Page 1

Ranger RC Compact Scales

Instruction Manual

Page 2

@@@@@

Page 3

Table of contentsRanger RC

Table of contents

Page

1 Introduction .....................................................................................5

1.1 Safety instructions .............................................................................5

1.2 Description ......................................................................................6

1.3 Putting into operation ......................................................................10

2 Operation ......................................................................................12

2.1 Switching on and off .......................................................................12

2.2 Zeroing / Zero point correction ..........................................................12

2.3 Simple weighing .............................................................................12

2.4 Weighing with tare ..........................................................................13

2.5 Calling up the gross weight and tare value .........................................14

2.6 Displaying weight values with a higher resolution ...............................14

2.7 Displaying the capacity available ......................................................14

2.8 Dynamic weighing ..........................................................................14

2.9 Printing results ...............................................................................15

2.10 Switching scales .............................................................................15

2.11 Cleaning ........................................................................................16

3 Counting .......................................................................................17

3.1 Counting parts into a container .........................................................17

3.2 Counting parts out of a container ......................................................17

3.3 Counting with variable reference quantity ...........................................18

3.4 Counting with minimum accuracy ....................................................18

3.5 Reference optimization ....................................................................18

3.6 Counting with automatic reference determination ................................19

3.7 Counting with two scales .................................................................19

4 Settings in the menu ......................................................................21

4.1 Operating the menu ........................................................................21

4.2 Overview .......................................................................................23

4.3 Scale settings (SCALE) ....................................................................26

4.4 Application settings (APPLICATION) ..................................................28

4.5 Terminal settings (TERMINAL) ..........................................................30

4.6 Configuring interfaces (COMMUNICATION) .........................................31

4.7 Diagnosis and printing out of the menu settings (DIAGNOS) ................34

5 Interface description ......................................................................35

5.1 OHAUS interface commands ............................................................35

5.2 SICS interface commands ................................................................37

5.3 TOLEDO Continuous mode ..............................................................40

6 Event and error messages ..............................................................42

7 Technical data and accessories ......................................................44

7.1 Technical data ................................................................................44

7.

2 Accessories ....................................................................................49

3

Page 4

Table

of contents

Ranger RC

8 Appendix ...................................................................................... 50

8.1 Information for certified scales in EC countries ................................... 50

2 Safety checks ................................................................................. 50

8.

8.3 Table of Geo Values ........................................................................51

8.4 Sample protocols ...........................................................................54

9 Index ............................................................................................55

4

Page 5

1 Introduction

1.1 Safety instructions

IntroductionRanger RC

CAUTION

Do

Ou

DANGER!

Electric shock hazard!

DANGER!

Electric shock hazard if the mains cable is damaged!

CAUTION!

On

!

not use Ranger RC in hazardous areas!

r product range includes special devices for hazardous areas.

Always pull out the mains plug before any work on the device.

Check the mains cable for damage regularly and replace it immediately if it is damaged.

On the rear side of the device, maintain a clearance of at least 3 cm in order to

prevent the mains cable bending too much.

no account open the device!

warranty is void if this stipulation is ignored. The device may only be opened by

The

authorized persons.

Call OHAUS Service.

5

Page 6

troduction

In

Ranger RC

CAUTION!

Handle the compact scale with care.

scale is a precision instrument.

The

When the weighing pan has been removed, never clean the area under the load

plate holder with a solid object!

Do not put excessive loads on the scale.

Avoid banging the weighing pan.

Disposal

Observe the valid environmental regulations when disposing of the scale.

If the device has a rechargeable battery:

The

battery contains heavy metals and therefore must not be disposed of with normal

waste.

Observe the local regulations for disposing of environmentally hazardous materials

.

e Use with foodstuffs

Not

Parts

coming into contact with foodstuffs have smooth surfaces and are easy to clean.

The ma

terials used do not splinter and are free of harmful substances.

With foodstuffs, it is recommended to use the supplied protective cover.

Clean the protective cover regularly and carefully.

Replace damaged or very dirty protective cover immediately.

1.2 Description

This user manual applies to the following types of compact scales:

• Compact scale RC..S with strain gauge weighing cell

• Compact scale RC..M with Monobloc

The compact scales are available in a small and large size in various capacities and

resolution

The

rech

One of the following options can also be ordered:

s.

power supply is carried out via a built-in power supply device, an internal

argeable battery with an external mains adapter or an external battery.

• Additional interface RS232 or RS485

• Ethernet interface

• USB interface

• Digital I/O

• Analog second scale interface

6

Page 7

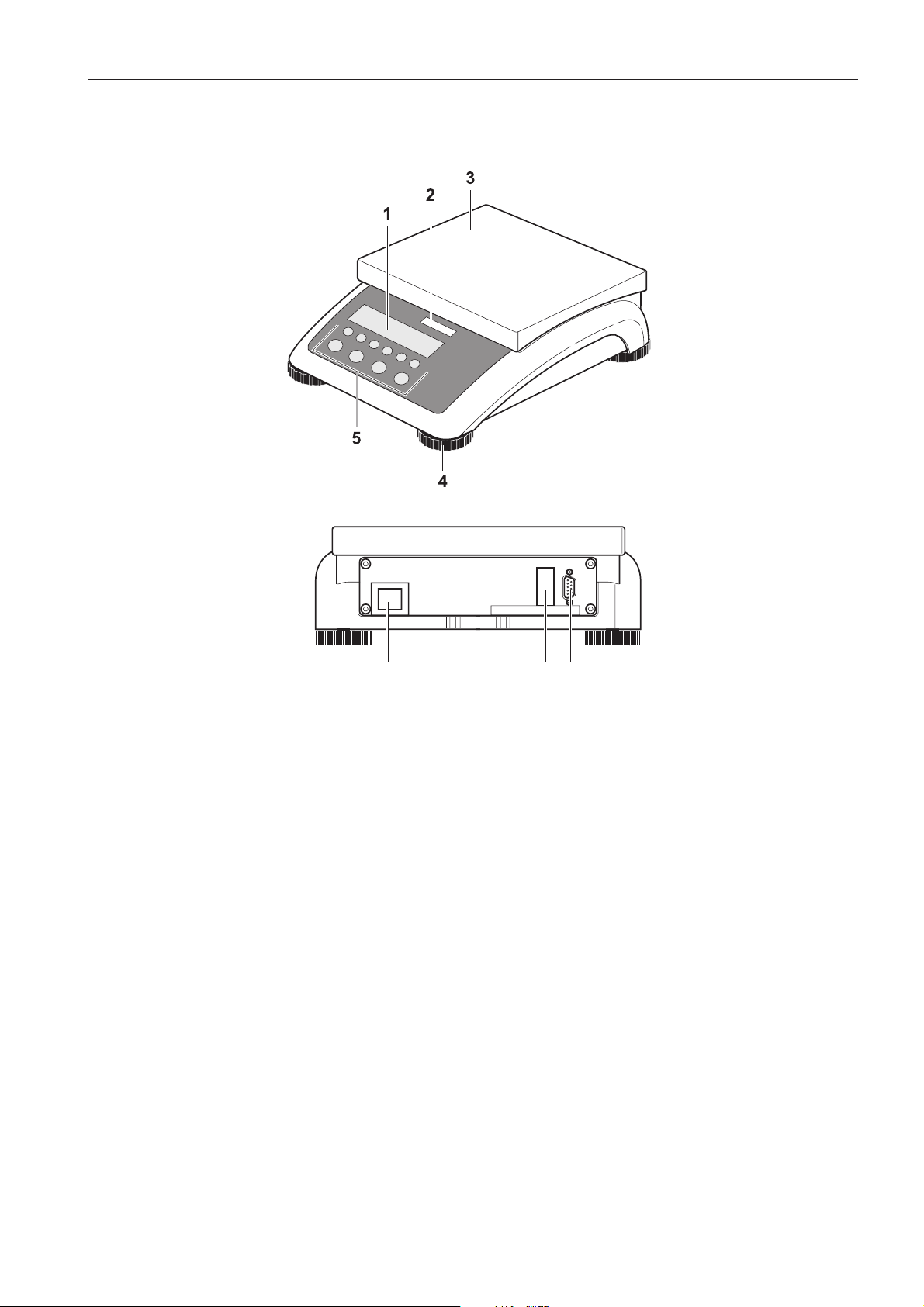

1.2.1 Overview

1 Display

2 Scale specifications

3 Load plate

4 Adjustable foot

5 Keys

IntroductionRanger RC

1 Power supply

connection

2 Optional interface

3 RS232 interface

321

7

Page 8

troduction

In

Ranger RC

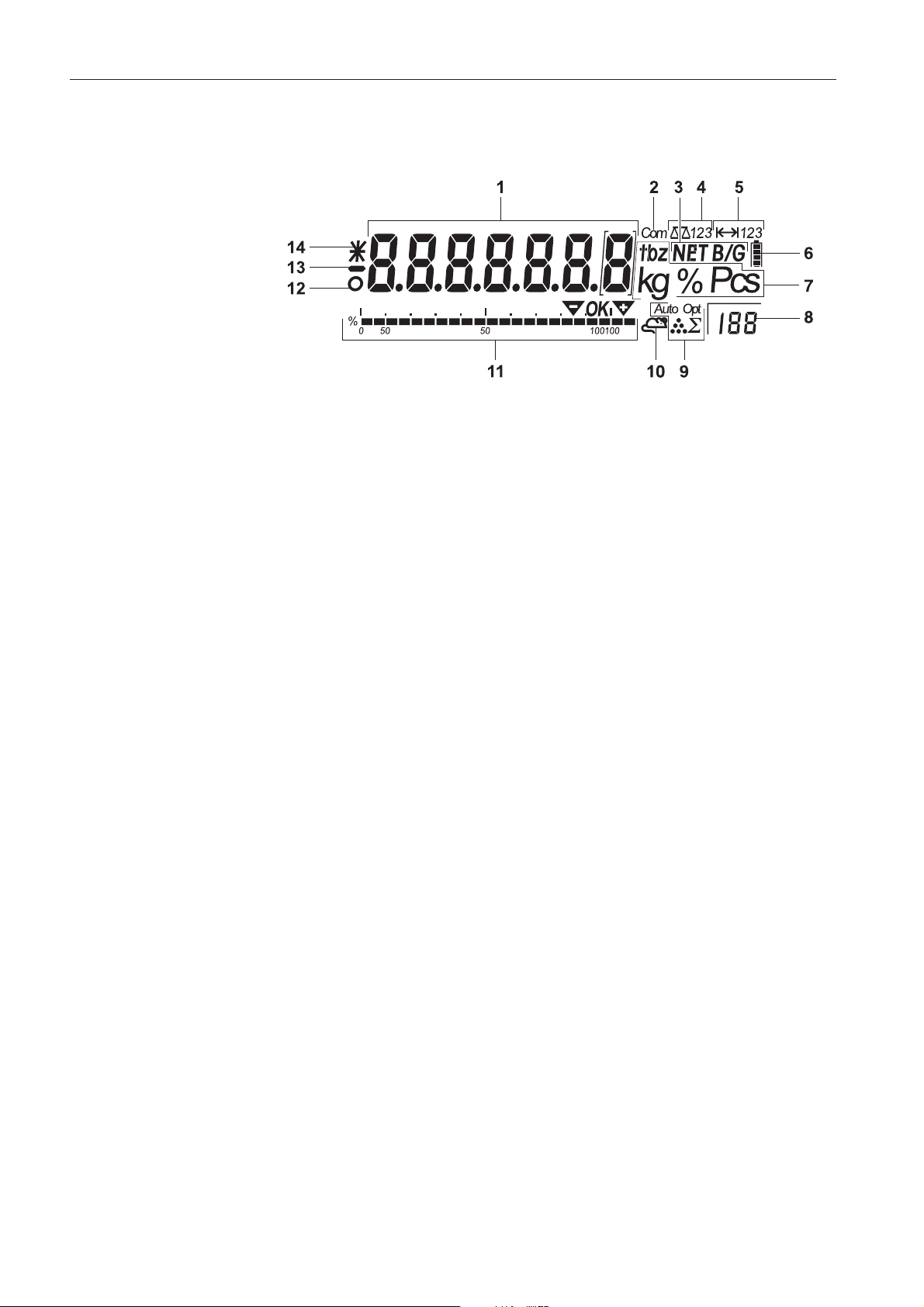

1.2.2 Display

1 7-segment display, 7 digits, with decimal point

2 Active interface

3 Symbol for displaying gross and net values

4 Active scale

5 Weighing range display

6 Battery charge level; only present on scales with a battery

7 Weight units

8 Selected reference quantity

9 Symbols for optimizing the average piece weight

10 Symbol for dynamic weighing

11 Graphic display of the weighing range

12 Stability monitor (goes out when a stable weight value is reached)

13 Sign

14 Identification for changed or calculated weight values, e.g. higher resolution,

minimum weight not reached

8

Page 9

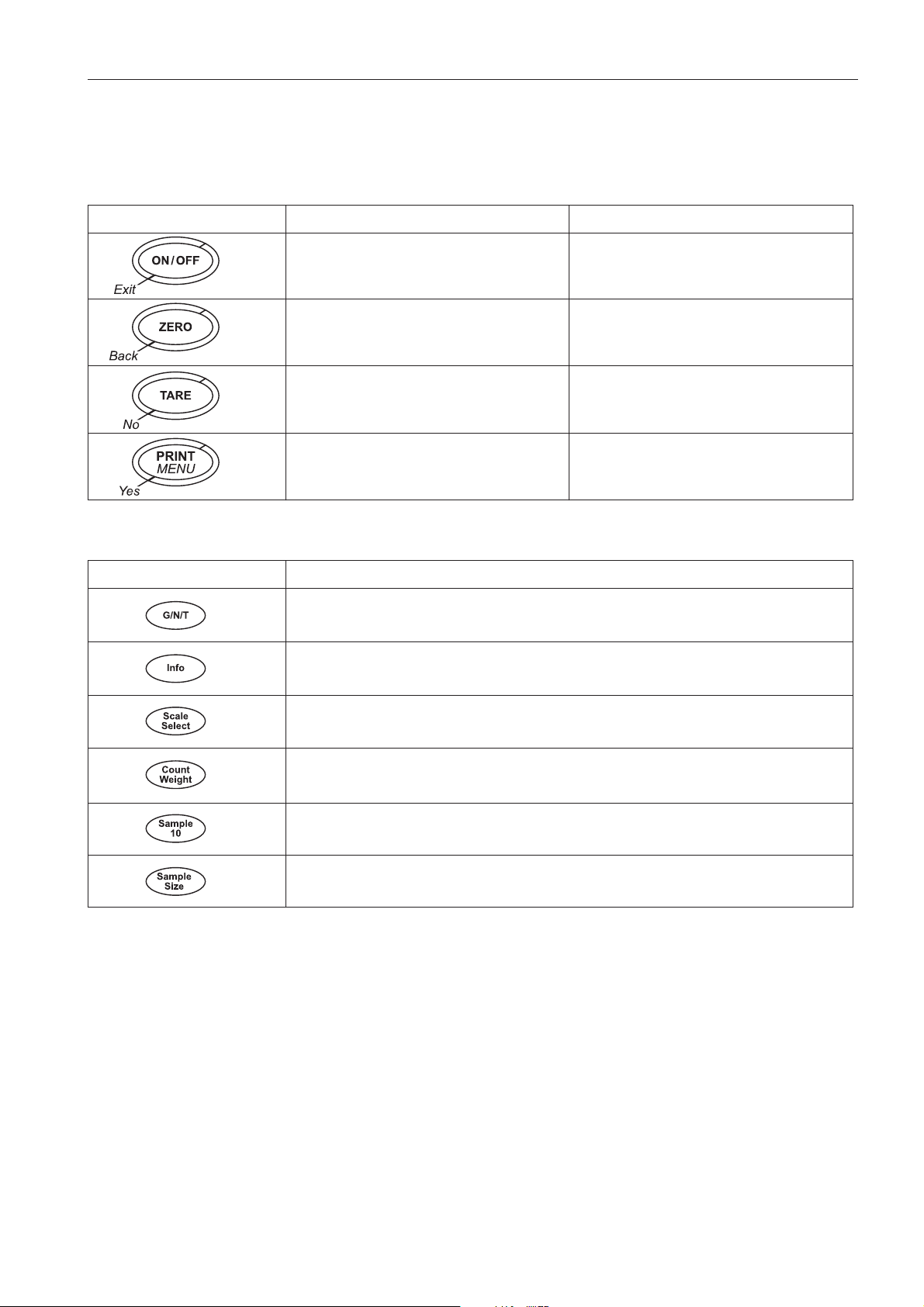

1.2.3 Keypad

Main

functions

Ke

y Function in operating mode Function in the menu

Switching device on / off, abort To the last menu item –End-

Setting scale to zero Scrolling back

Taring scale Scrolling forward

IntroductionRanger RC

Transfer

key press: Calling up menu

Long

Additional functions

Key Function

Switching between gross and net weight; displaying tare specification

Calling up additional information, e.g. gross weight, average piece weight, higher

resolut

ion ...

Switching the scale

Switching between weight value and number of pieces

Determining

Determining

key

Activating menu item

Accepting selected setting

average piece weight from 10 pieces

average piece weight from any number of pieces

9

Page 10

troduction

In

1.3 Putting into operation

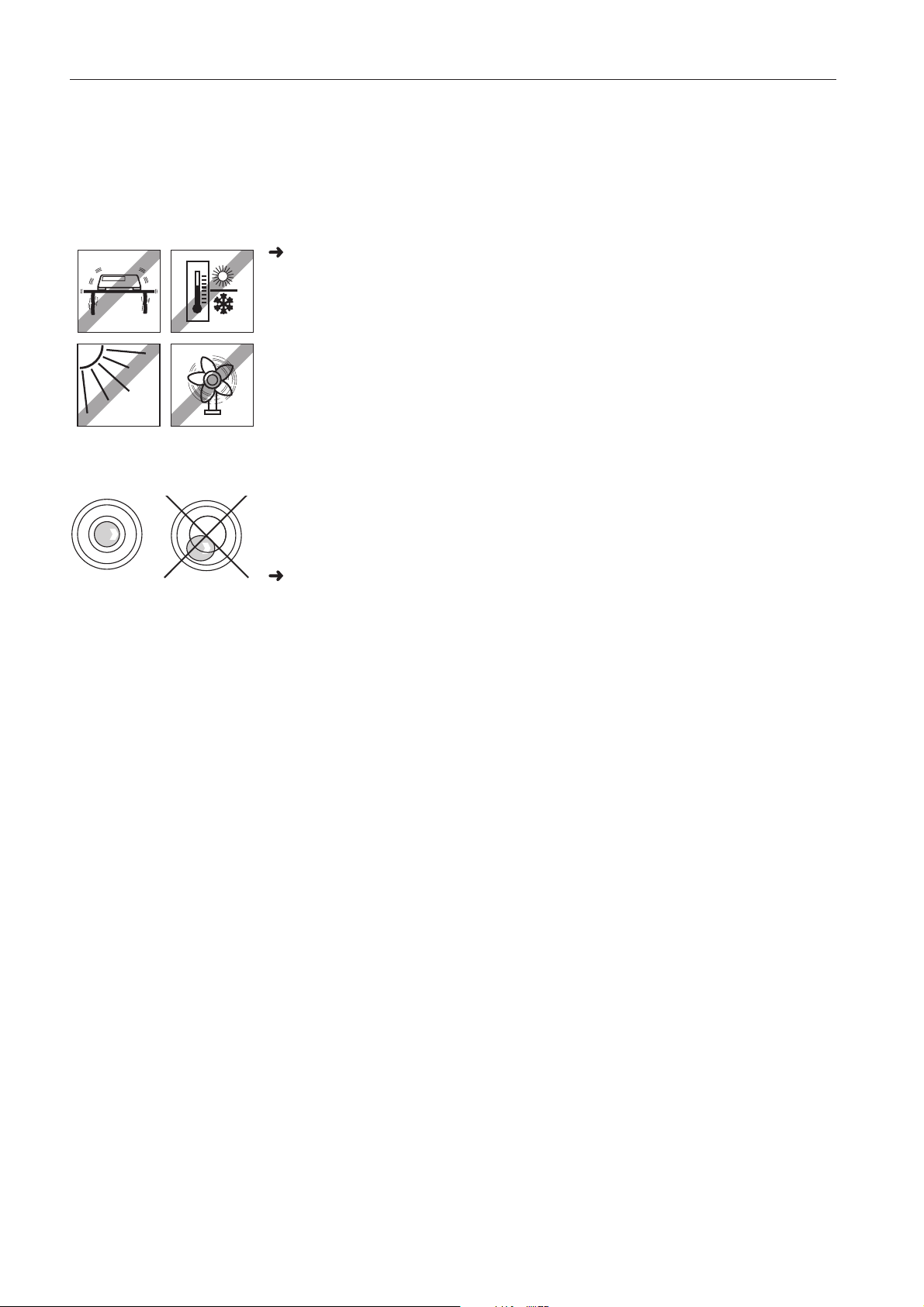

1.3.1 Selecting or changing the location

The correct location is crucial to the accuracy of the weighing results!

Select a stable, vibration-free and if possible a horizontal location.

ound must be able to safely bear the weight of the fully loaded scale.

The gr

Observe the following environmental conditions:

• No direct sunlight

• No strong drafts

• No excessive temperature fluctuations

Aligning the scale

Onl

y scales that have been aligned precisely horizontally provide accurate weighing

re

sults. The certified scales have a spirit level to simplify alignment.

Ranger RC

Major geographical

location

changes

Turn the adjustable feet of the scale until the spirit level’s air bubble is inside the

circle.

inner

The manufacturer adjusts each scale to the local gravity conditions (GEO value). In

the event of major geographical location changes, this setting must be adjusted by a

rvice technician. Certified scales must also be recertified observing the national cer-

se

cation regulations. These steps are not necessary for scales with an internal cali-

tifi

br

ation weight.

10

Page 11

1.3.2 Connecting the power supply

CAUTION!

Before connecting the scale to the mains, check whether the voltage value printed on

rating plate corresponds with the local mains voltage.

the

Never connect the device if the voltage value printed on the rating plate is different

local mains voltage.

to the

Plug the mains plug into the socket.

After connection, the device performs a self-test. When the zero display appears,

the

device is ready to weigh.

Calibrate the device in order to obtain the greatest possible precision, see

Sectio

n 4.3.2.

e Partially certified scales (scales with first-level certification) must be certified by an

Not

authorised body or by the OHAUS Service.

Call OHAUS Service.

IntroductionRanger RC

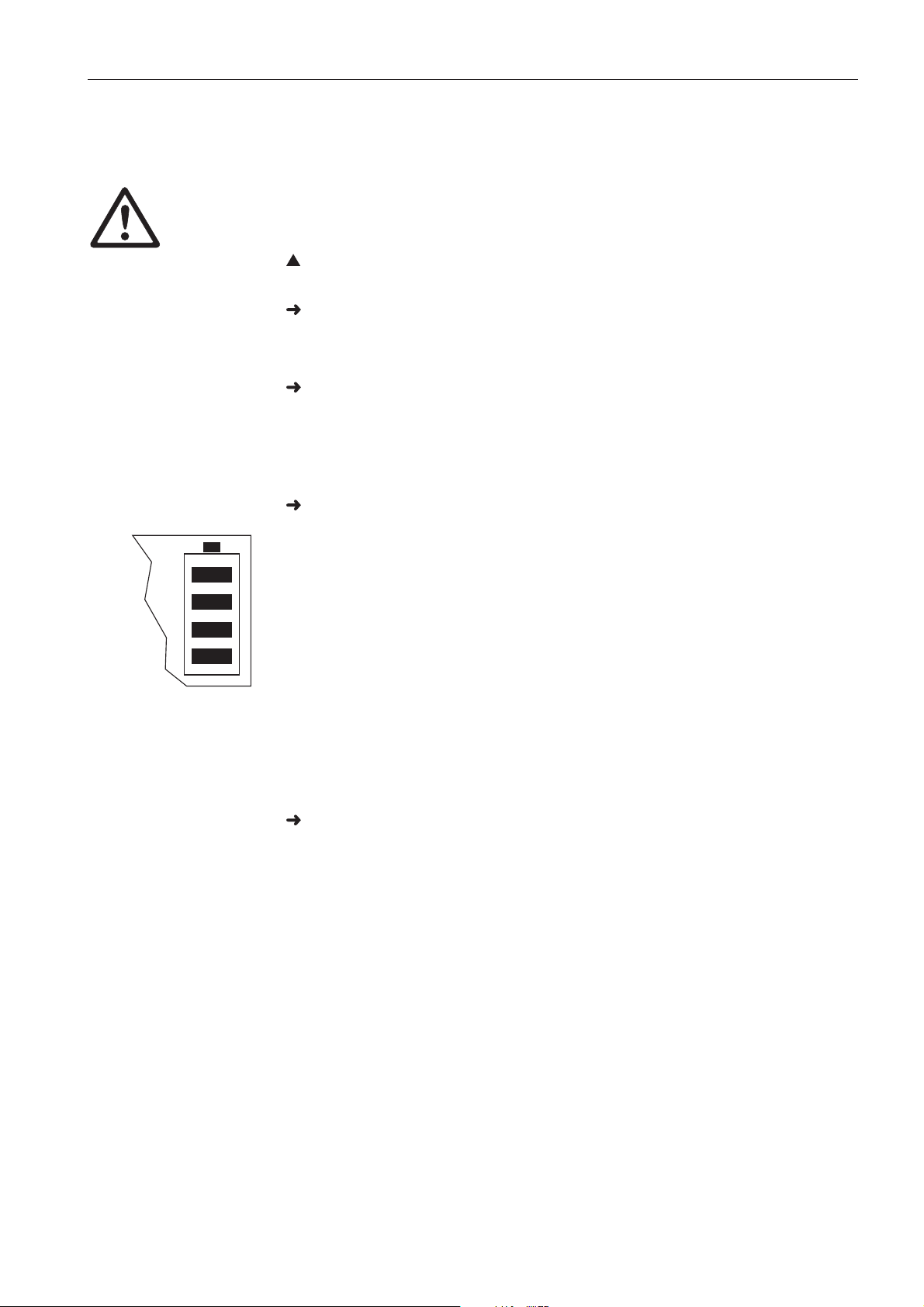

Scales with a built-in battery can work independently from the mains for approximately 30 hours in normal operation. A prerequisite for this is that the background

lighting is switched off and that no peripheral devices are connected.

The device automatically switches to battery operation as soon as the mains supply

is

interrupted. When the mains supply is restored, the device automatically switches

back to mains operation.

The

battery symbol indicates the present charging level of the battery. 1 segment cor-

res

ponds to approx. 25 % capacity. When the symbol flashes the battery must be

rged (min. 4 hours). The charging period is extended if work is continued during

cha

rging. The battery is protected against overcharging.

cha

e The battery’s charging capacity can be reduced under continuous mains operation.

Not

To maintain the charging capacity, after a maximum of 4 weeks discharge the bat-

completely before recharging it.

tery

11

Page 12

Operation

2 Operation

2.1 Switching on and off

Switching on Press ON/OFF.

Ranger RC

The scale conducts a display test. When the weight display appears, the scale is

dy to weigh.

rea

Switching

off Press ON/OFF.

Before

the display goes out, -OFF- appears briefly.

2.2 Zeroing / Zero point correction

Zeroing corrects the influence of slight changes on the load plate.

Manual 1. Unload scale.

2. Press ZERO.

The zero display appears.

Automatic In the case of scales that cannot be certified, the automatic zero point correction can

be deactivated in the menu or the amount can be changed.

As standard, the zero point of the scale is automatically corrected when the scale is

unloaded.

2.3 Simple weighing

1. Place weighing sample on scale.

2. Wait until the stability monitor goes out.

12

3. Read weighing result.

Page 13

2.4 Weighing with tare

2.4.1 Taring

Place the empty container on the scale and press TARE.

The zero display and the symbol NET appear.

The tare weight remains saved until it is cleared.

2.4.2 Clearing the tare

Unload scale and press TARE.

The symbol NET goes out, the zero display appears.

If A.CL-tr is activated in the menu, the tare weight is automatically cleared as soon

as the scale is unloaded.

.3 Automatic taring

2.4

Pr

erequisite

OperationRanger RC

A-tArE is activated in the menu, the symbol T flashes in the display.

.4 Chain tare

2.4

Pr

The

With

aced between individual layers in a container.

pl

1. Place the first container or packaging material on the scale and press TARE.

2. Weigh the weighing sample and read/print out the result.

3. Place the second container or packaging material on the scale and press TARE

Place the container or packaging material on the scale.

The packaging weight is automatically saved as the tare weight, the zero display

and the symbol NET appear.

erequisite

tare function CHAIn.tr is activated in the menu.

this function it is possible to tare several times if, for example, cardboard is

The packaging weight is automatically saved as the tare weight, the zero display

and the symbol NET appear.

again.

The total weight on the scale is saved as the new tare weight. The zero display

appears.

4. Weigh the weighing sample in the second container and read/print the result.

5. Repeat the last two steps for other containers.

13

Page 14

Operation

2.5 Calling up the gross weight and tare value

1. Press G/N/T.

The gross weight is displayed for 2 seconds.

2. Press G/N/T again while the gross weight is displayed.

tare value is displayed. After a few seconds, the scale changes back to the net

The

wei

ght display.

2.6 Displaying weight values with a higher resolution

Press Info.

The current weight value is displayed for 2 seconds in a higher resolution. The

scale then changes back to the normal resolution.

2.7 Displaying the capacity available

The scale has a graphic display of the scale capacity available. The bar indicates how

ny per cent of the scale capacity is already occupied and what capacity is still

ma

available. In the example, approx. 65 % of the scale capacity is occupied.

Ranger RC

2.8 Dynamic weighing

With the dynamic weighing function, it is possible to weigh restless weighing samples

such

pl

With

ations

manual start Prerequisite

With

AVErAGE -> MAnuAL is selected in the menu.

The

1. Place the weighing sample on the scale and wait until it has stabilized.

2. Press PRINT to start dynamic weighing.

3. Unload the scale to be able to start a new dynamic weighing operation.

as live animals. If this function is activated, the symbol appears in the dis-

ay.

dynamic weighing, the scale calculates the mean value from 56 weighing oper-

within 4 seconds.

weighing sample must be heavier than 5 scale divisions.

During dynamic weighing, horizontal segments appear in the display, and the

dynamic result

is then displayed with the symbol *.

14

Page 15

With automatic start Prerequisite

AVErAGE -> AUtO is selected in the menu.

weighing sample must be heavier than 5 scale divisions.

The

1. Place the weighing sample on the scale.

The scale starts the dynamic weighing automatically.

During dynamic weighing, horizontal segments appear in the display, and the

dynamic result

2. Unload the scale to be able to perform a new dynamic weighing operation.

2.9 Printing results

If a printer or computer is connected to the scale, the weighing results can be printed

or sent to a computer.

out

Press PRINT.

The display contents are printed out and transferred to the computer. See

Sect

ion 8.4 for sample protocols.

OperationRanger RC

is then displayed with the symbol *.

2.10 Switching scales

If a second scale or a weighing platform is connected, e. g. via the optional analog

cond scale interface, the currently active scale is shown in the display.

se

The

second scale can be operated in exactly the same way as the first scale.

Press Scale Select.

The d

isplay changes from one scale to the other.

15

Page 16

Operation

2.11 Cleaning

CAUTION!

Electric shock hazard!

Before cleaning with a damp cloth, pull out the mains plug to disconnect the unit

from

the power supply.

CAUTION!

When the weighing pan has been removed, never clean the area under the load plate

holder with a solid objec

This could damage the weighing cell.

Other cleaning information:

• Use damp cloths.

• Do not use any acids, alkalis or strong solvents.

Ranger RC

t!

• Do not clean using a high-pressure cleaning unit or under running water.

• If very dirty, remove the weighing pan, protective cover (if present) and adjustable

and clean these items separately.

feet

• Follow all the relevant instructions regarding cleaning intervals and permissible

cleaning

agents.

16

Page 17

3 Counting

The Ranger RC compact scales have additional functions for piece counting.

The

relevant settings in the menu are described in Section 4.4.1.

3.1 Counting parts into a container

1. Place the empty container on the scale and press TARE.

The container is tared and the zero display appears.

2. Place 10 reference parts on the scale and press Sample 10.

-or-

Place the number of pieces displayed above the key Sample Size on the scale

and

press Sample Size.

The scale determines the average piece weight and then shows the number of

ces.

pie

CountingRanger RC

3. Add more parts to the container until the required number of pieces is reached.

e

Not

• The average piece weight remains saved in the factory setting until a new average

pie

ce weight is determined.

• With Count Weight it is possible to switch between the number of pieces and the

ght.

wei

• When the number of pieces is displayed, it is possible to display the average

weight with Info, i. e. the weight of a single reference part, for 2 seconds.

piece

• If A.CL-APW ON is set in the menu, the average piece weight is automatically

cleared

mine

• If ACCurCY ON is set in the menu, the accuracy achieved is briefly shown after

the

after each counting operation. The average piece weight must be deter-

d again for the next counting operation.

number of pieces is determined.

3.2 Counting parts out of a container

1. Place the full container on the scale and press TARE.

The

container is tared and the zero display appears.

2. Remove 10 reference parts and press Sample 10.

-or-

Remove the number of pieces displayed above the key Sample Size and press

Sample Size

The

scale determines the average piece weight and then shows the number of

pie

ces removed, together with a minus sign.

3. Remove more parts from the container until the required number of pieces is

reache

.

d.

17

Page 18

Counting

3.3 Counting with variable reference quantity

If VAr-SPL ON is set in the menu, it is possible to select from 5 preset reference

quantities

The rest of the counting process is as described earlier.

via Sample Size.

Press Sample Size as often as necessary until th e display above the key has

changed to the desired reference quantity.

3.4 Counting with minimum accuracy

The item Min.rEFW in the menu allows to preset a minimum accuracy of 97.5 %,

99.

0 % or 99.5 %. On the basis of this, the scale calculates the minimum reference

necessary to reach the defined accuracy.

weight

1. Place the reference parts on the scale and press Sample 10 or Sample Size.

2. If the average piece weight is not sufficient to ensure the desired accuracy,

Ad

d x PCS appears.

3. Add the displayed number of pieces.

Ranger RC

The scale then automatically determines the average piece weight with the larger

reference

The rest of the counting process is as described earlier.

quantity.

3.5 Reference optimization

The greater the reference quantity, the more accurately the scale determines the

number

3.5

.1 Automatic reference optimization

rEF.OPt -> AUtO must be set in the menu for this. The symbol Auto Opt appears

in the display.

1. Place the reference parts on the scale and press Sample 10 or Sample Size.

2. Place additional reference parts, max. the same number as for the first reference

The

of pieces.

de

termination, on the scale.

The

scale automatically optimises the average piece weight with the larger number

of reference parts

rest of the counting process is as described earlier.

.

18

Not

e The reference optimization can be performed several times.

Page 19

3.6 Counting with automatic reference determination

Prerequisite

A-SMPL ON is set in the menu.

➜ Place the number of pieces displayed above the key Sample Size into the

container.

The

scale automatically determines the average piece weight and then shows the

quantity.

The

rest of the counting process is as described earlier.

3.7 Counting with two scales

For piece counting, it is possible to connect a second scale or weighing platform, e. g.

a floor scale for counting a large number of pieces via the optional analog second

interface.

scale

The

necessary settings for the application and interface parameters are described in

the Sections 4.

4.1, 4.6.1 and 4.6.4.

CountingRanger RC

1 Counting with a reference scale

3.7.

erequisite

Pr

The

connected second scale is configured as reference scale.

1. Place the reference parts on the reference scale and press Sample 10 or

.

ty is displayed.

ity.

Not

Sample Size

scale determines the average piece weight and changes to the display in

The

pie

ces (PCS).

2. Place the parts to be counted on the first scale.

The total quanti

• If tOtAL-Ct -> bULK is set in the menu, only the number of pieces on the bulk

e

scale is displayed.

• If tOtAL-Ct -> bOtH is set in the menu, the reference quantity is added to the

bulk quant

19

Page 20

Counting

3.7.2 Counting with a bulk scale

Pr

erequisite

connected second scale is configured as bulk scale.

The

1. Place the reference parts on the first scale and press Sample 10 or Sample Size.

The scale determines the average piece weight and changes to the display in

pie

ces (PCS).

2. Place the parts to be counted on the bulk scale.

The total quantity is displayed.

e

Not

• If tOtAL-Ct -> bULK is set in the menu, only the number of pieces on the bulk

scale is displayed on the bulk scale.

• If tOtAL-Ct -> bOtH is set in the menu, the reference quantity is added to the

bulk quantity.

.3 Counting with an auxiliary scale

3.7

Ranger RC

e This configuration allows counting of diverse parts, for example very small parts on

Not

scale and large parts on the other scale.

one

erequisite

Pr

The connected second scale is configured as an auxiliary scale. The scale doesn’t

chang

e automatically but only after pressing the Scale Select key.

1. Activate the appropriate scale.

2. Place the reference parts on this scale and press Sample 10 or Sample Size.

The scale determines the average piece weight and changes to the display in

pie

ces (PCS).

3. Place the parts to be counted on the same scale.

number of pieces is displayed.

The

20

Page 21

4 Settings in the menu

Settings can be changed and functions can be activated in the menu. This enables

adaptation to individual weighing requirements.

The menu consists of 6 main blocks containing various submenus on several levels.

4.1 Operating the menu

4.1.1 Calling up the menu and entering the password

The menu differentiates between 2 operating levels: Operator and Supervisor. The

Supervisor level can be protected by a password. When the device is delivered, both

levels are accessible without a password.

Operator menu 1. Press MENU and keep it pressed until COdE appears.

2. Press MENU again.

Settings in the menuRanger RC

The menu item tErMINL appears. Only the submenu dEVICE is accessible.

Supervisor menu 1. Press MENU and keep it pressed until COdE appears.

2. Enter the password and confirm with Yes.

The

first menu item SCALE appears.

e No supervisor password has been defined when the device is first delivered. Therefore

Not

respond

If a password has still not been entered after a few seconds, the scale returns to weighing mode.

Emergency password for Supervisor access to the menu

If

got

to the password inquiry with Menu when you call up the menu for the first time.

a password has been issued for Supervisor access to the menu and you have for-

ten it, you can still enter the menu:

Press ZERO 3 times and confirm with Yes.

21

Page 22

tings in the menu

Set

COdE

Ranger RC

4.1.2 Selecting and setting parameters

SCALE

CAL dISPLAY tArE

APPLIC

...

tErMIN

dEVICE ACCESS

PWr.OF

SLEEP

L COMMUNI

rESEt

F b.LIGHt

Scrolling on one level Scroll forward: Press No.

Scroll back: Press Back.

COM 1

MOdE

COM 2

PriNtE

dIAGNOS

...

r PArAMEt

rSt

.

COMX

End

Activating

accepting se

22

menu items/

lection

Exiting men

Press Yes.

u 1. Press Exit.

The

last menu item END appears.

2. Press Yes.

The

inquiry SAVE appears.

3. Confirm inquiry with Yes to save the settings and return to weighing mode.

-or-

Press No to discard changes and return to weighing mode.

Page 23

Settings in the menuRanger RC

4.2 Overview

Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 Page

SCALE SCALE1/SCALE2 26

CAL 26

APPLI

dISPLAY UNIt1

UN

It2 g, kg, oz, lb, t

rESOLU

UNt.rOLL

tArE A-tArE

AIn.tr ON, OFF

Ch

A.CL-tr

ZErO AZM OFF; 0.5 d; 1 d; 2 d; 5 d; 10 d 27

rEStArt

ON

/OFF

FILtEr VibrAt

OCESS UNIVEr, dOSING

Pr

StABILI FASt, StAndrd, PrECISE

FACt tEMP

Min.WEiG ON/OFF

rESEt SUrE? 28

C COUNt VAr-SPL

g, kg, oz, lb, t

ON

, OFF

ON

, OFF

ON

, OFF

LOW

, MEd, HIGH,

OFF, 1K

ON

, OFF

ON

, OFF

, 2K, 3K, 5K

26

27

27

27

28

28

28

tERMIN

L-qtY Sq1 ... Sq5

SP

Mi

n.reFW OFF, 97.5%, 99.0%, 99.5%

F OPt OFF, AUtO

rE

A-

SMPL

A.

CL-APW

AC

CurCY

tAL.Ct bULK, bOth

tO

ON

ON

ON

, OFF

, OFF

, OFF

AVErAGE OFF, AUtO, MAnuAL 29

rESEt SUrE? 29

L dEVICE SLEEP OFF, 1 min, 3 min, 5 min 30

r OFF YES, NO

PW

b.

LIGHt

ON, OFF

ACCESS SUPErVI 30

rESEt SUrE? 30

23

Page 24

tings in the menu

Set

Ranger RC

Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 Page

COMMUNI COM 1/COM 2 MOdE Print 31

A.Print

CONtINU

dIALOG

CONt.OLd

dIAL.OLd

dt-b GrOSS ON, OFF

tArE ON, OFF

nEt ON, OFF

dt-G GrOSS ON, OFF

tArE ON, OFF

nEt ON, OFF

COnt-Wt

COnt-Ct

2nd.dISP

rEF

bULK

AuXILIA

PriNtEr tEmPLat StdArd, tEMPLt1,

Lt2

tEMP

ASCi.Fm

t LINE.FMt MULtI

SINGLE

tH 1 ... 100

LENG

SEPA

rAt , ;...

LF 0 ... 9

Add

PA

rAMEt bAUd 300 ... 38400 32

PArit

Y 7 nonE, 8 nonE, 7 odd,

8 odd, 7 EVEN, 8 EVEN

H.SHAK

NEt.Add

E NO, XONXOFF, nEt 422,

485

nEt

r 0 ... 31

31

24

ChECSu

Vc

rS

t.COMx SUrE? 32

M

c

ON

ON

, OFF

, OFF

Page 25

Settings in the menuRanger RC

Level 1 Level 2 Level 3 Level 4 Level 5 Level 6 Page

COMMUNI OPtION EtH.NEt IP.AddrS, SUbNEt, GAtEWAY 32

USb USb tESt 32

dIAGNO

diGitAL IN 1 ... 4 OFF, ZErO, tArE,

ANALOG Mode rEF, bULK, AuXILIA,

dEF.PrN tEMPLt1/

tE

MPLt2

t, rEF 10, rEF n,

Prin

SCAL

E, Unit

T 1 ... 4 OFF, StAbLE, bEL.Min,

OU

AbV.

Min, UndErLd,

Ld, StAr

OVEr

bYPA

SS

E 1 ...

LIN

LINE 2

0

USEd, HEAdEr,

NOt.

SCAL

E.NO, GrOSS, tArE,

APW, rEF Ct, PCS,

nEt,

LN, CrLF, F FEEd

StAr

32

32

33

S tESt SC intErN/ExtErN 34

KboArd

dISPLAY

SNr

SNr2

LiSt

LiSt2

rESEt.AL SUrE?

25

Page 26

tings in the menu

Set

4.3 Scale settings (SCALE)

4.3.1 SCALE1/SCALE2 – Selecting scale

This menu item only appears if an analog second scale or a weighing platform is connected.

.2 CAL – calibration (adjustment)

4.3

This menu item is not available for certified scales without internal calibration weight.

In

ternal For scales with an internal calibration weight:

1. Unload scale.

2. Activate menu item CAL with Yes. The scale calibrates with the internal calibration weight. -Int CAL- appears in the display. After calibration is completed,

-don

E- appears briefly in the display, and the scale automatically returns to

wei

ghing mode.

External For scales without an internal calibration weight:

Ranger RC

1. Unload scale.

2. Activate menu item CAL with Yes. The scale determines the zero point.

- appears in the display. The calibration weight to be placed on the scale then

–0

in the display.

flashes

3. If necessary, change the weight value displayed with No.

4. Place the calibration weight on the scale and confirm with Yes.

scale calibrates with the calibration weight loaded. After calibration is com-

The

pleted, -donE

- appears briefly in the display, and the scale automatically returns

to weighing mode.

3 DISPLAY – weighing unit and display accuracy

4.3.

UNIt1 Select weighing unit 1: g, kg, oz, lb, t

2 Select weighing unit 2: g, kg, oz, lb, t

UNIt

rESOL

UNt.rO

U Select readability (resolution), model-dependent

LL When UNT.rOLL is switched on, the weight value can be displayed in all available

units and as pieces with Count Weight.

Note

s

• On certified scales, the weighing units oz and lb are displayed with the symbol *.

• On certified scales, resolutions that deviate from the scale definition are displayed

thout a weighing unit and with the symbol *.

wi

• On dual-range/dual interval scales, resolutions marked with |<–> 1/2| are

divided

up into 2 weighing ranges / intervals, e.g. 2 x 3000 d.

26

Page 27

4.3.4 TARE – tare function

Settings in the menuRanger RC

A-tAr

E Switching on/off automatic taring

CHAIn.tr Switching on/off chain tare

A.CL-tr Switching on/off automatic taring with automatic clearing of the tare weight when the

load

is removed from scale

4.3.

5 ZERO – automatic zero update

AZM On certified scales, this menu item does not appear.

Switching on/off automatic zero update and selecting zeroing range.

Possible settings: OFF; 0.

.6 RESTART – automatic saving of zero point and tare value

4.3

5 d; 1 d; 2 d; 5 d; 10 d

ON/OFF When the Restart function is activated, the last zero point and tare value are saved.

After switching off / on or after a power interruption, the device continues to work with

the

saved zero point and tare value.

4.3

.7 FILTER – adaptation to the ambient conditions and the weighing type

VIbrAt Adaptation to the ambient conditions

LOW

ME

HI

PrOCES

UN

dO

StAbIL

FA

St

Pr

• Very steady and stable environment. The scale works very quickly, but is very

sensitive to external influences.

d • Normal environment. The scale operates at medium speed.

GH • Restless environment. The scale works more slowly, but is insensitive to external

influenc

es.

S Adaptation to the weighing process

IVEr

SING

• Universal setting for all weighing samples and normal weighing goods

• Dispensing liquid or powdery weighing samples

I Adjusting the weighing speed

St

Andrd

ECISE

• The scale operates very fast.

• The scale operates at medium speed.

• The scale operates with the greatest possible reproducibility.

slower the scale works, the greater the reproducibility of the weighing results.

The

27

Page 28

tings in the menu

Set

4.3.8 FACT – automatic temperature-dependent adjustment

This menu item appears only on scales with an internal calibration weight.

TEM

P Defining the temperature difference for automatic calibration

F

OF

• Switching off automatic calibration in the case of a temperature difference

Ranger RC

/2K/3K/5K

1K

4.3

.9 MIN.WEIG – minimum weight

• Automatic calibration in the case of a temperature change of 1 K, 2 K, 3 K or 5 K

the last adjustment

since

This menu item appears only if the service technician has saved a minimum weight.

ON/OFF Switching minimum weight function on/off

If the weight on the scale falls below the stored minimum weight, an * appears on

the display in front of the weight indicator.

0 RESET – resetting scale settings to factory settings

4.3.1

SUrE? Confirmation inquiry

• Reset the scale settings to factory settings with Yes

• Do not reset scale settings with No

4.4 Application settings (APPLICATION)

4.4.1 COUNT – settings for counting

VAr-SPL Adaptation of the reference quantity

SPL-qt

Min.re

rEF.OP

28

ON

F

OF

Y Reference quantity

Sq

1 ... Sq5

FW Monitoring the minimum reference weight

OF

F

.5, 99.0,

97

.5

99

t Optimizing the average piece weight

F

OF

AU

tO • Automatic reference optimization

• The reference quantity can be changed in operating mode

• Counting only with defined reference quantities

• Define 5 fixed reference quantities

• No monitoring of the minimum reference weight

• Monitoring the minimum reference weight so that a counting accuracy of

5 %, 99.0 % or 99.5 % is achieved

97.

• No reference optimization

Page 29

Settings in the menuRanger RC

A-SMP

L Automatic determination of the average piece weight

ON

• After taring, the average piece weight is determined with the next weight placed

on the scale and the displayed reference quantity

OFF

• No automatic determination of the average piece weight

A.CL-APW Automatic clearing of the average piece weight

ON

• When the load is taken off the scale after a counting operation, the average piece

ht is automatically cleared. The next counting operation begins with deter-

weig

mining the average piece weight again.

OFF

• The average piece weight is maintained until a new average piece weight is deter-

mined

ACCurCY Displaying the counting accuracy

ON

• After the average piece weight is determined, the counting accuracy that can be

achie

ved is shown briefly in the display.

OFF • No counting accuracy display

tOtAl.

Ct Counting on two scales

LK

bU

bO

th • Display number of pieces for all parts on the bulk and the reference scale

• Display number of pieces for the parts on the bulk scale only

4.4.2 AVERAGE – determining the average weight for an unstable load

OFF Calculating average weight switched off

AUt

O Calculating average weight with automatic start of the weighing cycle

MAnuA

L Calculating average weight with manual start of the weighing cycle via PRINT

4.4

.3 RESET – resetting application settings to factory settings

SUrE? Confirmation inquiry

• Reset the application settings to factory settings with Yes

• Do not reset the application settings with No

29

Page 30

tings in the menu

Set

4.5 Terminal settings (TERMINAL)

4.5.1 DEVICE – Sleep mode, energy-saving mode and display backlighting

SLEE

P This menu item only appears on devices in mains operation.

When SLEEP is activated, the scale switches off display and backlighting after the

time period set when not in use. The display and backlighting are switched on again

at

the press of a key or if the weight changes.

Possible settings: OFF, 1 min, 3 min, 5 min

PWr OFF This menu item only appears on devices in battery operation.

When PWr OFF is activated, the device switches itself off automatically after

approx. 3 minutes when not in use.

b.LIGHt Switching the display backlighting on/off.

On scales with a battery, the background lighting switches itself off automatically if

e has been no activity on the scale for 5 seconds.

ther

Note This menu item is accessible without a Supervisor password.

Ranger RC

4.5

.2 ACCESS – password for Supervisor menu access

SUPErVI Password entry for Supervisor menu access

ENtER.C Request to enter password

Enter the password and confirm with Yes

rE

tYPE.C Request to repeat the password entry

Enter the password again and confirm with Yes

s

Note

.3 RESET – resetting terminal settings to the factory settings

4.5

• The password can consist of up to 4 characters.

• The PRINT key must not be part of the password. It is required for confirming

assword.

the p

• The ZERO key may only be used in combination with another key.

• If you enter an impermissible code or make a typing error in the repetition,

.Err. appears in the display.

COdE

SUrE? Confirmation inquiry

• Reset terminal settings to the factory settings with Yes

• Do not reset the terminal settings with No

30

Page 31

4.6 Configuring interfaces (COMMUNICATION)

4.6.1 COM1/COM2 -> MODE – operating mode of the serial interface

Prin

t Manual data output to the printer with PRINT

Settings in the menuRanger RC

A.Prin

CONtIN

dIALO

t Automatic output of stable results to the printer (e. g. for series weighing operations)

U Ongoing output of all weight values via the interface

G Bi-directional communication via OHAUS or MT-SICS commands, control of the

scale via PC

CONt.O

Ld As per CONtINU, see above, but with 2 fixed blanks in front of the unit (compatible

with Spider 1/2/3)

dIAL.O

Ld As per dIALOG, see above, but with 2 fixed blanks in front of the unit (compatible

with Spider 1/2/3)

dt-b DigiTOL-compatible format.

GROSS

tArE

nEt

• Transfer of the gross weight, identified with "G"

• Transfer of the tare weight

• Transfer of the net weight

dt-G As per dt-b, see above, gross weight identified with "G"

COnt-Wt TOLEDO Continuous mode

COnt-Ct TOLEDO Continuous mode, transfer of the number of pieces

2nd.dISP For connecting a second display (automatically activates the 5-V voltage supply at

)

Pin 9

rE

F Data transfer from the reference scale (automatic switchover)

K Data transfer from the quantity scale (automatic switchover)

bUL

AuXILI

A Data transfer from the reference or quantity scale (manual switchover)

.2 COM1/COM2 -> PRINTER – settings for protocol printout

4.6

is menu item only appears if the mode "Print" or "A.Print" is selected.

Th

tEmPLat Selecting protocol printout

dArd

St

tE

tE

ASCi.F

LI

LE

SE

Ad

mPLt1

mPLt2

mtT Selecting formats for the protocol printout

NE.Fmt

NGtH

PArAt

d LF

• Standard printout

• Printout in accordance with Template 1

• Printout in accordance with Template 2

• Line format: MULtI (multi-line) or SINGLE (single-line)

• Line length: 0 ... 100 characters, appears only with line format MULtI

• Separator: , ; . / \ _ and space; appears only with line format SINGLE

• Line feed: 0 ... 9

31

Page 32

tings in the menu

Set

4.6.3 COM1/COM2 -> PARAMET – communication parameter

bAU

d Selecting baud rate: 300, 600, 1200, 2400, 4800, 9600, 19200, 38400 baud

Ranger RC

PArit

H.SHAK

Y Selecting parity: 7 none, 8 none, 7 odd, 8 odd, 7 even, 8 even

E Selecting Handshake: NO, XONXOFF, nEt422, nEt485 (network operation

as

per RS485 standard via the optional RS422/RS485 interface, only for COM1)

NET.Addr Assigning network address: 0 ... 31, only for NET 485

ChECSuM Activating checksum byte (appears only in TOLEDO Continuous mode)

Vcc Switching 5V voltage, e.g. for a bar code reader, on / off

.4 COM1/COM2 -> RESET COM1/RESET COM2 – resetting serial interface to factory

4.6

set

tings

SUrE? Confirmation inquiry

• Reset interface settings to factory settings with Yes

• Do not reset the interface settings with No

.5 OPTION – configuring options

4.6

If no option is installed or is not yet configured, N.A. appears in the display.

EtH.NEt Configuration of the Ethernet interface

IP

.AddrS • Enter IP address

SU

BNEt • Enter Subnet address

GA

tEWAY • Enter Gateway address

US

b Configuration of the USB interface

b TEST

US

• Test of the USB interface. After the test has been passed, rEAdY appears in the

display.

diGitA

L Configuration of the digital inputs/outputs

1 ... 4 Configuring inputs 1 ... 4

IN

OF

F

O

ZEr

E

tAr

PriN

rEF 1

rEF

SCAL

t

UNI

t

0

n

E

• Input not assigned

• ZERO Key

• TARE Key

• PRINT Key

• Sample 10 Key

• Sample Size Key

• Scale Select Key

• Count Weight Key

32

Page 33

OU

T 1 ... 4

Settings in the menuRanger RC

• Configuring outputs 1 ... 4

OFF

StAbLE

bEL.MIN

AbV.MIN

UNdErLd

OVErLd

StAr

• Output not assigned

• Stable weight value

• Minimum weight not reached

• Minimum weight reached or exceeded

• Insufficient load

• Overload

• Changed/calculated value

ANALOG Configuration of the analog second scale interface

Mode Operating mode of the second scale

rEF

bULK

AuXILIA

• Second scale can only be used to determine the average piece weight

• Second scale can only be used as bulk scale

• No difference between reference and bulk scale, all functions available on the

scale selected

BYPASS

• Second scale interface not assigned

4.6.6 DEF.PRN – configuring templates

tEMPLt1/tEMPLt2 Selecting Template 1 or Template 2

LINE 1 ... 20 Select line

NOt.U

HEAdE

SEd

• Line not used

r • Line as header. The contents of the header must be defined via an interface com-

mand,

SCALE

GROS

tAr

nE

AP

rEF C

PC

StARL

CrL

F FEE

.NO • Scale number

S • Gross weight

E • Tare weight

t • Net weight

W • Average piece weight

t • Reference quantity

S • Pieces

N • Line with ***

F • Line feed (blank line)

d • Page feed

see Section 5.1.

33

Page 34

tings in the menu

Set

tESt SC

Internal Testing scale with internal calibration weight

External Testing scale with external calibration weight

Ranger RC

4.7 Diagnosis and printing out of the menu settings (DIAGNOS)

• -Int CAL- appears in the display during the test.

• After completion of the test, ideally *d=0.0g briefly appears in the display, after

ch the scale changes to the next menu item KboArd.

whi

1. The scale checks the zero point. -0- appears in the display. The test weight

flashes

in the display.

2. If necessary, change the weight value displayed with No.

3. Put the calibration weight on the scale and confirm with Yes.

4. The scale checks the calibration weight put on them.

5. After the test is completed, the deviation from the last calibration briefly appears

the display, ideally *d=0.0g, after which the scale changes to the next menu

in

item KboArd.

KboArd Keyboard test

PUSH 1 ... 10

• First press the large keys on the bottom row in order:

ON/OFF, ZERO, TARE, PRINT

• Then press the smaller keys in the top row:

G/N/T

, Info, Scale Select, Count Weight, Sample 10, Sample Size

the key works, the scale changes to the next key.

If

Note

You cannot abort the keyboard test!

you have selected the menu item KboArd, you must press all keys.

If

dISPLA

SN

SNr

LiS

LiSt

rESEt.

Y Display test: The scale displays all functioning segments

r Display of the serial number

2 Display of the serial number of scale 2. This menu item only appears if an analog

cond scale is connected.

se

t Printout of a list of all menu settings

2 Printout of a list of all menu settings of scale 2. This menu item only appears if an

second scale is connected.

analog

AL Resetting all menu settings to the factory settings

rE? Confirmation inquiry

SU

34

• Reset all menu settings to the factory settings with Yes

• Do not reset the menu settings with No

Page 35

5 Interface description

5.1 OHAUS interface commands

The Ranger RC scales support the OHAUS command set. With OHAUS commands,

it

is possible to configure, query and operate the scale from a PC.

.1 Available OHAUS commands

5.1

Interface descriptionRanger RC

Comm

0S Set to print weight value immediately (stable or unstable) after P command

1S Set to print stable weight value after P command

SA Set to print stable weight value automatically

CA Set to print weight value continuosly

xA Set to print weight value at specified interval, where x = 1 to 3600 (seconds)

P Print displayed weight value

Z Zero the scale

T Tare the scale

xT Define the Preset Tare, where x = tare weight in grams

H x

and "y" = header text in quotes (up to 24 characters).

PSI Change to MT-SICS command set

POH Return to OHAUS command set

NOTE: All commands must be followed by a carriage return, line feed <CR><LF>

and Meaning

"y" Define the Header H<space>x<space>"y", where x = 1, 2, 3, 4, 5 (line number)

.2 Requirements for communication between scale and PC

5.1

• The scale must be connected to the RS232, RS485, USB or Ethernet interface of a

with a suitable cable.

PC

• The interface of the scale must be set to "Dialog" mode, see Section 4.6.1.

• A terminal progam must be available on the PC, e.g. HyperTerminal.

• The communication parameters baud rate and parity must be set in the terminal

program and on the scale to the same values, see Section 4.6.3.

5.1.3 Notes on network operation via the optional interface RS422/485

to 32 scales can be networked with the optional RS422/485 interface. In network

Up

operation,

sent

the scales must be addressed from the computer before commands can be

and weighing results received.

35

Page 36

5.1.4 Output format

Response to the P command

Field

1 2 3 4 5 6 7 8 9 10

POL SP SP W W W W W W W SP UN UN SP ST SP N N N CR LF

Field 1: POL = polarity, space if positive, - if negative

Fields 2, 4, 6, 8: SP = space

Field 3:

Field 5: UN =

W = weight up to 6 digits plus the decimal point

unit of measure 1 or 2 characters

Field 7: ST = stability status, space when stable, ? when unstable,

Field 9: N =

Field 10: CR

NET or B/G

LF = carriage return, line feed

Response t

o the Print key

Line Field

1 2 3

1

S C A L E : SP SC CR LF

1 2 3 4 5 6 7 8 9

2

G SP SP SP SP SP SP SP SP SP SP SP SP SP POL W W W W W W W SP UN UN SP ST CR LF

3

T SP SP SP SP SP SP SP SP SP SP SP SP SP POL W W W W W W W SP UN UN SP CR LF

4

N SP SP SP SP SP SP SP SP SP SP SP SP SP POL W W W W W W W SP UN UN SP ST CR LF

Ranger RCInterface description

Line 1

Field 1: SCALE:SP = heading and space

Field 2: SC =

Field 3: CR LF = carriage return, line feed

Lines 2, 3, 4

Field 1: G =

Field 2: SP =

Field 3: POL = pola

scale identifier, 1 = scale 1, 2 = scale 2

Gross, T = Tare, N = Net

space, up to 13

rity, space if positive, - if negative

Field 4: W = weight, up to 6 digits plus the decimal point

Field 5, 7: SP = space

Field 6: UN =

unit of measure, 1 or 2 characters

Field 8: ST = stability status, space when stable, ? when unstable, does not apply to Line 3

Field 9: CR LF =:carriage return, line feed

36

Page 37

5.2 SICS interface commands

The Ranger RC compact scales support the command set MT-SICS (METTLER

TOLEDO

co

into

To use the MT-SICS commands, first send the OHAUS command PSI. To return to the

OHAUS command set, send the OHAUS command POH.

5.2

.1 Available SICS commands

and Meaning

Comm

LEVEL 0 @ Reset the scale

I0 Inquiry of all available SICS commands

I1 Inquiry of SICS level and SICS versions

I2 Inquiry of scale data

I3 Inquiry of scale software version

Standard Interface Command Set). With SICS commands, it is possible to

nfigure, query and operate the scales from a PC. SICS commands are divided up

various levels.

Interface descriptionRanger RC

I4 Inquiry of serial number

S Send stable weight value

SI Send weight value immediately

R Send weight value repeatedly

SI

Z Zero the scale

ZI Zero immediately

LEVEL 1 D Write text into display

DW Weight display

K Keyboard check

SR Send and repeat stable weight value

T Tare

TA Tare value

TA

C Clear tare

TI Tare immediately

LEVEL 2 C2 Calibrate with the external calibration weight

C3 Calibrate with the internal calibration weight

I1

0 Inquire or set scale ID

1 Inquiry of scale type

I1

P10

0 Print out on the printer

37

Page 38

Comm

and Meaning

P101 Print out stable weight value

P102 Print out current weight value immediately

PWR Power On/Off

SIRU Send weight value in the current unit immediately and repeat

SIU Send weight value in the current unit immediately

SNR Send stable weight value and repeat after every weight change

SNRU Send stable weight value in the current unit and repeat after every weight change

SRU Send weight value in the current unit and repeat

ST After pressing the Transfer key, send the stable weight value

SU Send stable weight value in the current unit

TST2 Start test function with external weight

TST3 Start test function with internal weight

LEVEL 3 PW Average piece weight

Ranger RCInterface description

LEVEL SPECIAL I31 Header for the printout

ICP Send configuration of the printout

LST Send menu settings

M01 Weighing mode

M02 Stability setting

M03 Autozero function

9 Send calibration weight

M1

M2

1 Inquire/set weight unit

P Print text

P13

0 Weight value, unit and price

S Number of pieces

PC

PR

N Print out at every printer interface

F Average piece weight

RE

RS

T Restart

R Send weight value immediately and repeat quickly

SFI

SI

H Send weight value immediately in high resolution

U Switch weight unit

SW

38

SX Send stable data record

I Send data record immediately

SX

SX

IR Send data record immediately and repeat

U Switch weight unit

Page 39

5.2.2 Requirements for communication between scale and PC

• The scale must be connected to the RS232, RS485, USB or Ethernet interface of a

with a suitable cable.

PC

• The interface of the scale must be set to "Dialog" mode, see Section 4.6.1.

• A terminal progam must be available on the PC, e.g. HyperTerminal.

• The communication parameters baud rate and parity must be set in the terminal

program and on the scale to the same values, see Section 4.6.3.

5.2.3 Notes on network operation via the optional interface RS422/485

to 32 scales can be networked with the optional RS422/485 interface. In network

Up

operation,

sent

the scales must be addressed from the computer before commands can be

and weighing results received.

Interface descriptionRanger RC

Description of the step

1. Host addresses the scale, e.g. with the address

s Host Direction Scale

<ESC>

3A –––>

3A hex.

2. Host sends a SICS command, e.g. SI SI <CRLF> –––>

3. The scale confirms receipt of the command and

send

s the address back

4. The scale responds to the command and returns

of the bus to the host

control

<––– <ESC> 3A

<––– S_S____45.02_kg

<CRLF>

39

Page 40

5.3 TOLEDO Continuous mode

5.3.1 TOLEDO Continuous commands

The scale supports the following input commands in TOLEDO Continuous mode:

Comm

and Meaning

P <CR><LF> Print out the current result

T <CR><LF> Tare the scale

Z <CR><LF> Zero the display

C <CR><LF> Clear the current value

Tx.xxx <CR><LF> Define tare

5.3.2 Output format in TOLEDO Continuous mode

Weight values are always sent in the following format in TOLEDO Continuous mode:

Status Field 1 Field 2

Ranger RCInterface description

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

STX SWA SWB SWC MSD – – – – LSD MSD – – – – LSD CR CHK

Field 1

Field 2

STX

SWA, SWB, SWC

MSD

LSD

CR

CH

K

6 digits for the

weight value that is sent without a decimal point and unit

6 digits for the tare weight that is sent without a decimal point and unit

ASCII characters 02 hex, characters for "start of text"

Status words A, B, C, see below

Most significant digit

Least significant digit

Carriage

Ch

ch

Return, ASCII characters 0D hex

ecksum (2-part complement of the binary sum of the 7 lower bits of all previously sent

aracters, incl. STX and CR)

40

Page 41

Interface descriptionRanger RC

Status word A

Status Bit

Function Selection 6 5 4 3 2 1 0

Decimal

pos

ition

X00 0 1 0 0 0

X0 0 0 1

X 0 1 0

0.X 0 1 1

0.0X 1 0 0

0.00X 1 0 1

0.000X 1 1 0

0.0000X 1 1 1

Numerical

increment

X1 0 1

X2 1 0

X5 1 1

Status word B Status word C

Function / value Bit Function / value Bit

Gross / net: Net = 1 0 0 0

Sign: Negative = 1 1 0 1

Overload = 1

Movement

2 0 2

= 1 3 Print request = 1 3

lb/kg: kg = 1 4 Extended = 1 4

1 5 1 5

Powerup

= 1 6 Manual taring, only kg = 1 6

41

Page 42

6 Event and error messages

Error Cause Remedy

Ranger RCEvent and error messages

Display Dark

Insufficient load

Overload

• Back lighting set too dark Set back lighting (b.LIGHt)

br

ighter

• No mains voltage Check mains

• Unit switched off Switch on unit

• Mains cable not plugged in Plug in mains plug

• Brief fault Switch device off and back on

again

• Load plate not on the scale Place load plate on the scale

• Weighing range not reached

• Weighing range exceeded Unload scale

Set to zero

Reduce preload

• Result not yet stable If necessary adjust vibration

adapter or weigh dynamically

• Function not permissible Unload scale and set to zero

• Zeroing not possible with over-

Unload scale

load or insufficient load

42

• Average piece weight too low Select and place larger number of

• No valid value from the reference

e

scal

reference parts

Check cable connection between

its

the un

on the scale

Check interface settings

• No calibration Unplug the mains plug then plug

it back in; switch unit off and then

back on in battery mode

Calibrate scale

Call OHAUS Service

• Average piece weight too low Counting is not possible on this

scale with this average piece

weight

Page 43

Err

or Cause Remedy

Event and error messagesRanger RC

Weight display unstable

• Unstable weight value when

referencing

Ensure stable surroundings

Ensure that the weighing pan is

movable

freely

Adjust vibration adapter

• Printout not yet ended End printout

Repeat required action

• Switching the weighing unit

impermissible during dynamic

End dynamic weighing

Switch weighing unit

weighing

• EAROM checksum error Unplug the mains plug then plug

it back in; switch unit off and then

back on in battery mode

Call OHAUS Service

• Restless installation location Adjust vibration adapter

• Draft Avoid drafts

• Restless weighing sample Dynamic weighing

• Contact between weighing pan

Remedy contact

and/or weighing sample and

surr

oundings

• Mains fault Check mains

Incorr

ect weight display • Incorrect zeroing Unload scale, set to zero and

t weighing operation

repea

• Incorrect tare value Clear tare

• Contact between weighing pan

Remedy contact

and/or weighing sample and

surr

oundings

• Scale tilted Level scale

43

Page 44

7 Technical data and accessories

7.1 Technical data

7.1.1 Type key

The Ranger RC compact scales are available with various capacities and platforms that can be seen from the complete type designation.

Example

RC6RS compact scale with capacity 6 kg and small platform

RC35LM compact scale with capacity 35 kg and large platform

RC3SM compact scale with capacity 3 kg and extra-small platform

7.1.

2 General data

RC..S, RC..M

Ranger RCTechnical data and accessories

Applications

• Weighing

• Dynamic weighing

• Counting with fixed or variable reference quantity

• Counting with reference and bulk scale

Settings • Resolution selectable

• Weighing unit selectable: g, kg, oz, lb, t

• Taring function: manual, automatic, chain tare

• Automatic zero point correction when the scale is switched on and during oper-

ation

• Filter for adapting to the ambient conditions (vibration adapter)

• Filter for adapting to the weighing type, e.g. dispensing (weighing process

adapter)

• Switch-off function, sleep mode for mains-operated devices, energy-saving

mode for battery operation

• Display lighting

• Add mode for determining the piece weight when counting

• Reference optimization

• Graphic display of the weighing range

Ac

curacy class OIML/NTEP • RC..S

• RC..M

y

Displa

Keypa

44

d

• LCD (liquid crystal display), digits 16 mm high, with back lighting

• Pressure point membrane keypad

• Scratch-proof labeling

III

II

Page 45

Technical data and accesoriesRanger RC

RC..S, RC..M

Housing • Diecast aluminum housing; chromium nickel steel weighing pan

• Dimensions, see Page 47

Protection Class (IEC 529,

N 40050, EN60529)

DI

• IP43 (not with Ethernet interface)

Mains connection Direct connection to the mains (MAINS supply voltage fluctuations up to ±10% of

the nominal voltage):

• 230 V, 50 Hz, 70 mA

• 240 V, 50 Hz, 70 mA

• 120 V, 60 Hz, 90 mA

• 100 V, 50/60 Hz, 90 mA

For

battery operation:

• Connection via mains adapter: 90 – 264 V, 47 – 63 Hz, 300 mA

• Infeed on the unit: 24 V, 1.3 A

Ba

ttery operation If the voltage supply is interrupted, the unit automatically switches over to battery

operation

Ambient conditions

• Use

• Altitude

• Temperature range RC..S

• Temperature range RC..M

• Overvoltage category

Indoor use only

up to 2000 m

0 .. +40 °C / 14 .. 104 °F

–1

+10 .. +30 °C / 50 .. 86 °F

II

• Contamination level

• Relative humidity

Int

erfaces

Re

solution of the analog

second scale interface

• 1 RS232 interface integrated

• 1 other optional interface possible

• 300000 points in noncertified configuration

• 7000 points in certified configuration

Supply of the weighing cell • 8.2 V

2

Maximum relative humidity 80 % for

temperatures up to 31 °C / 88 °F,

decreasing linearly to 50 % relative

humidity

at 40 °C / 104 °F

45

Page 46

7.1.3 Weighing ranges and readability RC..S

The RC..S compact scales with strain gauge weighing cells are supplied in the configuration 2 x 3000 d. Higher legibilities are available from the factory with the

optional "Premium" weighing cells.

Ranger RCTechnical data and accessories

Capacit

y Configuration

2 x 3000 d (standard) 1 x 6000 d (with optional

Weighing

ranges

1.5 kg / 3 kg 0.5 g / 1 g 3 kg 0.5 g

3 kg

6 kg 3 kg / 6 kg 1 g / 2 g 6 kg 1 g

15 kg 6 kg / 15 kg 2 g / 5 g 15 kg 2 g

35 kg 15 kg / 35 kg 5 g / 10 g 35 kg 5 g

60 kg 30 kg / 60 kg 10 g / 20 g 60 kg 10 g

.4 Weighing ranges and readability RC..M

7.1

Configurations up to 1 x 60.000 e are possible with the RC..M compact scales with

Bloc technology. Certified RC..M compact scales are supplied as standard with

Mono

internal calibration weight.

an

Model Weighing interval(s) Readability d Verification

Readability

(certified)

"Premium"

Weighing

range

weighing cells

Readability

(certified

lue e

va

)

RC3DSM 600 g / 3,1

RC3SM 3,100 g

0.01 0.1 g

RC6DSM 1,200 g / 6,

RC6SM 6,100 g

0.01 0.1 g

RC6DRM 1,200 g / 6,

RC6RM 6,100

g 0.2 g 0.2 g

RC15DLM 3,500 g / 1

RC15LM 15,10

0 g 0.5 g 0.5 g

RC35DLM 7,000 g / 3

RC35LM 35,10

0 g 0.1 g 1 g

00 g 0.01 g / 0.1 g 0.1 g

100 g 0.01 g / 0.1 g 0.1 g

100 g 0.1 g / 1 g 1 g

5,100 g 0.1 g / 1 g 1 g

5,100 g 0.1 g / 1 g 1 g

46

Page 47

7.1.5 Dimensions

Technical data and accessoriesRanger RC

A B C D E F G H I K L

1)

RC..S..

RC..R..

RC..L..

1)

Dimenions in mm

335 265 100 240 200 46 276 208 216 165 165

1)

335 265 100 240 200 46 276 208 216 – –

1)

370 360 115 350 240 52 310 304 310 – –

.6 Net weights

7.1

Model without battery with battery with internal calibration

RC..RS 4.6 kg

RC..LS

RC..SM 4.9 kg

RC..RM 4.7 kg

RC..LM 10.5 kg

wei

5.3 kg –

8.2 kg 8.9 kg –

5.6 kg 5.4 kg

5.4 kg 5.2 kg

11.2 kg 11.7 kg

ght (without battery)

47

Page 48

7.1.7 Interface connections

The compact scale can be fitted with a maximum of 2 interfaces. The following combinations are possible:

COM

1 COM2 Note

RS232 –

RS232 RS232

RS485 RS232 COM1 can be optionally operated as RS422 or RS485

RS232 Ethernet

32 USB

RS2

RS232 Digital I/O

RS232 Analog second

scale

interface

7.1

.8 Assignment of the interface connections

Ranger RCTechnical data and accessories

Pin RS232

(COM1

COM2

/

)

RS

422

(4-wire,

COM1

)

RS485

(2-wire,

COM1

)

Digital I

(COM

2)

/O

Analog

Interface

1 – – – GND + Excitation (+8.2 VDC)

2 TxD1/2 TxD1– TxD1–/RxD1– OUT0 + Sense

3 RxD1/2 RxD1– – OUT1 Shield

4 – – – OUT2 – Sense

5 GND GND GND OUT3 – Excitation (GND)

6 – – – IN0 –

7 – TxD1+ TxD1+/RxD1+ IN1 + Signal

8 – RxD1+ – IN2 – Signal

9 VCC VCC VCC IN3 –

48

Page 49

7.2 Accessories

Designation Order number

In Use Cover for RC..R.. 21203719

In Use Cover for RC..L.. 21203720

32 Cable for PC 80500525

RS2

32 Cable for Second Scale

RS2

Technical data and accessoriesRanger RC

80500526

RS2

32 Cable for SF42 Printer

Anti-theft Device

Carrying Case for RC..R..

Carrying Case for RC..L..

Printer

80500571

80850000

80850083

80850084

SF42

49

Page 50

8 Appendix

8.1 Information for certified scales in EC countries

Weighing instruments verified at the place of manufacture bear the preceding mark on

the

packing label and green "M" sticker on the descriptive plate. They may be set to

k immediately.

wor

We

ighing instruments which are verified in two steps have no green "M" on the

descriptive plate and bear the preceding identifaction mark on the packing label. The

se

cond step of the verification must be carried out by the approved OHAUS Service or

by the W&M authorities. Please contact OHAUS Customer Service.

The

first calibration step of the verification has been carried out at the manufacturing

It comprises all tests according to EN45501-8.2.2. Scales with analog connec-

plant.

tion

to the weighing platform require an additional test according to EN45501-

3.5.3.3. However, this test is not mandatory if the terminal bears the same serial

number as the weighing platform.

Ranger RCAppendix

If national regulations in individual countries limit the period of validity of the certification, the operator of such a scale is himself responsible for its timely re-certification.

8.2 Safety checks

The compact scales of the Ranger RC series have been checked by accredited testing

institutions. They have passed the safety checks listed below and carry the relevant

symbols. Production is subject to production monitoring by the inspection

test

off

ices.

Country Test symbol Standard

Canada

US

A

Other

countries CB Scheme

(no

identification)

CAN/CSA-C

UL Std

. No. 61010A-1

IEC/EN610

22.2 No. 1010.1-92

10-1:2001

50

Page 51

8.3 Table of Geo Values

For weighing instruments verified at the manufacturer’s, the geo value indicates the

country or geographical zone for which the instrument is verified. The geo value set in

the instrument (e.g."Geo 18") appears briefly after switch-on or is specified on a label.

Table GEO VALUES 3000e shows the geo values for European countries.

Table GEO VALUES 6000e/7500e shows the geo values for different gravitation

zone

s.

8.3

.1 GEO VALUES 3000e, OIML Class III (European Countries)

AppendixRanger RC

Geographical

latitude Geo value Country

46°22' – 49°01' 18 Austria

49°30' – 51°30' 21 Belgium

41°41' – 44°13' 16 Bulgaria

42°24' – 46°32' 18 Croatia

48°34' – 51°03' 20 Czechia

54°34' – 57°45' 23 Denmark

57°30' – 59°40' 24 Estonia

25

59°48' – 64°00'

64°00'

41°20'

45°00'

47°00'

34°48'

45°45'

63°17'

51°05'

– 70°05'

– 45°00'

– 51°00'

– 55°00' 20 Germany

– 41°45' 15 Greece

– 48°35' 19 Hungary

– 67°09' 26 Iceland

– 55°05' 22 Ireland

26

17

19

*

*

Finland

ance

Fr

35°47'

55°30'

47°03'

53°54'

49°27'

50°46'

57°57'

64°00'

49°00'

36°58'

43°37'

– 47°05' 17 Italy

– 58°04' 23 Latvia

– 47°14' 18 Liechtenstein

– 56°24' 22 Lithuiania

– 50°11' 20 Luxemburg

– 53°32' 21 Netherlands

– 64°00'

– 71°11'

24

26

*

Norway

– 54°30' 21 Poland

– 42°10' 15 Portugal

– 48°15' 18 Romania

51

Page 52

Ranger RCAppendix

Geographical

latitude Geo value Country

47°44' – 49°46' 19 Slovakia

45°26' – 46°35' 18 Slovenia

36°00' – 43°47' 15 Spain

55°20' – 62°00'

62°00'

45°49'

– 69°04'

– 47°49' 18 Switzerland

24

26

*

Sweden

35°51' – 42°06' 16 Turkey

49°00' – 55°00'

55°00'

– 62°00'

21

23

*

United

Kingdom

* factory setting

52

Page 53

8.3.2 GEO VALUES 6000e/7500e OIML Class III (Height ≤1000 m)

AppendixRanger RC

Geograhical latitud

e Geo value

00°00' – 12°44' 5

05°46' – 17°10' 6

12°44' – 20°45' 7

17°10' – 23°54' 8

20°45' – 26°45' 9

23°54' – 29°25' 10

26°45'

– 31°56' 11

29°25' – 34°21' 12

31°56' – 36°41' 13

34°21' – 38°58' 14

36°41' – 41°12' 15

38°58' – 43°26' 16

41°12' – 45°38' 17

43°26' – 47°51' 18

45°38' – 50°06' 19

47°51' – 52°22' 20

50°06' – 54°41' 21

52°22'

54°41'

57°04'

59°32'

62°09'

64°55'

67°57'

71°21'

75°24'

– 57°04' 22

– 59°32' 23

– 62°09' 24

– 64°55' 25

– 67°57' 26

– 71°21' 27

– 75°24' 28

– 80°56' 29

– 90°00' 30

53

Page 54

8.4 Sample protocols

Weighing with tare Dynamic weighing Printout with header

G = Gross weight

N = Net weight

T = Tare

Dyn

WT = dynamically determined weight

Ranger RCAppendix

Protocol of

SOFTWARE VER 16-1-1.04

SCALE

------------METROLO :NO APPr

SNR :0000000

Scale Build

SCAL.TYP :SINGLE.R

BAS.UNIT :g

SCL.CAP :6100.00

RESOL. :0.01 g

GEO :19

DISPLAY

UNIt1 :g

UNIt2 :kg

RESOLU :0.01 g

UNt.rOLL :OFF

tArE

A-TArE :OFF

CHAIn.tr :ON

A.CL-tr :OFF

PB.TArE :ON

ZERO

Z-CAPT :-2 18

AZM :0.5 d

RESTART :OFF

FILTER

VIBRAT :MED

PROCESS :UNIVEr

StABILI :StAnDrD

Min.WEiG

SEt.VAL :0.000 g

ONOFF :OFF

the scale settings (menu point List, see page 34)

APPLICATION

-------------

COUNT

VAr-SPL

Spl-Qty

SQ1 :5

SQ2 :10

SQ3 :25

SQ4 :50

SQ5 :100

Min.RefW :99

REF OPT :OFF

A-SMPL :ON

A.CL-APW :OFF

ACCurCy :ON

tOtAL.Ct :BULK

DYNAMIC :OFF

TERMINAL

-------------

DEVICE

SLEEP :OFF

B.LIGHt :ON

COMMUNICATION

--------------

COM 1

MODE 1:Print

PriNtEr

tEmPLat 1:StdArd

ASCi.Fmt

LINE.FMT1:MULTI

LENGtH 1:24

ADD LF 1:0

PARAMET

BAUD 1:2400

PAriTY 1:8 odd

H.SHAKE 1:XONXOFF

ChECSUM 1:OFF

Vcc 1:OFF

COM 2

MODE 2:DIALOG

PARAMET

BAUD 2:9600

PAriTY 2:8 nonE

H.SHAKE 2:XONXOFF

ChECSUM 2:OFF

Vcc 2:OFF

OPTION

EtH.NEt :N.A.

USB :N.A.

ANALOG :N.A.

DiGitAL :N.A.

DEF.PrN

tEmPLt1

tEmPLt2

54

Page 55

9 Index

IndexRanger RC

A

Accessorie

Adjustmen

Alignment ............................... 10

Ambient

Application

Auxiliary scale......................... 20

Averag

C

Calibrat

Calling

Capacity

Chain tar

Continuous mod

Counting parts ........................ 17

D

Dimension

Displa

Display

Dynamic weighin

E

Erro

F

Filte

I

Interfaces

K

Keyboar

M

Mains

Men

Menu structure ........................ 22

Minimum accurac

s ............................ 49

t ............................. 26

conditions .................. 45

s............................ 44

e............................ 14, 29

e................................. 26

up the gross weight ...... 14

utilisation .................. 14

e............................... 13

e .................... 40

s ............................ 47

y .................................... 8

accuracy..................... 26

g............. 14, 29

r messages ....................... 42

r ...................................... 27

Configure.......................... 31

Connection

d.................................. 9

connection .................... 45

u

Application ....................... 28

Communicatio

Diagnosi

Operation ......................... 21

Overvie

Scal

Termina

s...................... 48