Page 1

Ohaus Corporation

29 Hanover Road

Florham Park NJ

07932-0900

PRECISION

Electronic Balances

Models

GT4100G and GT4100DG

Advanced

Instruction Manual

Page 2

NOTE:NOTE:

NOTE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH

NOTE:NOTE:

THE LIMITS FOR A CLASS A DIGITAL DEVICE, PURSUANT TO PART 15 OF

THE FCC RULES.

THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION

AGAINST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED

IN A COMMERCIAL ENVIRONMENT. THIS EQUIPMENT GENERATES, USES,

AND CAN RADIATE RADIO FREQUENCY ENERGY AND, IF NOT INSTALLED

AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE

HARMFUL INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF

THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE HARMFUL

INTERFERENCE IN WHICH CASE THE USER WILL BE REQUIRED TO CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

THIS DIGITAL APPARATUS DOES NOT EXCEED THE CLASS A LIMITS FOR

RADIO NOISE EMISSIONS FROM DIGITAL APPARATUS AS SET OUT IN THE

INTERFERENCE-CAUSING EQUIPMENT STANDARD ENTITLED “DIGITAL APPARATUS”, ICES-003 OF THE DEPARTMENT OF COMMUNICATIONS.

CET APPAREIL NUMERIQUE RESPECTE LES LIMITES DE BRUITS

RADIOELECTRIQUES APPLICABLES AUX APPAREILS NUMERIQUES DE

CLASSE A PRESCRITES DANS LA NORME SUR LE MATERIEL BROUILLEUR :

“APPAREILS NUMERIQUES”, NMB-003 EDICTEE PAR LE MINISTRE DES COMMUNICATIONS.

Unauthorized changes or modifications to this equipment are not permitted.

The exclamation

point within the triangle is a warning

sign alerting you of

important instructions accompanying the product.

2

Page 3

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

INTRODUCTION.................................................................................................. 7

DESCRIPTION ..................................................................................................... 7

FEATURES .......................................................................................................... 7

UNPACKING ........................................................................................................ 8

INSTALLATION .................................................................................................... 8

Environment .................................................................................................. 8

Leveling the Balance..................................................................................... 8

Power Requirements..................................................................................... 9

Voltage Setting .............................................................................................. 9

Platform and Platform Support ...................................................................... 9

OPERATION ...................................................................................................... 10

Switch Functions ......................................................................................... 10

Symbols Used for Operation of the Balance ............................................... 11

Navigating the Menus ................................................................................. 12

Turning the Balance On .............................................................................. 13

Display Indications ...................................................................................... 13

Stabilization................................................................................................. 14

Moveable FineRange

Weighing ..................................................................................................... 14

ReZero ........................................................................................................ 14

Test Weight Mode ....................................................................................... 15

Dockage Mode ............................................................................................ 15

Entering and Reentering Dockage Mode .................................................... 16

FUNCTIONS AND MODES OF OPERATION ................................................... 17

CALIBRATION MENU ........................................................................................ 18

Calibration Menu Protection ........................................................................ 18

Calibration Masses...................................................................................... 18

Span Calibration.......................................................................................... 19

Linearity Calibration .................................................................................... 19

User Calibration .......................................................................................... 20

Cal Test....................................................................................................... 20

USER MENU ...................................................................................................... 21

User Menu Protection ................................................................................. 22

Reset ........................................................................................................... 22

Averaging Level .......................................................................................... 22

TM

(Model GT4100DG) .............................................. 14

3

Page 4

Stability Range ............................................................................................ 23

Auto-Zero .................................................................................................... 24

Beep Function ............................................................................................. 24

SETUP MENU .................................................................................................... 25

Setup Menu Protection................................................................................ 26

Reset ........................................................................................................... 26

Type Approved/LFT .................................................................................... 27

Unit Selection .............................................................................................. 27

Good Laboratory Practices...................................................................... 29

Time ............................................................................................................ 29

Date............................................................................................................. 30

Lockswitch................................................................................................... 31

List............................................................................................................... 32

PRINT MENU ..................................................................................................... 32

Print Menu Protection.................................................................................. 33

Reset ........................................................................................................... 33

Communication ........................................................................................... 33

Baud Rate................................................................................................ 34

Data Bits .................................................................................................. 34

Parity ....................................................................................................... 34

Stop Bits .................................................................................................. 35

Good Laboratory Practices (GLP)............................................................... 35

Print Options ............................................................................................... 36

Auto Print Feature ................................................................................... 36

Initialize.................................................................................................... 36

Print Stable Data Only ............................................................................. 38

Print Numeric Data Only.......................................................................... 38

Time......................................................................................................... 39

Date ......................................................................................................... 39

Reference ................................................................................................ 39

List............................................................................................................... 40

MENU LOCK-OUT PROTECTION..................................................................... 40

TYPE APPROVED BALANCE SEALING........................................................... 41

4

Page 5

RS232 INTERFACE ........................................................................................... 42

Hardware..................................................................................................... 42

Output Formats ........................................................................................... 42

RS232 Commands ...................................................................................... 42

CARE AND MAINTENANCE.............................................................................. 45

TROUBLESHOOTING ....................................................................................... 45

Error Codes List .......................................................................................... 46

SERVICE INFORMATION ................................................................................. 47

PARTS INFORMATION ..................................................................................... 48

REPLACEMENT PARTS ................................................................................... 48

ACCESSORIES ................................................................................................. 48

SPECIFICATIONS ............................................................................................. 49

LIMITED WARRANTY........................................................................................ 51

5

Page 6

6

Page 7

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

This manual covers Installation, Operation and Troubleshooting for the Ohaus Precision Advanced Series of Electronic balances, Models GT4100G, and GT4100DG.

Suffixes after the basic model number are: D = Moveable FineRange

Applications. To ensure proper operation of the balance, please read this manual

completely.

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

The Ohaus Precision Advanced GT Series balances are precision weighing instruments, designed to be versatile, accurate, easy to operate and will provide years of

service with virtually no maintenance. The Precision Advanced series is constructed

using a die-cast aluminum base finished with a durable corrosion resistant epoxy

powder paint. It contains solid-state precision electronics PC boards, and a seven and

a half, 0.45 inch digit, Vacuum Fluorescent display. Each balance operates through

a series of menus which enhances operation. A built in lockswitch prevents preset

settings from being changed.

TM

, G=Grain

FEATURES

Precision Advanced balances contain four main display menus which enable you to

calibrate and configure the balance for specific operating requirements.

MENU MENU

MENU When

MENU MENU

access to the calibration, user, setup and print menus..

switch is pressed and released with MENU displayed, allows

CALIBRATIONCALIBRATION

CALIBRATION Menu - Allows the balance to be calibrated by using either Span ,

CALIBRATIONCALIBRATION

User or Linearity calibration methods. A Test function is used to verify the last

calibration.

USERUSER

USER Menu - Allows the balance to be set for environmental conditions. Reset,

USERUSER

averaging level, stability range, auto-zero and beep (sound) functions can be set.

SETUPSETUP

SETUP Menu - Allows the balance to be customized for specific weighing functions.

SETUPSETUP

PRINTPRINT

PRINT Menu - Allows the selection of parameters under which the balance will

PRINTPRINT

interface to a computer or a printer.

Each of these menus contain selectable parameters which can be entered via the front

panel switches. Storing of the parameters is accomplished by selecting

completion of all selections in a particular menu. For a detailed description of each

feature, refer to the individual menus in this manual.

7

EndEnd

End

EndEnd

at the

Page 8

UNPACKINGUNPACKING

UNPACKING

UNPACKINGUNPACKING

Your Precision Advanced balance was shipped with the following items:

• Platform

• Platform Support

• Power Cord

• Instruction Manual

• Warranty Card

• In-Service Cover

• Sealing Kit

It is recommended to save the carton and packing material for storing, transporting the

balance or returning it for service.

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

EnvironmentEnvironment

Environment

EnvironmentEnvironment

The balance should always be used in an environment which is free from excessive air

currents, corrosives, vibration, and temperature or humidity extremes. These factors

will affect displayed weight readings.

DO NOTDO NOT

DO NOT install the balance:

DO NOTDO NOT

• Next to open windows or doors causing drafts or rapid temperature changes.

• Near air conditioning or heat vents.

• Near vibrating, rotating or reciprocating equipment.

• Near magnetic fields or equipment that generates magnetic fields.

• On an unlevel work surface.

PLATE

Leveling the BalanceLeveling the Balance

Leveling the Balance

Leveling the BalanceLeveling the Balance

The balance is equipped with a level indicator located at the rear of the balance and two

adjustable leveling feet. The leveling feet

are located under the front of the balance.

Adjust the leveling feet until the bubble appears in the center circle of the indicator.

LEVEL INDICATOR

8

Page 9

Power RequirementsPower Requirements

Power Requirements

Power RequirementsPower Requirements

WARNING

To avoid shock hazards, always be certain that the power cord is disconnect-To avoid shock hazards, always be certain that the power cord is disconnect-

•

To avoid shock hazards, always be certain that the power cord is disconnect-

To avoid shock hazards, always be certain that the power cord is disconnect-To avoid shock hazards, always be certain that the power cord is disconnected BEFORE removing the balance cover.ed BEFORE removing the balance cover.

ed BEFORE removing the balance cover.

ed BEFORE removing the balance cover.ed BEFORE removing the balance cover.

Even though the balance may have been switched OFF, high voltage isEven though the balance may have been switched OFF, high voltage is

•

Even though the balance may have been switched OFF, high voltage is

Even though the balance may have been switched OFF, high voltage isEven though the balance may have been switched OFF, high voltage is

present inside the balance as long as the power cord is connected.present inside the balance as long as the power cord is connected.

present inside the balance as long as the power cord is connected.

present inside the balance as long as the power cord is connected.present inside the balance as long as the power cord is connected.

A power cord has been furnished with the balance. DO NOT use any otherA power cord has been furnished with the balance. DO NOT use any other

•

A power cord has been furnished with the balance. DO NOT use any other

A power cord has been furnished with the balance. DO NOT use any otherA power cord has been furnished with the balance. DO NOT use any other

type of power cord other than the one furnished.type of power cord other than the one furnished.

type of power cord other than the one furnished.

type of power cord other than the one furnished.type of power cord other than the one furnished.

DO NOT create a safety hazard by defeating the grounding feature.DO NOT create a safety hazard by defeating the grounding feature.

DO NOT create a safety hazard by defeating the grounding feature.

DO NOT create a safety hazard by defeating the grounding feature.DO NOT create a safety hazard by defeating the grounding feature.

Voltage SettingVoltage Setting

Voltage Setting

Voltage SettingVoltage Setting

The balance can be damaged if operated

at an incorrect line voltage. If, for any

reason the balance

operate at your particular line voltage, it

may be checked in the following manner:

1. Locate the fuse holder in the lower

right-hand corner of the balance (when

viewed from the rear).

2. There is an arrow imprinted above the

fuse holder and the voltage (100, 120,

220 or 240) below the arrow indicates

the line voltage. See illustration.

3. If the balance is NOT set for operation

at the correct line voltage, remove the

power cord and pry the fuse holder

loose by inserting a small screwdriver

blade in the slot. Remove the fuse

holder and rotate it to the proper position with the correct line voltage lining

up with the arrow. If neccessary,

install the correct fuse for the required

line voltage. (See Replacement Parts

List for fuse rating).

HAS NOTHAS NOT

HAS NOT been set to

HAS NOTHAS NOT

SLOT

4. Insert the fuse holder.

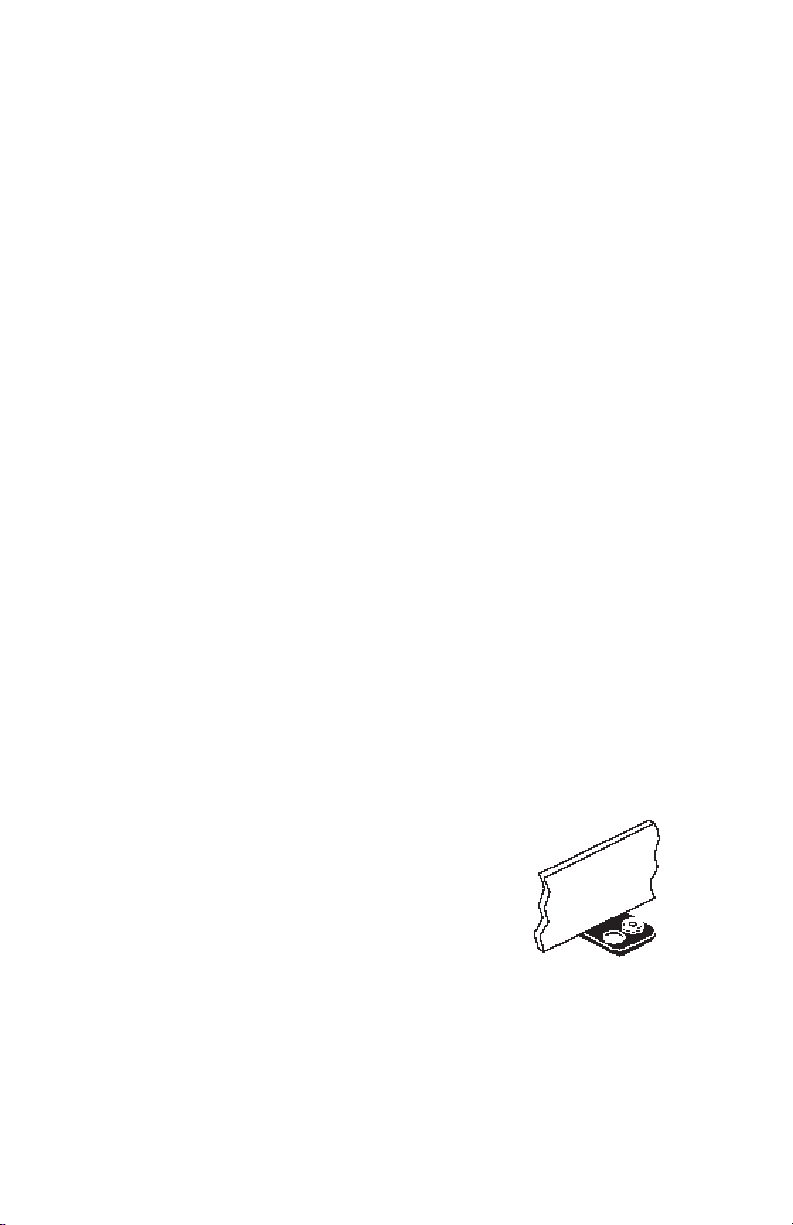

Platform and Platform SupportPlatform and Platform Support

Platform and Platform Support

Platform and Platform SupportPlatform and Platform Support

Insert the Platform Support into the hole in

the weighing mechanism as shown in the

illustration.

Place the Platform on the Platform Support making sure the Platform is properly

centered.

PLATFORM

PLATFORM

SUPPORT

9

Page 10

OPERATIONOPERATION

OPERATION

OPERATIONOPERATION

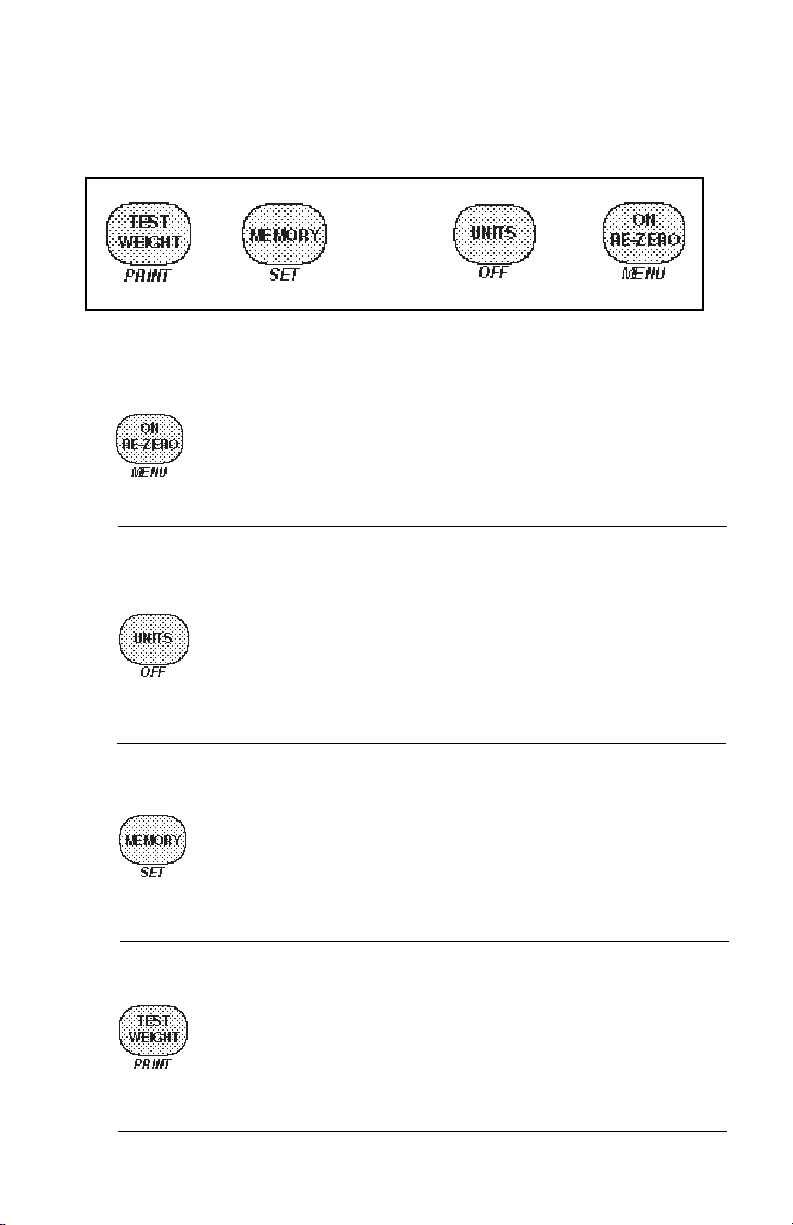

Switch FunctionsSwitch Functions

Switch Functions

Switch FunctionsSwitch Functions

Press and ReleasePress and Release

Press and Release:

Press and ReleasePress and Release

Turns on the balance if it is off, zeros the balance. Clears the dockage

memory. In the menu system, this button is used to accept a choice

or enter a submenu.

Extended PressExtended Press

Extended Press:

Extended PressExtended Press

Used to access the calibration, user, setup and print menus.

Press and ReleasePress and Release

Press and Release:

Press and ReleasePress and Release

Cycles balance through (g, oz, lb) weighing units that are enabled

and dockage (not Test Weight). If no valid dockage reference exists,

dockage will be skipped. In the menu system, this button is used to

change the indicated selection or move forward to the next menu

choice.

Extended PressExtended Press

Extended Press:

Extended PressExtended Press

Turns the balance off.

Press and ReleasePress and Release

Press and Release:

Press and ReleasePress and Release

Pressing this button will momentarily display the current memory

weight.

Extended PressExtended Press

Extended Press:

Extended PressExtended Press

Takes the current net weight on the platform and sets this value as the

100 percent memory value. Balance then indicates load as a

percentage of this value.

Press and ReleasePress and Release

Press and Release:

Press and ReleasePress and Release

Puts the balance in test weight mode. (Note that this requires a

calibrated volume container. In the menu system, moves the menu

in reverse order.

Extended PressExtended Press

Extended Press:

Extended PressExtended Press

Prints value on the display according to Print Menu settings.

10

Page 11

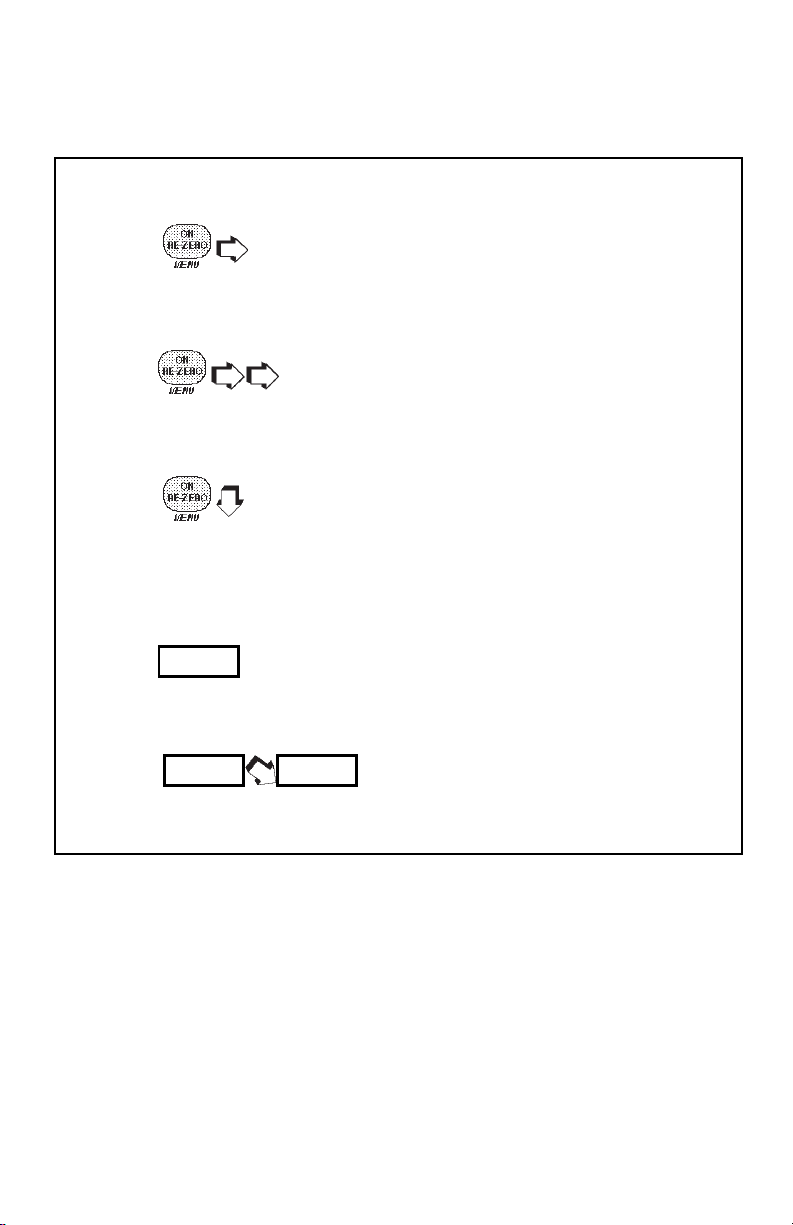

Symbols Used for Operation of the BalanceSymbols Used for Operation of the Balance

Symbols Used for Operation of the Balance

Symbols Used for Operation of the BalanceSymbols Used for Operation of the Balance

This instruction manual uses certain symbols to explain various operational procedures and actions that occur. Examples of the symbols used are shown as follows:

Pushbutton SwitchesPushbutton Switches

Pushbutton Switches:

Pushbutton SwitchesPushbutton Switches

=

=

Display Area Display Area

Display Area:

Display Area Display Area

NORMAL PRESS AND RELEASENORMAL PRESS AND RELEASE

NORMAL PRESS AND RELEASE

NORMAL PRESS AND RELEASENORMAL PRESS AND RELEASE

MULTIPLE PRESSESMULTIPLE PRESSES

MULTIPLE PRESSES

MULTIPLE PRESSESMULTIPLE PRESSES

PRESS AND HOLD FOR DESIRED DISPLAYPRESS AND HOLD FOR DESIRED DISPLAY

=

PRESS AND HOLD FOR DESIRED DISPLAY

PRESS AND HOLD FOR DESIRED DISPLAYPRESS AND HOLD FOR DESIRED DISPLAY

DISPLAY AREA - AS A RESULT OF USER ACTIONDISPLAY AREA - AS A RESULT OF USER ACTION

DISPLAY AREA - AS A RESULT OF USER ACTION

DISPLAY AREA - AS A RESULT OF USER ACTIONDISPLAY AREA - AS A RESULT OF USER ACTION

DISPLAY AREA - AUTO CHANGE OCCURSDISPLAY AREA - AUTO CHANGE OCCURS

DISPLAY AREA - AUTO CHANGE OCCURS

DISPLAY AREA - AUTO CHANGE OCCURSDISPLAY AREA - AUTO CHANGE OCCURS

11

Page 12

NANA

VIGAVIGA

NA

VIGA

NANA

VIGAVIGA

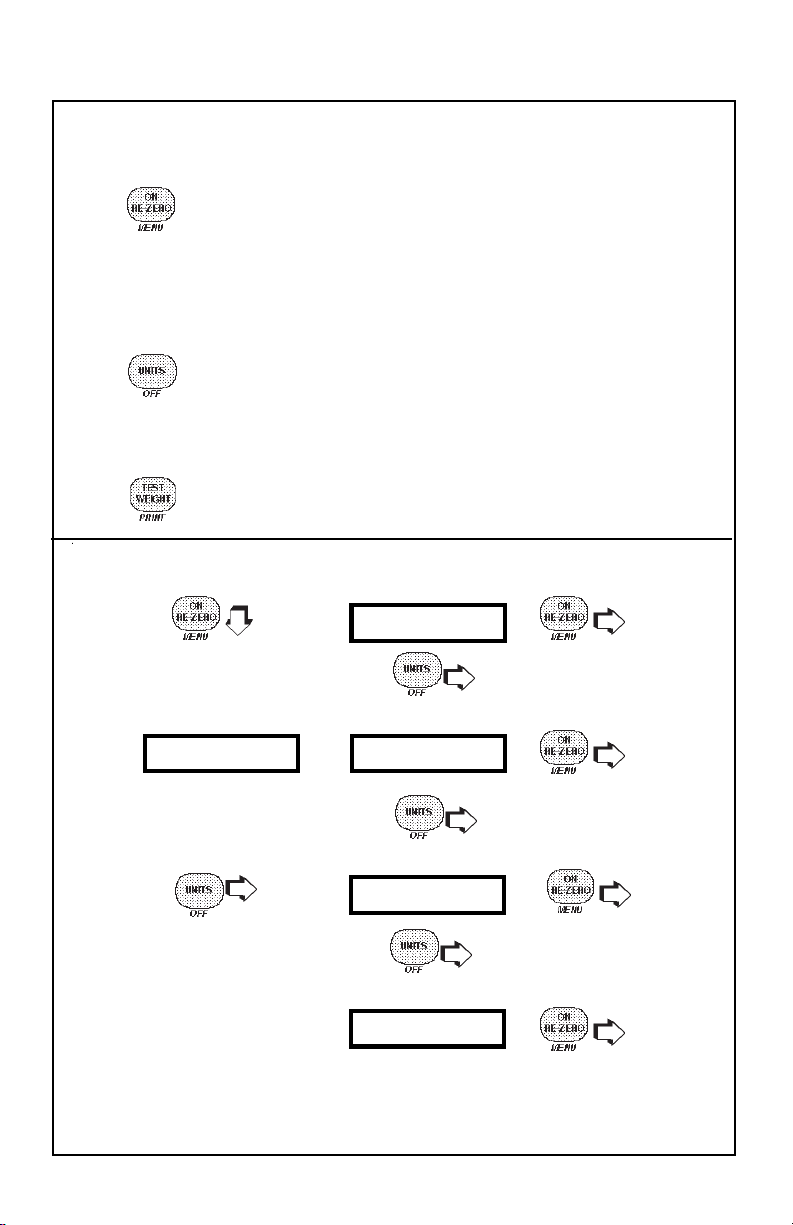

Three buttons on the balance are used to navigate through the menus.

Performs three functions:

1. When intially pressed turns the balance on.

2. When the balance is on, pressing and holding this button will

alternate the display from MENU to a weighing mode.

3. When in any menu, pressing this button will accept menu selection.

Performs two functions:

1. Sucessive presses will step through the menu selections.

2. When pressed and held, turns balance off.

When in the menus, each press moves the menu in reverse order.

TING TING

TING

TING TING

THE MENUSTHE MENUS

THE MENUS

THE MENUSTHE MENUS

WITH THE BALANCE TURNED ON

STEPS 1STEPS 1

STEPS 1.

STEPS 1STEPS 1

START START

START

START START

3. 3.

3.

3. 3.

DISPLAYDISPLAY

DISPLAY

DISPLAYDISPLAY

5A.BACKS UP

MENUMENU

MENU

MENUMENU

TO TO

TO

TO TO

NEXT DISPLAY NEXT DISPLAY

NEXT DISPLAY

NEXT DISPLAY NEXT DISPLAY

5. 5.

5.

5. 5.

TO TO

TO

TO TO

NEXT DISPLAY NEXT DISPLAY

NEXT DISPLAY

NEXT DISPLAY NEXT DISPLAY

7. 7.

7.

7. 7.

TO TO

TO

TO TO

END END

END

END END

12

ADVANCES ADVANCES

ADVANCES

ADVANCES ADVANCES

2.2.

2.

2.2.

ADVANCES ADVANCES

ADVANCES

ADVANCES ADVANCES

4. ACCEPTS

ADVANCES ADVANCES

ADVANCES

ADVANCES ADVANCES

6. ACCEPTS

88

8.

88

STORES

ACCEPTSACCEPTS

ACCEPTS

ACCEPTSACCEPTS

ACCEPTS &ACCEPTS &

ACCEPTS &

ACCEPTS &ACCEPTS &

Page 13

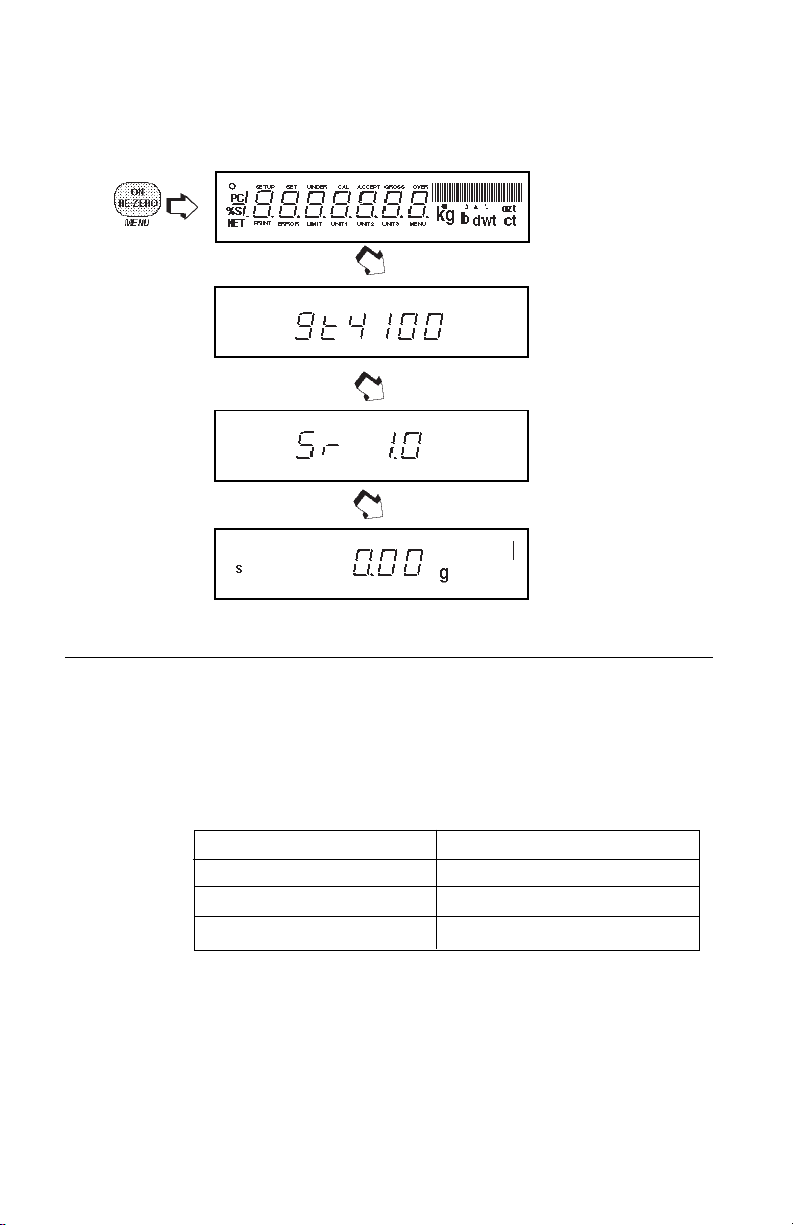

Turning the Balance ONTurning the Balance ON

Turning the Balance ON

Turning the Balance ONTurning the Balance ON

1. With no load on the platform, connect the power cord to a suitable power source.

The balance signals one long beep to indicate power has been applied.

2.

Display IndicationsDisplay Indications

Display Indications

Display IndicationsDisplay Indications

The following table describes each of the display indicators.

DISPLAY INDICATORSDISPLAY INDICATORS

DISPLAY INDICATORS

DISPLAY INDICATORSDISPLAY INDICATORS

g g

g grams

g g

ozoz

oz ounces

ozoz

%%

% (dockage) F.M.

%%

SS

S stability indicator

SS

13

lblb

lb pounds

lblb

UNIT 1UNIT 1

UNIT 1 lb/bu

UNIT 1UNIT 1

OO

O center of zero

OO

%S%S

%S memory set display

%S%S

Page 14

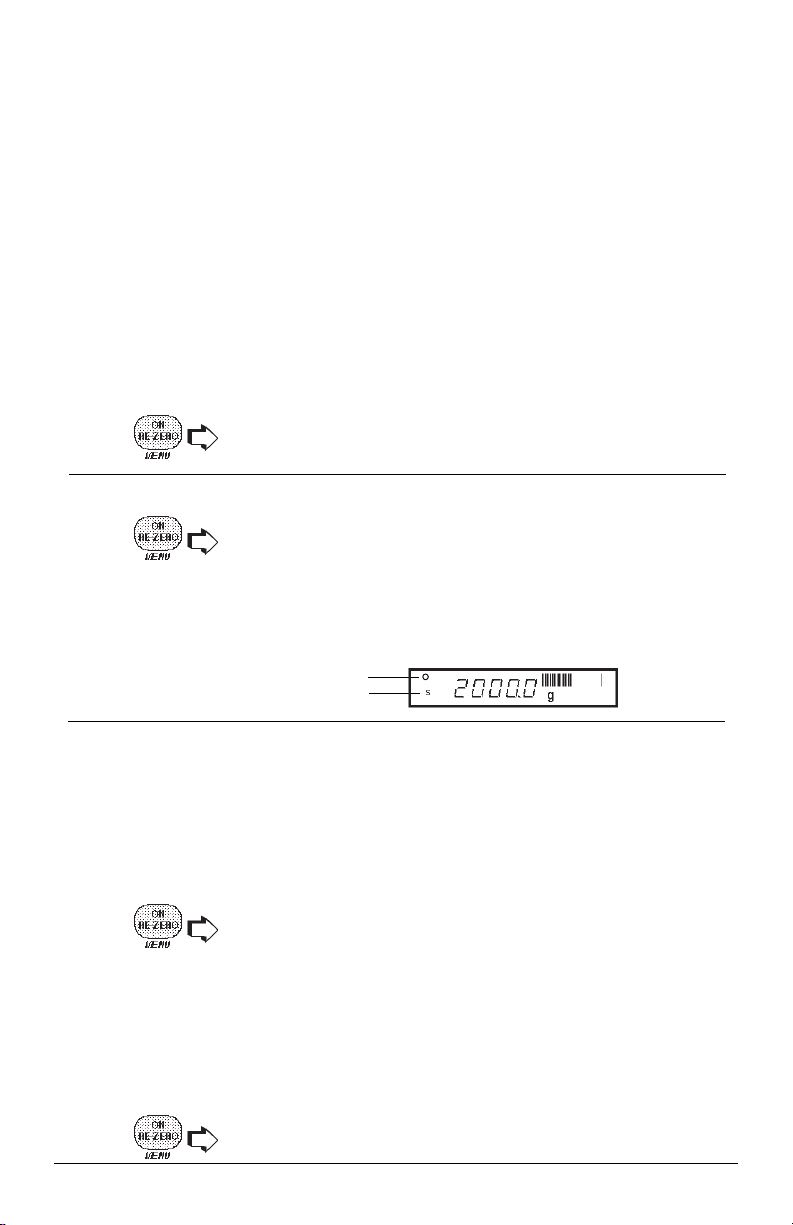

StabilizationStabilization

Stabilization

StabilizationStabilization

Before initally using the balance, allow time for it to adjust to its new environment. The

balance only requires to be plugged in to warm up. Recommended warm up period

is twenty (20) minutes. The balance is powered whenever it is plugged into a power

source.

TMTM

TM

Moveable FineRangeMoveable FineRange

Moveable FineRange

Moveable FineRangeMoveable FineRange

Model GT4100DG contains a Moveable FineRangeTM feature.

When the weight of the object on the platform exceeds the capacity limit of the

Moveable FineRangeTM, the balance will automatically change to the coarse range.

To return to the fine range:

1.The load is reduced to below the capacity limit of the fine range.

2. .

WeighingWeighing

Weighing

WeighingWeighing

1. to rezero the display.

2.Place the object(s) or material to be weighed on the platform.

3.Wait for the stability indicator to appear before reading the weight.

STABILITY INDICATOR

TMTM

(Model GT4100DG) (Model GT4100DG)

(Model GT4100DG)

(Model GT4100DG) (Model GT4100DG)

CENTER OF ZERO

Re-ZeroRe-Zero

Re-Zero

Re-ZeroRe-Zero

When weighing material or objects that must be held in a container, zeroing stores the

container weight in the balance’s memory, separate from the weight of the material in

the container.

1.Place an empty container on the platform. Its weight is displayed.

2. , the display blanks until stable weight readings are received, then

indicates zero. The container’s weight is stored in memory.

3.Add material to the container. As material is added, its net weight is displayed.

4.Removing the container and material from the platform will cause the balance

to display the container’s weight as a negative number.

5. resets the balance to zero.

14

Page 15

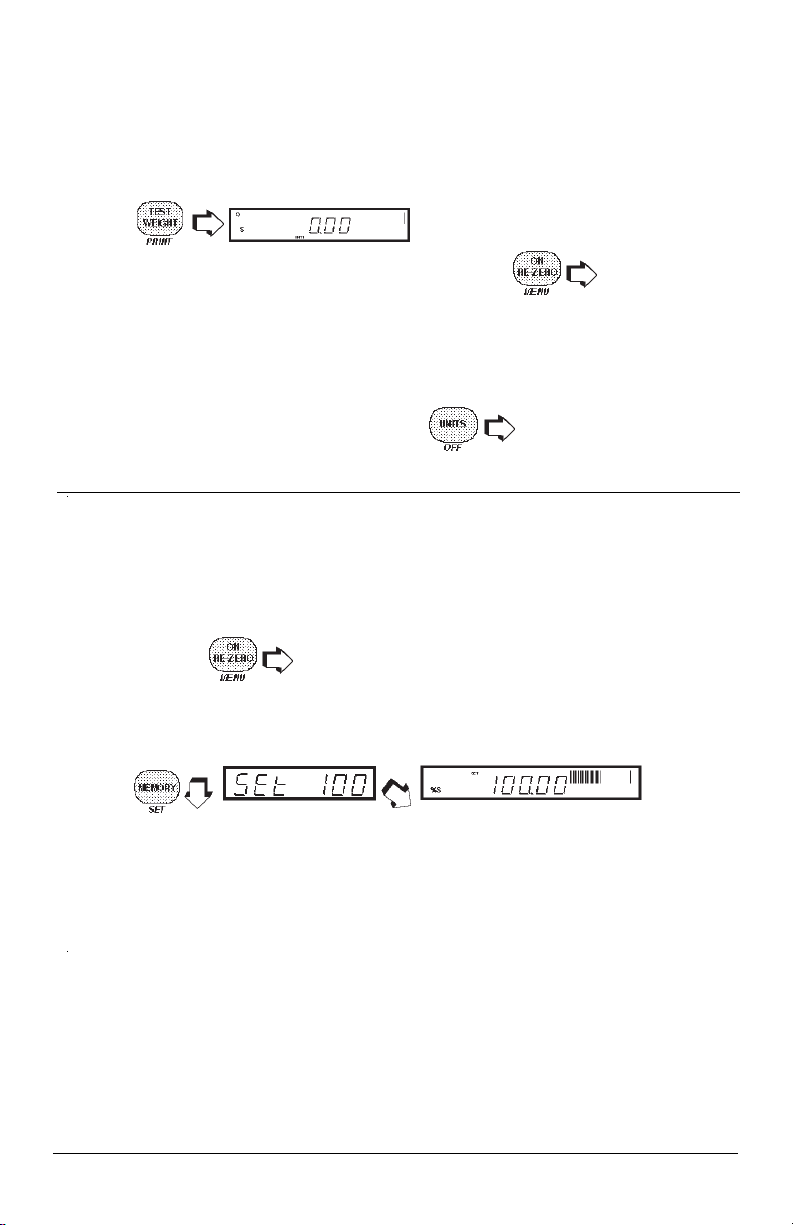

Test Weight ModeTest Weight Mode

Test Weight Mode

Test Weight ModeTest Weight Mode

A quart measure is required for this procedure. Test Weight in lb/bu is calculated as

follows:

sample wt. (g) x 0.0705479 = test wt. (lb/bu)

1.

2.Place an empty quart container on the platform,

3.Remove the container, fill it with sample material and place it on the platform.

4.To return to standard weighing mode,

Dockage ModeDockage Mode

Dockage Mode

Dockage ModeDockage Mode

NOTENOTE

NOTE: The minimum sample weight which can be used for dockage mode is 120

NOTENOTE

grams. A smaller sample size will display Err 7.1

1.With the balance in any weighing mode, place an empty container on the

2.Fill the container with the sample material to the desired weight (100% value).

3.

.

balance.

Weight is displayed in lb/bu (Unit 1).

platform,

to rezero the balance.

to rezero the

.

4.Remove the sample and process it to remove any dockage material.

NOTENOTE

NOTE: While the sample is being processed, the balance may be used in other

NOTENOTE

weighing modes without disturbing the weight stored in memory. See Exiting and

Reentering Dockage Mode.

5.Fill the container with the material from which the dockage (foreign material) has

been removed and place on the platform. The balance will display the weight

of the dockage material as a

NOTENOTE

NOTE: If the balance is rezeroed while using other weighing modes, the initial zero

NOTENOTE

reference (established in the dockage procedure) will be lost. When you reenter the

dockage mode,

on the platform before weighing the dockage material.

YOU MUST REZERO THE BALANCE YOU MUST REZERO THE BALANCE

YOU MUST REZERO THE BALANCE again with the empty container

YOU MUST REZERO THE BALANCE YOU MUST REZERO THE BALANCE

percentage of the original sample weighpercentage of the original sample weigh

percentage of the original sample weight.

percentage of the original sample weighpercentage of the original sample weigh

15

Page 16

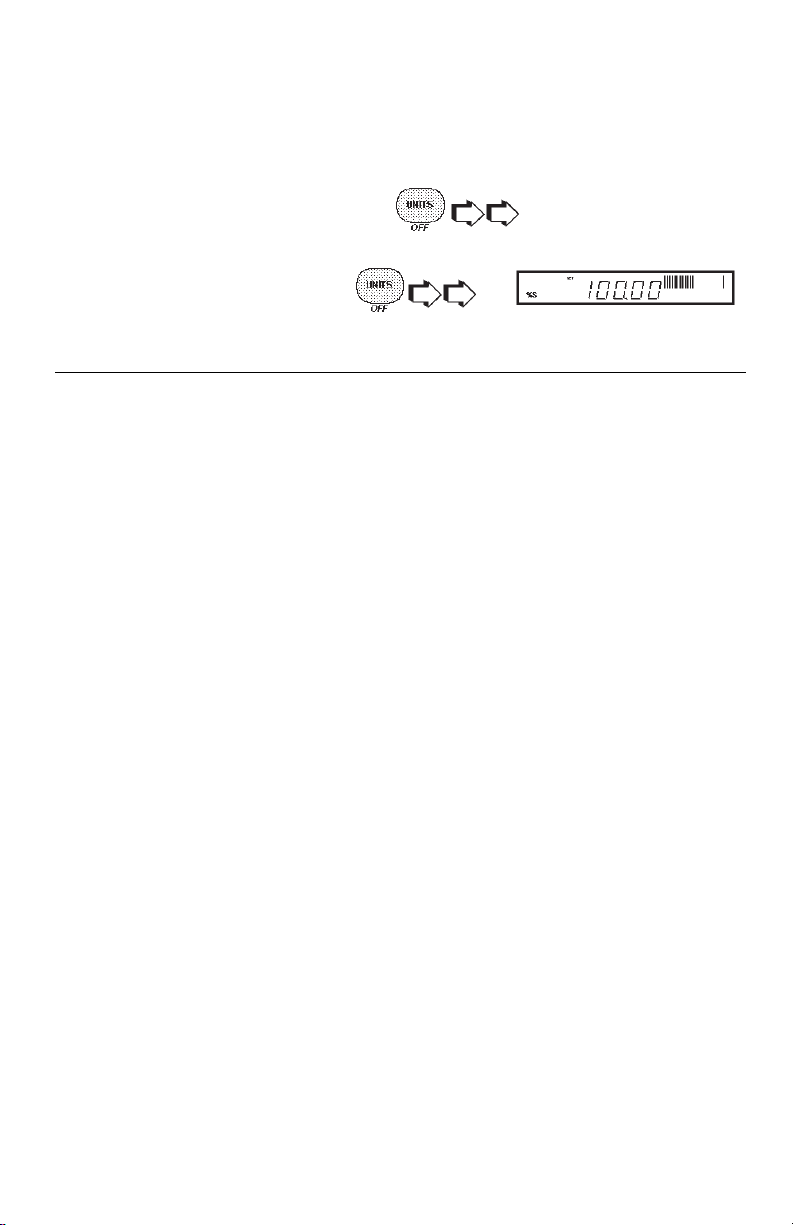

Exiting and Reentering Dockage ModeExiting and Reentering Dockage Mode

Exiting and Reentering Dockage Mode

Exiting and Reentering Dockage ModeExiting and Reentering Dockage Mode

If it desired to use the balance for other weighing modes while a dockage sample is

being processed, perform the following steps:

1.To access other weighing modes,

2.To reenter the dockage mode,

appears.

for desired display.

until

16

Page 17

FUNCTIONS AND MODES OF OPERATIONFUNCTIONS AND MODES OF OPERATION

FUNCTIONS AND MODES OF OPERATION

FUNCTIONS AND MODES OF OPERATIONFUNCTIONS AND MODES OF OPERATION

Each submenu of the GT Balance contains numerous selections which can be set for

specific operations. To customize the operation of the balance for specific measurements, functions and printing, it is necessary to make selections in each menu. The

following illustration identifies the major items in each menu. The factory default

settings are shown in bold type.

CAL

CAL SPAN

CAL LINEARITY

CAL USER

Enter #

CAL TEST

END, CAL

USER

RESET

YESYES

YES/NO

YESYES

AL

0,

STABILITY

5d5d

.

5d, 1d, 2d, 5d

5d5d

AUTO ZERO

OFF,

3d

BEEP

ON/

END, USER

11

1, 2, 3

11

.5d.5d

.5d, 1d,

.5d.5d

OFFOFF

OFF

OFFOFF

SETUP

RESET

YESYES

YES/NO

YESYES

LFT

ON/

SELECT UNITS

gg

g, oz, lb

gg

STATISTICS

GLP

TIME

Type

Set

End, Time

OFFOFF

OFF

OFFOFF

Enable

ON/OFF

Standard Dev.

ON/OFF

Mean

ON/OFF

Sum

ON/OFF

High

ON/OFF

Low

ON/OFF

Difference

ON/OFF

End, Statistics

Time

ON/OFF

Bal ID #

ON/OFF

ID #

ON/OFF

Proj. #

ON/OFF

Cal

ON/OFF

Name

ON/OFF

End, GLP

USUS

US, Euro

USUS

Enter #

DATE

Type

USUS

US, Euro

USUS

Set

Enter #

End, Date

LOCKSWITCH

Cal

YESYES

YES/NO

YESYES

User

NONO

YES/

NO

NONO

Setup

YESYES

YES/NO

YESYES

Print

NONO

YES/

NO

NONO

End, Lockswitch

LIST

END

PRINT

RESET

YESYES

YES/NO

YESYES

COMMUNICATION

Baud

300, 1200,

24002400

2400, 4800,

24002400

9600

Data Bits

7 7

7 or 8

7 7

Parity Bit

Odd, Even,

NoneNone

None, 1, 0

NoneNone

Stop Bits

1 or

End, Comm.

GLP

ID #

Project #

End, GLP

PRINT OPTIONS

Auto Print

ON/OFF

Stable Data

ON/OFF

Numeric Data

ON/OFF

Time

ON/OFF

Date

ON/OFF

Reference

ON/OFF

End, Print

Options

LIST

END, PRINT

22

2

22

17

Page 18

CALIBRATION MENUCALIBRATION MENU

CALIBRATION MENU

CALIBRATION MENUCALIBRATION MENU

Precision Advanced balances features CalTestTM which offers a choice of three

100%100%

100%).

100%100%

Cal Span Cal Span

Cal Span

Cal Span Cal Span

calibration

calibration methods: Cal Span, Cal Linearity, and Cal User.

ensures that the balance reads correctly within specifications using two weight values:

zero and a weight value at either 25%, 50%, 75% of or at the balance’s full capacity.

Cal LinearityCal Linearity

Cal Linearity

Cal LinearityCal Linearity

within the balance’s weighing range. Three weight values are used: zero, a weight

value at midpoint of the balances weighing range, and a weight value at or near the

balance’s specified capacity.

calibrated using a mass of known value by entering that value into the balance.

Test Test

Test

allows the stored calibration data to be tested against the current mass being

Test Test

used for the test. The following figure illustrates the sequence in which submenus

appear on the Calibration menu. Item shown bolded is a default setting.

calibration minimizes deviation between actual and displayed weights

Cal User Cal User

Cal User

Cal User Cal User

CALIBRATION MENUCALIBRATION MENU

CALIBRATION MENU

CALIBRATION MENUCALIBRATION MENU

CAL SPAN

0, 25%, 50%, 75% or Span Weight (

CAL LINEARITY

0, Linearity & Span Weight.

CAL USER

Enter #

CAL TEST

0, Span Weight.

END, Calibration

is a method where the balance can be

NOTENOTE

NOTE: Cal Span, Cal Linearity

NOTENOTE

and Cal User are disabled for

Type Approved/LFT balances.

Cal Cal

Cal

Cal Cal

Calibration Menu ProtectionCalibration Menu Protection

Calibration Menu Protection

Calibration Menu ProtectionCalibration Menu Protection

NOTESNOTES

NOTES:

NOTESNOTES

1. Calibration may be locked out to prevent unauthorized personnel from changing

calibration. If calibration has been locked out, you can only access Cal Test.

2. To lock out calibration menu, after calibration, refer to the section titled Menu

Lock-Out Protection.

Calibration MassesCalibration Masses

Calibration Masses

Calibration MassesCalibration Masses

A 2kg and 4 kg mass are required for calibration. If you begin calibration and realize

calibration masses are not available, exit the menu. The balance will retain previously

stored calibration data. Calibration should be performed as necessary to ensure

accurate weighing. Masses must meet or exceed ASTM Class 1 Tolerance. Calibration masses are available as accessories.

18

Page 19

Span CalibrationSpan Calibration

Span Calibration

Span CalibrationSpan Calibration

1. .

2.

3. , no mass on platform.

4.

must be placed on the platform.

5.Place mass on platform.

6.

the balance when -C- is displayed.the balance when -C- is displayed.

the balance when -C- is displayed.

the balance when -C- is displayed.the balance when -C- is displayed.

7.Remove mass from platform. Span calibration is complete. The balance is now

in a weighing mode.

Linearity CalibrationLinearity Calibration

Linearity Calibration

Linearity CalibrationLinearity Calibration

1.Repeat steps 1 and 2 of Span Calibration above.

2. .

3.

.

, no mass on platform.

, value of mass which

Do not disturbDo not disturb

.

Do not disturb

Do not disturbDo not disturb

4.

must be placed on the platform.

5.Place mass on platform.

6.

which must be placed on the platform.

7.Place mass on platform.

8.

balance when -C- is displayed.balance when -C- is displayed.

balance when -C- is displayed.

balance when -C- is displayed.balance when -C- is displayed.

9.Remove mass from platform. Linearity calibration is complete. The balance is

now in a weighing mode.

, value of mass which

, value of next mass

Do not disturb theDo not disturb the

Do not disturb the

Do not disturb theDo not disturb the

19

Page 20

User CalibrationUser Calibration

User Calibration

User CalibrationUser Calibration

User calibration is used when it is desired to calibrate the balance using a mass of

known value. Proceed as follows:

1.

2. .

3.

4. . The value of last calibration mass is displayed.

5.

6. to accept flashing digit and proceed to next digit . If a

previous digit which was entered requires correction .

7.Set the number to match the value of the selected calibration mass. Number

must bemust be

must be

must bemust be

8.After the digit has been accepted, is displayed.

9.Place calibration mass on platform.

10.

.

.

FLASHING DIGITFLASHING DIGIT

FLASHING DIGIT

FLASHING DIGITFLASHING DIGIT

to change value of flashing digit.

at least

25%25%

25% of the full span value. If value is less, an error will display.

25%25%

Do not disturb the balance when -C- isDo not disturb the balance when -C- is

Do not disturb the balance when -C- is

Do not disturb the balance when -C- isDo not disturb the balance when -C- is

displayed displayed

displayed

displayed displayed

11.Remove mass from platform. The balance is now in a weighing mode.

Cal TestCal Test

Cal Test

Cal TestCal Test

Cal Test offers a choice of the span calibration value (1/4, 1/2, 3/4 or full). To ensure

reproducibility, this feature allows a check of a known calibration mass against last

stored calibration information.

1.

2. .

3. .

.

.

20

Page 21

Cal Test (Cont.)Cal Test (Cont.)

Cal Test (Cont.)

Cal Test (Cont.)Cal Test (Cont.)

4. , no mass on the platform.

5. , value of mass which

must be placed on the platform.

6.

allows the selection of either 25%, 50%, 75%, or 100% of full

span to be used to calibrate the balance.

5.Place required mass on platform.

6.

. While -C- is

displayed, the balance weighs the test mass based on current calibration data,

then displays the difference between the measured value and requested value.

The display shown is an example of when the test mass equals the mass value

stored in memory.

7.Remove mass from platform. After a short period of time, the balance returns

to the weighing mode.

USER MENUUSER MENU

USER MENU

USER MENUUSER MENU

The User menu is used to adapt the balance to environmental conditions. It

contains submenus which enable you to turn features on or off, and program

Reset

balance parameters.

settings.

averaging level.

Reset

does not appear if menu has been locked out. AL specifies the

STB

automatic zero threshold.

various balance conditions.

changes all submenus to original factory default

specifies the desired stability range.

Beep,

when set on, provides audible tones to signify

End User

is used to exit the Setup menu and store

Auto Zero

sets the

the selections. The following figure illustrates the sequence in which submenus

appear on the User menu. Items shown in bold type are the default settings.

USER MENUUSER MENU

USER MENU

USER MENUUSER MENU

RESET

YESYES

YES/NO

YESYES

AL

11

0,

1, 2, 3

11

STABILITY

5d5d

.

5d, 1d, 2d, 5d

5d5d

AUTO ZERO

.5d.5d

OFF,

.5d, 1d,

.5d.5d

3d

BEEP

OFFOFF

ON/

OFF

OFFOFF

END, User

21

Page 22

User Menu ProtectionUser Menu Protection

User Menu Protection

User Menu ProtectionUser Menu Protection

The User menu may be locked out to prevent unauthorized personnel from changing

the settings. If -SAFE- is displayed, the User menu has been locked out. Settings may

be viewed but not changed. To lock out the User menu, refer to the section titled Menu

Lock-Out Protection.

ResetReset

Reset

ResetReset

This submenu enables you to reset all User menu selections to the

settings:

Beep

Averaging Level

OFF. OFF.

OFF. Reset does not appear if the menu has been locked out.

OFF. OFF.

1

2.

3.

4. .

5.

6.

.

double short beep

AL 1AL 1

AL 1,Stability Range

AL 1AL 1

.

.

to select or .

. If is selected, the balance signals a

.

.5d,.5d,

.5d, Auto-Zero Tracking

.5d,.5d,

factory default

.5d.5d

.5d and

.5d.5d

Averaging LevelAveraging Level

Averaging Level

Averaging LevelAveraging Level

Averaging level compensates for vibration or excessive air currents. Factory default

setting is shown in bold type.

AL 0 reduced stability, fastest stabilization time

ALAL

AL

ALAL

AL 2 more stability, slow stabilization time

AL 3 maximum stability, slowest stabilization time

NOTENOTE

NOTE: Averaging level does not affect balance accuracy, but it does affect stabilization

NOTENOTE

time.

1 normal stability, normal stabilization time1 normal stability, normal stabilization time

1 normal stability, normal stabilization time

1 normal stability, normal stabilization time1 normal stability, normal stabilization time

22

Page 23

Averaging Level (Cont.)Averaging Level (Cont.)

Averaging Level (Cont.)

Averaging Level (Cont.)Averaging Level (Cont.)

To view or change the averaging level:

1.Access the Averaging Level

2.

3. to select through .

4.

Stability RangeStability Range

Stability Range

Stability RangeStability Range

The stability range specifies how much a displayed weight may change while the

stability indicator remains ON. When a displayed weight changes beyond the

allowable range, the stability indicator turns OFF indicating an unstable condition.

Factory default setting is shown in bold type.

.5 d.5 d

.5 d

.5 d.5 d

1 d Reduced range.

2 d Normal range.

5 d Largest range: stability indicator is ON even though displayed weight

When the RS232 interface is configured to print stable data only, the stability range also

governs data output. Displayed data will only be output if it is within the selected stability

range.

To view or change the stability range:

.

Smallest range: stability indicator is ON only when displayedSmallest range: stability indicator is ON only when displayed

Smallest range: stability indicator is ON only when displayed

Smallest range: stability indicator is ON only when displayedSmallest range: stability indicator is ON only when displayed

weight is within .5 divisionsweight is within .5 divisions

weight is within .5 divisions.

weight is within .5 divisionsweight is within .5 divisions

changes slightly.

,

submenu.

1.Access the Stability Range submenu.

2. .

3.

4. .

to select through

23

Page 24

Auto-ZeroAuto-Zero

Auto-Zero

Auto-ZeroAuto-Zero

Auto-Zero minimizes the effects of temperature changes and shift on the zero reading.

By defining a threshold level in divisions, the balance maintains the zero display until

the threshold is exceeded. Factory default setting is shown in bold type.

OFF Turns Auto-Zero OFF.

.5 d.5 d

.5 d

.5 d.5 d

1 d Sets threshold to 1 division.

3 d Sets threshold to 3 divisions.

To view or change the auto-zero setting:

Sets threshold to .5 divisions.Sets threshold to .5 divisions.

Sets threshold to .5 divisions.

Sets threshold to .5 divisions.Sets threshold to .5 divisions.

1.Access the Auto-Zero

2.

3. to select through .

4.

Beep FunctionBeep Function

Beep Function

Beep FunctionBeep Function

A beep (sound) feature is a tone or series of tones emitted to annunciate various

balance conditions. The table below defines when the beeps are sounded if turned ON.

The default setting for the Beep menu is OFF. To turn the sound feature ON, proceed

as follows:

1.Access the

2.

3. to select or .

4.

.

.

submenu.

.

.

submenu.

GT BEEPSGT BEEPS

GT BEEPS

GT BEEPSGT BEEPS

Power-On Single long beep (Plug in, not front panel On) Single long beep *

Key Press Single short beep

Reset in Menu Double short beep *

* Indicates that the beep cannot be disabled.

24

Page 25

SETUP MENUSETUP MENU

SETUP MENU

SETUP MENUSETUP MENU

The Setup menu is used to customize the operation of the balance for your specific

requirements. It contains submenus which enable you to turn features on or off, and

program balance parameters.

Reset

settings.

does not appear if menu has been locked out.

for type approved operation.

Reset

changes all submenus to original factory default

LFT

sets the balance

SEL

(selection) specifies one of three weighing units.

Additional submenus are: Statistics, Good Laboratory Practices, Time, Date, Lock

Switch, List and End. The following figure illustrates the sequence in which submenus

appear on the Setup menu. Items shown in bold type are the default settings.

SETUP

RESET

YESYES

YES/NO

YESYES

LFT

OFFOFF

ON/

OFF

OFFOFF

SELECT UNITS

gg

g, oz, lb

gg

STATISTICS

Enable

ON/OFF

Standard Dev.

pop, sample, OFF

Mean

ON/OFF

Sum

ON/OFF

High

ON/OFF

Low

ON/OFF

Difference

ON/OFF

End, Statistics

GLP

Time

ON/OFF

Bal ID #

ON/OFF

ID #

ON/OFF

Proj. #

ON/OFF

Cal

ON/OFF

Name

ON/OFF

End, GLP

TIME

Type

USUS

US, Euro

USUS

Set

Enter #

End, Time

DATE

Type

USUS

US, Euro

USUS

Set

Enter #

End, Date

LOCKSWITCH

Cal

YESYES

YES/NO

YESYES

User

NONO

YES/

NO

NONO

Setup

YESYES

YES/NO

YESYES

Print

NONO

YES/

NO

NONO

End, Lockswitch

LIST

END

25

Page 26

Setup Menu ProtectionSetup Menu Protection

Setup Menu Protection

Setup Menu ProtectionSetup Menu Protection

The Setup menu may be locked out to prevent unauthorized personnel from changing

the settings. If -SAFE- is displayed, the Setup menu has been locked out. Settings

may be viewed but not changed. To lock out the Setup menu, refer to the section titled

Menu Lock-Out Protection.

ResetReset

Reset

ResetReset

This submenu enables you to reset

settings shown below. Reset does not appear if the menu has been locked out.

Function Default

1. .

allall

all Setup menu selections to the factory default

allall

Reset Yes

LFT Off

Unit Selection grams

Statistics All-Off

GLP Off

Time U.S.

Date U.S.

Lockswitch Cal Yes

User No

Setup Yes

Print No

2.

3.

4.

5.

6.

double short beep

.

.

.

to select or .

. If is selected, the balance signals a

.

26

Page 27

Type Approved/LFTType Approved/LFT

Type Approved/LFT

Type Approved/LFTType Approved/LFT

LFT can be set to ON or OFF. Selecting ON automatically sets the parameters shown

in the table to conform to type approved requirements. For sealing method, refer to

Type Approved Sealing section. Default setting are shown as follows:

Auto Zero .5 d

Lockswitch Setup & Calibration

Stable Data Locked ON

1.Access the submenu.

2.

3. to select or .

4. .

Unit SelectionUnit Selection

Unit Selection

Unit SelectionUnit Selection

The Unit Selection (SEL) submenu permits the selection of weighing units for use

during operation. The balance can display weights in every unit of measure listed

shown below. The default setting is shown in bold type.

To view or change the various weighing units:

1.Access the

2.

.

gg

GramsGrams

g

Grams

gg

GramsGrams

oz Ounces

lb Pounds

menu.

to select first unit .

3.

status is displayed.

4.Set each unit ON or OFF by repeating steps 2 and 3.

5.

to select or , next unit

.

27

Page 28

StatisticsStatistics

Statistics

StatisticsStatistics

Statistics provides printed display data of: Standard Deviation either population or

sample, Mean, Sum, High, Low and Difference readings. Each can be individually set

ON or OFF.

1. To select one or more parameters, access the

2.

3.

turned off without losing the individual settings programmed into memory.

4.

5.

6. .

7.

8.

9.

10.

to select or

, , .

.

.

. Enable allows the statistics feature to be

.

.

.

menu.

11.

12.

13.

14.

15. Continue the same procedure to set Sum, High, Low and Difference para meters and finish by selecting

to select other parameters.

to accept.

to select or .

.

28

Page 29

Good Laboratory PracticesGood Laboratory Practices

Good Laboratory Practices

Good Laboratory PracticesGood Laboratory Practices

Good Laboratory Practices (GLP) submenu allows the selection of Time, Balance

Identification Number, Identification Number, Project Number, Calibration and Name

data to be printed. The purpose of this submenu is to permit the printing of the above

selected items. These items are not displayed. The default setting is off.

When an external printer is used, and all items are set ON and the balance is calibrated,

the printer will print out calibration data for audit trail purposes and will indicate date,

and time. The Balance ID number is a factory set number. It should be noted that the

ID number and Project number must be entered in the Print/GLP submenu before

printed data is available. Since all of the settings for the GLP submenu are done in a

similliar manner, only one example is shown.

1.Access the

2.

3. .

4.

5.

6.Repeat steps above for Balance ID#, ID#, Project#, Calibration and Name.

TimeTime

Time

TimeTime

Time is a feature which enables the balance to be set to the current time in either U.S.A.

standards (12 hour periods) or European/Military standards (24 hour periods). The

default setting is US Standard. To enter time, proceed as follows:

1.Access the

2. .

to select or .

submenu under

.

.

submenu which is under the Setup submenu.

SETUP

Options menu.

3.

4. to select or .

5.

6. .

.

.

29

Page 30

Time (Cont.)Time (Cont.)

Time (Cont.)

Time (Cont.)Time (Cont.)

7. first two digits are flashing.

8.

9.

NOTE NOTE

NOTE:

NOTE NOTE

10.

11.

12.

13.

DateDate

Date

DateDate

Date is a feature which enables the balance to be set to a U.S.A. date standard or

European date standard. U.S. standard has the month, date followed by the year each

separated by (/) in the printout. The European date standard has the day first, followed

by the month and then the year each separated by a period. The default setting is US

Standard.

or to change flashing digits to current local hour.

flashes the last two digits.

will back up display.

or changes minutes display.

to accept. AM or PM is flashing, A for AM, P for PM.

to select AM to PM.

.

1. Access the

2. .

3. .

4. to select or (European).

5. .

6. .

7. first two digits are flashing.

submenu which is under Setup submenu.

30

Page 31

Date (Cont.)Date (Cont.)

Date (Cont.)

Date (Cont.)Date (Cont.)

8. to change flashing digit to current month for US or day for

European standard.

9.

10.

11.

10.

11.

LockswitchLockswitch

Lockswitch

LockswitchLockswitch

Lockswitch enables you to lock out one or more menu selections. Each menu can be

individually locked on or off after all functions have been set. The

SetupSetup

Setup and

SetupSetup

menu and then locked by the switch located under the front of the control panel. See

Menu Lockout Section. Cal Test under Calibration remains functional with the

Lockswitch On or Off. Before performing the lockout procedure, decide which

functions of the balance are to be locked on or off.

PrintPrint

Print menus can be individually locked on or off by selecting the appropriate

PrintPrint

1.Access the

2. to access either Calibration, User, Setup or print submenus.

to change digits.

to change year.

flashes two centered digits.

last two digits are year.

.

submenu.

CalibrationCalibration

Calibration,

CalibrationCalibration

User,User,

User,

User,User,

3. to select desired submenu.

4. to access a selected submenu.

5. to select or .

YES = locked, NO = not locked.YES = locked, NO = not locked.

YES = locked, NO = not locked.

YES = locked, NO = not locked.YES = locked, NO = not locked.

6.

7. to change to other submenus.

8. To change all submenus, repeat steps 2 through 6.

to accept.

31

Page 32

ListList

List

ListList

This submenu can be used to output a listing of current menu settings via the RS232

interface. When selected, all menu settings for the User, Setup and Print menus will

be output either to an external printer or computer. To use this feature, your balance

must be connected to a computer or printer.

1.Access the

2.

menu under the Print menu.

to obtain a listing of current settings. The display

indicates a series of dots traveling right to left when the balance is sending

information .

PRINT MENUPRINT MENU

PRINT MENU

PRINT MENUPRINT MENU

The Print menu provides a number of options which includes: reset, communications,

good laboratory practices, and list.

submenu to factory default settings.

data bits, parity bit type and stop bits.

Reset

sets all submenus contained in the Print

Communication

GLP

specifies baud rate, number of

Good laboratory practices permits the

entering of your own identification number and project number which shows up on

printing.

Print Options

Enables/disables Auto print feature, specifies time interval for

automatic output of displayed data and/or a range of displayed weight values that

cannot be output. The following items can be turned on or off: Stable data-only feature,

numeric only or full display data for output, time and date. Items shown in bold type are

default settings. Items shown in italics in the print menu below appear only if the

appropriate Functions are turned on. Items shown in bold type are the default settings.

PRINT MENUPRINT MENU

PRINT MENU

PRINT MENUPRINT MENU

RESET

YESYES

YES/NO

YESYES

COMMUNICATION

Baud

300, 1200,

4800, 9600

Data Bits

77

7 or 8

77

Parity Bit

Odd, Even,

1, 0

Stop Bits

1 or

End, Comm.

GLP

ID #

Project #

End,GLP

24002400

2400,

24002400

None None

None,

None None

2 2

2

2 2

PRINT OPTIONS

Auto Print

Cont, interval,

offoff

on stb,

off

Initialize Auto Print

Stable Data

Numeric Data

Time

Date

Reference

End, Print Options

LIST

END, PRINT

offoff

Interval, non print lo,

non print hi

OFFOFF

ON/

OFF

OFFOFF

OFFOFF

ON/

OFF

OFFOFF

OFFOFF

ON/

OFF

OFFOFF

OFFOFF

ON/

OFF

OFFOFF

OFFOFF

ON/

OFF

OFFOFF

32

Page 33

Print Menu ProtectionPrint Menu Protection

Print Menu Protection

Print Menu ProtectionPrint Menu Protection

The Print menu may be locked out to prevent unauthorized personnel from changing

settings. If SAFE is displayed, the Print menu has been locked out. Settings may be

viewed but not changed. To lock out the Print menu or unlock, refer to the section titled

Menu Lock-Out Protection.

ResetReset

Reset

ResetReset

This submenu enables you to reset

settings shown below. Reset does not appear if the menu has been locked out.

allall

all Print menu selections to the factory default

allall

Function Default

1.

2. .

3.

4. .

5.

6.

doubleshort beep

a

Baud Rate br2400

Data Bits 7 data

Parity none

Stop Bits 2 stop

Auto Print OFF

Autp Print interval 1 second

Non Print Low Limit 0

Non Print High Limit 0

Stable data Only OFF

Numeric Data Only OFF

Time OFF

Date OFF

.

.

to select or .

.

. If is selected, the balance signals

CommunicationCommunication

Communication

CommunicationCommunication

The Communication submenu contains submenus which permit the setting of: baud

rates, data bits, parity and stop bits necessary for communications to an external

printer or computer.

Access the Communication submenu.

33

Page 34

Baud RateBaud Rate

Baud Rate

Baud RateBaud Rate

This submenu is used to select the desired baud rate. There are five available baud

rates to choose from: 300, 1200, 2400, 4800 and 9600. The default setting is 2400

baud.

To view or change the baud rate:

1.Access the

submenu to display the current setting.

2. .

3.

to change setting. Normal baud rate is .

4. .

Data BitsData Bits

Data Bits

Data BitsData Bits

The total number of bits for Data, Parity and Stop must equal 9 or 10. (see examples).

The balance will not permit you to select a combination that does not equal 9 or 10. The

default setting is 7 data.

To set the number of data bits to 7 or 8:

EXAMPLESEXAMPLES

EXAMPLES

EXAMPLESEXAMPLES

8 Data + 2 Stop + No Parity = 10

8 Data + 1 Stop + Odd Parity = 10

7 Data + 1 Stop + Odd Parity = 9

1.Access the submenu.

2. accept.

3.

to change setting.

4. .

ParityParity

Parity

ParityParity

Parity can be set to Odd, Even, None, or a marker of 0 or 1. The default setting is none.

To set parity, proceed as follows:

1. Access the

submenu.

2. accept.

3.

to change setting.

34

Page 35

Parity (Cont.)Parity (Cont.)

Parity (Cont.)

Parity (Cont.)Parity (Cont.)

4.

NOTE: NOTE:

NOTE: If all selections do not appear, total number of data, parity and stop bits is

NOTE: NOTE:

currently < 8 or > 10, data or stop bits must be changed.

Stop BitsStop Bits

Stop Bits

Stop BitsStop Bits

The number of stop bits can be set to 1 or 2. The default setting is 2. To set stop bits,

proceed as follows:

1.Access the Bits submenu.

2.

3. to change setting.

4.

NOTE: NOTE:

NOTE: If all selections do not appear, total number of data, parity and stop bits is

NOTE: NOTE:

currently < 8 or > 10, data or parity bits must be changed.

Good Laboratory Practice (GLP)Good Laboratory Practice (GLP)

Good Laboratory Practice (GLP)

Good Laboratory Practice (GLP)Good Laboratory Practice (GLP)

This submenu enables the storage of an identification number and/or a project number.

When entered into the balance, the identification number and project number are

available when printing. The reason the entries are made under the Print submenu,

is that when legal for trade operation (LFT) is enabled, the Setup submenu is locked

out, leaving the Print submenu free to make entries.

accept.

.

.

1.Access

2.

3. first digit is flashing.

4.

5. accepts value and moves to second digit.

6.

7. .

submenu.

.

changes the value of the first digit.

to change digits.

35

Page 36

Good Laboratory Practice (GLP) (Cont.)Good Laboratory Practice (GLP) (Cont.)

Good Laboratory Practice (GLP) (Cont.)

Good Laboratory Practice (GLP) (Cont.)Good Laboratory Practice (GLP) (Cont.)

NOTENOTE

NOTE: allows going back to the previous digit for correction.

NOTENOTE

8. To enter project number, repeat steps 2 through 6, except enter

submenu.

Print OptionsPrint Options

Print Options

Print OptionsPrint Options

This submenu contains additional features which can be set and include Auto Print,

Initialize Auto Print, Stable Data, Numeric Data, Time, Date and Reference data.

To change any of the above listed options, enter the

Auto Print FeatureAuto Print Feature

Auto Print Feature

Auto Print FeatureAuto Print Feature

When enabled, the Auto Print feature causes the balance to automatically output

display data in one of three ways: continuously, at user specified time intervals, or upon

stability.

To select one of these Auto Print methods, or to turn the feature off:

1.Access the

2.

3.

4.

NOTENOTE

NOTE: If you select interval to automatically output data at user specified time

NOTENOTE

intervals, the interval is entered in the Initialize submenu which follows.

InitializeInitialize

Initialize

InitializeInitialize

This submenu allows you to:

to accept current setting.

.

submenu.

, , or

.

submenu.

• Specify a time interval (in seconds) for automatic output.

• Exclude a range of weights from being output, or specify a range for output, by the

Auto Print feature.

It does not appear on the Print menu if Auto Print is set to OFF. Use the following

procedure to set these features:

36

Page 37

InitializeInitialize

Initialize

InitializeInitialize

1.Access the

submenu under the Print Options submenu.

2.If Interval was selected in the Auto Print submenu, is displayed,

and you may continue with step 3. If interval was not selected,

is displayed. Proceed to step 7.

3.

to enter time interval for automatic data output when

is displayed. The current interval from to

(in seconds) is displayed.

4.

to increase or to decrease the interval number.

5 .

6.

to enter a range of non printing values, is dis-

played.

7 , the current value for the low end of the range is displayed with

the first digit flashing

.

To exclude dataTo exclude data

To exclude data

8.To change the number, start with

the first digit (flashing).

to change the

To exclude dataTo exclude data

WITHIN SELECTED RANGE:WITHIN SELECTED RANGE:

WITHIN SELECTED RANGE:

WITHIN SELECTED RANGE:WITHIN SELECTED RANGE:

Example:non-PL=7g, non-PH=11g

SET non-PL < non-PH

Values <7

OR OR

OR >11 will be output.

OR OR

value to any number from -9 to +9.

To exclude dataTo exclude data

To exclude data

A minus sign will light to indicate a

negative value.

9.When the desired value is

displayed,

to accept it and

To exclude dataTo exclude data

OUTSIDE SELECTED RANGE:OUTSIDE SELECTED RANGE:

OUTSIDE SELECTED RANGE:

OUTSIDE SELECTED RANGE:OUTSIDE SELECTED RANGE:

Example:non-PL=11g, non-PH=7g

Set non-PL > non-PH

Values >7

AND AND

AND <11 will be output.

AND AND

the next digit will begin flashing.

10.Set all digits in the same manner. If an error is made, to backup to

the desired digit and change it.

37

Page 38

Initialize (Cont.)Initialize (Cont.)

Initialize (Cont.)

Initialize (Cont.)Initialize (Cont.)

11.After the last digit is entered, is displayed again.

for the NON-PH high limit.

12

13.Change the number as needed using the same procedure as in step 9.

14.After the last digit is entered,

15.

16. .

Print Stable Data OnlyPrint Stable Data Only

Print Stable Data Only

Print Stable Data OnlyPrint Stable Data Only

When enabled, this feature permits only stable display data to be output. To set the

feature ON or OFF, proceed as follows:

1.Access the submenu under the Print Options menu.

2. to accept.

3.

4. .

to view the current value for the high end of the range.

displayed again.

.

to select or .

Print Numeric Data OnlyPrint Numeric Data Only

Print Numeric Data Only

Print Numeric Data OnlyPrint Numeric Data Only

This submenu is used to select numeric data only, or full display data for RS232 output.

Set this feature ON to output numeric display data only, or OFF to output full display

data as follows:

1. Access the

2. to display the current status.

3. to select or .

4. .

submenu under the Print Option menu.

38

Page 39

TimeTime

Time

TimeTime

When the Time function is set ON, allows the balance to output the current time to the

printer. To set the Time feature ON or OFF, proceed as follows:

1.Access the

2.

3. to select or .

4.

DateDate

Date

DateDate

When the Date function is set ON, allows the balance to output the current date to the

printer. To set the Date feature ON or OFF, proceed as follows:

1.Access the submenu.

2.

3. to select or .

4.

ReferenceReference

Reference

ReferenceReference

When the Reference function is set ON, prints the value of weight used as a reference

in FM % mode. When set to Current, the printer prints the current reference

immedediately.

to display current status.

to display the current status.

submenu under the Print Option menu.

.

.

1.Access the

2.

3.

4.

submenu under the Print Options submenu

to display the current status.

to select , or .

.

39

Page 40

ListList

List

ListList

This submenu can be used to output a listing of current menu settings via the RS232

interface. When selected, all menu settings for the Print menu will be output either to

an external printer or computer. To use this feature, your balance must be connected

to a computer or printer.

1.Access the

2. to obtain a listing of current settings, when is displayed. The display indicates a series of dots traveling right to left when the

balance is sending information .

MENU LOCK-OUT PROTECTIONMENU LOCK-OUT PROTECTION

MENU LOCK-OUT PROTECTION

MENU LOCK-OUT PROTECTIONMENU LOCK-OUT PROTECTION

Access to the

Lockswitch located on the PC board inside the balance. The Lockswitch locks out

menus selected in the Lockswitch menu. The default setting for the Lockswitch is

OFF.

1.Turn the display off and unplug the power cord.

CalibrationCalibration

Calibration

CalibrationCalibration

UserUser

,

User

UserUser

submenu under the Print submenu.

SetupSetup

,

Setup

SetupSetup

and

Print Print

Print

menus, can be disabled using the

Print Print

WARNING

• To avoid shock hazards, always be

certain that the power cord is disconnected BEFORE removing the balance

cover.

• Even though the balance may have

been switched OFF, high voltage is

present inside the balance as long as

the power cord is connected.

• A power cord has been furnished with

the balance. DO NOT use any other

type of power cord other than the one

furnished.

DO NOT create a safety hazard by

defeating the grounding feature.

LOCKSWITCH

LOCATED INSIDE OF

BALANCE

2.Remove the platform and platform support.

3.Remove the two (2) cover screws and tilt the cover towards the right side of the

balance.

4.The menu Lockswitch is located on the front of the PC board. The OFF position

is to the left facing the front of the balance.

5.Select the desired position on the Lockswitch and reassemble the balance.

40

Page 41

TYPE APPROVED BALANCE SEALINGTYPE APPROVED BALANCE SEALING

TYPE APPROVED BALANCE SEALING

TYPE APPROVED BALANCE SEALINGTYPE APPROVED BALANCE SEALING

Precision Advanced Electronic Balances with a "G & DG" suffix, may be sealed for type

approved applications. Type Approved balances include a lead seal with wire and

security screw as shown in the figures below.

Type approved balances are Class II devices, consult local Weights and Measures

officials to determine sealing method requirements.

After the balance has been set up properly and the menus are locked out (see section

titled Type Approved/LFT), proceed as follows to seal the balance: Turn OFF and

unplug the balance. Remove Platform and Platform Support.

• LEAD SEAL METHOD• LEAD SEAL METHOD

• LEAD SEAL METHOD

• LEAD SEAL METHOD• LEAD SEAL METHOD

1.Pass the wire through the Security

Screw and the lances on the Plate

as shown in the illustration.

2.Crimp the lead seal tightly.

3.Reinstall items removed.

LEAD SEAL

SEALING STICKER

LOCATION

BALANCE SEALING

41

Page 42

RS232 INTERFACERS232 INTERFACE

RS232 INTERFACE

RS232 INTERFACERS232 INTERFACE

Precision Advanced balances are equipped with a bi-directional RS232 compatible

interface for communication with printers and computers. When the balance is

connected directly to a printer, displayed data can be output at any time by simply

pressing PRINT, or by using the Auto Print feature.

Connecting the balance to a computer enables you to operate the balance from the

computer, as well as receive data such as displayed weight, weighing mode, stability

status, etc.

The following sections describe the hardware and software provided with the balance.

HardwareHardware

Hardware

HardwareHardware

On the rear of the balance, a 9-pin subminiature “D” connector is provided for interfacing to other devices. The pinout and pin

connections are shown in the adjacent

illustration.

The balance will not output any data unless pin 5 (CTS) is held in an ON state (+3

to +15 VDC). Interfaces not utilizing the

CTS handshake may tie pin 5 to pin 6 to

defeat it.

Output FormatsOutput Formats

Output Formats

Output FormatsOutput Formats

Data output can be initiated in one of three

ways: 1) By pressing PRINT; 2) Using the

Auto Print feature; 3) Sending a print command (“P”) from a computer.

The output format is illustrated in the RS232

command table which follows.

1 5VDC (5 mA max.)

2 Data Out (TXD)

3 Data In (RXD)

4* Tare (External signal)

5 Clear To Send (CTS)

6 Data Terminal Ready (DTR)

7 Ground

8 Request To Send (RTS)

9* Print (External signal)

* External PRINT and/or TARE

switches may be installed as shown

in the diagram. Momentary contact switches must be used.

TARE *

PRINT *

RS232 CommandsRS232 Commands

RS232 Commands

RS232 CommandsRS232 Commands

All communication is accomplished using standard ASCII format. Only the characters shown in the following table are

acknowledged by the balance. Any other

commands, control characters or spaces

are ignored. Commands sent to the

balance must be terminated with a carriage return (CR) or carriage return-line line feed

(CRLF). For example, a tare command should appear as shown in the adjacent

diagram. Data output by the balance is always terminated with a carriage return - line

feed (CRLF).

42

TARE COMMAND

Field: T CR LF

Length: 1 1 1

Page 43

RS232 COMMAND TABLERS232 COMMAND TABLE

RS232 COMMAND TABLE

RS232 COMMAND TABLERS232 COMMAND TABLE

CommandCommand

Command

CommandCommand

CharacterCharacter

Character

CharacterCharacter

??

? Print current mode

??

nnnAnnnA

nnnA Set Auto Print feature to “nnn”

nnnAnnnA

CC

C Begin span calibration

CC

xDxD

xD Set 1 second print delay (set x = 0 for OFF, or x = 1 for ON)

xDxD

EE

E Exit percent weighing, FM

EE

DescriptionDescription

Description

DescriptionDescription

(see table).

Field: Mode Stab CR LF

Length: 5 1 1 1

Grams g

Pounds lbs

ounces oz

nnn = 0 Turns feature OFF

nnn = S Output on stability

nnn = C Output is continuous

nnn = 1-256 Sets Auto Print

blank if stable

“ ? ” if unstable

Interval

xx

II

x

I Set Averaging Level to “x”,

xx

II

LL

L Begin linearity calibration

LL

MM

M Same effect as pressing mode button

MM

xMxM

xM Places balance in mode “x”,

xMxM

where x = 0 to 3 (see table).

where x = 1 to 13 (see table).

If unit or mode is not already

enabled, command will be ignored.

43

0 = minimum level

1=

2=

3 = maximum level

1 = grams

2 = ounces

3 = pounds

Page 44

CommandCommand

Command

CommandCommand

CharacterCharacter

Character

CharacterCharacter

PP

P Print display data

PP

xSxS

xS Set stable data only printing (set x = 0 for OFF, or x = 1 for ON).

xSxS

TT

T Same effect as pressing rezero button

TT

VV

V Print EPROM version

VV

DescriptionDescription

Description

DescriptionDescription

When “numeric only” display

data is selected for output in

the RS232 menu, the Mode

field is not output.

Field: Weight Mode Stab CR LF

Length: 9 1 5 1 1 1

Displayed weight sent right justified

w/lead zero blanking.

Nine characters include:

decimal point (1)

weight (7 max))

polarity (1): blank if positive

Field: Model # EPROM # CR LF

Length: 7 15 1 1

Same as ?

command

“ - ” if negative

Balance Model

xZxZ

xZ Set Auto Zero to “x”,

xZxZ

x%x%

x% Downloads reference weight “x” for percent mode. “x” must be in grams.

x%x%

Esc LEsc L

Esc L Prints listing of Setup and Print menu settings.