Ohaus I150-S User Manual

Ohaus CorporationOhaus Corporation

Ohaus Corporation

Ohaus CorporationOhaus Corporation

29 Hanover Road

Florham Park NJ

07932-0900

I150 Electronic Indicator

Models I150-P and I150-S

Instruction Manual

NOTE:NOTE:

NOTE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO

NOTE:NOTE:

COMPLY WITH THE LIMITS FOR A CLASS A DIGITAL DEVICE, PURSUANT TO PART 15 OF THE FCC RULES.

THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION AGAINST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED IN A COMMERCIAL ENVIRONMENT. THIS

EQUIPMENT GENERATES, USES, AND CAN RADIATE RADIO FREQUENCY ENERGY AND, IF NOT INSTALLED AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE HARMFUL

INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF

THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE

HARMFUL INTERFERENCE IN WHICH CASE THE USER WILL BE

REQUIRED TO CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

THIS DIGITAL APPARATUS DOES NOT EXCEED THE CLASS A LIMITS FOR RADIO NOISE EMISSIONS FROM DIGITAL APPARATUS AS

SET OUT IN THE INTERFERENCE-CAUSING EQUIPMENT STANDARD

ENTITLED "DIGITAL APPARATUS", ICES-003 OF THE DEPARTMENT

OF COMMUNICATIONS.

CET APPAREIL NUMÉRIQUE RESPECTE LES LIMITES DE BRUITS

RADIOÉLECTRIQUES APPLICABLES AUX APPAREILS NUMÉRIQUES

DE CLASSE A PRESCRITES DANS LA NORMA SUR LE MATÉRIAL

BROUILLEUR : "APPAREILS NUMÉRIQUES", NMB-003 ÉDICTÉE PAR

LE MINISTRE DES COMMUNICATIONS.

This apparatus has been designed and tested according to DIN 57 411

Pt. 1/VDE 0411 Pt. 1, Safety Requirements for Electronic Measuring

Apparatus, and has been supplied in a safe condition. This instruction

manual contains information and warnings which must be followed by

the user to ensure safe operation and to retain the apparatus in safe

condition.

Unauthorized changes or modifications to this equipment are not

permitted.

The exclamation

point within the triangle is a warning

sign alerting you of

important instructions accompanying the product.

2

PREFACEPREFACE

PREFACE

PREFACEPREFACE

The I150 Electronic Indicator is a highly versatile device which is designed for a variety

of applications. It can be used with virtually any load receiver which provides a

compatible output signal. This instruction manual contains the information needed to

install, configure and operate the I150. Read it before attempting to operate the

indicator.

The I150 is a software controlled indicator with a host of user-programmable features.

Calibrating and setting up operating parameters are easily accomplished using the

front panel keypad and display. These are a few of the standard features included with

the indicator:

RS-232 Interface: RS-232 Interface:

RS-232 Interface: The bi-directional RS-232 interface enables the indicator to

RS-232 Interface: RS-232 Interface:

communicate with printers and computers. Instructions on connecting and using the

interface are included in this manual.

Parts Counting: Parts Counting:

Parts Counting: The parts counting feature allows you to count parts in a number of

Parts Counting: Parts Counting:

ways. You can enter the average piece weight and start counting, or let the indicator

perform averaging and display the count.

Single/Dual Platform Operation: Single/Dual Platform Operation:

Single/Dual Platform Operation: The I150 is a two-channel indicator which permits

Single/Dual Platform Operation: Single/Dual Platform Operation:

you to monitor two load receivers. Switch to either load receiver by pressing a single

button.

Checkweighing and Filling: Checkweighing and Filling:

Checkweighing and Filling: Set point indicators and digital outputs are provided for

Checkweighing and Filling: Checkweighing and Filling:

these applications. In checkweighing, the indicators and digital outputs correspond to

OVER, UNDER and ACCEPT values. In filling processes, they can be used to activate

preset feedrates and cutoff points of filling devices.

ClassificationsClassifications

Classifications

ClassificationsClassifications

Both models I150-P and I150-S have been tested and certified to comply with the

following regulations:

Weights and MeasuresWeights and Measures

Weights and Measures

Weights and MeasuresWeights and Measures

• National Institute of Standards and Technology Handbook 44 Class III and IIIL

• Consumer and Corporate Affairs Canada Weights and Measures Act and Regula-

tions general class.

SafetySafety

Safety

SafetySafety

• Underwriters Laboratory 114 and 466

• Canadian Standards Association C22.2 No. 151-m1986

• National Electrical Manufacturers Association Standard 250 Type 4 (NEMA 4)

• International Electrotechnical Commission Pub. 529 Index of Protection 65-(IP65)

• DIN VDE 0411

LEGAL FOR TRADE NOTELEGAL FOR TRADE NOTE

LEGAL FOR TRADE NOTE

LEGAL FOR TRADE NOTELEGAL FOR TRADE NOTE

Throughout this manual, the abbreviation “LFT” represents “Legal For Trade”.

3

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

PAGE

UNPACKING ........................................................................................................ 6

INSTALLATION.................................................................................................... 7

Power Connections....................................................................................... 7

Load Receiver Connections.......................................................................... 8

Installing “Gain Setting” Shorting Jumpers................................................... 9

RS-232 Connections................................................................................... 10

RS-232 Shorting Jumpers .......................................................................... 10

Digital Output Connections ......................................................................... 11

Turning the I150 ON ................................................................................... 12

Display Indicator Functions......................................................................... 1 2

Key Functions ............................................................................................. 13

USING MENUS TO CONFIGURE THE I150 .................................................... 14

SETUP SUBMENU ..................................................................................... 18

Legal For Trade....................................................................................... 19

Sense ...................................................................................................... 19

Number of Load Reeceivers ................................................................... 20

Zero ......................................................................................................... 20

Calibration Unit ........................................................................................ 21

Full Scale Point........................................................................................ 21

Graduations............................................................................................. 22

Calibration Point ...................................................................................... 22

Linearization Point ................................................................................... 23

End .......................................................................................................... 23

SCALE SUBMENU ..................................................................................... 24

Reset to Factory Defaults ....................................................................... 25

Averaging Level....................................................................................... 25

Stability Range ........................................................................................ 26

Unit Selection .......................................................................................... 27

Auto-Zero Tracking .................................................................................. 28

Custom Unit Conversion Factor.............................................................. 28

Average Display Cycle ............................................................................ 31

Parts Count Error Level .......................................................................... 3 1

Set Point .................................................................................................. 3 2

Set ........................................................................................................... 32

Store ........................................................................................................ 34

Retain Zero Data ..................................................................................... 3 5

End .......................................................................................................... 35

CALIBRATION SUBMENU ......................................................................... 36

Dead Load ............................................................................................... 3 6

Zero Adjustment .................................................................................. 37

Calibration ............................................................................................... 37

End .......................................................................................................... 39

4

PAGE

RS-232 SUBMENU ..................................................................................... 40

Baud Rate ............................................................................................... 4 1

Number of Data Bits................................................................................ 41

Number of Stop Bits ................................................................................ 4 1

Parity ....................................................................................................... 41

Sample Size (APW) (for Auxiliary Sample Scale)................................... 4 2

Auto Print Feature ................................................................................... 42

Non Printing Weight Values and Auto Print Time Interval...................... 43

Print Stable Data Only............................................................................. 4 4

Print Block or Display Data ..................................................................... 44

Print Numeric Display Data Only ............................................................ 4 5

Time......................................................................................................... 45

Date ......................................................................................................... 45

End .......................................................................................................... 46

Exit All Menus ............................................................................................. 46

Disabling Menu Changes for Legal For Trade Installations .............................. 47

Closing the Cover............................................................................................... 4 8

LFT SEALING .................................................................................................... 48

OPERATION ...................................................................................................... 48

Selecting a Weighing Unit........................................................................... 48

Weighing ..................................................................................................... 49

Taring .......................................................................................................... 49

View/Enter Time and Date.......................................................................... 51

Parts Counting ............................................................................................ 5 2

Parts Counting With An Auxiliary Sample Scale ........................................ 55

Checkweighing............................................................................................ 57

Filling and Emptying Processes.................................................................. 5 8

Animal Weighing ......................................................................................... 61

Using ID Codes........................................................................................... 61

RS-232 INTERFACE.......................................................................................... 65

TROUBLESHOOTING ....................................................................................... 70

Error Codes ................................................................................................. 7 2

SPECIFICATIONS ............................................................................................. 73

REPLACEMENT PARTS ................................................................................... 74

ACCESSORIES ................................................................................................. 74

CARE AND MAINTENANCE ............................................................................. 75

SERVICE INFORMATION ................................................................................. 75

LIMITED WARRANTY ....................................................................................... 75

5

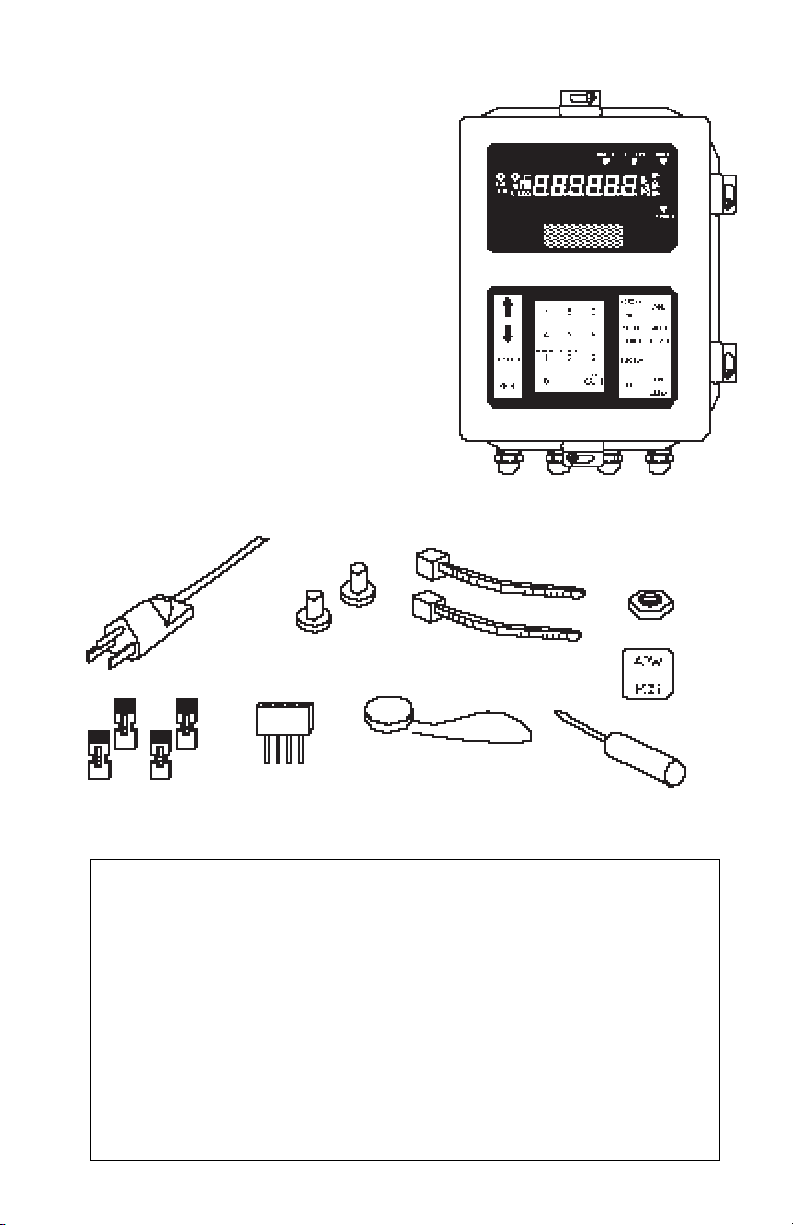

UNPACKINGUNPACKING

UNPACKING

UNPACKINGUNPACKING

Verify that your indicator was shipped

with the following items:

• I150-P or I150-S indicator

• power cord

• instruction manual

• warranty card

• an accessory kit including:

- two hole plugs

- one calibration seal

- one capacity label sheet

- one screwdriver

- one 5/16" #6-32 hex nut

- two cable ties

- four shorting jumpers

- one press-on “APW/PCS” label

- one setpoint connector

I150 Indicator

Power

Cord

Hole Plugs

Calibration Seal

Shorting Jumpers

• To avoid shock hazards, always be certain that the power cord is

disconnected from the wall outlet BEFORE opening the enclosure.

• Even though the I150 may have been switched OFF, high voltage is

present inside the enclosure as long as power cord is connected to a power

source.

• DO NOT use any other type of power cord other than the one that was

furnished with the indicator.

• DO NOT create a safety hazard by defeating the grounding feature.

Setpoint

Connector

WARNINGWARNING

WARNING

WARNINGWARNING

Cable Ties

Screw Driver

Hex Nut

Label

6

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

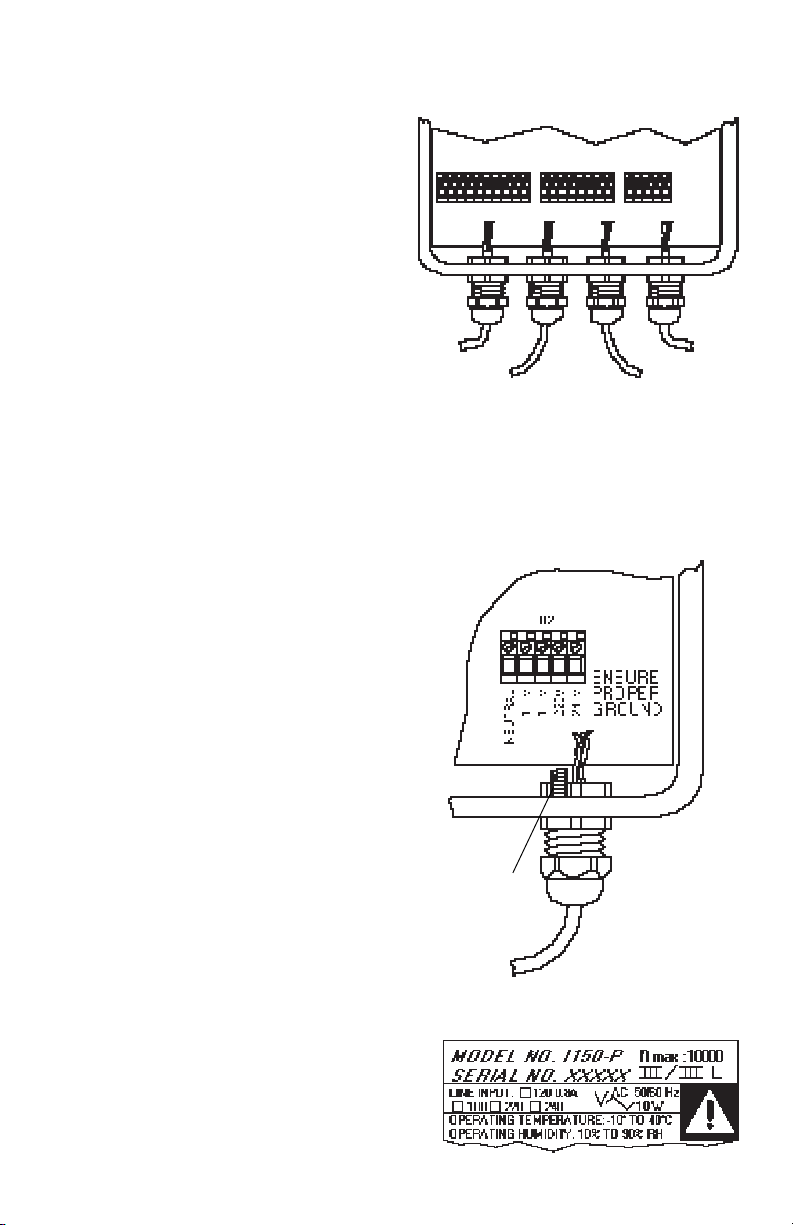

Power ConnectionsPower Connections

Power Connections

Power ConnectionsPower Connections

Using a small screwdriver, connect the

power cord to TB2 located on the main

circuit board inside the enclosure as follows (see diagram):

1. Pass the power cord through the seal

bushing of the liquid tight connector

on the lower right of the enclosure.

2. Connect the ground wire (green or

green/yellow) to the case ground

screw located inside the enclosure,

just above the seal bushing. Secure

the wire to the screw using the #6-32

hex nut provided in the accessory kit.

TB1

Load

Receiver #2

Cable

TB3

Load

Receiver #1

Cable

TB2

RS232

Cable

Power

Cord

Tighten nut to minimum torque of 10

inch-pounds to ensure ground continuity.

3. Connect the NEUTRAL wire (WHITE

or BLUE) to the terminal labeled NEUTRAL.

4. Connect the BLACK or BROWN wire

to the terminal labeled with the appropriate line voltage (100V, 120V,

220V or 240V).

CAUTION: Indicator may be damaged if operated at incorrect voltage.

5. Permanently mark the appropriate

line voltage box on the serial number

label located on the side of the enclosure.

Case

Ground

Screw

Power

Cord

7

6. After the connections have been

made, fasten two cable ties (included

in the accessory kit) around the power

cord as shown in the diagram. The

cable ties secure the power cord so it

cannot be pulled out of the enclosure.

7. Tighten the seal bushing until resistance is felt against the cable. Turn

the cap nut an additional full turn to

secure the cable.

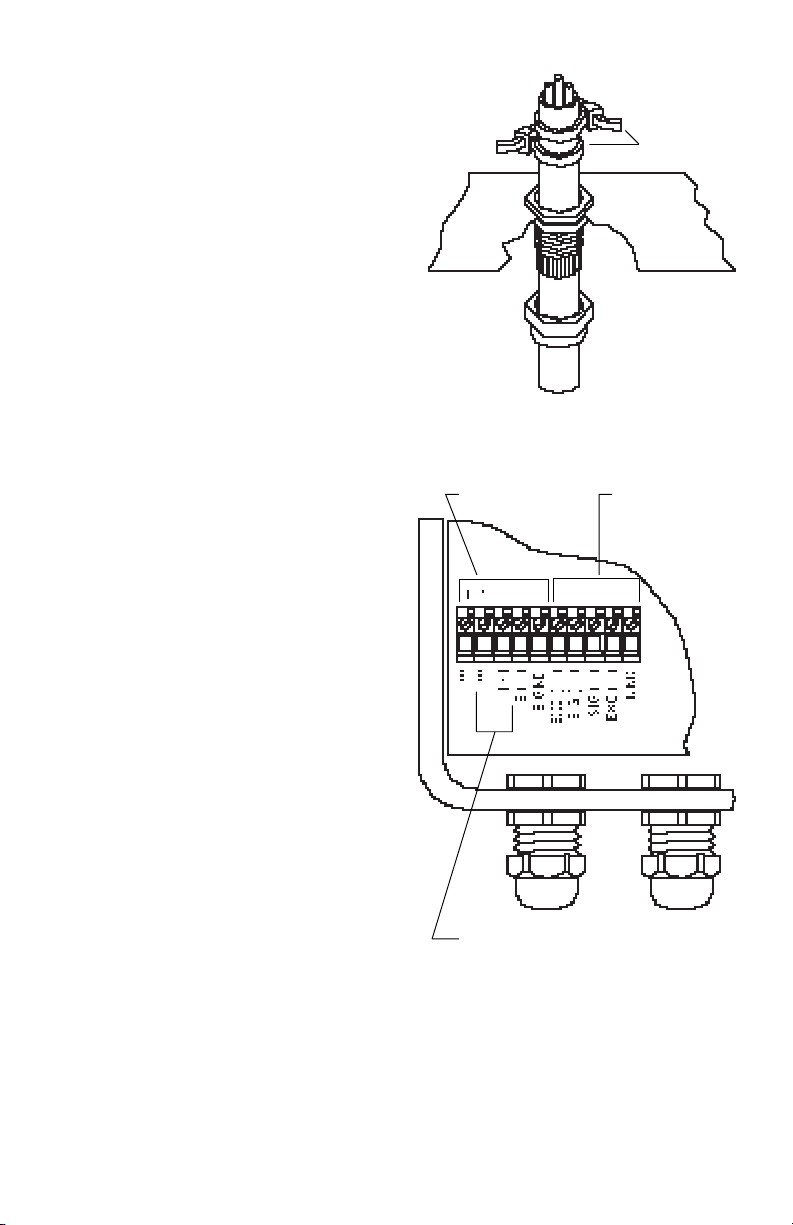

Load Receiver ConnectionsLoad Receiver Connections

Load Receiver Connections

Load Receiver ConnectionsLoad Receiver Connections

Using a small screwdriver, connect the

load cell cable to TB1 located on the main

circuit board inside the enclosure as follows (see diagram):

1. Pass the cable from the load

receiver(s) through one of the two

liquid tight connector(s) seal bushings on the lower left of the enclosure.

Load Receiver

#2

Cable Ties

Load Receiver

#1

2. Make the connections according to

the markings on the circuit board.

3. After the connections have been

made, tighten the seal bushing until

resistance is felt against the cable.

Turn the cap nut an additional full

turn to secure the cable.

NOTE: Remote sensing is available only

on load receiver #1. Load receiver #2 may

not be used.

For Ohaus LB, PL and WB platforms,

leads are color coded as follows:

Black: EXC (-) Green: EXC (+)

White: SIGNAL (-) Red: SIGNAL (+)

Yellow: SENSE (-) Blue: SENSE (+)

For Ohaus WBS platforms:

Black: EXC (-) Red: EXC (+)

White: SIGNAL (-) Green: SIGNAL (+)

SENSE connections from Load

Receiver #1. (Load Receiver #2 IS

NOT USED)

8

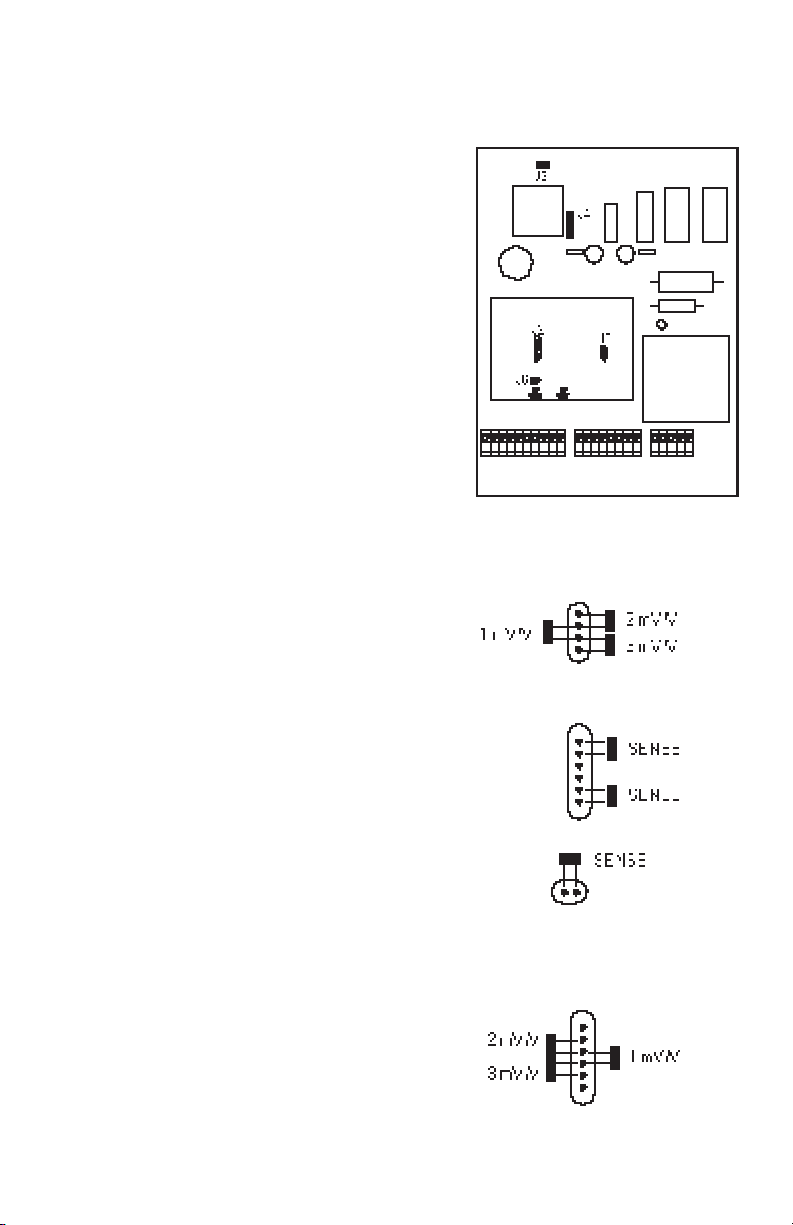

Installing “Gain Setting”Installing “Gain Setting”

Installing “Gain Setting”

Installing “Gain Setting”Installing “Gain Setting”

Shorting JumpersShorting Jumpers

Shorting Jumpers

Shorting JumpersShorting Jumpers

The gain setting for the I150 must be set

to match the output signal of the load

receiver(s) being used. There are three

possible configurations:

1. Single load receiver without SENSE.

2. Single load receiver with SENSE.

3. Dual load receivers.

The gain setting is selected by installing

shorting jumpers on connectors “J6”, “J5”

and “J2” of the main circuit board as

necessary. Refer to the diagrams and use

the following as a guide.

The factory default gain setting has been

set to single load receiver, at 2mV/V,

without SENSE.

For Single Load Receiver Operation:For Single Load Receiver Operation:

For Single Load Receiver Operation:

For Single Load Receiver Operation:For Single Load Receiver Operation:

Install one shorting jumper on connector

“J5” in the position labeled with the gain

that matches the output of the load receiver in use: 1, 2 or 3 mV/V.

If the SENSE connection is being used,

install two shorting jumpers on “J2”, and

one on “J6” as shown in the diagram.

For Dual Load Receiver Operation:For Dual Load Receiver Operation:

For Dual Load Receiver Operation:

For Dual Load Receiver Operation:For Dual Load Receiver Operation:

Install one shorting jumper on “J5” as for

one cell operation. Install one shorting

jumper on “J2” in the position labeled with

the gain matching the output of the second load receiver: 1, 2 or 3 mV/V.

NOTE: During dual receiver operation,

SENSE jumpers must be removed.

J5

J2

J6

J2

9

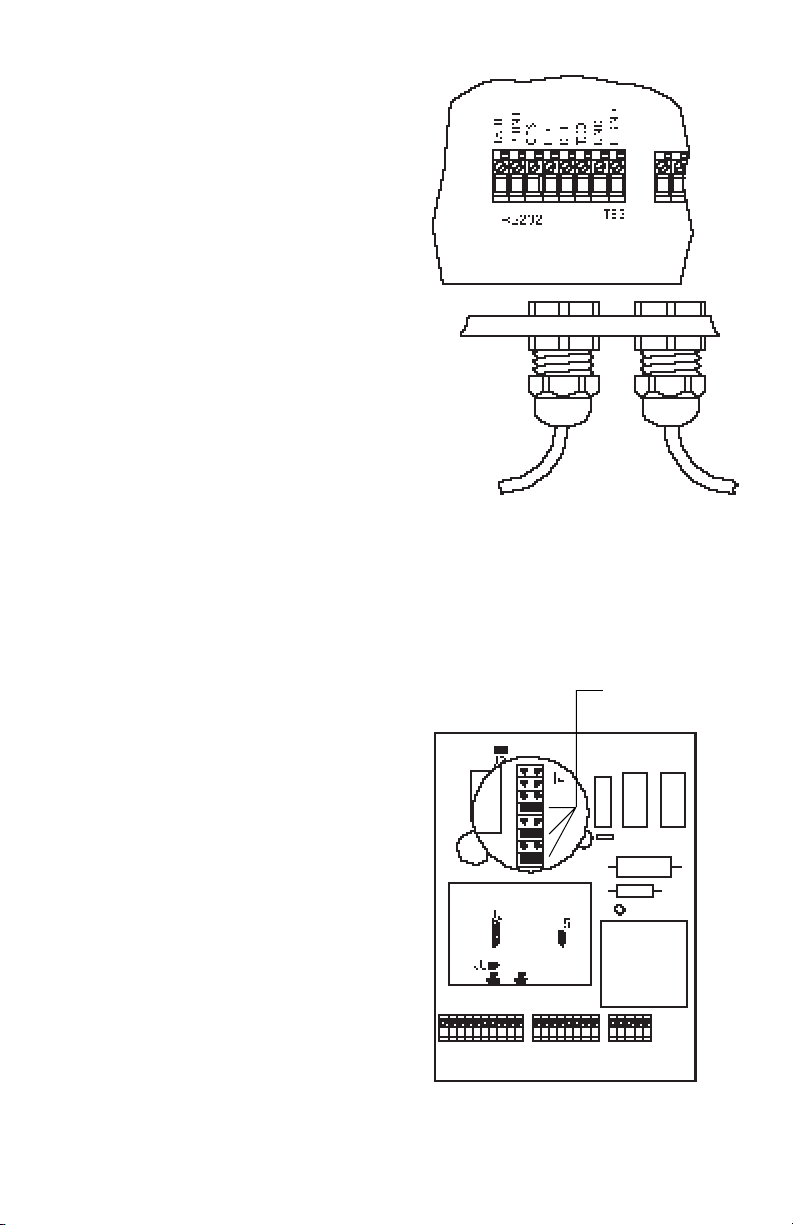

RS-232 ConnectionsRS-232 Connections

RS-232 Connections

RS-232 ConnectionsRS-232 Connections

Using a small screwdriver, connect the

RS-232 interface cable to TB3 located

between TB1 and TB2 on the main circuit

board as follows:

1. Pass the RS-232 cable through the

seal bushing of the liquid tight connector next to the one used for the

power cord.

2. Make the connections according to

the markings on the circuit board.

3. After the connections have been

made, tighten the seal bushing until

resistance is felt against the cable.

Turn the cap nut an additional full

turn to secure the cable.

RS-232 Connections For AuxiliaryRS-232 Connections For Auxiliary

RS-232 Connections For Auxiliary

RS-232 Connections For AuxiliaryRS-232 Connections For Auxiliary

Sample Scale (Parts Counting Option)Sample Scale (Parts Counting Option)

Sample Scale (Parts Counting Option)

Sample Scale (Parts Counting Option)Sample Scale (Parts Counting Option)

If an auxiliary sample scale will be used

for parts counting, refer to “Parts Counting With An Auxiliary Sample Scale” in the

OPERATION section for RS-232 wiring.

RS232

Cable

Power

Cord

Shorting

Jumpers

RS-232 Shorting JumpersRS-232 Shorting Jumpers

RS-232 Shorting Jumpers

RS-232 Shorting JumpersRS-232 Shorting Jumpers

Three shorting jumpers are factory installed on connector J4 of the main circuit

board to enable the RS-232 feature.

10

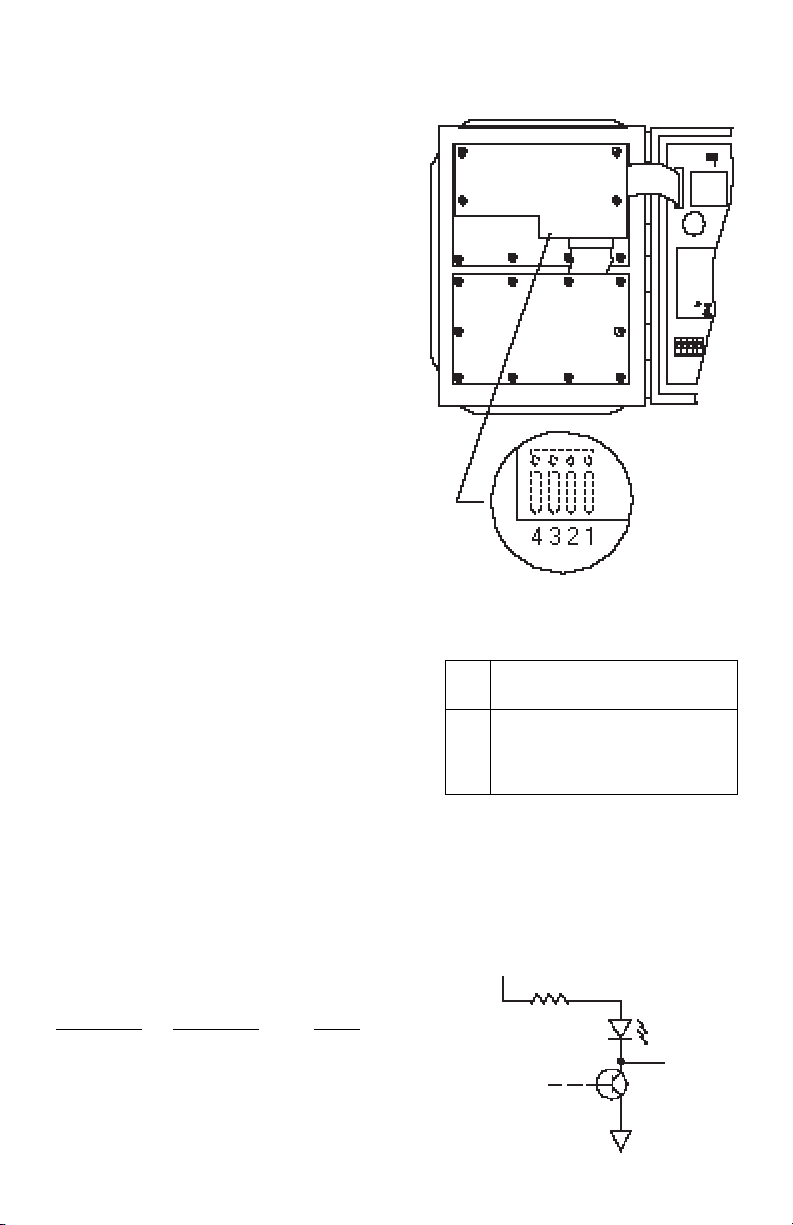

Digital Output ConnectionsDigital Output Connections

Digital Output Connections

Digital Output ConnectionsDigital Output Connections

Digital outputs are provided for checkweighing and filling applications where

the I150 will be used to control other

devices. Refer to “Checkweighing” and

“Filling and Emptying Processes” in the

OPERATION section of this manual for

instructions on using these features.

The digital outputs are accessed via a 4pin header which is located on the component side of the display circuit board (see

diagram).

Use the setpoint connector provided in

the accessory kit, and a suitable cable for

connecting to the header. The cable must

be round to fit properly through one of the

liquid tight connectors.

1. Locate the 4-pin header on the display circuit board.

2. Pass the cable through any free liquid tight connector.

3. Connect the cable wires to the socket

connector according to the pin connections shown in the table.

4. Plug the setpoint connector into the

4-pin header on the display circuit

board. Make sure the connector is

properly oriented.

Display

Circuit

Board

Header is on

component

side of circuit

board.

PIN CONNECTIONS

APPLICATION

Pin Checkweighing Filling/Emptying

1 UNDER DRIBBLE

2 GND GND

3 OVER PREACT

4 ACCEPT TARGET

5. Tighten the seal bushing until resistance is felt against the cable.

Output SpecificationsOutput Specifications

Output Specifications

Output SpecificationsOutput Specifications

Test

Parameter Conditions Value

V

V

OH

OL

IOH = -2mA max. 2.4 V min.

IOL = 16mA max. 0.5 V max.

Outputs are ACTIVE LOW: LED is ON,

when output is LOW (V

)

OL

11

+5V

475 ohms

LED

DIGITAL

OUTPUT

PIN

Turning the I150 ONTurning the I150 ON

Turning the I150 ON

Turning the I150 ONTurning the I150 ON

After all connections have been made, plug in the power cord; the Power ON LED will

ONON

ON

light. Press ZERO on the front panel. All display segments and indicators will light

ONON

ZEROZERO

ZERO

ZEROZERO

briefly, and then clear.

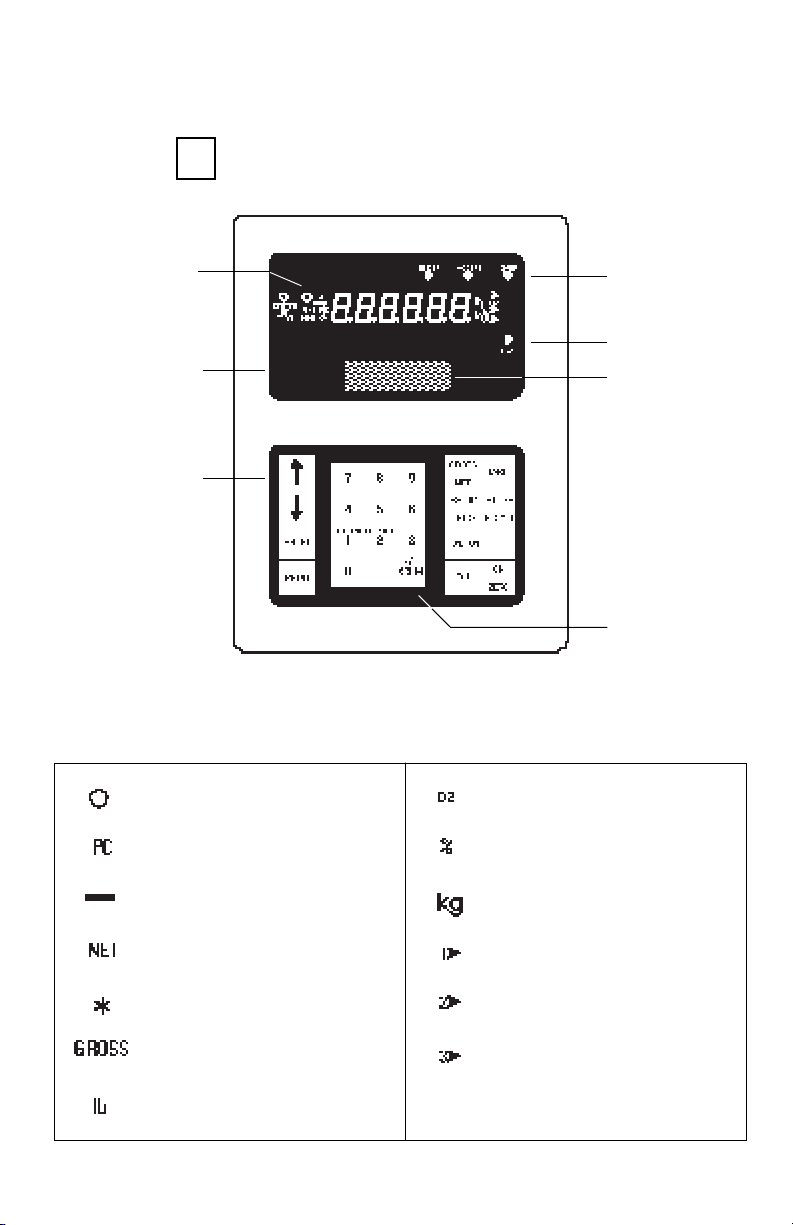

Display Indicators

Display Window

Keypad

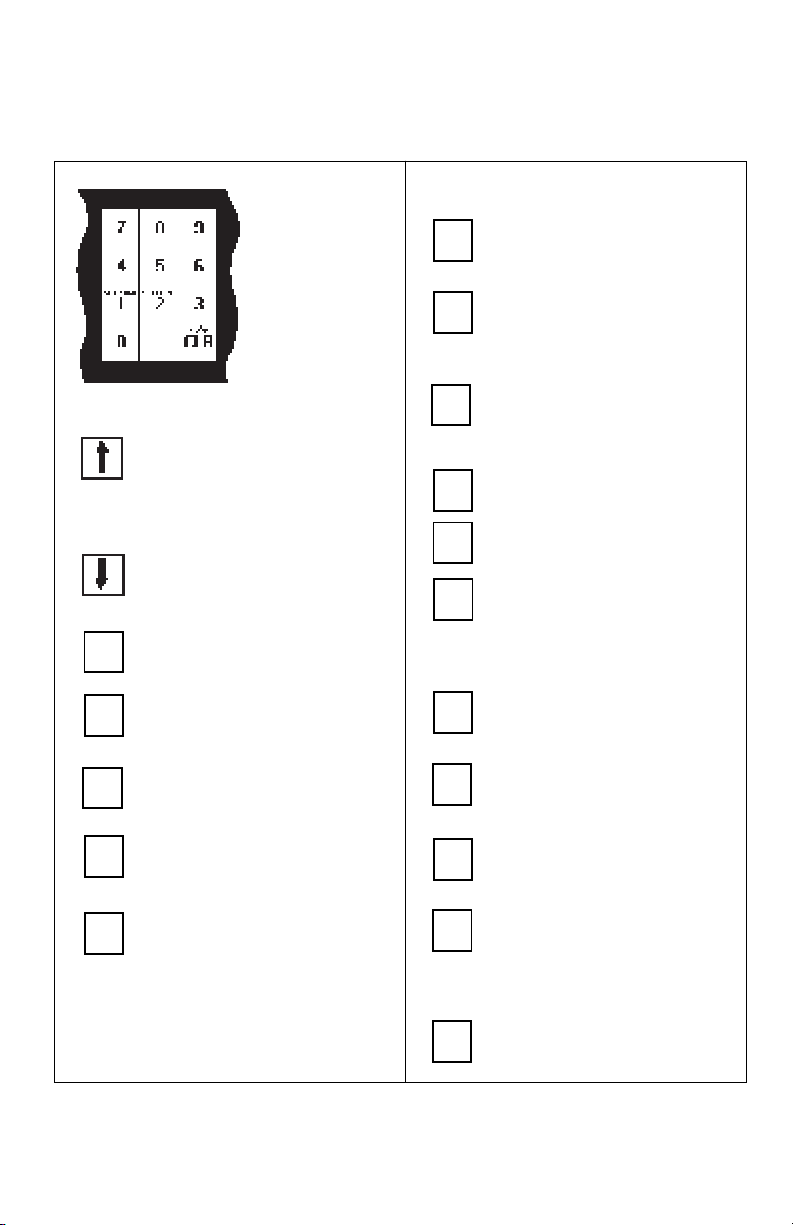

Display Indicator FunctionsDisplay Indicator Functions

Display Indicator Functions

Display Indicator FunctionsDisplay Indicator Functions

Lights when scale is at center

of zero.

Indicates the I150 is in parts

counting mode.

Indicates that the currently displayed value is negative.

Indicates currently displayed

weight is net weight.

Lights when displayed weight

is stable (non LFT only).

Indicates currently displayed

weight is gross weight.

Lights when current weighing

unit is pounds.

Setpoint LEDs

Power ON LED

Capacity Label

Window

Numeric Keypad

Lights when current weighing

unit is ounces (non LFT only).

Indicates displayed value is a

percentage.

Lights when current weighing

unit is kilograms .

Indicates load receiver #1 is

displayed (non LFT only).

Indicates load receiver #2 is

displayed (non LFT only).

Lights when current weighing

unit is custom unit (non LFT

only).

12

Key FunctionsKey Functions

Key Functions

Key FunctionsKey Functions

ENTERENTER

ENTER

ENTERENTER

PRINTPRINT

PRINT

PRINTPRINT

SETPOINTSETPOINT

SETPOINT

SETPOINTSETPOINT

11

1

11

Numeric Keypad;

used to enter

numeric values

when applicable.

Switches display from one load

receiver to another. Steps

backward through menu selections.

Switches display from one load

receiver to another. Steps forward through menu selections.

Used during configuration.

Outputs data via the RS232

interface.

Used with FUNCTION key to

view/enter setpoint 1.

GROSSGROSS

GROSS

GROSSGROSS

NETNET

NET

NETNET

SETUPSETUP

SETUP

SETUPSETUP

UNITSUNITS

UNITS

UNITSUNITS

FUNCTIONFUNCTION

FUNCTION

FUNCTIONFUNCTION

OFFOFF

OFF

OFFOFF

TARETARE

TARE

TARETARE

STORESTORE

STORE

STORESTORE

RECALLRECALL

RECALL

RECALLRECALL

44

4

44

55

5

55

Switches display between

gross and net weights.

Changes current weighing

unit. Used with FUNCTION

key to access menus.

Used in conjunction with other

keys to provide alternate function.

Turns I150 off.

Enters tare values.

Used alone to retrieve ID

Codes and data, or with FUNCTION key to store ID codes

and data.

Used with FUNCTION key to

start/stop filling processes.

Used with FUNCTION key to

view/enter time.

SETPOINTSETPOINT

SETPOINT

SETPOINTSETPOINT

22

2

22

- / +- / +

- / +

- / +- / +

CLRCLR

CLR

CLRCLR

Used with FUNCTION key to

view/enter setpoint 2.

Clears numeric entries. Aborts

calibration. Clears memory location when used with ID

Codes. Aborts average display cycle. Used with FUNCTION key to change polarity of

numeric entries (+ or -).

13

ONON

ON

ONON

ZEROZERO

ZERO

ZEROZERO

Used with FUNCTION key to

66

6

66

view/enter date.

Blank key used for parts counting with APW/PCS label. Inactive in Legal for Trade applications.

Turns I150 ON. Zeroes display.

USING MENUS TOUSING MENUS TO

USING MENUS TO

USING MENUS TOUSING MENUS TO

CONFIGURE THE I150CONFIGURE THE I150

CONFIGURE THE I150

CONFIGURE THE I150CONFIGURE THE I150

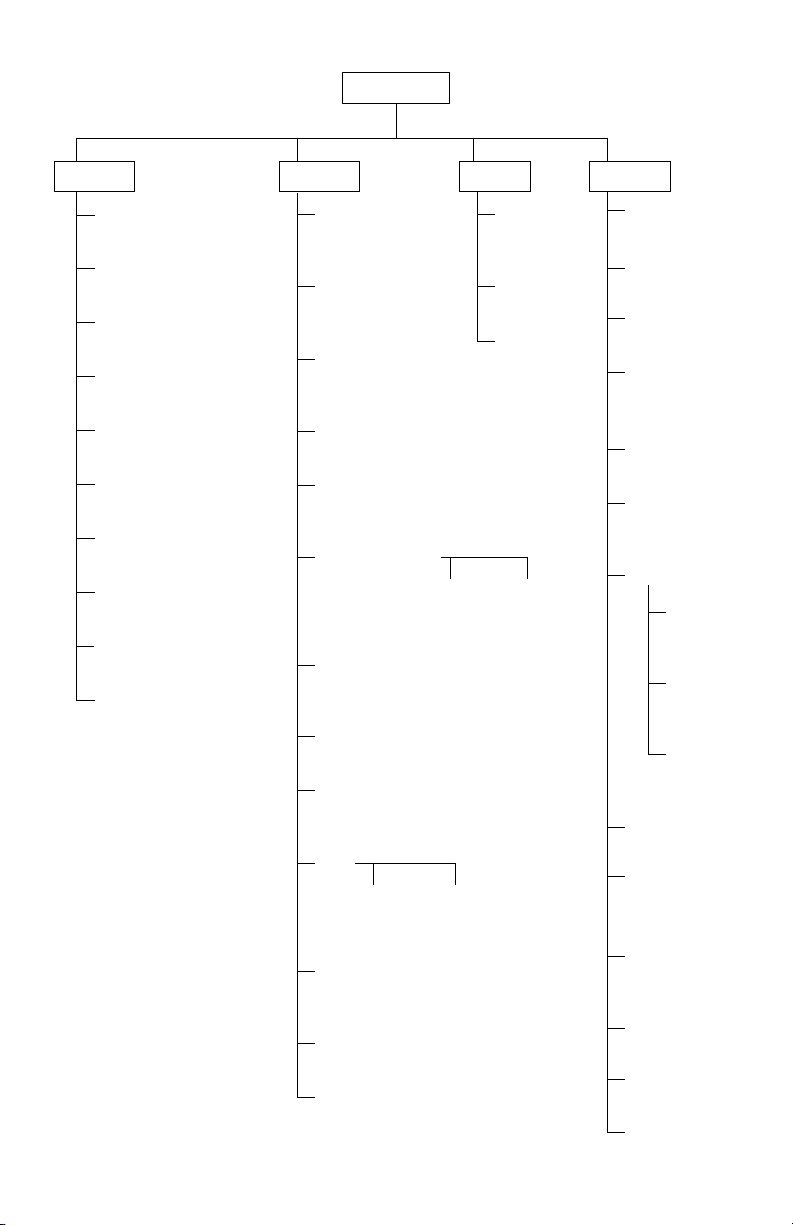

Configuring the I150 for your specific

requirements is accomplished through a

series of “menus”. There is one “main”

menu which includes four “submenus”.

The submenus contain the parameters to

be programmed.

The menus are accessed using the front

panel buttons and viewed on the display.

Using these menus, you will program

parameters such as display resolution,

load receiver capacity, the number of load

receivers used, and others. The menus

are also used to calibrate the indicator.

TO ACCESS THE MAIN MENU:TO ACCESS THE MAIN MENU:

TO ACCESS THE MAIN MENU:

TO ACCESS THE MAIN MENU:TO ACCESS THE MAIN MENU:

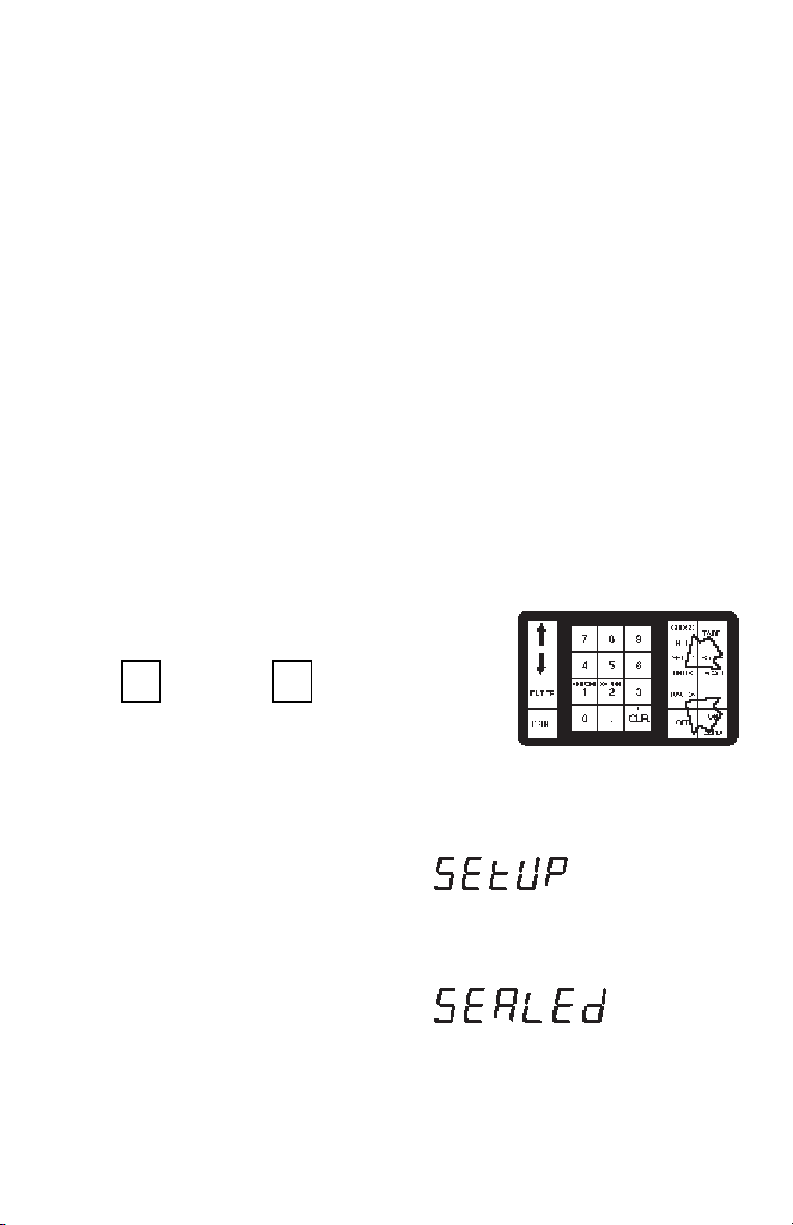

SETUPSETUP

SETUP

FUNCTIONFUNCTION

FUNCTION

FUNCTIONFUNCTION

Press FNCT, then press SETP.

SETUPSETUP

UNITSUNITS

UNITS

UNITSUNITS

The word “SEtUP” will be displayed which

is the first item on the main menu. The

following table shows the sequence in

which the submenus will appear on the

main menu.

If the word “SEALEd” is displayed, it indicates that the I150 has been configured

and sealed for Legal For Trade use. Setup

parameters may not be changed. They

may only be viewed. See “Disabling Menu

Changes For Legal For Trade Installations”.

14

MAIN MENU

SETUP

LFT

ON or OFF

Sense

ON or OFF

Platform

Single or Dual

Zero

Enter % value

Cal. Unit

lb or kg

Full Scale Capacity Pt.

Enter value

Graduation Size

Enter value

Cal Pt.

Enter value

Linearity Pt.

1/2 Cal Pt. or none

End

SCALE CAL RS-232

Reset

to factory

defaults

d Load

adjust

0-5%

Baud

Data

AL

Enter value

0, 1, 2 or 3

Calib

perform

Stop

End

Stb

Enter value

0.5, 1 or 3

Parity

Select

active units

APW

AT

0.5, 1, 3 or

OFF

Auto P

Custom Units

Init

Exp. Mantissa

Enter Enter

value value

AD

Enter value

1 - 255

PC Err

Enter % value

Set Pt.

chec, fill, unfill

or OFF

Stable

Set

Print

Dribble Preact

Enter Enter

value value

nu (numeric

Store

tare, in-out

or apw

data only)

time

Retain

ON or OFF

date

End

Enter value

Enter value

Enter value

none, odd

or even

Enter value

select

parameter

nonP Lo

Enter

value

nonP Hi

Enter

value

Interval

Enter

value

ON or OFF

display or

block data

ON or OFF

ON or OFF

ON or OFF

15

End

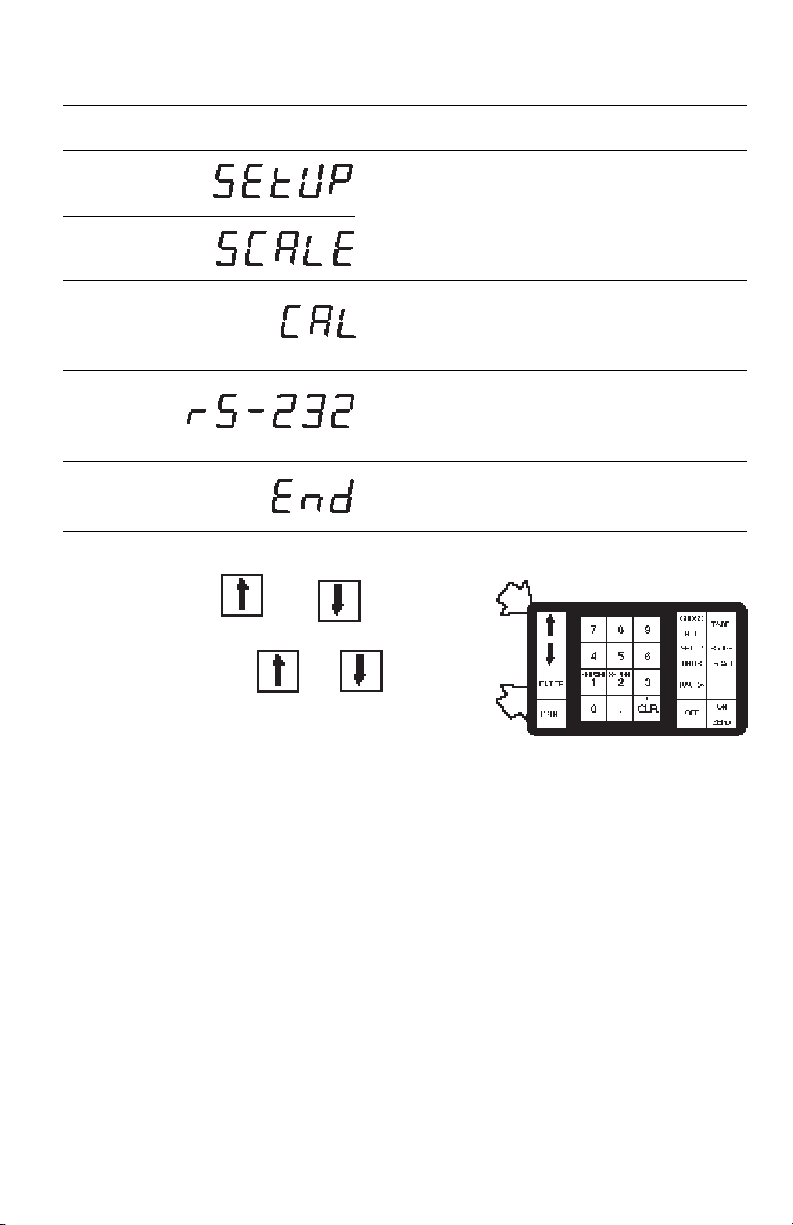

MAIN MENUMAIN MENU

MAIN MENU

MAIN MENUMAIN MENU

Displayed SubmenuDisplayed Submenu

Displayed Submenu

Displayed SubmenuDisplayed Submenu

Only one menu selection will be displayed

at a time. Use the UPUP and DOWN keys

to step through the menu selections. By

repeatedly pressing UPUP or DOWN,

you can view all of the selections on the

DescriptionDescription

Description

DescriptionDescription

Setup and scale submenus are used to

configure the I150 software for the load

receiver(s) being used and to display

weight measurements according to your

requirements.

Calibration submenu is used to adjust

load receiver zero potentiometers and

to calibrate the I150.

RS-232 submenu is used to configure

the interface communication parameters.

End is used to exit the menus and

SAVE CHANGES .

menu.

When you select one of the submenus,

you gain access to a specific group of

operating parameters.

How To Use MenusHow To Use Menus

How To Use Menus

How To Use MenusHow To Use Menus

When initially setting up the I150, it is

recommended to view all of the parameters. Once configured, you can view or

change a particular parameter while bypassing others. The following procedures

apply whenever you use menus.

16

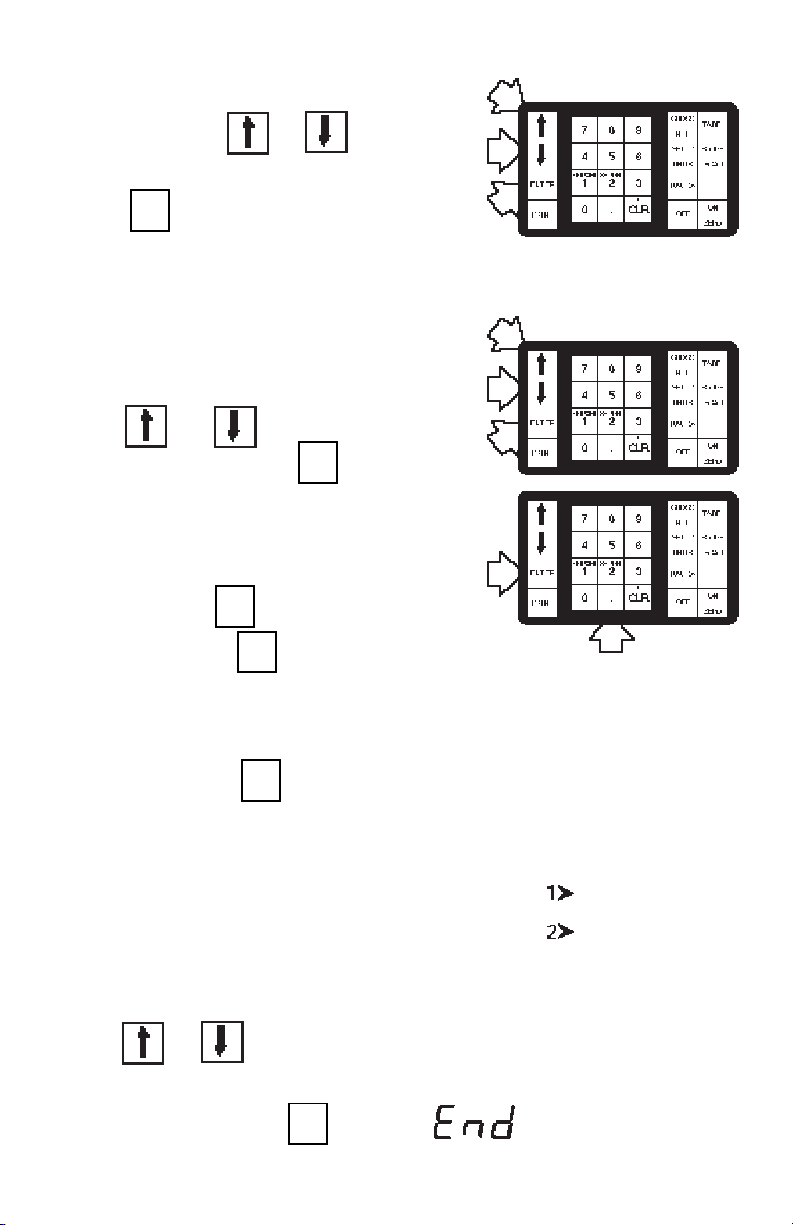

To select an item from a menu:To select an item from a menu:

To select an item from a menu:

To select an item from a menu:To select an item from a menu:

Repeatedly press UPUP or DOWN until

the desired selection is displayed, then

ENTERENTER

ENTER

press ENTER to select it.

Selections and Numeric Entries:Selections and Numeric Entries:

Selections and Numeric Entries:

Selections and Numeric Entries:Selections and Numeric Entries:

ENTERENTER

Some parameters offer you selections to

make while others require you to enter a

numeric value.

To make a selection:To make a selection:

To make a selection:

To make a selection:To make a selection:

Press UPUP or DOWN to display the

ENTERENTER

ENTER

desired setting, then press ENTER.

To enter a numeric value:To enter a numeric value:

To enter a numeric value:

To enter a numeric value:To enter a numeric value:

ENTERENTER

Enter the number using the numeric key-

ENTERENTER

ENTER

pad, then press ENTER. Errors can be

ENTERENTER

cleared by pressing CLER.

- / +- / +

- / +

- / +- / +

CLRCLR

CLR

CLRCLR

If an invalid number is entered, an acceptable number will automatically be substituted.

ENTERENTER

ENTER

If this occurs, press ENTR to accept the

ENTERENTER

new entry.

Dual Load Receivers:Dual Load Receivers:

Dual Load Receivers:

Dual Load Receivers:Dual Load Receivers:

If the I150 is configured for operation with

two load receivers, some parameters must

be entered separately. The load receiver

indicators in the display will show which

one is currently active. To change from

one load receiver to the other,

press UPUP or DOWN.

To exit from any menu:To exit from any menu:

To exit from any menu:

To exit from any menu:To exit from any menu:

ENTERENTER

ENTER

Select “End” , then press ENTER to exit.

ENTERENTER

Load Receiver #1

Load Receiver #2

17

SETUP SUBMENUSETUP SUBMENU

SETUP SUBMENU

SETUP SUBMENUSETUP SUBMENU

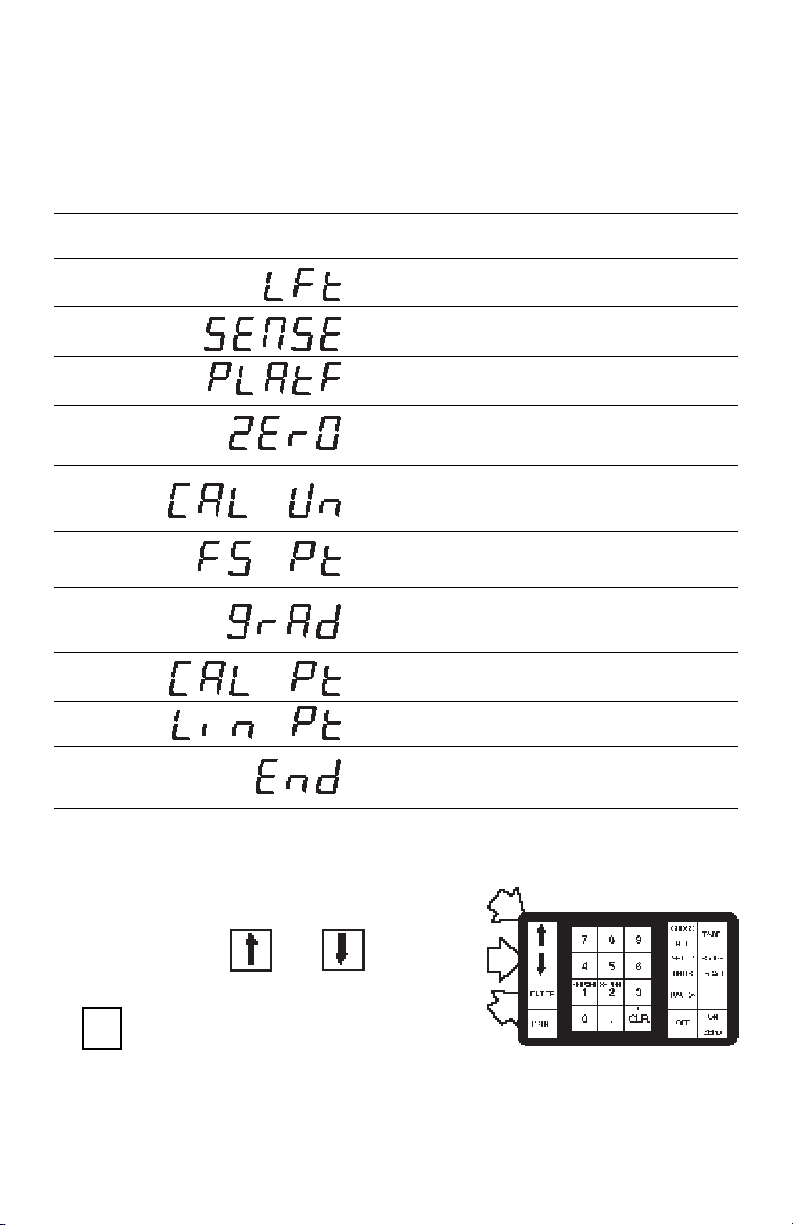

The Setup submenu is used to view or change the parameters outlined in the following

table. The table shows the sequence in which the parameters appear on the display.

SETUP SUBMENUSETUP SUBMENU

SETUP SUBMENU

SETUP SUBMENUSETUP SUBMENU

Displayed ParameterDisplayed Parameter

Displayed Parameter

Displayed ParameterDisplayed Parameter

DescriptionDescription

Description

DescriptionDescription

sets I150 for Legal for Trade operation

enables/disables load cell sensing

configures I150 for 1 or 2 load receivers

specifies allowable percentage of max

load that can be zeroed out

specifies the weighing unit that will be

used for calibration

specifies full scale capacity

specifies increment of calibration unit in

which indicator will display weight

specifies the span calibration point

specifies the linearization point

used to exit the Setup menu

To select a parameter,

Repeatedly press UPUP or DOWN to

display the desired parameter, then press

ENTERENTER

ENTER

ENTERENTER

ENTER.

18

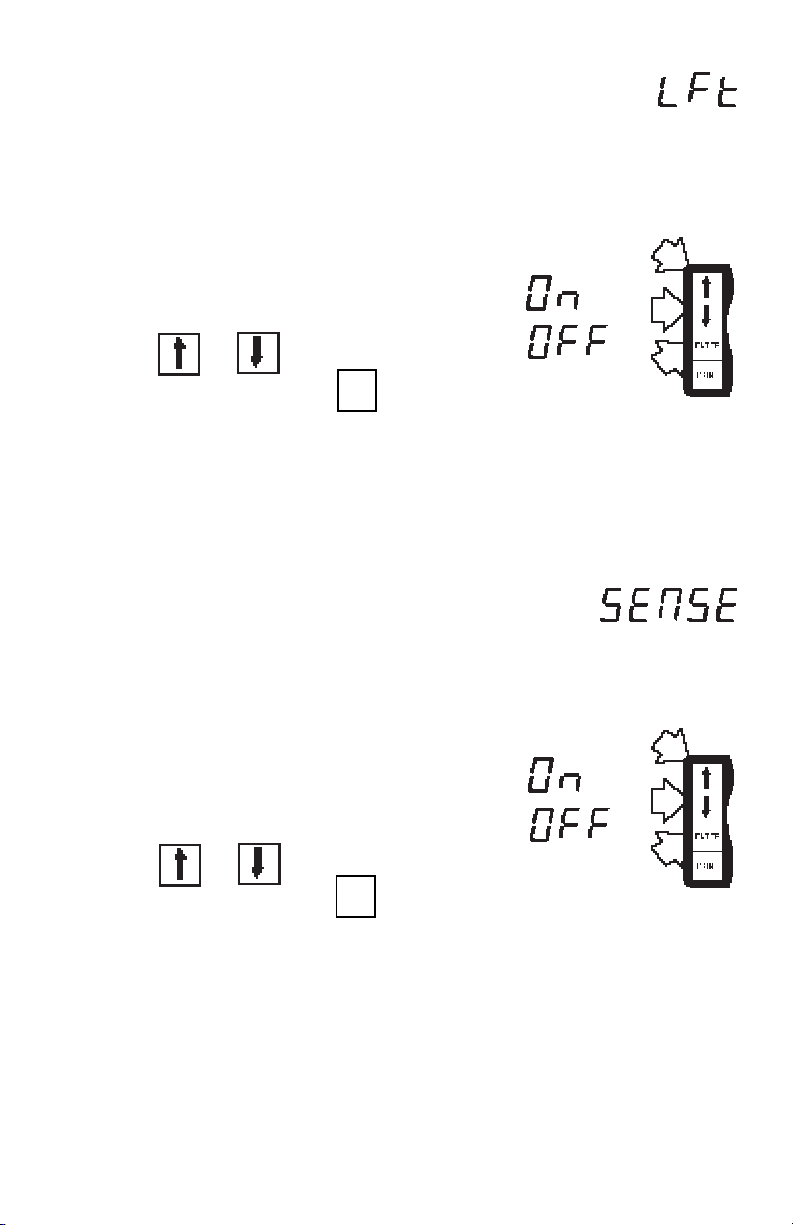

Legal For TradeLegal For Trade

Legal For Trade

Legal For TradeLegal For Trade

This parameter can be set to ON or OFF.

Selecting ON automatically sets certain

parameters for legal for trade requirements, disables others, and limits the

overall display resolution to 1:10,000.

When this parameter is set to ON, only

load receiver #1 may be used.

To set this parameter ON or OFF:

Press UPUP or DOWN to display the

ENTERENTER

ENTER

desired setting, then press ENTER

ENTERENTER

to return to the setup submenu.

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

RECALIBRATION IS REQUIRED if LFT

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

is switched from OFF to ON and greater

than 1:10,000 resolution exists.

SenseSense

Sense

SenseSense

Sense is used to compensate for signal

losses when load receivers are located

long distances from the indicator. When

this feature is used, only load receiver #1

may be connected to the indicator. If two

load receivers are used, OFF must be

selected for this parameter.

To set the Sense parameter ON or OFF:

Press UPUP or DOWN to display the

ENTERENTER

ENTER

desired setting, then press ENTER

ENTERENTER

to return to the setup submenu.

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

RECALIBRATION IS REQUIRED if

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

SENSE parameter is changed.

19

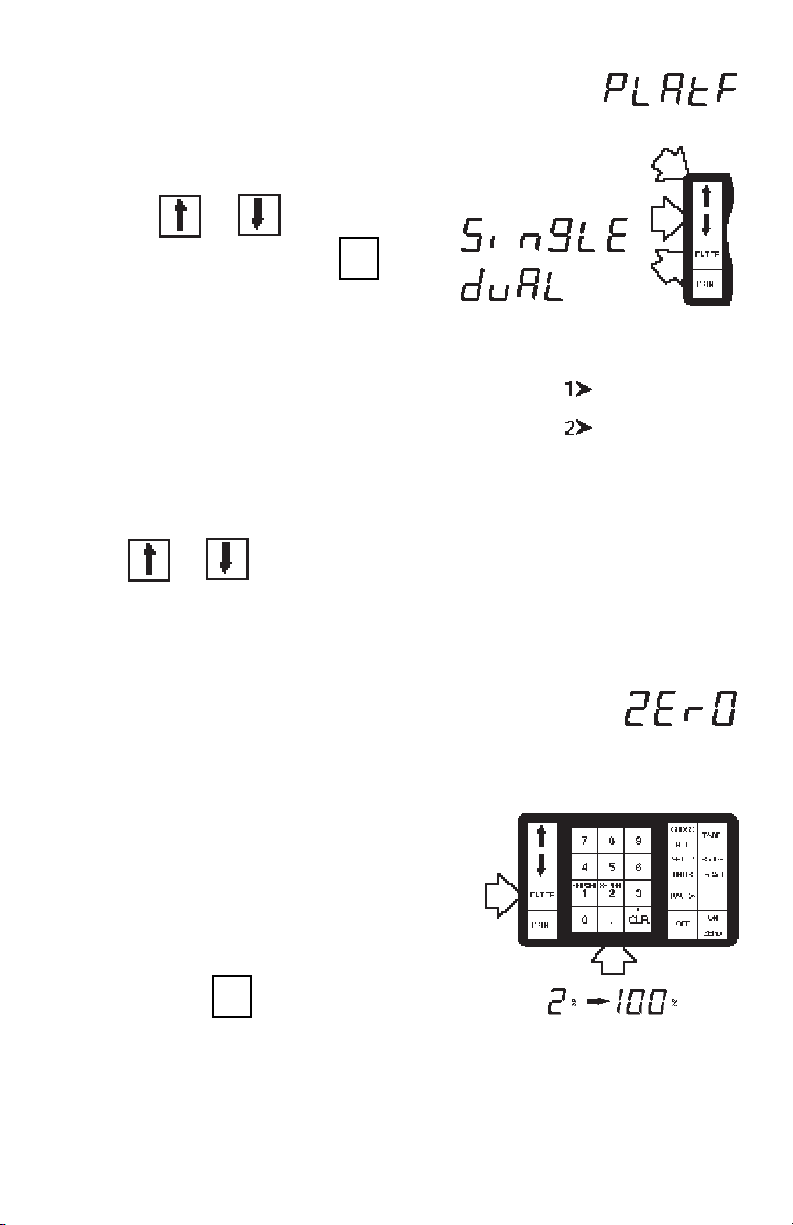

Number of Load ReceiversNumber of Load Receivers

Number of Load Receivers

Number of Load ReceiversNumber of Load Receivers

The I150 is configured for operation with

one (single) or two (dual) load receivers

using this parameter:

Press UPUP or DOWN to display the

ENTERENTER

ENTER

desired setting, then press ENTER

ENTERENTER

to return to the setup submenu.

If Dual is selected:If Dual is selected:

If Dual is selected:

If Dual is selected:If Dual is selected:

If dual is selected, the load receiver indicators on the display will light to show

which load receiver is currently being

displayed. Some parameters can be set

separately for load receiver 1 and 2.

To switch from one to the other,

press UPUP or DOWN.

LFT NOTE:LFT NOTE:

LFT NOTE: “SingLE” is automatically se-

LFT NOTE:LFT NOTE:

lected when LFT is set to ON.

Load Receiver #1

Load Receiver #2

ZeroZero

Zero

ZeroZero

This parameter specifies the percentage

of full capacity load that may be cleared

by pressing ZERO. Zero limits may be

required in certain applications. The value

can be set to any number from 2% to

100%.

To set the allowable Zero:

Enter the desired percentage (from 2

to 100) using the numeric keypad,

ENTERENTER

ENTER

then press ENTER to return to the

ENTERENTER

setup submenu.

LFT NOTE:LFT NOTE:

LFT NOTE: Must be set to ≤4% zero for

LFT NOTE:LFT NOTE:

Canadian Legal for Trade installations.

20

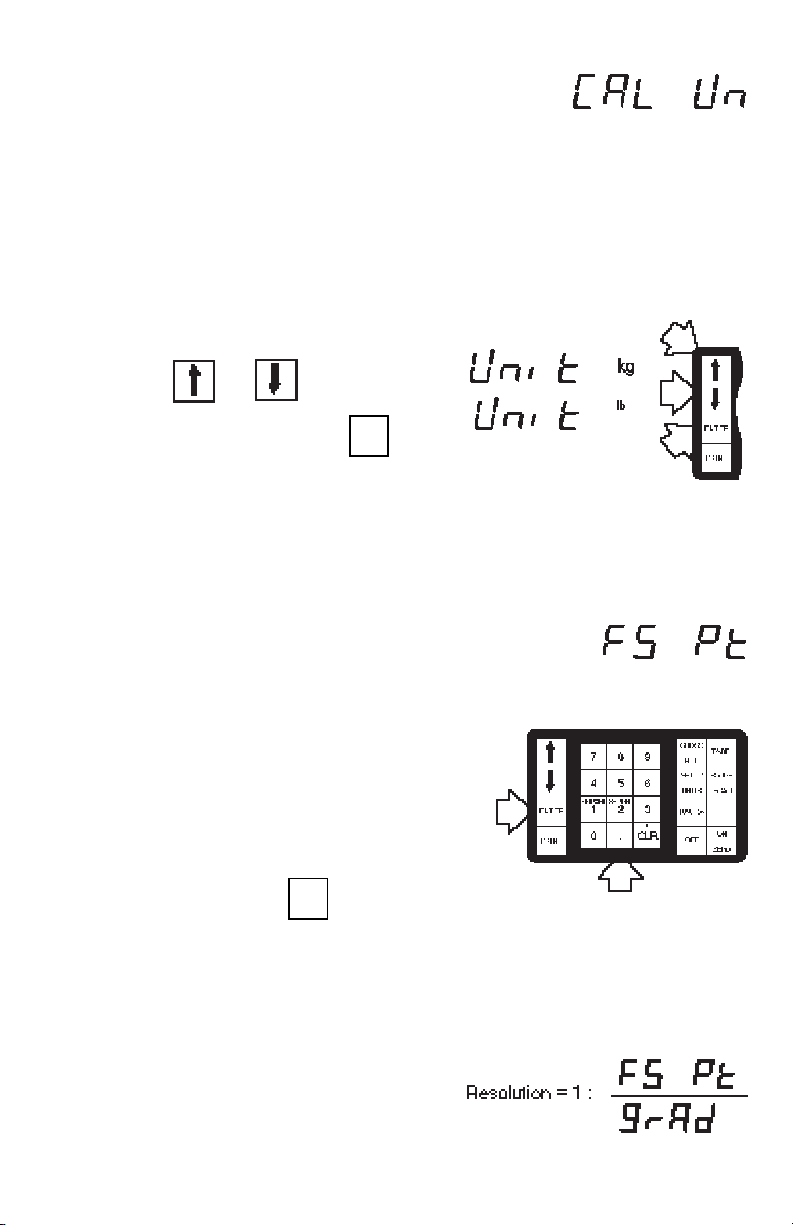

Calibration UnitCalibration Unit

Calibration Unit

Calibration UnitCalibration Unit

The indicator can be calibrated using

pounds or kilograms; no other units are

acceptable. If dual load receivers are

used, the same calibration unit applies to

both.

When you access this parameter, the

display will show the word “Unit” and the

current calibration unit indicator.

To change the calibration unit:

Press UPUP or DOWN to switch to

ENTERENTER

ENTER

the desired unit, then press ENTER

ENTERENTER

to return to the setup submenu

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

RECALIBRATION IS REQUIRED if the

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

calibration unit is changed. Setup submenu changes are not saved if you exit

menus without recalibrating.

Full Scale PointFull Scale Point

Full Scale Point

Full Scale PointFull Scale Point

The maximum capacity of the load receiver is entered in this parameter using

the same weighing unit selected for the

calibration unit.

To enter the full scale point:

Enter the number using the numeric

ENTERENTER

ENTER

keypad, then press ENTER to return

ENTERENTER

to the setup submenu.

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

RECALIBRATION IS REQUIRED if the

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

full scale point is changed. Setup submenu changes are not saved if you exit

menus without recalibrating.

LFT NOTE:LFT NOTE:

LFT NOTE: Resolution is limited to

LFT NOTE:LFT NOTE:

1:10,000 for Legal for Trade installations.

Enter Full Scale Point

21

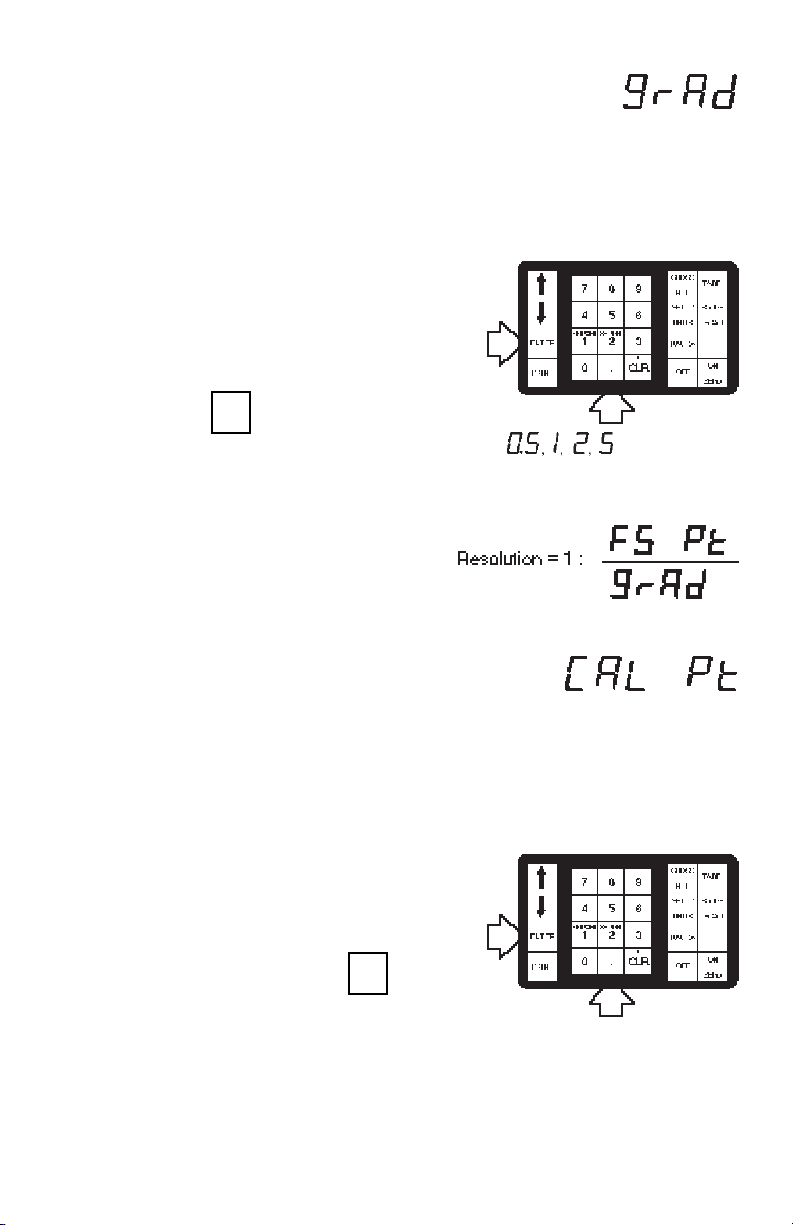

GraduationsGraduations

Graduations

GraduationsGraduations

This parameter specifies the increments

in which the last digit of the display will

count, and sets the decimal point position. Graduations can be set to a decimal

multiple of 1, 2, or 5 (i.e. .02, .2, 2, 20,

etc.).

To set graduations:

Enter the desired number (with decimal point) using the numeric keypad,

ENTERENTER

ENTER

then press ENTER to return to the

ENTERENTER

setup submenu.

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

RECALIBRATION IS REQUIRED if the

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

graduations setting is changed. Setup

submenu changes are not saved if you

exit menus without recalibrating.

LFT NOTE:LFT NOTE:

LFT NOTE: Resolution is limited to

LFT NOTE:LFT NOTE:

1:10,000 for Legal for Trade installations.

Calibration PointCalibration Point

Calibration Point

Calibration PointCalibration Point

The calibration point is the weight value

that will be used to calibrate the indicator.

It can be any value from 10% to 100% of

the Full Scale Point and must be entered

in the same weighing unit selected for the

calibration unit.

To enter the calibration point:

Enter the desired value using the

numeric keypad, then press ENTER

to return to the setup submenu.

ENTERENTER

ENTER

ENTERENTER

or .1, .2, .5, Etc.

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

RECALIBRATION IS REQUIRED if the

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

calibration point is changed. Setup submenu changes are not saved if you exit

menus without recalibrating.

22

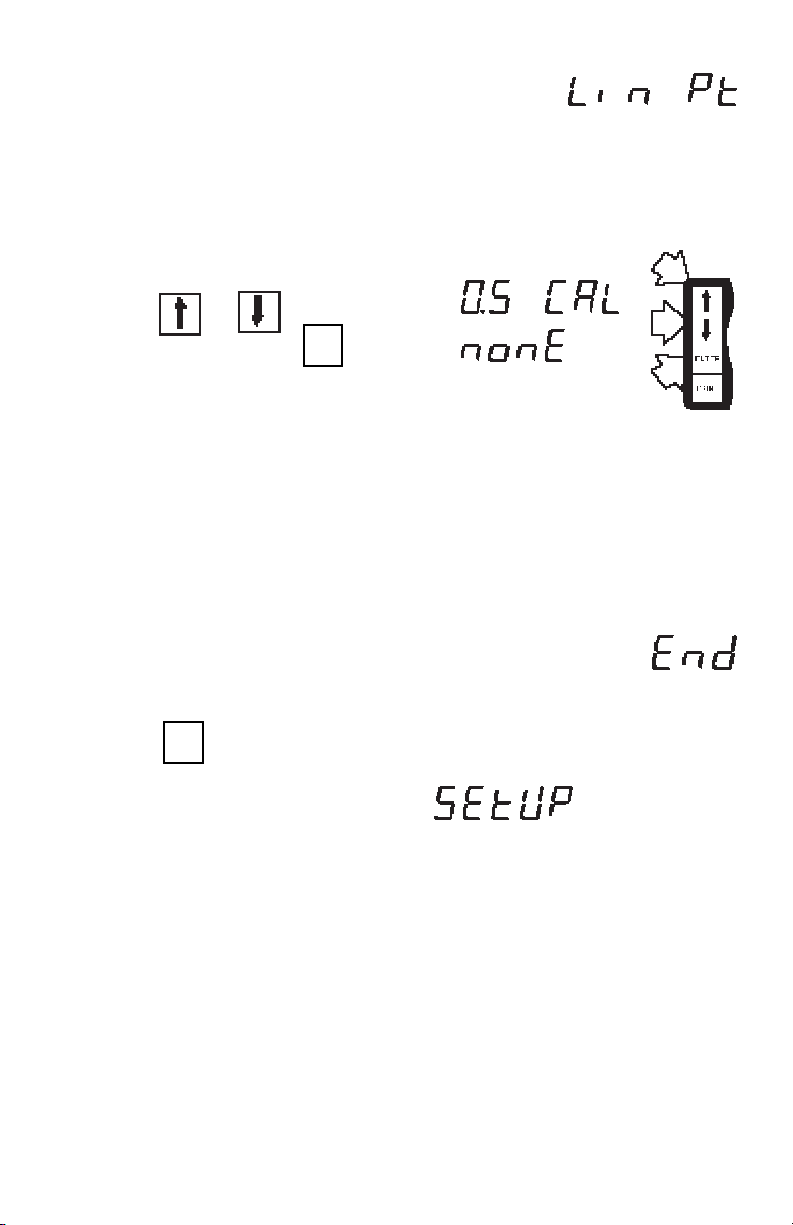

Linearization PointLinearization Point

Linearization Point

Linearization PointLinearization Point

This parameter is used when 3-point linearization is required. The linearization

point can be set to either 1/2 of the

Calibration point, or “NONE” to disable 3point linearization.

To set the linearization point:

Press UPUP or DOWN to display the

ENTERENTER

ENTER

desired setting, press ENTER to re-

ENTERENTER

turn to the setup submenu.

LFT NOTE:LFT NOTE:

LFT NOTE: Parameter does not appear

LFT NOTE:LFT NOTE:

on menu when LFT is set to ON.

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

RECALIBRATION IS REQUIRED if the

RECALIBRATION IS REQUIREDRECALIBRATION IS REQUIRED

linearization point is changed. Setup submenu changes are not saved if you exit

menus without recalibrating.

EndEnd

End

EndEnd

You must select “End” to exit the Setup

submenu. To exit the setup submenu:

ENTERENTER

ENTER

1. Press ENTEwhen “End” is displayed.

ENTERENTER

2. “SEtUP” will be displayed and the

main menu will be returned.

NOTE: Parameter settings are permanently stored in memory when you use

“End” to exit from the Main menu, or when

the OFF key is pressed. However, Setup

submenu parameter changes require recalibration in order to be saved.

23

Loading...

Loading...