Page 1

Ohaus Discovery Balances

Instruction Manual

Page 2

Page 3

Ohaus Corporation, 19A Chapin Road, P.O. Box 2033 Pine Brook, New Jersey, 07058, USA

Declaration of Conformity We, Ohaus Corporation, declare under our sole responsibility that the balance models listed below marked with “CE”

- are in conformity with the directives and standards mentioned.

Instrument Type: Discovery Series

EC Marking: EC Directive Applicable Standards

73/23/EEC

Low Voltage

89/336/EEC

Electromagnetic compatibility

EN61010-1: 2001

EN61326:1997+A1:A2:01+A3:03 (class B)

EN61326:1997+A1:A2:01+A3:03 (minimal requirements)

For non-automatic weighing instruments used in an Article 1, 2.(a) application, additional metrological marking according to Annex IV of

Council directive 90/384/EEC must be attached to the instrument

90/384/EEC

Non-Automatic

Weighing Instruments

* Applies only to certified non-automatic weighing instruments.

Date: April 1, 2006

Ted Xia

President

Ohaus Corporation

Pine Brook, NJ USA

EN45501:1992 *

Urs Müller

General Manager

Ohaus Europe

Greifensee, Switzerland

Page 4

Important notice for verified weighing instruments

Weighing Instruments verified at the place of manufacture bear one of the preceding mark on the packing label and the green

‘M’ (metrology) sticker on the descriptive plate. They may be put into service immediately.

Weighing Instruments to be verified in two stages have no green ‘M’ (metrology) on the descriptive plate and bear

one of the preceding identification mark on the packing label. The second stage of the initial verification must be

carried out by the approved service organization of the authorized representative within the EC or by the national

weight & measures (W+M) authorities.

The first stage of the initial verification has been carried out at the manufacturers work. It comprises all tests according to the

adopted European standard EN 45501:1992, paragraph 8.2.2.

If national regulations limit the validity period of the verification, the user of the weighing instrument must strictly observe the

re-verification period and inform the respective W+M authorities.

Disposal

In conformance with the European Directive 2002/96/ EC on Waste Electrical and Electronic Equipment (WEEE) this device

may not be disposed of in domestic waste. This also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point specified for electrical and electronic

equipment.

If you have any questions, please contact the responsible authority or the distributor from which you purchased this device.

Should this device be passed on to other parties (for private or professional use), the content of this regulation must also be

related.

Thank you for your contribution to environmental protection.

Compliance to the following standards is indicated by the corresponding marking on the product.

Mark Standard

AS/NZS CISPR 22, AS/NZS 61000.4.3

N13123

CAN/CSA C22.2 No. 61010-1-04

UL Std No 61010A-1

MC173467

FCC Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Industry Canada Note

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

ISO 9001 Registration

In 1994, Ohaus Corporation, USA, was awarded a certificate of registration to ISO 9001 by Bureau Veritus Quality International (BVQI), confirming

that the Ohaus quality management system is compliant with the ISO 9001 standard’s requirements. On May 15, 2003, Ohaus Corporation,

USA, was re-registered to the ISO 9001:2000 standard.

Page 5

EN-1Ohaus Discovery

TABLE OF CONTENTS

1. INTRODUCTION ............................................................................................................................................................... EN-3

1.1 Description ..................................................................................................................................................................... EN-3

1.2 Features ......................................................................................................................................................................... EN-3

1.3 Safety Precautions ........................................................................................................................................................... EN-3.

2. INSTALLATION ................................................................................................................................................................. EN-4

2.1 Unpacking ...................................................................................................................................................................... EN-4

2.2 Installing Components ..................................................................................................................................................... EN-4

2.2.1 Assembly ......................................................................................................................................................... EN-4

2.3 Selecting the location ....................................................................................................................................................... EN-4

2.4 Leveling the Balance ....................................................................................................................................................... EN-4

2.5 Connecting Power .......................................................................................................................................................... EN-5

2.5.1 AC Adapter ......................................................................................................................................................... EN-5

2.5.2 Turning Power On and Off .................................................................................................................................... EN-5

2.6 Initial Calibration ............................................................................................................................................................. EN-5

3. OPERATION ....................................................................................................................................................................... EN-7

3.1 Overview of Controls & Display Functions .......................................................................................................................... EN-7

3.2 Button Control Functions .................................................................................................................................................. EN-9

3.3 Using the Button Control Functions .................................................................................................................................. EN-10

3.3.1 Setting the Balance to Zero .............................................................................................................................. EN-10

3.3.2 Taring ............................................................................................................................................................. EN-10

3.3.3 Changing Units of Measure ............................................................................................................................... EN-10

3.3.4 Changing Application Modes ............................................................................................................................. EN-10

3.3.5 Printing Data ................................................................................................................................................... EN-10

3.3.6 Calibration ...................................................................................................................................................... EN-10

3.4 Menu ..................................................................................................................................................................... EN-11

3.4.1 Menu Structure ................................................................................................................................................. EN-11

3.4.2 Menu Navigation ............................................................................................................................................. EN-12

3.4.3 Changing Settings ........................................................................................................................................... EN-12

3.5 Application Modes ......................................................................................................................................................... EN-13

3.5.1 Weighing ........................................................................................................................................................ EN-13

3.5.2 Parts Counting ................................................................................................................................................ EN-13

3.5.3 Percent Weighing ............................................................................................................................................ EN-14

3.5.4 Check Weighing .............................................................................................................................................. EN-15

3.5.5 Dynamic/Animal Weighing ............................................................................................................................... EN-15

3.5.6 Gross, Net, Tare Weighing ................................................................................................................................ EN-16

3.5.7 Totalize .......................................................................................................................................................... EN-17

3.5.8 High Point ...................................................................................................................................................... EN-17

3.5.9 Density ........................................................................................................................................................... EN-18

3.5.10 Statistics ......................................................................................................................................................... EN-25

3.3.11 Pipette Calibration ........................................................................................................................................... EN-28

Page 6

EN-2 Ohaus Discovery

TABLE OF CONTENTS (Cont.)

3.6 Additional Features ........................................................................................................................................................ EN-30

3.6.1 Weigh Below .................................................................................................................................................... EN-30

3.7 Balance Settings ........................................................................................................................................................... EN-30

3.7.1 Menu Setup .................................................................................................................................................... EN-30

3.7.2 Calibration ...................................................................................................................................................... EN-31

3.7.3 Setup ............................................................................................................................................................. EN-35

3.7.4 Readout ......................................................................................................................................................... EN-35

3.7.5 Mode ............................................................................................................................................................. EN-35

3.7.6 Unit ................................................................................................................................................................ EN-36

3.7.7 Print ............................................................................................................................................................... EN-37

3.7.8 RS232 ........................................................................................................................................................... EN-37

3.7.9 GLP Data ........................................................................................................................................................ EN-37

3.7.10 GLP Print ........................................................................................................................................................ EN-38

3.7.11 Reset ............................................................................................................................................................. EN-38

3.7.12 Lockout .......................................................................................................................................................... EN-39

3.7.13 End ................................................................................................................................................................ EN-39

3.8 Sealing Access to the Balance Settings ............................................................................................................................ EN-40

3.9 Printing Data ................................................................................................................................................................ EN-40

4. MAINTENANCE ................................................................................................................................................................. EN-41

4.1 Calibration ................................................................................................................................................................... EN-41

4.2 Cleaning ..................................................................................................................................................................... EN-41

4.3 Troubleshooting ............................................................................................................................................................ EN-41

4.4 Service Information ........................................................................................................................................................ EN-42

4.5 Parts ..................................................................................................................................................................... EN-42

4.6 Accessories .................................................................................................................................................................. EN-42

5. TECHNICAL DATA ............................................................................................................................................................... EN-43

5.1 Drawings ..................................................................................................................................................................... EN-43

5.2 Specifications ............................................................................................................................................................... EN-44

5.3 Capacity x Readability ................................................................................................................................................... EN-45

5.4 Communication ............................................................................................................................................................ EN-45

5.4.1 Commands ..................................................................................................................................................... EN-45

5.4.2 Connections .................................................................................................................................................... EN-46

Limited Warranty ..................................................................................................................................................................... EN-47

Page 7

1 INTRODUCTION

This manual contains installation, operation and maintenance instructions for the Ohaus Discovery balances. Please read the manual completely before using the balance.

1.1 Description

Ohaus Discovery balances are precision weighing instruments that will provide you with years of service if properly cared for. The Ohaus

Discovery balances are available in capacities from 110 grams to 310 grams.

1.1.1 Model Name Designations

Example: DV214CD

DV = Product family abbreviation Discovery

214 = 210g model with 0.0001g readability

C = With internal calibration (AutoCal)

D = Dual range model

1.2 Features

The Ohaus Discovery balances include many application modes.

• Weighing, Parts Counting

• Animal Weighing

• Check Weighing

• Percent Weighing

• Totalization

• Density, G/N/T

• Pipette Calibration

• High Point, Statistics

Other Standard features include:

• Two line backlit LCD

• In-use cover

• RS232 interface

• Weigh below hook

• Automatic Internal Calibration

• Overload and Underload indicators

• Lock-out switch safeguards pre-set parameters

• Legal for Trade models

• AC Adapter operation (AC Adapter included)

• Adjustable feet and level bubble

• Anti static wipes

EN-3Ohaus Discovery

1.3 Safety Precautions

Please follow these safety precautions:

• Verify that the input voltage printed on the AC Adapter matches the local AC power supply

• Use the balance only in dry locations

• Do not operate the balance in hostile environments

• Do not drop loads on the pan

• Service should be performed only by authorized personnel

Page 8

EN-4 Ohaus Discovery

2 INSTALLATION

2.1 Unpacking

Carefully remove your Discovery balance and each of its components from the package. Save the packaging to ensure safe storage and transport.

2.2 Installing Components

Refer to the illustration and instructions below to identify and assemble your Discovery balance with its components. All components must be

installed before using the balance.

2.2.1 Assembly

1. Open the side doors of the balance, then Install the Shield, Wind Ring and Pan as shown in the illustration.

2. Place the In-Use cover on the front panel of the balance.

Pan

In-Use Cover

Installation of Balance Components

Wind Ring

Shield

2.3 Selecting the Location

Locate the balance on a firm, steady surface. Avoid locations with excessive air currents, vibrations, heat sources, or rapid temperature

changes.

2.4 Leveling the Balance

Before the balance is used, the feet should be adjusted so that the scale is level with the surface. This will enable accurate weighing. You will

see a level bubble indicator in a small round window inside the weighing compartment. Level the balance by adjusting the leveling feet so the

bubble is centered in the circle, as shown below.

Balance level

Page 9

EN-5Ohaus Discovery

2.5 Connecting Power

2.5.1 AC Adapter

Connect the AC Adapter to the wall outlet. Connect the plug into the receptacle on the rear of the balance.

For use with CSA Certified (or equivalent approved) power source, which must have a limited circuit output.

2.5.2 Turning Power On and Off

Press the On/Zero button to turn power on.

The balance performs a segment check. The balance then displays the last selected application

mode.

To turn power off, press and hold the Off button until OFF is displayed, then release the button.

2.6 Initial Calibration

When the balance is first installed, and when it is moved to another location, it must be calibrated to ensure accurate weighing results. The

Discovery balance has built in Advanced AutoCal which can calibrate the balance automatically and does not require calibration masses. If

preferred, the balance can be manually calibrated with external masses. Have the appropriate calibration masses available before beginning

calibration. Refer to Section 3.7.2 for masses and calibration procedure.

IMPORTANT:

Balance should acclimate to its new surroundings for at least 8 hours. Balance electronics should be warmed up for 2

hours prior to use.

Page 10

EN-6 Ohaus Discovery

Page 11

3 OPERATION

3.1 Overview of Controls & Display Functions

1

2

3

EN-7Ohaus Discovery

10

4 5 6 7 8

TOP VIEW BOTTOM VIEW REAR VIEW

TABLE 3-1. DISCOVERY CONTROL FUNCTIONS.

4

1 Level Bubble

2 Pan

3 Wind Ring

4 Tare Buttons

5 On / Zero Off Button

6 Print Unit Button

7 Function Mode Button

8 Calibrate Menu Button

9 Weigh Below Cover and Screw

10 Leveling Feet

11 Lockout Reset Switch

12 COM 1 Connector

13 Power Connector

11 12 13

9

Page 12

EN-8 Ohaus Discovery

3.1 Overview of Controls & Display Functions (Cont.)

14

13

12

11

10

1

Digital Display Window

TABLE 3-2. DISCOVERY DISPLAY FUNCTIONS.

1 Primary (7 Segment) Display

2 Brackets

3 Units of Measurement

4 Memory Indicator

5 Pieces Indicator

6 Secondary (14 Segment) Display

7 Gross Indicator

8 Brutto Indicator

9 Tare Indicator

10 Preset Tare Indicator

11 Net Indicator

12 Stability Indicator

13 Negative Indicator

14 Center of Zero Indicator

2

56789

3

4

Page 13

3.2 Button Functions

Four multifunction buttons and two tare buttons are used to to operate the balance and navigate the menus. The function of each button is

shown below.

Press and Release

Press and Hold

Menu Function

EN-9Ohaus Discovery

Primary Function Tare

• Performs tare

operation.

Secondary Function Off

Menu Function Yes

On/Zero

• If balance is off,

turns balance on.

• Zeros balance.

• Turns balance off.

• Accepts the current

(blinking) setting on

the display.

• When editing in the

alpha-numeric field,

increments to the

next digit.

Print

• Sends the current

display value to the

serial interface.

Unit

• Change weighing

unit. Press and hold

will scroll through

units.

No

• Rejects the current

setting (blinking) on

the display.

• Increments a value

being entered.

Function

• Operation is dependent on the application mode.

Mode

• Change application

mode.

Back

• Reverts back to the

previous menu item.

• Decrements a value

being entered.

Cal

• Initiates calibration

function.

Menu

• Press and hold

allows entering the

menu.

Exit

• Immediately exits

menu mode.

• Aborts calibration

in progress.

Page 14

EN-10 Ohaus Discovery

3.3 Using the Button Control Functions

3.3.1 Setting the Balance to Zero

Remove the load from the pan and press the Zero button to set the display to zero.

When the weighing pan is empty, the Center of Zero indicator turns on when the measurement is within + 1/4 division (d) of the zero setting.

3.3.2 Taring

Taring refers to the action of allowing for the weight of a container so that only the weight of objects held in the container (net weight) is displayed.

To Tare

Place the empty container on the pan and press the Tare button.

Add material to the container. The net weight of the material is displayed.

To clear the Tare value, remove the container from the pan and press the Tare button.

Auto Tare

Auto Tare automatically tares the first item placed on the pan.

Auto Tare must be set ON in the Setup sub-menu (See Section 3.7.3 Setup Sub-menu).

The secondary display shows CONTAINER (blinking). When the container is placed on the pan, it is automatically tared and Net weight is

displayed. The Tare value is automatically cleared when the container is removed from the pan.

Preset Tare

A preset tare may be entered by using a computer connected to the COM 1 Connector. To enter a Preset Tare, send the xT command to the balance where x is the value in grams. Enter a value of 0 to clear the preset tare.

3.3.3 Changing Units of Measure

The Discovery balance can be configured to measure in a variety of units, including custom units. The Unit Sub-menu is used to enable or disable a specific unit.

To select a unit of measure:

Press and hold the Unit button, then release it when the desired unit is displayed.

Note: If the desired unit is not displayed, it must be turned on in the Unit menu (See Section 3.7.6).

3.3.4 Changing Application Modes

The Discovery balance can be configured to operate in various application modes. The Mode Sub-menu is used to enable or disable a specific

application mode.

Press and hold the Mode button and release it when the desired mode is shown on the secondary display. Note: If the desired mode is not

displayed, it must be turned on in the Mode menu. (See Section 3.7.5).

3.3.5 Printing Data

Press the Print button to send the displayed value to the COM port (See Section 3.10).

3.3.6 Calibration

Press the Cal button to enter the calibration mode. (See Section 3.7.2).

Page 15

3.4 MENU

3.4.1 Menu Structure

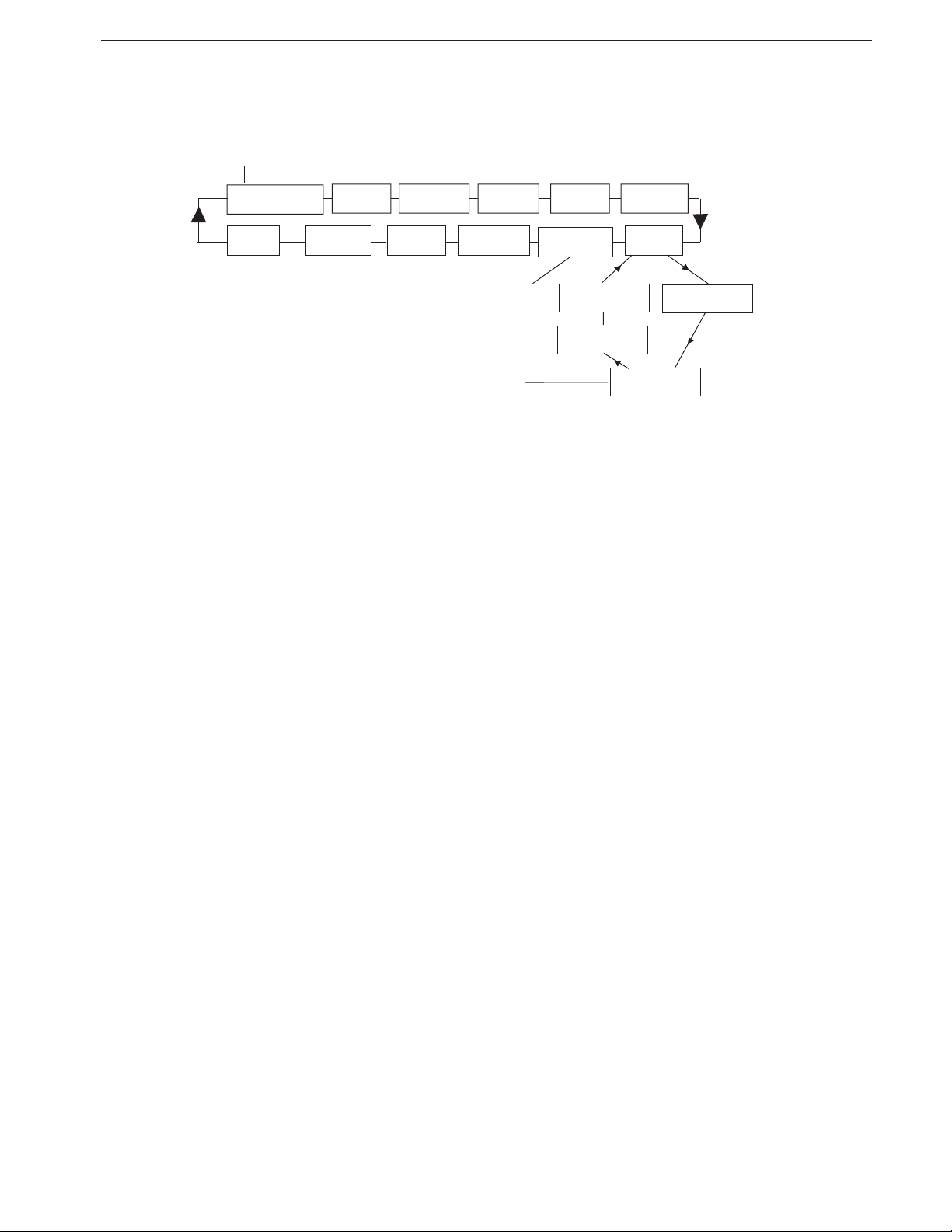

The Discovery balance menu structure is illustrated below.

CALIBRATE (3.7.2)

AutoCal

Span

Calibration Test (Cal Test)

Calibration Adjust (Cal Adj)

End Cal

SETUP (3.7.3)

Legal Trade

Auto Tare

Auto Off

End Setup

EN-11Ohaus Discovery

READOUT (3.7.4)

Auto Zero

Filter

Gross Ind.

End Read

MODE (3.7.5)

Weighing

Parts Counting

Percent Weighing

Check Weighing

Animal Weighing

GNT

Totalize

High Point

Density

Statistics

Pipette

End Mode

RS232 (3.7.8)

Baud

Parity

Handshake

End RS232

UNIT (3.7.6)

mg

g

ct

oz

ozt

GN

dwt

m

t HK

t SG

t TW

Custom

End Unit

GLP DATA (3.7.9)

User ID

Proj ID

Time

Date

End GLP Data

PRINT (3.7.7)

Output When Stable

GLP Tare

Auto Print

Content Num Only

Header, Gross,

Net, Tare, Ref,

Result, GLP

Layout Line Format

4LF

Form Feed

List

End Print

GLP PRINT (3.7.10)

Time

Balance ID

User ID

Project ID

Difference

Name

End GLP Prt

RESET (3.7.11)

Setup GLP Data

Readout GLP Print

Mode Lockout

Unit Global

Print End Reset

RS232

LOCKOUT (3.7.12)

Cal RS232

Setup GLP Data

Readout GLP Print

Mode Reset

Unit Lock Set

Print End Lockout

END (3.7.13)

Page 16

EN-12 Ohaus Discovery

3.4.2 Menu Navigation

The Discovery menu structure consists of three levels. The top level is the main menu which consists of a number of sub-menus.

Enter

CALIBRATE SETUP READOUT MODE UNIT PRINT

END LOCKOUT RESET GLP PRINT GLP DATA RS232

The second level of the menu structure is the sub-menu

level. Each sub-menu is a loop that consists of a

number of menu items.

The bottom level of the menu structure is the menu item

level. Each menu item level consists of two or more

settings

SECOND LEVEL

BOTTOM LEVEL

TOP LEVEL

Typical Sub-Menu

Typical Menu Item

END RS232 BAUD

HANDSHAKE

PARITY

3.4.3 Changing Settings

To change a menu setting, perform the following steps:

ENTER THE MENU

Press and hold the Menu button until MENU appears on the primary (7-Segment) display. Release the button and the first sub-menu appears

on the secondary display (14-Segment) Calibration (blinking).

Note: When the secondary display is blinking, press Yes to accept.

Press No or Back or view another selection.

SELECT THE SUB-MENU

Press the No button to select the next sub-menu or the Back button to select the previous sub-menu in the loop. Press the Yes button to select

the sub-menu that appears on the secondary display (blinking). The sub-menu name now appears on the primary display and the first menu

item in the sub-menu now appears on the secondary display (blinking).

SELECT THE MENU ITEM

Press the No button to select the next setting or the Back button to select the previous setting in the loop. Press the Yes button to select and save

the setting on the secondary display (blinking) as the new menu item setting.

EXIT THE MENU

Press the Exit button at any time to quickly exit the menu or select END sub-menu and press the Yes button.

Page 17

EN-13Ohaus Discovery

3.5 Application Modes

The Discovery balance incorporates Weighing, Parts Counting, Percent Weighing, Check Weighing, Animal/Dynamic Weighing, Gross/Net/tare

Weighing, Totalize, High Point, Density, Statistics and Pipette application modes. The default setting has the weighing mode turned on and all

other application modes turned off.

Note: Before using any application modes, they must be turned on in the Mode menu (See Section 3.7.5).

3.5.1 Weighing

Use this mode to determine the weight of items in the selected unit of measure. The Discovery balance is shipped with grams enabled. Before

using other units of measure, these units must be turned on in the Unit menu ( See Section 3.7.6 ).

Weigh

Press and hold Mode until the display shows WEIGH, then release the button.

Press Zero to zero the balance.

Place objects to be weighed on the pan to display the weight.

The example displays a 200 gram weight in grams unit of measure

3.5.2 Parts Counting

Use the Parts Counting Mode to count samples of uniform weight.

Press and hold Mode until MODE COUNT is displayed, then release the button.

Establish an Average Piece Weight (APW).

Each time a new type of part is counted, the nominal weight of one piece (Average Piece Weight)

must be established using a small quantity of pieces. This APW is stored until replaced by another

APW.

When entering parts counting from another mode, CLEAR APW? (blinking) will appear in the

lower display.

Press No to use the previously saved APW.

Otherwise, press Yes to establish a new APW.

The current weight (0.0000) is shown on the primary display and the default sample size (PLACE

10) is shown on the secondary display.

To change the sample size, press and hold the No button to increment the sample size through

the range of 1 to 99. A short press will increment size by 1, a long press will increment size by

10. Release the button when the desired sample size appears on the secondary display. Back

button for reverse.

Place the specified number of parts on the pan.

A short press of the Function button will accept the sample size and calculate the APW. The

primary display will now indicate the number of parts. The weight is shown on the secondary

display.

Page 18

EN-14 Ohaus Discovery

3.5.2 Parts Counting (Cont.)

Pressing the Function button displays the APW on the secondary display. The example shows an

APW of 2.000g. Press the Function button again to return to Parts Counting Mode.

To establish a new APW from Count Mode, press Mode until COUNT appears. Press No to increment, Back to decrement, Exit to leave without saving and press Yes to accept.

APW Optimization

The only adjustment for Parts Counting is APW Optimization. APW Optimization is set On or Off in the Mode menu when Parts Counting is

turned On. When APW Optimization is set on, the APW is automatically optimized. This results in more accurate parts counting. The factory

default is On.

When a new APW has been established, APW Optimization occurs when the number of pieces added to the pan are between one and three

times the number already on the pan. The secondary display will momentarily indicate APW OPT.

3.5.3 Percent Weighing

Use the Percent Weighing Mode to measure the weight of a sample as a percentage of a pre-established reference weight. Refer to Section 3.7.5 to enable Percent Weighing. Press and hold Mode

button until MODE PERCENT is displayed

To Establish a Reference Weight

PERCENT is displayed with CLEAR REF? (blinking). Press the No button to use the stored reference

weight and begin Percent Weighing.

Press Yes to continue. PUT SAMPLE (blinking) will be shown on the display.

Place the sample on the pan and press the Function button. The balance indicates the sample

weight on the primary display as 100%. The actual sample weight is shown on the secondary

display. This example illustrates 20 grams as the reference weight.

Remove the reference weight and place the item to be compared on the pan. The balance indicates the actual percentage on the primary display. The secondary display indicates the weight in

the selected measuring unit.

Pressing the Function button momentarily displays the reference weight on the secondary display.

Pressing the Function button a second time will return to the actual weight.

Establish New Reference Weight

Press and hold the Mode button until PERCENT is shown on the secondary display. PUT SAMPLE

will blink on the lower display. Add new reference weight and press Function button to accept new

100% reference.

Page 19

3.5.4 Check Weighing

Check Weighing is used to compare the weight of a sample against target limits.

Press and hold Mode button MODE CHECK is displayed, then release the button.

To Establish Check Weighing Parameters

CHECK is displayed with CHG PARAM? (blinking). Press the No button to use the stored limits and

begin Check Weighing, or press Yes to set Check Weighing limits.

Setting Under and Over Lmits

The primary display shows UNDER or OVER indicating which limit is being entered. The secondary

display shows the previous setting (blinking). Press the Yes button. The primary display shows

UNDER. The secondary display indicates the previous entry with the first digit (blinking). Press

the Yes button to accept the digit and advance to the next digit. Press the No button and Back button to edit the setting. The Under Limit is the first to be edited followed by the Over Limit. Press the

Yes button to accept the limit settings. To skip quickly to the end of settings, press Exit.

Editing Limits

The limits are edited one digit at a time. The digit being edited is blinking. Its value can be incremented by pressing the No button or decremented by pressing the Back button. When the desired

value is displayed, press the Yes button to accept the value and proceed to the next digit.

When all digits have been edited, the new limit value is shown (blinking) on the secondary display. Press the Yes button to accept the limit settings.

EN-15Ohaus Discovery

When editing of the Over limit is complete, Check Weighing begins.

Place the sample on the pan. The UNDER/ACCEPT/OVER status is shown on the primary display

while the actual weight of the item is shown on the secondary display.

To Establish New Check Weighing Parameters

Press and hold the Mode button until CHECK is shown on the secondary display.

3.5.5 Dynamic/Animal Weighing

Enter this mode to weigh an unstable load, such as a moving animal. Refer to Section 3.7.5 to

enable Animal Weighing and set Filter to either Low, Medium or High, the default is Medium.

Press and hold Mode button, MODE ANIMAL is displayed, then release the button.

To Establish Animal Weighing Parameters

ANIMAL CHG PARAM? (blinking) is displayed. Press the Yes button. MODE SET SEMI (blinking) is

displayed.

NOTE: SET AUTO, SET SEMI or SET MANUAL may be displayed intially depending upon previous

settings.

Press the No button to change the setting and Yes to accept. The balance shows READY on the

secondary display.

Page 20

EN-16 Ohaus Discovery

3.5.5 Dynamic/Animal Weighing (Cont.)

Automatic Mode

Place subject on the pan, the balance will automatically start a countdown. At the end of the

countdown period, the subject weight is displayed. The balance returns to the ready condition

when the animal is removed from the pan. If the Function button is pressed before the animal is

removed from the pan, the primary display shows the actual weight and the secondary display

shows CLEAR PAN until the animal is removed from the pan. The balance then returns to the

Ready condition.

Semiautomatic Mode

Place subject on the pan, the balance will automatically start a countdown. Remove the animal

from the pan and press the Function button to return to the ready condition. If the Function button is pressed while the animal is on the pan, the primary display shows the actual weight and

the secondary display shows CLEAR PAN. The balance returns to the Ready condition when the

animal is removed from the pan.

Manual Mode

Place subject on the pan and press the Function button, the balance will start a countdown.

Remove the animal from the pan and press the Function button to return to the ready condition.

If the Function button is pressed while the animal is on the pan, the primary display shows the

actual weight and the secondary display shows CLEAR PAN. The balance returns to the Ready

condition when the animal is removed from the pan.

During Animal Cycle

The primary display shows the countdown of the Filter Level setting (Low (5 sec) Medium (10

sec), High (15 sec). The secondary display shows BUSY. This Animal Filter setting is configured

in the Mode menu when Animal Weighing is turned On.

Completed Animal Cycle

The primary display shows the weight of the animal and the secondary displays shows HOLD.

To Establish New Animal Weighing Parameters

Press and hold the Mode button until ANIMAL is shown on the secondary display.

3.5.6 Gross, Net, Tare Weighing

Gross/Net/Tare (G/N/T) application allows the balance to display Gross (sample plus container weight), NET (sample weight) and TARE (container weight). The primary display will show the reading of the net (or tare) weight. The secondary display will show the reading of the gross

weight. Refer to section 3.7.5 to enable G/N/T weighing.

G/N/T Weighing

Press and hold Mode button, MODE GNT is displayed, then release button. Clear pan and press

the On/Zero button to zero the balance before beginning.

Place a container on the pan then press the Tare button. The container’s weight is stored in

memory in the balance. Place the material in the container. The balance immediately calculates

the Gross, Net and Tare weights.

A short press of the Function Mode button will toggle the 7 segment display to show the tare

weight and the net weight. Example shown represents a container weight of 20g and material of

50g. The gross weight is displayed as 70g. Before a new container is used, zero the balance by

using the On/Zero button. A short press of the Print button will print the G/N/T weights. Net and

Tare have to be turned On in the Print Content sub-menu.

Page 21

3.5.7 Totalize

Totalize measures the cumulative weight of items. Refer to Section 3.7.5 to enable totalizing.

Press the Mode button, then release when MODE TOTALIZE is displayed. The primary display

shows the current weight.

To Establish Totalize Parameters

The primary display shows TOTAL and the secondary display shows CHG PARAM? (blinking). At

this point you can select either a manual or automatic mode. Press the Yes button. MODE is

shown in the primary display with SET MANUAL in the secondary display (blinking). Press the No

button to change mode and Yes to accept.

Manual Mode

When entering the manual mode, the primary display shows the current weight, the secondary display shows the current totalized weight. Pan must be clear and stable before beginning process.

secondary display will blink when balance is ready to begin totalizing weights.

Place the item on the pan. Press the Function button to add the weight of the item to the total. The

new total is shown on the secondary display when stability is reached.

EN-17Ohaus Discovery

Remove the item from the pan. Balance must be stabilized at zero before next item can be placed.

The primary display indicates the current weight on the pan. The secondary display indicates the

total accumulated weight.

Add the next item and press the Function button. The display shown indicates a cumulative weight

of 70 grams. Remove item from pan and repeat process for each new item.

Automatic Mode

After entering the automatic mode, place the item on the pan. The weight of the item is shown on

the primary display. The secondary display will show BUSY (blinking) after the item is added until

the balance is stabilized and then shows the new total on the secondary display. Remove the item

from the pan. Balance must be stabilized at zero before next item can be placed, then add the

next item.

To Establish New Totalize Parameters

Press and hold the Mode button until TOTALIZE is shown on the secondary display.

3.5.8 High Point

The High Point Mode allows the user to capture and store the highest (stable) weight in a series of

weight measurements. Refer to Section 3.7.5 to enable High Point mode. Press the Mode button

until HI POINT is shown on the secondary display. When set On, the primary display will indicate

the current weight reading, the secondary display will indicate the highest weight reading. The

example indicates a current weight of 50.0000 g and a high point reading of 55.0000 g. Press

Function button to view lowest reading in memory.

To reset High Point and clear memory, press and hold Mode until High Point is shown on lower

display.

Page 22

EN-18 Ohaus Discovery

3.5.9 Density

Refer to section 3.7.5 to enable density measurements. Follow the procedures as indicated after initial setup in Section 3.7.5. Read the information concerning density measurements after the procedure which references an Ohaus Kit used specifically for density measurements.

Four methods of density determinations can be made with the Discovery balance. These are:

1. Solids more dense than water,

2. Solids less dense than water,

3. Liquid density,

4. Porous material (impregnated with oil).

A Density Determination Kit Part Number 80850045 is designed to be used with Ohaus Discovery balances. Illustrations in this procedure refer

to the density kit, however, you may use whatever lab apparatus that will suit the requirements for density measurements. A built in reference

density table for water at temperatures between 10ºC and 30ºC is included in the balance software. Review this entire section before attempting

density measurements.

When making density measurements, the material should weigh at least 10.0 mg on an analytical balance and 100 mg on a precision balance.

Balance Preparation with Ohaus Density Kit (Optional)

Allow the balance to warm up sufficiently before making measurements.

Open either the left or right side door of the balance and remove

the Pan as shown. Insert the Bracket into the balance where the

Pan was removed.

The Equalizing Washer is not used.

Bracket

Support

Balance Preparation

Equalizing

Washer

Place the Support into position over the bracket making sure the Support does not make contact with the Bracket as shown in illustration.

Install beaker on support as shown.

Bracket

Kit Components

Weigh Below Hook

Support

Support Mounting

Bracket

Beaker Installation

NOTE: Beaker and thermometer are not supplied as part of the density kit.

Page 23

3.5.9 Density (Cont.

The density Q is the quotient of the mass m and the volume V.

m

Q =

V

Density determinations are performed by using Archimedes’ principle. This principle states that every solid body immersed in a fluid loses

weight by an amount equal to that of the fluid it displaces. The density table for water is included in the Discovery balance software.

The density of a solid is determined with the aid of a liquid whose density, Qo, is known (water is used as an auxiliary liquid). The solid is

weighed in air (A) and then in the auxiliary liquid (B). The density Q can be calculated from the two weighings as follows:

A

Q =

The balance allows direct determination of the buoyancy P (P =A - B ) and consequently the above formula can be simplified:

Q =

A -B

A

P

•Q0

•Q0

EN-19Ohaus Discovery

Q = Density of the solid

A = Weight of the solid in air

B = Weight of the solid in the auxiliary liquid

Q0 = Density of the auxiliary liquid at a given temperature (this value depends on the temperature). The density table for water is included in

Discovery balances.

P = Buoyancy of the solid in the auxiliary liquid (corresponds to A -B).

Mass

Sample

Sample Weighing in Air

Place the solid in the Weighing Pan on the Weigh Below Hook in the liquid as shown. Ensure that there are no air bubbles on the solid to be

weighed.

Sample Weighing in Liquid Buoyancy Sample Weighing

Close the draft shield doors and weigh the solid (buoyancy P). The display indicates the density in grams/cc.

Page 24

EN-20 Ohaus Discovery

3.5.9 Density (Cont.)

Solid Density Determinations for items Less Dense Than Water

For density determination of solids with a density less than

1 g/CM3, the bottom of the Weigh Below Hook for solids must be used as it holds the solid body below the surface of the auxiliary liquid. If the

buoyancy of the solid is greater than the weight of the Weigh Below Hook, the Weigh Below Hook must be weighted by placing an additional

mass on the submerged part of the Weigh Below Hook as shown.

Weigh the sample in air first as explained in the previous procedure.

After loading the additional mass, tare the balance and start the weighing again. Wait until the balance has reached stability and note the dis-

P

played weight

Improving the Accuracy of the Result of Solid Density

The following tips should help you improve the accuracy of the results in the density determination of solids.

Temperature

Solids are generally so insensitive to temperature fluctuations that the corresponding density changes are of no consequence. However, as work

is performed with an auxiliary liquid in the density determination of solids, their temperature must be taken into account as the temperature has

a greater effect with liquids and causes density changes in the order of magnitude 0.I to 1% per °C. This effect is already apparent in the third

decimal place of the result.

(buoyancy of the solid).

To obtain accurate results, we recommend that you always take the temperature of the auxiliary liquid into account on all density determinations.

Air Buoyancy

1 CM3 of air weighs approximately 1.2 mg (depending on the physical condition). As a consequence, in the weighing in air, each solid experiences a buoyancy of this magnitude (the so-called “air buoyancy”) per cm3 of its volume.

However, the air buoyancy must be taken into account only when a result is required with an accuracy of 3 to 4 decimal places. To correct for

this, the air buoyancy (0.0012 g per cm3 volume of the body) is added to the calculated result:

Calculated density + 0.0012 g/cm3 air buoyancy = effective density

Surface tension of the auxiliary liquid

Adhesion of the liquid to the Weigh Below Hook causes an apparent weight increase of up 3 mg.

As the Weigh Below Hook is immersed in the auxiliary liquid in both weighings of the solid (in air and in the auxiliary liquid), the influence of

the apparent weight increase can be neglected because the balance is tared before every measurement.

To reduce the effect of air bubbles and to ensure the greatest possible accuracy, use a few drops of a wetting agent (not supplied) and add

them to the auxiliary liquid.

Page 25

EN-21Ohaus Discovery

3.5.9 Density (Cont.)

Liquid Density Determinations

The density of a liquid can be made using a sinker of known volume. The sinker (sinker is not included in the kit) is weighed in air and then in

the liquid whose density is to be determined, The density, Q, can be determined from the two weighings as follows:

Q = Density of the liquid

A - B

Q =

V

In DENSITY SETUP, set Mode to Liquid Density and enter sinker volume in cc’s.

After weighing the sinker in air and then weighing the sinker immersed in liquid, the balance calculates the density of the liquid and is displayed

in grams/cc. See illustrations below for placement of the sinker. When the sinker is immersed in the liquid, it must not come into contact with

the bottom of the beaker.

A = Weight of the sinker in air

B = Weight of the sinker in liquid

V = Volume of the sinker

P = Buoyancy of the sinker in the liquid

( P = A-B)

Sinker

Sinker

Sinker in Air Sinker in water

Porous Material Density Determinations

The density of a porous (oil impregnated part) can be made with the balance. Weigh the part (dry) prior to oil impregnation and record its

weight. You must also know the density value of the oil to be used in immersing the part before starting. In this procedure, you will follow the

method for solid density measurements using water.

Enter the dry weight of the porous material and the density of oil used to impregnate the part.

To Determine Wet Density

Wet density of the sample can be calculated by following the normal Solid Density procedure using the oil impregnated part.

Page 26

EN-22 Ohaus Discovery

3.5.9 Density (Cont.

Before density measurements can be made, the density mode of operation must be set up in the Menu, Mode Sub-menu. It is in the Mode

Sub-menu where solid, porous, water or auxiliary liquids are selected.

After the basic parameters have been set, the balance density operation is further determined in the APPL DENSITY menu. This menu allows

the setting of Density, Temperature, Dry Weight of Porous Material, Sinker Volume and Density of Oil.

To Perform a Density Measurement

Refer to paragraph 3.7.5 for density set-up procedures.

A. Measuring the Density of a Solid Using Water

The following menu items should be turned on: SOLID, WATER.

Press and hold Mode until MODE DENSITY appears, DENSITY CHG PARAM? is displayed.

Press the Yes button, TEMP 20.00 C (blinking) is displayed. Measure the temperature of the

water with a precision thermometer and enter the temperature using the Yes, No and Back buttons.

When the last digit is entered, press the YES button to save.

The balance indicates 0.0000 IN AIR (blinking). Weigh the sample in air and press the Function

button.

Now, weigh the sample in water (liquid) and press the Function button. The balance displays the

result in grams per centimeter (g/cc). Typical samples are shown.

To Establish New Density Parameters

Press and hold the Mode button until DENSITY is shown on the secondary display.

B. Measuring the Density of a Buoyant Material Using Water

The following menu items should be turned on: SOLID, WATER.

Follow the same procedure in A except refer to Buoyancy Sample weighing illustrations and place

sample as shown.

Page 27

3.5.9 Density (Cont.

C. Liquid Density using Calibrated Sinker (Not supplied)

The following menu item should be turned on: LIQUID.

Press and hold the Mode button until MODE DENSITY is displayed, then release the button. DENSITY CHG PARAM? is displayed.

Press the Yes button VOLUME 00.000000 is displayed. Enter the volume of the sinker, use the

Yes, No and Back buttons.

The balance indicates 0.0000g IN AIR (blinking). Place the sinker on the pan and press the

Function button.

EN-23Ohaus Discovery

Place the sinker in the beaker (in liquid) as shown in previous illustration and press the Function

button. The balance displays the result in grams per centimeter (g/cc).

To Establish New Density Parameters

Press and hold the Mode button until DENSITY is shown on the secondary display.

D. Density of Solid using Auxilary Liquid

The following menu items should be turned on: SOLID, AUXILIARY.

Press and hold Function button until MODE DENSITY is shown. DENSITY CHG PARAM? is displayed.

Press the Yes button, DENSITY 0.000000 is displayed. Enter the density value of the auxiliary

liquid being used from a density table, use the Yes, No and Back buttons.

When the proper density value has been entered, press the Yes button.

The display now indicates TEMP 00.00 C (blinking). Enter the measured temperature of the auxiliary liquid with a precision thermometer and enter the value using the Yes, No and Back buttons,

then press the Yes button.

Page 28

EN-24 Ohaus Discovery

3.5.9 Density (Cont.

D. Density of Solid using Auxilary Liquid (Cont.)

The balance now indicates 0.0000 g IN AIR (blinking). Place the sample on the support and

weigh in air, press the Function button.

Carefully submerge the sample in the auxiliary liquid (in liquid) using the kit and press the Func-

tion button. The balance displays the result in grams per cubic centimeter (g/cc).

To Establish New Density Parameters

Press and hold the Mode button until DENSITY is shown on the secondary display.

NOTE: Sample illustrations values are not correct and are to be used as a guide only.

E. Density of Porous Material Using Oil

NOTE: Before starting this procedure, weigh the porous sample and record the dry

weight. This is important as you will have to enter this value later on.

The following should be turned On in the Setup Menu: POROUS, WATER.

Press and hold the Mode button until DENSITY is shown on the secondary display..

Press the Yes button, TEMP 20.00 C is displayed. Enter the water temperature from a precision

thermometer, then press the Yes button.

WEIGHT 00.00000 is displayed. Enter the weight of the porous material previously recorded, then

press the Yes button.

D OIL 0.000000 is displayed. Enter the density of the oil, then press Yes.

The balance indicates 0.0000g IN AIR (blinking). Immerse the porous material in oil to saturate it

and weigh, press the Function button.

Now, immerse the porous material in water (in liquid) and press the Function button. The balance

displays the result in grams per cubic centimeter (g/cc).

To Establish New Density Parameters

Press and hold the Mode button until DENSITY is shown on the secondary display.

NOTE: Sample illustration values are not correct and are to be used as a guide only.

Page 29

EN-25Ohaus Discovery

3.5.10 Statistics

Statistics are used when it is desired to compare a number of samples and examine the relative deviation of the samples along with other

statistical data. A minimum of three samples is required in this program. When a printer or computer is connected to the balance, all statistical

information can be observed and printed. Weighing, Animal Weighing and Check Weighing are the functions for providing Statistical Data.

Statistical Weighing

Refer to paragraph 3.7.5 for statistics set-up procedures.

Press and hold the Mode button until STATS is shown in the secondary display. STATS CHG

PARAM? (blinking) is displayed. Press the Yes button. SAMPLE SIZE 3 is displayed. Pressing the

No button increments the sample size and pressing the Back button decrements the sample size.

When the desired number of samples has been set, press the Yes button.

The display will change to 0.0000 g SAMPLE 1 (blinking).

Place the first sample on the pan and press the Function button. The display will show BUSY for a

few seconds and then display the weight of the first sample and SAMPLE 2 will be blinking on the

display.

Continue the procedure until all samples have been weighed. After the last sample has been

weighed, the display will indicate the Deviation of all samples.

By pressing the Function button repeately, you can observe the Deviation, Relative Deviation,

Mean, Sum, Maximum and Minimum readings.

To Establish Statistical Weighing Parameters

Press and hold the Mode button until STATS is shown on the secondary display.

Page 30

EN-26 Ohaus Discovery

3.5.10 Statistics (Cont.)

Statistical Check Weighing

Press and hold Mode button until STATS is shown on the secondary display.

For statistical Check Weighing, use the same general procedure as in Statistical Weighing.

UNDER 00.0000 g is displayed.

Using the No button to increment and the Back button to decrement and the Yes button to accept

and advance to the next digit, proceed to enter the under value for samples. Press the Yes button

to accept. The display changes to OVER 00.0000 g.

Using the No, Back and Yes button, enter the Over value. Press the Yes button to accept.

SAMPLE SIZE 3 is displayed on the sample illustration. The number will vary according to the

number of samples set in the Menu.

Using the No, Back and Yes buttons, enter the desired sample size, in this case, 5 was used, then

press the Yes button.

UNDER SAMPLE 1 is displayed. Place sample 1 on the pan, either UNDER, ACCEPT or OVER

SAMPLE 1 appears on the display. In this case the sample illustration indicates ACCEPT SAMPLE 1.

Press the Function button. Remove the first sample from the pan, the balance indicates UNDER

SAMPLE 2. Place the second sample on the pan and press the Function button. Repeat this

procedure for all of the samples.

When all of the samples have been entered, the display will indicate the Deviation.

By pressing the Function button repeately, the balance indicates the Relative Deviation, Mean,

Sum, Maximum and Minimum readings of all samples.

To Establish Statistical Check Weighing Parameters

Press and hold the Mode button until STATS is shown on the secondary display.

Page 31

3.5.10 Statistics (Cont.)

Statistical Animal Weighing

This procedure is very similiar in setup as Statistical weighing. Use the same general procedure.

Press and hold Mode button until STATS is shown on the secondary display. STATS CHG PARAM?

(blinking) is displayed. Press the Yes button, SAMPLE SIZE 5 is displayed. Pressing the No button increments the sample size, Back button decrements the sample size. Pressing the Yes button

accepts the digit and advances to the next digit. When the desired number of samples has been

selected, press the Yes button.

The display will change to 0.0000 g SAMPLE 1.

Place the first sample on the pan, then press the Function button. The display will show the

weight of the subject with a countdown period, then the weight of the subject with HOLD is displayed.

EN-27Ohaus Discovery

Press the Function button, the weight of the subject is displayed with CLEAR PAN. Remove the

subject from the pan and place a new subject on the pan then press the Function button.

Continue this procedure until all samples have been weighed. After the last sample has been

taken, the display will indicate the deviation.

By pressing the Function button repeately, the balance indicates the Relative Deviation, Mean,

Sum, Maximum and Minimum readings off all samples.

To print statistical results, refer to Sections 3.7.7, 3.7.8, 3.7.9 and 3.7.10 to set up printing.

Once setups are completed, press the Print button.

To Establish Statistical Animal Weighing Parameters

Press and hold the Mode button until STATS is shown on the secondary display.

Page 32

EN-28 Ohaus Discovery

3.5.11 Pipette Calibration

Pipette calibration checks the accuracy and precision values of pipettes by weight analysis. The balance is capable of recording data of each

pipette tested. The density table for water is included. If other liquids are used for pipette calibration, you must enter the liquid’s density in g/cc

at current room temperature. Since all calculations are made within the balance, it is also required that you know the atmospheric pressure. A

printout can be made which specifies all parameters of the calibration made. Parameters include test liquid, liquid density, H2O temperature,

barometer unit, barometer pressure, nominal and nominal units have to be set first.

Pipette calibration can be accomplished manually or automatically in the balance. Calculations

made within the balance provide results of Inaccuracy and Imprecision.

To Establish Pipette Calibration

Refer to paragraph 3.7.5 for Pipette set-up procedures. Enable Pipette Mode in the Menu where

the following parameters can be set (liquid, barometric pressure, etc.).

Press and hold Mode button until MODE PIPETTE is shown. Press the Yes button, MODE SET

MANUAL is displayed. You can select either AUTO or MANUAL. Use the No button to change selection and Yes button to accept.

Press the Yes button, TEMP 25.00 c is displayed. Press the No button to increment digit edit field

and Back button to decrement. Press the Yes button to save temperature value of the liquid used

in the pipettes.

B PRESS 1.000 ATM is displayed as an example, if a different pressure unit was initially selected,

you can now edit the value. Press the Yes button when finished with editing the value.

NOM 0.000 ML is displayed, the example illustrates ML was selected. You may now enter the Pipette dispensing value. For the purposes of this example, 0.330 ML was used and an Auto Mode

was selected. This allows a faster method of results with limited handling of the balance. Use the

No, Back and Yes buttons to edit the value.

Press the Yes button, INACC % 0.000000 is displayed. Enter the value shown on the Pipette

specification into the balance using the No, Yes and Back buttons. The example illustrates

5.000000 %, press the Yes button.

Page 33

3.5.11 Pipette Calibration (Cont.)

IMPREC % 0.000000 is displayed. Edit the value and press the Yes button. This value is specified on the Pipette. The example used was 5.000000 %. Press the Yes button to accept.

SAMPLE SIZE 10 is displayed. Using the Yes, No and Back buttons, change the sample size. The

example shown uses 5 samples. When sample size is entered, press the Yes button.

The balance is now ready to accept samples. It is essential that the balance be located

on a stable, vibration free surface and away from any drafts caused by heating and or

cooling outlets. The balance is very sensitive to external influences. When samples are

administered, the draft shield doors must be closed. Failure to adhere to these practices

will result in incorrect results.

EN-29Ohaus Discovery

0.0000 g SAMPLE 1 (blinking) is displayed. Place the receptacle container on the pan and press

the Tare button.

Place the first sample in the container, SAMPLE 1 will blink, press the Function button the display

will now momentarily show the microliter value then tares out the value for the next sample. Place

the remaining samples making sure the secondary display is indicating the next sample before

placing it into the container. The weight of each sample is shown during the calculation period.

When all of the samples have been taken, the balance calculates the Inaccuracy and Imprecision

either as a pass or fail in percentage. The examples shown here indicate passing.

Press the Function button to toggle between inaccuracy and imprecision displayed values.

To Establish New Pipette Parameters

Press and hold the Mode button until PIPETTE is shown on the secondary display.

•

•

•

Page 34

EN-30 Ohaus Discovery

3.6 Additional Features

3.6.1 Weigh Below

The Discovery balance is equipped

with a weigh below hook.

Note: Before turning the balance

over, remove the pan, wind shield

and shield to prevent damage to the

glass doors.

Weigh Below

Protective

Cover

To use this feature, remove power

from the balance and remove the

protective cover for the weigh below

opening as shown. Install the

weigh below hook.

The balance can be supported using

lab jacks or any other convenient

method. Make sure the balance

is level and secure. Use a string or

wire to attach items to be weighed.

Bottom View of Balance

Weigh Below Hook

Table Support

Balance With Weigh Below Hook Installed

3.7 Balance Settings

3.7.1 Menu Setup

Pressing the Menu button allows access to the menus shown below. Each menu contains additional sub-menus that are used to set the

balance parameters. This section of the manual contains all menus and descriptions required to set all parameters for the Discovery balance.

Please review the contents of each menu to get a better understanding of the balance’s capabilities before attempting to operate the balance.

The diagram below illustrates the main menu in the balance.

A long press of the Menu button will access the Main Menu.

Press the Yes button to enter the menu.

Press the No button to advance to the next menu selection.

Press Exit to return to the application mode.

Main Menu Sequence

Page 35

3.7.2 Calibration

Discovery balances offer a choice of 4 calibration methods: Internal Calibration (Advanced AutoCal), Span Calibration, Calibration Test and

Calibration Adjust.

EN-31Ohaus Discovery

• Advanced

AutoCal - Two internal masses are used for linearization of calibration by using three weight values: zero, a weight value at

midpoint of the balance’s weighing range, and a weight value at or near the balance’s specified capacity.

• Span - Span calibration ensures that the balance reads correctly within specifications using two weight values: zero and

a weight value between 25% and 100% of the balance’s capacity.

• Cal Test - Calibration test allows the stored calibration data to be tested against the current mass being used for the test.

• Cal Adj - AutoCal allows adjustment of the internal calibration.

Notes: Calibration may be locked out to prevent unauthorized personnel from changing calibration. If calibration has been locked out, you

can access Cal Test and AutoCal.

Before beginning calibration, have masses available. Masses required for calibration are listed in the table in this section.

To navigate the calibration menu, proceed as follows:

Press the Yes button to select the sub-menu selection.

Press No to advance to the next sub-menu selection.

press Back to go to previous sub-menu selection.

Press Exit to return to applicable mode.

Page 36

EN-32 Ohaus Discovery

3.7.2 Calibration (Cont.)

Automatic Internal Calibration

Before Automatic Internal calaibration can be used, it must be turned on first in Menu Calibrate.

With the balance on, press and hold the Cal button until MENU CALIBRATE is displayed, then

release the Cal button, CALIBRATE is (blinking).

Press the Yes button to enter calibration, CAL AUTO CAL is displayed.

Press the Yes button to select Autocal. After pressing the Yes button, AUTOCAL SET OFF is displayed.

Pressing the No button will change the display to AUTOCAL SET ON, then press the Yes button.

With Autocal set on, exit the Calibrate Menu. The balance may now be calibrated automatically

from the weighing mode.

Internal calibration can be accomplished without using an external weight. With the balance on,

press the Cal button, balance begins to calibrate.

Press Exit to abort calibration. When internal calibration is finished, the balance returns to the currently selected mode.

Automatic internal calibration is a feature included with all Discovery models. AutoCal will automatically calibrate the balance each time a change in temperature significant enough to affect

accuracy, or after every 11 hours.

Span Calibration

With the balance on, press and hold the Cal button, CALIBRATE (blinking) is displayed.

Press the Yes button to enter calibration.

Press the No button at AutoCal.

Press the Yes button to initiate span calibration.

First the zero reading is taken. Next the display shows the default span calibration weight value.

Press No to change to an alternate calibration weight. Press Yes when the desired calibration

weight is displayed.

Place the specified calibration weight on the pan. After calibration, remove the weight from the

pan.

To abort calibration at any time, press the Exit button.

Page 37

3.7.2 Calibration (Cont.)

Calibration Test

Calibration test allows a check of a known calibration mass against the last stored calibration

information in the balance.

Press and hold the Cal button until MENU CALIBRATE is displayed.

Press Yes to enter calibration.

Press No until CAL TEST is displayed.

Press Yes and follow the screen instructions.

Place the specified weight on the pan. After a short period, the display indicates the difference in

weight from the last calibration, and then will display the calibration weight on the pan. After the

test, remove the calibration weight from the pan. To leave the menu, press Exit.

EN-33Ohaus Discovery

Page 38

EN-34 Ohaus Discovery

3.7.2 Calibration (Cont.)

Calibration Adjust

Calibration Adjust may be used to adjust the result of the internal calibration by ±100 divisions.

Note: Before making a calibration adjustment, perform an internal calibration. To verify whether an adjustment is needed, place a test mass

on the pan and note the difference (in divisions) between the nominal mass value and the actual reading. Refer to Calibration Masses Table

and use the highest value from the Span Calibration Points column as the test mass. If the difference is within ±1 division, calibration adjustment is not required. If the difference exceeds ±1 division, calibration adjustment is recommended. Following a calibration adjustment, repeat

the internal calibration and verification procedures.

To perform a calibration adjustment, press the Cal button and release it when MENU CALIBRATE is

displayed.

Press Yes to enter the Calibration sub-menu. Press No until CAL ADJ is displayed.

Press Yes to enter the CAL ADJ menu item and view the current setting. If the actual reading was

less than the nominal mass value, a positive adjustment is required.

Press No until the setting matches the difference noted earlier in the procedure. If the actual reading was greater than the nominal mass value, a negative adjustment is required.

Press Back until the setting matches the difference noted earlier in the procedure. Press Yes to

accept and store the setting.

CALIBRATION MASSES TABLE

Model Span Calibration Points (1) Weight Class

DV114C 100g ASTMI Class I OIML E1

DV214C 200g ASTMI Class I OIML E1

DV314C 300g ASTMI Class I OIML E1

DV215CD 200g ASTMI Class I OIML E1

Page 39

3.7.3 Setup

EN-35Ohaus Discovery

SETUP

Legal Trade On/Off

Auto Tare On/Off

Auto Off Off, 1, 2, 5 min

Back Light On/Off

End Setup

Legal Trade

When set On, the balance operates in compliance with Weights and

Measures regulations.

When the LEGAL TRADE menu item setting is set to ON, the following

conditions apply:

• The CALIBRATION menu is hidden.

• The LEGAL TRADE menu item is hidden.

• The AUTO ZERO menu item setting is set to 0.5d and locked.

• The OUTPUT WHEN STABLE menu item setting is set to ON

and locked.

• The CONTINUOUS setting in the AUTO PRINT menu item is

hidden.

Auto Tare

When set On, the balance will automatically tare the first item placed

on the pan.

Auto Off

When set to 1, 2 or 5 minutes, the balance will turn off in the

selected time interval if there has been no activity. Set to OFF for

continuous operation.

Backlight

When set On, display is illuminated at all times with balance on.

End Setup

Press the Yes button, to advance to the Readout submenu. Press

the No button to return to the LEGAL TRADE menu item.

3.7.4 Readout

READOUT

Auto Zero Off, .5d, 1d, 2d, 5d

Filter Low, Medium, High

Gross Ind. G, B, Off

End Read

Auto Zero

Allows setting the balance auto zero level setting: Off, .5, 1, 2 or 5

divisions. Balance maintains zero until threshold is exceeded.

Filter

Allows setting the balance filter level: Low, Medium, High. Compensates for vibration or excessive air currents.

Gross Ind.

Allows setting the gross indicator to G (gross), B (brutto) or Off.

End Read

Press the Yes button to advance to the Mode sub-menu. Press No to

return to Auto Zero.

3.7.5 Mode

The Mode sub-menu is used to turn Application modes On or Off.

MODE

Weigh On/Off

Count On/Off

Apw Optimize On/Off

End Count

Percent On/Off

Check Weigh On/Off

Animal On/Off

Filter

Low, medium, High

End Animal

GNT On/Off

Totalize On/Off

High Point On/Off

Density On/Off

D Mode

Liquid, Solid

Aux Liquid

Water, Other

Porous

On/Off

End Density

Statistics On/Off

S Mode

Weigh, Check,

Animal

Low, Medium, High

Pipette On/Off

Set Liquid

Water, Other

Set B Unit

Atm, Inhg, Hpa,

Mbar, Mmhg, Psia

Set N Unit

ML, UL

End Pipette

End Mode

Weigh

Use to set the Weighing Mode On or Off.

Page 40

EN-36 Ohaus Discovery

Count

Use to set the Counting Mode On or Off. If Count is set On, APW

optimize can be set On or Off.

Percent

Allows setting the percent weighing mode On or Off.

Check Weigh

Use to set the Check Weighing Mode On or Off.

Animal

Use to set the Animal Weighing Mode to: Auto, Semi, Manual or Off. If

set to Auto, Semi or Manual, level (averaging period) can be set to 5,

10 or 15 seconds.

G/N/T

Use to set the GNT mode On or Off.

Totalize

Use to set Totalize mode to: Manual, Auto or Off.

High Point

Use to set High Point On or Off.

Density Mode

Use to set Density Mode to Liquid or Solid, adjust liquid parameters

and select Porous Mode on or off.

3.7.6 Unit

The Unit sub-menu is used to turn measuring units On or Off.

UNIT