Ohaus Corporation

29 Hanover Road

Florham Park NJ

07932-0900

PRECISION

Electronic Balances

GT Series

Advanced

Instruction Manual

NOTE:NOTE:

NOTE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH

NOTE:NOTE:

THE LIMITS FOR A CLASS A DIGITAL DEVICE, PURSUANT TO PART 15 OF

THE FCC RULES.

THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION

AGAINST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED

IN A COMMERCIAL ENVIRONMENT. THIS EQUIPMENT GENERATES, USES,

AND CAN RADIATE RADIO FREQUENCY ENERGY AND, IF NOT INSTALLED

AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE

HARMFUL INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF

THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE HARMFUL

INTERFERENCE IN WHICH CASE THE USER WILL BE REQUIRED TO CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

THIS DIGITAL APPARATUS DOES NOT EXCEED THE CLASS A LIMITS FOR

RADIO NOISE EMISSIONS FROM DIGITAL APPARATUS AS SET OUT IN THE

INTERFERENCE-CAUSING EQUIPMENT STANDARD ENTITLED “DIGITAL APPARATUS”, ICES-003 OF THE DEPARTMENT OF COMMUNICATIONS.

CET APPAREIL NUMERIQUE RESPECTE LES LIMITES DE BRUITS

RADIOELECTRIQUES APPLICABLES AUX APPAREILS NUMERIQUES DE

CLASSE A PRESCRITES DANS LA NORME SUR LE MATERIEL BROUILLEUR :

“APPAREILS NUMERIQUES”, NMB-003 EDICTEE PAR LE MINISTRE DES COMMUNICATIONS.

Unauthorized changes or modifications to this equipment are not permitted.

The exclamation

point within the triangle is a warning

sign alerting you of

important instructions accompanying the product.

2

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

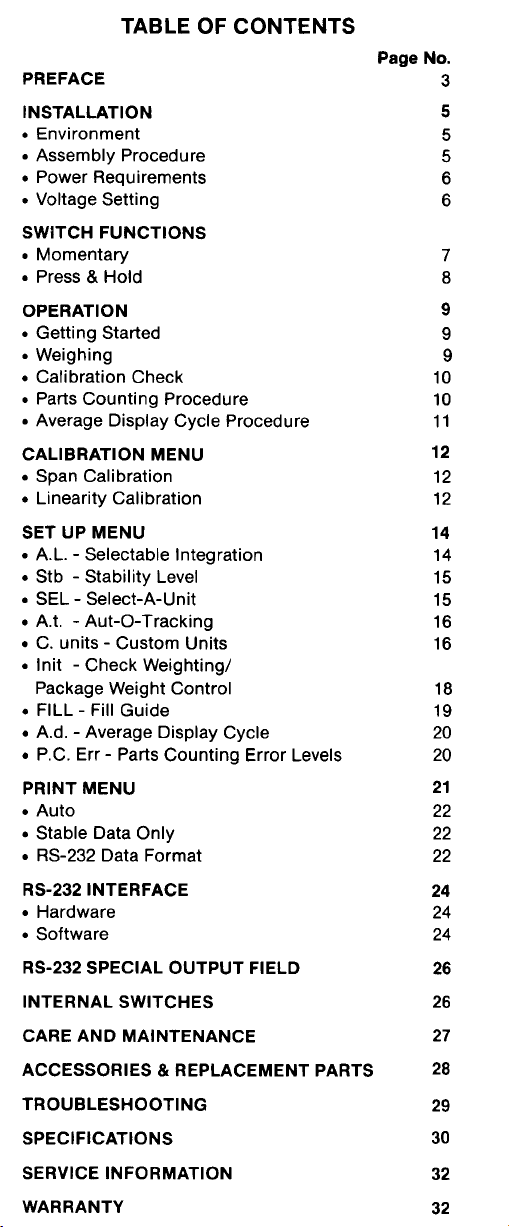

INTRODUCTION.................................................................................................. 7

DESCRIPTION.....................................................................................................7

FEATURES..........................................................................................................7

UNPACKING ........................................................................................................ 8

INSTALLATION.................................................................................................... 8

Environment.................................................................................................. 8

Below Balance Hook..................................................................................... 8

Leveling the Balance..................................................................................... 9

Power Requirements .................................................................................... 9

Voltage Setting .............................................................................................. 9

Draft Shield (Models GT210, GT410 and GT4100D)................................. 10

Platform and Platform Support ................................................................... 10

Model GT8000T Tower Assembly Installation ............................................ 10

RS232 Interface.......................................................................................... 1 1

Hardware ................................................................................................. 11

Output Formats ....................................................................................... 11

RS232 Commands ...................................................................................... 11

OPERATION ...................................................................................................... 14

Switch Functions......................................................................................... 1 4

Symbols Used for Operation of the Balance .............................................. 15

Navigating the Menus ................................................................................. 16

Operational Guide/Index ............................................................................. 17

Turning the Balance On.............................................................................. 18

Display Indications ...................................................................................... 19

Stabilization................................................................................................. 19

Moveable FineRange

Weighing ..................................................................................................... 20

Zero/Tare .................................................................................................... 20

Auto Tare .................................................................................................... 20

Percent Weighing ........................................................................................ 21

Parts Counting ............................................................................................ 2 2

Check Weighing .......................................................................................... 23

Animal Weighing ......................................................................................... 24

Fill Guide ..................................................................................................... 25

Reference Weight ................................................................................... 25

TM

(Models GT410D and GT4100D) ......................... 19

3

Reference Number .................................................................................. 2 6

High Point.................................................................................................... 26

Printing Data ............................................................................................... 27

Time and Date......................................................................................... 27

List ........................................................................................................... 28

Span Calibration Printout ........................................................................ 29

Linearity Calibration Printout ................................................................... 29

Calibration Test Printout.......................................................................... 29

Statistics Printout .................................................................................... 30

Sampling .................................................................................................. 30

Percent Weighing .................................................................................... 31

Parts Counting ......................................................................................... 31

Check Weighing ...................................................................................... 32

FillGuideTM................................................................................................ 32

MENUS .............................................................................................................. 33

MENU LOCK-OUT PROTECTION .................................................................... 34

TYPE APPROVED BALANCE SEALING .......................................................... 36

CALIBRATION MENU ........................................................................................ 36

Calibration Menu Protection ....................................................................... 36

Calaibration Masses ................................................................................... 36

Span Calibration ......................................................................................... 37

Linearity Calibration ................................................................................... 3 7

User Calibration .......................................................................................... 38

Cal Test....................................................................................................... 38

USER MENU...................................................................................................... 39

User Menu Protection ................................................................................. 39

Reset........................................................................................................... 40

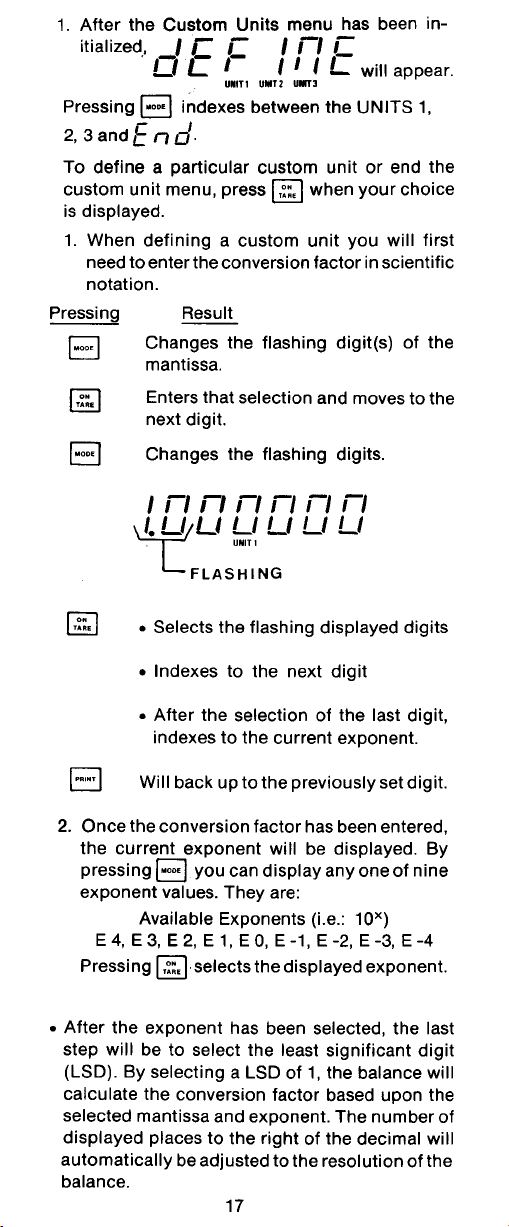

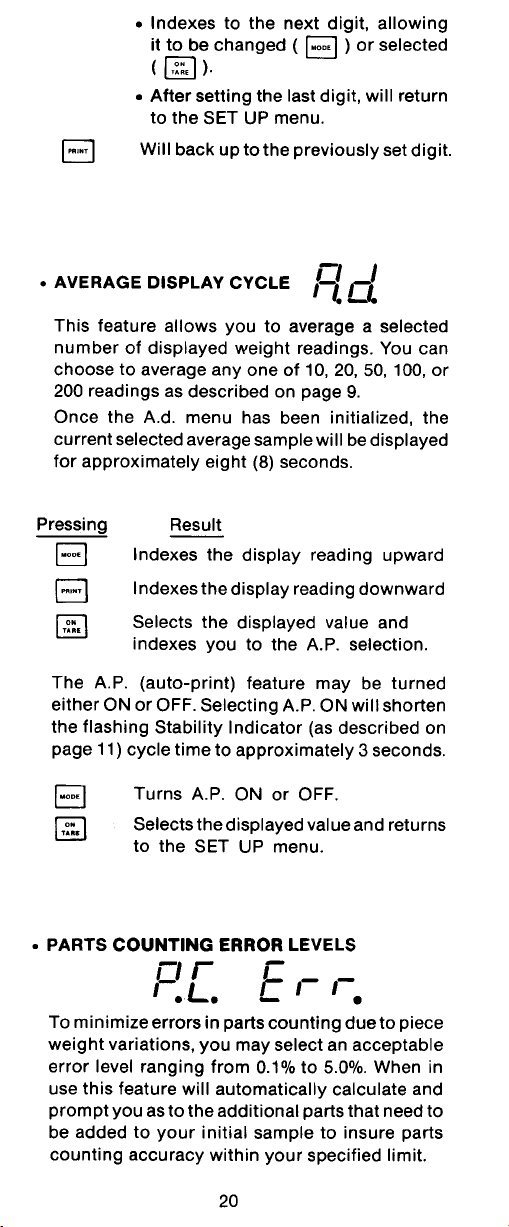

Averaging Level .......................................................................................... 40

Stability Range ............................................................................................ 41

Auto-Zero .................................................................................................... 41

Beep Function ............................................................................................. 42

Exiting User Menu ....................................................................................... 4 2

4

SETUP MENU.................................................................................................... 42

Setup Menu Protection ............................................................................... 44

Reset........................................................................................................... 44

Type Approved/LFT .................................................................................... 45

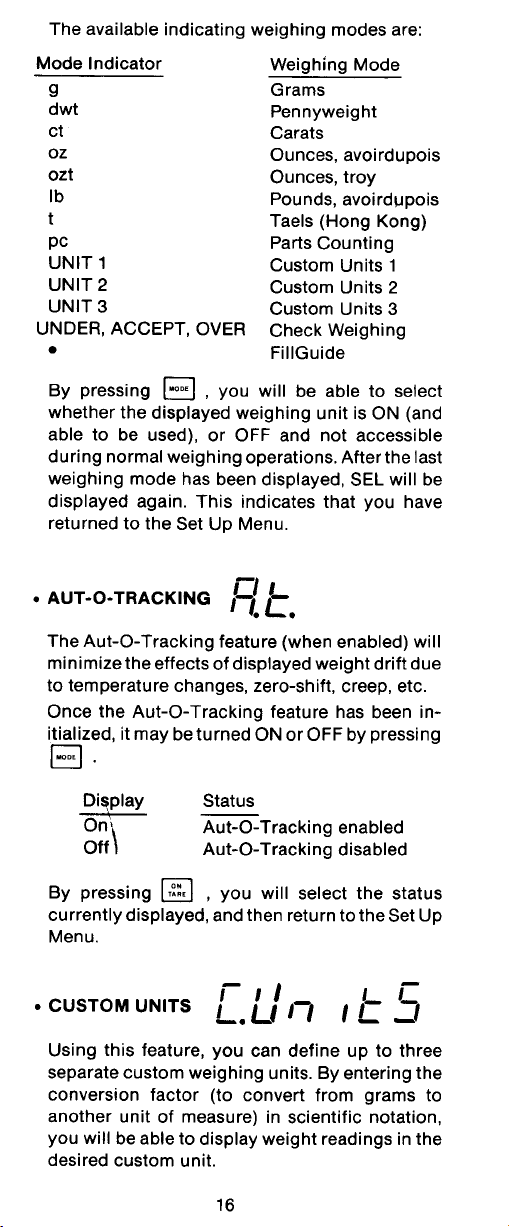

Unit Selection .............................................................................................. 45

Functions ..................................................................................................... 4 6

Statistics...................................................................................................... 47

Net............................................................................................................... 48

Auto Tare .................................................................................................... 48

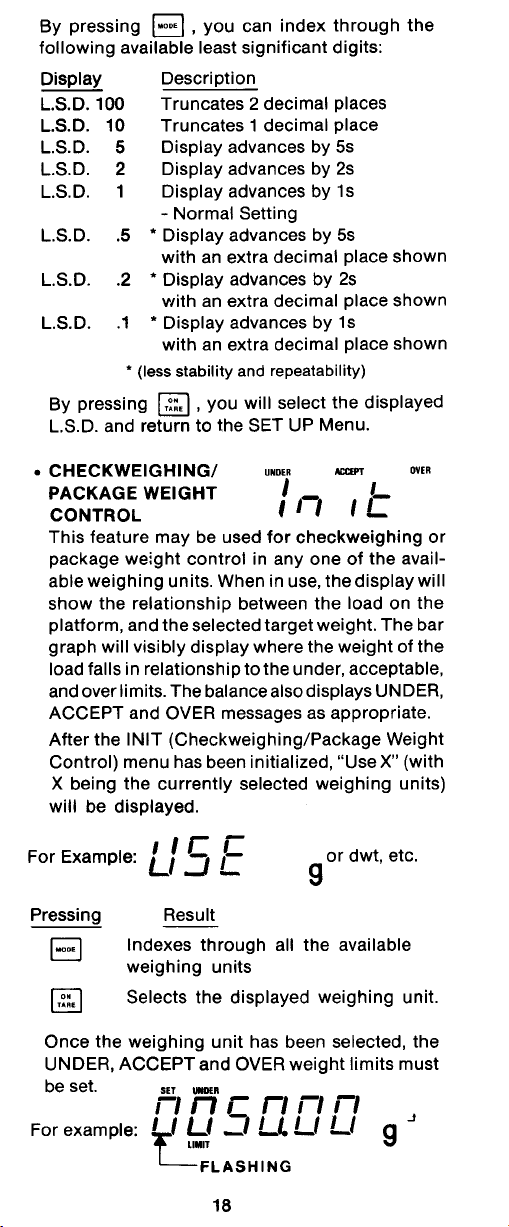

Custom Unit or Volume Selection............................................................... 49

Operating Procedure ............................................................................... 50

Good Laboratory Practices......................................................................... 51

Parts Counting Error ................................................................................... 51

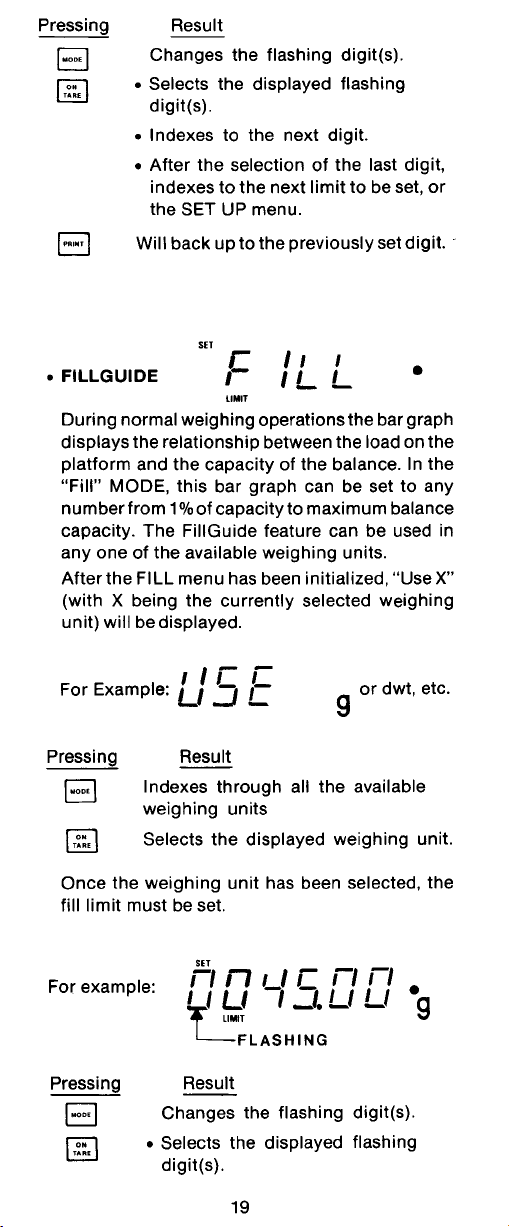

Check Weighing Options ............................................................................ 51

Sample Displays ......................................................................................... 53

Animal Weighing Options ........................................................................... 54

Fill Option .................................................................................................... 54

Time ............................................................................................................ 56

Date............................................................................................................. 57

Lockswitch................................................................................................... 58

List............................................................................................................... 59

Exit Setup Menu ......................................................................................... 59

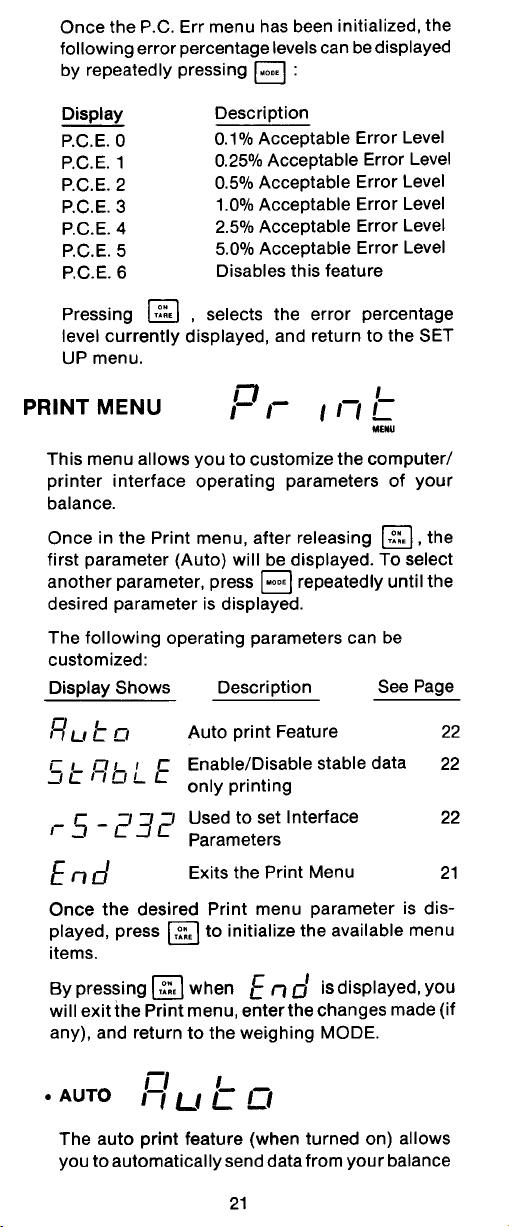

PRINT MENU ..................................................................................................... 60

Print Menu Protection ................................................................................. 6 0

Reset........................................................................................................... 61

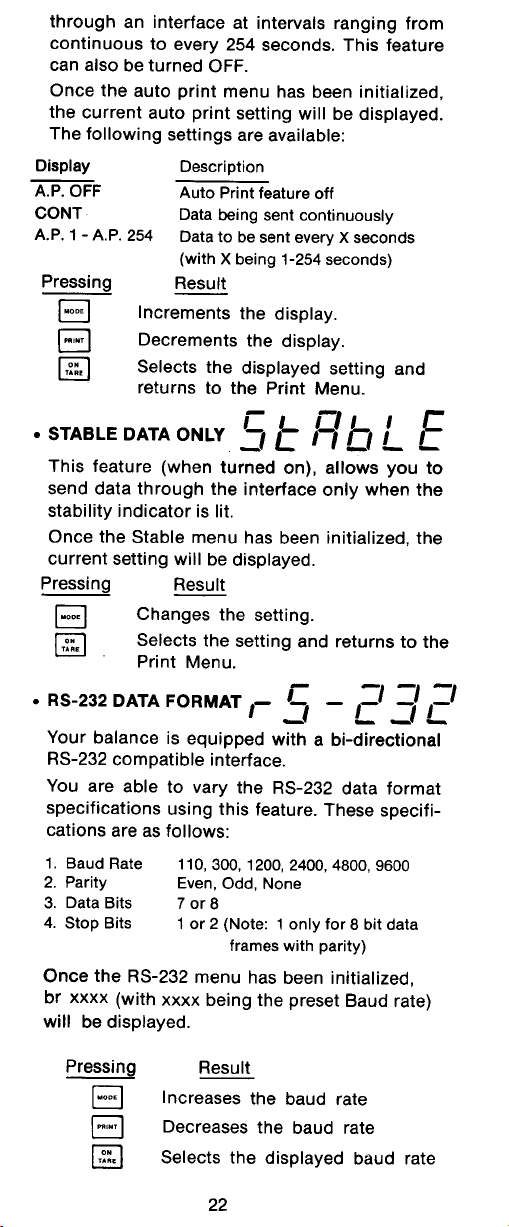

Communication ........................................................................................... 61

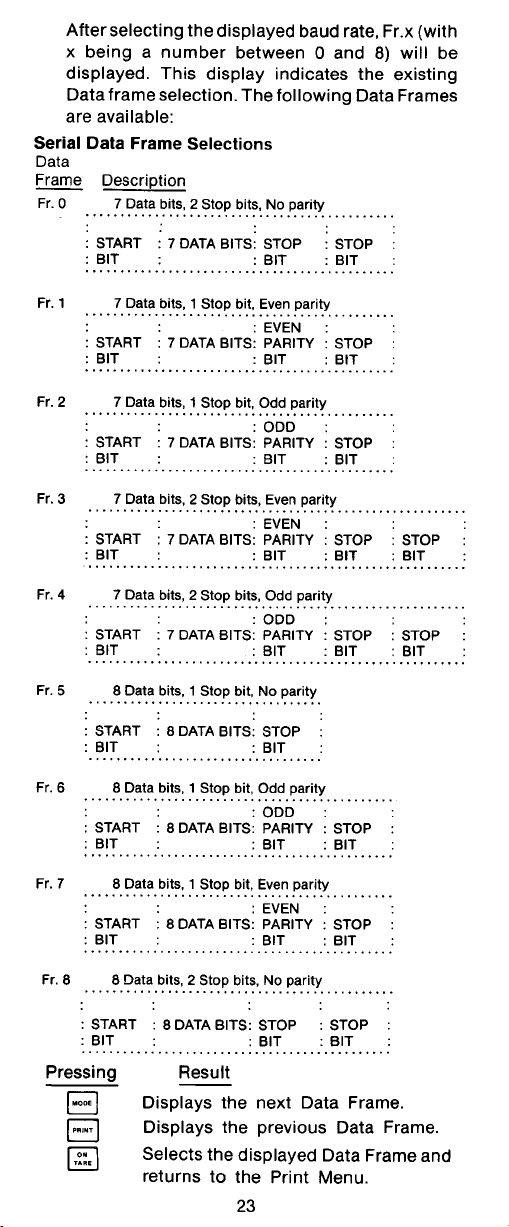

Baud Rate ............................................................................................... 62

Data Bits .................................................................................................. 62

Parity ....................................................................................................... 62

Stop Bits .................................................................................................. 63

Good Laboratory Practices (GLP) .............................................................. 63

Print Options ............................................................................................... 6 4

Auto Print Feature ................................................................................... 64

5

Initialize.................................................................................................... 64

Print Stable Data Only............................................................................. 66

Print Numeric Data Only ......................................................................... 66

Time......................................................................................................... 66

Date ......................................................................................................... 67

Reference ................................................................................................ 67

Difference ................................................................................................ 67

List ........................................................................................................... 68

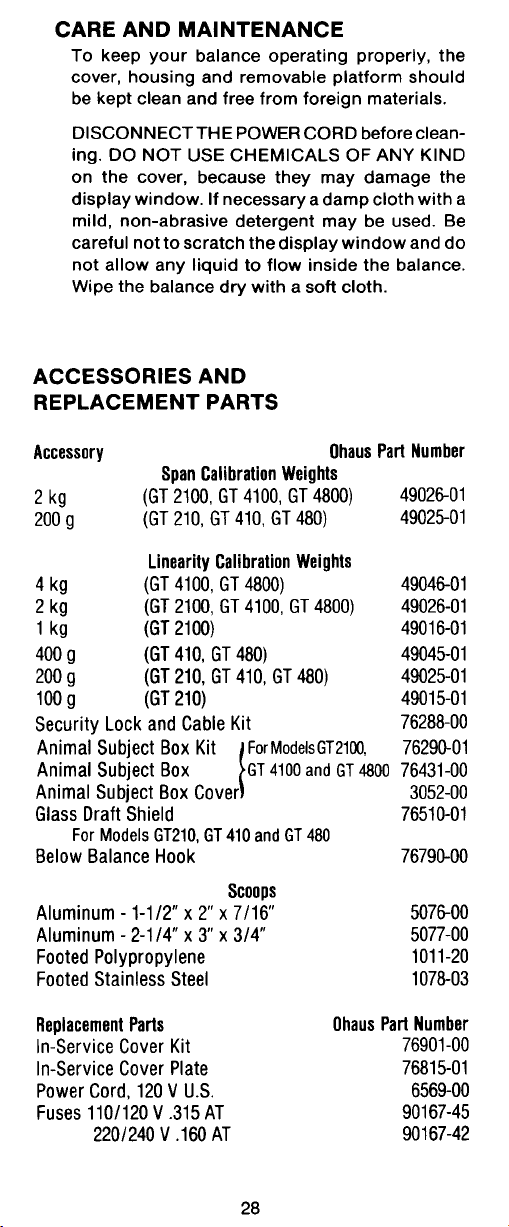

CARE AND MAINTENANCE ............................................................................. 69

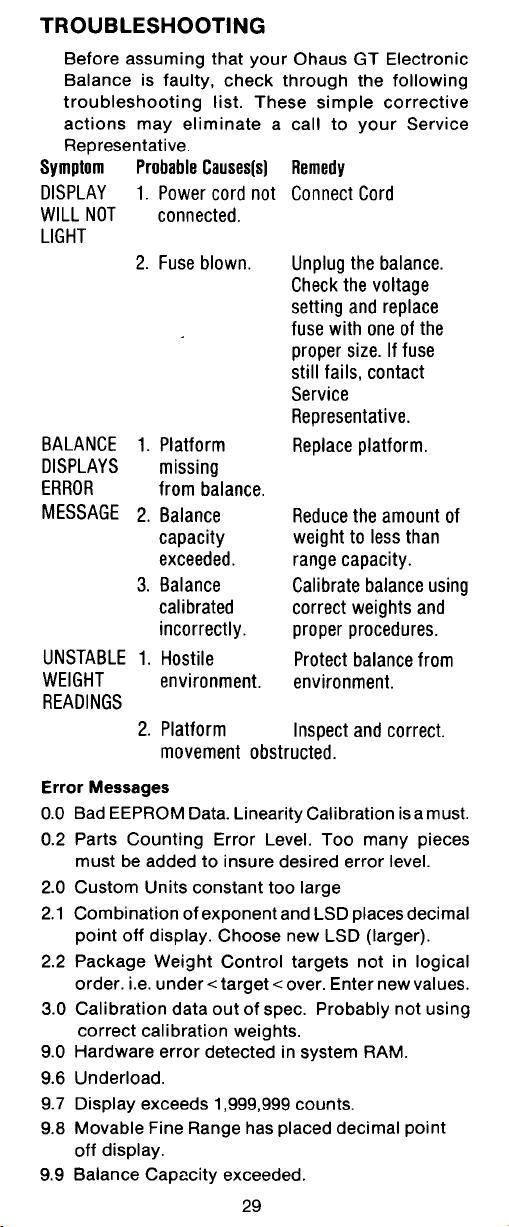

TROUBLESHOOTING ....................................................................................... 69

Error Codes List .......................................................................................... 70

SERVICE INFORMATION ................................................................................. 72

REPLACEMENT PARTS ................................................................................... 72

ACCESSORIES ................................................................................................. 72

SPECIFICATIONS ............................................................................................. 73

LIMITED WARRANTY ....................................................................................... 75

6

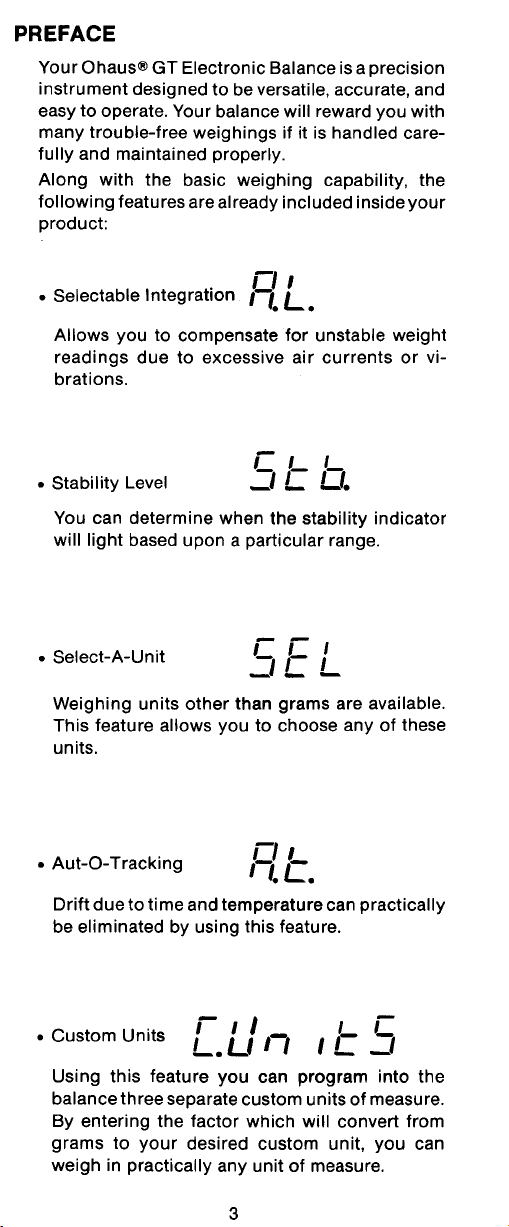

INTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

This manual covers Installation, Operation and Troubleshooting for the Ohaus

Precision Advanced Series of Electronic balances, Models GT210, GT400, GT410,

GT2100, GT4000, GT4100, and GT8000. Suffixes after the basic model number are:

D = Moveable FineRangeTM, T=Tower Mount and V=Non Type Approved. Models with

an E suffix = Type Approved with CE conformance and bear official markings (Max,

Min, Class, etc.) on a serial number plate located on the side of the balance. To ensure

proper operation of the balance, please read this manual completely.

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

The Ohaus Precision Advanced GT Series balances are precision weighing instruments, designed to be versatile, accurate, easy to operate and will provide years of

service with virtually no maintenance. The Precision Advanced series is constructed

using a die-cast aluminum base finished with a durable corrosion resistant epoxy

powder paint. It contains solid-state precision electronics PC boards, and a seven and

a half, 0.45 inch digit, Vacuum Fluorescent display. Each balance operates through

a series of menus which enhances operation. A built in lockswitch prevents preset

settings from being changed. To prevent measurements from being affected by air

currents, a Draft Shield is mounted to the balance and is standard with Models GT210,

GT410 and GT410D.

FEATURES

Precision Advanced balances contain four main display menus which enable you to

calibrate and configure the balance for specific operating requirements.

MENU MENU

•

MENU When switch is pressed and released with MENU displayed, allows

MENU MENU

entry into other menus.

CALIBRATIONCALIBRATION

•

CALIBRATION Menu - Allows the balance to be calibrated by using either Span

CALIBRATIONCALIBRATION

or Linearity calibration methods. A Test function is used to verify the last

calibration.

USERUSER

•

USER Menu - Allows the balance to be set for environmental conditions. Reset,

USERUSER

averaging level, stability range, auto-zero and beep (sound) functions can be set.

SETUPSETUP

•

SETUP Menu - Allows the balance to be customized for specific weighing

SETUPSETUP

functions.

PRINTPRINT

•

PRINT Menu - Allows the selection of parameters under which the balance will

PRINTPRINT

interface to a computer or a printer.

Each of these menus contain selectable parameters which can be entered via the front

panel switches. Storing of the parameters is accomplished by selecting

completion of all selections in a particular menu. For a detailed description of each

feature, refer to the individual menus in this manual.

7

EndEnd

End

EndEnd

at the

INSTALLATION

UNPACKINGUNPACKING

UNPACKING

UNPACKINGUNPACKING

Your Precision Advanced balance was shipped with the following items:

• Platform

• Platform Support

• Power Cord

• Below Balance Weighing Hook

• Draft Shield included with Models: GT210, GT410 and GT410D

• Instruction Manual

• Warranty Card

• In-Service Cover

• Sealing Kit (Type Approved/Legal for Trade)

It is recommended to save the carton and packing material for storing, transporting the

balance or returning it for service.

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

EnvironmentEnvironment

Environment

EnvironmentEnvironment

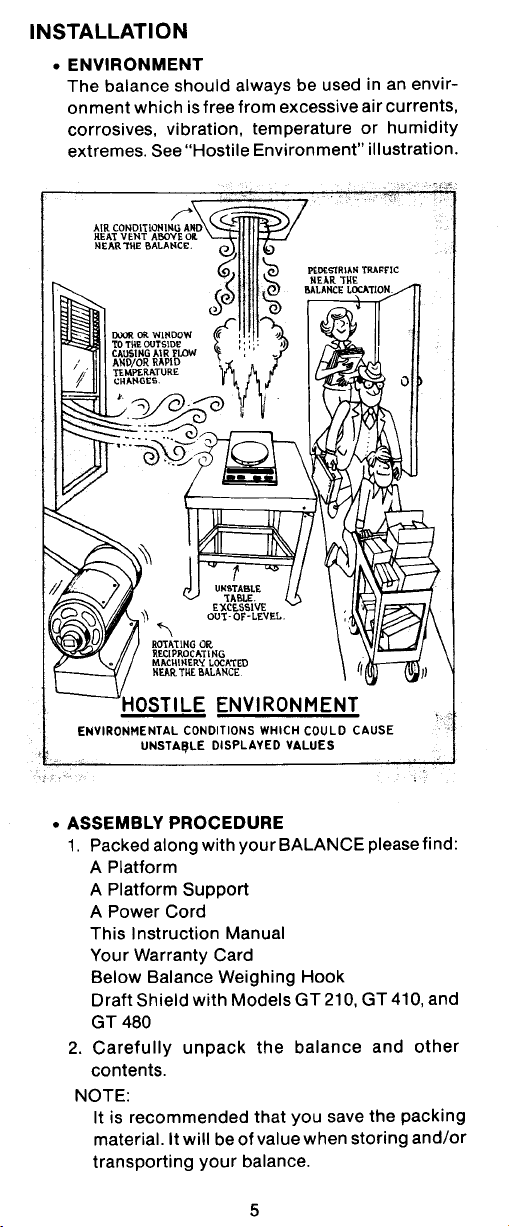

The balance should always be used in an environment which is free from excessive

air currents, corrosives, vibration, and temperature or humidity extremes. These

factors will affect displayed weight readings.

DO NOTDO NOT

DO NOT install the balance:

DO NOTDO NOT

• Next to open windows or doors causing drafts or rapid temperature changes.

• Near air conditioning or heat vents.

• Near vibrating, rotating or reciprocating equipment.

• Near magnetic fields or equipment that

generates magnetic fields.

• On an unlevel work surface.

Below Balance HookBelow Balance Hook

Below Balance Hook

Below Balance HookBelow Balance Hook

A common application for this item is for

determination of density or specific gravity.

Mount the balance on a suitable surface

which allows below balance weighing. If the

below balance hook will be used, it may be

installed in the bottom of the balance. Remove the protective plug at the bottom of

the balance and screw the hook into the

threaded hole in the Platform Support which

is visible through the access hole in the

bottom of the balance.

8

PLATE

BELOW BALANCE HOOK

Leveling the BalanceLeveling the Balance

Leveling the Balance

Leveling the BalanceLeveling the Balance

The balance is equipped with a level indicator

located at the rear of the balance and two

adjustable leveling feet. The leveling feet are

located under the front of the balance. Adjust

the leveling feet until the bubble appears in the

center circle of the indicator.

NOTENOTE

NOTE: A level indicator and leveling feet are

NOTENOTE

not included on Models GT400, GT4000 and

GT8000.

Power RequirementsPower Requirements

Power Requirements

Power RequirementsPower Requirements

WARNING

To avoid shock hazards, always beTo avoid shock hazards, always be

•

To avoid shock hazards, always be

To avoid shock hazards, always beTo avoid shock hazards, always be

certain that the power cord is dis-certain that the power cord is dis-

certain that the power cord is dis-

certain that the power cord is dis-certain that the power cord is disconnected BEFORE removing theconnected BEFORE removing the

connected BEFORE removing the

connected BEFORE removing theconnected BEFORE removing the

balance cover.balance cover.

balance cover.

balance cover.balance cover.

Even though the balance may haveEven though the balance may have

•

Even though the balance may have

Even though the balance may haveEven though the balance may have

been switched OFF, high voltage isbeen switched OFF, high voltage is

been switched OFF, high voltage is

been switched OFF, high voltage isbeen switched OFF, high voltage is

present inside the balance as longpresent inside the balance as long

present inside the balance as long

present inside the balance as longpresent inside the balance as long

as the power cord is connected.as the power cord is connected.

as the power cord is connected.

as the power cord is connected.as the power cord is connected.

INSTALLATION

LEVEL INDICATOR

A power cord has been furnishedA power cord has been furnished

•

A power cord has been furnished

A power cord has been furnishedA power cord has been furnished

with the balance. DO NOT use anywith the balance. DO NOT use any

with the balance. DO NOT use any

with the balance. DO NOT use anywith the balance. DO NOT use any

other type of power cord other thanother type of power cord other than

other type of power cord other than

other type of power cord other thanother type of power cord other than

the one furnished.the one furnished.

the one furnished.

the one furnished.the one furnished.

DO NOT create a safety hazard byDO NOT create a safety hazard by

DO NOT create a safety hazard by

DO NOT create a safety hazard byDO NOT create a safety hazard by

defeating the grounding feature.defeating the grounding feature.

defeating the grounding feature.

defeating the grounding feature.defeating the grounding feature.

Voltage SettingVoltage Setting

Voltage Setting

Voltage SettingVoltage Setting

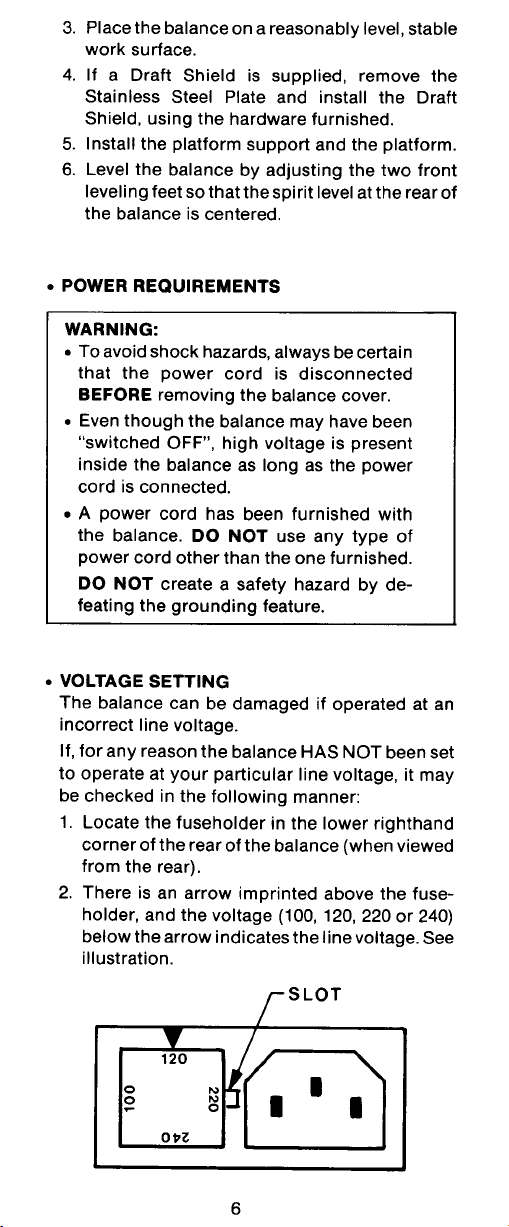

The balance can be damaged if operated

at an incorrect line voltage. If, for any

reason the balance

operate at your particular line voltage, it

may be checked in the following manner:

1. Locate the fuse holder in the lower

right-hand corner of the balance

(when viewed from the rear).

2. There is an arrow imprinted above

the fuse holder and the voltage (100,

120, 220 or 240) below the arrow

indicates the line voltage. See illustration.

HAS NOTHAS NOT

HAS NOT been set to

HAS NOTHAS NOT

SLOT

9

INSTALLATION

3. If you wish to change the line voltage setting, remove the power cord and pry

the fuse holder loose by inserting a small screwdriver blade in the slot. Remove

the fuse holder and rotate it to the proper position with the correct line voltage

lining up with the arrow. If neccessary, install the correct fuse for the required

line voltage. (See Replacement Parts List for fuse rating).

4. Insert the fuse holder.

Draft Shield (Models GT210, GT410Draft Shield (Models GT210, GT410

Draft Shield (Models GT210, GT410

Draft Shield (Models GT210, GT410Draft Shield (Models GT210, GT410

and GT 410D)and GT 410D)

and GT 410D)

and GT 410D)and GT 410D)

To install the Draft Shield:

1. Remove the two existing screws and

washers located on top of the balance.

2. Position the Draft Shield on top of the

balance as shown.

3. Insert the two screws, with washers

(supplied with the Draft Shield) though

the holes in the Draft Shield into the

balance. Tighten both screws securely.

DRAFT SHIELD

Platform and Platform SupportPlatform and Platform Support

Platform and Platform Support

Platform and Platform SupportPlatform and Platform Support

Insert the Platform Support into the hole

in the weighing mechanism as shown in

the illustration.

Place the Platform on the Platform Support making sure the Platform is properly

centered.

Model GT8000T Tower Assembly InstallationModel GT8000T Tower Assembly Installation

Model GT8000T Tower Assembly Installation

Model GT8000T Tower Assembly InstallationModel GT8000T Tower Assembly Installation

Remove the four (4) flat head screws from the mounting holes at the lower left (

when viewing the rear of the balance), and set them aside. Install the Tower

Assembly on the mounting holes using the screws. The Tower Display unit may

be tilted to the desired viewing angle. If the viewing angle is not going to be

changed, tighten the Hex Socket set screw at the lower left (when viewing the rear

of the Display Unit). The increased tension will prevent the Display Unit from

accidentally tilting.

10

PLATFORM

PLATFORM

SUPPORT

INSTALLATION

RS232 INTERFACERS232 INTERFACE

RS232 INTERFACE

RS232 INTERFACERS232 INTERFACE

Precision Advanced balances are equipped with a bi-directional RS232 compatible

interface for communication with printers and computers. When the balance is

connected directly to a printer, displayed data can be output at any time by simply

pressing PRINT, or by using the Auto Print feature.

Connecting the balance to a computer enables you to operate the balance from the

computer, as well as receive data such as displayed weight, weighing mode,

stability status, etc.

The following sections describe the hardware and software provided with the

balance.

HardwareHardware

Hardware

HardwareHardware

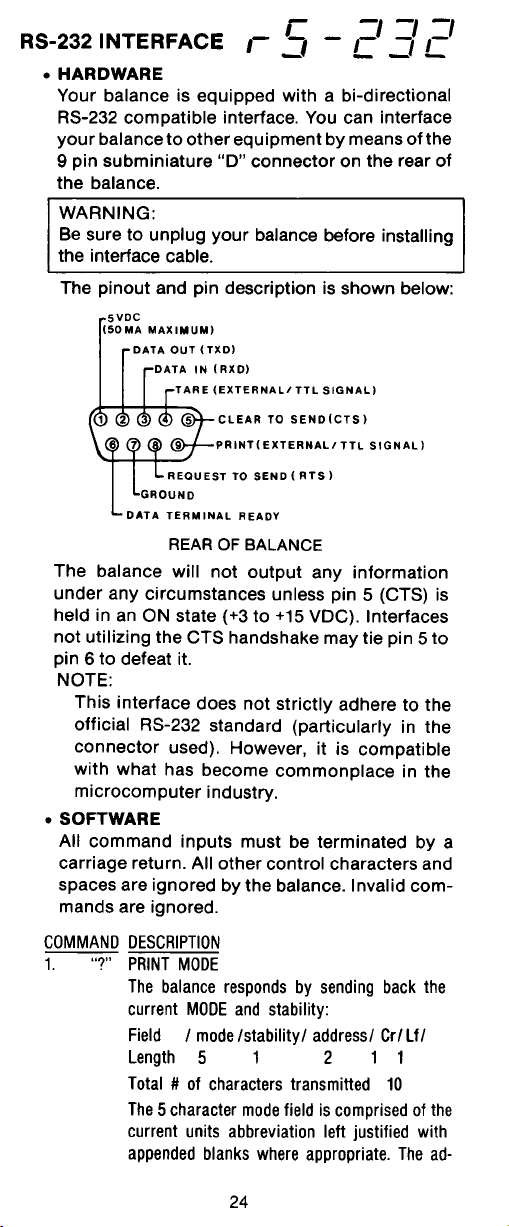

On the rear of the balance, a 9-pin subminiature “D” connector is provided for

interfacing to other devices. The pinout

and pin connections are shown in the

adjacent illustration.

The balance will not output any data

unless pin 5 (CTS) is held in an ON state

(+3 to +15 VDC). Interfaces not utilizing

the CTS handshake may tie pin 5 to pin 6

to defeat it.

Output FormatsOutput Formats

Output Formats

Output FormatsOutput Formats

Data output can be initiated in one of three

ways: 1) By pressing PRINT; 2) Using the

Auto Print feature; 3) Sending a print

command (“P”) from a computer.

The output format is illustrated in the

RS232 command table which follows.

RS232 CommandsRS232 Commands

RS232 Commands

RS232 CommandsRS232 Commands

All communication is accomplished using

standard ASCII format. Only the characters shown in the following table are acknowledged by the balance. Any other

commands, control characters or spaces

are ignored. Commands sent to the

balance must be terminated with a carriage return (CR) or carriage return-line

line feed (CRLF). For example, a tare

command should appear as shown in the

adjacent diagram. Data output by the

balance is always terminated with a carriage return - line feed (CRLF).

TARE *

PRINT *

1 5VDC (5 mA max.)

2 Data Out (TXD)

3 Data In (RXD)

4* Tare (External signal)

5 Clear To Send (CTS)

6 Data Terminal Ready (DTR)

7 Ground

8 Request To Send (RTS)

9* Print (External signal)

* External PRINT and/or TARE

switches may be installed as shown

in the diagram. Momentary contact

switches must be used.

11

INSTALLATION

RS232 COMMAND TABLERS232 COMMAND TABLE

RS232 COMMAND TABLE

RS232 COMMAND TABLERS232 COMMAND TABLE

CommandCommand

Command

CommandCommand

CharacterCharacter

Character

CharacterCharacter

??

? Print current mode

??

nnnAnnnA

nnnA Set Auto Print feature to “nnn”

nnnAnnnA

CC

C Begin span calibration

CC

xDxD

xD Set 1 second print delay (set x = 0 for OFF, or x = 1 for ON)

xDxD

DescriptionDescription

Description

DescriptionDescription

(see table).

Field: Mode Stab CR LF

Length: 5 1 1 1

Grams

Pennyweight

Carats

Avoidupois ounces

Troy ounces

Grains

Taels

nnn = 0 Turns feature OFF

nnn = S Output on stability

nnn = C Output is continuous

nnn = 1-256 Sets Auto Print

blank if stable

“ ? ” if unstable

Momme

Pounds

Pounds:ounces

Custom unit

Parts counting

Percent weighing

Error

Interval

EE

E Exit parts counting or percent weighing

EE

xx

II

x

I Set Averaging Level to “x”,

xx

II

LL

L Begin linearity calibration

LL

MM

M Same effect as pressing mode button

MM

xMxM

xM Places balance in mode “x”,

xMxM

where x = 0 to 3 (see table).

where x = 1 to 13 (see table).

If unit or mode is not already

enabled, command will be ignored.

12

0 = minimum level

1=

2=

3 = maximum level

1 = grams

2 = pennyweight

3 = carats

4 = avoidupois ounces

5 = troy ounces

6 = grains

7 = taels

8 = momme

9 = pounds

10 = pounds:ounces

11 = custom unit

12 = parts counting

13 = percent weighing

INSTALLATION

CommandCommand

Command

CommandCommand

CharacterCharacter

Character

CharacterCharacter

PP

P Print display data

PP

xSxS

xS Set stable data only printing (set x = 0 for OFF, or x = 1 for ON).

xSxS

TT

T Same effect as pressing rezero button

TT

VV

V Print EPROM version

VV

DescriptionDescription

Description

DescriptionDescription

When “numeric only” display

data is selected for output in

the RS232 menu, the Mode

field is not output.

Field: Weight Mode Stab CR LF

Length: 9 1 5 1 1 1

Displayed weight sent right justified

w/lead zero blanking.

Nine characters include:

decimal point (1)

weight (7 max))

polarity (1): blank if positive

Field: Model # EPROM # CR LF

Length: 7 15 1 1

Same as ?

command

“ - ” if negative

Balance Model

xZxZ

xZ Set Auto Zero to “x”,

xZxZ

x%x%

x% Downloads reference weight “x” for percent mode. “x” must be in grams.

x%x%

x#x#

x# Downloads average piece weight “x” for parts counting mode. “x” must be in

x#x#

Esc LEsc L

Esc L Prints listing of Setup and Print menu settings.

Esc LEsc L

Esc REsc R

Esc R Resets Setup and Print menus to factory defaults.

Esc REsc R

Esc SEsc S

Esc S Save current settings.

Esc SEsc S

where x = 0 to 3 (see table).

Command is ignored if percent mode is disabled. If percent mode is enabled,

balance will automatically switch to percent mode display.

grams. Command is ignored if parts counting mode is disabled. If parts counting

is enabled, balance will automatically switch to parts count display.

CAUTION: This will reset RS232 configuration.

"98101-XX Sr*XX.X"

0 = OFF

1 = .5 d

2=1 d

3=3 d

13

OPERATION

OPERATIONOPERATION

OPERATION

OPERATIONOPERATION

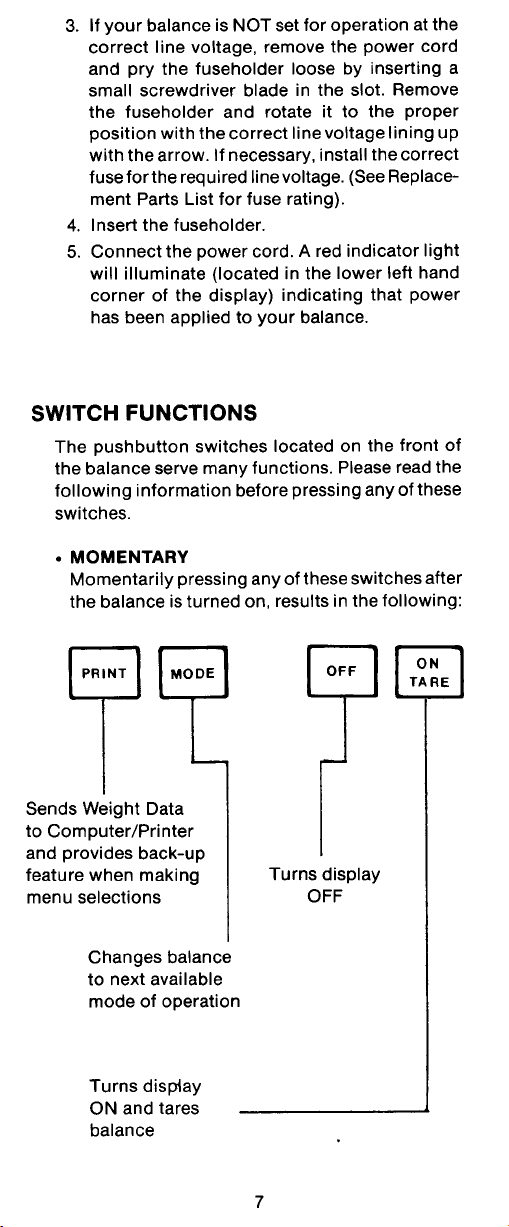

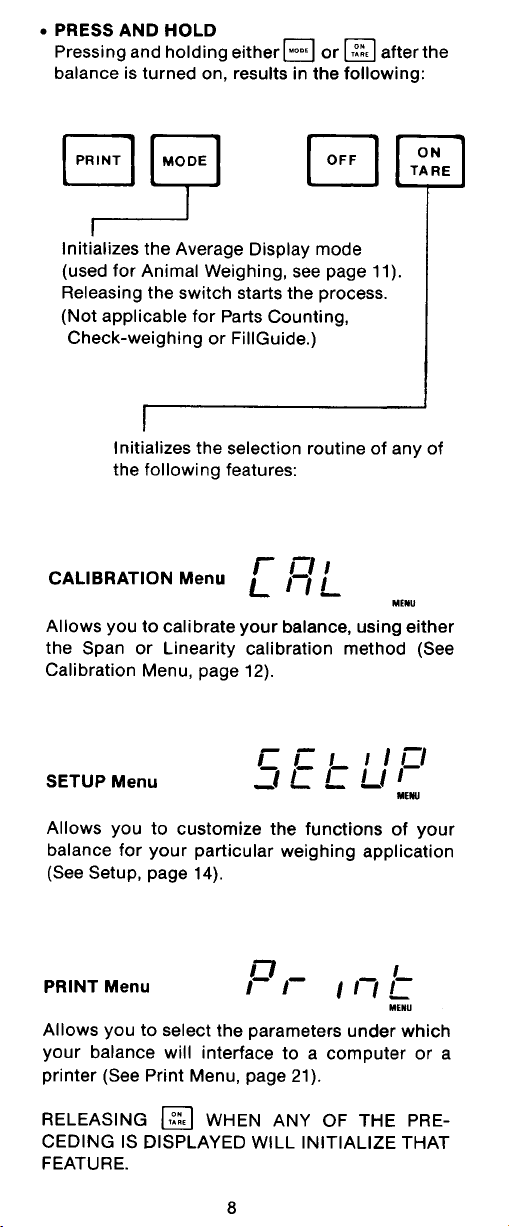

Switch FunctionsSwitch Functions

Switch Functions

Switch FunctionsSwitch Functions

The pushbutton switches located on the front of the balance serve many functions.

please read the following information before pressing any of these switches.

Pressing any of these switches after the balance is turned on results in the following:

Sends weight data, statistical data, GLP data to computer/printer. In menus, allows returning to a previous

menu step.

Selects weighing units functions or options. In menus,

changes to next step or value.

When the balance is first turned on and it completes its checks, and is calibrated, it

can be used to weigh or tare materials without setting the menus.

There are many features and functions in the GT Balance, and if you do not address

all of the features, the balance has built-in default settings shown on each menu page.

Before using the balance, carefully review the Symbols Used for Operation of the

Balance shown on page 15, Navigating the Menus on page 16 and Operational Guide/

Index on page 17.

Please read the entire manual as there are many features which can be enabled. The

balance is shipped from the factory ready to operate with default settings as shown

in the menus.

The balance is a high precision instrument and will give you years of service if kept

clean and handled carefully. If you have any problems operating the instrument or

require additional information, please feel free to contact our Product Service

Department at (800) 526-0659.

Turns display OFF.

Turns display ON and ReZeros/Tares the balance. In

menus, accepts chosen parameter.

14

Symbols Used for Operation of the BalanceSymbols Used for Operation of the Balance

Symbols Used for Operation of the Balance

Symbols Used for Operation of the BalanceSymbols Used for Operation of the Balance

This instruction manual uses certain symbols to explain various operational procedures and actions that occur. Examples of the symbols used are shown as follows:

Pushbutton SwitchesPushbutton Switches

Pushbutton Switches:

Pushbutton SwitchesPushbutton Switches

=

=

Display Area Display Area

Display Area:

Display Area Display Area

NORMAL PRESS AND RELEASENORMAL PRESS AND RELEASE

NORMAL PRESS AND RELEASE

NORMAL PRESS AND RELEASENORMAL PRESS AND RELEASE

MULTIPLE PRESSMULTIPLE PRESS

MULTIPLE PRESS

MULTIPLE PRESSMULTIPLE PRESS

PRESS AND HOLD FOR DESIRED DISPLAYPRESS AND HOLD FOR DESIRED DISPLAY

=

PRESS AND HOLD FOR DESIRED DISPLAY

PRESS AND HOLD FOR DESIRED DISPLAYPRESS AND HOLD FOR DESIRED DISPLAY

DISPLAY AREA - AS A RESULT OF USER ACTIONDISPLAY AREA - AS A RESULT OF USER ACTION

DISPLAY AREA - AS A RESULT OF USER ACTION

DISPLAY AREA - AS A RESULT OF USER ACTIONDISPLAY AREA - AS A RESULT OF USER ACTION

DISPLAY AREA -SWITCHES BACK AND FORTHDISPLAY AREA -SWITCHES BACK AND FORTH

DISPLAY AREA -SWITCHES BACK AND FORTH

DISPLAY AREA -SWITCHES BACK AND FORTHDISPLAY AREA -SWITCHES BACK AND FORTH

DISPLAY AREA - AUTO CHANGE OCCURSDISPLAY AREA - AUTO CHANGE OCCURS

DISPLAY AREA - AUTO CHANGE OCCURS

DISPLAY AREA - AUTO CHANGE OCCURSDISPLAY AREA - AUTO CHANGE OCCURS

15

OPERATION

Navigating the MenusNavigating the Menus

Navigating the Menus

Navigating the MenusNavigating the Menus

There are

CALIBRATION USER SETUP PRINT

To enter the menusTo enter the menus

To enter the menus, the button is pressed and held until MENU is displayed.

To enter the menusTo enter the menus

When released, CAL is displayed which is the Calibration menu.

When in the menusWhen in the menus

When in the menus, repeated pressing of

When in the menusWhen in the menus

menus. CALIBRATION USER SETUP PRINT END

Each menu contains selections (submenus) which can be set for specific operations.

The button is used to advance though the submenu selections.

four menusfour menus

four menus used in the balance:

four menusfour menus

advances through the

MENU

The

button enters or accepts the submenu selection and returns to the

beginning of the submenu selection.

The button is used to backup in the submenu if a change is desired.

The following sample illustrates the

END USEREND USER

END USER

END USEREND USER

ONON

ON

ONON

BEEPBEEP

BEEP

BEEPBEEP

<

<

<

OFFOFF

OFF

OFFOFF

ONON

ON

ONON

AUTO-ZEROAUTO-ZERO

<

AUTO-ZERO

AUTO-ZEROAUTO-ZERO

<

<

OFFOFF

OFF

OFFOFF

USERUSER

USER

USERUSER

RESETRESET

RESET

RESETRESET

STABILITYSTABILITY

STABILITY

STABILITYSTABILITY

USER menu USER menu

USER menu and submenu items

USER menu USER menu

NOTE:NOTE:

NOTE:

NOTE:NOTE:

>

YESYES

YES

YESYES

ALAL

AL

ALAL

<

<

NONO

NO

NONO

00

0

00

>

<

<

11

1

11

<

22

2

22

<

33

3

33

Each menu is constructed

in the form of a loop. Advancing from one submenu item to the next by

using the

will eventually return to

the beginning of the

>

OFFOFF

OFF

OFFOFF

<

.5d.5d

.5d

.5d.5d

<

menu. .

<

1d1d

1d

1d1d

<

3d3d

3d

3d3d

RULES: UseRULES: Use

RULES: Use

RULES: UseRULES: Use

button to advance.button to advance.

button to advance.

button to advance.button to advance.

button

Use Use

Use

Use Use

Use Use

Use

Use Use

After selections are made, always exit menus through END After selections are made, always exit menus through END

After selections are made, always exit menus through END

After selections are made, always exit menus through END After selections are made, always exit menus through END

store settings. store settings.

store settings.

store settings. store settings.

button to enter or accept submenu. button to enter or accept submenu.

button to enter or accept submenu.

button to enter or accept submenu. button to enter or accept submenu.

button to backup.button to backup.

button to backup.

button to backup.button to backup.

16

MENU MENU

MENU

MENU MENU

to to

to

to to

OPERATION

Operational Guide/IndexOperational Guide/Index

Operational Guide/Index

Operational Guide/IndexOperational Guide/Index

The Operational Guide/Index lists the pages for all balance operations and options.

After settings are made, exit menus to save settings.

FUNCTION FUNCTION

FUNCTION

FUNCTION FUNCTION

1.1.

Turning the Balance ONTurning the Balance ON

1.

Turning the Balance ON

1.1.

Turning the Balance ONTurning the Balance ON

2.2.

Weighing (grams)Weighing (grams)

2.

Weighing (grams)

2.2.

Weighing (grams)Weighing (grams)

3.3.

Zero/TaringZero/Taring

3.

Zero/Taring

3.3.

Zero/TaringZero/Taring

4.4.

Auto TareAuto Tare

4.

Auto Tare

4.4.

Auto TareAuto Tare

5.5.

ListList

5.

List

5.5.

ListList

6.6.

Printing DataPrinting Data

6.

Printing Data

6.6.

Printing DataPrinting Data

7.7.

Menu LockoutMenu Lockout

7.

Menu Lockout

7.7.

Menu LockoutMenu Lockout

8.8.

CalibrationCalibration

8.

Calibration

8.8.

CalibrationCalibration

9.9.

Percent WeighingPercent Weighing

9.

Percent Weighing

9.9.

Percent WeighingPercent Weighing

10.10.

Parts CountingParts Counting

10.

Parts Counting

10.10.

Parts CountingParts Counting

11.11.

Check weighingCheck weighing

11.

Check weighing

11.11.

Check weighingCheck weighing

12.12.

Animal WeighingAnimal Weighing

12.

Animal Weighing

12.12.

Animal WeighingAnimal Weighing

13.13.

Fill GuideFill Guide

13.

Fill Guide

13.13.

Fill GuideFill Guide

14.14.

High PointHigh Point

14.

High Point

14.14.

High PointHigh Point

15.15.

Custom UnitsCustom Units

15.

Custom Units

15.15.

Custom UnitsCustom Units

16.16.

Changing UnitsChanging Units

16.

Changing Units

16.16.

Changing UnitsChanging Units

17.17.

StatisticsStatistics

17.

Statistics

17.17.

StatisticsStatistics

18.18.

NetNet

18.

18.18.

19.19.

19.

19.19.

20.20.

20.

20.20.

21.21.

21.

21.21.

22.22.

22.

22.22.

23.23.

23.

23.23.

24.24.

24.

24.24.

25.25.

25.

25.25.

26.26.

26.

26.26.

27.27.

27.

27.27.

28.28.

28.

28.28.

29.29.

29.

29.29.

30.30.

30.

30.30.

31.31.

31.

31.31.

/Gross Weighing/Gross Weighing

Net

/Gross Weighing

NetNet

/Gross Weighing/Gross Weighing

Legal for TradeLegal for Trade

Legal for Trade

Legal for TradeLegal for Trade

GLPGLP

GLP

GLPGLP

TimeTime

Time

TimeTime

DateDate

Date

DateDate

LockswitchLockswitch

Lockswitch

LockswitchLockswitch

Averaging LevelAveraging Level

Averaging Level

Averaging LevelAveraging Level

StabilityStability

Stability

StabilityStability

Auto ZeroAuto Zero

Auto Zero

Auto ZeroAuto Zero

Beep FunctionBeep Function

Beep Function

Beep FunctionBeep Function

Reset UserReset User

Reset User

Reset UserReset User

Reset SetupReset Setup

Reset Setup

Reset SetupReset Setup

Reset PrintReset Print

Reset Print

Reset PrintReset Print

CommunicationsCommunications

Communications

CommunicationsCommunications

TO OPERATETO OPERATE

TO OPERATE

TO OPERATETO OPERATE

( (

(See pages) (See pages)

( (

1818

18

1818

2020

20

2020

2020

20

2020

2020

20

2020

2828

28

2828

27 to 3227 to 32

27 to 32

27 to 3227 to 32

3434

34

3434

36 to 3936 to 39

36 to 39

36 to 3936 to 39

2121

21

2121

2222

22

2222

2323

23

2323

2424

24

2424

2525

25

2525

2626

26

2626

5050

50

5050

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

--------

SETUPSETUP

SETUP

SETUPSETUP

--------

----

--------

--------

----

--------

--------

----

--------

--------

----

-------59, 6859, 68

59, 68

59, 6859, 68

61 to 6861 to 68

61 to 68

61 to 6861 to 68

--------

----

--------

--------

----

-------46, 6746, 67

46, 67

46, 6746, 67

46, 51, 6746, 51, 67

46, 51, 67

46, 51, 6746, 51, 67

46, 52, 53, 6746, 52, 53, 67

46, 52, 53, 67

46, 52, 53, 6746, 52, 53, 67

46, 5446, 54

46, 54

46, 5446, 54

46, 54, 6746, 54, 67

46, 54, 67

46, 54, 6746, 54, 67

4646

46

4646

4949

49

4949

4545

45

4545

4545

45

4545

4848

48

4848

4545

45

4545

51, 6351, 63

51, 63

51, 6351, 63

56, 6656, 66

56, 66

56, 6656, 66

57, 6757, 67

57, 67

57, 6757, 67

5858

58

5858

4040

40

4040

4141

41

4141

4141

41

4141

4242

42

4242

4040

40

4040

4444

44

4444

6161

61

6161

61 to 6361 to 63

61 to 63

61 to 6361 to 63

17

OPERATION

Turning the Balance ONTurning the Balance ON

Turning the Balance ON

Turning the Balance ONTurning the Balance ON

1. With no load on the platform, connect the power cord to a suitable power

source. The balance signals one long beep to indicate power has been applied.

2.

NOTENOTE

NOTE: The display check countdown appears only in the first 60 seconds after

NOTENOTE

plugging it in and only if the balance is turned on and only when the balance has

been previously set with Type Approved/Legal for Trade set on.

•

•

•

•

•

18

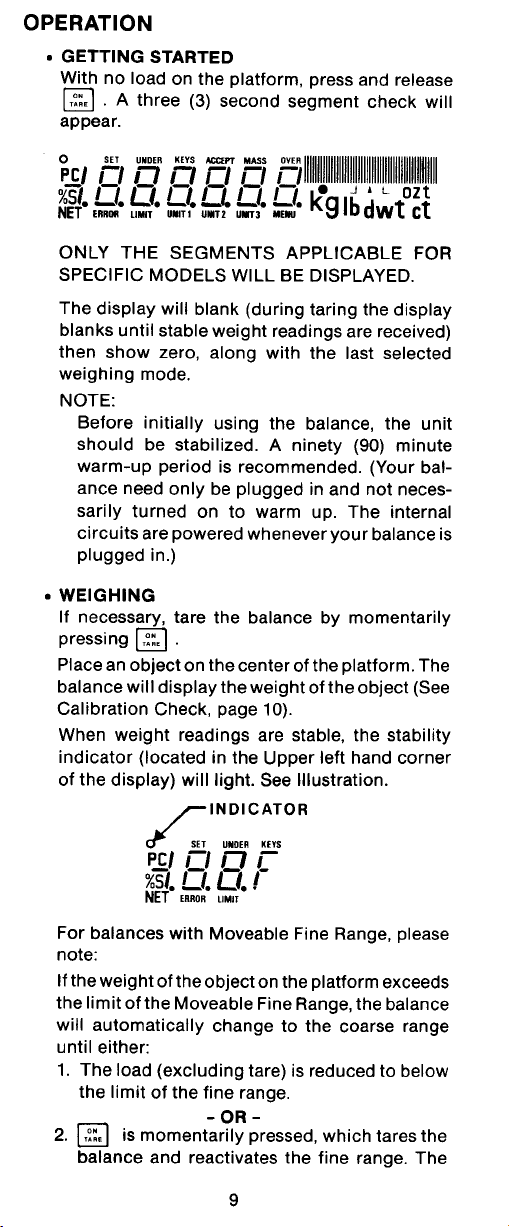

Display IndicationsDisplay Indications

Display Indications

Display IndicationsDisplay Indications

The following table describes each of the display indicators.

DISPLAY INDICATORSDISPLAY INDICATORS

DISPLAY INDICATORS

DISPLAY INDICATORSDISPLAY INDICATORS

StabilizationStabilization

Stabilization

StabilizationStabilization

OPERATION

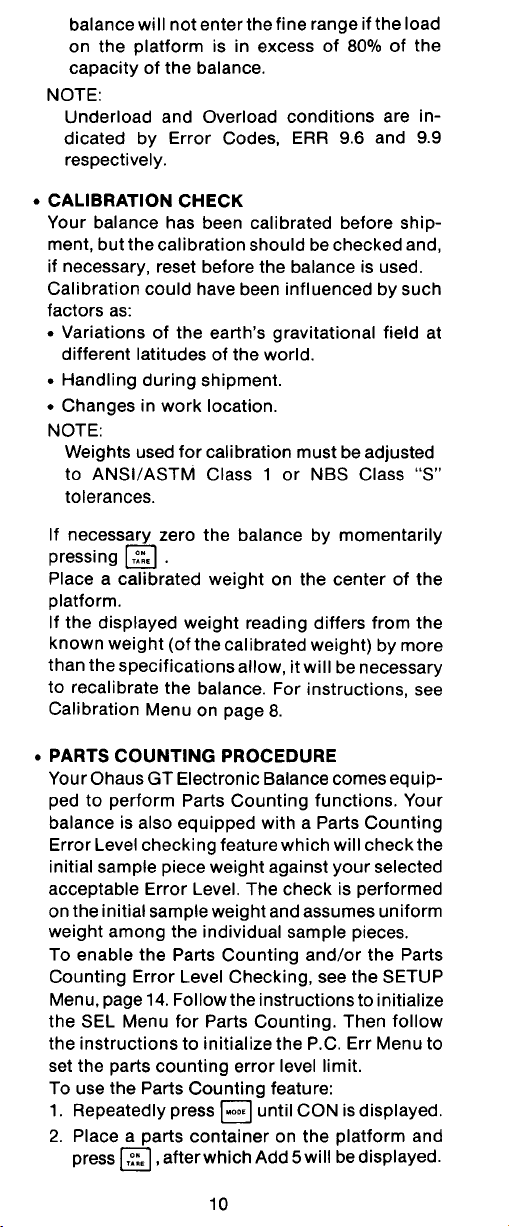

Before initially using the balance, allow time for it to adjust to its new environment. The

balance only requires to be plugged in to warm up. Recommended warm up period

is twenty (20) minutes. The internal circuits of the balance are powered whenever

it is plugged into a power source.

TMTM

TM

Moveable FineRangeMoveable FineRange

Moveable FineRange

Moveable FineRangeMoveable FineRange

Models GT410D and GT4100D both contain a Moveable FineRangeTM feature. When

the weight of the object on the platform exceeds the capacity limit of the Moveable

FineRangeTM, the balance will automatically change to the coarse range until either:

1. The load is reduced to below the capacity limit of the fine range.

2.

tares the balance and recalls the fine range. Taring procedure can

be done repeatedly until capacity of the balance is reached.

TMTM

(Models GT410D and GT4100D) (Models GT410D and GT4100D)

(Models GT410D and GT4100D)

(Models GT410D and GT4100D) (Models GT410D and GT4100D)

19

OPERATION

WeighingWeighing

Weighing

WeighingWeighing

NOTENOTE

NOTE: The GT Series balances are shipped with grams only enabled and is labeled

NOTENOTE

in this manner. When the balance is to be used with other Type Approved/Legal

for Trade units of measure, the desired unit must be enabled and the appropriate

label from the card supplied must be attached to the balance

1.

2. Place the object(s) or material to be weighed on the platform.

3. Wait for the stability indicator to appear before reading the weight.

STABILITY INDICATOR

NOTENOTE

NOTE: The capacity guide (bars) indicates the percentage of the current weight to

NOTENOTE

the balance capacity. The example above illustrates a 4000 gram weight, (balance

full capacity 4100 grams).

Zero/TareZero/Tare

Zero/Tare

Zero/TareZero/Tare

When weighing material or objects that must be held in a container, taring stores the

container weight in the balance’s memory, separate from the weight of the material

in the container.

1. Place an empty container on the platform. Its weight is displayed.

NOTENOTE

NOTE: The container must weigh at least 100 times the readability of the balance (ie,

NOTENOTE

GT4K x 0.1 or 10 grams).

2.

indicates zero. The container’s weight is stored in memory.

3. Add material to the container. As material is added, its net weight is displayed.

4. Removing the container and material from the platform will cause the balance

to display the container’s weight as a negative number.

5.

Auto TareAuto Tare

Auto Tare

Auto TareAuto Tare

Auto Tare is

to page 42. Auto Tare is used in an application where taring is done automatically

without touching any controls on the balance. This is indicated by a small arrow in the

display. When this option is set on, each time an object is first placed on the balance

platform, it is automatically tared and two short beeps will sound. When a second

object is placed on the platform along with the first object such as a container, only

the net weight is displayed. The container weight is not shown. After removal of all

material from the platform, the next object placed on the platform is auto tared. The

default setting is off.

to rezero the display.

CAPACITY GUIDE

, the display blanks until stable weight readings are received, then

resets the balance to zero.

enabled onlyenabled only

enabled only

enabled onlyenabled only

when Auto Tare is selected under the Setup menu. Refer

NOTENOTE

NOTE: Auto Tare is disabled for LFT.

NOTENOTE

AUTO TARE INDICATOR

20

OPERATION

Percent WeighingPercent Weighing

Percent Weighing

Percent WeighingPercent Weighing

Percent Weighing is

the Percent Function is selected under the

Setup menu. Refer to page 40. Percent

weighing permits you to place a reference

load on the balance, then view other loads

as a percentage of the reference. The load

you place on the platform as a reference

may be displayed as any percentage you

select from 5% to 100% (in 1% increments). One hundred percent does not

necessarily have to represent the reference load. Subsequent loads, displayed as a

percentage of the reference are limited only by the capacity of the balance. The

default setting is Reference 100%.

To perform percent weighing when in a weighing mode, use the following procedure:

1. .

2. Place an empty container on the pan (if one will be used).

enabled only enabled only

enabled only

enabled only enabled only

when

EXAMPLE EXAMPLE

EXAMPLE

EXAMPLE EXAMPLE

A 10g reference load is set for 20%:

• A subsequent load of 100 g will be

displayed as 200%.

• A subsequent load of 200 g will be

displayed as 400%.

3.

NOTENOTE

NOTE: The reference percentage can be changed to any value from 5 to 100.

NOTENOTE

4.

NOTENOTE

NOTE:

NOTENOTE

command through the RS232 Interface, where x = 5 to 100.

5. When the selected reference value appears on the display, place the

reference load in the container (or directly on the platform if no container is

used).

6. , display indicates the reference load as

the percentage entered. The bar graph indicates the load relative to the

capacity of the balance.

7. Remove the reference load from the balance and replace it with another

load. The second load is displayed as a percentage of the reference.

8. to view alternate display in units.

9. To restart percent weighing at any time,

does not return to a lower number. Instead, it sends Set x%

. This is the current reference percentage.

increments to .

.

10. to exit to a weighing mode.

21

OPERATION

Parts CountingParts Counting

Parts Counting

Parts CountingParts Counting

Parts Counting is

Setup menu. Refer to page 40. In the parts counting mode, the balance displays the

quantity of parts you place on the platform. Since the balance determines the quantity

based on the average weight of a single part, all parts must be reasonably uniform in

weight. The accuracy of parts counting results is determined by the error level entered

in PC Err of the Setup Options submenu. Refer to page 51. The default setting for

PC Err is off.

To perform parts counting when in a weighing mode, use the following procedure:

enabled onlyenabled only

enabled only

enabled onlyenabled only

when the Parts Counting Function is selected in the

1.

2.

to use as a reference for counting. The default for the sample size is 5 parts,

but this can be changed to 10, 20, 30, 40, 50, or 100 parts by

(Larger samples yield more accurate results). Add the required number of

sample pieces to the platform.

3.

4. If Add X is displayed, the sample is too small to provide results within the

selected error level (PC Error of the Setup Options submenu).

NOTENOTE

NOTE: X represents the number of additional parts needed to provide a sufficient

NOTENOTE

sample.

5. Add the required number of parts, then again.

6. To count additional pieces, add them to the platform. The display indicates the

actual number of pieces based on their sample size. Tolerance will be within

whatever was selected under the Parts Counting Error Level.

NOTENOTE

NOTE: If the balance controls are not touched, the sample size is stored in memory.

NOTENOTE

You can continue to use the balance to measure quantities as long as the

samples to be measured are of the same weight.

7.

. The balance requires a sample of the parts

to display the weight of the pieces on the pan.

.

(indicates 5 pieces).

8.

9. To restart parts counting, .

10.

again to display the number of pieces.

, the balance returns to a weighing mode.

22

OPERATION

Check WeighingCheck Weighing

Check Weighing

Check WeighingCheck Weighing

Check Weighing is

the Setup menu. Refer to page 46. Refer to page 52, Check Weighing Options under

the Setup menu to set the Reference Type and Display Type options. In the check

weighing mode, a reference weight can be set into the balance either as a reference

weight on the pan or as a user entered number. The balance display shows either

under, accept or over as each sample is weighed.

reference weight reference weight

If

reference weight was selected under CW Options submenu:

reference weight reference weight

1. With the balance in the weighing mode, .

enabled only enabled only

enabled only

enabled only enabled only

when the Check Weighing Function is selected in

NOTENOTE

NOTE: If

NOTENOTE

10.

11. . to accept the value.

12. Repeat steps 10 and 11and set all digits to the desired value. When the last

reference numberreference number

reference number was selected, go to step 7.

reference numberreference number

2. Place a sample weight on the pan which is considered to be the under limit

for check weighing.

3. .

4. Place a sample weight on the pan which is considered to be the over weight

limit for check weighing.

5. . The display blanks until a stable reading is achieved, then it goes

to either the (Normal, None or Sign) display type previously selected in CW

Options submenu to indicate under, over or acceptacle limits of the objects

being weighed.

6. Check weighing can now be made by removing a sample and placing a new

sample on the pan.

reference numberreference number

If

reference number was selected under the CW Options submenu:

reference numberreference number

7. With the balance in the weighing mode,

8.

9.

digit is entered, display changes to an over value to be entered with the

to return to weighing .

indicates under value with first digit flashing.

until the first digit (under weight) is correctly displayed.

.

first digit flashing

NOTENOTE

NOTE: allows going back.

NOTENOTE

23

.

OPERATION

Check Weighing (Cont.)Check Weighing (Cont.)

Check Weighing (Cont.)

Check Weighing (Cont.)Check Weighing (Cont.)

13. Repeat steps 10 and 11 to set the over value. When the last digit is entered,

the display indicates one of three display modes for check weighing.

14. Check weighing can now be performed by removing a sample and placing a

new sample on the platform.

15. allows other weighing units to be displayed if previously

selected.

Animal WeighingAnimal Weighing

Animal Weighing

Animal WeighingAnimal Weighing

Animal Weighing is

the Setup menu. Refer to page 46. To set options, refer to page 55, Animal Weighing

Options under the Setup Options submenu.

With the balance in a weighing mode, proceed as follows:

enabled only enabled only

enabled only

enabled only enabled only

when Animal Weighing Function is selected under

1.

2. Place the container on the platform.

NOTENOTE

NOTE:

NOTENOTE

3.

4. Place the subject in the container. The balance indicates a countdown to

The balance then displays the actual weight of the subject with flashing unit

indicator and returns to after approximately six sec-

onds. Repeat steps 1 through 4 for another subject or

another weighing cycle.

NOTENOTE

NOTE: If Auto Print is enabled, the display returns to ready in approximately one

NOTENOTE

second.

5.

NOTENOTE

NOTE:

NOTENOTE

to start over.

to return to weighing mode.

. This cycle accommodates for movement.

to return to weighing mode while display shows

.

while the same subject is on the balance will cause Animal Weighing

(Animal Weighing Container).

. The container weight is tared.

to start

24

OPERATION

Fill GuideFill Guide

Fill Guide

Fill GuideFill Guide

Fill Guide is

enabled onlyenabled only

enabled only

enabled onlyenabled only

when Fill Guide

Function is selected under the Setup menu.

Refer to page 46. To set options, refer to

page 55, Fill Options under the Setup

Options submenu.

TM

The FillGuide

is a bar graph which appears in the upper right hand portion of the

display. When the load on the balance is at the balance's capacity, all of the segments

are on. When the load is at half capacity, only the first half of the segments are on.

During normal operation of the balance, the bar graph displays the relationship

between the load on the pan and the capacity of the balance. In the Fill Guide mode,

the bar graph can be set to a desired target value. The FillGuide

in any one of the available weighing units.

The Fill Option under the Setup Options submenu provides two choices for a reference

weight (similar to check weighing). Either a mass can be placed on the pan and used

as a reference weight or a number can be entered to establish the weight value. Both

methods are used to establish a reference for a 100% bar graph reading. Target

parameter provides two choices, one is fill to the reference weight. The other option

sets the reference weight to a negative value and allows the operator to see the delta

between the actual fill weight and the target weight.

With the balance in a weighing mode, proceed as follows:

FILLGUIDETM BAR GRAPH

TM

FILLGUIDE

TM

INDICATOR

feature can be used

Reference WeightReference Weight

Reference Weight

Reference WeightReference Weight

With the balance in a weighing mode, and if reference weight was selected under Fill

Options submenu proceed as follows:

1.

.

2. Place a sample weight on the pan which is the reference weight

. Assumes 50 grams weight reference.

3. . The display indicates a 50 gram mass

(target = reference. For target = to zero, display shows 0.0000 as the actual

weight of the sample with the bar graph at 100%.

4. The Fill Guide feature can now used by placing samples on the pan. If the

sample is equal to the reference weight used to calibrate the fill mode, the

actual weight is displayed with a full bar graph. When target is selected, the

balance will show the normal weight of the object on the pan.

5. to exit the fill option mode.

6. , the balance is now in a weighing mode.

25

OPERATION

Fill Guide (Cont.)Fill Guide (Cont.)

Fill Guide (Cont.)

Fill Guide (Cont.)Fill Guide (Cont.)

Reference NumberReference Number

Reference Number

Reference NumberReference Number

If reference number was selected under the Fill Option submenu with the balance in

a weighing mode, proceed as follows:

1.

2.

value.

3.

4.

5. Repeat steps 3 and 4 until all digits are set. When the last digit is entered ,

the balance is automatically in the fill mode.

6. The fill mode can now be used by placing samples on the pan. If the sample

weight equals the reference weight, the bar graph indicates 100%, the weight

is displayed.

7.

8. , the balance is now in a weighing mode.

High PointHigh Point

High Point

High PointHigh Point

High Point is

menu. Refer to page 46. High point is a feature which permits a number of samples

to be weighed with the balance

sample weightsample weight

sample weight

sample weightsample weight

disregarded and not displayed.

until the first digit is correctly displayed.

to accept the digit.

to exit the fill option mode.

enabled onlyenabled only

enabled only

enabled onlyenabled only

. The samples which are in between the low and high points are

when High Point Function is selected under the Setup

.

. Set the flashing digit to the desired weight

storing the loweststoring the lowest

storing the lowest

storing the loweststoring the lowest

sample weight and the

highest highest

highest

highest highest

NOTENOTE

NOTE: When using this function, the balance does not respond to weights below 100

NOTENOTE

digits.

With the balance in a weighing mode, proceed as follows:

1.

played, indicating the function is on.

2. Place the first sample on the balance pan. When the balance has stabilized,

the weight is displayed. Remove the weight.

3. Place a second sample on the pan. After the balance stabilizes, the second

sample weight is displayed if it is greater than the first sample. This procedure

can be continued with a number of samples. The highest weight sample is

always displayed.

. , LIMIT is dis-

26

OPERATION

High Point (Cont.)High Point (Cont.)

High Point (Cont.)

High Point (Cont.)High Point (Cont.)

4. To view the lowest and highest sample weight. The display LIMIT

flashes, the lowest sample weight is displayed followed by two short beeps,

the display then indicates the highest sample weight for a few seconds then

automatically changes back to the normal weighing mode.

40g40g

40g

40g40g

20g20g

20g

20g20g

5g5g

5g

5g5g

ORDER SAMPLES TAKEN IN

5. To use the High Point function again, repeat steps 1 through 4.

6. to exit High Point and return to a weighing

mode.

Printing DataPrinting Data

Printing Data

Printing DataPrinting Data

4g4g

4g

4g4g

NOT DISPLAYED

2g2g

2g

2g2g

Printing data to an external computer or printer requires that the communications

parameters in the Print menu be set first. Refer to page 60 Print menu. A wide variety

of printing options are available, refer to page 64, Print Options under the Print menu

and set the desired options before proceeding. To print data,

This section defines the various printing setups with printing samples.

Time and DateTime and Date

Time and Date

Time and DateTime and Date

When time and date are entered in the

balance through the Setup menu and with

both Time and Date options set to ON

under the Print Options submenu, each

printout starts with the time and date on

the first line.

27

6/22/95 1:00:30 PM

.

OPERATION

Printing Data (Cont.)Printing Data (Cont.)

Printing Data (Cont.)

Printing Data (Cont.)Printing Data (Cont.)

ListList

List

ListList

List is a convienent method of examining

which parameters are set up in the balance. The parameters do not show up on

the display but print out when selected.

Both the Setup and Print menus have a

List function.

When LIST is displayed in either the Setup

or Print Menu,

rameters of the User, Setup and Print

menus to be printed on an external printer

or computer screen.

The sample shown, indicates the status in

three menus.

causes the pa-

GT MODEL 98101-18 Sr 1.0

User Menu

AL = 3, Stb = 1d

AZT = Off, Beep = Off

Setup Menu

LFT is Off

Enabled Modes:

g, dwt,

oz, ozt,

tael, momme,

lb, custom

Tael = Hong Kong

C. Units:

1.000000 EXx1

Units = custom

Functions = None

Statistics On

Std Dev = Sample

Mean = On

Sum = On

Max = On

Min = On

Diff = On

Total = Off

Auto Tare = Off

GLP

Time/Date On

Bal Id = On

User Id = On

Project # = On

Cal = On

Time = US 12:00:00 PM

Date = US 4/1/94

Lock Switch is Off

28

Print Menu

RS-232 = 2400: N: 7: 2

Print Options

Auto Print = Off

Interval = 2

Non - PL = 0.000

Non - PH = 50.000

Stable Print = Off

Nu = Off

Time = On

Date = On

Print Ref = On

Print Ref = On

Printing Data (Cont.)Printing Data (Cont.)

Printing Data (Cont.)

Printing Data (Cont.)Printing Data (Cont.)

Span Calibration PrintoutSpan Calibration Printout

Span Calibration Printout

Span Calibration PrintoutSpan Calibration Printout

With GLP on, when performing a Span

calibration, a printout is automatically

made after the calibration mass is placed

on the platform and

Linearity Calibration PrintoutLinearity Calibration Printout

Linearity Calibration Printout

Linearity Calibration PrintoutLinearity Calibration Printout

When performing a Linearity calibration

with GLP on, a printout is automatically

made after the calibration mass is placed

on the platform and

is pressed.

is pressed.

OPERATION

- - - - - SPAN CAL - - - - - -

4/01/95 12:00:00 PM

Bal Id 1234

Cal: 4000.00g

Old: 4000.00g

Dif: 0.00g

Wt. Ref......................................

ID 2056853

PR 100012

Name........................................

- - - - - END - - - - -

- - - - - LIN CAL - - - - - 4/01/95 12:00:00 PM

Bal Id 1234

Cal: 4000.00g

Old: 3999.94g

Dif: 0.06g

Wt. Ref......................................

ID 2056853

PR 100012

Name........................................

Calibration Test PrintoutCalibration Test Printout

Calibration Test Printout

Calibration Test PrintoutCalibration Test Printout

When performing a Calibration Test with

GLP on, a printout is available. When the

display indicates the mass value to be

placed on the platform, the balance the

automatically displays the calibration

weight required.

- - - - - END - - - - -

- - - - - CAL TEST - - - - - 4/01/95 12:00:00 PM

Bal Id 1234

Cal: 4000.00g

Act: 4000.04g

Dif: 0.04g

Wt. Ref......................................

ID 2056853

PR 100012

Name........................................

- - - - - END - - - - -

29

OPERATION

Printing Data (Cont.)Printing Data (Cont.)

Printing Data (Cont.)

Printing Data (Cont.)Printing Data (Cont.)

Statistics PrintoutStatistics Printout

Statistics Printout

Statistics PrintoutStatistics Printout

When statistics is enabled, a printout can be made with any of the major balance

functions such as; Percent, Parts Counting, Check Weighing, Animal Weighing and

FillGuide

Enable, Standard Deviation, Mean, Sum, High, Low and Difference which can be

turned on or off. Statistics can be printed any time the balance is operational and

statistics is enabled (turned on).

For example, to weigh ten samples and obtain a printout, proceed as follows:

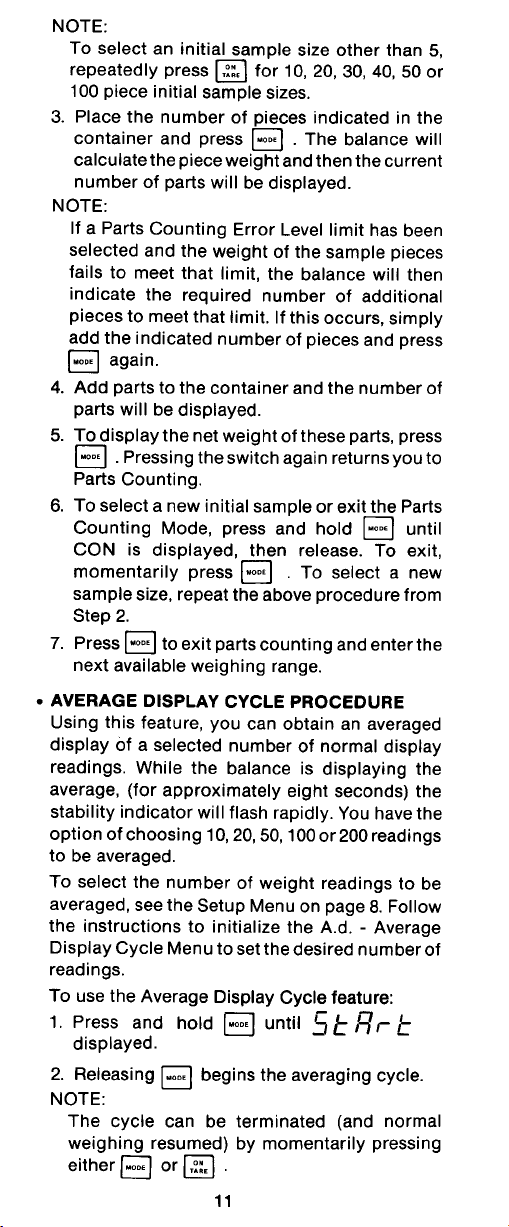

SamplingSampling

Sampling

SamplingSampling

TM

. Under the Setup Options menu, Statistics has parameters such as

1.

2. Place the

display to show.

3.

appears and the printer outputs

the first sample weight.

4. Remove the first sample.

5. Place the

platform, wait for the stability

indi- cator

6.

appears and the printer outputs

the second sample weight.

7. Remove the second sample.

NOTENOTE

NOTE: The weight of each sample is

NOTENOTE

shown on the display and printed.

Maximum sample size = 256.

8. Repeat procedure for as many

samples as required.

9.

to end the sampling procedure.

Printout completes the data.

See sample at right.

firs

t sample on the platform, wait for the stability indicator

second

S S

S on the display to show.

S S

sample on the

.

- - - - - START - - - - 4/01/95 12:00:00 PM

1 49.54 g

2 49.54 g

3 49.56 g

4 49.57 g

5 50.03 g

6 50.54 g

7 50.04 g

8 50.04 g

9 50.03 g

10 50.04 g

- - - - - - - - - - - - - - - - - - - - -- SD Pop. 0.314

Mean 49.893

Sum 498.93

Maximum 50.54

Diff 1.00

Finish 12:05:00 PM

Bal Id 1234

ID 2056853

PR 100012

Name......................................

S S

S on the

S S

- - - - - - END - - - - - -

30

Printing Data (Cont.)Printing Data (Cont.)

Printing Data (Cont.)

Printing Data (Cont.)Printing Data (Cont.)

Percent WeighingPercent Weighing

Percent Weighing

Percent WeighingPercent Weighing

OPERATION

Statistical printouts of Percent Weighing

are similar to sampling statistics. Loads

on the balance platform may be displayed

as a percentage from 5% to 100% in 1%

increments. To obtain a printout in this

mode, the balance must be set up in

Percent Weighing. Refer to basic Sampling procedure for operation. The sample

illustration shown at the right had the

balance reference set to 100% using a

weight of 17.398 grams.

- - - - - START - - - - 4/01/95 12:00:00 PM

1 5 Pcs

2 5 Pcs

3 15 Pcs

4 23 Pcs

5 36 Pcs

6 42 Pcs

7 52 Pcs

8 50 Pcs

9 41 Pcs

10 50 Pcs

- - - - - - - - - - - - - - - - - - - - -- SD Pop. 17.530

Mean 31.900

Sum 319.00

Maximum 52.00

Diff 5.00

Finish 12:05:00 PM

PC Ref 0.496 g

Bal Id 1234

ID 2056853

PR 100012

Name....................................

- - - - - - - - END - - - - - -

- - - - - START - - - - 4/01/95 12:00:00 PM

1 99.9%

2 100.1%

3 100.0%

4 55.9%

5 123.2%

6 155.9%

7 102.8%

8 102.9%

9 105.9%

10 105.7%

- - - - - - - - - - - - - - - - - - - - -- SD Pop. 23.276

Mean 105.230

Sum 1052.30

Maximum 155.90

Diff 100.00

Finish 12:05:00 PM

Bal Id 1234

ID 2056853

PR 100012

Name......................................

- - - - - - END - - - - - -

Parts CountingParts Counting

Parts Counting

Parts CountingParts Counting

When the balance is in a Parts Counting mode, each time a batch of items

are counted, they can be recorded

statistically by pressing as

described in the Sampling procedure.

The example shown on the left used

a sample weighing 0.496 gram each.

31

OPERATION

Printing Data (Cont.)Printing Data (Cont.)

Printing Data (Cont.)

Printing Data (Cont.)Printing Data (Cont.)

Check WeighingCheck Weighing

Check Weighing

Check WeighingCheck Weighing

When the balance is in a Check Weighing

mode, each sample can be checked either to show or print an under, accept or

over weight on the printout. Use the

procedure described in Sampling to obtain data by pressing each time a

sample is weighed. A numeric entry of

50.00 grams was used for this sample

printout.

- - - - - START - - - - 4/01/9512:00:00 pm

1 50.78 g ACCEPT

2 52.74 g ACCEPT

3 55.25 g ACCEPT

4 57.63 g OVER

5 52.79 g ACCEPT

6 51.78 g ACCEPT

7 50.79 g ACCEPT

8 47.79 g UNDER

9 47.79 g UNDER

10 50.30 g ACCEPT

- - - - - - - - - - - - - - - - - - - - - - - -

SD Pop. 2.682

Mean 51.964

Sum 519.64

Maximum 57.63

Diff 9.84

Finish 12:05:00 PM

Min Ref 50.00 g

Max Ref 53.00 g

Bal Id 1234

ID 2056853

PR 100012

Name......................................

4/01/95 12:00:00 PM

1999.9 g

Fill Ref 1999.98 g

Fill Dif - 0.01 g

4/01/94 12:01:00 PM

2023.87 g

Fill Ref 1999.98 g

Fill Dif- 23.89 g

4/01/94 12:02:00 PM

2050.28 g

Fill Ref 1999.98 g

Fill Dif - 50.30 g

- - - - - - END - - - - - -

TMTM

TM

FillGuideFillGuide

FillGuide

FillGuideFillGuide

When the balance is in a FillGuideTM mode,

each sample can be checked on the printout. By accessing the Custom Units submenu, Density settings can be in

Liters, Fluid Ounces or Quarts

procedure described in Sampling to obtain

data by pressing

sample is weighed. A standard mass of

2,000 grams was used for this sample

printout and a sample taken each minute.

32

TMTM

Milliliter,

. Use the

each time a

MENUS

MENUSMENUS

MENUS

MENUSMENUS

Each submenu of the GT Balance contains numerous selections which can be set for

specific operations. To customize the operation of the balance for specific measurements, functions and printing, it is necessary to make selections in each menu. The

following illustration identifies the major items in each menu and the factory default

settings are shown in bold type with the exception of the Setup Options and Print

options which are shown in their respective menus. Shaded areas only appear in the

menu if the appropriate function or weighing unit is selected in the Setup menu.

CAL

CAL SPAN

CAL LINEARITY

CAL USER

Enter #

CAL TEST

END, CAL

USER

RESET

YES/NO

AL

0,

STABILITY

5d5d

.

5d, 1d, 2d, 5d

5d5d

AUTO ZERO

OFF,

3d

BEEP

ON/

END, USER

11

1, 2, 3

11

.5d.5d

.5d, 1d,

.5d.5d

OFFOFF

OFF

OFFOFF

SETUP

RESET

YES/NO

LFT

ON/

SELECT UNITS

gg

g, dwt, ct, oz, oz t,

gg

UNIT 1 (grain), t

UNIT 2 (mommes),

lb, UNIT 3 (custom)

FUNCTIONS

Percent

Parts Counting

Check Weighing

Animal Weighing

FillGuide

High Point

NoneNone

None

NoneNone

SETUP OPTIONS

Statistics

Enable

Standard Dev.

Mean

Sum

High

Low

Difference

End, Statistics

Net

Auto Tare

Custom Units

Factor

Density

End