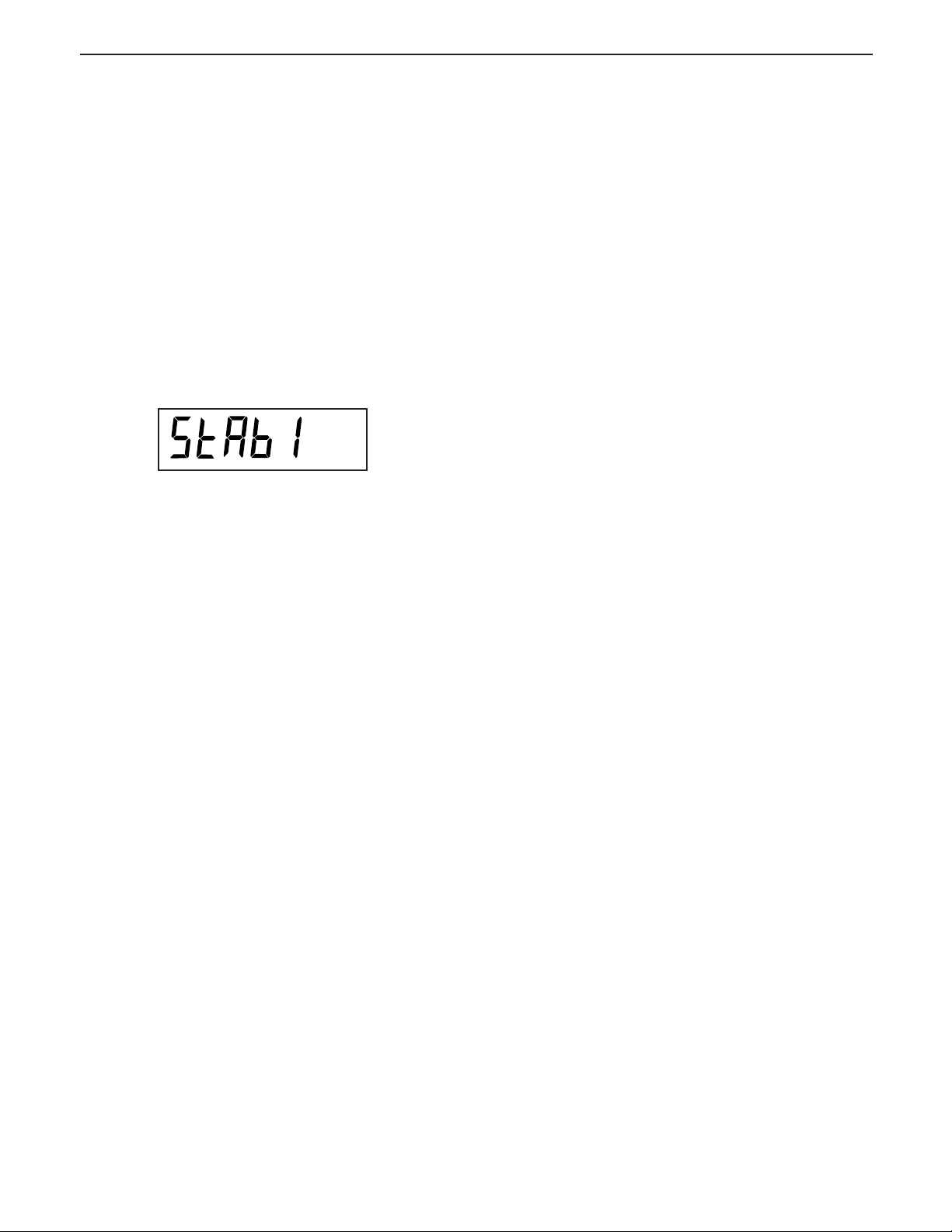

STABILITY

The stability range specifies the weighing results and must

be within a preset tolerance limit for a certain time to turn

the stability indicator ON. When a displayed weight changes

beyond the allowable range, the stability indicator turns

OFF, indicating an unstable condition. Factory default setting is shown in bold type.

.5d Smallest range: stability indicator is

1d Normal setting. - Fixed for LFT

3d More stable course

Press G/N/T/

bility range specifies the weighing results and must b e

within a preset tolerance limit for a certain time to turn

the stability indicator ON. When a displayed weight

changes beyond the allowable range, the stability indicator turns OFF, indicating an unstable condition. 0.5 d

smallest range, stability indicator is ON only when displayed weight is stable within 0.5 divisions. 1 d-stable

within 1 division. 3 d-largest range, stability indicator is

ON even though displayed weight changes 3 divisions.

Factory default setting is 1.

UNITS

button,and select LO or HI.

ON only when displayed weight is

within .5 divisions.

MENU

button, StAb1 is displayed.The sta-

Press PRINT/

mal 1d stability is default/recommended.

UNITS

button,and select 0.5,

11

1, or 3.Nor-

11

EN-16

4.4.4 Readout Menu (Cont.)

Procedure

UNITS SELECTION

Press G/N/T/

Press PRINT/

the default setting.

MENU

UNITS

Trooper Scale

button, Un OFF g is displayed.

button, and select ON or OFF. OFF is

Press G/N/T/

is unit pounds which can be turned ON or OFF. This will

be displayed when CAL UNIT kg was selected. When lb

was selected as calibration unit, kg will display.

Press PRINT/

the default setting.

Press G/N/T/

unit is ounces which can be turned ON or OFF. Default

setting is ON.

Press PRINT/

NOTE: If CAL Unit is kg, then UNIT kg is fixed to ON menu

not shown. The same if CAL Unit is set to lb.

AUTO ZERO

Press G/N/T/

the Auto Zero Threshold setting. Auto Zero minimizes the

effects of temperature changes and small disturbances

on the zero reading. The Scale maintains the zero display until the threshold is exceeded. Settings are shown

as follows:

button, Un ON lb is displayed. This

MENU

UNITS

MENU

UNITS

MENU

button,and select ON or OFF. ON is

button, Un ON oz is displayed.This

button,and select ON or OFF.

button, AZt 0.5 is displayed. This is

OFF

0.5d Sets threshold to 0.5 divisions. - Fixed in LFT

1d Sets threshold to 1 division.

3d Sets threshold to 3 divisions.

Factory default setting is 0.5d.

Press PRINT/

UNITS

button,and select either 0.5, 1 or 3.

Trooper Scale

4.4.4 Readout Menu (Cont.)

EN-17

AUTO POWER OFF

MENU

Press G/N/T/

the Auto Off Timer. When set ON, the Scale will shut off

automatically after 5 minutes has elapsed based on the

condition that no button is pressed and the scale platform is stable during that period.

Press G/N/T/

OFF is the default setting.

RETAIN ZERO DATA

Press G/N/T/

is Retain Zero Data which can be turned on or off.

When set On, the Scale stores the current zero point and

restores it on the power-up.

button, AOtOFF is displayed. This is

MENU

button,and select ON or OFF.

MENU

button, Un rZdOFFis displayed. This

Press PRINT/

the default setting.

LCD BACK LIGHT

Press G/N/T/

select to have the LCD backlight either on contiuously,

off or in an automatic mode which turns off the display

in 5 seconds.

Press PRINT/

Auto. Auto is the default setting.

EP

This is service function and is not a user operated command. OFF is the default setting.

SAVE

Press G/N/T/

played. All settings are retained.

Press G/N/T/

is displayed which is the next menu or press PRINT/

UNITS

UNITS

MENU

UNITS

MENU

MENU

button to go back to Setup menu without saving.

button, and select ON or OFF. OFF is

button, bLAutOis displayed. You can

button, and either select ON, OFF or

button to end this block, SAVE is dis-

button, setting are saved and PRINT

NOTE: (If initial setup, go to the next paragraph. To exit

from the Setup, press PRINT/

PRINT then to LOCKSW, then QUIT. Press G/N/T/

button to go back to the weighing mode).

UNITS

button to skip to

MENU

EN-18

Trooper Scale

4.4.5 Print Menu

The Print menu provides data communication settings which can be entered. It contains 9 submenus: Reset, Baud rate,

Parity Bit, Data Length, Stop Bits, Auto Print, Interval, Stable and Save.

Procedure

PRINT

To select any of the items in the Print menu, proceed as

follows: NOTE: If you have entered from the preceeding

menu, disregard the first step.

With the Scale ON, press and hold the

ton until MENU is displayed. When you release the G/N/

T/

MENU

UNITS

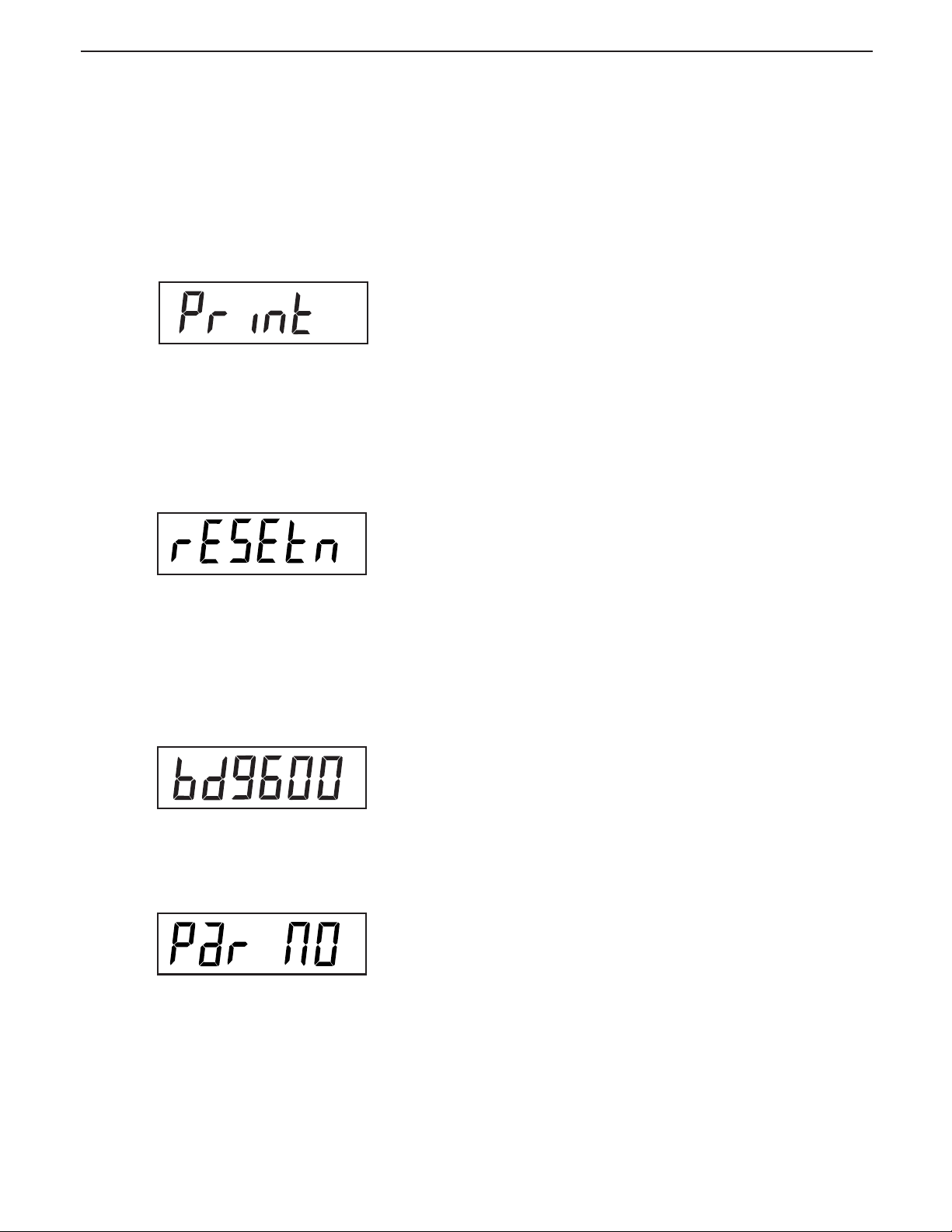

RESET

Press G/N/T/

lows resetting the Print menu to factory defaults.

rESETn = no does not reset settings. rESETy = yes will

reset the entire Print menu as follows:

Baud rate =2400, parity =none, data length=7,

stop bit=2.

Press PRINT/

BAUD RATE

Press G/N/T/

Press PRINT/

rate. Baud rate selections are: 1200, 2400, 4800 9600

and 19200. 9600 is the default setting.

button, CAL is displayed, then press

button, until Print is displayed.

MENU

MENU

button, rESEtn is displayed. Thisal-

UNITS

button, and select N or Y.

button, bd9600 is displayed.

UNITS

button, and select desired baud

G/N/T/

MENU

PRINT/

but-

PARITY

Press G/N/T/

the parity bit.

Press PRINT/

NO=none, Odd=odd, E=even. Default setting is none.

MENU

UNITS

button, PAr NO is displayed. This is

button, and select desired parity of

Trooper Scale

4.4.5 Print Menu

Procedure (Cont.)

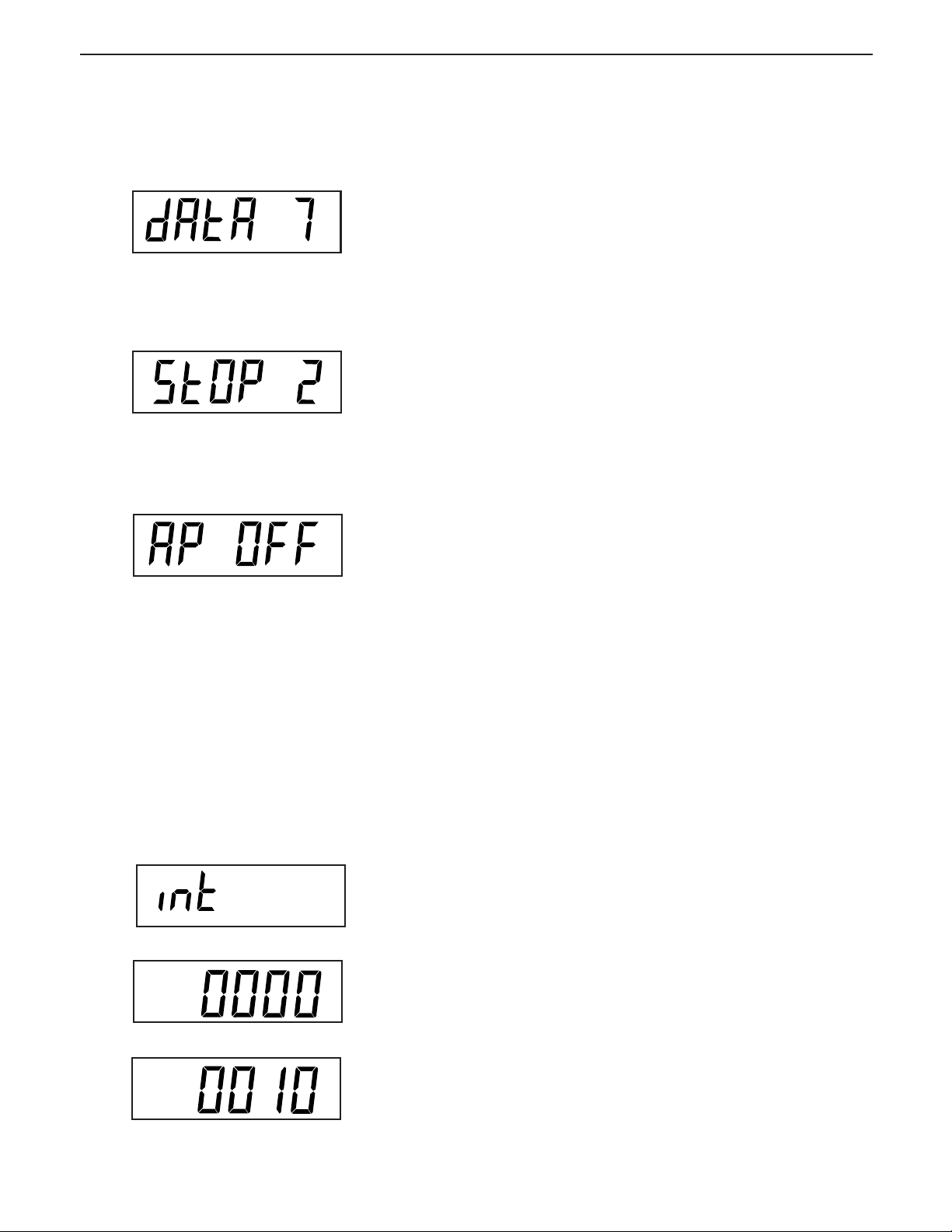

DATA

Press G/N/T/

the data length.

MENU

EN-19

button, dAtA 7 is displayed. This is

Press PRINT/

of 7 or 8. Default setting is 7.

STOP BITS

Press G/N/T/

the stop bit.

Press PRINT/

1 or 2. Default setting is 2.

AUTO PRINT

Auto print has settings which enables data to a printer or

PC to be set Off, run continuously, at selected preset intervals or on stability. On stability will print first stable nonzero value after each change in weighing value.

Press G/N/T/

Press PRINT/

Continous, Interval or On Stability. Default setting is OFF.

UNITS

button, and select desired data length

MENU

MENU

button, StOP 2 is displayed. This is

UNITS

button, and select desired stop bit of

button, AP OFF is displayed.

UNITS

button, and select either Off,

INTERVAL - PRINTING

When interval has been selected in the previous step, you

may now set an interval from 1 to 3600 seconds. If Interval was not selected, ignore these steps.

Press G/N/T/

seconds, a second display appears which allows you to

set in the time in seconds.

Pressing the PRINT/

left to right. Sample at left indicates 10 seconds.

NOTE: 0000 not valid.

MENU

button, int is displayed, after a few

UNITS

button advances the zero from

EN-20

4.4.5 Print Menu

Trooper Scale

INTERVAL - PRINTING (Cont.)

Pressing the TARE button increments the digit from 1 to

0. When the desired number of seconds have been entered, press the G/N/T/

STABLE

When set ON, allows only stable weight values to be printed.

When set OFF, prints immediate value with an indication of

stability. In LFT, fixed to ON.

MENU

button. Stb OFF is displayed.

With Stb OFF displayed, press PRINT/

select ON or OFF. Default setting is OFF.

SAVE

Press G/N/T/

played. All settings are retained.

Press G/N/T/

displayed which is the next menu or press PRINT/

button to go back to Read menu without saving.

NOTE: (If initial setup, go to the next paragraph. To exit

from the Setup, press PRINT/

LOCKSW, then QUIT. Press G/N/T/

to the weighing mode).

MENU

button to end this block, SAVE is dis-

MENU

button to save settings, LOCSW is

UNITS

MENU

UNITS

button, and

UNITS

button to skip to

button to go back

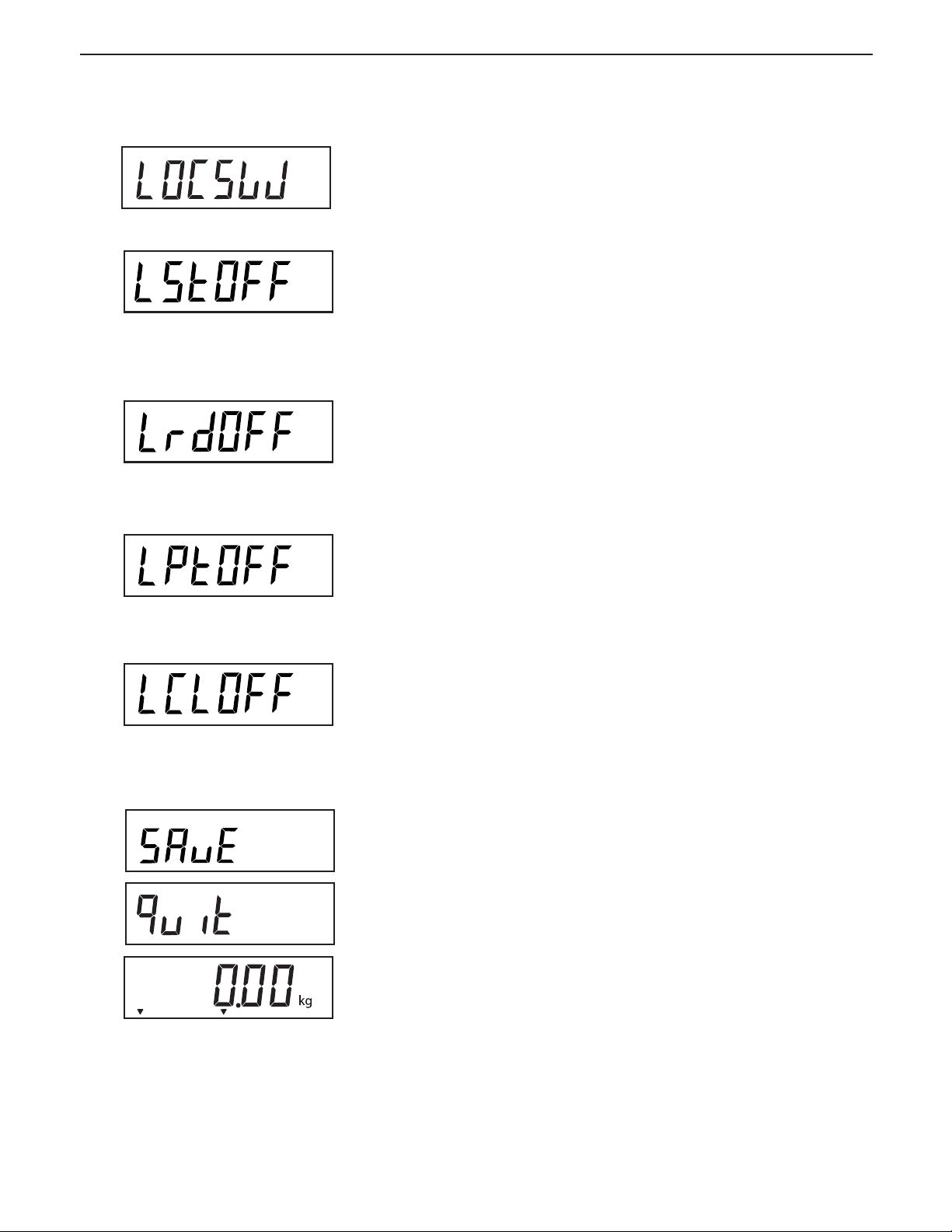

4.4.6 Lockout Switch Menu

Lockout Switch menu (LOCSW) is a software controlled option which can lock the settings in the Calibration, Setup,

Readout, and Print menus to prevent tampering. When used in conjunction with the Lock Switch on the printed circuit

board, the Calibration, Setup, Readout and Print menus can be read only and not changed by an operator or the switch

can be left in place and the LOCSW menu is used to prevent accidental changes..

Procedure

To select any of the items in the Lockswitch menu, proceed

as follows: NOTE: If you have entered from the preceeding

menu, disregard the first step.

Trooper Scale

4.4.6 Lockout Switch Menu (Cont.)

EN-21

Procedure (Cont.)

With the Scale ON, press and hold the

ton until MENU is displayed. When you release the G/N/

T/

MENU

button, CAL is displayed, then press PRINT/

UNITS

button, until LOCSW is displayed.

G/N/T/

MENU

but-

Press G/N/T/

MENU

button, LSTOFF is displayed. This

permits locking the Setup menu. OFF is unlocked, ON is

read only (locked). This menu is hidden if the CAL jumper

is off.

Press

PRINT/

Press G/N/T/

UNITS

button, and select ON or OFF.

MENU

button, LrdOFF displayed. This permits locking the Readout menu. OFF is unlocked, ON is

read only (locked).

Press PRINT/

Press G/N/T/

UNITS

MENU

button, and select ON or OFF.

button, LPtOFF is displayed. This

permits locking the Print menu. OFF is unlocked, ON is

read only (locked).

Press PRINT/

Press G/N/T/

UNITS

button, and select ON or OFF.

MENU

button, LCLOFF is displayed. This permits locking the Calibration menu. OFF is un locked, ON

is hidden (locked). This menu is hidden if the LFT switch

is in the LFT position.

Center

of Zero

Gross

Brutto

Press PRINT/

Press G/N/T/

UNITS

MENU

button, and select ON or OFF.

button to end this block, SAVE is

displayed.

Press G/N/T/

Press PRINT/

MENU

MENU

, Quit is displayed.

UNITS

button to go to CAL or press G/N/T/

button, Scale returns to a weighing mode.

NOTE: At this point, the Lock Switch must be set in order

to lock out the menus.

EN-22

Trooper Scale

5. CALIBRATION AND SEALING

Span calibration ensures that the Scale reads correctly within specifications. For best results, calibrate at full capacity.

Calibration unit can be set to either kg or lb.

NOTE: When the Scale is used in Legal for trade applications, the calibration menu is locked out and is not

accessable.

Before beginning calibration,

masses are not available, exit the menu. The Scale will retain previously stored calibration data. Calibration should be

performed as necessary to ensure accurate weighing. You have a choice of either span or linearity calibration. Span

calibration checks zero and full span calibration points. Linearity calibration checks zero, mid span and full span

points.

Before calibrating the scale, first determine if a recalibration is really needed. Place the available calibration masses

onto the platform. As each mass is added, the scale display should show the correct weight to within +/- 1 scale

division. If the scale is within the tolerance, there is no need to recalibrate the scale.

If it is determined that the scale must be recalibrated do not continue until you are certain that you have suitable

calibration masses.

This is to prevent unauthorized personnel from changing calibration.

IMPORTANT:

make sure masses are available. If you begin calibration and realize calibration

If calibration masses are available you must select the correct calibration units (pound masses or kilogram masses)

before calibrating the scale. The desired unit can be chosen in the setup menu on page 10.

After the desired calibration unit has been chosen, advance to the LOCSW menu to turn the calibration lock switch off.

This software lock is in place to prevent accidental calibration.

Procedure

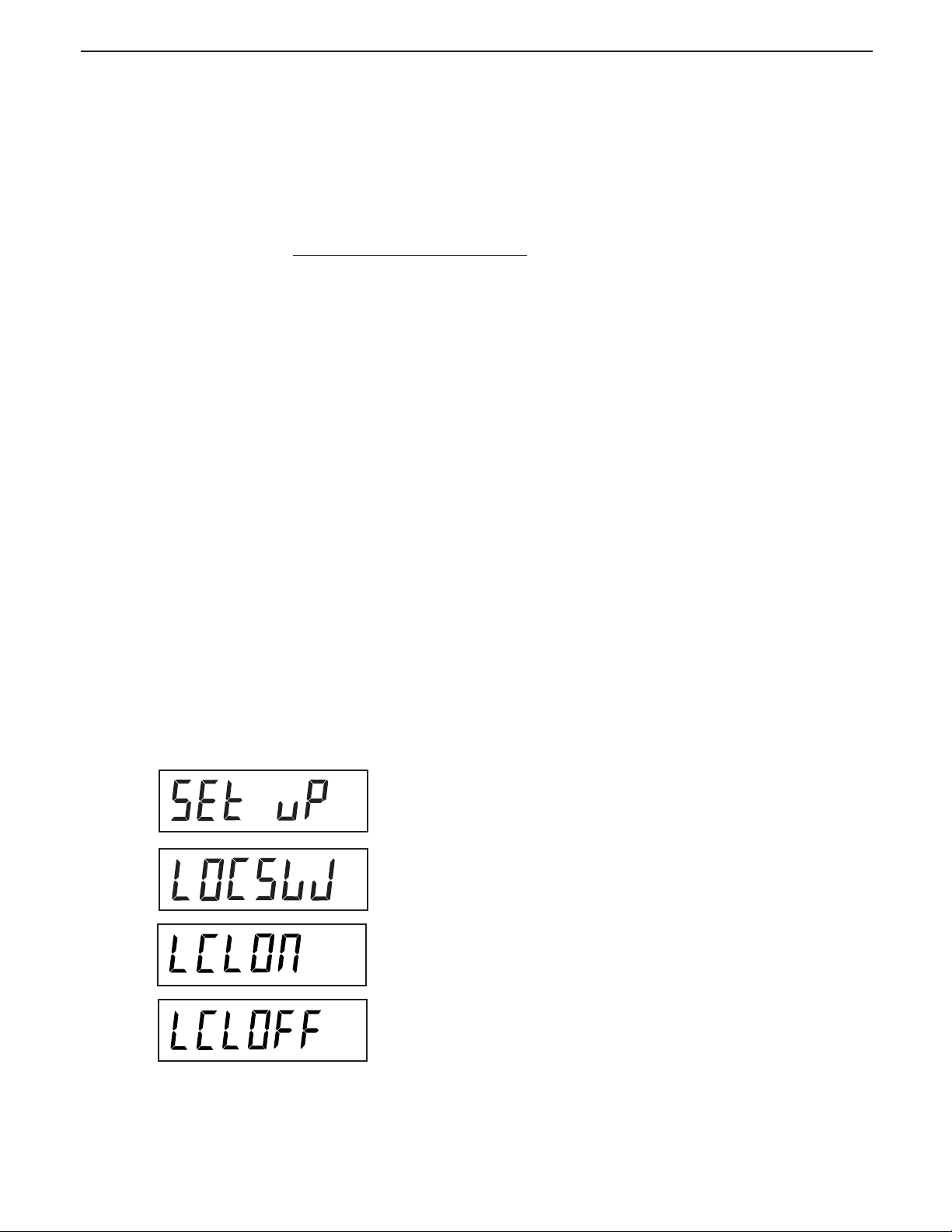

TURNING CALIBRATION LOCK SWITCH OFF

To turn the software lock off:

MENU

Press and hold the G/N/T/

pears. Release it and SETuP appears. (if already in the

main menu, skip to the next step).

Repeatedly press the PRINT/

displayed.

Repeatedly press the G/N/T/

displayed.

UNITS

Press the PRINT/

until LCLOFF appears.

button to scroll through the choices

button until MENU ap-

UNITS

MENU

button until LOCSW is

button until LCL ON is

Press the G/N/T/

returns to weighing

Before calibrating, make sure that you have the correct

masses available:

MENU

button repeatedly until the scale

Trooper Scale

5. CALIBRATION AND SEALING (Cont.)

Cal in kg: Span cal choices Linearity cal (fixed)

TR3RS 1, 2, 3kg 2 & 3 kg

TR6RS 2, 4, 6kg 4 & 6 kg

TR15RS 5, 10, 15kg 10 & 15 kg

TR30RS 10, 20, 30kg 20 & 30 kg

Cal in lb: Span cal choices Linearity cal (fixed)

TR3RS 2, 4, 6 lb 4 & 6 lb

TR6RS 5, 10, 15 lb 10 & 15 lb

TR15RS 10, 20, 30 lb 20 & 30 lb

TR30RS 20, 40, 60 lb 40 & 60 lb

EN-23

Procedure (Cont.)

TURNING SOFTWARE LOCK OFF

For span calibration, there are a number of choices for

calibration. The highlighted number is the default.

To change the span calibration value read the setup section of the menu on page 10. In the Setup menu, change

the CP selection to the desired value.

When the desired selection has been chosen and the

masses are available, you are ready to begin the calibration routine.

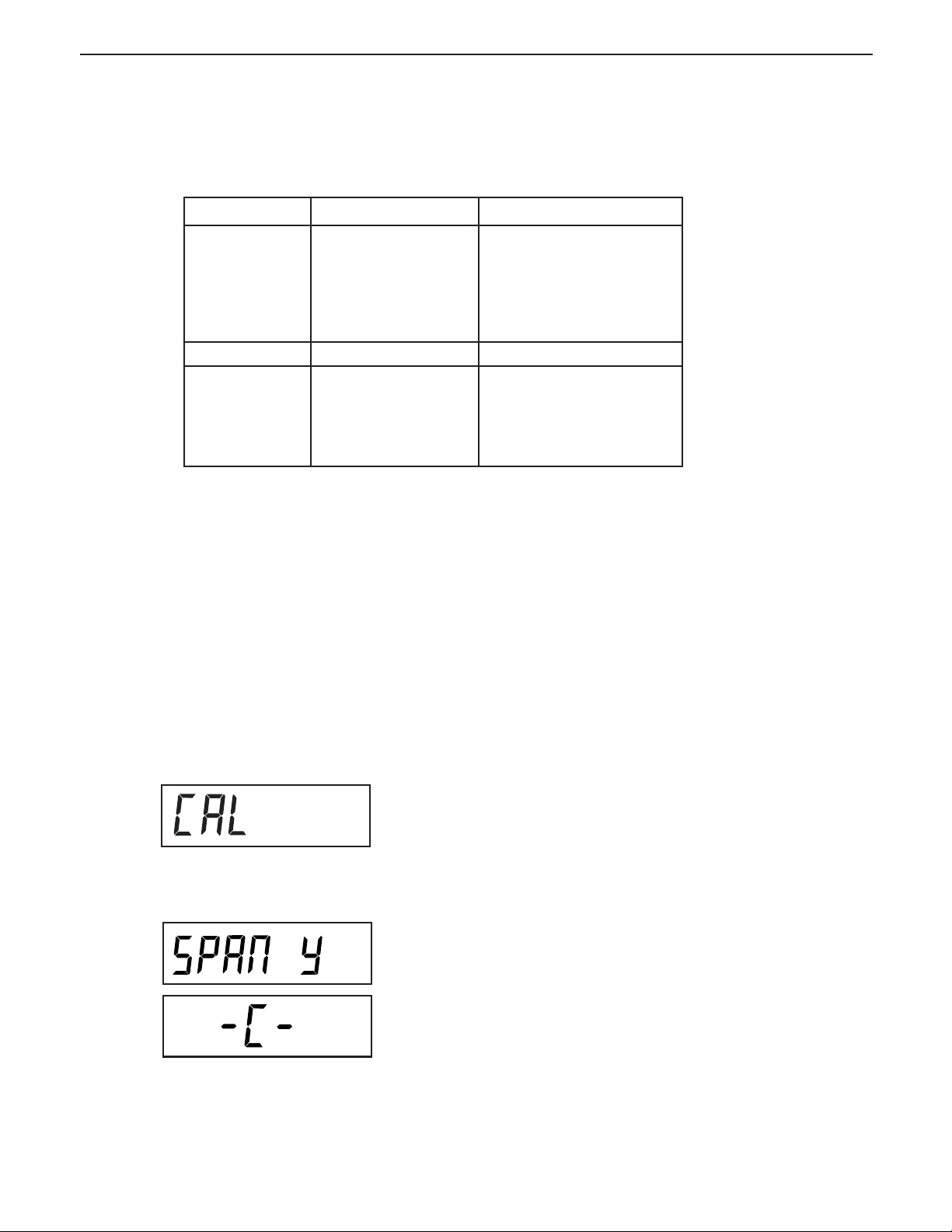

Procedure

SPAN CALIBRATION

With the Scale ON, press and hold the

button until MENU is displayed. When you release t h e

G/N/T/

MENU

shows SETuP, read the section on turning off the Calibration Lock Switch or check the settings for legal for trade.

Press G/N/T/

button, CAL is displayed. If the display

MENU

button, SPAN Y is displayed.

G/N/T/

MENU

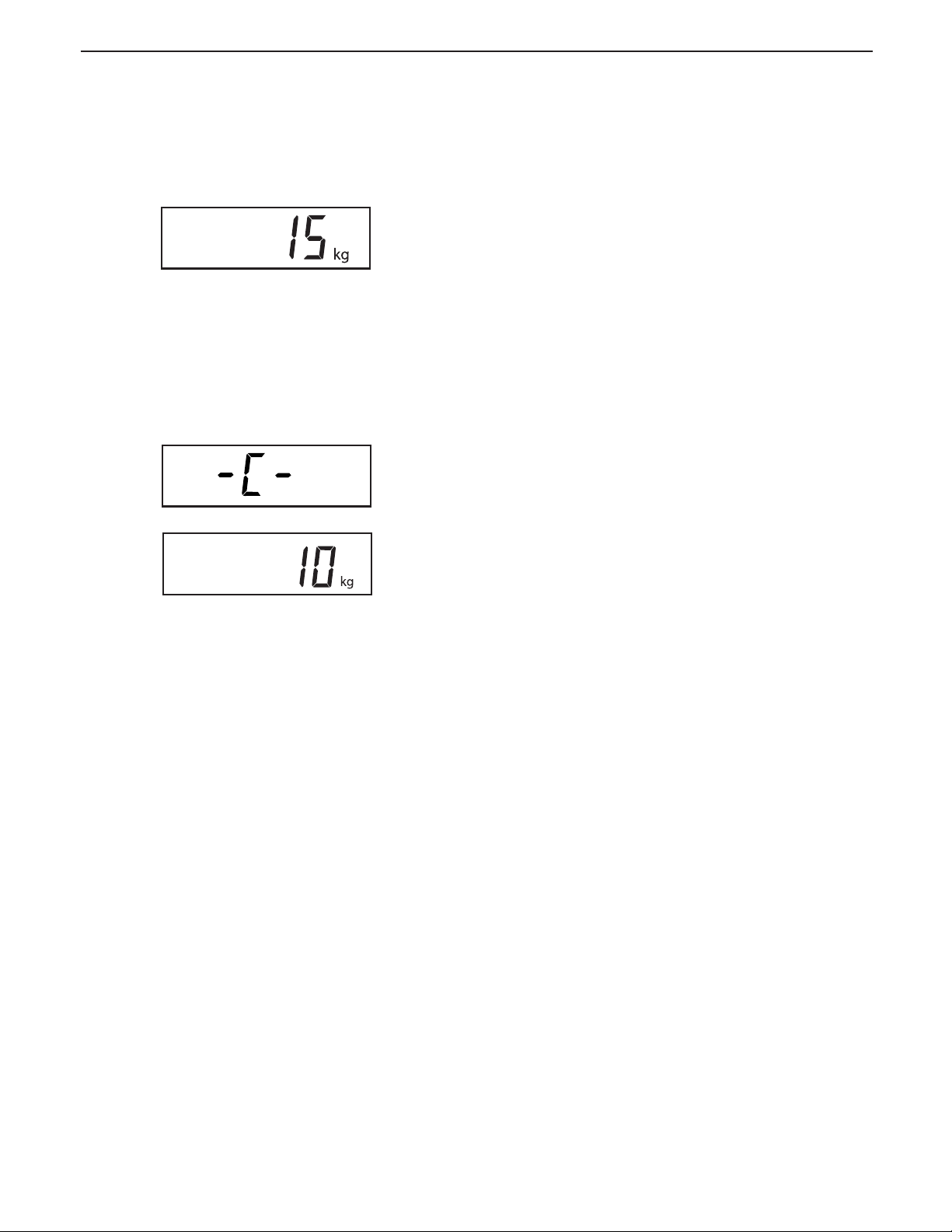

Press G/N/T/

MUST be stable during this period and is establishing a

zero point. After a few seconds, the requested weight

value is displayed.

MENU

button, -C- is displayed. The scale

EN-24

5. CALIBRATION AND SEALING (Cont.)

Trooper Scale

Procedure (Cont.)

SPAN CALIBRATION

Place the indicated mass on the platform. Keep the platform stable during this period. The sample illustration

indicates a 15kg scale.

If at this point you are uncertain of the process or if the

correct weights are not available, the calibration routine

can be aborted by pressing the PRINT/

by turning the scale off by pressing and holding the ON/

ZERO/

OFF

button.

MENU

Press G/N/T/

button, -C- is displayed while the

Scale stores the reading and then displays the weight of

the mass.

UNITS

button, or

*

If the calibration was successful, the calibration mass is

displayed and the calibration data is saved automati-

Gross

Brutto

cally. If unsuccessful, refer to the troubleshooting section.

Remove calibration masses from platform.

After the calibration routine is complete, check the scale

again to see if the scale has been accurately calibrated.

If so return to the lockout menu and restore the calibration software lock to “ON”:

NOTE: If the Scale is to be used for legal for trade applications, it must be calibrated and the LFT Lock Switch must

be set ON to lock out the menus. Refer to paragraph 5.1

for sealing for legal for trade use.

Loading...

Loading...