Ohaus AP250E, AP310E, AP210E, AP110E, AP250D Service Manual

...

ANALYTICAL

Menu

Menu

Electronic Balances

Models

AP1 10, AP210, AP310, AP250D,

AP1 10E, AP210E, AP310E and

AP250E

Plus

Instruction Manual

NOTE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH THE LIMITS FOR

Menu

Menu

A CLASS A DIGITAL DEVICE, PURSUANT TO PART 15 OF THE FCC RULES.

THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION AGAINST HARMFUL

INTERFERENCE WHEN THE EQUIPMENT IS OPERATED IN A COMMERCIAL ENVIRONMENT.

THIS EQUIPMENT GENERATES, USES, AND CAN RADIATE RADIO FREQUENCY ENERGY AND,

IF NOT INSTALLED AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY

CAUSE HARMFUL INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE HARMFUL INTERFERENCE IN WHICH

CASE THE USER WILL BE REQUIRED TO CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

THIS DIGITAL APPARATUS DOES NOT EXCEED THE CLASS A LIMITS FOR RADIO NOISE

EMISSIONS FROM DIGITAL APPARATUS AS SET OUT IN THE INTERFERENCE-CAUSING EQUIPMENT STANDARD ENTITLED “DIGITAL APPARATUS”, ICES-003 OF THE DEPARTMENT OF

COMMUNICATIONS.

CET APPAREIL NUMERIQUE RESPECTE LES LIMITES DE BRUITS RADIOELECTRIQUES

APPLICABLES AUX APPAREILS NUMERIQUES DE CLASSE A PRESCRITES DANS LA NORME

SUR LE MATERIEL BROUILLEUR: “APPAREILS NUMERIQUES”, NMB-003 EDICTEE PAR LE

MINISTRE DES COMMUNICATIONS.

Unauthorized changes or modifications to this equipment are not permitted.

The exclamation

point within the triangle is a warning

sign alerting you of

important instructions accompanying the product.

TABLE OF CONTENTS

Menu

Menu

INTRODUCTION ............................................................................................................. 1

DESCRIPTION ................................................................................................................ 1

FEATURES ..................................................................................................................... 1

UNPACKING ................................................................................................................... 2

INSTALLATION ............................................................................................................... 3

Environment ............................................................................................................. 3

Weigh Below Hook ................................................................................................... 3

Leveling the Balance ................................................................................................ 4

Installing the Pan Assembly ..................................................................................... 4

In-Service Cover....................................................................................................... 4

RS232 Interface ....................................................................................................... 5

Hardware .............................................................................................................. 5

Output Formats..................................................................................................... 5

RS232 Commands ................................................................................................... 5

Connecting Power .................................................................................................... 8

Spare Fuse............................................................................................................... 8

Self Test ................................................................................................................... 8

OPERATION ................................................................................................................... 9

Switch Functions ...................................................................................................... 9

Symbols Used for Operation of the Balance .......................................................... 10

Navigating the Menus............................................................................................. 11

Operational Guide/Index ........................................................................................ 12

Turning the Balance On ......................................................................................... 13

Display Indications ................................................................................................. 13

Stabilization ............................................................................................................ 14

Auto Range (AP250D and E Only)......................................................................... 14

Weighing ................................................................................................................ 14

Taring ..................................................................................................................... 14

Percent Weighing ................................................................................................... 15

Parts Counting........................................................................................................ 16

Check Weighing ..................................................................................................... 17

Animal Weighing .................................................................................................... 18

Fill Guide ................................................................................................................ 19

Reference Weight ............................................................................................... 19

i

Reference Number ............................................................................................. 20

Menu

Menu

High Point............................................................................................................... 20

Printing Data........................................................................................................... 21

Time and Date .................................................................................................... 21

List ...................................................................................................................... 22

Automatic Calibration Printout ............................................................................ 23

User Calibration Printout .................................................................................... 23

Calibration Test Printout ..................................................................................... 23

Statistics Printout ................................................................................................ 24

Sampling............................................................................................................. 24

Percent Weighing ............................................................................................... 25

Parts Counting .................................................................................................... 25

Check Weighing ................................................................................................. 26

FillGuide

MENUS.......................................................................................................................... 27

MENU LOCK-OUT PROTECTION................................................................................ 28

CALIBRATION MENU ................................................................................................... 29

Calibration Menu Protection ................................................................................... 29

Auto Calibration...................................................................................................... 29

User Calibration...................................................................................................... 30

Cal Test .................................................................................................................. 31

Cal End................................................................................................................... 31

TM

........................................................................................................... 26

USER MENU ................................................................................................................. 32

User Menu Protection............................................................................................. 32

Reset ...................................................................................................................... 32

Averaging Level...................................................................................................... 33

Stability Range ....................................................................................................... 33

Auto-Zero ............................................................................................................... 34

Dual Range Function.............................................................................................. 34

Exiting User Menu .................................................................................................. 34

ii

SETUP MENU ............................................................................................................... 35

Menu

Menu

Setup Menu Protection........................................................................................... 36

Reset ...................................................................................................................... 36

Type Approved/LFT................................................................................................ 37

Unit Selection ......................................................................................................... 37

Functions................................................................................................................ 38

Statistics ................................................................................................................. 39

Net.......................................................................................................................... 40

Custom Unit or Volume Selection .......................................................................... 40

Good Laboratory Practices..................................................................................... 42

Parts Counting Error............................................................................................... 43

Check Weighing Options........................................................................................ 43

Sample Displays..................................................................................................... 44

Animal Weighing Options ....................................................................................... 46

Fill Option ............................................................................................................... 46

Time ....................................................................................................................... 47

Adjust ..................................................................................................................... 48

Date........................................................................................................................ 49

Lockswitch.............................................................................................................. 50

List.......................................................................................................................... 50

Exit Setup Menu ..................................................................................................... 50

PRINT MENU ................................................................................................................ 51

Print Menu Protection............................................................................................. 51

Reset ...................................................................................................................... 52

Communication ...................................................................................................... 52

Baud Rate........................................................................................................... 53

Data Bits ............................................................................................................. 53

Parity................................................................................................................... 54

Stop Bits ............................................................................................................. 54

Good Laboratory Practices (GLP) .......................................................................... 54

Print Options........................................................................................................... 55

Auto Print Feature .............................................................................................. 55

Initialize............................................................................................................... 56

iii

Print Stable Data Only ........................................................................................ 57

Menu

Menu

Print Numeric Data Only ..................................................................................... 57

Time.................................................................................................................... 58

Date .................................................................................................................... 58

Reference ........................................................................................................... 58

Difference ........................................................................................................... 59

List ...................................................................................................................... 59

CARE AND MAINTENANCE......................................................................................... 60

TROUBLESHOOTING .................................................................................................. 60

Error Codes List ..................................................................................................... 61

SERVICE INFORMATION............................................................................................. 63

REPLACEMENT PARTS............................................................................................... 63

ACCESSORIES............................................................................................................. 63

SPECIFICATIONS......................................................................................................... 64

DECLARATION OF CONFORMITY.............................................................................. 65

LIMITED WARRANTY................................................................................................... 69

iv

INTRODUCTION

Menu

Menu

INTRODUCTION

This manual covers Installation, Operation and Troubleshooting for the Ohaus ANALYTICAL Plus Series of Electronic balances, Models AP110, AP210, AP310, AP250D, AP110E,

AP210E, AP310E and AP250E. Suffixes after the basic model number are: D = Moveable

FineRange

Min, Class, etc.) on a serial number plate located on the side of the balance. To ensure proper

operation of the balance, please read this manual completely.

TM

and E= Type Approved with CE conformance and bear official markings (Max,

DESCRIPTION

The Ohaus ANALYTICAL Plus Series balances are high precision weighing instruments,

designed to be versatile, accurate, easy to operate and will provide years of service with

virtually no maintenance. The Analytical Plus series is constructed using a die-cast

aluminum base finished with a durable corrosion resistant epoxy powder paint. The weighing

area is protected from air currents by a draft shield. It contains solid-state precision

electronics PC boards, and a seven and a half, 0.5 inch digit, Vacuum Fluorescent display.

Each balance operates through a series of menus which enhances operation. A built in

lockswitch prevents preset settings from being changed.

FEATURES

Analytical Plus balances contain four main display menus which enable you to calibrate and

configure the balance for specific operating requirements. MENU When

pressed and released with MENU displayed, allows access to the calibration, user, setup

and print menus.

ON

TARE

switch is

CALIBRATION Menu - Allows the balance to be calibrated by using either Auto, User or

Test calibration methods. The test function is used to verify the last calibration.

USER Menu - Allows the balance to be set for environmental conditions. Reset,

averaging level, stability range and auto-zero functions can be set.

SETUP Menu - Allows the balance to be customized for specific weighing functions.

PRINT Menu - Allows the selection of parameters under which the balance will interface

to a computer or a printer.

Each of these menus contain selectable parameters which can be entered via the front panel

switches. Storing of the parameters is accomplished by selecting at the completion of all

selections in a particular menu. For a detailed description of each feature, refer to the

individual menus in this manual.

1

INSTALLATION

Menu

Menu

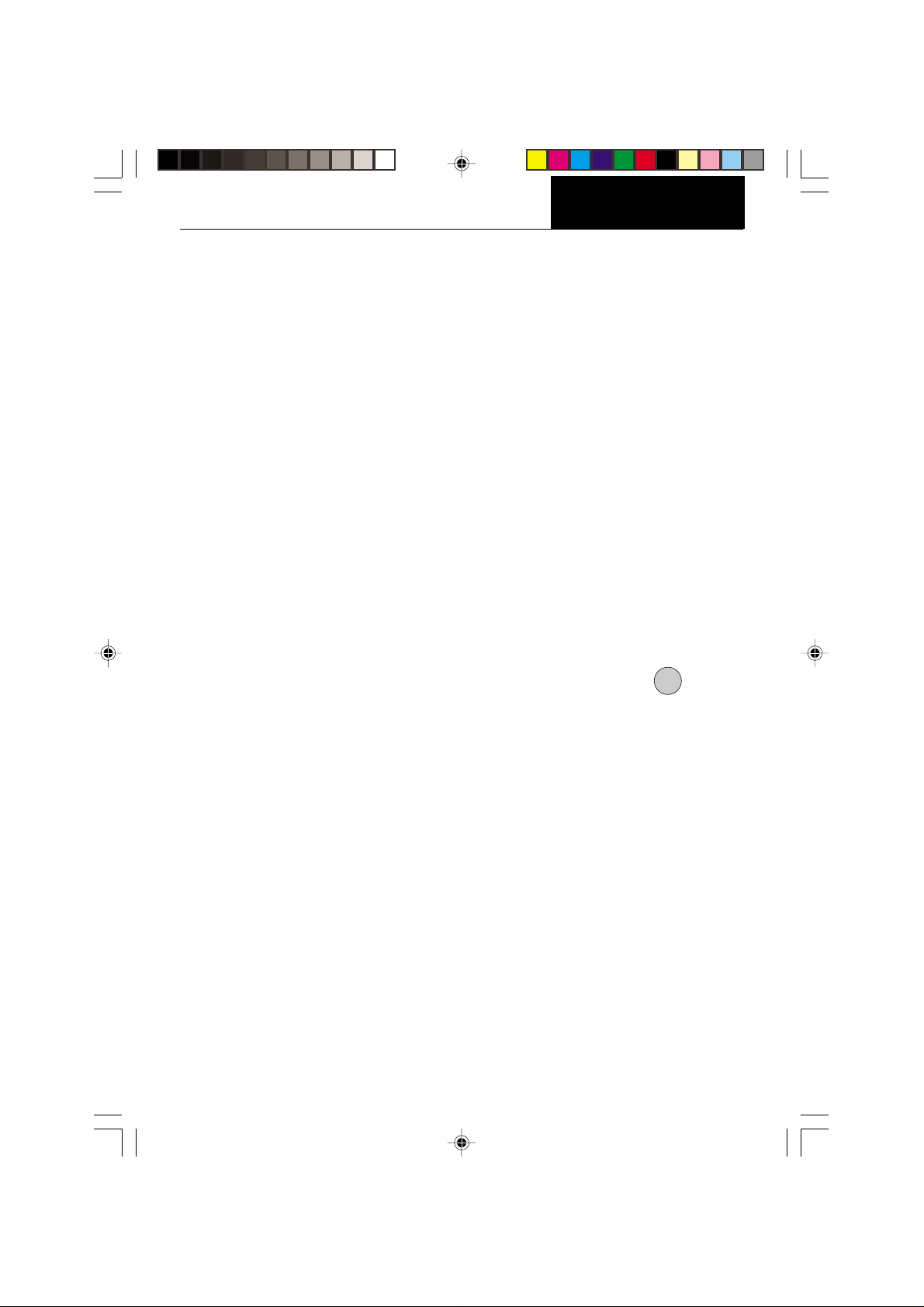

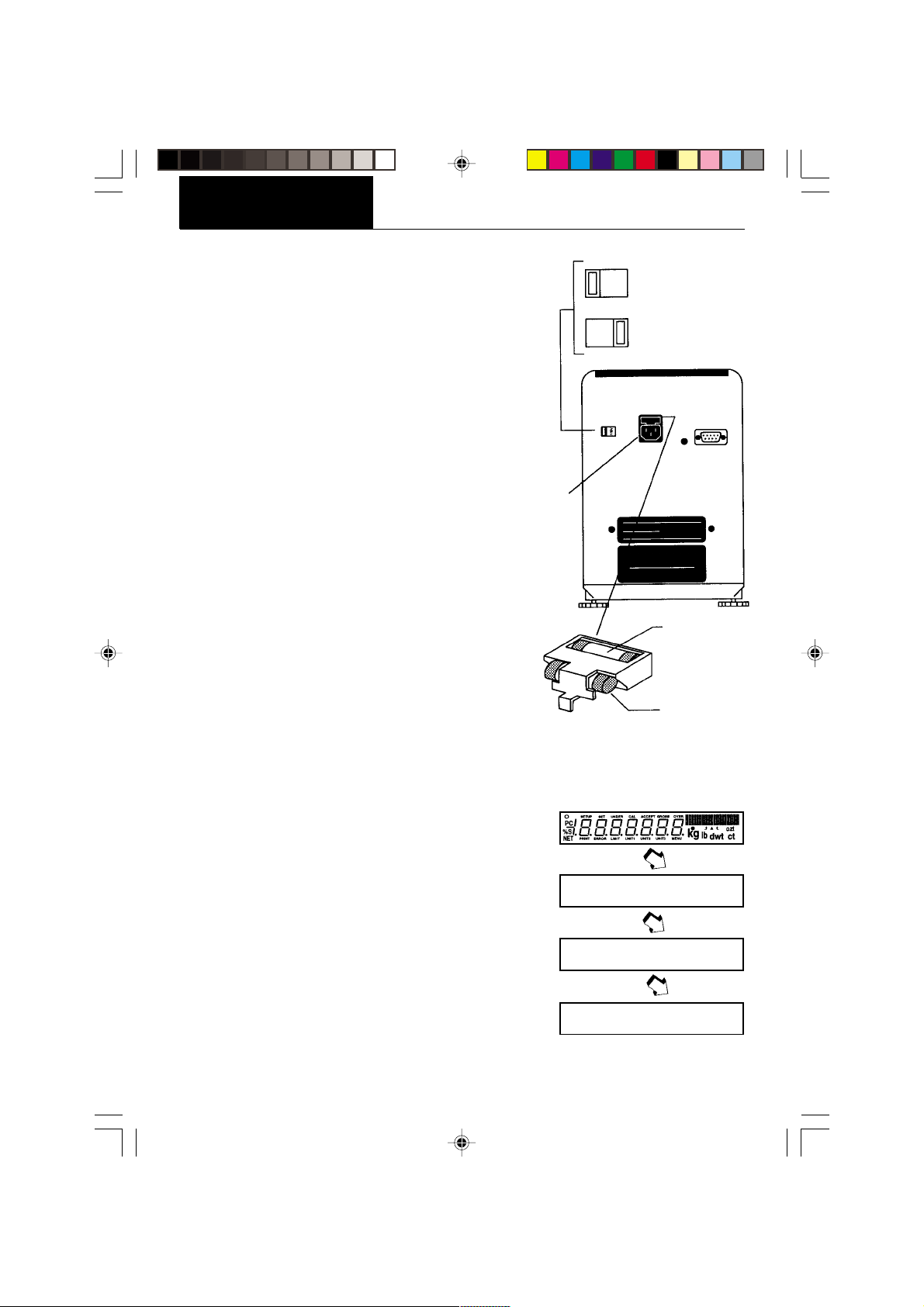

UNPACKING

Your ANALYTICAL Plus balance was shipped with the following items:

• Pan assembly (including pan, shield, ring and assembly instructions)

• In-service cover

• AC power cord

• Spare fuse

• Instruction manual

• Warranty card

Remove the contents from the carton and carefully remove all packing material. It is

recommended to save the carton and packing material for storing and/or transporting the

balance. Verify that all of the components have been included and there has been no

damage during shipment.

ANALYTICAL

BALANCE

In-Service Cover

Plus

REAR VIEW

Pan

Ring

Shield

2

INSTALLATION

Menu

Menu

INSTALLATION

Environment

The balance should always be used in an environment which is free from excessive air

currents, corrosives, vibration, and temperature or humidity extremes. These factors will

affect displayed weight readings.

DO NOT install the balance:

• next to open windows or doors causing drafts or rapid temperature changes.

• near air conditioning or heat vents.

• near vibrating, rotating or reciprocating equipment.

• near magnetic fields or devices that may generate magnetic fields (i.e. motors, alterna-

tors, etc.)

• on an unlevel work surface.

Install the balance in the location where it will be used before proceeding.

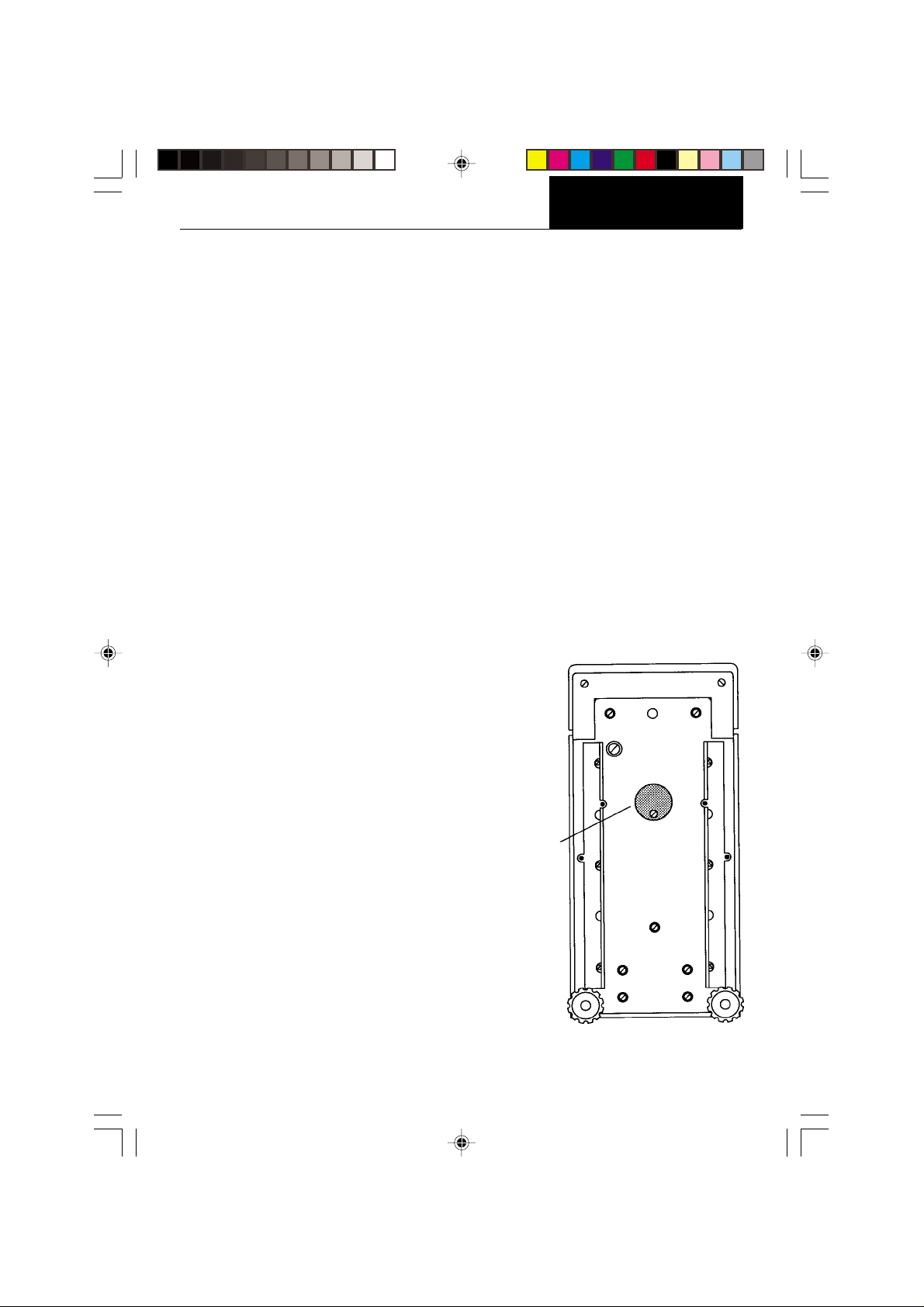

Weigh Below Hook

A weigh below hook is provided inside the

bottom cover under the protective plate

shown in the illustration.

To access the weigh below hook, carefully turn the balance on it's side, loosen

the screw which secures the cover plate,

rotate the plate to clear the hole, then

secure the plate in that position. Return

the balance to an upright position. Mount

the balance on a stable, level elevated

platform and install a hook.

Weigh Below

Hook Cover

Plate

3

INSTALLATION

Menu

Menu

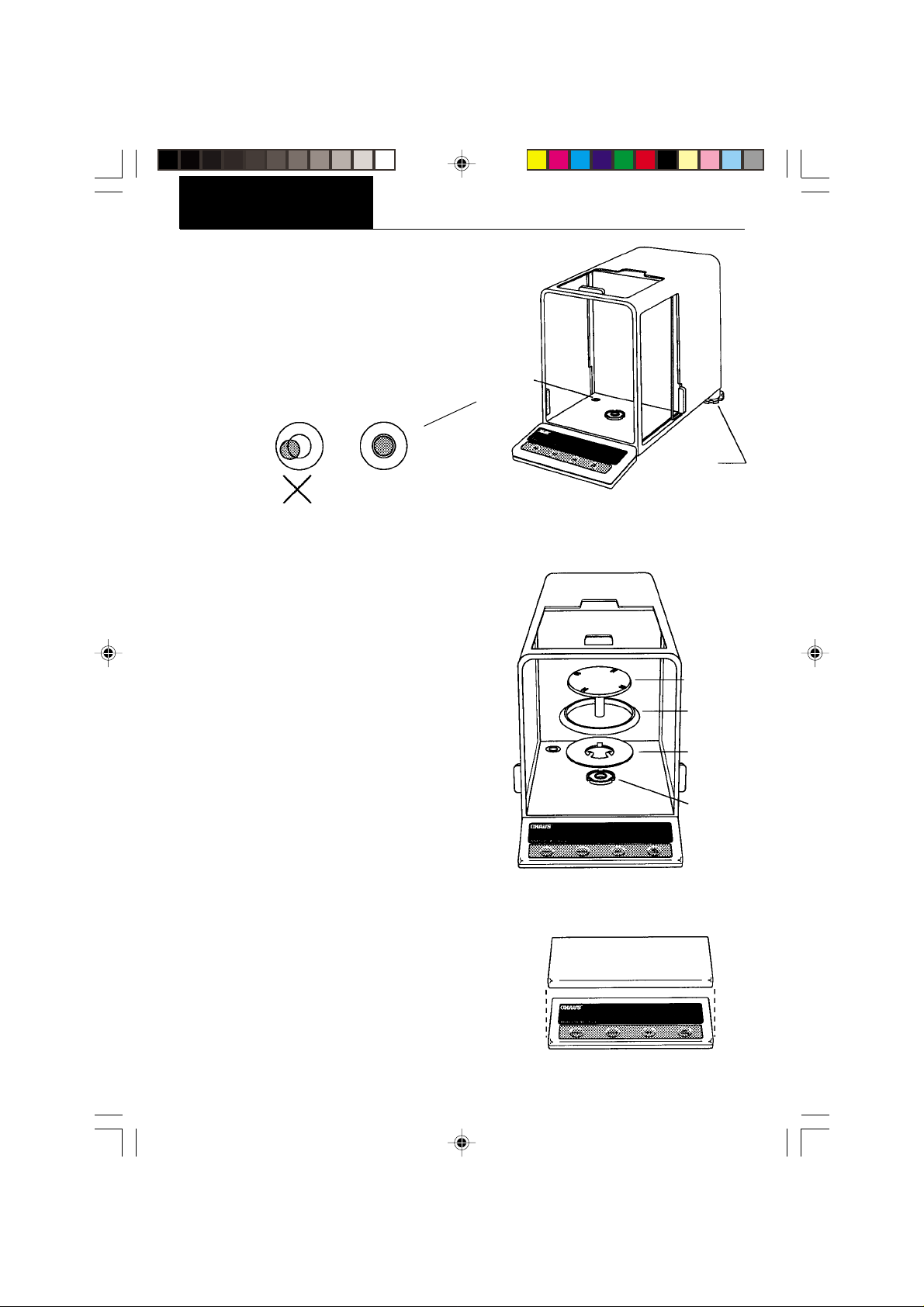

Leveling the Balance

The balance is equipped with a level indicator on

the floor of the weighing chamber and two

adjustable leveling feet at the rear. Adjust the

leveling feet until the bubble appears in the

center circle of the level indicator.

Installing the Pan Assembly

1. Place the shield onto the keyed bushing

and press it down into place. The bent tabs

must be facing upward and the shield should

be flat against the chamber floor.

Level

Indicator

Leveling

Feet

2. Place the ring over the shield. The lip on the

bottom of the ring should fit against the

shield to keep it from moving.

3. Insert the pan in the load receiver hole,

matching the key on the pan shaft with the

slot in the hole. Gently press the pan down

into place.

In-Service Cover

Place the cover snugly over the display unit.

Pan

Ring

Shield

Keyed

Bushing

4

INSTALLATION

Menu

Menu

RS232 INTERFACE

ANALYTICAL Plus balances are equipped with a bi-directional RS232 compatible interface

for communication with printers and computers. When the balance is connected directly to

a printer, displayed data can be output at any time by simply pressing PRINT, or by using

the Auto Print feature.

Connecting the balance to a computer enables you to operate the balance from the

computer, as well as receive data such as displayed weight, weighing mode, stability status,

etc.

The following sections describe the hardware and software provided with the balance.

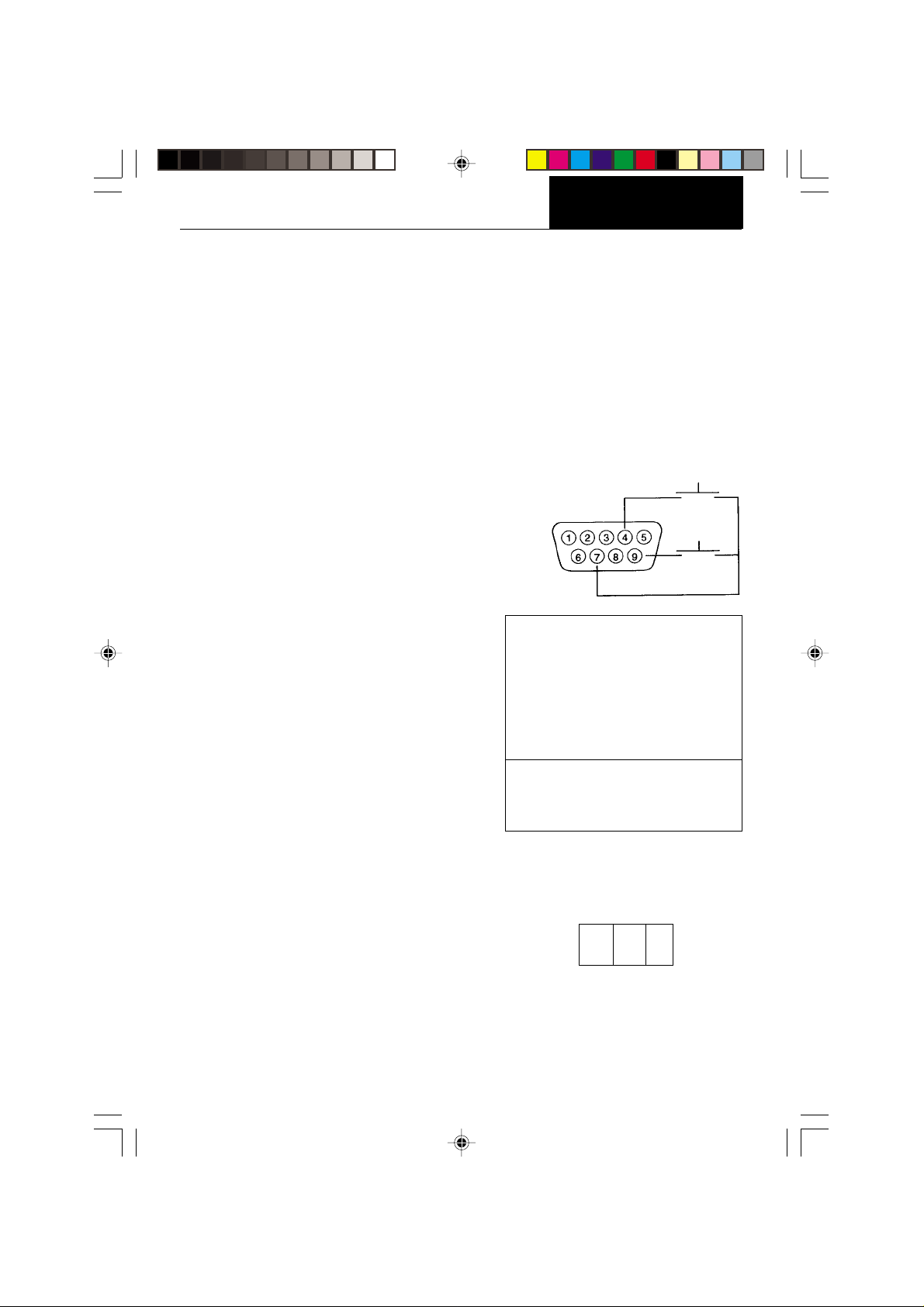

Hardware

On the rear of the balance, a 9-pin subminiature “D” connector is provided for interfacing to

other devices. The pinout and pin connections

are shown in the adjacent illustration.

The balance will not output any data unless pin

5 (CTS) is held in an ON state (+3 to +15 V dc).

Interfaces not utilizing the CTS handshake

may tie pin 5 to pin 6 to defeat it.

Output Formats

Data output can be initiated in one of three

ways: 1) By pressing PRINT; 2) Using the Auto

Print feature; 3) Sending a print command

(“P”) from a computer.

The output format is illustrated in the RS232

command table which follows.

RS232 Commands

All communication is accomplished using standard ASCII format. Only the characters shown

in the following table are acknowledged by the

balance. Any other commands, control characters or spaces are ignored. Commands sent

to the balance must be terminated with a

carriage return (CR) or carriage return-line line

feed (CRLF). For example, a tare command

should appear as shown in the adjacent diagram. Data output by the balance is always

terminated with a carriage return - line feed

(CRLF).

TARE *

PRINT *

1 5 V dc (5 mA max.)

2 Data Out (TXD)

3 Data In (RXD)

4* Tare (External signal)

5 Clear To Send (CTS)

6 Data Terminal Ready (DTR)

7 Ground

8 Request To Send (RTS)

9* Print (External signal)

* External PRINT and/or TARE

switches may be installed as

shown in the diagram. Momentary

contact switches must be used.

TARE COMMAND

Field: T CR LF

Length: 1 1 1

5

INSTALLATION

Menu

Menu

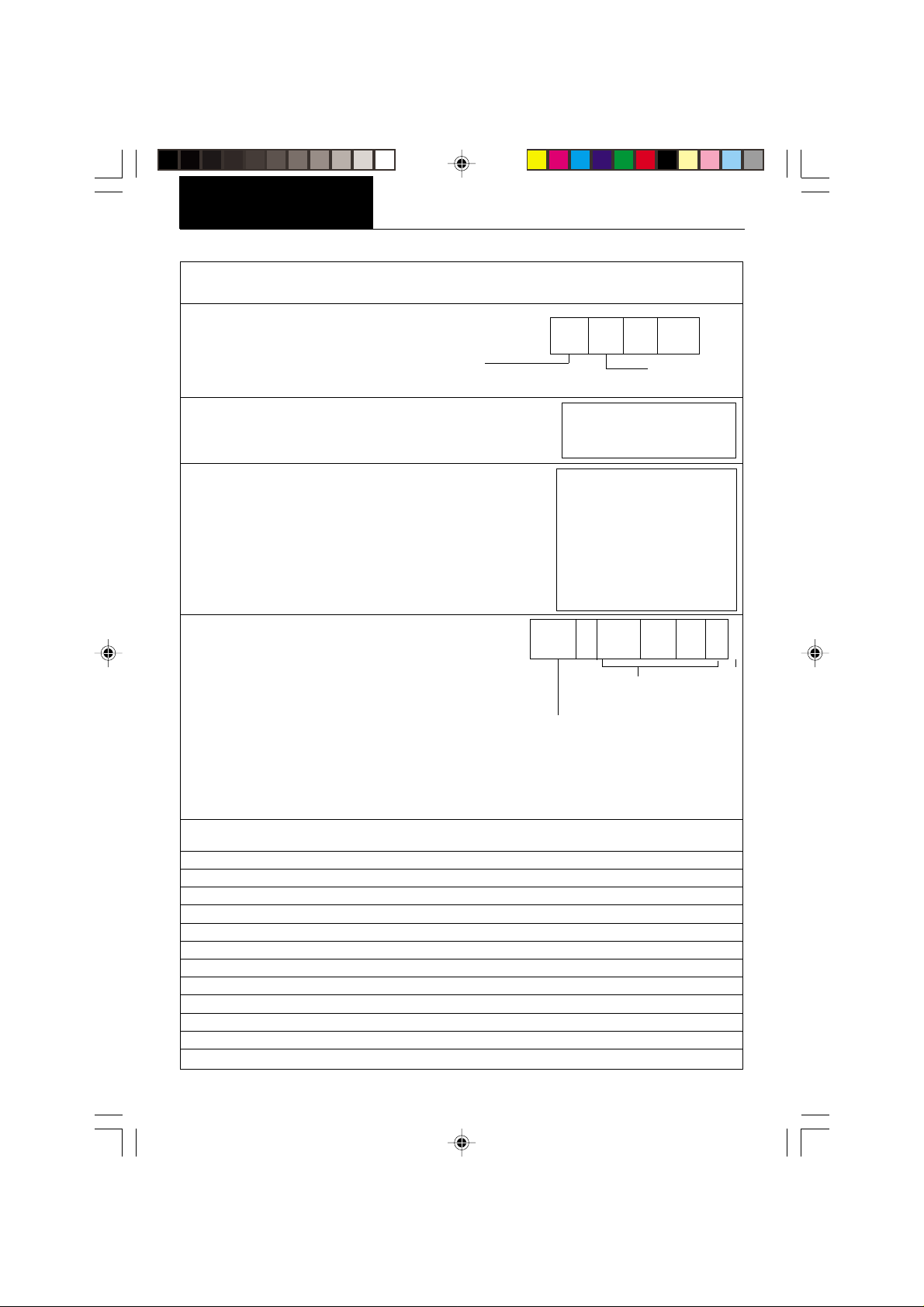

Command

Character Description

RS232 COMMAND TABLE

? Print current unit.

Grams, Dwt, Carat, Oz Av, Oz t, Grain, Tael 1,

Tael 2, Tael 3, Momme, Custom Unit

xI Set averaging level to “x”, where x = 0, 1, 2

xM Places balance in mode “x”, where x = 1 to 11

(see table).

If unit is not already enabled,

command will be ignored.

P Print display data

When “numeric only” displaydata is

selected for output in the RS232 menu,

the Mode field is not output.

hhmmss TIME Set current time to “hh: mm: ss”, hh is between 0 - 23.

TIME Print current time.

mmddyy DATE Set current date “mmddyy”.

DATE Print current date.

% Print current % ref.

# Print current ref., any function.

AC Abort calibration /Test.

C Start an auto calibration.

E Go to initial state of current function.

F Print current function.

M Same as mode button.

xD Set 1 second print delay (set x = 0 for OFF, or x = 1 for ON).

ID Print current ID string.

xxxxID Enter ID string (xxxx limit to 8 characters).

Field: Mode Stab CR LF

Length: 5 1 1 1

0 = minimum level

1=

2 = maximum level

1 = grams

2 = pennyweight

3 = carats

4 = avoidupois ounces

5 = troy ounces

6 = grains

7 = taels

8 = mommes

11 = custom unit

Field: Weight Mode Stab CR LF

Length: 10 1 5 1 1 1

Displayed weight sent right justified

w/lead zero blanking.

Nine characters include:

decimal point (1)

weight (7 max))

polarity (1): blank if positive

6

blank if stable

“ ? ” if unstable

Same as ?

command

“ - ” if negative

Command

Menu

Menu

Character Description

xS Set stable data only printing (set x = 0 for OFF, or x = 1 for ON.

T Same effect as pressing on tare button.

V Print EPROM version

Field: Model # 1 EPROM # CR LF

Length: 6 16 1 1

INSTALLATION

Balance Model

x# Set current ref., any function, CW takes two reference separated by a space.

x% Doanloads reference weight “x” for percent mode. “x” must be in grams. Command is

ignored if percent mode is disabled. If percent mode is enabled, balance will automatically

switch to percent mode display.

xF Set current function to “x”. x = 0 to 6. Setup menu must be unlocked.

xZ Set Auto Zero to “x”. x = 0 for OFF, x = 1 for ON

xSL Set stability level. User menu must be unlocked. x = 0 to 3

Z Zero request (Gross tare) if Net/Gross enabled.

nnnA Set Auto Print feature to “nnn” (see table).

nnn = 0 Turns feature OFF

nnn = S Output on stability

nnn = C Output is continuous

nnn = 1-256 Sets Auto Print interval

Esc L Prints listing of Setup and Print menu settings.

Esc R Resets Setup and Print menus to factory defaults.

CAUTION: This will reset RS232 configuration.

Esc S Save current settings.

“98101-xx Sr#x.xx”

0 = None

1 = Percent

2 = Parts Counting

3 = Check Weighing

4 = Animal Weighing

5 = Fill Guide

6 = High Point

7

INSTALLATION

Menu

Menu

Connecting Power

1. Before connecting the power cord, check

that the line voltage switch located at the

rear of the balance is set correctly for your

location. If not, use a small screwdriver to

set the switch correctly.

2. Make sure the doors to the weighing chamber are closed.

2. Connect the power cord receptacle to the

plug on the rear of the balance.

3. Plug the power cord only into a convenient

grounded AC outlet. The balance signals

one long beep to indicate power has been

applied.

Spare Fuse

A spare fuse is provided in the fuse holder as

shown in the diagram. All models use a

T 160 mA/250 V fuse.

Power

Connection

Fuse Holder

115V

230V

Line

Voltage

Switch

For 100-120 V∼

For 220 240 V∼

Active Fuse

Spare Fuse

Self Test

When power is applied to the balance, it begins

a self test cycle. During this time, the display

cycles as shown.

NOTE: Sr shown in the display is the software

revision and may be different in your balance.

After the self test is completed, the display turns

off. Allow the balance to stabilize for about 2

hours before using it.

s R 3.1

c h e c · ·

8

OPERATION

Menu

Menu

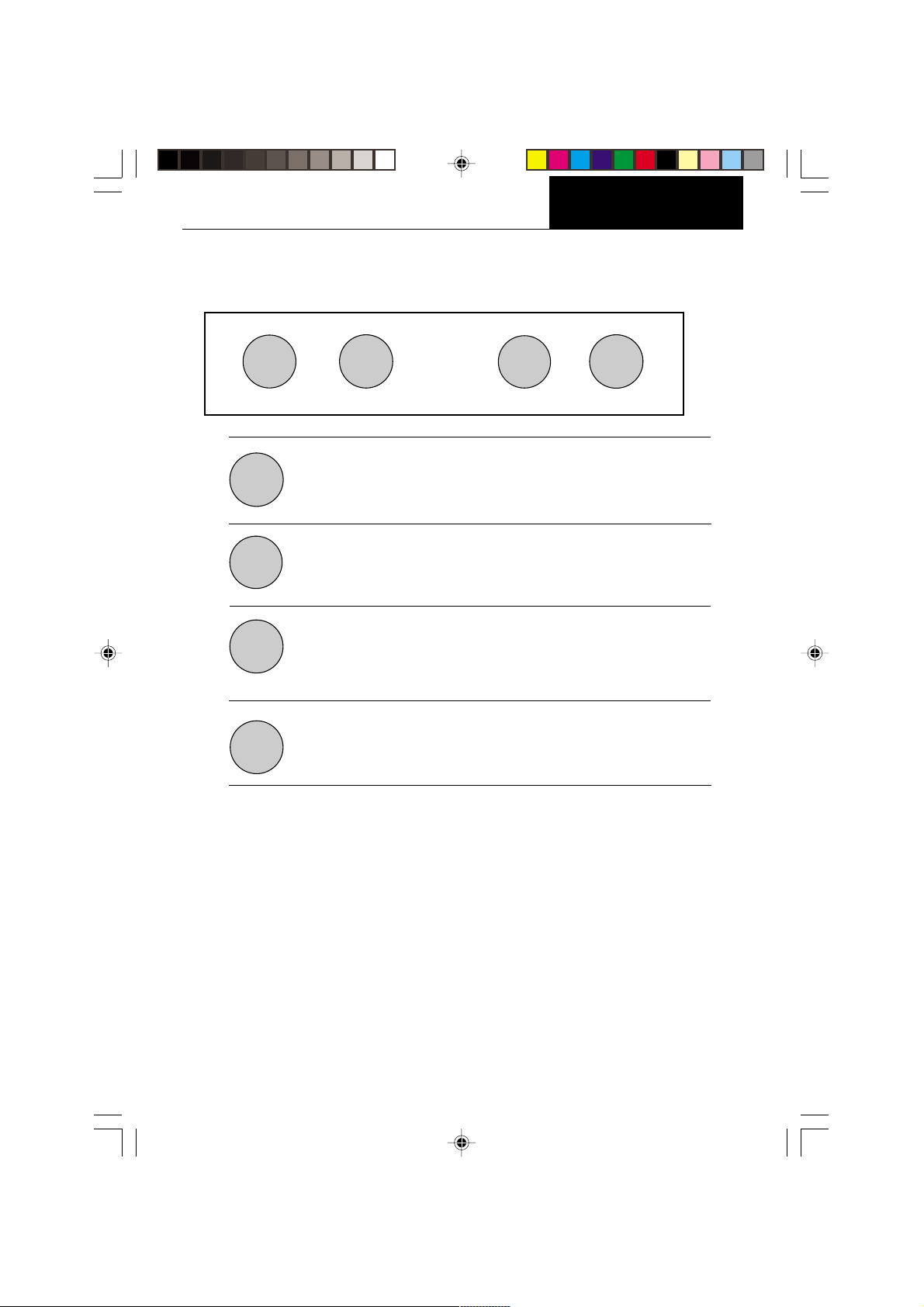

Switch Functions

OPERATION

PRINT

ON

TARE

OFF

MODE

PRINT

MODE

Press and Release:

Turns on the balance if it is off, zeros the balance. In the menu

system, this button is used to accept a choice or enter a submenu.

Press and Release:

Turns the balance off.

Press and Release:

Selects weighing units functions or options. In menus, changes to

next step or value.

Press and Release:

Sends weight data, statistical data, GLP data to computer/printer. In

menus, allows returning to a previous menu step.

OFF

ON

TARE

Before using the balance, carefully review the Symbols Used for Operation of the Balance

shown on page 10, Navigating the Menus on page 11and Operational Guide/Index on page

12.

Please read the entire manual as there are many features which can be enabled. The

balance is shipped from the factory ready to operate with default settings as shown in the

menus.

The balance is a high precision instrument and will give you years of service if kept clean

and handled carefully. If you have any problems operating the instrument or require

additional information, please feel free to contact our Customer Service Department at

(800) 526-0659.

9

OPERATION

Menu

Menu

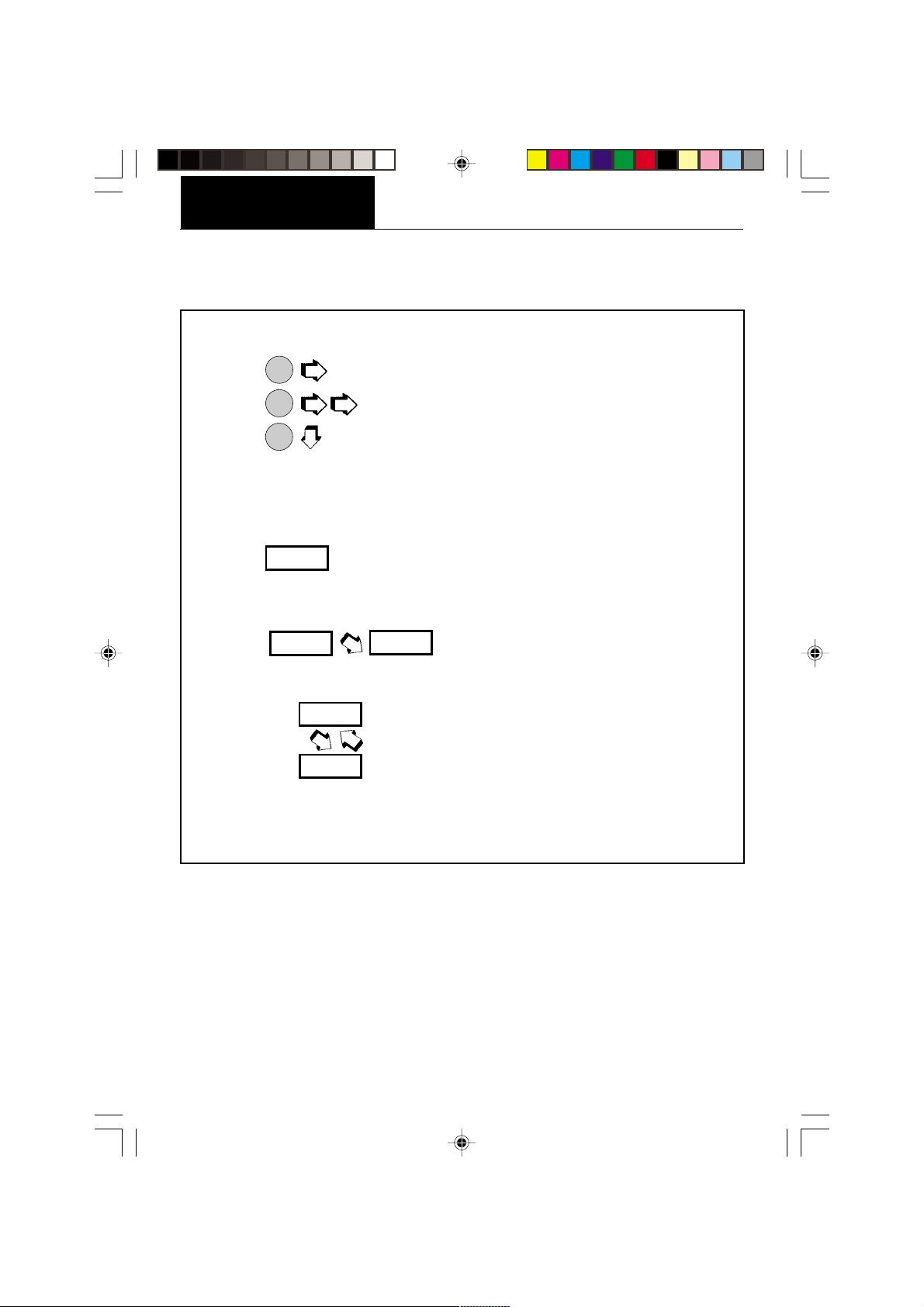

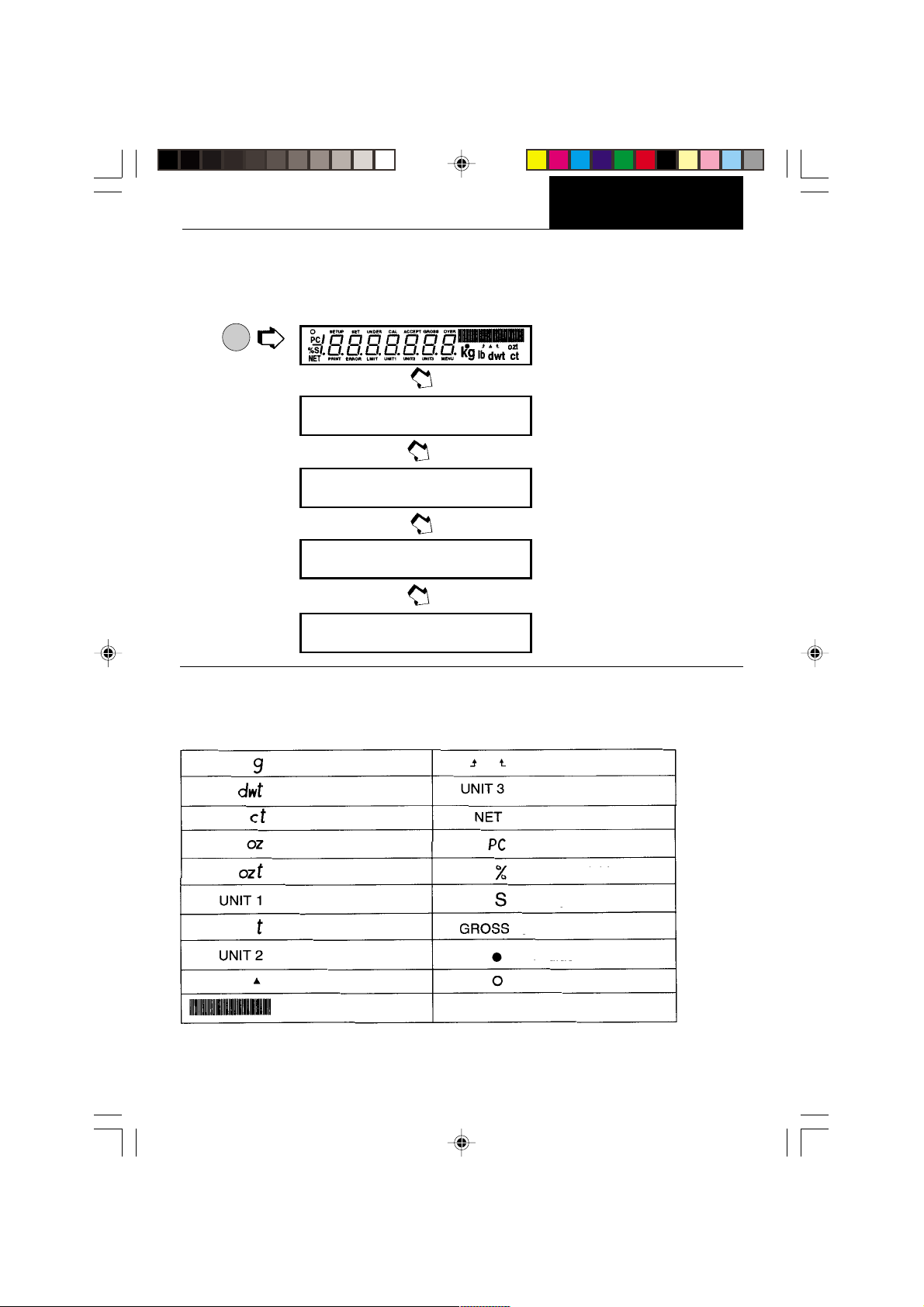

Symbols Used for Operation of the Balance

This instruction manual uses certain symbols to explain various operational procedures and

actions that occur. Examples of the symbols used are shown as follows:

Pushbutton Switches:

ON

= NORMAL PRESS AND RELEASE

TARE

ON

= MULTIPLE PRESS

TARE

ON

Display Area:

= PRESS AND HOLD FOR DESIRED DISPLAY

TARE

DISPLAY AREA - AS A RESULT OF USER ACTION

DISPLAY AREA - AUTO CHANGE OCCURS

DISPLAY AREA -SWITCHES BACK AND FORTH

10

OPERATION

Menu

Menu

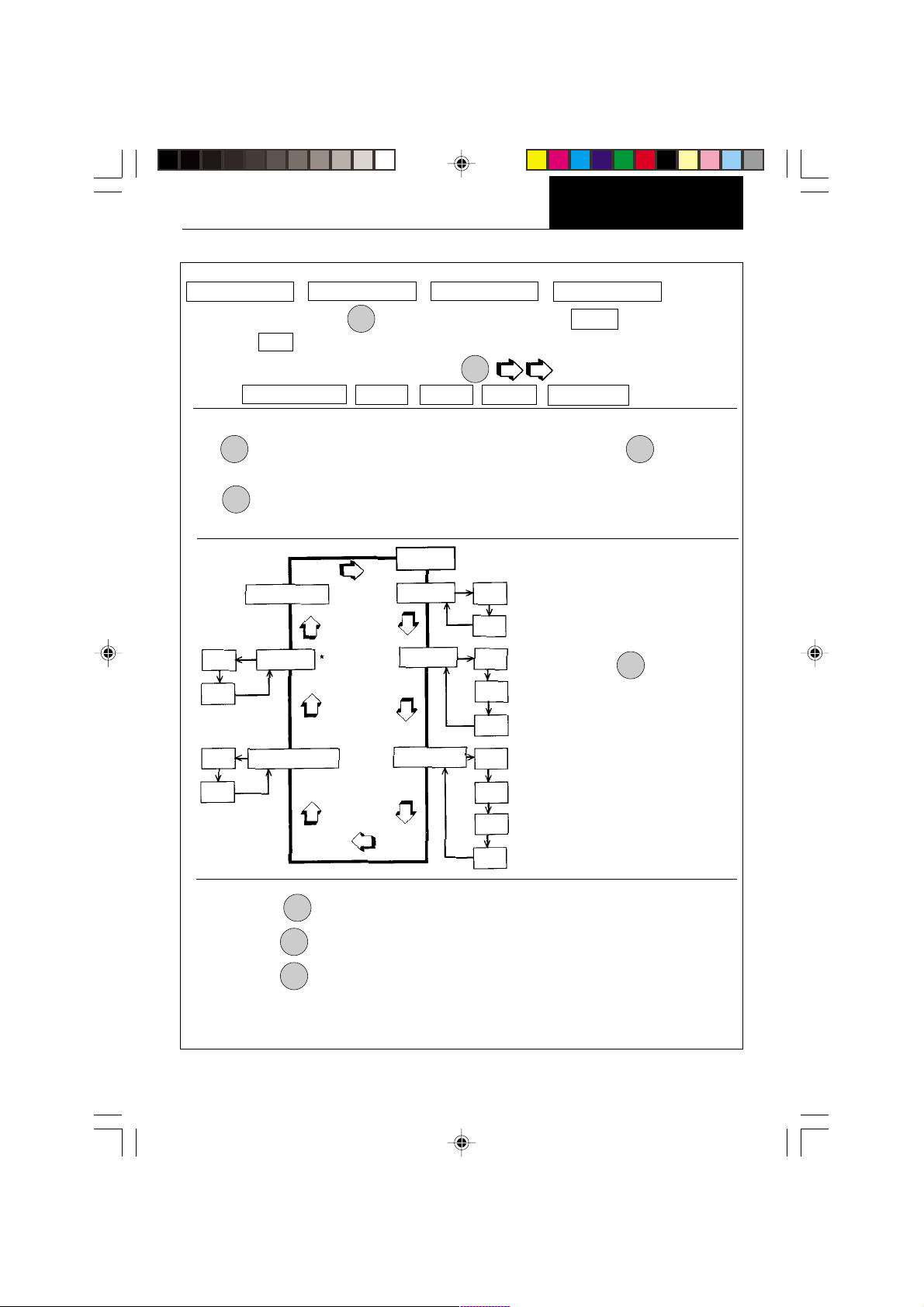

Navigating the Menus

There are four menus used in the balance:

CALIBRATION USER SETUP PRINT

To enter the menus, the

released, CAL is displayed which is the Calibration menu.

When in the menus, repeated pressing of

menus. CALIBRATION USER SETUP PRINT END

Each menu contains selections (submenus) which can be set for specific operations.

MODE

The

button is used to advance though the submenu selections. The

or accepts the submenu selection and returns to the beginning of the submenu selection.

PRINT

The

button is used to backup in the submenu if a change is desired.

The following sample illustrates the USER menu and submenu items

ON

button is pressed and held until MENU is displayed. When

TARE

MODE

advances through the

MENU

ON

button enters

TARE

END USER

ON

DUAL

OFF

AUTO ZERO

ON

OFF

RULES: Use

Use

Use

After selections are made, always exit menus through END

store settings.

USER

RESET

YES

NO

AL

STABILTY

MODE

button to advance.

ON

button to enter or accept submenu.

TARE

PRINT

button to backup.

NOTE:

Each menu is constructed

in the form of a loop.

Advancing from one

submenu item to the next

0

1

by using the

will eventually return to

the beginning of the menu

2

* Only on AP250D Models.

0

1

2

3

MODE

button

to

MENU

11

OPERATION

Menu

Menu

Operational Guide/Index

The Operational Guide/Index lists the pages for all balance operations and options. After

settings are made, exit menus to save settings.

FUNCTION TO OPERATE SETUP

(See pages) (See pages)

1. Turning the Balance ON 13 ----

2. Weighing (grams) 14 ----

3. Taring 14 ----

4. Percent Weighing 15 38

5. Parts Counting 16 38, 43

6. Check weighing 17 38, 43

7. Animal Weighing 18 38, 46

8. Fill Guide 19 38, 46

9. High Point 20 38

10. Printing Data 21 to 26 50, 51, 55 to 59

11. List 22 50, 59

12. Menu Lockout 28 ----

13. Calibration 29 to 31 ----

14. Net/Gross Weighing ---- 40

15. Custom Units ---- 40

16. GLP ---- 42, 54

17. Time ---- 47, 48

18. Date ---- 49

19. Lockswitch ---- 50

20. Legal for Trade ---- 35, 37

21. Changing Units ---- 37

22. Statistics ---- 39

23. Averaging Level ---- 32, 33

24. Stability ---- 32, 33

25. Auto Zero ---- 32, 34

26. Dual Range (AP250D) ---- 32, 34

27. Reset User ---- 32

28. Reset Setup ---- 36

29. Reset Print ---- 52

30. Communications ---- 52 to 54

12

OPERATION

Menu

Menu

Turning the Balance ON

1. After the Self Test in the Installation Section is completed (power applied to the

balance), make sure the pan on the balance is clear, then, close the chamber doors.

ON

TARE

ap25FD

sR3.1

2.

˛

0.00000

s

g

g

Display Indications

The following table describes each of the display indicators.

DISPLAY INDICATORS

grams check weighing limits

pennyweight custom unit/volume

carats net indicator

ounces parts counting

troy ounces percent weighing

grains stability indicator

taels gross (total) indicator

mommes fill guide

user calibration indicator center of zero

I

capacity guide

13

OPERATION

Menu

Menu

Stabilization

Before initally using the balance, allow time for it to adjust to its new environment. The

balance only requires to be plugged in to warm up. Recommended warm up period is twenty

(20) minutes. The balance is powered whenever it is plugged into a power source.

Auto Range (AP250D and E Only)

Modes AP250D and E offer both a fine range (0.01 mg readability from 0 to 52 g) and a coarse

range (0.1 mg over 52 g). When first turned on, the balance is in the fine range. It remains

in this range until the weight on the pan exceeds 52 g. When weight on the pan is greater

than 52 g, the balance switches to the coarse range.

If weight on the pan falls below 52 g, it automatically switches back to the fine range.

Weighing

ON

1.

to rezero the display.

TARE

2. Place the object(s) or material to be weighed on the pan.

3. Wait for the stability indicator to appear before reading the weight.

STABILITY INDICATOR

200.0000

s

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

g

NOTE: The capacity guide (bars) indicates the percentage of the current weight to the

balance capacity. The example above illustrates a 200 gram weight, (balance full capacity

210 grams).

CAPACITY GUIDE

Taring

When weighing material or objects that must be held in a container, taring stores the

container weight in the balance’s memory, separate from the weight of the material in the

container.

1. Place an empty container on the pan. Its weight is displayed.

ON

2.

3. Add material to the container. As material is added, its net weight is displayed.

4. Removing the container and material from the pan will cause the balance to display the

5.

, the display blanks until stable weight readings are received, then indicates

TARE

zero. The container’s weight is stored in memory.

container’s weight as a negative number.

ON

resets the balance to zero.

TARE

14

Percent Weighing

Menu

Menu

OPERATION

Percent Weighing is

Percent Function is selected under the Setup

menu. Refer to page 38. Percent weighing

permits you to place a reference load on the

balance, then view other loads as a percentage of the reference. The load you place on the

platform as a reference may be displayed as

any percentage you select from 5% to 100%

enabled only

when the

EXAMPLE

A 10g reference load is set for 20%:

• A subsequent load of 100 g will be

displayed as 200%.

• A subsequent load of 200 g will be

displayed as 400%.

(in 1% increments). One hundred percent does

not necessarily have to represent the reference load. Subsequent loads, displayed as a

percentage of the reference are limited only by the capacity of the balance. The default

setting is Reference 100%.

To perform percent weighing when in a weighing mode, use the following procedure:

ON

1.

TARE

pCT cON

.

%

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

2. Place an empty container on the pan (if one will be used).

ON

3.

. This is the current reference percentage.

TARE

seT 100

%

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

NOTE: The reference percentage can be changed to any value from 5 to 100.

MODE

4.

NOTE:

seT 5

increments to .

%

PRINT

does not return to a lower number. Instead, it sends Set x%

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

seT 100

%

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

command through the RS232 Interface, where x = 5 to 100.

5. When the selected reference value appears on the display, place the reference load

in the container (or directly on the pan if no container is used).

ON

8.

, display indicates the reference load as the percent-

TARE

100.0

%s

IIIIIIIIIIIIIIIIIIIIIIIIIIIIII II I

age entered. The bar graph indicates the load relative to the capacity of the balance.

9. Remove the reference load from the balance and replace it with another load. The

second load is displayed as a percentage of the reference.

10.

MODE

to view alternate display in units.

100.0000

%s

11.To restart percent weighing at any time,

ON

12.

to exit to a weighing mode.

TARE

IIIIIIIIIIIIIIIIIIIIIIIIIIII I

g

ON

TARE

pCT cON

.

%

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

15

OPERATION

Menu

Menu

Parts Counting

Parts Counting is

menu. Refer to page 38. In the parts counting mode, the balance displays the quantity of

parts you place on the pan. Since the balance determines the quantity based on the average

weight of a single part, all parts must be reasonably uniform in weight. The accuracy of parts

counting results is determined by the error level entered in PC Err of the Setup Options

submenu. Refer to page 43. The default setting for PC Err is off.

To perform parts counting when in a weighing mode, use the following procedure:

enabled only

when the Parts Counting Function is selected in the Setup

ON

1.

TARE

ON

2.

TARE

PC

.

. The balance requires a sample of the parts to use

pc cON

PC

aDD 5

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

as a reference for counting. The default for the sample size is 5 parts, but this can be

changed to 10, 20, 30, 40, 50, or 100 parts by

MODE

(Larger samples yield

more accurate results). Add the required number of sample pieces to the pan.

ON

3.

TARE

PC

(indicates 5 pieces).

5

5

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

4. If Add X is displayed, the sample is too small to provide results within the selected error

level (PC Error of the Setup Options submenu).

NOTE:X represents the number of additional parts needed to provide a sufficient sample.

5. Add the required number of parts, then

ON

again.

TARE

6. To count additional pieces, add them to the pan. The display indicates the actual

number of pieces based on their sample size. Tolerance will be within whatever was

selected under the Parts Counting Error Level.

NOTE:If the balance controls are not touched, the sample size is stored in memory. You

can continue to use the balance to measure quantities as long as the samples to be

measured are of the same weight.

MODE

7.

to display the weight of the pieces on the pan.

MODE

8.

again to display the number of pieces.

9. To restart parts counting,

MODE

10.

, the balance returns to a weighing mode.

ON

TARE

PC

pc cON

.

16

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

Check Weighing

Menu

Menu

OPERATION

Check Weighing is

enabled only

when the Check Weighing Function is selected in the

Setup menu. Refer to page 38. Refer to page 43, Check Weighing Options under the Setup

menu to set the Reference Type and Display Type options. In the check weighing mode, a

reference weight can be set into the balance either as a reference weight on the pan or as

a user entered number. The balance display shows either under, accept or over as each

sample is weighed.

If reference weight was selected under CW Options submenu:

1. With the balance in the weighing mode,

ON

.

TARE

seT Ref

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

NOTE:If reference number was selected, go to step 7.

2. Place a sample weight on the pan which is considered to be the under limit for check

weighing.

ON

3.

.

TARE

seT Ref

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

4. Place a sample weight on the pan which is considered to be the over weight limit for

check weighing.

ON

. The display blanks until a stable reading is achieved, then it goes to either

5.

TARE

the (Normal, None or Sign) display type previously selected in CW Options submenu

to indicate under, over or acceptacle limits of the objects being weighed.

6. Check weighing can now be made by removing a sample and placing a new sample

on the pan.

If reference number was selected under the CW Options submenu:

7. With the balance in the weighing mode,

ON

.

TARE

seT Ref

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I

MODE

8.

9.

10.

11.

to return to weighing.

ON

TARE

MODE

until the first digit (under weight) is correctly displayed.

ON

to accept the value.

TARE

UNDER

000.0000

indicates under value with first digit flashing.

g

12.Repeat steps 10 and 11and set all digits to the desired value. When the last digit is

entered, display changes to an over value to be entered with the first digit flashing

000.0000

NOTE:

PRINT

OVER

.

g

allows going back.

17

Loading...

Loading...